Patents

Literature

36 results about "Strain gauge transducer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

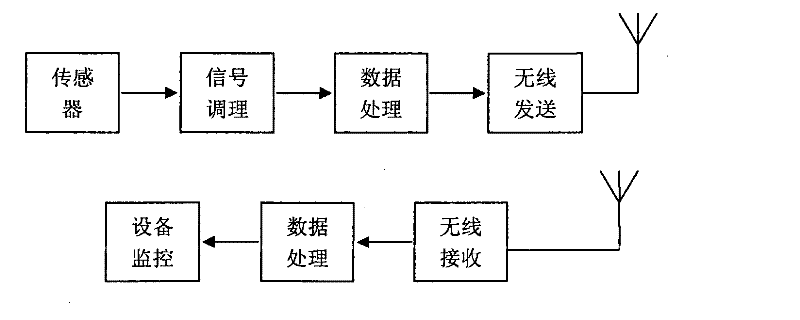

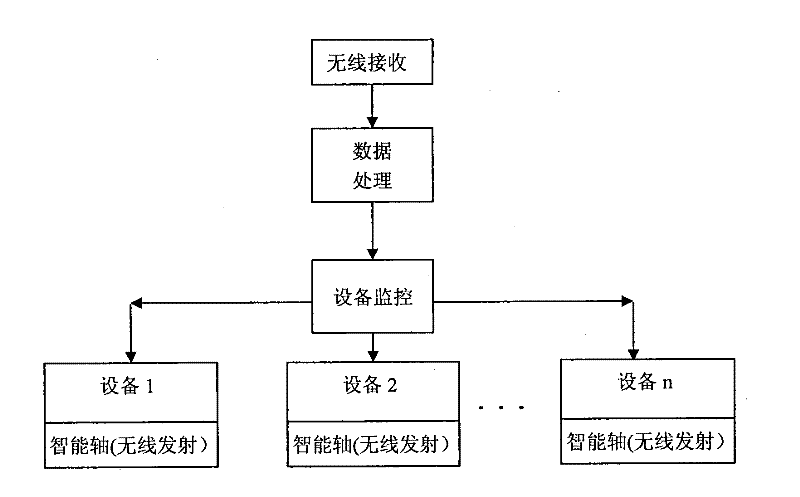

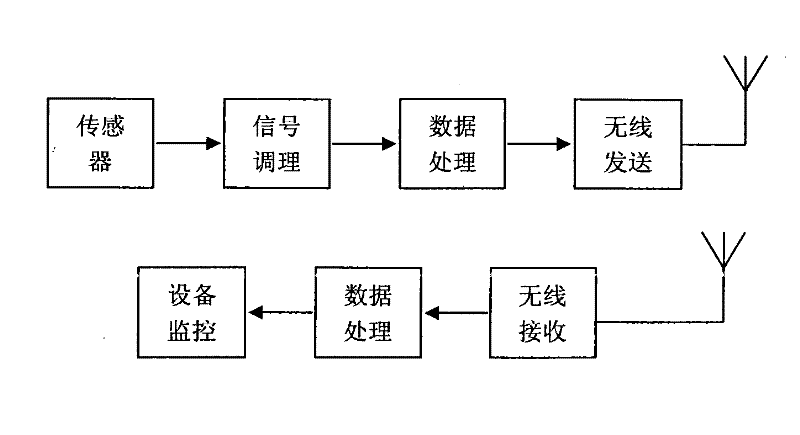

Intelligent monitoring method for transmission shaft

InactiveCN101750211ARealize online detectionProtection securityMachine part testingWork measurementDrive shaftStrain gauge transducer

The invention provides an intelligent monitoring method for a transmission shaft. A strain-gauge transducer, a photoelectric speed sensor, a data acquisition unit and a wireless transmitting device are embedded on the transmission shaft through a micromachining process; the strain-gauge transducer and the photoelectric speed sensor are connected with the data acquisition unit; and the data acquisition unit is connected with the wireless emitting device; a wireless receiving device is arranged on a shaft sleeve or a part which is not directly connected with the transmission shaft; the strain-gauge transducer and the photoelectric speed sensor detect operating data of the transmission shaft real time, and the operating data is processed by the data acquisition unit and continuously emitted by the wireless emitting device; and the wireless receiving device receives a signal emitted by the wireless emitting device, performs data processing and immediately emits an alarm signal when the force moment of the transmission shaft reaches or surpasses a design arrange. The method realizes on-line detection of parameters of transmission torque, speed and the like of the transmission shaft, can monitor operating parameters of equipment, performs failure prediction and alarm, and automatically stops the operation of the equipment.

Owner:徐庆莘

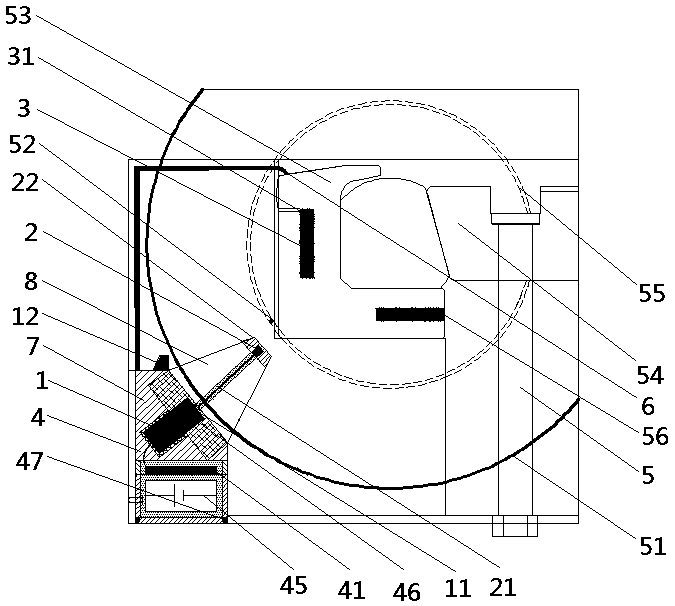

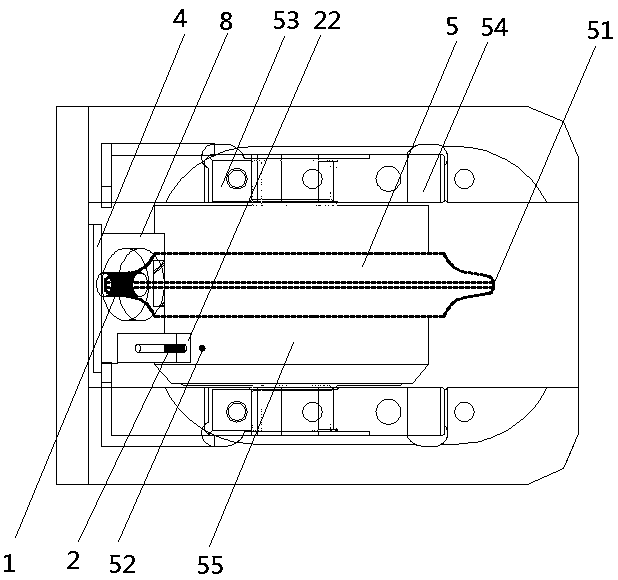

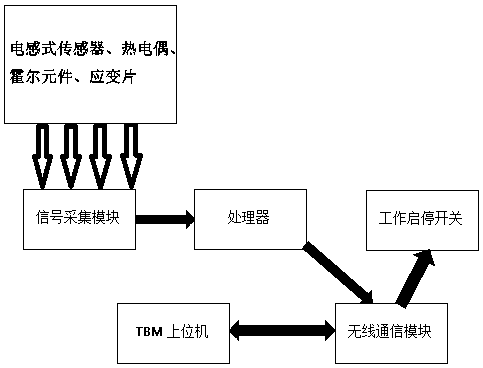

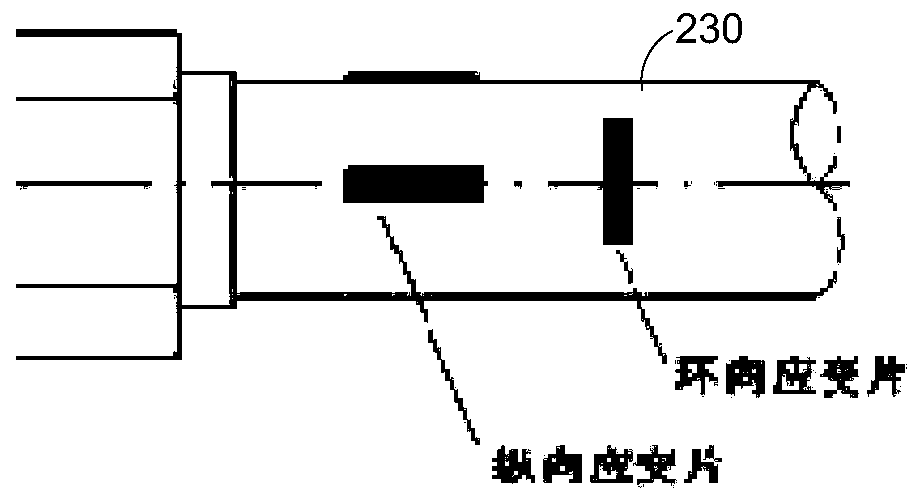

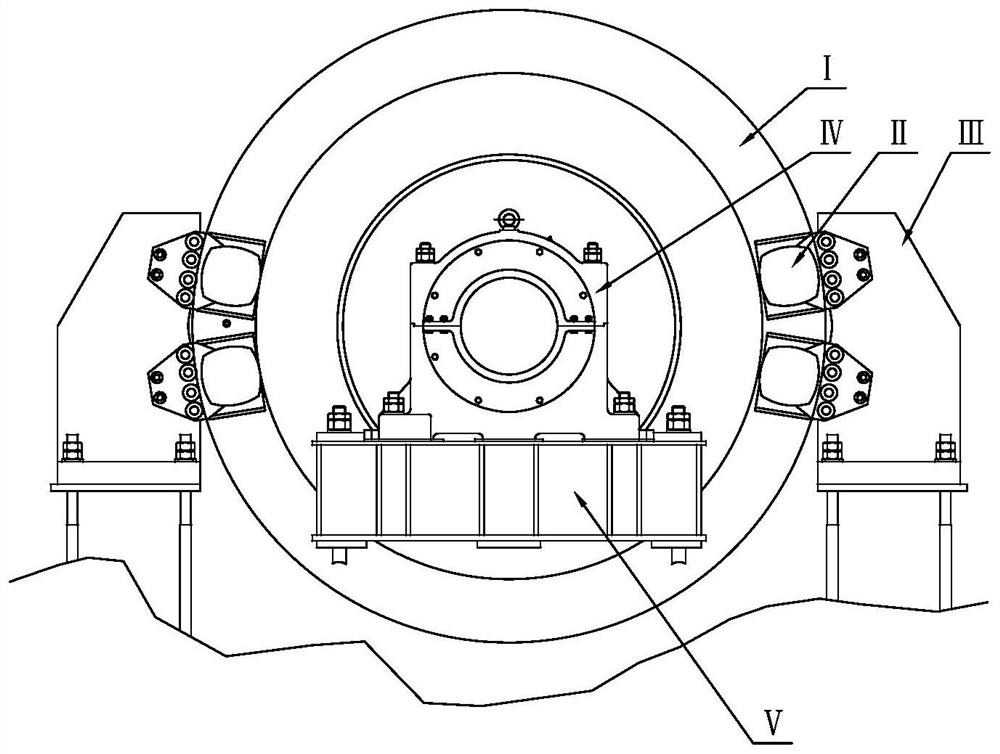

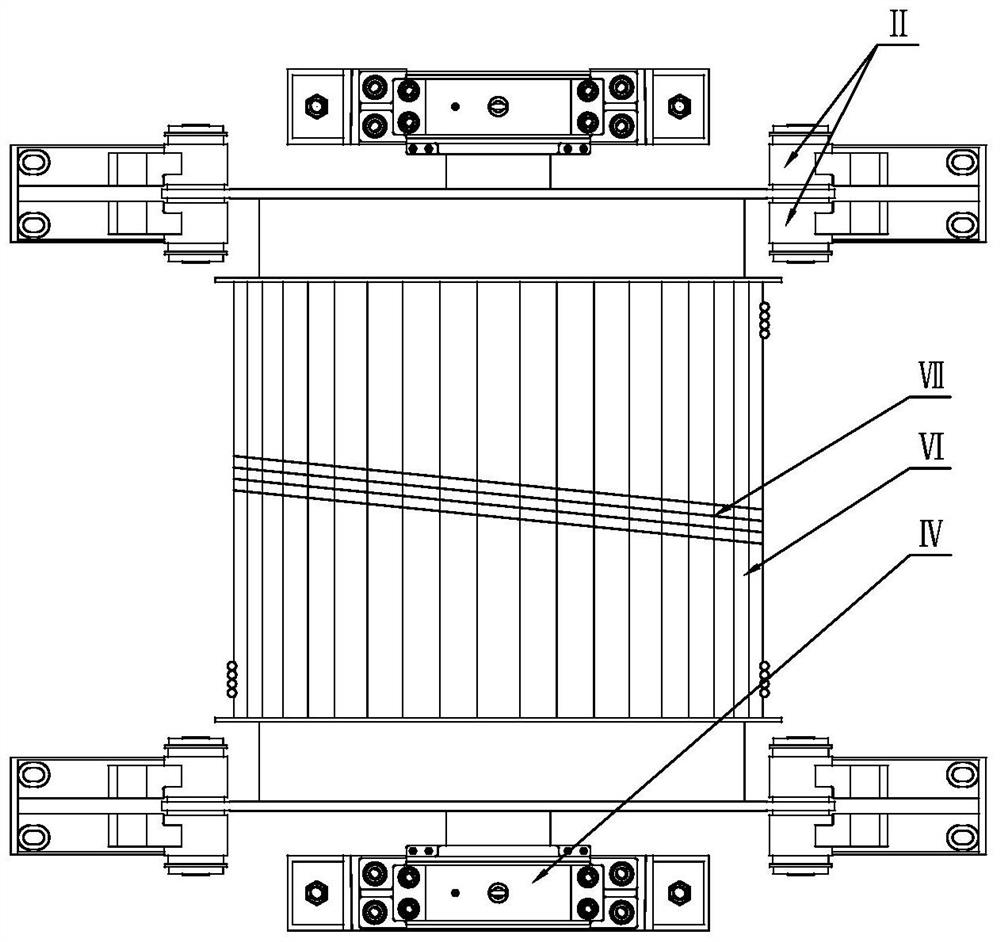

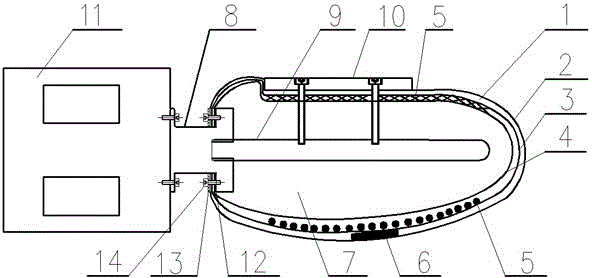

TBM hob full-state real-time on-line monitoring system and measurement method thereof

PendingCN107655393AMonitor wearMonitor speedThermometers using electric/magnetic elementsForce measurementStrain gauge transducerMonitoring system

The invention discloses a TBM hob full-state real-time on-line monitoring system and a measurement method thereof. The system comprises an inductive sensor, a Hall component, a strain gauge and a sensor base. The inductive sensor and the Hall component are arranged in the sensor base. The inductive sensor corresponds to a cutter ring of a TBM hob. The TBM hob is provided with a magnetic block which is opposite to the Hall component. A shaft hole of the TBM hob is provided with a support wedge block and a tensioning wedge block. The strain gauge is arranged in the support wedge block. A signalprocessing unit is arranged in the sensor base. The inductive sensor, the Hall component and the strain gauge are connected to the signal processing unit. The signal processing unit is connected to aTBM upper computer through a wireless communication module. In the invention, four index parameters of an abrasion loss of the TBM hob, a rotation speed of the TBM hob, a stress of the TBM hob and a working temperature of the TBM hob can be monitored; and through real-time monitoring, a working state of the TBM hob can be timely controlled and a damaged condition of the TBM hob can be timely knownso that the TBM hob can be timely repaired or replaced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

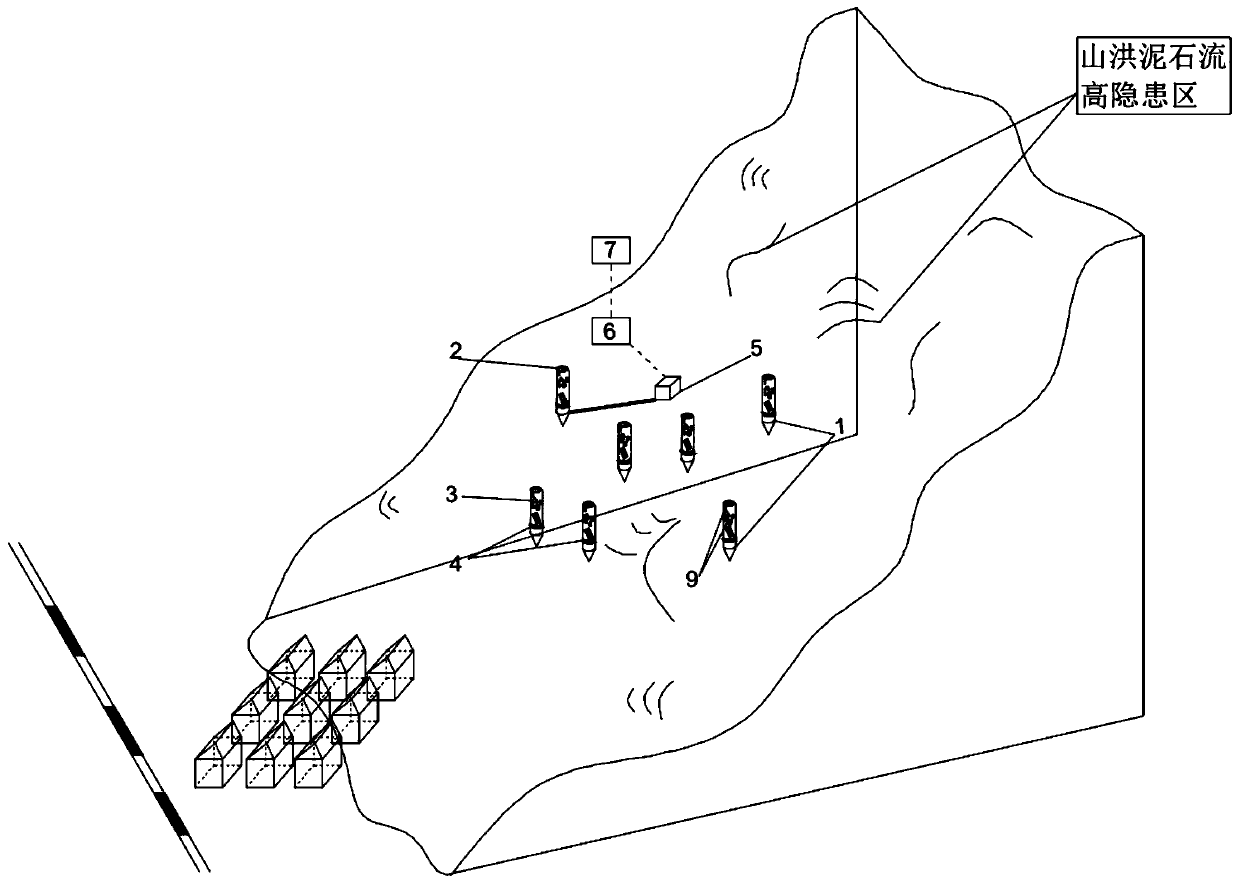

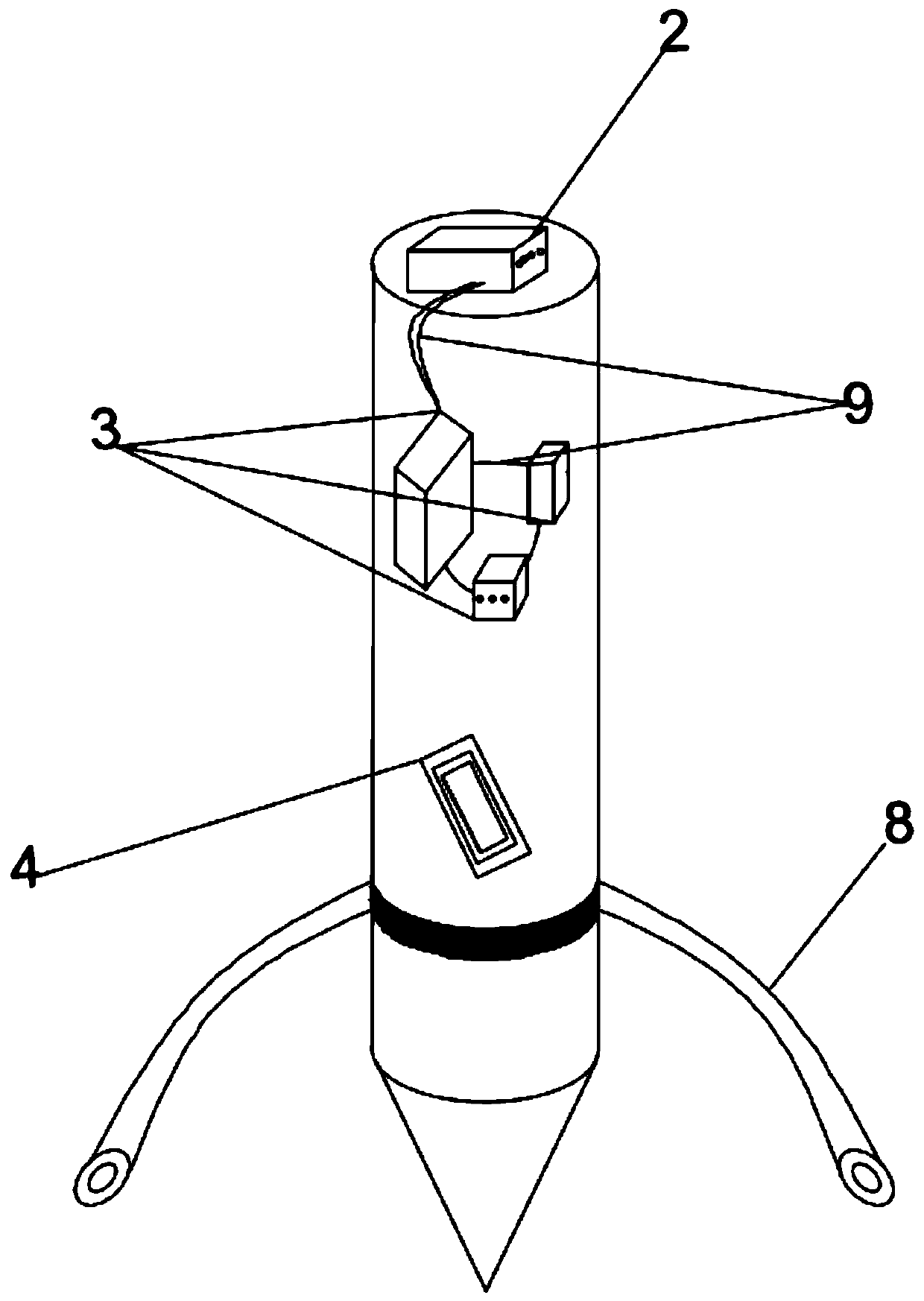

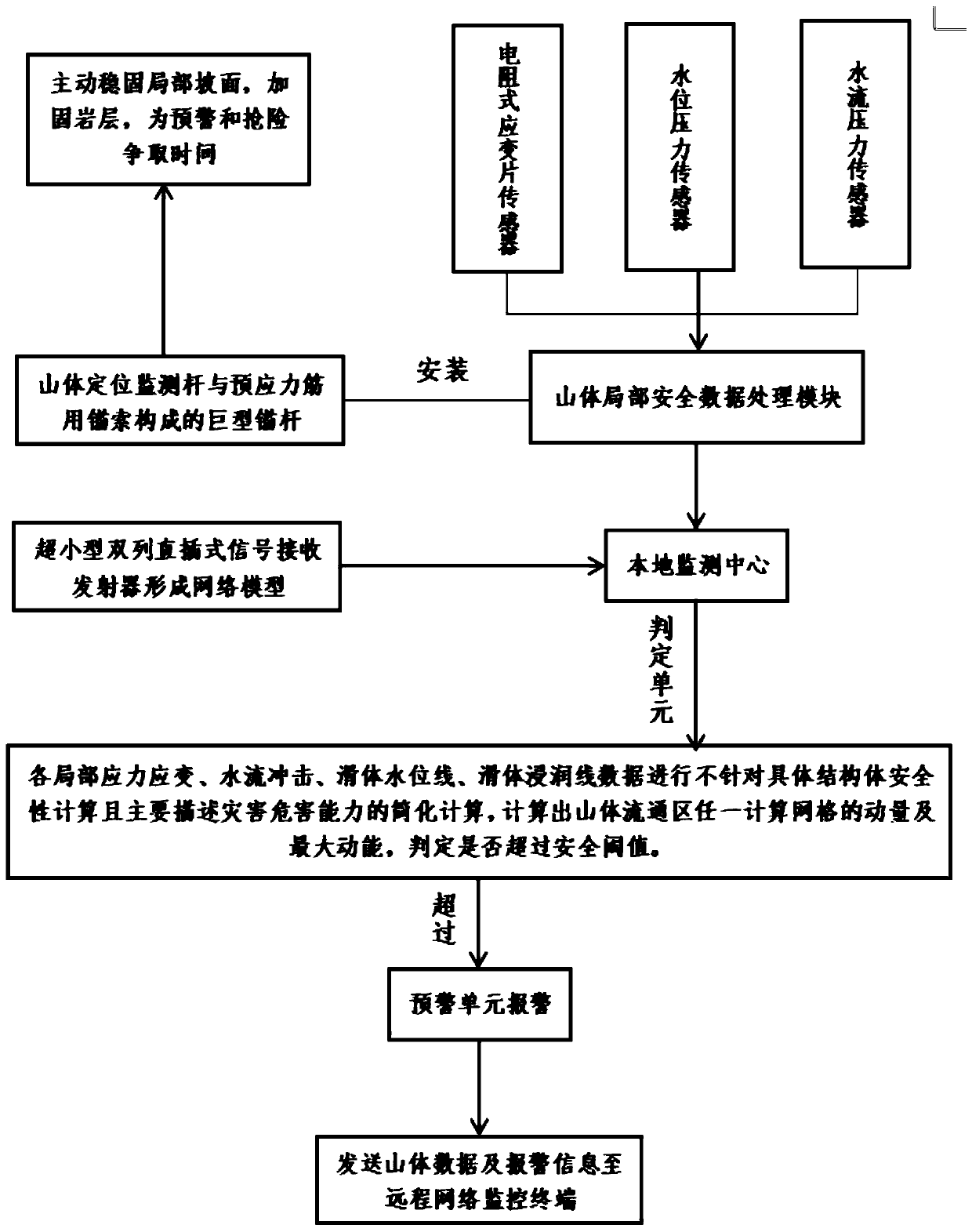

Mountain torrent debris flow high-hidden-danger area monitoring and early warning system

PendingCN111325948ASolve the single determination factorSolve the low linkage effectHuman health protectionAlarmsData synchronizationGeological disaster

The invention relates to the field of geological disaster safety monitoring and particularly relates to a mountain torrent debris flow high-hidden-danger area monitoring and early warning system. Thesystem comprises a mountain torrent debris flow high-hidden-danger area, a mountain positioning monitoring rod, a power supply device, a safety data synchronous acquisition module and an ultra-small double-in-line signal receiving and transmitting device. The safety data synchronous acquisition module is composed of a resistance-type strain gauge sensor, a water level pressure sensor and a water flow pressure sensor. The acquisition modules are arranged around an outer side of the mountain positioning monitoring rod; anchor cables for fixing prestressed tendons can actively stabilize a local slope surface; a local safety data processing module carries out denoising, amplification and signal standardization processing on collected environment sensing data and image signals and then transmits the processed signals to a local monitoring center; and the local monitoring center calculates and judges the received information and transmits the information to a remote network monitoring terminal. Therefore, early warning is performed in time when mountain torrent debris flow disasters happen, and an effect of reinforcing a local foundation is achieved.

