Patents

Literature

176 results about "Quartz resonator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

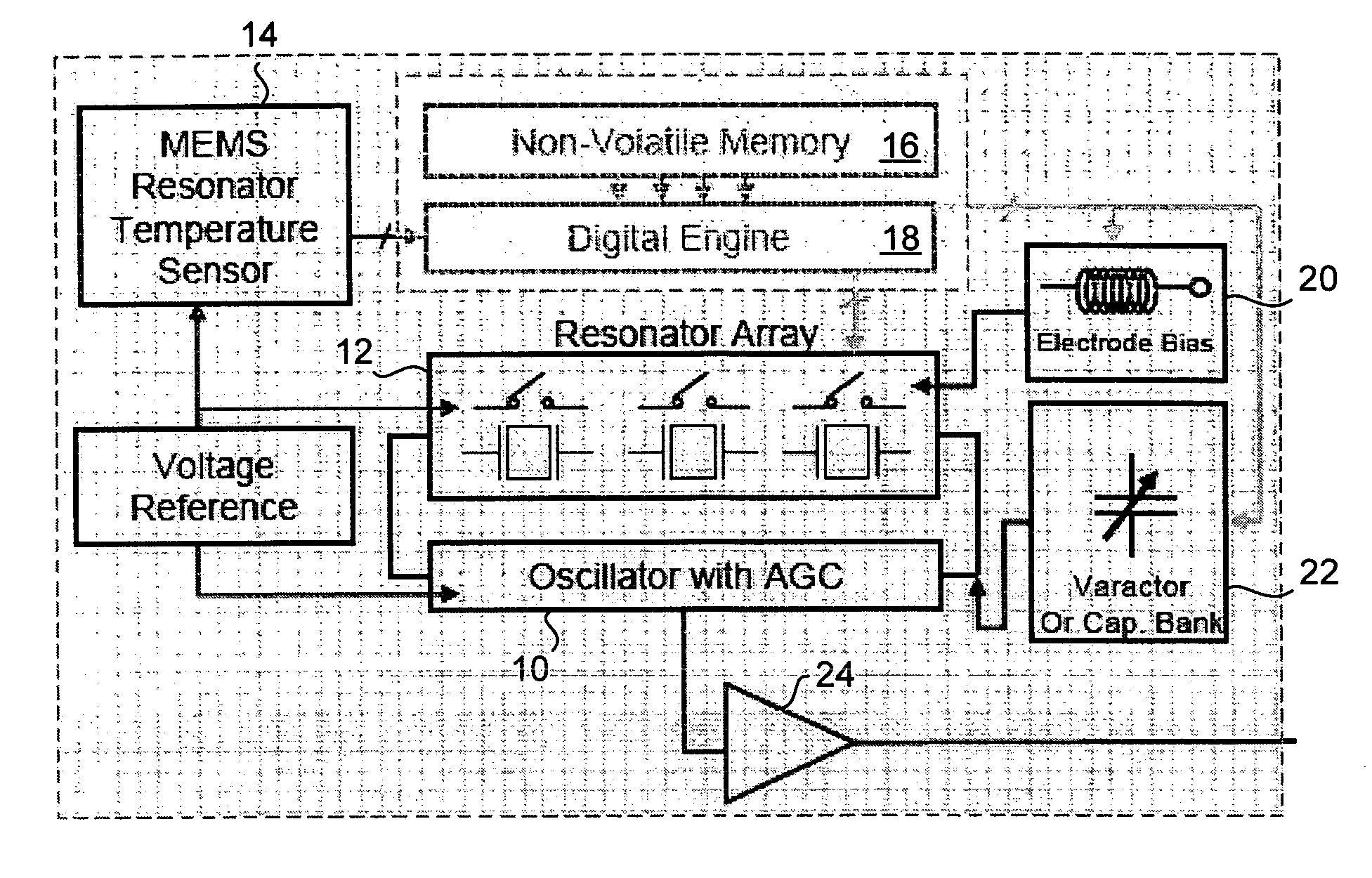

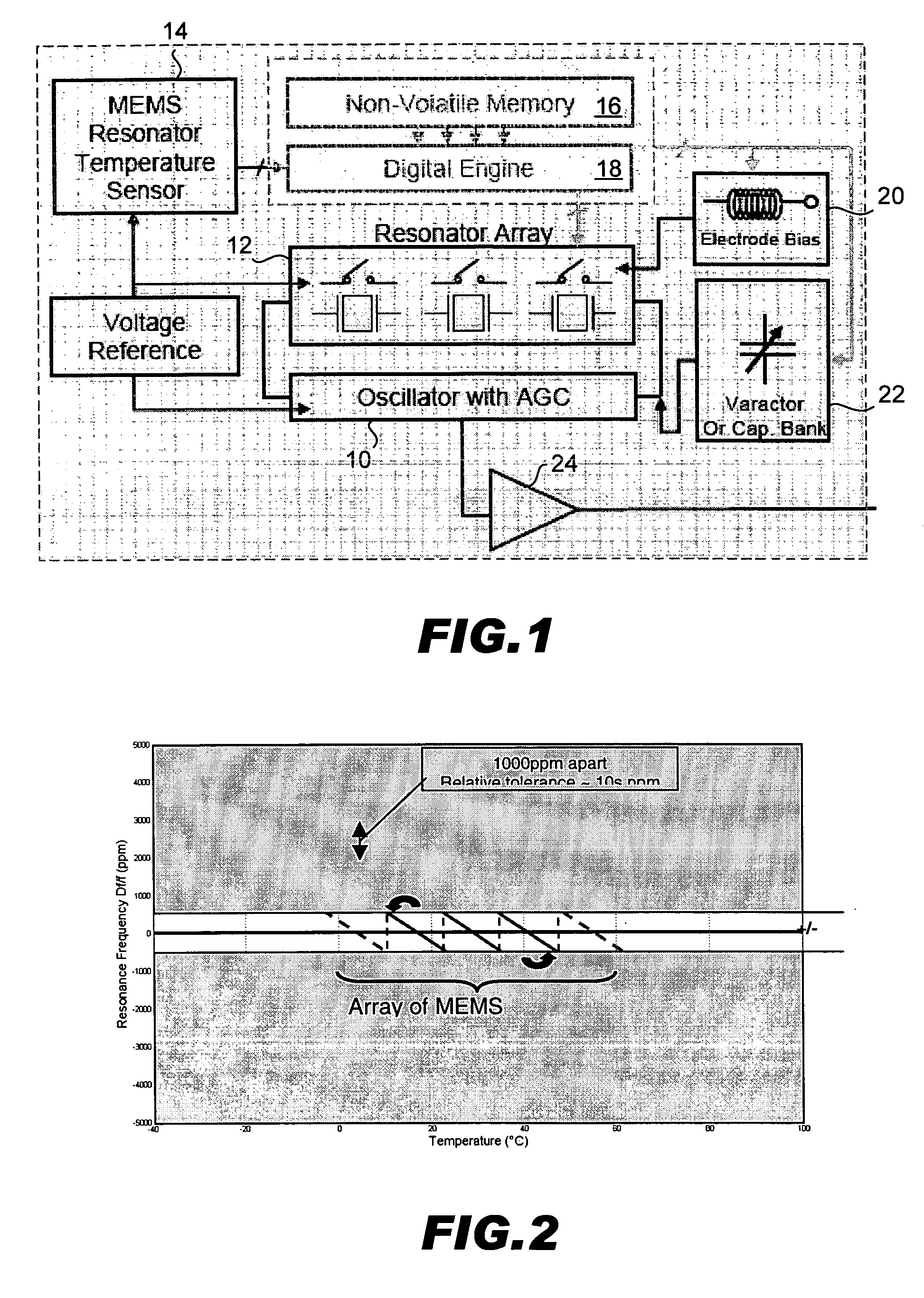

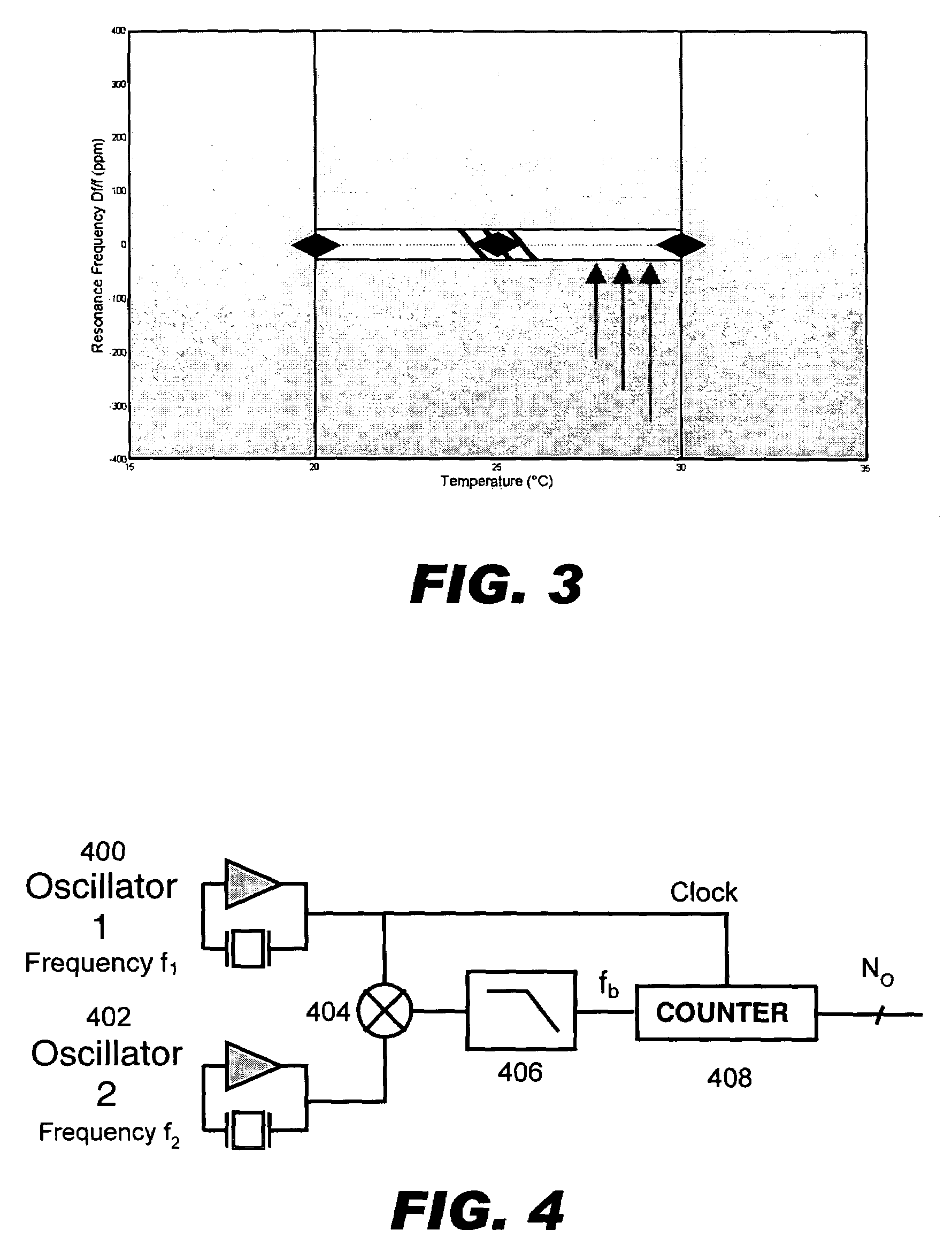

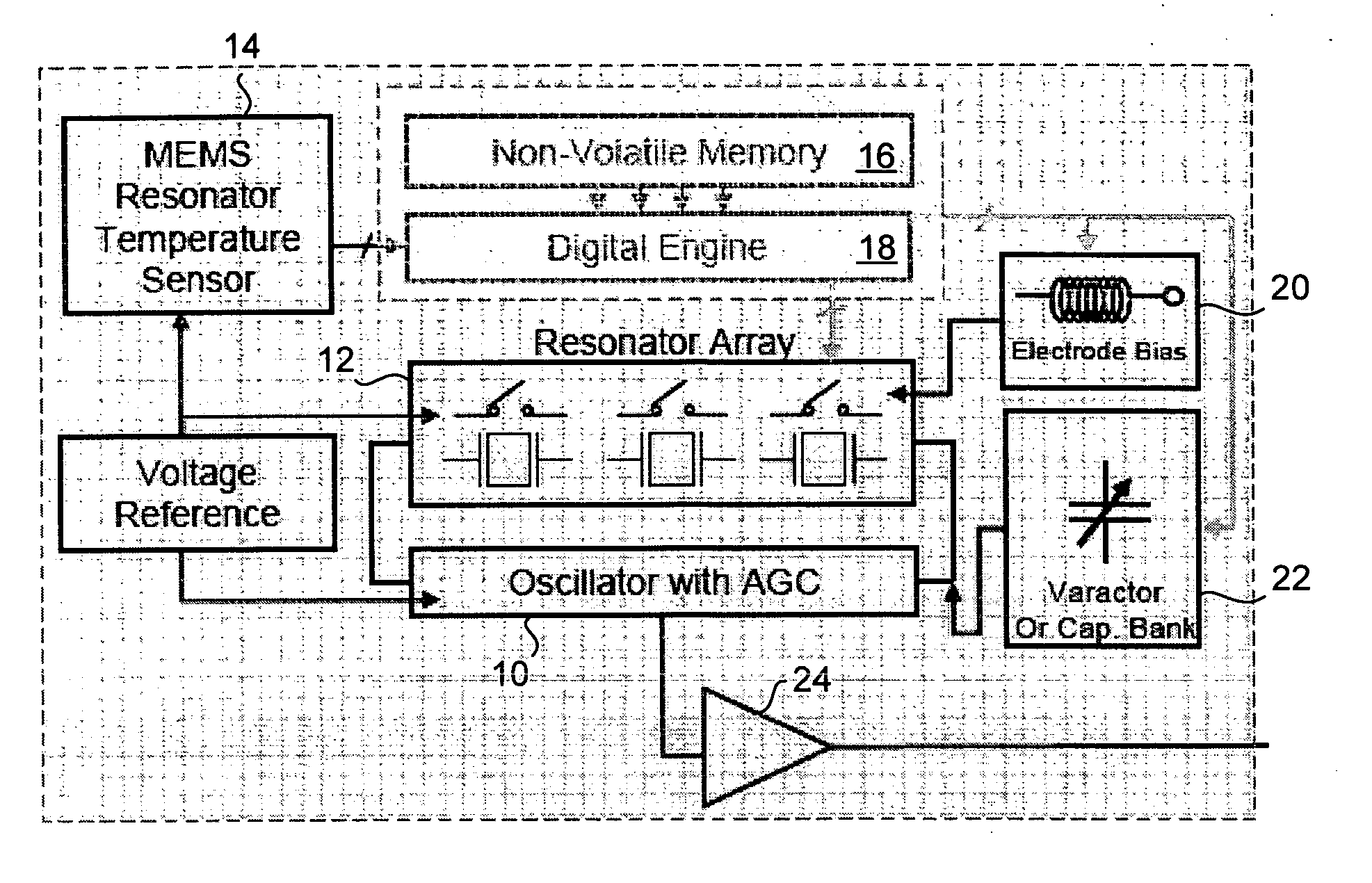

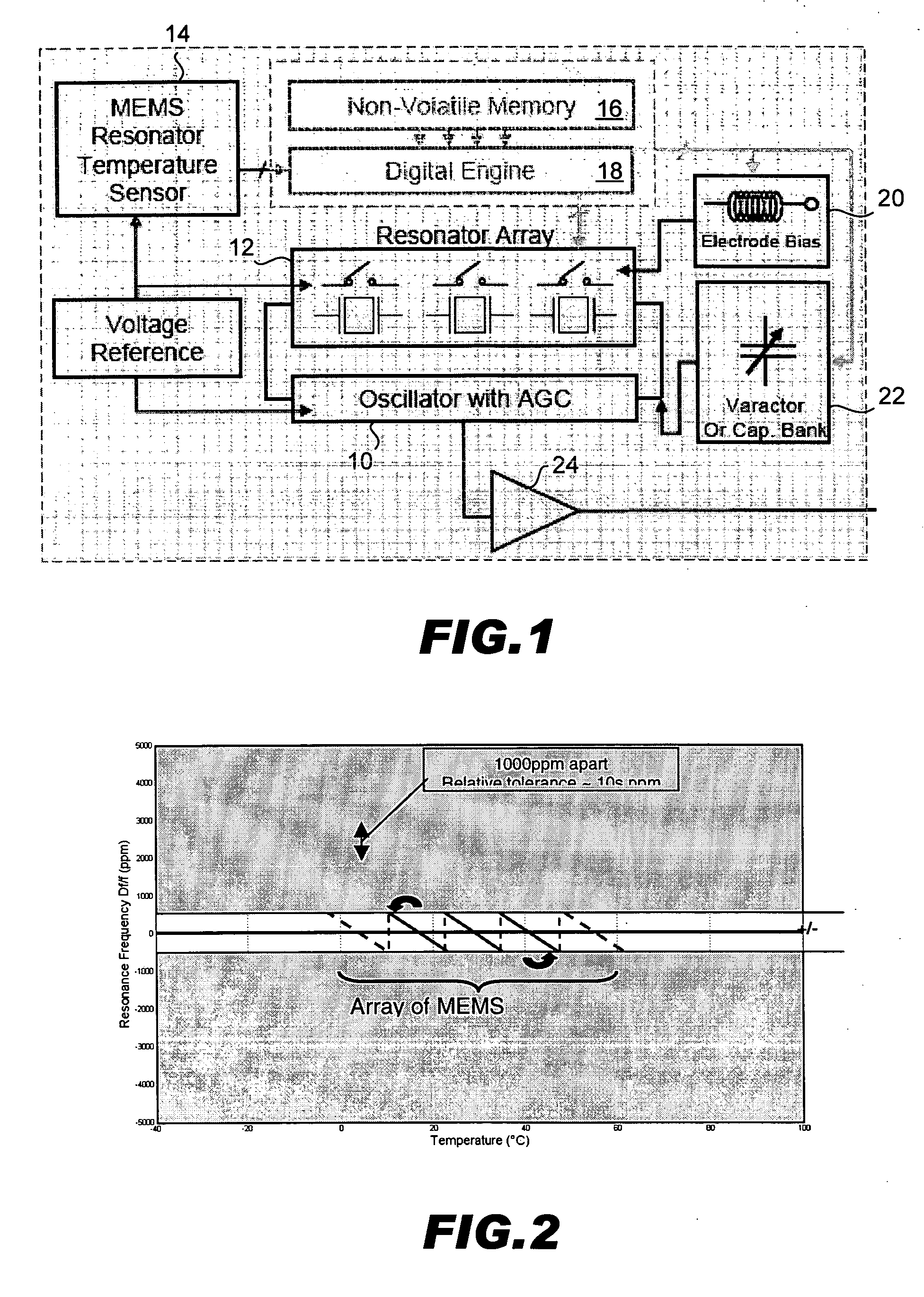

Temperature compensated oscillator including MEMS resonator for frequency control

ActiveUS7211926B2Small deviceLow costPiezoelectric/electrostriction/magnetostriction machinesTemperatue controlQuartz resonatorSignal function

Disclosed is an oscillator that relies on redundancy of similar resonators integrated on chip in order to fulfill the requirement of one single quartz resonator. The immediate benefit of that approach compared to quartz technology is the monolithic integration of the reference signal function, implying smaller devices as well as cost and power savings.

