Patents

Literature

120results about How to "Improve cropping accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

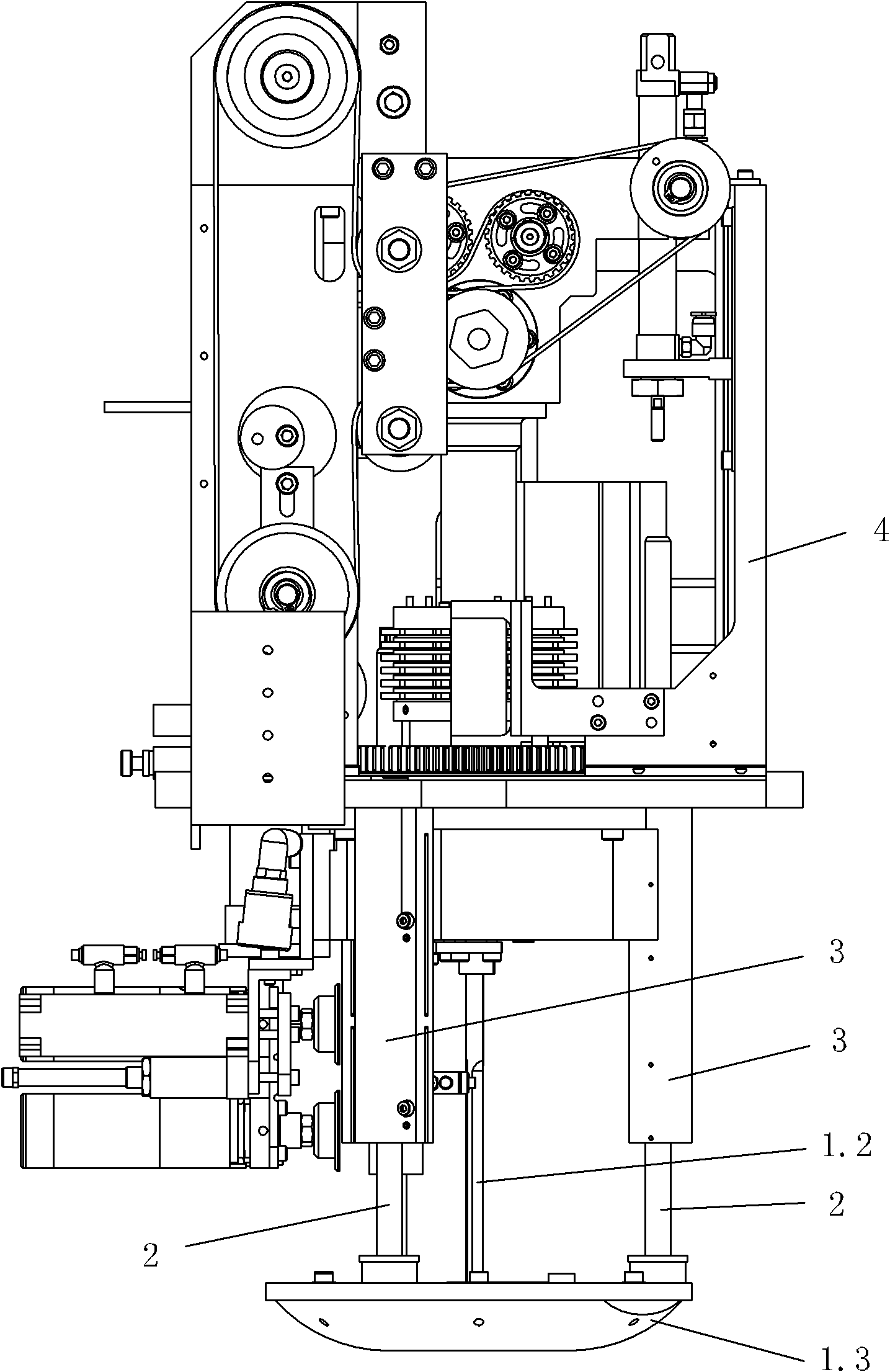

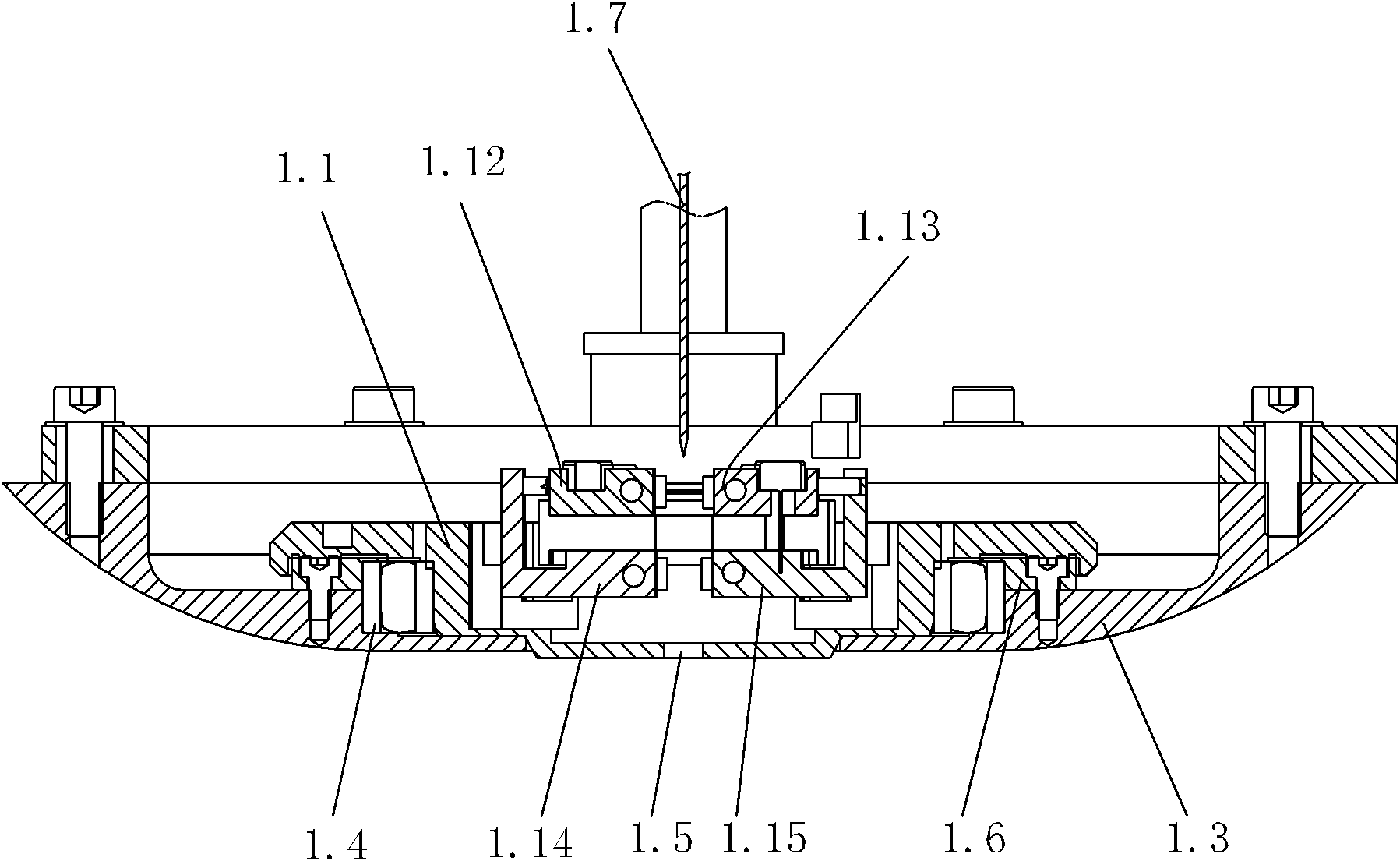

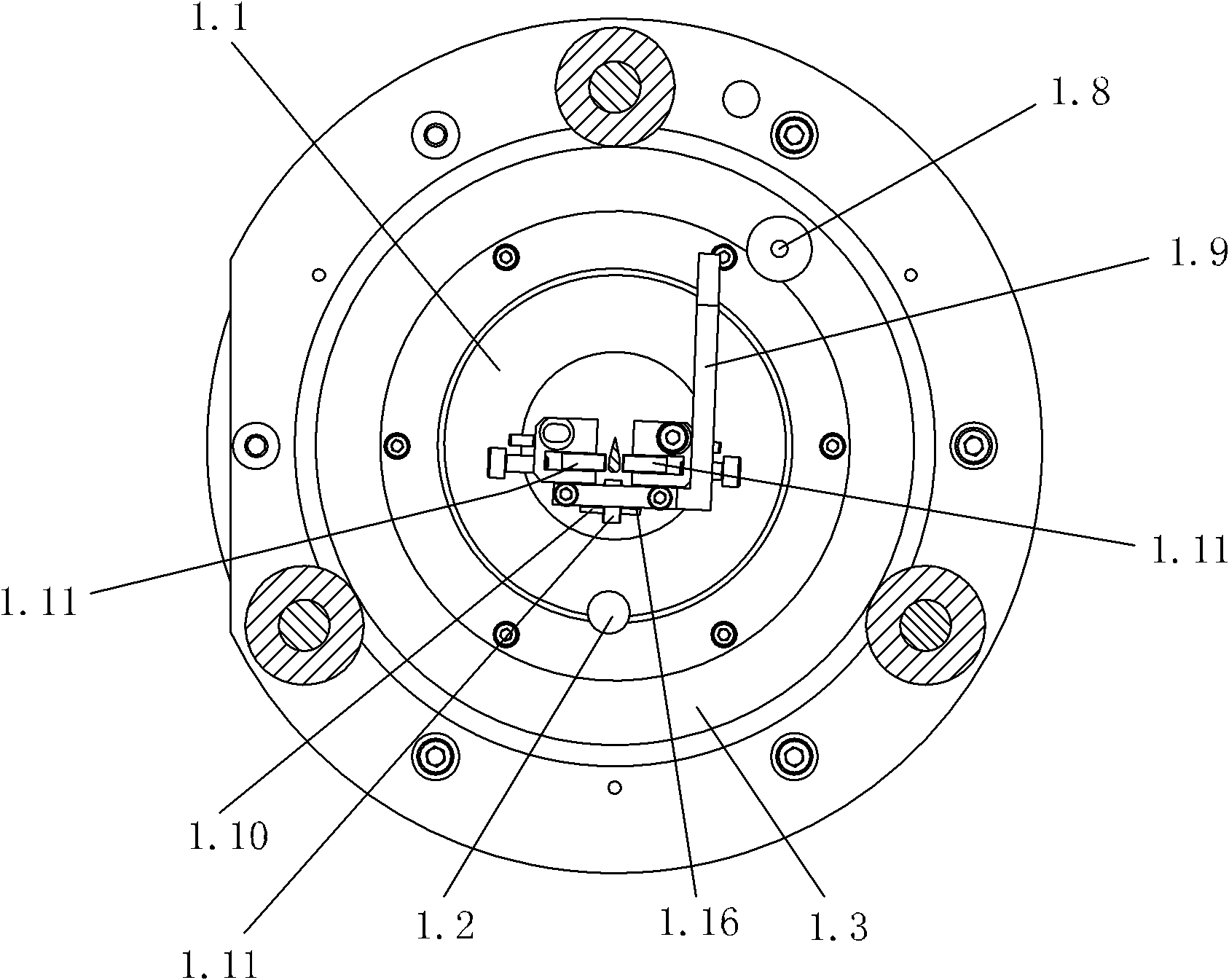

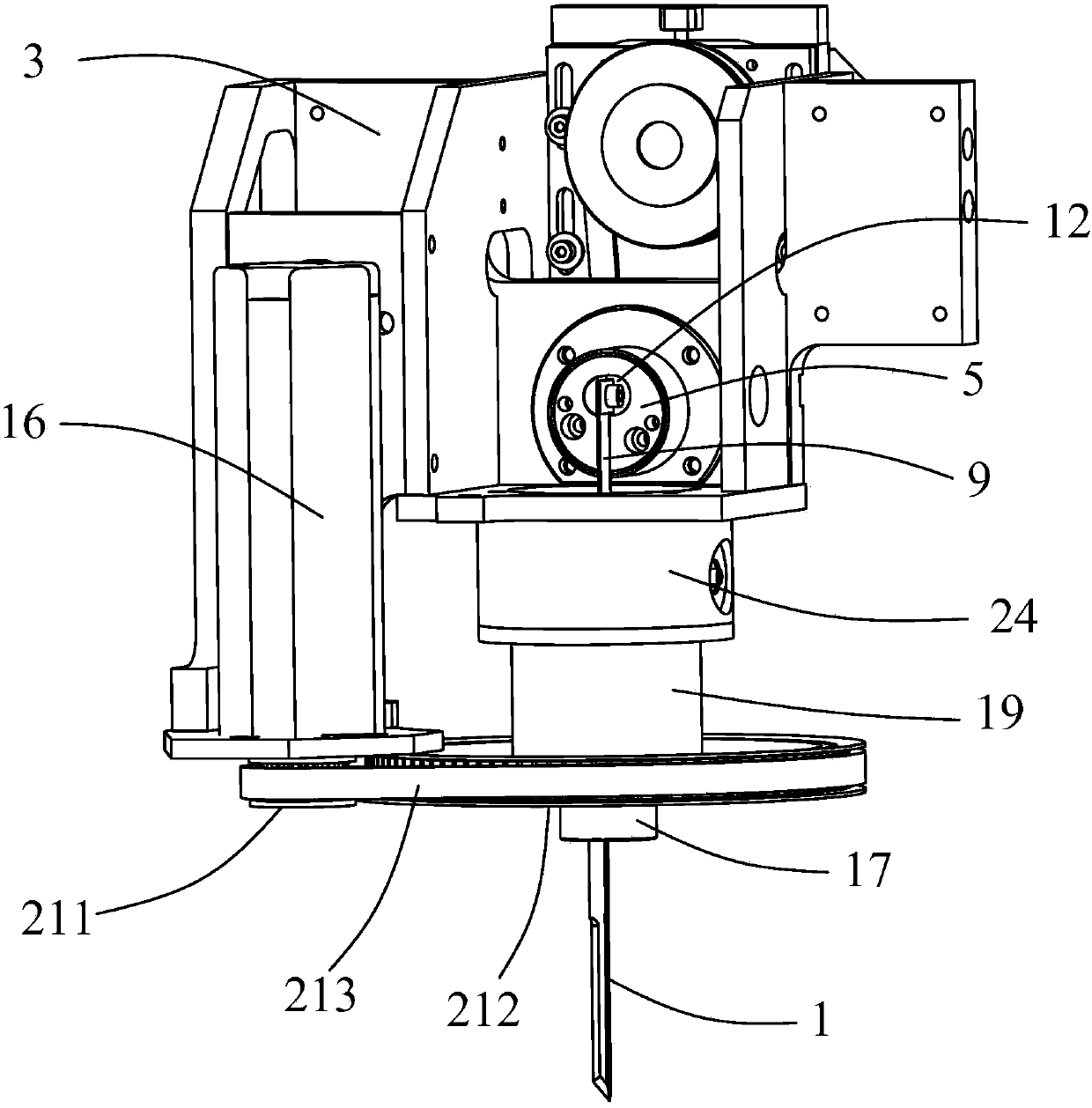

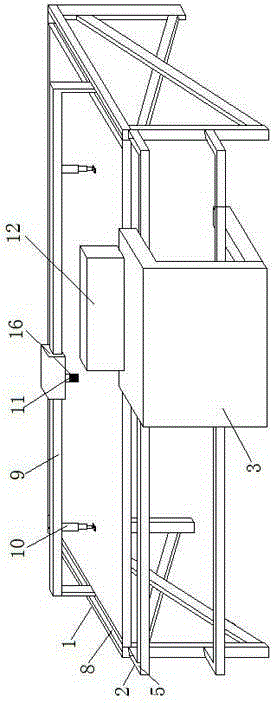

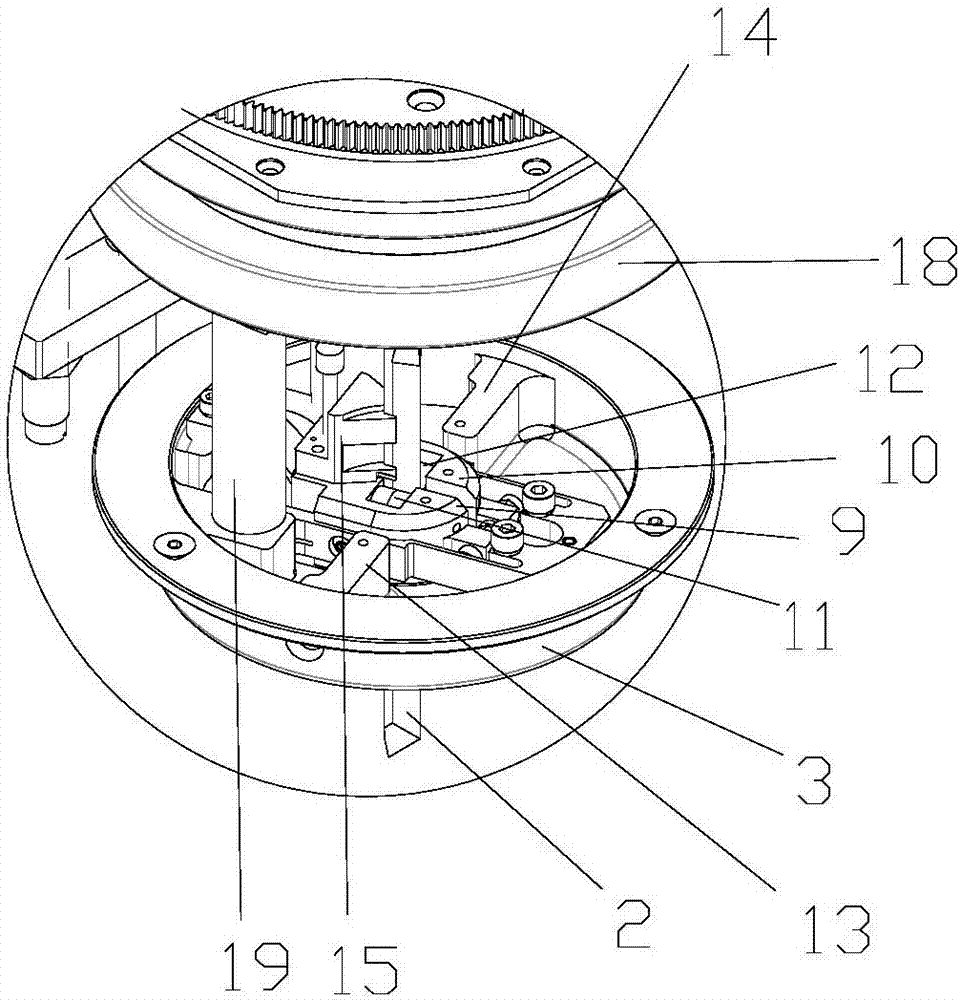

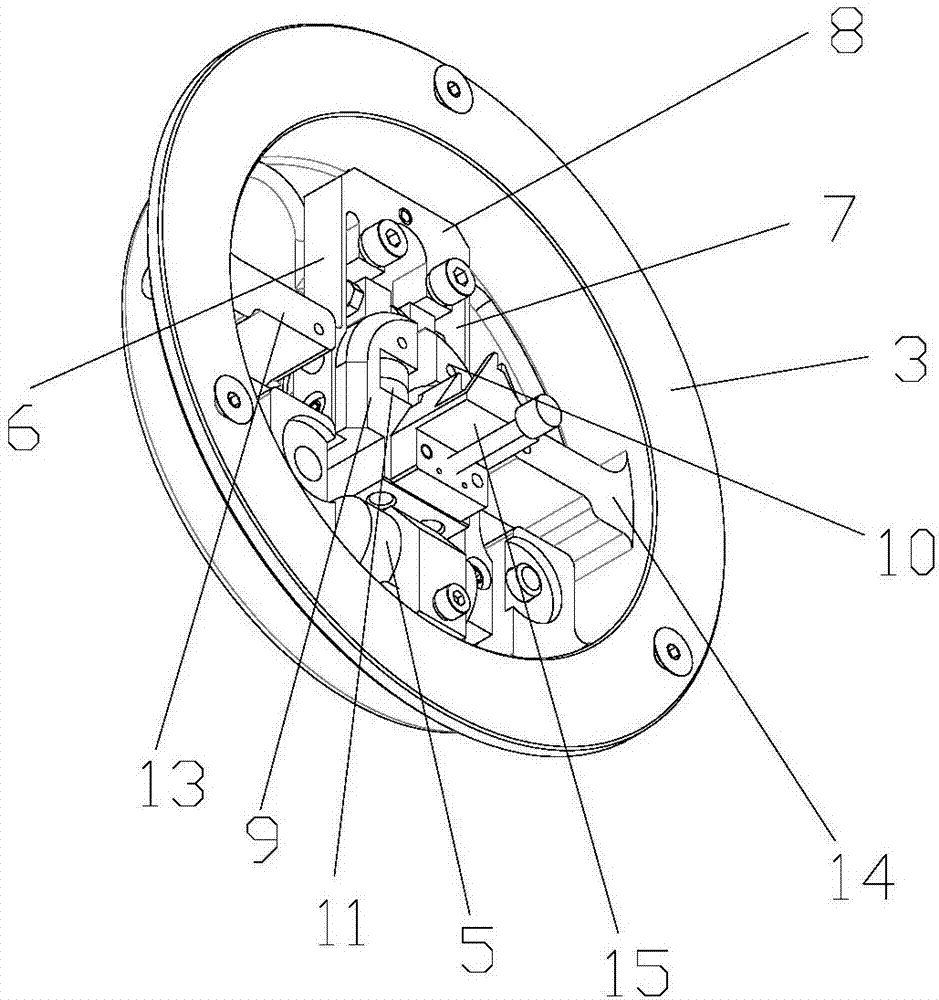

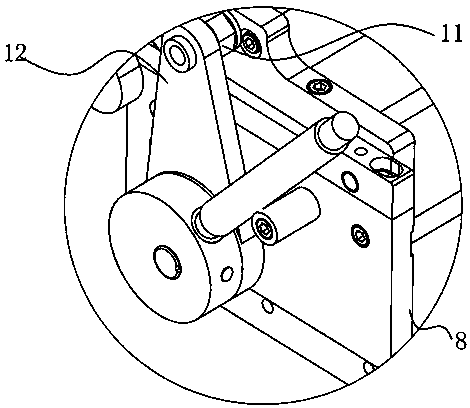

Cutter for high-layer automatic cutting bed

ActiveCN101947791AImprove cropping accuracyAvoid the situationMetal working apparatusEngineeringMechanical engineering

The invention belongs to the technical field of automatic cutting equipment, in particular to a cutter for a high-layer automatic cutting bed. An inner disc concentric with an outer disc is arranged inside the outer disc; the inner disc comprises an intelligent correction system, a guide wheel and an inner disc rotating device, wherein the intelligent correction system corrects an induced offset of a rotation angle and a design angle of the cutter; the guide wheel guides the cutter; the inner disc is arranged inside the outer disc through the inner disc rotating device and can rotate relativeto the outer disc; and the intelligent correction system and the guide wheel are arranged on the inner disc rotating device. The cutter for the high-layer automatic cutting bed is separated into a fixed part and a rotatable part, namely the outer disc and the inner disc, and effectively avoids the condition that a shell fabric is raised due to excessive turning during cutting at a large angle; and the arranged intelligent correction system can correct an offset angle due to the reacting force of the shell fabric. Therefore, the cutting precision of the high-layer automatic cutting bed is improved.