Owner:NANCHANG UNIV

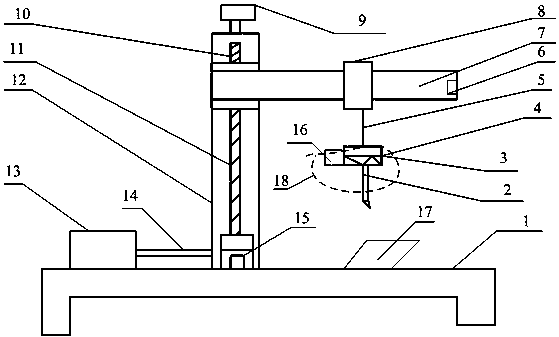

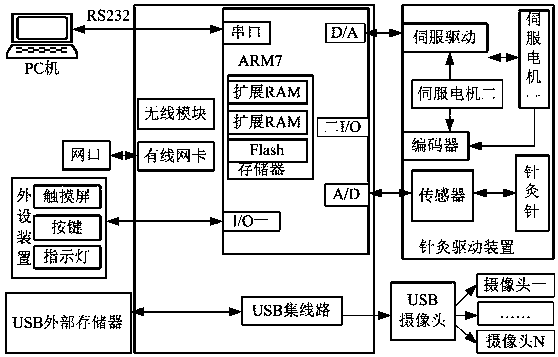

Simple acupuncture device

InactiveCN110478615ASimple structureConvenient AcupunctureElectrotherapyAcupunctureStrain gaugeAcupuncture therapy

The invention discloses a simple acupuncture device, comprising a base, an acupuncture body device, a cantilever, a bracket, a controller, and an acupuncture head device. The lower end of the bracketis provided with a sliding rod on which a lead screw is installed. The cantilever is connected to the lead screw. An upper sliding table of the cantilever in the bracket is provided with a servo motorII. The cantilever is equipped with a connecting rod, a USB camera, a servo motor I and the acupuncture head device. The right end of the cantilever is equipped with the USB camera that is equipped with a camera 1, ..., and a camera N. The connecting rod at the lower end of the servo motor I is connected with the acupuncture head device. The acupuncture head device comprises an acupuncture body,a spring piece, a strain gauge, and a sensor. The sensor is installed at the left end of the strain gauge. The acupuncture body is provided with more than five kinds of acupuncture needles. The simpleacupuncture device of the invention can realize acupuncture therapy for patients, and has simple structure, convenient acupuncture and high usability, and can produce good economic and social benefits.

Owner:张万军

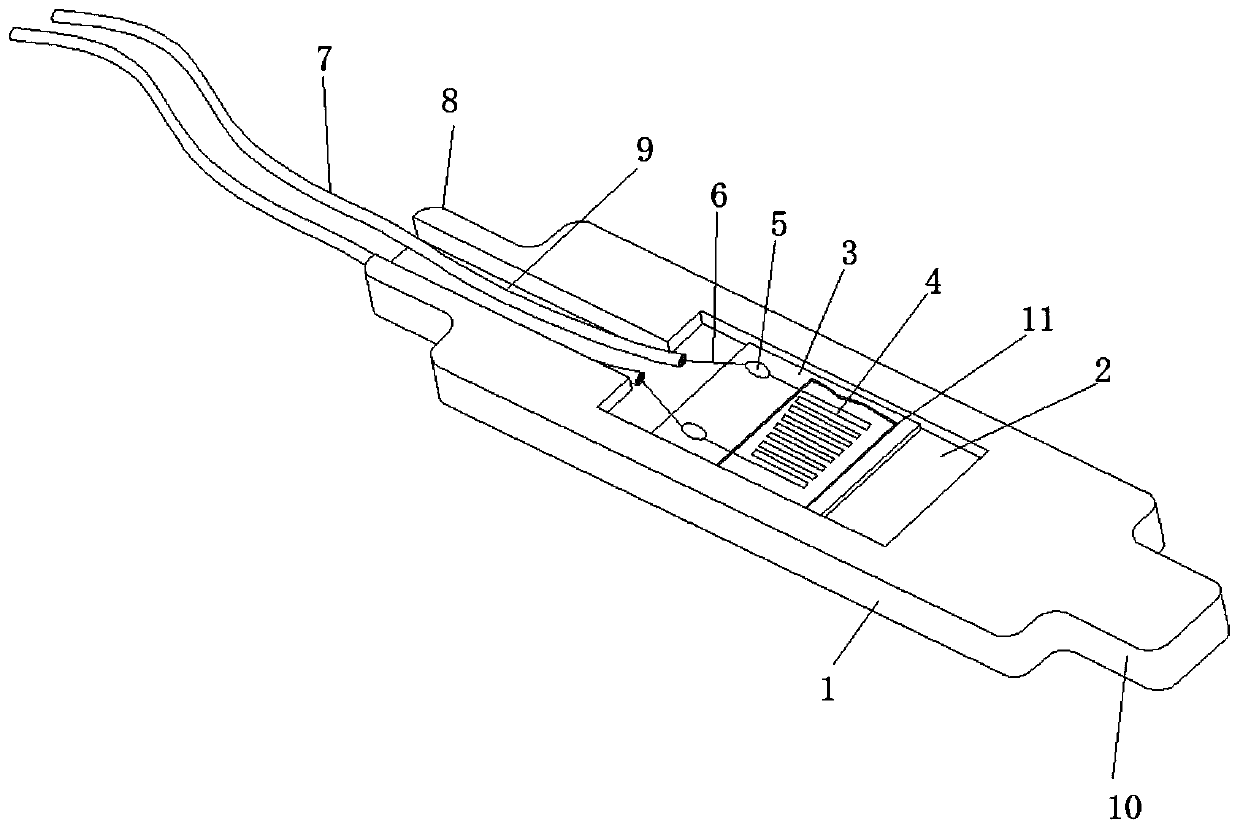

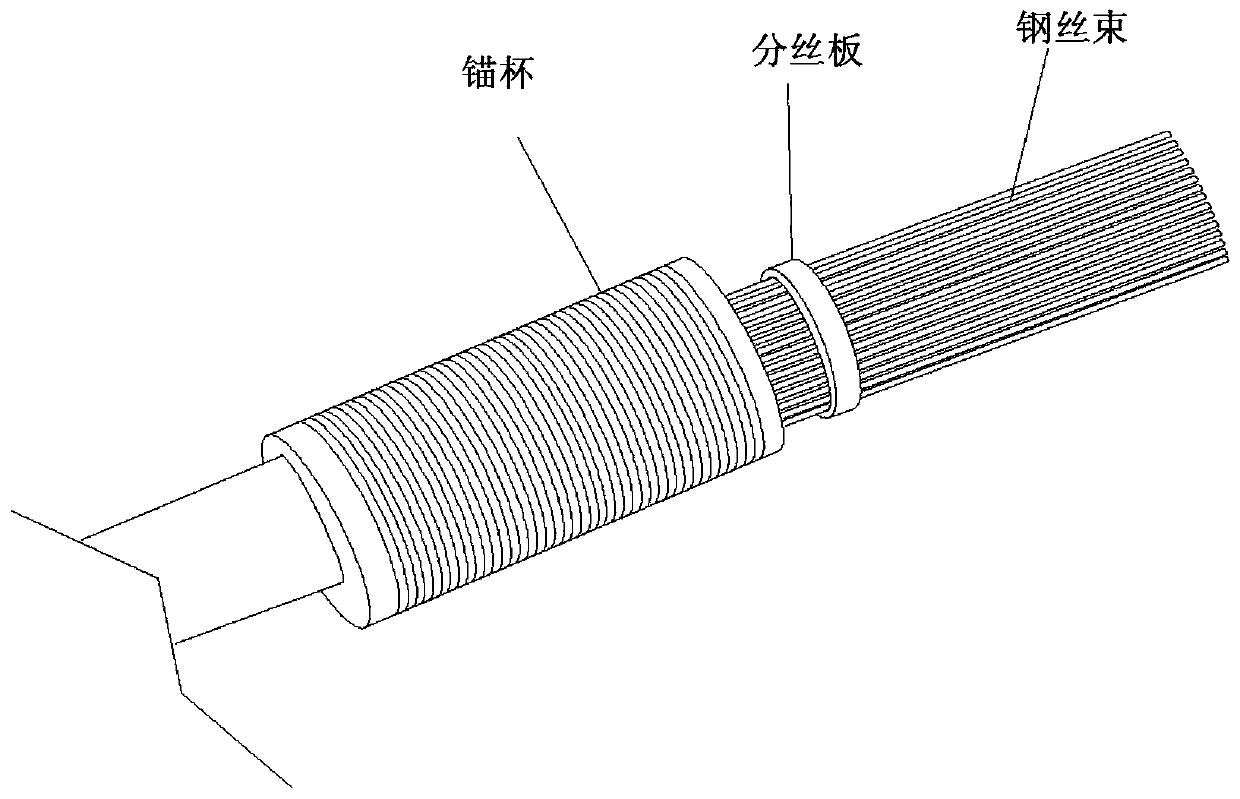

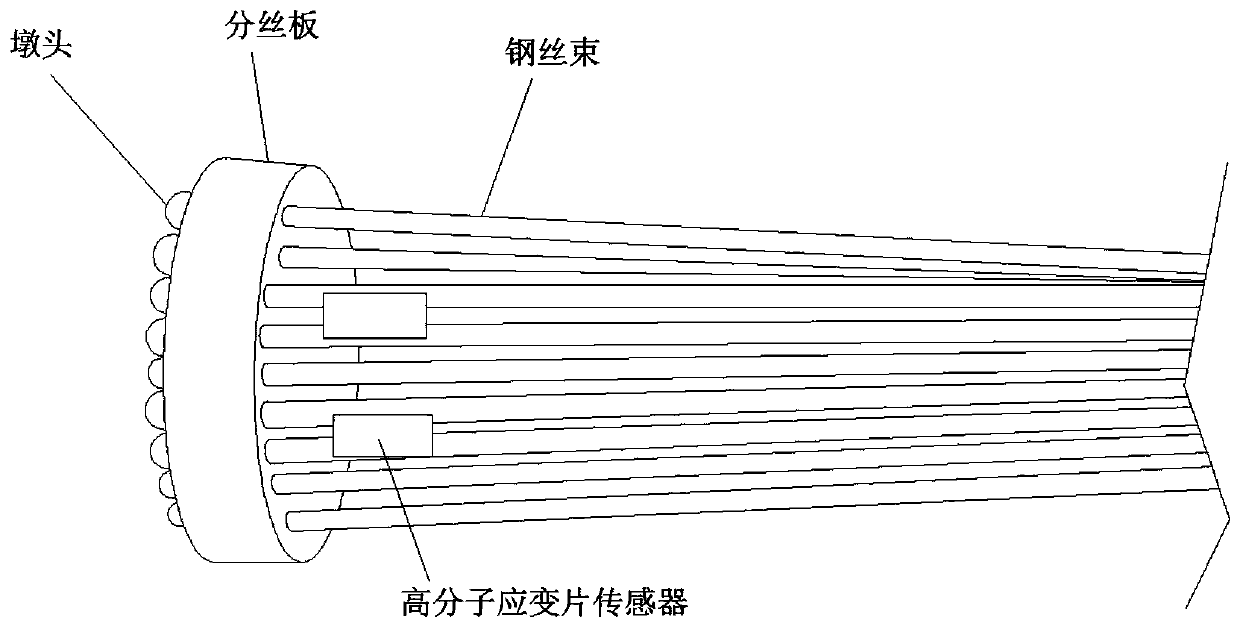

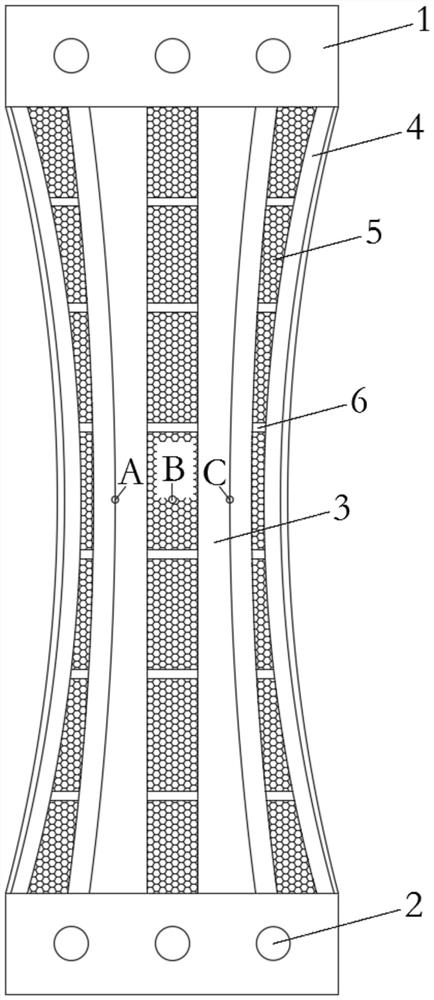

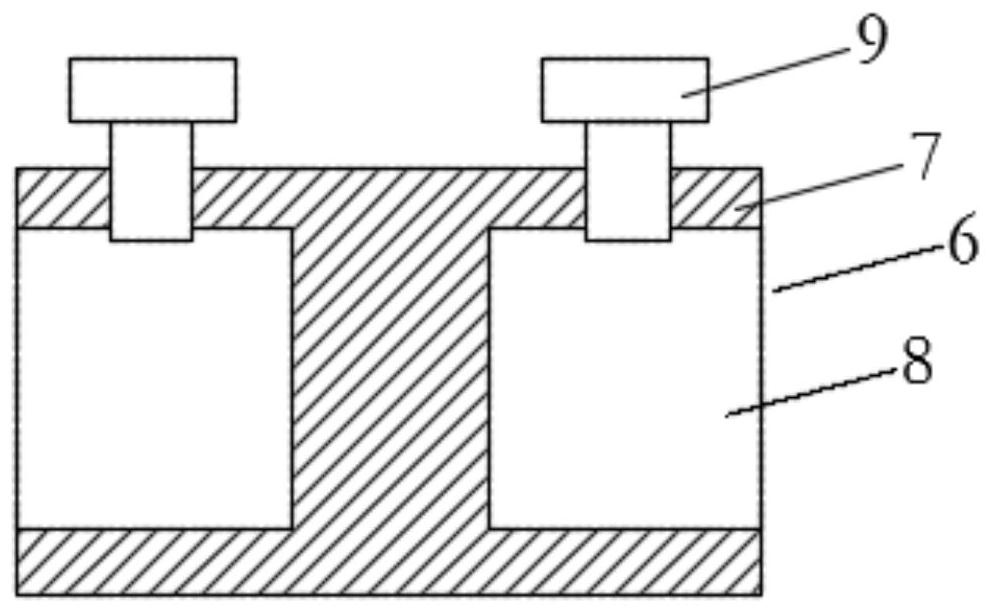

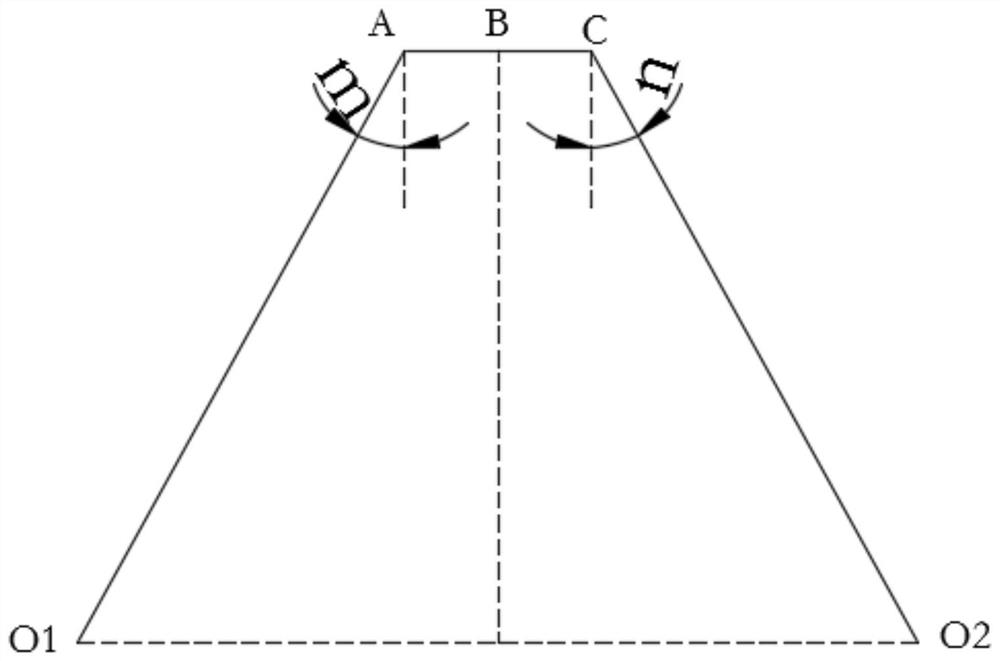

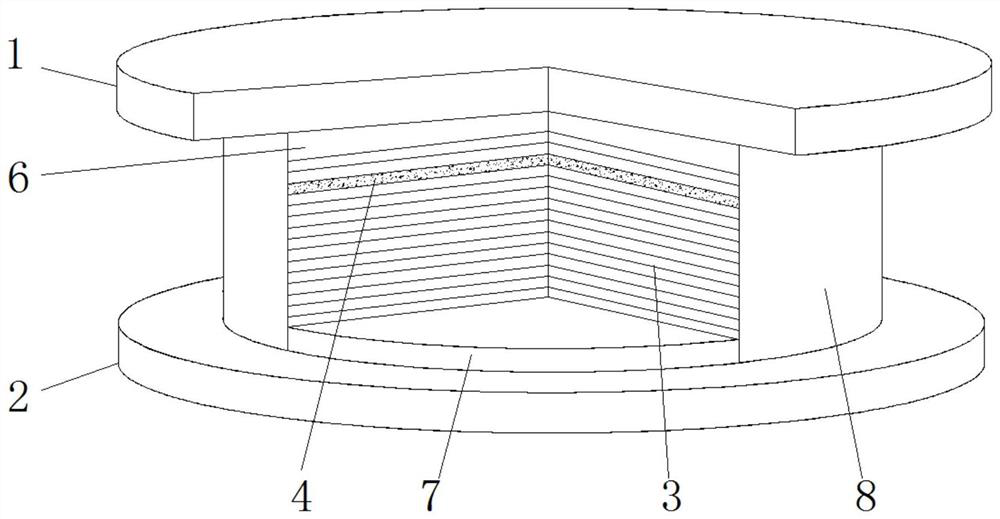

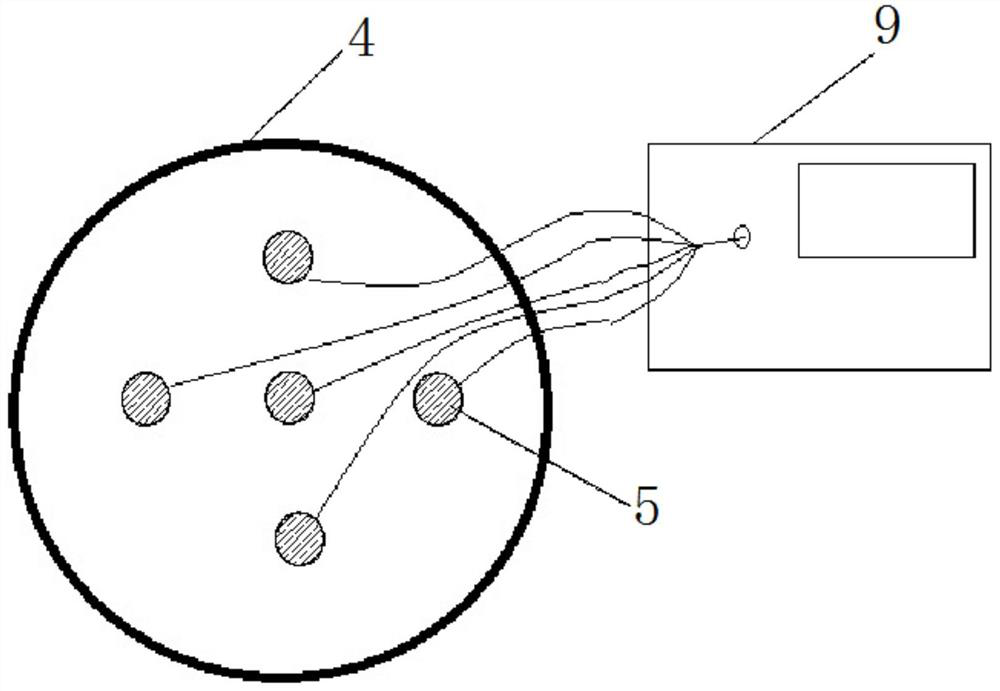

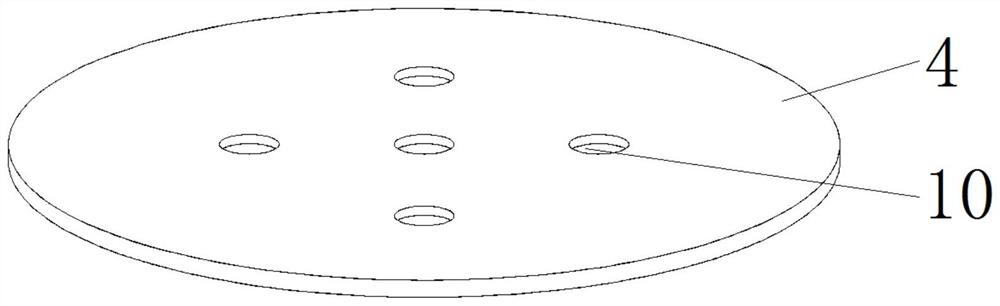

Polymer strain gauge sensor and intelligent cable manufacturing method

PendingCN111337178ALubricating and non-stickyPrecise measurement of strain forceBridge structural detailsApparatus for force/torque/work measurementPolymer scienceStrain gauge transducer

The invention discloses a polymer strain gauge sensor and an intelligent cable manufacturing method. The polymer strain gauge sensor comprises a polymer block and a high-temperature strain gauge, a strain gauge groove is formed in the middle position of the macromolecule block; high-temperature strain gauges are adhered to the interiors of the strain gauge grooves through high-temperature glue; the high-temperature strain gauge comprises a substrate and metal sensitive wires, the metal sensitive wires are distributed on the substrate, welding spots are arranged on the two sides of one end of the substrate, one ends of the metal sensitive wires are welded to the welding spots, high-temperature wires are welded to the other ends of the welding spots, and the outer sides of the high-temperature wires are sleeved with shielding sleeves. According to the invention, a specially-made high-molecular strain gauge sensor is pasted on a steel wire to form the intelligent cable; the high-molecularblock of the high-molecular strain gauge sensor is made of polytetrafluoroethylene, so that the high-molecular strain gauge sensor is good in sealing performance, high in lubrication and non-stickiness, good in electric insulativity and aging resistance and excellent in temperature resistance, and can deform under the long-term action of stress, so that the strain force of the intelligent cable can be measured more accurately.