Owner:RGT UNIV OF CALIFORNIA

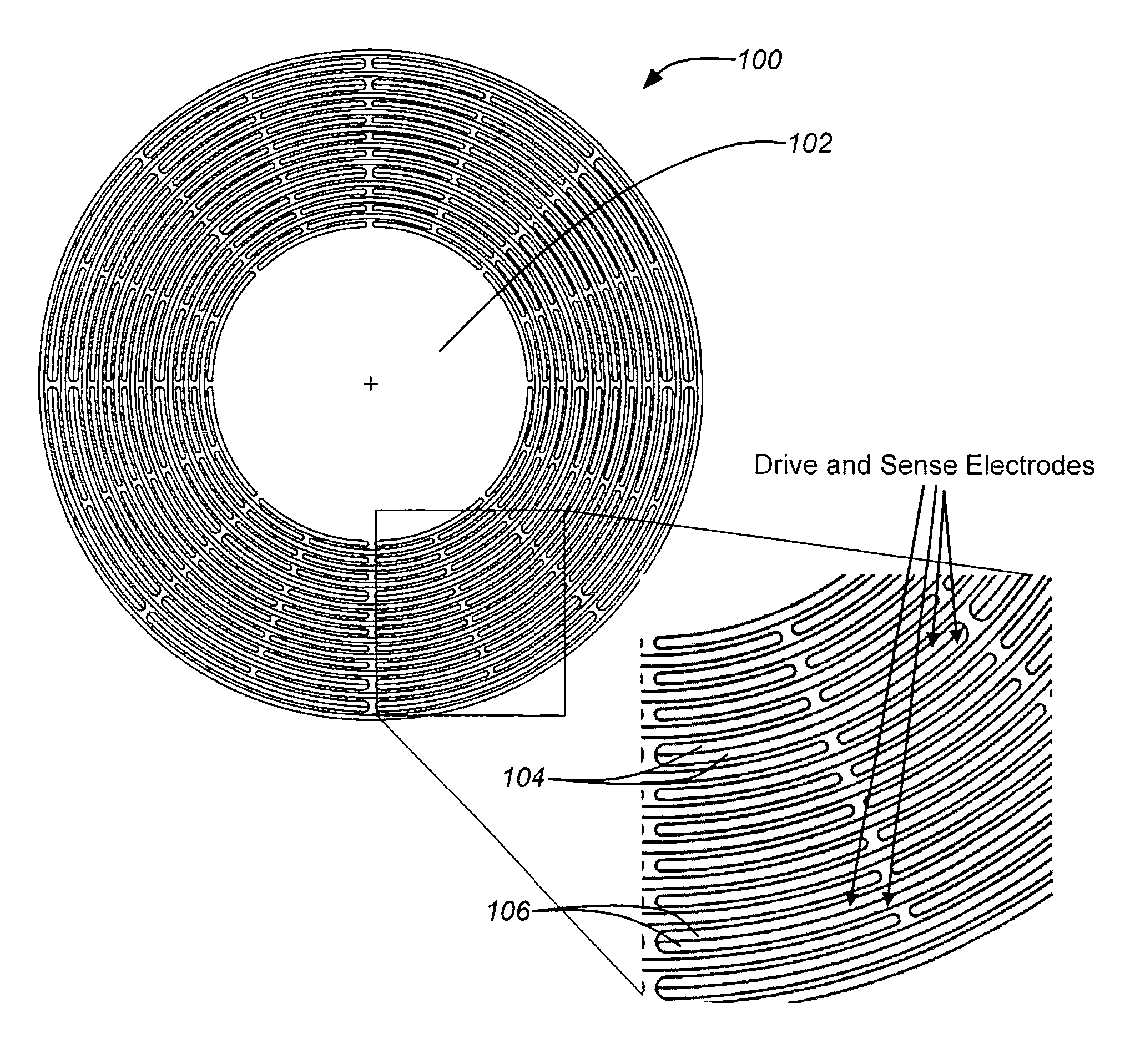

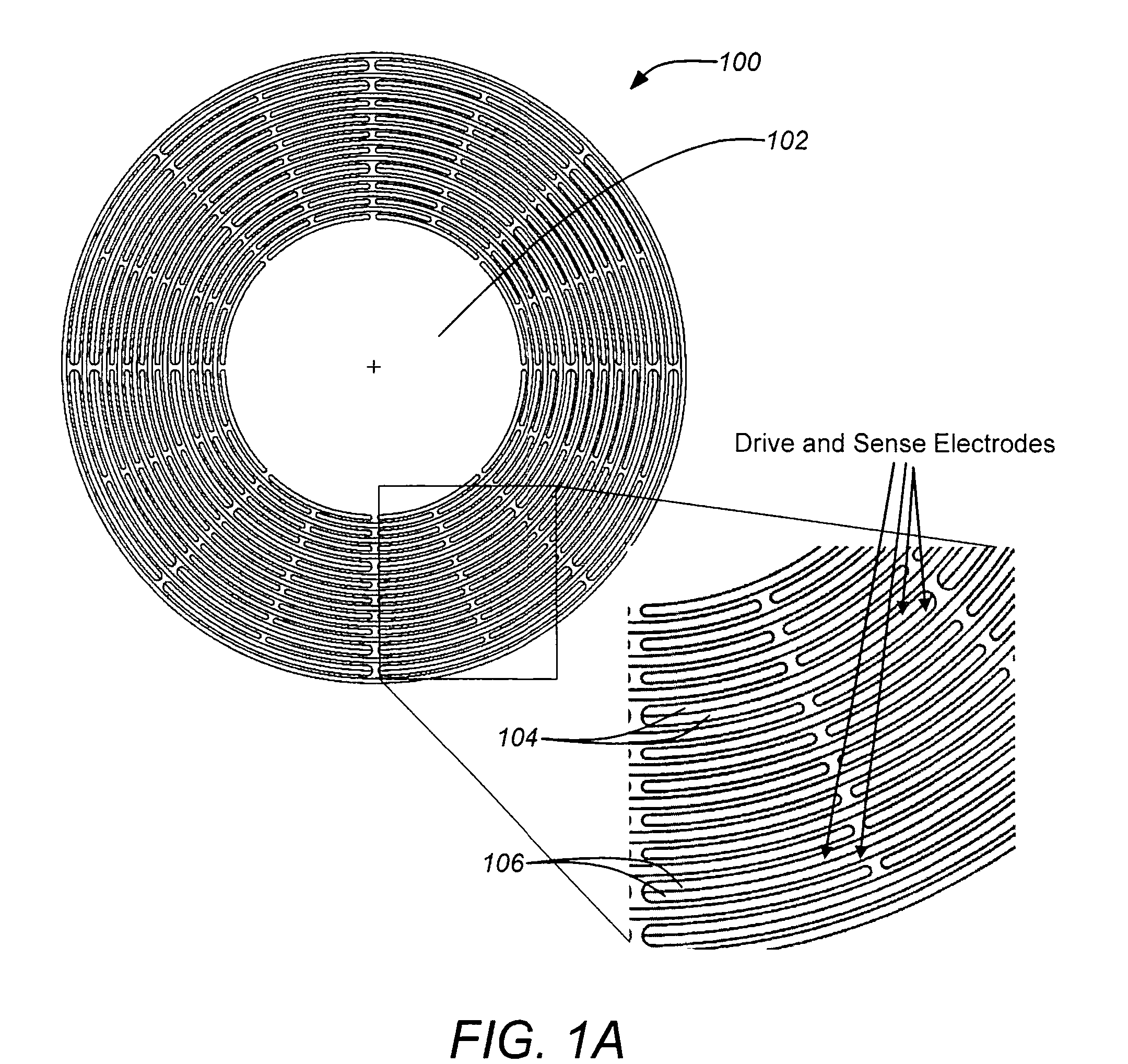

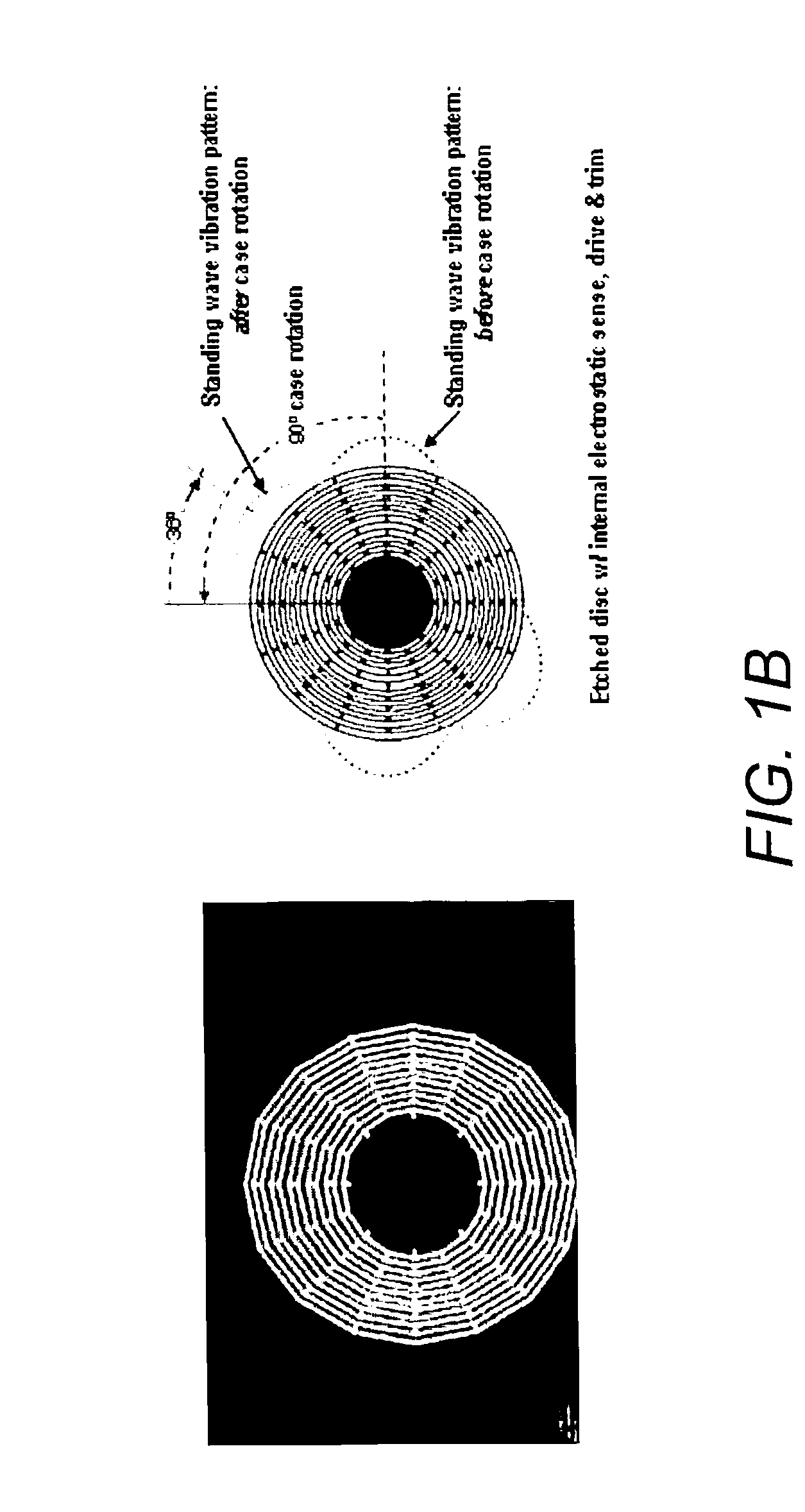

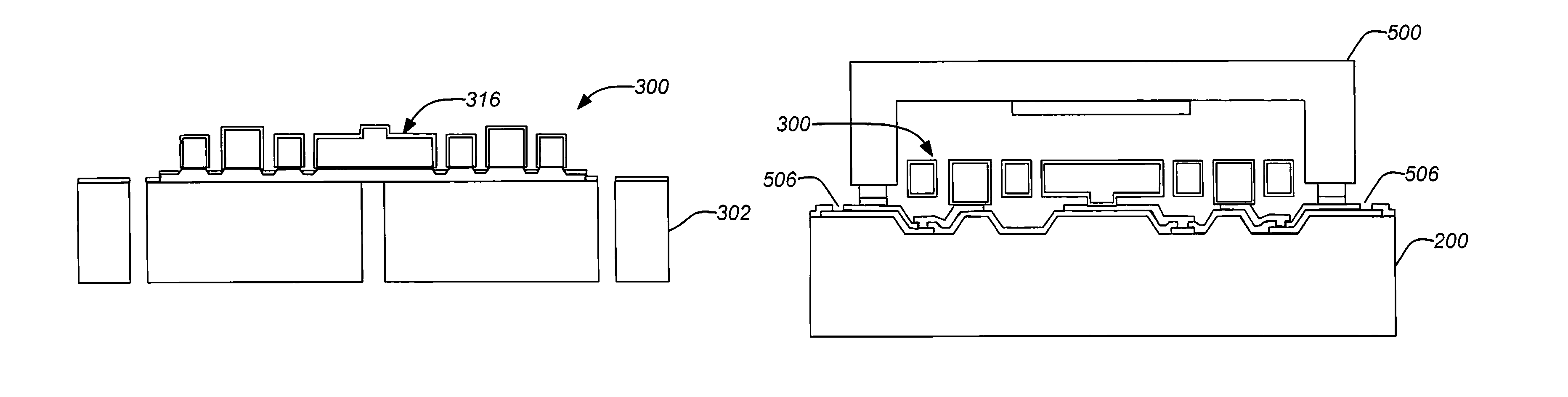

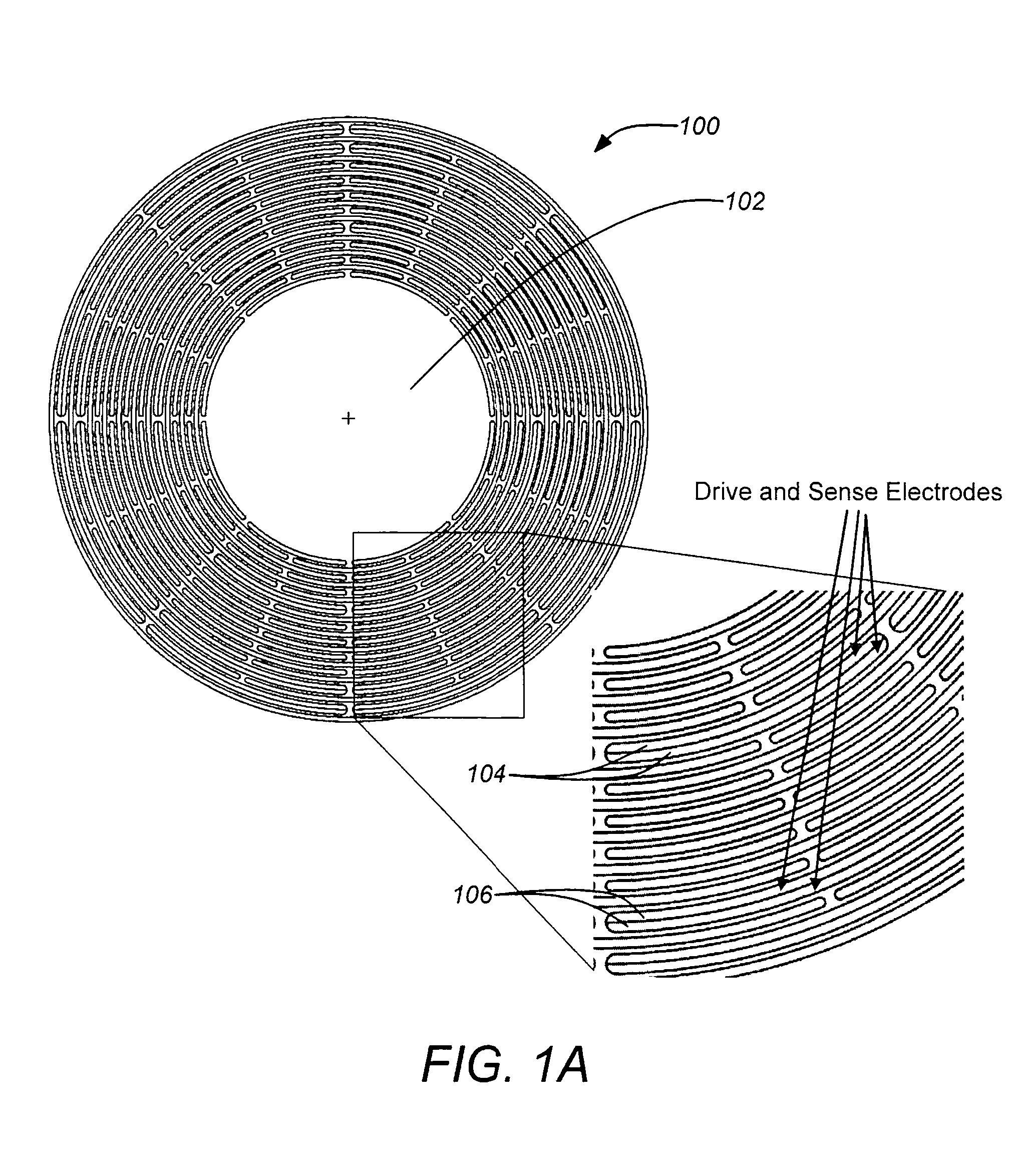

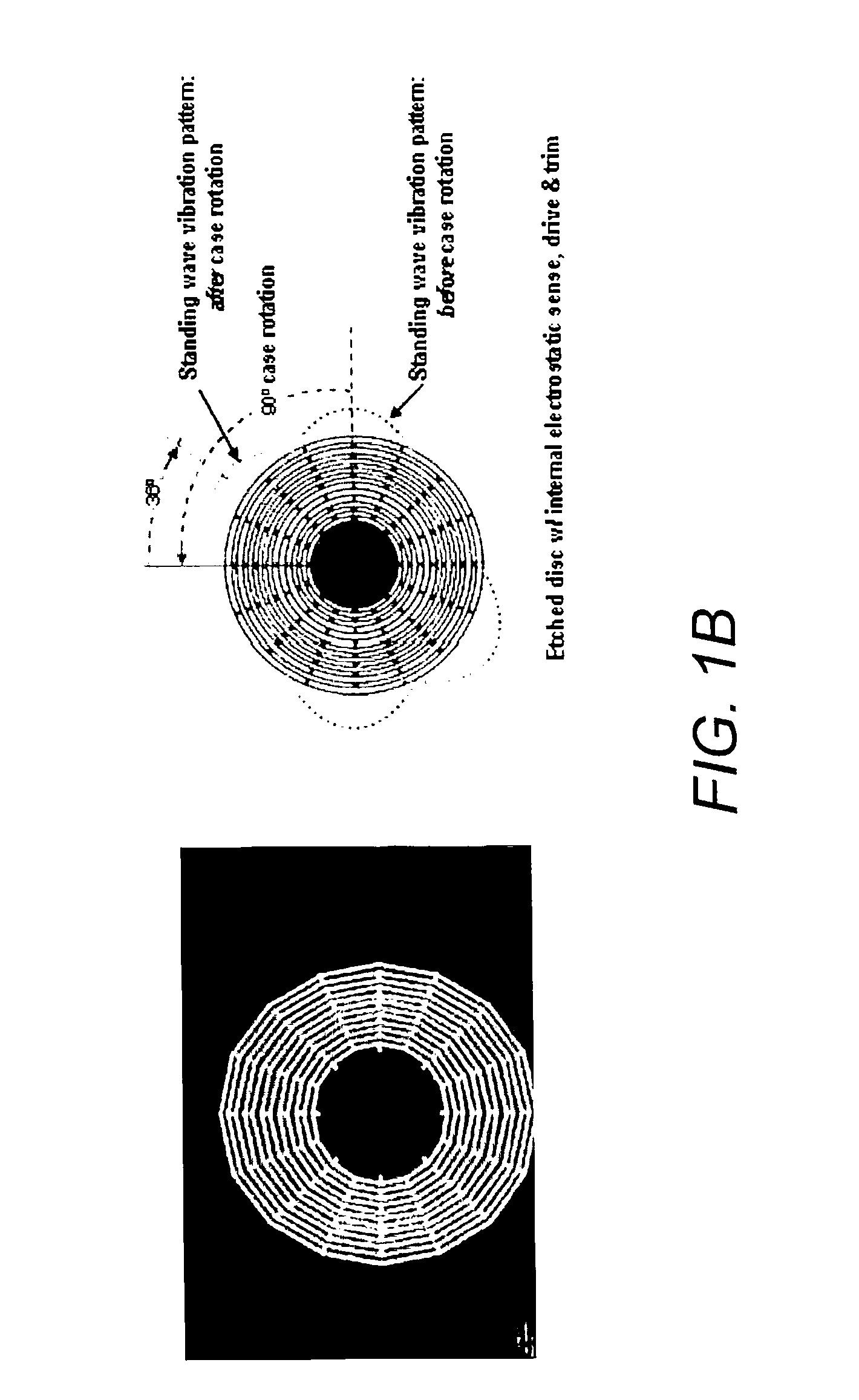

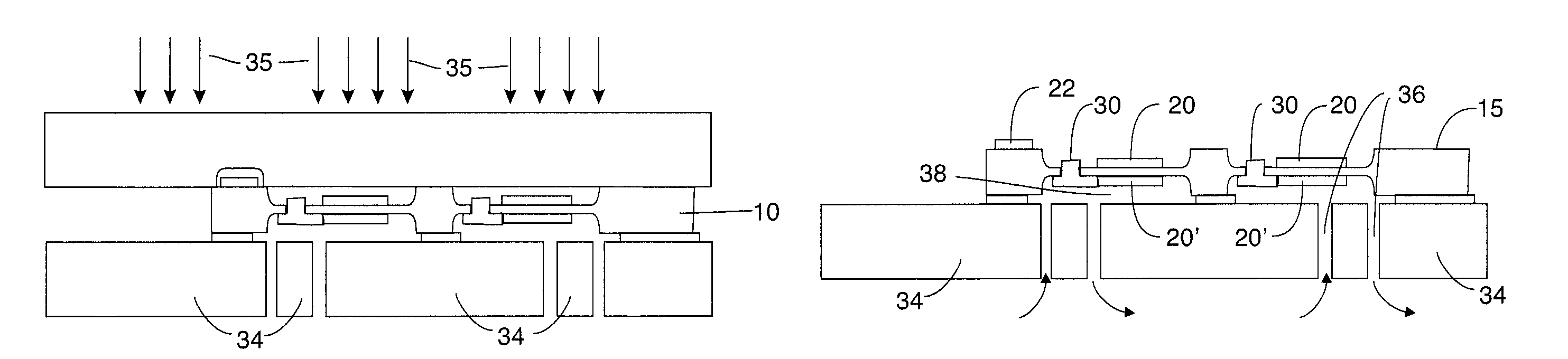

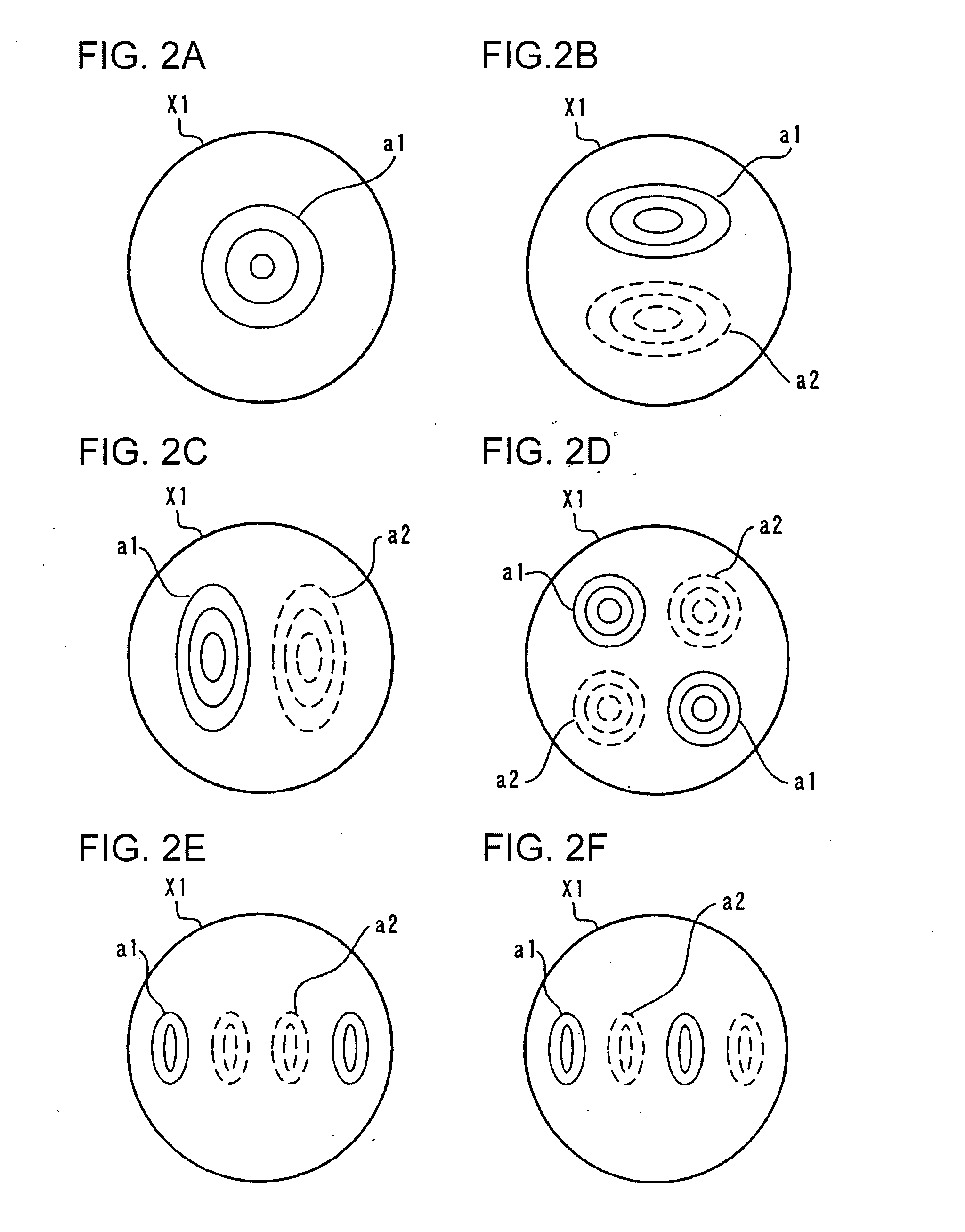

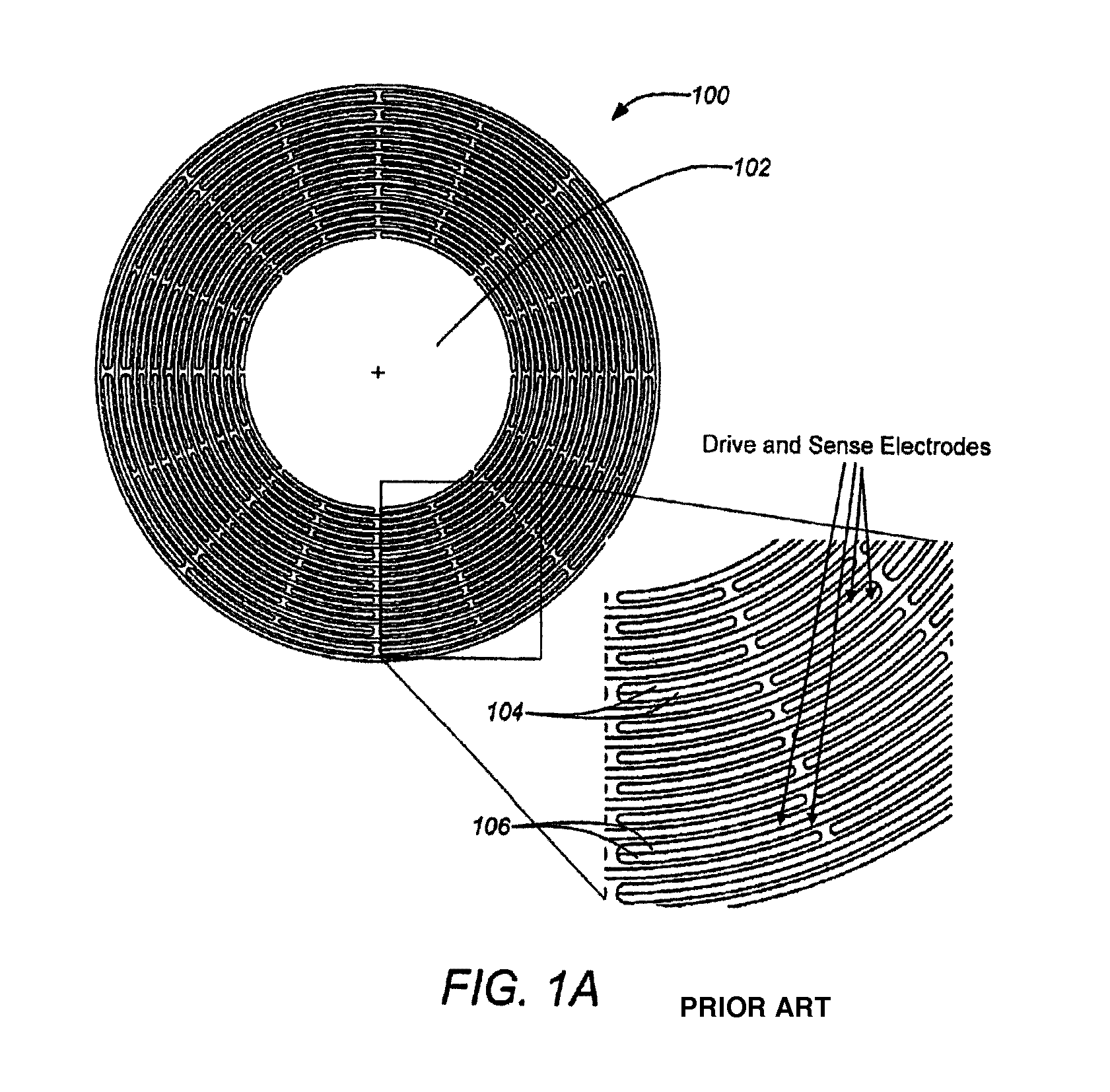

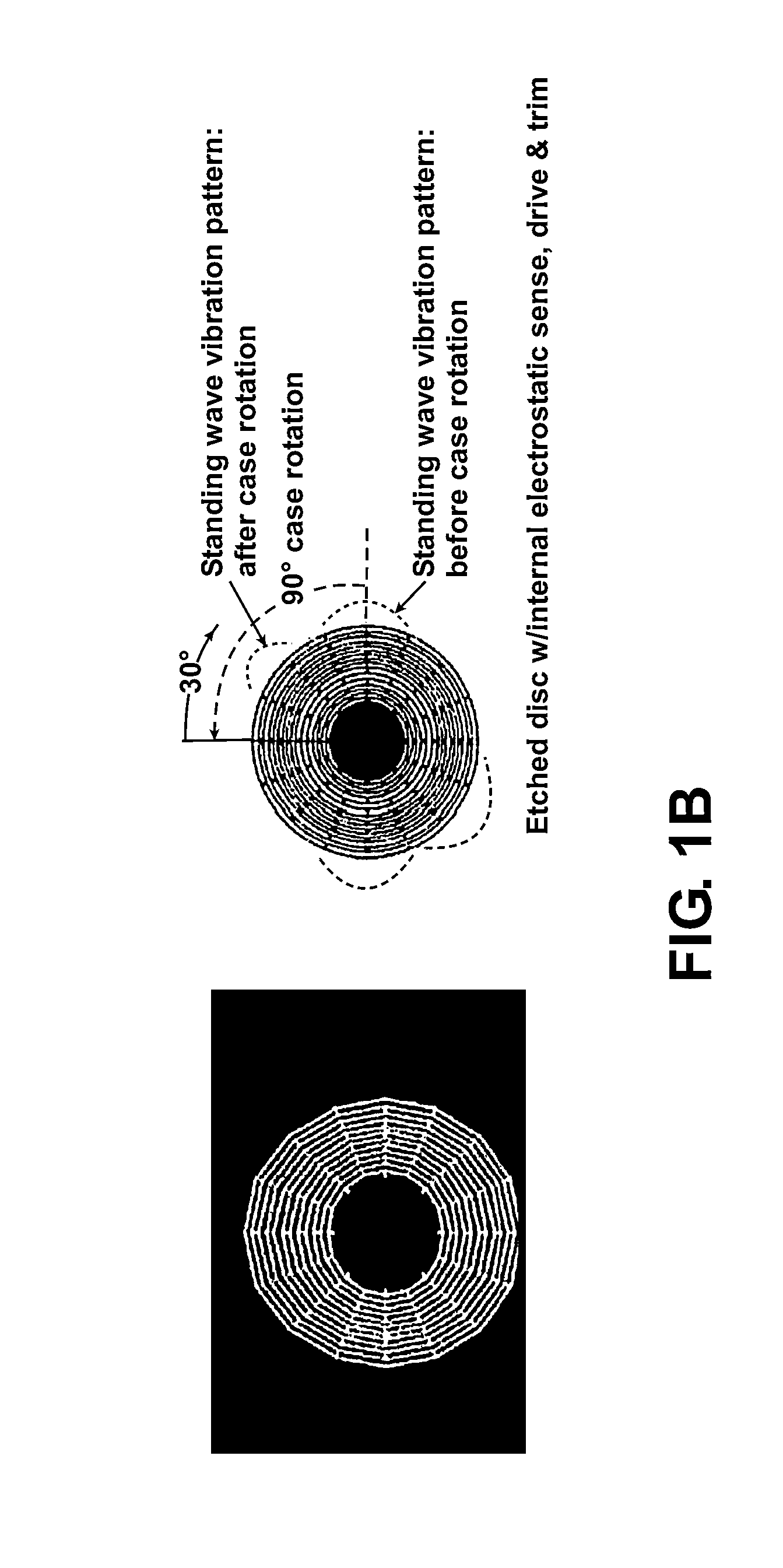

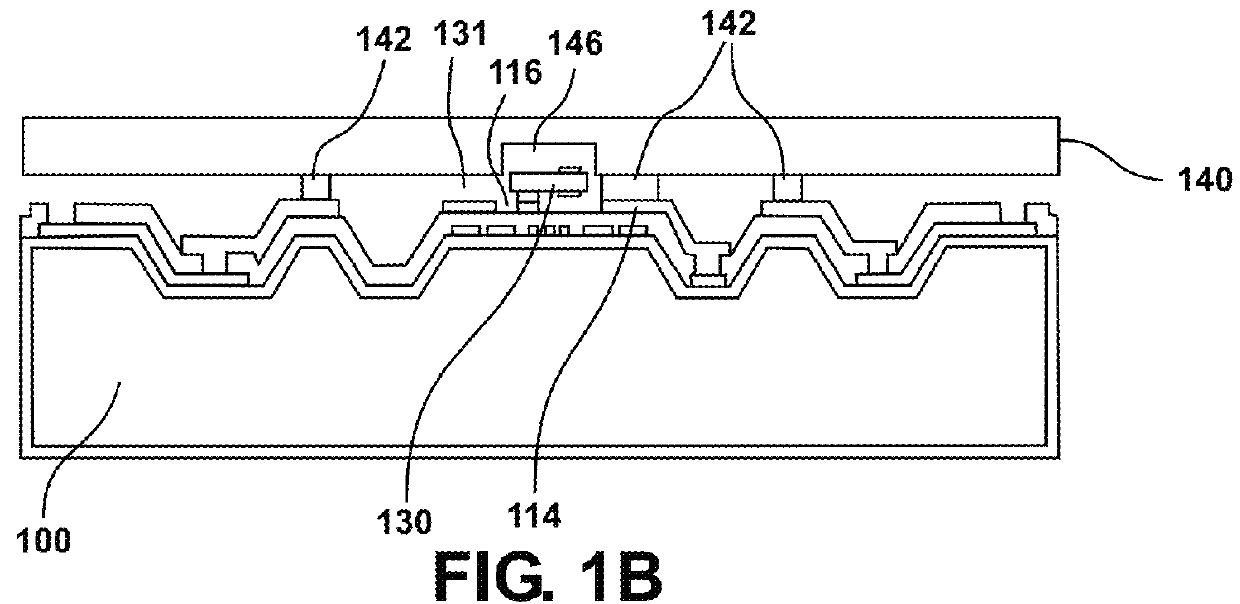

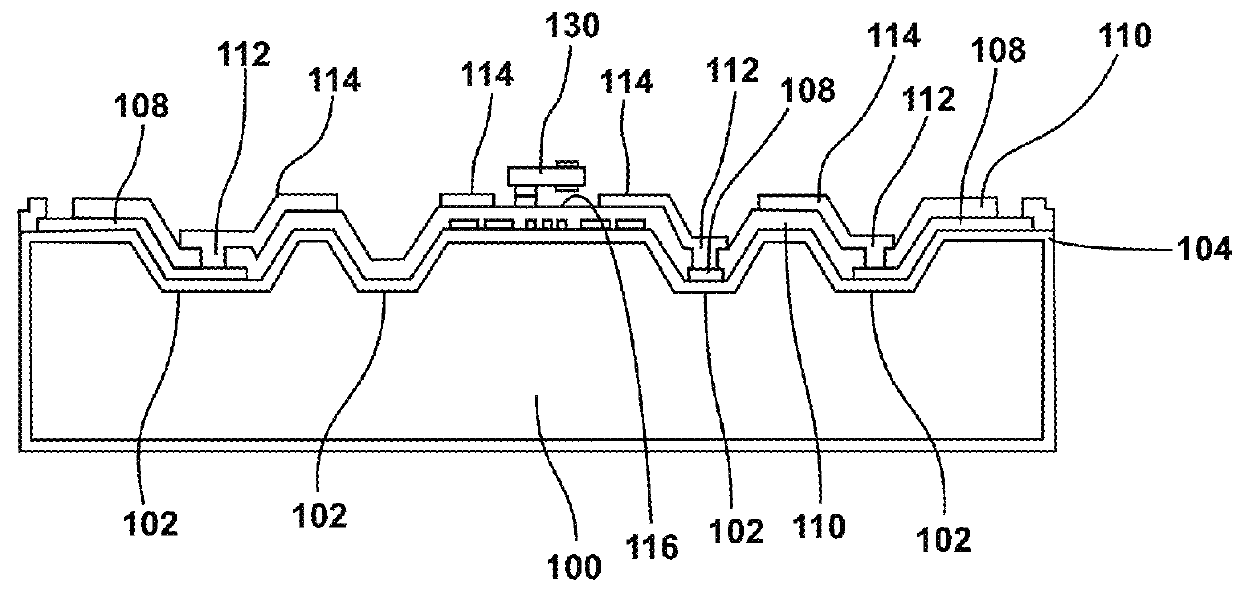

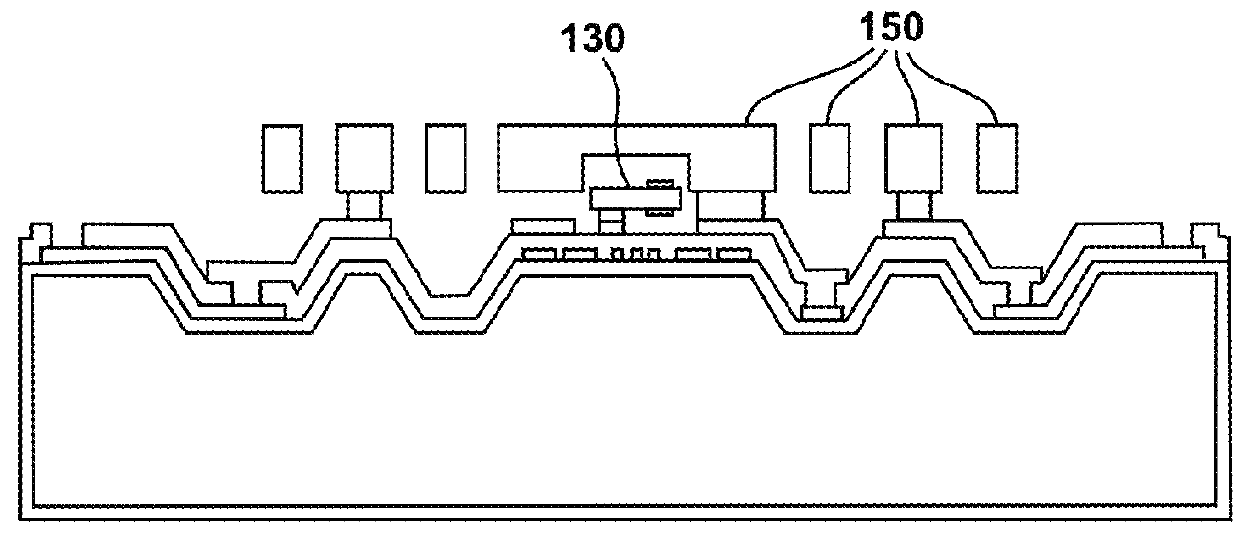

Disc resonator gyroscopes

ActiveUS20070017287A1Low anchor lossHigh QAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCapacitanceCircular disc

Embodiments of the present invention are directed to apparatuses and methods of making a micromachined resonator gyroscope, e.g. a disc resonator gyro (DRG), including one or more of the following novel features. Embodiments of the invention may comprise a triple-wafer stack gyroscope with an all fused quartz (or all silicon) construction for an electrical baseplate, resonator and vacuum cap. This can yield superior thermal stability over prior art designs. A typical resonator embodiment may include a centrally anchored disc with high aspect-ratio in-plane electrostatic drive and sense electrodes to create large capacitance. A silicon sacrificial layer may be employed for attaching a quartz resonator wafer to a quartz handle wafer for high aspect-ratio etching. In addition, embodiments of the invention may comprise a low thermal stress, wafer-level vacuum packaged gyroscope with on-chip getter. An ultra-thin conductive layer deposited on the quartz resonator may also be utilized for high Q.

Owner:THE BOEING CO

Disc resonator gyroscopes

ActiveUS7581443B2Low anchor lossHigh QAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCapacitanceGyroscope

Embodiments of the present invention are directed to apparatuses and methods of making a micromachined resonator gyroscope, e.g. a disc resonator gyro (DRG), including one or more of the following novel features. Embodiments of the invention may comprise a triple-wafer stack gyroscope with an all fused quartz (or all silicon) construction for an electrical baseplate, resonator and vacuum cap. This can yield superior thermal stability over prior art designs. A typical resonator embodiment may include a centrally anchored disc with high aspect-ratio in-plane electrostatic drive and sense electrodes to create large capacitance. A silicon sacrificial layer may be employed for attaching a quartz resonator wafer to a quartz handle wafer for high aspect-ratio etching. In addition, embodiments of the invention may comprise a low thermal stress, wafer-level vacuum packaged gyroscope with on-chip getter. An ultra-thin conductive layer deposited on the quartz resonator may also be utilized for high Q.

Owner:THE BOEING CO

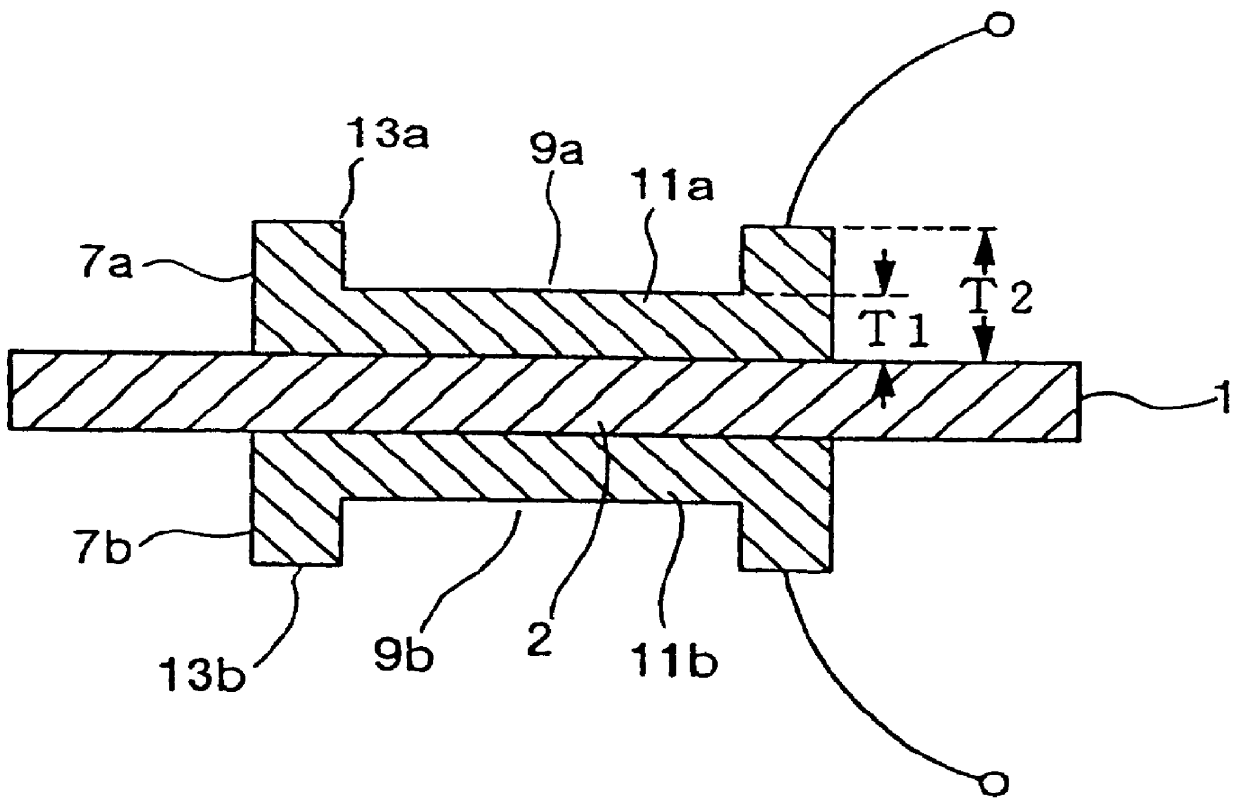

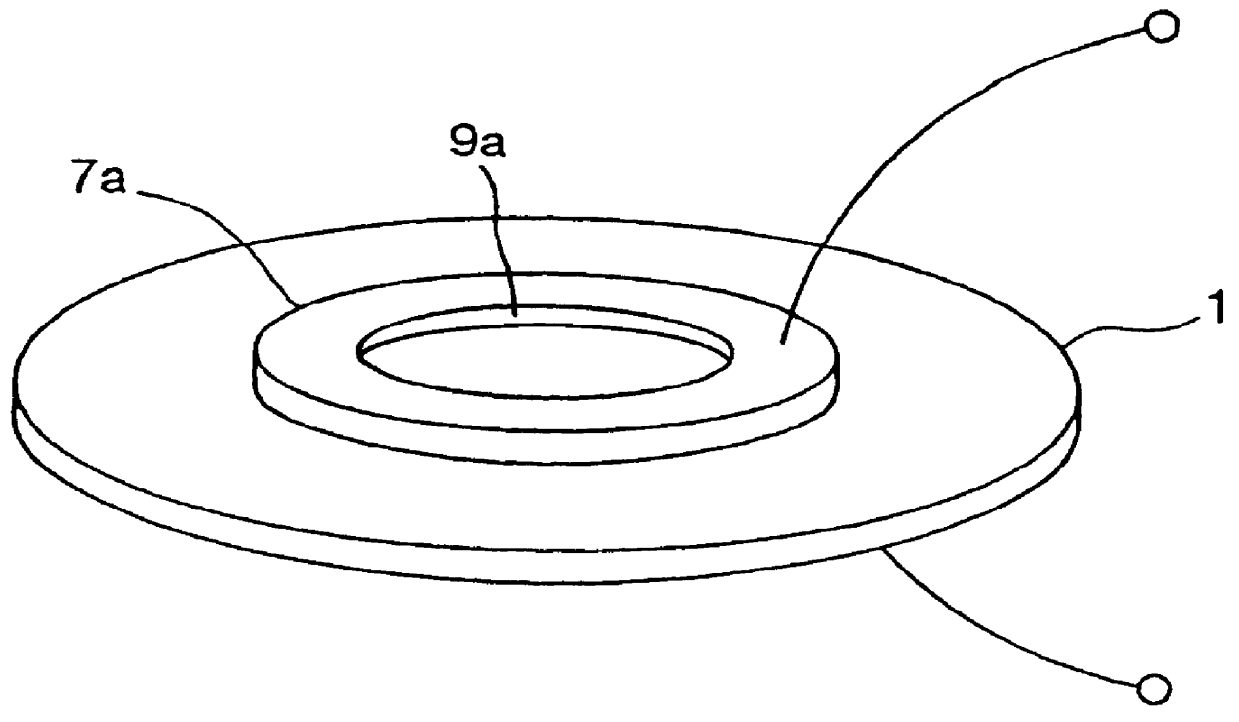

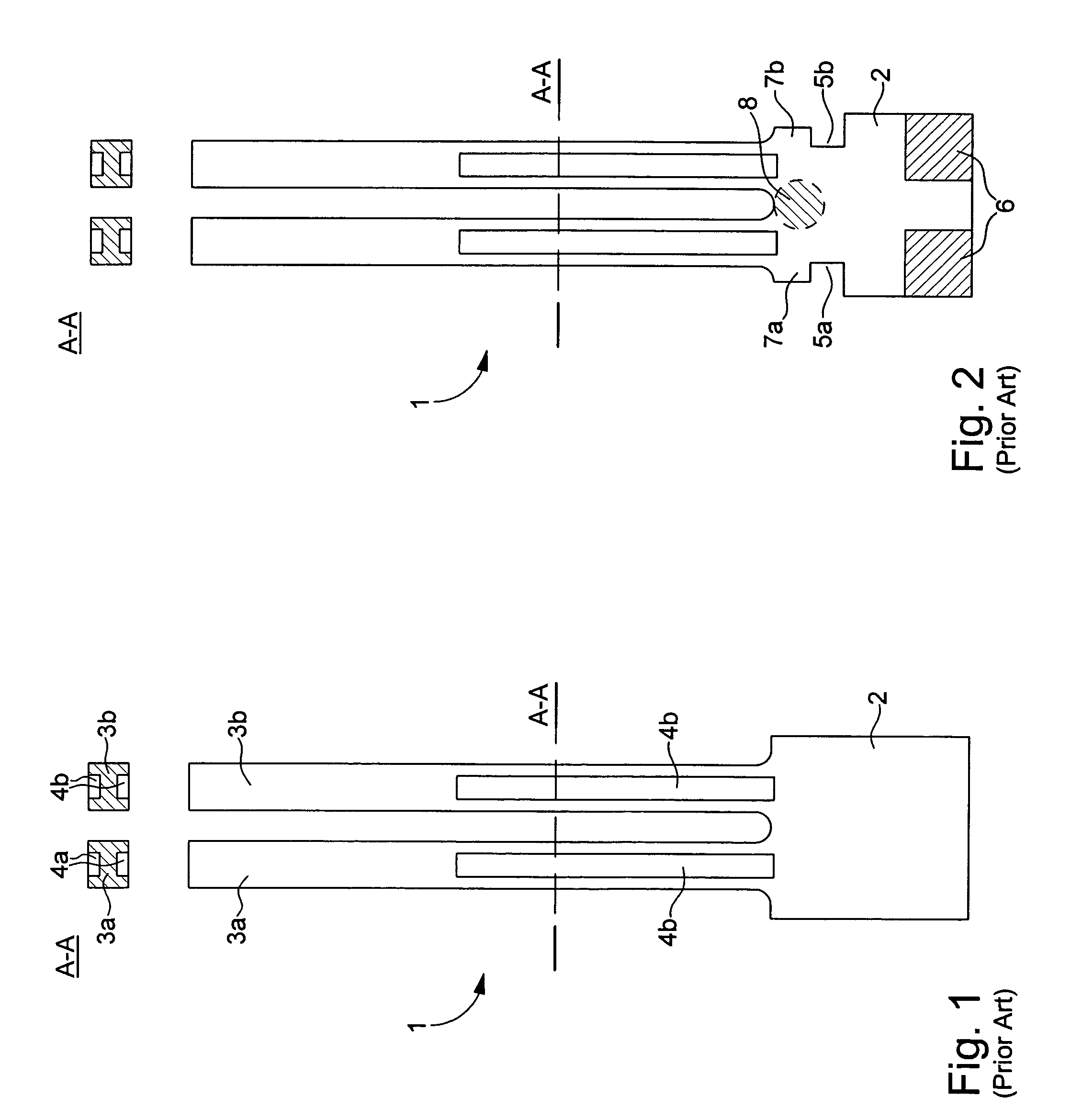

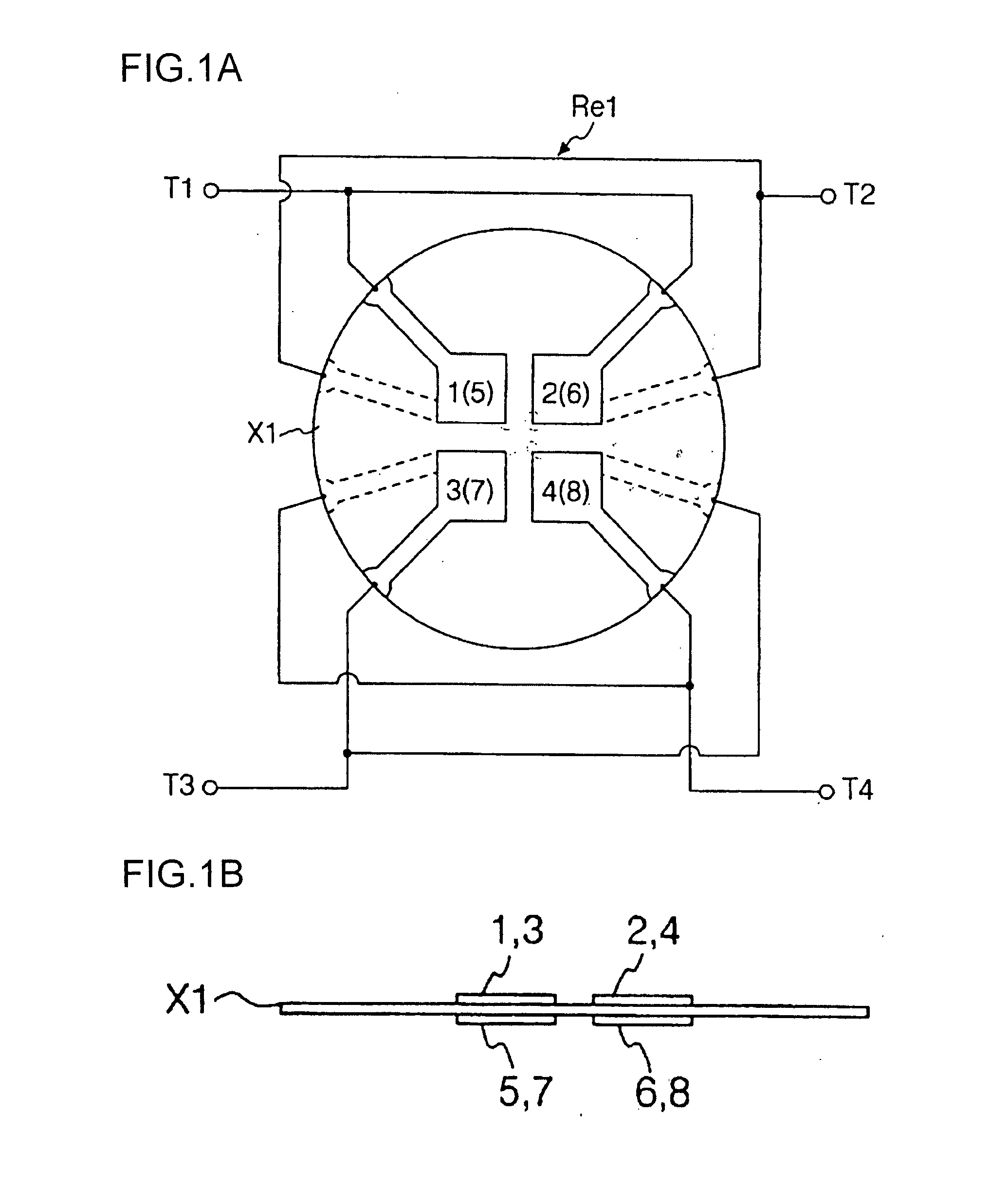

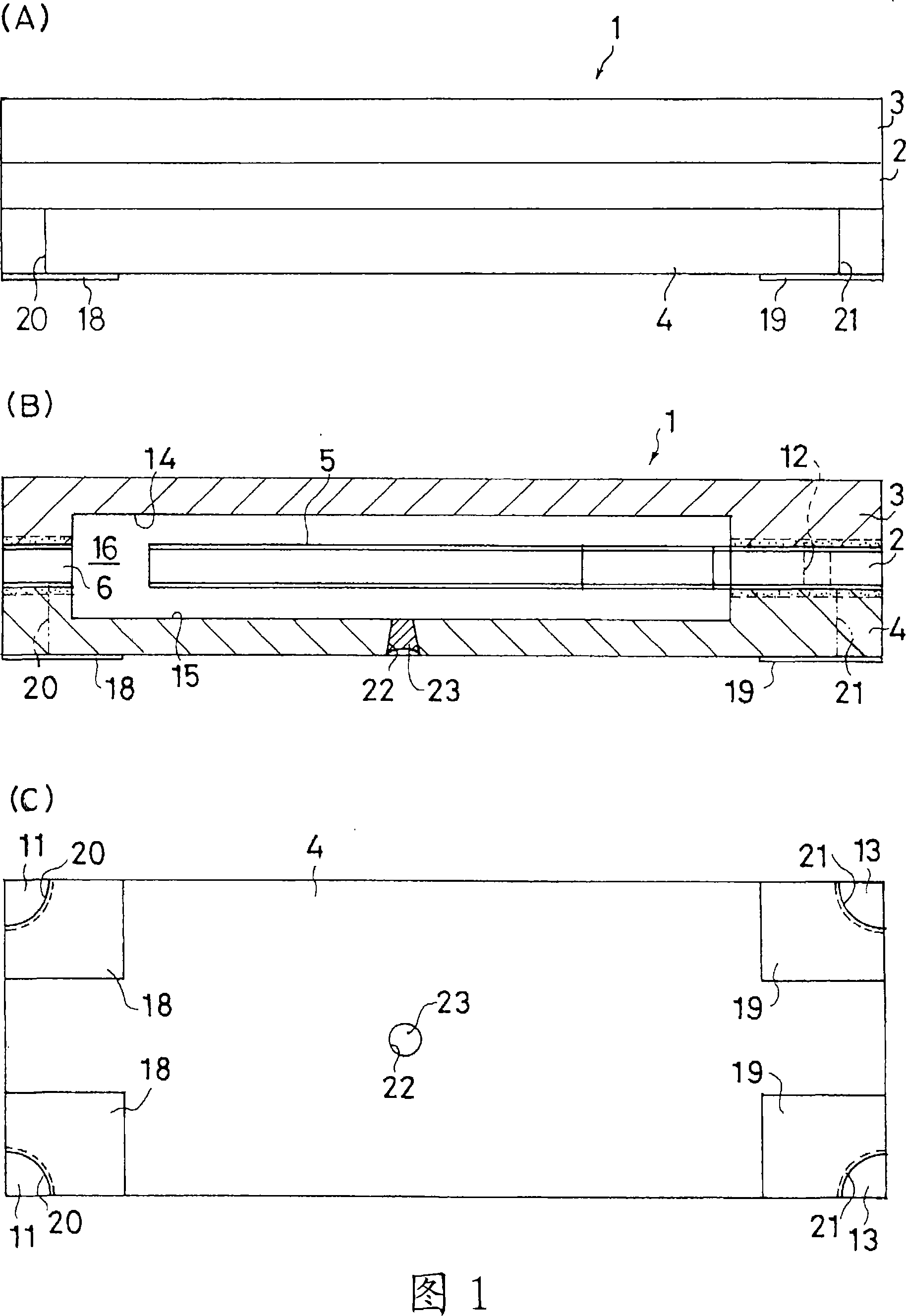

Piezoelectric vibrator and method for manufacturing the same

InactiveUS6111341APiezoelectric/electrostriction/magnetostriction machinesImpedence networksCapacitanceLimit value

PCT No. PCT / JP97 / 03807 Sec. 371 Date Dec. 21, 1998 Sec. 102(e) Date Dec. 21, 1998 PCT Filed Oct. 22, 1997 PCT Pub. No. WO98 / 38736 PCT Pub. Date Sep. 3, 1998In a piezoelectric vibrator which has excitation electrodes respectively disposed on the top surface and undersurface of a piezoelectric substrate, at least one of the excitation electrodes being an inverted-mesa electrode that has a recess formed in the opposite side of the electrode from the side which contacts the piezoelectric substrate. Thus, an AT-cut quartz resonator in which the capacitance ratio gamma is reduced to a value below the limit value can be provided as a result of use of the inverted-mesa electrodes as excitation electrodes.

