Patents

Literature

143results about How to "Accurate speed measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

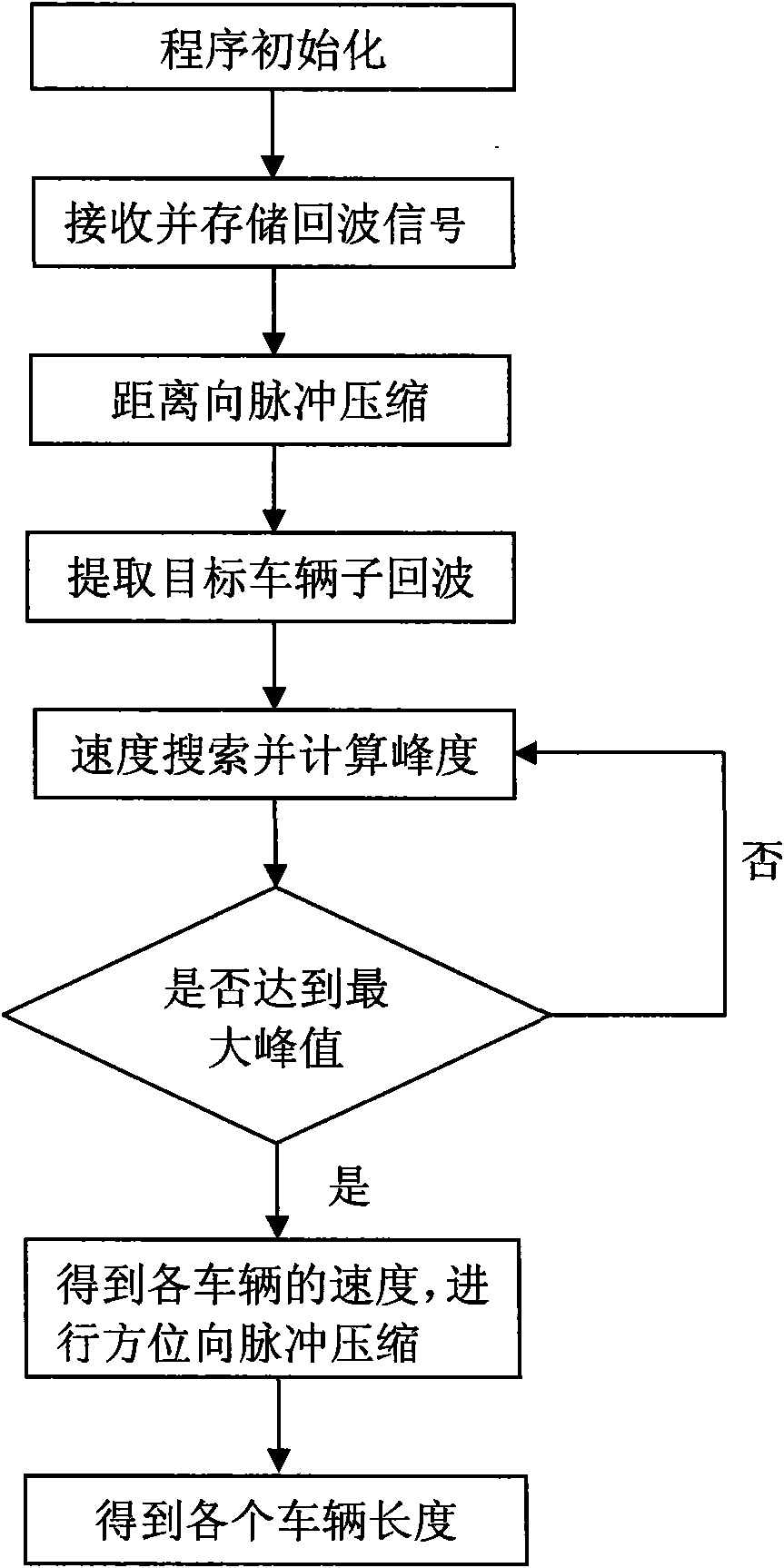

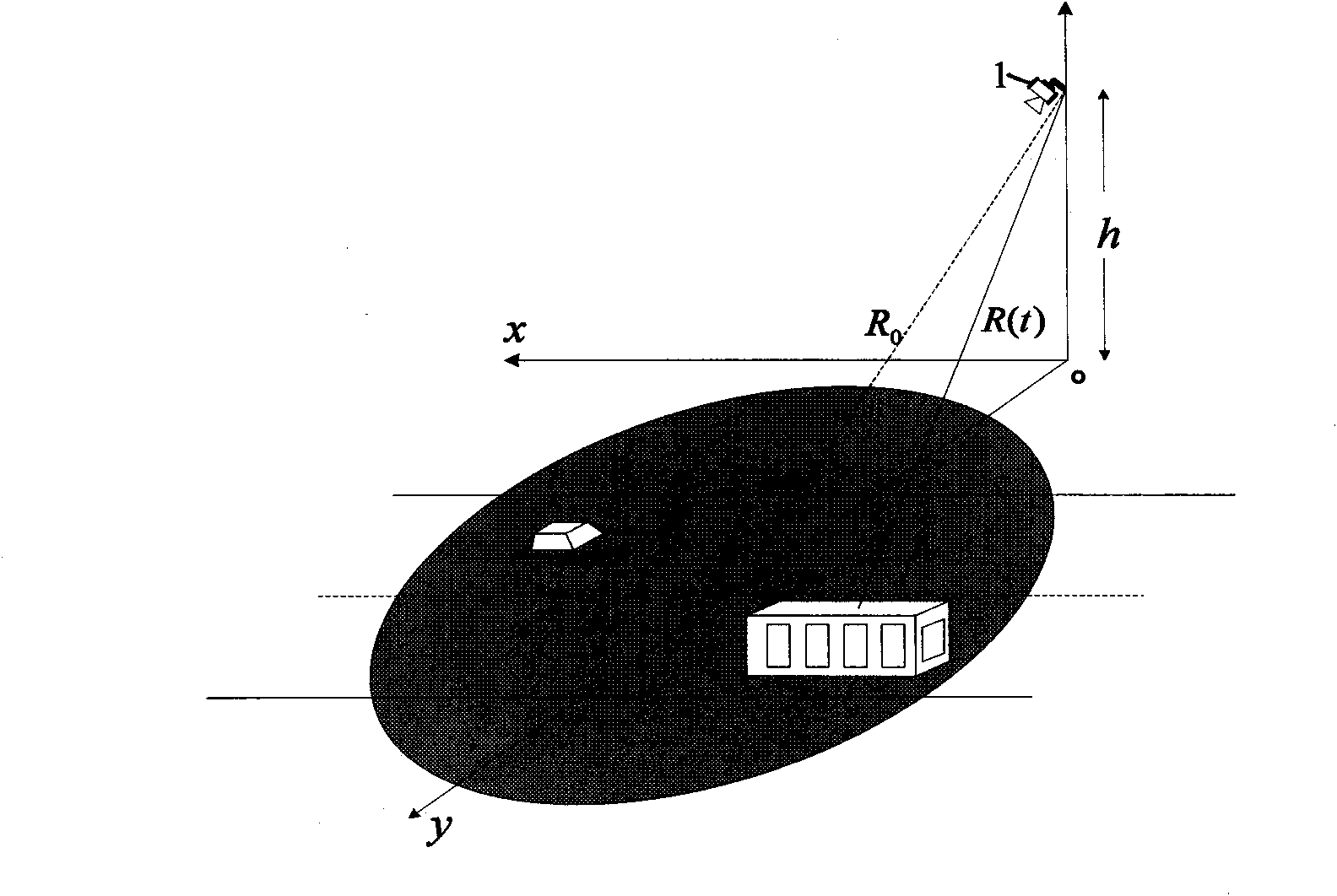

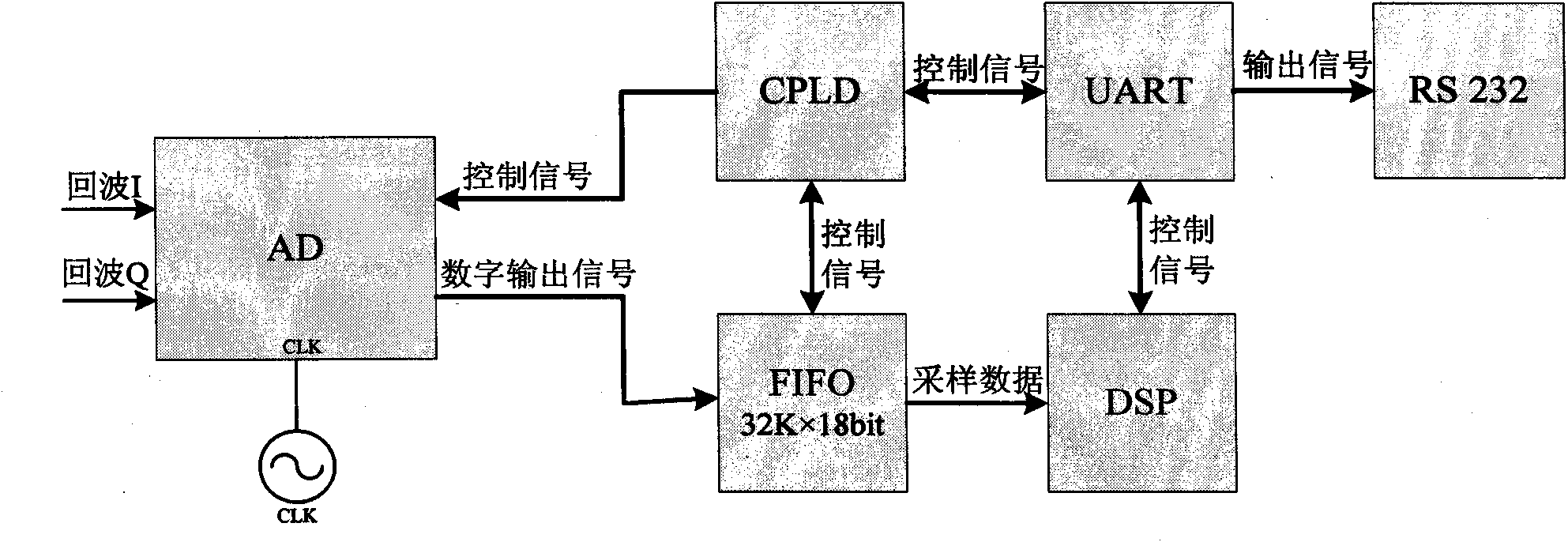

Method for controlling microwave vehicle detecting radar

InactiveCN101561970AExpand the scope of detectionAccurate speed measurementDetection of traffic movementRadio wave reradiation/reflectionLow speedAzimuth direction

The invention discloses a method for controlling microwave vehicle detecting radar, comprising the following steps: microwave detecting radar work parameter is evaluated; pulse compression in the range direction is carried out; sub-echo of each target vehicle is respectively extracted, and whether advancing vehicle exists is judged, speed search is carried out on data of each sub-echo of advancing vehicle, one matched filtering function is obtained after each search, pulse compression in the azimuth direction is carried out, and then the kurtosis value is calculated; if the largest kurtosis value is obtained, the search speed corresponding to the largest kurtosis value is the traveling speed of the vehicle, frequency modulation slope in the azimuth direction is calculated according to the speed and pulse compression in the azimuth direction is carried out, and then signals of each range gates are added and are compared with the set threshold to obtain vehicle length; if the largest kurtosis value is not obtained, then search is kept on by returning to the previous step. The invention has numerous monitoring lanes, wide detection range and more precise detecting speed, can detect vehicle with low speed or even standing vehicle precisely, and can estimate vehicle length, thereby facilitating traffic control.