Owner:GUANGXI UNIV

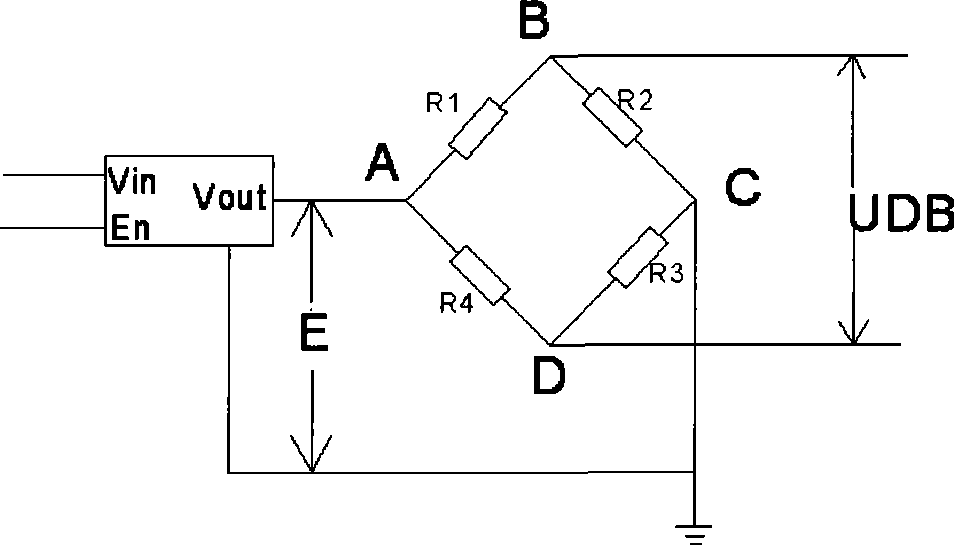

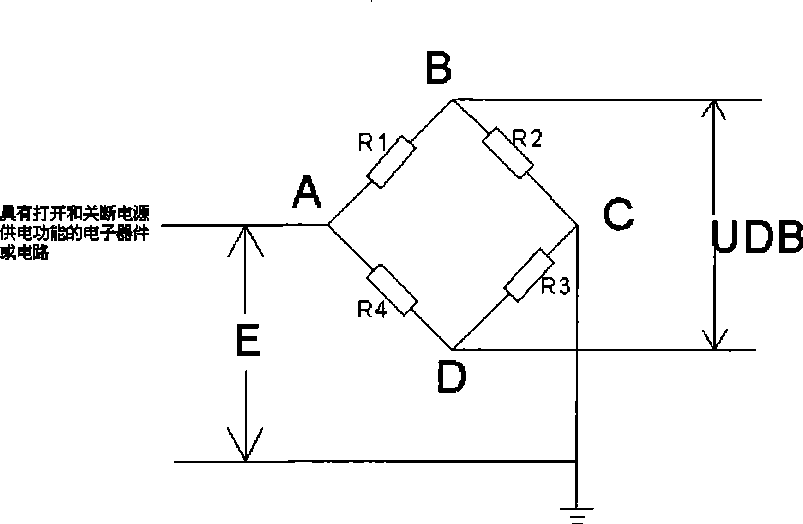

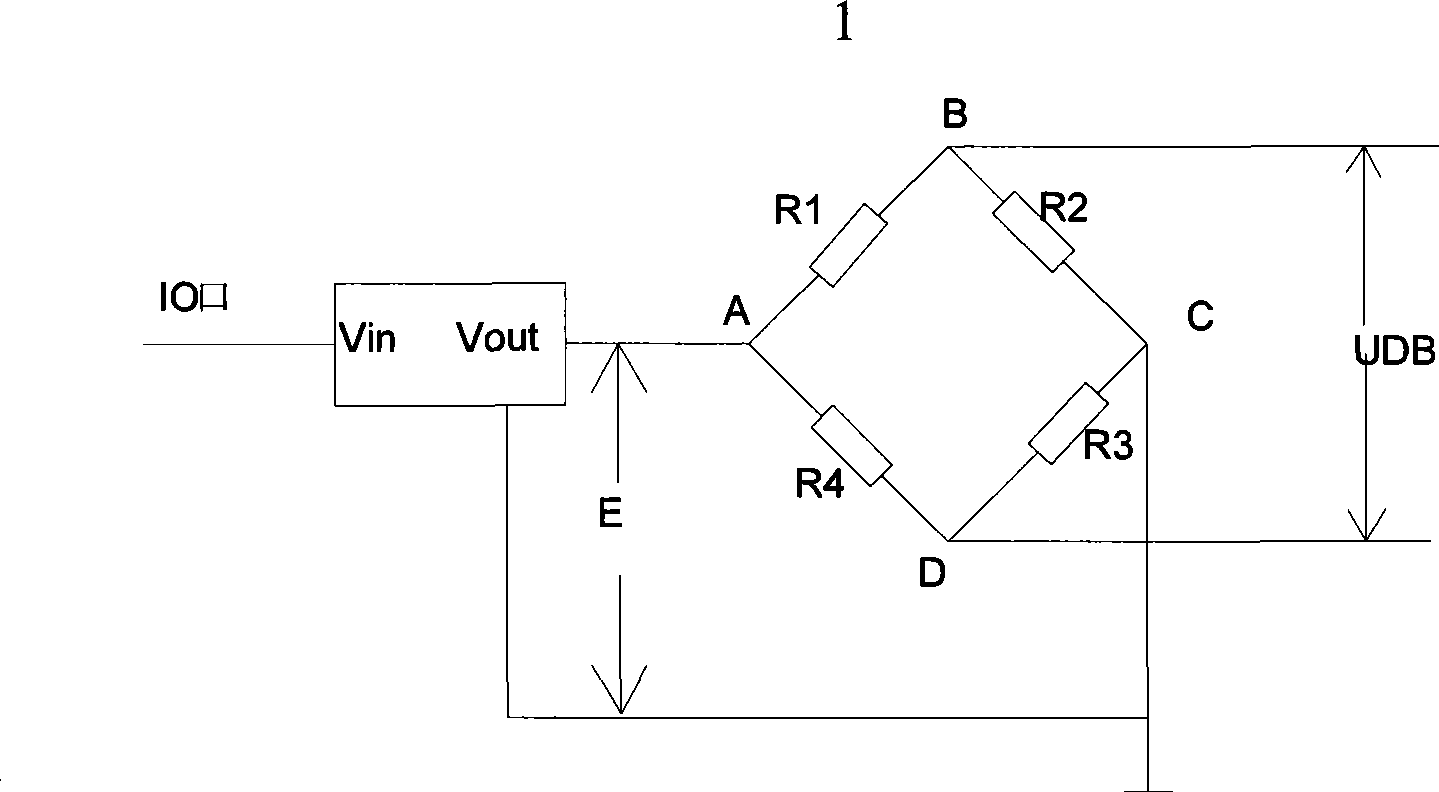

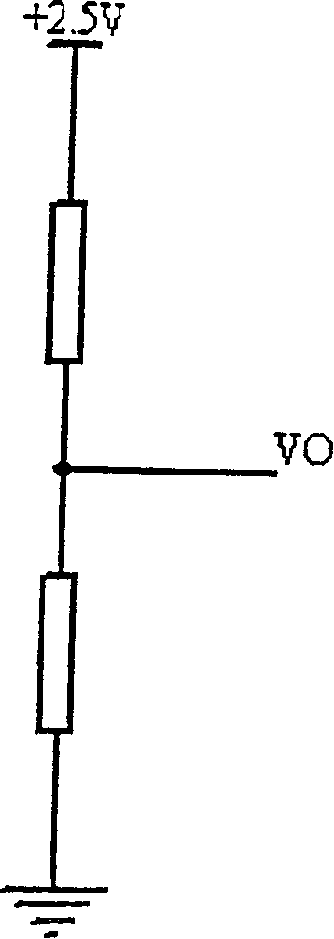

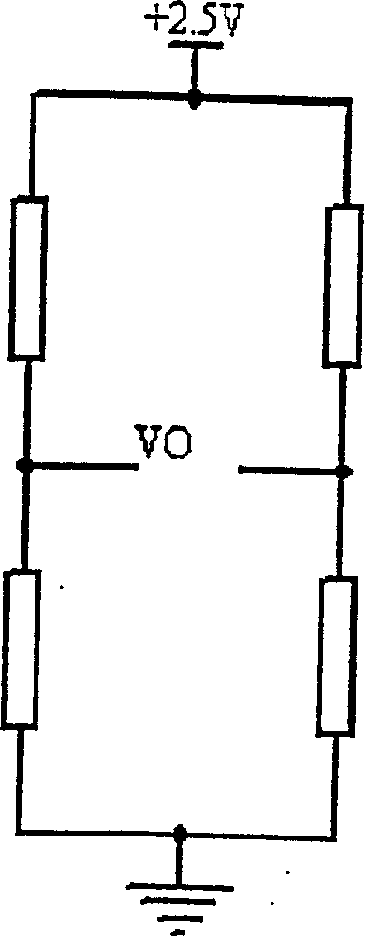

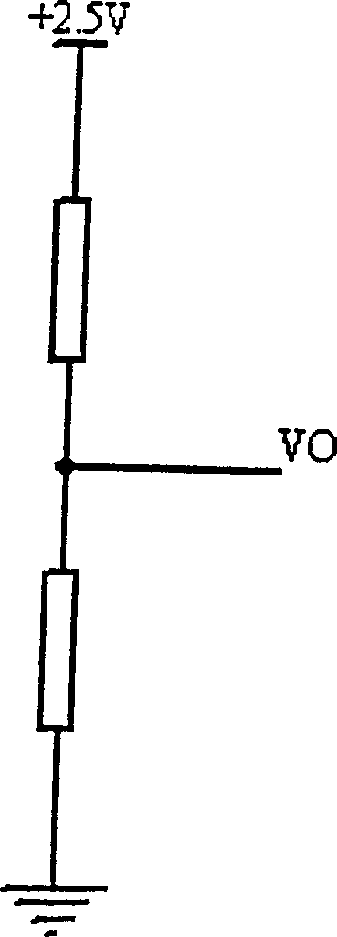

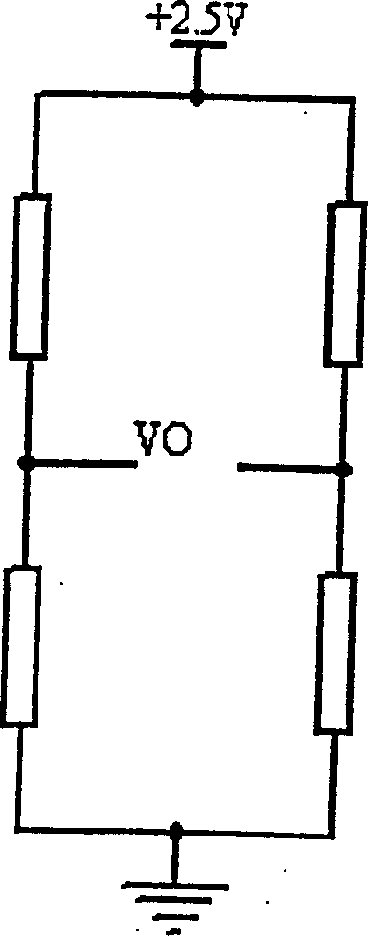

Resistance strain type sensor feed circuit and voltage control method

InactiveCN101430213AExtended service lifeReduce power consumptionConverting sensor output electrically/magneticallyElectrical resistance and conductanceStrain gauge transducer

The invention relates to a power supply circuit of a resistance strain gauge transducer which performs measurement by the resistance strain gauge transducer, and a voltage control method thereof. The circuit comprises the transducer and a power supply which is in bridge connection with the transducer; and a power supply terminal and an earth terminal of the resistance strain gauge transducer are connected with a power supply output terminal and the earth terminal of the controllable power supply in parallel. The invention provides the power supply circuit of the resistance strain gauge transducer, which lowers the power consumption of various applications, improves the service life of the power supply, and reduces the operation cost and maintenance cost of a system.

Owner:ZHEJIANG XIANXIN SCI & TECH CO LTD

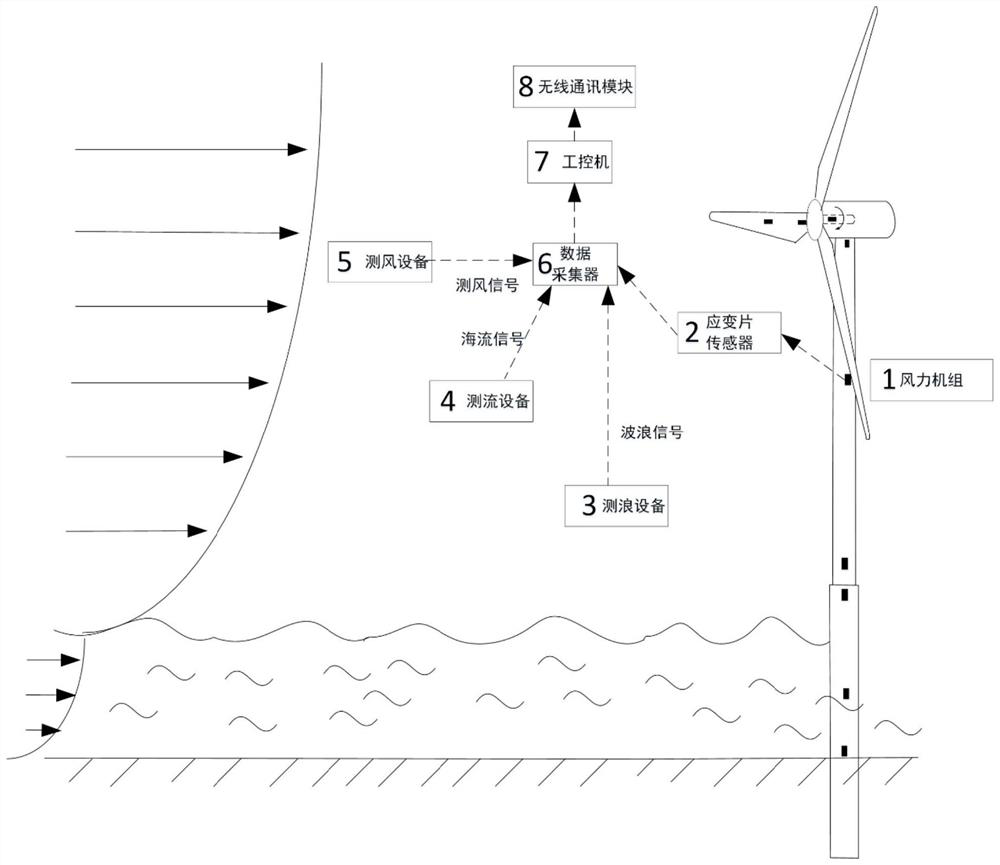

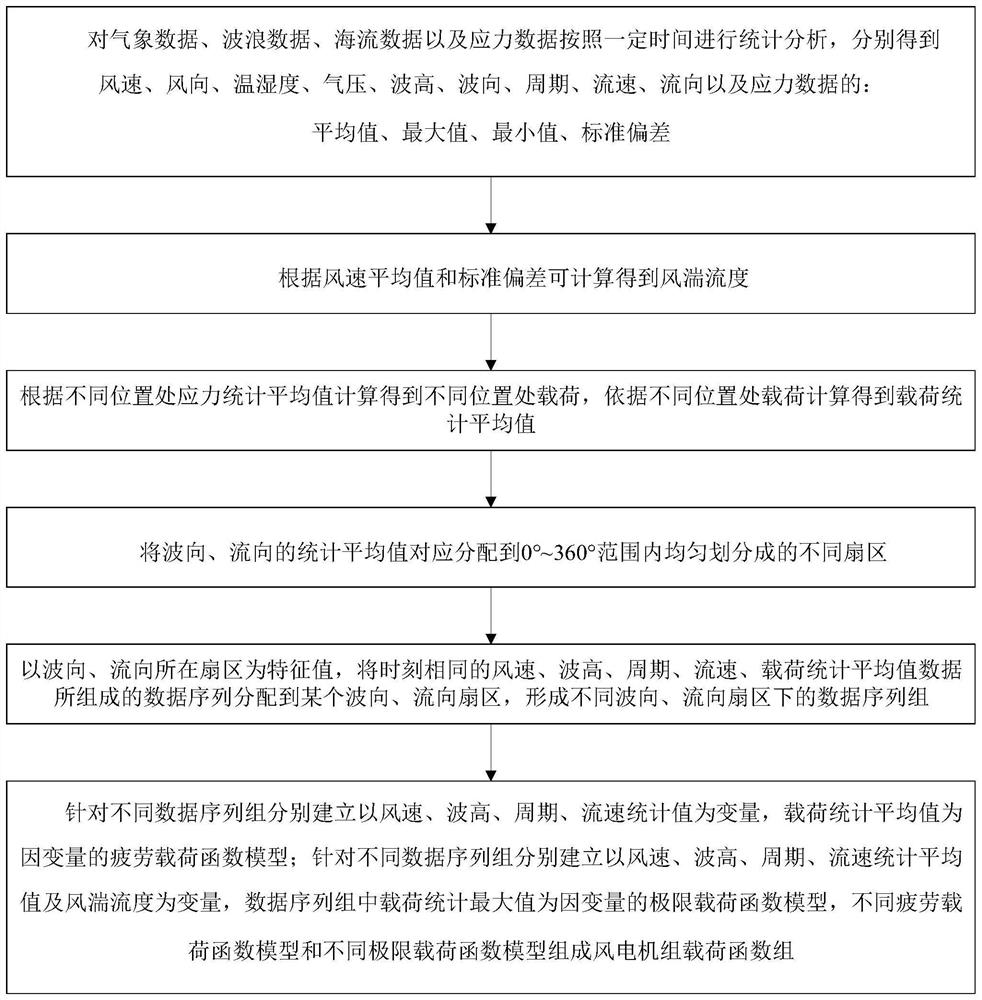

Offshore wind turbine generator load testing device and method

PendingCN113250915AAccurate assessment of load distributionSimple structural designMachines/enginesWind motor monitoringWireless transmissionMarine engineering

The invention discloses an offshore wind turbine generator load testing device and method. The device comprises wind measuring equipment, wave measuring equipment, flow measuring equipment, a strain gauge sensor, data collectors, an industrial personal computer and a wireless communication module. The wind measuring equipment, the wave measuring equipment, the flow measuring equipment and the strain gauge sensor are respectively connected with one data collector, and each data collector is connected with the industrial personal computer. The industrial personal computer is connected with the wireless communication module, and the wireless communication module is used for sending out data of the industrial personal computer in a wireless transmission mode. Besides wind, waves and flow serve as factors influencing the load of a fan, the load borne by the fan can be modeled more accurately, the influence of different factors on the load of the fan can be evaluated accurately, and therefore the load distribution of a wind turbine generator is evaluated accurately in the design stage to optimize the structural design of the fan.

Owner:HUANENG CLEAN ENERGY RES INST +3

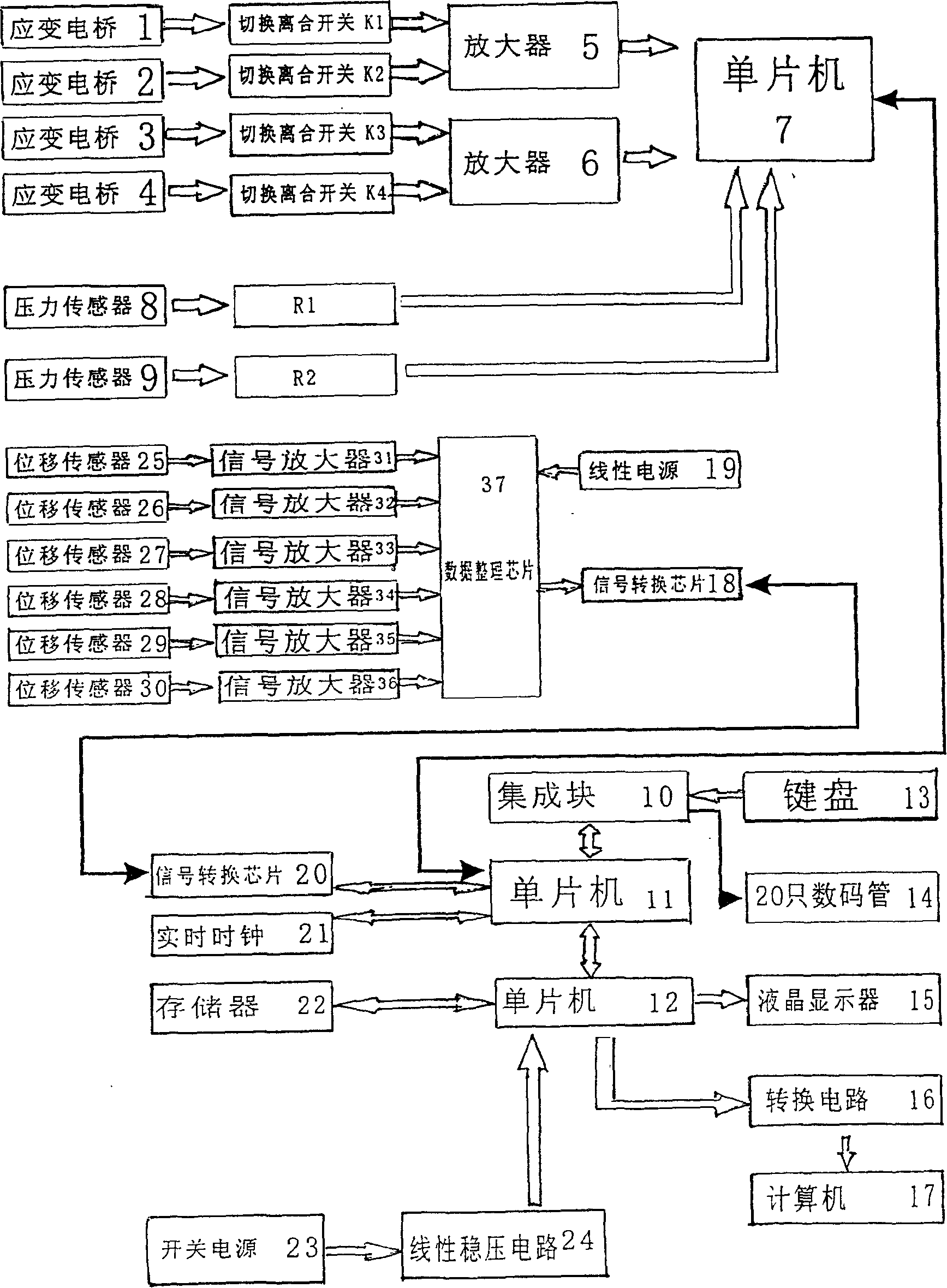

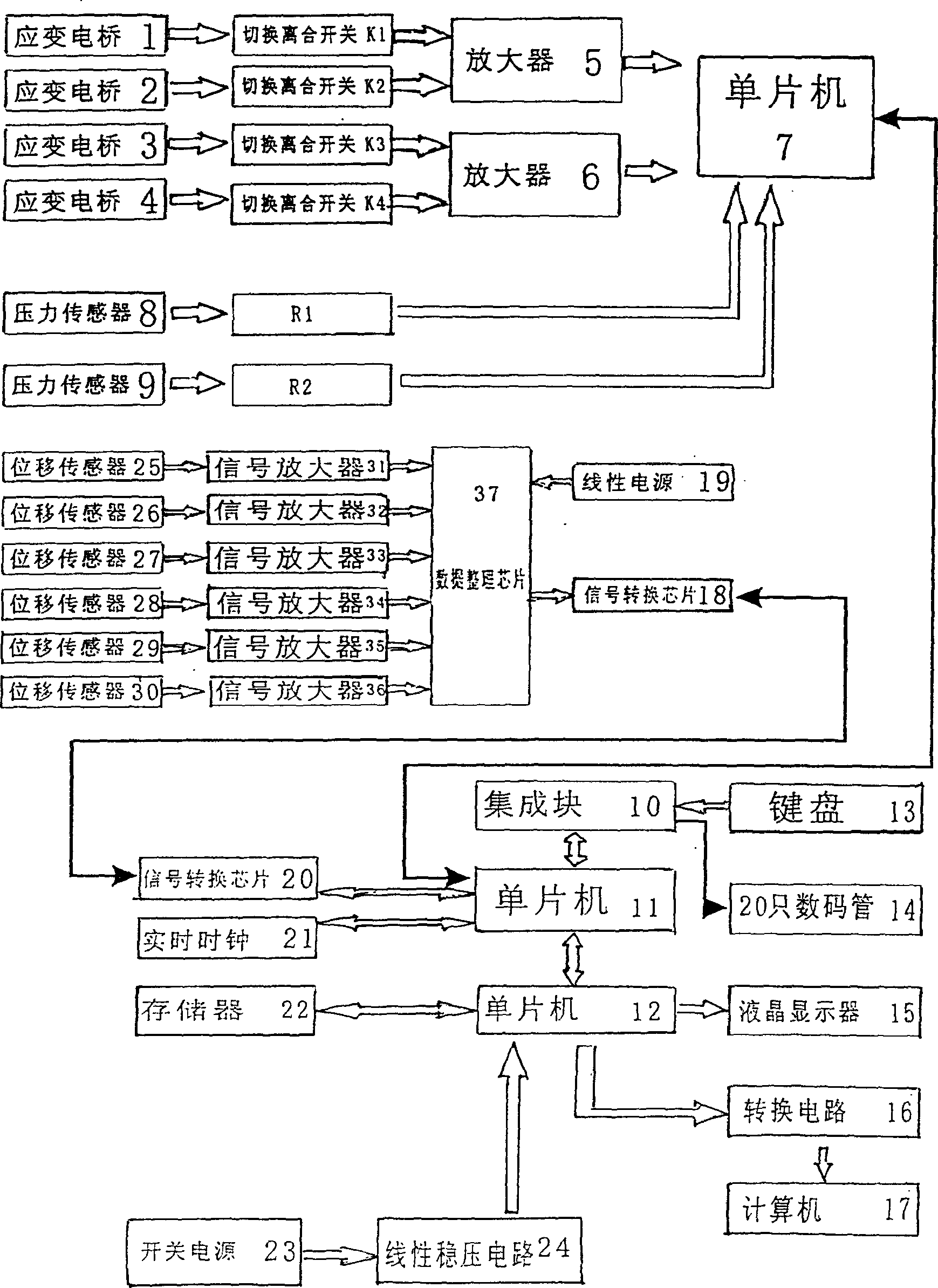

Multi-window data collector for rock-soil mechanics testing

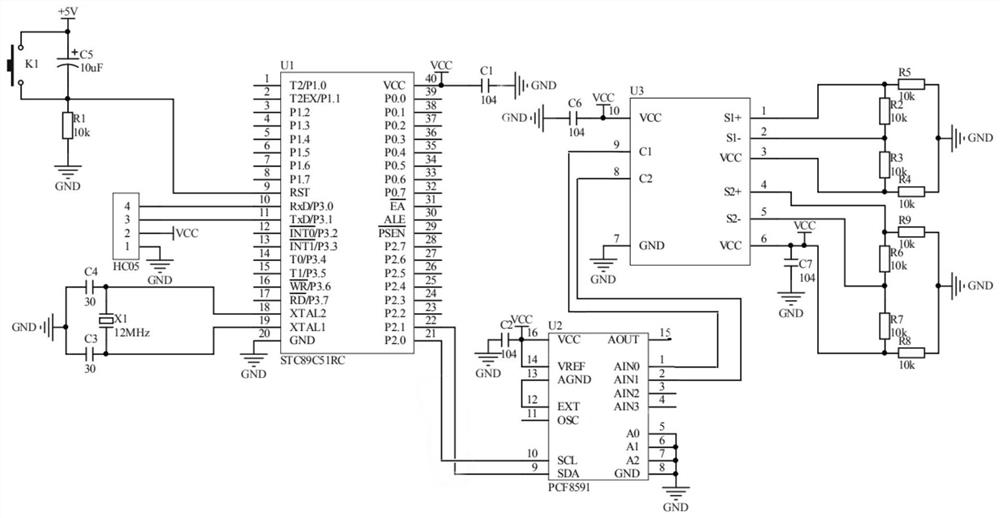

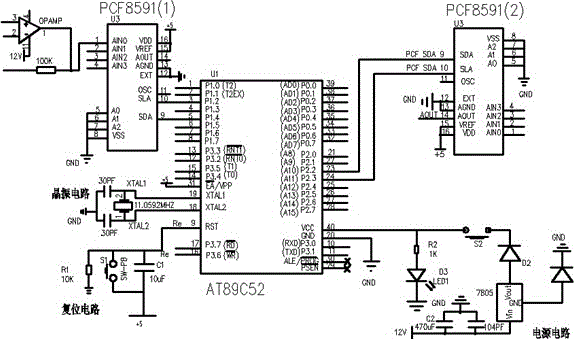

InactiveCN100394459CEasy to organizePromote generationElectric signal transmission systemsMeasurement devicesMicrocontrollerSoil mechanics