Owner:TOYO TSUSHINKI

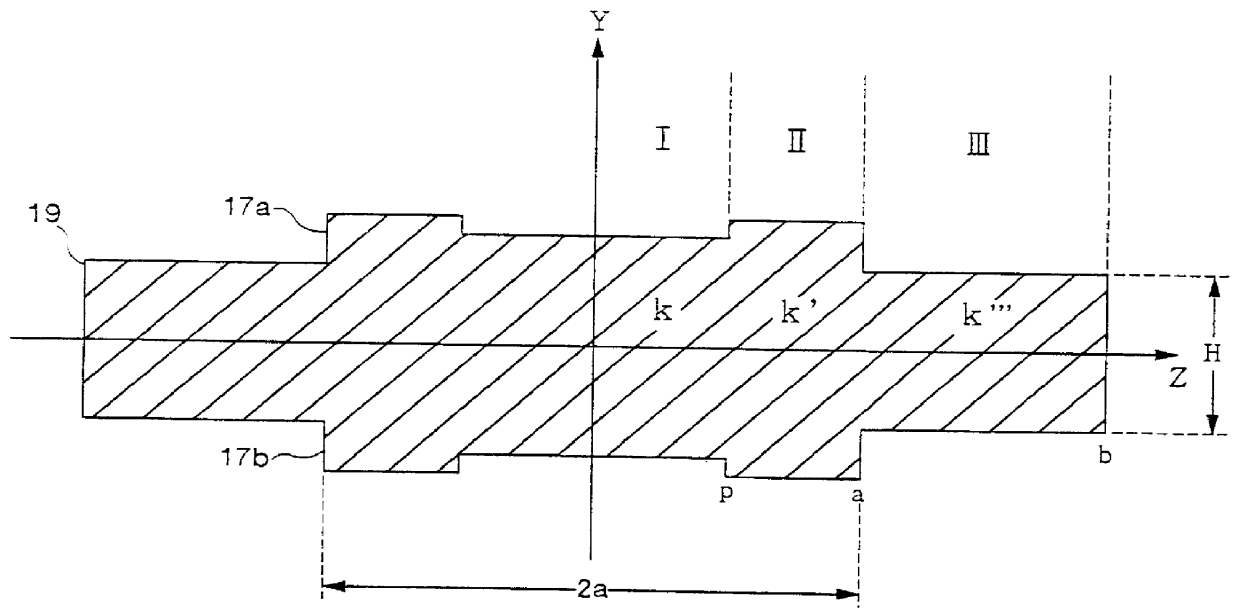

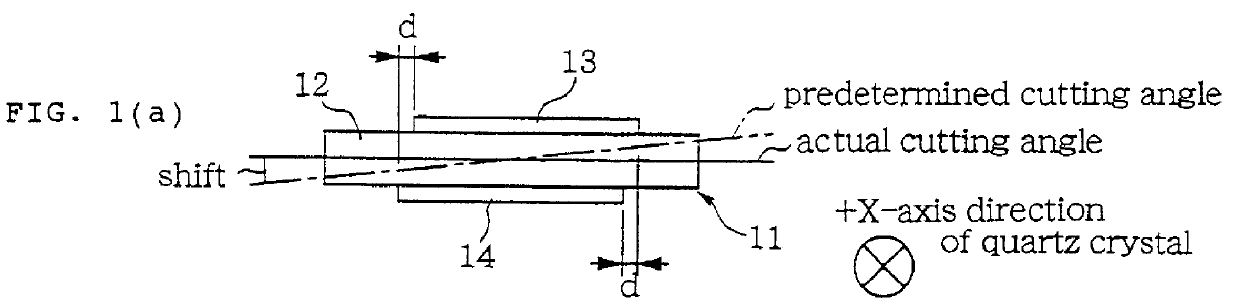

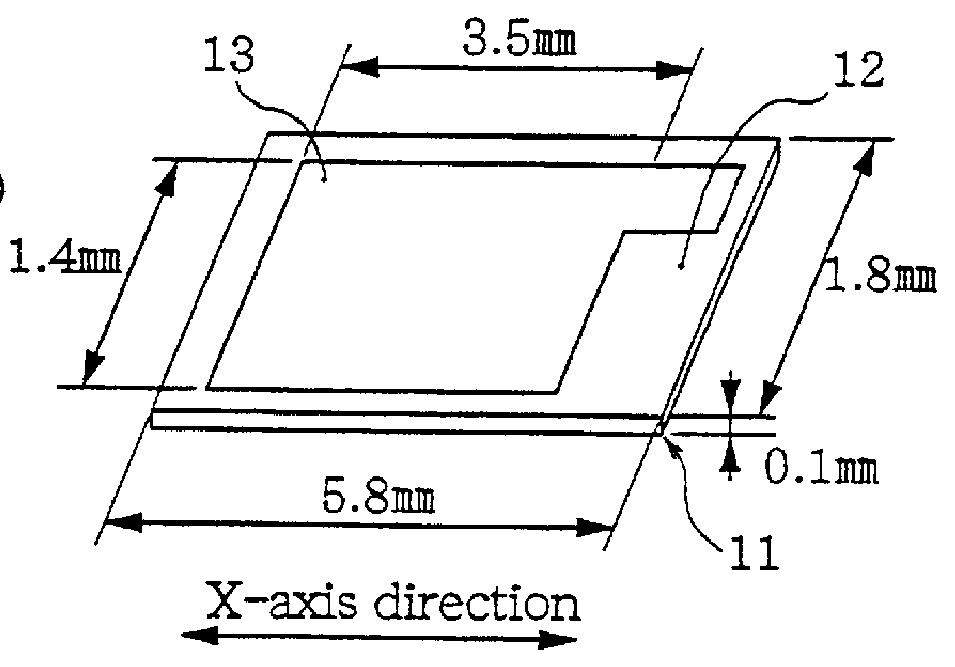

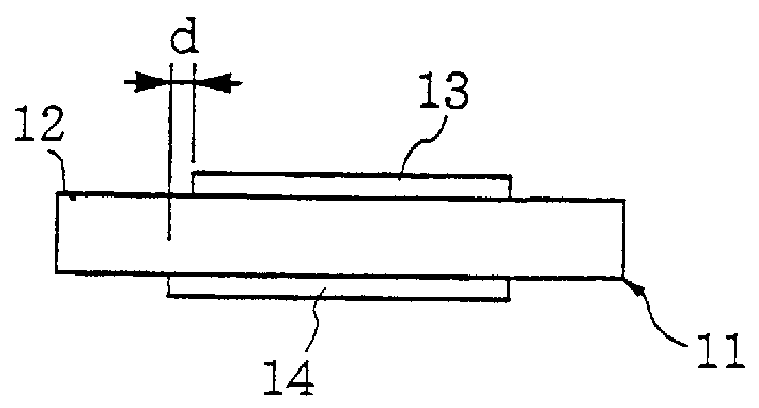

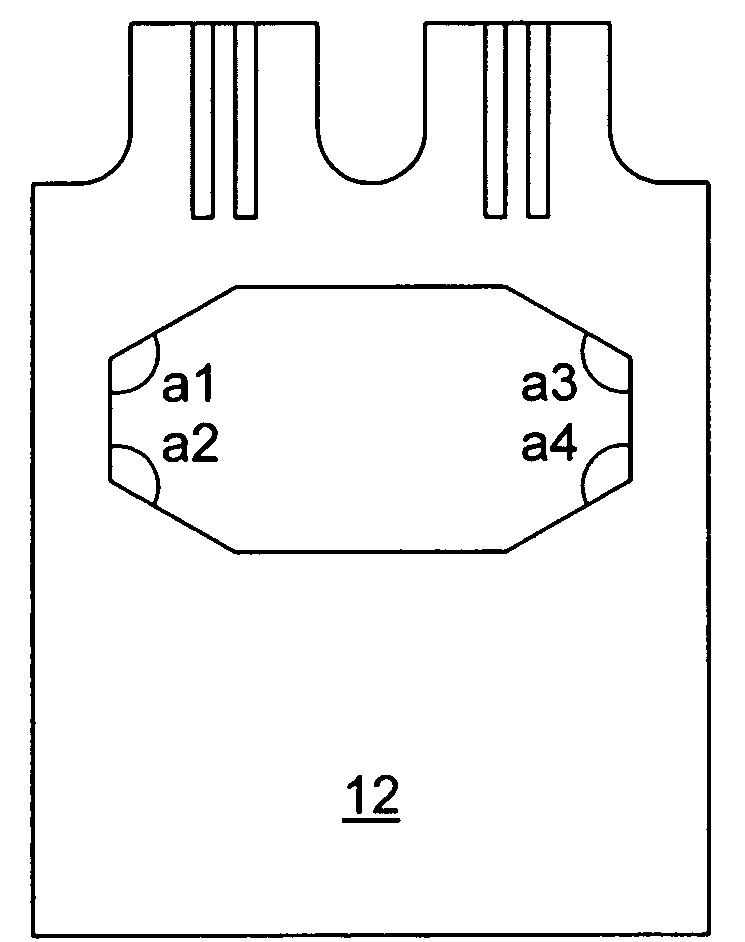

At-cut crystal resonator

InactiveUS6114801AImprove productivityEasy to correctPiezoelectric/electrostriction/magnetostriction machinesImpedence networksProduction rateIndustrial equipment

PCT No. PCT / JP98 / 01526 Sec. 371 Date Dec. 14, 1998 Sec. 102(e) Date Dec. 14, 1998 PCT Filed Apr. 2, 1998 PCT Pub. No. WO98 / 47226 PCT Pub. Date Oct. 22, 1998In an AT-cut quartz resonator having excitation electrodes formed on two principal surfaces of an AT-cut quartz substrate, the two electrodes are displaced a predetermined amount apart in a direction orthogonal to the X-axis direction so that a frequency deviation in a temperature range of from -10 DEG C. to 50 DEG C. is less than + / -2.5 ppm. Further, in an AT-cut quartz resonator in which vertically opposed electrodes on both principal surfaces of a quartz substrate are slightly displaced apart in opposite directions along the Z' axis of quartz crystal, a balancing load is formed on a piezoelectric substrate on the side opposite to the direction of displacement of the electrodes. Thus, the present invention dispenses with the need for raising the ratio of conforming to nonconforming quartz substrates by eliminating variations in their cutting angle, but makes it possible to use nonconforming quartz substrates to offer customers low-cost quartz resonators of oscillation frequencies following various specs, by making easy, simple structural modifications of slightly changing the electrode arrangement or structure, or by making simple improvements to the conventional quartz resonator manufacturing process. In the manufacture of oscillators for use in consumer-electronics equipment, it is possible to fulfill any particular specs without inserting a temperature compensating circuit in the oscillation circuit. In regards to industrial equipment, any adjustments need not be made to the temperature compensating circuit in the oscillation circuit, and this improves the productivity of various communications equipment and various electronics equipment and reduces their manufacturing costs.

Owner:TOYO TSUSHINKI

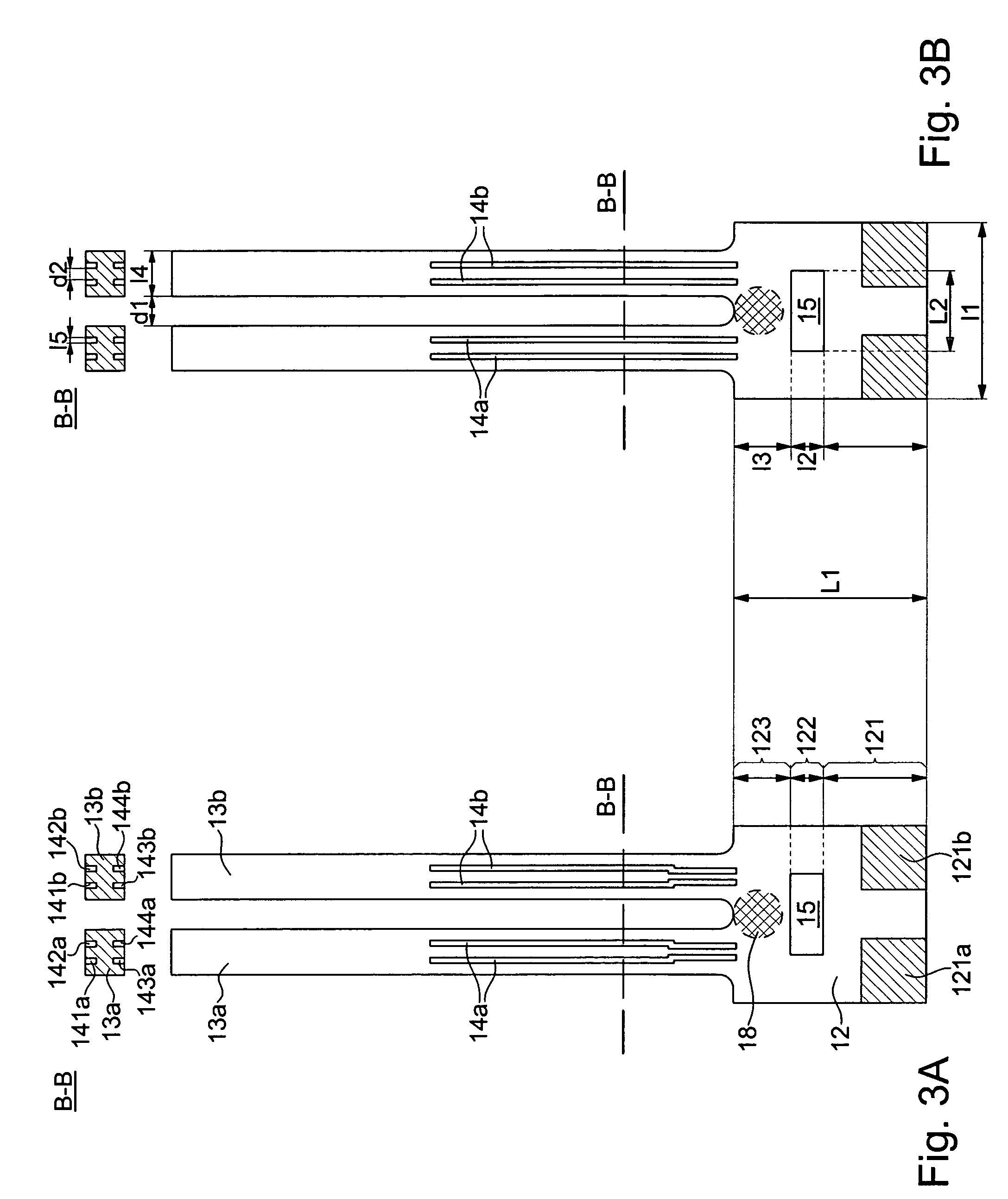

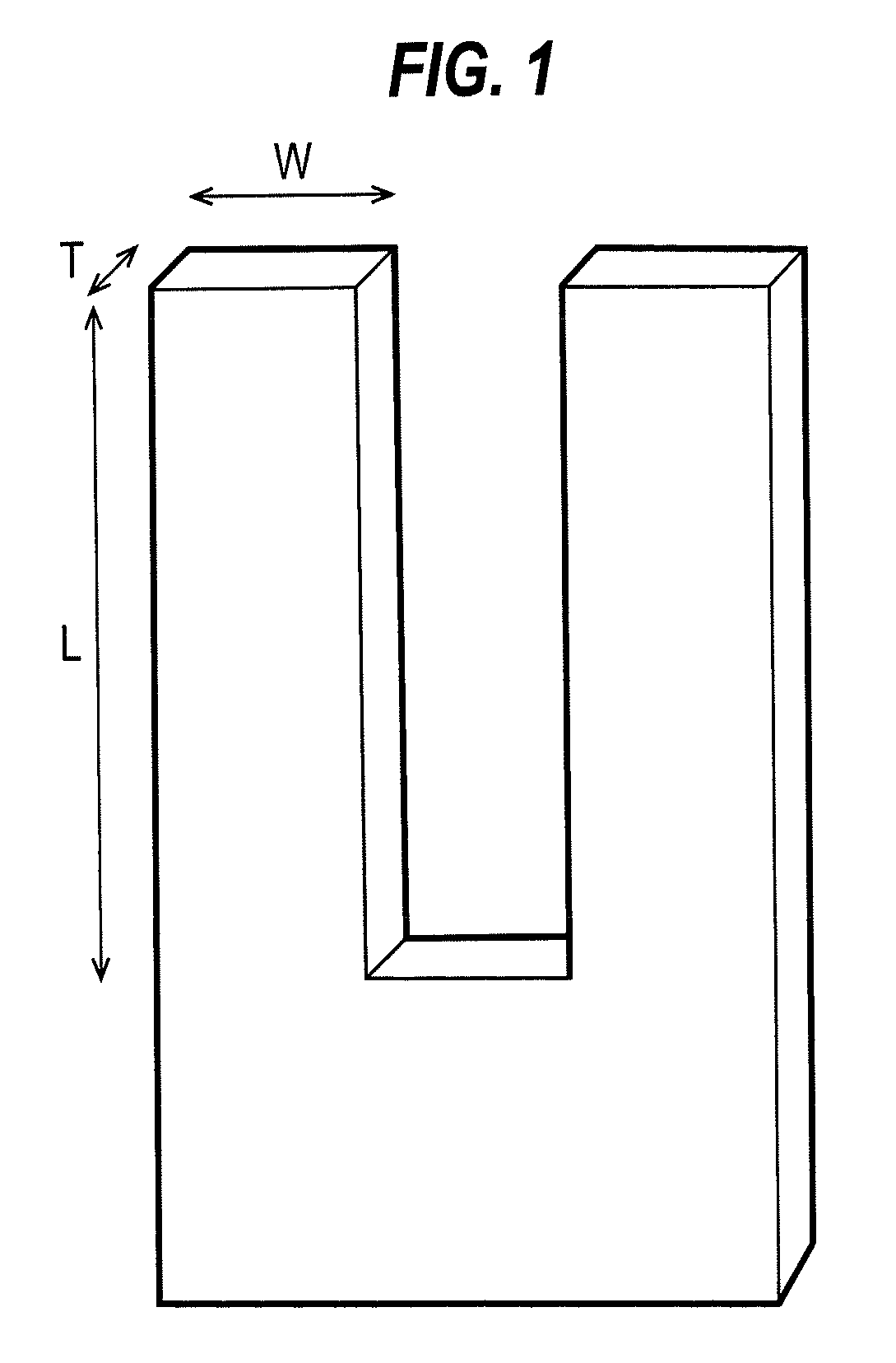

Quartz resonator of small dimensions

ActiveUS7253554B2Small sizeImprove seismic performancePiezoelectric/electrostriction/magnetostriction machinesImpedence networksEngineeringQuartz resonator

