Patents

Literature

85results about "Devices using fluids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

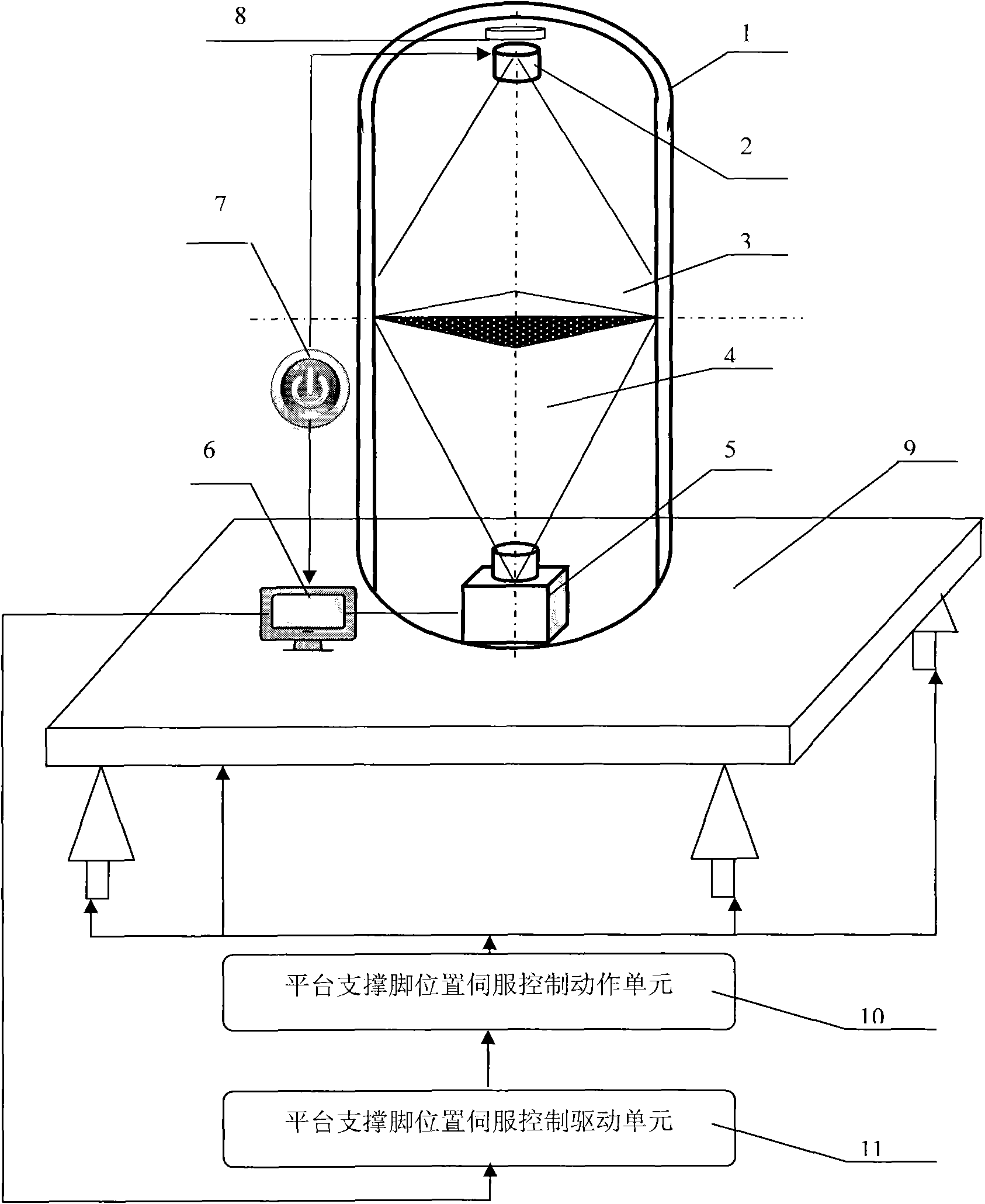

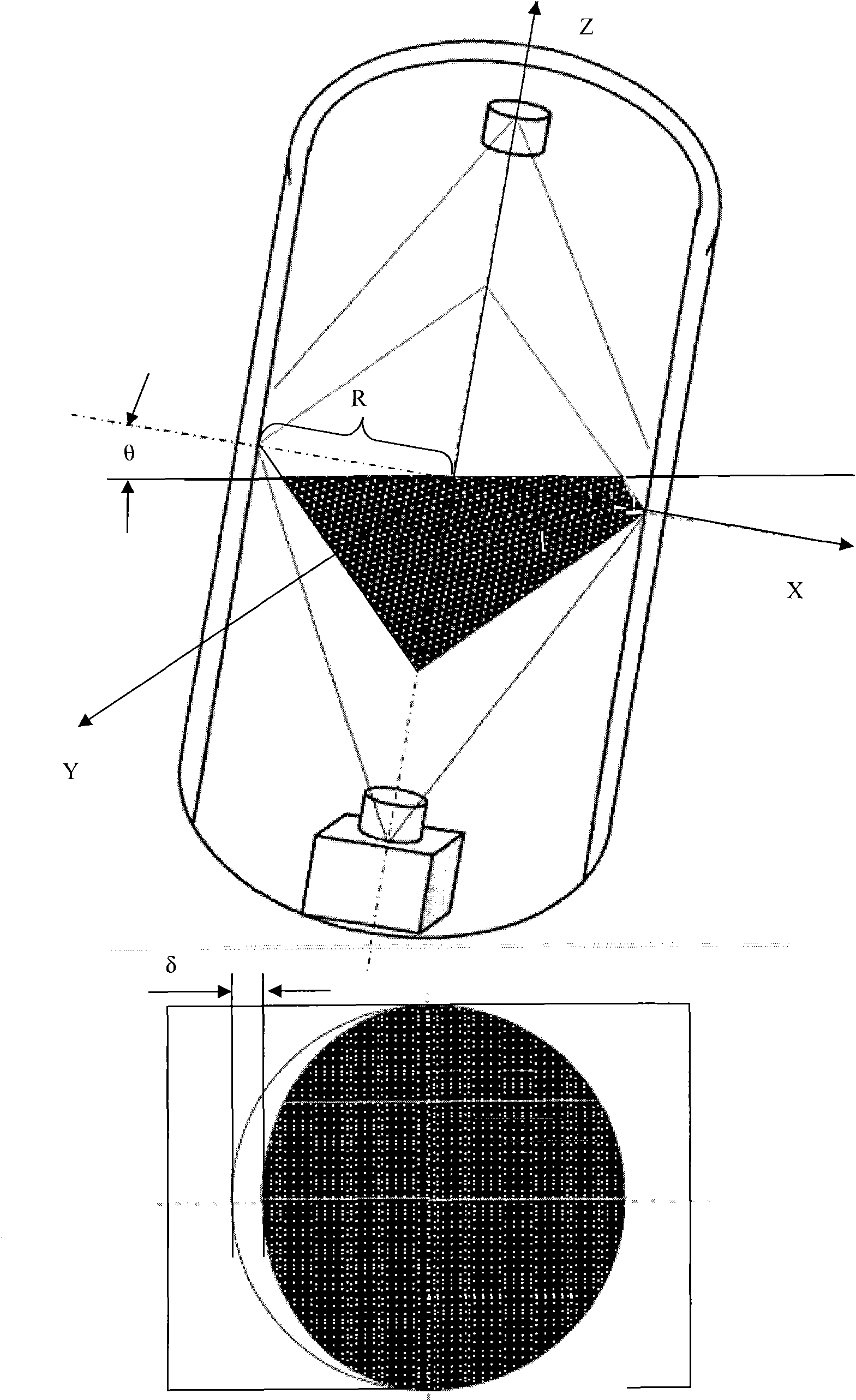

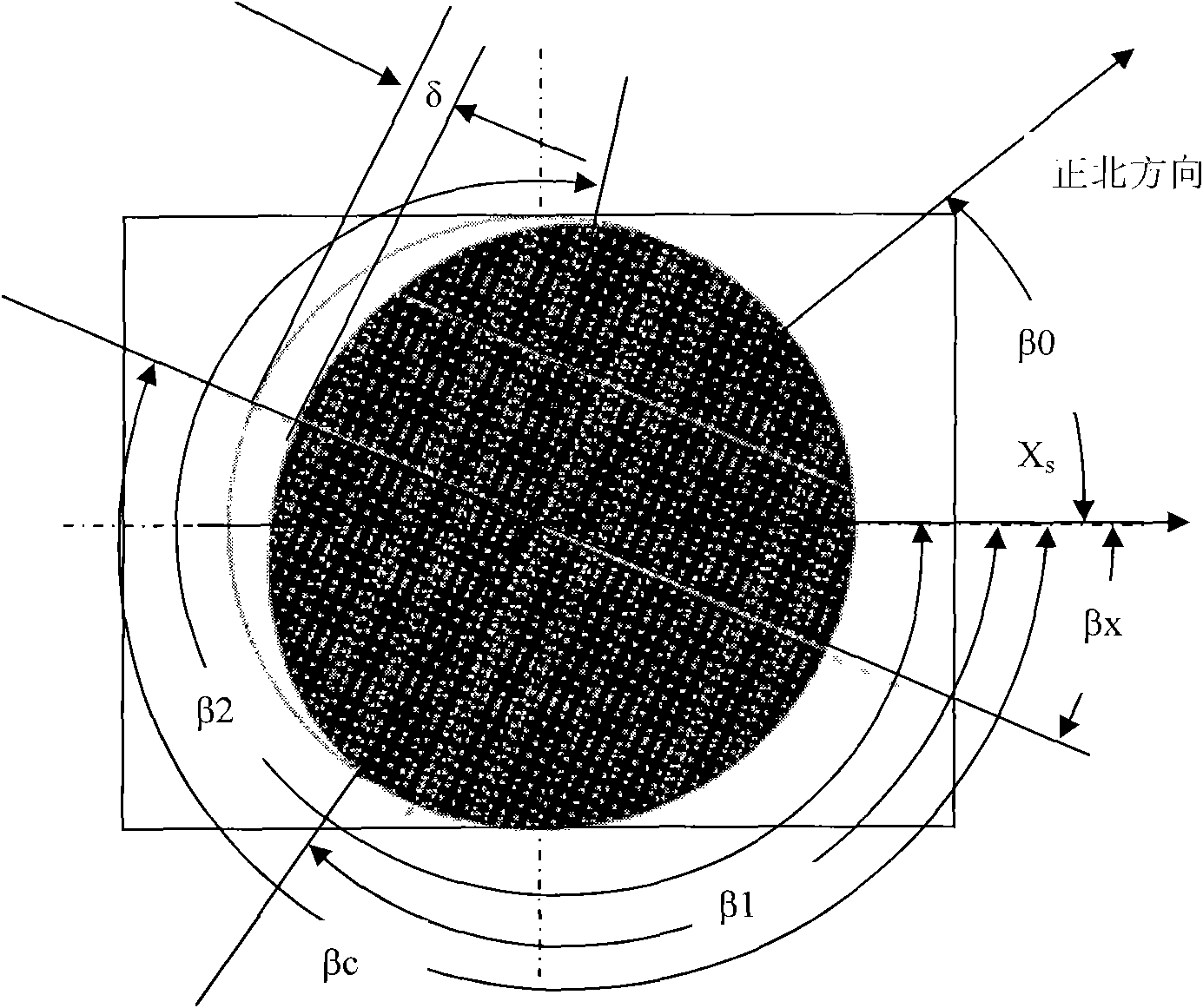

Platform leveling device based on cylindrical model

ActiveCN101825461ASatisfy Leveling ControlImprove resolutionAcceleration measurementIncline measurementOperabilityMeasurement precision

A platform leveling device based on a cylindrical model comprises an all-dimensional tilt sensor shell, an LED lighting source, a closed transparent conical container, light-tight liquid, a camera, an embedded system, a power source, a compass, a platform, a platform supporting leg position servo control action unit and a platform supporting leg position servo control drive unit, wherein the closed transparent conical container is formed by combining two cones in the same size back to back; the container is filled with the light-tight liquid which is half the volume of the container; the non-light-tight part of the transparent conical container, which is shot by the camera in front, is analyzed, judged and computed to obtain the measurement parameters of the platform to be measured, such as tilt angle, tilt azimuth and the like; and the multi-supporting leg platforms which are irregularly arranged are horizontally and automatically adjusted by using the measurement parameters according to different leveling strategies. The device has good operability, high measurement accuracy, good stability, strong applicability, low manufacture cost and strong real time and safe reliability.