The invention relates to a soil and rock mechanics feature test multi window data acquisition device. Four strain gages are sticking on the rock sample to form full bridge or half bridge output circuit that has four switches K1-K4. The output of every two bridge output circuit connects to the input end of an amplifier (5, 6). And the output end connects to the input of MCU (7). Two pressure sensors (8, 9) connect to power ground and connect to MCU (7). The displacement sensor connects to data working up chip (37) and signal transforming chip (18), which connects to signal transforming chip (20). The chip (20) connects to MCU (11). And MCU (11) connects to integration block (10) that is connected to 20 LED and key board, MCU (7), and MCU (12). MCU (11) and MCU (12) connect to LCD. The 20 LEDs forms four display window that each has five LEDs.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

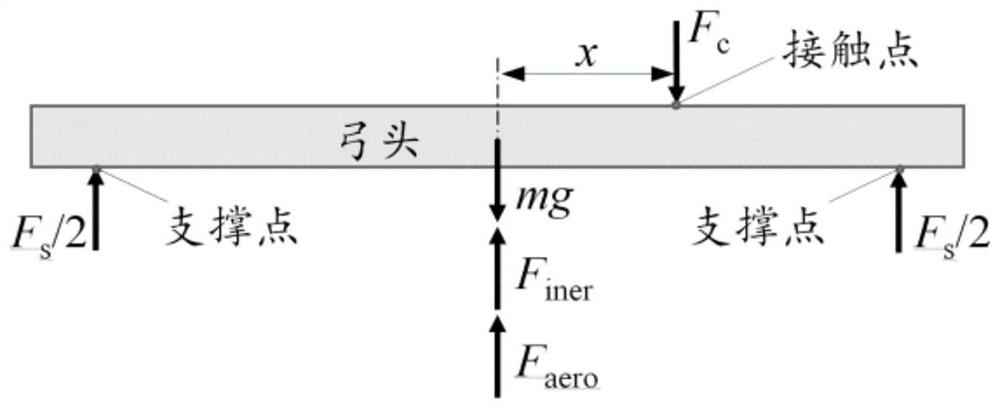

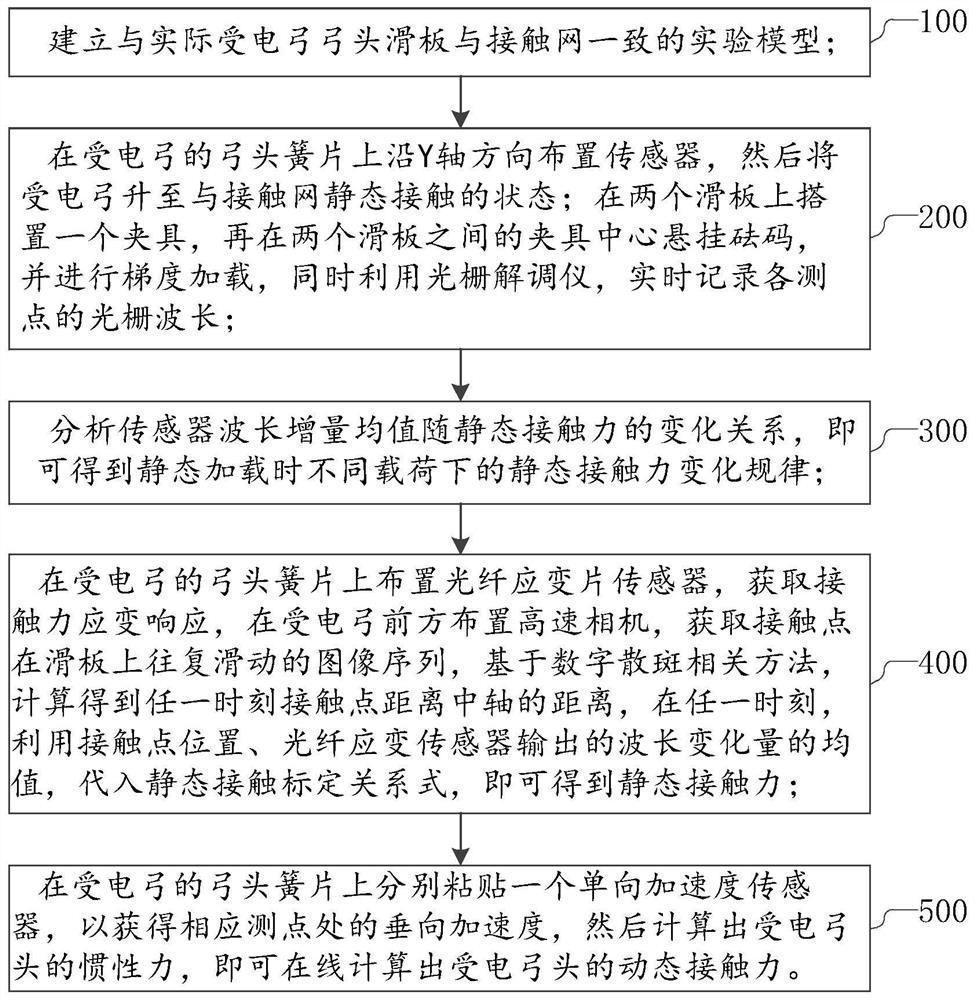

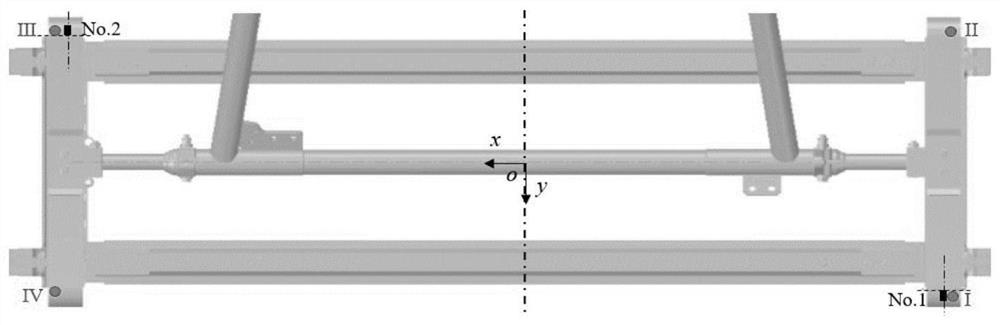

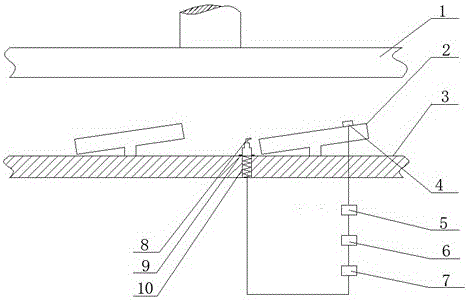

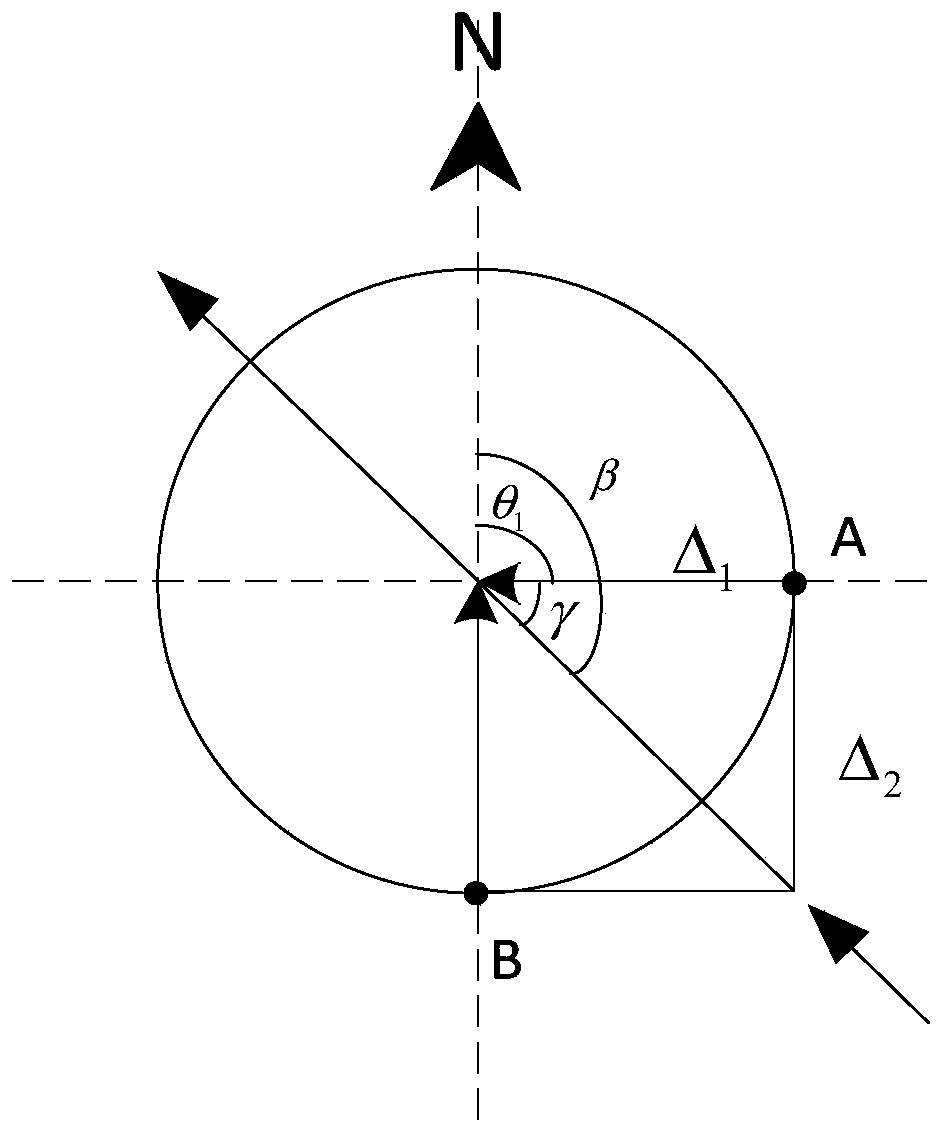

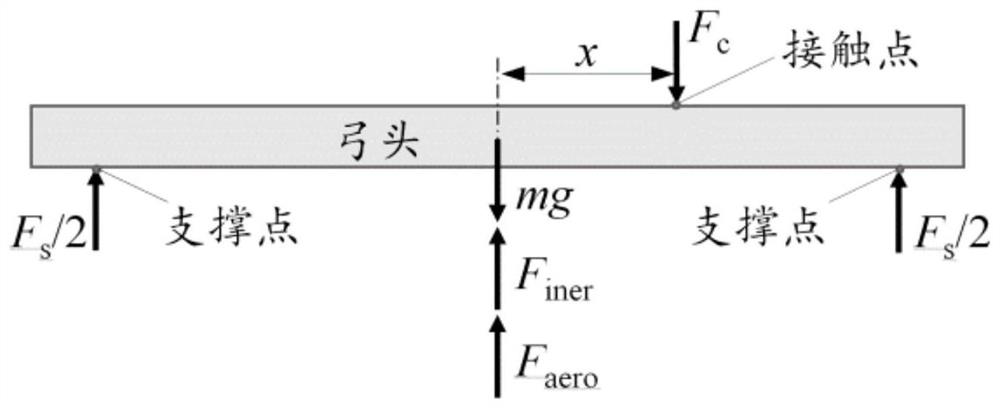

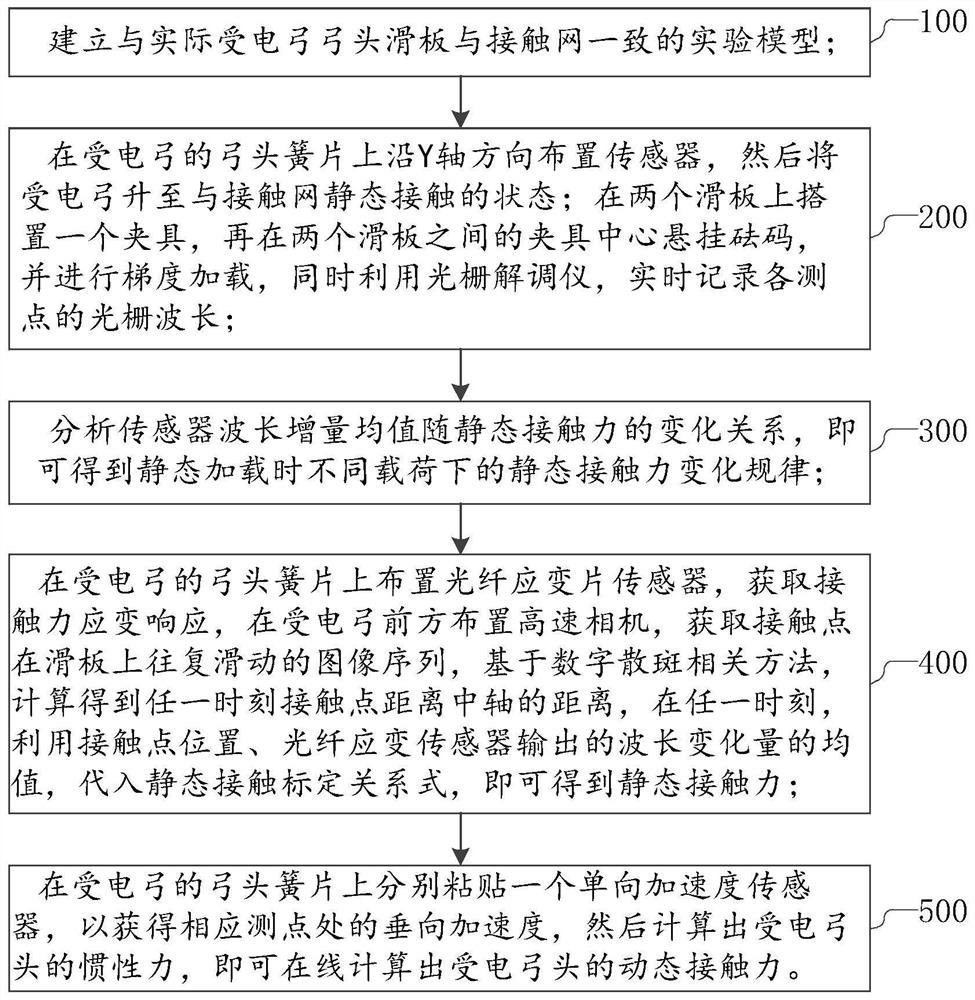

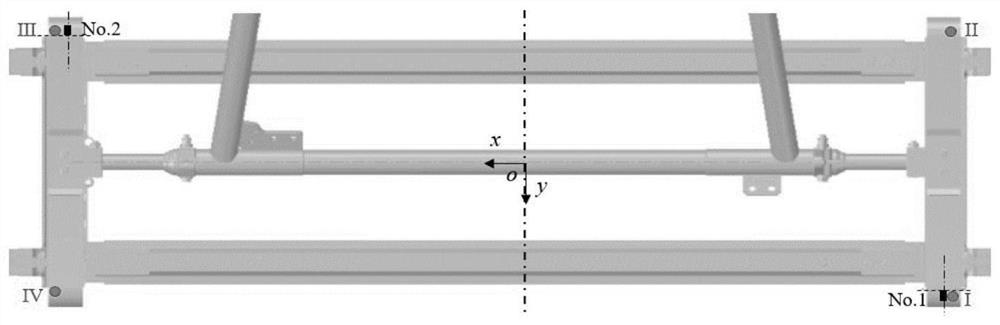

Pantograph-catenary contact force on-line test scheme

ActiveCN112129445AAvoid influenceAvoid errorsRailway vehicle testingApparatus for force/torque/work measurementGratingSolid structure

The invention provides a pantograph-catenary contact force on-line test scheme. The pantograph-catenary contact force on-line test scheme comprises the following steps that an experimental model is established; sensors are arranged on a pantograph head reed on the back face of a pantograph at intervals in the Y-axis direction, a clamp is erected on a sliding plate, weights are hung in the center of the clamp, and grating wavelengths of all measuring points are recorded in real time; static contact force change rules under different loads during static loading are obtained; an optical fiber strain gauge sensor is arranged on the pantograph head reed, a high-speed camera is arranged in front of the pantograph, and the static contact force is obtained; and the dynamic contact force of a pantograph head can be calculated on line by firstly calculating the inertia force of the pantograph head through a one-way acceleration sensor. A scheme of installing the strain sensor at the pantograph head reed is provided, higher sensitivity can be obtained, and the influence of periodic replacement of the sliding plate can be avoided. By means of an optical measurement digital speckle correlationmethod, direct measurement of a contact point position at any moment in the loading process can be achieved, the contact force can be directly deduced reversely in combination with strain values of the measuring points, and a sliding plate solid structure does not need to be simplified.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Multi-window data collector for rock-soil mechanics testing

InactiveCN1904962AEasy to organizePromote generationElectric signal transmission systemsMeasurement devicesMicrocontrollerSoil mechanics

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

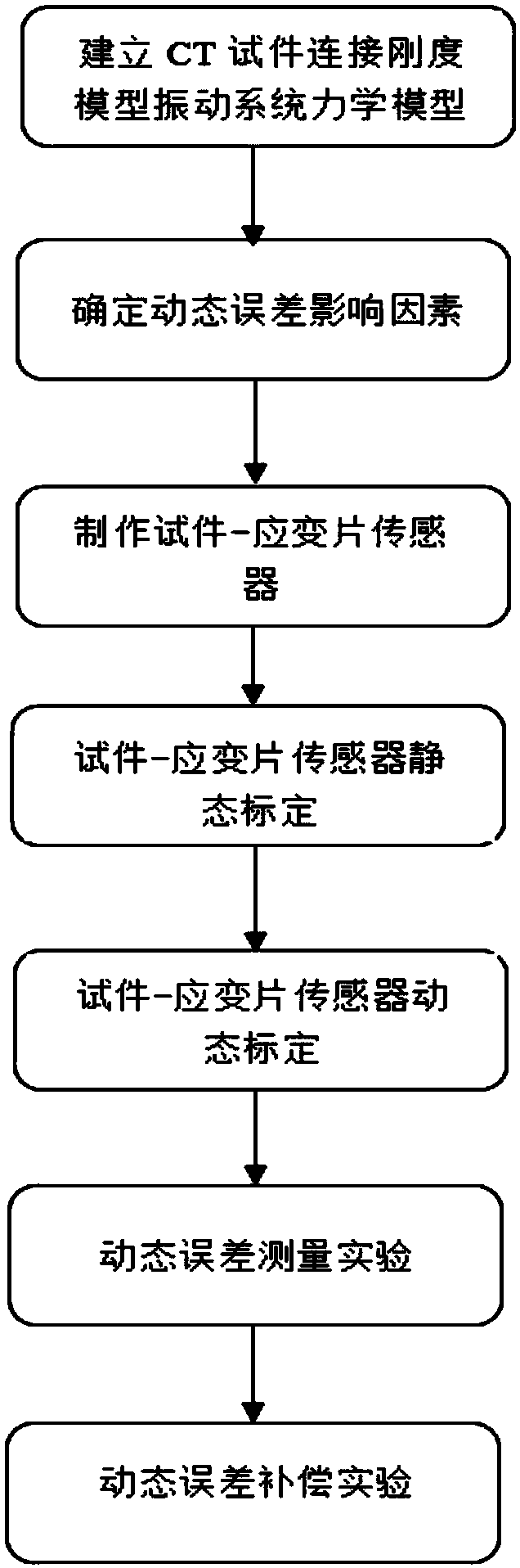

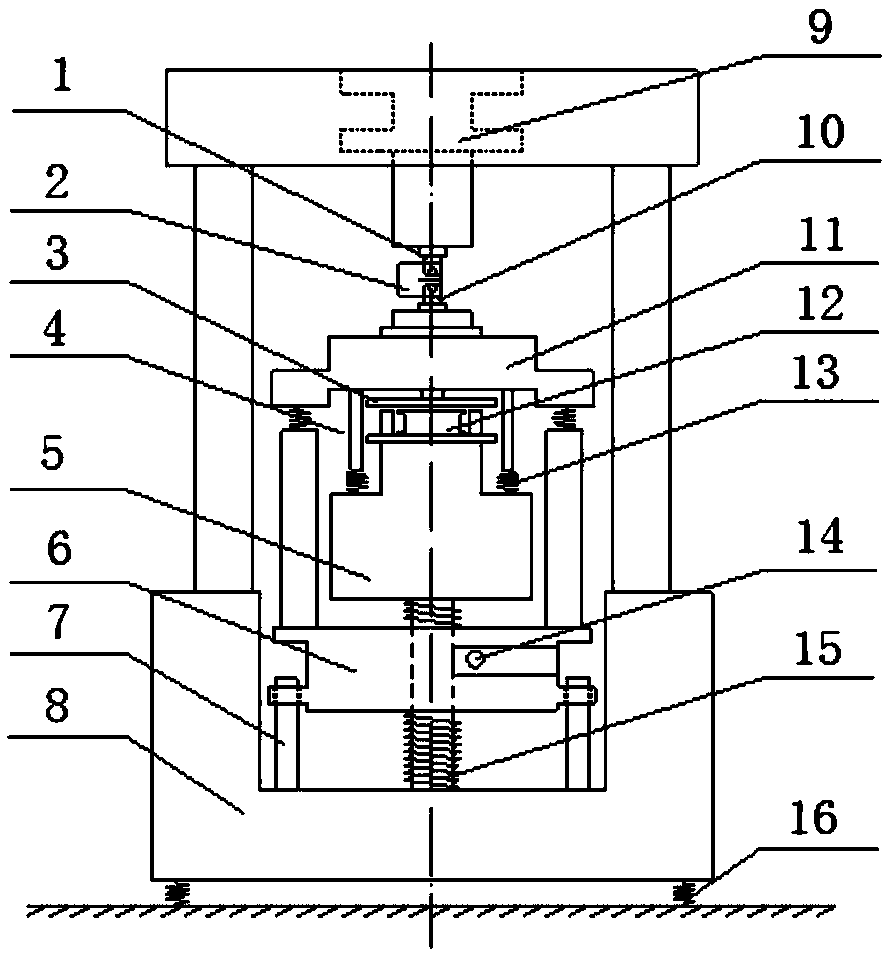

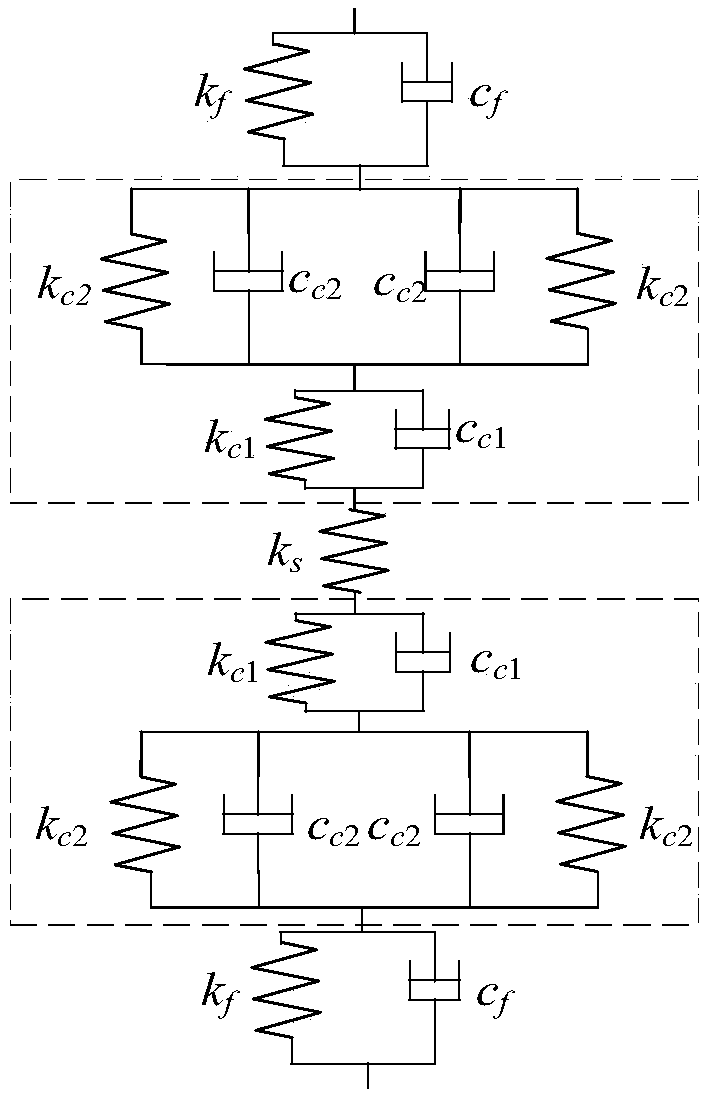

Resonant fatigue testing machine dynamic load error online compensation method

ActiveCN108827804AHigh measurement accuracyMaterial strength using repeated/pulsating forcesElectrical resistance and conductanceObservational error

A resonant fatigue testing machine dynamic load error online compensation method comprises following steps: (1) establishing a compact tension (CT) specimen connection rigidity model and a three freedom degree damping vibration mechanical model, and analyzing related factors that influence the dynamic load error; (2) determining key factors that influence the dynamic load error; (3) pasting a resistance strain gauge on a position that is close to the tip of a crack of a CT specimen with a prefabricated crack to produce a specimen-strain gauge sensor; (4) statically calibrating the specimen-strain gauge sensor by a standard force sensor; (5) starting a fatigue testing machine to dynamically calibrate the specimen-strain gauge sensor, which has been statically calibrated in the step (4); and(6) according to static load and online measured crack length, carrying out bilinear interpolation on the data of dynamic calibration of the step (5) to obtain dynamic load measurement error; and carrying out error compensation based on the dynamic load measured value. The precision of the dynamic load online measurement of a fatigue testing machine is effectively improved.