Owner:中国人民解放军理工大学气象学院

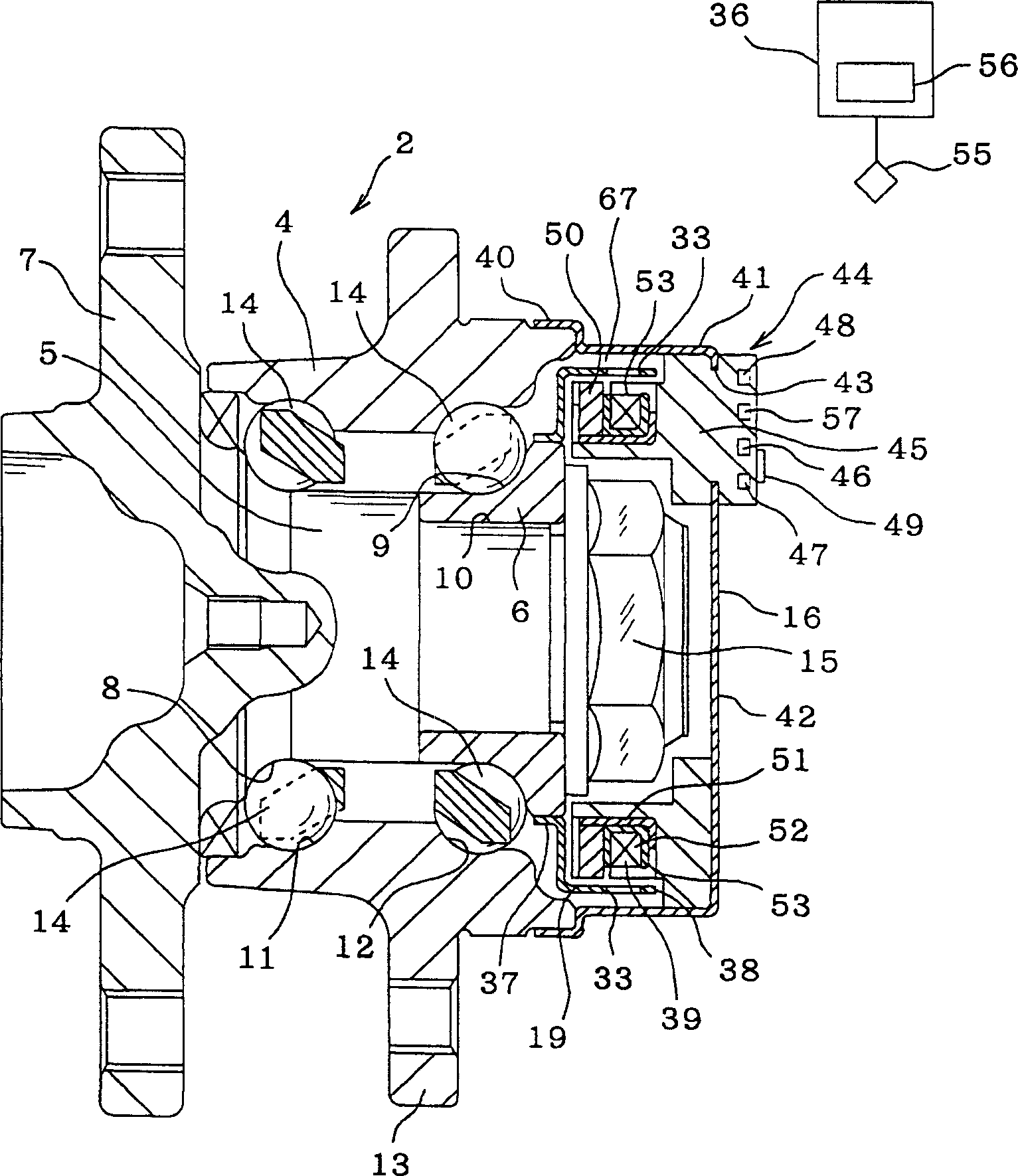

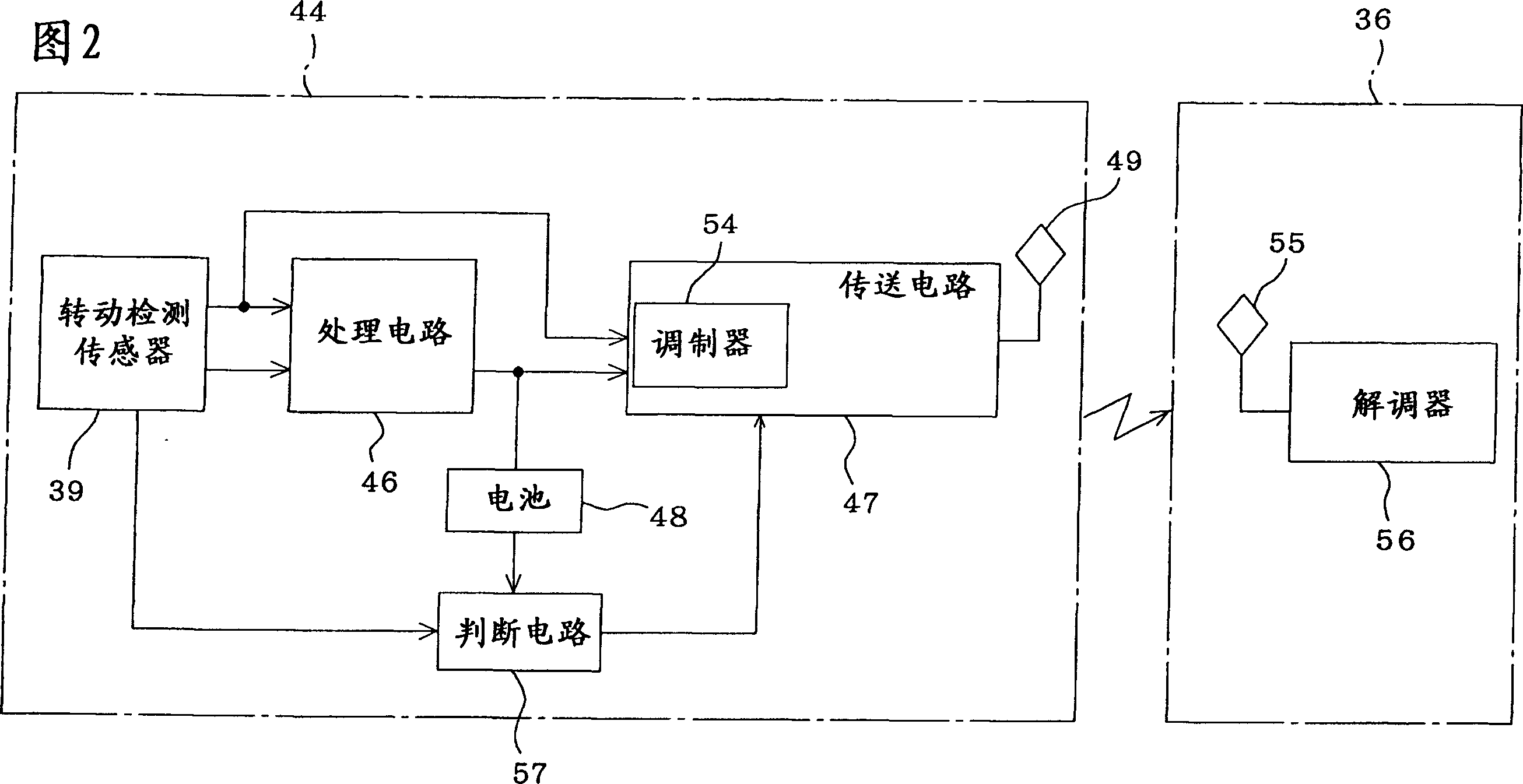

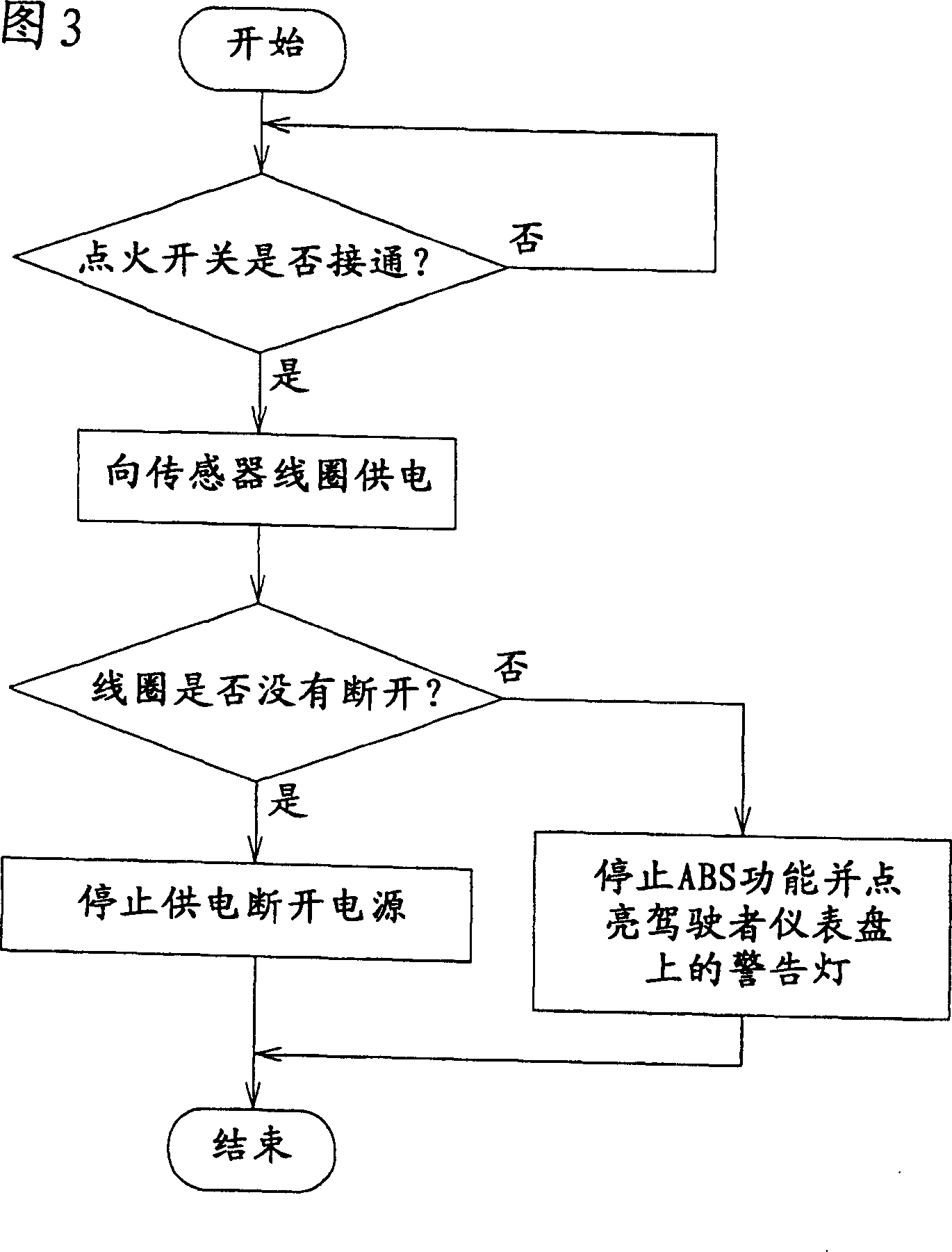

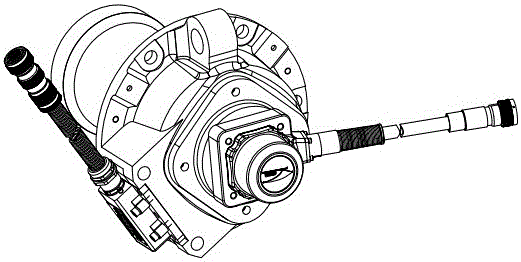

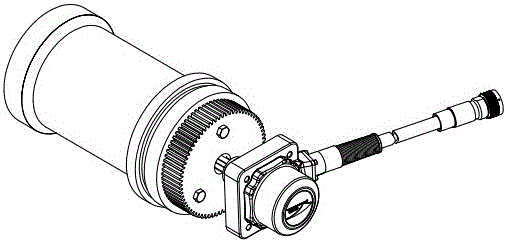

Rotational speed sensor device

InactiveCN1412564AAccurate measurement of different types of statesAccurate speed measurementRoller bearingsBearing assemblyWireless transmissionRolling-element bearing

A rotation-speed sensor device is provided, comprising an encoder supported by a rotating race of a rolling bearing unit for vehicle wheel support to be concentric with the rotating race and having a detected portion the characteristics of which are alternately changed in a circumferential direction, a rotation detection sensor supported by a non-rotating member on the vehicle chassis side and having a detecting portion facing the detected portion to produce a detection signal, a wireless transmission device for sending the detection signal from the rotation detection sensor to a controller provided on the vehicle chassis side, and a self-diagnosis circuit to judge whether there is an error or not in the rotation detection sensor.