Owner:BULLMER ELECTROMECHANICAL TECH

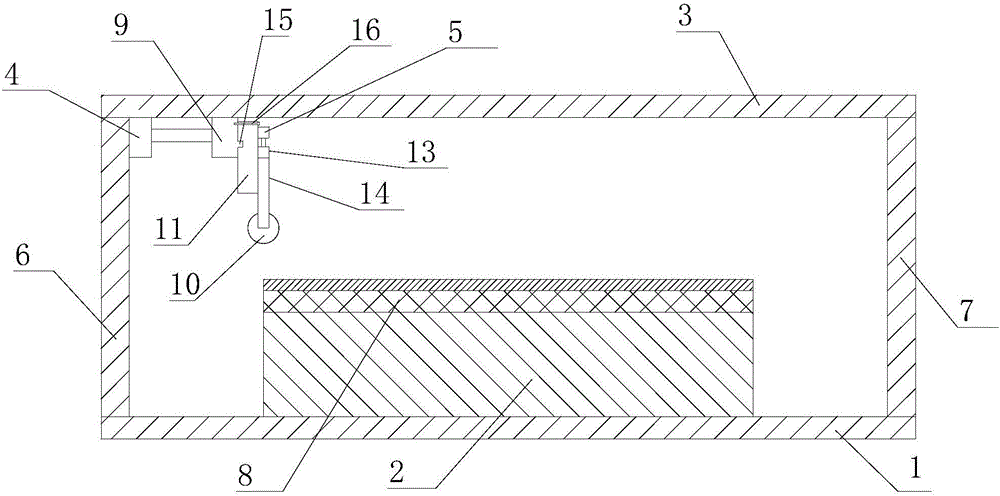

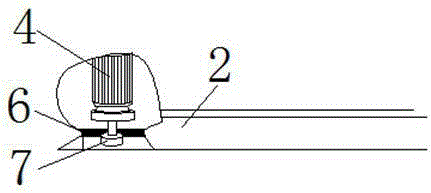

Corrugated paper cutting device

InactiveCN105922315ASimple structureFast croppingMetal working apparatusArticle deliveryEngineeringKnife blades

The invention discloses a corrugated paper cutting device. The corrugated paper cutting device comprises a support, a conveying plate, a driving mechanism, a controller, a cutting mechanism, a first pressing and holding mechanism and a second pressing and holding mechanism. Guide rails are arranged on the support. The conveying plate is movably mounted on the guide rails. A plurality of grooves are formed in the conveying plate at intervals and are sequentially arranged in the length direction of the guide rails. The length direction of the grooves is perpendicular to or obliquely crosses with the length direction of the guide rails. The driving mechanism is used for driving the conveying plate to move in the length direction of the guide rails. The driving mechanism is in communication connection with the controller. The cutting mechanism is used for cutting corrugated paper and comprises a driving unit and a blade. The driving unit drives the blade to move close to the grooves or far from the grooves. The corrugated paper cutting device is simple in structure and good in corrugated paper cutting effect.

Owner:BENGBU ZHENHUA PACKING MACHINERY

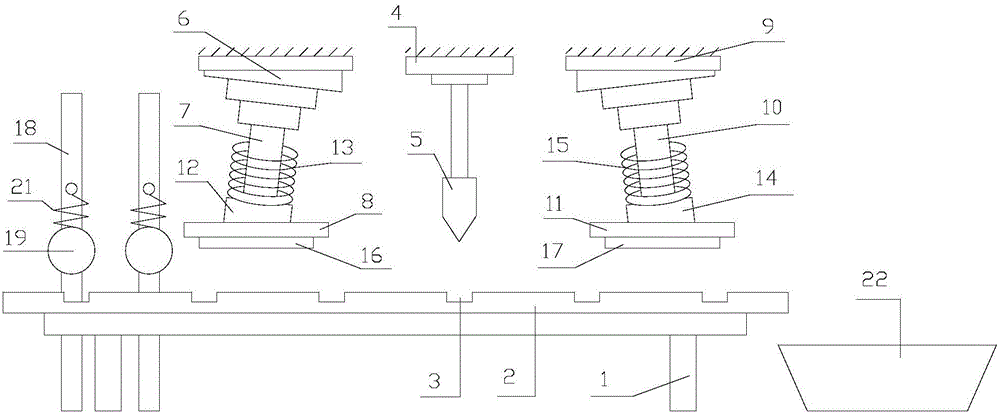

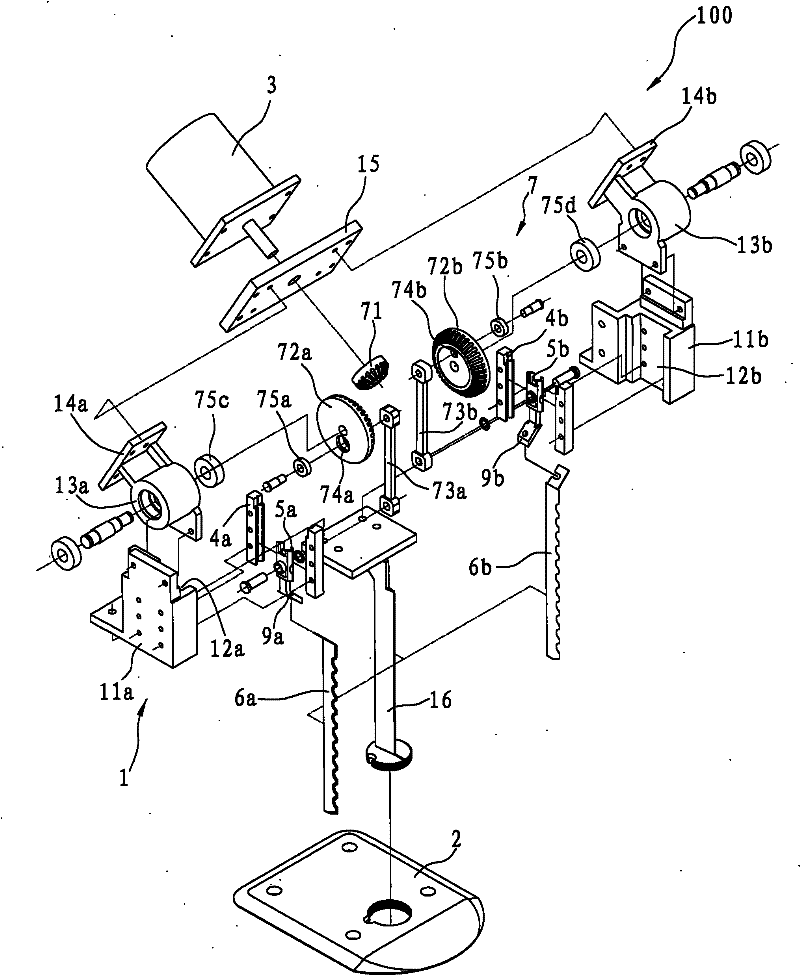

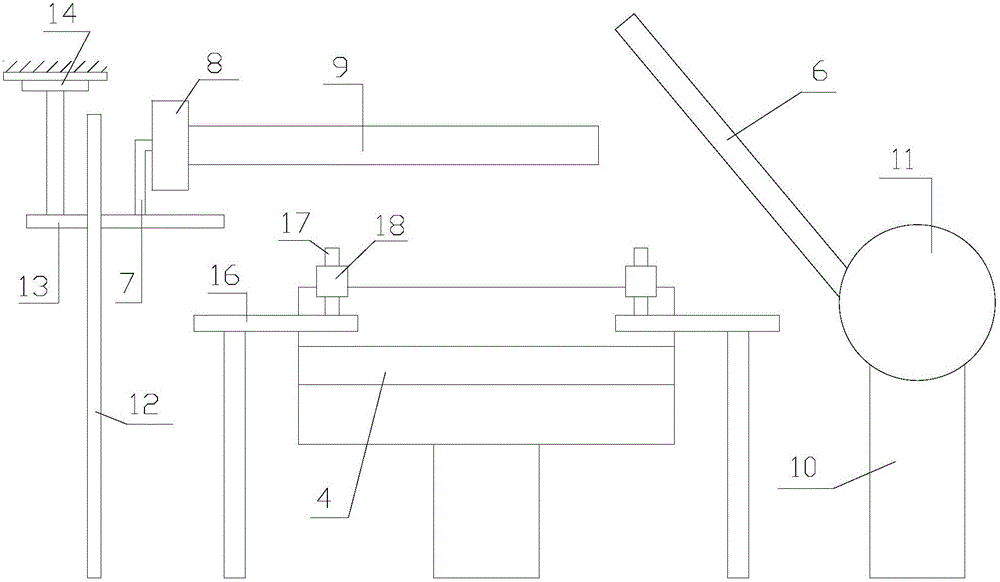

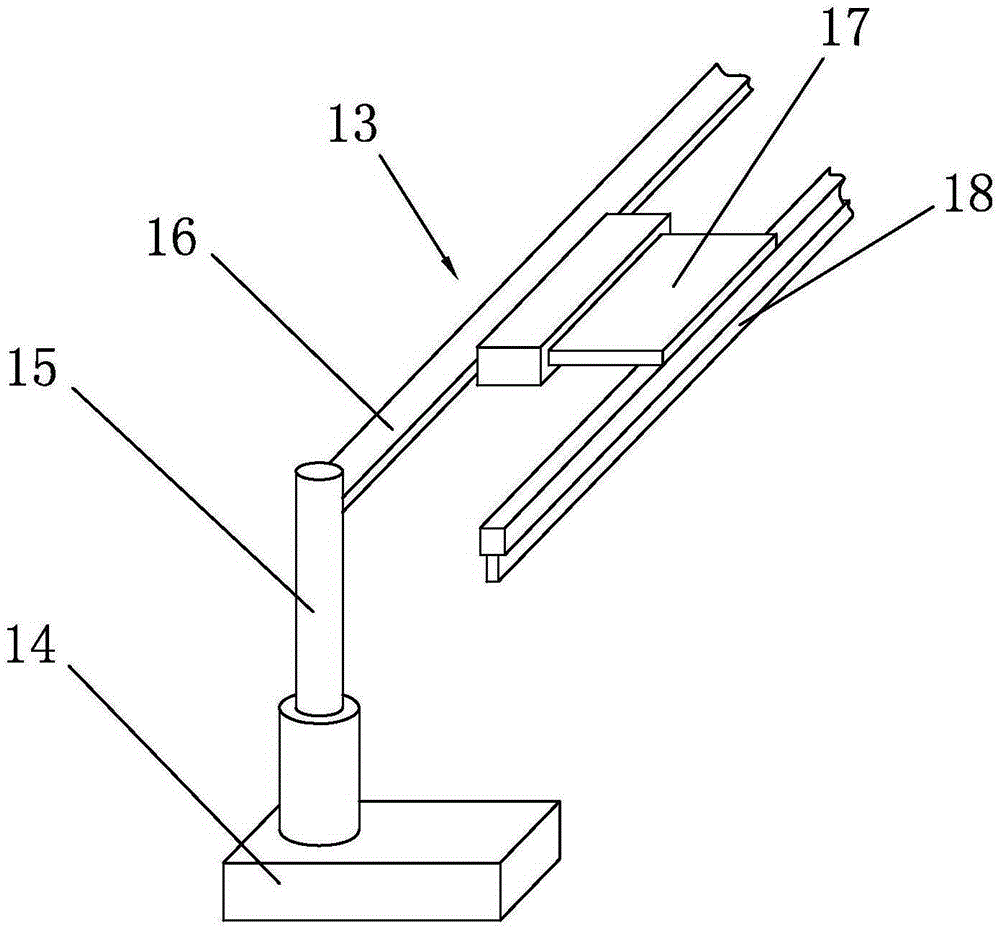

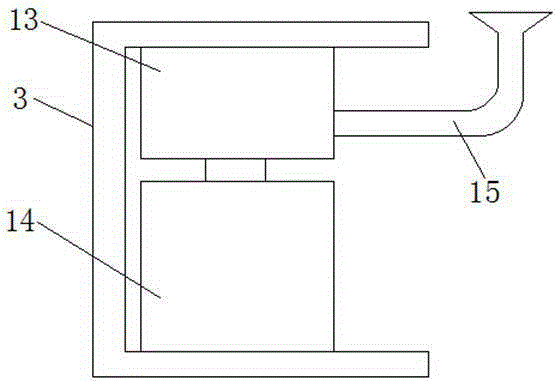

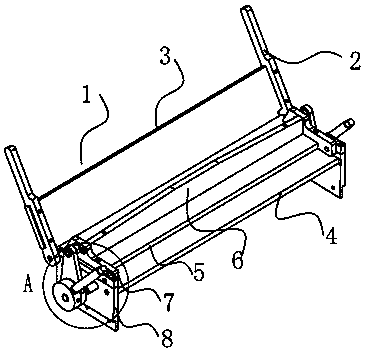

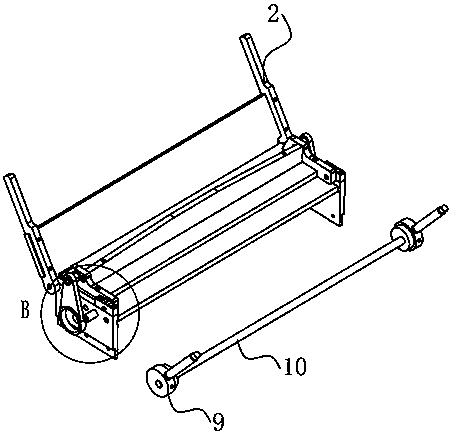

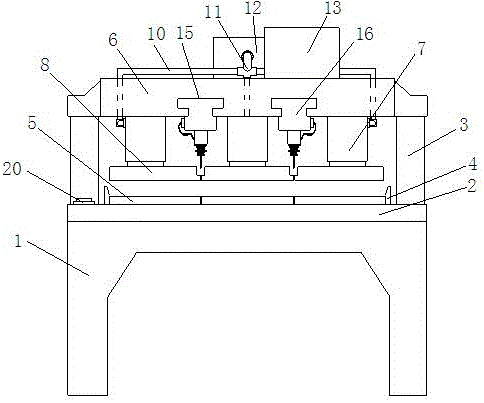

Double-blade cutting machine

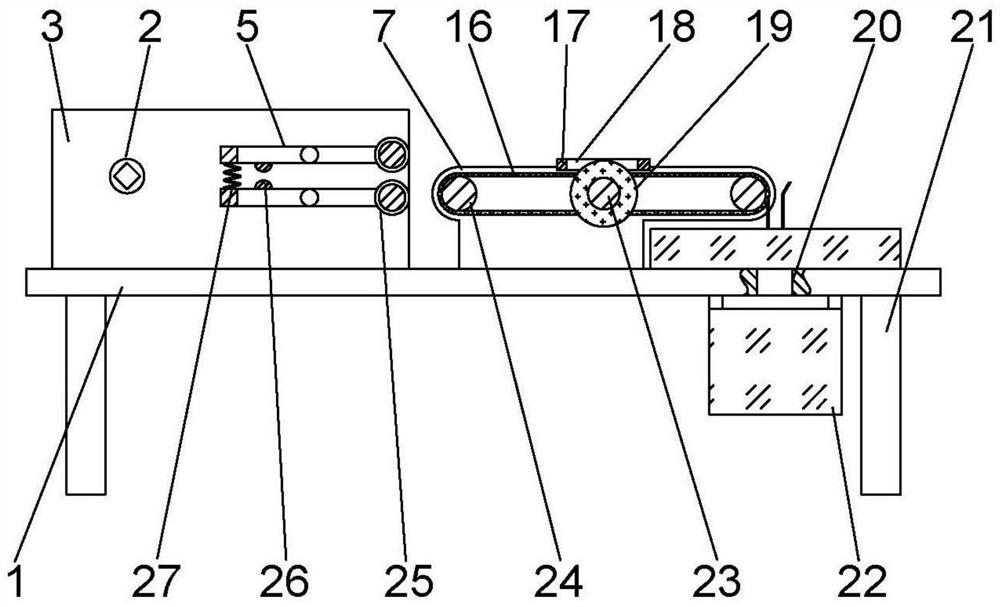

InactiveCN102002845AChange cropping modeImprove cropping accuracySevering textilesEngineeringChassis

The invention discloses a double-blade cutting machine which comprises a rack, a chassis, a transmission mechanism and an electrical machine, a first sliding rail mechanism, a second sliding rail mechanism, a first ram, a second ram, a first blade and a second blade which are arranged on the rack, the first sliding rail mechanism and the second sliding rail mechanism are fixedly connected on the rack, the first ram is in sliding arranged on the first sliding rail mechanism, one end of the first ram is in moving connected with the transmission mechanism, the other end is fixedly connected with the first blade, the second ram is in sliding arranged on the second sliding rail mechanism, and one end of the second ram is in moving connected with the transmission mechanism, the other end is fixedly connected with the second blade, the transmission mechanism transmits the rack and drives the first sliding rail mechanism and the second rail mechanism moving in the same speed and the adverse direction, the first blade and the second blade are parallel and in separation state, and the cutting edges of the first blade and the the second blade are close to the application point of cloth. The invention can enhance the cutting accuracy and efficiency and has the function of saving energy.

Owner:厦门易凯得工贸有限公司

Double-blade cutting machine

InactiveCN102002845BChange cropping modeImprove cropping accuracySevering textilesEngineeringKnife blades

The invention discloses a double-blade cutting machine which comprises a rack, a chassis, a transmission mechanism and an electrical machine, a first sliding rail mechanism, a second sliding rail mechanism, a first ram, a second ram, a first blade and a second blade which are arranged on the rack, the first sliding rail mechanism and the second sliding rail mechanism are fixedly connected on the rack, the first ram is in sliding arranged on the first sliding rail mechanism, one end of the first ram is in moving connected with the transmission mechanism, the other end is fixedly connected withthe first blade, the second ram is in sliding arranged on the second sliding rail mechanism, and one end of the second ram is in moving connected with the transmission mechanism, the other end is fixedly connected with the second blade, the transmission mechanism transmits the rack and drives the first sliding rail mechanism and the second rail mechanism moving in the same speed and the adverse direction, the first blade and the second blade are parallel and in separation state, and the cutting edges of the first blade and the the second blade are close to the application point of cloth. The invention can enhance the cutting accuracy and efficiency and has the function of saving energy.

Owner:厦门易凯得工贸有限公司

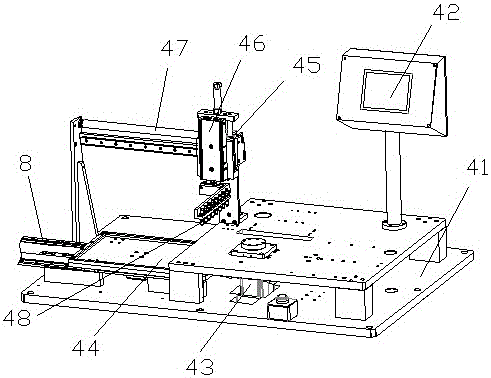

Printing and cutting method for intelligent cutting machine

ActiveCN106192352AMeet the production process requirementsImprove cropping accuracyImage enhancementImage analysisImaging processingComputer terminal

The invention relates to a printing and cutting method for an intelligent cutting machine comprising following steps: fabrics is placed on a conveyor belt and conveyed to a position where a cutting tool locates through a material loading bed, wherein the material loading bed is provided with an image acquisition device; the image acquisition device is used for continuously acquiring images; the image data acquired by the image acquisition device is transferred to a control terminal; the control terminal splices an integral continuous fabrics image through an image processing program; background color images are superimposed on the basis of the original fabrics image data by the control terminal; data processing is performed on the fabrics image and background color images by the control terminal and then printing contours on the fabrics are generated as cutting tracking data; the control terminal outputs control instructions to the cutting machine to cut the fabrics according to the cutting tracking data. The method can ensure that the track of the actual cutting can match the printed pattern outline under the distorted state of the fabrics so that the final cut product conforms to the production technology demand of the printed pattern fabrics.

Owner:长园和鹰科技(河南)有限公司

Paperboard cutting and processing equipment

ActiveCN105922331APrevent deviationGuarantee subsequent processing accuracyMetal working apparatusPaperboardEngineering

The invention discloses paperboard cutting and processing equipment. The equipment comprises a mounting frame, a conveyor belt, a rotary shaft, a first driving unit, a cutting part and a pressing and holding part. The conveyor belt is mounted on the mounting frame. The upper surface of the conveyor belt is provided with a plurality of accommodating grooves which are evenly distributed in the length direction of the conveyor belt. The length direction of the accommodating grooves is perpendicular to the length direction of the conveyor belt. The lower surface of the conveyor belt is provided with first gears which are distributed in the length direction of the conveyor belt. The rotary shaft is rotatably mounted on the mounting frame. One end of the rotary shaft is arranged in a space defined by the conveyor belt. The local peripheral surface of the rotary shaft is provided with second gears which are distributed in the circumferential direction of the rotary shaft. The second gears are engaged with the first gears. The first driving unit is used for driving the rotary shaft to rotate. The cutting part is used for cutting paperboards and comprises a second driving unit and a blade. The second driving unit is used for driving the blade to move close to the accommodating grooves or far from the accommodating grooves. The paperboard cutting and processing equipment is good in paperboard cutting effect.

Owner:BENGBU ZHENHUA PACKING MACHINERY

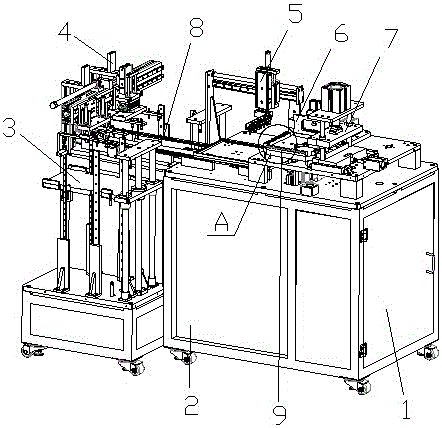

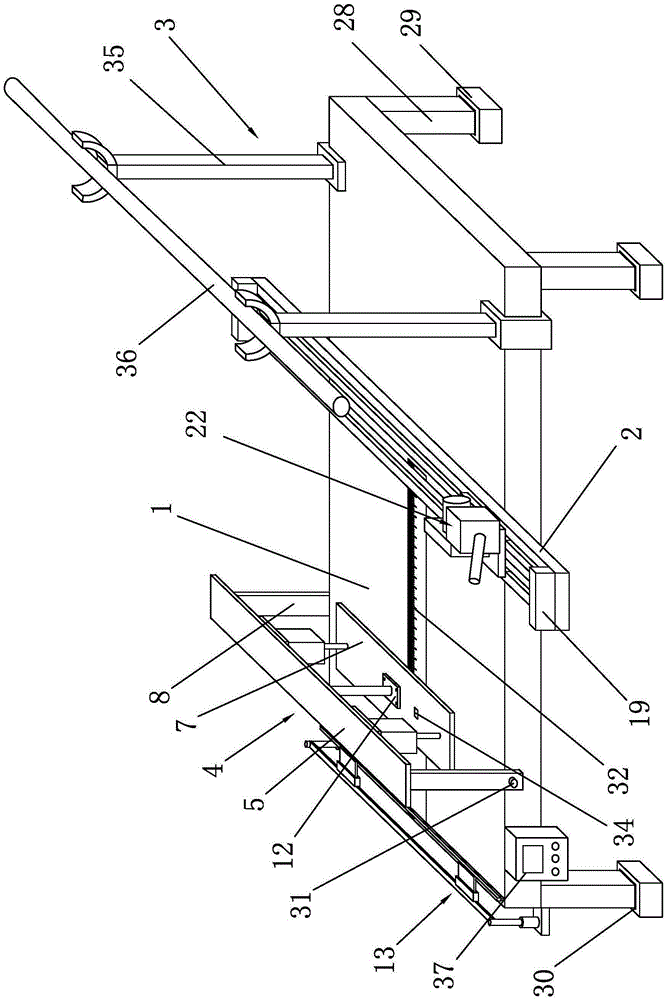

Full-automatic cutting machine

ActiveCN106563946AReduce energy consumptionImplement automatic croppingOther manufacturing equipments/toolsLarge fixed membersDistribution controlEngineering

The invention relates to a full-automatic cutting machine. The full-automatic cutting machine comprises a machine frame; the machine frame is provided with a power distribution control box and a touch operation screen which are matched with each other; the power distribution control box is provided with a workbench platen; the workbench platen is provided with a bracket and a rotary motor extending out of the bracket; the rotary motor is provided with a square rotary platform; a material loading mold is arranged on the rotary platform, and the rear side and the right side of the rotary platform are provided with a creasing device and a cutting device which are matched with the material loading mold correspondingly; the cutting device comprises a shearing frame arranged on the workbench platen; the shearing frame is connected with a propelling air cylinder arranged on the right side of the workbench platen and is provided with a shearing air cylinder, and a cutting knife is arranged below the shearing air cylinder. According to the full-automatic cutting machine, the square rotary platform is adopted, the four edges of the square rotary platform are provided with metal sheet material loading molds, and metal sheets are sequentially matched with the creasing device and the cutting device through the rotary platform, so that energy consumption is reduced, automatic cutting can also be achieved, the labor intensity is greatly relieved, and the cutting quality is improved.