Owner:ZHEJIANG UNIV OF TECH

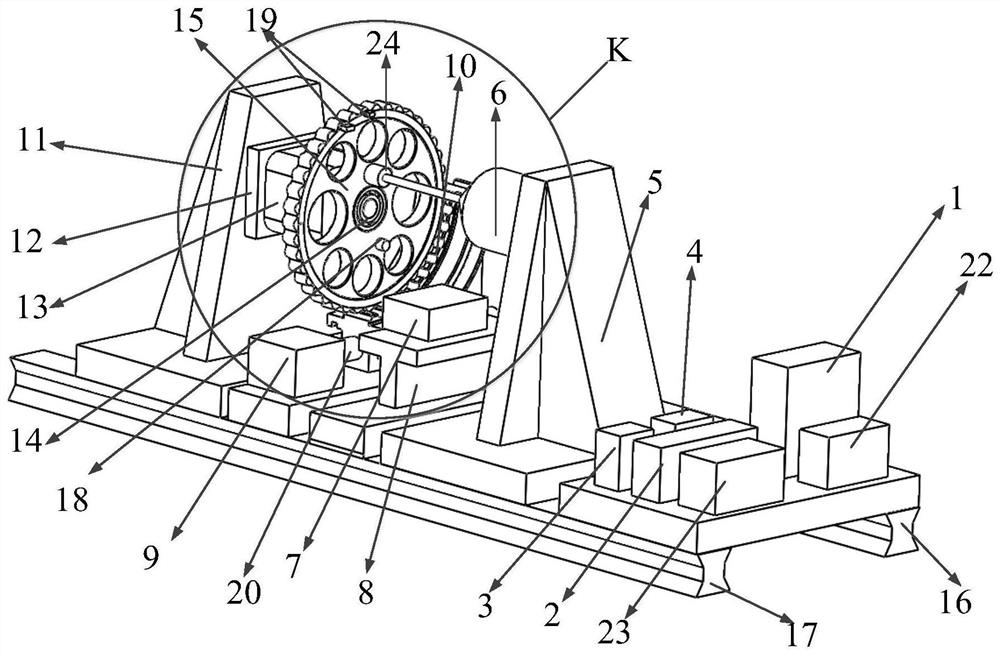

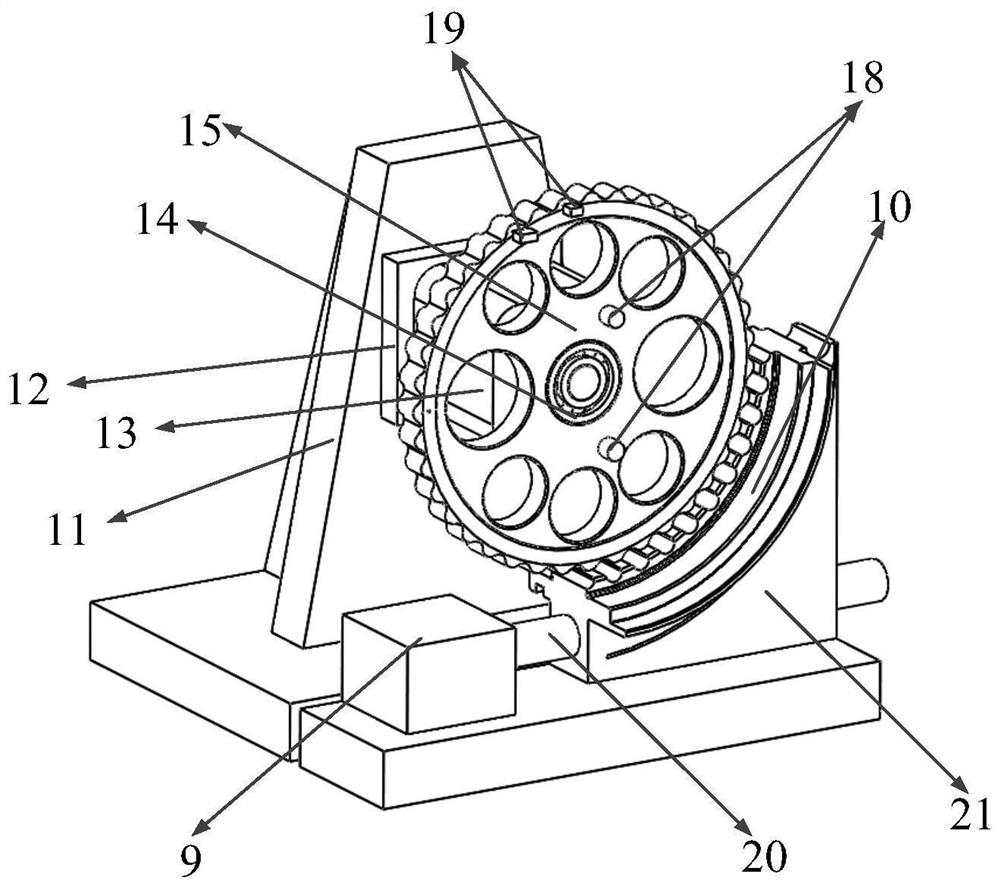

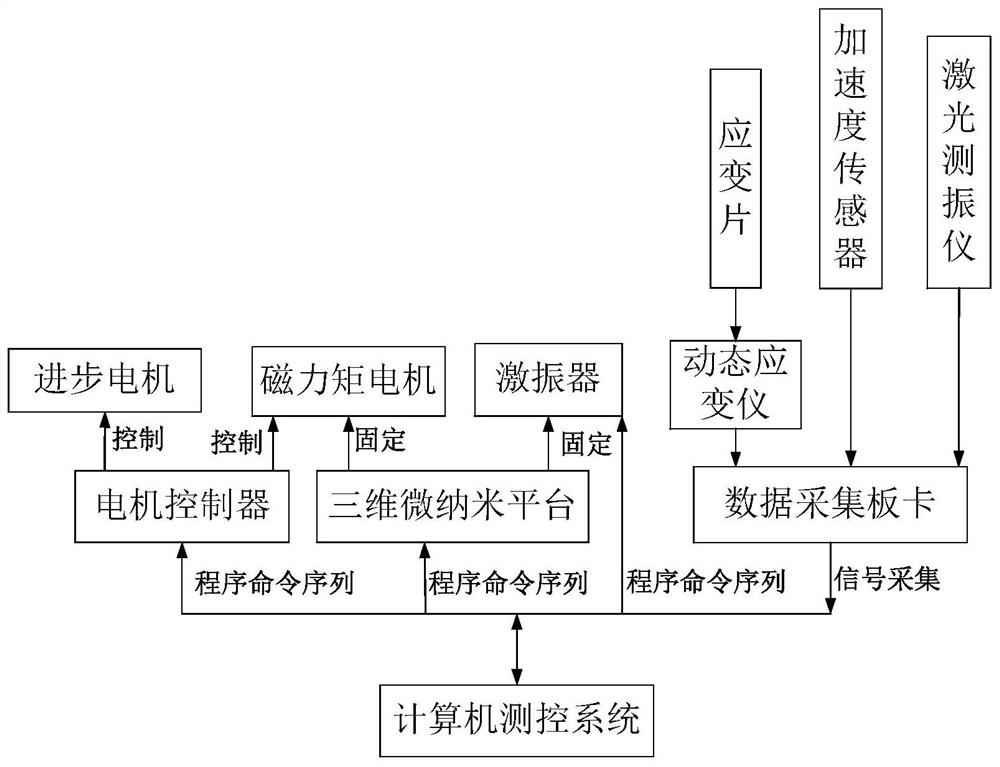

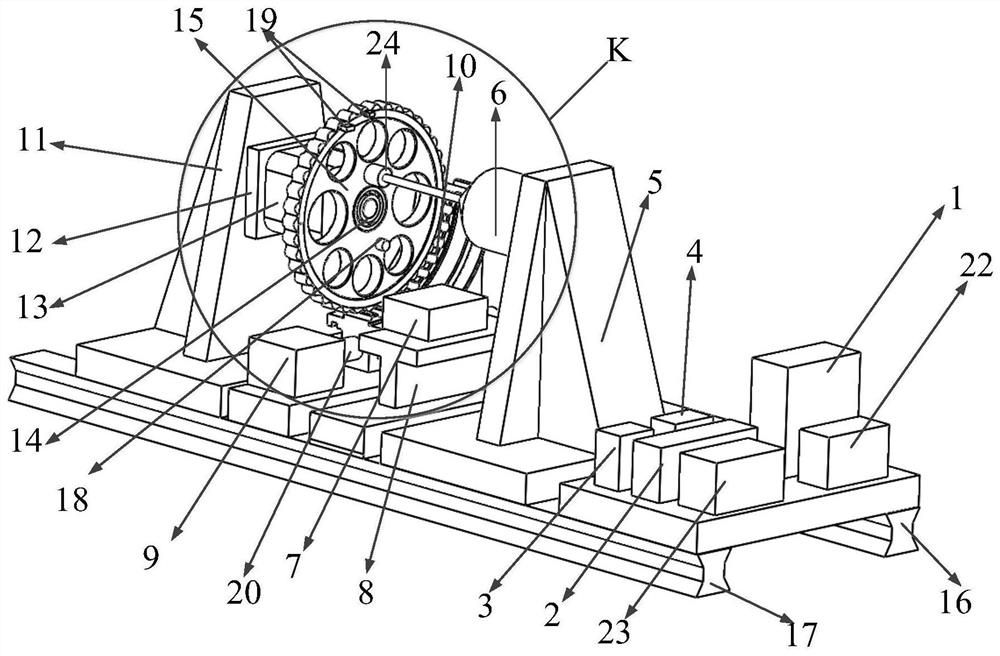

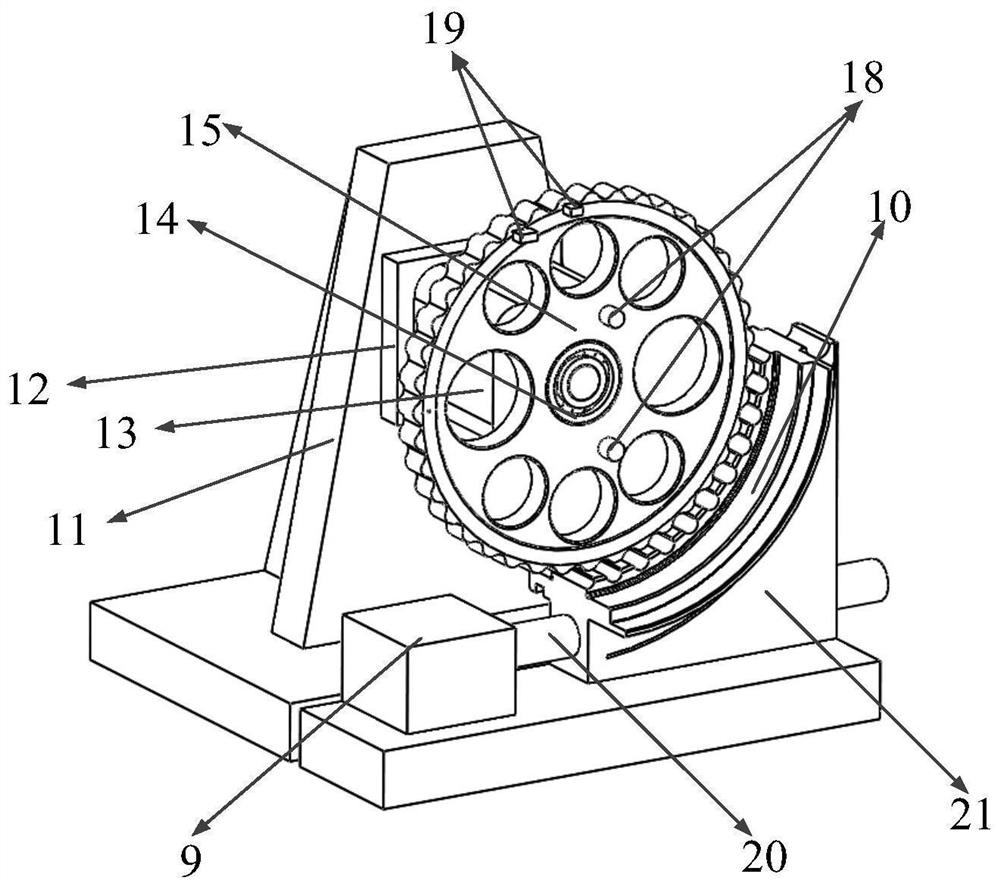

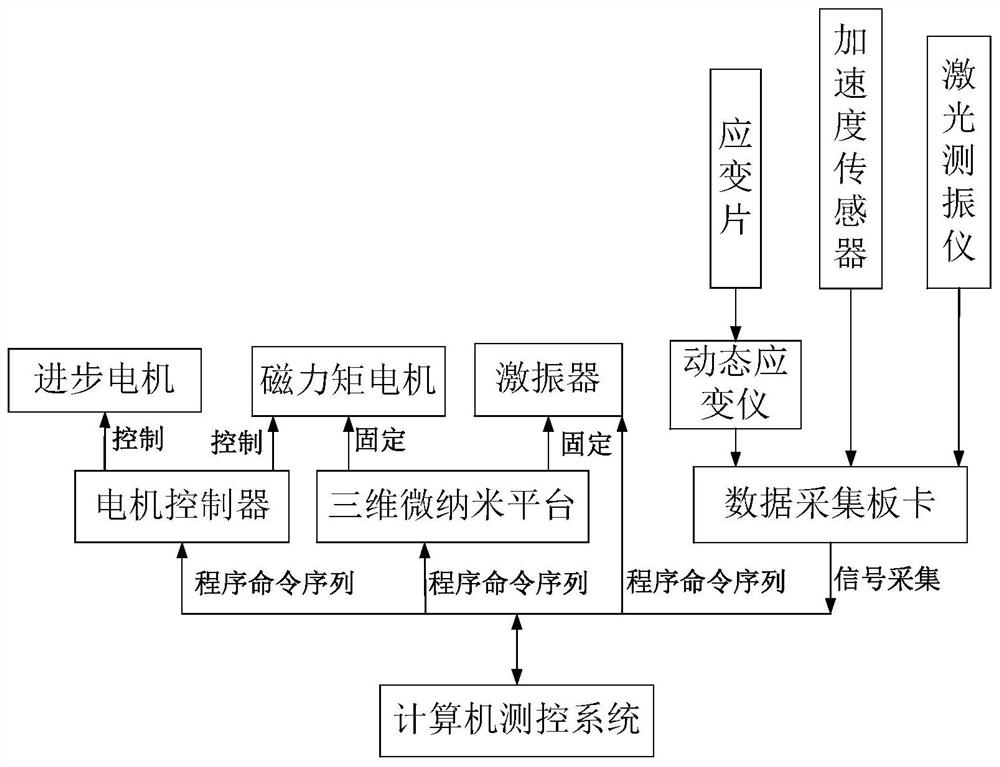

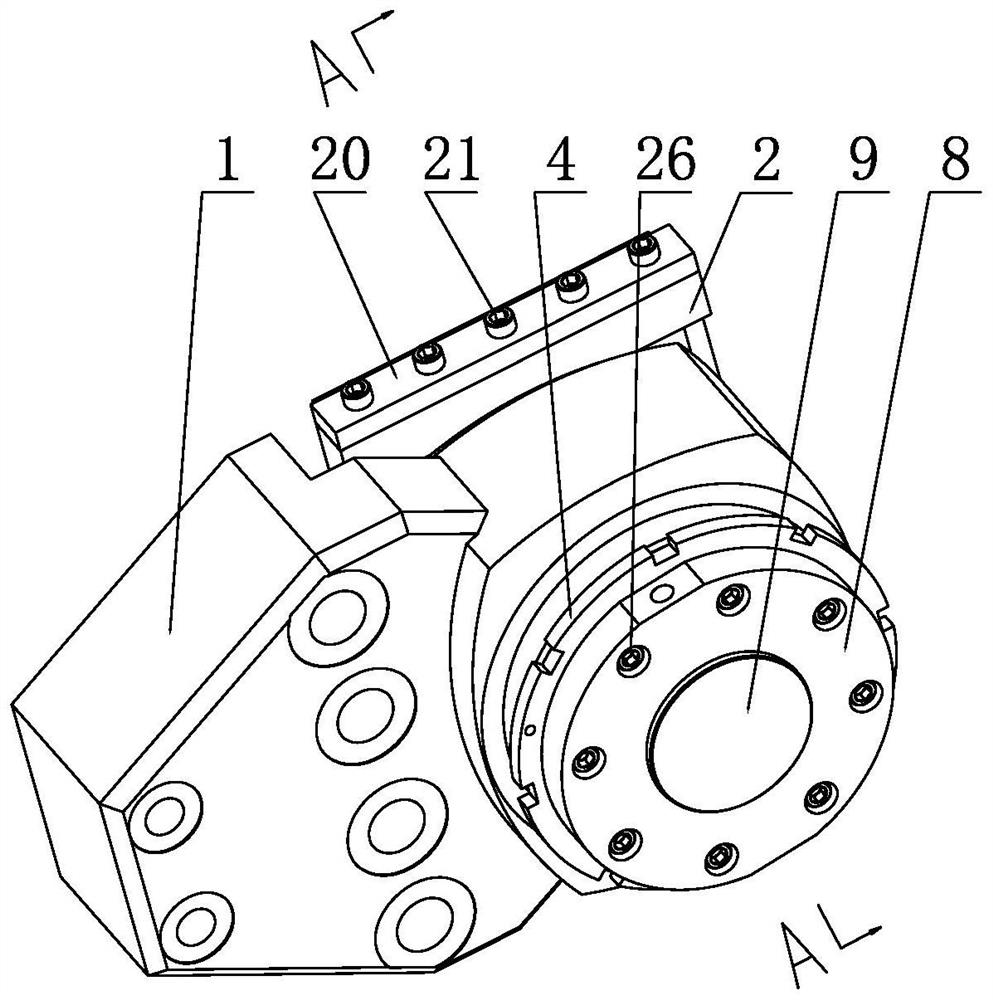

Measuring system and method for obtaining inherent frequency of cycloidal gear of speed reducer under different working conditions

ActiveCN111795820ASimple designQuick checkMachine part testingSubsonic/sonic/ultrasonic wave measurementReduction driveControl system

The invention discloses a measuring system and method for obtaining the inherent frequency of a cycloidal gear of a speed reducer under different working conditions. The system comprises a fine adjustment displacement mechanism, a magnetic torque motor power device, a detection special pin wheel housing, an acceleration sensor, strain gauge sensors, a sensor, a vibration exciter, a vibration meterand a measurement and control system. The magnetic torque motor power device and the vibration exciter are oppositely arranged on the fine adjustment displacement mechanism; the magnetic torque motorpower device is connected with the to-be-detected cycloidal gear; the acceleration sensor is arranged on the outer surface of the to-be-detected cycloidal gear, the strain gauge sensors are respectively arranged at the tooth root parts of the to-be-detected cycloidal gear and the detection special pin wheel housing, the output end of the vibration exciter abuts against the side end surface of theto-be-detected cycloidal gear, the vibration meter is arranged on one side of the to-be-detected cycloidal gear, and the force sensor is arranged at the front end of the vibration exciter; and the measurement and control system is respectively connected with the acceleration sensor, the strain gauge sensors, the vibration exciter and the vibration meter. On-line rapid measurement of the vibrationinherent frequency of the reducer cycloidal gear under different working conditions is realized, the measurement precision is high, and the operation is simple.

Owner:NINGBO UNIV

Tilting-pad thrust bearing device automatically adjusting oil film thickness

InactiveCN106438674AFind and fix unbalanced load problemsExtend working lifeBearing assemblyShaftsVoltage converterElectrical resistance and conductance

The invention provides a tilting-pad thrust bearing device automatically adjusting oil film thickness. The device comprises a runner plate, pads, a base, threaded holes, resistance strain-gauge transducers, resistance-voltage converters, analog-digital converters, controllers, high-pressure oil nozzles and gaskets on the high-pressure oil nozzles. By means of the resistance strain-gauge transducers, the resistance-voltage converters and the analog-digital converters, the deformation amount of the current pad can be converted into a numerical value, then, the controller is used for judging whether the corresponding high-pressure oil nozzle is needed to spray oil to the pad or not, and then the oil film thickness of the pad is changed. The tilting-pad thrust bearing device is simple in structure, the unbalance loading problem of a tilting-pad thrust bearing can be quickly found and solved only by additionally arranging a set of control systems and high-pressure oil nozzles based on a mechanical structure of the original tilting-pad thrust bearing, and the service life of the tilting-pad thrust bearing is prolonged to a great extent.

Owner:HARBIN UNIV OF SCI & TECH

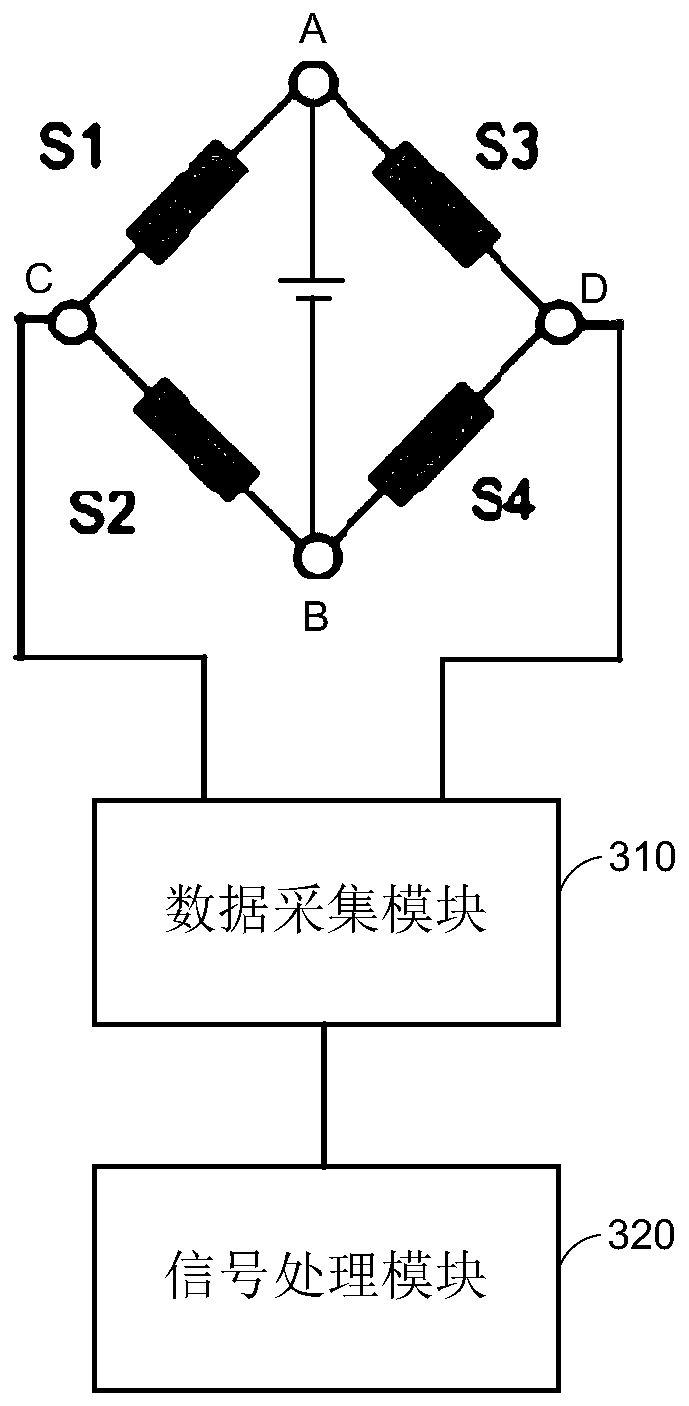

Plunger pump rotating speed measuring method and device

The invention discloses a plunger pump rotating speed measuring method and device. The device can comprise a strain gauge sensor, wherein the strain gauge sensor is located on a hydraulic pipeline connected with the output end of a plunger pump; a data acquisition module which is used for acquiring a measurement signals on the strain gauge sensor when the plunger pump outputs pulsating fluid to ahydraulic pipeline; and a signal processing module which is used for determining the pulsation frequency of the pulsating fluid in the hydraulic pipeline on the basis of the energy spectral density ofthe measurement signals and determining the rotating speed of the plunger pump on the basis of the pulsation frequency.