Owner:ZHEJIANG UNIV OF TECH

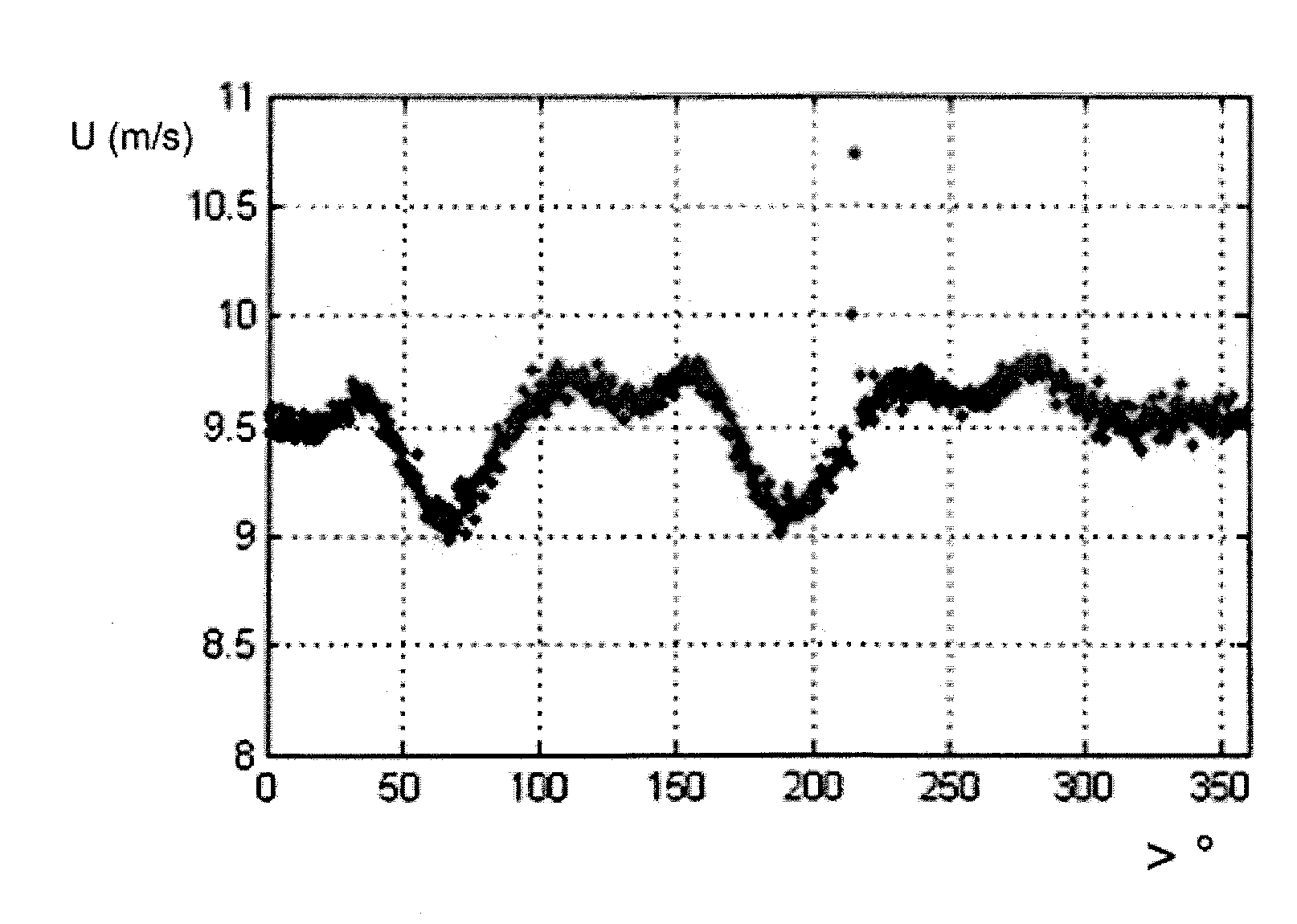

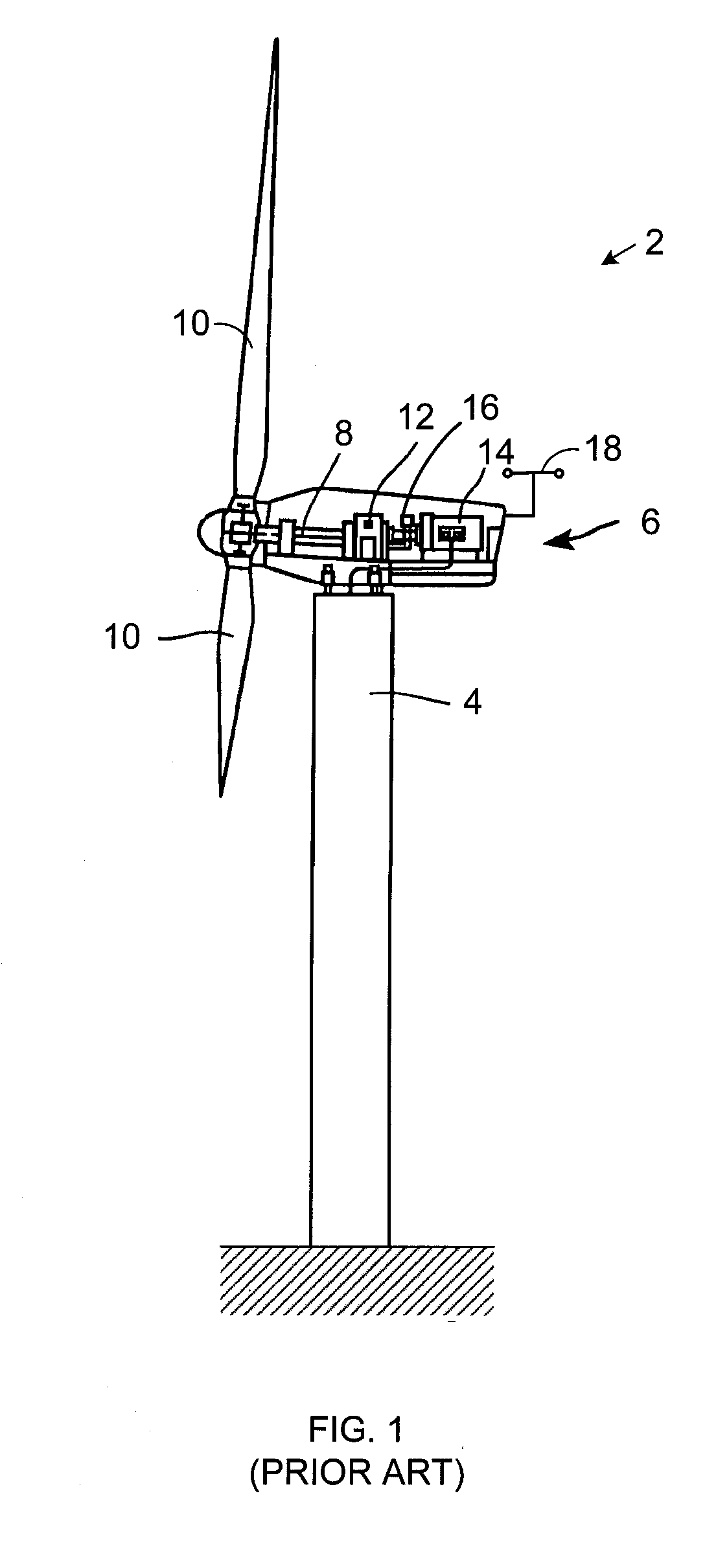

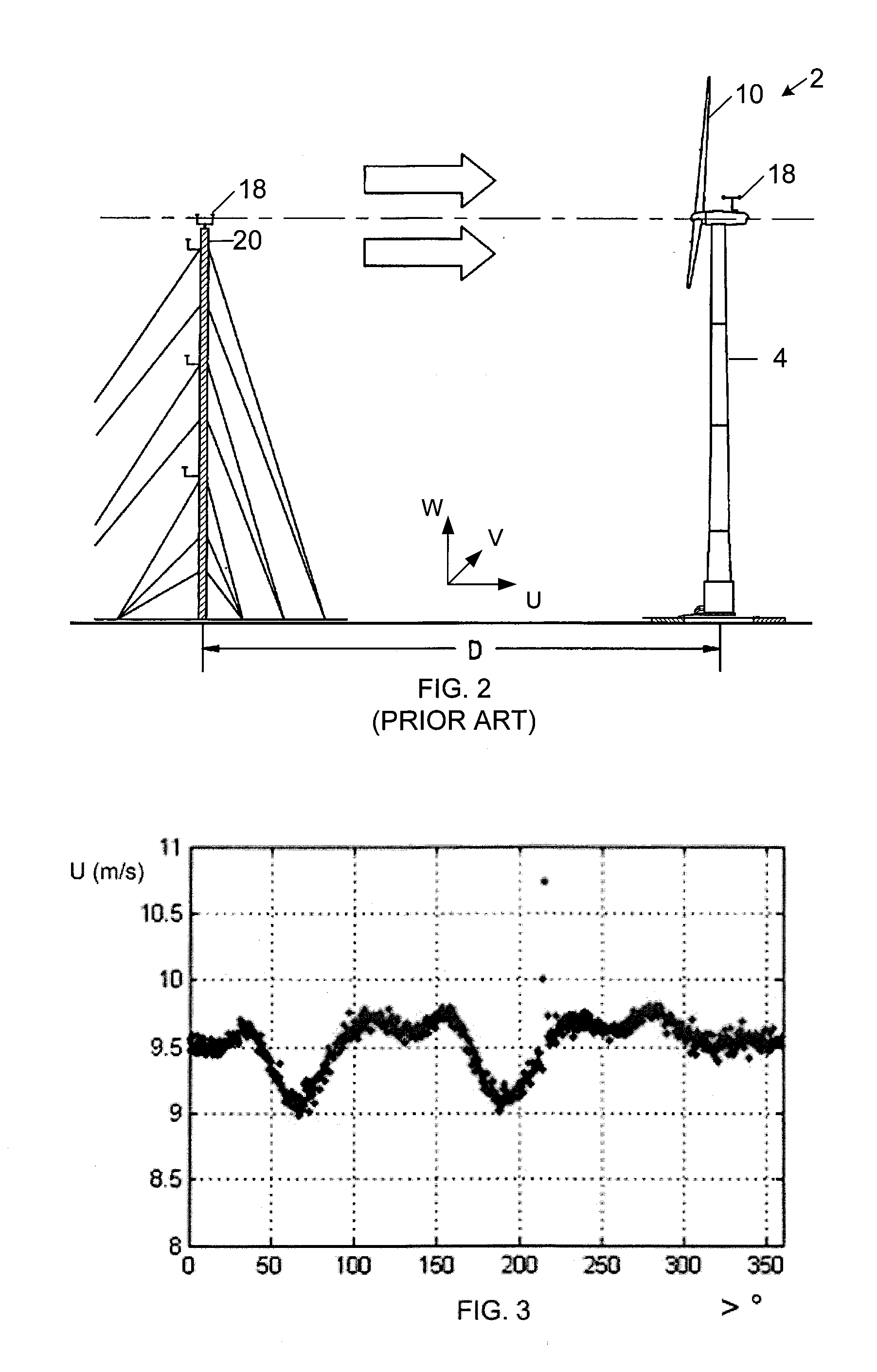

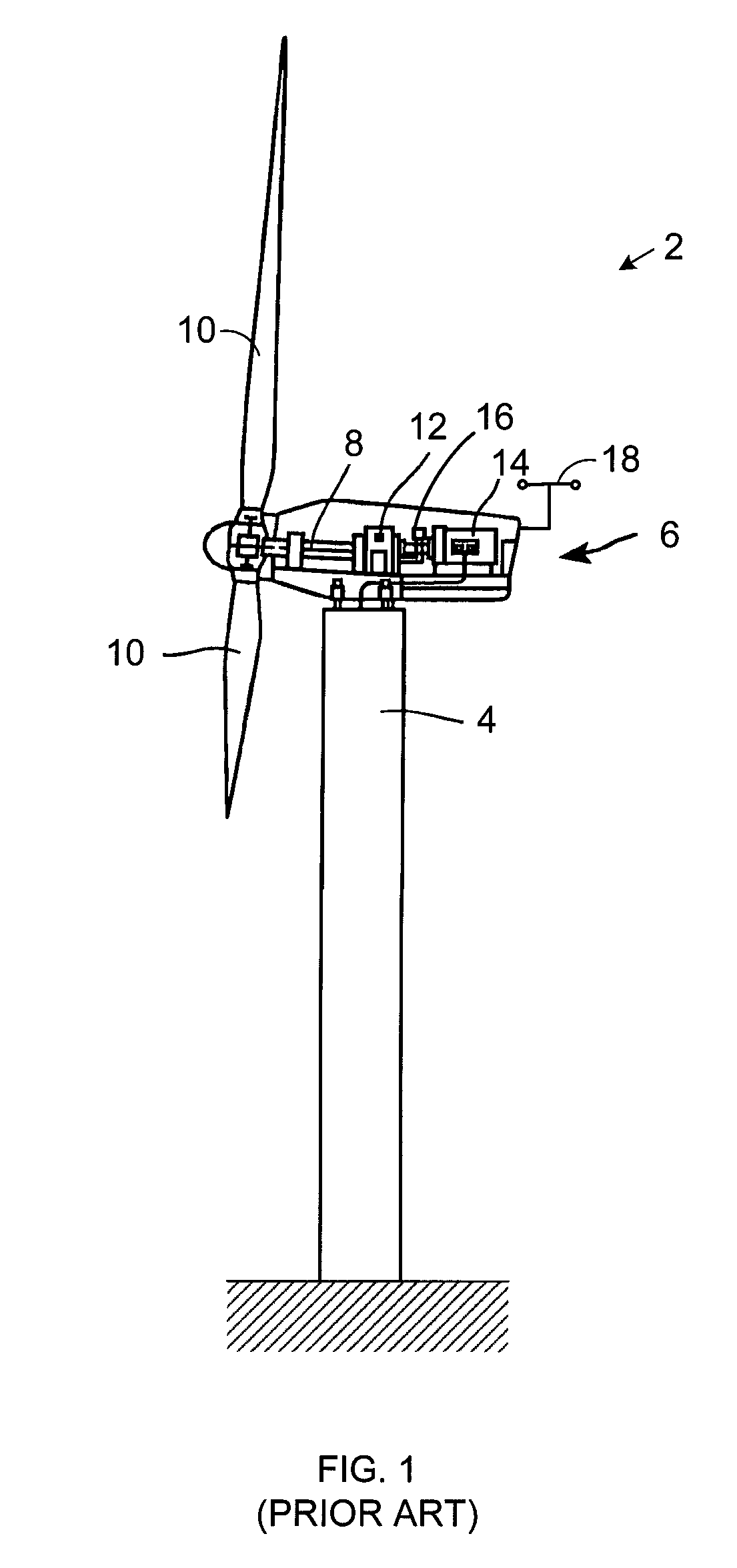

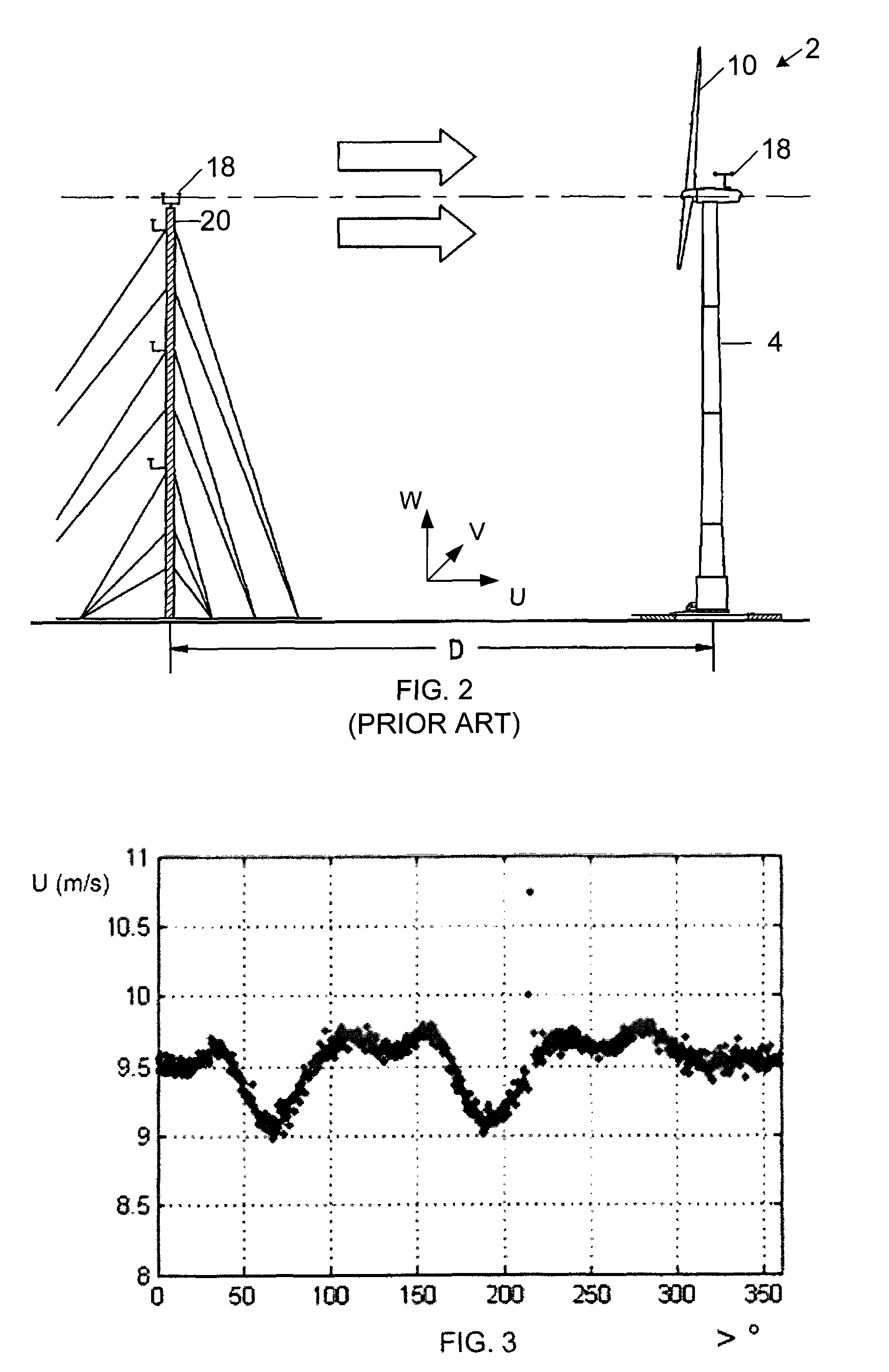

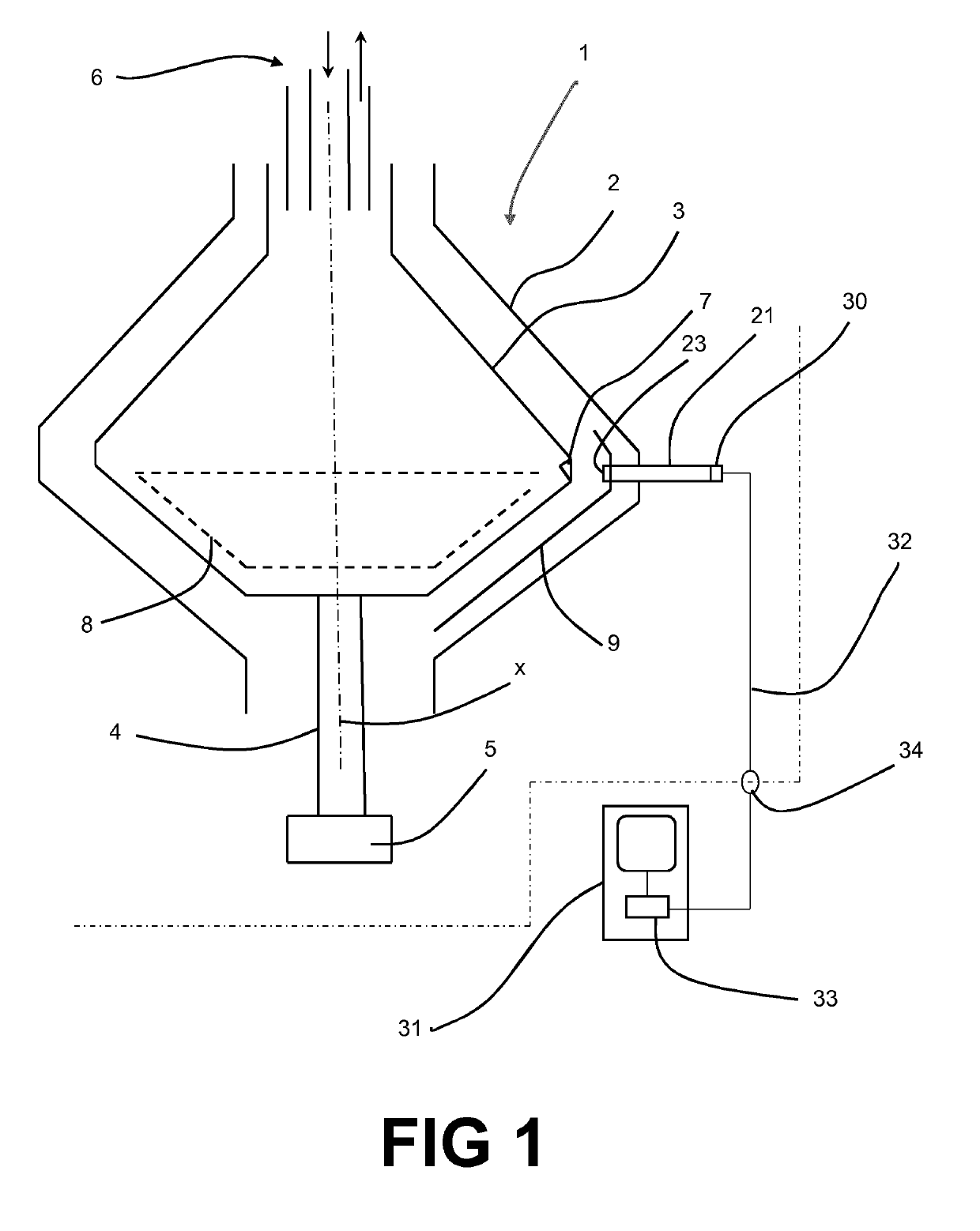

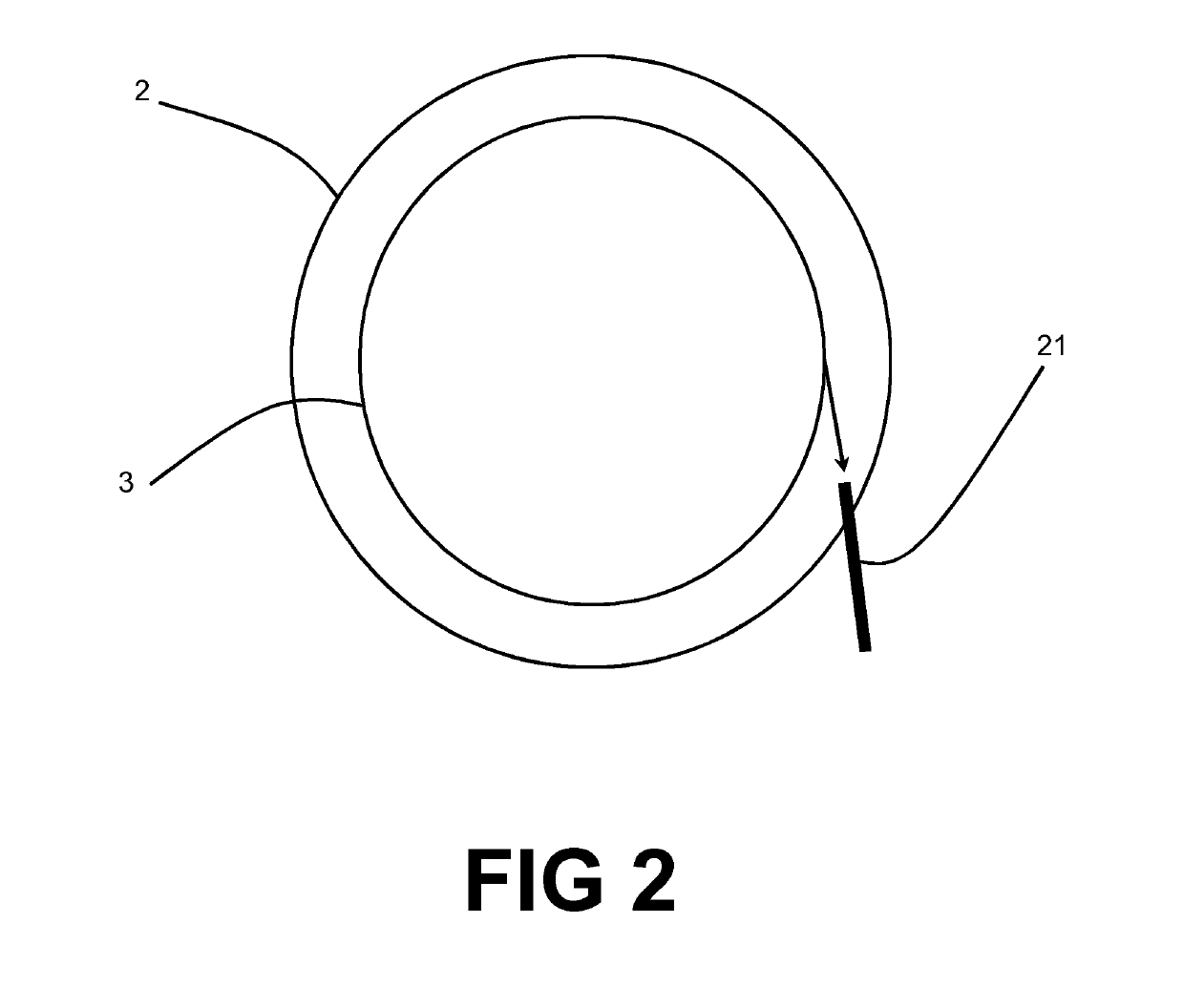

Wind turbine anemometry compensation

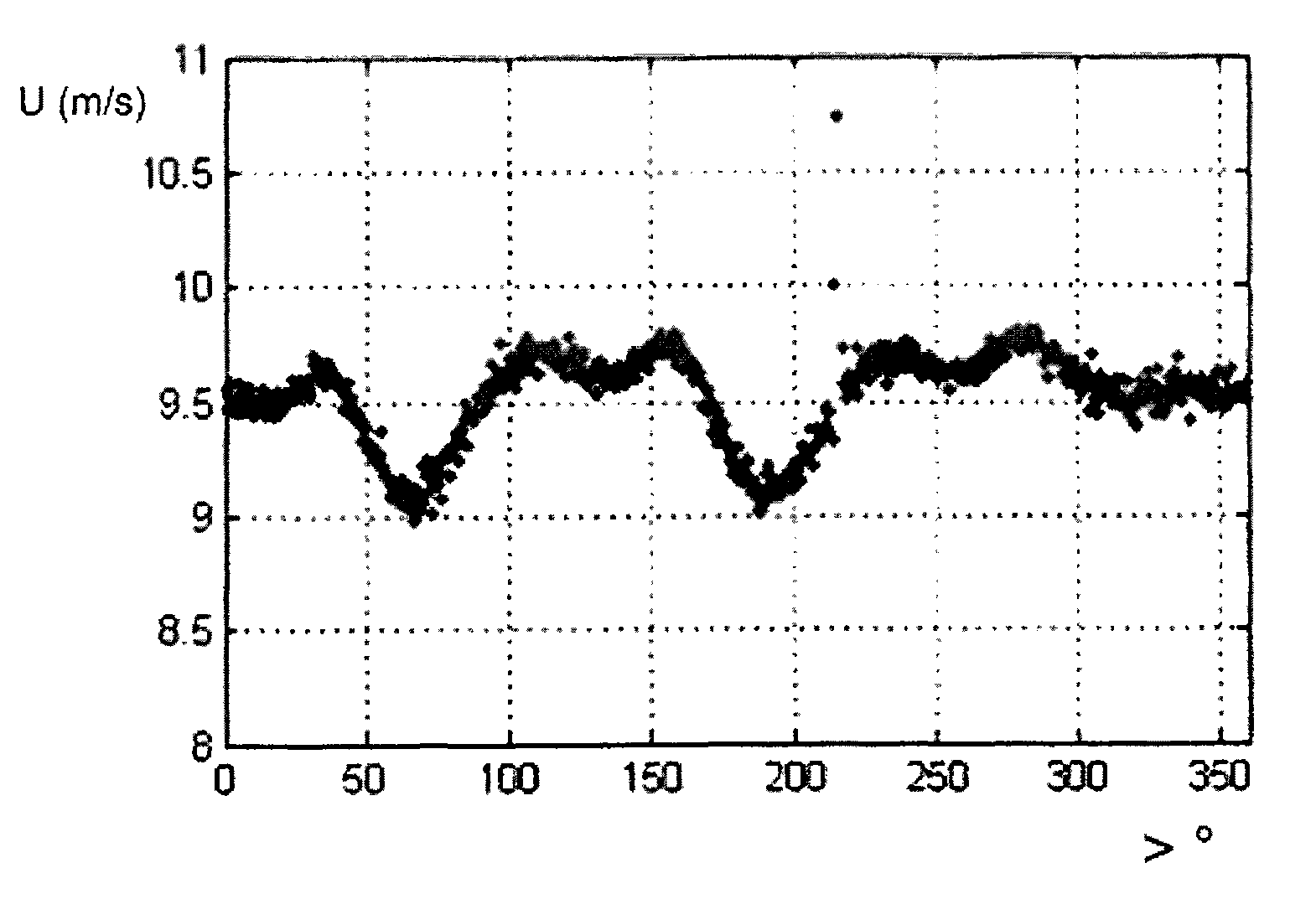

A system for estimating a freestream wind characteristic for a wind turbine having a rotor includes estimating a nacelle wind speed for the turbine; determining, from the estimated nacelle wind speed, at least one angular position of the rotor for measuring a nacelle wind characteristic for the turbine; and measuring the nacelle wind characteristic at the determined angular position of the rotor.

Owner:GENERAL ELECTRIC CO

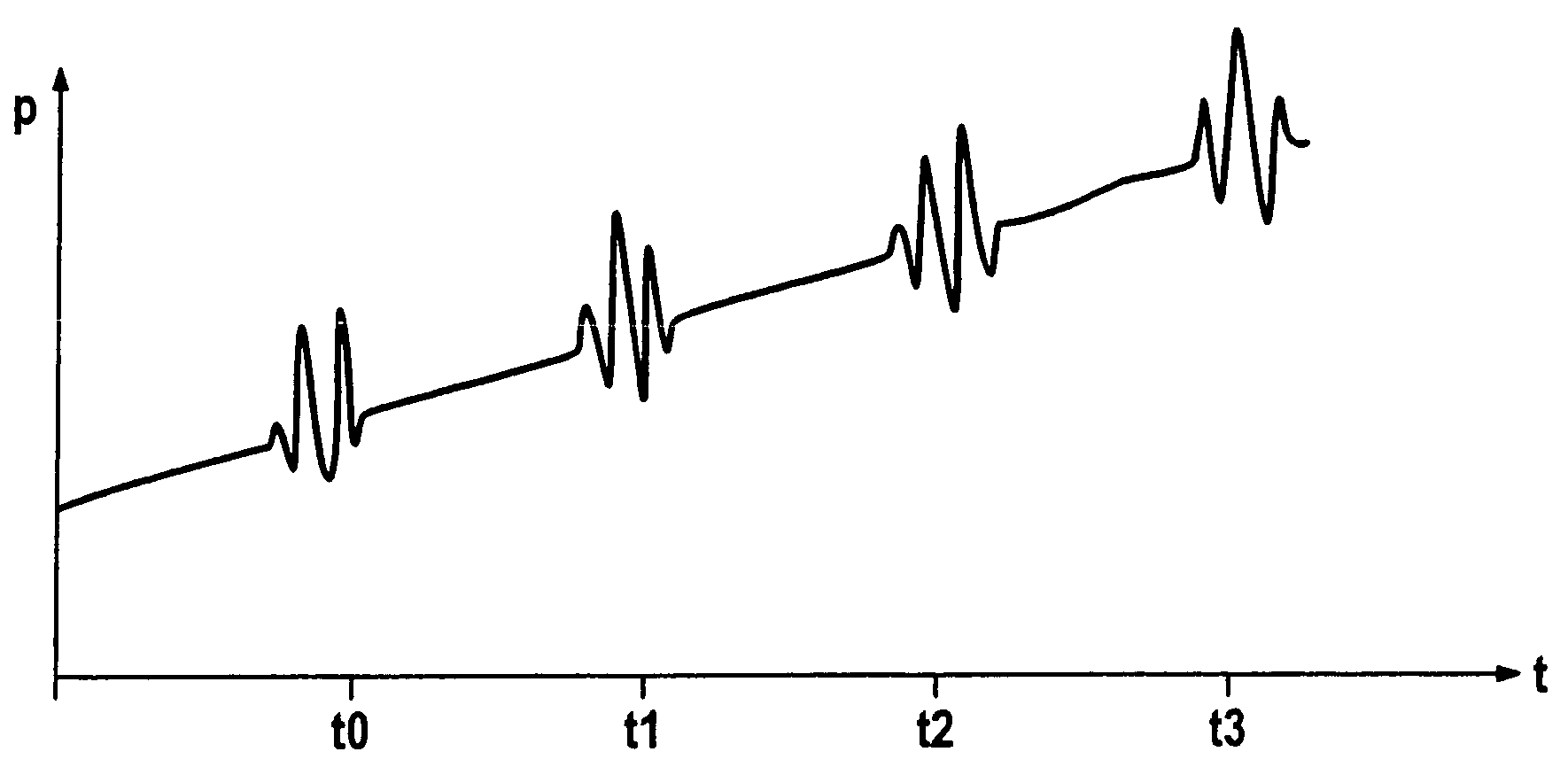

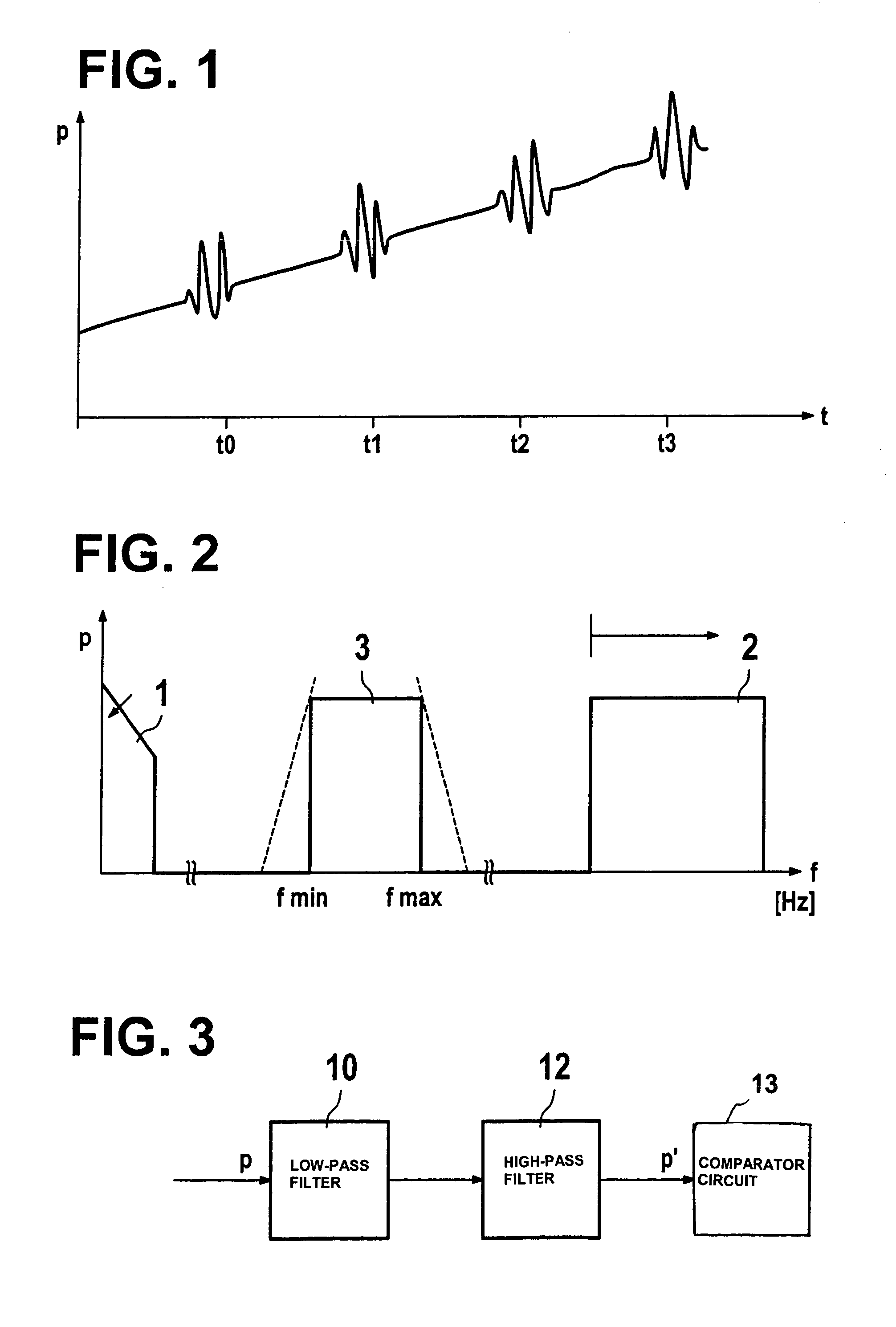

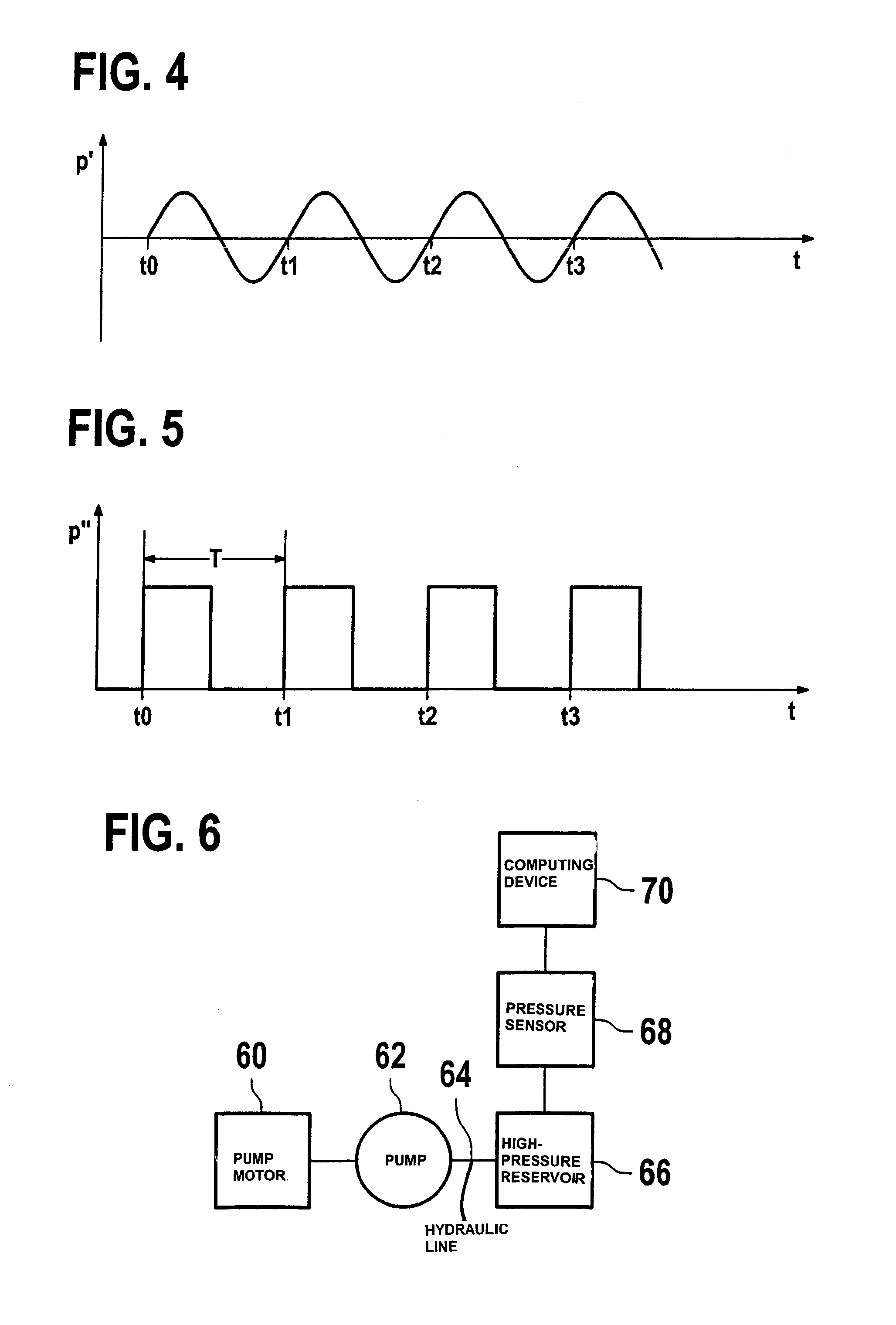

Method and device for detecting the speed of a pump

InactiveUS7083391B2Low priceOut interferenceInflated body pressure measurementFlexible member pumpsHydraulic pumpHydraulic fluid

A method and a system for detecting the speed of a pump motor of a hydraulic pump system are provided, in which pump system a pump is driven by a pump motor to deliver hydraulic fluid into a pump reservoir. In accordance with the present invention, a pressure signal representing the fluid-delivery activity of the pump is detected, and the pressure peaks within this pressure signal identified. The speed of the pump motor is determined on the basis of the frequency or the time intervals of these pressure peaks.

Owner:ROBERT BOSCH GMBH

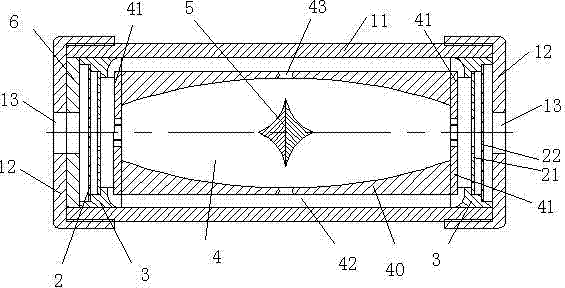

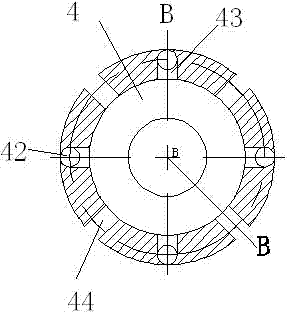

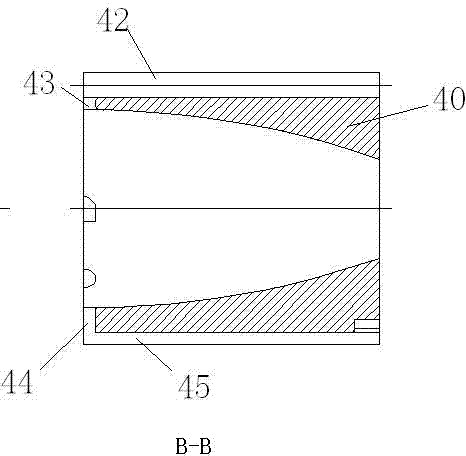

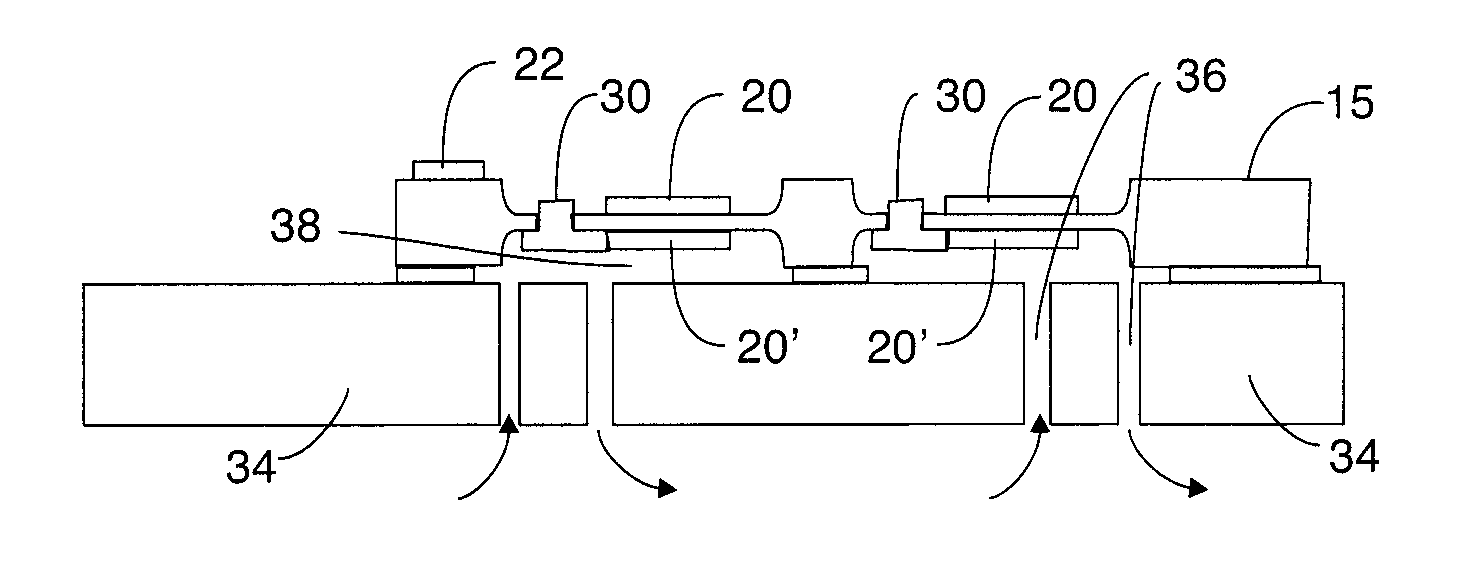

Airflow Angular Velocity Sensor

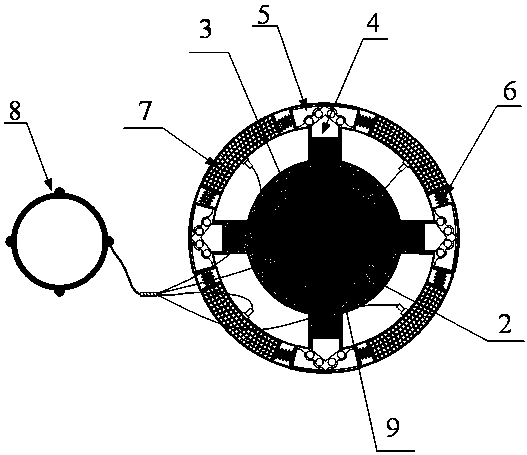

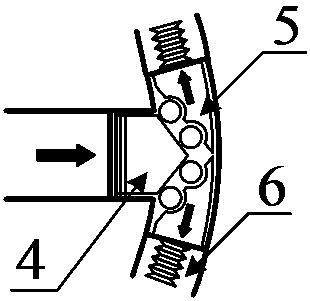

InactiveCN102288775AImprove impact resistanceSimple structureDevices using fluidsSignal processing circuitsTransducer

The invention discloses an airflow type angular velocity transducer, which comprises a testing cavity, a sensitive element arranged at a center position of the testing cavity, two piezoelectric pumps which are symmetrically arranged at two ends of the testing cavity, a gas circulation channel communicated with the testing cavity and the piezoelectric pumps, and a signal processing circuit, wherein the testing cavity is a cavity symmetrical about an axial center and a radial center; two ends of the testing cavity are provided with air inlets; a certain distance is formed between the two piezoelectric pumps and the two ends of the testing cavity; gases in the transducer can circulate in a confined space formed by the testing cavity, the gas circulation channel and the piezoelectric pumps; the sensitive element has a plate frame structure of which the periphery is provided with four groups of thermistor wires; vertical distances between straight lines where the groups of thermistor wiresare positioned and a central position of the sensitive element are the same; opposite two groups of thermistor wires are parallel to each other; adjacent two groups of thermistor wires are vertical to each other; and the center of the sensitive element and the centers of the air inlets are positioned on a center line of the testing cavity.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Wind turbine anemometry compensation

A system for estimating a freestream wind characteristic for a wind turbine having a rotor includes estimating a nacelle wind speed for the turbine; determining, from the estimated nacelle wind speed, at least one angular position of the rotor for measuring a nacelle wind characteristic for the turbine; and measuring the nacelle wind characteristic at the determined angular position of the rotor.

Owner:GENERAL ELECTRIC CO

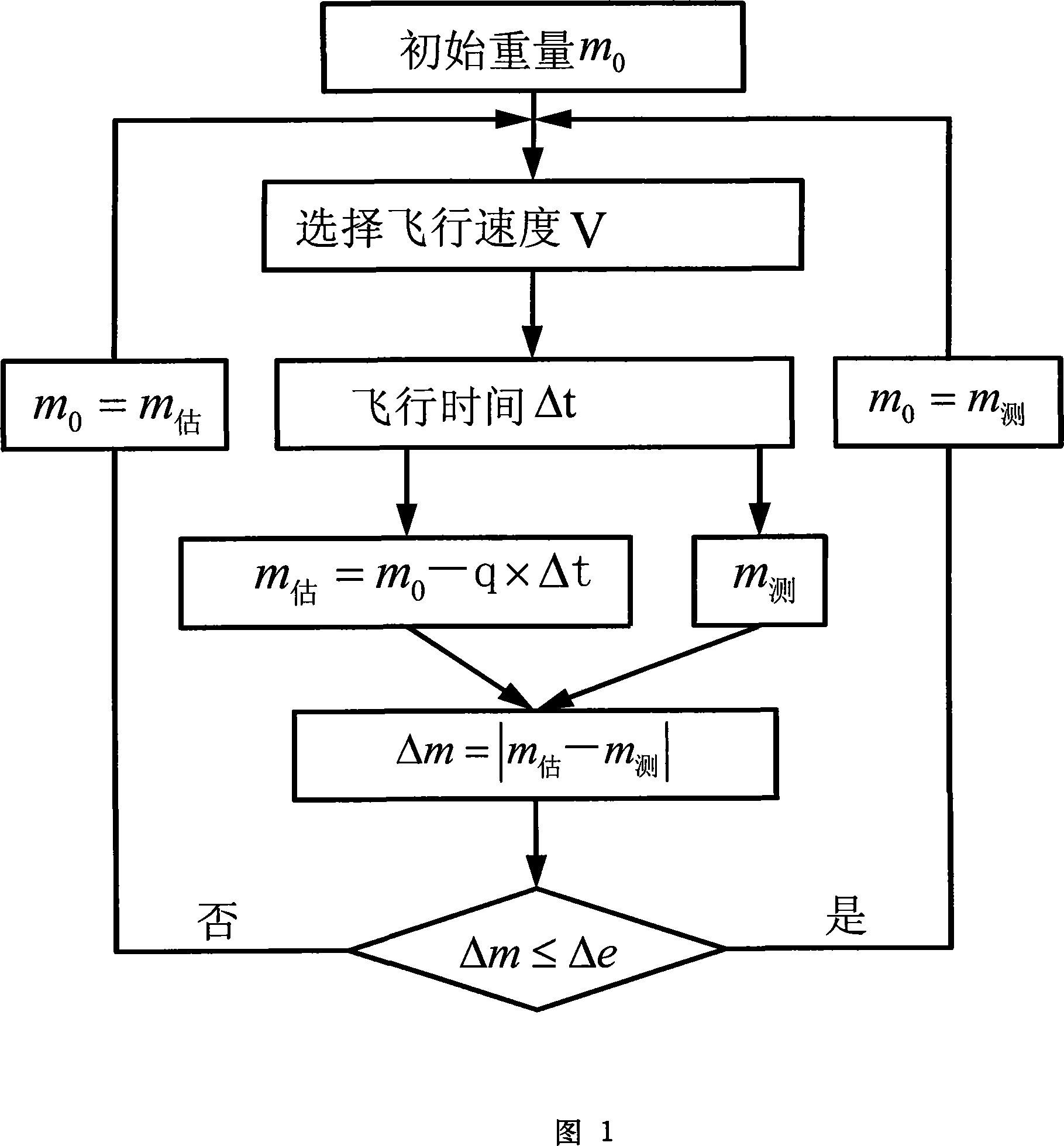

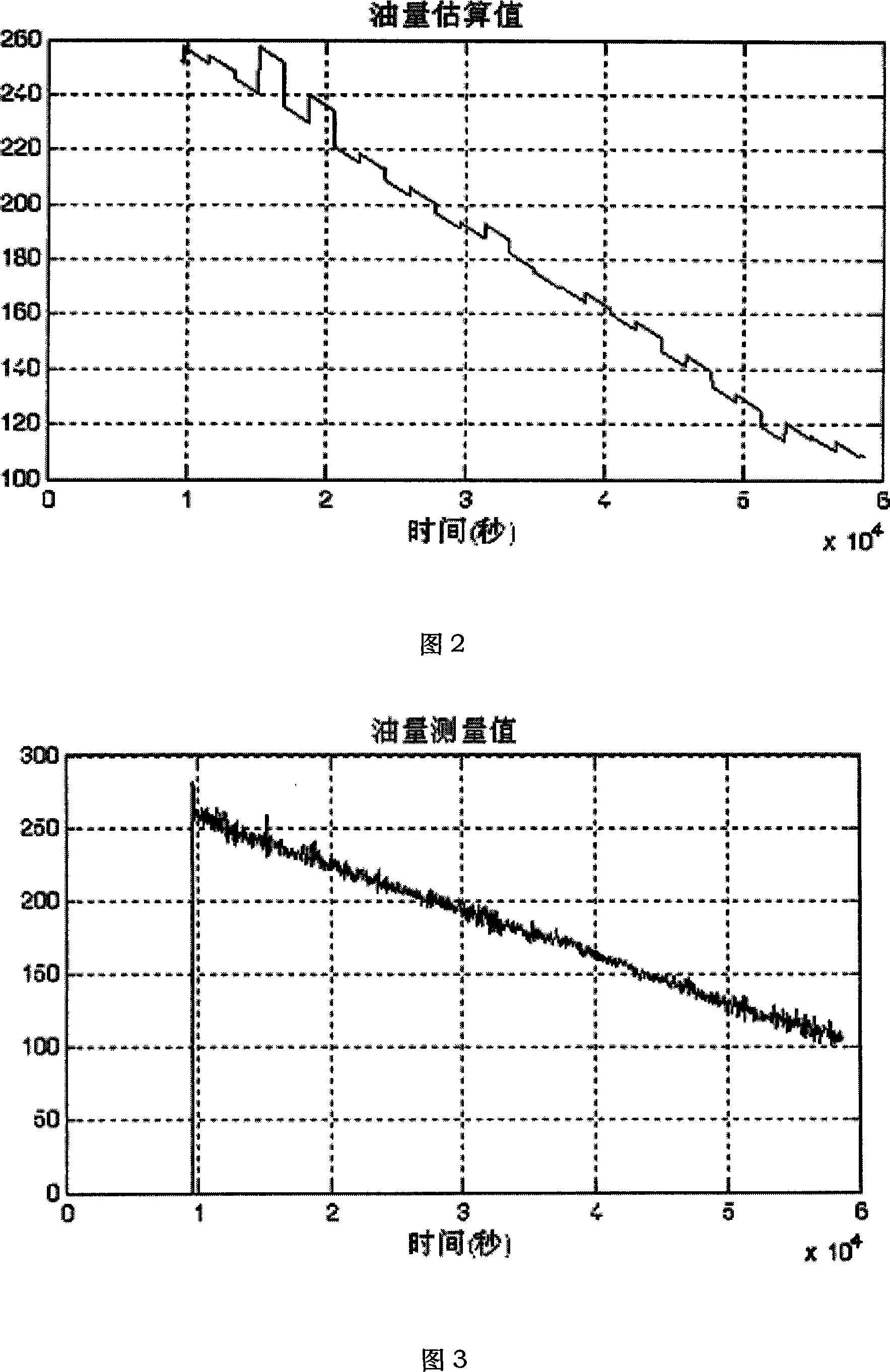

Aerial craft oil mass measurement error correcting method

InactiveCN101210839AAvoid Accidental Measurement ErrorsMeet the precision requirementsTesting/calibration apparatusDevices using fluidsCapacitanceChemical industry

The invention relates to the technical field of automatic liquid level and object level measuring, more particularly to a four-wire system radio-frequency admittance liquid level and object level meter and a method thereof. The meter comprises an LC oscillatory circuit, a bridge circuit, a prime amplifying circuit, a detection synchronous circuit, a detection circuit, a signal amplifying circuit, an MSP430F147 single chip microcomputer, a 93C46EEPROM memory circuit, a liquid crystal display, an AD420 electric current output circuit, a keystroke input circuit, an electric relay output circuit and a continuous liquid level control automatic gearshift circuit. The signal of material level variation subjected to detection and integration is converted to a DC signal, transmitted to a CPU processor for processing, and then transmitted to the liquid crystal display for displaying. Comparing with the capacitance radio-frequency admittance and two-wire system radio-frequency admittance, the inventive product has great advantages in sales for chemical industry and sewage treatment industry, and the debugging and maintenance costs are reduced. The inventive product is irreplaceable in position measurement in high pressure high temperature and narrow space.