Owner:DONGGUAN UNIV OF TECH

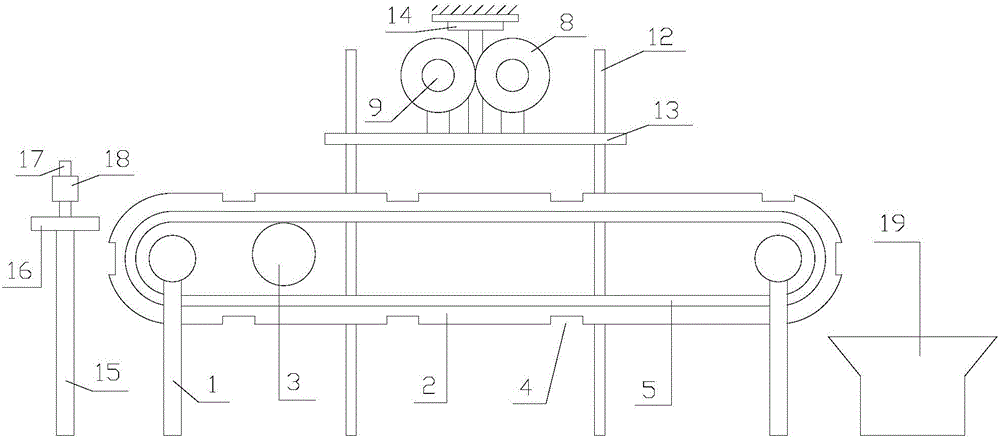

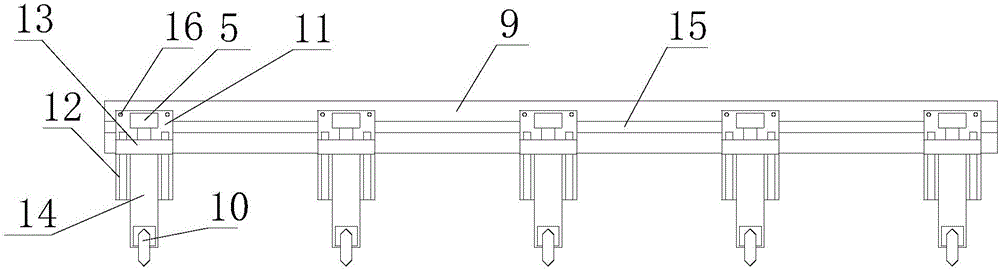

Continuous type printing paperboard clipping processing equipment

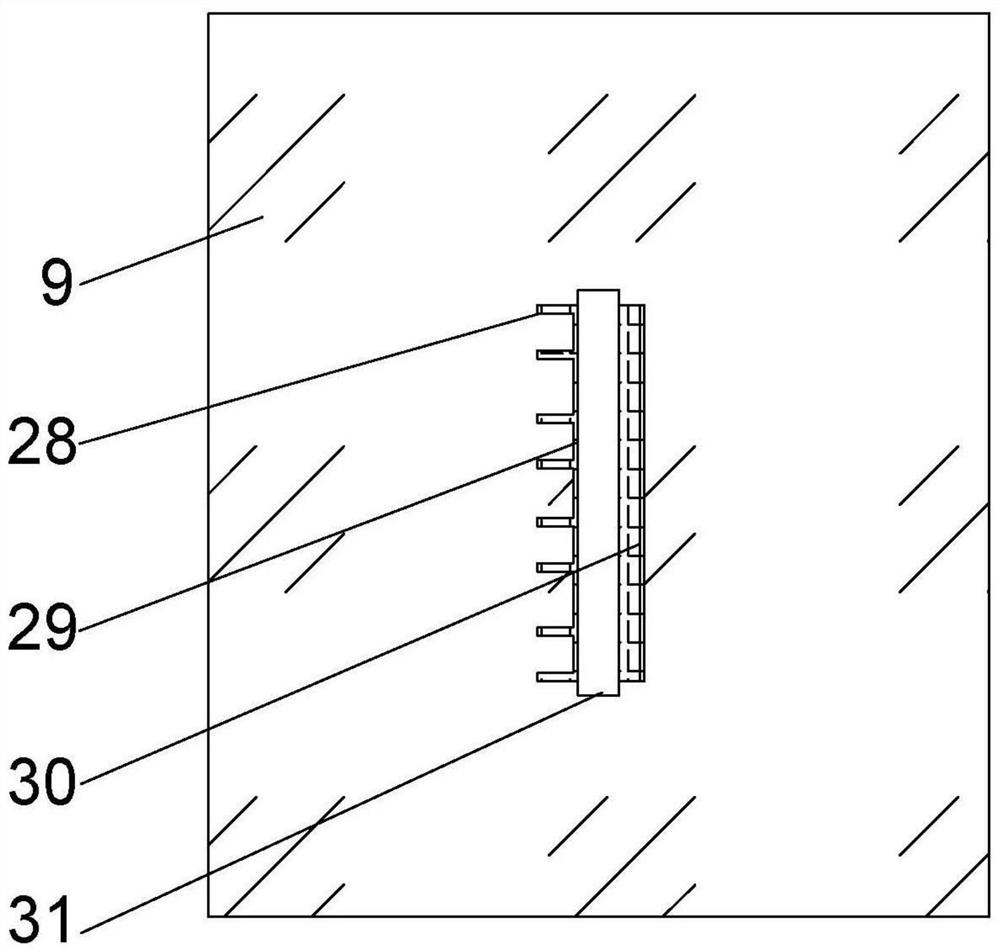

ActiveCN106003824AGuaranteed flat and perfectImprove cropping accuracyPaper-makingBox making operationsPaperboardEngineering

The invention discloses continuous type printing paperboard clipping processing equipment. The continuous type printing paperboard clipping processing equipment comprises a base, a worktable, a first driving mechanism, a mounting frame, a clipping mechanism, a second driving mechanism, third driving mechanisms, a monitor and a control mechanism; a conveying roller group is arranged on the worktable; a detection station is arranged at a discharging end of the conveying roller group; the clipping mechanism comprises a movable plate and a plurality of cutting knives, wherein the movable plate is movably mounted on the mounting frame and is parallel to the base; the movable plate is arranged in the conveying direction of the conveying roller group; in the conveying direction of the conveying roller group, the cutting knives are arranged in parallel on the movable plate; the monitor is used for monitoring whether the paperboard reaches the detection station; the control mechanism is connected with the first driving mechanism, the second driving mechanism, the plurality of third driving mechanisms and the monitor and is used for controlling the first driving mechanism, the second driving mechanism, the third driving mechanisms and the monitor to act. The continuous type printing paperboard clipping processing equipment disclosed by the invention is high in clipping precision, fast in clipping speed and high in processing efficiency; and a clipped paperboard is discharged in time and is fed to the conveying roller group in time, thereby realizing continuous processing of the paperboard.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

Multifunctional underwear cutting table with cutting, dust collection and sorting functions

InactiveCN107336274AEasy to operateOptimize operating timeSevering textilesSortingEngineeringInverted u

A multifunctional underwear cutting table with cutting, dust collection and sorting functions comprises a cutting device, a smoking device, a hot cutting device and a sorting device. The cutting device comprises a workbench, a support, a laser head and a cloth cutting machine, the workbench is rectangular, first grooves are formed in one side edge and the other opposite side edge, the support is in an inverted-U shape, two supporting legs of the support are arranged in the first grooves separately, the laser head is hung at the top of the support, and the cloth cutting machine is fixedly installed at one end of the workbench. A graduated scale is arranged at one end of the workbench. Supporting legs are arranged at the four corner ends of the lower side of the workbench, and pulleys capable of being used for moving are arranged at the bottoms of the supporting legs. The multifunctional underwear cutting table is provided with the cutting device, the smoking device, the hot cutting device and the sorting device, the cutting device, the smoking device, and the hot cutting device and the sorting device are organically combined and converted, so that compared with the prior art that an underwear cutting table is only provided with a cutting device, the multifunctional underwear cutting table has the advantages of being multifunctional in characteristic and high in practical performance.

Owner:谢泽波

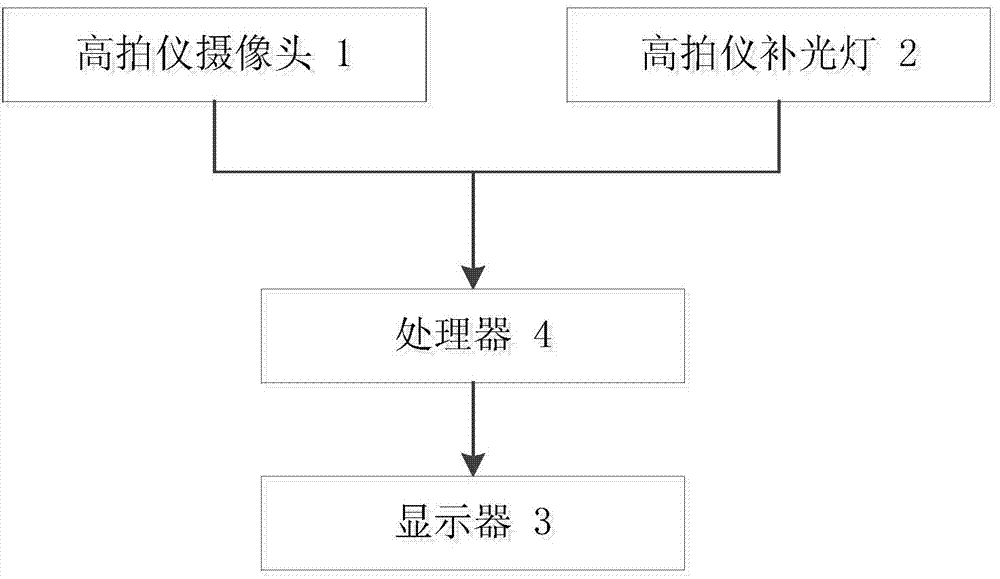

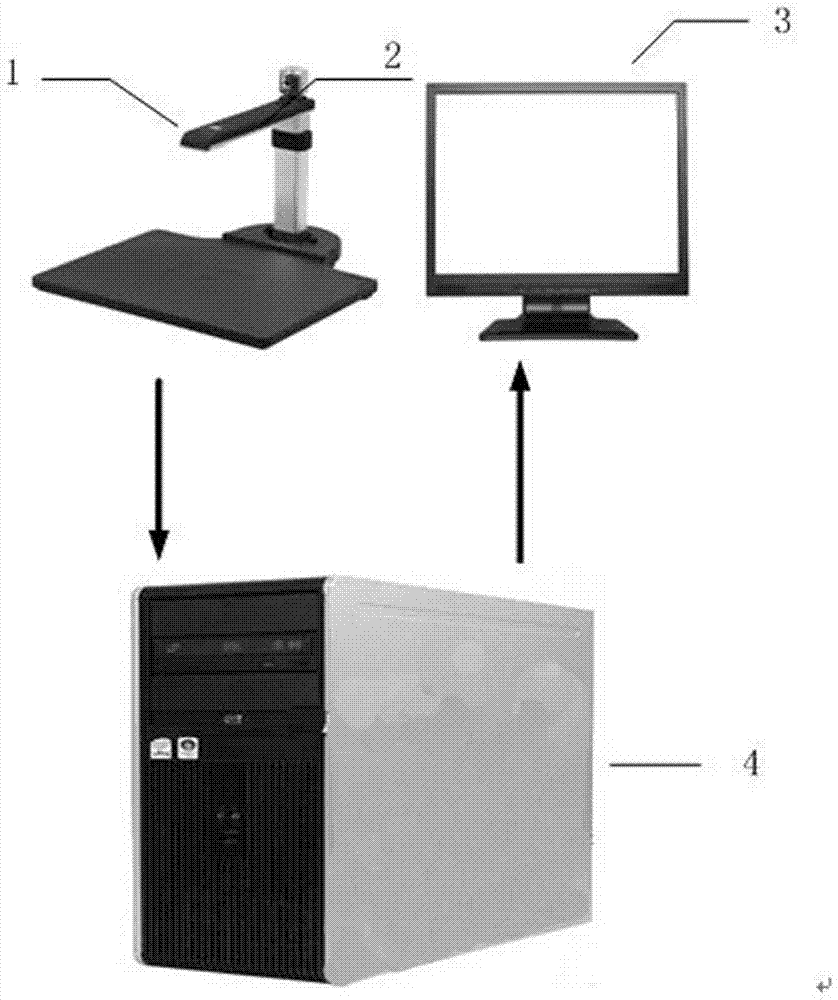

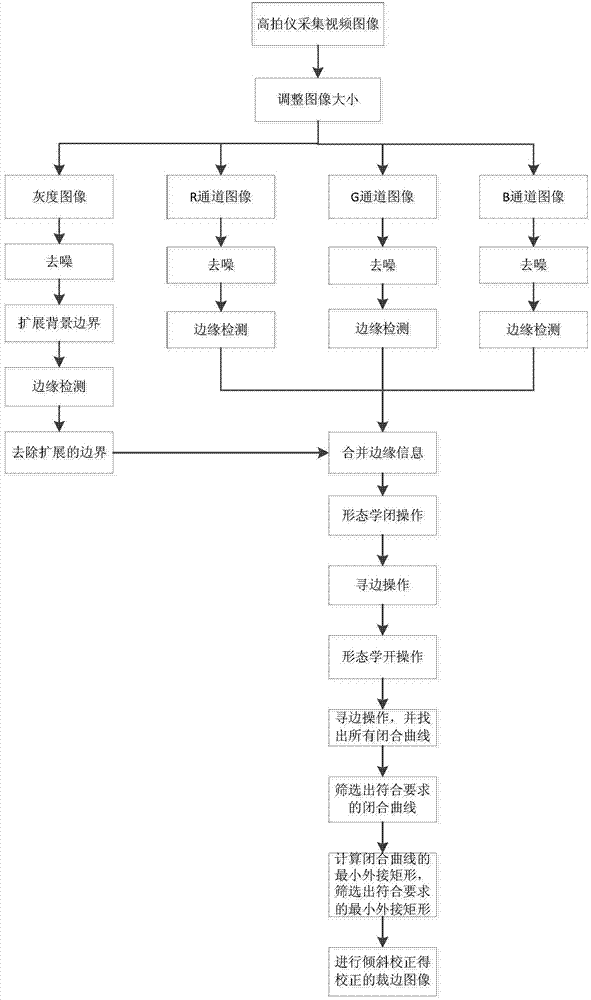

High-speed photographing instrument voucher intelligent edge cutting and correcting system and high-speed photographing instrument voucher intelligent edge cutting and correcting method based on silhouette extraction

ActiveCN104240259AImprove efficiencyImprove cropping accuracyImage analysisContour segmentationDisplay device

The invention discloses a high-speed photographing instrument voucher intelligent edge cutting and correcting system based on silhouette extraction. The high-speed photographing instrument voucher intelligent edge cutting and correcting system based on silhouette extraction comprises a high-speed photographing instrument camera (1), a high-speed photographing instrument light supplementing lamp (2), a display (3) and a processor (4) with an image edge cutting and correcting function, wherein the high-speed photographing instrument camera (1) is used for acquiring voucher images in a video; the high-speed photographing instrument light supplementing lamp (2) is used for improving brightness under the condition that an external environment is dark; the high-speed photographing instrument camera (1) and the high-speed photographing instrument light supplementing lamp (2) are connected with the processor (4) with the image edge cutting and correcting function; the voucher images which are acquired by the high-speed photographing instrument camera (1) are subjected to edge cutting and correction treatment by the processor (4); and the display (3) is connected with the processor (4) and is used for displaying a processing result of the processor (4). By the high-speed photographing instrument voucher intelligent edge cutting and correcting system, manual operation is not required; and the anti-interference property and the adaptability of the voucher bill edge cutting method are improved.

Owner:GUOGUANG ELECTRONICS INFORMATION TECH

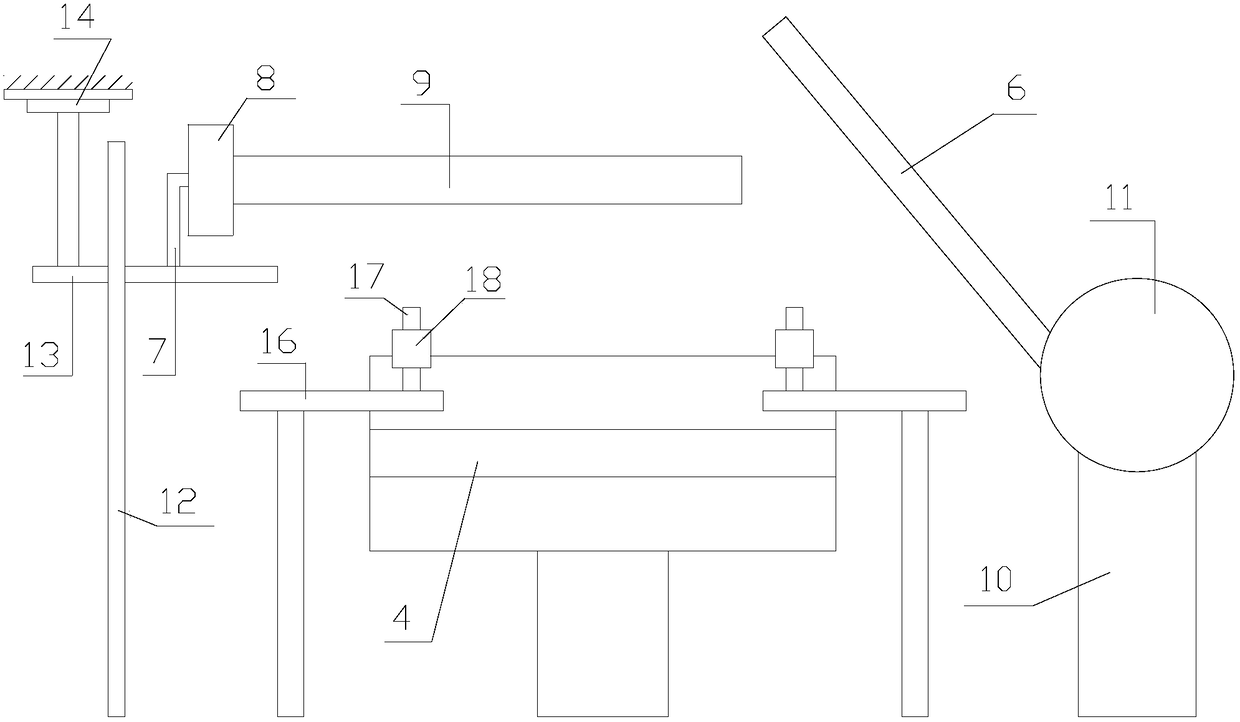

Efficient cloth cutting machine for garment production

The invention discloses an efficient cloth cutting machine for garment production. The efficient cloth cutting machine for garment production comprises a cutting work table, a guide rail and a raw material support frame, wherein a cloth pressing device is arranged above the cutting work table and comprises an installing plate, a pushing air cylinder and a cloth pressing plate; the center part of the cloth pressing plate is provided with a rebounding device; the left side of the cutting work table is provided with a cleaning device; the cleaning device comprises a telescopic post, a connecting plate, a telescopic plate and a hair brush; a cutting device is arranged on the guide rail and comprises a cutter, an electric motor, a handle and a position limiting plate; the bottom surface of the position limiting plate is provided with a position limiting convex block. The efficient cloth cutting machine has the advantages that the structure is simple; the practicability is high; through the design of the cloth pressing device, the quality of cloth cut by the cloth cutting machine is higher; the resource waste is reduced; meanwhile, due to the design of the cleaning device, through the effects of a telescopic post and the telescopic plate, the hair brush can cleanly clean the surface on the cutting work table; the use is more convenient and simpler; the cost is reduced; the integral utilization efficiency is improved.

Owner:SHAOXING HENRY TIE FASHION

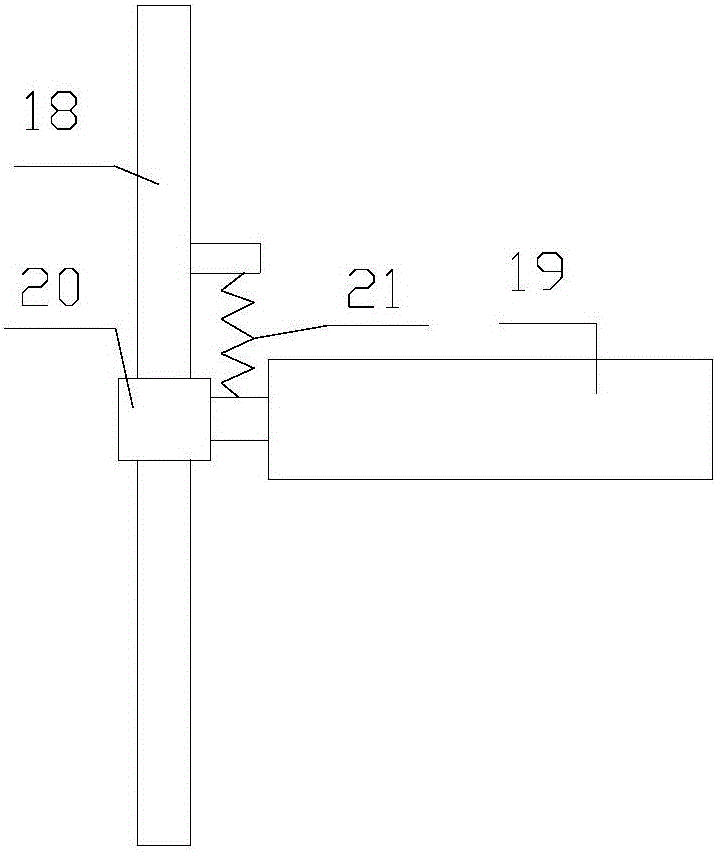

Garment tailoring device suitable for families

The invention relates to a tailoring device, in particular to a garment tailoring device suitable for families. The technical aims that in the garment tailoring device suitable for families, fabrics cannot be tailored to be damaged, and tailoring is accurate are achieved. The garment tailoring device suitable for families comprises a bottom plate, supporting rods, a containing plate, an installingframe, a motor, a rotating shaft, a threaded rod, a nut, first sliding rails, a first sliding block, a guiding sleeve, a guiding rod, a pressing block, a first spring and the like; the supporting rods are symmetrically arranged on the left side on the bottom plate left and right, the containing plate is connected to the top ends of the supporting rods, the installing frame is arranged on the leftside of the top of the containing plate, the motor is installed on the right side of the top in the installing frame, and the rotating shaft is connected on an output shaft of the bottom of the motor. According to the a garment tailoring device suitable for families, the effects that tailor fabrics cannot be tailored to be damaged, and tailoring is accurate are achieved; the fabrics are pressed through the pressing block and tailored through a tailoring cutter, the tailoring accuracy is increased, and the fabrics cannot be tailored to be damaged.