Owner:ETA SA MFG HORLOGERE SUISSE

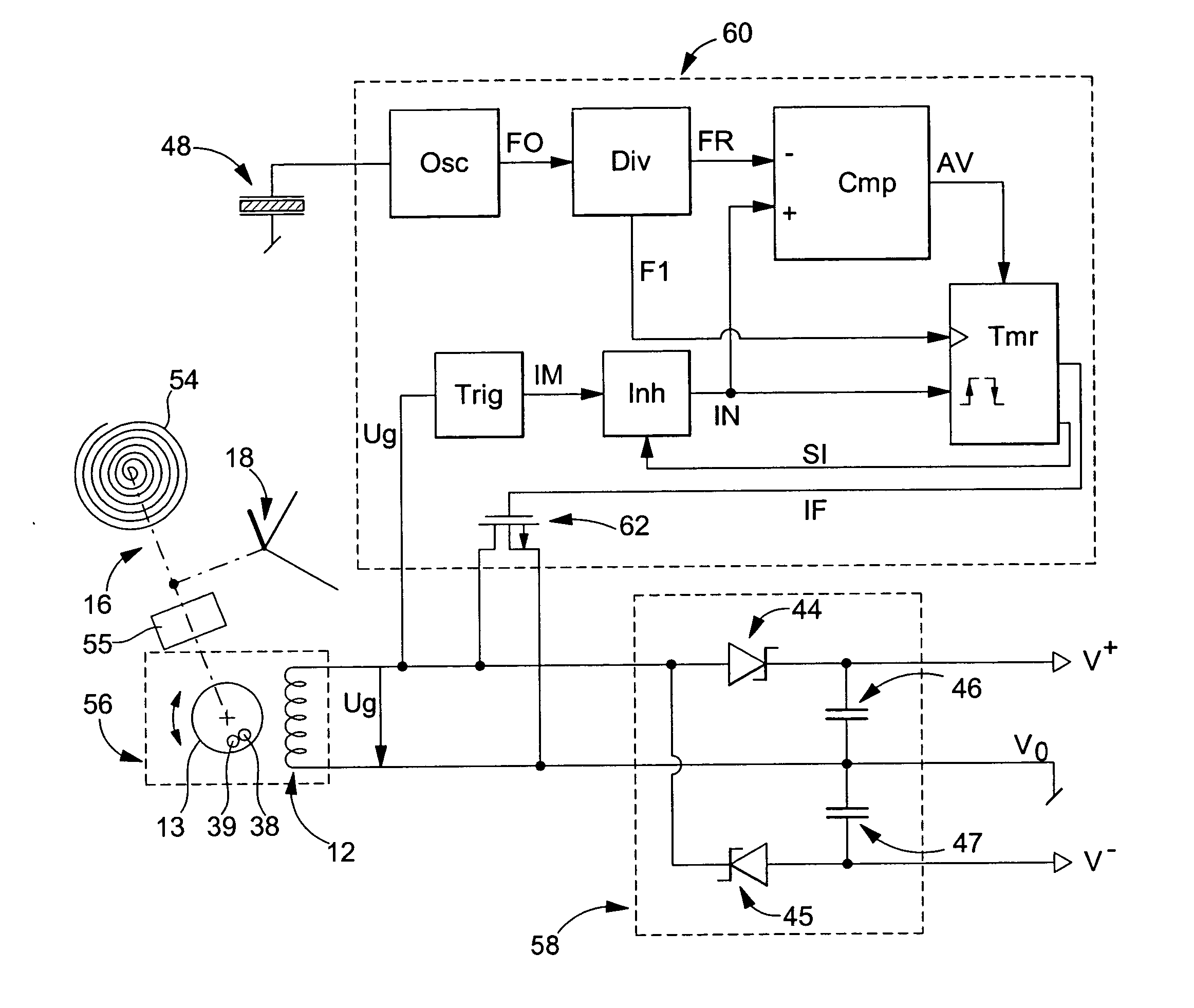

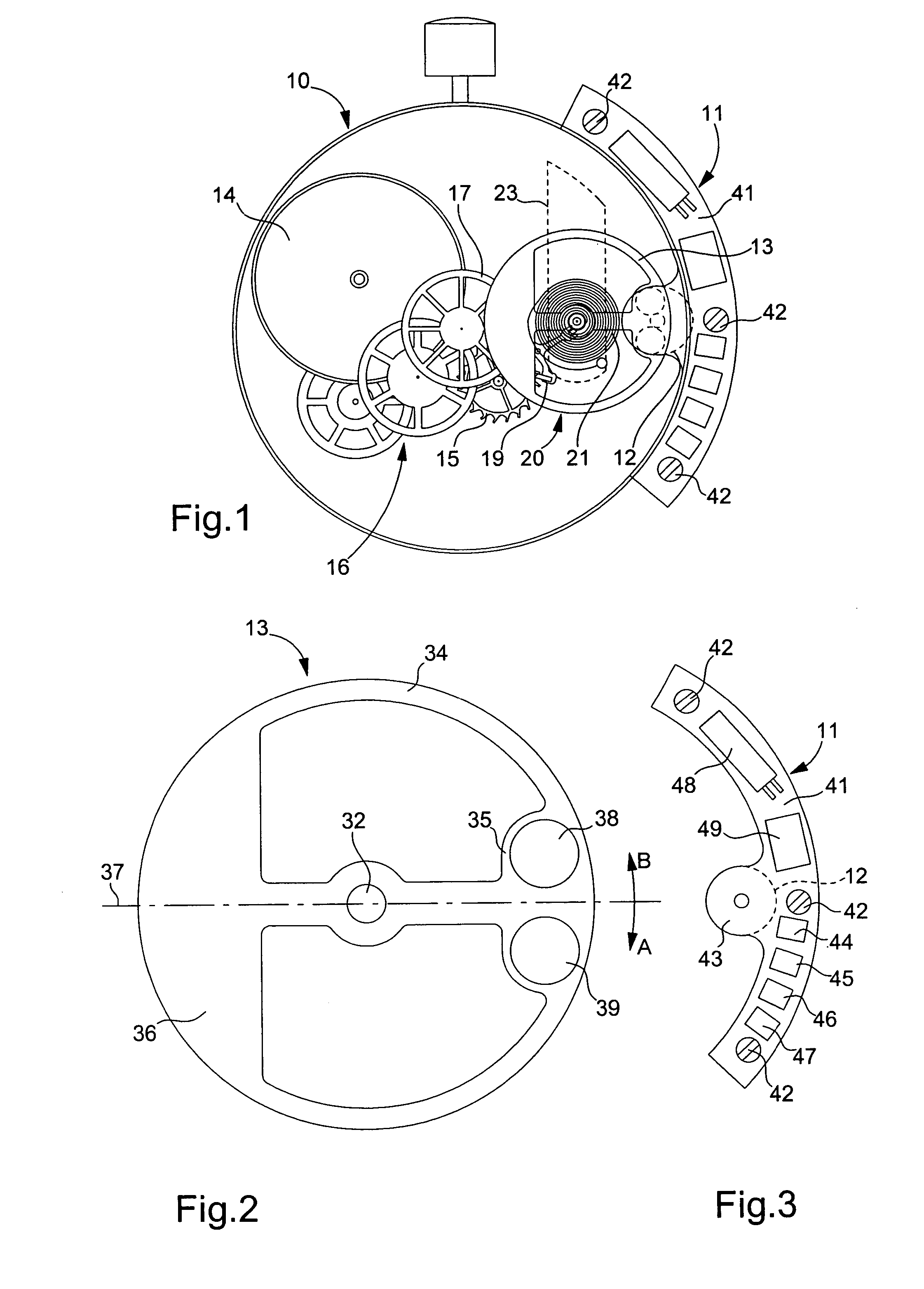

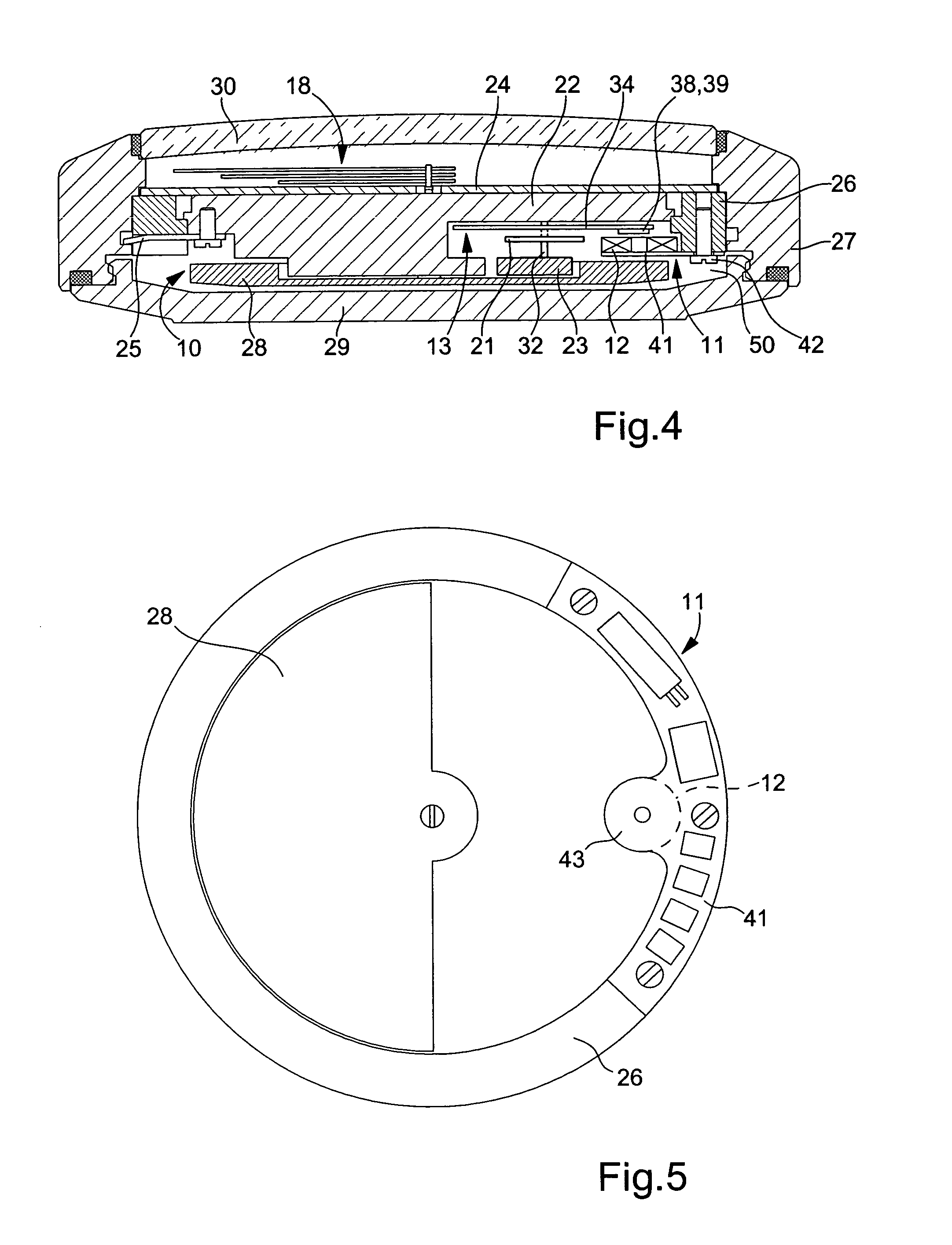

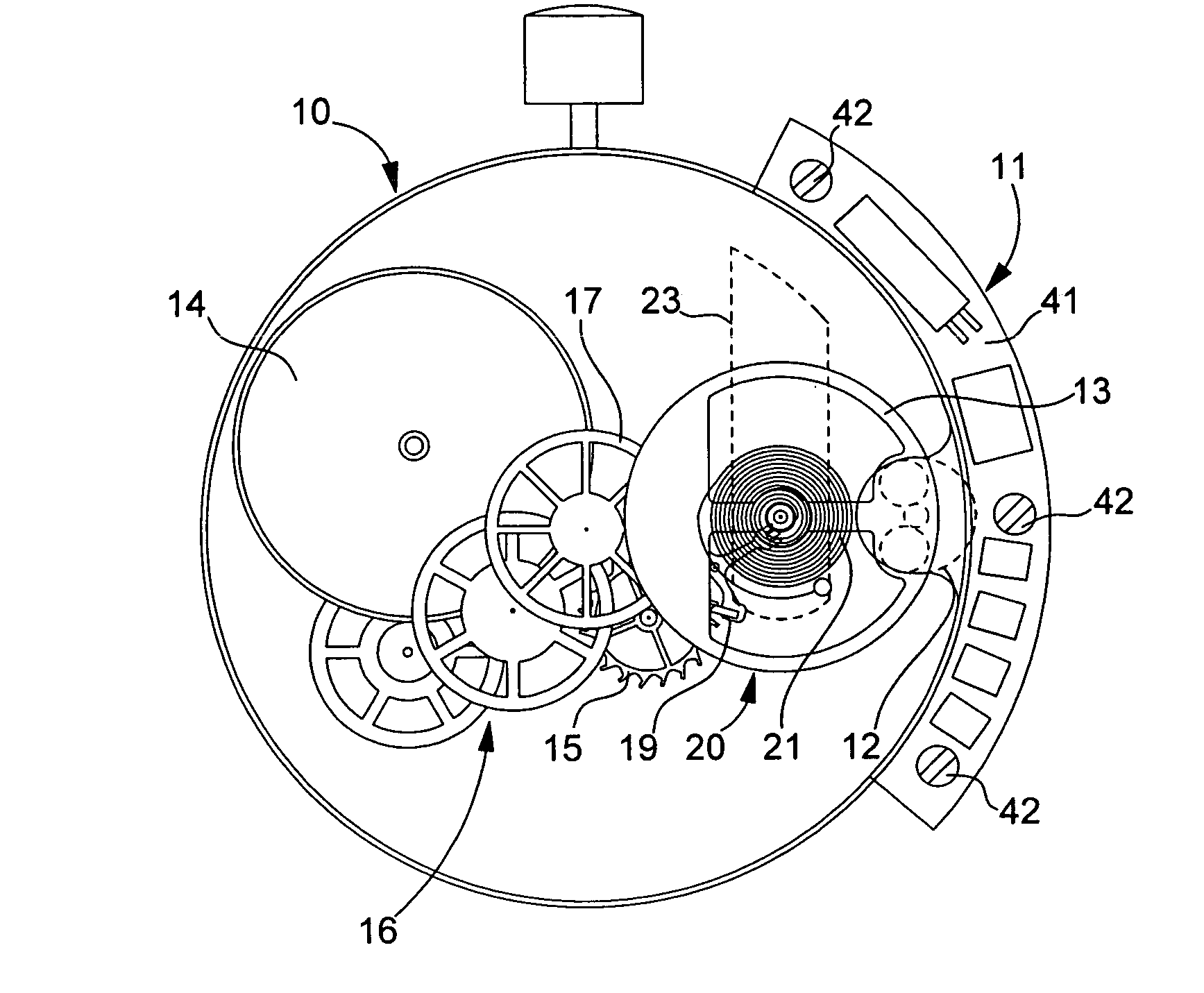

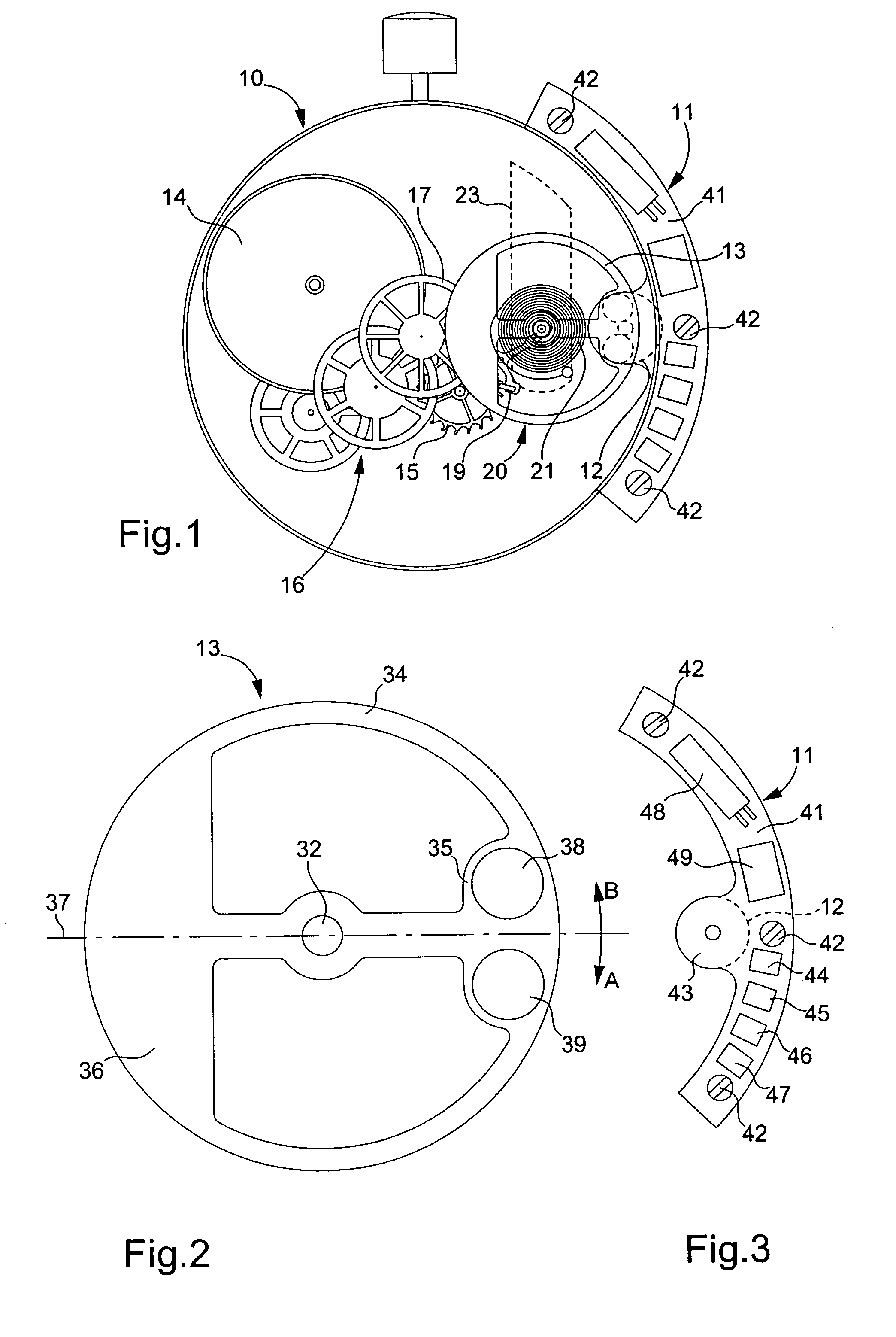

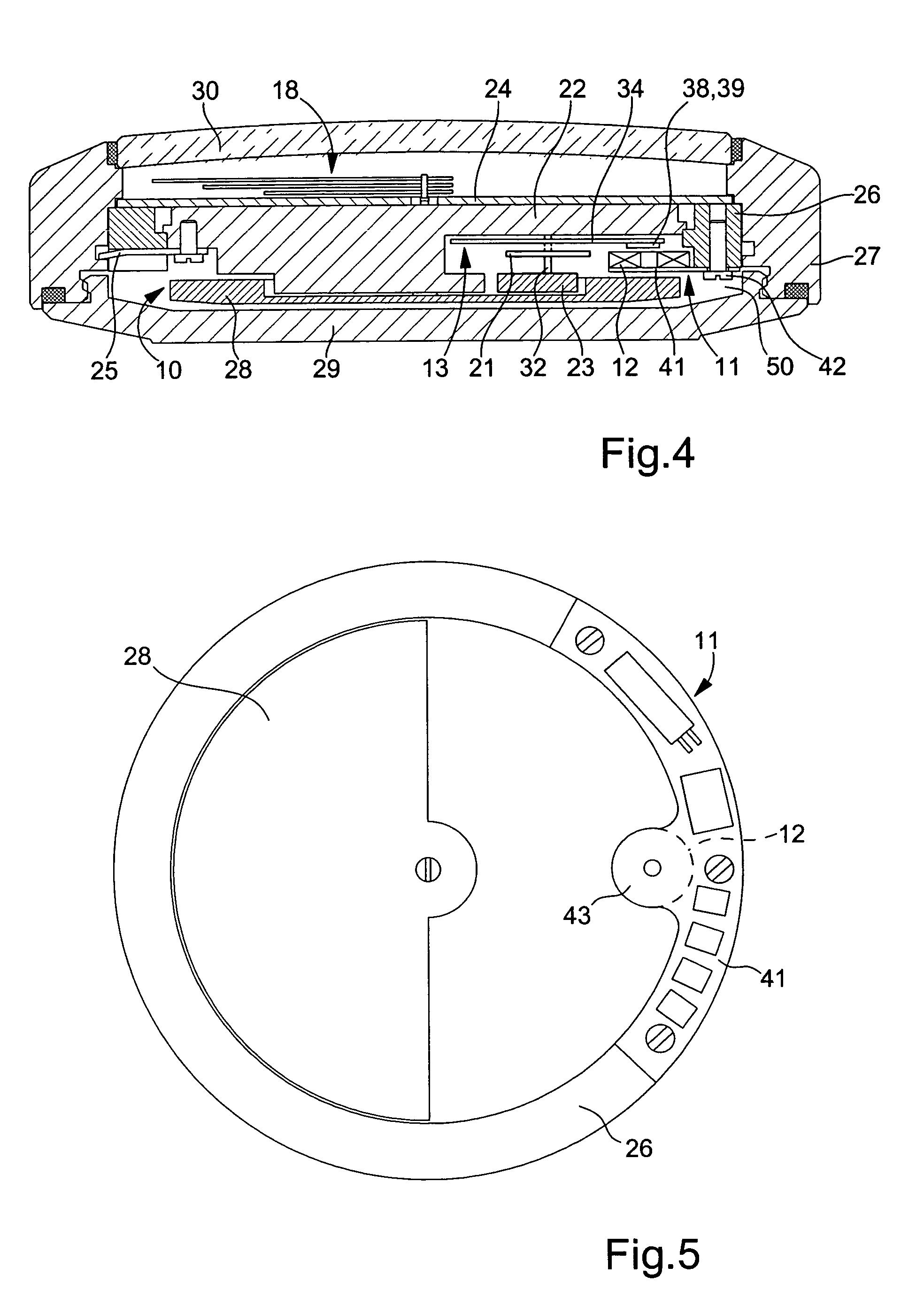

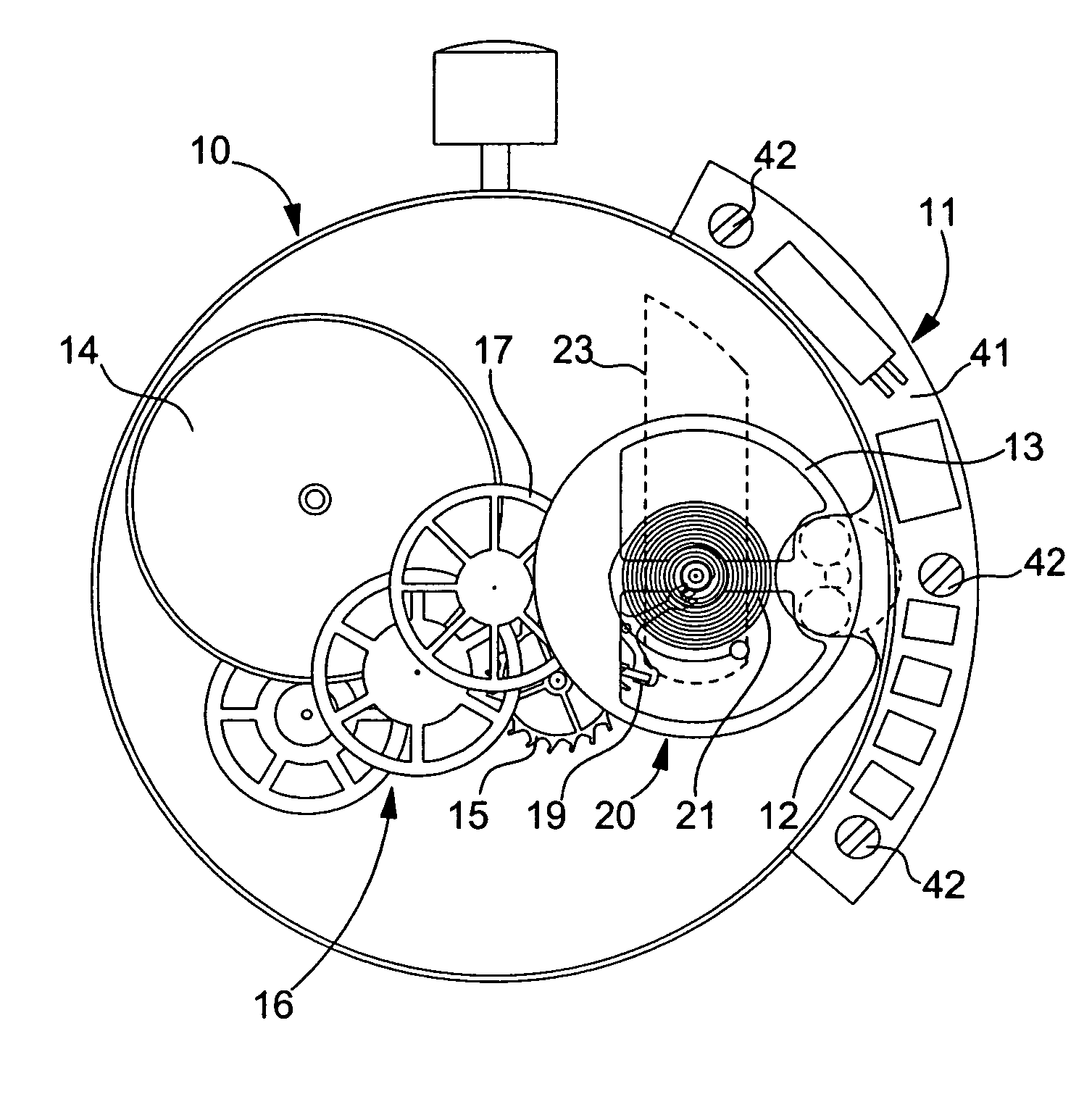

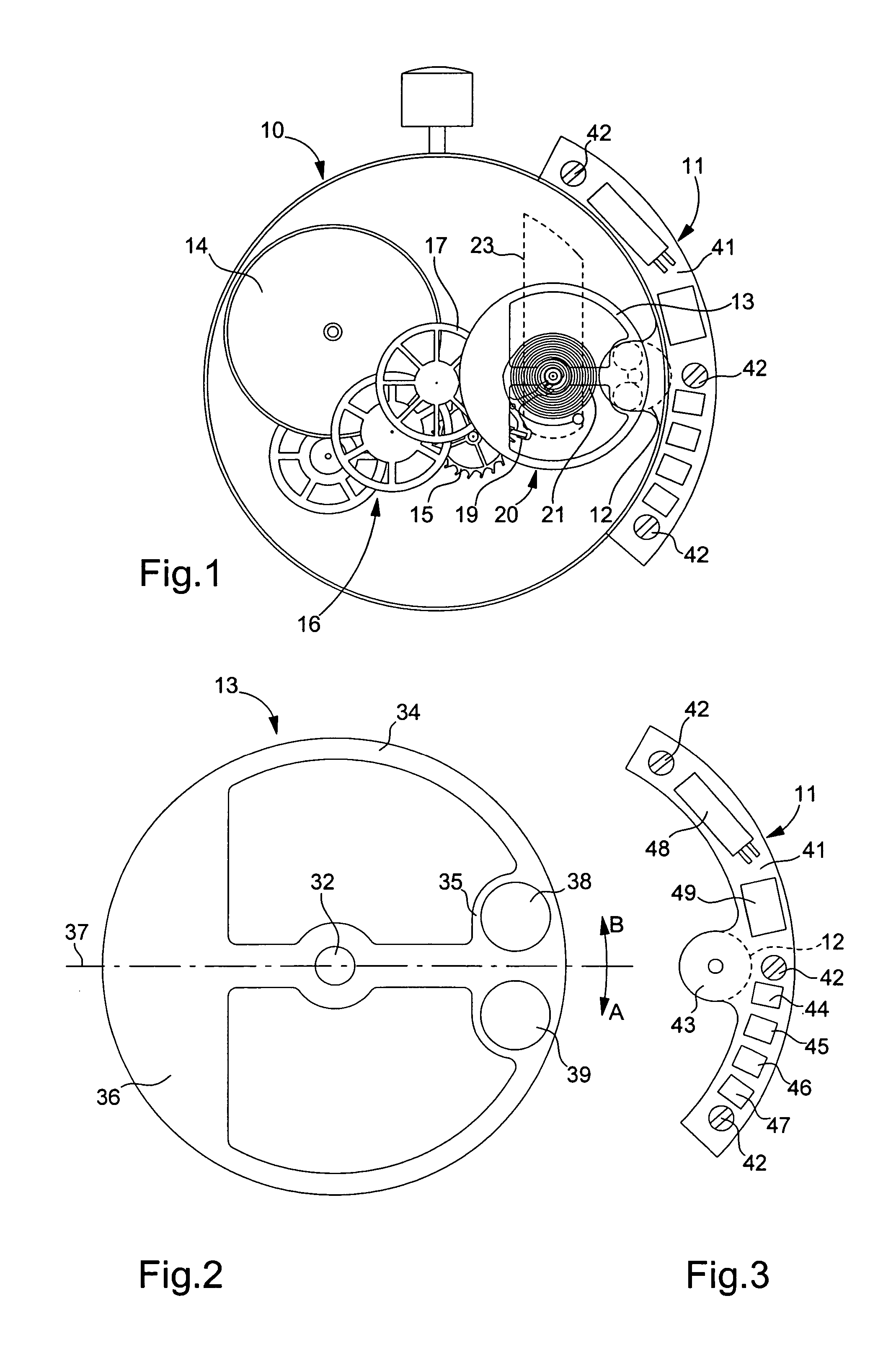

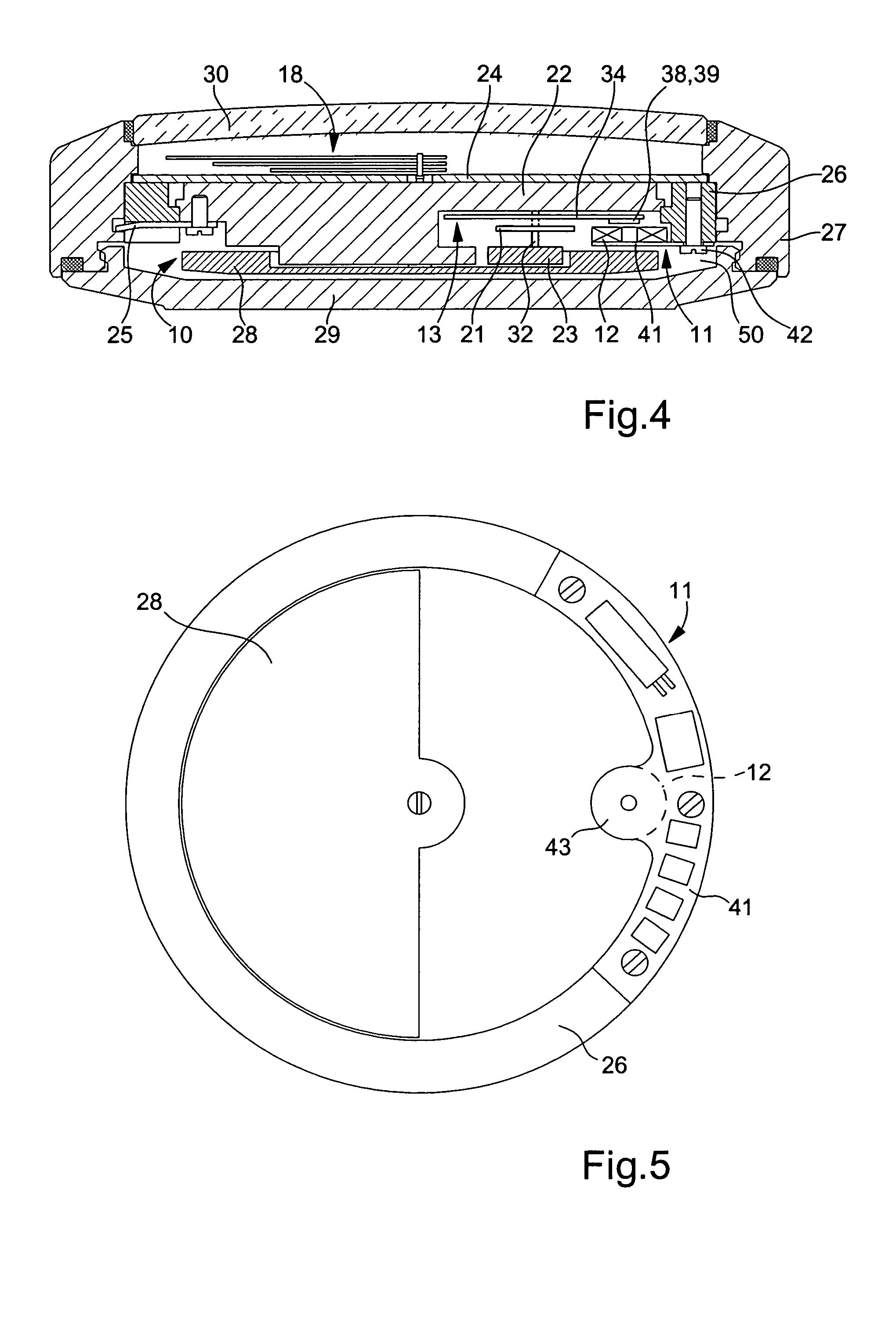

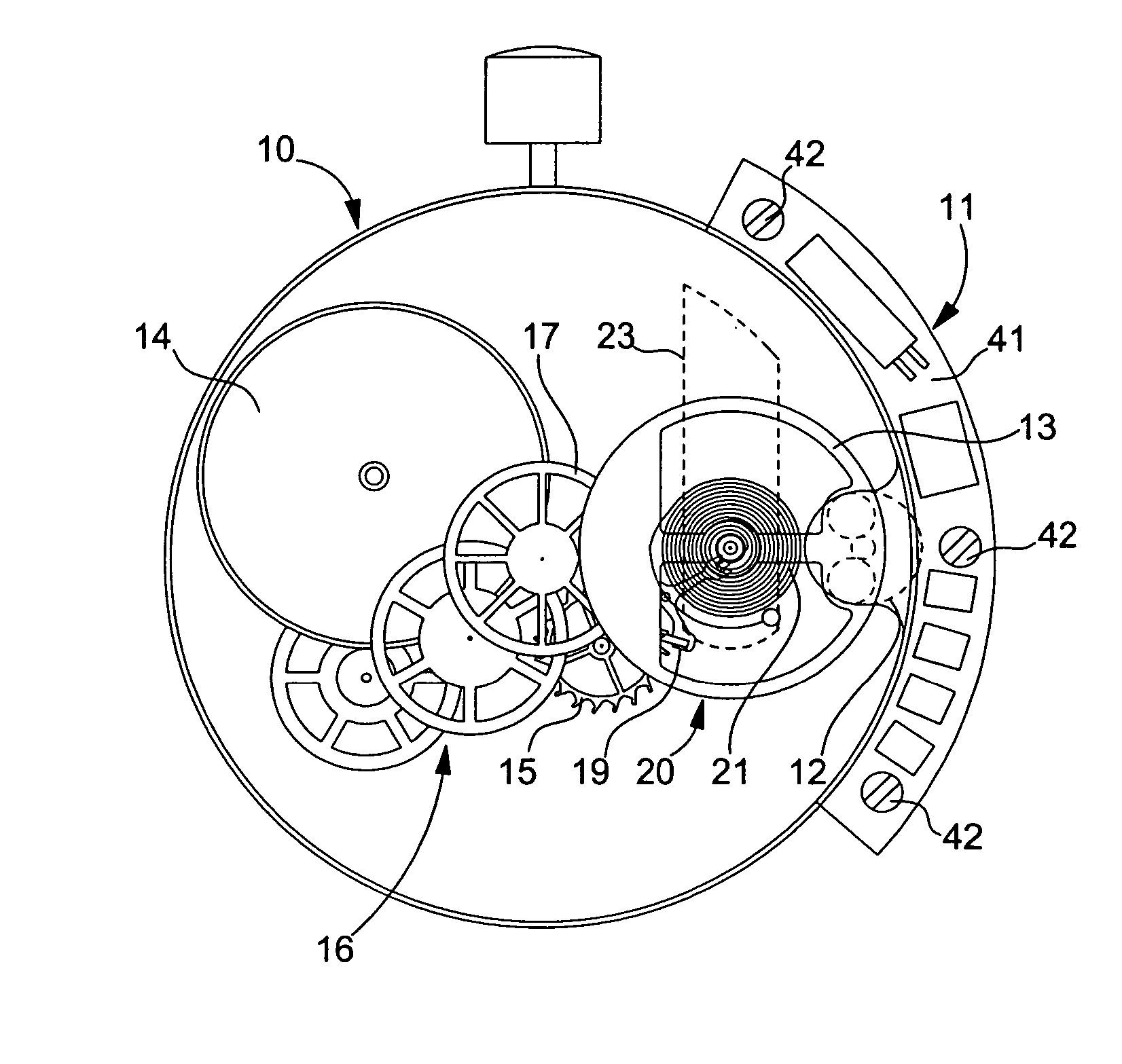

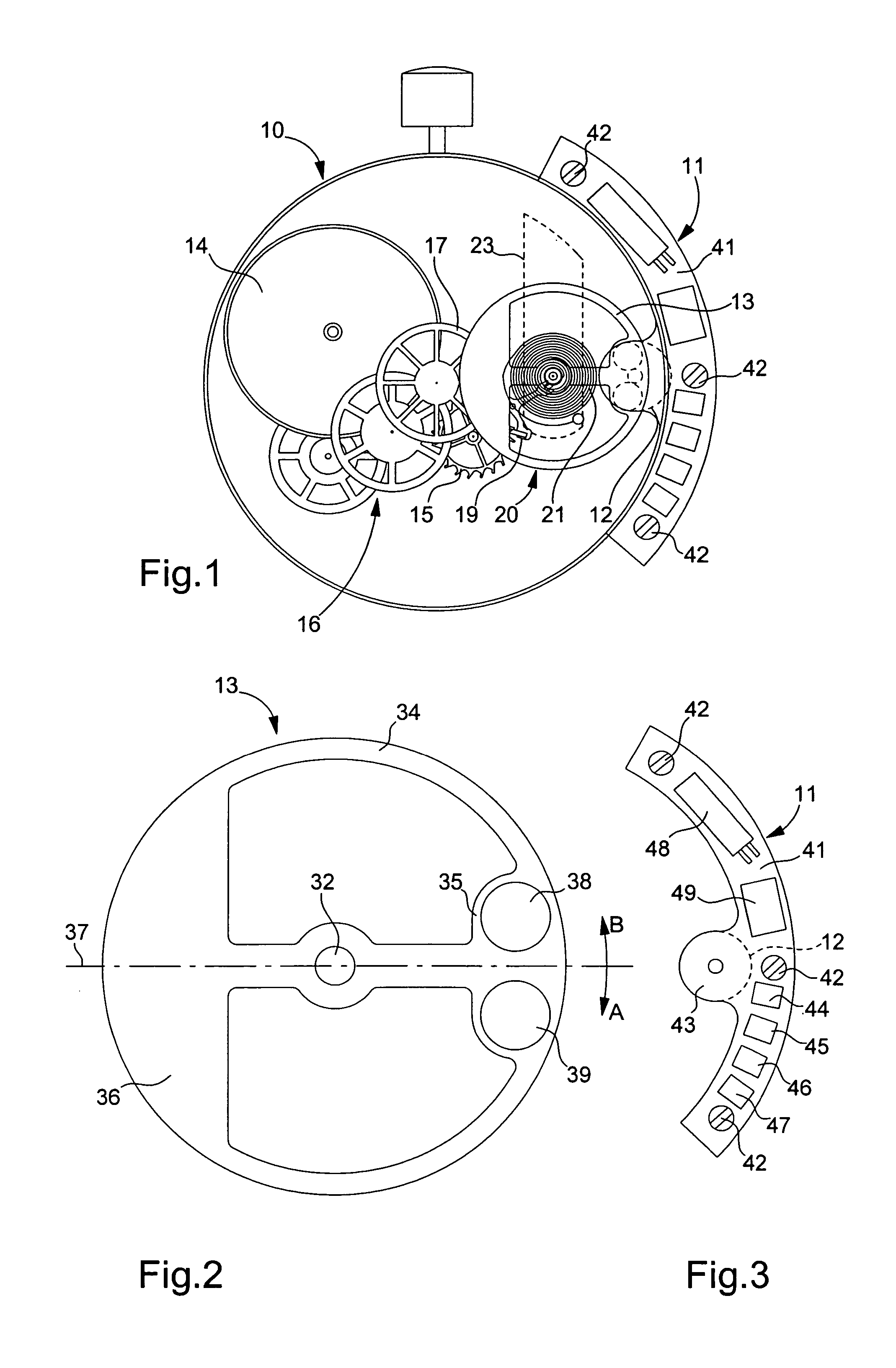

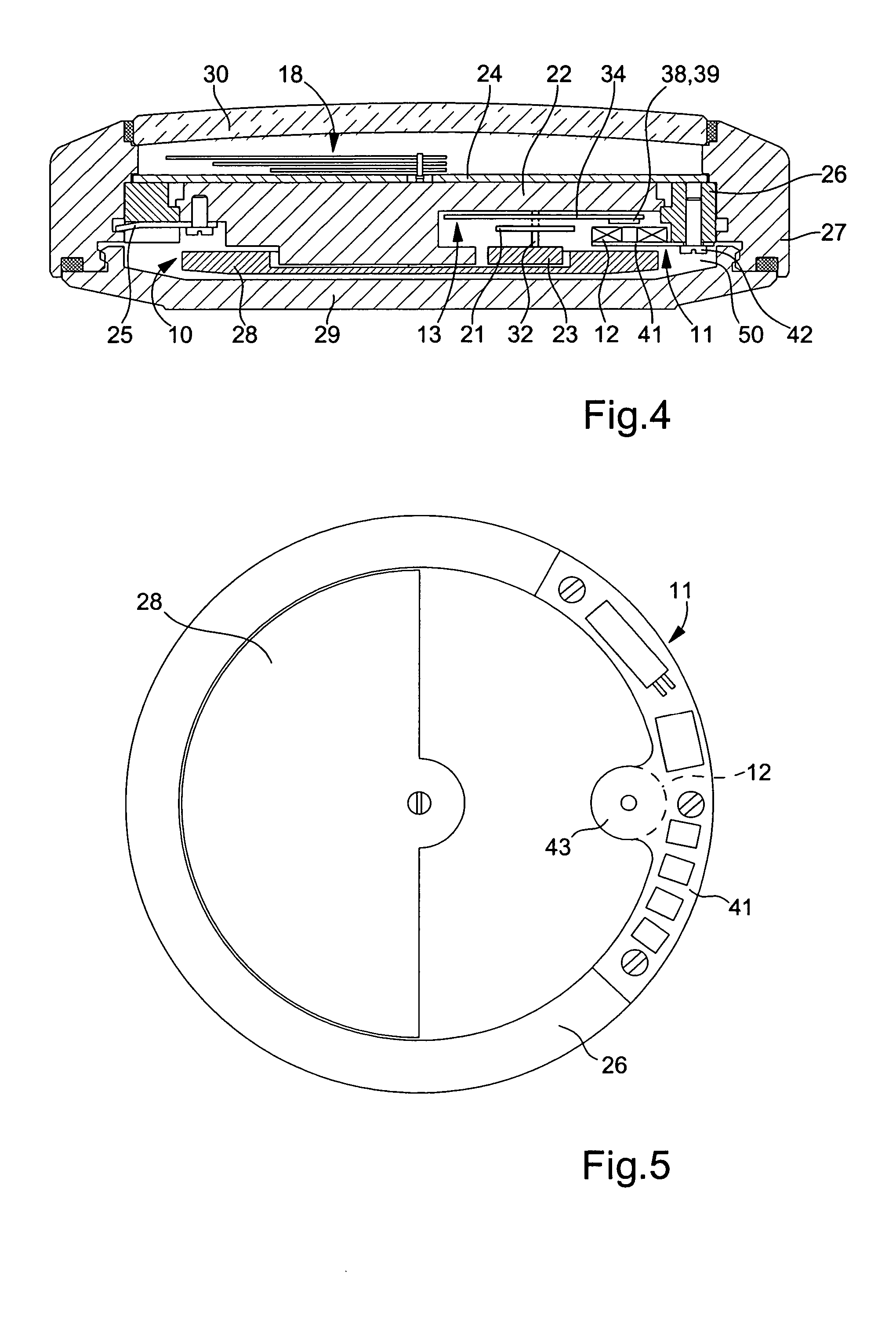

Timepiece having a mechanical movement associated with an electronic regulator

ActiveUS20050036405A1Easy to installEfficient couplingEscapementsFrequency stabilisation mechanismElectromagnetic couplingEngineering

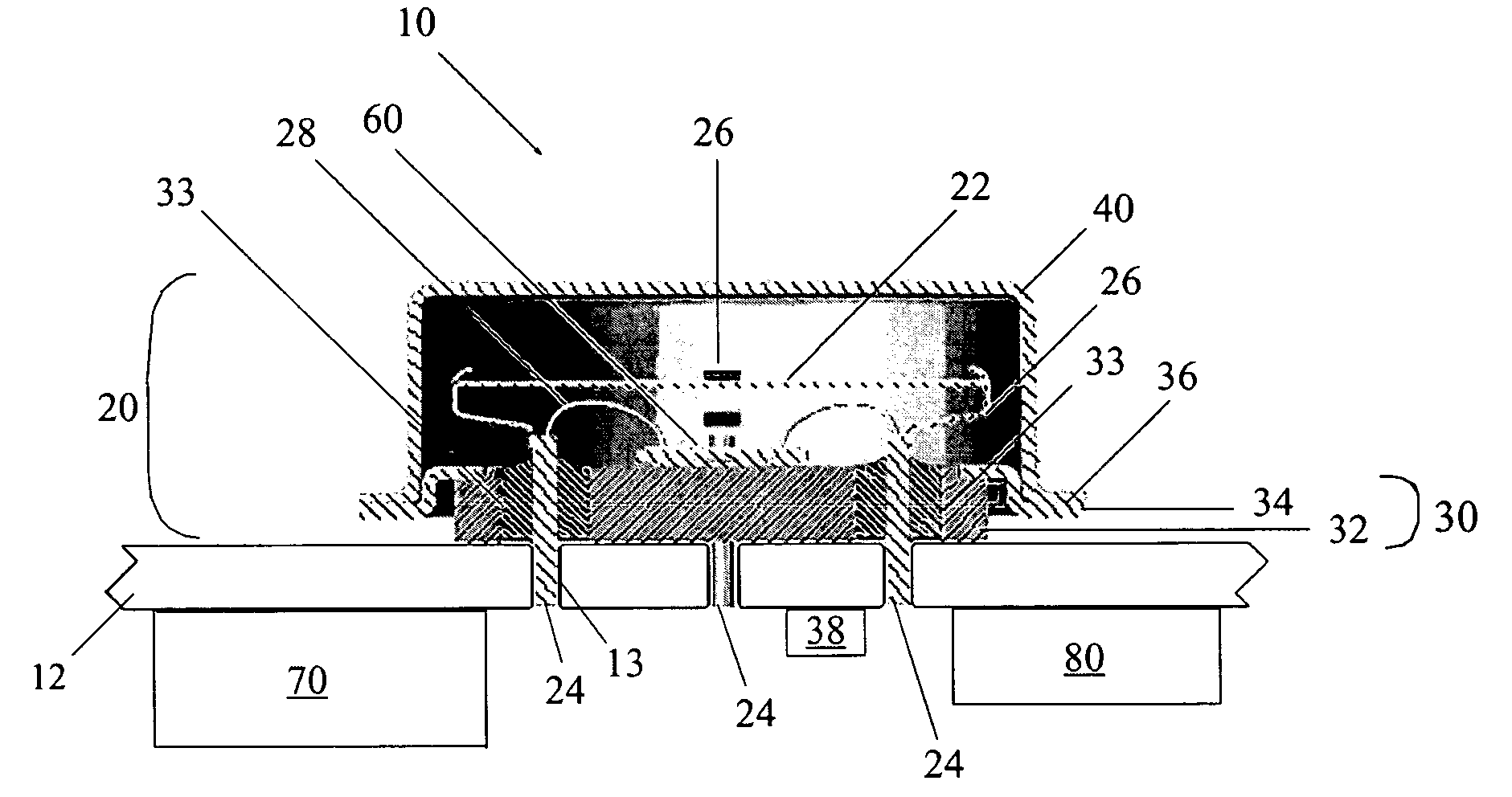

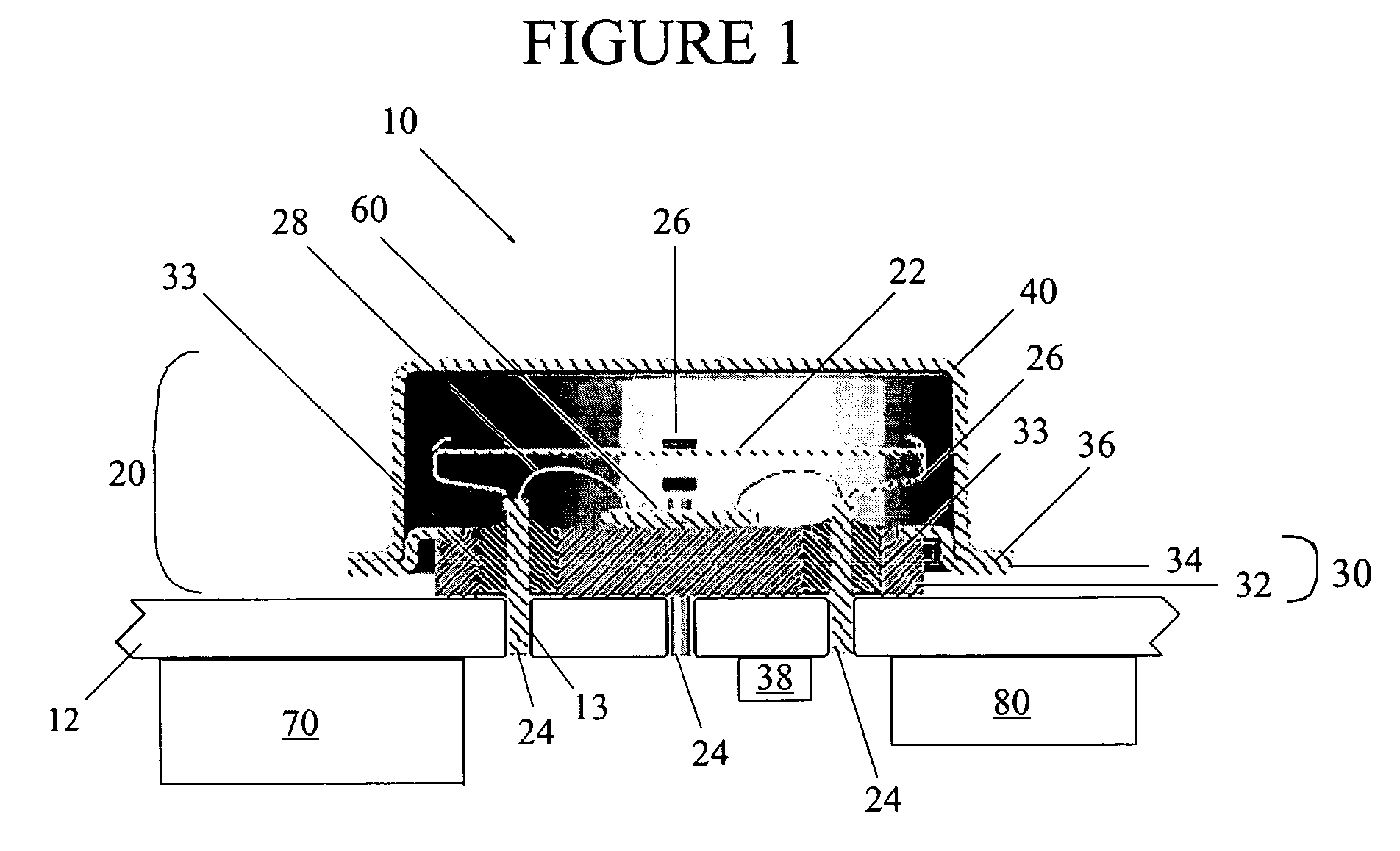

There is disclosed a wristwatch having a case containing a mechanical watch movement (10) driven by a spring barrel (14) and provided with a mechanical regulator with a balance and balance-spring, which is associated, via electromagnetic coupling, with an electronic regulator driven by a quartz resonator. The rim of the balance (13) is provided with a pair of permanent magnets (38, 39). The electronic regulator includes a fixed coil (12) arranged for cooperating with said magnets via electromagnetic coupling, a rectifier (58) provided with at least one capacitor, and a circuit (60) for enslaving the frequency of the mechanical regulator to the frequency of the oscillator by braking obtained by briefly short-circuiting the coil. In order to enable a common type of mechanical movement to be used, only the balance of which is altered, the electronic regulator is formed by a structural module (11) that is entirely separate from the mechanical watch movement (10). This module can be fixed to the movement plate, or, conversely, carried by the watchcase independently of said movement, in particular via a casing ring (26). Apart from the coil, all of the rest of the electronic module (11) is preferably located outside the mechanical movement.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

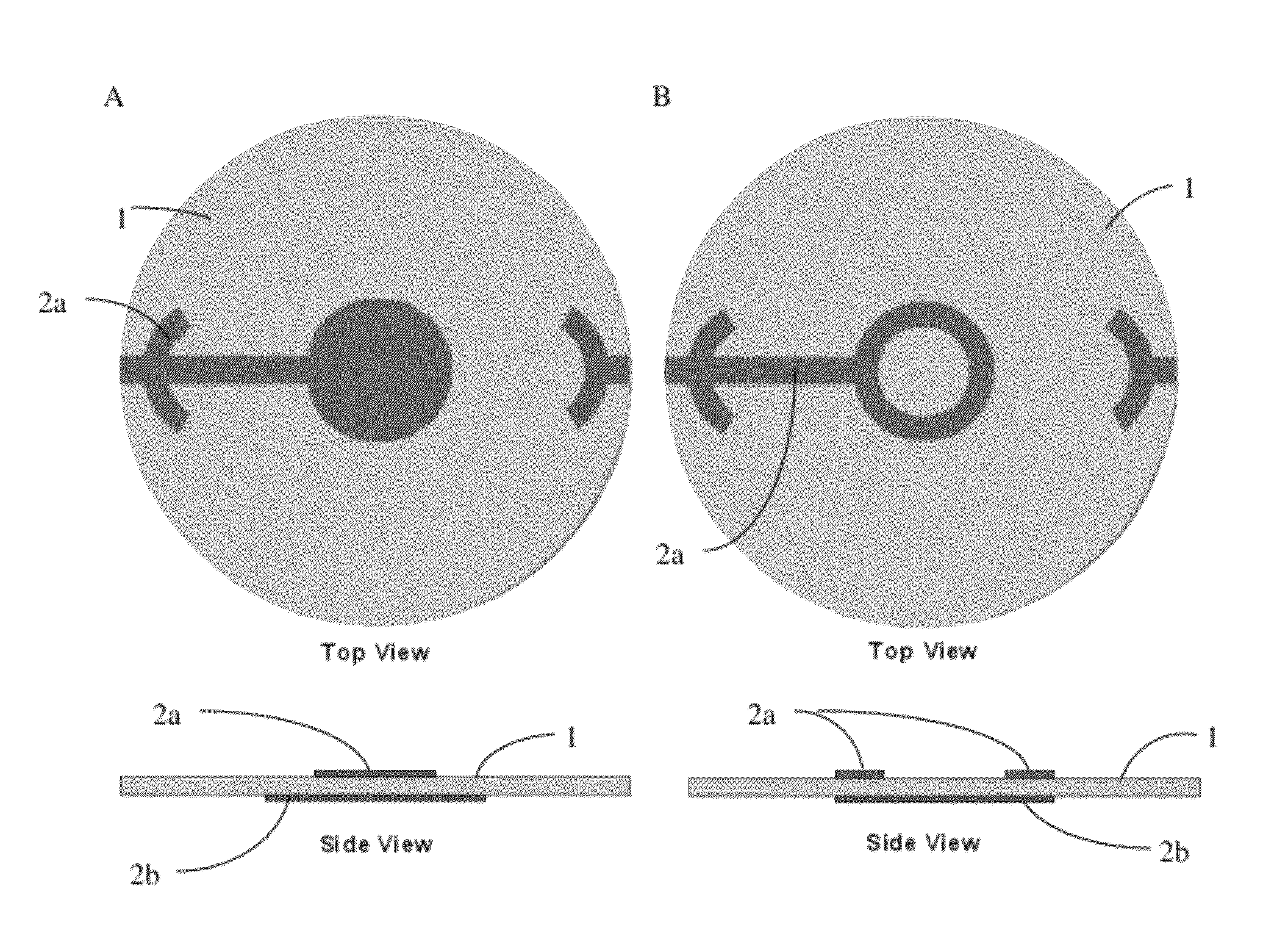

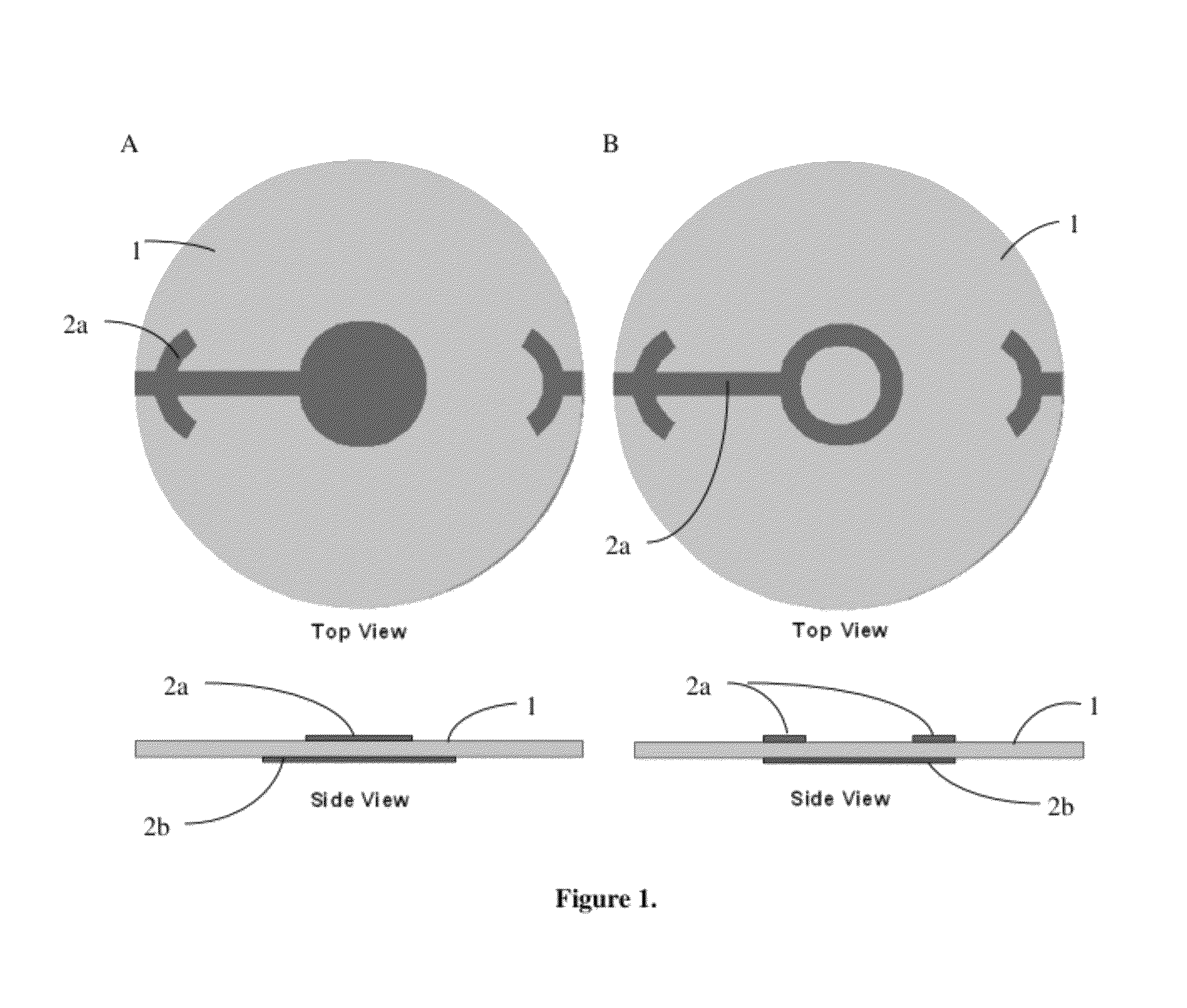

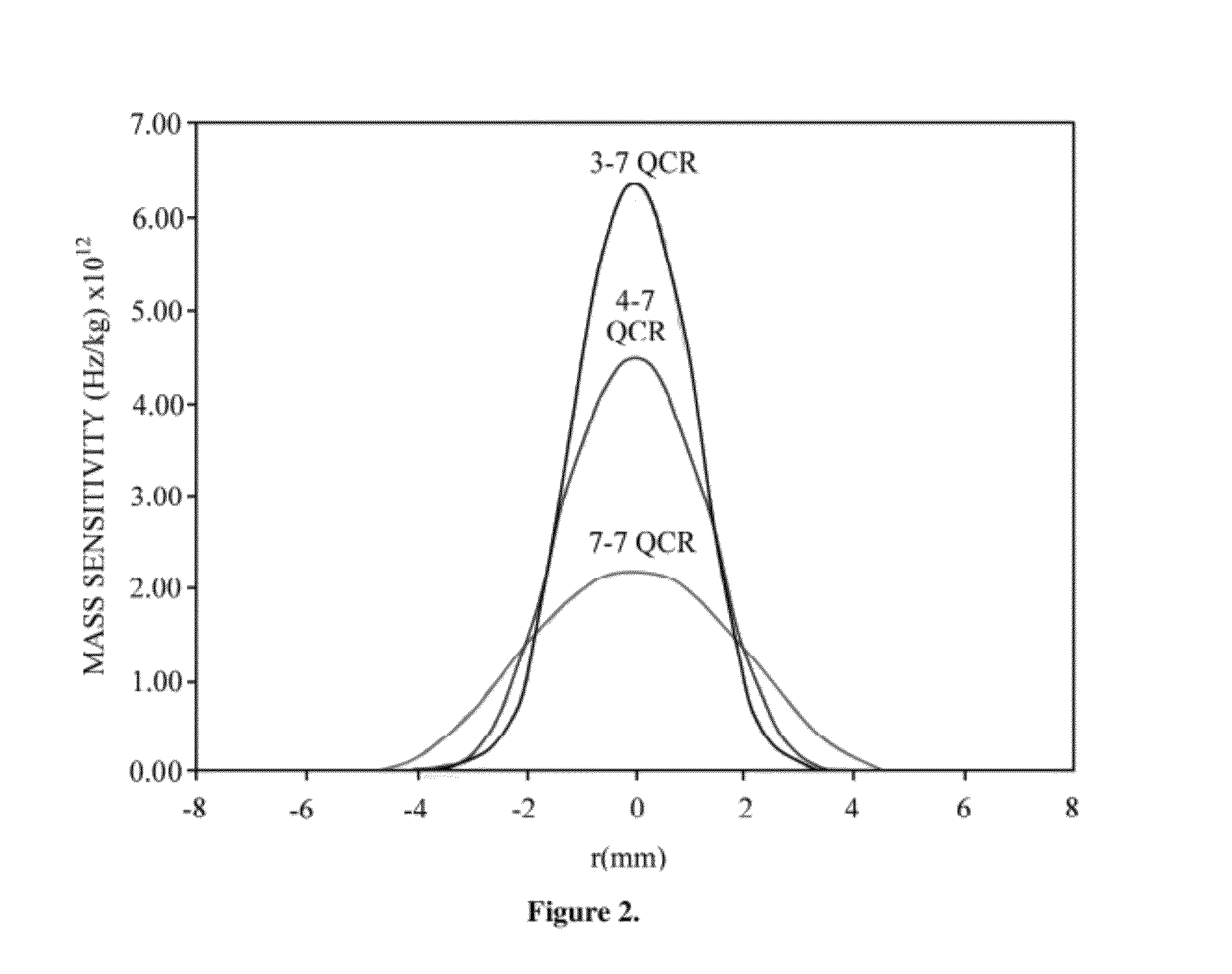

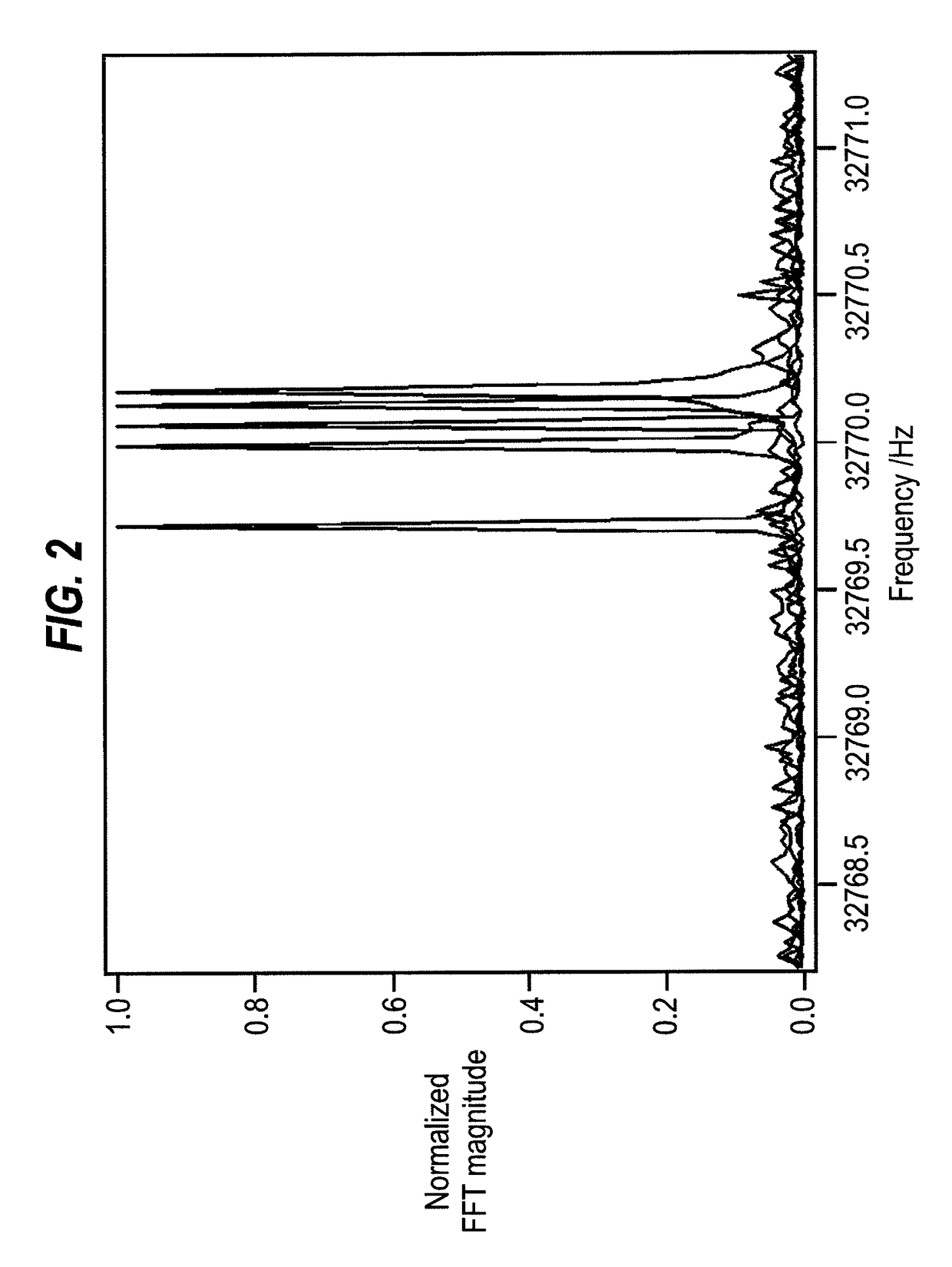

Uniform mass sensitivity thickness shear mode quartz resonator

ActiveUS8215171B1Accurate and inexpensive characterizationUniform sensitivityAnalysing fluids using sonic/ultrasonic/infrasonic wavesWeighing apparatus using elastically-deformable membersMass loadingSensitivity distribution

A ring electrode design that produces a uniform mass sensitivity distribution across a TSM device is presented. A new technique and apparatus to measure this mass sensitivity distribution is also presented. Novel electrode geometries on thickness shear mode (TSM) quartz resonators achieve radial uniformity of mass sensitivity, how receptive the device is to mass loadings, and high frequency stability across the active sensing area of the sensor device. The device allows for absolute mass measurement down to the nanogram level. Fabricated devices utilizing model predictions were tested using this apparatus, and good agreement between theory and experiment is found.

