Quartz crystal resonator, preparation and application thereof

A quartz crystal and resonator technology, applied in the field of quartz crystal resonators, achieves the effects of fast response, high sensitivity and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

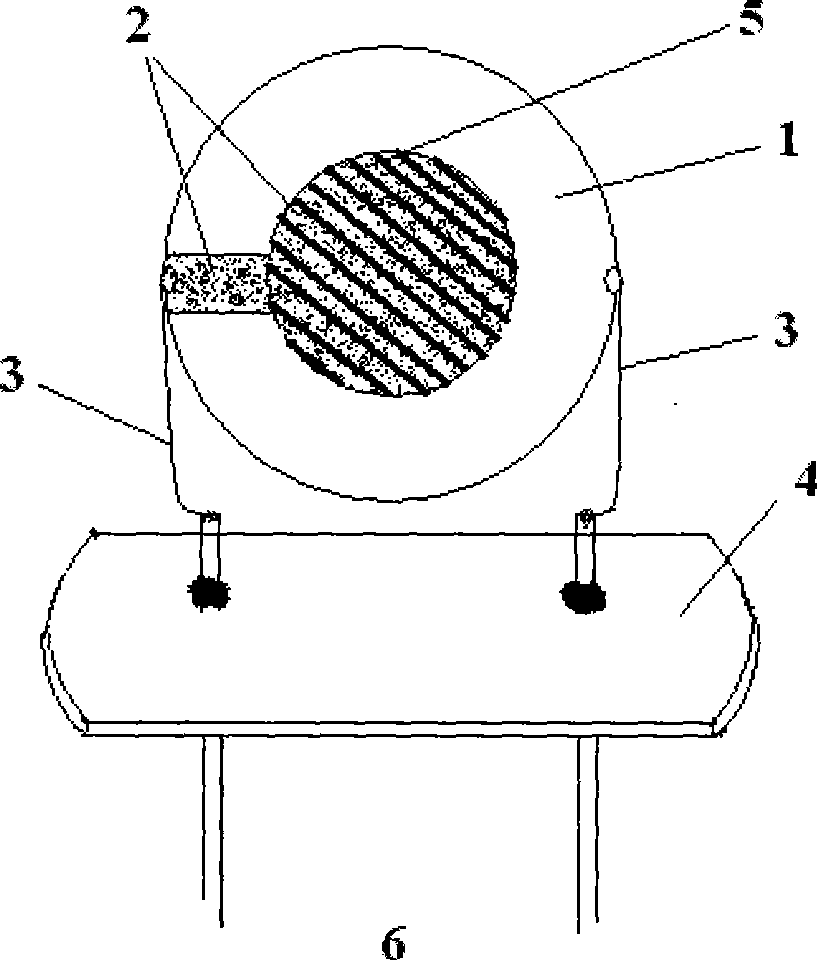

[0042] A. Take the quartz crystal oscillator and soak it in absolute ethanol, ultrasonically clean it for 3 minutes, dry it, measure the fundamental frequency with QCM, and record the precise frequency value f 0 =9992120Hz, package the chip for use;

[0043] B. Accurately weigh 70mg of ionic liquid [C 4 MIm]Cl, dissolved in 7mL of chloroform, prepared as a 10mg / mL coating solution.

[0044] C. Suspend the cleaned 9992120Hz quartz crystal oscillator in 10mg / mL ionic liquid [C 4 MIm]Cl in a chloroform solution for 30 sec, until the volatile organic solvent chloroform on the surface of the wafer is volatilized.

[0045] D. Purge the coated quartz crystal oscillator at 60°C with 60mL / min of high-purity nitrogen, the frequency is stable for 1-2 hours, and the frequency f is measured on the QCM 1 =9987750Hz, then the frequency reduction value |Δf|=|f 1 -f 0 |=|9987550Hz-9992120Hz|=4550Hz is the decrease in oscillation frequency caused by a slight increase in wafer quality cause...