Owner:晋江诺研机械设计有限公司

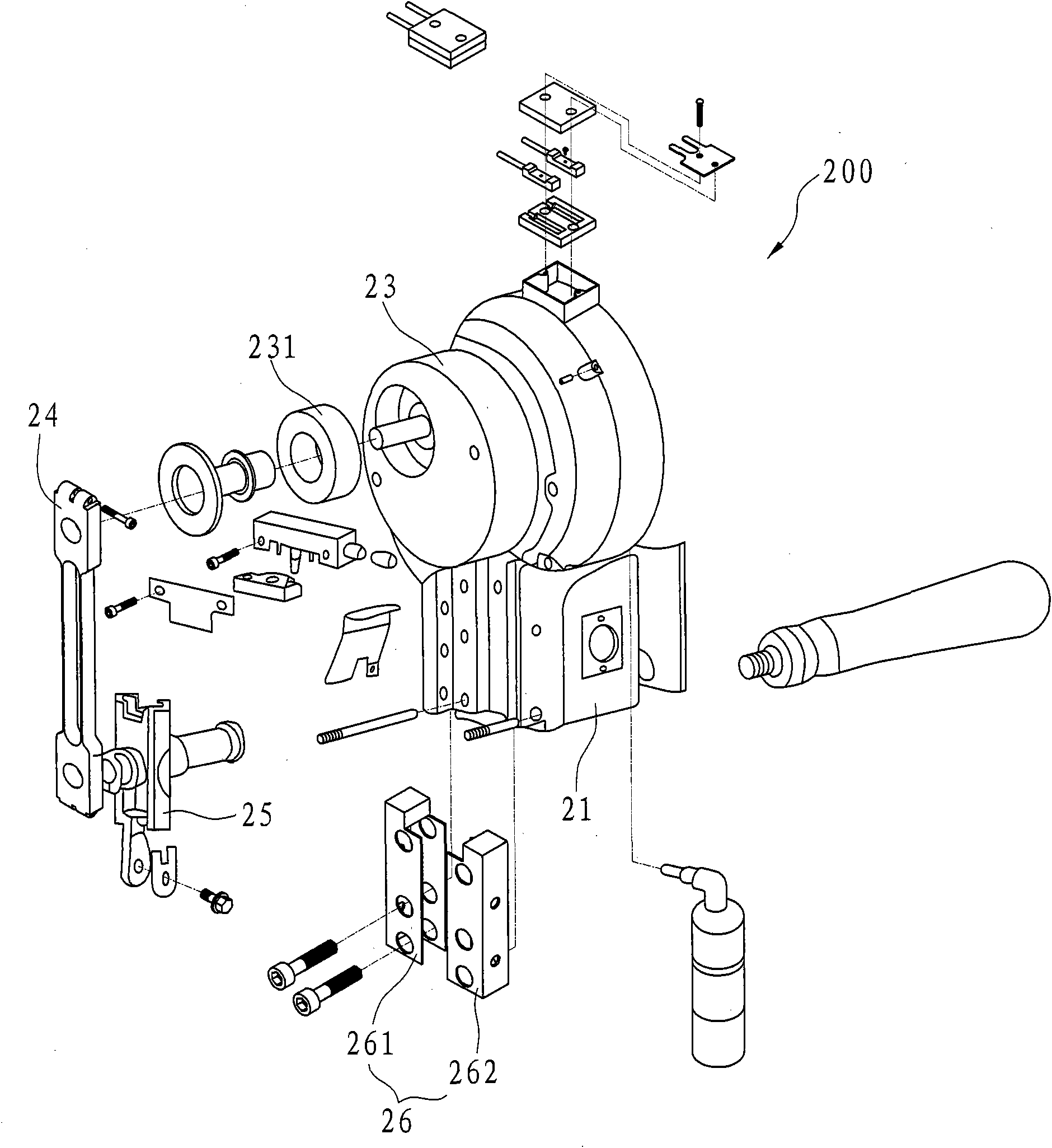

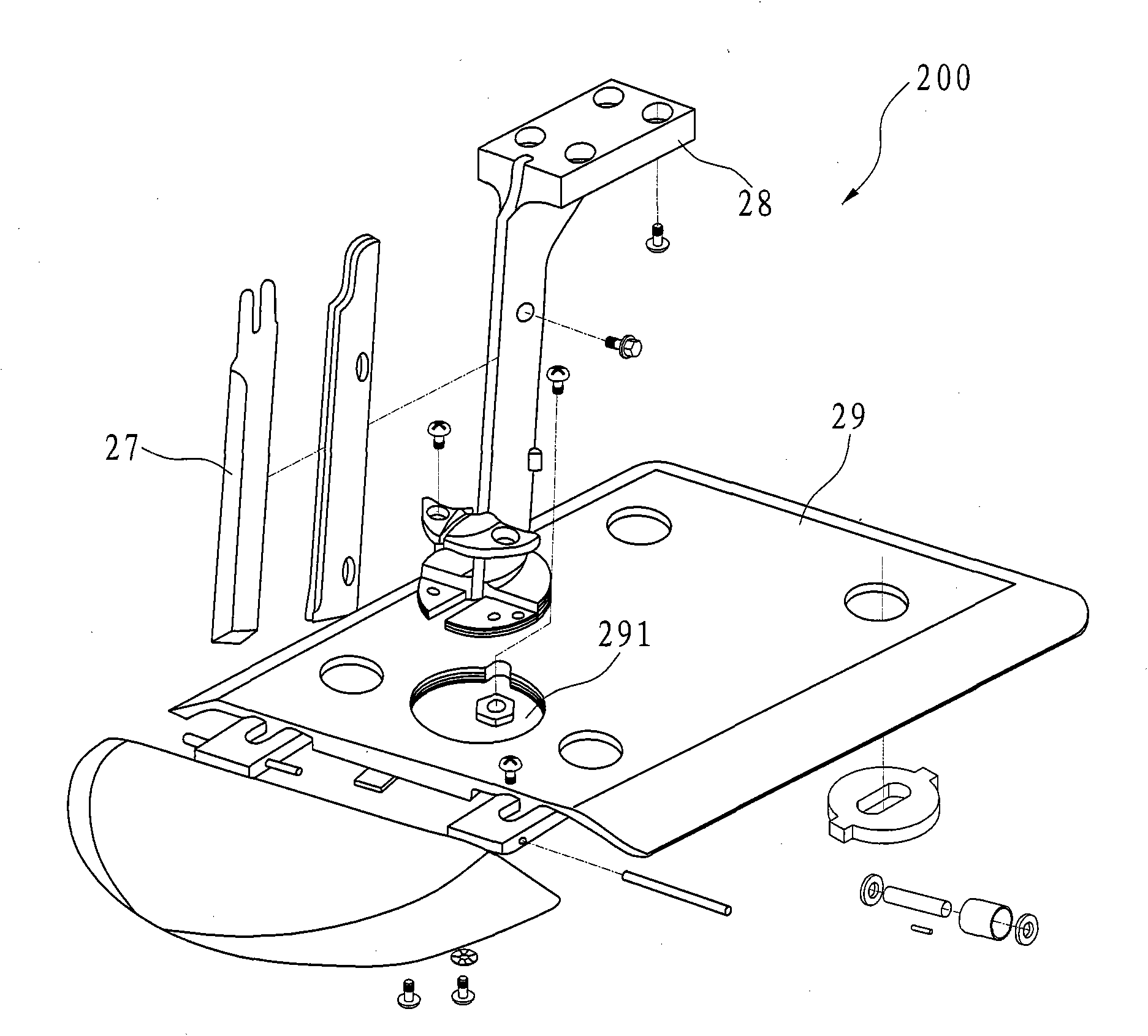

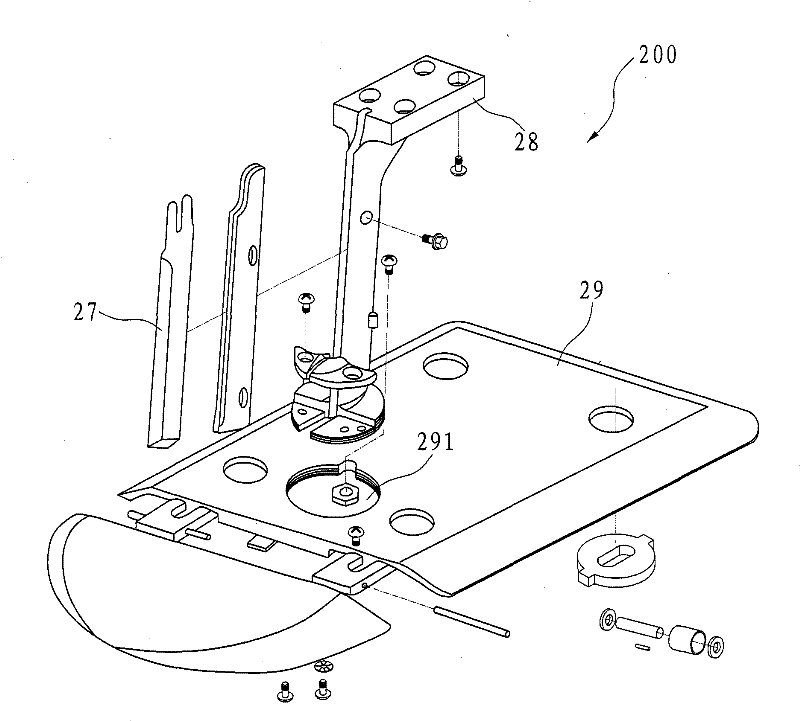

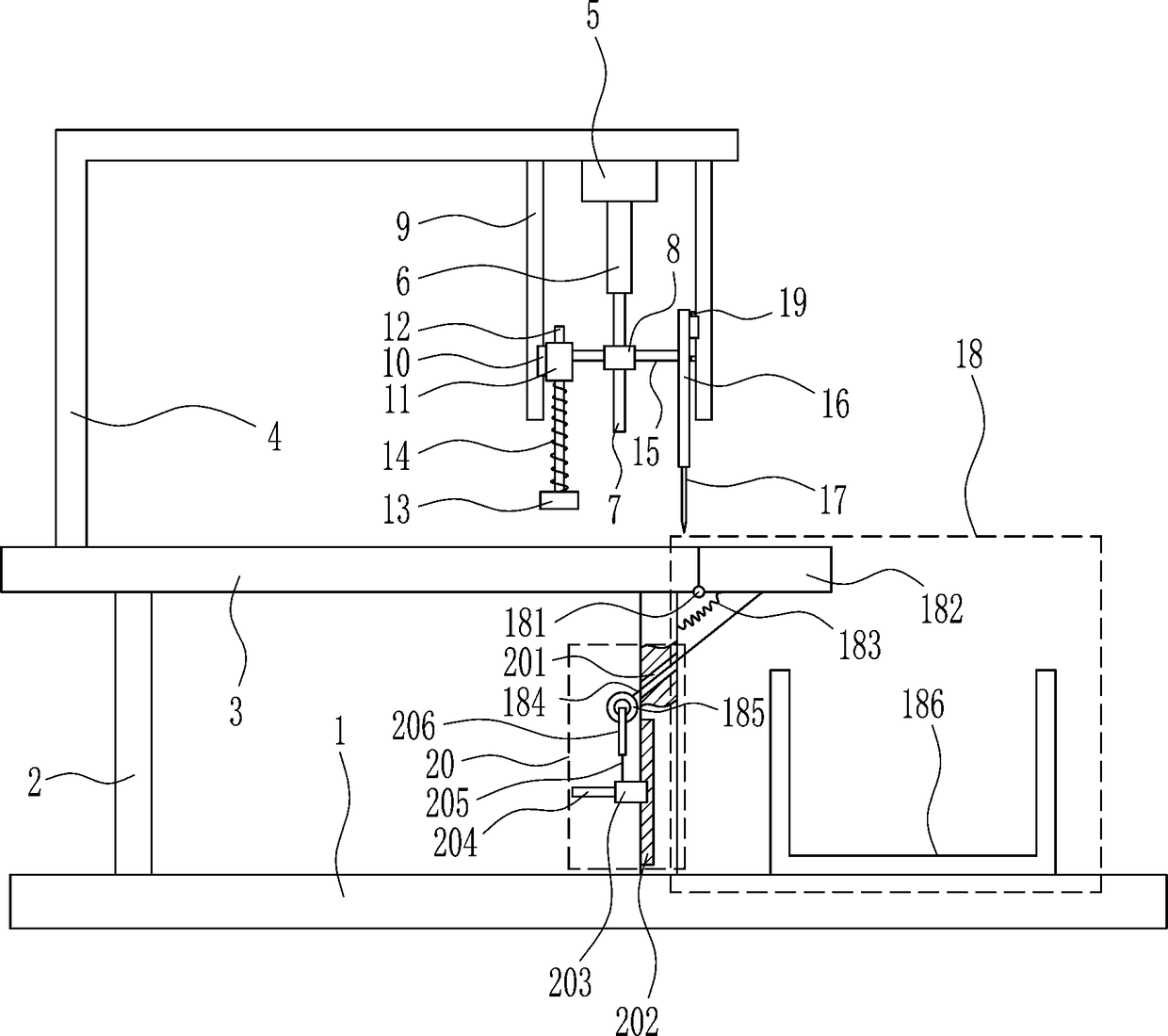

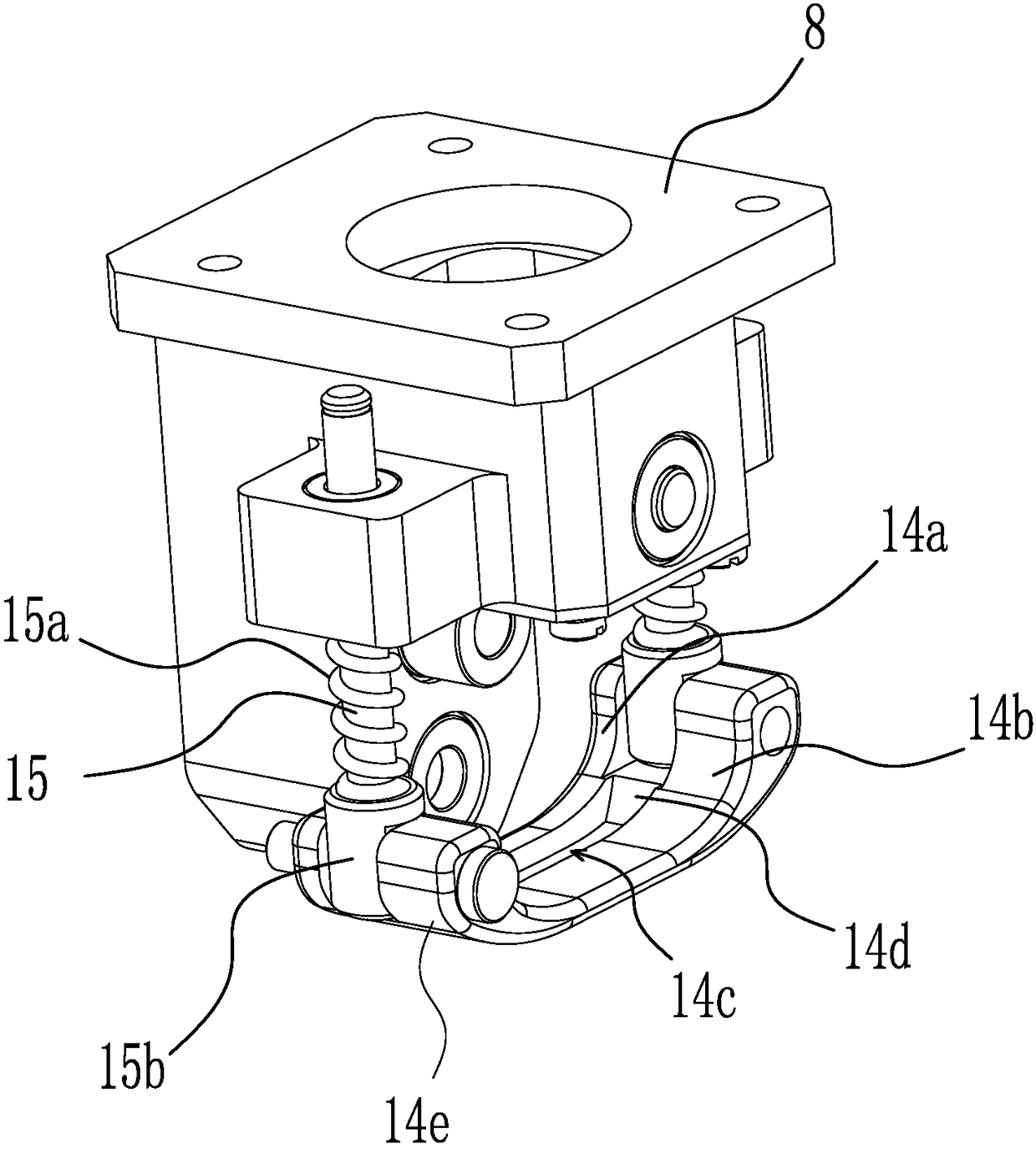

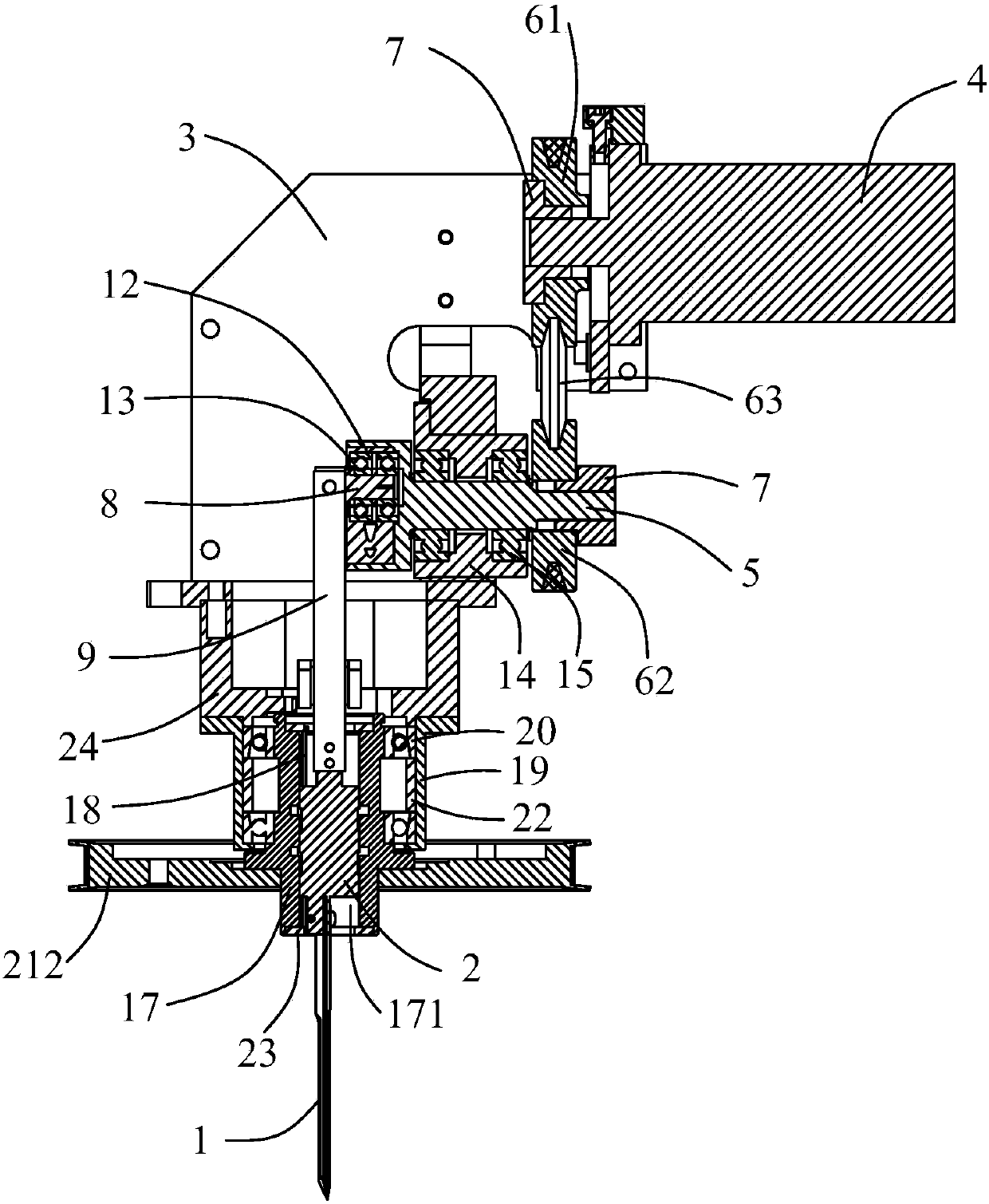

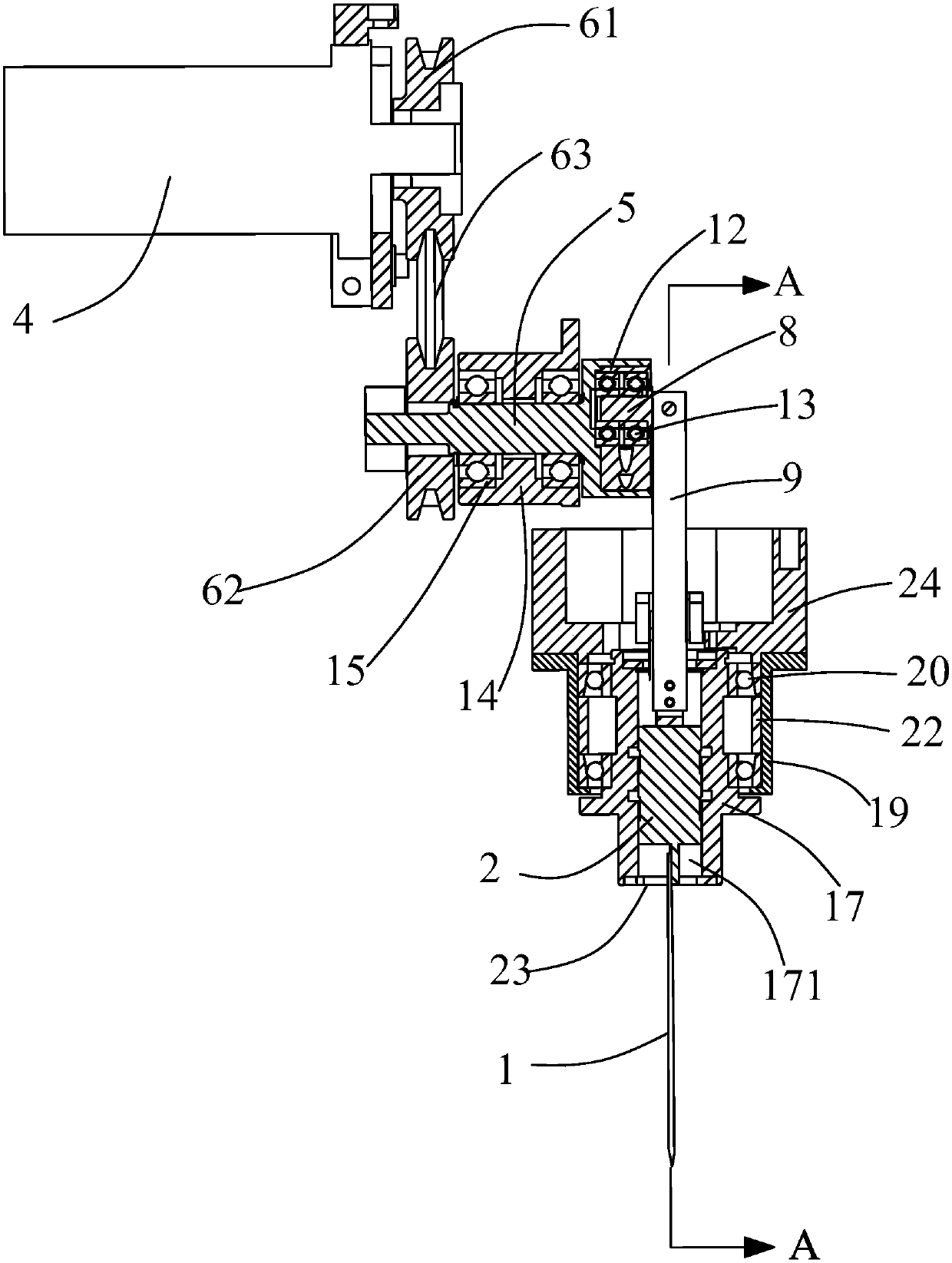

Cutter device for sewing machine

ActiveCN108301132AWon't wrinkleGuaranteed accuracyWorkpiece carriersPressersBlade plateCotton material

The invention provides a cutter device for a sewing machine and belongs to the technical field of machinery. The problem of low cloth cutting precision of an existing cutter device is solved. The cutter device for the sewing machine comprises a lifting rack, a cutter, a pressure foot and a lower cutter plate which can rotate, a rotation rack which can rotate along with the lower cutter plate synchronously is arranged on the lifting rack, and the pressure foot and the cutter are arranged on the lower portion of the rotation rack; the pressure foot comprises a first press plate and a second press plate, a strip-shaped gap for the lower portion of the cutter to penetrate through is formed between the first press plate and the second press plate, and the width of the strip-shaped gap is slightly larger than the thickness of the cutter. The cutter device for the sewing machine is reasonable in structure and high in cutting precision.