Owner:BANK OF AMERICA CORP +1

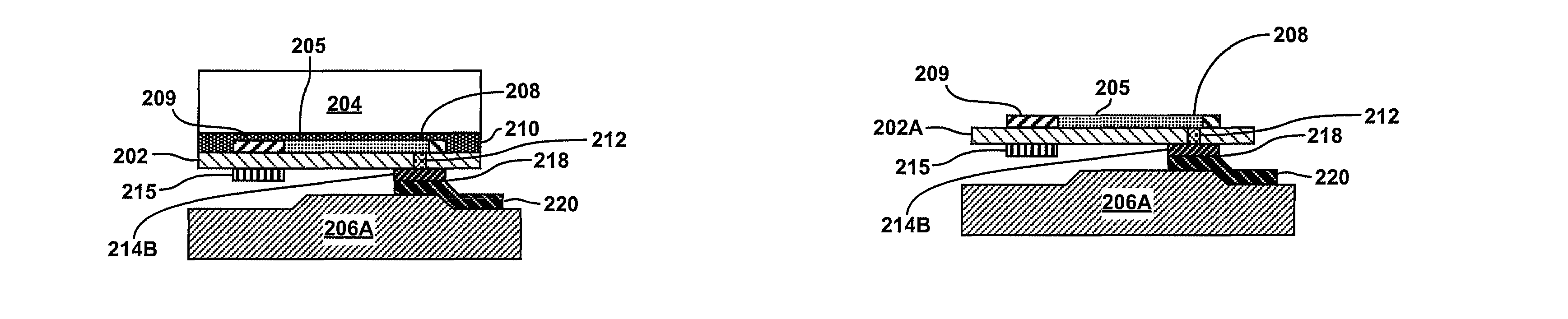

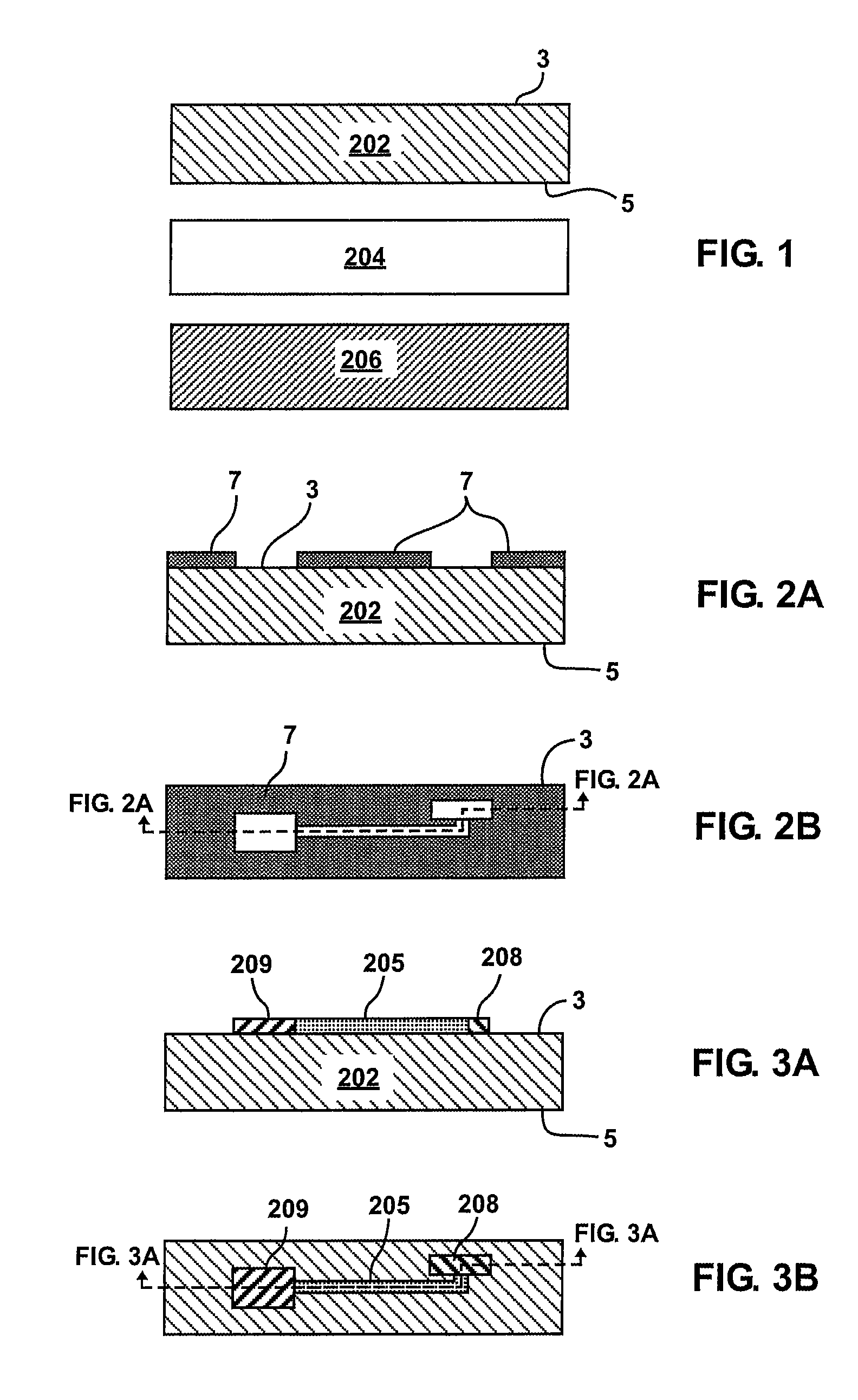

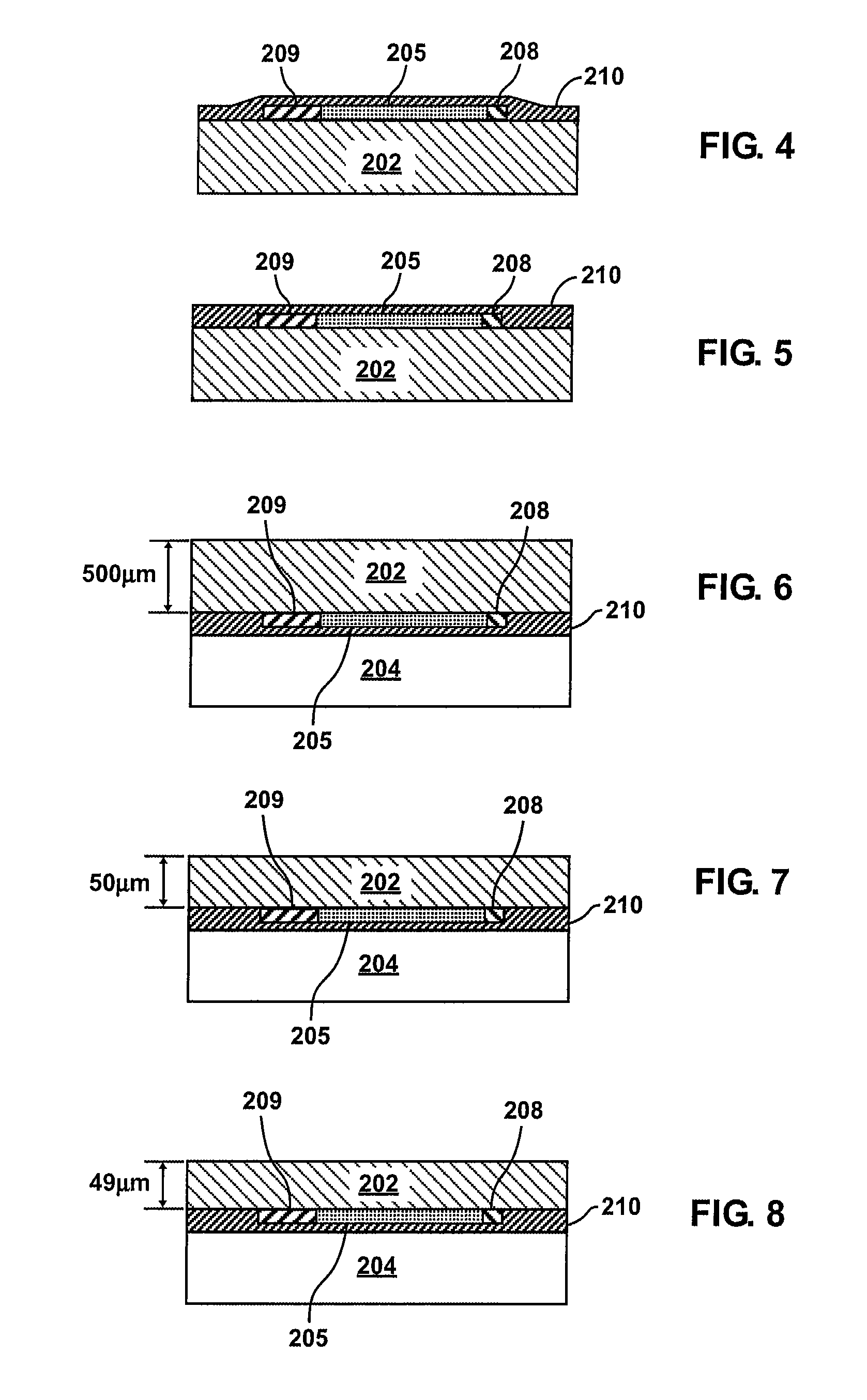

Method of fabricating an ultra thin quartz resonator component

ActiveUS7802356B1Piezoelectric/electrostrictive device manufacture/assemblyTransducer detailsInterposerQuartz resonator

A method for manufacturing a resonator is presented in the present application. The method includes providing a handle substrate, providing a host substrate, providing a quartz substrate comprising a first surface opposite a second surface, applying interposer film to the first surface of the quartz substrate, bonding the quartz substrate to the handle substrate wherein the interposer film is disposed between the quartz substrate and the handle substrate, thinning the second surface of the quartz substrate, removing a portion of the bonded quartz substrate to expose a portion of the interposer film, bonding the quartz substrate to the host substrate, and removing the handle substrate and the interposer film, thereby releasing the quartz substrate.

Owner:HRL LAB

Timepiece having a mechanical movement associated with an electronic regulator

ActiveUS7306364B2Efficient couplingSmall shapeFrequency stabilisation mechanismSynchronous motors for clocksElectromagnetic couplingEngineering

There is disclosed a wristwatch having a case containing a mechanical watch movement (10) driven by a spring barrel (14) and provided with a mechanical regulator with a balance and balance-spring, which is associated, via electromagnetic coupling, with an electronic regulator driven by a quartz resonator. The rim of the balance (13) is provided with a pair of permanent magnets (38, 39). The electronic regulator includes a fixed coil (12) arranged for cooperating with said magnets via electromagnetic coupling, a rectifier (58) provided with at least one capacitor, and a circuit (60) for enslaving the frequency of the mechanical regulator to the frequency of the oscillator by braking obtained by briefly short-circuiting the coil. In order to enable a common type of mechanical movement to be used, only the balance of which is altered, the electronic regulator is formed by a structural module (11) that is entirely separate from the mechanical watch movement (10). This module can be fixed to the movement plate, or, conversely, carried by the watchcase independently of said movement, in particular via a casing ring (26). Apart from the coil, all of the rest of the electronic module (11) is preferably located outside the mechanical movement.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

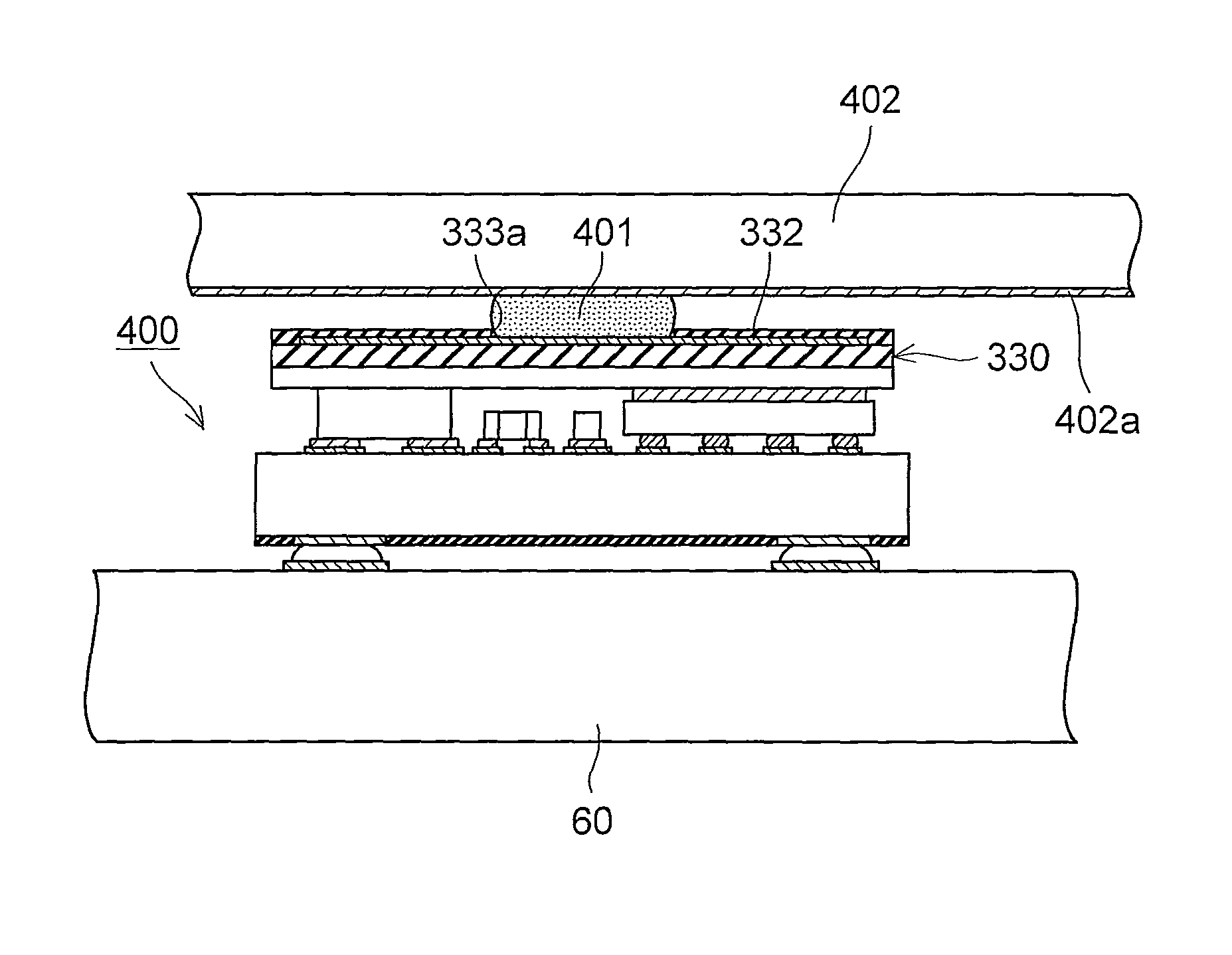

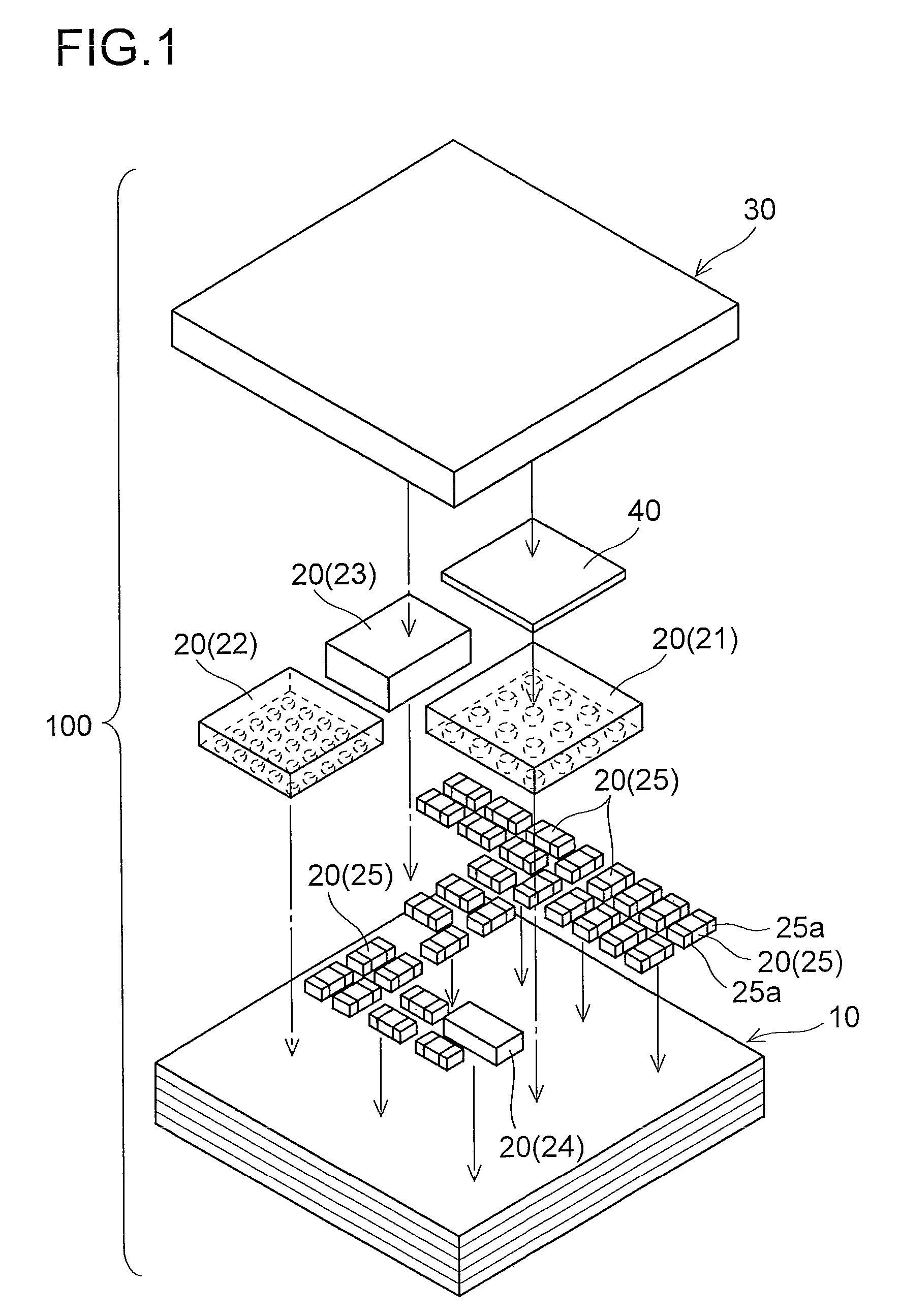

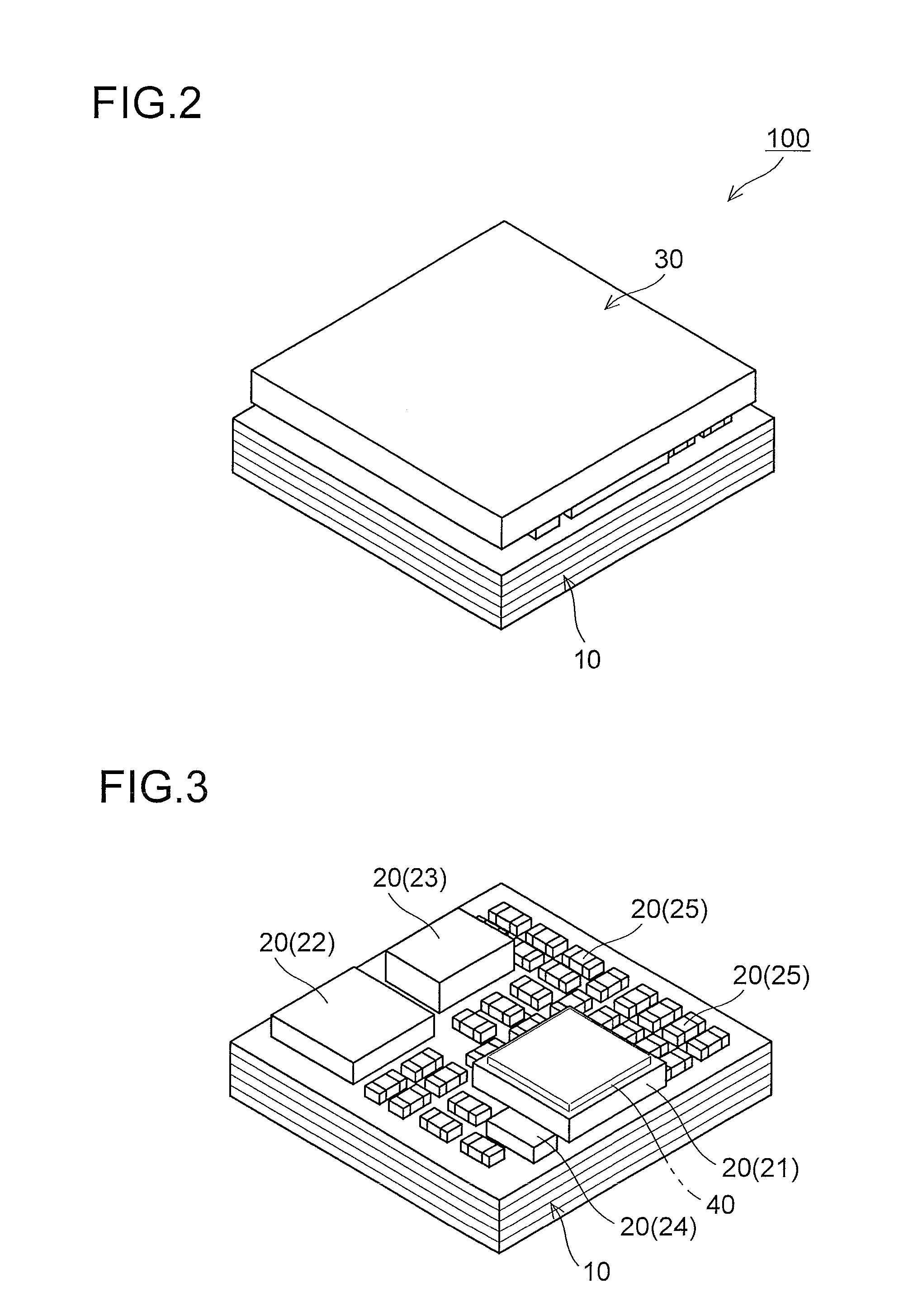

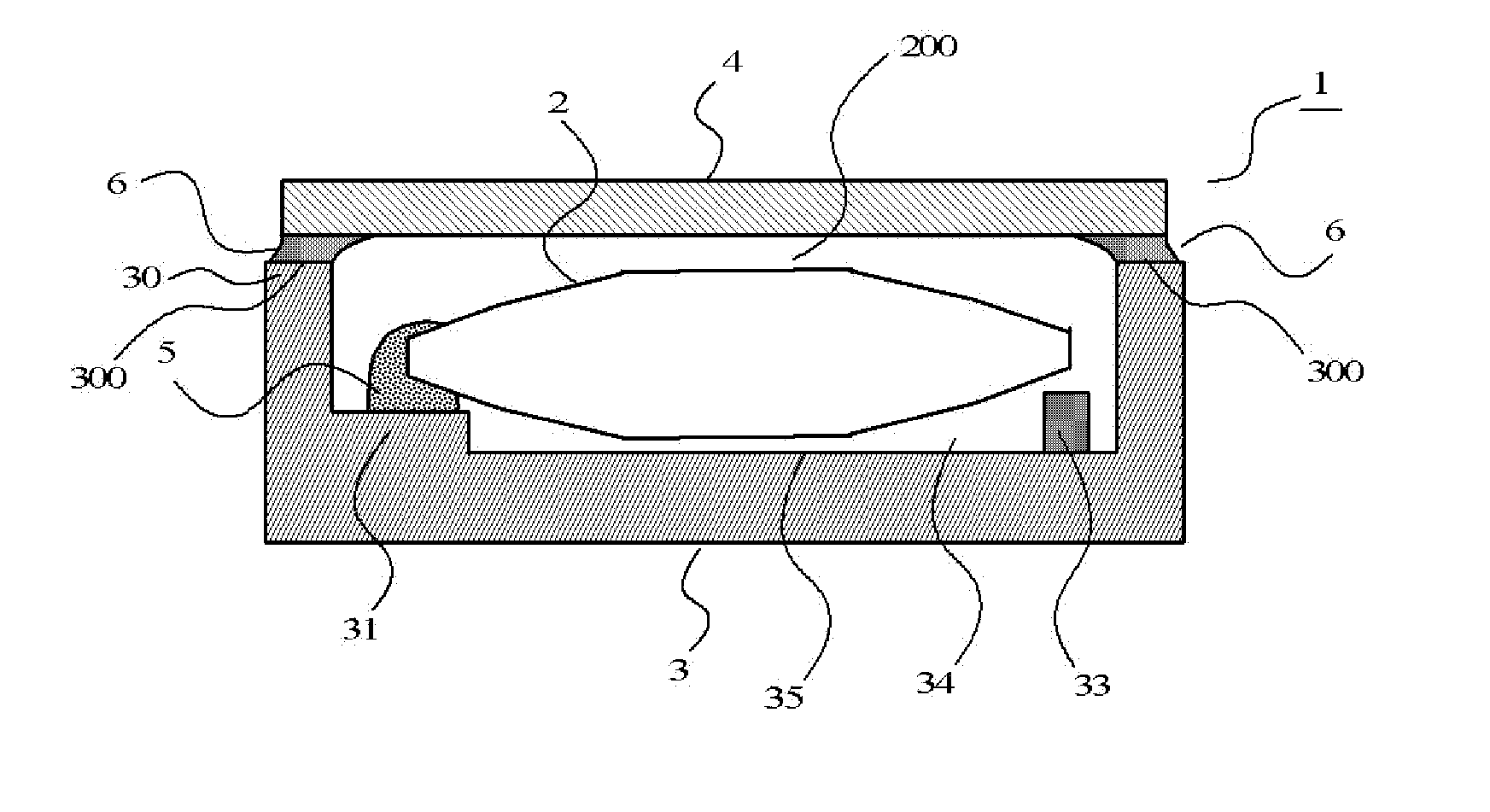

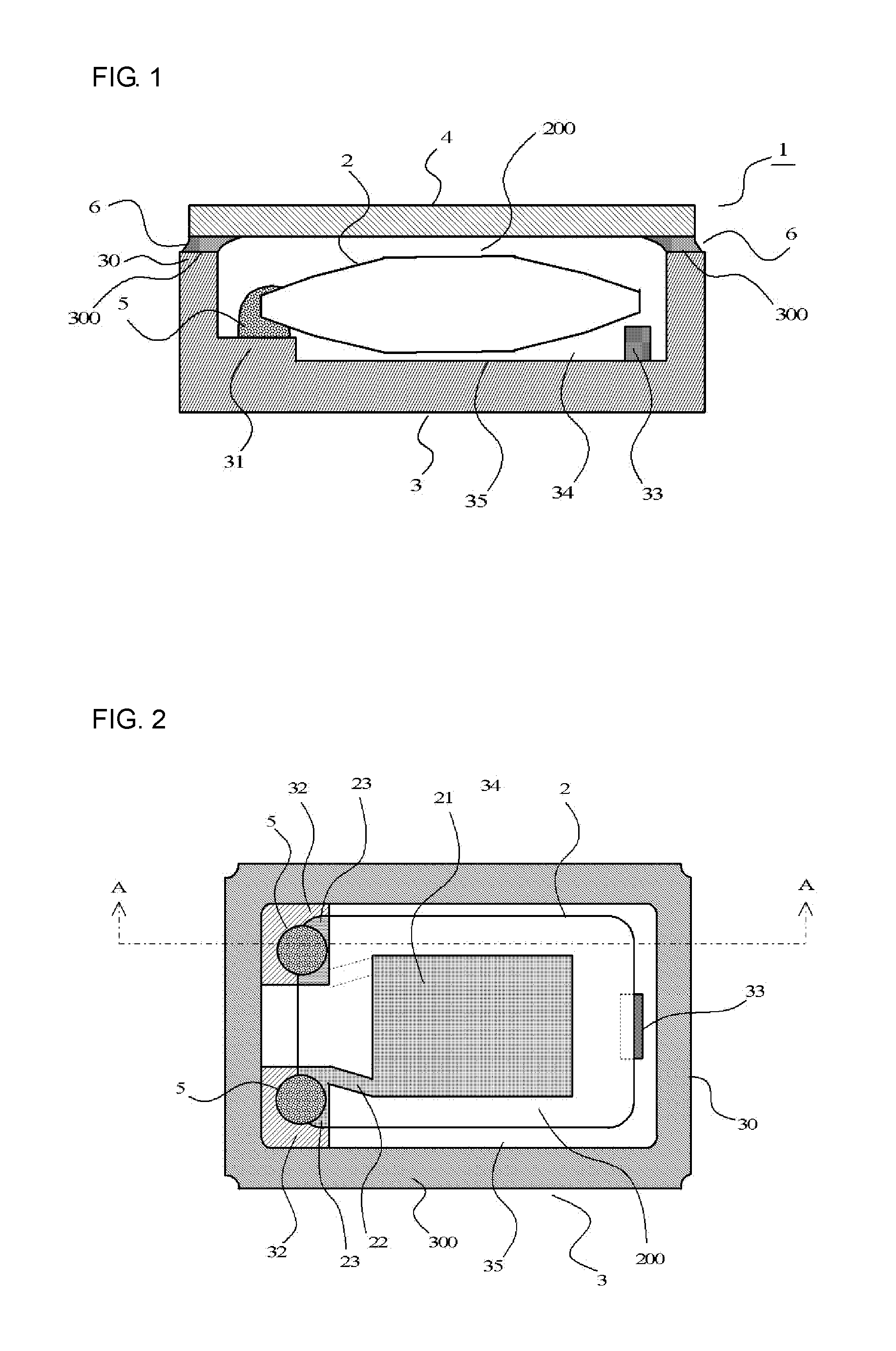

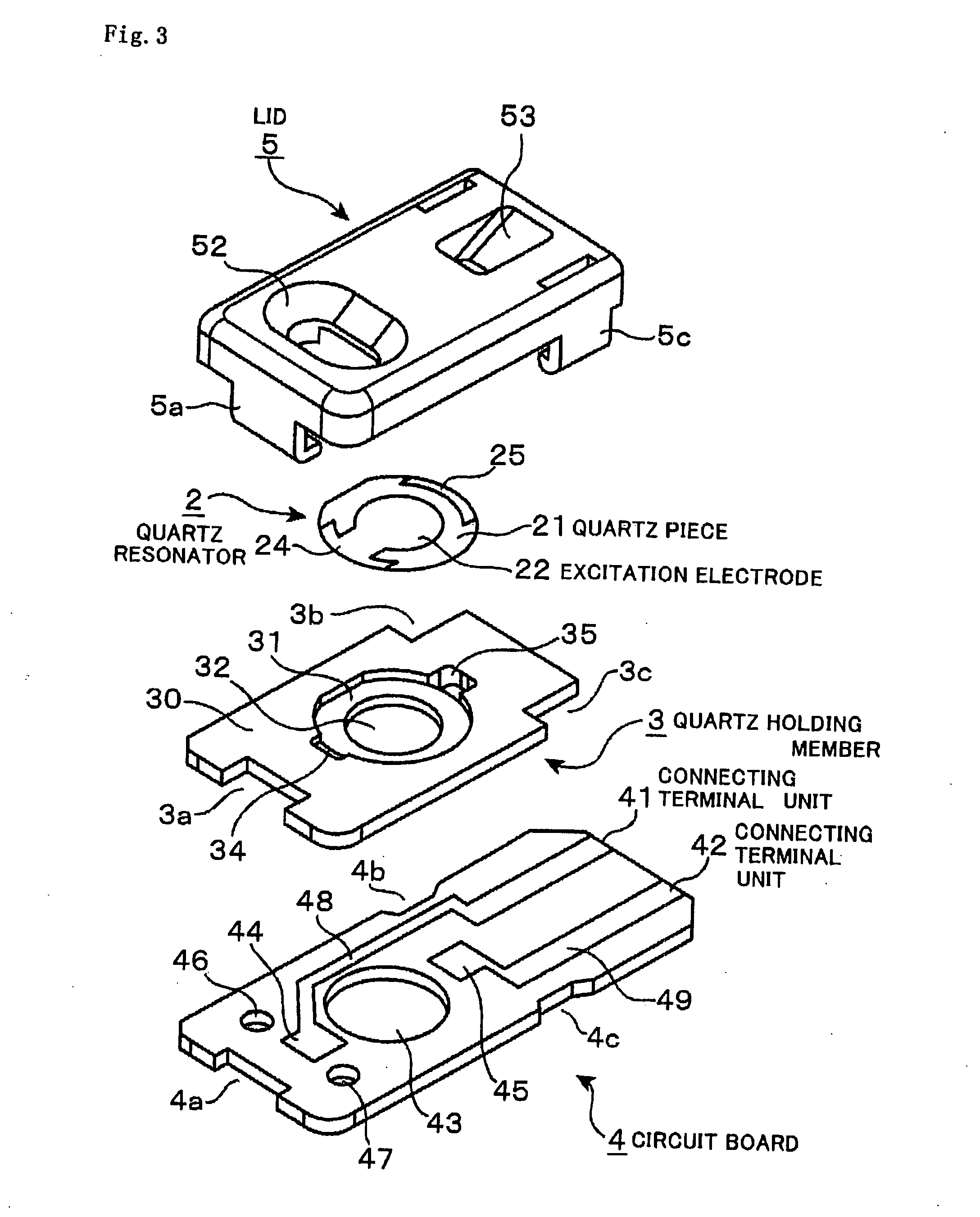

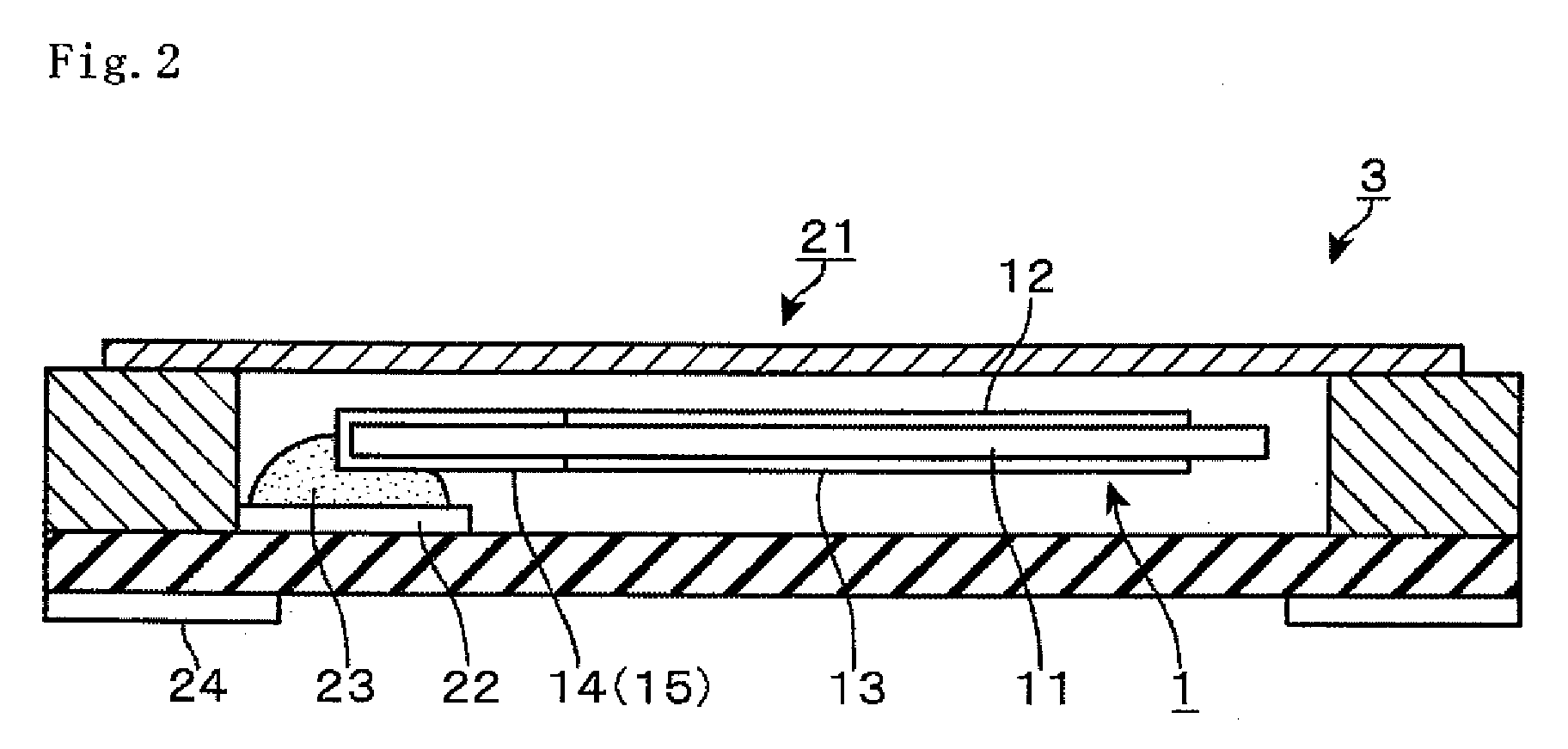

Electronic component module

ActiveUS8179678B2Improve reliabilityEasy to handleMagnetic/electric field screeningSemiconductor/solid-state device detailsElectronic componentQuartz resonator

Provided is an electronic component module which has high reliability and is capable of suppressing reduction in handling performance of a mounting machine. An electronic component module includes a plurality of electronic components mounted on a top surface of a module substrate, a planar top plate covering the electronic components, and a top plate holding member for holding the top plate. The plurality of electronic components include a quartz resonator, and a RF-IC which has a height smaller than that of the quartz resonator and is disposed on the top surface of the module substrate so as to be side by side with the quartz resonator. In addition, the top plate is fixed to the quartz resonator, and the top plate holding member for holding the top plate is disposed between the RF-IC and the top plate.