Owner:NSK LTD

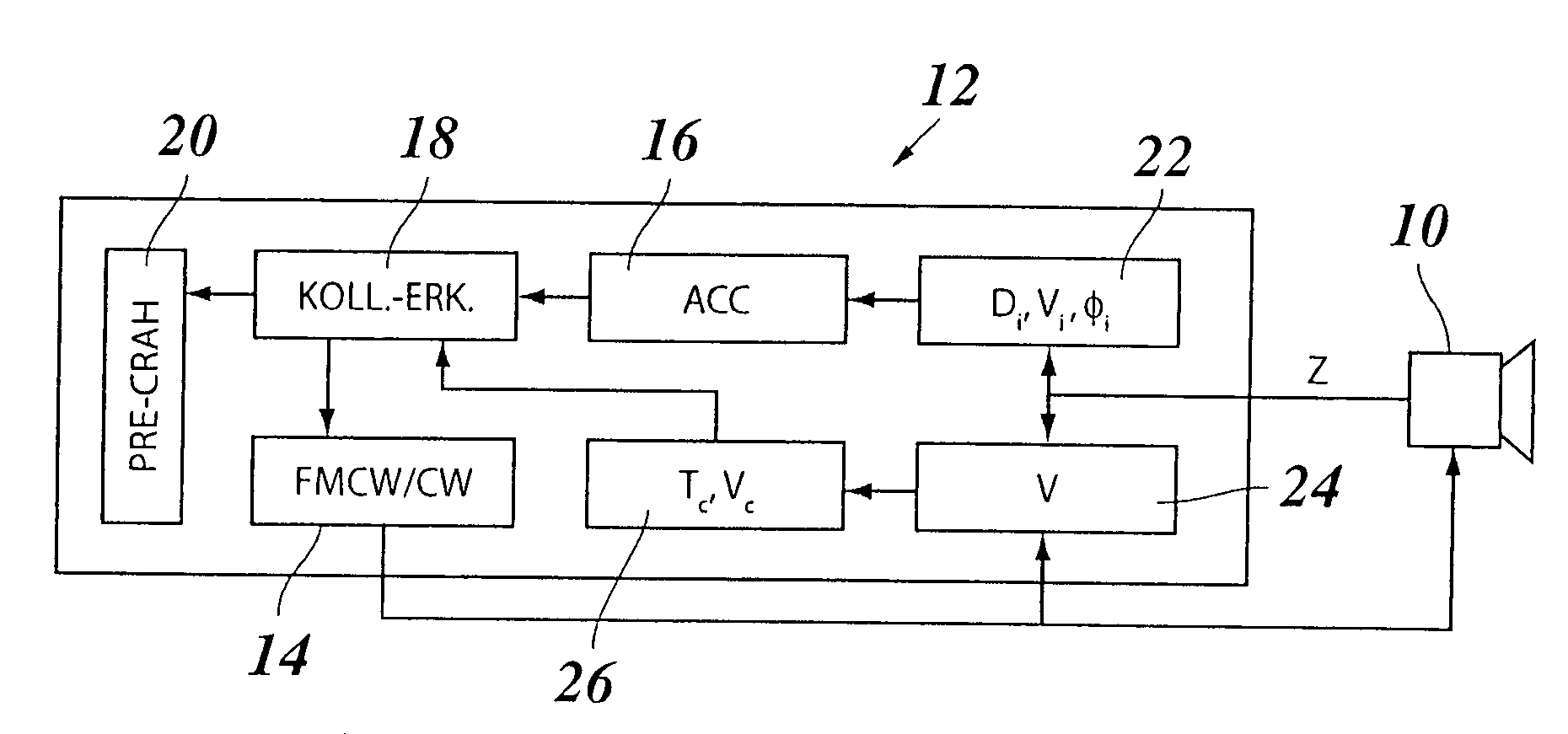

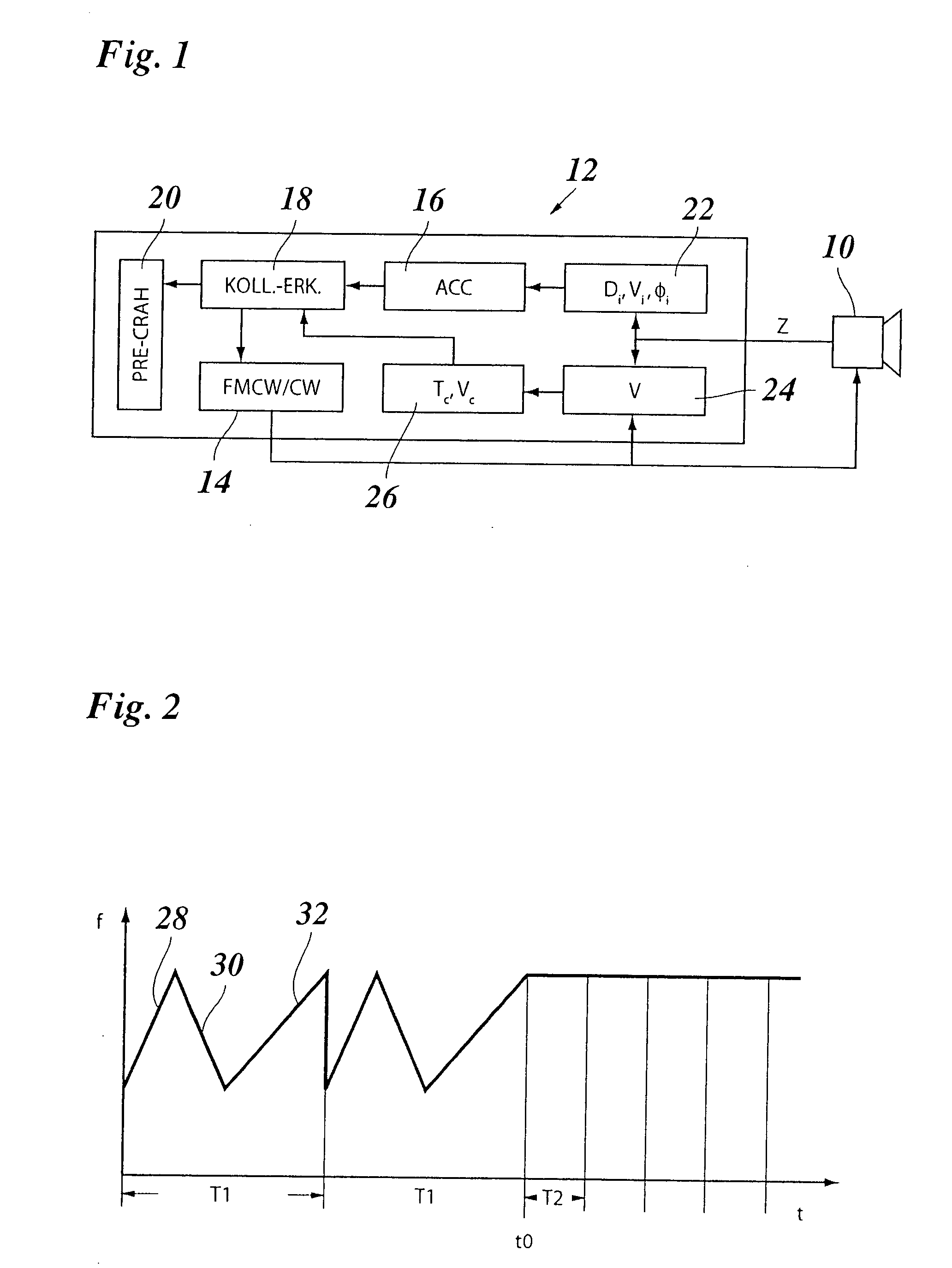

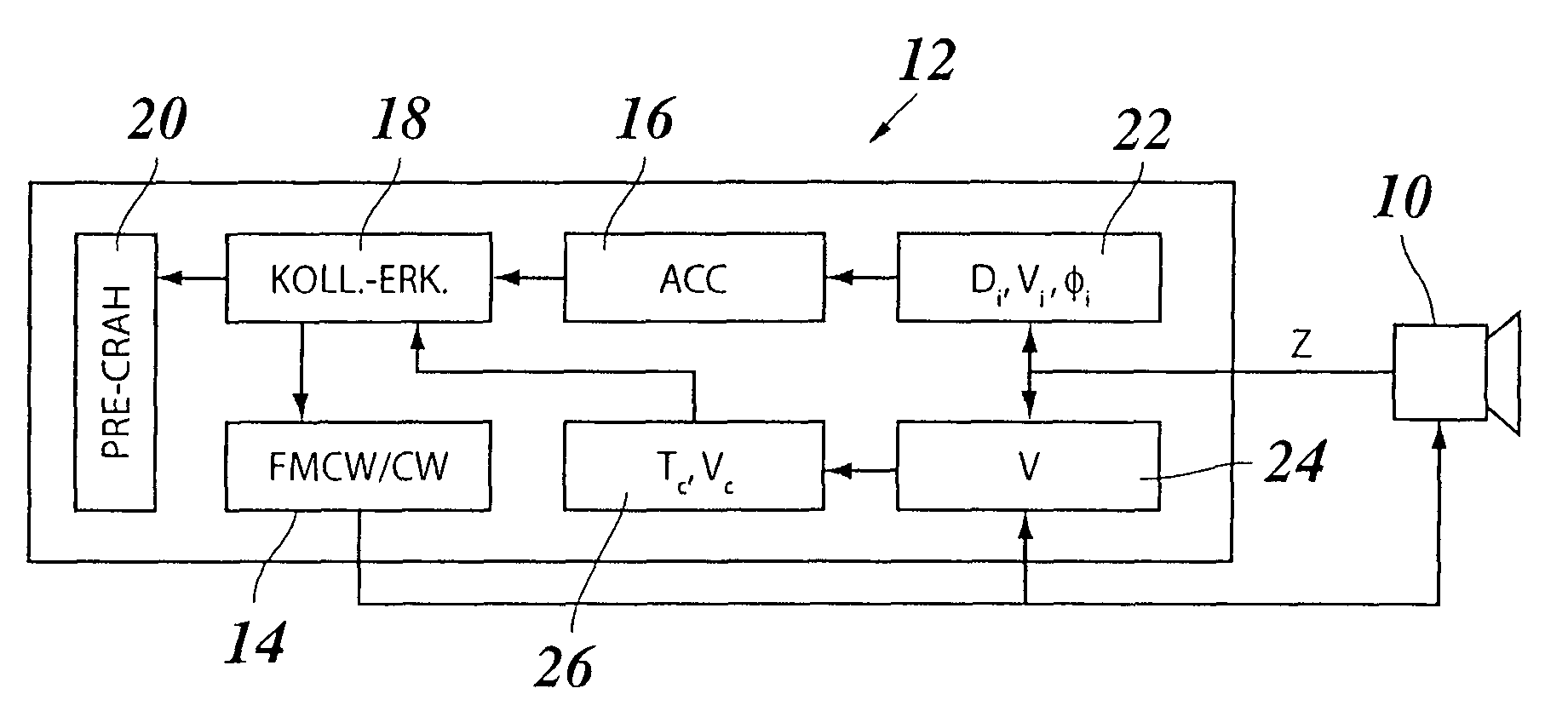

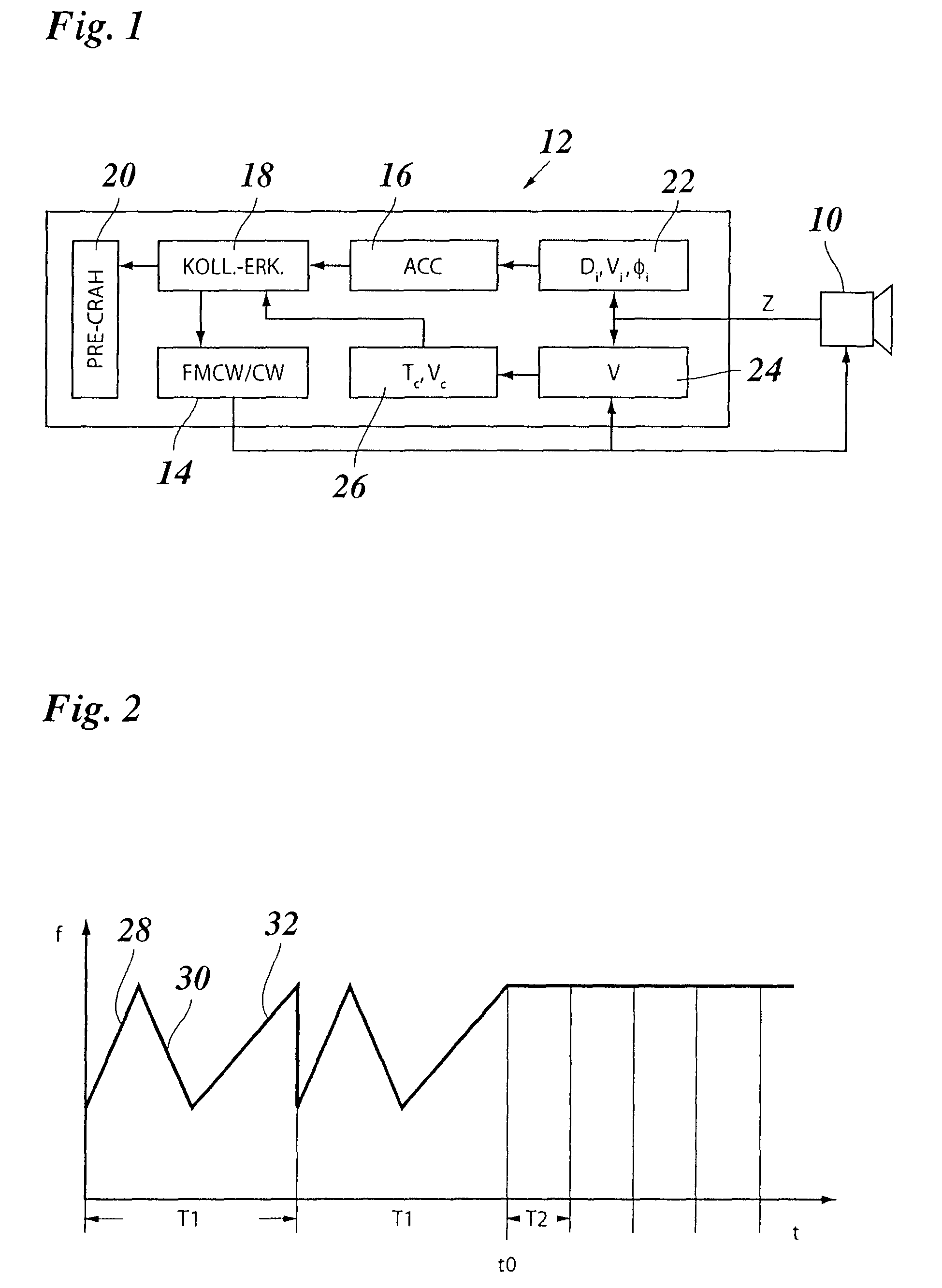

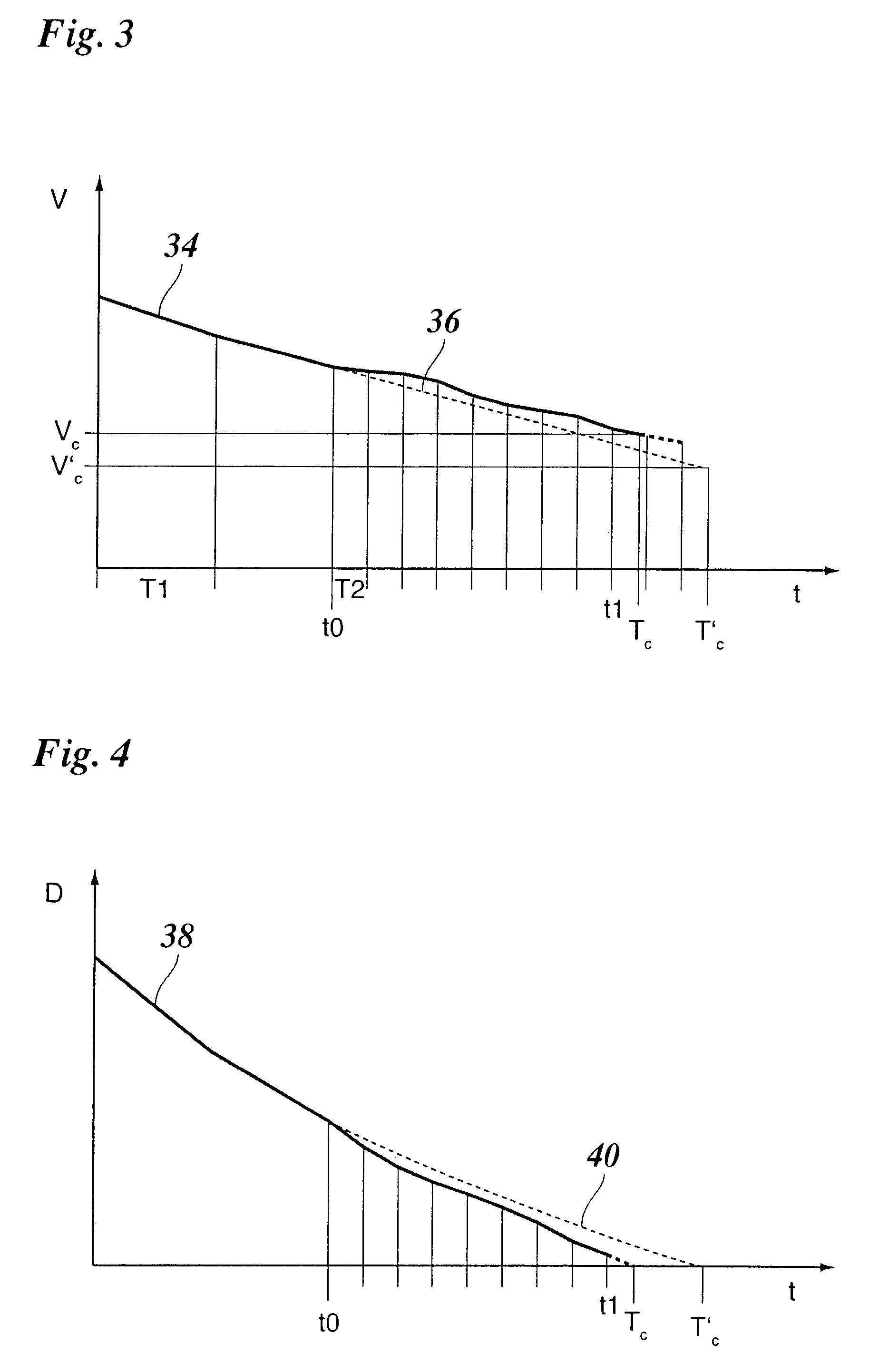

Radar System for Motor Vehicles

InactiveUS20080291078A1Evaluation procedure be substantially simplifyHigh temporal resolutionPedestrian/occupant safety arrangementRadio wave reradiation/reflectionCollision systemRelative velocity

A radar system for motor vehicles, having a radar sensor and an evaluation device for measuring distances and relative velocities of objects in the surrounding field of the vehicle, and a collision detection device, which, on the basis of the measured distances and relative velocities, recognizes an imminent collision and delivers data on the expected time of collision and the impact