Owner:ZHEJIANG ZOJE SEWING MACHINE

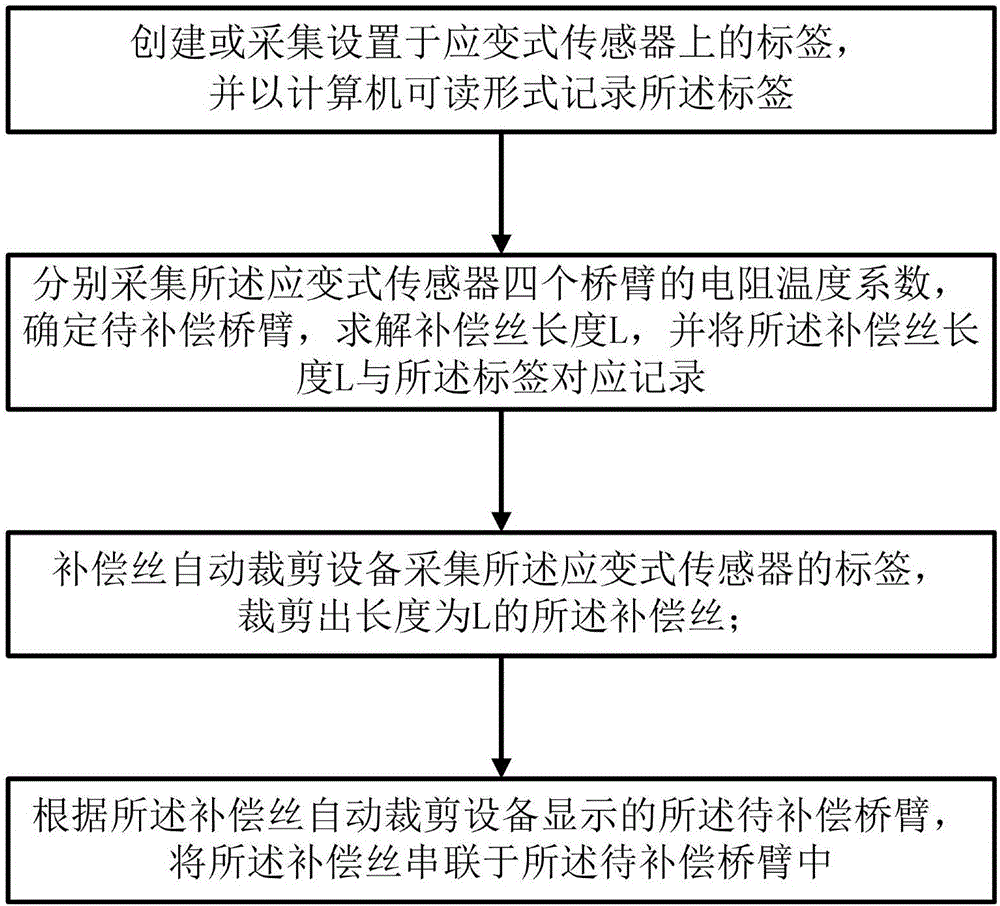

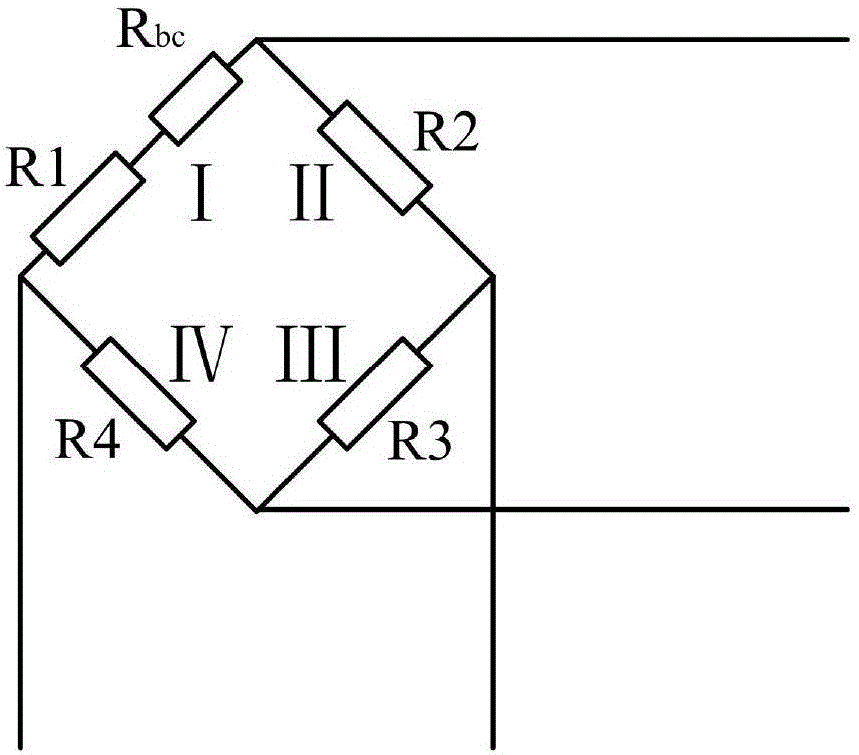

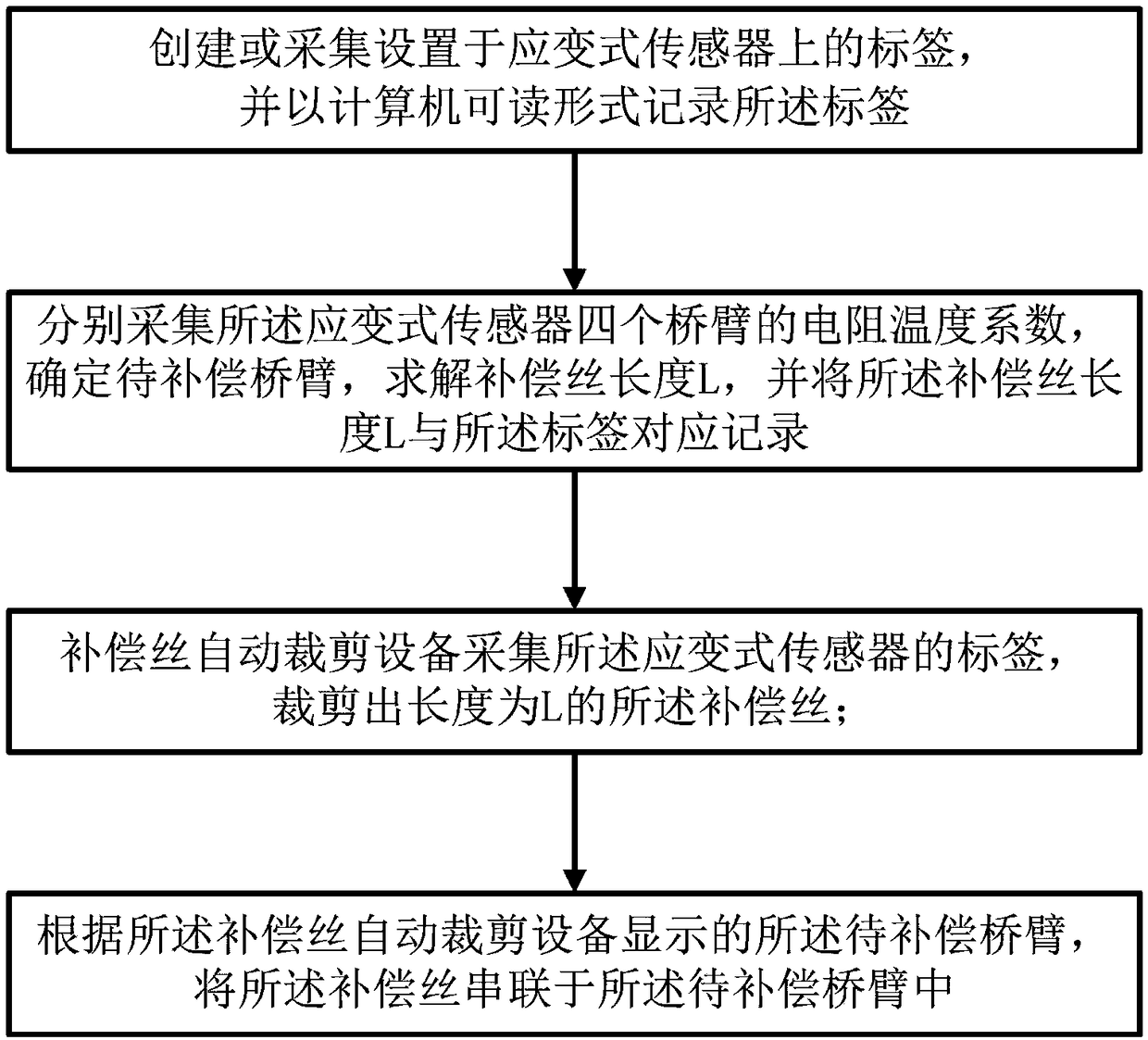

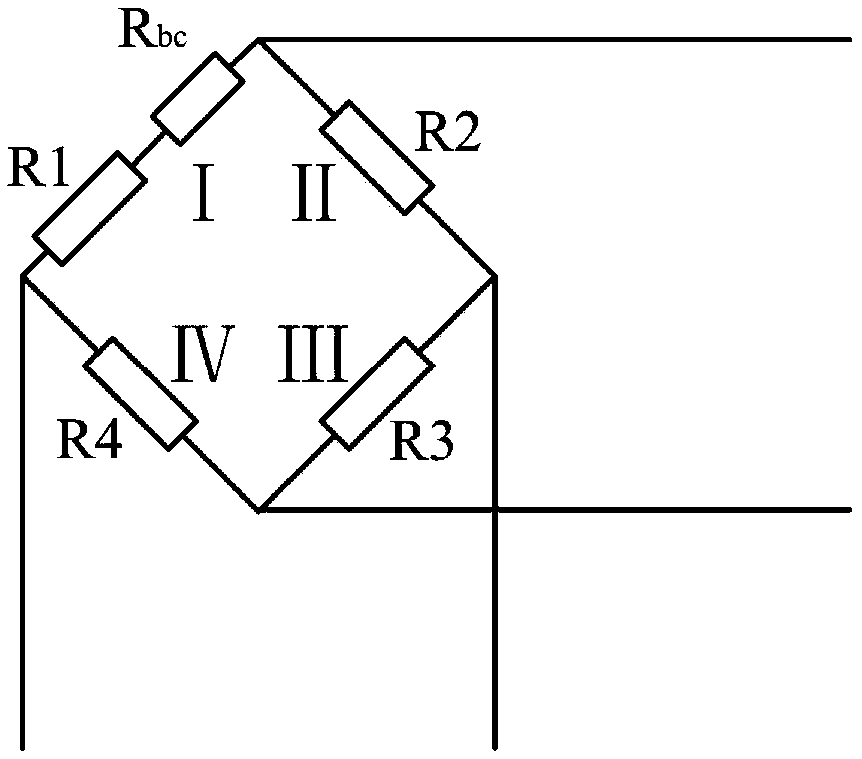

Temperature compensation method of strain gauge transducer

ActiveCN106768217AImprove cutting efficiencyImprove cropping accuracyWeighing apparatus using elastically-deformable membersTemperature coefficientEngineering

The invention discloses a temperature compensation method of a strain gauge transducer, wherein the temperature compensation method relates to the field of strain gauge transducer manufacture. The temperature compensation method comprises the following steps of S1, creating or acquiring a label which is arranged on the strain gauge transducer, and recording the label; S2, respectively acquiring resistance temperature coefficients of four bridge arms of the strain gauge transducer, determining a to-be-compensated bridge arm, solving a compensation wire length L, and correspondingly recording the compensation wire length L and the label; S3, acquiring the label of the strain gauge transducer by compensation wire automatic cutting equipment, and cutting the compensation wire with length of L; and S4, according to the to-be-compensated bridge arm which is displayed by the compensation wire automatic cutting equipment, connecting the compensation wire with the to-be-compensated bridge arm. According to the temperature compensation method, the label on the strain gauge transducer is acquired in a computer-readable manner; and furthermore a compensation wire parameter which corresponds with the label is recorded, thereby realizing no requirement for artificial recording and preventing errors. The compensation wire with the preset length is cut through the automatic cutting equipment, thereby improving cutting efficiency and improving cutting precision.