Owner:BEIHANG UNIV

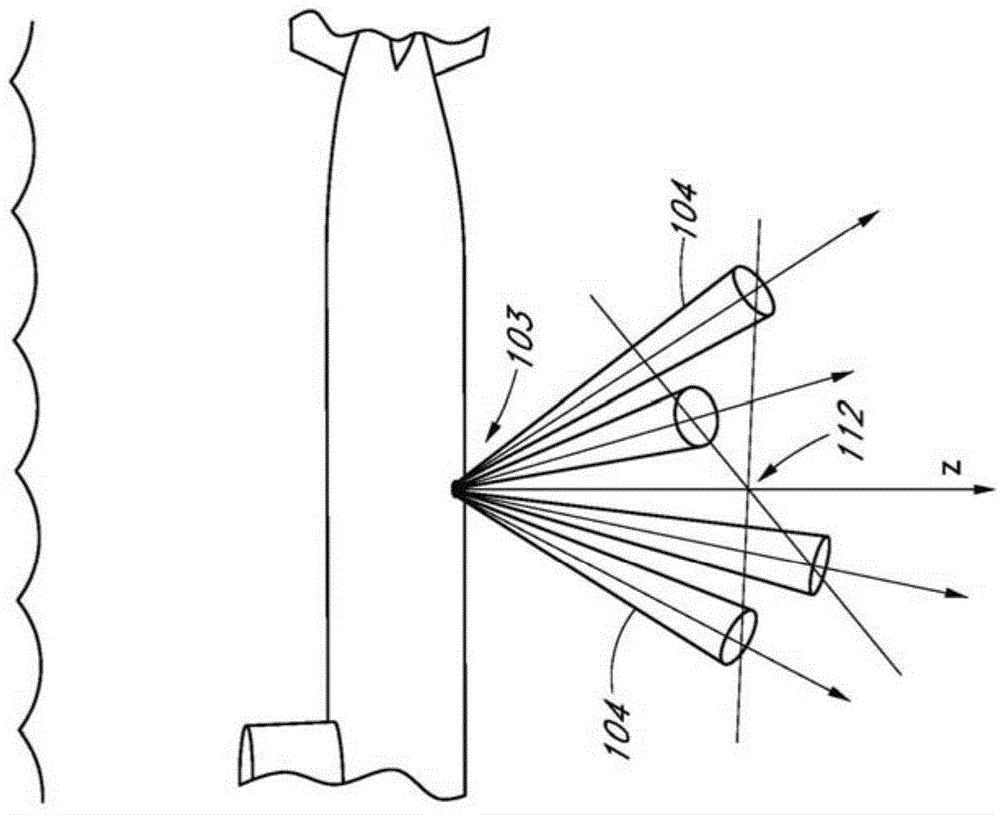

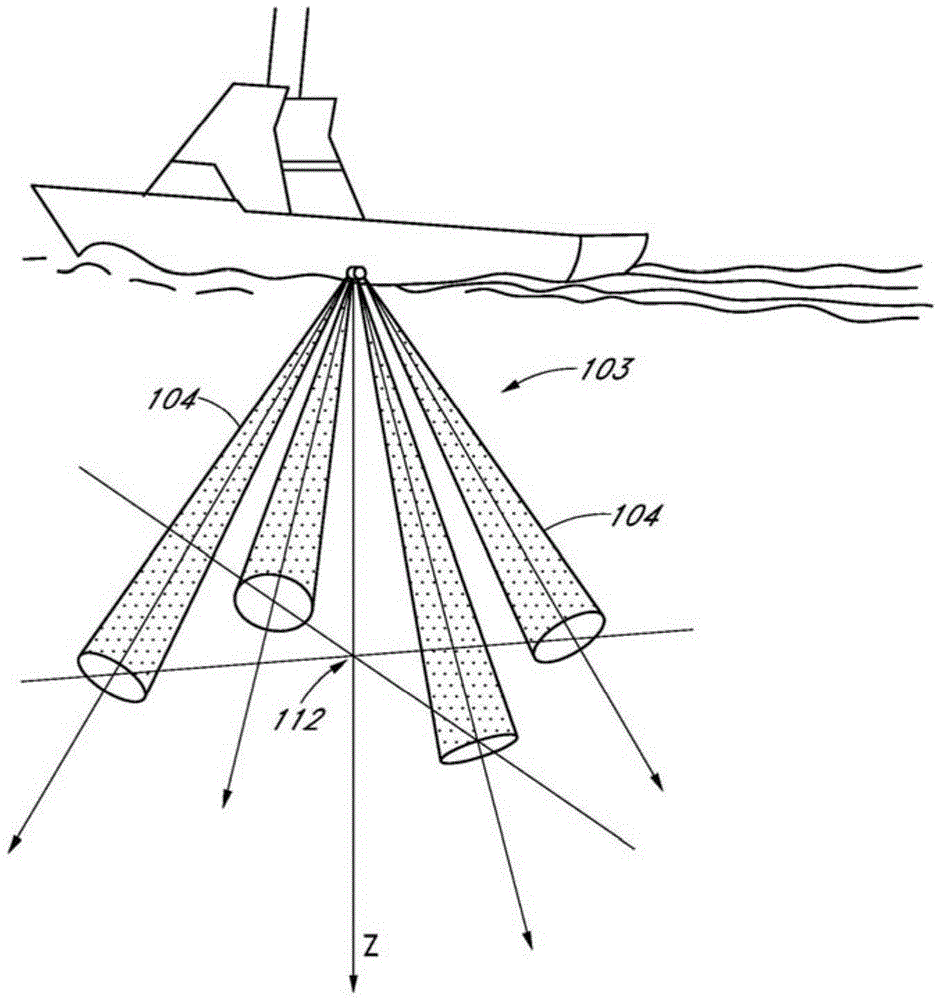

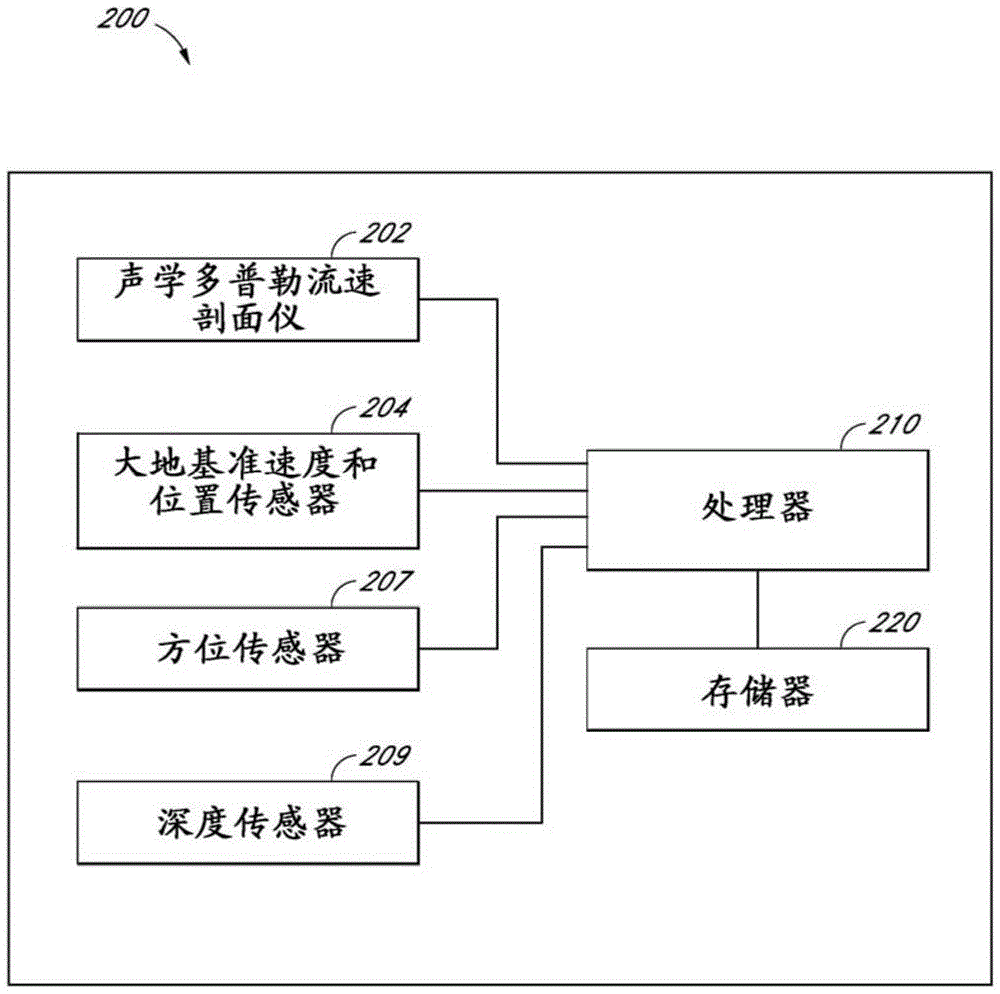

System and method for water column aided navigation

InactiveCN104870940ANavigation by speed/acceleration measurementsSatellite radio beaconingKaiman filterReference current

Underwater vehicles may fix their position from GPS at the surface of the water and use bottom track for dead reckoning once it has descended to within tracking range of the bottom of a body of water. This disclosure describes a method and system for navigation through the water through depths where GPS is not available using current profiles from sonar systems including acoustic Doppler current profilers (ADCP). This extrapolation of earth referenced current profiles can provide a way to estimate vehicle motion below the surface before the vehicle reaches the bottom. Once bottom track is achieved, the corrected reference for vehicle motion improves the vehicle position estimate. A Kalman filter updates vehicle position and current profile estimates during descent, and the bottom track when the bottom comes within range to enable navigation of underwater vehicles.

Owner:特励达仪器有限公司

Resonator with a fluid cavity therein

ActiveUS8593037B1Vibration measurement in solidsMeasurement of fluid loss/gain ratePiezoelectric quartzQuartz resonator

A quartz resonator flow cell has a piezoelectric quartz wafer with an electrode, pads, and interconnects disposed on a first side thereof. The piezoelectric quartz wafer has a second electrode disposed on a second side thereof, the second electrode opposing the first electrode. A substrate is provided having fluid ports therein and the piezoelectric quartz wafer is mounted to the substrate such that the second side thereof faces the substrate with a cavity being formed between the substrate and the wafer. The fluid ports in the substrate are aligned with the electrode on the second side of the piezoelectric quartz wafer which is in contact with the cavity.

Owner:HRL LAB

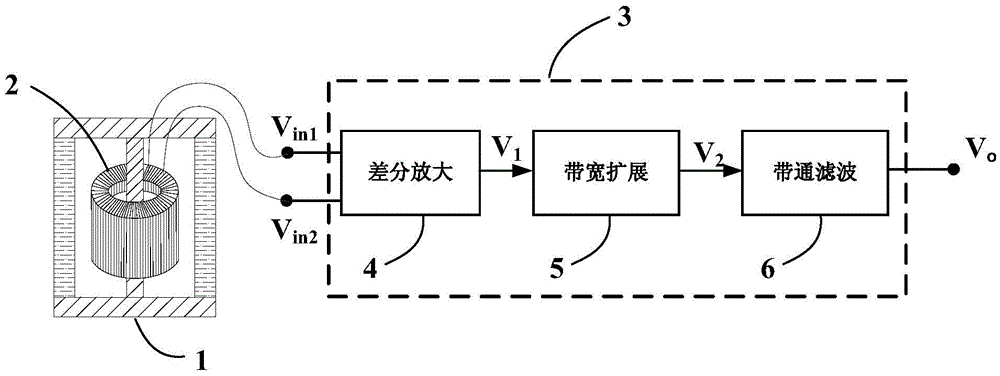

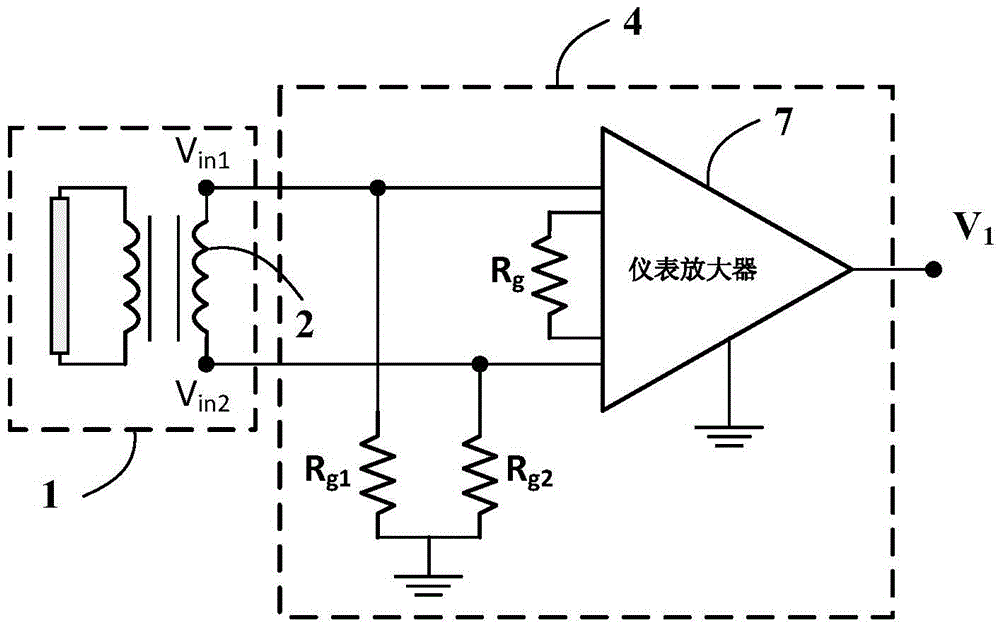

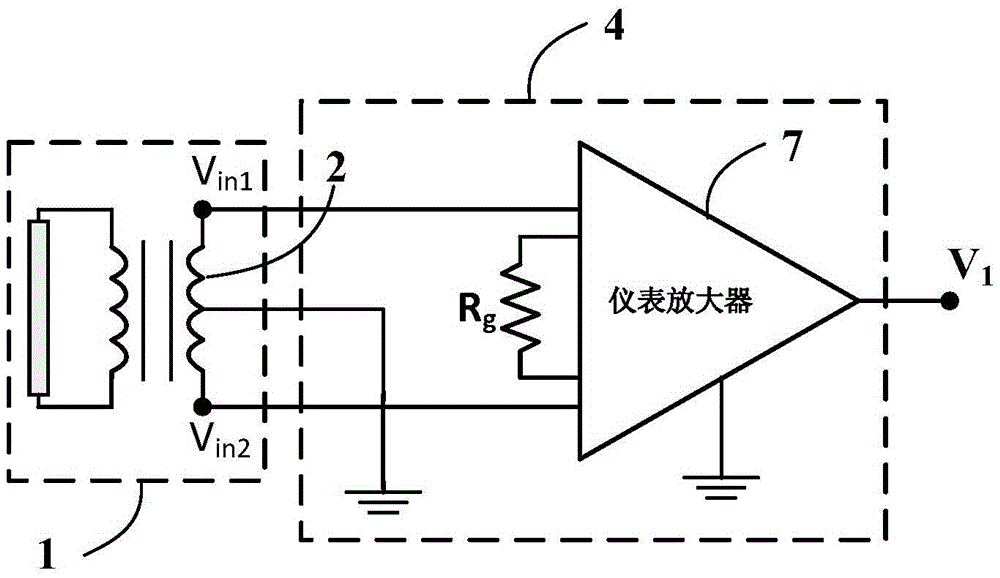

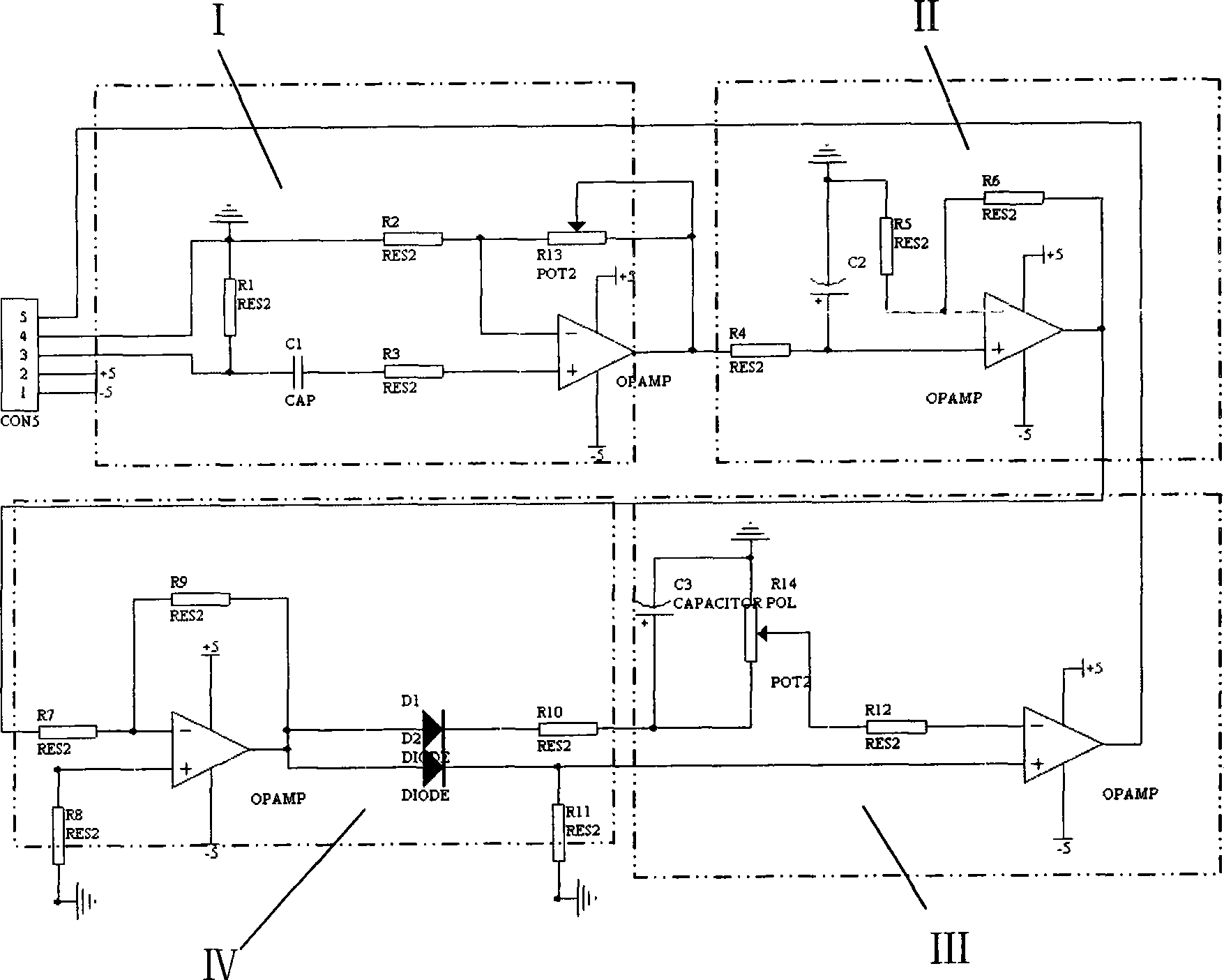

Detection device for MHD angular-rate sensor

ActiveCN105486882AImprove scalabilityWorking bandwidthTesting/calibration of speed/acceleration/shock measurement devicesDevices using electric/magnetic meansNoise levelAngular rate sensor

The invention relates to a detection circuit for a magnet-hydro-dynamics (MHD) angular-rate sensor. The detection circuit is formed by function modules: a differential amplification module, a bandwidth expansion module and a band-pass filtering module and the like, and can control noise level of the sensor effectively, improve weak signal detection capability and expand work bandwidth. Besides, the detection circuit can achieve the effect of suppressing zero position bias and zero position temperature drift of the sensor under the condition of not adding a special zero position bias adjusting module and a zero position temperature drift compensation module.

Owner:BEIJING RES INST OF TELEMETRY +1

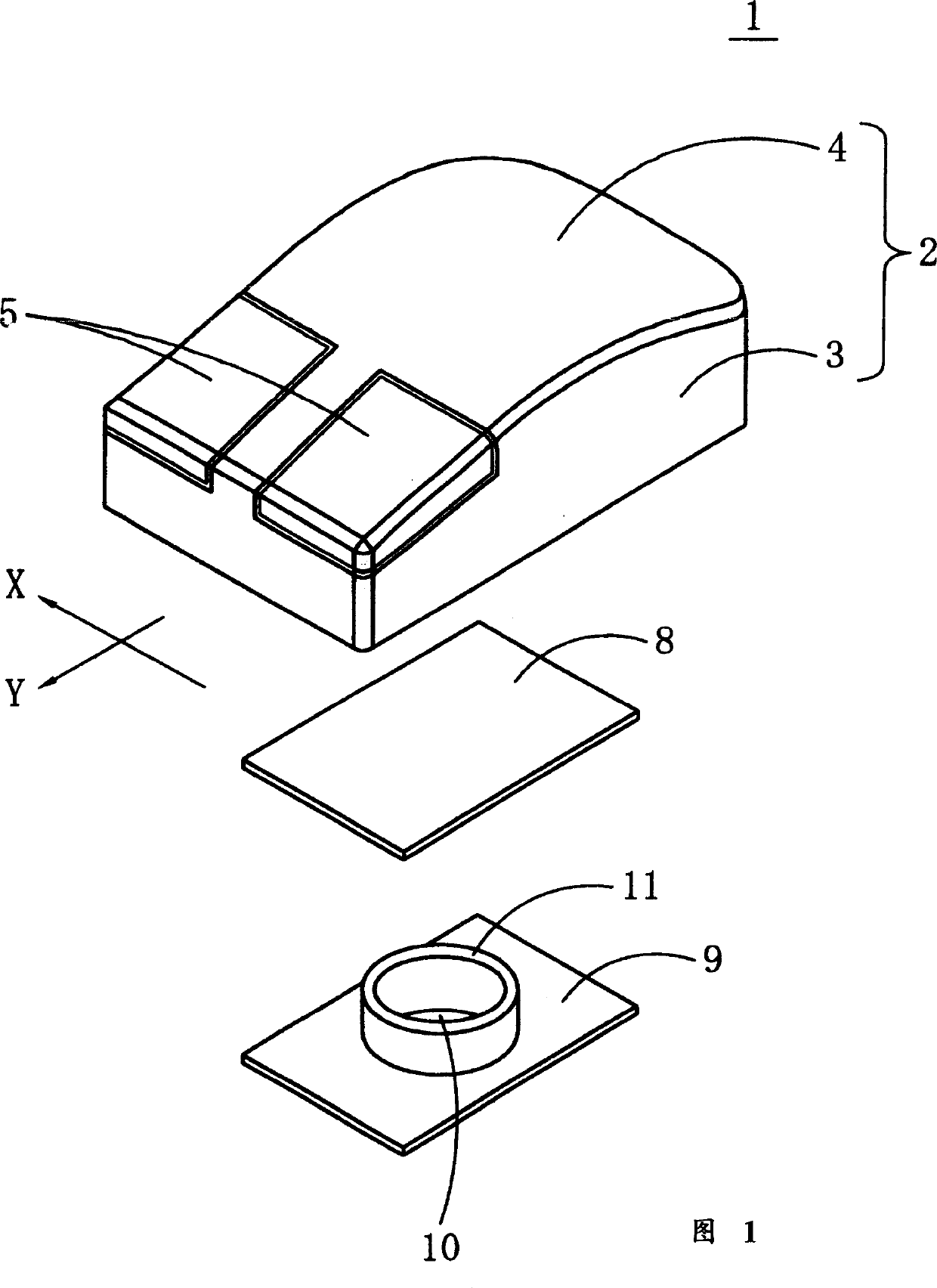

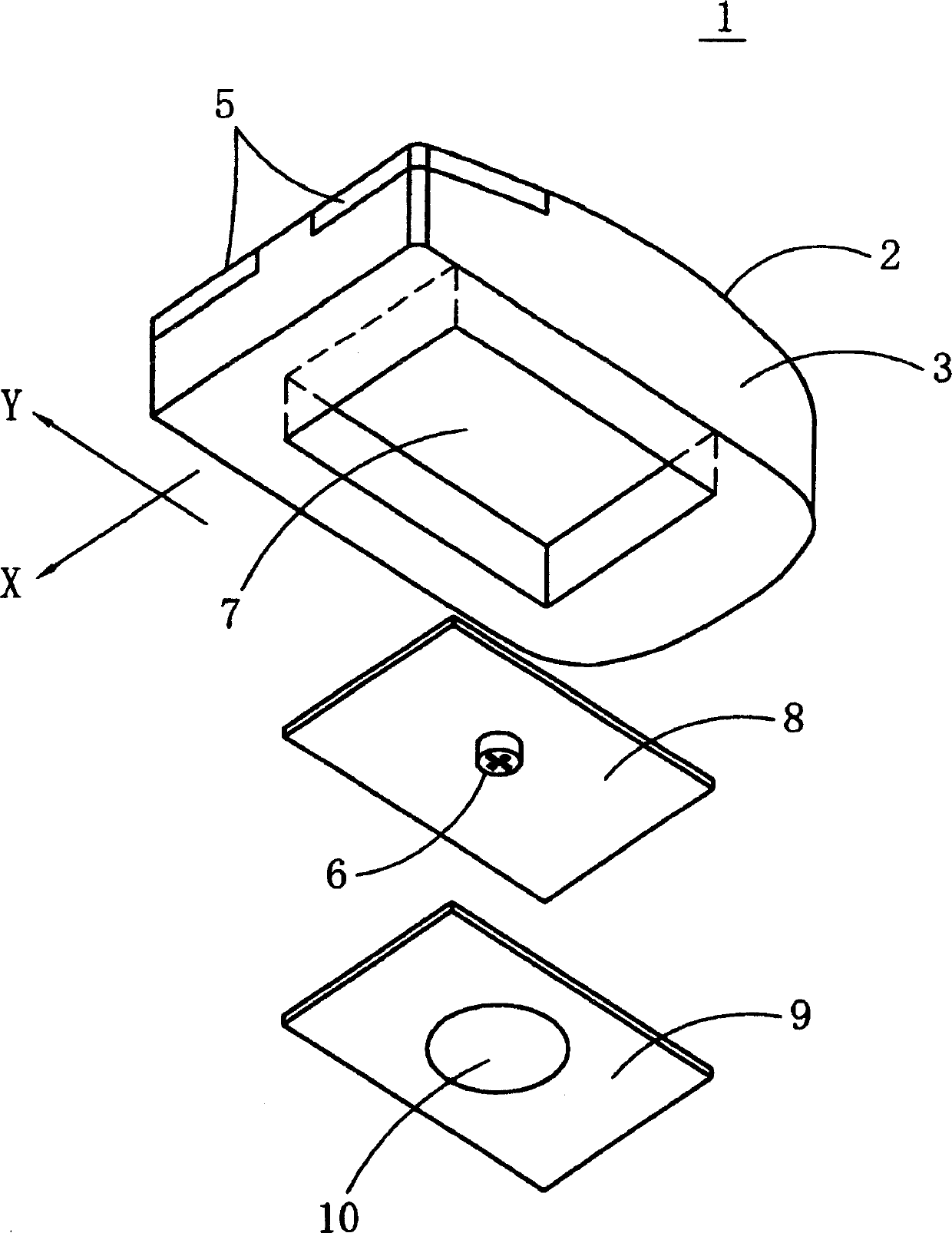

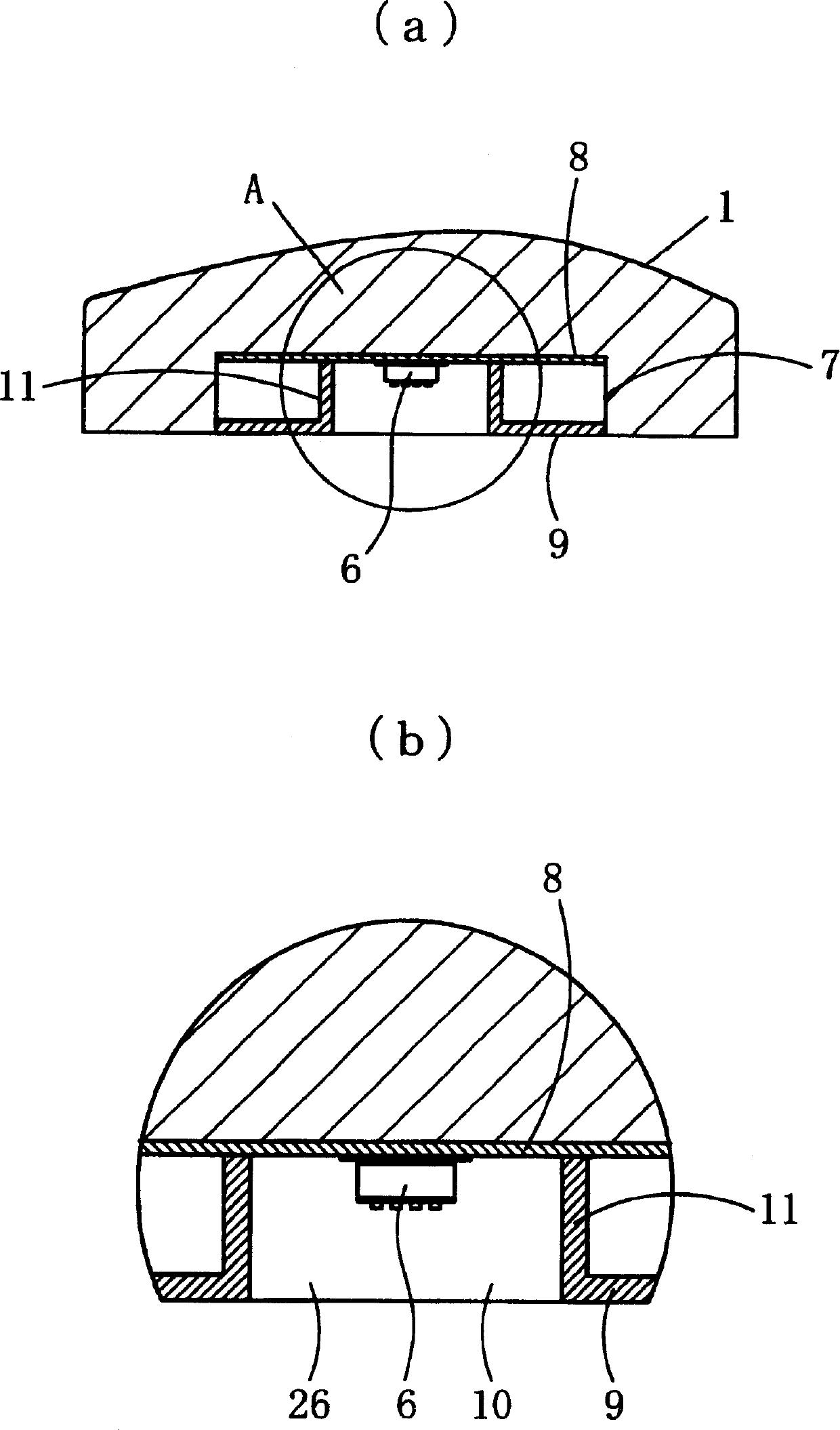

Pointing device for position

InactiveCN1466713APrevent intrusionHigh sensitivityAcceleration measurement using interia forcesVolume/mass flow measurementPointing deviceLower face

A circuit substrate 8 mounting a flow sensor 6 thereto is stored into a concave portion 7 formed on the lower face of a mouse case 2. When a mouse 1 is moved, a flow of the air is relatively caused by inertia of the air, etc. The movement of the mouse 1 is detected by detecting the flow velocity of this air by the flow sensor 6.

