Voltage transformation type speed measurement device for magnetic liquid

A technology of magnetic liquid and speed measuring device, which is applied in the direction of devices using fluid, devices using electric/magnetic methods, etc., which can solve problems such as poor long-distance accuracy, poor environmental adaptability of photoelectric sensors, and inaccurate speed measurement results. It achieves the effects of high temperature adaptability, adjustable measurement speed range and wide measurement speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

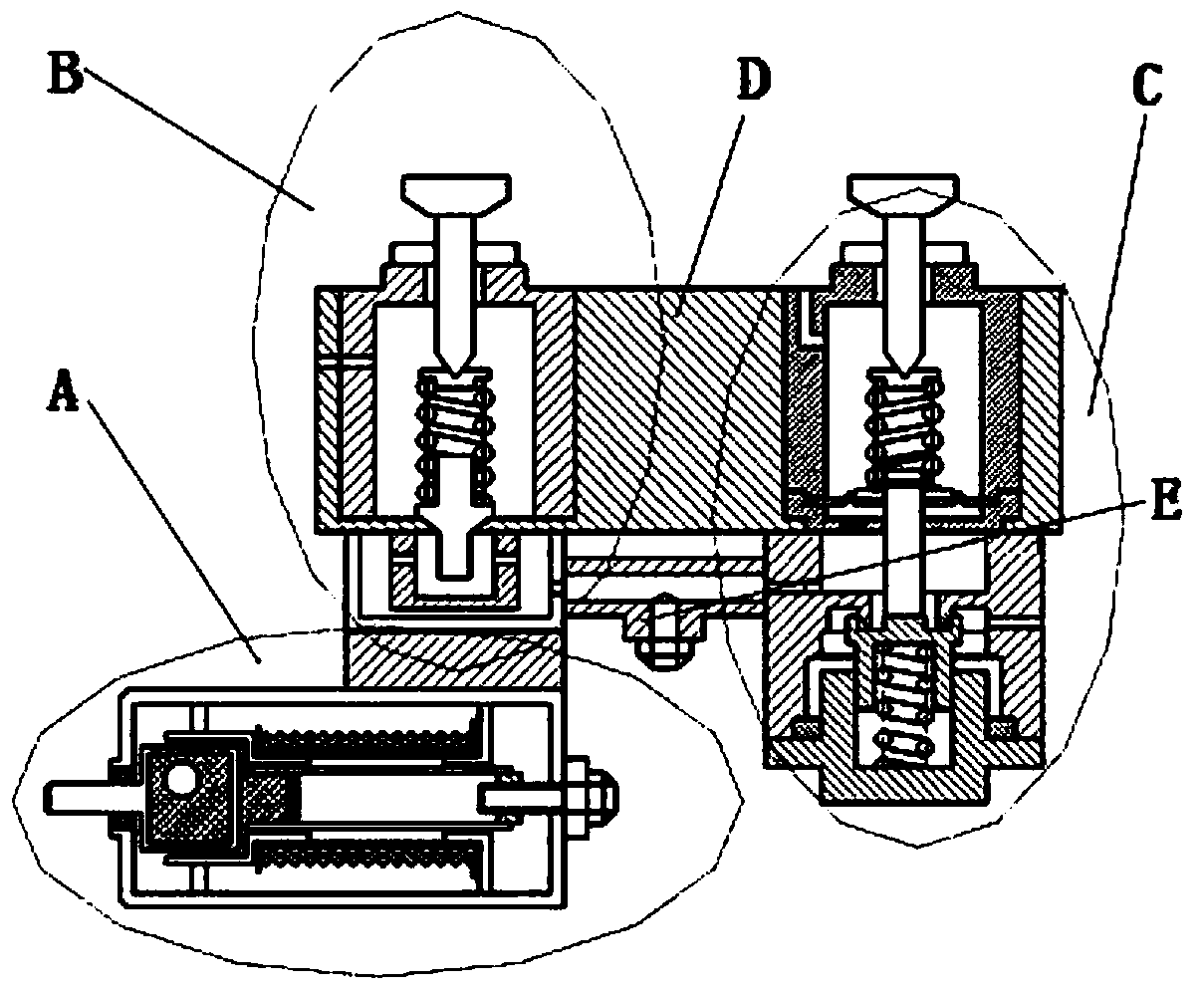

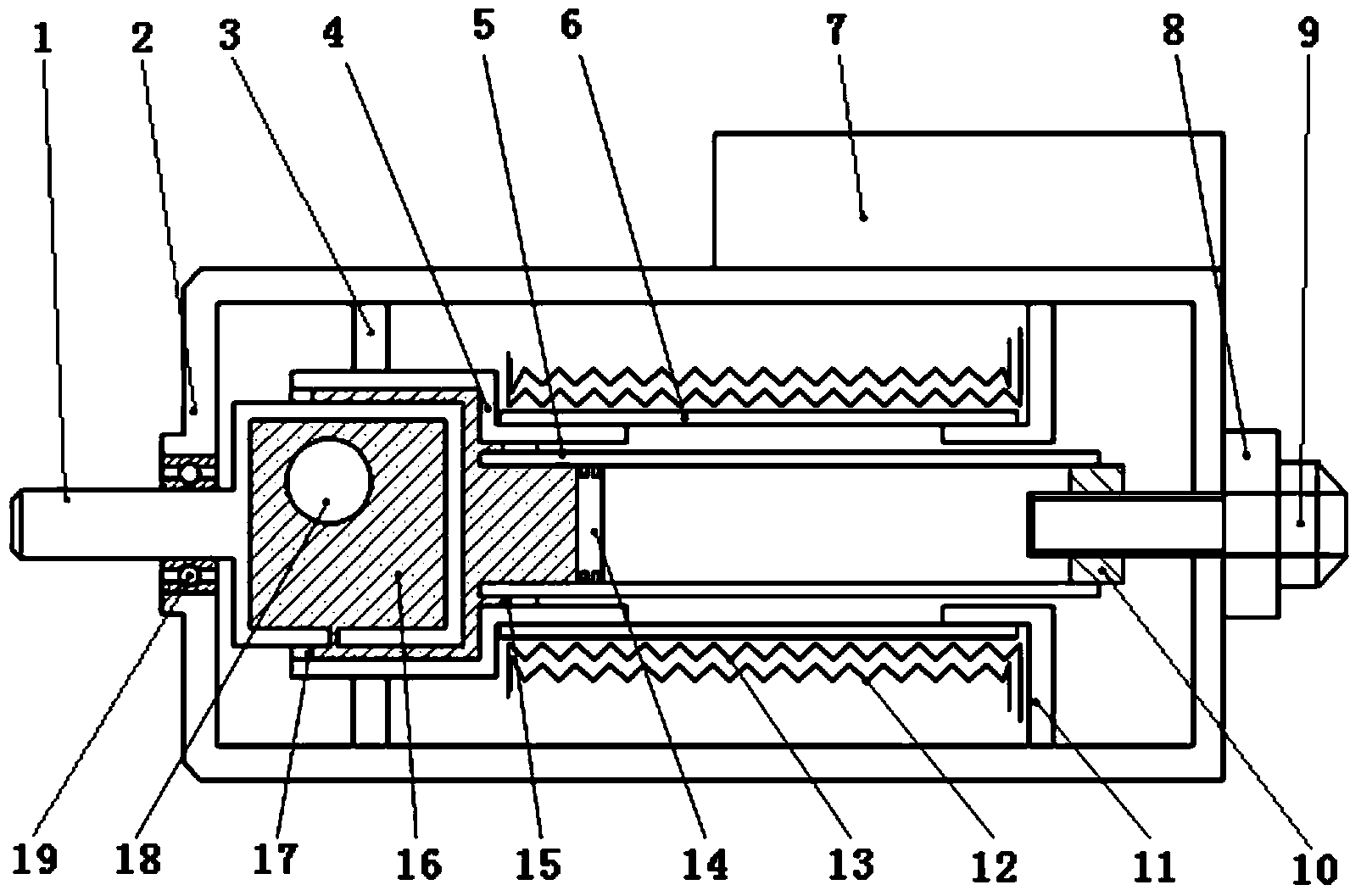

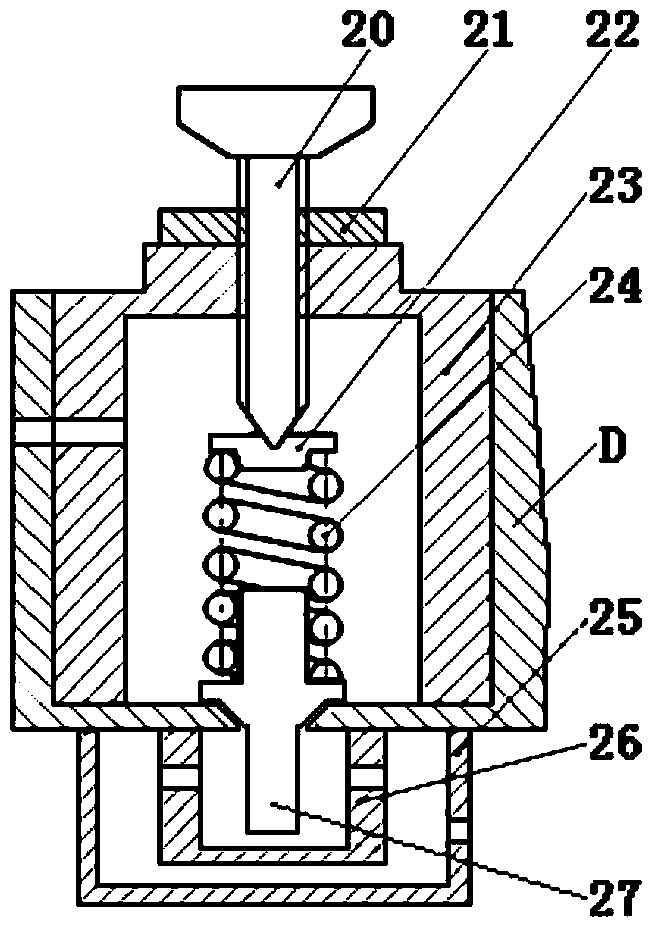

[0045] Refer to attached Figure 1-Figure 9 As shown, the present invention consists of a variable pressure sensing device A, a constant pressure maintaining device B, a pressure control device C, a housing D, a connecting device E and a connecting boss 7, wherein the variable pressure sensor housing of the variable pressure sensing device A 2 The upper right part is affixed to the lower surface of the lower cover 25 of the constant pressure maintaining device B via the connecting boss 7; the outer surface of the valve body I23 of the constant pressure maintaining device B is affixed to the inner surface of the left disc 61 of the housing D, The valve seat I26 of the constant pressure maintaining device B is affixed to the lower surface of the left disc 61 in the housing D, and the lower cover 25 of the constant pressure maintaining device B is affixed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com