Owner:RUIMA ELECTRIC MFG FUJIAN

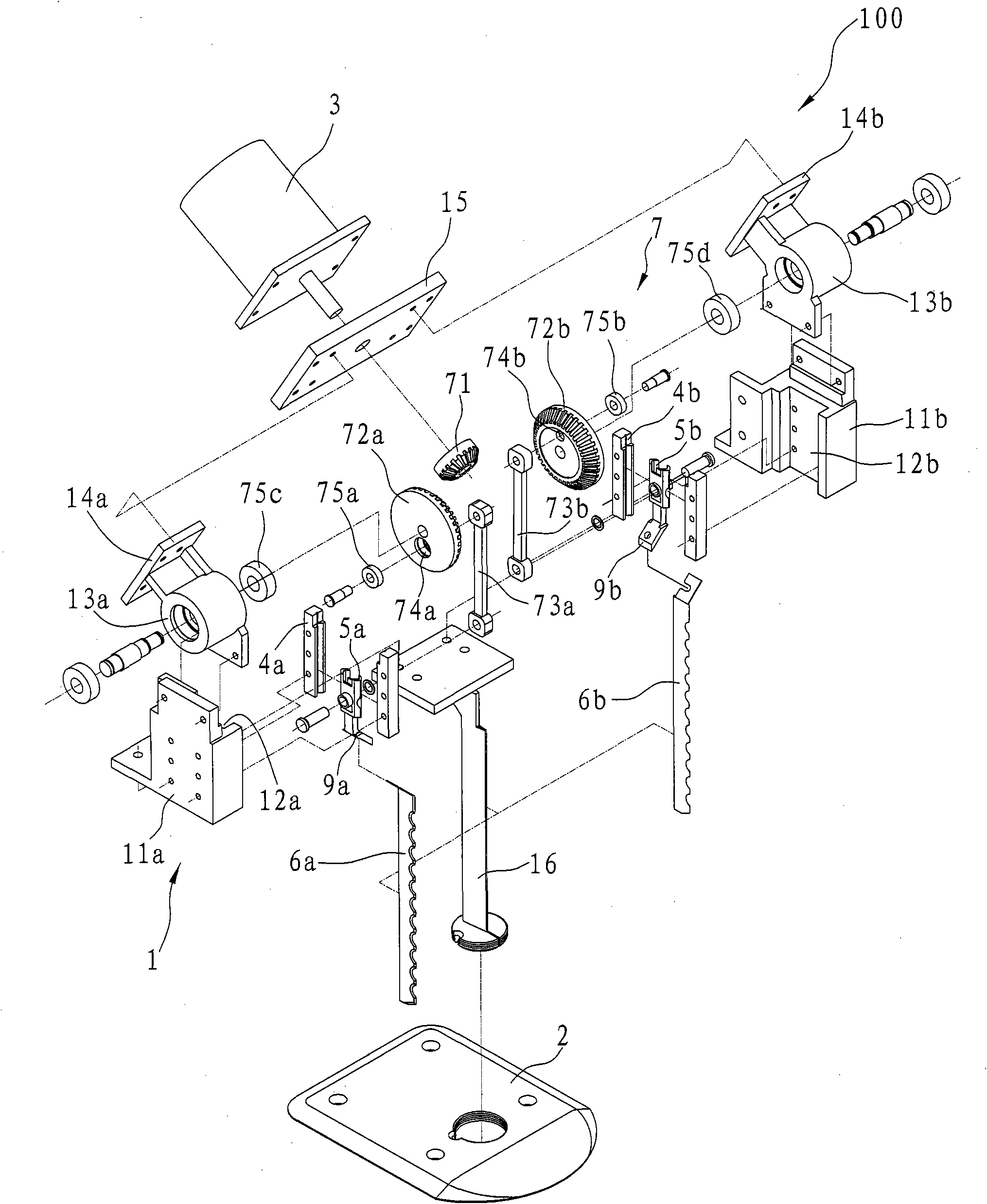

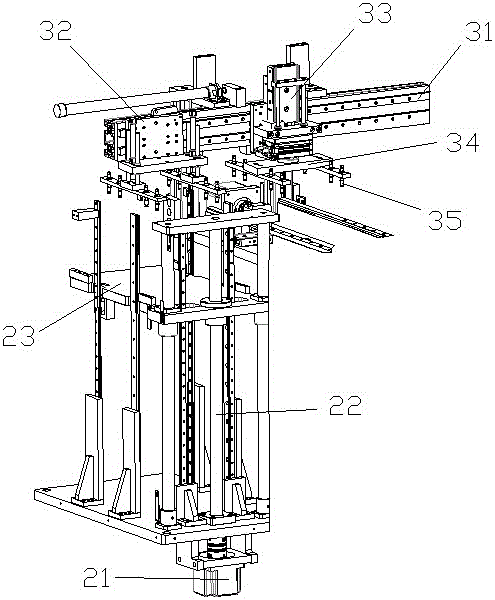

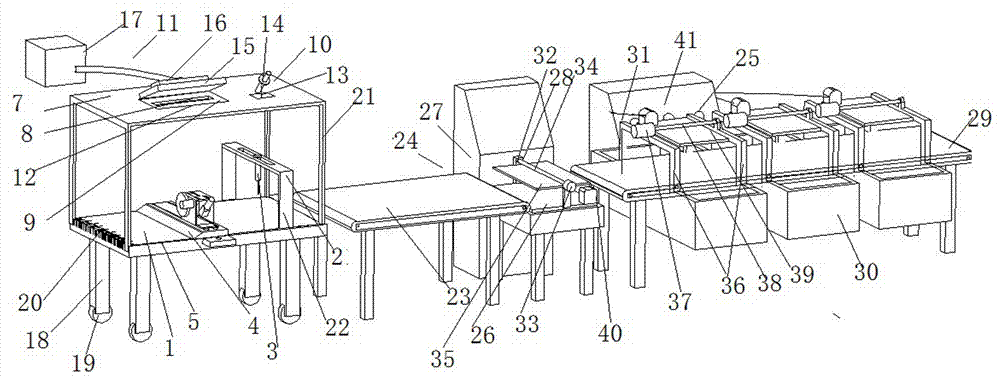

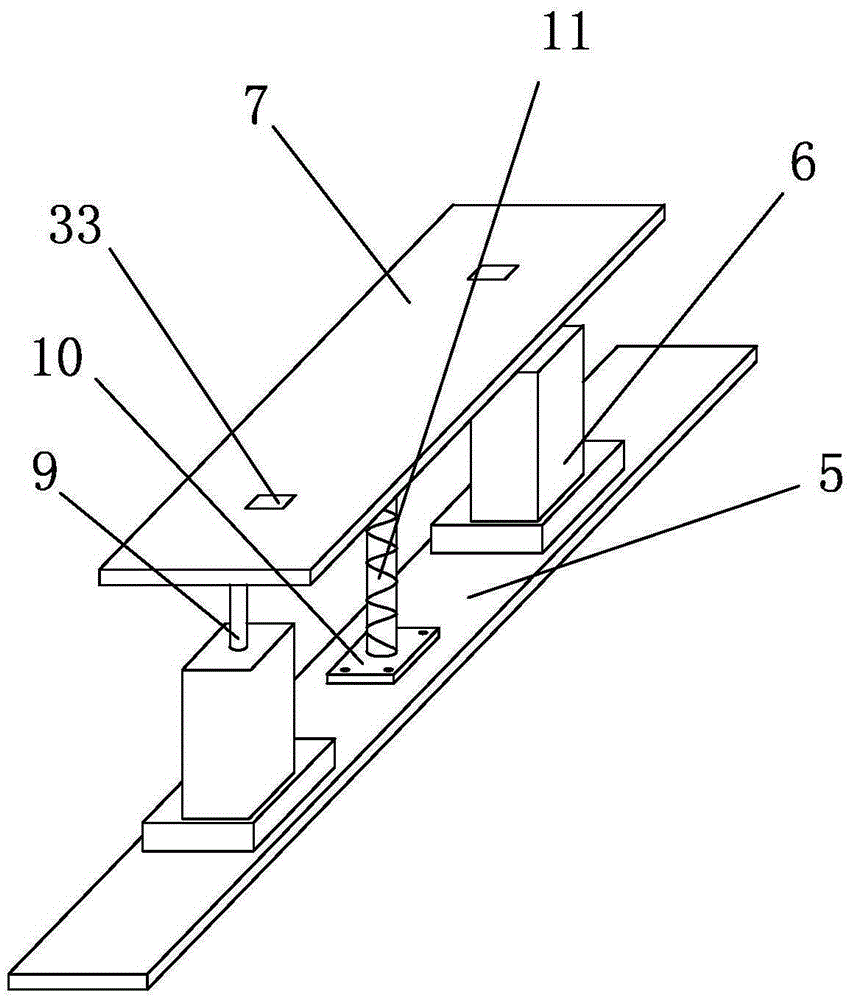

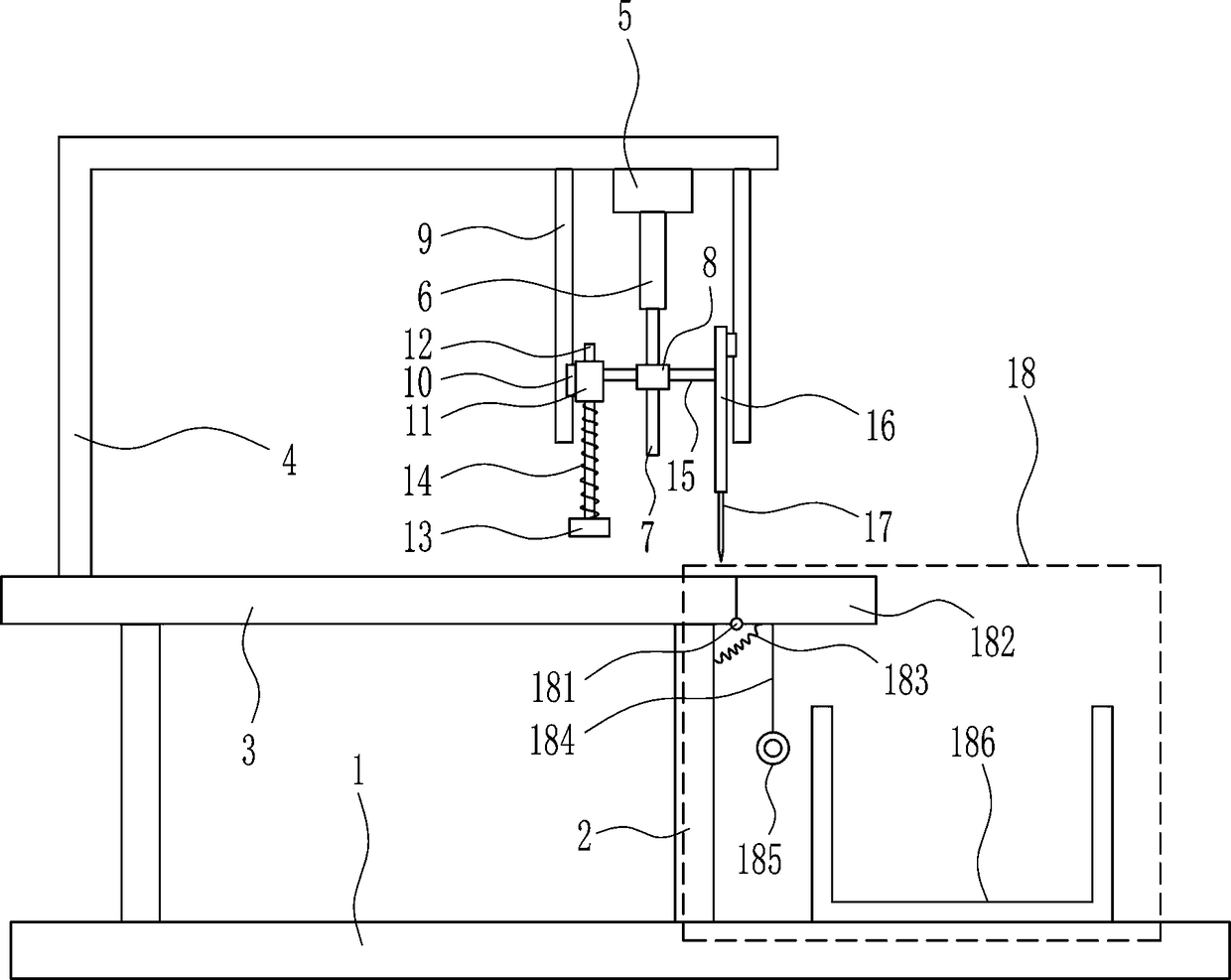

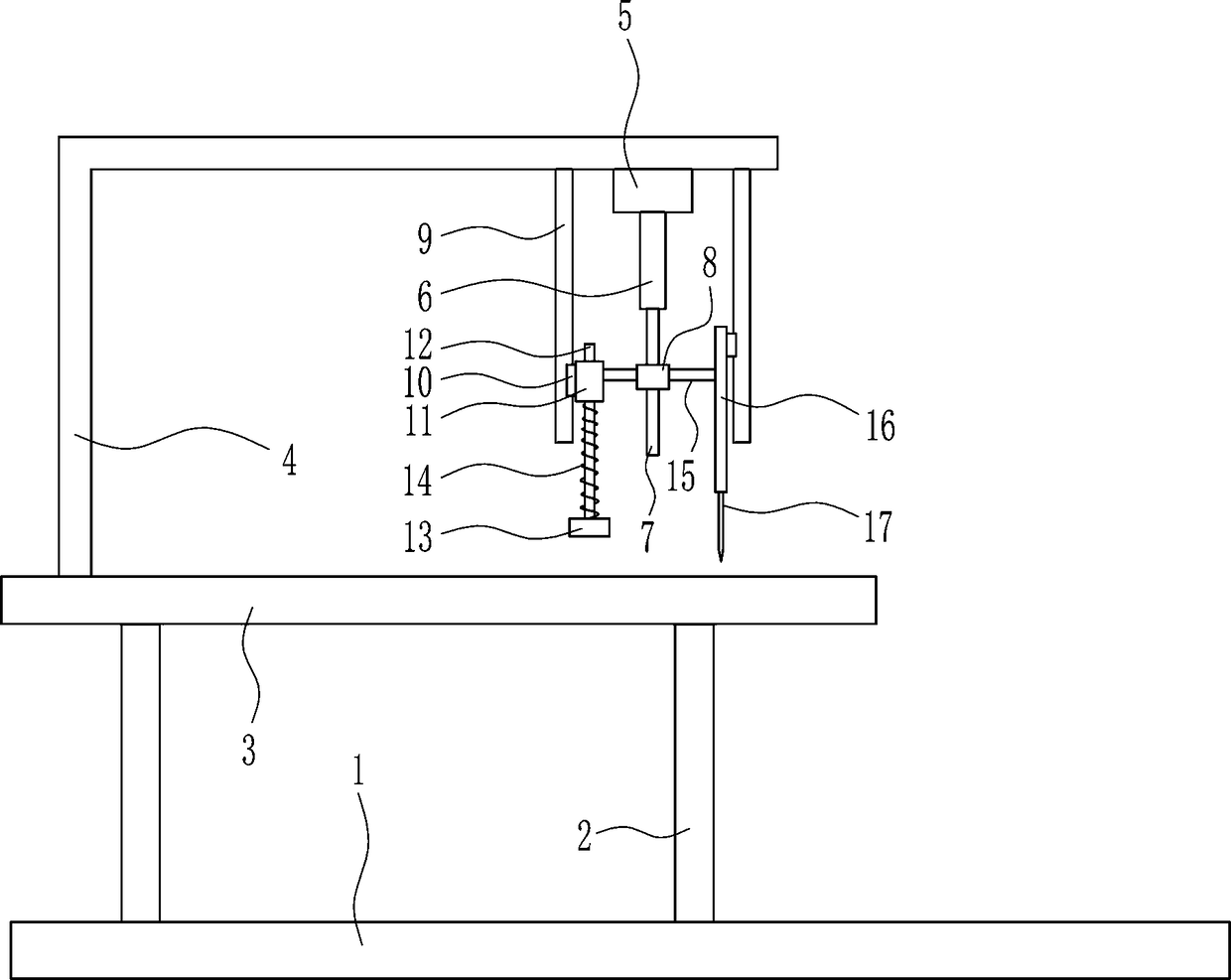

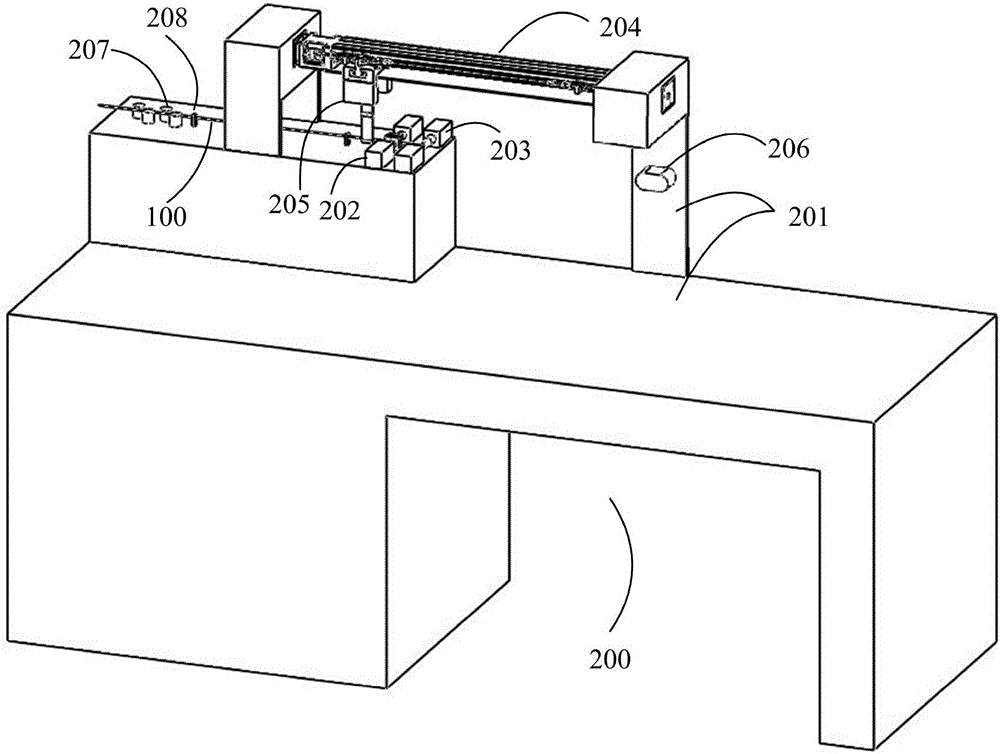

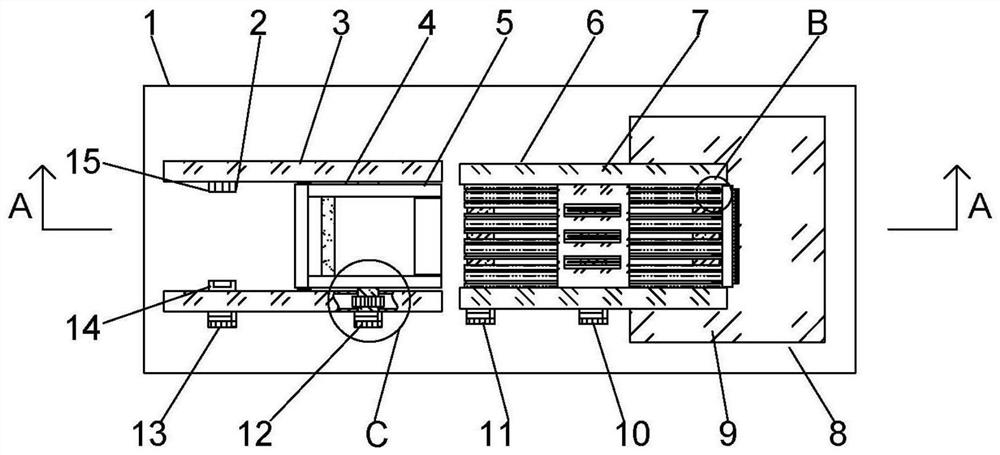

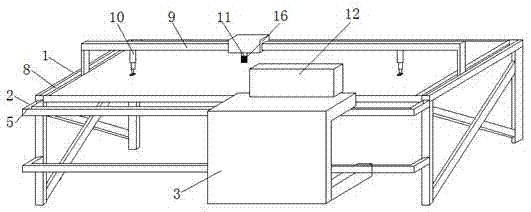

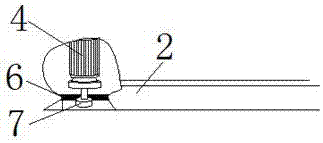

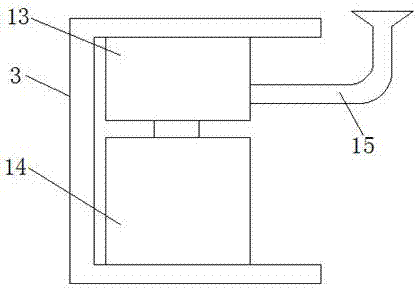

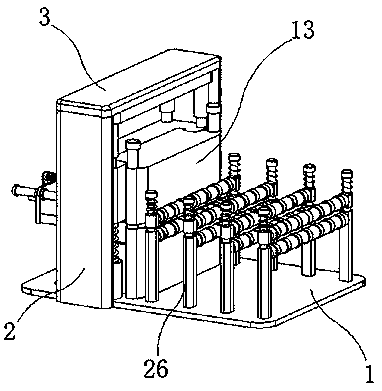

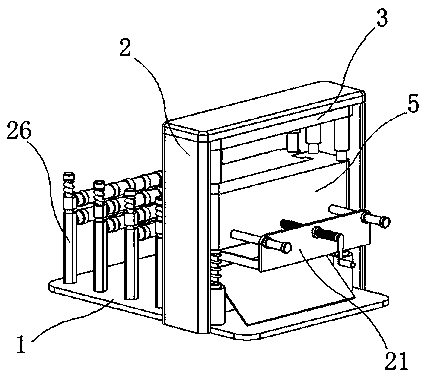

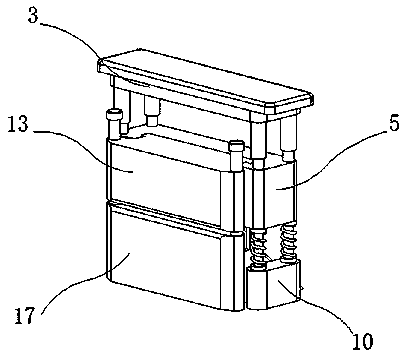

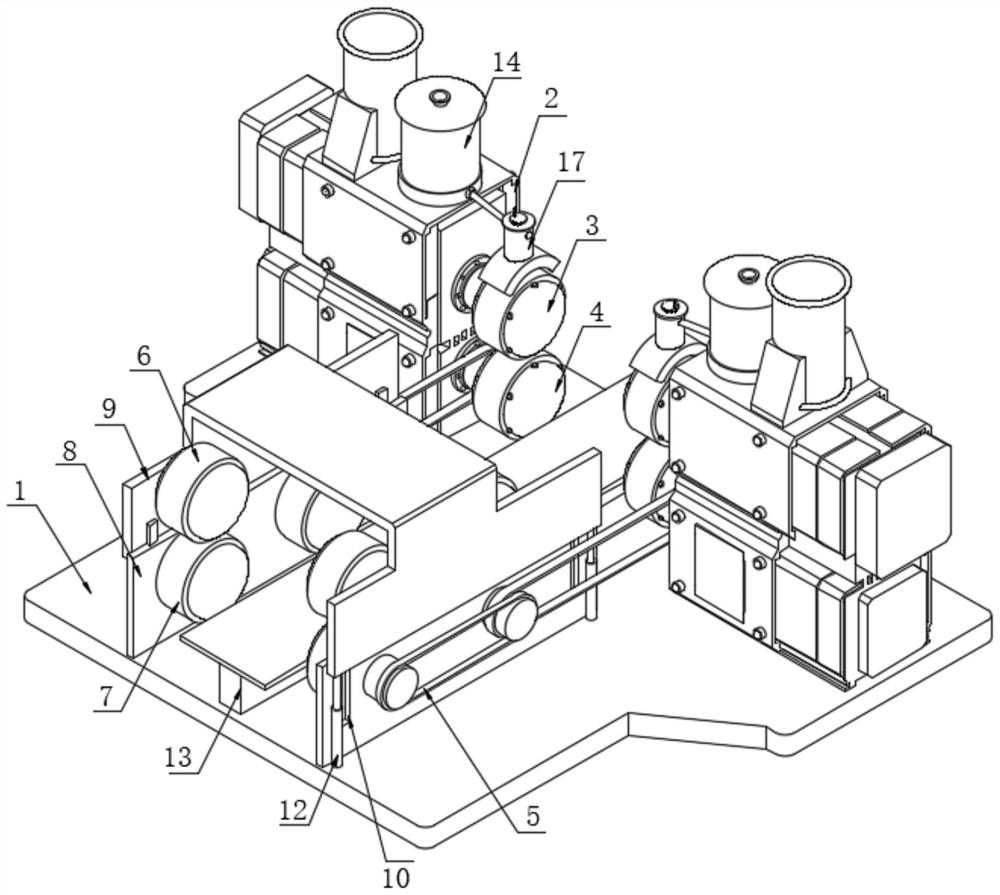

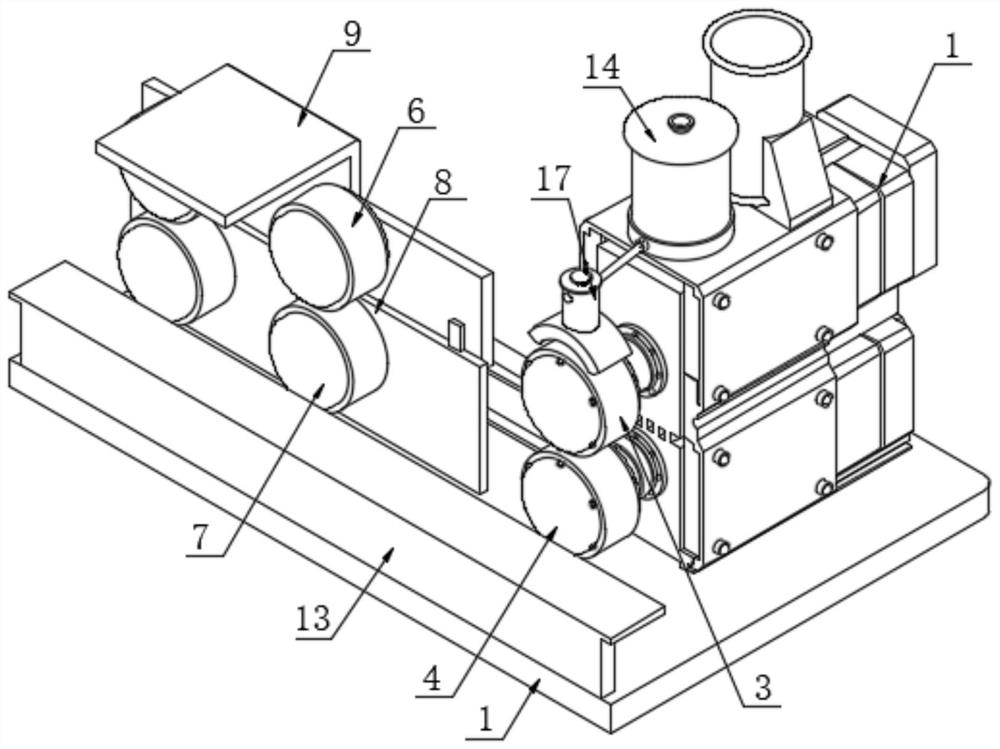

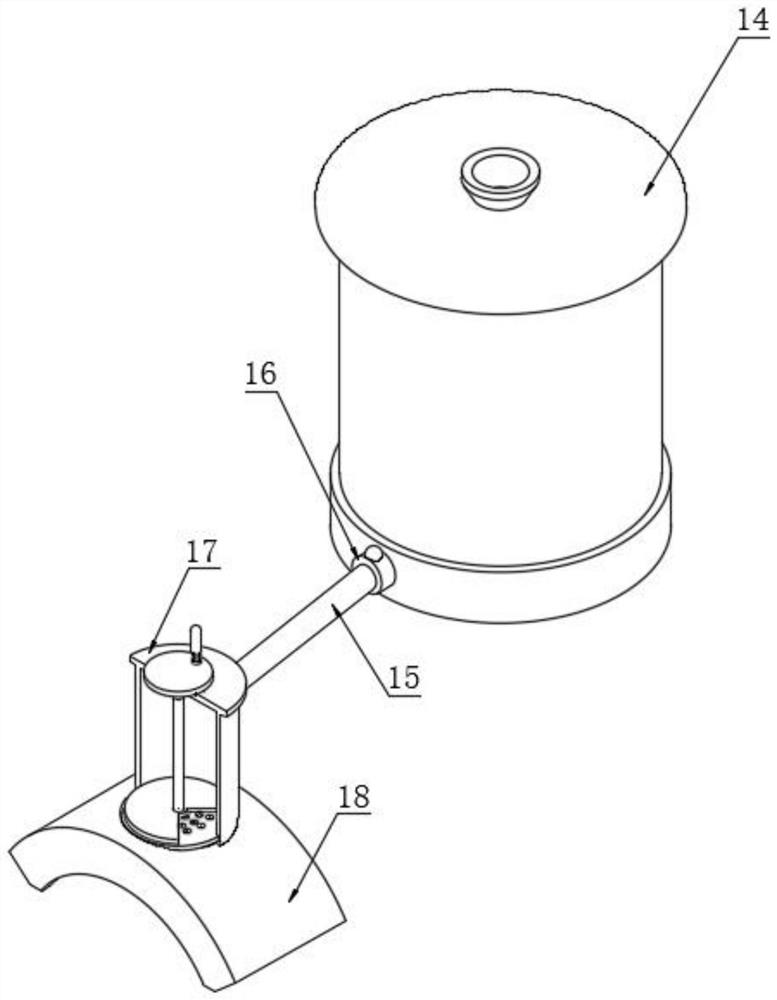

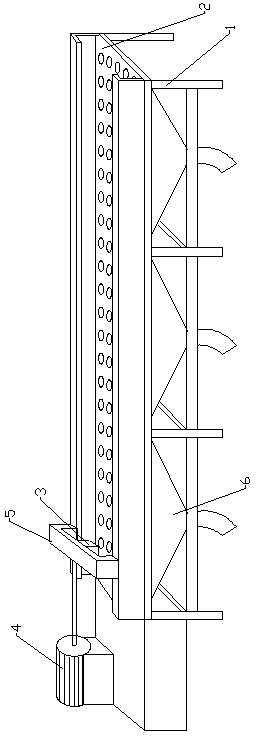

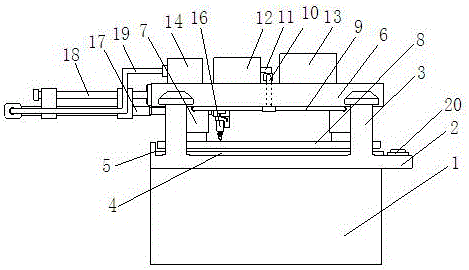

Cutting device for automatic cutting system

ActiveCN105970590BImprove cropping accuracyImprove cutting efficiencySevering textilesEngineeringUltimate tensile strength

The invention provides a clipping device of an automatic clipping system. The clipping device comprises a rack, a clipping tool extending vertically, an X-direction moving support, a Y-direction moving support and a vertical moving mechanism, wherein the X-direction moving support is mounted on the rack and capable of moving in the front and back direction; the Y-direction moving support is mounted on the X-direction moving support and capable of moving laterally; the vertical moving mechanism is mounted on the Y-direction moving support and provided with a rotatable tool fixing bar capable of reciprocating vertically, and the upper end of the clipping tool is fixedly connected with the lower end of the tool fixing bar. According to the clipping device, the clipping tool can move front and back in the X direction, move laterally in the Y direction, reciprocate vertically in the Z direction and rotate, and accordingly purposes of automatic fabric cutting and clipping are achieved; the clipping device has high clipping precision, high clipping speed, high clipping efficiency and low labor intensity.

Owner:BULLMER ELECTROMECHANICAL TECH

Antibacterial cream for baby soft tissue and preparation method of baby soft tissue

PendingCN111821203AImprove functionalityReduce workloadCosmetic preparationsToilet preparationsSodium lactatePhenolic content in tea

The invention discloses antibacterial cream for baby soft tissue and a preparation method of the baby soft tissue. The antibacterial cream comprises the following components: 90-95% of pure water, 5-9% of glycerol, 1-2% of pentaerythritol, 0.01-0.02% of a bacteriostatic agent, 0.05-0.2% of a moisturizing factor and 0.3-0.8% of a softener, wherein the bacteriostatic agent comprises one or more of glycerol monolaurate, tea polyphenol and chitosan; the moisturizing factor comprises one or more of propylene glycol, amino acid, sodium lactate and urea; and the softener comprises one or more of polyether type hydrophilic organic silicon and amino modified organic silicon. The antibacterial cream has the beneficial effects that the soaked soft tissue is automatically cut into the target size through a cutting device, compared with manual cutting, the workload of workers is greatly reduced, and the cutting precision is improved.

Owner:浙江新远实业有限公司

A kind of cardboard cutting and processing equipment

ActiveCN105922331BPrevent deviationGuarantee subsequent processing accuracyMetal working apparatusCardboardConveyor belt

The invention discloses paperboard cutting and processing equipment. The equipment comprises a mounting frame, a conveyor belt, a rotary shaft, a first driving unit, a cutting part and a pressing and holding part. The conveyor belt is mounted on the mounting frame. The upper surface of the conveyor belt is provided with a plurality of accommodating grooves which are evenly distributed in the length direction of the conveyor belt. The length direction of the accommodating grooves is perpendicular to the length direction of the conveyor belt. The lower surface of the conveyor belt is provided with first gears which are distributed in the length direction of the conveyor belt. The rotary shaft is rotatably mounted on the mounting frame. One end of the rotary shaft is arranged in a space defined by the conveyor belt. The local peripheral surface of the rotary shaft is provided with second gears which are distributed in the circumferential direction of the rotary shaft. The second gears are engaged with the first gears. The first driving unit is used for driving the rotary shaft to rotate. The cutting part is used for cutting paperboards and comprises a second driving unit and a blade. The second driving unit is used for driving the blade to move close to the accommodating grooves or far from the accommodating grooves. The paperboard cutting and processing equipment is good in paperboard cutting effect.

Owner:BENGBU ZHENHUA PACKING MACHINERY

Controllable automatic cutting table

ActiveCN106388105ASimple structureEasy to operateSevering textilesClothes making applicancesEngineeringLinear motor

The invention discloses a controllable automatic cutting table. The controllable automatic cutting table comprises a workbench, wherein two U-shaped guide frames are arranged at the front end of the workbench, a guide groove is arranged in one side of each U-shaped guide frame, the two guide grooves are arranged on the side surfaces of the two U-shaped guide frames back to back, a mobile platform is mounted between the two U-shaped guide frames, and the mobile platform is U-shaped. Two hydraulic rods are adopted for fixing cloth, so that the deviation is avoided; a linear motor moves linearly on a guide rail, so that a laser locator aligns at positioning lines on patterns of the cloth, and then the patterns on all the layers of cloth align at each other; through the movement of the laser locator and a displacement sensor, a cutting device is indirectly drive to move, so that the work efficiency of workers is improved, the complete consistency of all the layers of cloth is guaranteed, the cutting precision is high, and no cloth waste is caused; moreover, through a dust suction pipe below the cutting device, the impurities left after cutting are sucked into an impurity collecting box, and thus the sanitation of the operation environment is guaranteed.