Owner:ORMON CORP

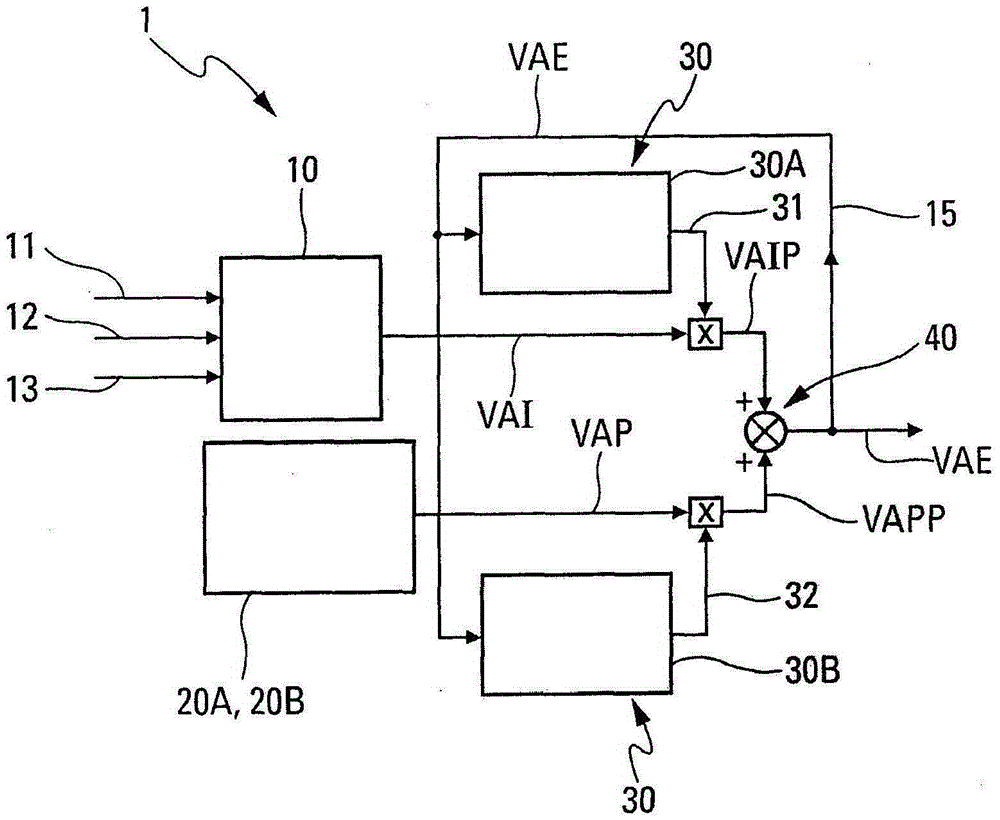

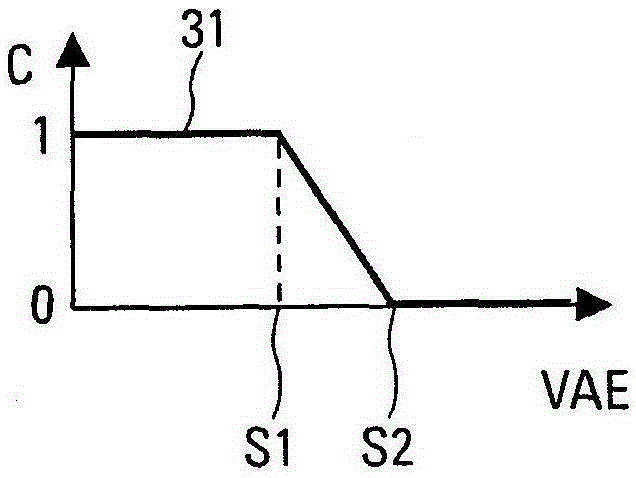

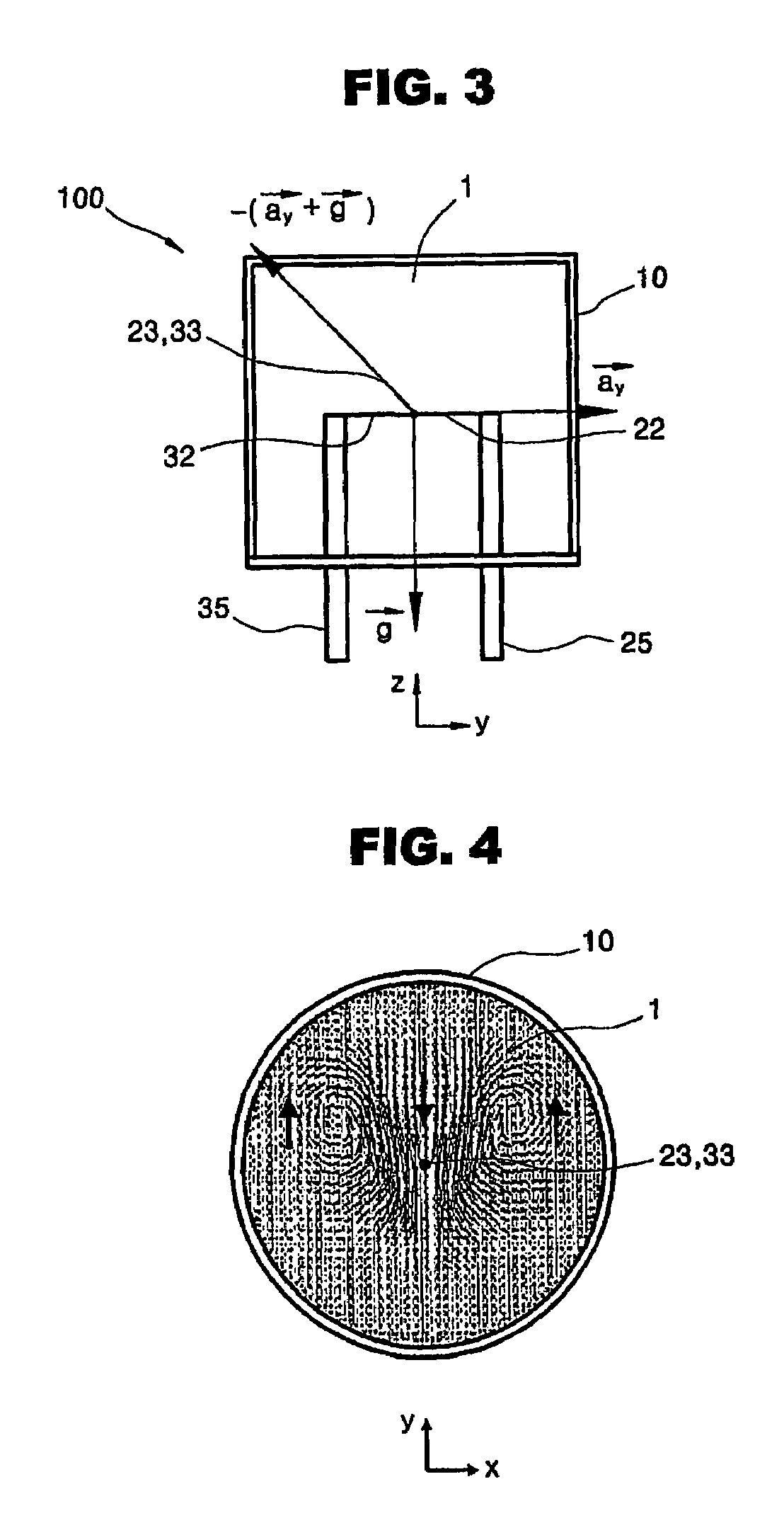

Method and device for estimating the airspeed of an aircraft

ActiveCN105675901AAirspeed estimateAccurate airspeed estimatesFluid speed measurement using pressure differenceTesting/calibration of speed/acceleration/shock measurement devicesEstimation methodsEngineering

A method and device for estimating the airspeed of an aircraft are disclosed. The device (1) includes a first estimation unit (10) configured to estimate the airspeed of the aircraft according to a first estimation method, a second estimation unit (20A, 20B) configured to estimate the airspeed of the aircraft according to a second estimation method, a weighting unit (30) configured to weight the two airspeeds estimated by the first and second estimation methods and a computation unit (40) configured to sum the weighted airspeeds so as to obtain an estimated airspeed (VAE) of the aircraft.

Owner:AIRBUS OPERATIONS (SAS)

Voltage transformation type speed measurement device for magnetic liquid

InactiveCN104316717AAdjustable constant air pressure valueWide range of measurements and adjustableDevices using electric/magnetic meansDevices using fluidsCircular discMagnetic liquids

The invention provides a voltage transformation type speed measurement device for magnetic liquid, and belongs to the technical field of analyzing and measuring. A voltage transformation sensor shell of a voltage transformation sensing device is fixedly connected with a lower cover of a constant-voltage maintaining device through a connection boss. The valve body outer surface of the constant-voltage maintaining device is fixedly connected with the inner surface of a left circular disc of the shell. A valve base is fixedly connected with the lower surface of the left circular disc in the shell. The lower cover is fixedly connected with the lower surface of the left circular disc in the shell. A hole in the valve body is communicated with a hole in the left circular disc in the shell. A cylinder on the lower portion of the valve core is matched with a conical hole in the left circular disc in the shell in a sliding mode. The conical face of the valve core is matched with the surface of the conical hole in the shell. An upper valve body of a pressure control device, the outer surface of a feed-back valve and the inner surface of a right circular disc of the shell are fixedly connected. The top face of a lower valve body is fixedly connected with the bottom face of the right circular disc of the shell. An opening b of an air guide tee joint of a connection device is communicated with a hole of the lower cover in the pressure maintaining device, and an opening c is communicated with a hole in the lower valve body in the pressure control device. By means of the voltage transformation type speed measurement device, the rotation speeds within different ranges can be measured, and the device is adjustable, high in speed measurement temperature adaptability and stable and accurate in speed measurement.

Owner:JILIN UNIV

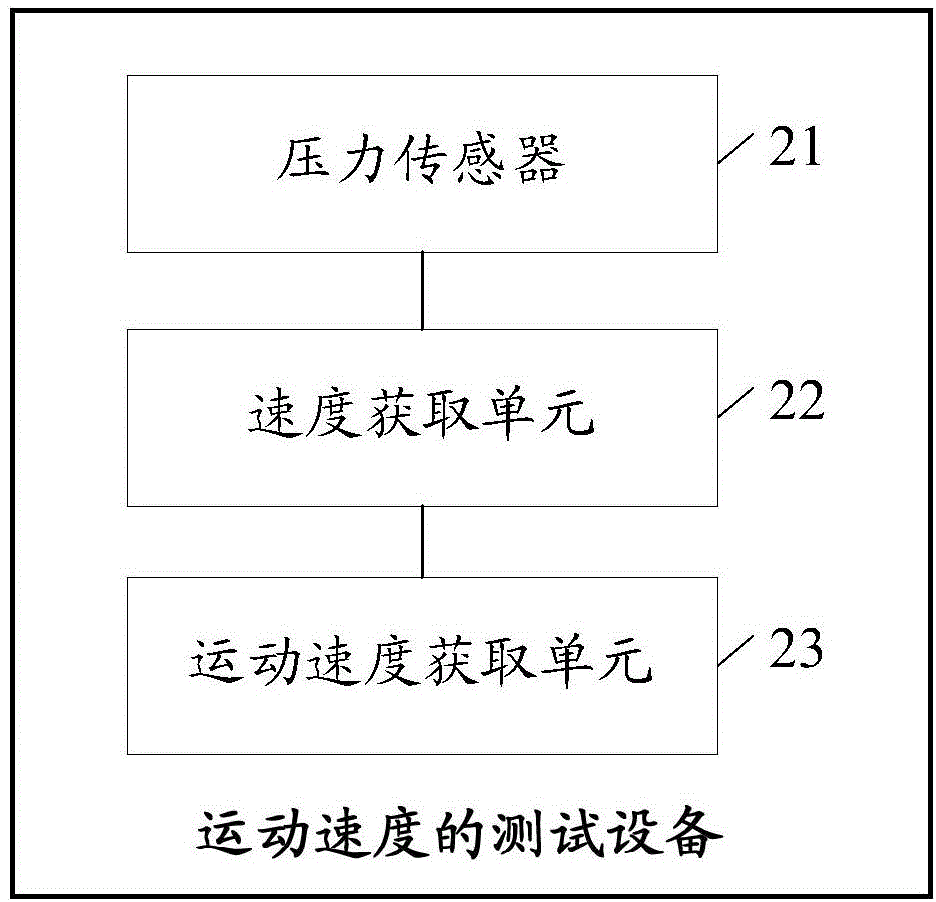

Method and device for testing movement speed

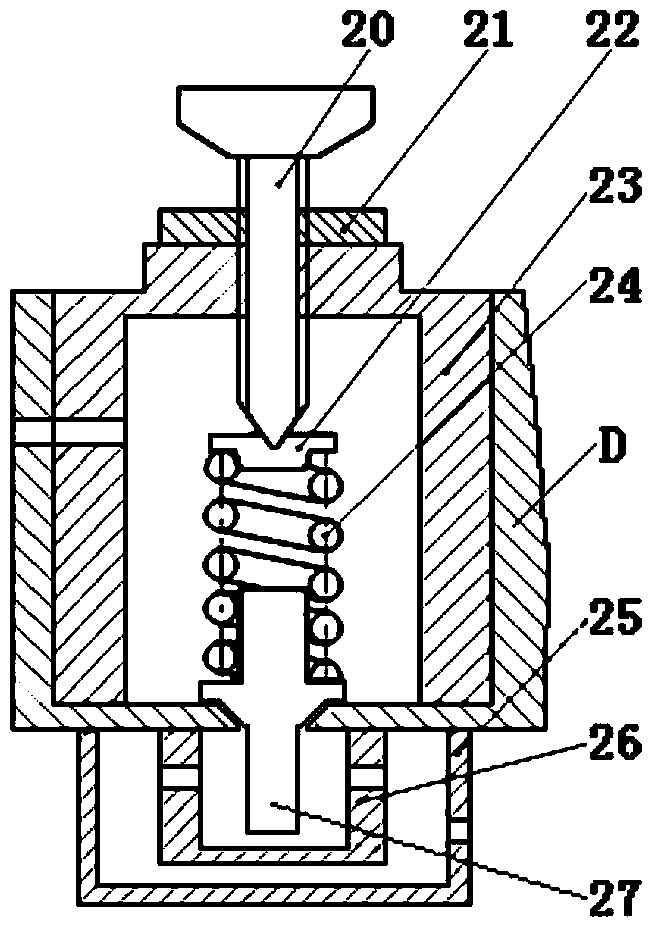

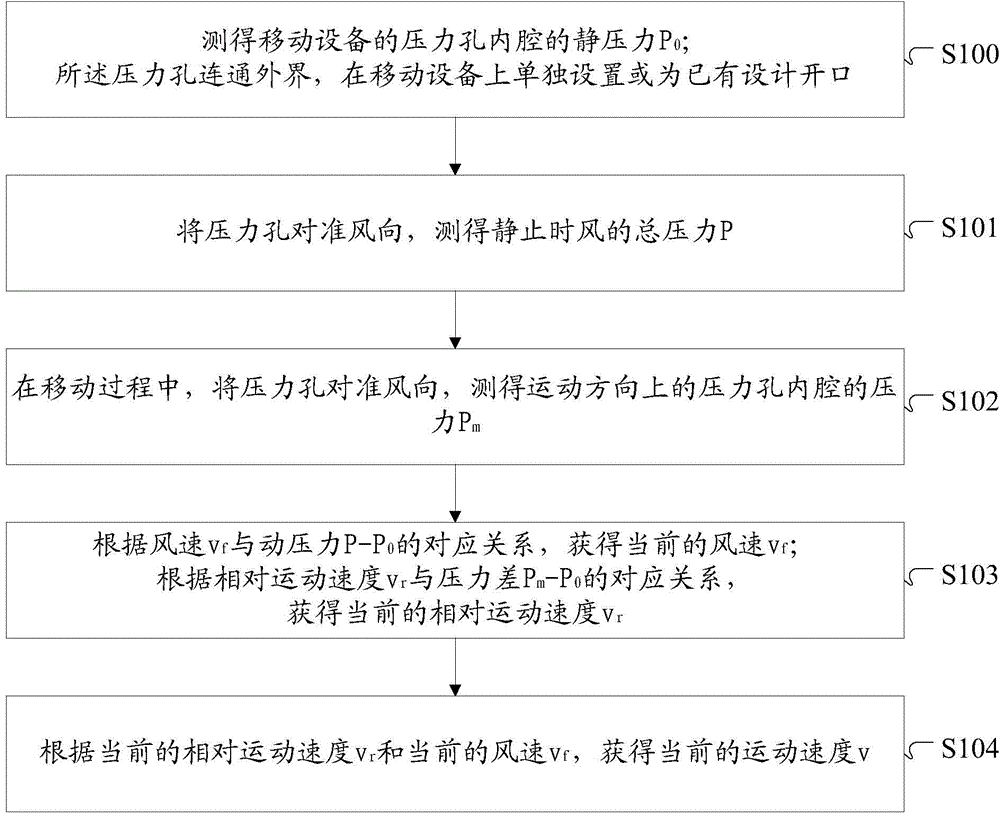

ActiveCN104597273AHigh precisionImprove stabilityFluid speed measurement using pressure differenceNavigation by speed/acceleration measurementsEngineeringPressure difference

The invention discloses a method and device for testing movement speed. The method includes the steps: measuring static pressure P0 of an inner cavity of a pressure hole of a mobile device; individually forming an opening or a designed opening in the mobile device; aligning the pressure hole to the wind direction, and measuring total pressure P of wind in the static state; aligning the pressure hole to the wind direction in the moving process, and measuring the pressure Pm of the inner cavity of the pressure hole in the movement direction; acquiring current wind speed vf according to the corresponding relationship between the wind speed vf and movable pressure P-P0; acquiring current relative movement speed vr according to the corresponding relationship between relative movement speed vr and pressure difference Pm-P0; acquiring current movement speed v according to the current relative movement speed vr and the current wind speed vf. The pressure hole is communicated with the outside. The movement speed can be rapidly acquired, testing results are accurate and reliable, and the technical scheme is completely different from a scheme of testing the movement speed by a GPS (global positioning system) in the prior art.

Owner:GOERTEK MICROELECTRONICS CO LTD

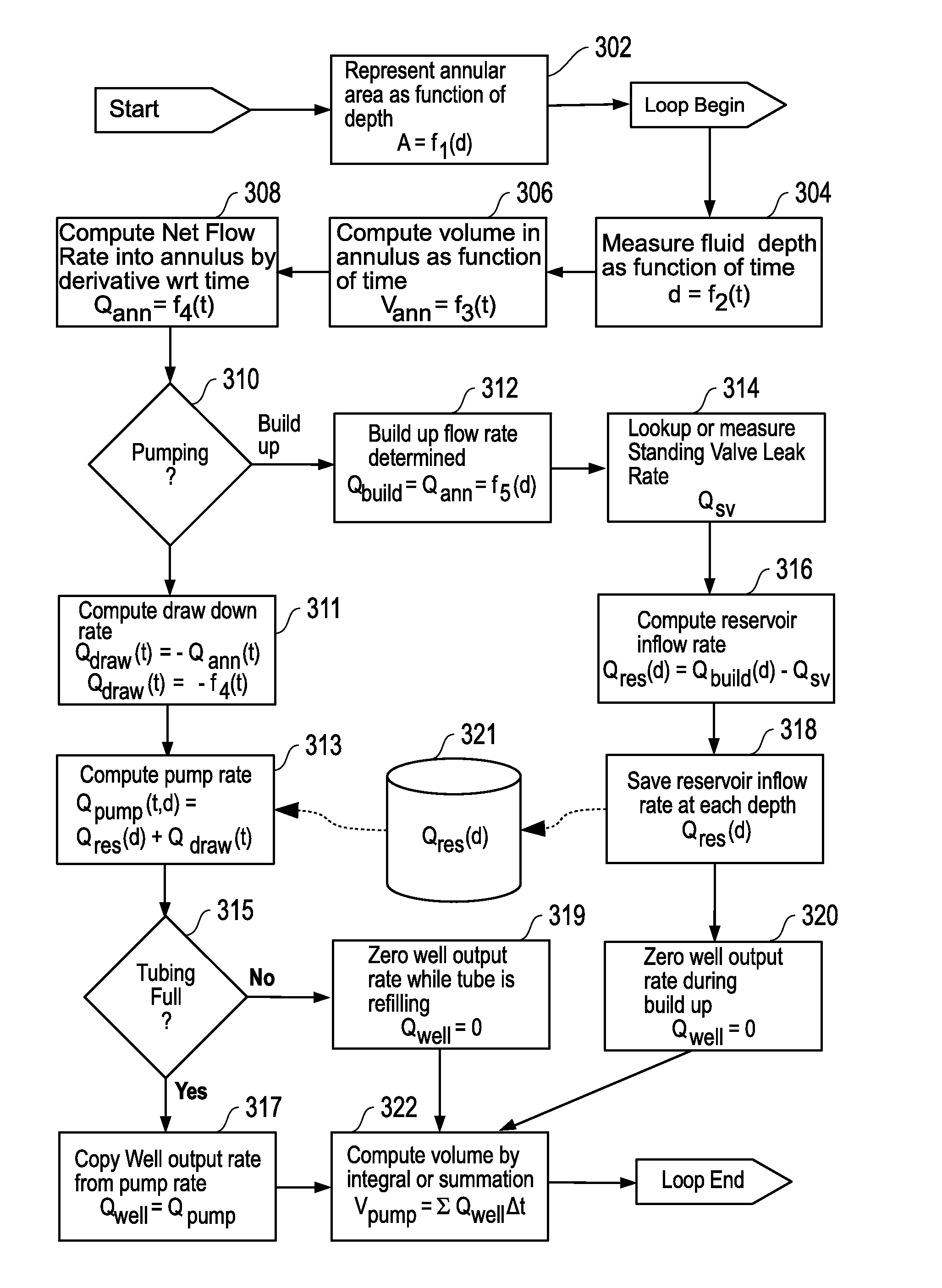

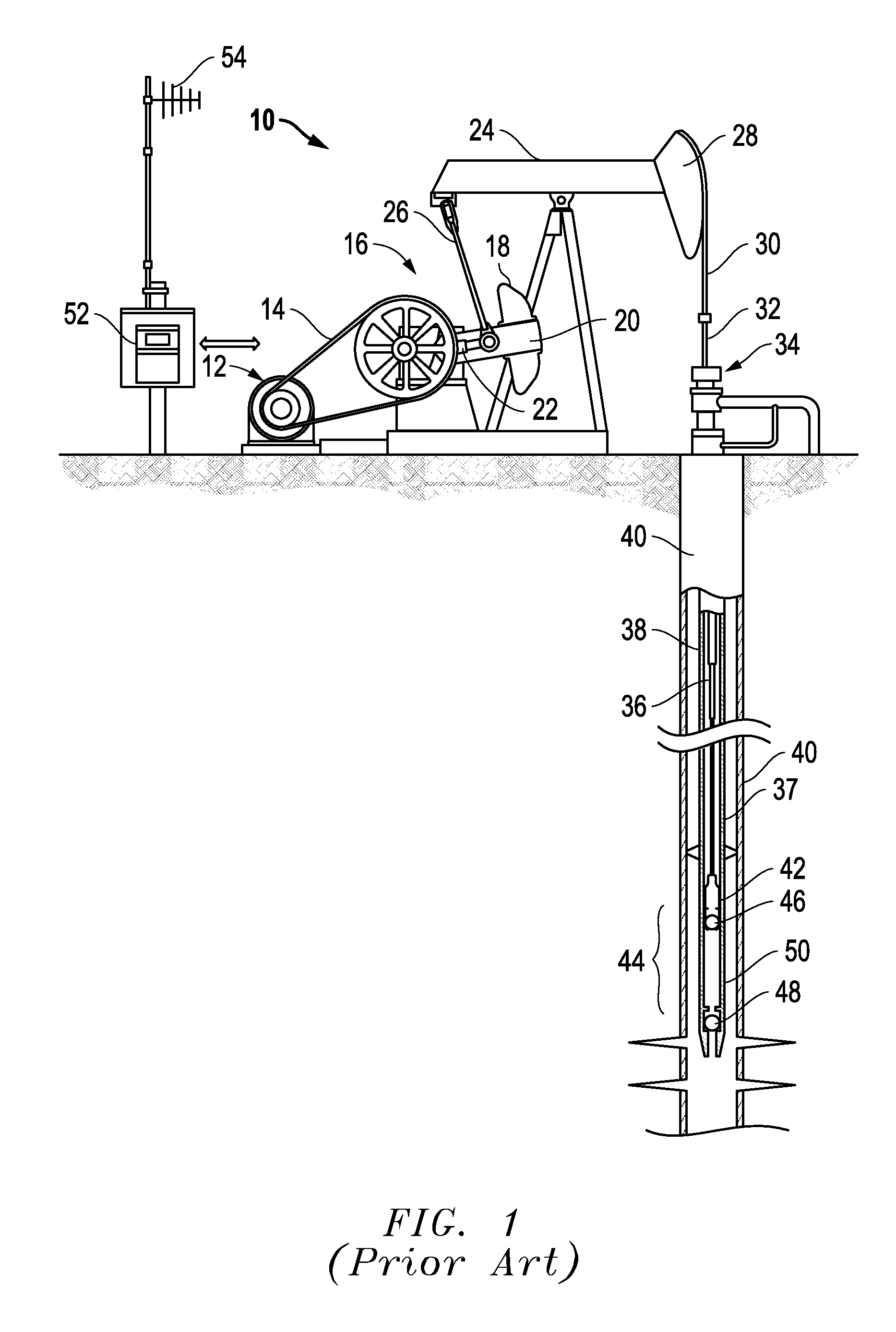

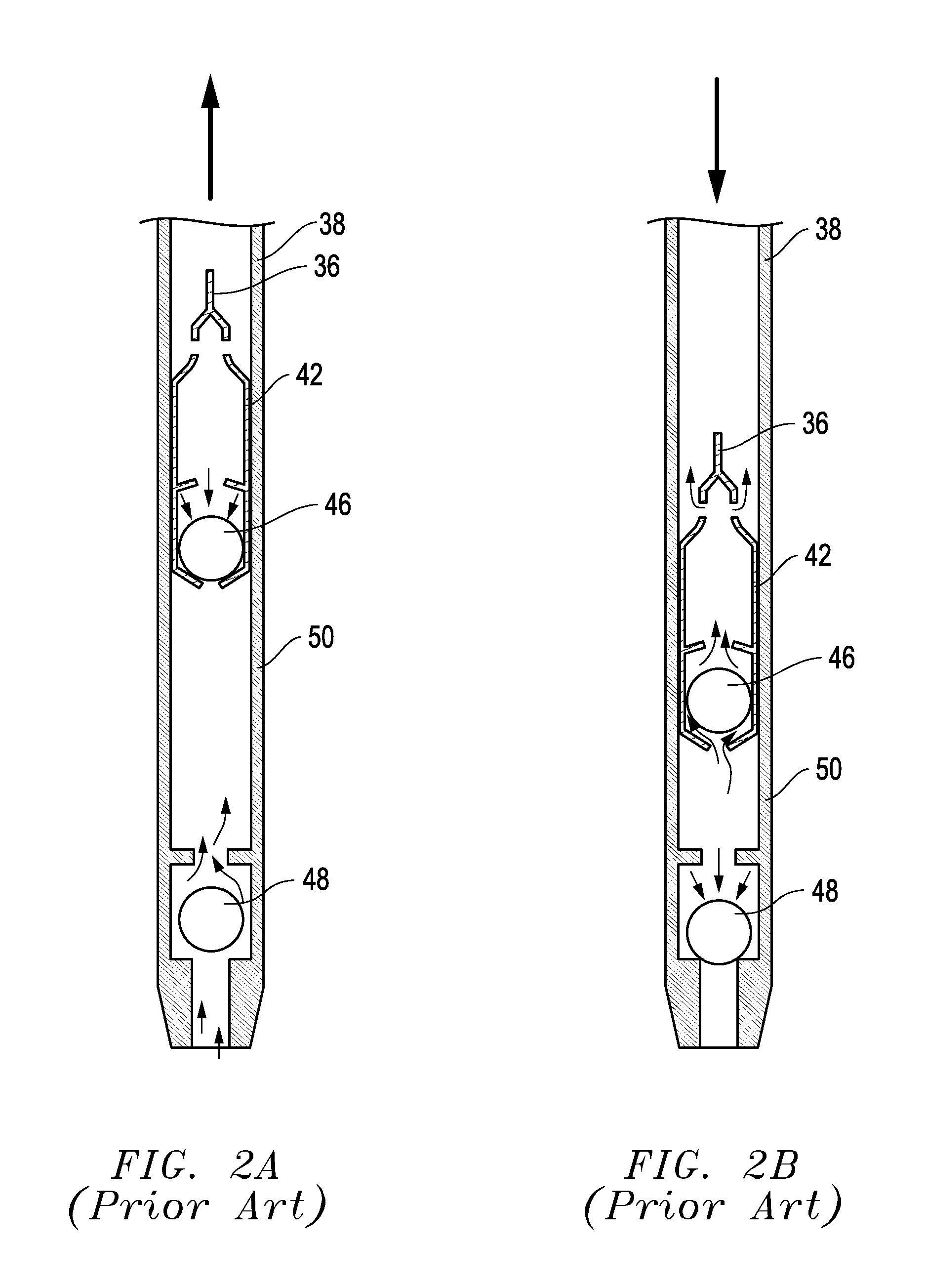

System and Method for Measuring Well Flow Rate

The present invention discloses an improved system for measurement of the liquid flow rate and totalized liquid production of a producing well. In the method of the present invention, liquid production rate in a pumping well is determined by calculation based upon wellbore geometry and continuously monitoring the depth of the fluid level within the wellbore. It is applicable to any pump lifted well where it is possible to shut the pump off periodically. Accuracy is enhanced with this method by properly accounting for pump leakage and where pump leakage is either known or can be estimated within reasonable limits or where it is measured during the pump shut off cycle.

Owner:CHEVROU USA INC

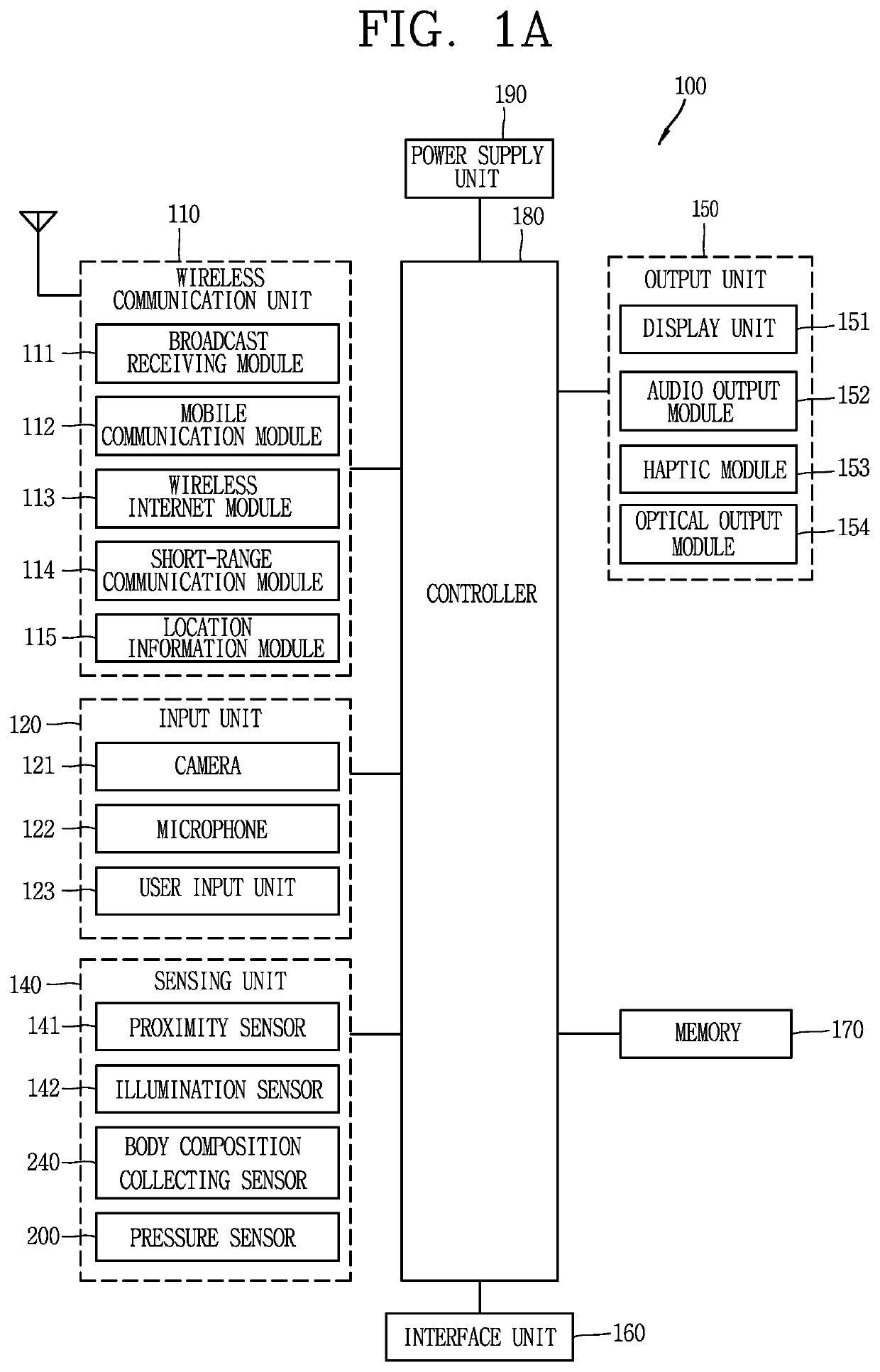

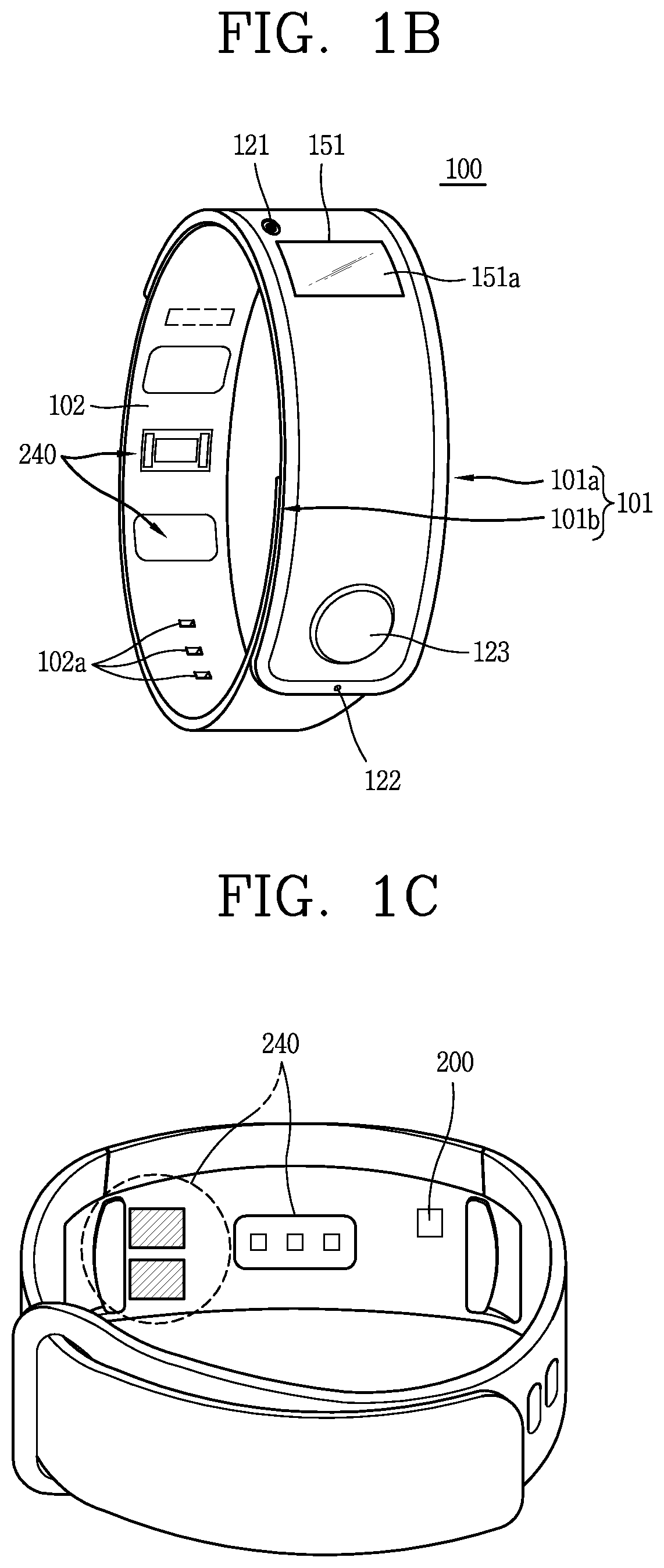

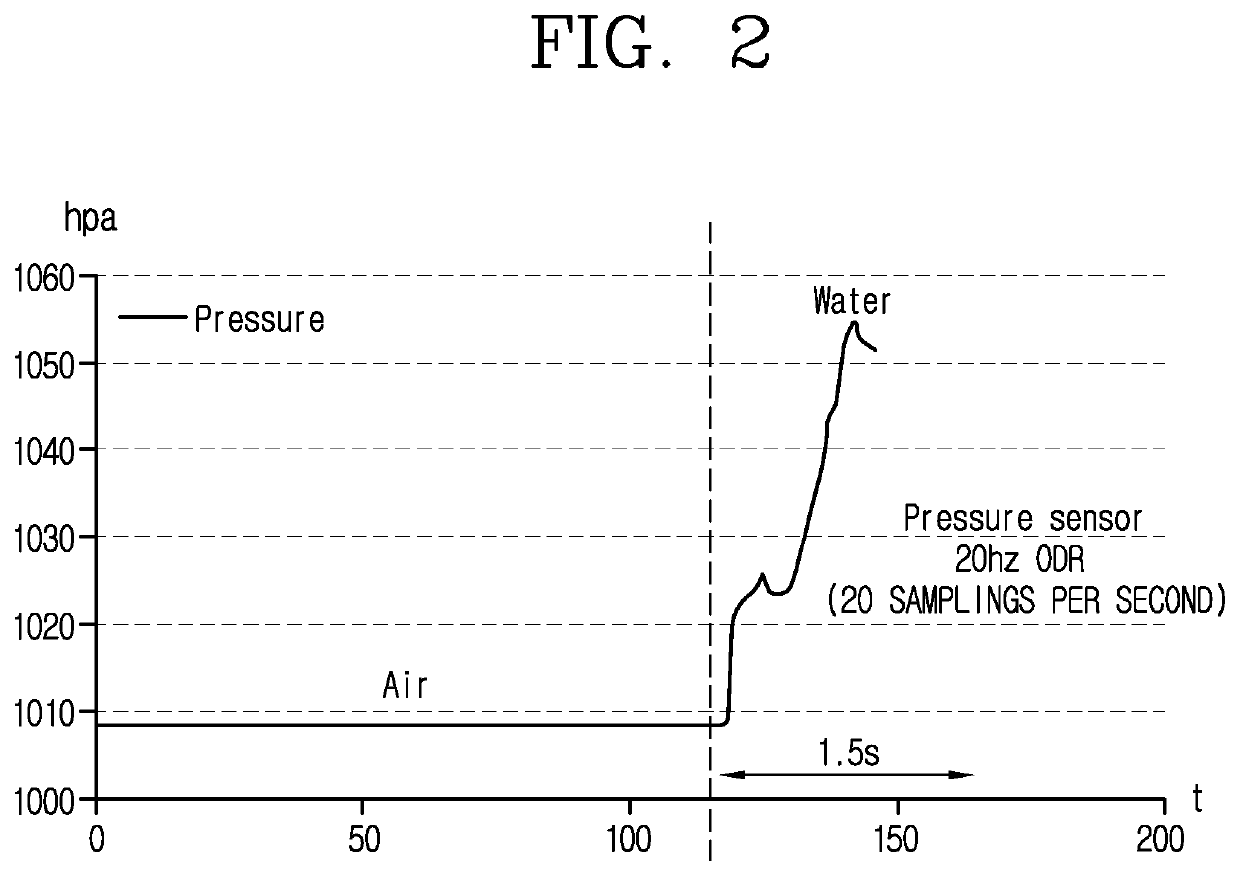

Watch-type terminal

InactiveUS20200064781A1Appropriate performanceAccurate pressure detectionMechanical clocksVisual indicationsEngineeringControl theory

Provided is a watch-type terminal comprising: a main body which can be mounted on an area of a human body; a pressure sensor which is mounted on an area of the main body in an on-land mode and detects an external pressure change; and a control unit which switches the on-land mode to an underwater mode and controls the execution of a particular function, in case the pressure change is greater than or equal to a preset reference change amount.