velocity to a precrash system. The radar sensor is switchable by the collision detection device to a velocity measurement mode in which a more precise measurement of the relative velocity is made.

Owner:ROBERT BOSCH GMBH

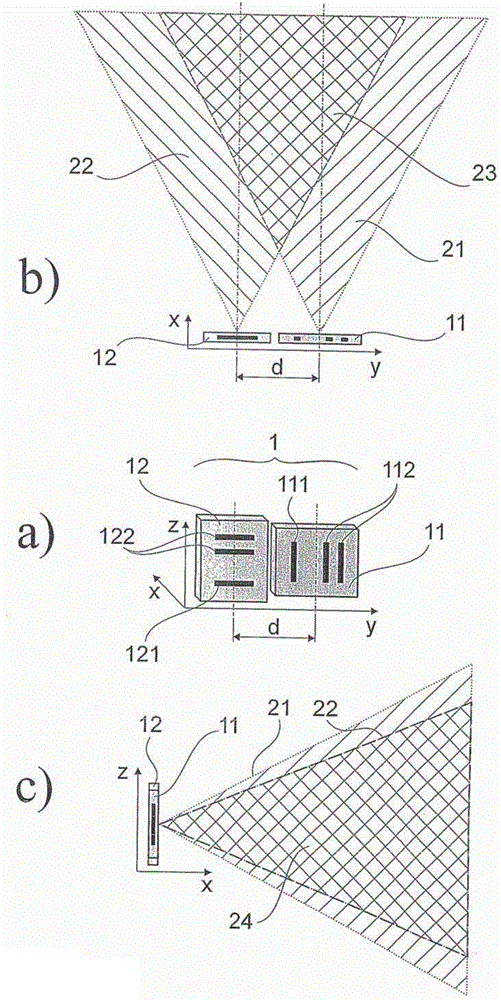

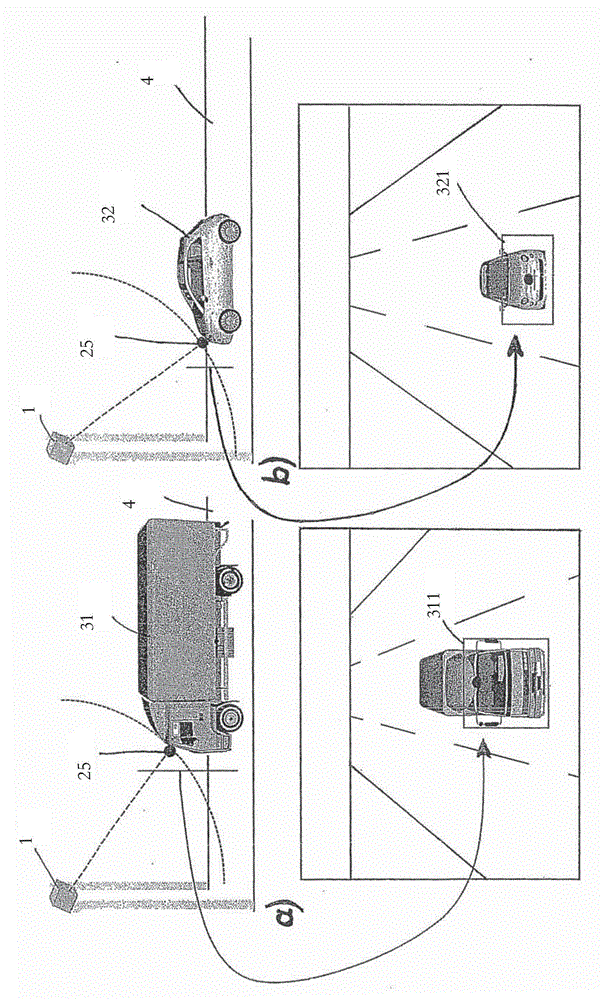

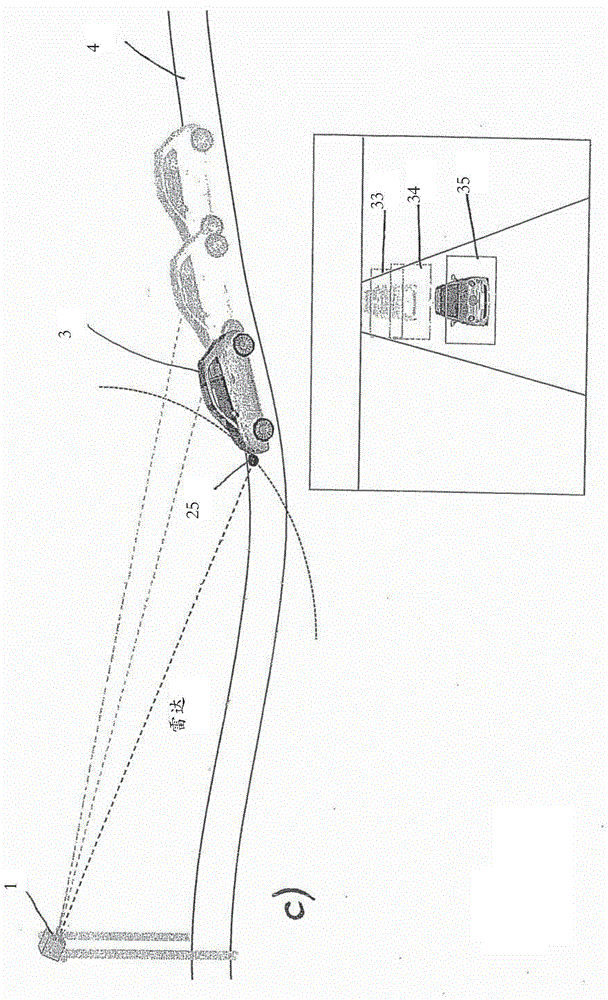

Traffic monitoring system for speed measurement and assignment of moving vehicles in a multi-target recording module

InactiveCN104134354AReduce uncertaintyImprove reliabilityRoad vehicles traffic controlRadio wave reradiation/reflectionSpeed measurementMultiple target

The invention relates to a traffic monitoring system for speed measurement and assignment of moving vehicles in a multi-target recording module. The object of finding a new possibility for more accurate speed measurement and reliable assignment of vehicles, wherein the problems with regard to assigning speeds to vehicles at relatively great distances and measurement uncertainties associated therewith are reduced, is achieved according to the invention by virtue of the fact that, besides a first, azimuthally measuring tracking radar sensor, at least one further tracking radar sensor having an antenna structure that is of the same type but is operated at a different frequency is arranged in a manner rotated by a defined angle relative to the antenna structure of the first tracking radar sensor, such that the further tracking radar sensor forms an antenna structure for acquiring at least one signal component for the reconstruction of vertical distances, extents and elevation angle positions of the moving vehicles and provides measurement data at its sensor output.