Owner:长沙金鼠服饰有限公司

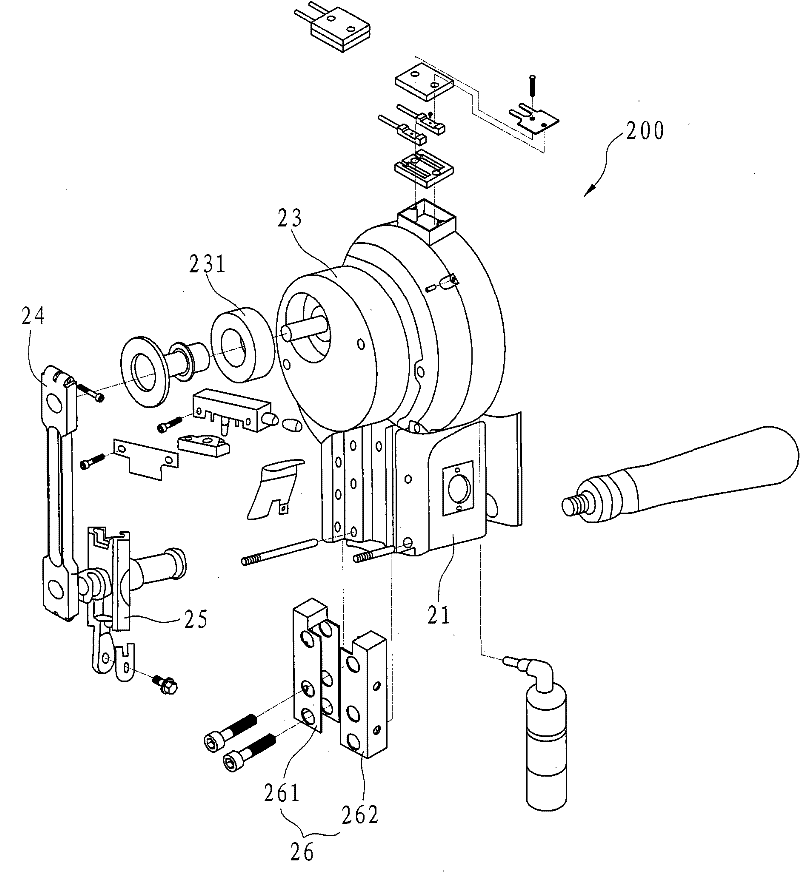

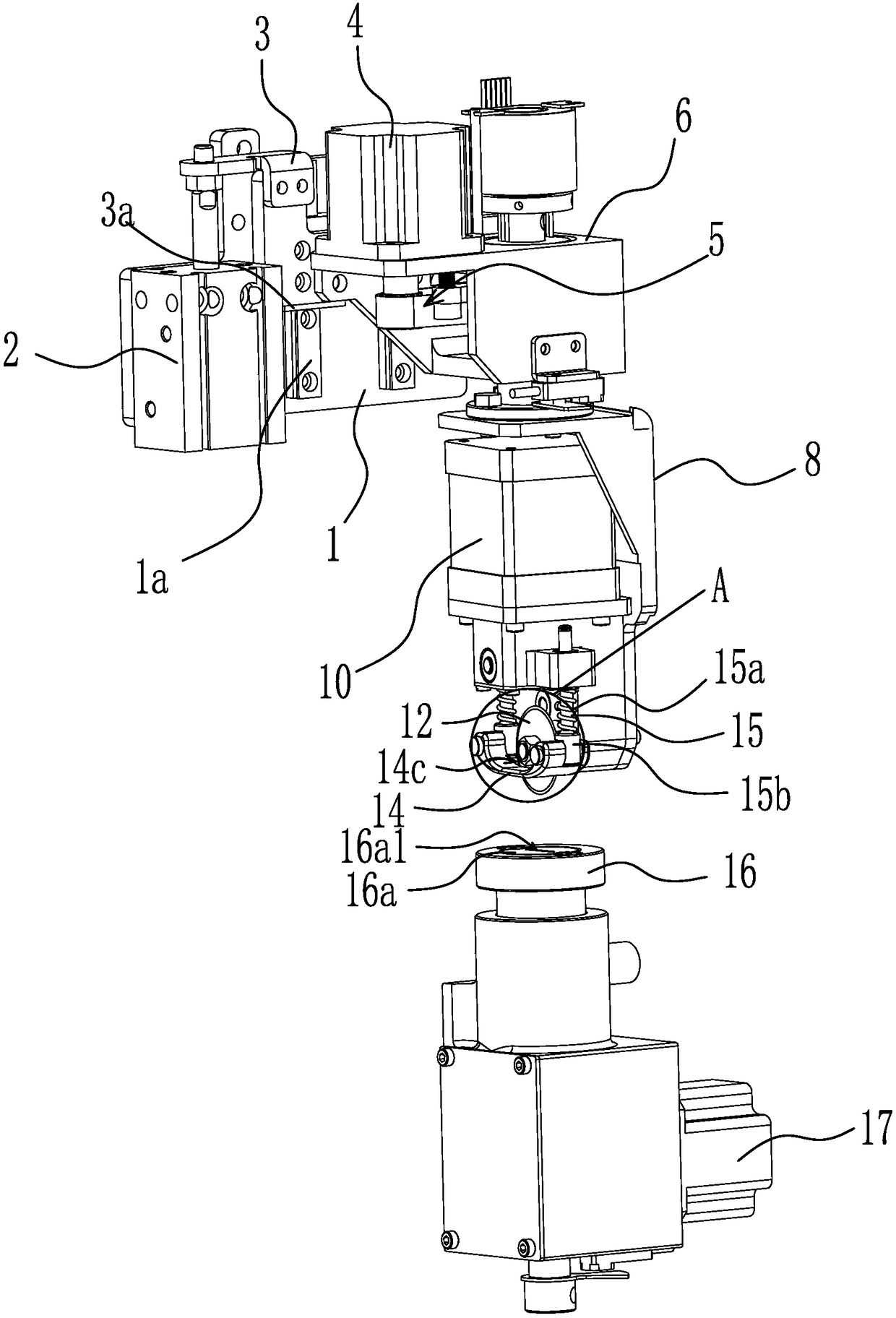

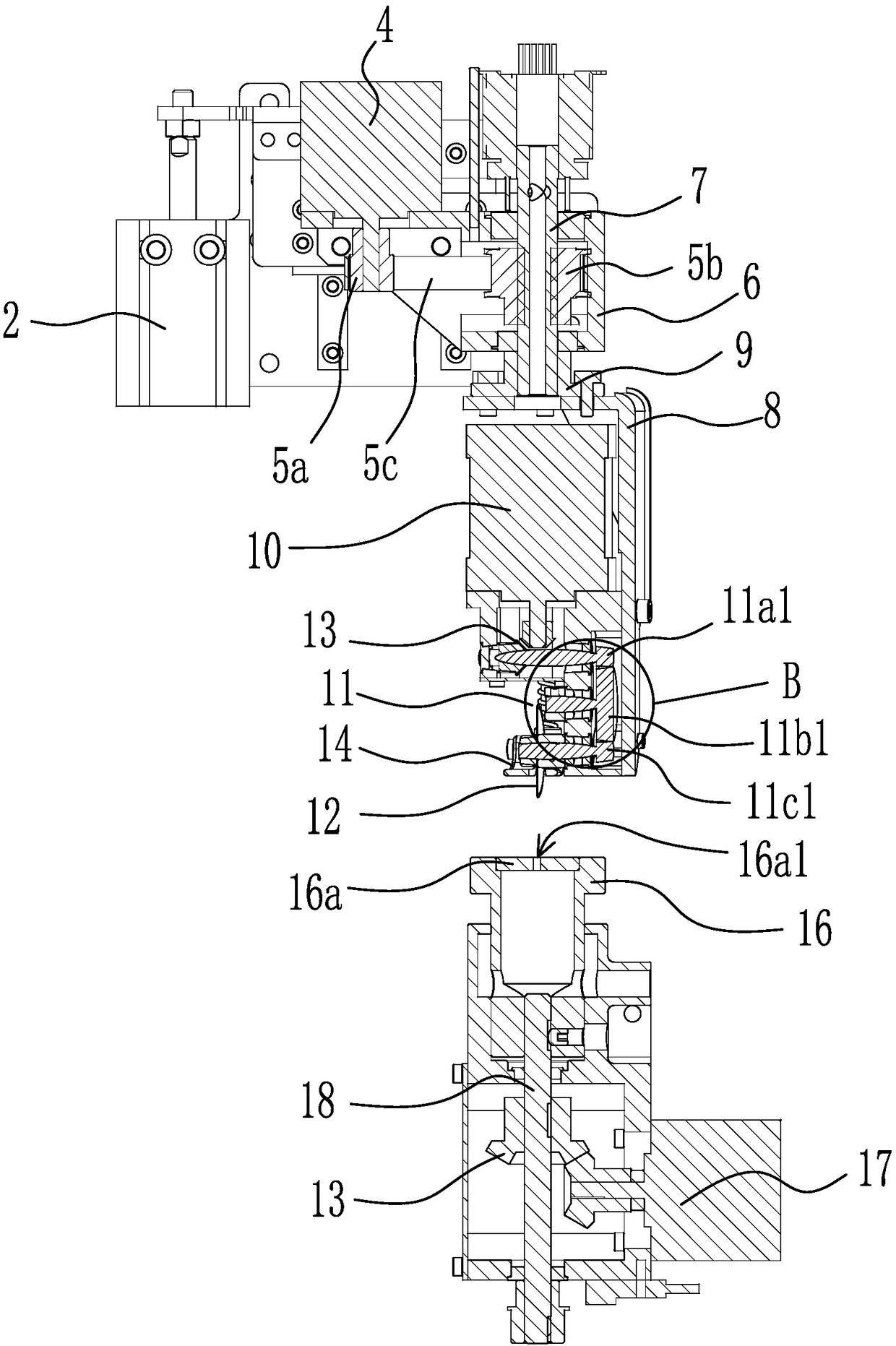

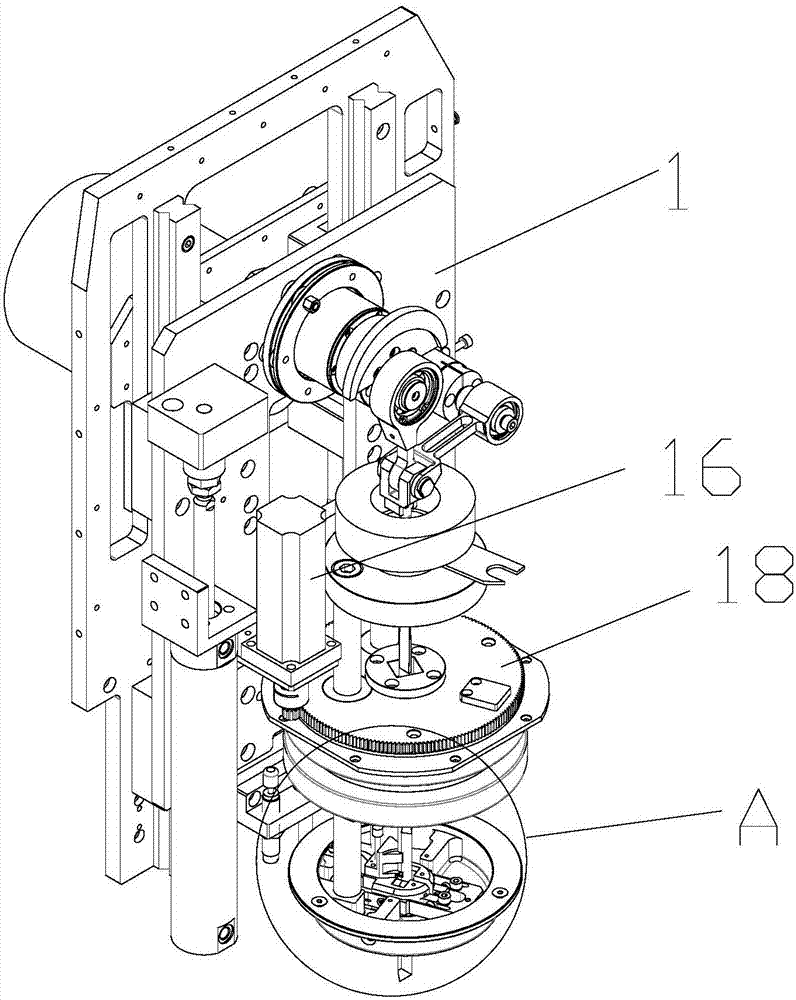

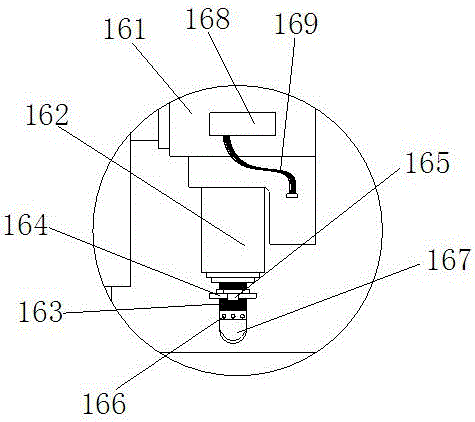

Machine head of cutting machine and cutting machine

PendingCN107099991AImprove cropping accuracyAdjust motion in real timeSevering textilesMechanical engineeringControl system

The invention relates to a cutting device, in particular to a machine head of a cutting machine and the cutting machine. The machine head of the cutting machine comprises a cutter, a cutter disc synchronously rotating with the cutter and a driving mechanism driving the cutter and the cutter disc to move. The machine head of the cutting machine further comprises a measuring mechanism arranged on the cutter disc and used for measuring the position of the cutter with respect to the cutter disc when the cutter disc and the cutter synchronously moves. The measuring mechanism and the driving mechanism are electrically connected with a control system, the control system is used for controlling the driving mechanism when the measuring mechanism measures that the cutter deviates with respect to the cutter disc, and the driving mechanism drives the cutter to move in the direction opposite to the deviation direction of the cutter till the cutter returns to an initial position with respect to the cutter. It is ensured that the cutter walks according to a preset track, and accordingly the cutting precision of the cutting machine is improved.

Owner:长园和鹰科技(河南)有限公司

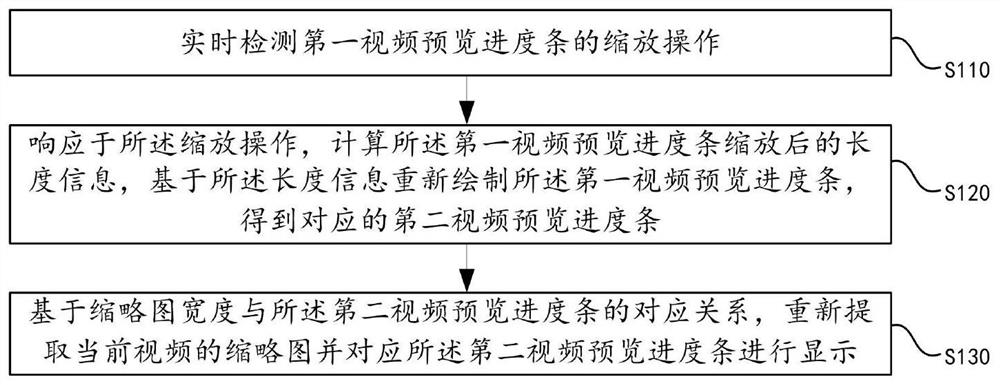

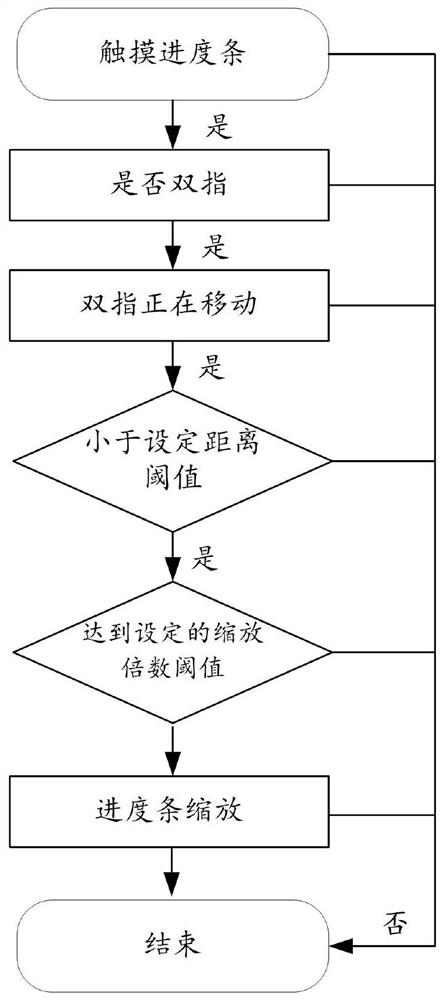

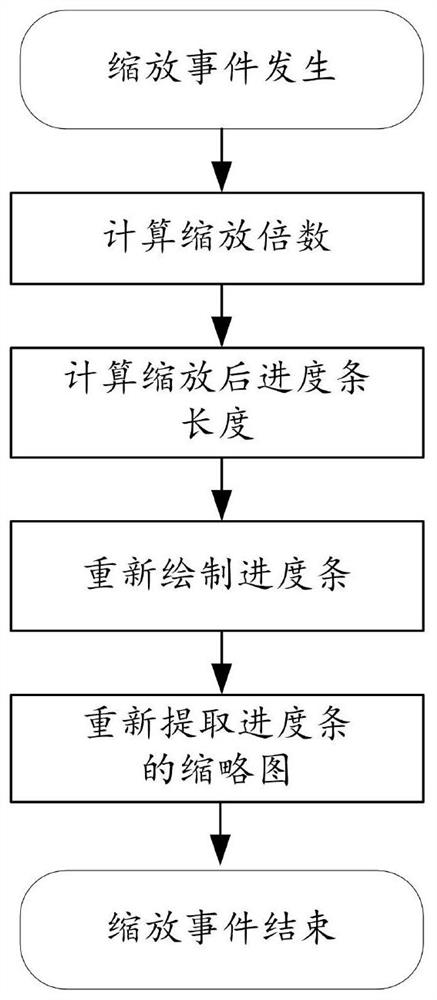

Video preview progress bar scaling method, system and device and storage medium

ActiveCN112540713AAdd preview detailsImprove cropping accuracySelective content distributionInput/output processes for data processingThumbnailEngineering

The embodiment of the invention discloses a video preview progress bar zooming method, system and device and a storage medium. According to the technical scheme provided by the embodiment of the invention, the scaling operation of the first video preview progress bar is detected in real time, the length information of the scaled first video preview progress bar is calculated in response to the scaling operation, and the first video preview progress bar is redrawn based on the length information, so that the corresponding second video preview progress bar is obtained; and based on the corresponding relationship between the thumbnail width and the second video preview progress bar, re-extracting the thumbnail of the current video and displaying the thumbnail corresponding to the second videopreview progress bar. By adopting the technical means, the video preview progress bar can be zoomed, video preview details are increased by retaking the thumbnail, and the video cropping precision isimproved.

Owner:GUANGZHOU BAIGUOYUAN NETWORK TECH

Controllable automatic cutting platform

The invention discloses a controllable automatic cutting platform which comprises a working table, wherein two U-shaped guide racks are arranged at the front end of the working table; a guide groove is formed in one side of each U-shaped guide rack; the two guide grooves are opposite to each other and are formed in side surfaces of the two U-shaped guide racks; a moving platform is mounted betweenthe two U-shaped guide rack; and the moving platform is U-shaped. A piece of cloth is fixed through two hydraulic rods, then the cloth is not deviated and is moved along a straight line on a guide track through a linear motor, a laser positioning device is aligned to positioning lines on cloth patterns, patterns on different layers of cloth are aligned to one another, a cutter is indirectly driven to move through movement of the laser positioning device and a displacement sensor, then the working efficiency of an operator is improved, the cloth of different layers is completely accordant, high cutting precision is achieved, the phenomenon of cloth waste is avoided, impurities generated after cutting are sucked into an impurity collection tank through a dust collection tube below the cutter, and thus the sanitation of an operation environment is ensured.

Owner:华巧波

Uniform-cutting cutting device for inflaming retarding environment-friendly polylactic acid plastic production

The invention discloses a uniform-cutting cutting device for inflaming retarding environment-friendly polylactic acid plastic production, and relates to the technical field of polylactic acid plasticproduction. The device comprises a base and a fixed base, side stand columns are fixed to the left side and the right side of the base, a top plate is connected between the side stand columns, the side stand columns and the top plate are fixedly connected, a hydraulic rod is arranged below the top plate, a cutting plate is connected to the lower portion of the hydraulic rod, cutting plate slidingsleeves are arranged on the left side and the right side of the cutting plate, positioning columns are arranged in the middles of the cutting plate sliding sleeves, and the cutting plate sliding sleeves and the positioning columns are in embedded sliding connection. According to the uniform-cutting cutting device for inflaming retarding environment-friendly polylactic acid plastic production, thehydraulic rods and the cutting plates form a vertical sliding structure, the polylactic acid plastic is cut, the cutting plates can carry out up and down parallel movement in the vertical direction through telescopic operation of the hydraulic rods, and the polylactic acid plastic is cut.

Owner:银金达(上海)新材料有限公司

A temperature compensation method for strain sensor

ActiveCN106768217BAvoid mistakesImprove cutting efficiencyWeighing apparatus using elastically-deformable membersEngineeringStrain sensor

The invention discloses a temperature compensation method of a strain gauge transducer, wherein the temperature compensation method relates to the field of strain gauge transducer manufacture. The temperature compensation method comprises the following steps of S1, creating or acquiring a label which is arranged on the strain gauge transducer, and recording the label; S2, respectively acquiring resistance temperature coefficients of four bridge arms of the strain gauge transducer, determining a to-be-compensated bridge arm, solving a compensation wire length L, and correspondingly recording the compensation wire length L and the label; S3, acquiring the label of the strain gauge transducer by compensation wire automatic cutting equipment, and cutting the compensation wire with length of L; and S4, according to the to-be-compensated bridge arm which is displayed by the compensation wire automatic cutting equipment, connecting the compensation wire with the to-be-compensated bridge arm. According to the temperature compensation method, the label on the strain gauge transducer is acquired in a computer-readable manner; and furthermore a compensation wire parameter which corresponds with the label is recorded, thereby realizing no requirement for artificial recording and preventing errors. The compensation wire with the preset length is cut through the automatic cutting equipment, thereby improving cutting efficiency and improving cutting precision.

