A kind of plate shearing machine and the production process of explosion-proof wave valve using the plate shearing machine

A technology of shearing machine and frame, which is applied to the attachment of shearing machines, manufacturing tools, shearing devices, etc. It can solve the problems of reduced sealing of explosion-proof wave valves and reduced precision of plate shearing, so as to improve manufacturing accuracy, The effect of improving cutting accuracy and improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

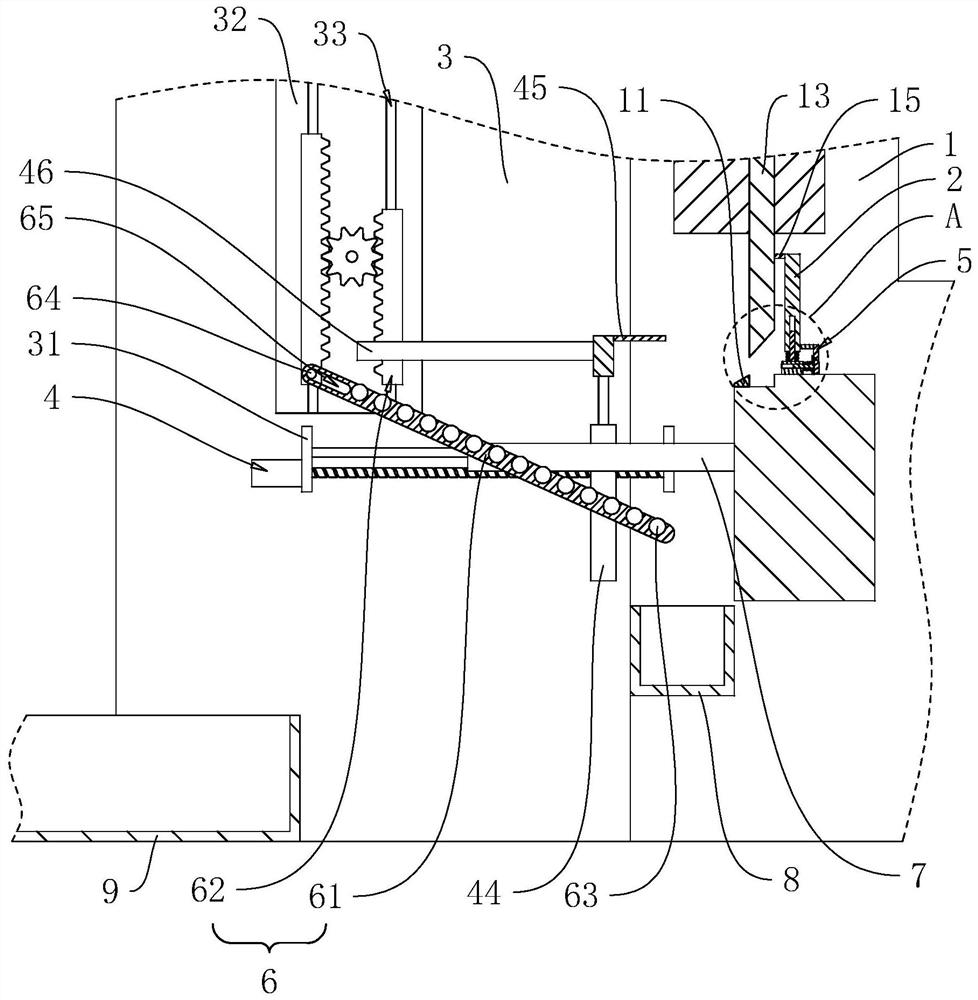

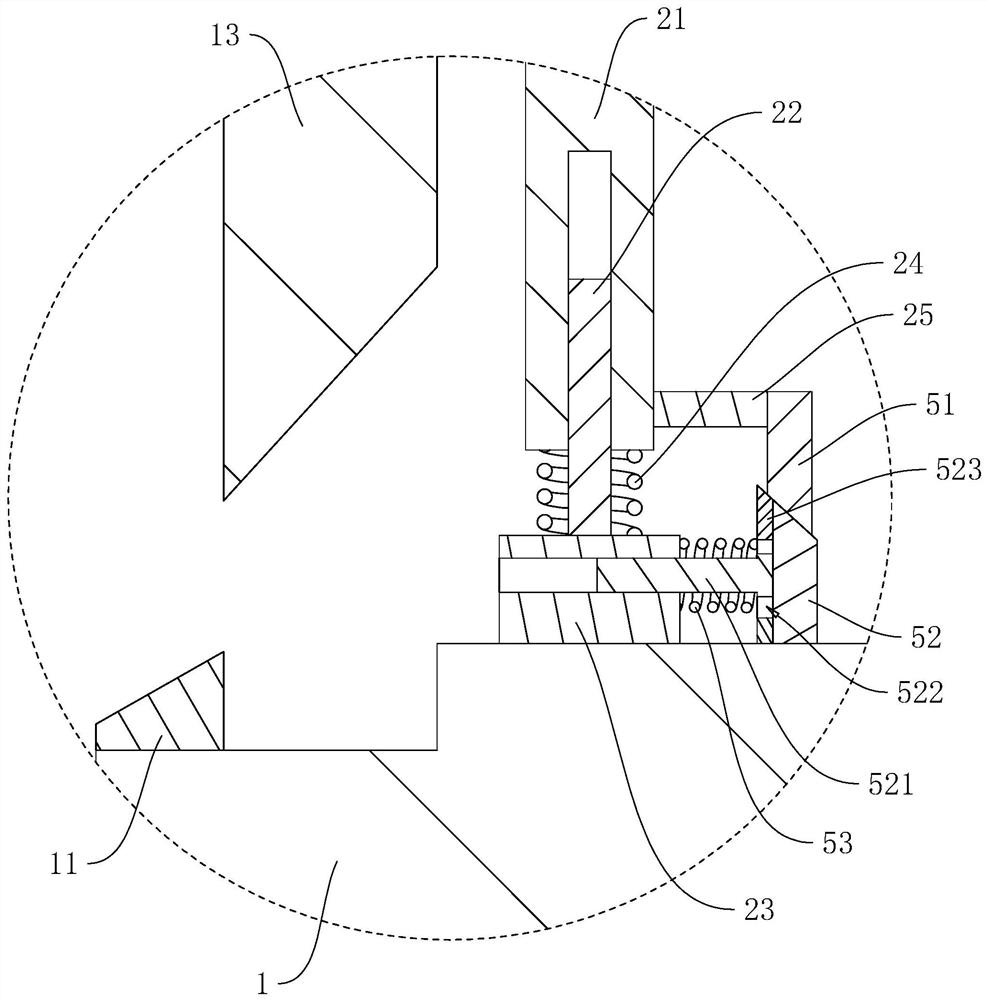

[0047] The following is attached Figure 1-5 The application is described in further detail.

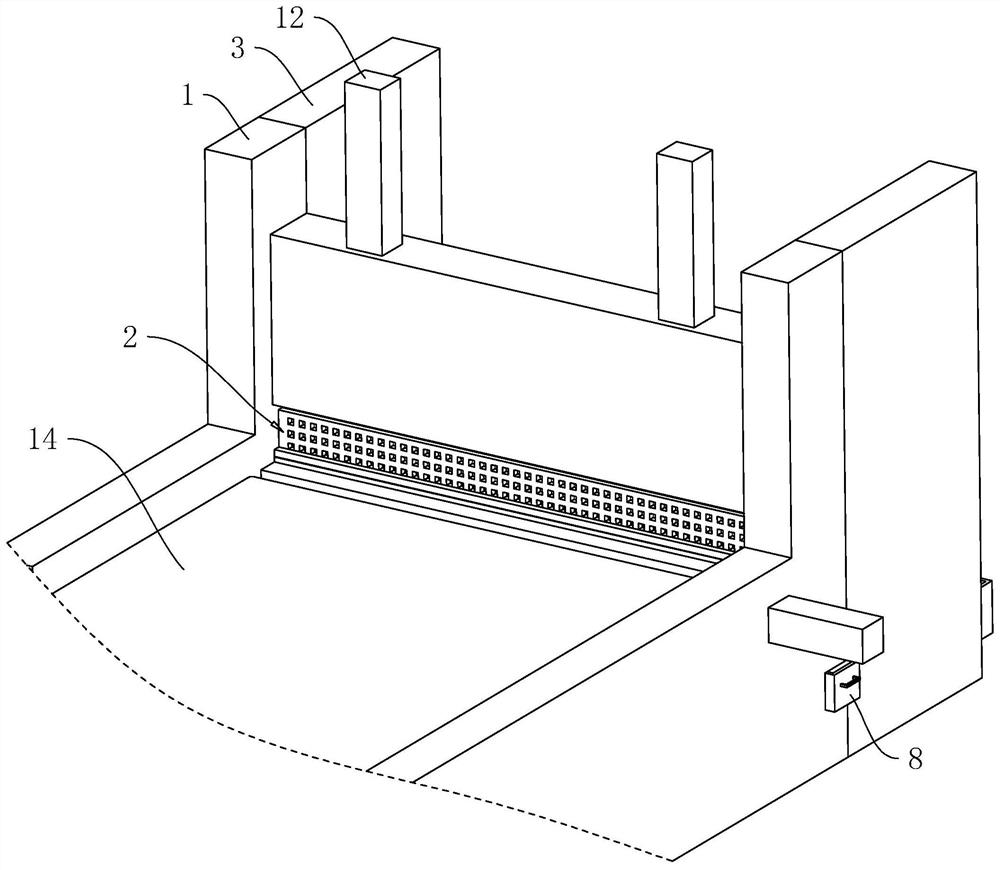

[0048] The embodiment of the present application discloses a shearing machine. refer to figure 1 as well as figure 2 , a plate shearing machine includes a frame 1, a lower cutting knife 11 and a first driving member are fixedly connected to the frame 1, the first driving member includes a driving hydraulic cylinder 12, and the driving hydraulic cylinder 12 is vertically fixedly connected to the frame 1 On the frame 1, an upper cutting knife 13 is vertically slidably connected, and the upper cutting knife 13 is fixedly connected to the piston rod of the driving hydraulic cylinder 12, and a space for plate cutting is formed between the lower cutting knife 11 and the upper cutting knife 13 The frame 1 is fixedly connected with a feeding conveyor belt 14, which is located on the side of the frame 1 facing the feeding end, and the length direction of the feeding conveyor belt 14 is pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com