Owner:JENOPTIK ROBOT GMBH

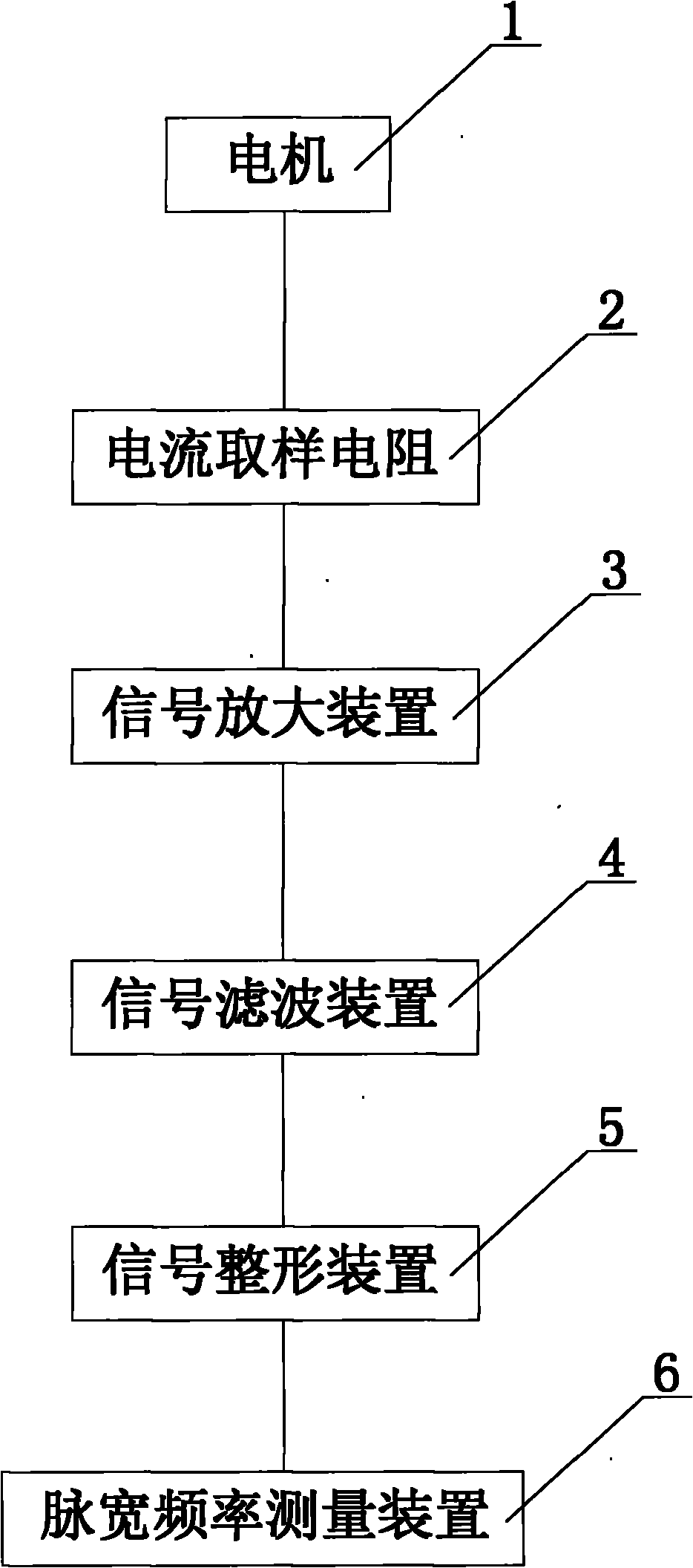

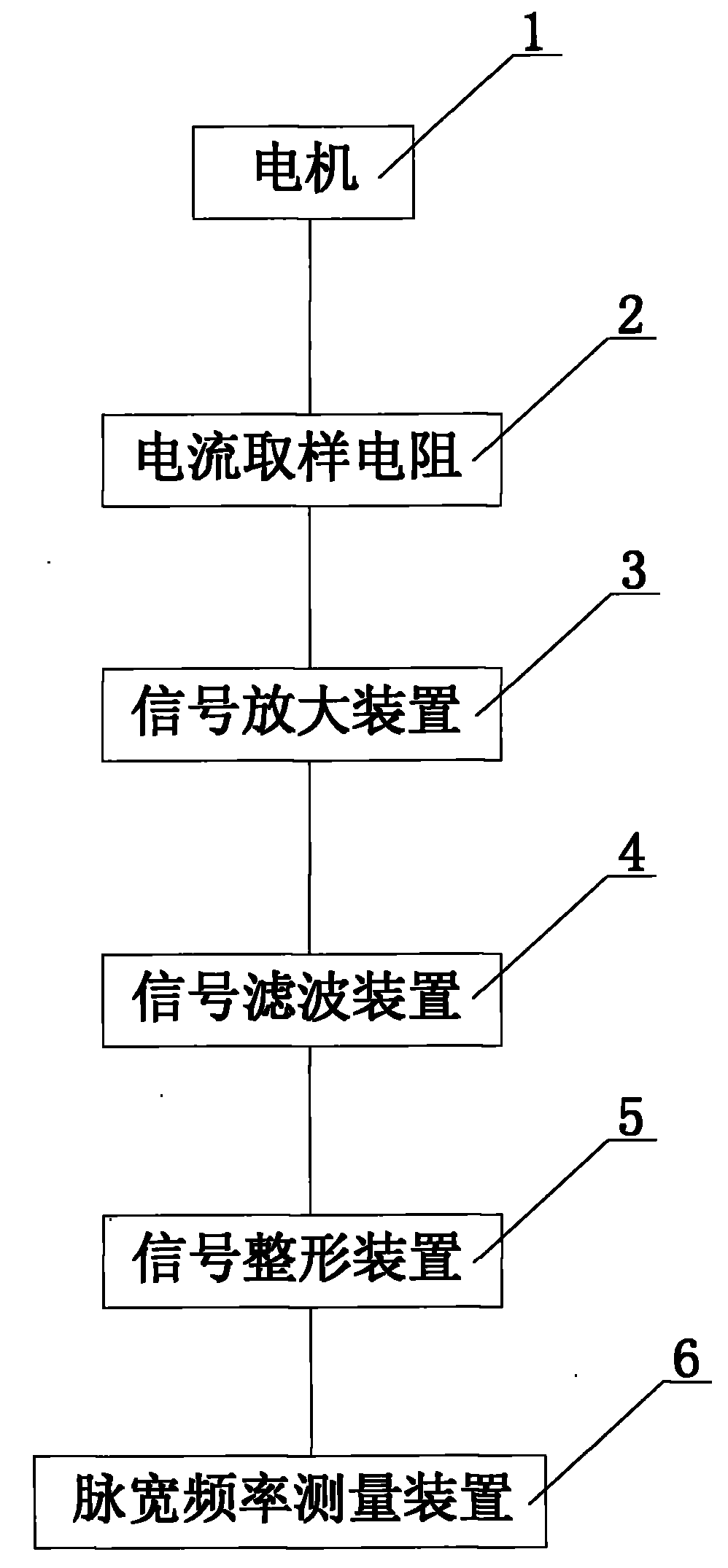

Measuring device and method of rotating speed of brush motor

InactiveCN102004166AAccurate speed measurementEasy to operateLinear/angular speed measurementElectrical resistance and conductanceBandpass filtering

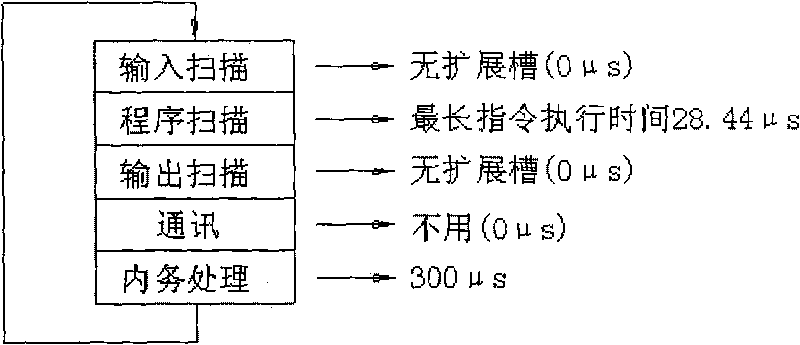

The invention provides a measuring device and method of the rotating speed of a brush motor. The measuring device comprises a current sampling resistor, a signal amplifying device, a signal filtering device, a signal shaping device and a pulse width and frequency measuring device which are sequentially connected, wherein the current sampling resistor is connected with the brush motor. The measuring method comprises the following steps of: converting a current break pulse into a small voltage signal through the current sampling resistor when a current break pulse signal of the brush motor is generated during the commutation of a commutator of the brush motor; amplifying the small voltage signal into a large voltage signal through the signal amplifying device; carrying out bandpass filtering through the signal filtering device to select a sinusoidal signal of a commutating pulse of the commutator; shaping the sinusoidal signal into a rectangular wave pulse signal through the signal shaping device; measuring a pulse width or frequency through the pulse width and frequency measuring device, and carrying out conversion according to the number of pole pairs of the commutator of the brush motor to obtain the final rotting speed of the brush motor. The measuring device can be used for accurately measuring the rotating speed of the brush motor, is easy to operate and can enhance the production efficiency.