Owner:LG ELECTRONICS INC

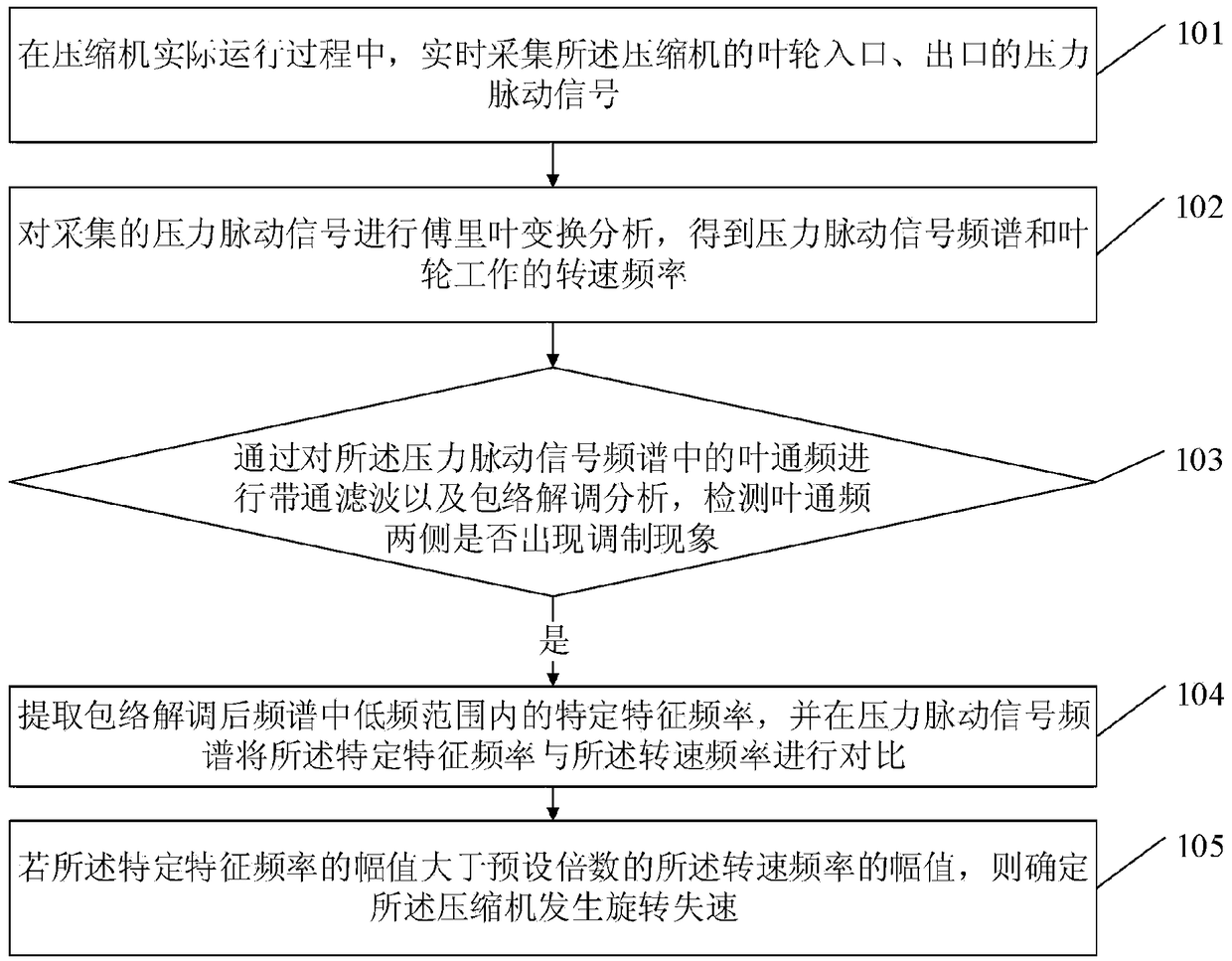

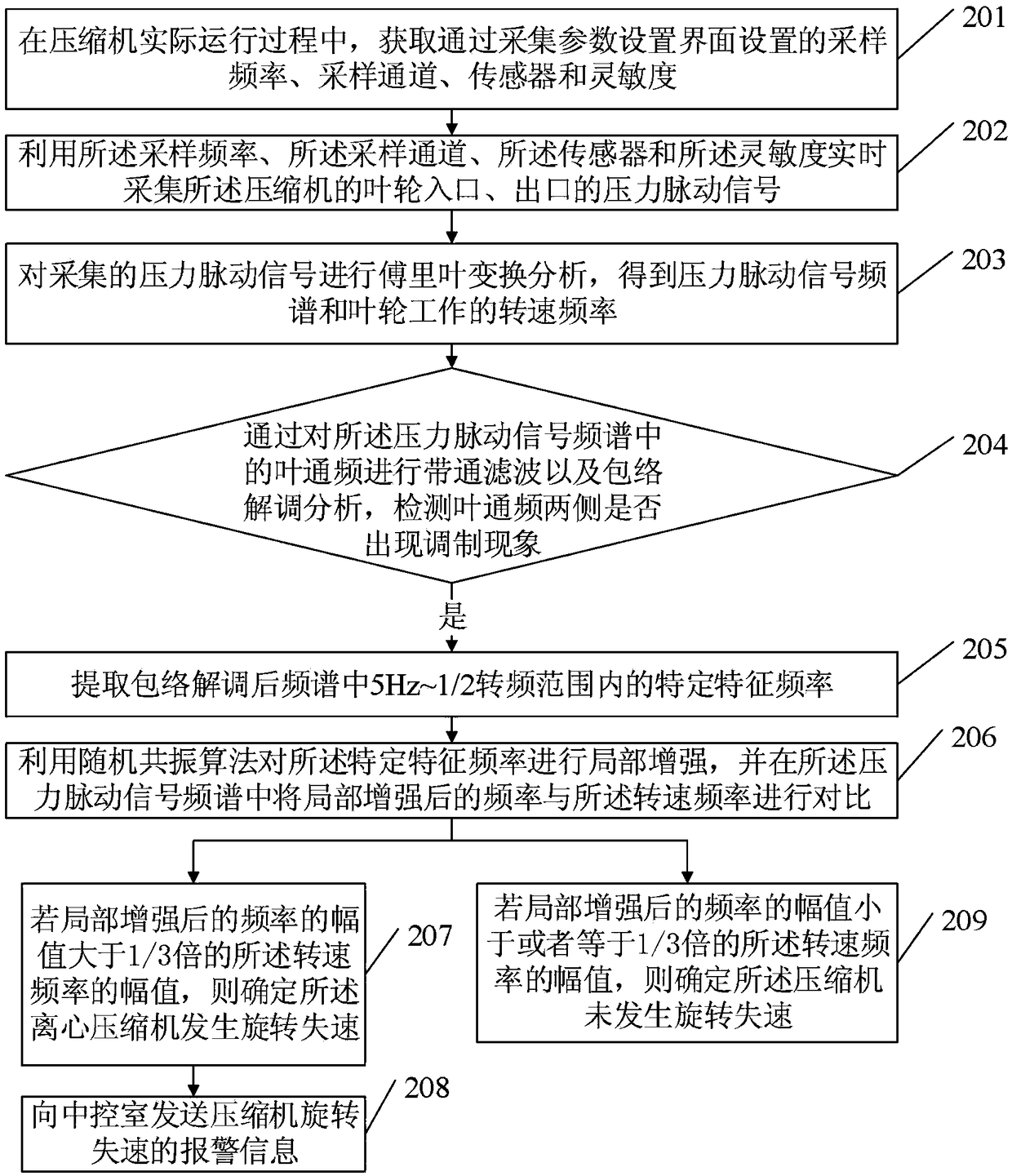

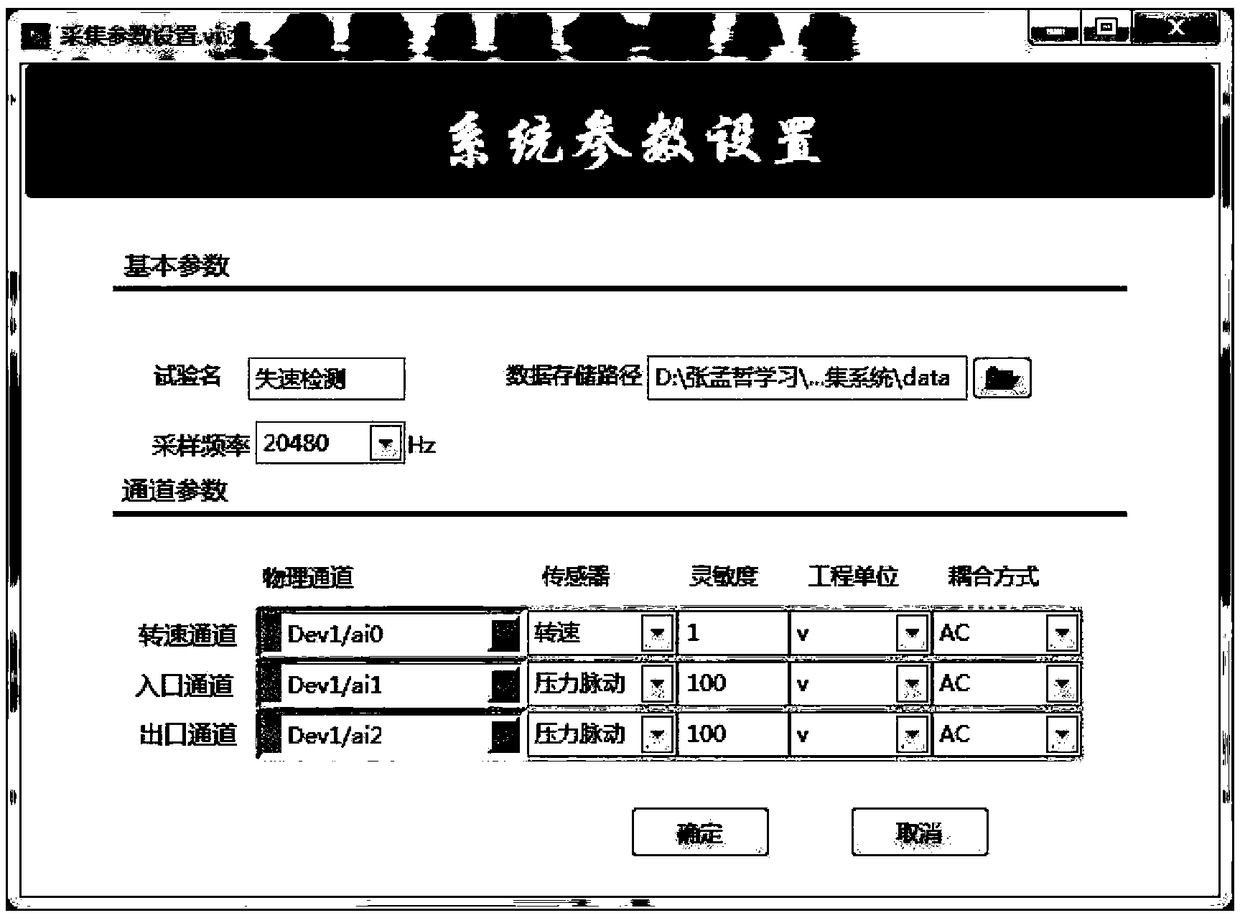

Monitoring method and device for rotating stall of compressor

ActiveCN109030849ASpinning Stall MonitoringSpinning stall is accurate and efficientPump controlDevices using fluidsImpellerFrequency spectrum

The invention discloses a monitoring method and device for rotating stall of a compressor and relates to the technical field of equipment fault diagnosis. The main purpose is to accurately and effectively monitor the rotating stall of the compressor based on a pressure pulsation signal during the actual operation of the compressor. The method comprises the following steps: collecting pressure pulsation signals of an impeller inlet and outlet of the compressor in real time during the actual operation of the compressor; performing Fourier transform analysis, band-pass filtering and envelope demodulation analysis on the collected pressure pulsation signals, and detecting whether a modulation phenomenon appears on both sides of the leaf band frequency; if yes, extracting a specific characteristic frequency in a low frequency range of the frequency spectrum after envelope demodulation, and comparing the specific characteristic frequency with the rotating speed frequency at which the impeller works in the pressure pulsation signal spectrum; if the magnitude of the specific characteristic frequency is greater than the magnitude of the rotating speed frequency of a predetermined multiple,determining that the rotating stall happens to the compressor. The monitoring method and device for rotating stall of the compressor in the invention are suitable for monitoring the rotating stall ofthe compressor.

Owner:大连透平机械技术发展有限公司

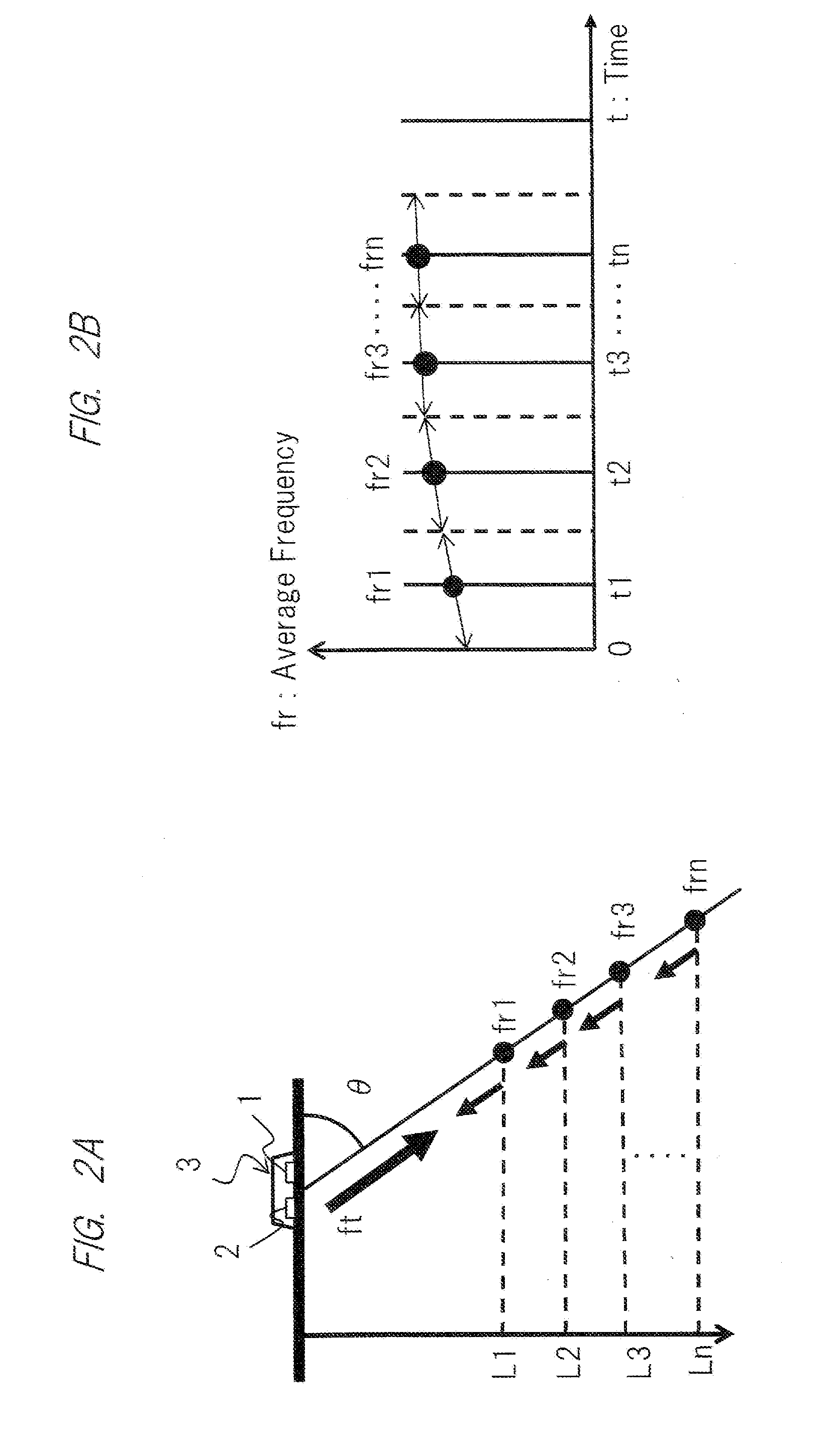

Ship speed meter and ship speed measurement method

ActiveUS20150025834A1Accurate acquisitionAccurate speedNavigational aid arrangementsDigital computer detailsCurrent velocityArithmetic processing unit

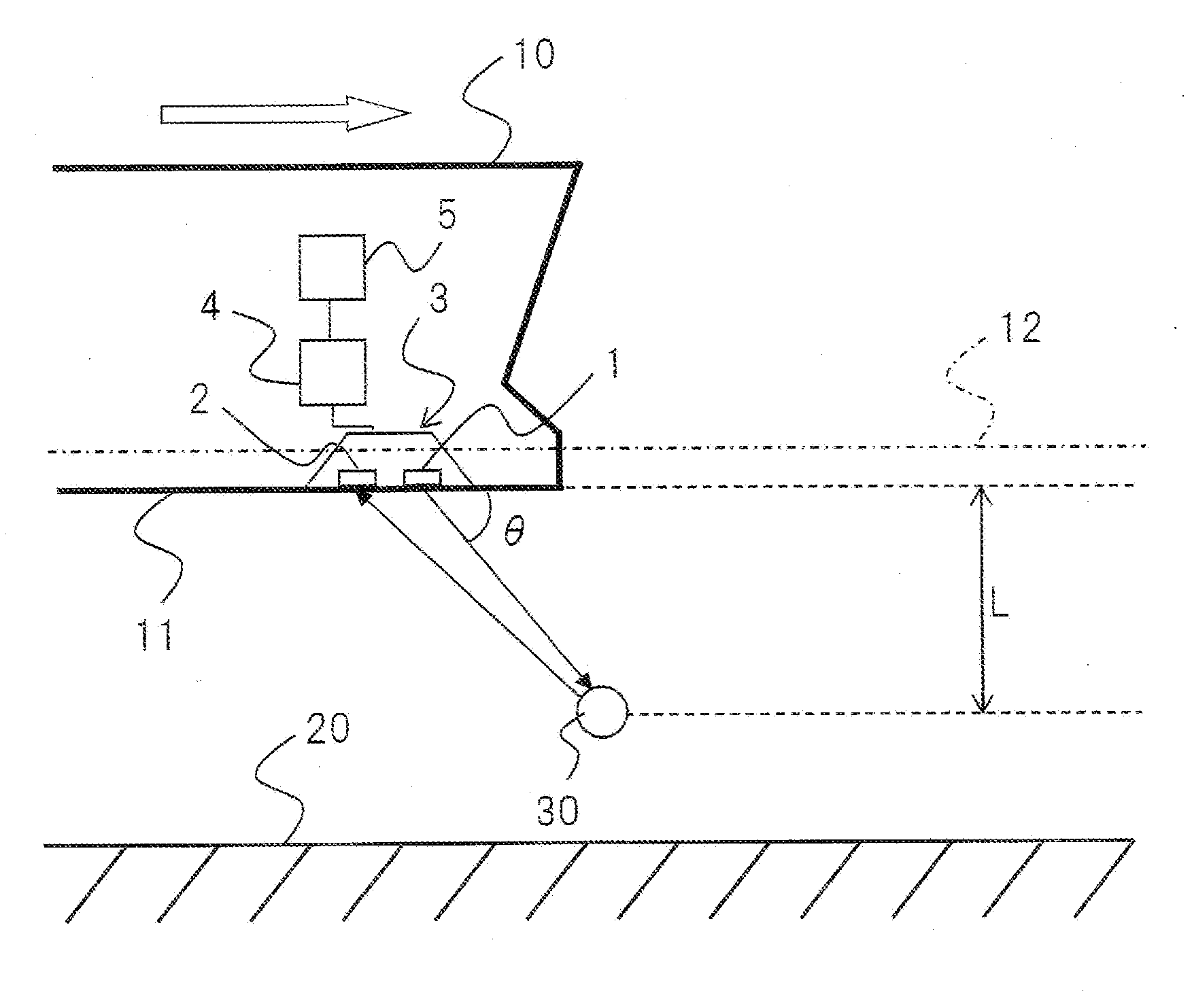

A ship's speed meter for measuring a speed relative to the water of a ship 10, the ship's speed meter including a wave transmitter 1 for emitting a sound wave toward a sea bottom 20, a wave receiver 2 for detecting a plurality of reflected waves, which are reflected waves of the sound wave having been emitted from the wave transmitter 1, reflected by a plurality of reflecting objects 30 positioned at different water depths, and an arithmetic processing unit 4 for calculating a ship's speed relative to the water of the ship 10 based on a frequency difference of the sound wave and the reflected wave. The arithmetic processing unit 4 obtains a change rate of a current velocity in a water depth direction by obtaining current velocities at a plurality of different water depths based on a frequency difference between the sound wave and the plurality of reflected waves, and calculates a current velocity at a water depth at which the change rate is smaller than or equal to a threshold value as the ship's speed relative to the water of the ship 10.

Owner:NIPPON YOOSEN KABUSHIKI KAISHA

Method and device for measuring acceleration and/or inclination by using thermal convection of a fluid

InactiveUS7562574B2Simple structureSimple manufacturing processAcceleration measurement using interia forcesTesting/calibration of speed/acceleration/shock measurement devicesElectricityEngineering