Owner:COMAC +1

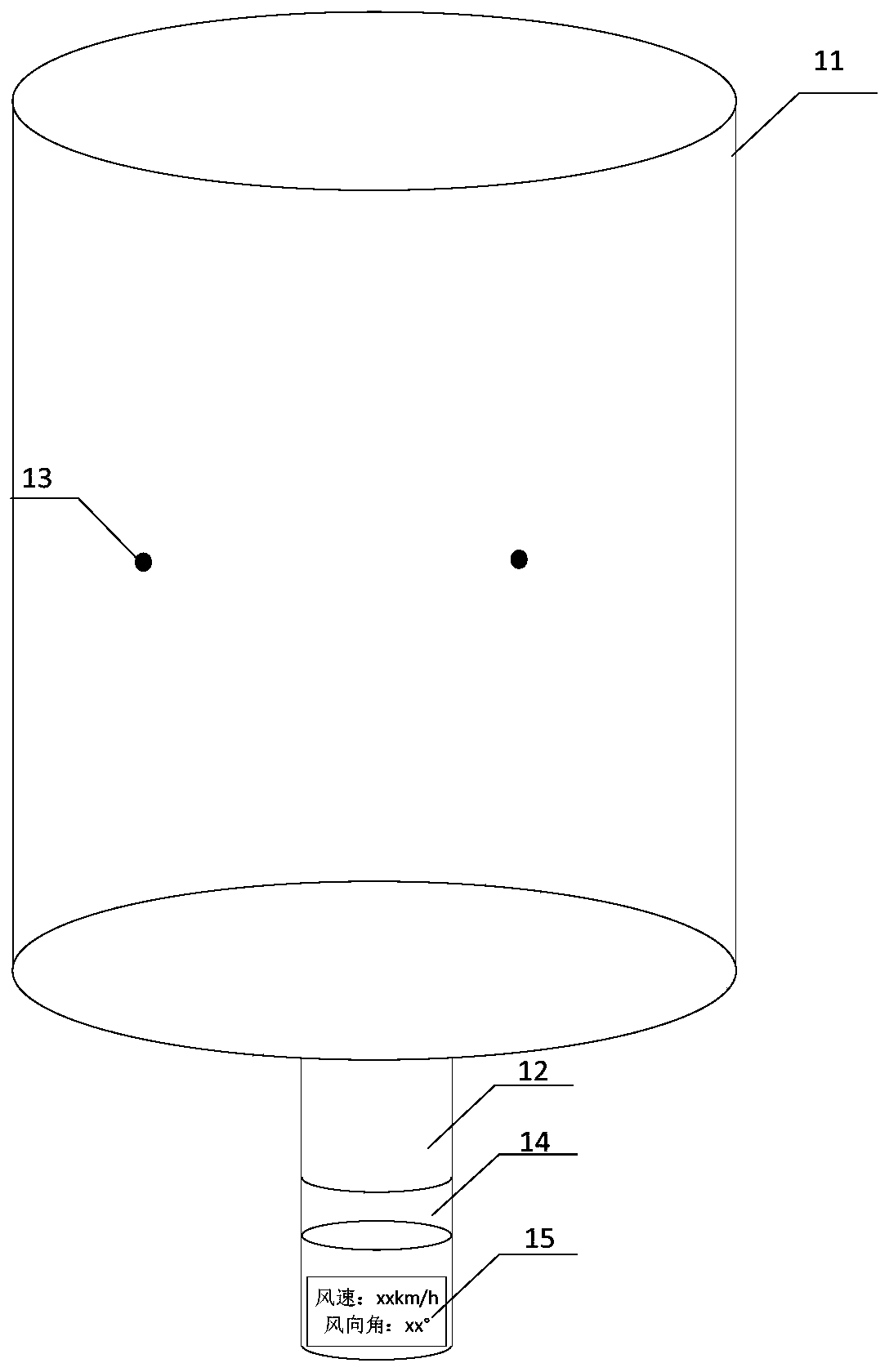

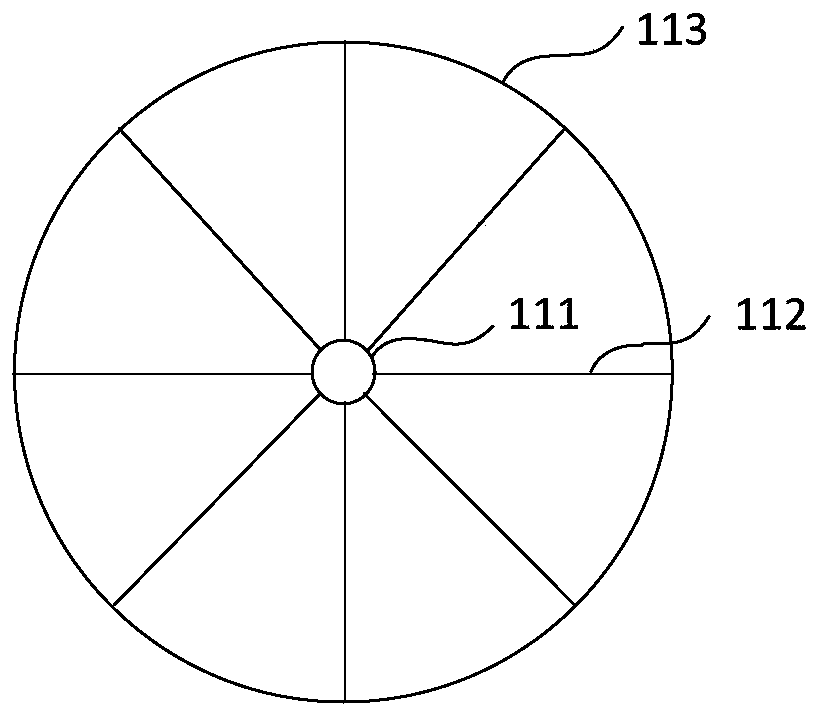

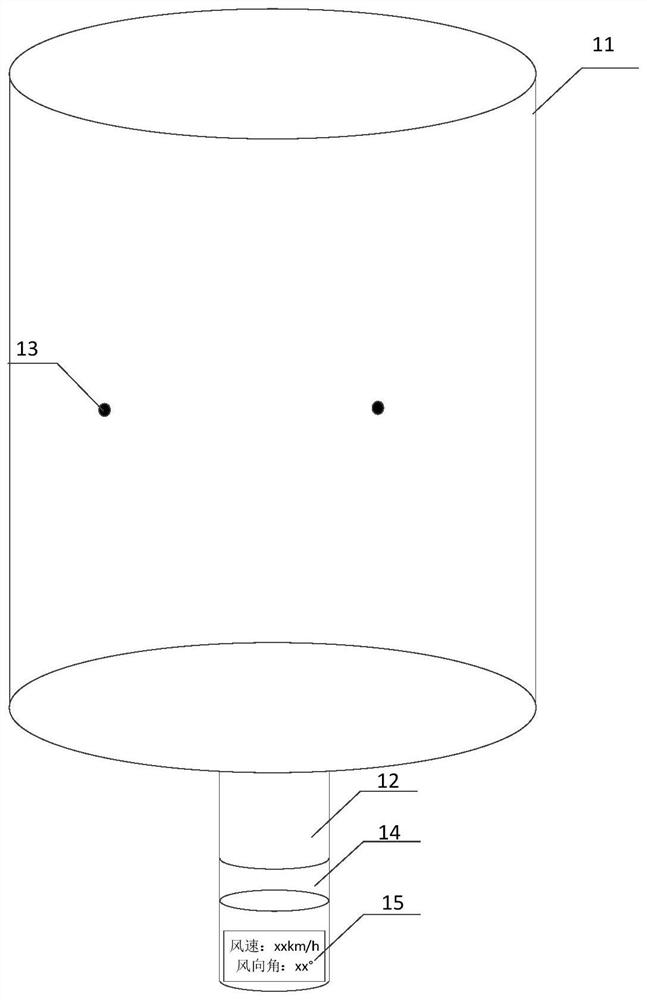

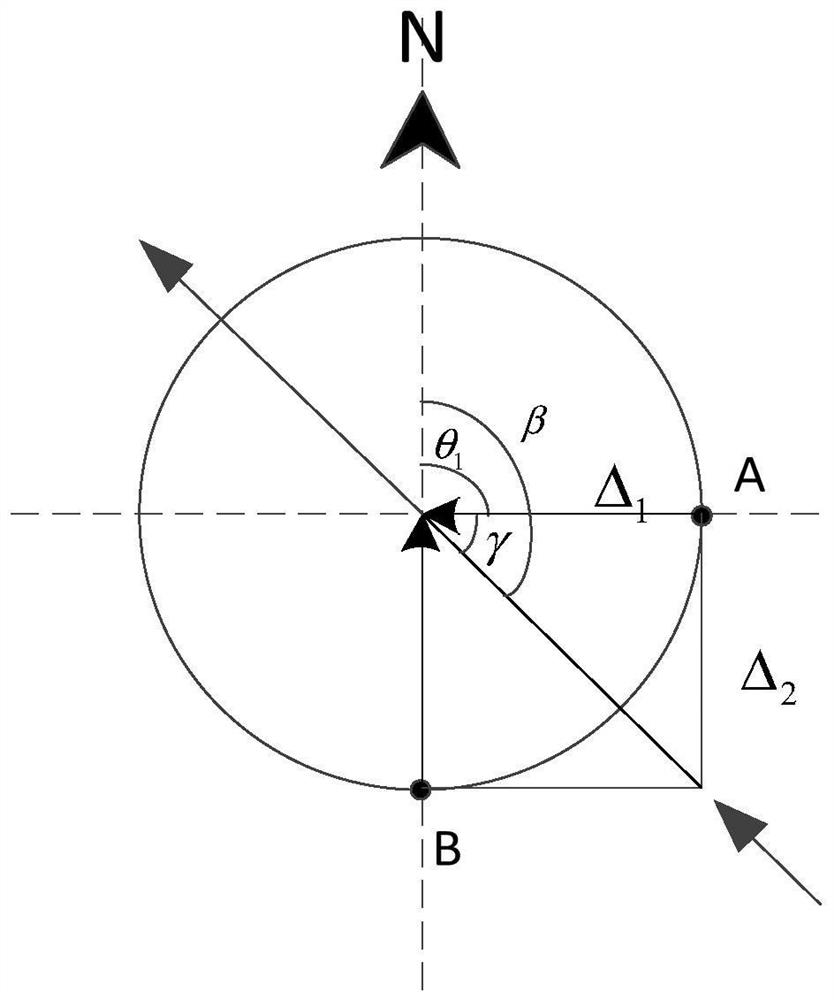

Wind speed and direction testing device and method

ActiveCN110927824AIndication of weather conditions using multiple variablesIndication/recording movementStrain gauge transducerEngineering

The invention is suitable for the technical field of wind speed and wind direction detection, and provides a wind speed and wind direction testing device and method, and the wind speed and direction testing device comprises a testing head, a supporting rod, at least two strain gauge sensors, a temperature sensor, a barometer, and a main control board. The testing head is a cylinder, the testing head of the cylinder generates regular strain when wind blows to the surface of the testing head of the cylinder, and the strain reflects the speed and wind direction of wind flow. The at least two strain gauge sensors are arranged on the test head and used for detecting strain borne by the cylindrical test head, and the main control board can determine the current wind speed and wind direction according to the strain detected by the at least two strain gauge sensors, the current temperature and the current pressure intensity. The device does not need mechanical parts, and is sensitive in response, high in test precision and small in error.

Owner:SHIJIAZHUANG TIEDAO UNIV

A scheme for online testing of pantograph-catenary contact force

ActiveCN112129445BAvoid errorsEnables direct measurementRailway vehicle testingApparatus for force/torque/work measurementGratingOnline test

The invention provides an online testing scheme of pantograph-catenary contact force. Firstly, an experimental model is established; sensors are arranged at intervals along the Y-axis direction on the bow reed on the back of the pantograph, a clamp is set up on the slide plate and then a weight is hung in the center of the clamp. Record the grating wavelength of each measuring point in real time; obtain the static contact force change rule under different loads during static loading; then arrange the optical fiber strain gauge sensor on the bow reed, and arrange a high-speed camera in front of the pantograph to obtain the static contact force; through The unidirectional acceleration sensor first calculates the inertial force of the pantograph head to calculate its dynamic contact force online. The present invention proposes a scheme of installing a strain sensor at the reed of the bow head, which can not only obtain higher sensitivity, but also avoid the influence of regular replacement of the slide plate. Using the optical digital speckle correlation method, the direct measurement of the contact point position at any time during the loading process can be realized , Combined with the strain value of the measuring point, the contact force can be directly reversed without simplifying the physical structure of the slide.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Measurement system and method for obtaining natural frequency of reducer cycloid wheel under different working conditions

ActiveCN111795820BSimple designQuick checkMachine part testingSubsonic/sonic/ultrasonic wave measurementWire wheelReduction drive

The invention discloses a measurement system and method for obtaining the natural frequency of a cycloid wheel of a reducer under different working conditions, including a fine-tuning displacement mechanism, a magnetic torque motor power device, a special pin gear housing for detection, an acceleration sensor, a strain gauge sensor, a sensor, The exciter, vibrometer and measurement and control system, the power device of the magnetic torque motor and the exciter are relatively arranged on the fine-tuning displacement mechanism, the power device of the magnetic torque motor is connected with the cycloid wheel to be detected, and the acceleration sensor is arranged on the cycloid wheel to be detected On the outer surface, the strain gauge sensors are respectively set at the tooth roots of the cycloidal wheel to be tested and the special pin gear housing for testing. On one side of the wire wheel, the force sensor is arranged at the front end of the exciter; the measurement and control system is respectively connected with the acceleration sensor, the strain gauge sensor, the exciter and the vibration measuring instrument. Realize the online rapid measurement of the natural frequency of the cycloid wheel vibration of the reducer under different working conditions, with high measurement accuracy and simple operation.

Owner:NINGBO UNIV

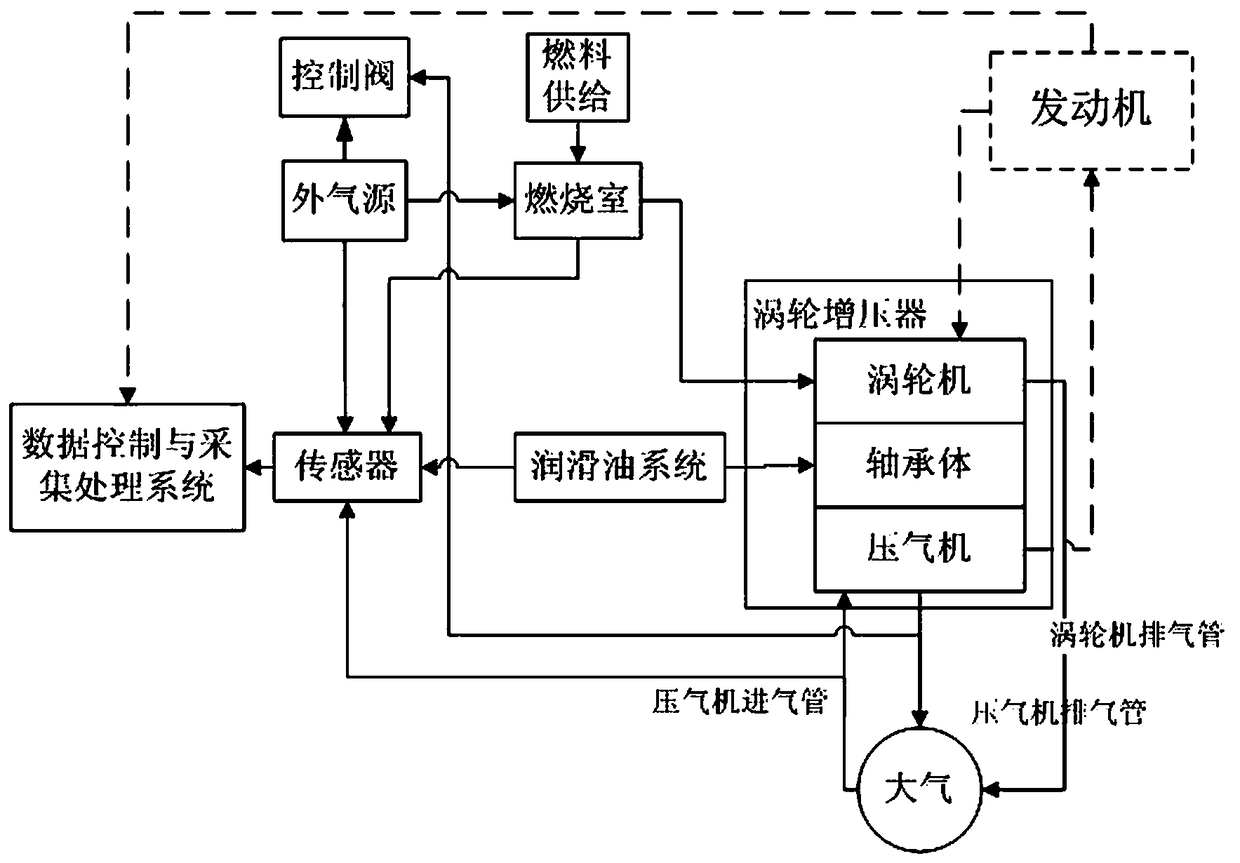

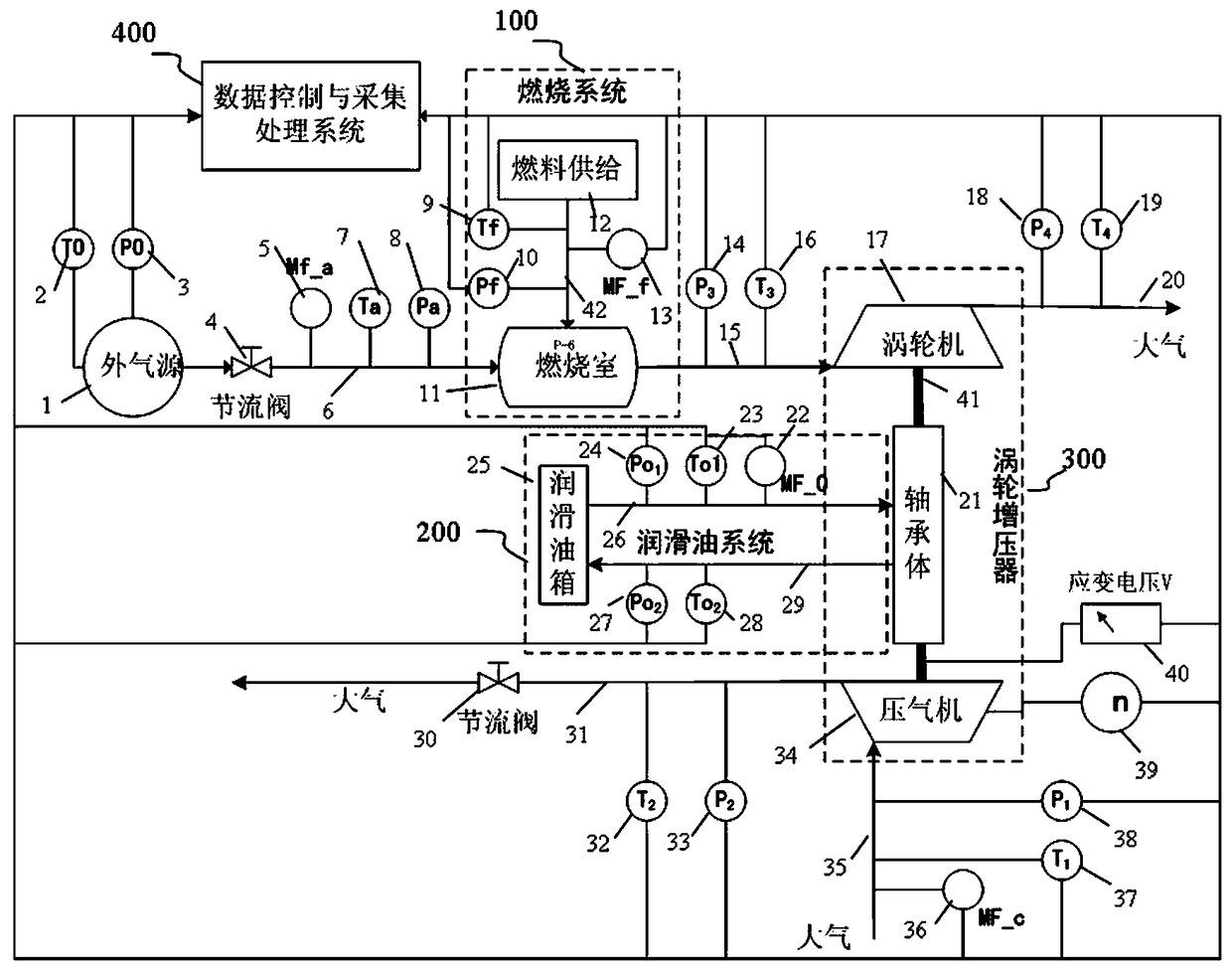

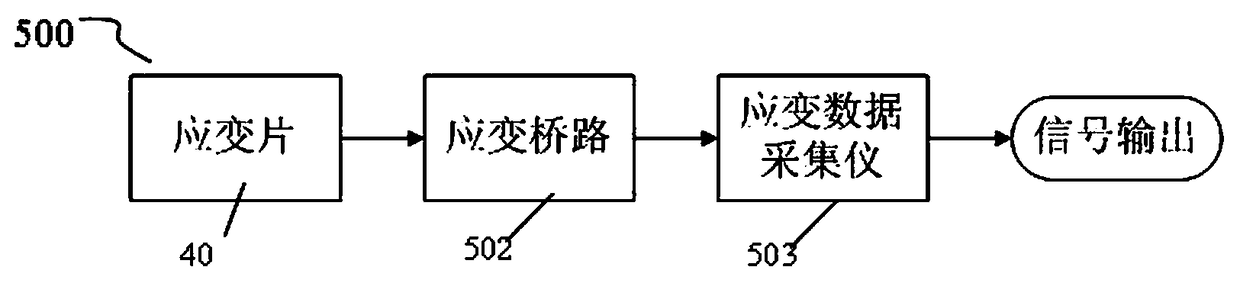

A turbocharger axial force measurement system and its testing method

ActiveCN106248278BHigh sensitivityFast transient responseApparatus for force/torque/work measurementCombustion chamberTurbocharger

The invention provides an axial force measuring system for a turbocharger. The system comprises a combustion system, a lubricating oil system, a data control and acquisition processing system, an external pipeline auxiliary system, and sensors. The combustion system includes a fuel supply system and a combustion chamber connected with an external gas source. The lubricating oil system includes a lubricating oil box connected with a turbocharger by a pipeline. The sensors that are arranged inside a work device on a pipeline separated by the work device inside the turbocharger consists of a pressure sensor, a temperature sensor, a flow sensor, a rotating speed sensor, and strain gauge sensor. The external pipeline auxiliary system enables a gas circuit and an oil circuit to be connected. The data control and acquisition processing system is used for collecting sensor data and processing and outputting the data. In addition, the invention also relates a testing method. An all-condition condition can be simulated for testing; and testing not only can be realized on the measuring system but also can be realized on an engine. The system and method have advantages of good visual effect and high accuracy and sensitivity.