Embodiment 2

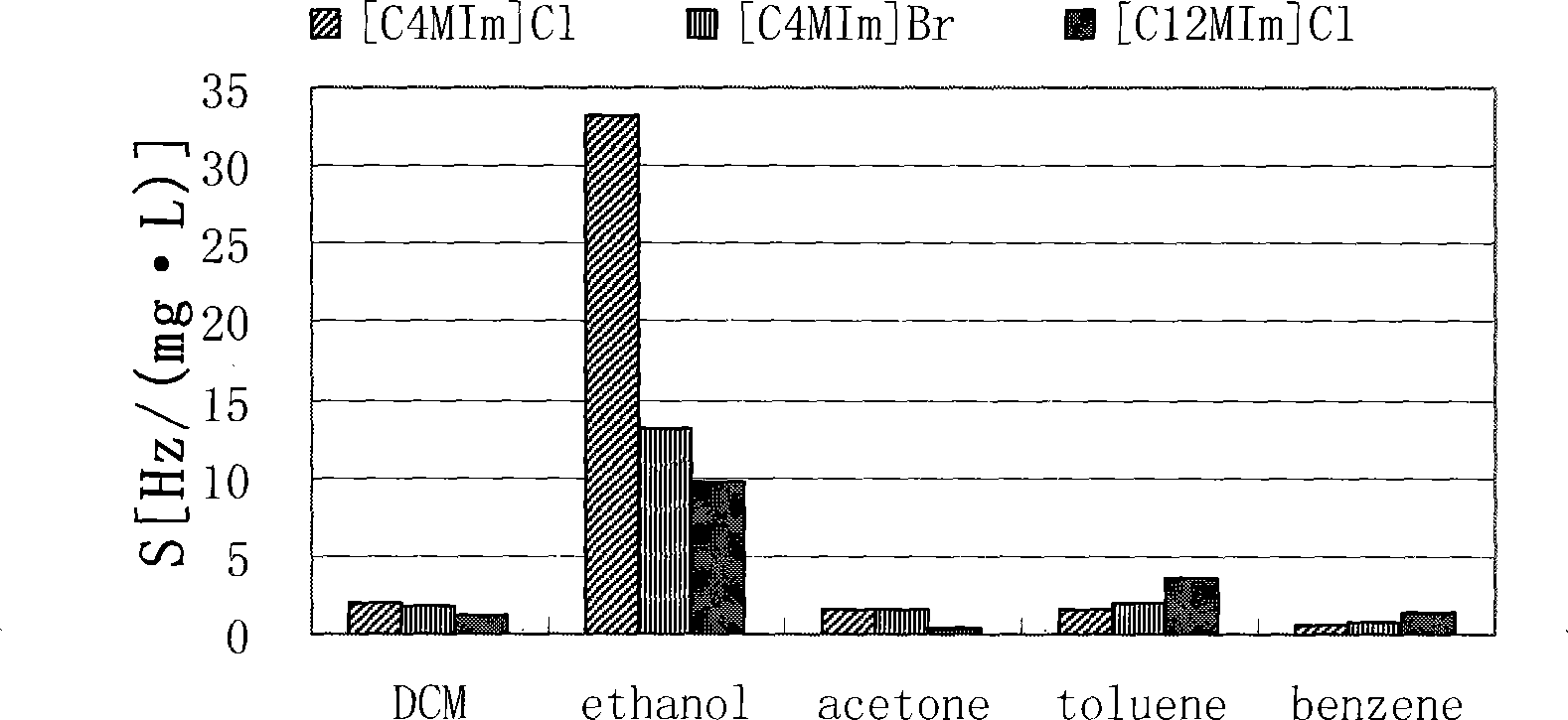

[0049] Use the ionic liquid prepared in embodiment 1 [C 4 MIm]Cl is a QCM oscillator with sensitive membrane material, and the response sensitivities to dichloromethane (DCM), ethanol (ethanol), acetone (acetone), toluene (toluene) and benzene (benzene) were measured respectively, as shown in the attached image 3 shown. In particular, the sensitivity here refers to the amount of frequency change caused by a unit concentration. It is usually expressed as: S=Vf / Vc, and its unit is generally Hz / ppm or Hz / vol%. attached by image 3 It can be seen that the ethanol sensor of the present invention has an absolute advantage in selectivity to ethanol gas and is basically free from interference from other organic pollutants.

[0050] Test conditions: The temperature of the detection cell is 30°C, the gas flow rate is 120mL / min, and the carrier gas and diluent gas used are both nitrogen.

Embodiment 3

[0052] Use coated ionic liquid [C in embodiment 1 4 MIm]Cl is a QCM oscillator with sensitive membrane material, and the frequency response value of the sensor is measured for 70-2500ppm ethanol gas, and the relationship curve between frequency change and concentration is made, as shown in the attached Figure 4 As shown, the two form a good linear relationship (R 2 =0.9992), therefore, by measuring the frequency change value caused by a certain concentration of ethanol gas on the QCM ethanol sensor, and substituting it into the frequency-concentration relationship equation C=15.0|Δf|+29.8, the concentration value of the measured gas can be obtained, The unit is ppm.

[0053] Test conditions: The temperature of the detection cell is 30°C, the gas flow rate is 50-150mL / min, and the carrier gas and diluent gas used are both nitrogen.

[0054] For example, the measurement process of 709ppm ethanol gas is as attached Figure 5 As shown, the measurement conditions: the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com