Owner:LEE JEUNG WOO

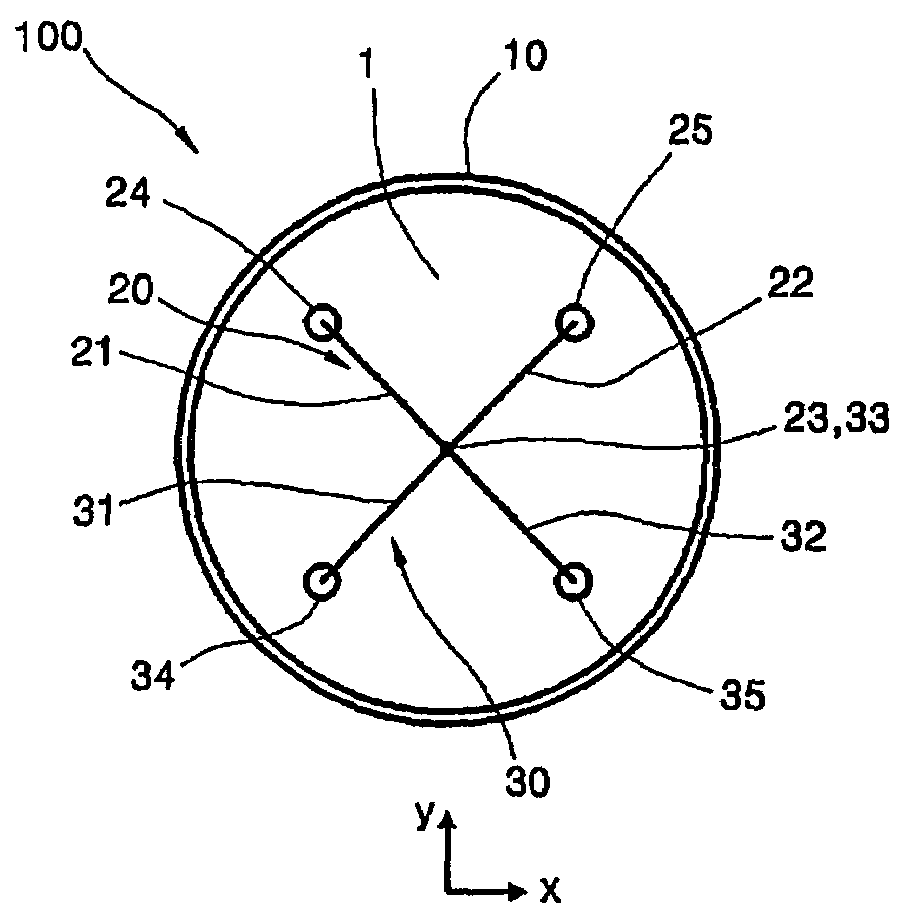

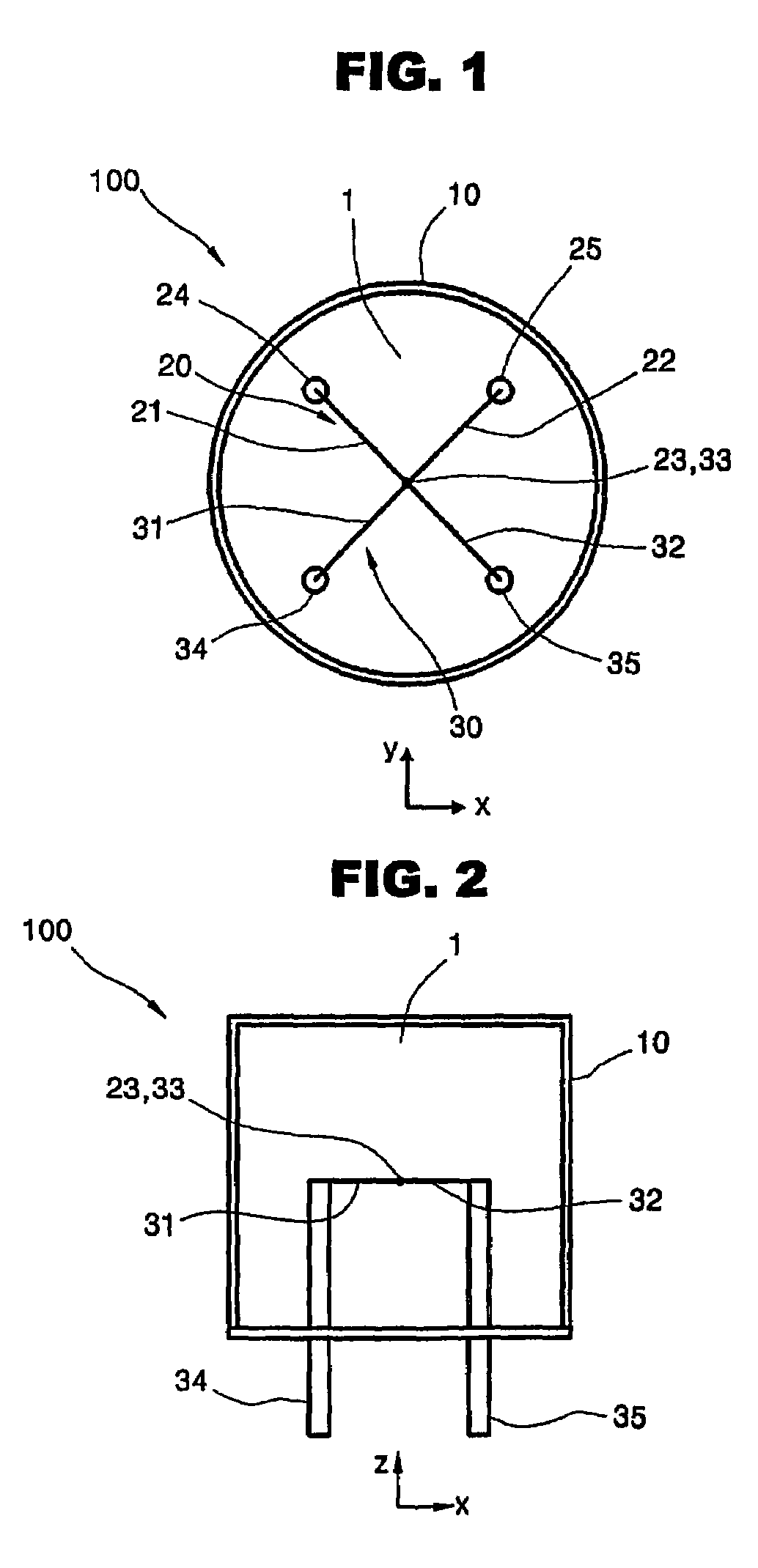

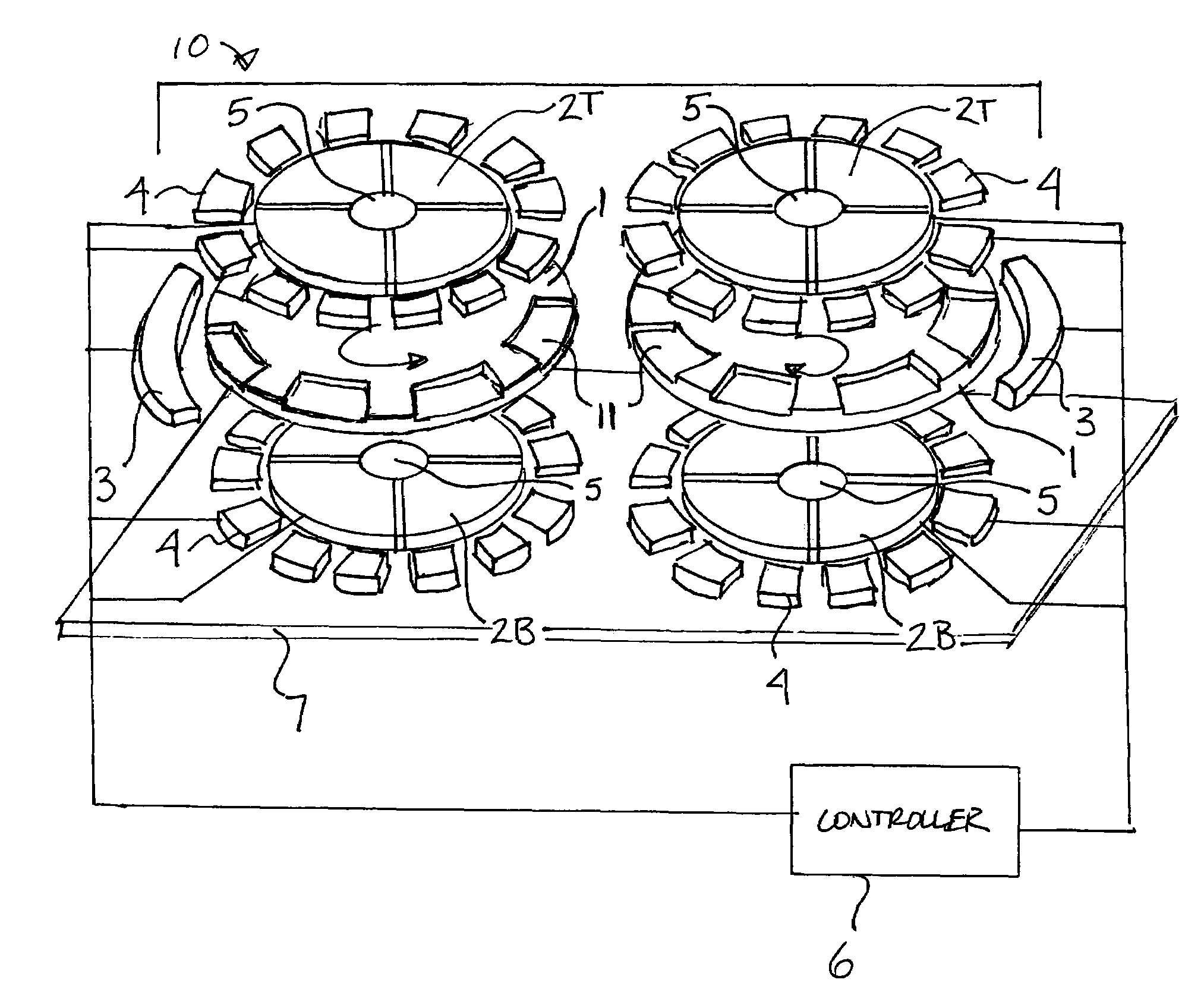

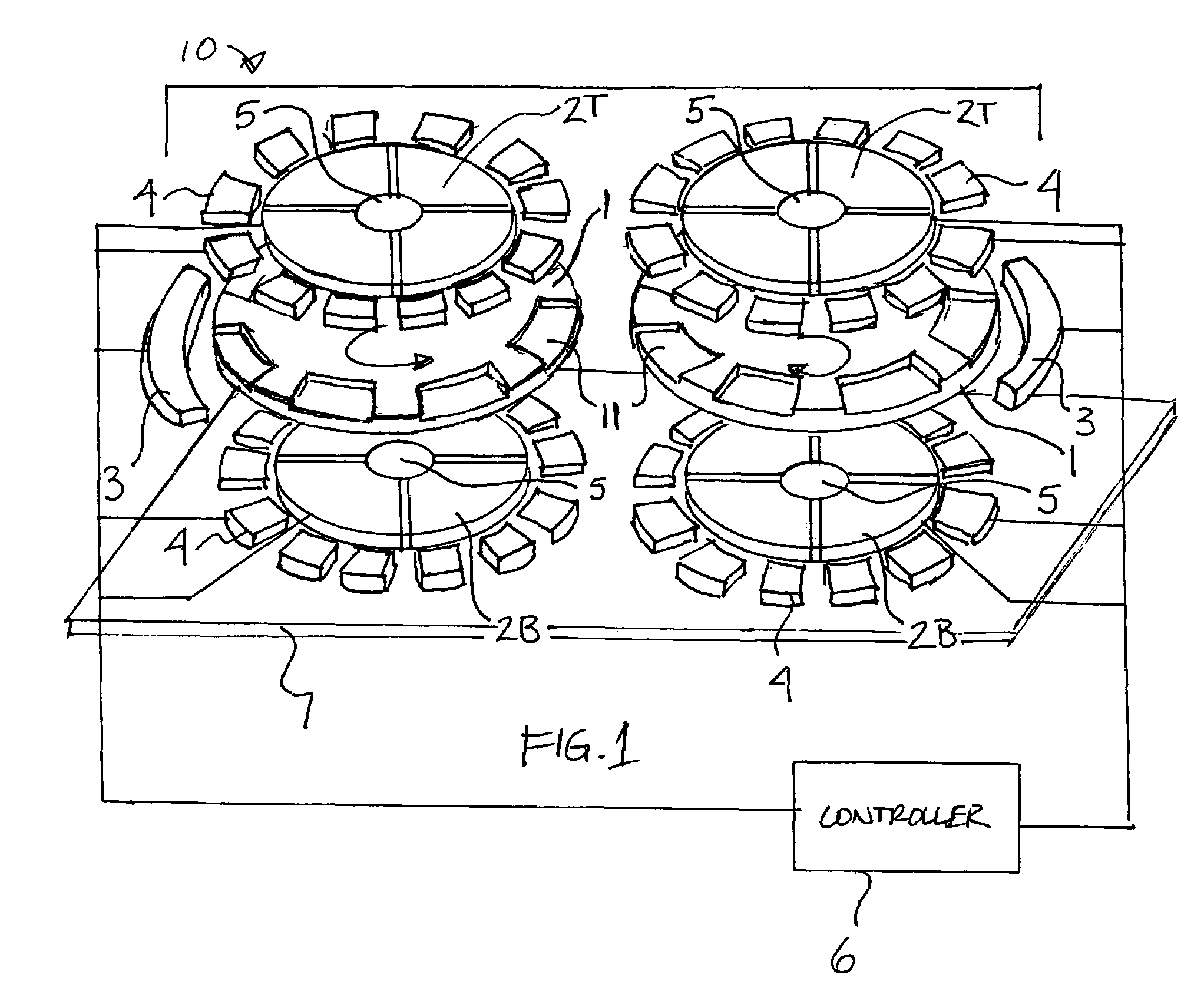

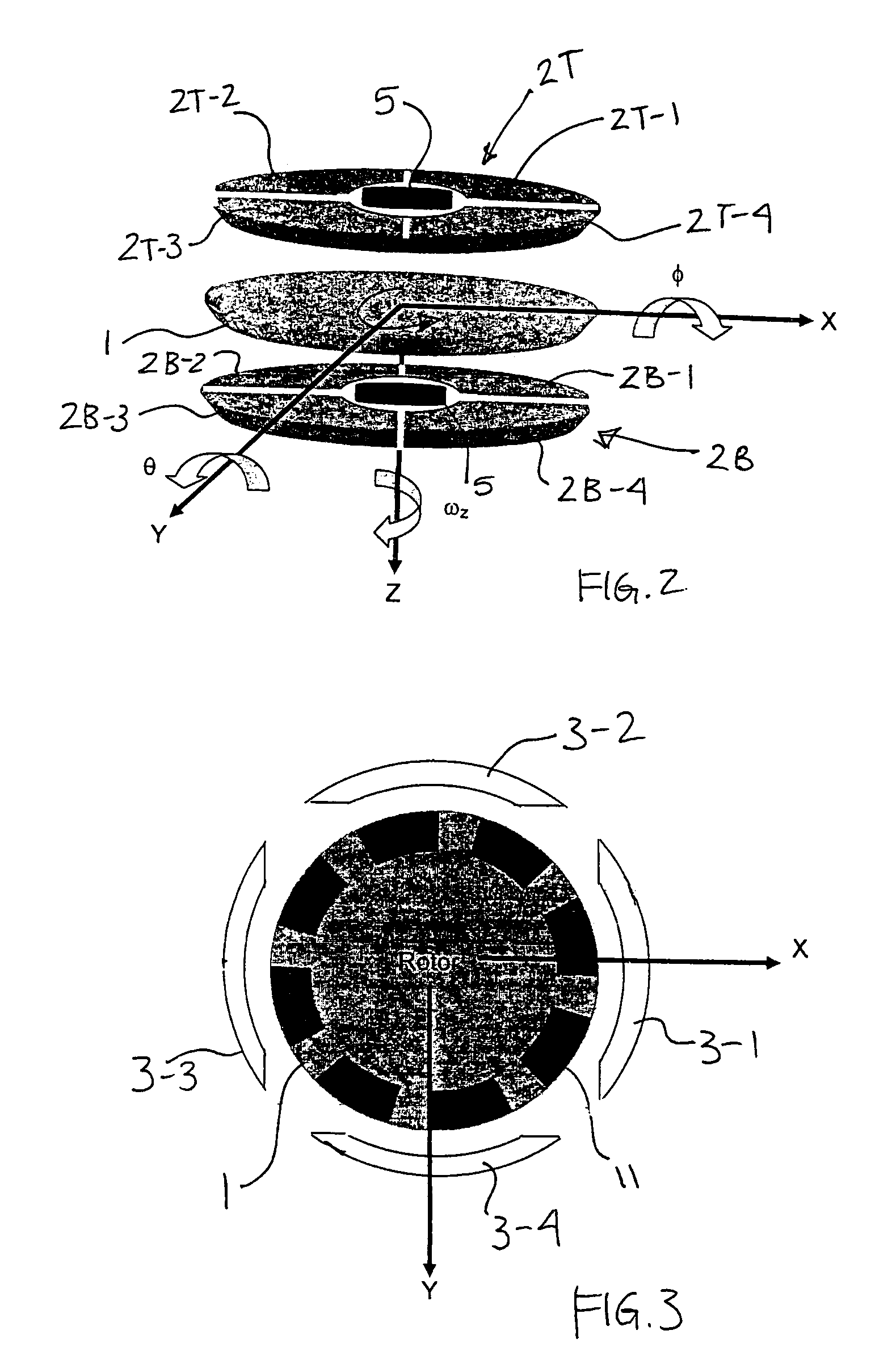

Motion sensor and method for detecting motion

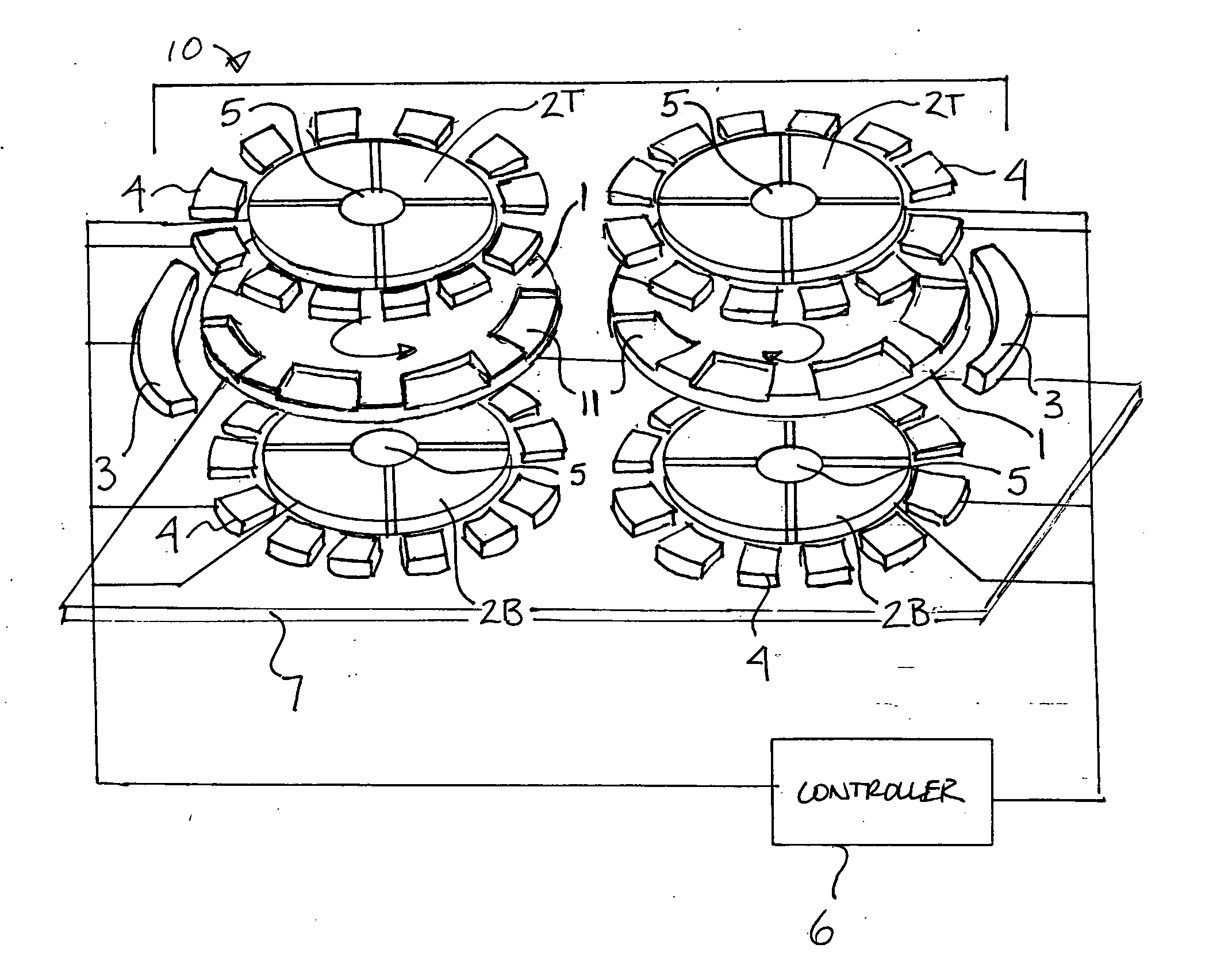

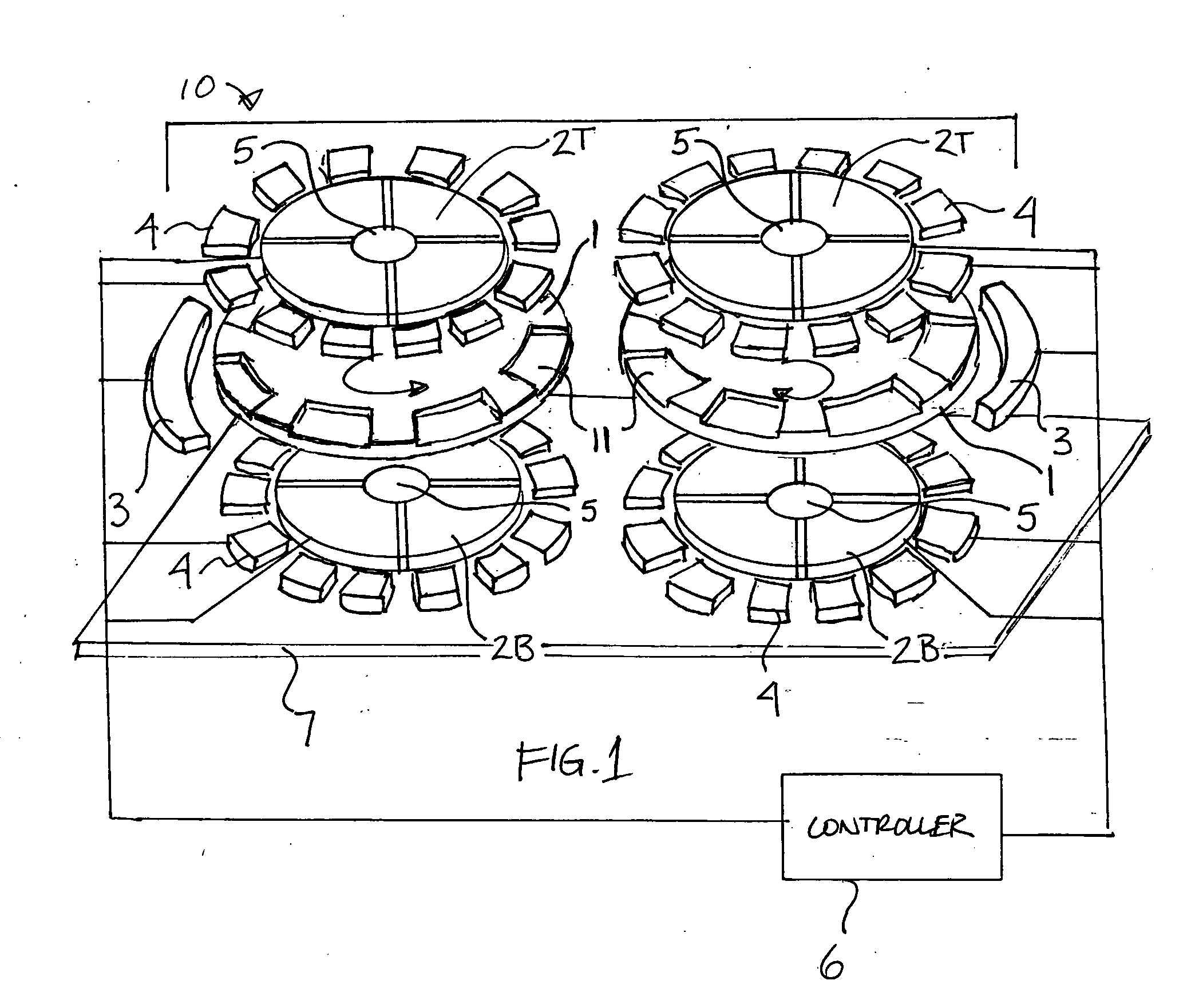

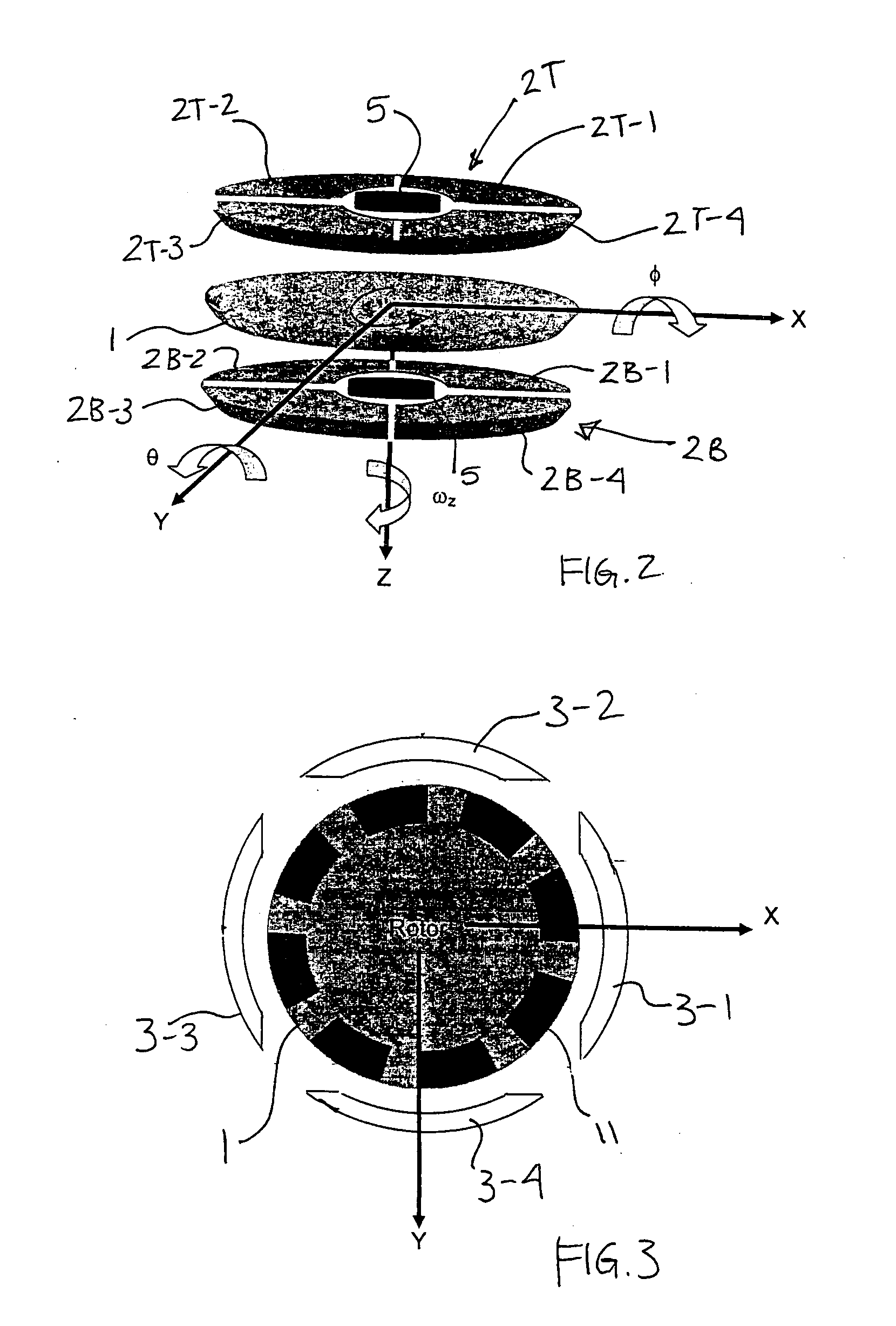

ActiveUS7426859B2Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular accelerationReference structure

A motion sensor may detect linear and / or angular acceleration and / or angular velocity of a body relative to one axis, two orthogonal axes or three orthogonal axes. Movement of the body or reference structure may be detected relative to one or more spinning rotors. The rotor(s) may be suspended for rotation and / or other movement relative to the reference structure without physical contacting the reference structure. In one embodiment, the rotor(s) may be electrostatically suspended in such a way that movement of the rotor(s) relative to the reference structure may be detected.

Owner:ARCHANGEL SYST

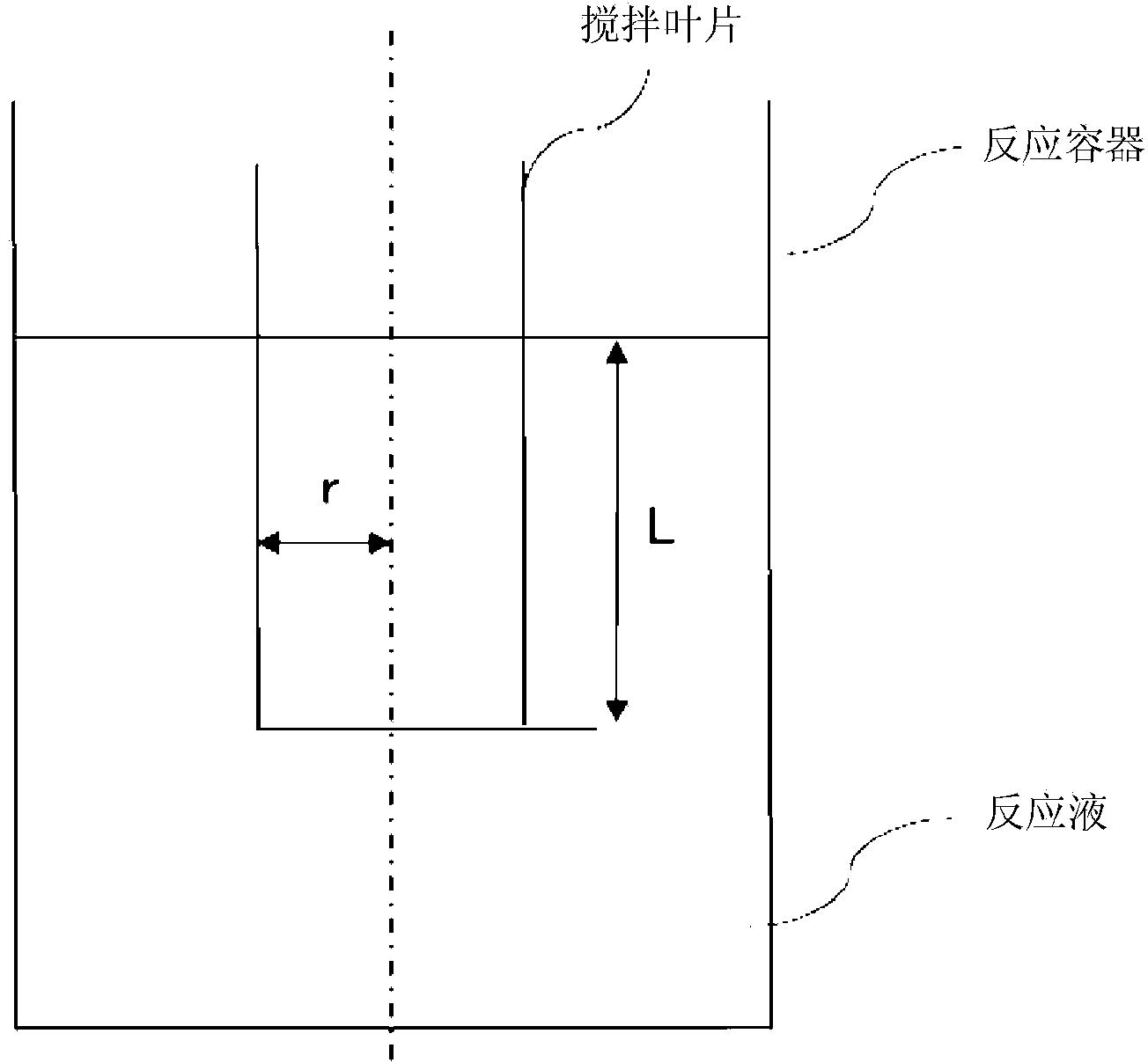

Reaction solution viscosity detection method, reaction solution viscosity detection device, method for obtaining reaction product, and manufacturing device for obtaining reaction product

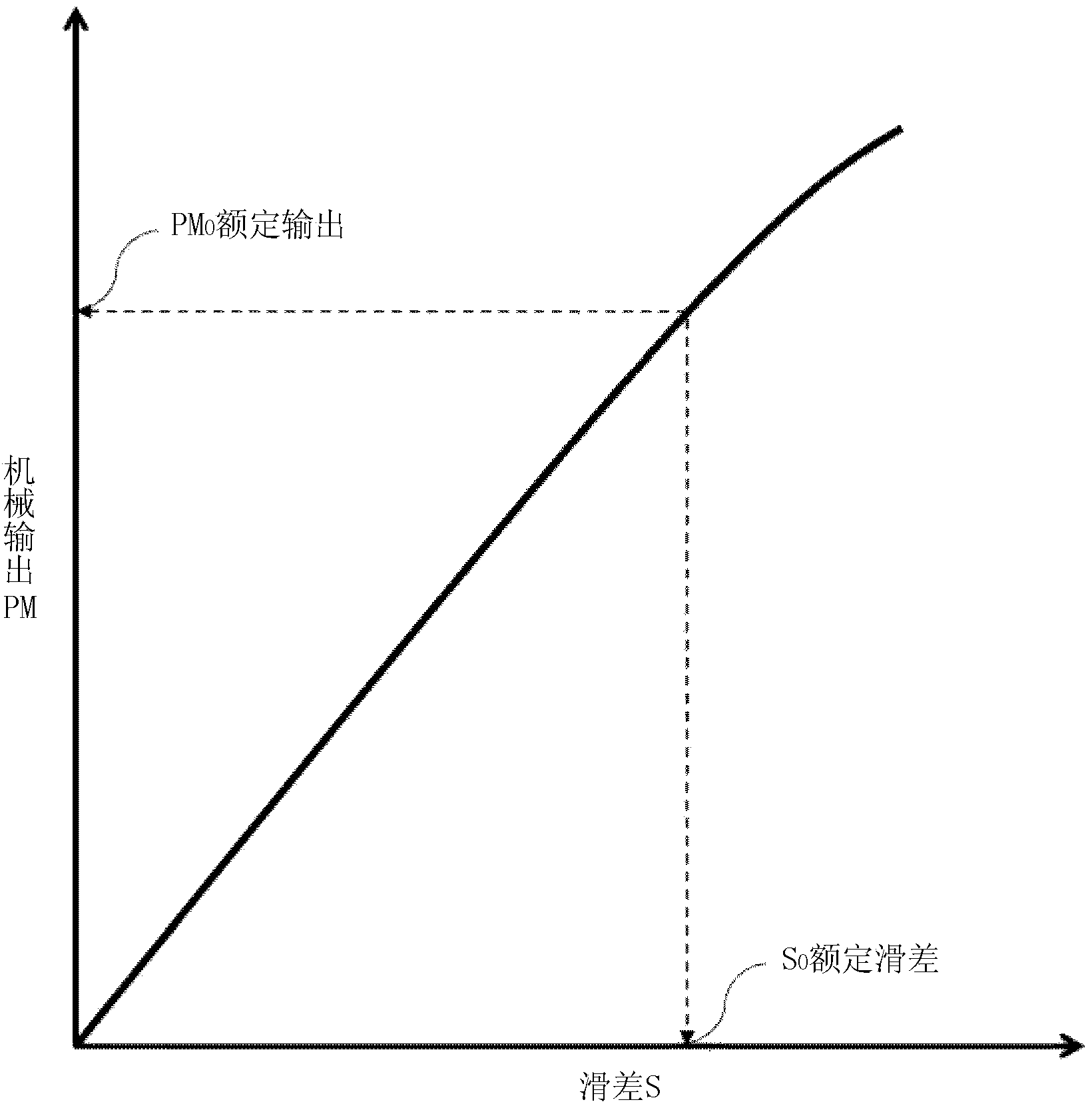

InactiveCN103430006ALow costReduce total timeFlow propertiesApparatus for force/torque/work measurementInduction motorProcess engineering

The present invention relates to a reaction product viscosity detection method having a viscosity detection process including a rotation speed detection process and other processes. The rotation speed detection process is a process for detecting the rotation speed of an induction motor in which the power loss (PL) occurring when power (P) is supplied consists of a power loss (A) and a power loss (B) and includes: a step (?) in which the difference between the power (P) and the power loss (A) is assumed to be a first-order approximation value (PM1) of the mechanical output of the induction motor and a first-order approximation value of the rotation speed given by the equation N1 = NS(1 - S1) is obtained from the relationship between the output (PM1) of the induction motor and slip (S1) given by the equation PM1 = ?S1; a step (??) in which the power loss (B1) is obtained based on the first-order approximation value (N1); and a step (???) in which a second-order approximation value (PM2) is assumed to be given by the equation P - (A + B1) and a second-order approximation value given by the equation N2 = NS(1 - S2) is obtained from the relationship between the output (PM2) and slip (S2) given by the equation PM2 = ?S2.

Owner:DIC CORP

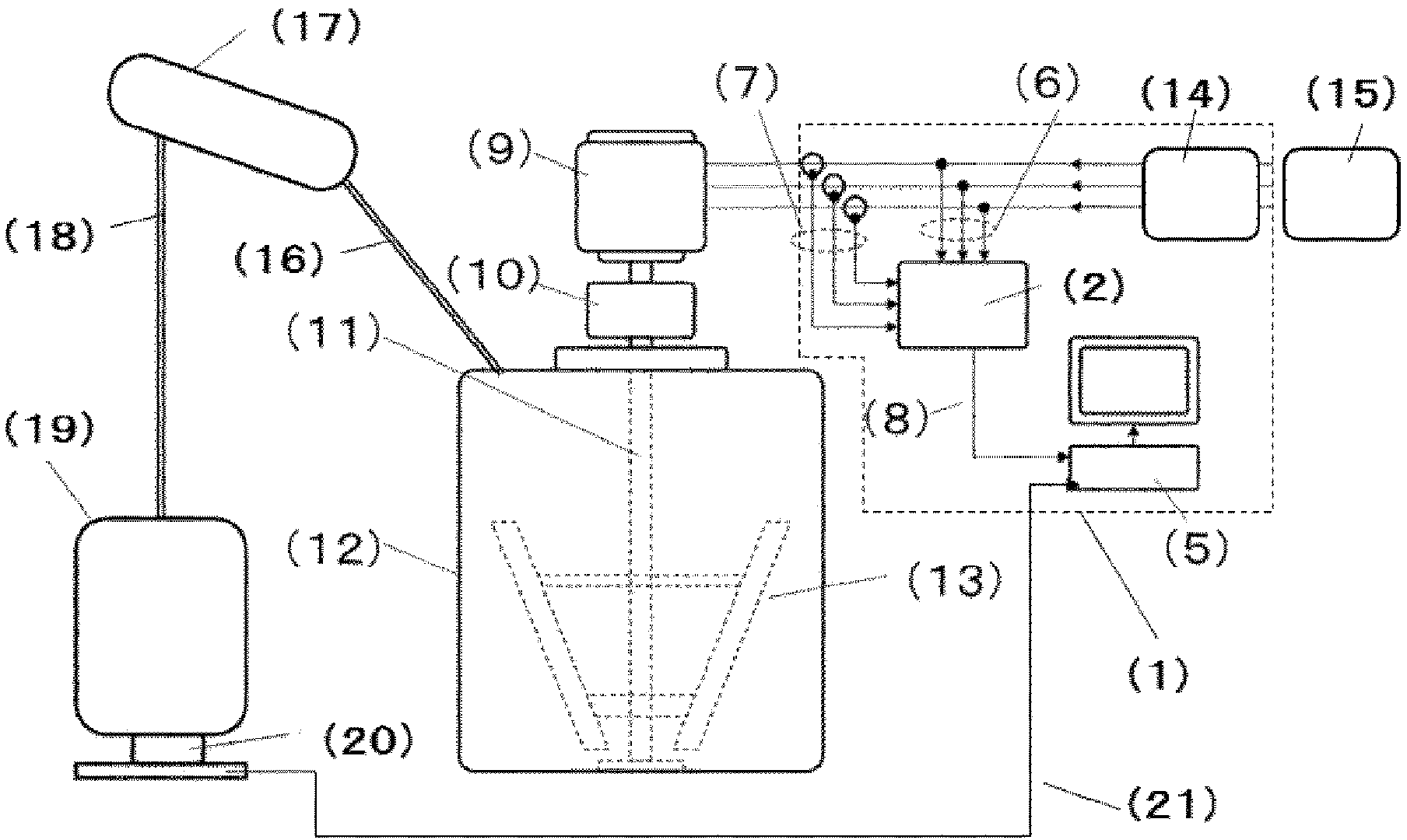

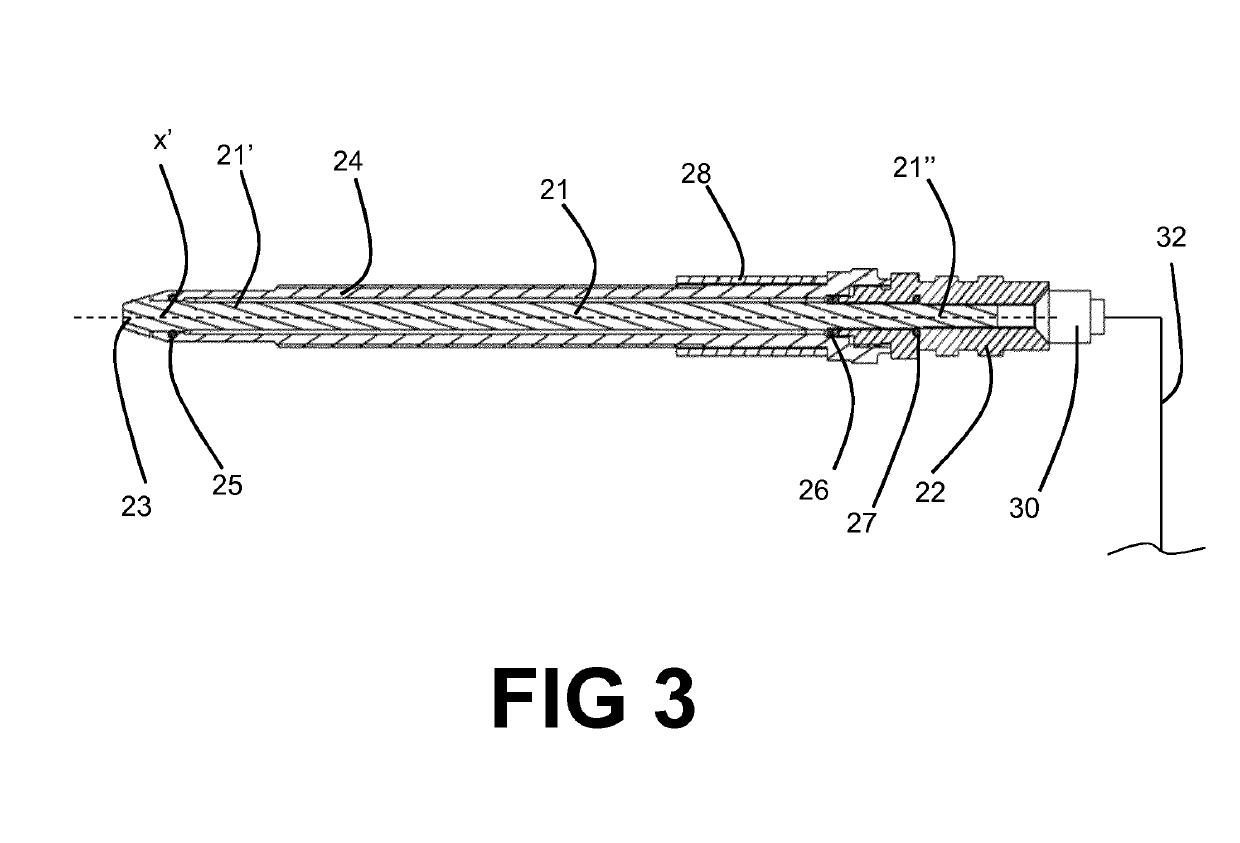

Centrifugal separator with a sensor device

ActiveUS20190143342A1Improve reliabilityReduce sensitivityDetection of fluid at leakage pointAcceleration measurement using interia forcesCentrifuge rotorBiomedical engineering

A centrifugal separator has a stationary casing and a centrifuge rotor, which is provided in the stationary casing and arranged to rotate around an axis of rotation at a rotary speed and which includes a plurality of nozzles for discharge of a product from the centrifuge rotor. The centrifugal separator includes a sensor device which includes a transfer element, which has a first part and a second part and which is configured to be mounted in such a way that the first part is located inside the stationary casing and outside the centrifuge rotor and that the second part is located outside the stationary casing. At least the first part of the transfer element has an elongated shape, a receiving head, which includes the first part of the transfer element. The sensor device further includes a sensor element, which is mounted to the second part of transfer element and which is configured to sense vibrations and / or shock pulses propagating from the receiving head to the sensor element, and an evaluation unit, which communicates with the sensor element for transmitting signals from the sensor element to the evaluation unit. The transfer element is mounted in the stationary casing, directed such that the end face of the receiving head faces the passing jets from the nozzles during rotation of the rotor. A centrifugal separator with such a sensor device is also disclosed.