Owner:NINGBO WEIFU TIANLI TURBOCHARGING TECH

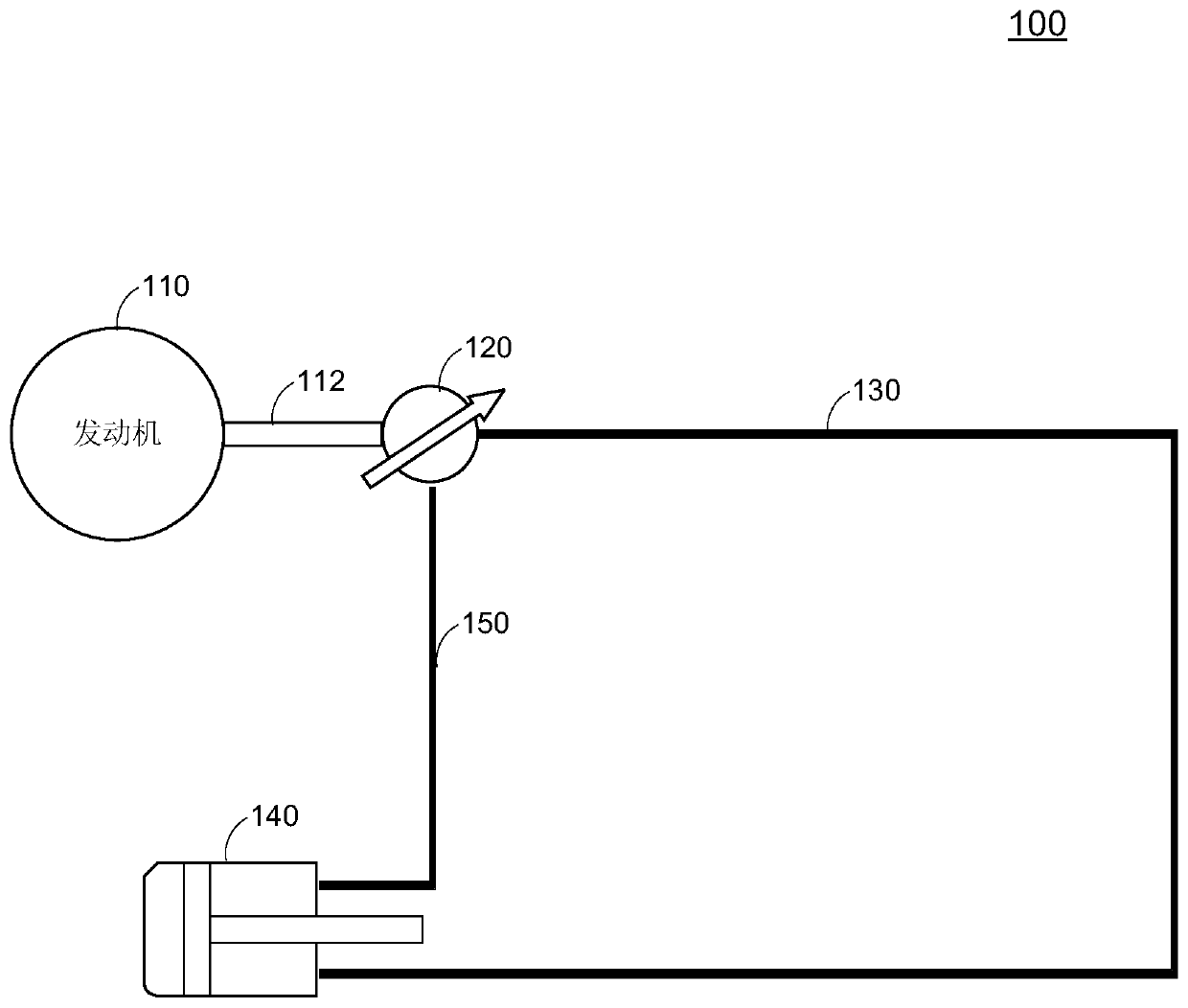

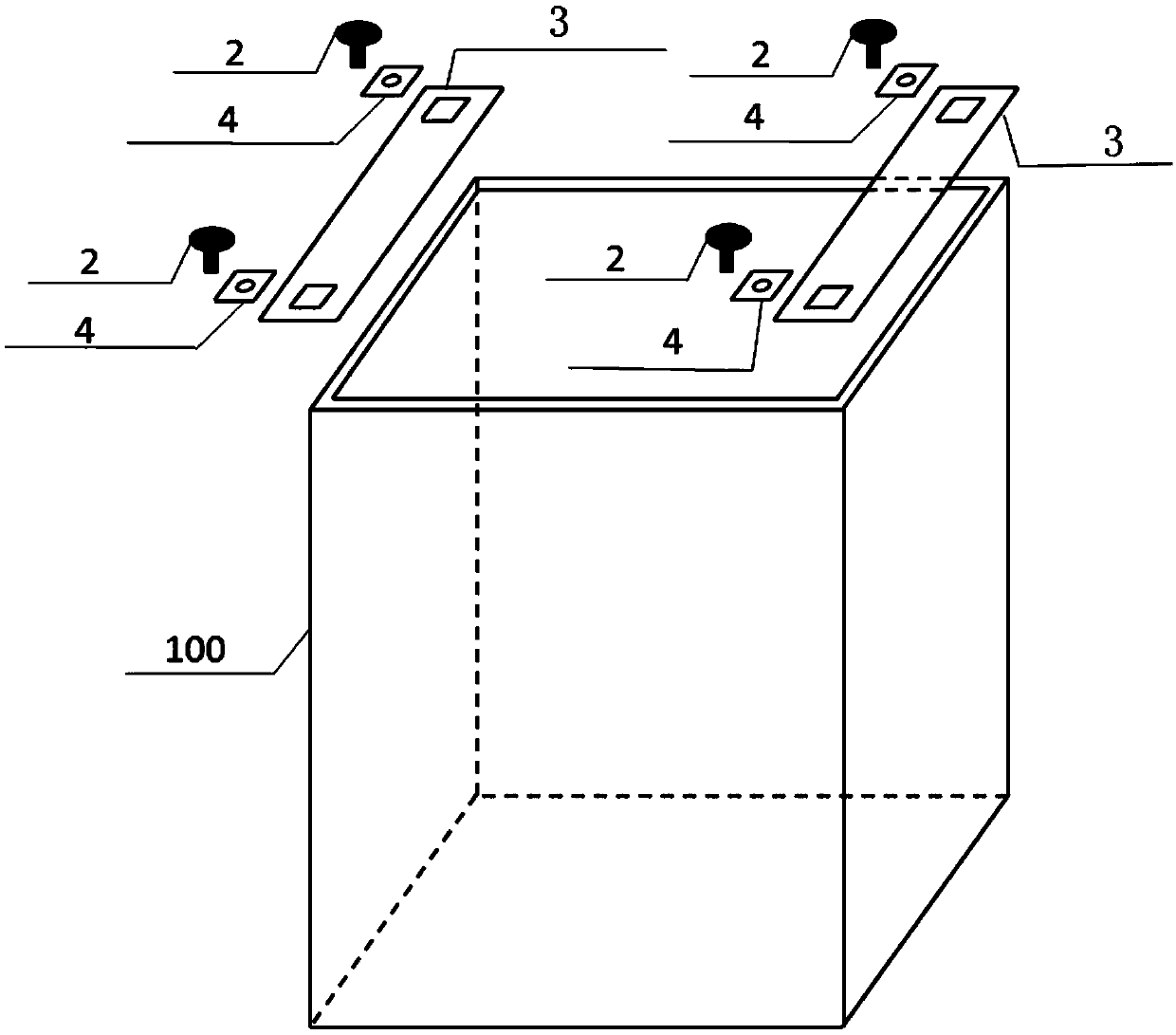

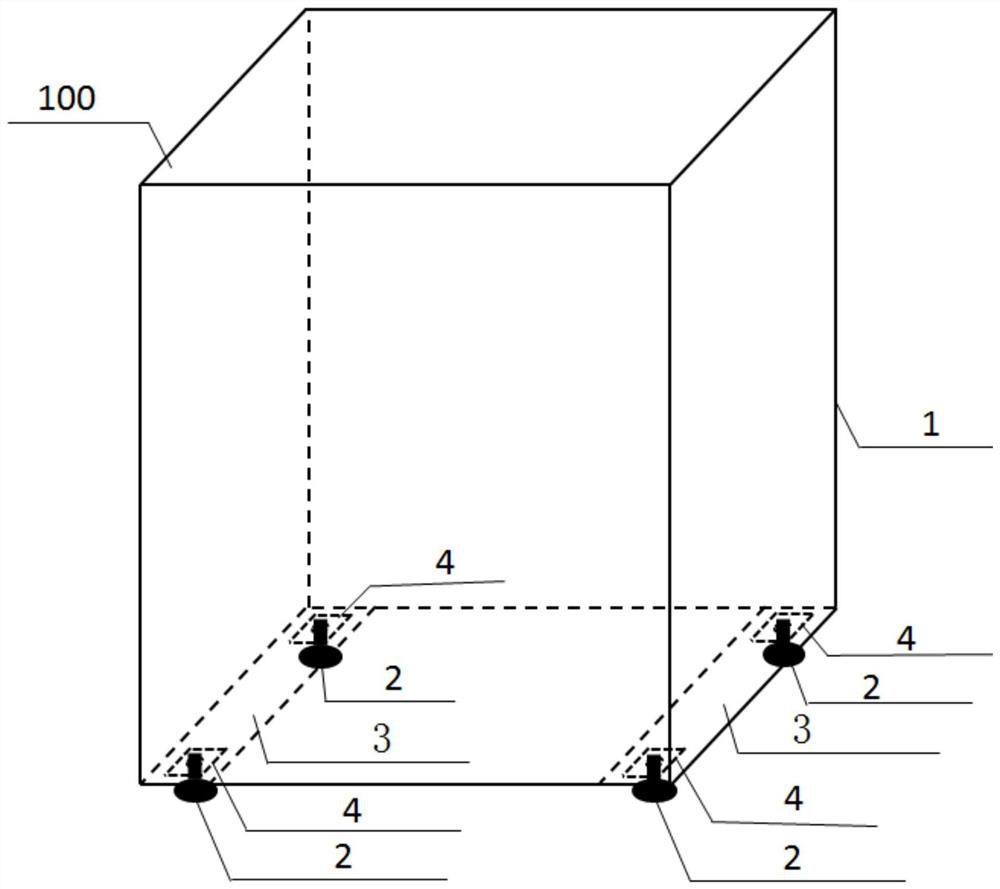

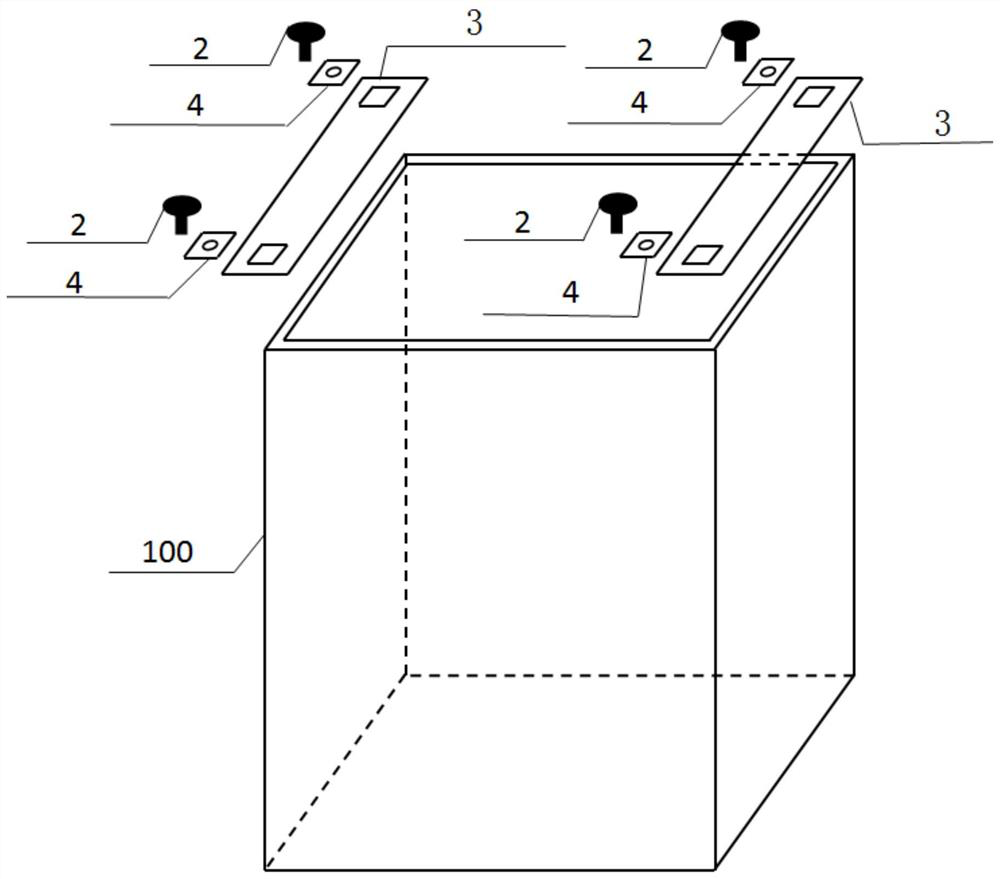

Control method and device of washing machine, machine readable storage medium and washing machine

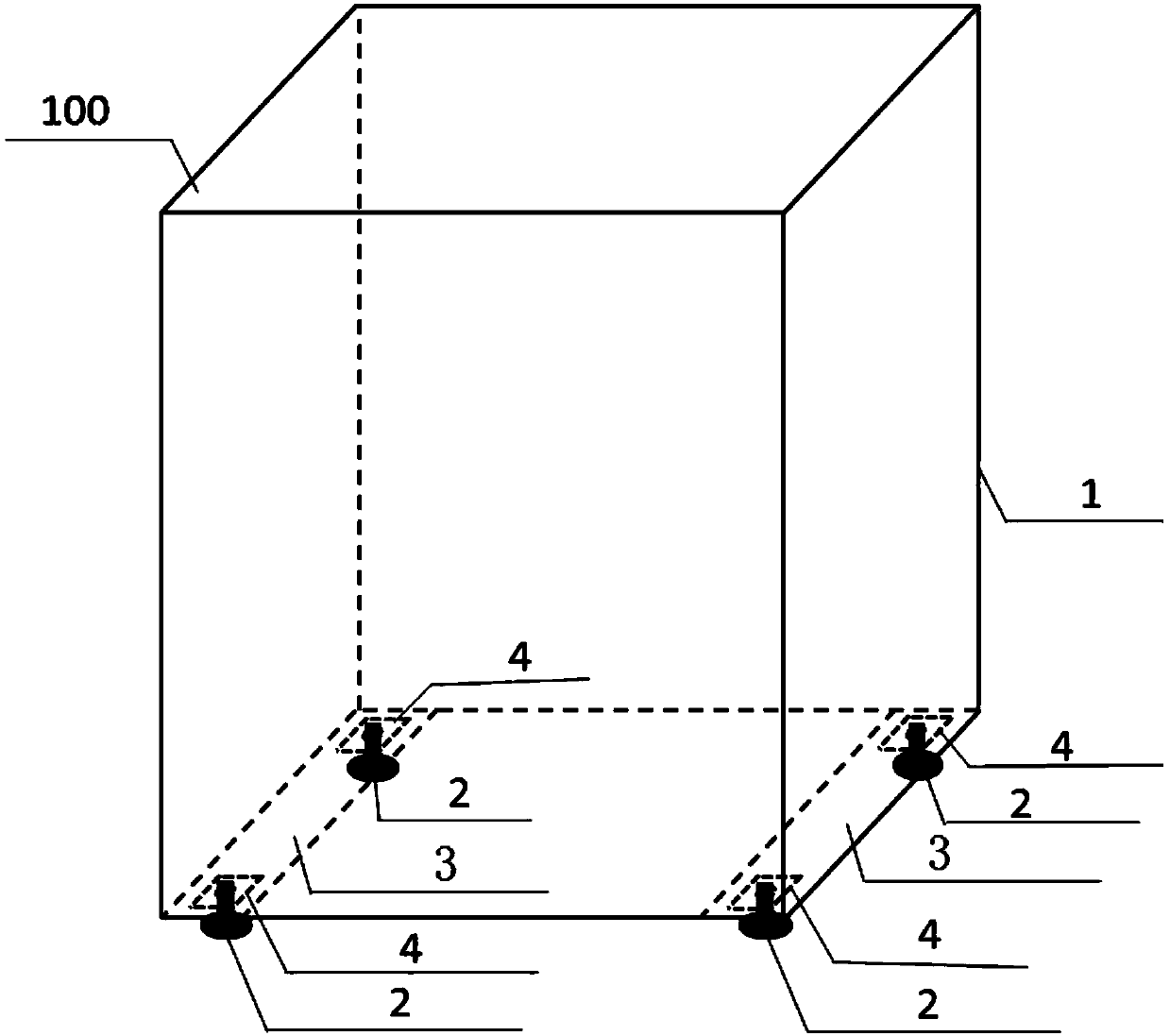

ActiveCN110894659ANot easy to interfereLow costOther washing machinesControl devices for washing apparatusLaundry washing machineControl manner

The invention discloses a control method and device of a washing machine, a machine readable storage medium and the washing machine. The control method comprises the following steps that S0, vibrationof the washing machine (100) is detected through an eccentricity detection bridge circuit (5), wherein at least one bridge arm resistor in the eccentricity detection bridge circuit (5) is a resistivestrain gauge sensor (4); S1, a voltage signal of the bridge circuit output end (51) of the eccentricity detection bridge circuit (5) is acquired, wherein the voltage signal characterizes the magnitude of vibration of the washing machine (100); and S2, a detection result of distribution eccentricity of clothes in the washing machine (100) is determined according to a fluctuation value of the voltage signal and a preset fluctuation threshold. A control mode is novel, stable and high-precision detection and control of eccentricity of the washing machine can be realized, and the cost is relatively low.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Barrel sensing intelligent brake for elevator

PendingCN114314408AEnsure braking safetyRealize digital transformationWinding mechanismsBrakeControl system

According to the barrel sensing intelligent brake for the elevator, a force transmission middle shaft is connected with a barrel through a sensor, and the sensor comprises a middle part connected with the force transmission middle shaft, an outer circumferential part connected with the barrel and a communicating spoke for transmitting elastic force accumulated by a disc spring from the middle part to the outer circumferential part; the side wall of the communicating spoke is provided with a strain gauge for converting deformation into an electric signal; and the sensor is provided with an integrated amplifying circuit which is used for processing the electric signal and is connected with a peripheral electric control system. When the elevator is braked, a direct quantitative and digital intelligent means is provided for judging the braking positive pressure of the elevator, signals can be visually and rapidly detected, digital conversion of analog signals is achieved, workers can rapidly know the braking positive pressure numerical value situation of the intelligent brake of the elevator, and the working efficiency is improved. When safety problems occur, judgment can be made quickly, measures can be taken, and braking safety of the elevator is guaranteed.

Owner:洛阳宏信重型机械有限公司 +2

Toppling deformation body monitoring and early warning device and monitoring and early warning method

PendingCN114111697AEfficient online monitoringEasy to monitor onlineMeasurement devicesClimate change adaptationSlope monitoringStrain gauge transducer

The invention discloses a toppling deformation body monitoring and early warning device and a toppling deformation body monitoring and early warning method, and relates to the technical field of slope monitoring, and the main points of the technical scheme are that the toppling deformation body monitoring and early warning device comprises a processor, a main substrate and two curved-surface substrates; the two curved-surface substrates are distributed on the two sides of the main substrate, and the sphere centers corresponding to the two curved-surface substrates are located below the two sides of the main substrate in an inclined mode. A plurality of strain gauge sensors are arranged on the same side surfaces of the main substrate and the two curved-surface substrates; and the strain gauge sensors are electrically connected with the processor. When toppling deformation occurs, the main substrate and the two curved surface substrates can adaptively generate cooperative deformation, a row of strain gauge sensors start detection at the same time to obtain deformation data under corresponding dimensions, and after the data are subjected to simulation analysis, conversion and other processing, a detection result directly representing the toppling deformation condition can be directly obtained. Efficient and simple on-line monitoring of toppling deformation is achieved, the overall structure is convenient to install, maintain and operate, and the application cost is low.

Owner:POWERCHINA CHENGDU ENG

Wind speed and wind direction testing device and testing method

ActiveCN110927824BIndication of weather conditions using multiple variablesIndication/recording movementStrain gauge transducerDirection detection

The present invention is applicable to the technical field of wind speed and direction detection, and provides a wind speed and direction testing device and a testing method. The wind speed and direction testing device includes: a test head, a support rod, at least two strain gauge sensors, a temperature sensor, a barometer and a main control plate. Wherein, the test head is a cylinder, and when the wind blows to the surface of the test head of the cylinder, the test head of the cylinder will produce regular strain, and the strain reflects the speed and direction of the wind flow. At least two strain gauge sensors are set on the test head to detect the strain on the cylinder test head, and the main control board can determine the current wind speed and wind direction according to the strain, current temperature and current pressure detected by at least two strain gauge sensors . The device does not need to be equipped with mechanical parts, and has the advantages of sensitive response, high testing precision and small error.

Owner:SHIJIAZHUANG TIEDAO UNIV

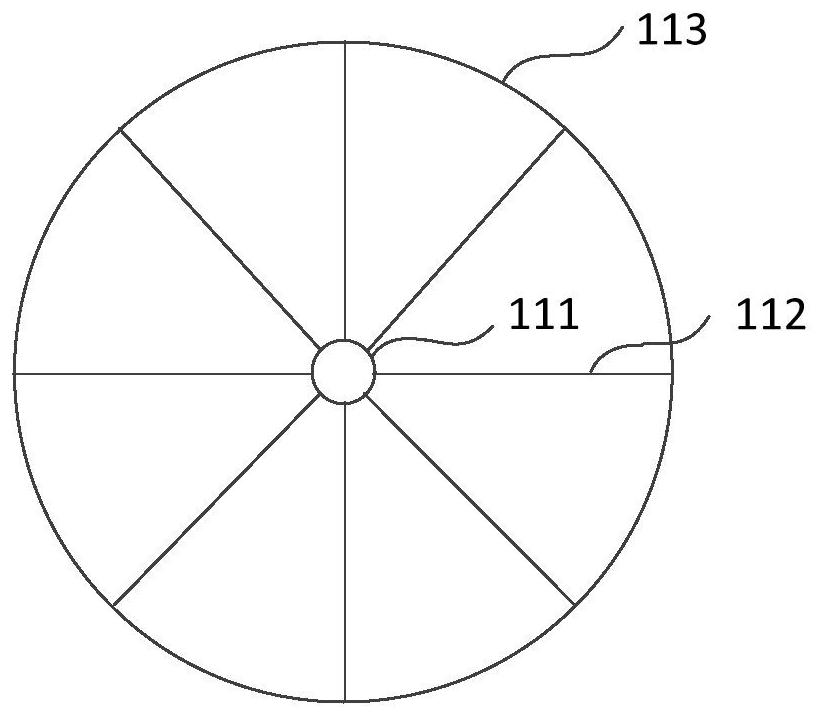

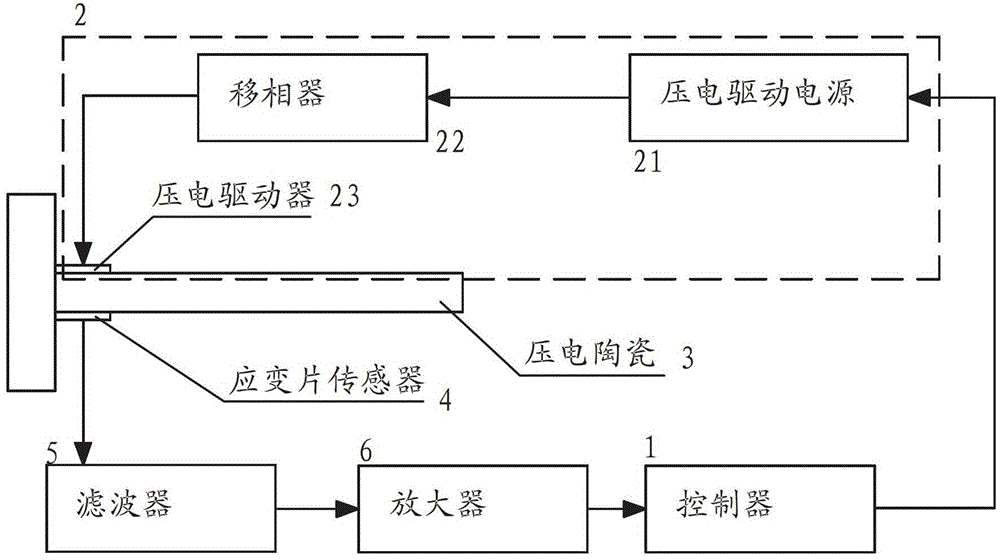

Closed loop control system of ultrasonic separator

InactiveCN102935309BEfficient detectionStable vibration frequencyMechanical oscillations controlElectricityAudio power amplifier

The invention discloses a closed loop control system of an ultrasonic separator. A controller is connected with a piezoelectric driving power source of a piezoelectric driving unit; a piezoelectric driver of the piezoelectric driving unit is mounted on a piezoelectric ceramic upper surface; a strain sheet sensor connected with a filter is arranged on a piezoelectric ceramic lower surface; the filter is connected with an amplifier; the amplifier is connected with a controller; the piezoelectric driving unit comprises the piezoelectric driving and is connected with a phase shifter; and the phase shifter is connected with the piezoelectric driver. With the adoption of the manner, the closed loop control system provided by the invention can be used for effectively detecting a vibration frequency and adjusting the vibration frequency by using feedback, so that the vibration frequency of the system can be kept stable. Therefore, the optimal separation effect can be realized.

Owner:SUZHOU VOCATIONAL UNIV

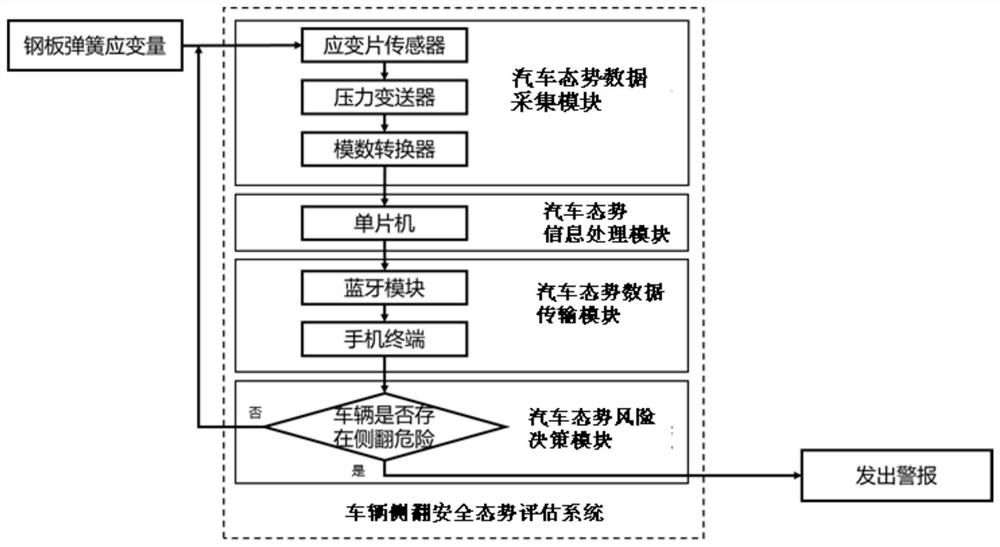

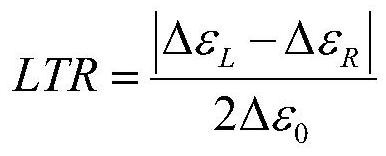

A vehicle rollover safety situation assessment system based on intelligent terminal

ActiveCN108216028BWith visualizationTimely detection of potential rollover risksSignalling/lighting devicesElectric/fluid circuitRolloverDriver/operator

The invention discloses a vehicle rollover safety situation evaluation system based on an intelligent terminal, which comprises a vehicle situation data acquisition module, a vehicle situation information processing module, a vehicle situation data transmission module and a vehicle situation risk decision-making module connected in sequence. In the present invention, the vehicle situation risk decision-making module is implanted into the Android system or the iOS system intelligent terminal, and the strain gauge sensor in the vehicle situation data acquisition module obtains the strain of the vehicle leaf spring, calculates the vehicle LTR and TTR values, and monitors the vehicle running state accordingly. When the risk of rollover of the vehicle is detected, an early warning message is issued to the driver in time to remind the driver to correct the driving operation and avoid accidents. The invention carries out a portable design on the automobile early warning system, releases early warning information through an intelligent terminal, and can issue visual early warning information to drivers.