Owner:SHARP KK

Temperature compensated oscillator including MEMS resonator for frequency control

ActiveUS20060261703A1SmallLow costRadiation pyrometryPiezoelectric/electrostriction/magnetostriction machinesQuartz resonatorSignal function

Disclosed is an oscillator that relies on redundancy of similar resonators integrated on chip in order to fulfill the requirement of one single quartz resonator. The immediate benefit of that approach compared to quartz technology is the monolithic integration of the reference signal function, implying smaller devices as well as cost and power savings.

Owner:RGT UNIV OF CALIFORNIA

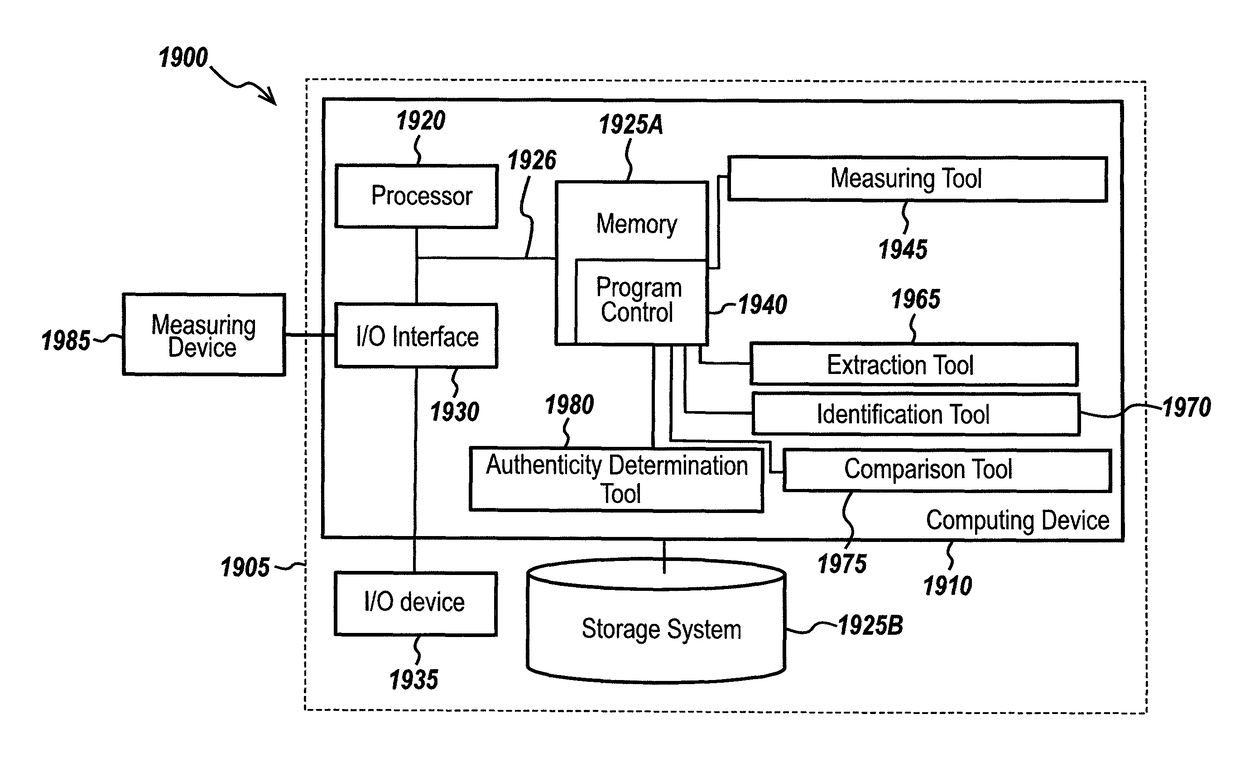

Method and system for authenticating a device

ActiveUS9772607B2Non-invasive and reliableFrequency setting mechanismResonant frequencyElectricityResonance

Owner:SICPA HLDG SA

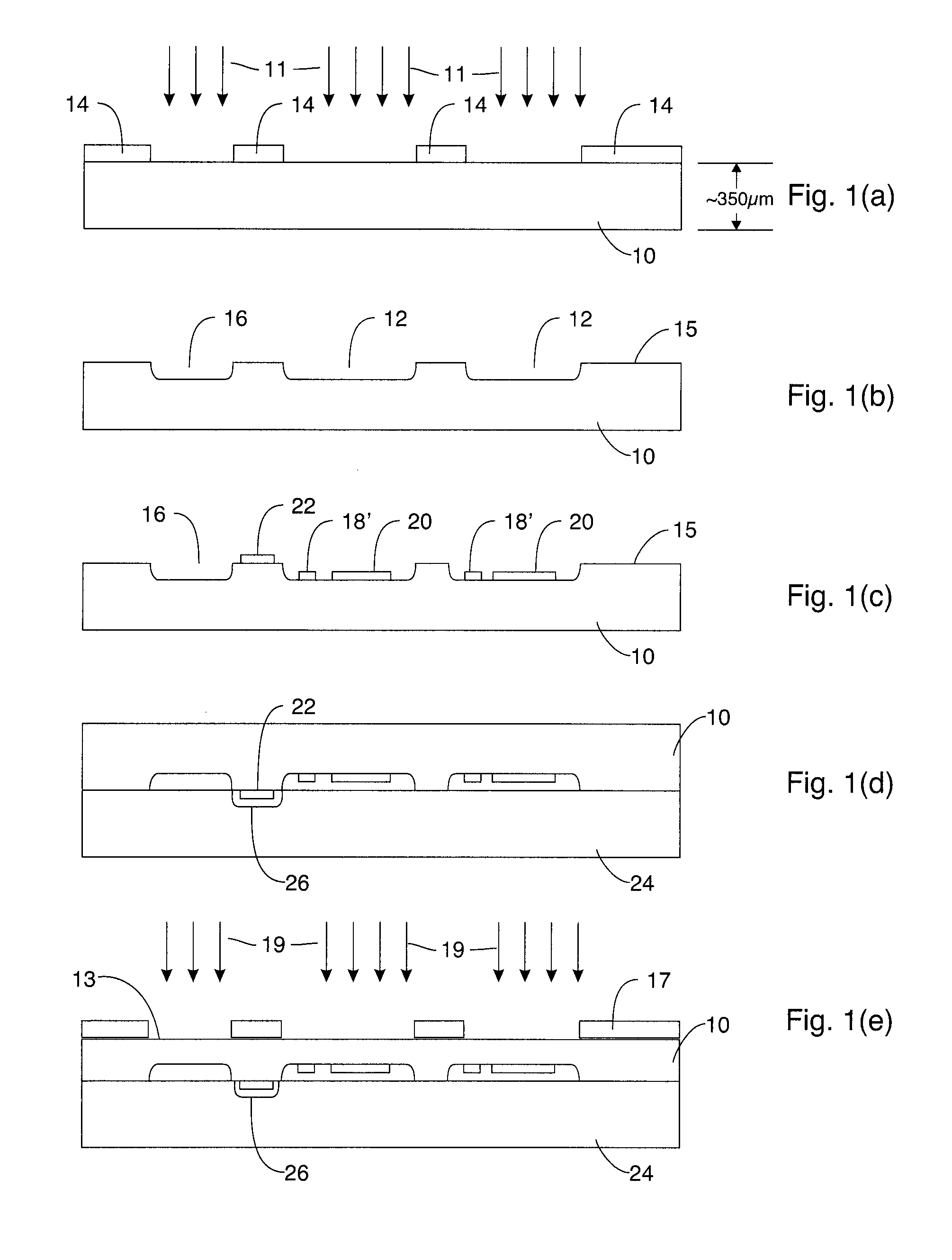

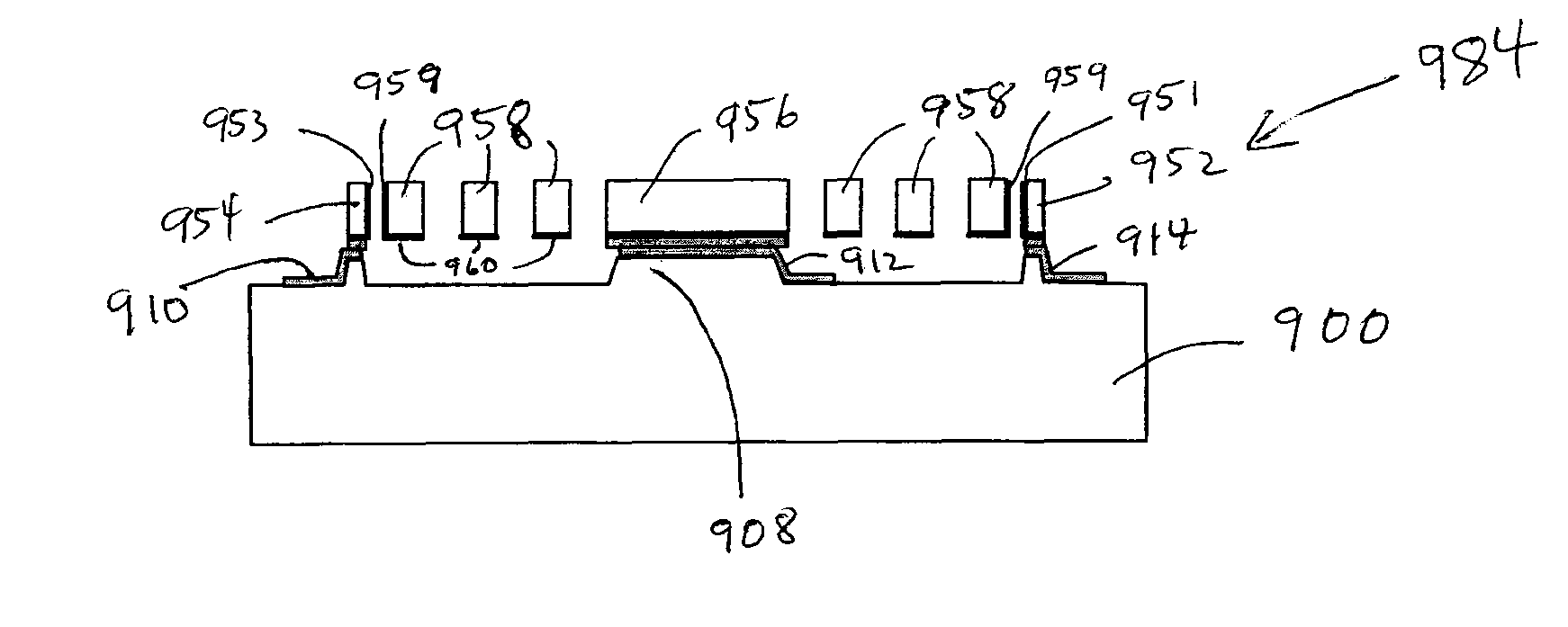

Method of fabricating quartz resonators

ActiveUS8176607B1Small volumeFirmly assembledPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive resonant transducersSmall sampleElectrical connection

A method for fabricating VHF and / or UHF quartz resonators (for higher sensitivity) in a cartridges design with the quartz resonators requiring much smaller sample volumes than required by conventional resonators, and also enjoying smaller size and more reliable assembly. MEMS fabrication approaches are used to fabricate with quartz resonators in quartz cavities with electrical interconnects on a top side of a substrate for electrical connection to the electronics preferably through pressure pins in a plastic module. An analyte is exposed to grounded electrodes on a single side of the quartz resonators, thereby preventing electrical coupling of the detector signals through the analyte. The resonators can be mounted on the plastic cartridge or on arrays of plastic cartridges with the use of inert bonding material, die bonding or wafer bonding techniques. This allows the overall size, cost, and required biological sample volume to be reduced while increasing the sensitivity for detecting small mass changes.

Owner:HRL LAB

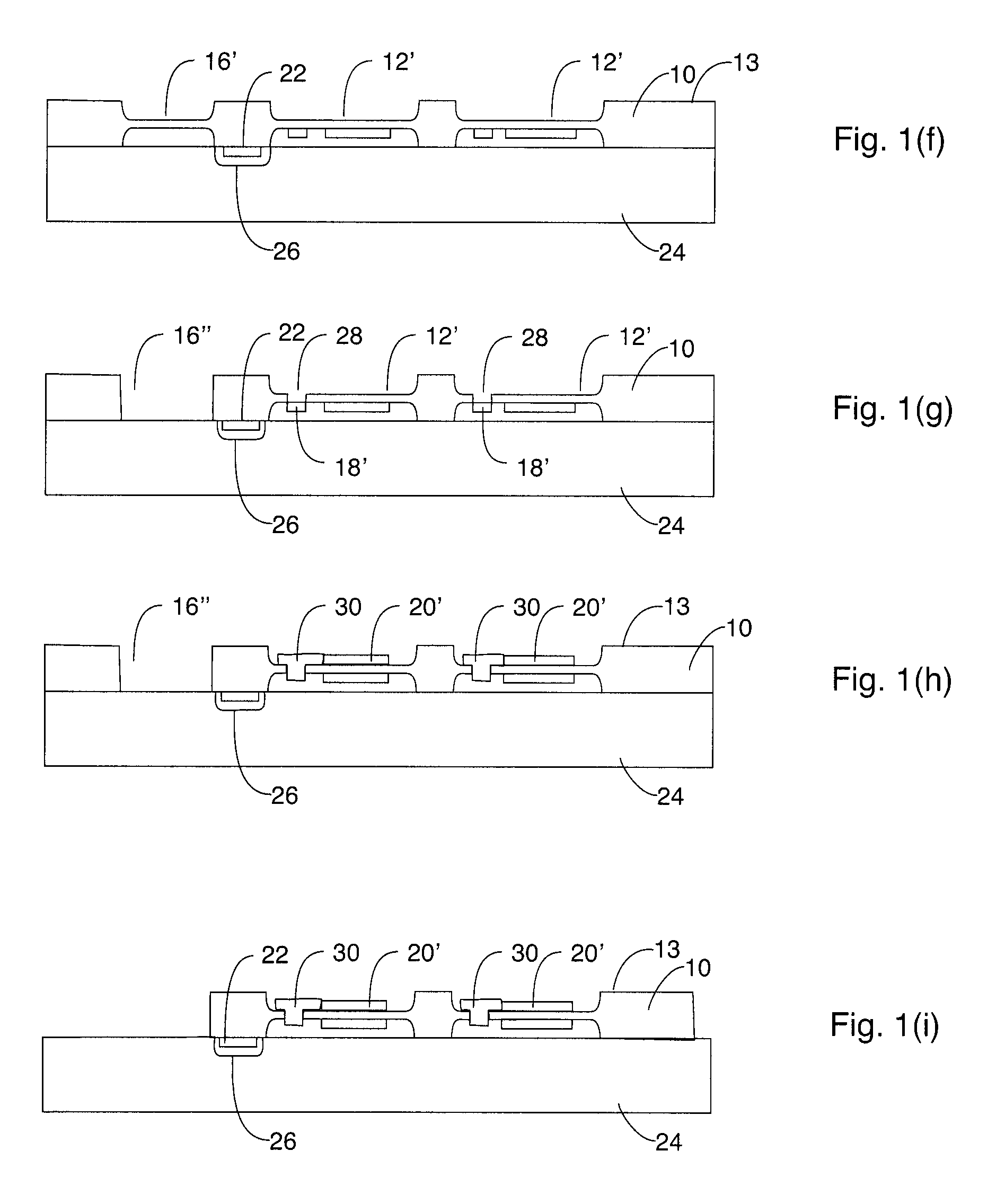

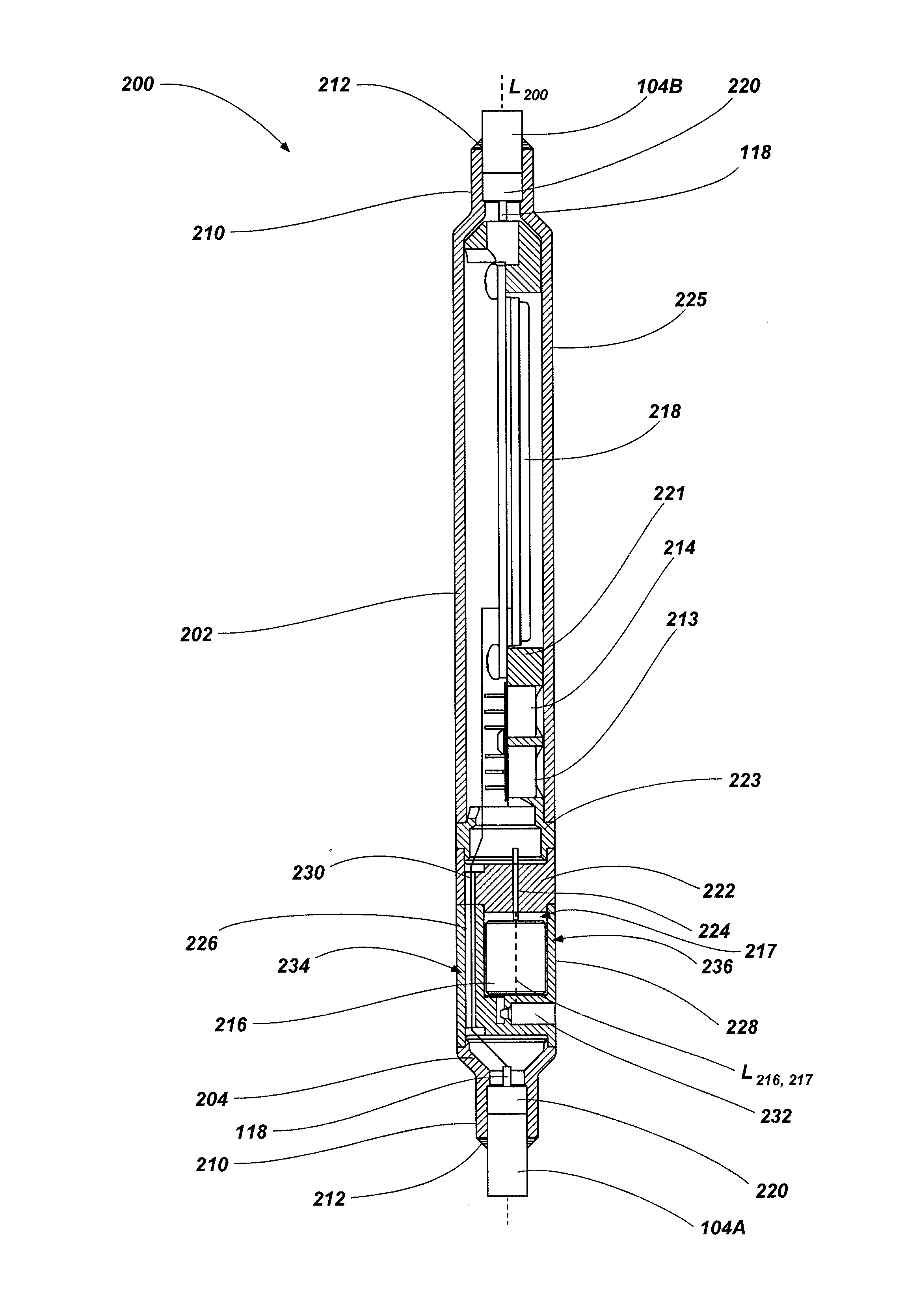

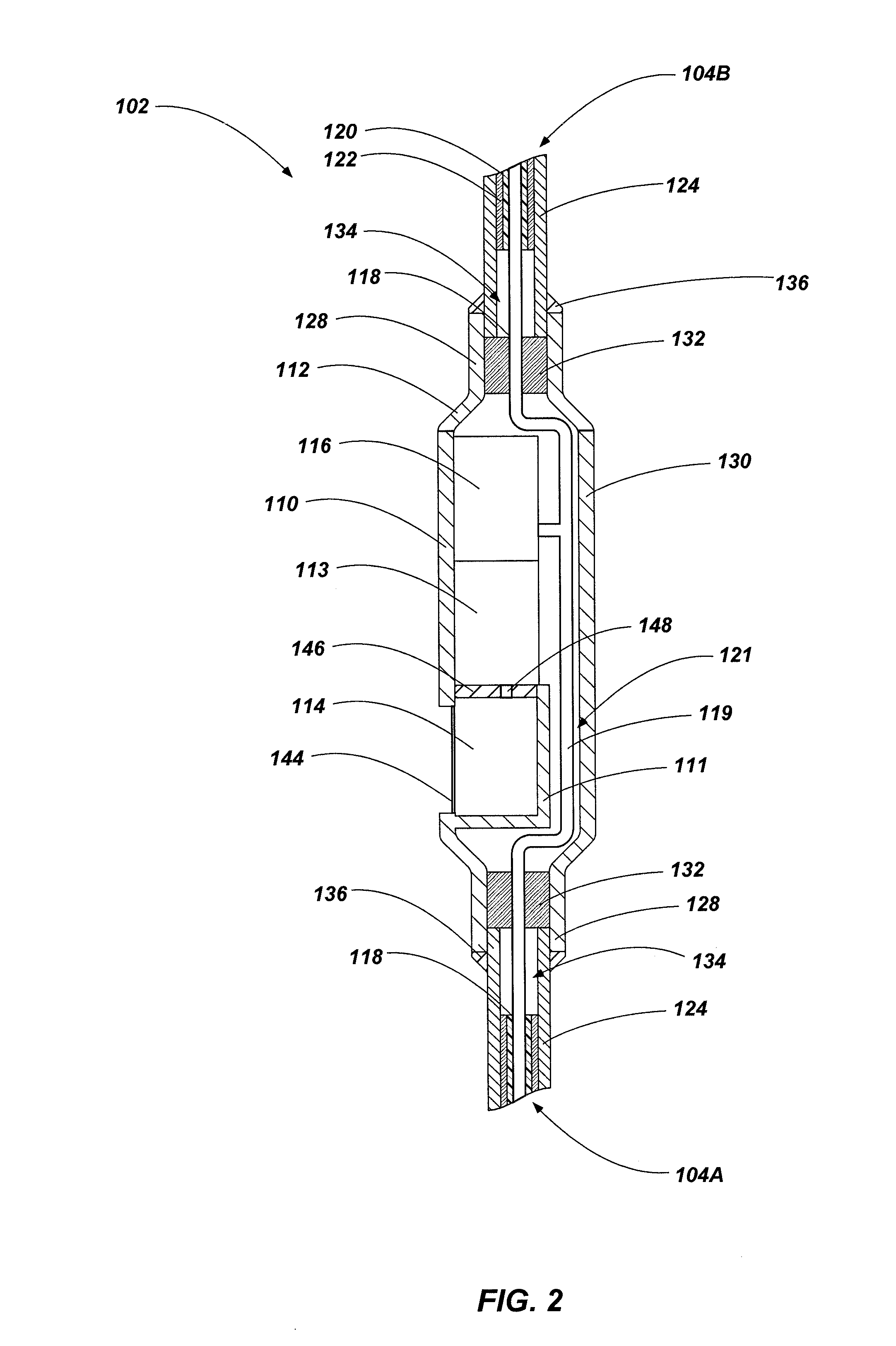

Downhole distributed pressure sensor arrays, downhole pressure sensors, downhole distributed pressure sensor arrays including quartz resonator sensors, and related methods

Downhole distributed pressure sensor arrays include sensor housings each comprising at least one pressure sensor in a pressure housing. Downhole pressure sensors include a housing, at least one pressure sensor in a pressure housing portion of the housing, and at least one isolation element positioned at an outer wall of the housing.

Owner:QUARTZDYNE

Quartz resonator package having a housing with thermally coupled internal heating element

InactiveUS20060022556A1Reduced thermal massProvides thermal stabilityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksControl circuitQuartz resonator

A resonator package includes a quartz resonator and a heating element within a sealed housing, wherein the heating element is thermally coupled to an external wall of the housing. The heated external wall of the housing is thermally coupled to a substrate to heat a local region of the substrate. The heated local region of the substrate thermally stabilizes an associated oscillator control circuit and heater control circuit which are external to the housing.

Owner:VECTRON INT INC

Resonance acoustical profiling system and methods of using same

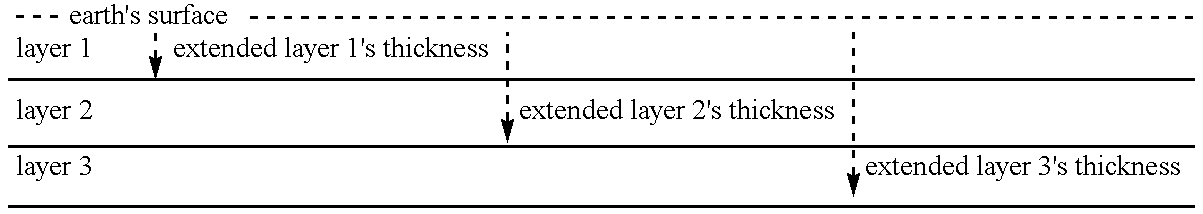

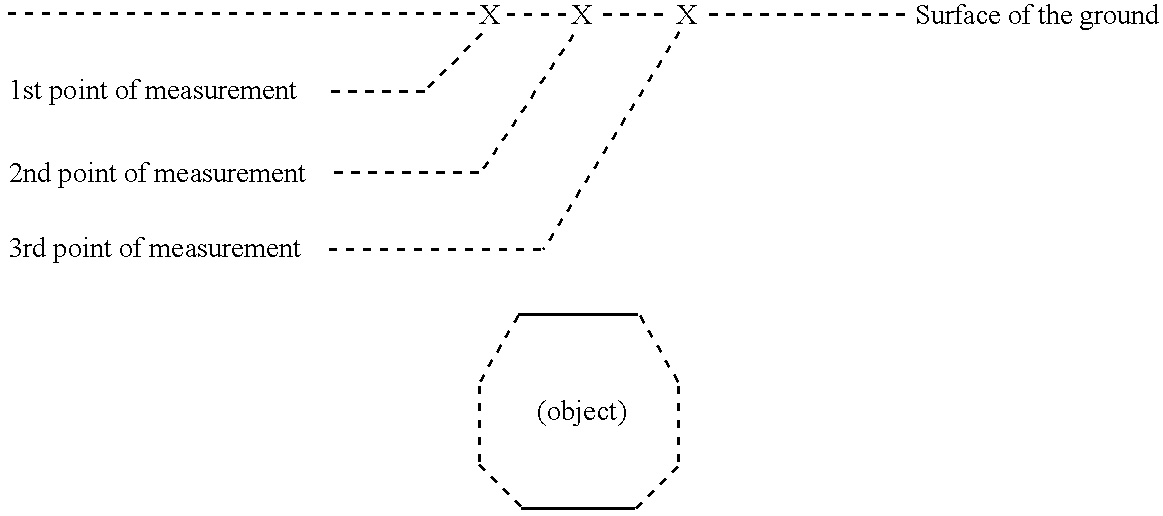

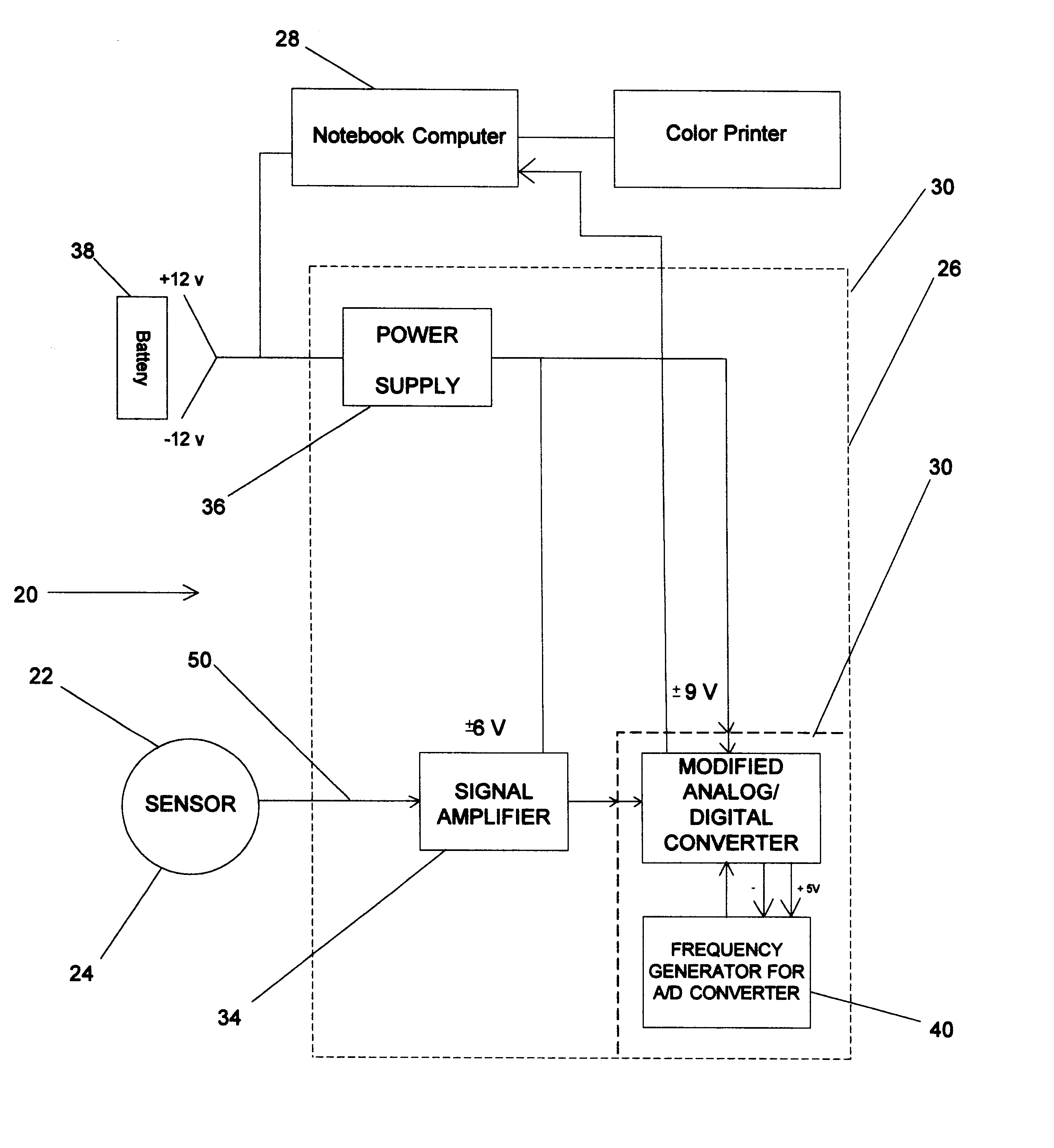

InactiveUS6199016B1High congestionHigh level of environmentalSeismic data acquisitionSeismic signal processingAudio power amplifierResonance

An apparatus and procedure for passively performing a geophysical survey. The RAP Equipment complex comprises an A / D Conversion Device, an external sensor, an external 12 volt battery, and a Notebook Computer in which resides a Fourier analysis program. The A / D Conversion Device is connected to the serial port of the Notebook Computer. The A / D Conversion Device comprises an Analog / Digital Converter modified to replace its quartz resonator with a Frequency Generator for providing a predetermined sampling rate, and a Signal Amplifier. An external sensor is attached by a cable to the input of the Signal Amplifier. A 12 volt power supply powers the Signal Amplifier, the modified A / D converter, and the Notebook Computer. In use, the external sensor is placed on the ground at the first spot it is desired to take a reading. The ground is then lightly tapped in the near vicinity of the sensor either with one's finger or a hammer. This tap causes the natural vibrations within the subsurface layers to be amplified. The sensor picks up these vibrations from the resonating layers, passes them on to the Signal Amplifier which in turn amplifies these signals and passes them on to the A / D Conversion Device. The A / D conversion Device converts these acoustical signals from analog form to digital form and passes them on to the serial port of the Notebook Computer which in turn creates a file of these digital signals.

Owner:ENVIRONMENTAL INVESTIGATIONS CORP

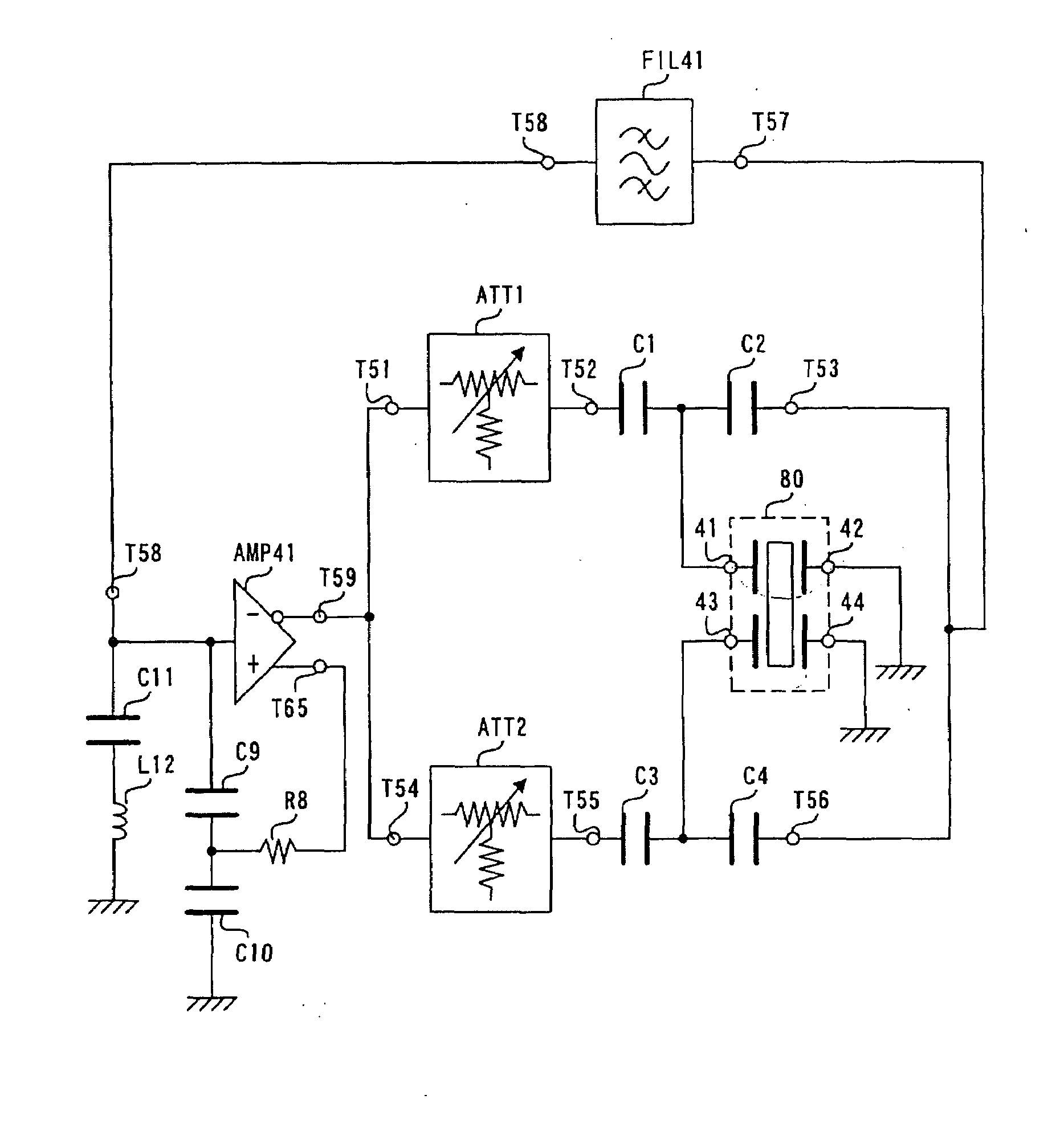

Composite Resonance Circuit and Oscillation Circuit Using the Circuit

InactiveUS20080136542A1High impedanceReducing voltage appliedPiezoelectric/electrostriction/magnetostriction machinesImpedence networksExcitation currentFrequency characteristic

There is provided a resonance circuit using piezoelectric vibrator such as a quartz resonator, a coil, a capacitor, or an element equivalent to them in combination. When two resonance circuits having different resonance frequencies are combined, it is possible to configure an oscillation circuit and a filter capable of freely adjusting the frequency characteristic by utilizing the phenomenon that by changing the excitation current or voltage of the respective resonance circuits independently from each other, antiresonance frequency of the entire composite resonance circuit can be changed.