Owner:ALFA LAVAL CORP AB

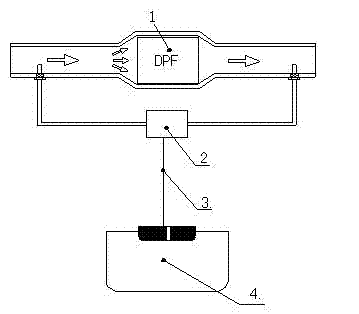

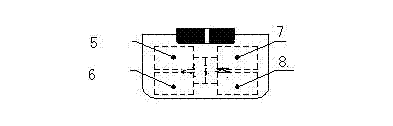

Device and method for measuring rotational speed of engine based on differential pressure signals of exhaust back pressure

The invention discloses a device and a method for measuring rotational speed of an engine based on differential pressure signals of exhaust back pressure. The device provided by the invention comprises a DPF particle collector, exhaust back pressure difference transducers, a signal transmission cable and a controller, wherein the exhaust back pressure difference transducers are arranged at the front end and the rear end of the particle collector and connected with the controller through the signal transmission cable; and a signal conditioning unit, a signal processing unit, a signal analysis unit and a communication unit are sequentially connected and arranged in the controller. The method provided by the invention includes the steps that pressure difference signals are isolated, filtered and amplified through the signal conditioning unit in the controller; then signal voltage is adjusted to the input range allowable for digital processing, and the digital to analog conversion is performed for sample data; Fourier transform (FFT) is performed for the signals, subjected to conversion, through a digital processing unit, and the impulse frequency is converted into the rotational speed value of the engine taking the revolution / minute (RPM) as the unit through the arranged engine stroke and the amount of cylinders; and finally, the rotational speed is output and displayed through the communication unit in the manner of UART or CAN. The device provided by the invention is not directly contacted with the rotating shaft of the engine, has simple structural form and reasonable design, and is convenient to install and debug.

Owner:MILITARY TRANSPORTATION UNIV PLA

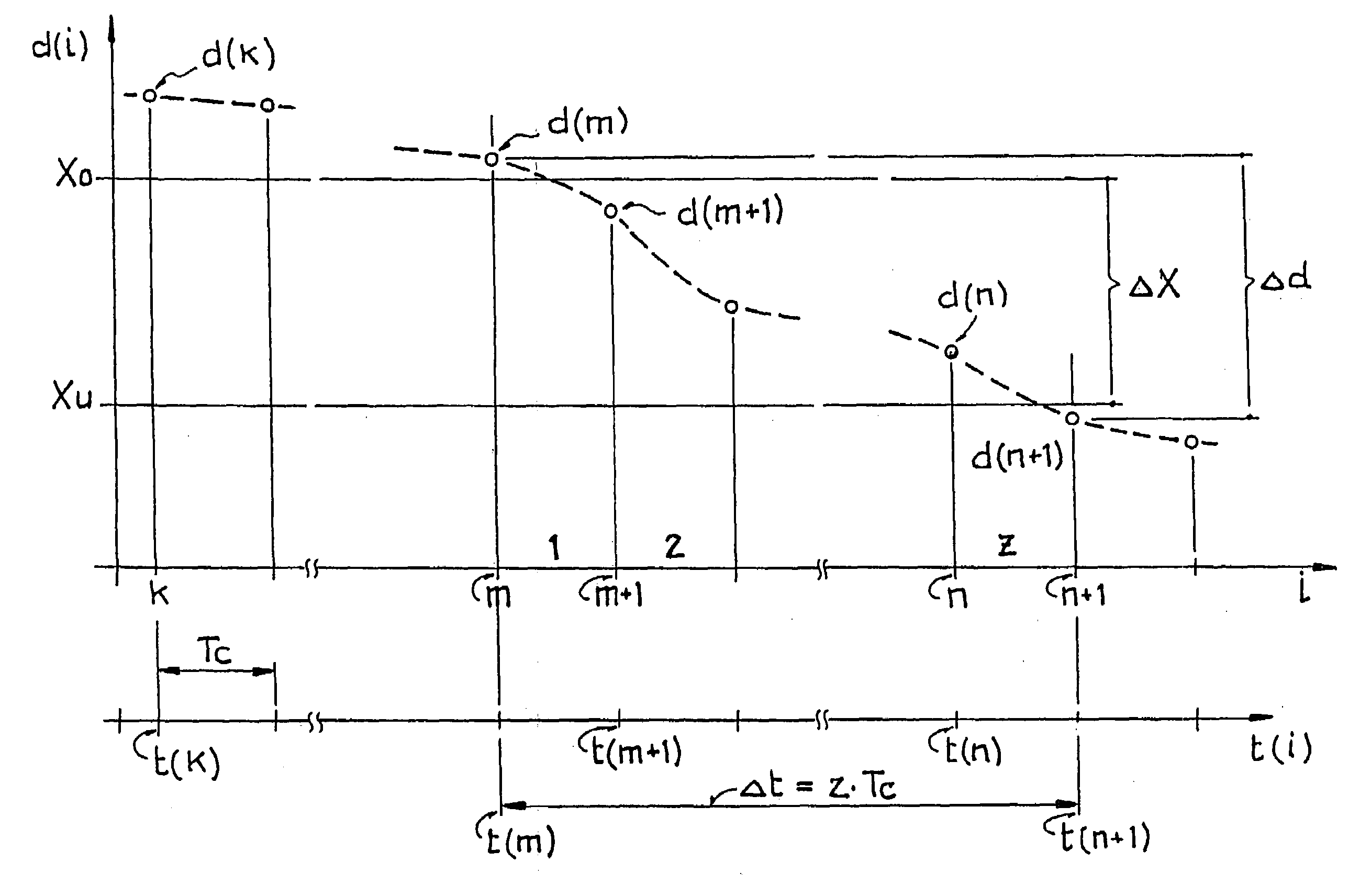

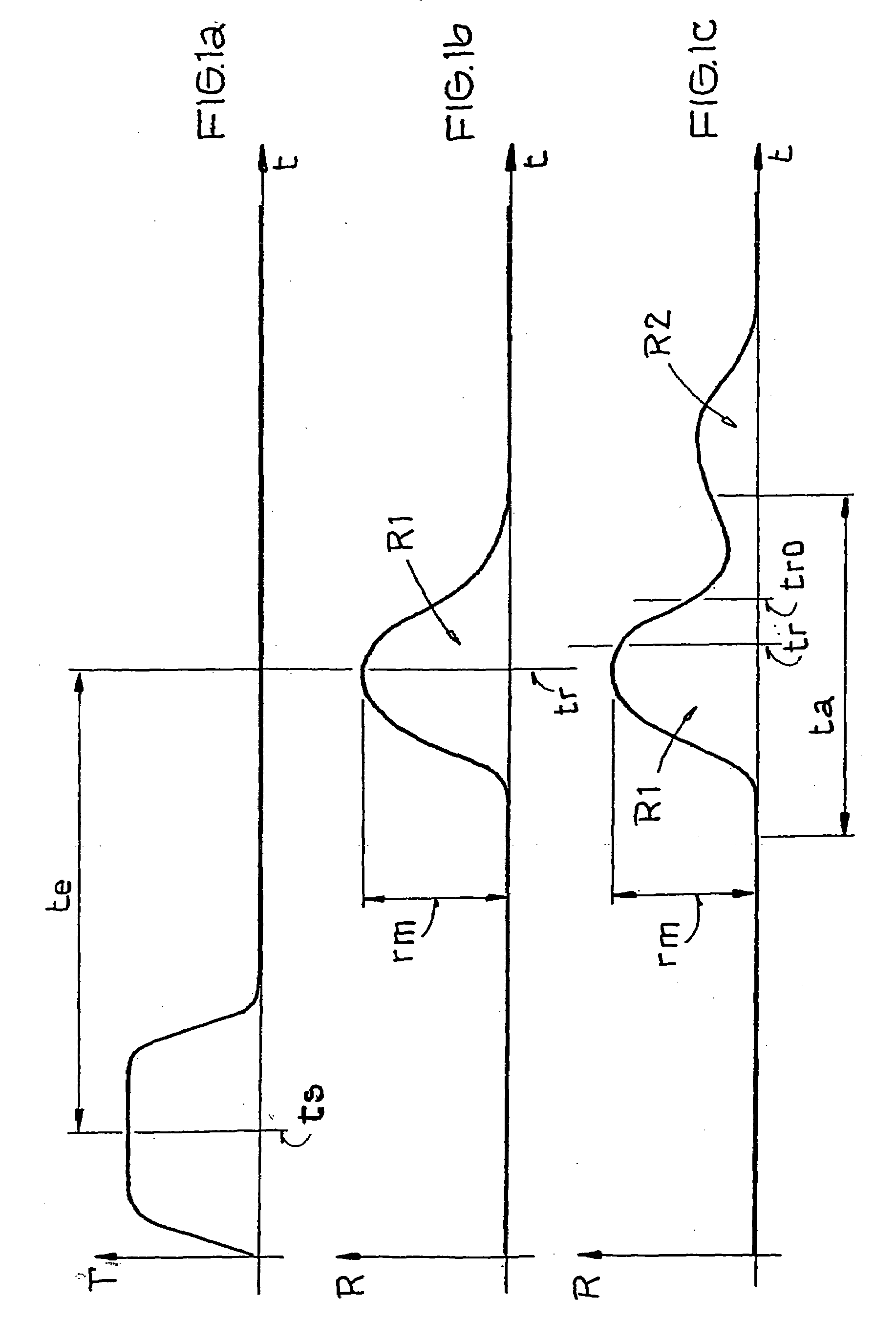

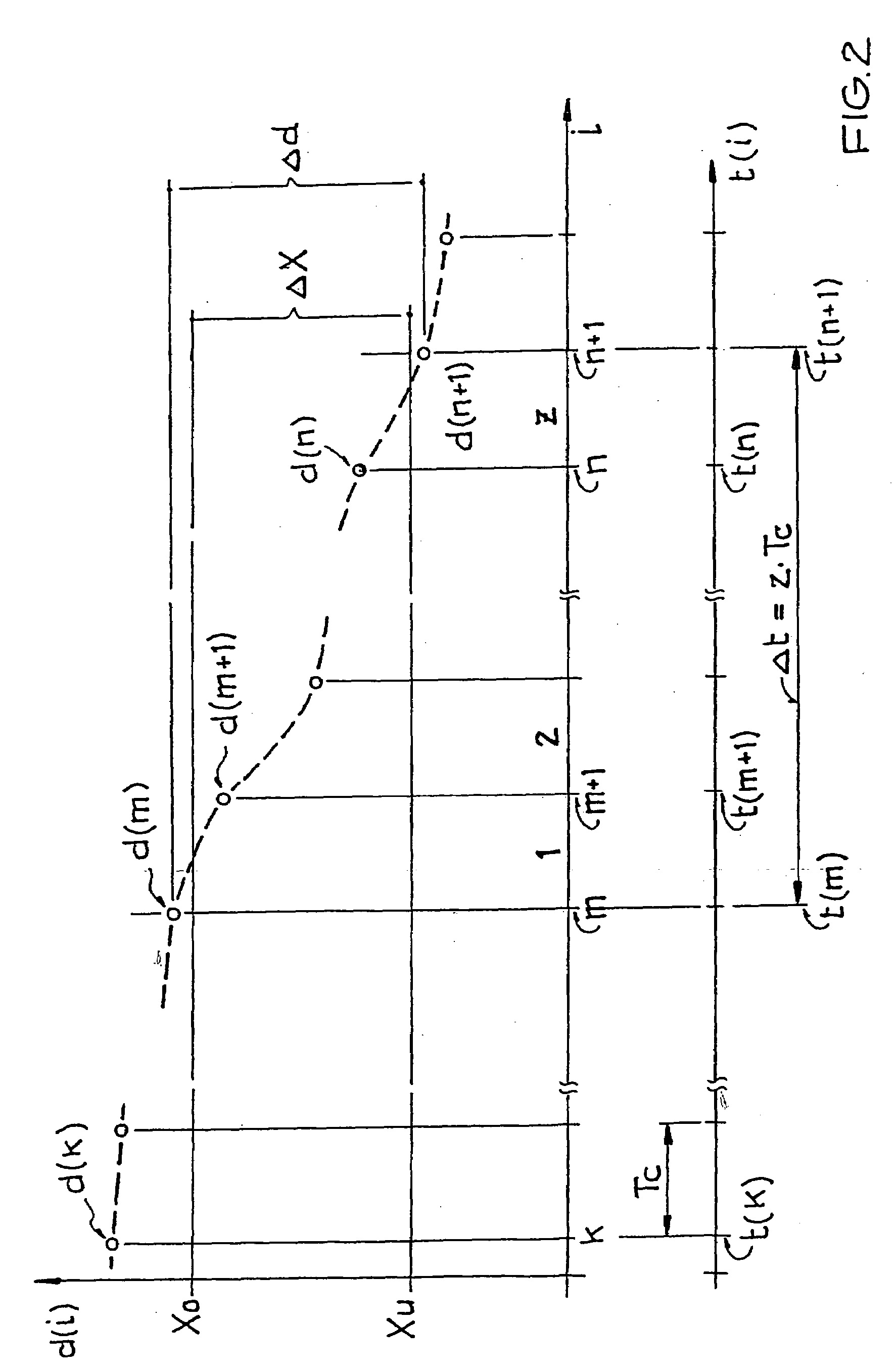

Method for determining the relative speed of an object

ActiveUS7119888B2Increase of intended protective effectOptical rangefindersDevices using optical meansMobile vehicleDriver/operator

Methods for the measurement of the object spacing distance or separation of objects are increasingly utilized in obstacle warning systems for motor vehicles, in order to warn the drivers of the motor vehicles of sources of danger on the roadway. It would be sensible or suitable in such a system, to take into account also the relative speed of objects approaching the motor vehicle. The new method shall enable the determination of the relative speed of an object in a simple manner and provide exact measurement results. In the new measurement method, the object separation is cyclically determined respectively after expiration of a prescribed cycle period. Furthermore, the number of the cycles is determined, within which the object separation changes so far that a prescribed separation band is completely traversed. The relative speed of the object is then calculated from the difference between the object separation determined before the entry into the separation band and the object separation determined after the exit out of the separation band, and from the determined number of cycles. Pre-crash sensing.

Owner:CONTI TEMIC MICROELECTRONIC GMBH

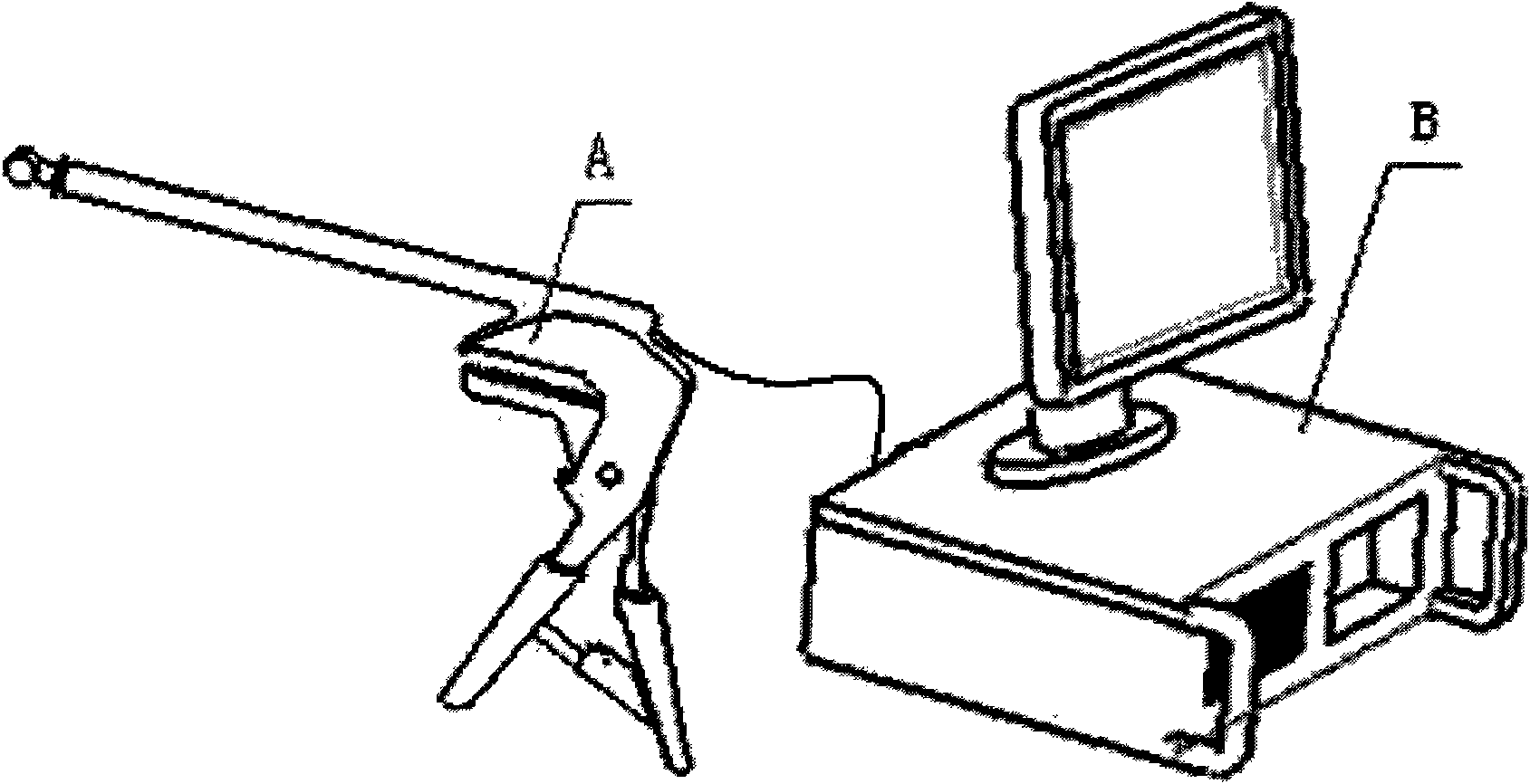

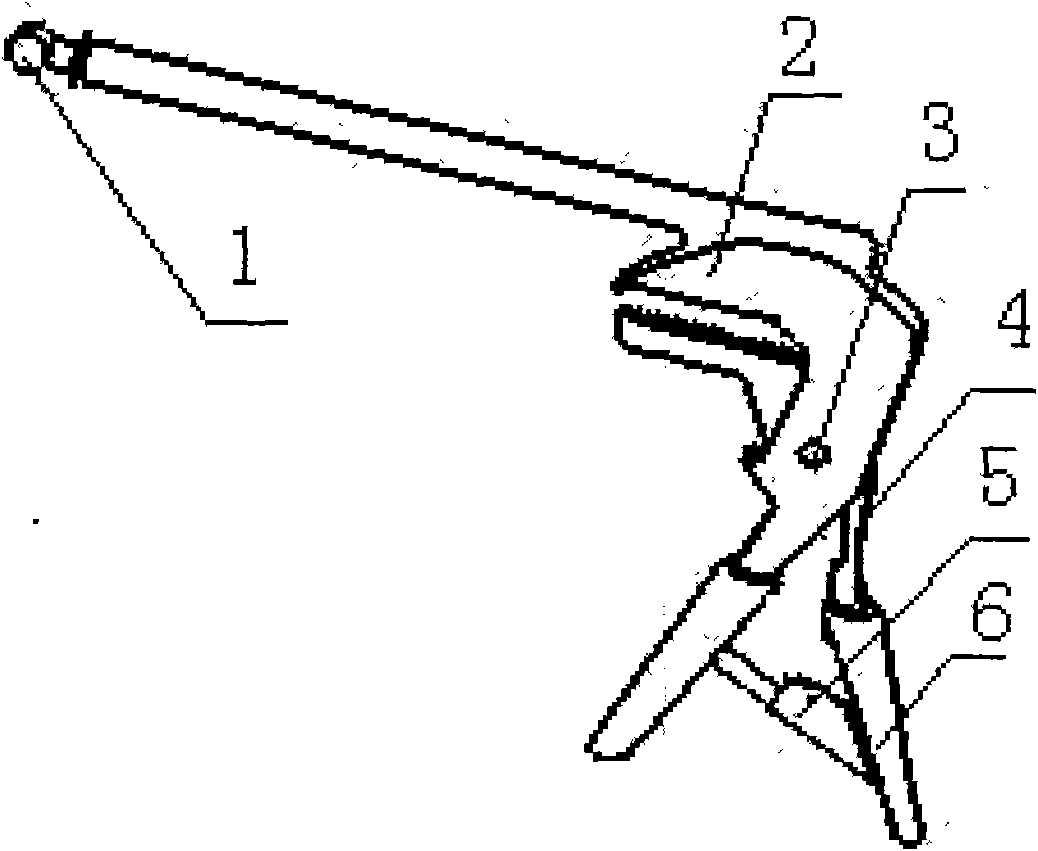

Rapid measurement device of speed of automobile engine

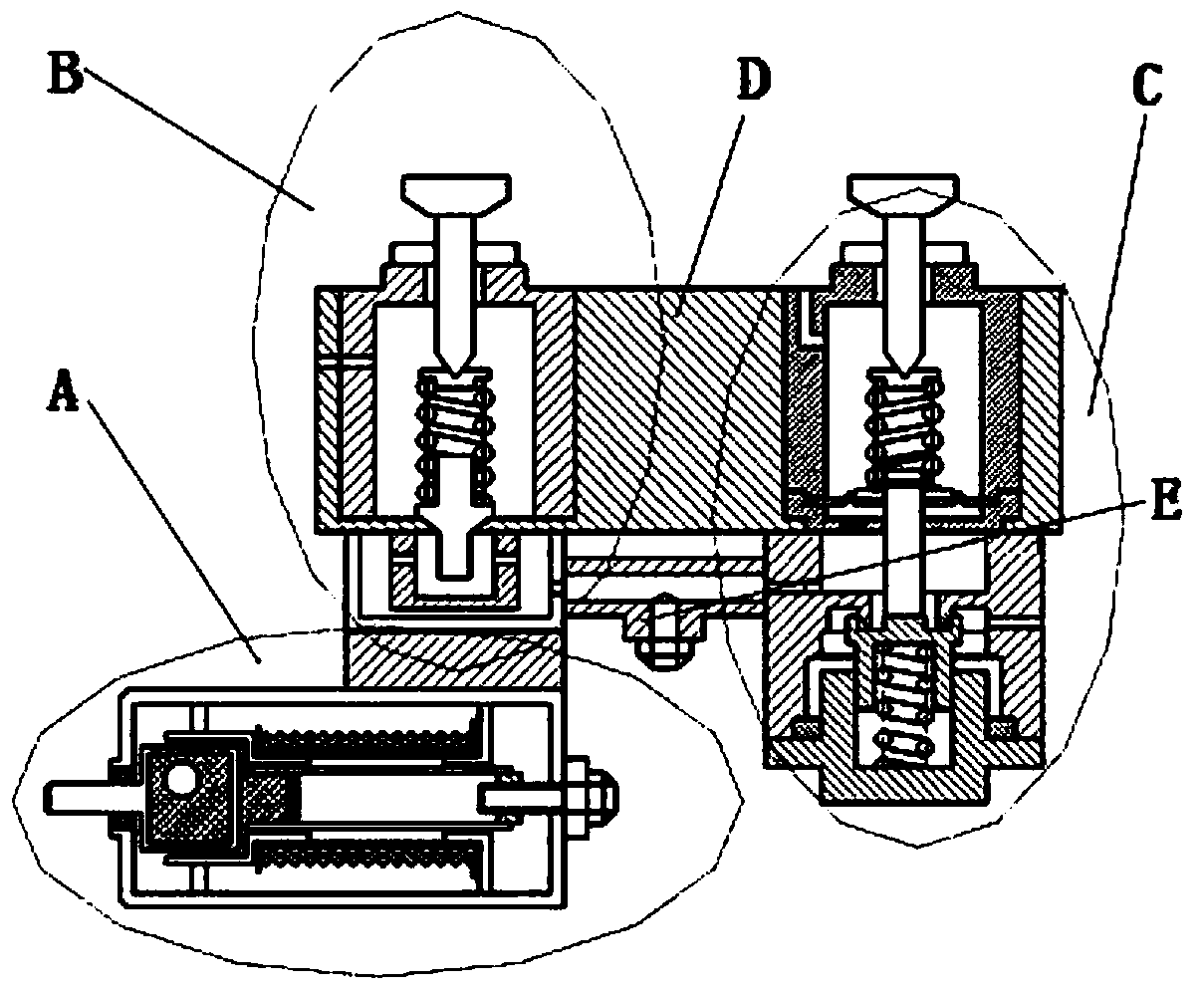

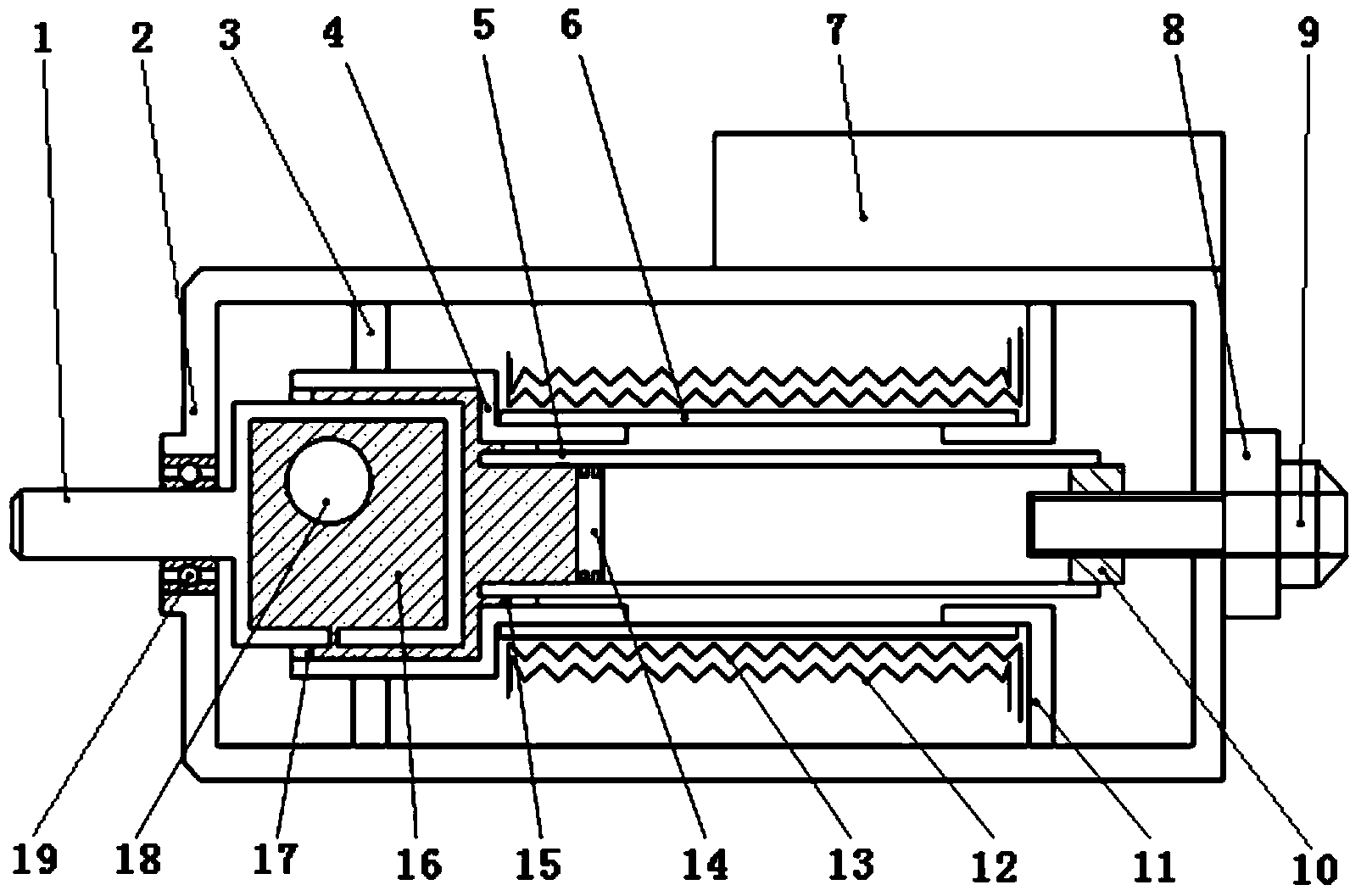

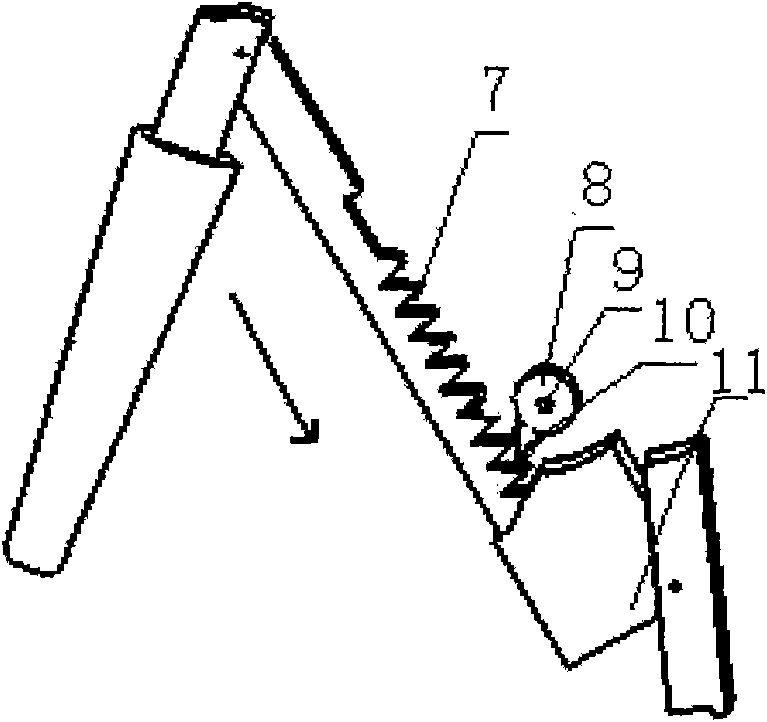

InactiveCN101672857AQuick measurementAccurate measurementDevices using fluidsShock waveMeasurement device

The invention relates to a rapid measurement device of speed of an automobile engine. The rapid measurement device mainly consists of a shock wave signal acquisition assembly (A) and a signal simulation processing assembly (B). The rapid measurement device is characterized in that the shock wave signal acquisition assembly (A) comprises an impact force sensor (1) and a rapid chucking device (2), wherein, the rapid chucking device (2) comprises a jaw opening, a return torsion spring (3), elastic arms (4), a locking device (5) and an elastic handle (6), the impact force sensor (1) is arranged atone end of a long bar which is fixed on the jaw opening, the return torsion spring (3) is arranged on jaw opening arms, the elastic handles (6) are respectively arranged at one end of the jaw openingarms, one of the jaw opening arms is the elastic arm (4), and the locking device (5) is arranged between the two elastic arms (4). The rapid chucking device (2) can help rapidly and stably mount theimpact force sensor in an automobile exhaust tube and can help rapidly disassemble the impact force sensor after measurement.