Owner:SOUTH CHINA UNIV OF TECH

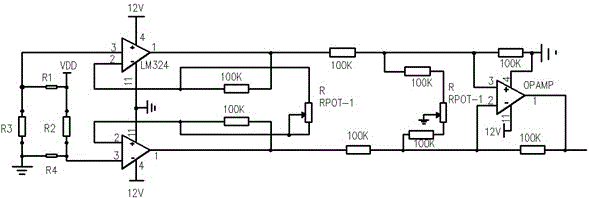

A bionic finger with controllable flexibility

InactiveCN103753593BGuaranteed deformationImprove the ability to coordinate with each otherProgramme-controlled manipulatorGripping headsMagnetorheological fluidHemt circuits

The invention relates to a bionic finger with controllable flexibility. The flexible and controllable bionic finger includes bionic skin poured into finger shape, electromagnetic coil, strain gauge sensor, magnetorheological fluid, sealing boss, rigid support body, finger control box, nail seat, sealant, sealing gasket, set screw; the bionic finger with controllable compliance The control circuit is mainly composed of three operational amplifiers with high common-mode rejection ratio amplifier circuit, digital-to-analog conversion and single-chip microcomputer chip principle circuit, crystal oscillator circuit, reset circuit, and power supply circuit; The flexible and controllable bionic finger It is a soft and controllable finger based on magnetorheological fluid, which can realize the continuous and controllable "liquid-solid" state transition of magnetorheological fluid; when applying force to the bionic finger, it can ensure that the deformation of the finger is within a certain range Inside, it will not be too large to damage, nor too small to be flexible. In order to improve the ability of the robot to coordinate with the outside world.

Owner:CHINA UNIV OF MINING & TECH

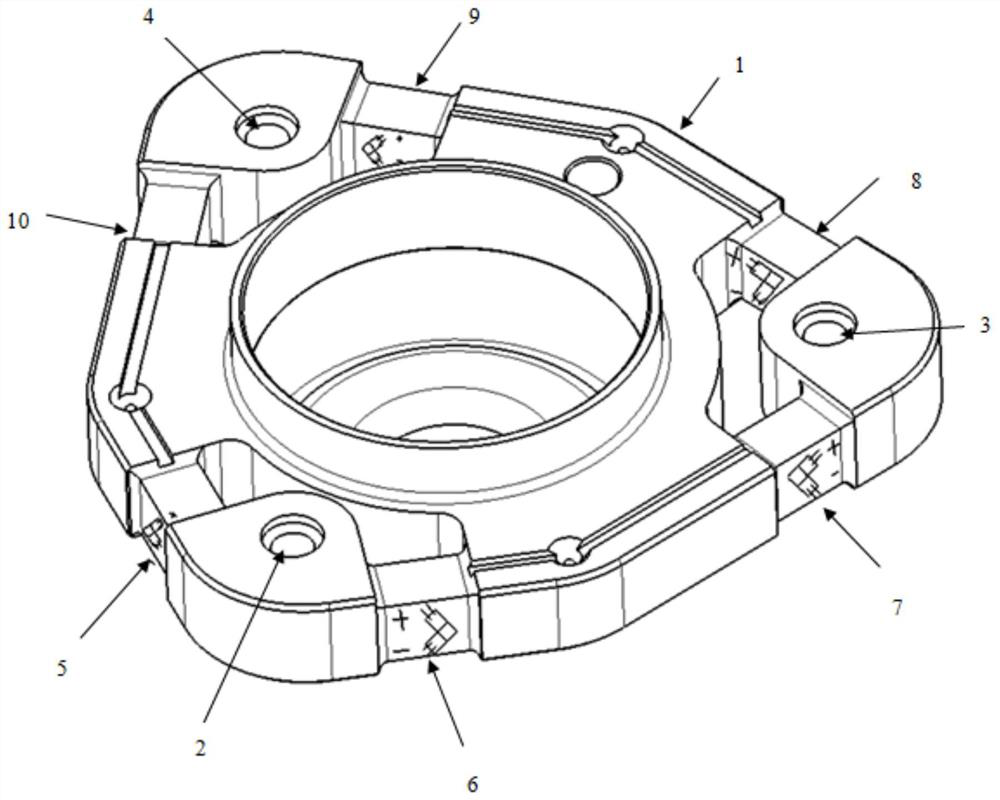

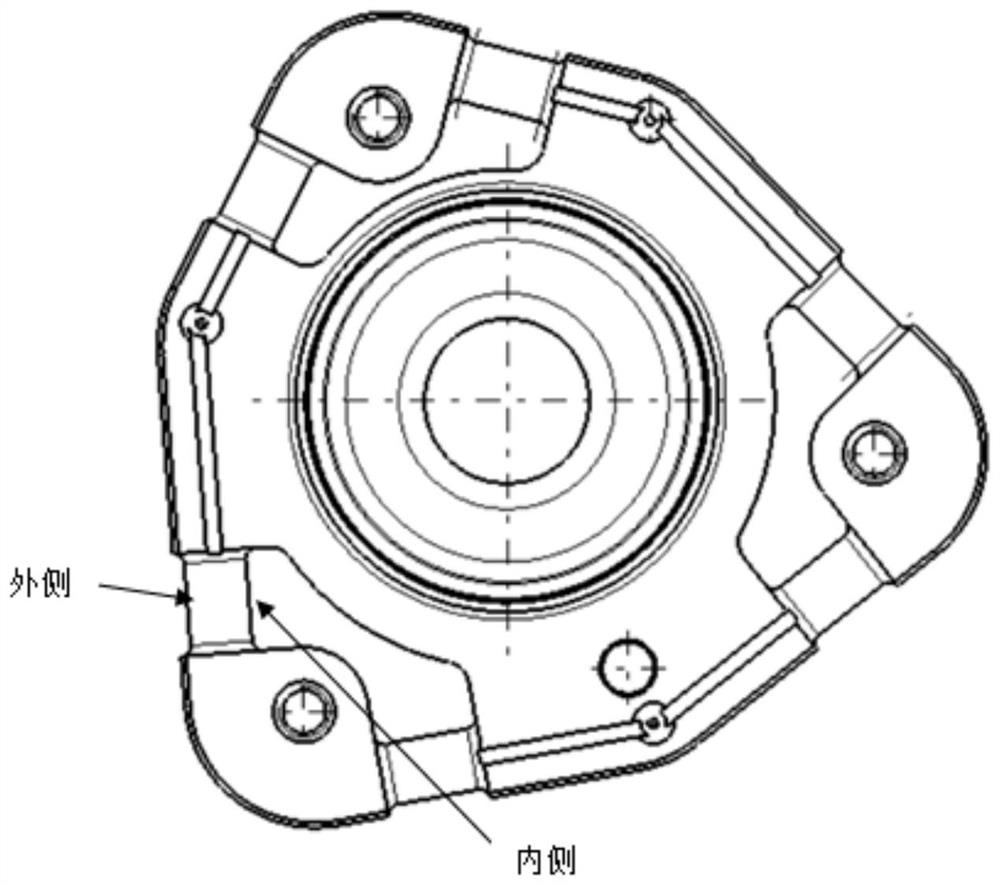

Intelligent spot welding rubber support

PendingCN114232468AComprehensive testing informationEasy to operateBridge structural detailsStrain gauge transducerSpot welding

Owner:GUANGXI UNIV

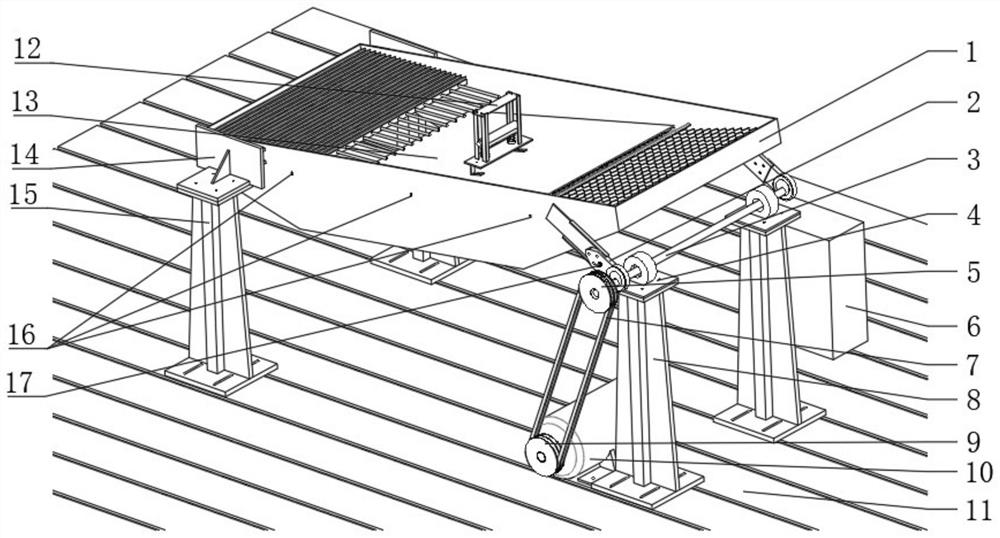

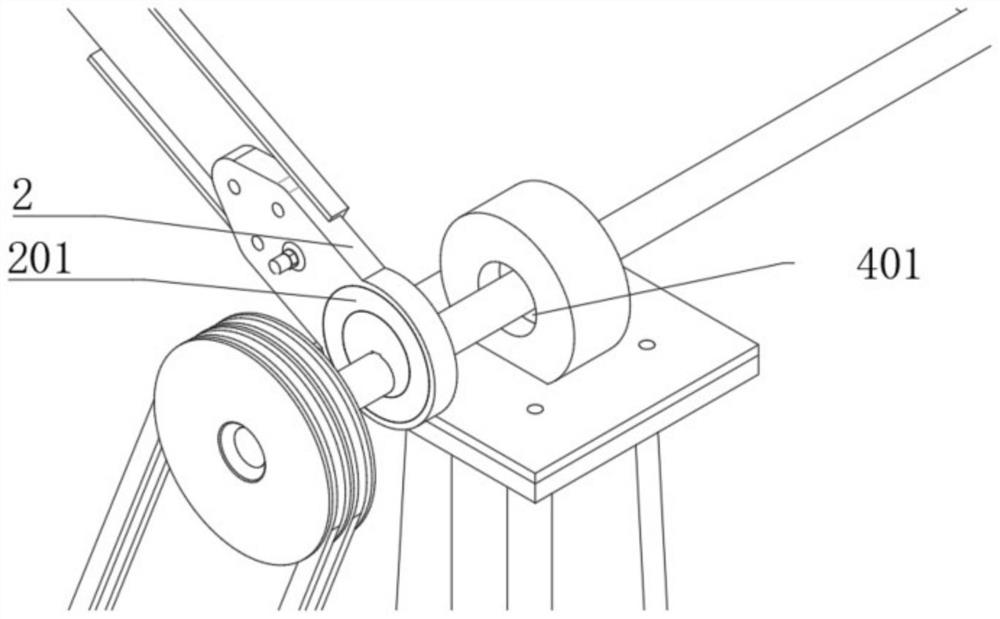

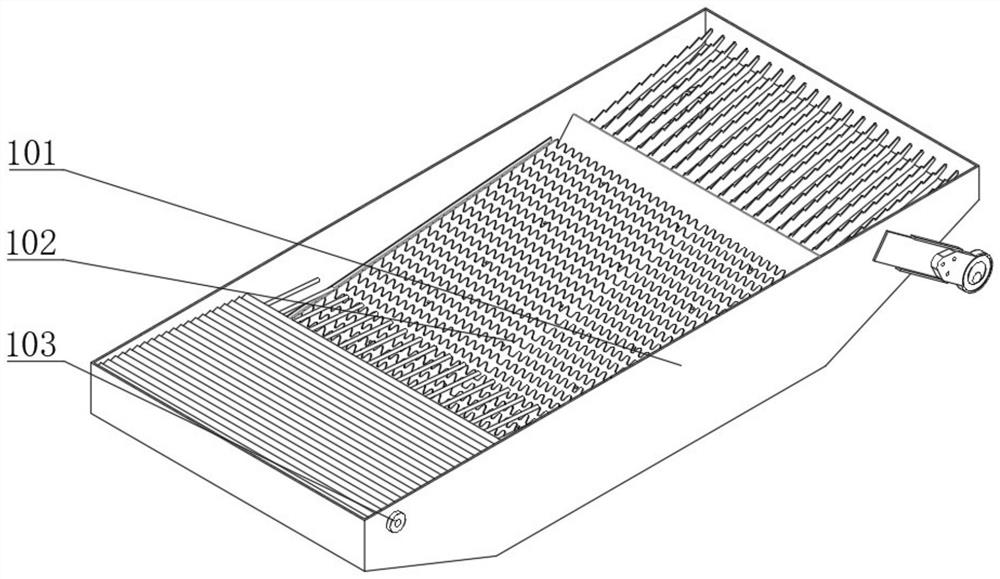

Test bed and test method for quality reliability of cleaning screen box

PendingCN114563204AEasy to installGuaranteed StrengthVibration testingShock testingInformation analysisSignal on

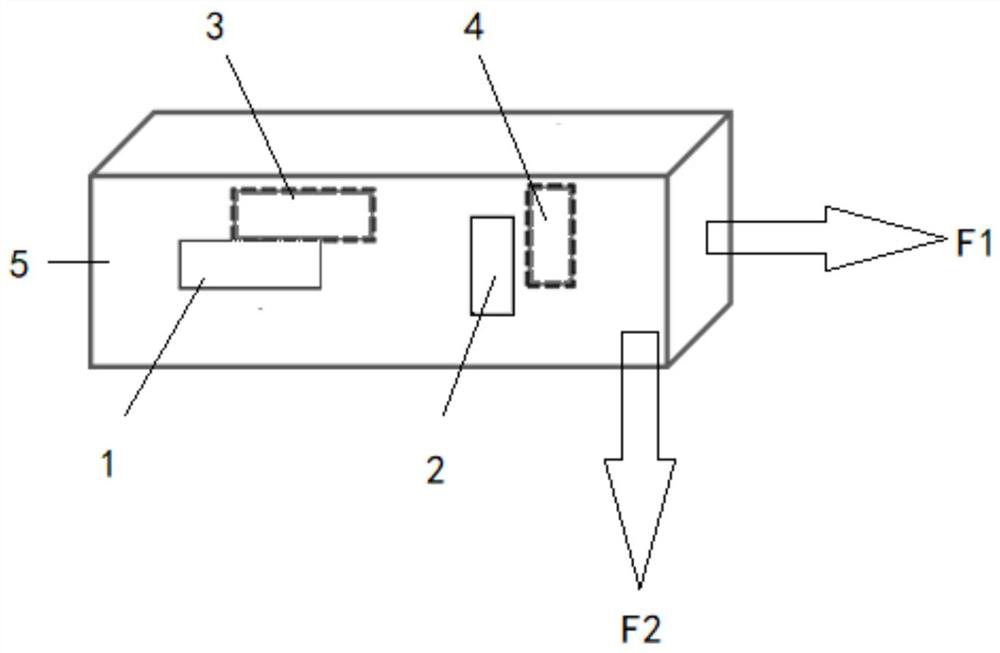

The invention provides a quality reliability test bed for a cleaning screen box. The quality reliability test bed comprises the cleaning screen box, a loading mechanism, a detection mechanism, an information analysis system, a power driving mechanism and a rack, the loading mechanism is mounted above the cleaning screen box and is used for simulating an impact load of a material on the cleaning screen box by applying a periodic load to the cleaning screen box; the detection mechanism comprises a plurality of strain gauge sensors and at least one three-way acceleration sensor and is used for collecting strain signals and vibration signals on the cleaning screen box; one end of the cleaning screen box is installed on the machine frame, the other end of the cleaning screen box is installed on the machine frame through a power driving mechanism, and the power driving mechanism is used for enabling the other end of the cleaning screen box to generate vibration. The information analysis system is connected with the detection mechanism and judges whether the condition of the sorting screen box is abnormal or not according to the collected strain signals and vibration signals. According to the invention, the abnormal condition of the cleaning screen box during the test can be found out, and the abnormal point can be positioned.

Owner:JIANGSU UNIV

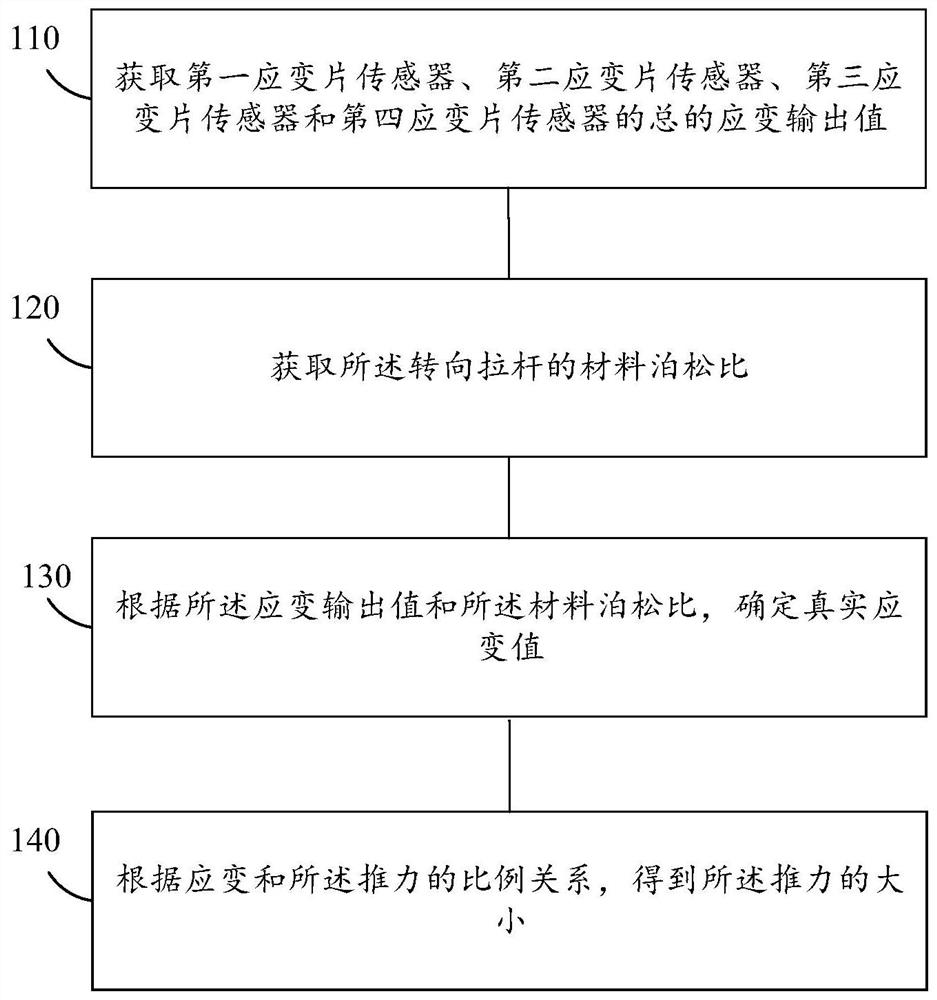

Thrust detection system, method and device for automobile steering pull rod and storage medium

Owner:GUANGQI HONDA +1

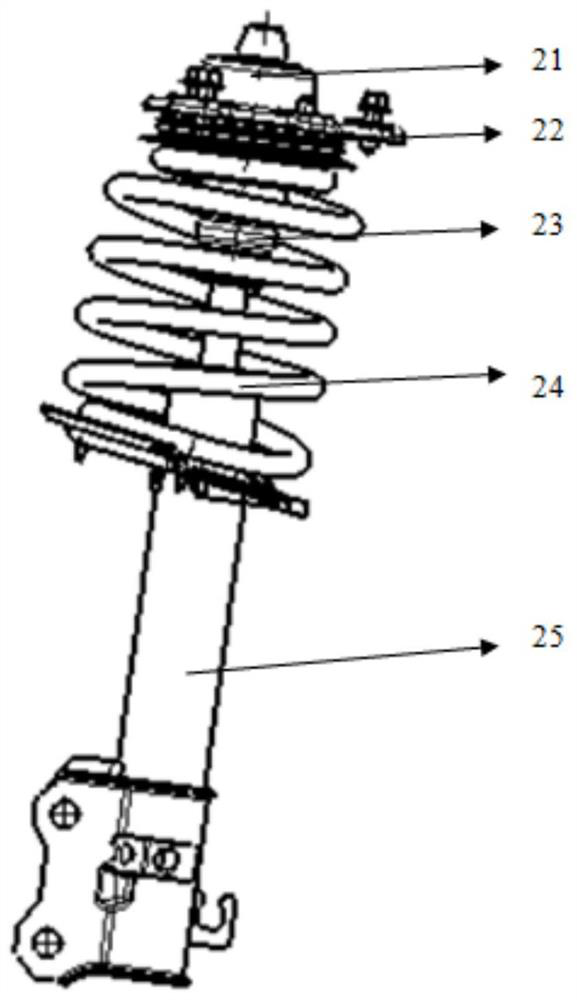

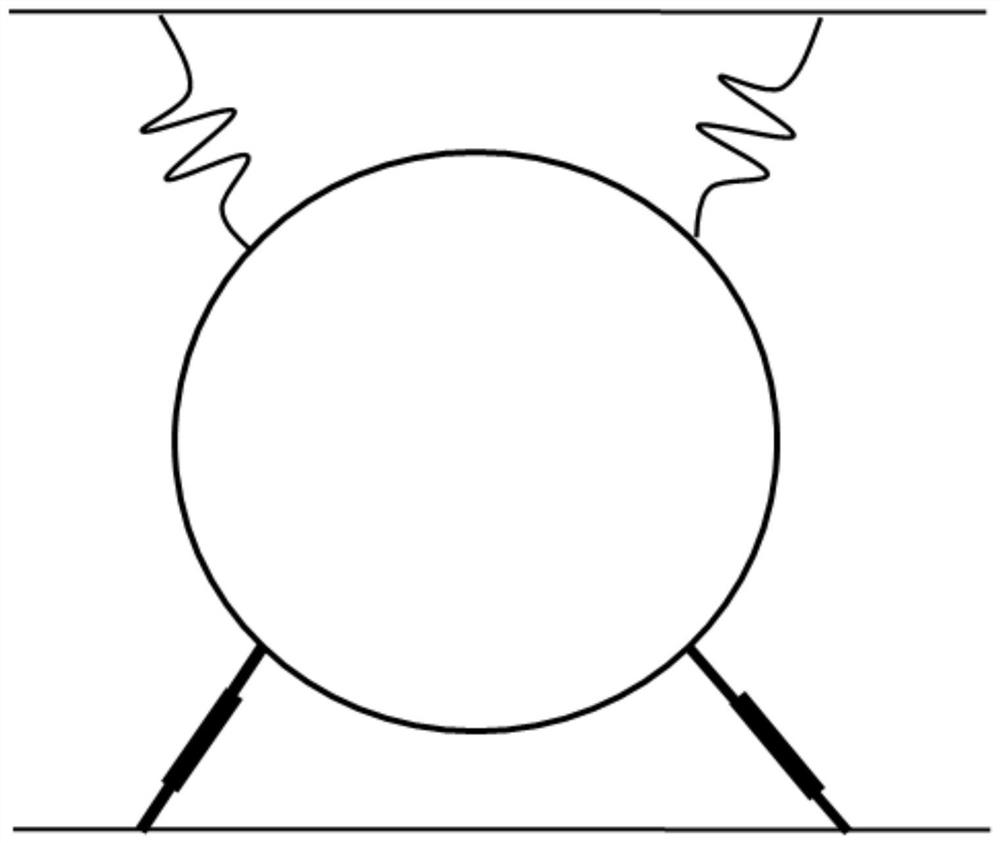

Shock absorber assembly load signal acquisition device

PendingCN112945549AImprove accuracyImprove development efficiencyVehicle testingMachine gearing/transmission testingStrain gauge transducerEngineering

The invention relates to a shock absorber assembly load signal acquisition device which comprises a shock absorber assembly body, a first mounting hole, a second mounting hole and a third mounting hole are distributed in the shock absorber assembly body, and a first strain gauge mounting groove and a second strain gauge mounting groove are formed in the left side and the right side of the first mounting hole respectively. A third strain gauge mounting groove and a fourth strain gauge mounting groove are formed in the left side and the right side of the second mounting hole respectively, a fifth strain gauge mounting groove and a sixth strain gauge mounting groove are formed in the left side and the right side of the third mounting hole respectively, each strain gauge mounting groove is provided with a set of strain gauge sensors, the positions of each set of strain gauge sensors are divided into the outer side and the inner side, and each side is divided into the positive electrode and the negative electrode. Positive and negative electrodes of the six groups of strain gauge sensors are connected in series to form a signal collection unit with a signal positive electrode, a signal negative electrode, a power supply positive electrode and a power supply negative electrode; objective and accurate load signals can be obtained, the accuracy of virtual design is improved, the number of times of engineering change is reduced, the development time and cost are saved, and the vehicle development efficiency is improved.

Owner:MAGNA STEYR AUTOMOTIVE TECHNOLOGY (SHANGHAI) LTD

Washing machine control method, device, machine-readable storage medium, and drum washing machine

ActiveCN110894659BNot easy to interfereLow costOther washing machinesControl devices for washing apparatusElectrical resistance and conductanceLaundry washing machine

The invention discloses a washing machine control method, a device, a machine-readable storage medium and a drum washing machine. The control method includes the steps of: S0: detecting the vibration of the drum washing machine (100) through an eccentricity detection bridge circuit (5), wherein the At least one bridge arm resistance in the eccentricity detection bridge circuit (5) is a resistive strain gauge sensor (4); S1: obtain the voltage signal of the bridge circuit output terminal (51) of the eccentricity detection bridge circuit (5) , the voltage signal characterizes the magnitude of the vibration of the drum washing machine (100); S2: Determine the detection result of the eccentricity of the laundry distribution in the drum washing machine (100) according to the fluctuation value of the voltage signal and a preset fluctuation threshold . The control method of the invention is novel, can realize stable, high-precision detection and control of the eccentricity of the washing machine, and has low cost.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com