Owner:HIRAMA KOICHI

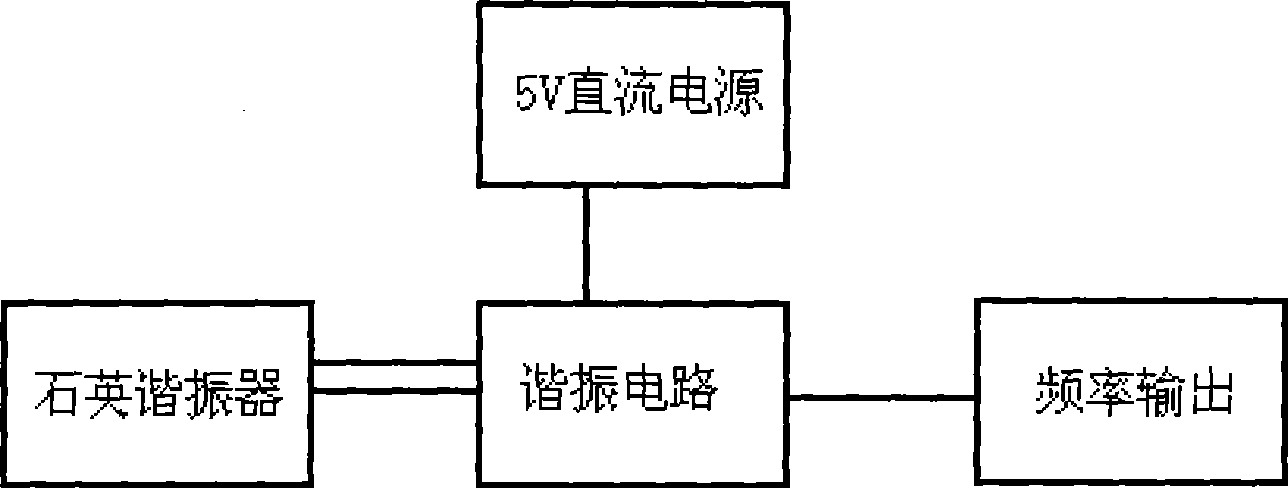

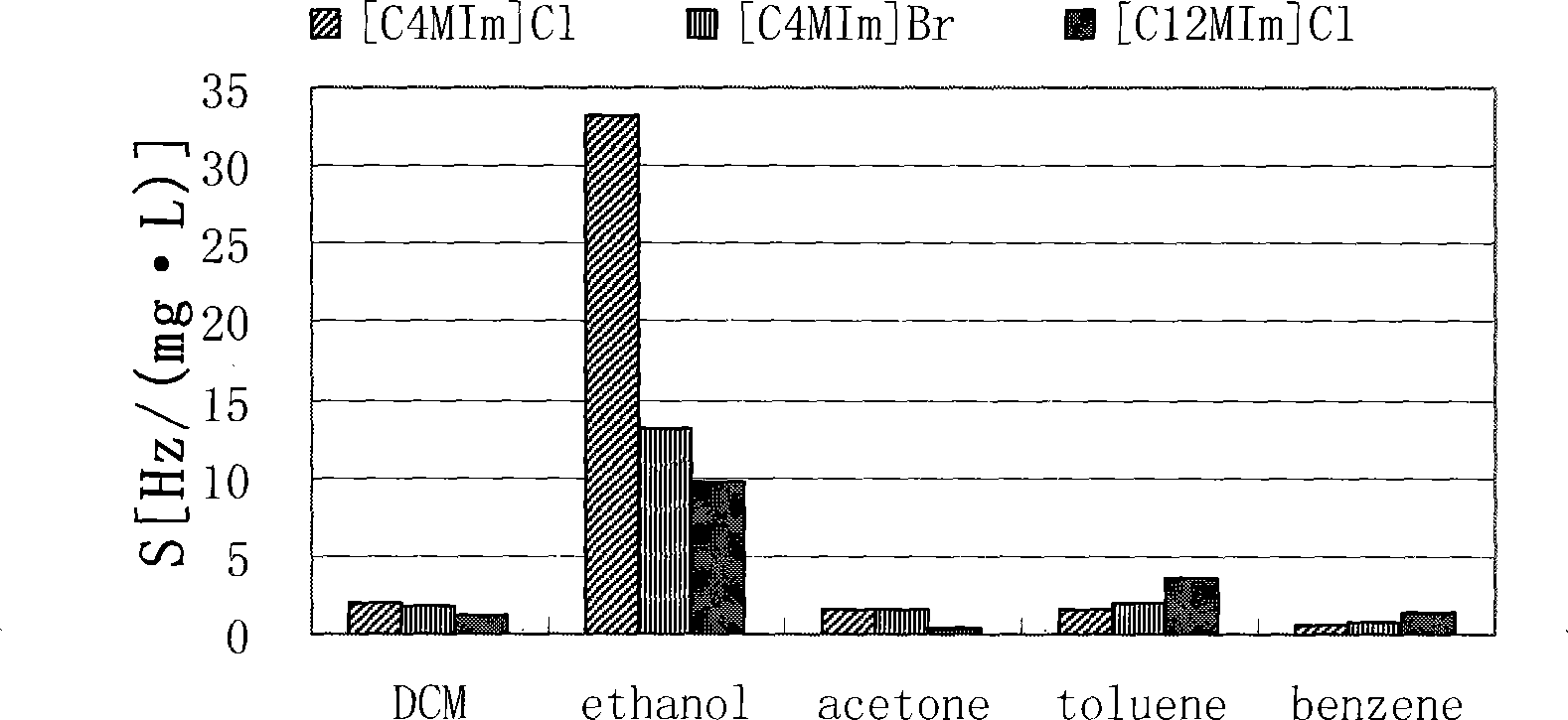

Quartz crystal resonator, preparation and application thereof

InactiveCN101398399ALower working temperatureSuitable for real-time detectionMaterial analysis by electric/magnetic meansQuartz crystal resonatorResponse Frequency

The invention relates to a gas sensor, in particular to a quartz crystal resonator which is sensitive to ethanol, and preparation and application thereof, comprising an AT-cut quartz wafer and a gold electrode fixed on the quartz wafer, wherein, the outer surface of the gold electrode and / or the quartz wafer is coated with an ionic liquid membrane. The resonator is applied to a conventional QCM sensor to prepare a QCM ethanol gas sensor, and the operation principle is the quartz crystal microbalance technology; the response frequency of the sensor is reduced with the fractional increase of the surface quality of the resonator caused by the absorption of the ethanol gas on the surface of a sensitive membrane of the quartz resonator, and the reduced value of the frequency and the concentration of the ethanol gas are linear. The gas sensor has the advantages of simple structure, small size, fast and real-time response, high sensitivity, good selectivity, no need of analog to digital conversion for the output of frequency signals, convenient batch production and the like, and is particularly suitable for measuring the concentration of the ethanol gas in the air in real time.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

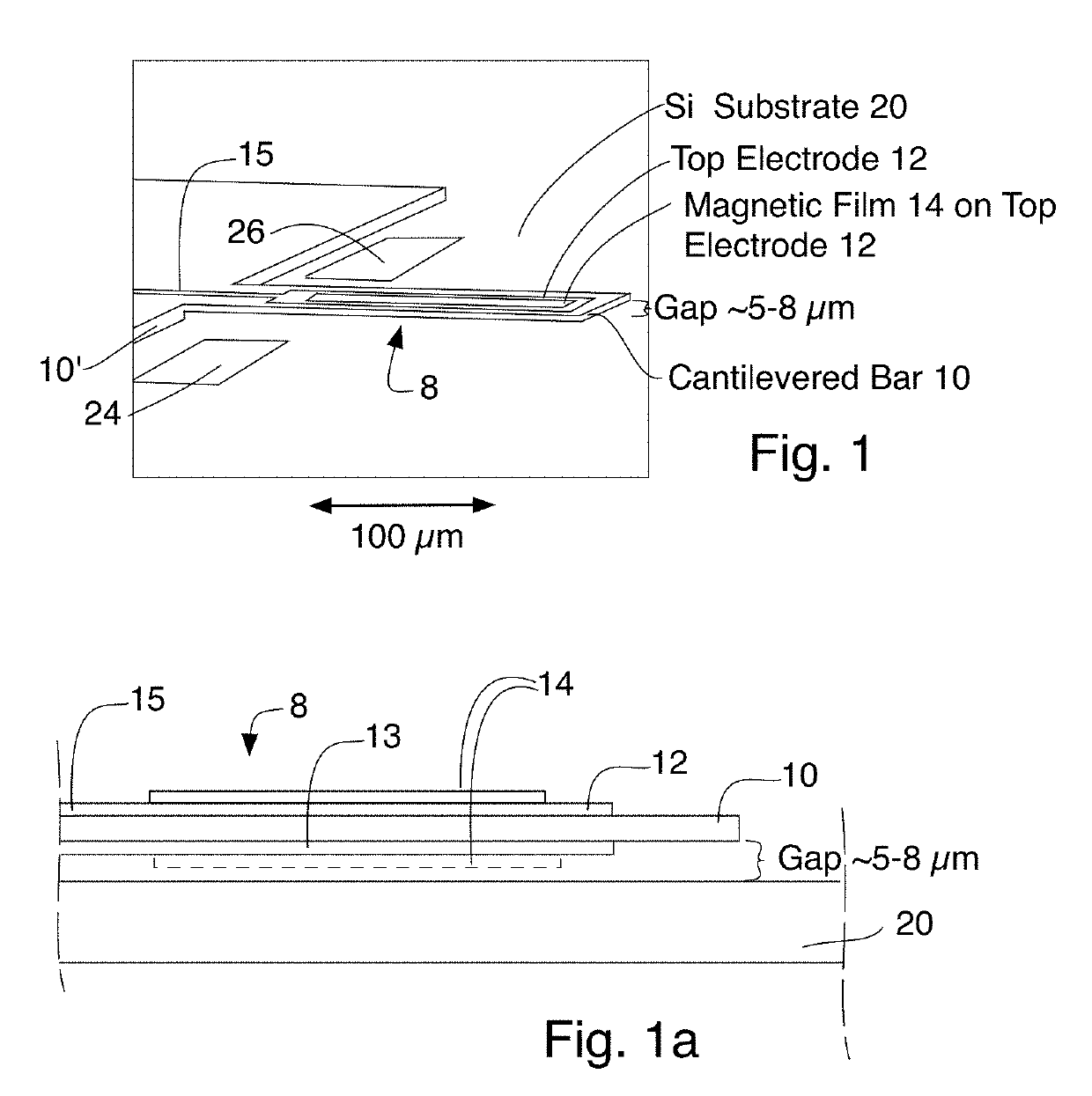

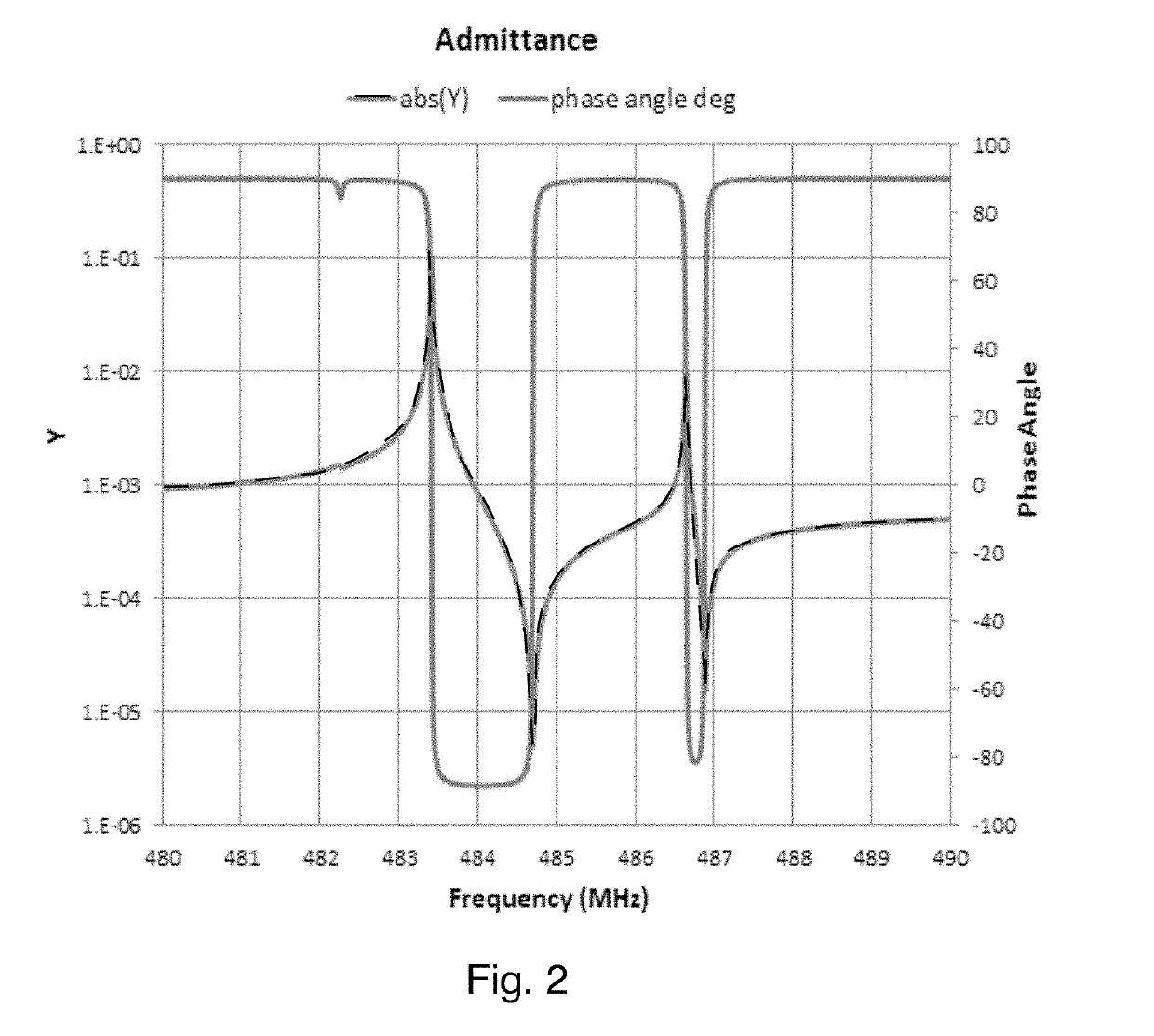

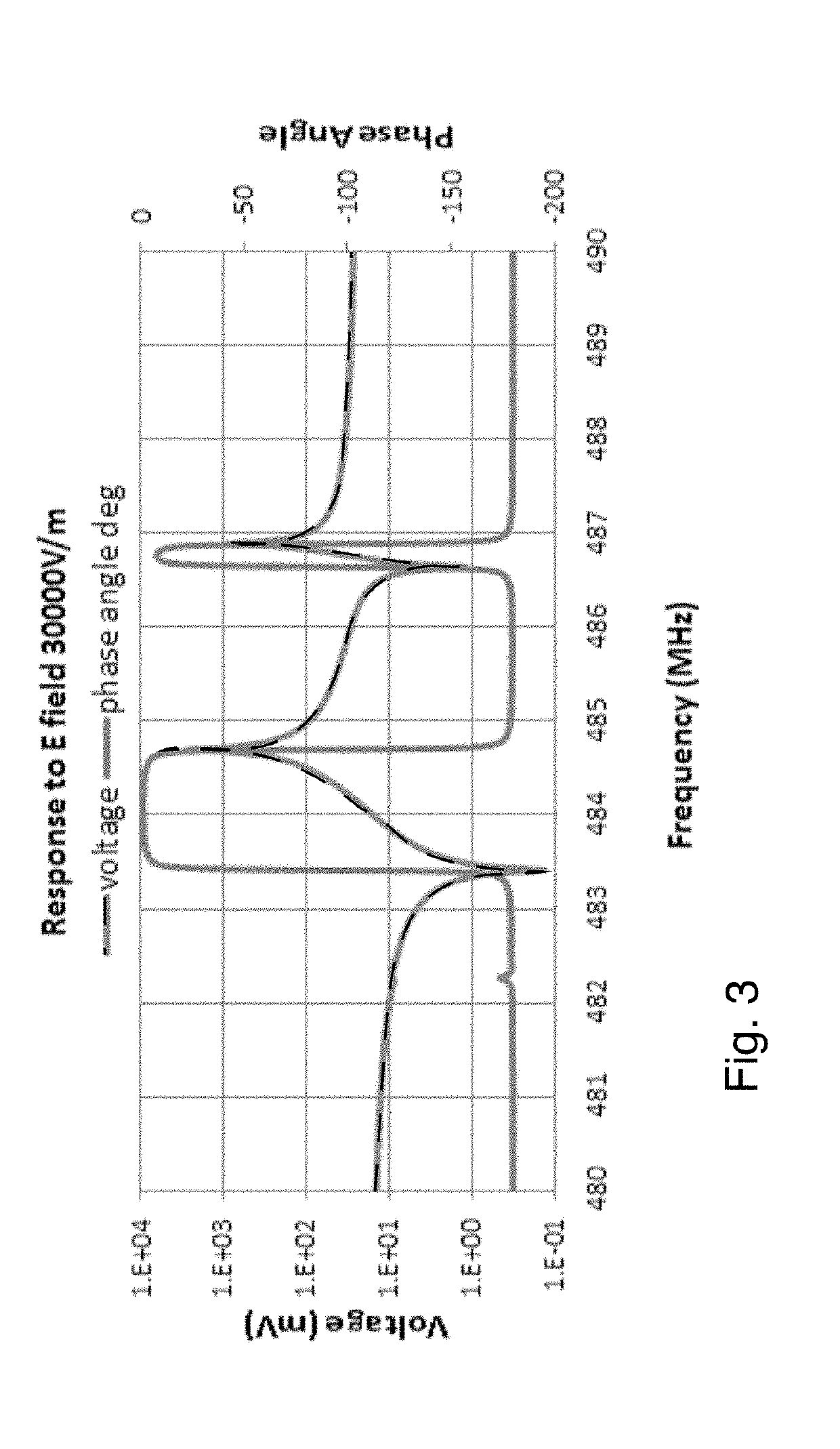

Dual Magnetic and Electric Field Quartz Sensor

ActiveUS20190250198A1Simplified determinationSensitive highReceivers monitoringElectromagentic field characteristicsRf fieldElectric field NMR

A RF field sensor in which a magnetostrictive film is deposited on one or more electrodes of one or more quartz resonator(s) in which an electric field of the RF field is detected along one axis of the RF field sensor and a magnetic field of the RF field is detected along an orthogonal axis of the RF field sensor simultaneously.

Owner:HRL LAB

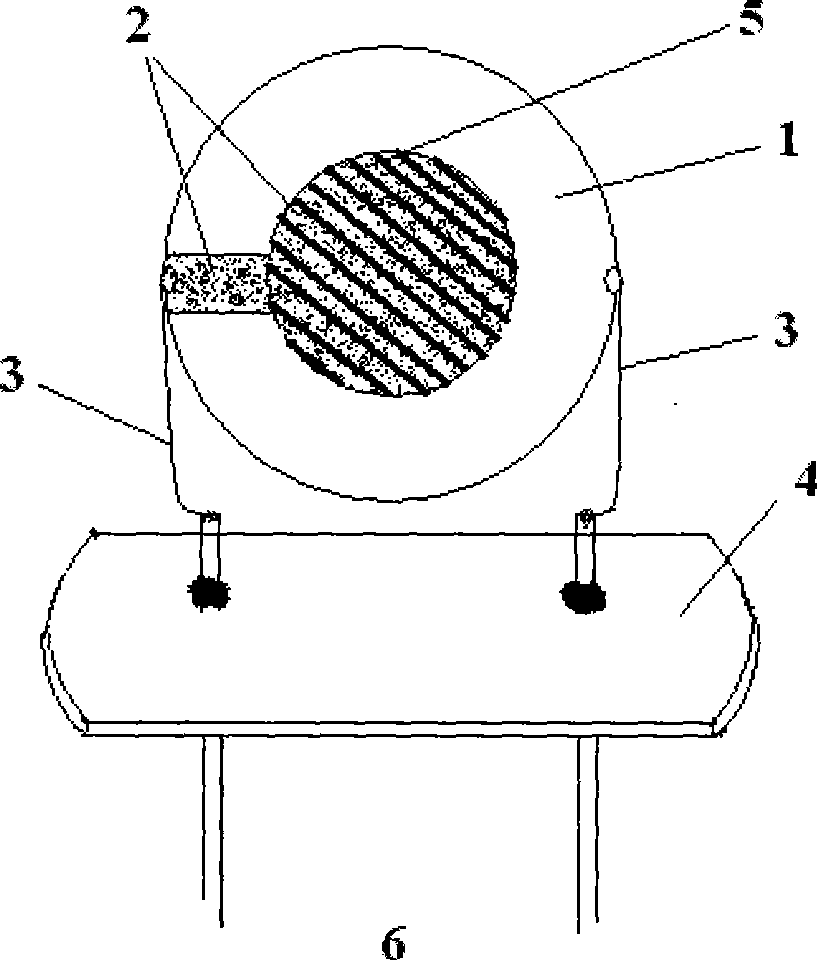

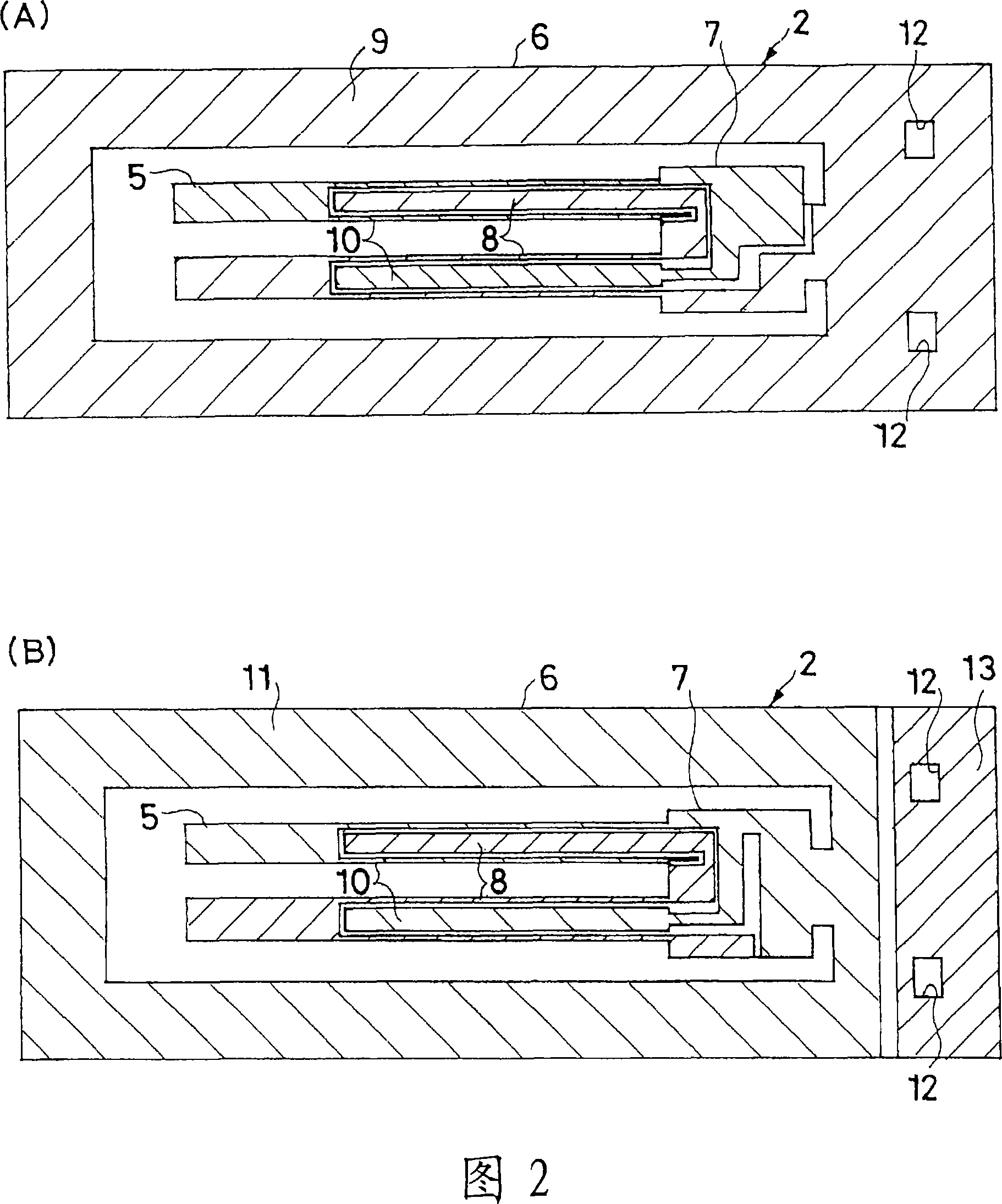

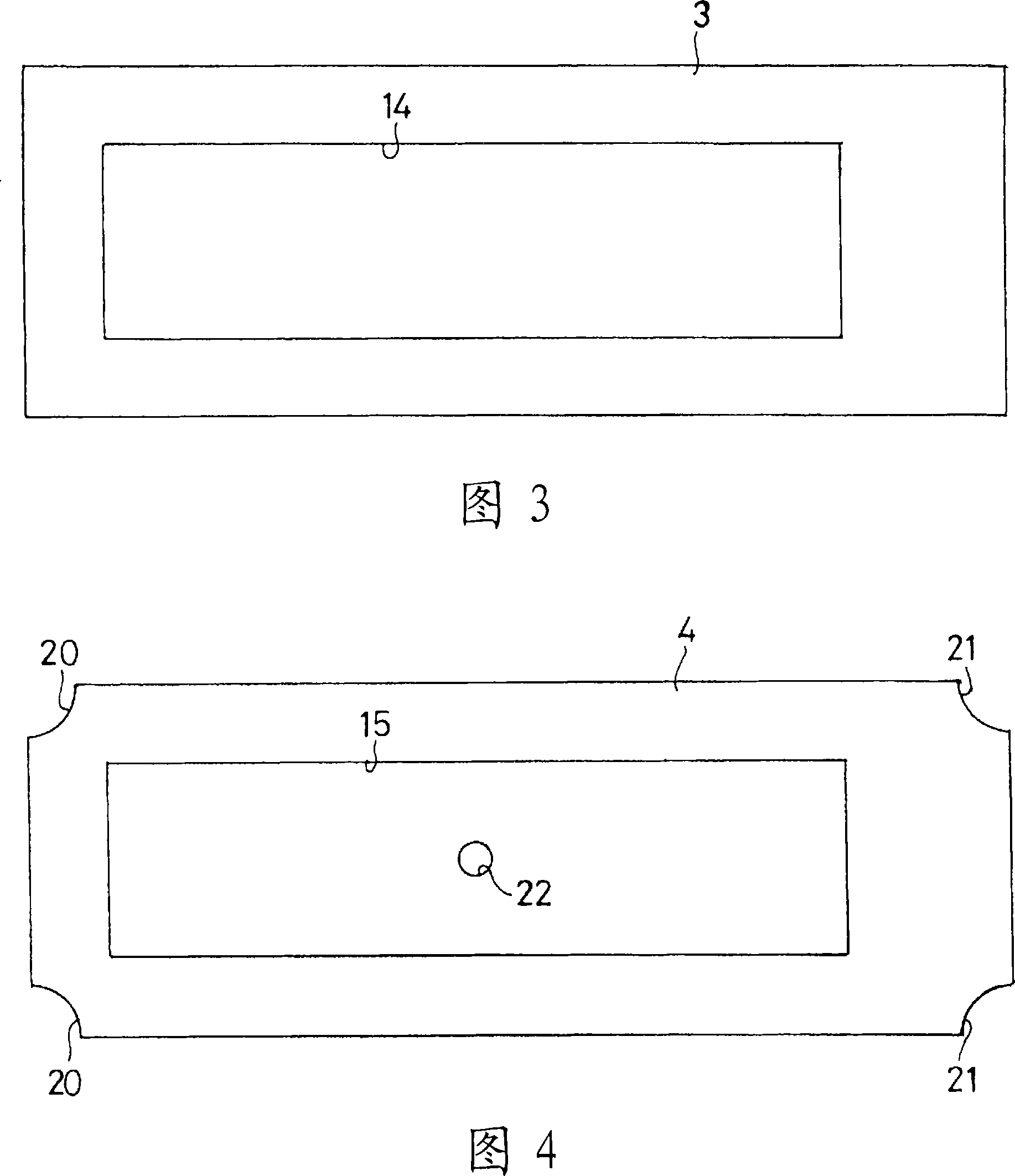

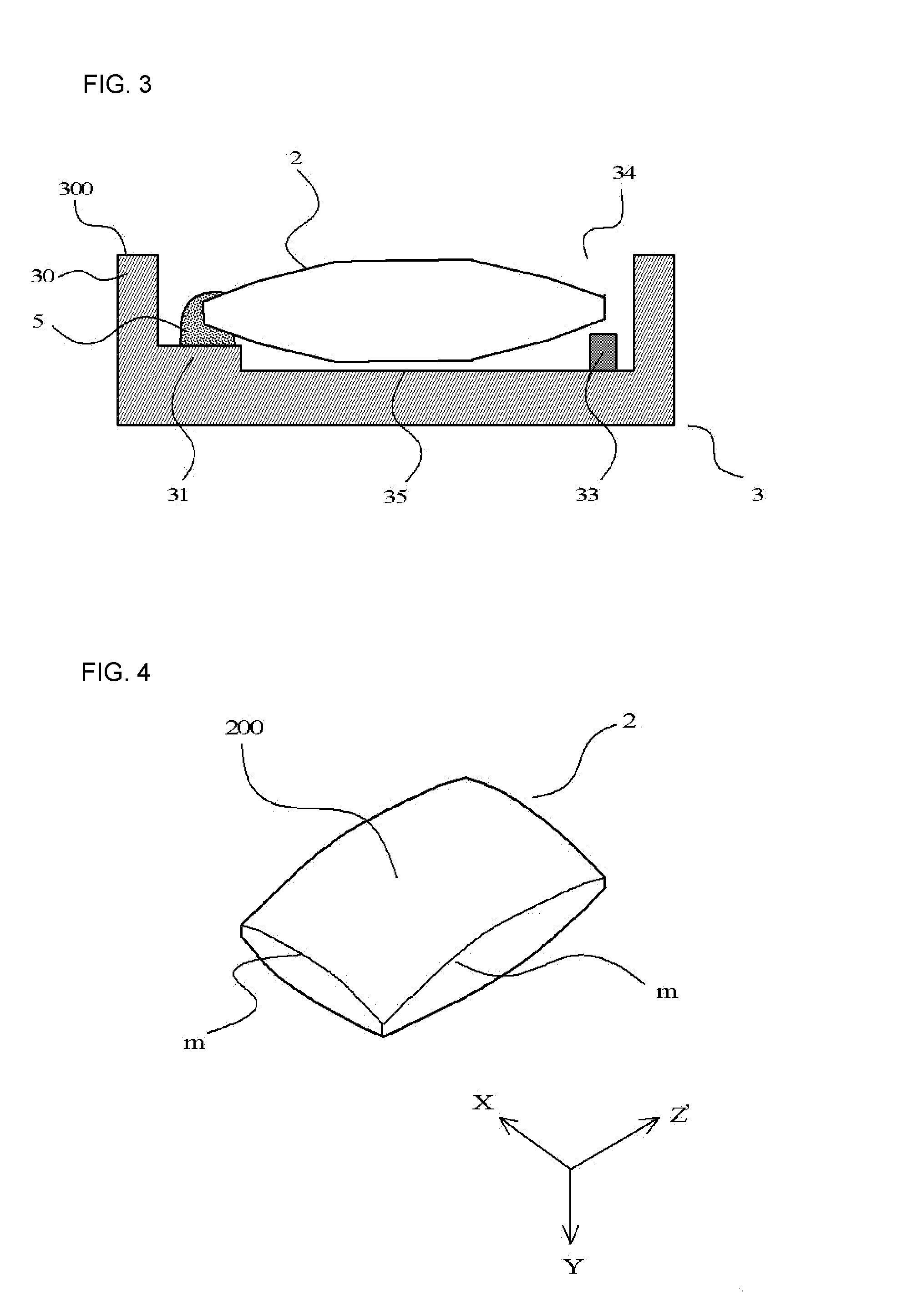

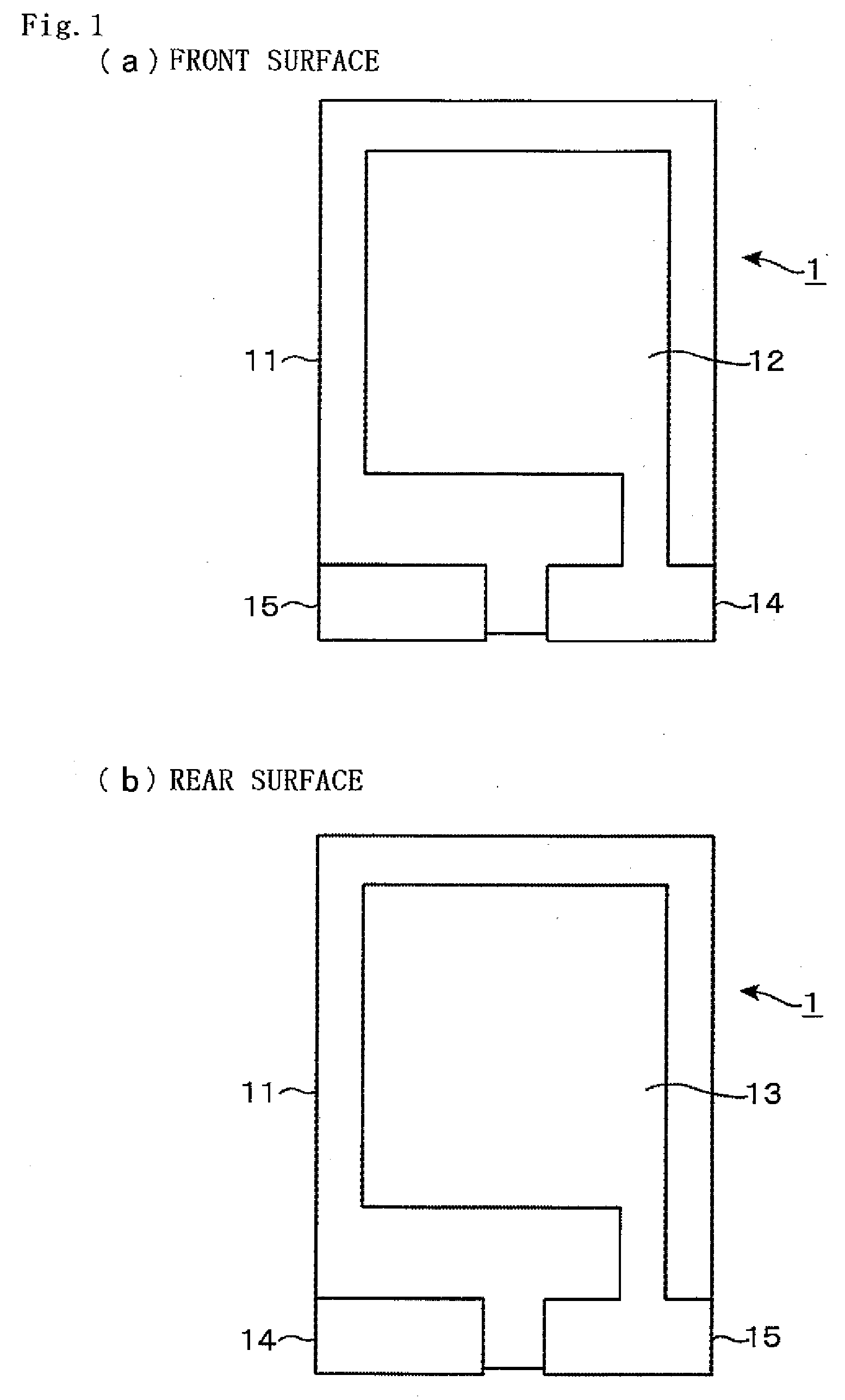

Piezoelectric resonator and manufacturing method thereof

InactiveCN101199113APiezoelectric/electrostrictive device manufacture/assemblyImpedence networksRoom temperatureEngineering

The quartz resonator (1 and 51) is provided with a structure which is integrally airtight-connected with upper-side and lower-side substrates (3, 4, 53 and 54) which are overlapped on the upper surface and the lower surface of a middle quartz plate (2 and 52) integrally forming a quartz resonator sheet (5 and 55) and a housing (6 and 56). The upper-side and lower-side substrates are respectively provided with a concave part on a surface facing to the middle quartz plate so as to form cavities (16 and 66) for airtight sealing the quartz resonator sheet in a suspension state. The upper and lower connection surface of the middle quartz plate forms a conductive film (9 and 11) after being grinded and processed at the lens surface. Each connection surface of the upper-side and lower-side substrates consists of bare quartz surfaces which are grinded and processed at the lens surface. In another embodiment, a metal film (67 to 69) is formed on each connection surface of the upper-side and lower-side substrates consists of bare quartz surfaces which are grinded and processed at the lens surface. The upper-side and lower-side substrates and the middle quartz plate are all or one by one overlapped with each other and are then pressurized at room temperature (heated optionally) after whose connection surfaces are surface-activated through plasma processes, so as to be airtight-connected with each other, thereby sealing the cavities in a vacuum or idle gas atmosphere.

Owner:SEIKO EPSON CORP

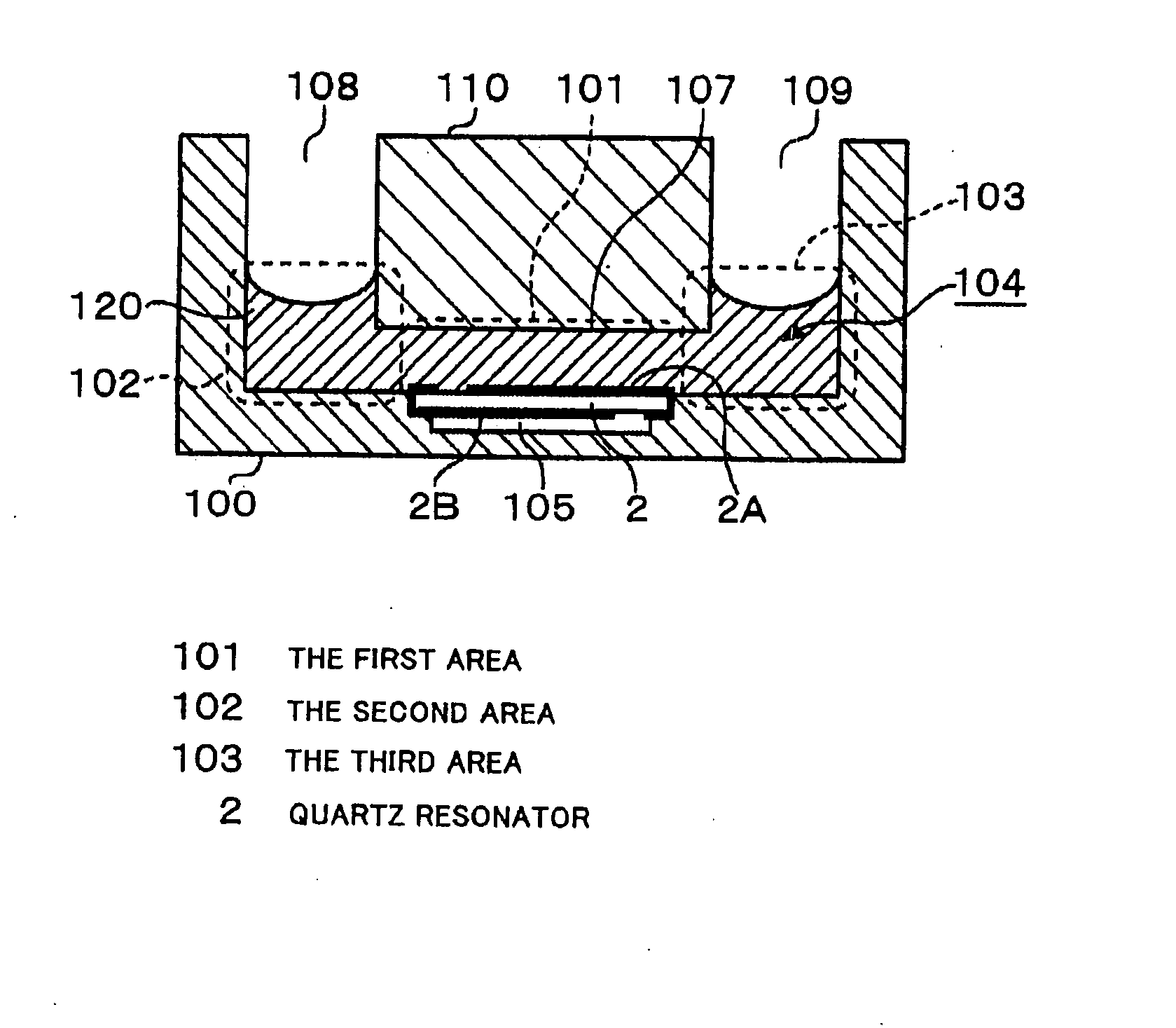

Quartz plate and quartz resonator in which the quartz plate is used

ActiveUS20130009521A1Improve featuresFavorable series resistance valuePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesResonanceQuartz resonator

An AT-cut quartz plate having chamfered ridge portions and an almost rectangular shape in planar view, wherein a resonance frequency is equal to or larger than 7 MHz and equal to or smaller than 9 MHz, lengths of long and short sides of the rectangular shape are equal to or larger than 1.5 mm and equal to or smaller than 2.4 mm, and equal to or larger than a frequency difference between primary vibration and sub-vibration is equal to or larger than 975 kHz and equal to or smaller than 1,015 kHz.