Owner:JILIN UNIV

Shaft rotating speed precision measuring system in full rotating speed and measuring method

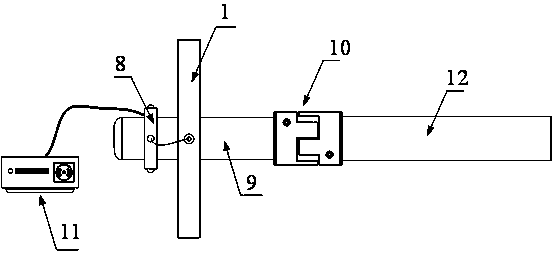

PendingCN108982900AThe structure is simple, reasonable and novelEasy to operateDevices using fluidsSystems designCoupling

The invention provides a shaft rotating speed precision measuring system in a full rotating speed. The measuring system comprises a measuring device, a wire collector, a device main shaft, a couplingand a signal processing module, the measuring device and the wire collector are coaxially fixed to the device main shaft, an output terminal of the wire collector is connected with the signal processing module, the device main shaft is connected with a rotating shaft through the coupling, the device main shaft and the measuring device and the wire collector fixed to the device main shaft are driven to move in the same rotating speed during full-rotating-speed rotation of the rotating shaft, the measuring device converts the measured rotating speed to an analog quantity voltage signal for output, the voltage signal is acquired by the wire collector, and the signal processing module converts the acquired voltage signal to a corresponding measurement rotating speed and displays the measurement rotating speed. According to the system, a shaft rotating speed precision measuring device, method and system in a full rotating speed is provided based on the centrifugal force effect and the piezoelectric effect, the structure of the device is simple, the method is concise and clear, the system design is reasonable, and good measuring performance is achieved for the rotating speed of the rotating shaft in the full rotating speed.

Owner:NANJING INST OF TECH +1

Motion sensor and method for detecting motion

ActiveUS20060090564A1Movement can be detectedAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsReference structureAngular acceleration

A motion sensor may detect linear and / or angular acceleration and / or angular velocity of a body relative to one axis, two orthogonal axes or three orthogonal axes. Movement of the body or reference structure may be detected relative to one or more spinning rotors. The rotor(s) may be suspended for rotation and / or other movement relative to the reference structure without physical contacting the reference structure. In one embodiment, the rotor(s) may be electrostatically suspended in such a way that movement of the rotor(s) relative to the reference structure may be detected.

Owner:ARCHANGEL SYST

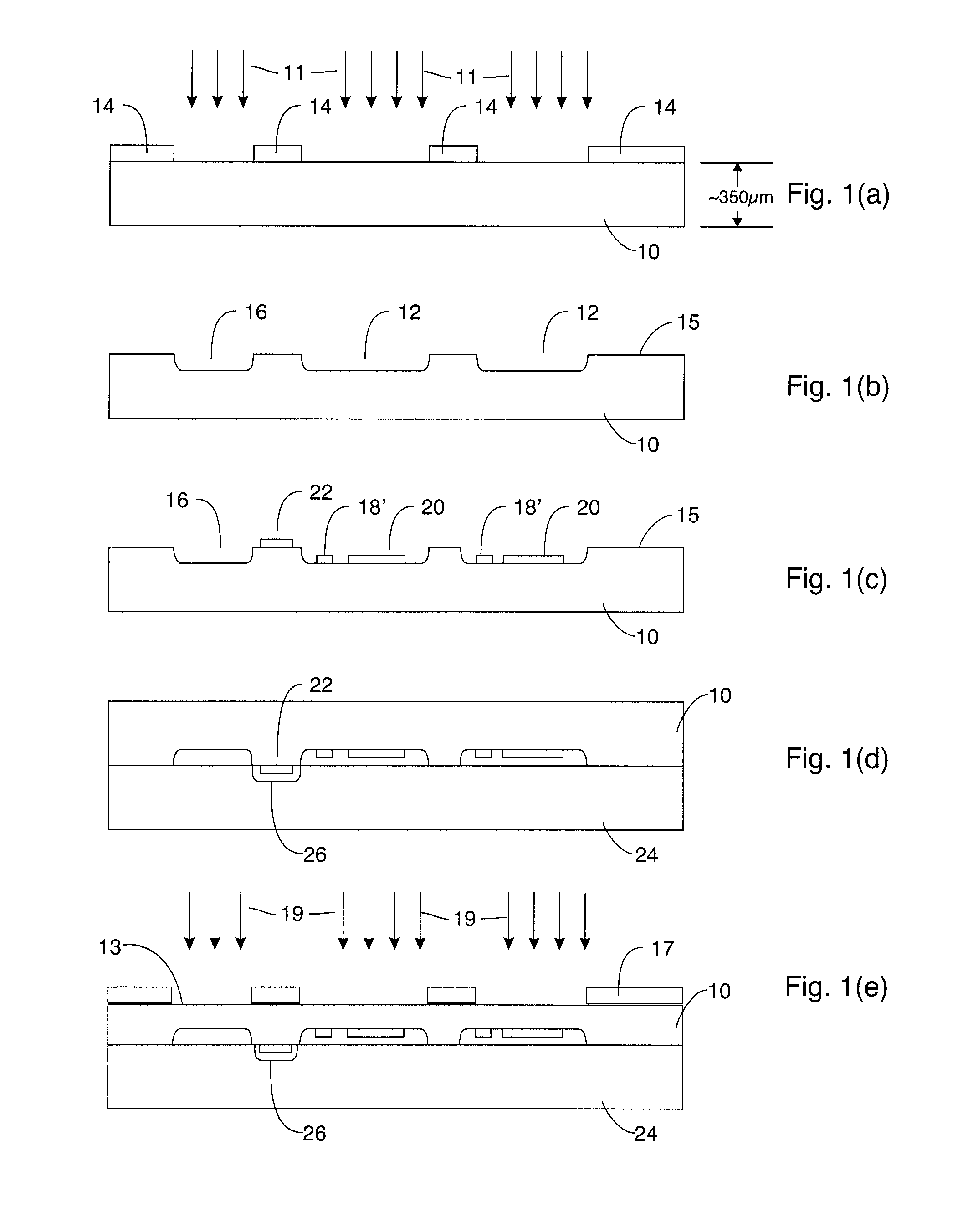

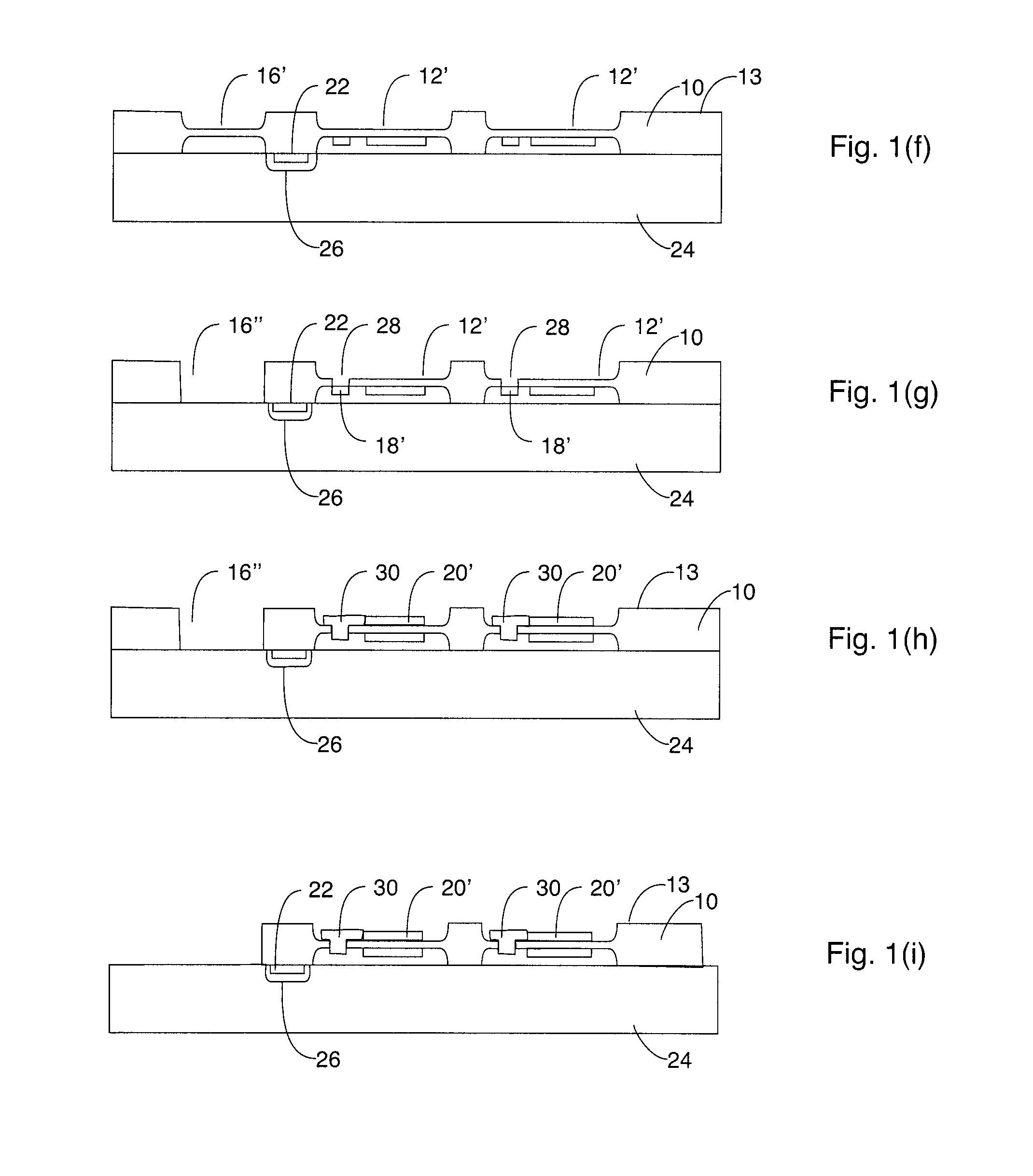

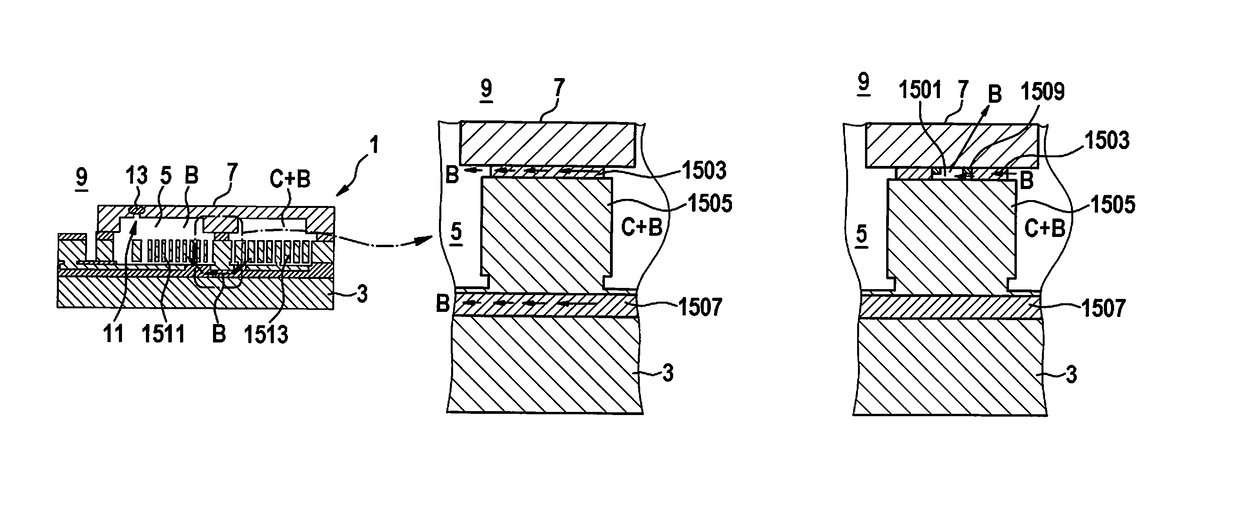

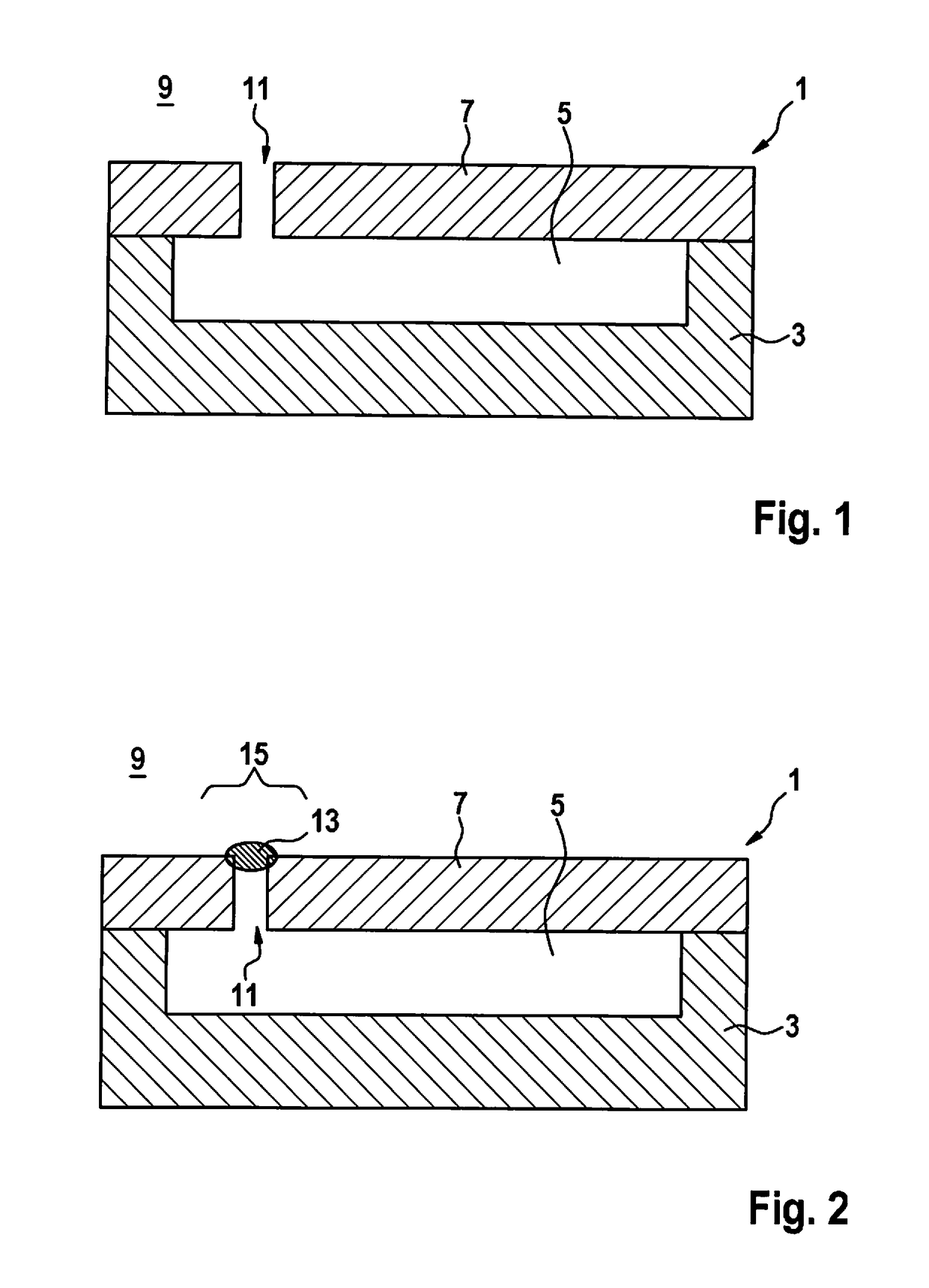

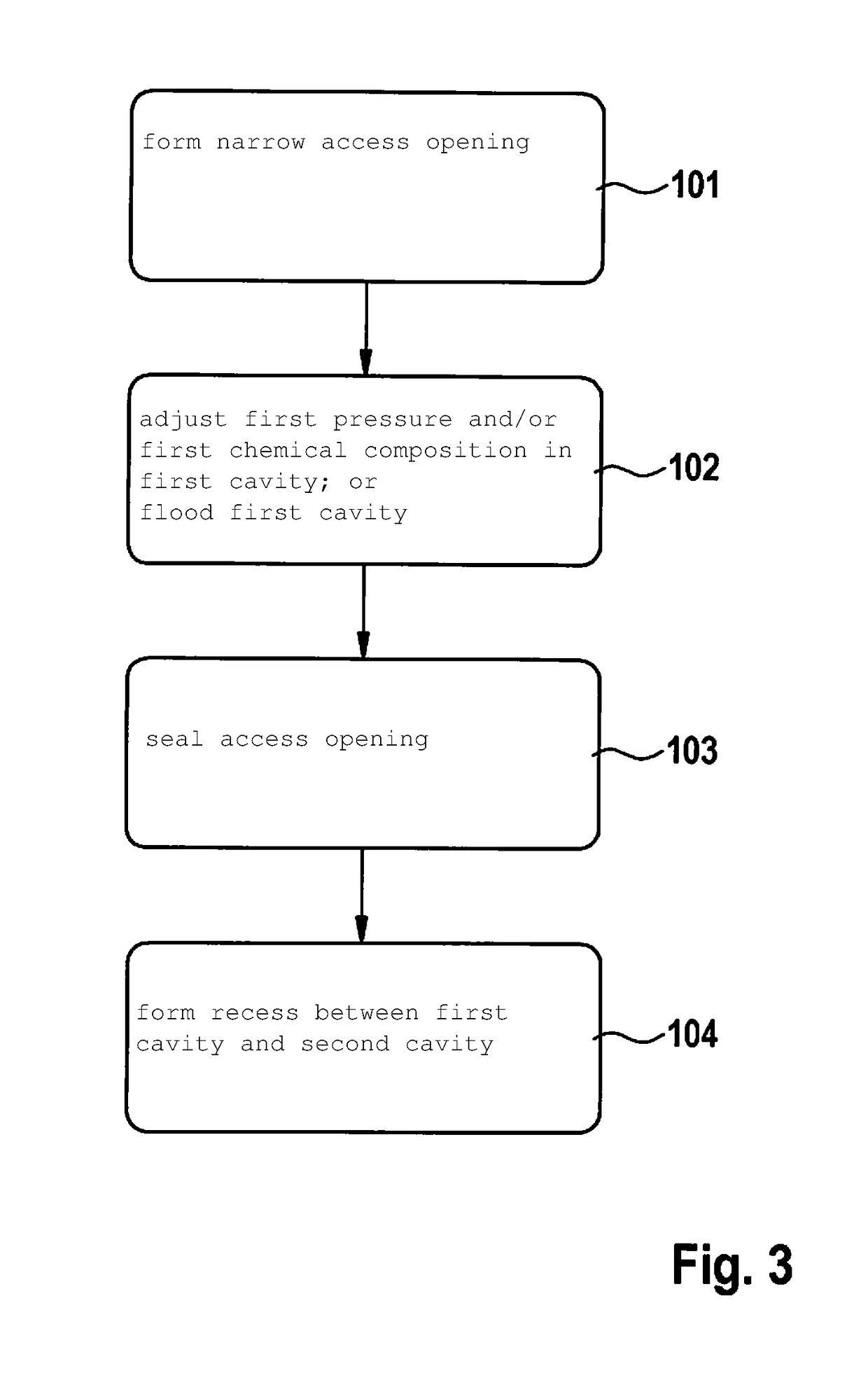

Micromechanical component including a diffusion stop channel

ActiveUS10029911B2Easy to useSimple and cost-effectiveDecorative surface effectsSolid-state devicesDiffusionChemical composition

A method for manufacturing a micromechanical component is provided including a substrate and including a cap, which is connected to the substrate and, together with the substrate, encloses a first cavity, a first pressure prevailing and a first gas mixture having a first chemical composition being enclosed in the first cavity, the cap together with the substrate enclosing a second cavity, a second pressure prevailing and a second gas mixture having a second chemical composition being enclosed in the second cavity. A recess situated essentially between the first cavity and the second cavity is formed for diverting at least one first particle type of the first gas mixture and / or at least one second particle type of the second gas mixture.

Owner:ROBERT BOSCH GMBH

Apparatus for detecting engine speed by exhaust pressure

InactiveCN101509928AAvoid influenceGuaranteed accuracyEngine testingDevices using fluidsElectricityDirect test

The invention discloses a device which detects the rotating speed of an engine by exhaust pressure, comprising an engine tail gas pressure collecting device, a pressure sensor, a signal processor, a central processor and a displayer; wherein, the pressure sensor collects the pressure signal of the tail gas in the engine tail gas pressure collecting device and converts the pressure signal into an electric signal which is transmitted to the signal processor so as to be converted into a digital pulse signal which is transmitted to the central processor, and the central processor calculates and displays the rotating speed value by the displayer according to the pulse signal; the device collects the frequency signal of engine exhaust pressure by utilizing the proportion relationship of engine exhaust frequency and rotating speed and the correspondence relationship of transient increasing and reducing of exhaust pressure and the frequency, thus obtaining a rotating speed signal, avoiding influence of external factor on the detection result, guaranteeing the accuracy of the detection result, being simple and convenient for use during detection, and being capable of directly testing the rotating speed of the vehicle engine on any random occasion; and the device has small volume and convenient carrying.

Owner:北京品今资本管理股份有限公司

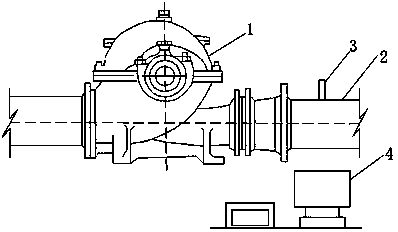

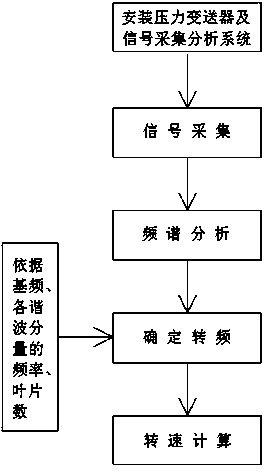

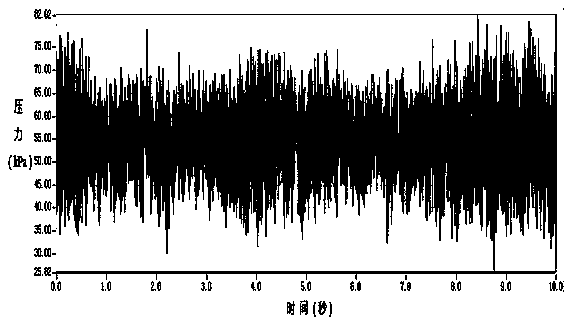

Method for testing rotary speed of water pump

A method for testing the rotary speed of a water pump comprises the following steps of installation of a pressure transmitter and a signal collecting analysis system, signal collection, spectral analysis, rotary frequency determination and rotary speed determination. The method has the advantages that the pressure transmitter is installed on the portion, close to a water pump outlet, of a water outlet pipe and can be used for measuring the rotary speed and measuring the water pump lift, so that experiment devices are reduced and experiment cost is saved; measurement is accurate, the application range is wide, and the method can be applied to on-site testing and experiments which are not suitable for other methods for measurement.

Owner:WUHAN UNIV

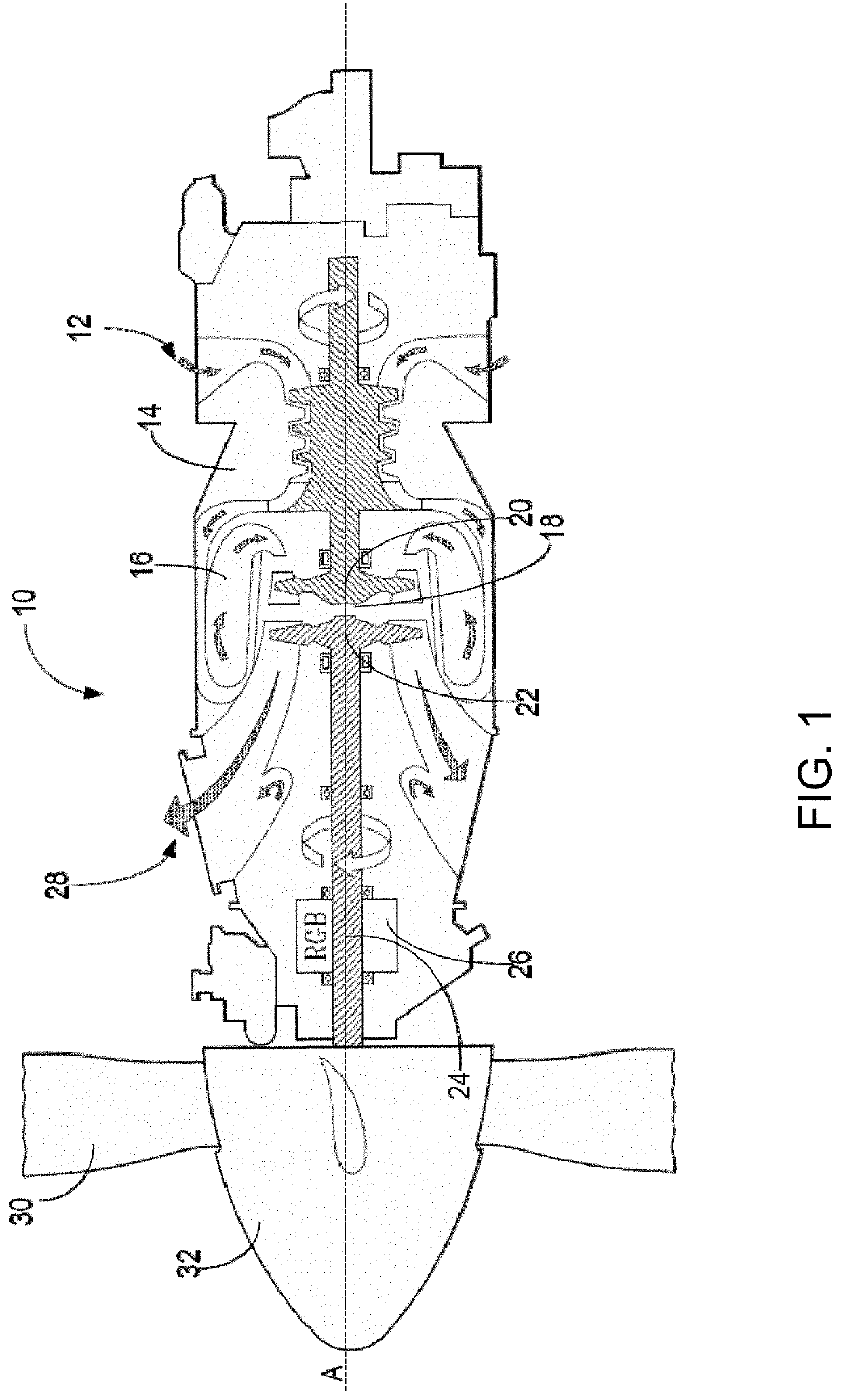

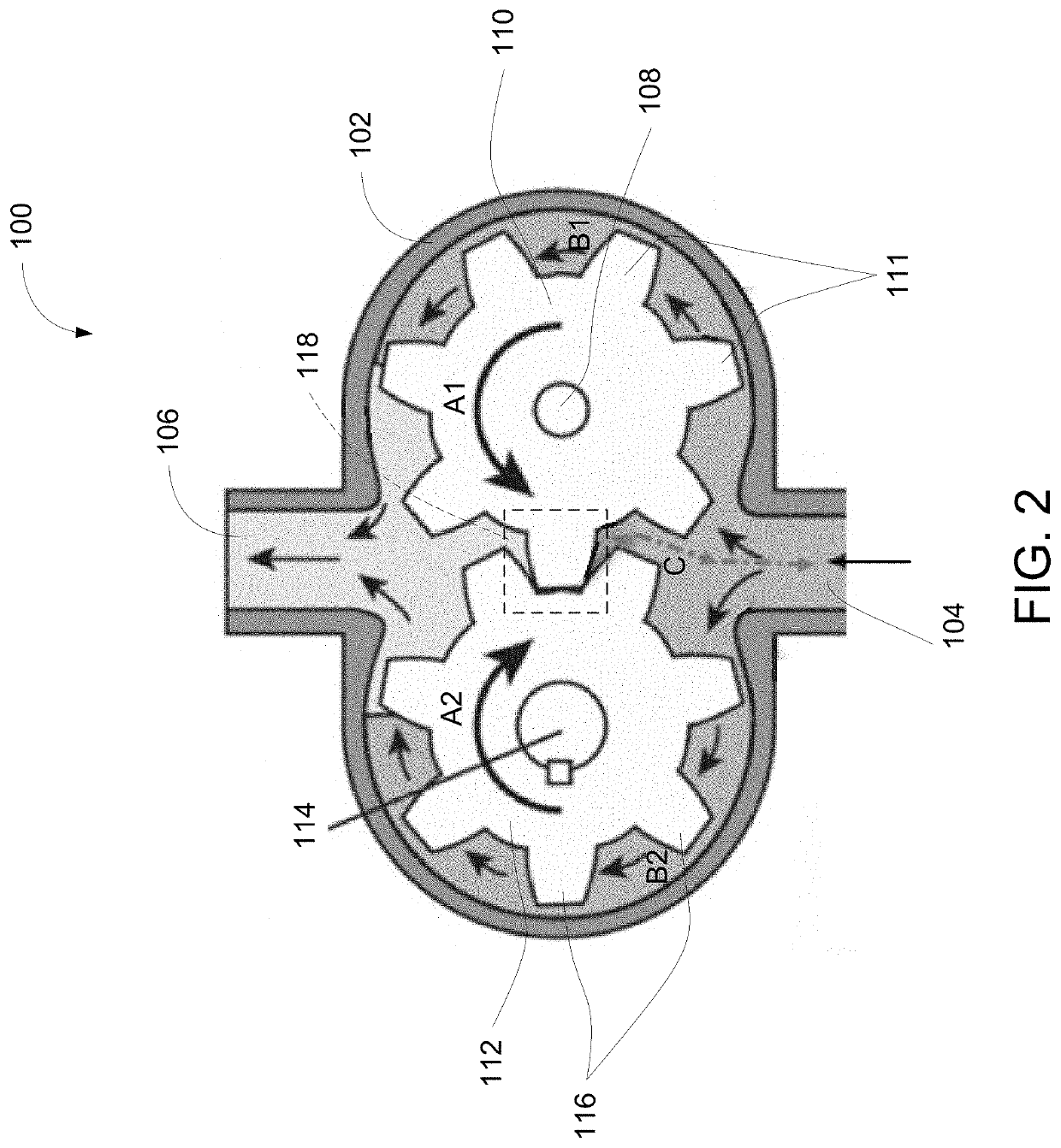

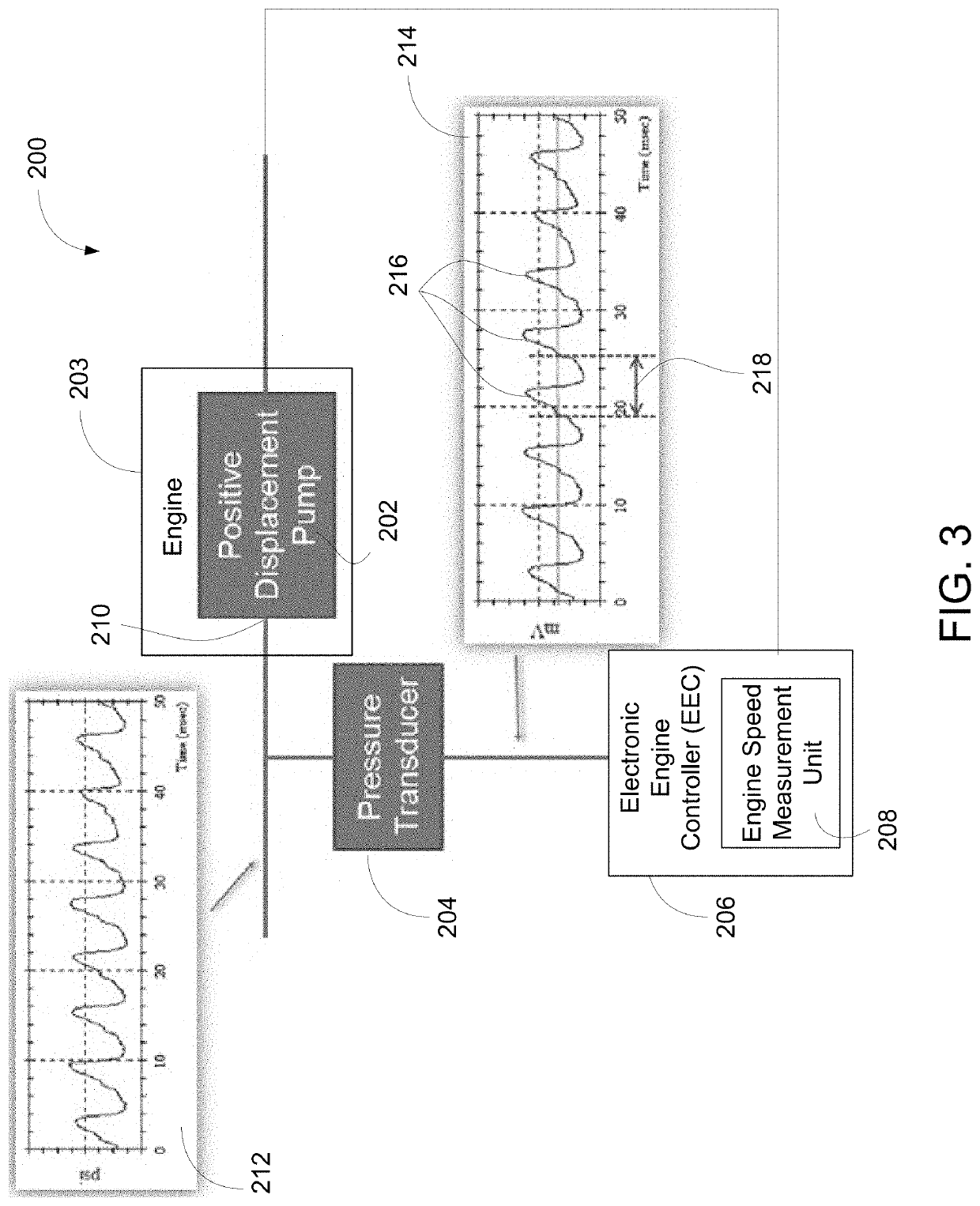

System and method for engine speed measurement

ActiveUS20200200787A1Internal-combustion engine testingWorking fluid for enginesControl theoryFluid supply

A system and method for measuring a speed of an engine are provided. The engine has a positive displacement pump drivingly connected to a rotor shaft thereof, the pump having an inlet for receiving a fluid supply and an outlet for outputting pressurized fluid. A sensor signal is received from a pressure sensing device provided at an inlet of the pump, the sensor signal comprising a series of periodic oscillations. A frequency of the oscillations is determined, the frequency proportional to a rotational speed of the rotor shaft. The speed of the engine is then determined from the frequency of the oscillations and the speed of the engine as determined is output for controlling operation of the engine.

Owner:PRATT & WHITNEY CANADA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com