Platform leveling device based on cylindrical model

A platform and leveling technology, applied in devices that use fluids, measuring devices, control/regulation systems, etc., can solve problems such as high manufacturing costs, high operating environment requirements, poor visibility and maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

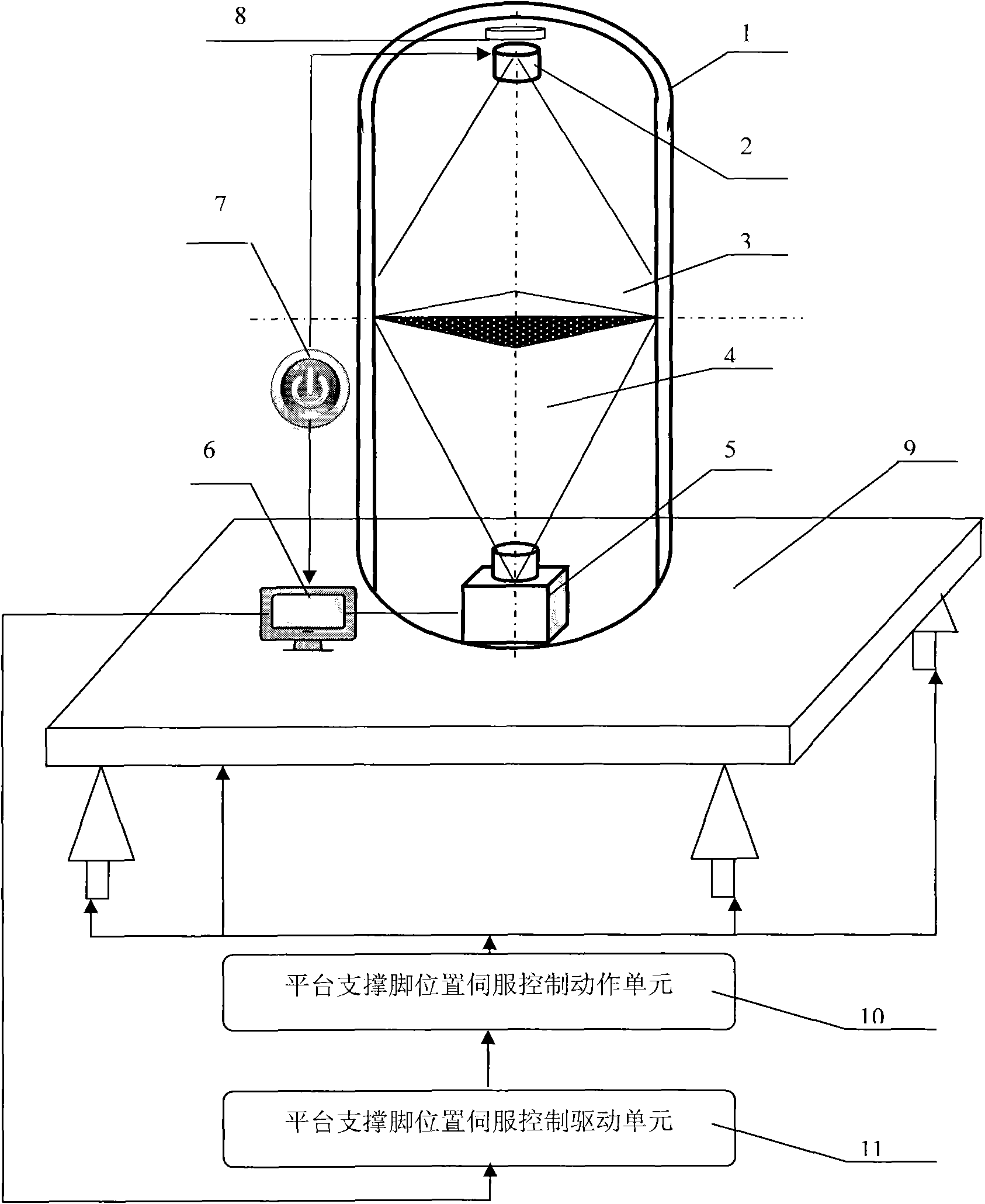

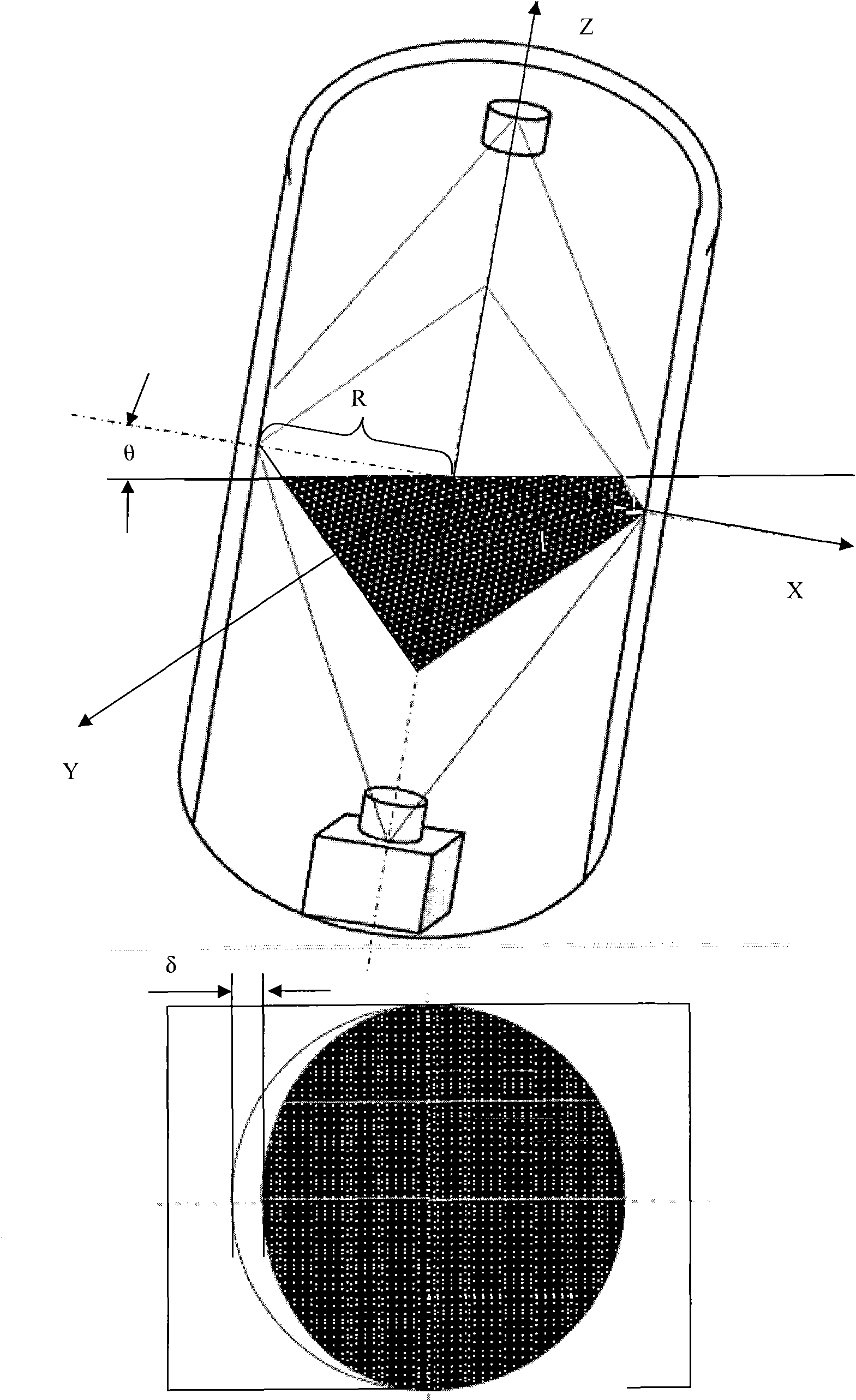

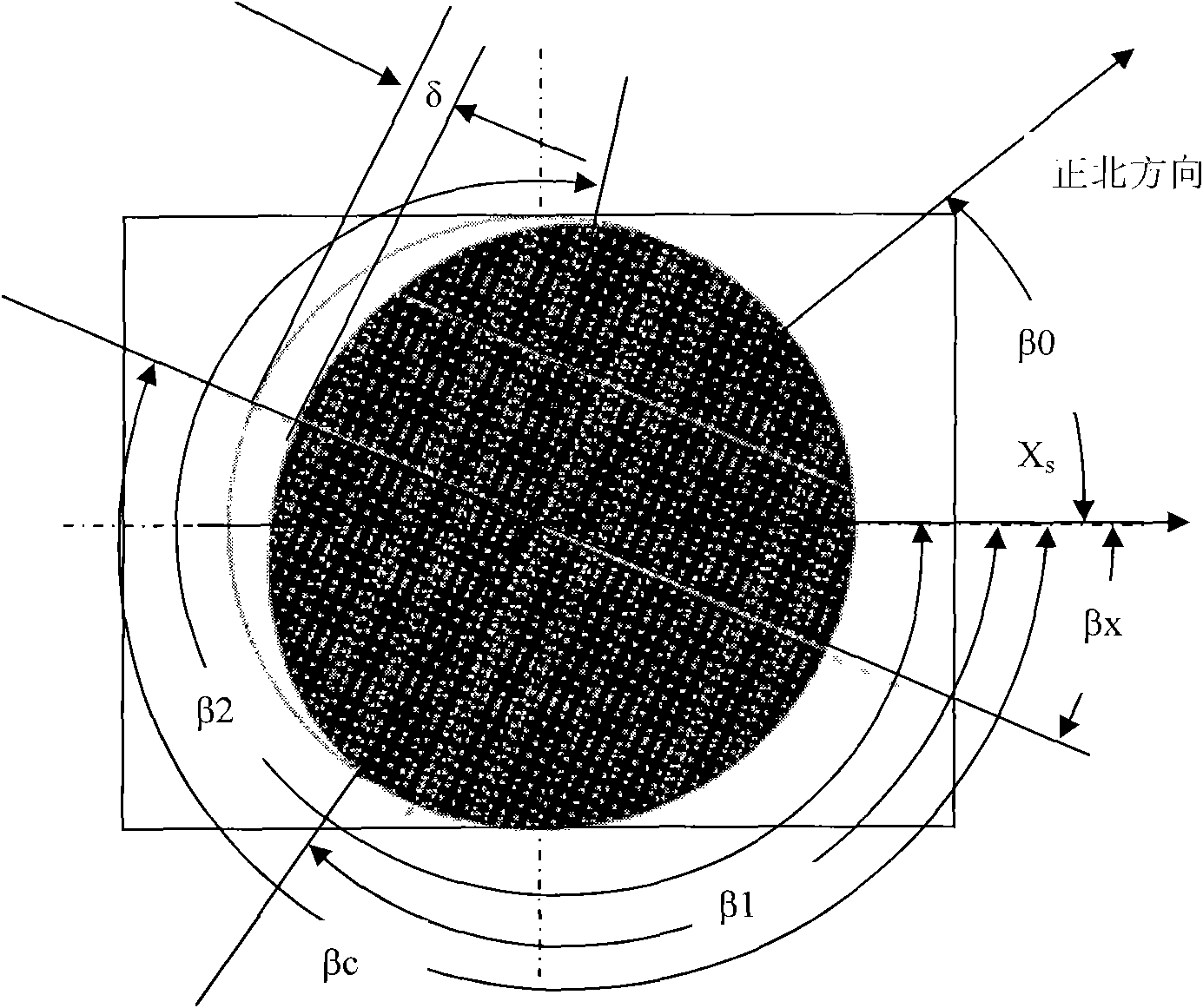

[0129] refer to Figure 1 to Figure 18 , a platform leveling method based on a cylindrical model, including an omnidirectional tilt sensor housing 1, an LED lighting source 2, a transparent cone container 3, an opaque liquid 4, a camera 5, an embedded system 6, a power supply 7 and a compass 8 , platform 9, platform support foot position servo control action unit 10 and platform support foot position servo control drive unit 11, the power supply 7 supplies power to the lighting source 2 and the embedded system 6, and the embedded The formula system 6 supplies power to the camera 5 through the USB interface, and the transparent cone container 3 is combined into a closed container by two cones of the same size in a back-to-back manner; the omni-directional tilt sensor housing 1 The transparent cone container 3 is fixed in the middle, the LED lighting source 2 is fixed in the upper part, and the camera 5 is fixed in the lower part; the LED lighting source 2 faces the transparent ...

Embodiment 2

[0233] The rest is the same as in Embodiment 1. For a platform without a position servo control leveling device, the adjusted displacement value of each support point is output on the man-machine interface, and the operator is prompted to operate according to the prompted content, so that the leveling of the platform can be quickly realized at one time. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com