Owner:DAISHINKU CORP

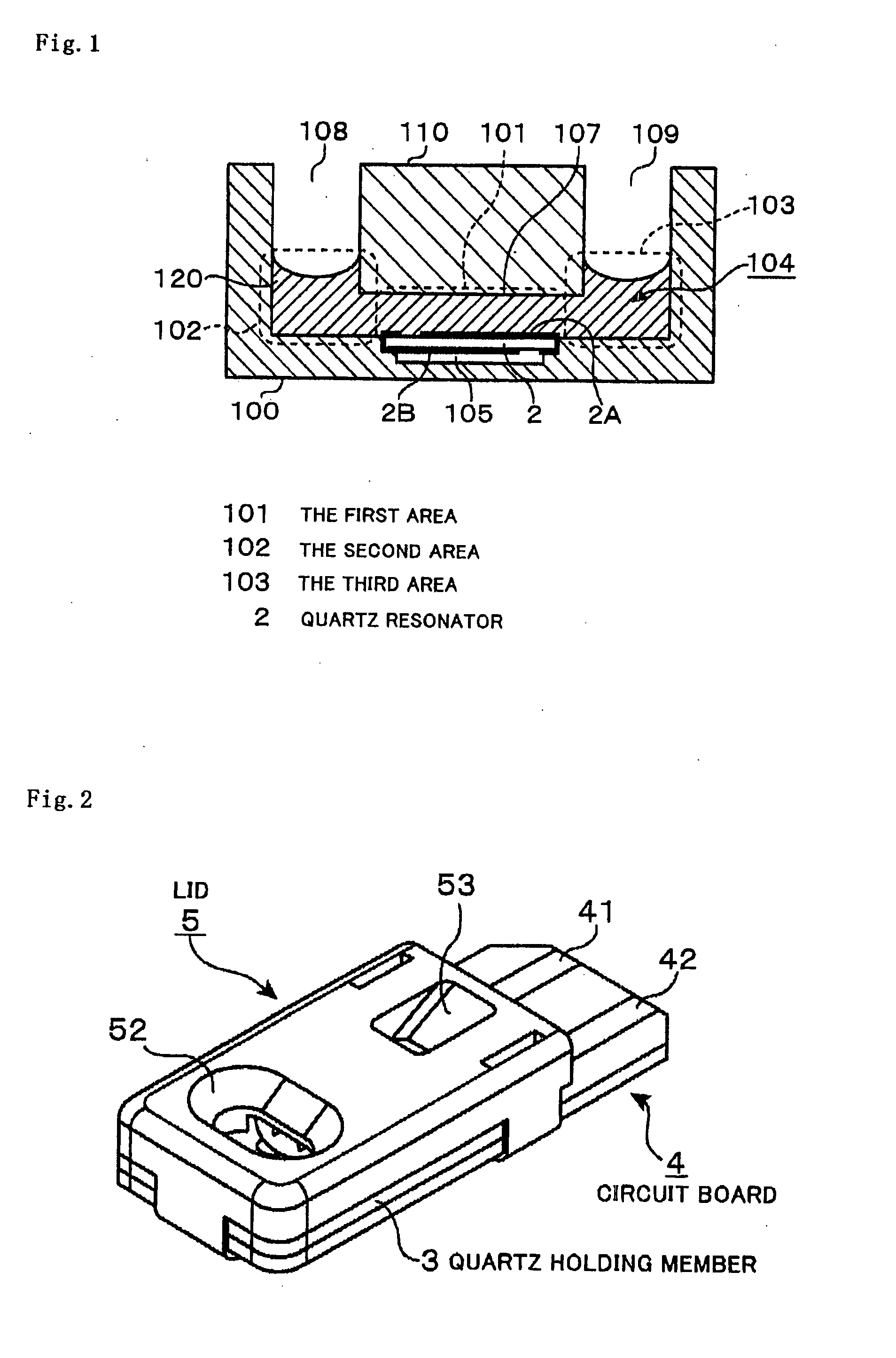

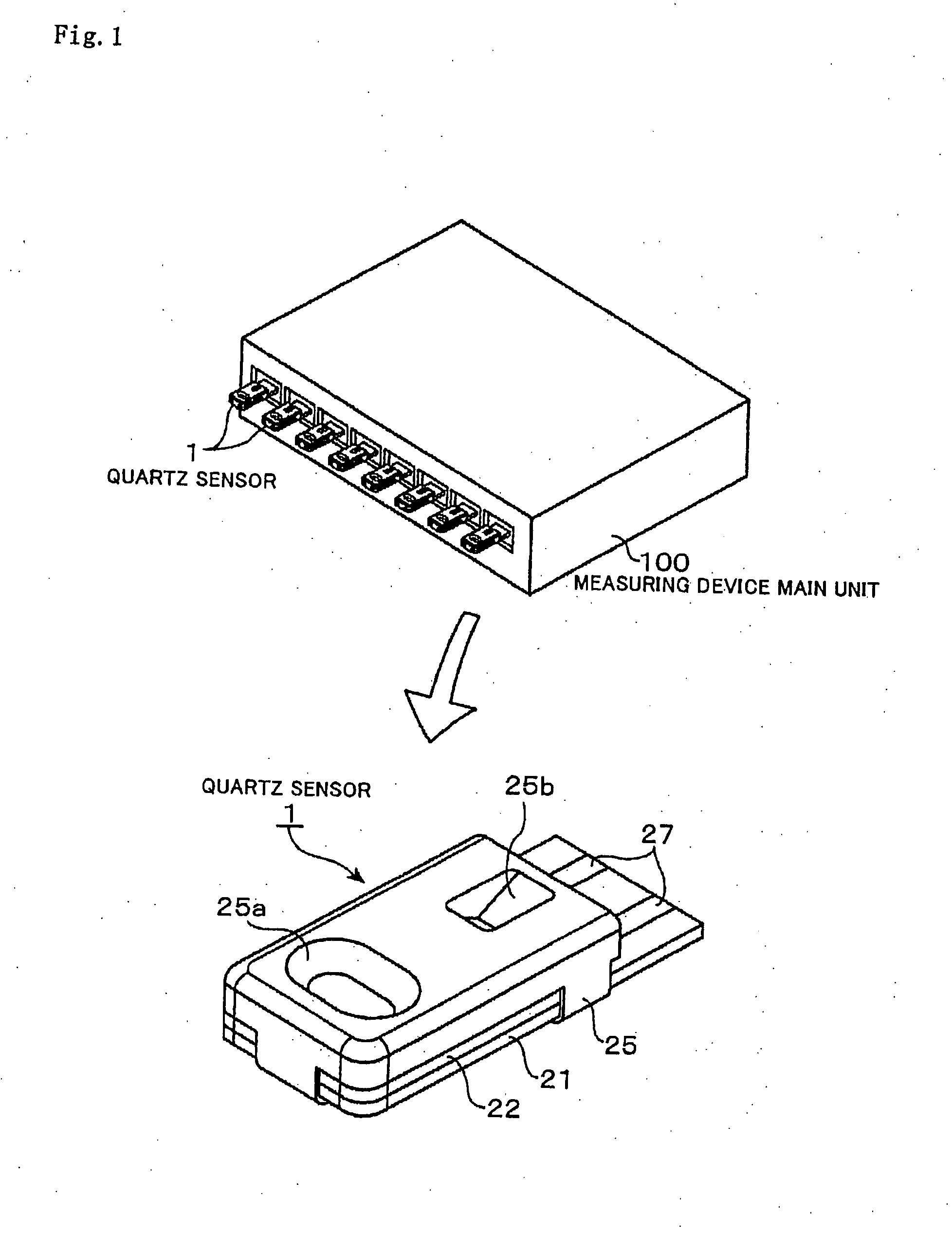

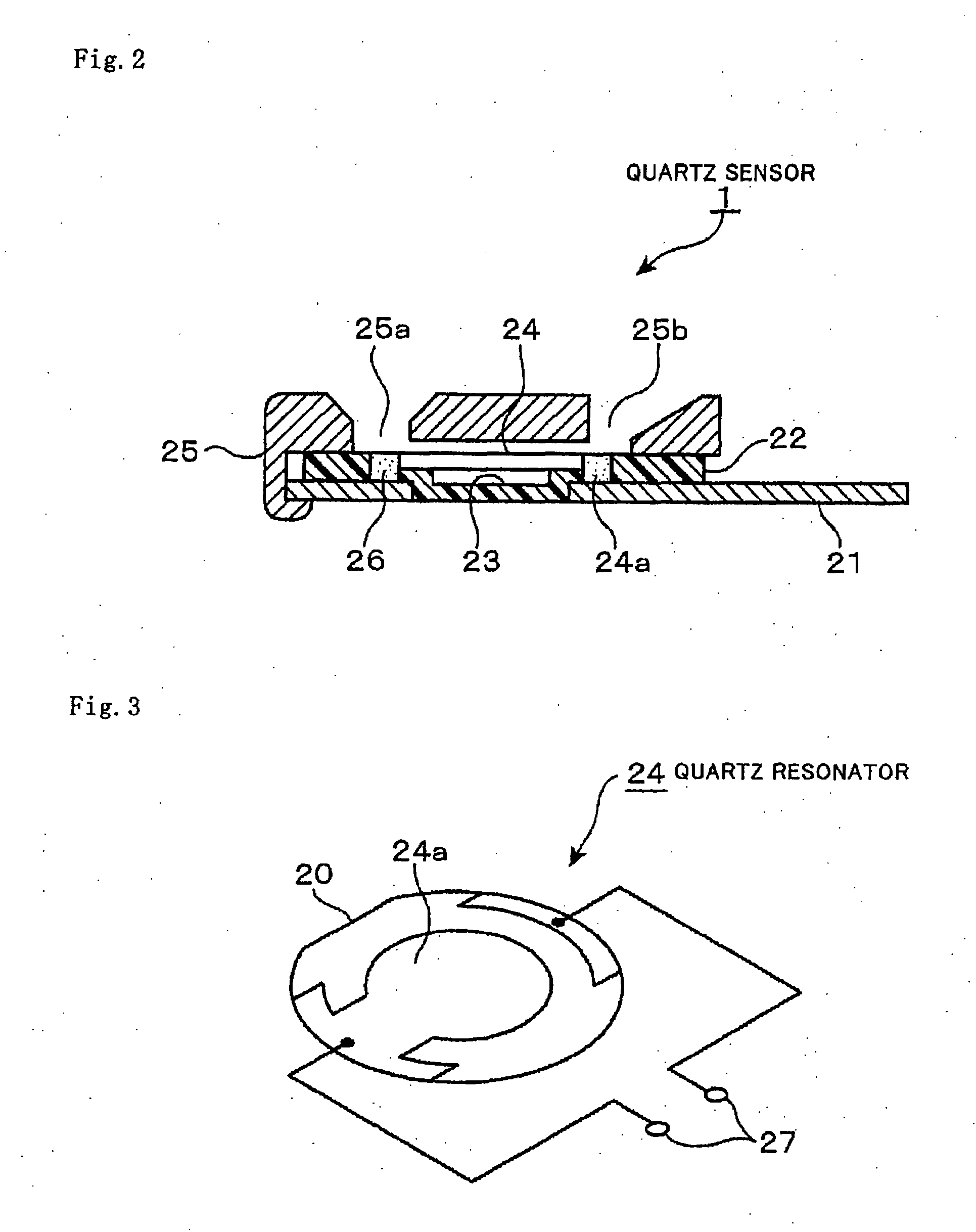

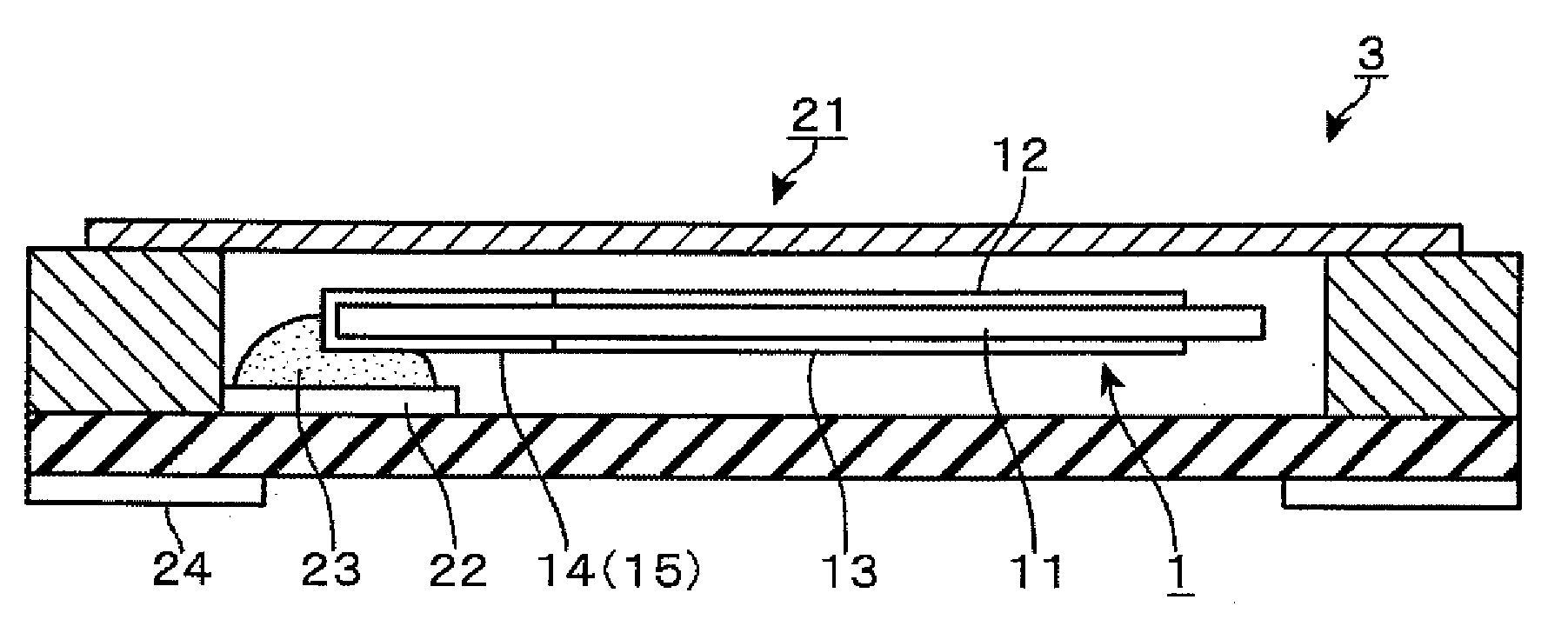

Quartz Sensor and Sensing Device

InactiveUS20080134767A1High measurement sensitivityReduce thicknessAnalysing fluids using sonic/ultrasonic/infrasonic wavesPiezoelectric/electrostriction/magnetostriction machinesAcousticsQuartz resonator

An object of the present invention is to provide a Langevin type quartz sensor which is high in measurement sensitivity, suppresses the influence of the surface tension of a sample solution during measurement, and enables an installed quartz resonator to stably oscillate. As a specific means to solve the problem, a quartz sensor including a housing area forming portion surrounding the upper space on one face side of the quartz resonator for forming a housing area of the sample solution; an opposing surface portion opposing to one surface side of the quartz resonator via the housing area and being larger than the area coming in contact with the sample solution in the quartz resonator; and a pouring opening formed in the outside area of the opposing surface portion and at a position higher than said opposing surface potion for pouring the sample solution into the housing area is composed and measurement is conducted in a standstill state where the sample solution is filled in the lower side of the opposing surface portion. Since stress due to the surface tension of the sample solution does not act in this state, the quartz resonator can oscillate with reliability. Therefore, the quartz sensor of the present invention can reduced the thickness of the quartz resonator, which realizes highly sensitive and highly accurate measurement.

Owner:NIHON DEMPA KOGYO CO LTD

Quartz-based disk resonator gyro with ultra-thin conductive outer electrodes and method of making same

ActiveUS8766745B1Impedence networksSpeed measurement using gyroscopic effectsGyroscopeQuartz resonator

A disk resonator gyroscope includes a quartz base, a quartz resonator disk having a central pillar connected to the base, the quartz resonator disk having a surface facing the base and having plurality of circumferential slots in the surface of the quartz resonator disk around the central pillar, and an electrode comprised of quartz and connected to the base outside of an outer edge of the resonator disk.

Owner:HRL LAB +1

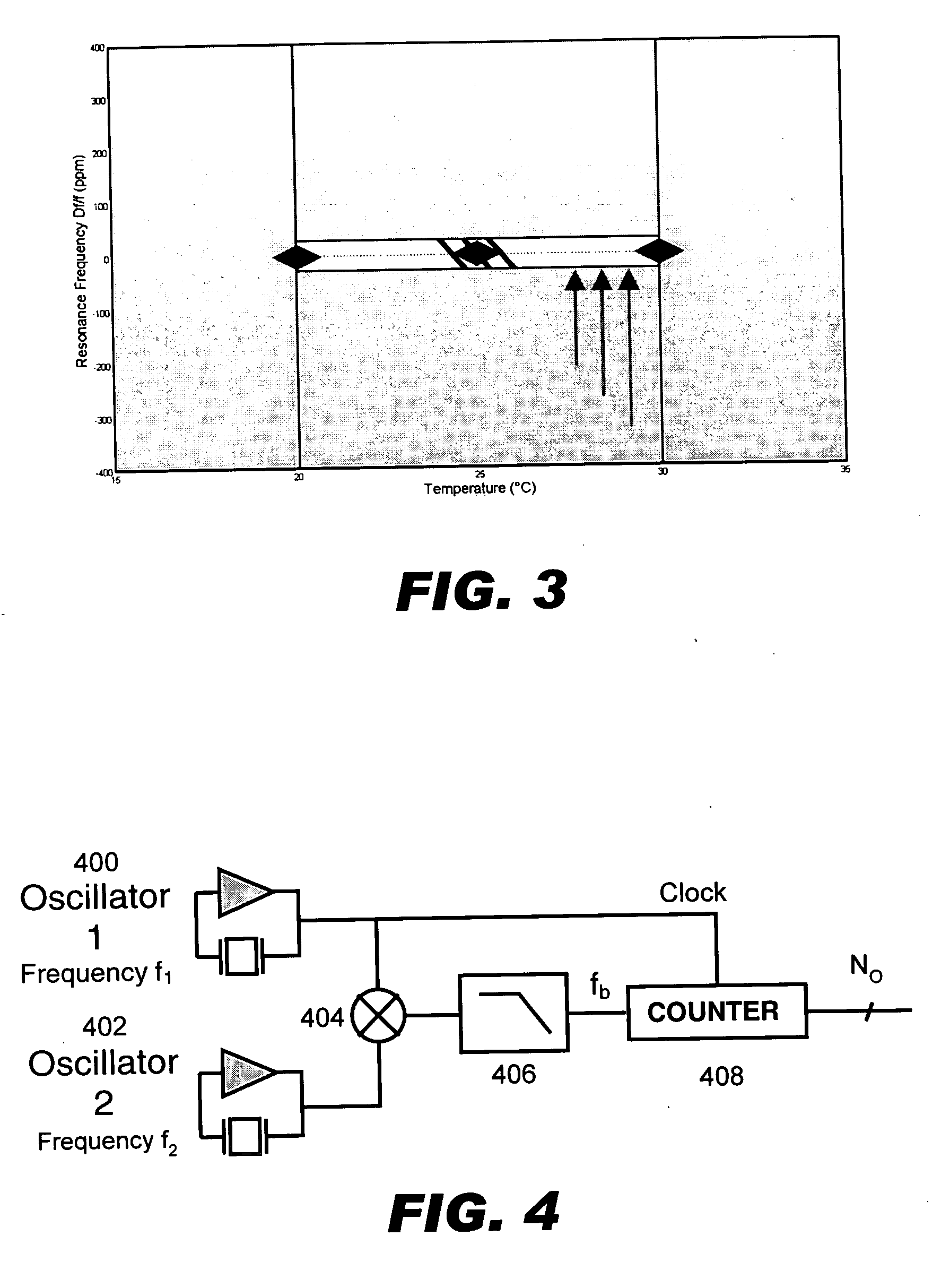

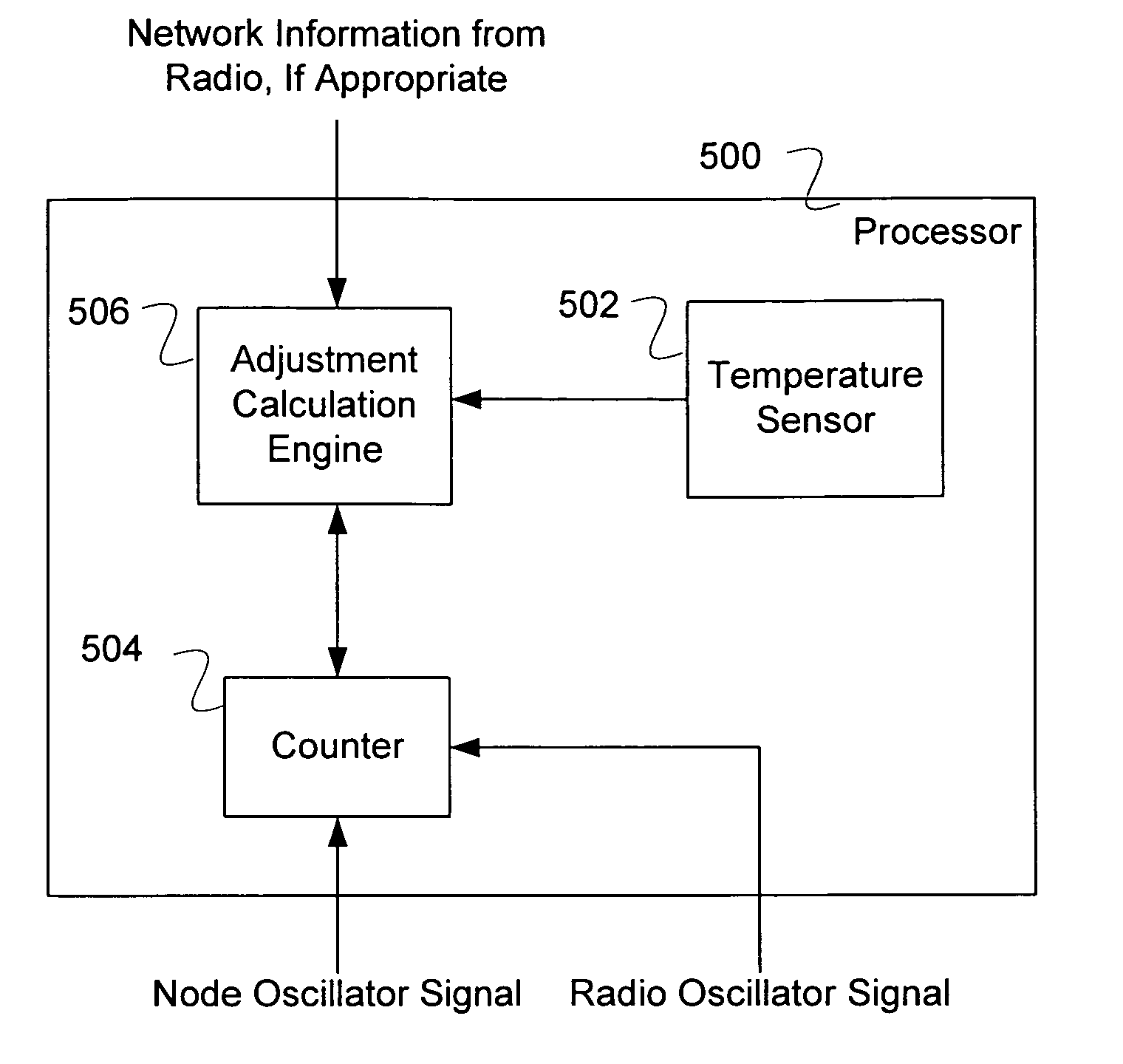

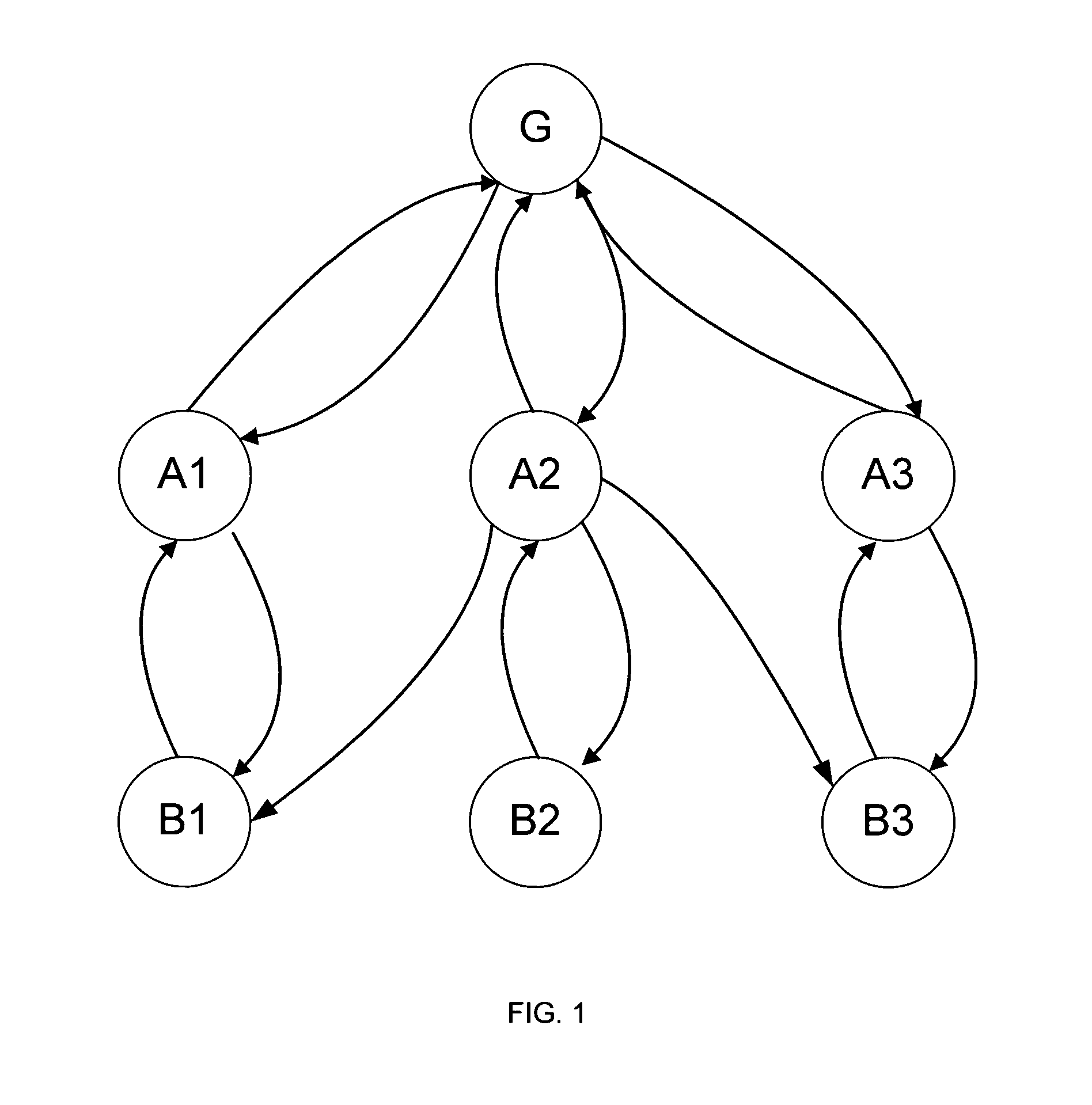

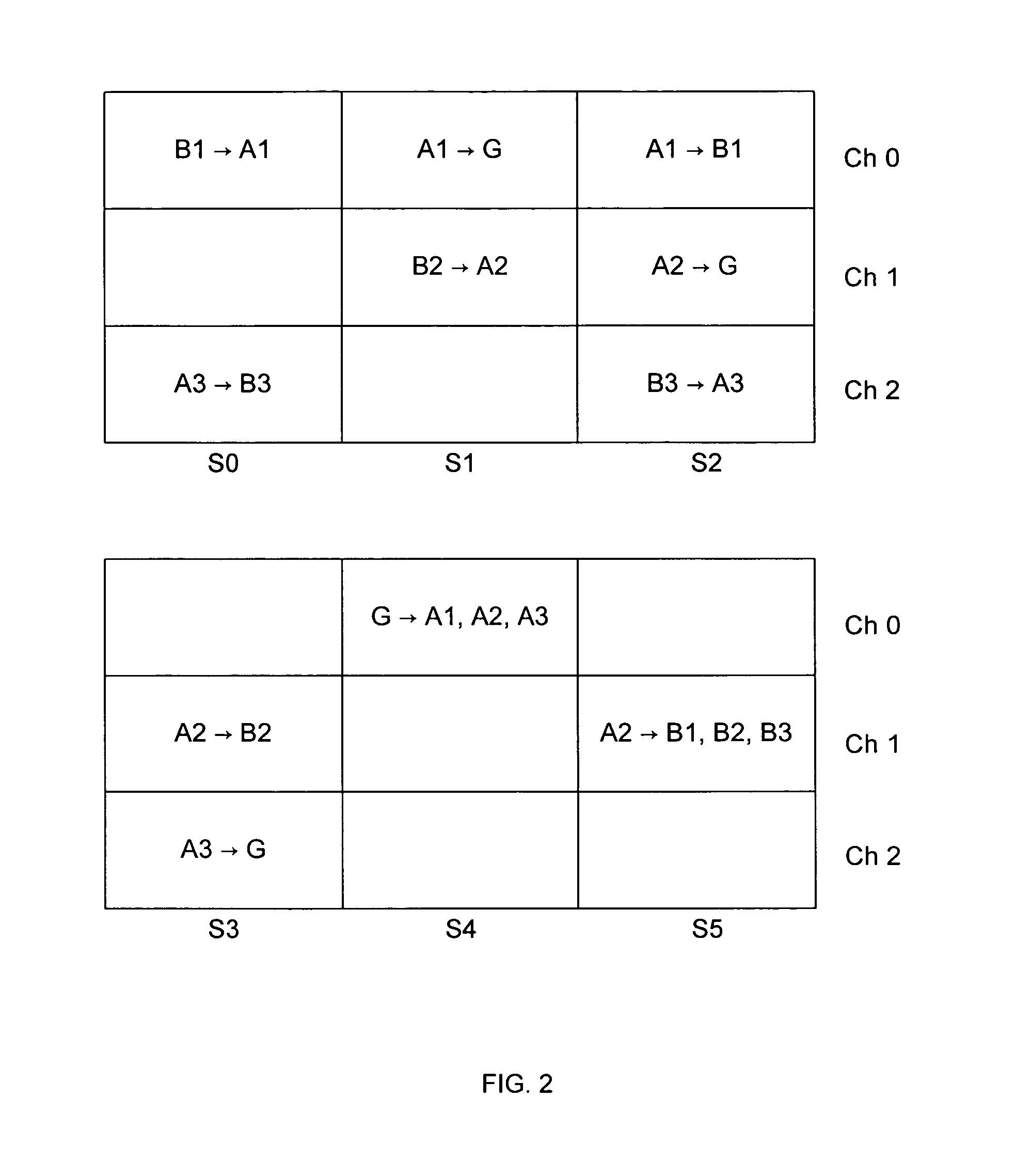

Timing calibration for crystal oscillators within a mesh network

Timing calibrator is disclosed. A first oscillator includes an output. The first oscillator includes a mechanically resonant element. A second oscillator includes an output. The second oscillator includes a quartz resonator. A frequency relater has an output, a first input, and a second input. The frequency relater has the first input coupled to the first oscillator output and the second input coupled to the second oscillator output.

Owner:ANALOG DEVICES INT UNLTD

Timepiece having a mechanical movement associated with an electronic regulator

ActiveUS7016265B2Efficient electromagnetic couplingClosely arrangedFrequency stabilisation mechanismElectric windingElectromagnetic couplingField line

There is disclosed a timepiece having a mechanical clockwork-movement (10) driven by a barrel spring (14) and provided with a mechanical regulator, with a balance and a balance spring, which is associated, via electromagnetic coupling, with an electronic regulator driven by a quartz resonator. The rim of the balance (13) balance is provided with at least one pair of permanent magnets (38, 39). The electronic regulator includes a fixed coil (12) arranged for cooperating with said magnets via electromagnetic coupling, a rectifier (58) provided with at least one capacitor, and a circuit for enslaving the frequency of the mechanical regulator to the oscillator frequency by braking obtained by briefly short-circuiting the coil. In order to use a mechanical movement of a common type, in which only the balance is altered, the coil (12) is located on the side of the balance-cock (23) with respect to the balance rim. The pair of magnets (38, 39) is covered by a plate of magnetic material in order to close field lines on the side of the plate. Apart from the coil, all of the rest of the electronic module (11) is located outside the mechanical movement.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Timepiece having a mechanical movement associated with an electronic regulator

ActiveUS20050073913A1Efficient electromagnetic couplingClosely arrangedEscapementsFrequency stabilisation mechanismElectromagnetic couplingField line

There is disclosed a timepiece having a mechanical clockwork-movement (10) driven by a barrel spring (14) and provided with a mechanical regulator, with a balance and a balance spring, which is associated, via electromagnetic coupling, with an electronic regulator driven by a quartz resonator. The rim of the balance (13) balance is provided with at least one pair of permanent magnets (38, 39). The electronic regulator includes a fixed coil (12) arranged for cooperating with said magnets via electromagnetic coupling, a rectifier (58) provided with at least one capacitor, and a circuit for enslaving the frequency of the mechanical regulator to the oscillator frequency by braking obtained by briefly short-circuiting the coil. In order to use a mechanical movement of a common type, in which only the balance is altered, the coil (12) is located on the side of the balance-cock (23) with respect to the balance rim. The pair of magnets (38, 39) is covered by a plate of magnetic material in order to close field lines on the side of the plate. Apart from the coil, all of the rest of the electronic module (11) is located outside the mechanical movement.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Resonator assembly comprising a silicon resonator and a quartz resonator

ActiveUS9250074B1Improve fidelityQuality improvementPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksGyroscopeQuartz resonator

A resonator assembly comprising a semiconductor substrate, a resonator gyroscope, the resonator gyroscope including a first resonator formed in a layer of a first material, and an oscillator on the semiconductor substrate, the oscillator including a second resonator formed of a second material, wherein the second resonator is attached in a cavity; the cavity comprising a first recess in said layer of a first material and the edges of the first recess being attached to the substrate, or the cavity comprising a second recess in said substrate and the edges of the second recess being attached to said layer of a first material.

Owner:HRL LAB

Sensing Device

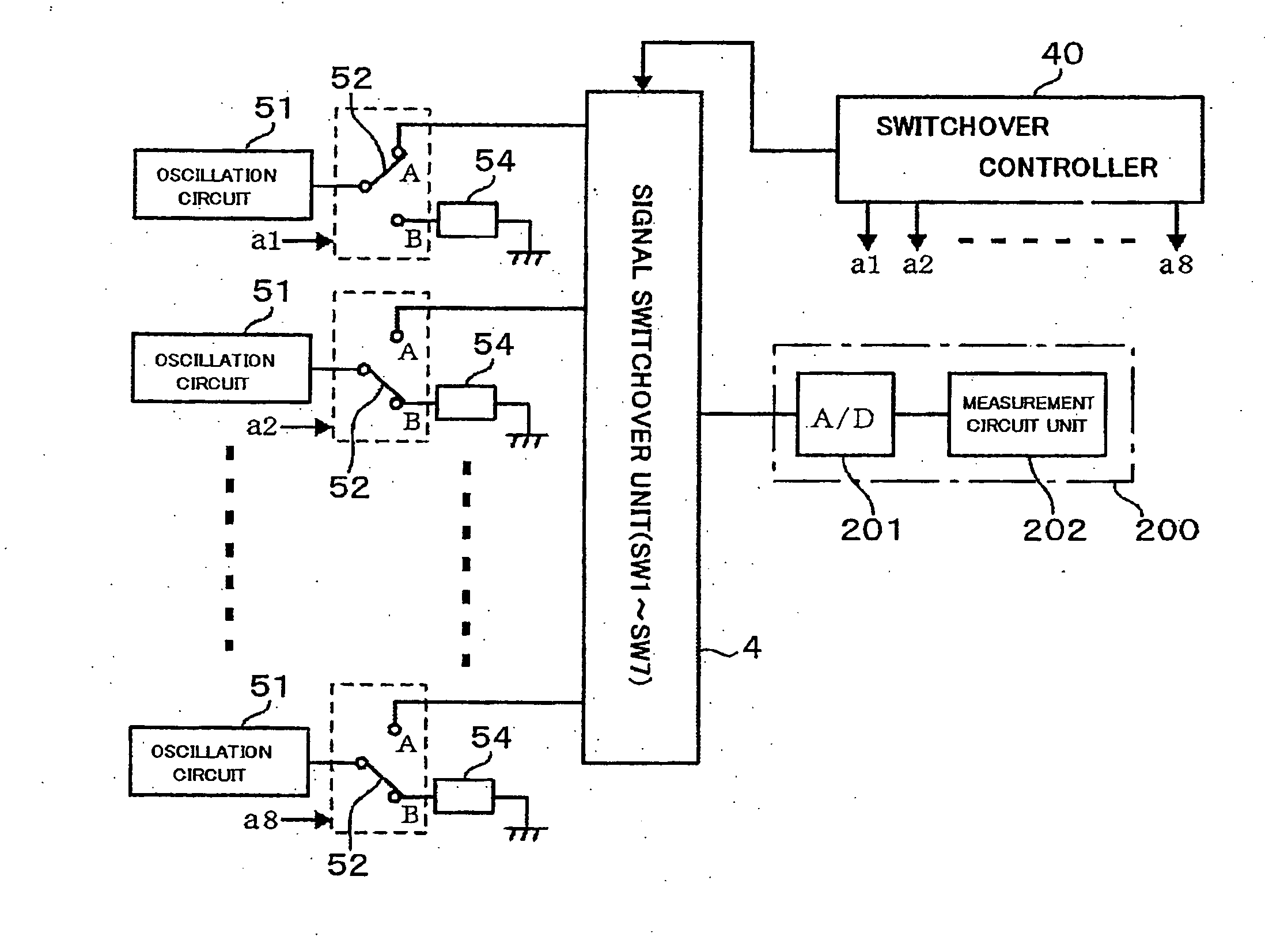

ActiveUS20080156097A1Avoid overlappingSimple circuit configurationVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesFrequency measurementsInstability

An object of the present invention is to avoid the instability of frequency measurement caused by spatial connection between quartz sensor adjacent to each other when a plurality of quartz sensors including a quartz resonator which varies the national frequency due to adsorption of an object to be detected. As a concrete means for solving the problem is to provide a common measuring unit 200 to measure the variation in frequency to each oscillation circuit 51 corresponding to each quartz sensor 1 so as to switchover and connect in turn, and as for the oscillation circuits 51 excepting the oscillation circuits 51 connected to the measuring unit 200 by the switches 52 serving as the load switchover unit, the load value on the output side of the oscillation circuit 51 included (relating to the measurement) in the channels connected to the measuring unit 200 and the load value on the output side of the standby oscillation circuits 51 are made different from each other, so that the respective oscillating frequencies are forcibly separated from each other.

Owner:NIHON DEMPA KOGYO CO LTD

Method of manufacturing quartz resonator element, quartz resonator element, quartz resonator, and quartz oscillator

InactiveUS20100066213A1Reduce the CI valueIncrease manufacturing costPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksQuartz resonatorQuartz substrate

To provide a method of manufacturing a quartz resonator element having a small CI value, a quartz resonator element manufactured by this method, a quartz resonator, and a quartz oscillator.In a method of manufacturing a quartz resonator element in which on a surface of a plate-shaped quartz piece, a thin film-shaped electrode in order to excite the quartz piece is provided, a first metal layer that is composed of chromium and whose thickness is not less than 20 Å nor more than 45 Å is formed on the surface of the quartz piece (P4), and next, a second metal layer that is composed of gold or silver and whose thickness is not less than 500 Å nor more than 950 Å is formed on an upper surface of the first metal layer (P5), and then, the electrode made up of the first metal layer and the second metal layer is provided (P6). Thereafter, a quartz substrate on which the electrode is formed is heated at a temperature range of not less than 200° C. nor more than 400° C., and the chromium composing the first metal layer is diffused into the second metal layer (P7).

Owner:NIHON DEMPA KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com