Owner:RUIMA ELECTRIC MFG FUJIAN

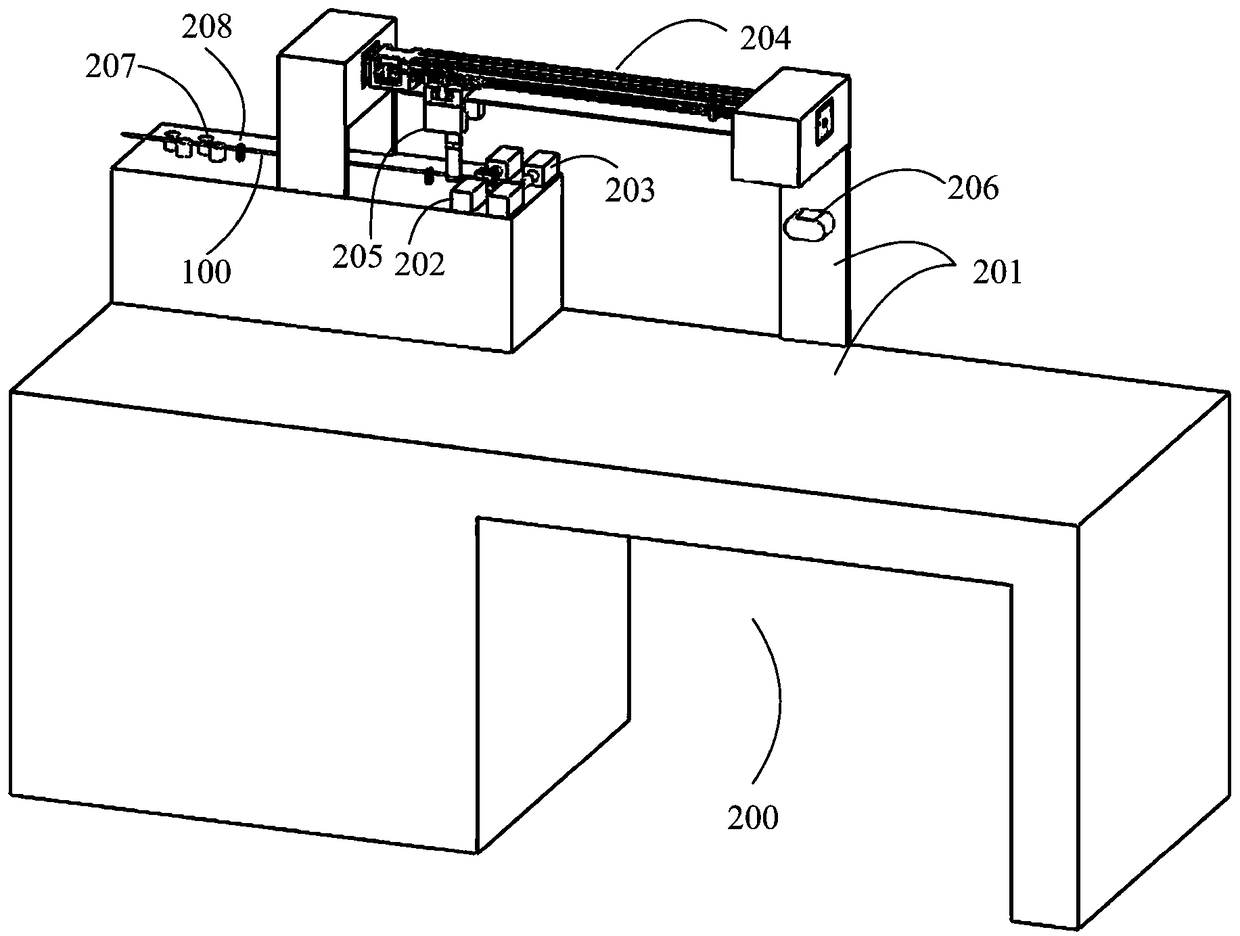

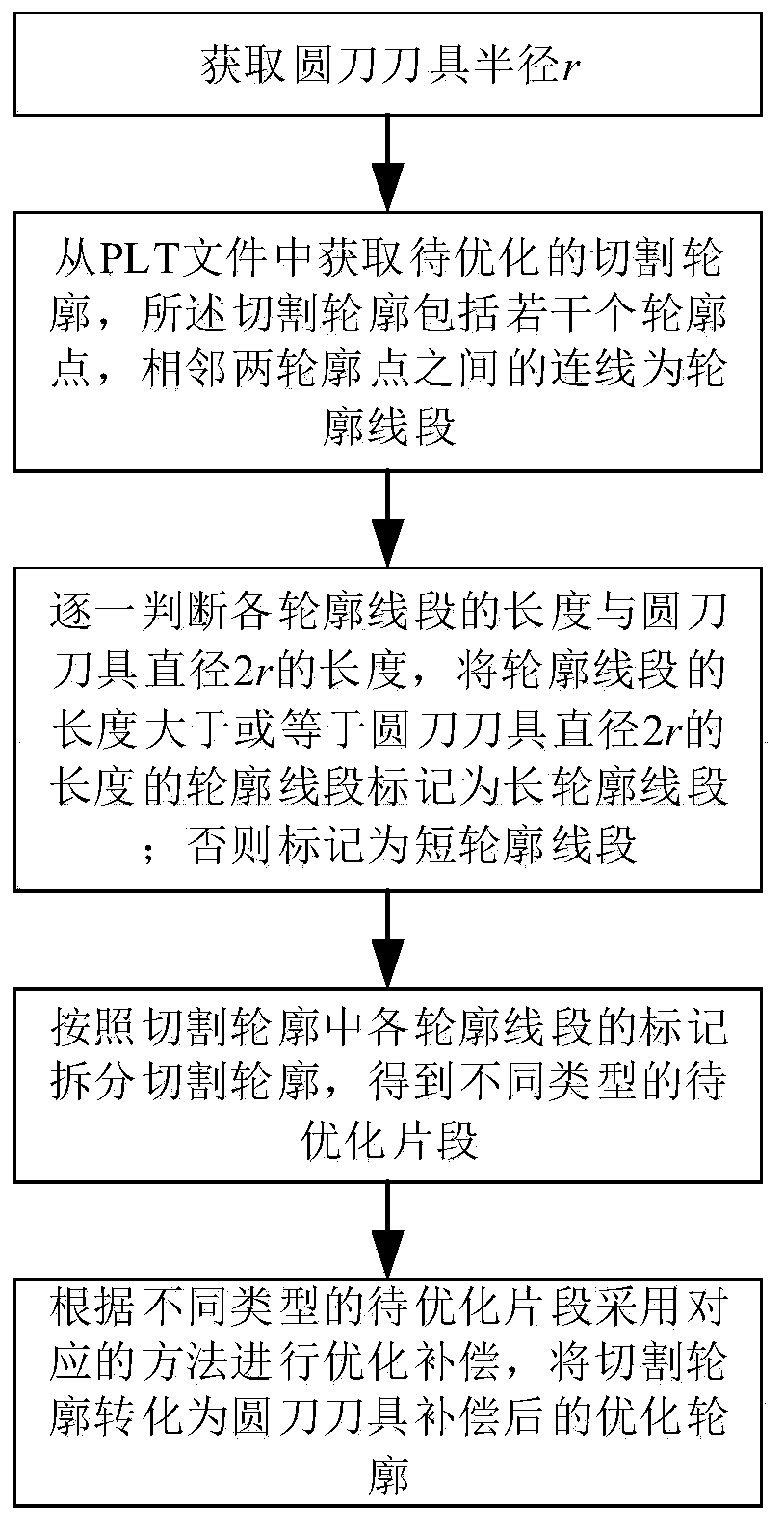

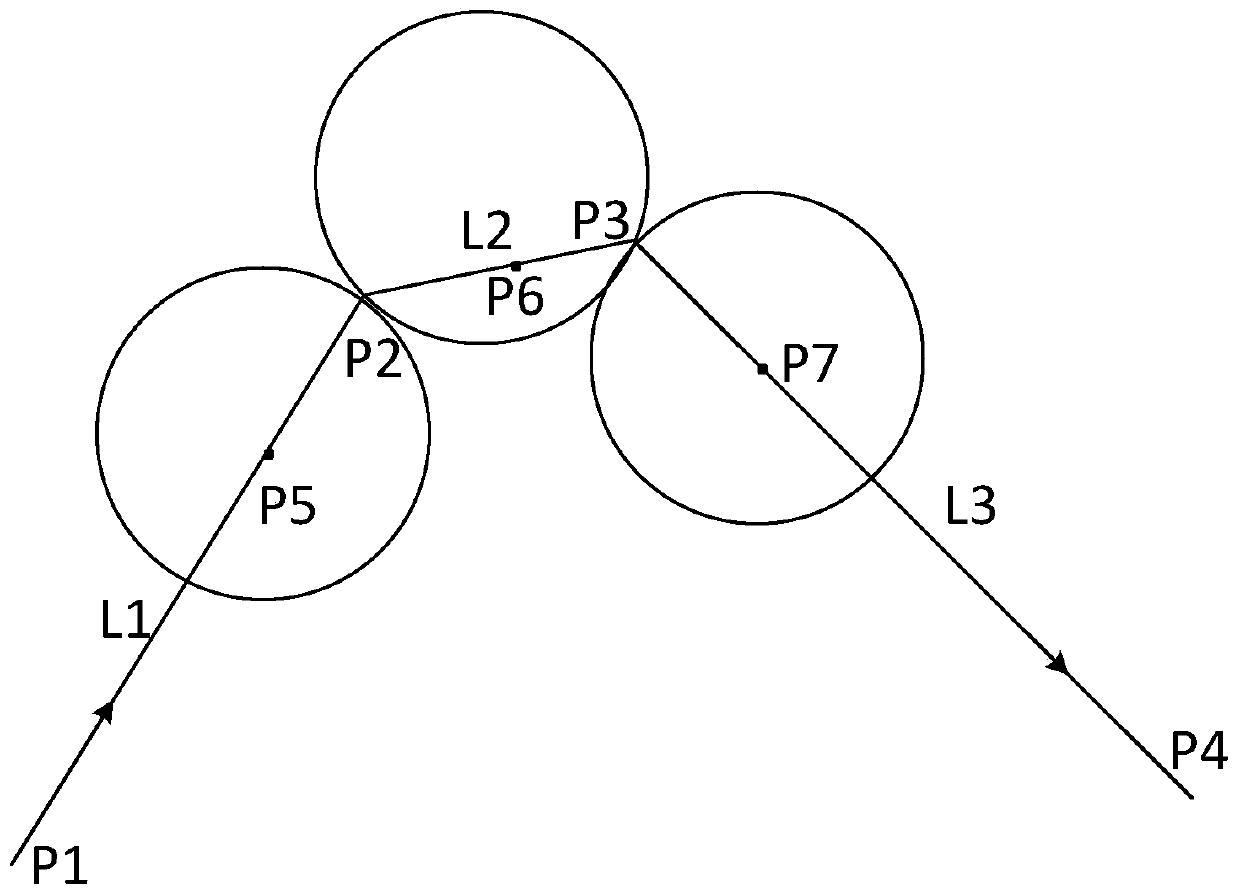

Cutting optimization method based on circular cutter compensation

InactiveCN111274654AAvoid overcuttingImprove cropping accuracyGeometric CADImage analysisAlgorithmStructural engineering

The invention discloses a cutting optimization method based on circular cutter compensation. The cutting optimization method comprises the steps: obtaining the radius r of a circular cutter; obtaininga to-be-optimized cutting contour from the PLT file, the cutting contour comprising a plurality of contour points, and a connection line between two adjacent contour points being a contour line segment; judging the length of each contour line segment and the length of the diameter 2r of the circular cutter one by one, and marking the contour line segment with the length greater than or equal to the length of the diameter 2r of the circular cutter as a long contour line segment; otherwise, marking as a short contour line segment; splitting the cutting contour according to the mark of each contour line segment in the cutting contour to obtain different types of to-be-optimized segments; and carrying out optimization compensation by adopting a corresponding method according to different types of to-be-optimized fragments, and converting the cutting contour into an optimized contour after circular cutter compensation. According to the method, the cutting contour is optimized according tothe radius of the circular knife, the over-cutting situation in the cutting process is avoided, the cutting precision is improved, and the optimization efficiency is high.

Owner:ZHEJIANG UNIV OF TECH

Environment-friendly wallpaper repairing device

InactiveCN111376641AReduce replacement timeImprove replacement efficiencyPaperhangingDrive motorSlide plate

The invention belongs to the field of wallpaper cutting devices, and discloses an environment-friendly wallpaper repairing device. The environment-friendly wallpaper repairing device is used for solving the problem that breakage portions of existing wallpaper are hard to repair. The environment-friendly wallpaper repairing device comprises a mounting plate, wherein a rotary rod which is rotatablyconnected with the mounting plate penetrates through the side wall of the mounting plate, a driving motor for driving the rotary rod to rotate is embedded in the side wall of the mounting plate, a vertical slide plate is fixed to one end of the rotary rod, a first telescopic rod is slidably connected to the side wall, away from the rotary rod, of the slide plate, and is in pin joint with a cutterblade through a fixing plate, a second telescopic rod used for being fixed to the slide plate is arranged below the first telescopic rod, a pressing plate is fixed to one end of the second telescopicrod, and a loading plate abuts against one side of the pressing plate. The environment-friendly wallpaper repairing device is simple in structure and convenient to use, the wallpaper at the breakage portions and new wallpaper are synchronously cut, the time for replacing the wallpaper is shortened, the efficiency of replacing the wallpaper is improved, the cutting precision is high, the situationthat the new wallpaper is wasted when cut excessively or insufficiently is avoided, the energy is saved, the environment is protected, the repaired wallpaper is attractive, and the breakage portions will be barely noticed.

Owner:ANHUI BAUHINIA WALLPAPER

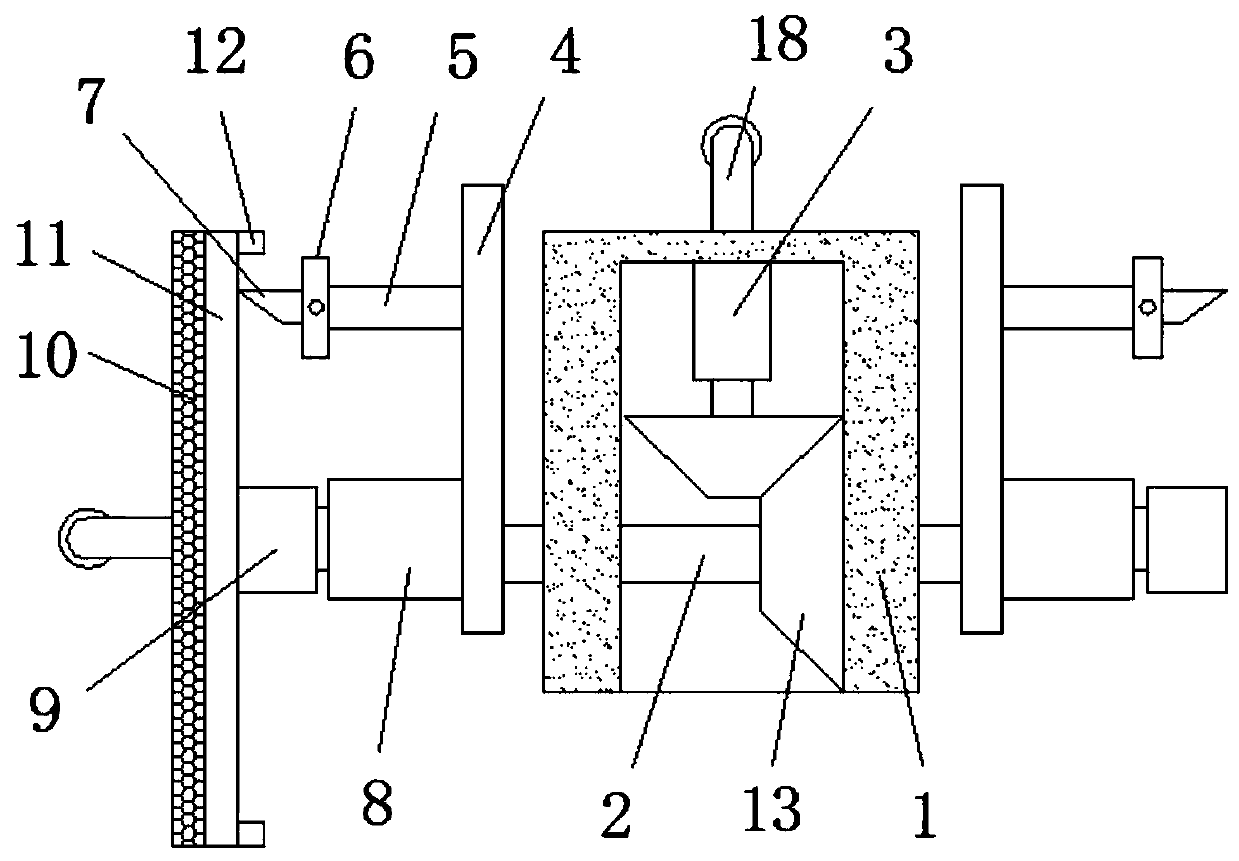

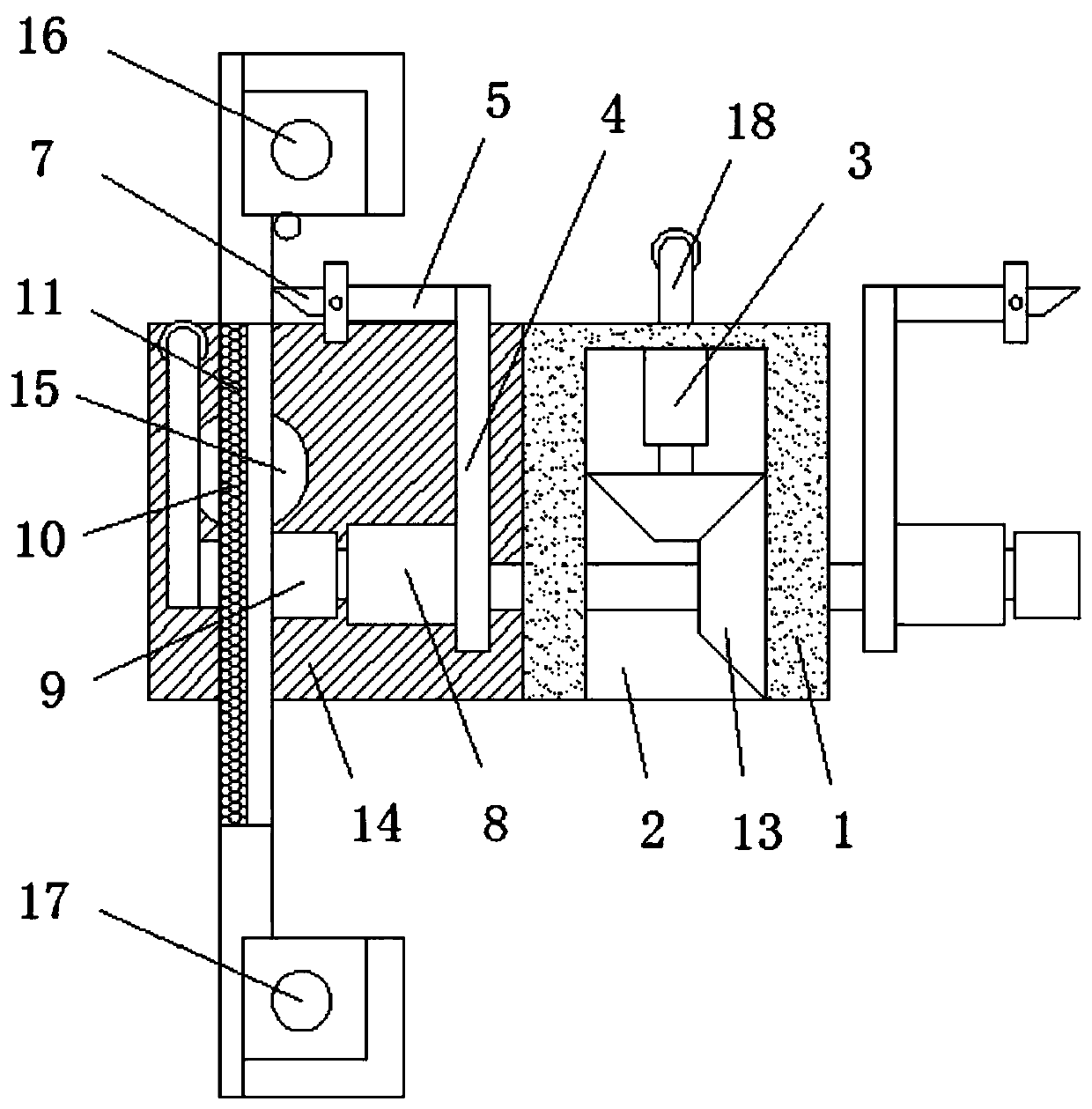

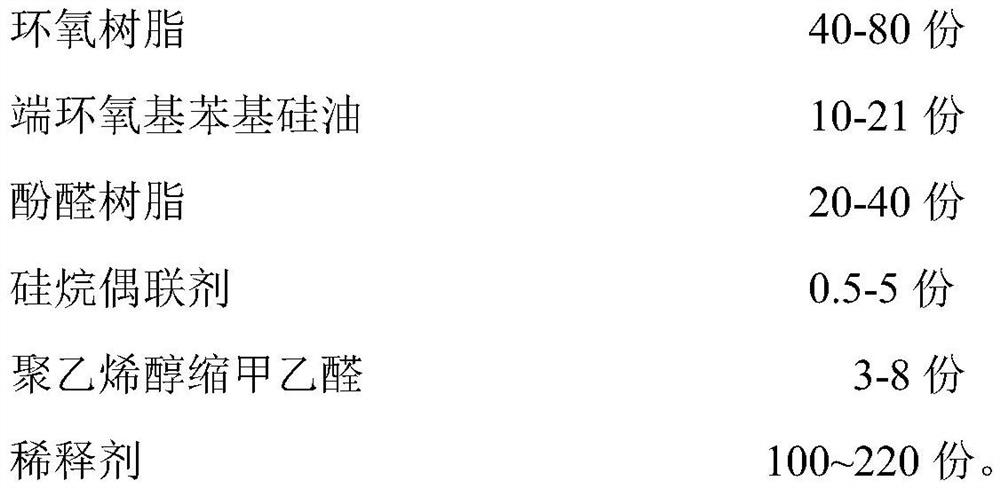

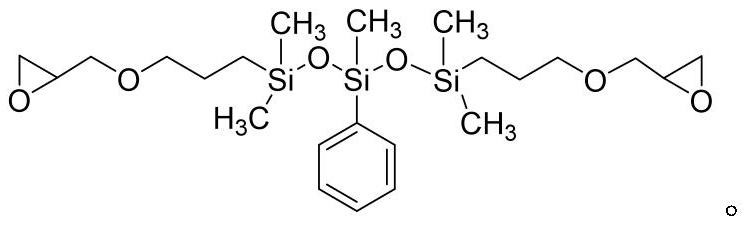

Modified epoxy resin adhesive and application thereof in hard mica plate

ActiveCN113831877AReduce stressImprove temperature resistanceNon-macromolecular adhesive additivesLaminationEpoxyPolymer science

The invention discloses a modified epoxy resin adhesive and an application thereof in a hard mica plate. The modified epoxy resin adhesive comprises the following components in parts by weight: 40 to 80 parts of epoxy resin, 10 to 21 parts of epoxy-terminated phenyl silicone oil, 20 to 40 parts of phenolic resin, 0.5 to 5 parts of a silane coupling agent, 3 to 8 parts of polyvinyl formal acetaldehyde, and 100 to 220 parts of a diluent. The epoxy resin adhesive overcomes the problems that a mica plate prepared from traditional epoxy resin is fragile after being cured, easy to degrade at high temperature, large in high-temperature smoke and peculiar smell, easy to crack during cutting, more in chippings, low in cutting precision and the like, and the epoxy resin adhesive for the mica plate is provided.

Owner:湖北晟特新材料有限公司

Trimming circle shear for galvanized steel sheet

PendingCN114406342AGuaranteed service lifeStable and efficient workShearing machinesMaintainance and safety accessoriesCircular discStructural engineering

The invention discloses a galvanized steel sheet trimming circle shear and belongs to the technical field of circle shears, the galvanized steel sheet trimming circle shear comprises a bottom plate, the upper surface of the bottom plate is fixedly connected with the lower surface of a circle shear body, the left side and the right side of the inner wall of the circle shear body are each provided with an upper cutter head and a lower cutter head, and the upper surface of the bottom plate is fixedly connected with the lower surfaces of two baffles; the opposite faces of the two baffles are each provided with two transmission rollers. According to the galvanized steel sheet trimming circle shear, by arranging the material box, the rotating disc, the storage box, the upper cutter disc, the spring, the clamping rod, the clamping groove, the fixing plate, the connecting base, an oil leakage hole, a discharging pipe and a protective cover, the clamping groove is effectively clamped into the corresponding clamping groove, the fixing plate is effectively limited, and compared with a traditional mode that the cutter disc is cleaned or lubricated regularly, the cutting efficiency is improved; according to the scheme, the upper cutter head is effectively lubricated in time, the oil dripping amount can be adjusted according to the machining state of the circle shear, the machining precision is improved while the service life of the circle shear is guaranteed, and efficient and stable work of the circle shear is facilitated.

Owner:襄阳嘉德机械有限公司

Laser cutting table

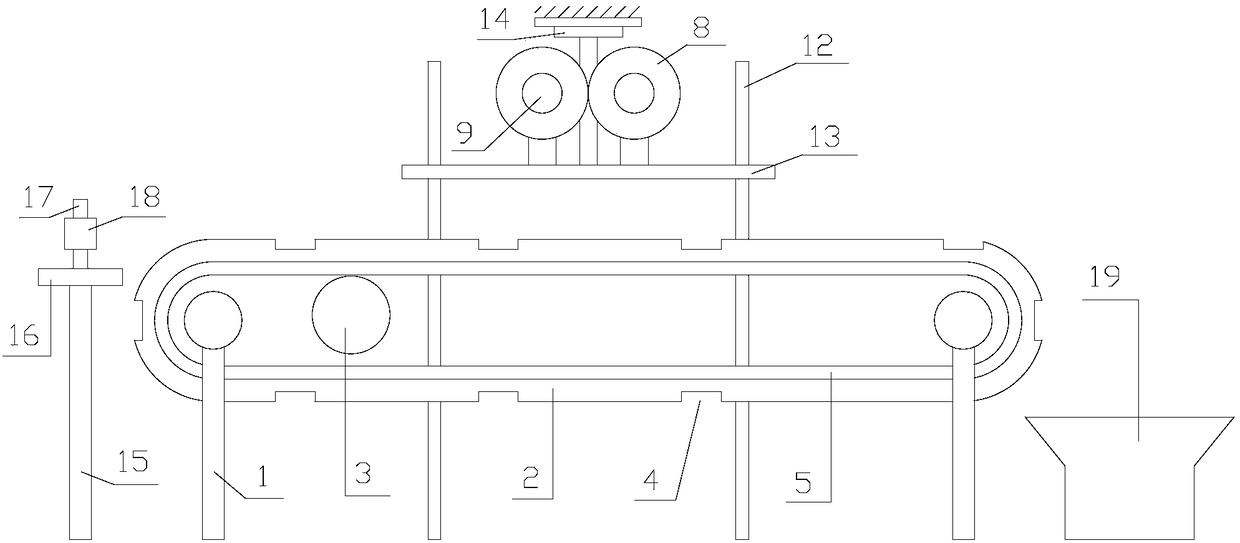

InactiveCN103789993ASimple structureEasy to use and maintainSevering textilesEngineeringLaser cutting

The invention discloses a laser cutting table which comprises a motor, a frame, a workbench, a discharge rubber roll, a feed rubber roll, a mesh belt, a tension adjusting device, a laser cutting device, a servo motor and a moving mechanism. The laser cutting device is disposed on the frame through the moving mechanism. The servo motor is disposed below the frame. The drive end of the servo motor is connected with the moving mechanism. The laser cutting table is simple in structure and convenient to use, the laser cutting device can be driven by the servo motor to move freely, the cutting area and flexibility of the cutting table are increased effectively, and cloth cutting efficiency and fineness are increased.

Owner:WUJIANG JIAYUN TEXTILE FINISHING

Precise positioning device for paper tailoring

ActiveCN107900997AGood effectSimple structureWork benchesMetal working apparatusFixed frameEngineering

The invention discloses a precise positioning device for paper tailoring. The precise positioning device comprises a plurality of obliquely arranged fixing frames. A connection plate is welded betweenthe two fixing frames. A workbench is welded to one ends of the fixing frames, a positioning plate is arranged above the workbench, a fixing plate is welded to the upper portion of the positioning plate, supporting plates are welded to the two ends of the fixing plate, baffles are welded to the two ends of the workbench, and one side of each baffle is provided with a rotating wheel. One side of each rotating wheel is provided with a rotating shaft in a clamped manner. The two sides of each supporting plate are each provided with a clamping bolt in a clamped manner, one side of each clamping bolt is provided with a transmission disk in a clamped manner, a clamping groove is formed below each transmission disk, a limiting rod is welded to the side wall of each baffle, and the side wall of each rotating wheel is provided with a rotating handle in a clamped manner. A user holds a cutter or other tailoring equipment to tailor papers along the outer edge of the positioning plate. The precise positioning device is simple in structure, obvious in effect, low in cost and high in practicality.

Owner:悦声纸业(中国)有限公司

Enameled decal paper cutting device

InactiveCN106738001AHigh cropping accuracyImprove cutting efficiencyMetal working apparatusPaper cutPulp and paper industry

The invention discloses an enameled decal paper cutting device which comprises a bearing rack, a cutting bearing table and a top plate. The cutting bearing table is mounted at the top of the bearing rack. A stand column is mounted on each of the two sides of the cutting bearing table. The top plate is mounted at the tops of the stand columns. Three telescopic assemblies are mounted at the bottom of the top plate. Pressing plates are mounted at the bottoms of the telescopic assemblies. Two slide grooves are formed in an inner cavity of the bottom of the top plate. Cutting mechanisms are slidably mounted on the inner sides of the slide grooves. The enameled decal paper cutting device can fix enameled decal paper while cutting the enameled decal paper by arranging side baffles and a tail baffle on the cutting bearing table, mounting the three telescopic assemblies at the bottom of the top plate and mounting the pressing plate at the bottom of the telescopic assembly, and the enameled decal paper cutting device can achieve high cutting accuracy and high cutting efficiency by mounting the cutting mechanisms in the slide grooves in the bottom of the top plate and mounting air pressure push rods on the back faces of the cutting mechanisms.

Owner:WUXI DONGHE METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com