Plunger pump rotating speed measuring method and device

A technology of speed measurement and plunger pump, which is applied in the field of hydraulic system and can solve the problem of difficulty in installing speed sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

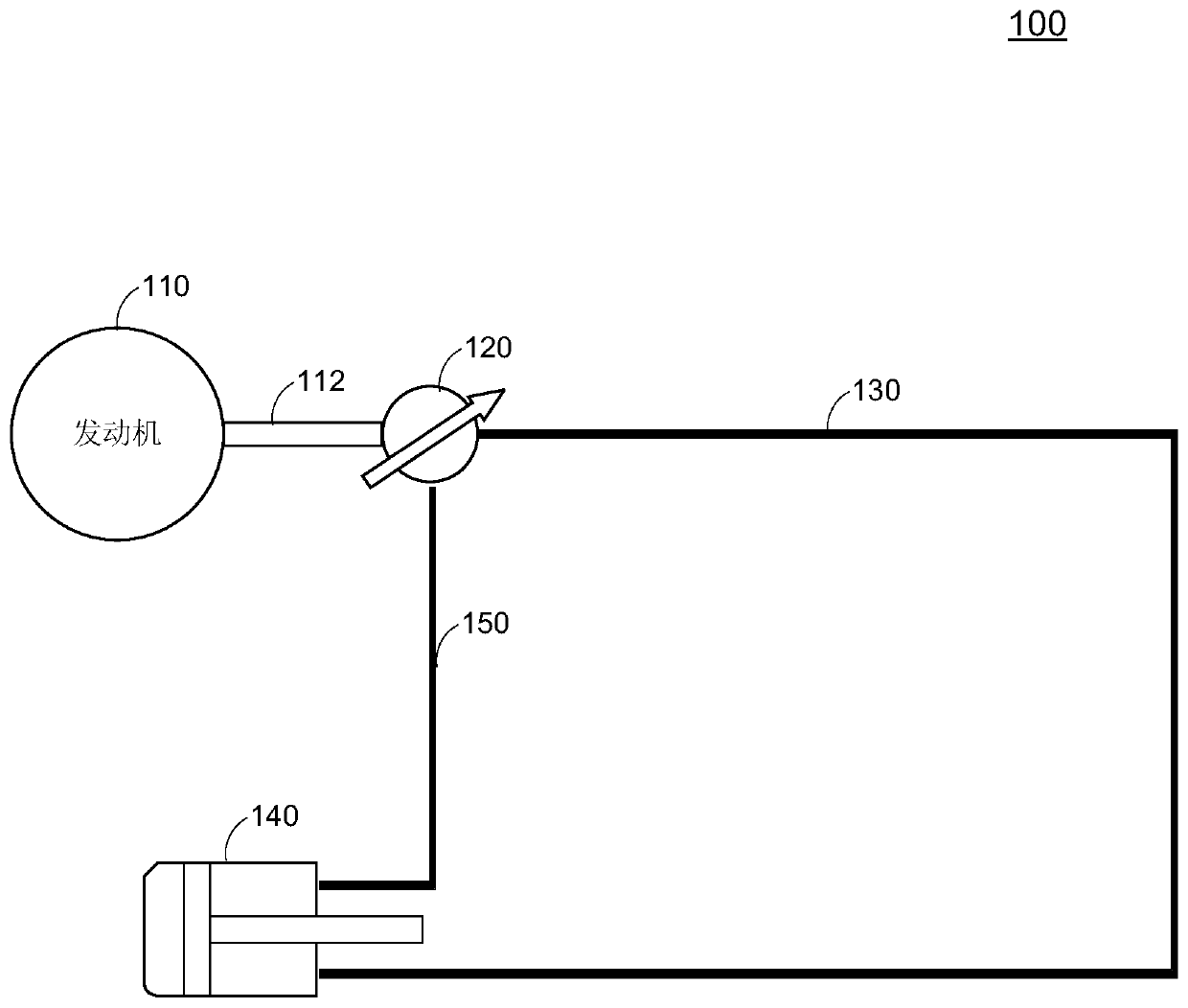

[0027] figure 1 is a system architecture diagram of a hydraulic system 100 according to an embodiment of the present invention. figure 1 It is shown that the hydraulic system 100 includes an engine 110, a drive shaft 112 connected to the engine 110, a plunger pump 120 connected to the drive shaft 112, and the plunger pump 120 is connected to the actuator 140 through a hydraulic line 130 and a return line 150 . The engine 110 may also be a power source such as an electric motor, an auxiliary power, a ram air turbine, or the like. When the hydraulic system 100 is working, the engine 110 rotates and drives the plunger pump 120 to rotate through the drive shaft 112 . The plunger pump 120 may include one or more plungers, and each plunger rotates with the plunger pump 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com