Owner:HANGZHOU ZHENGQIANG ELECTRONICS TECH

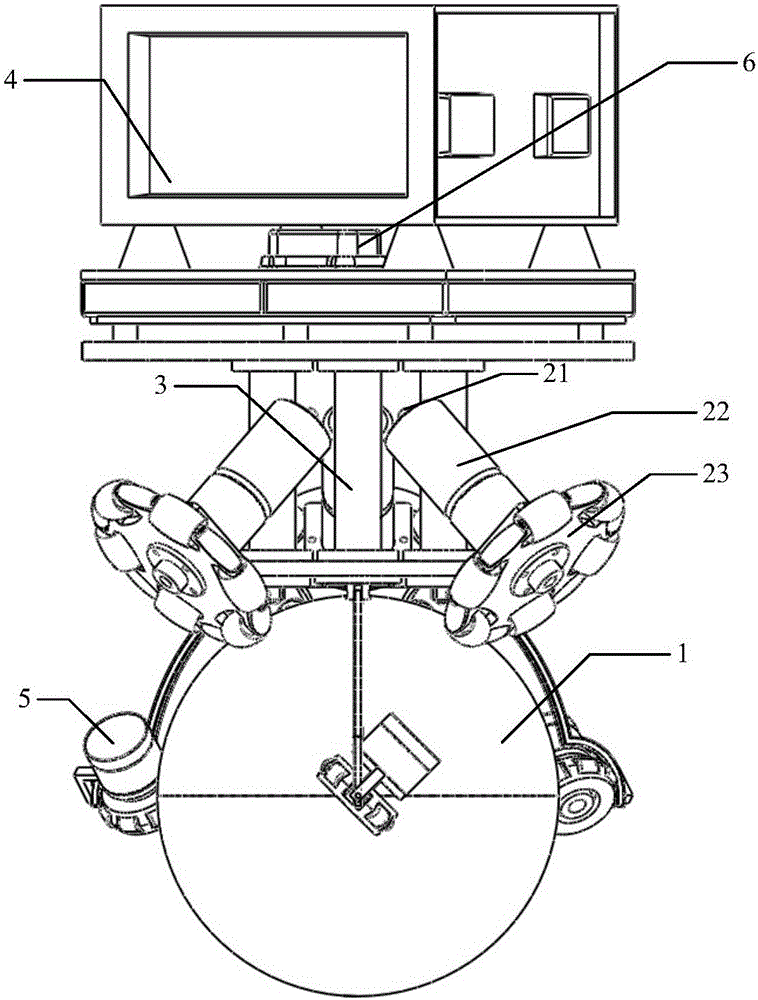

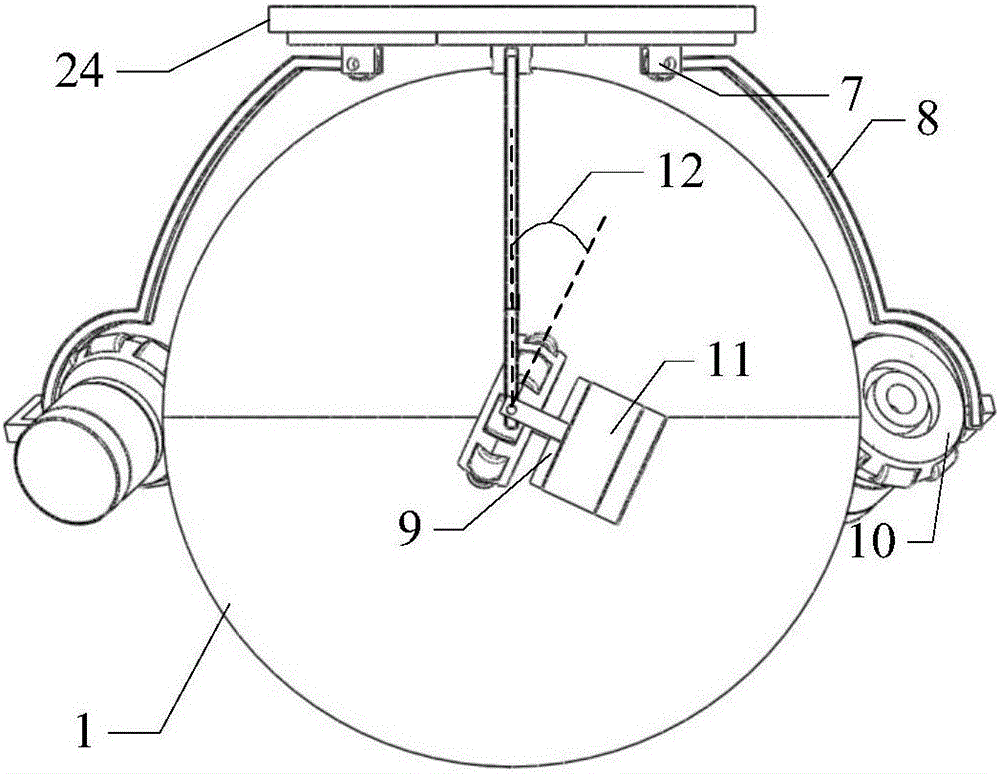

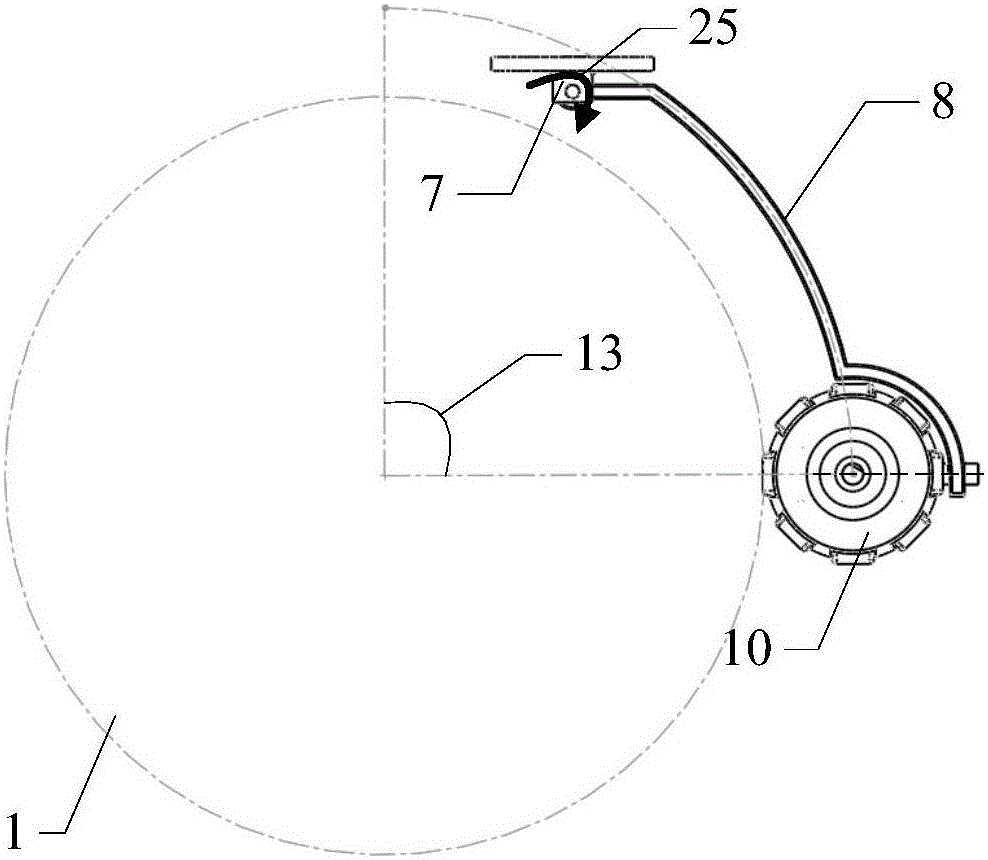

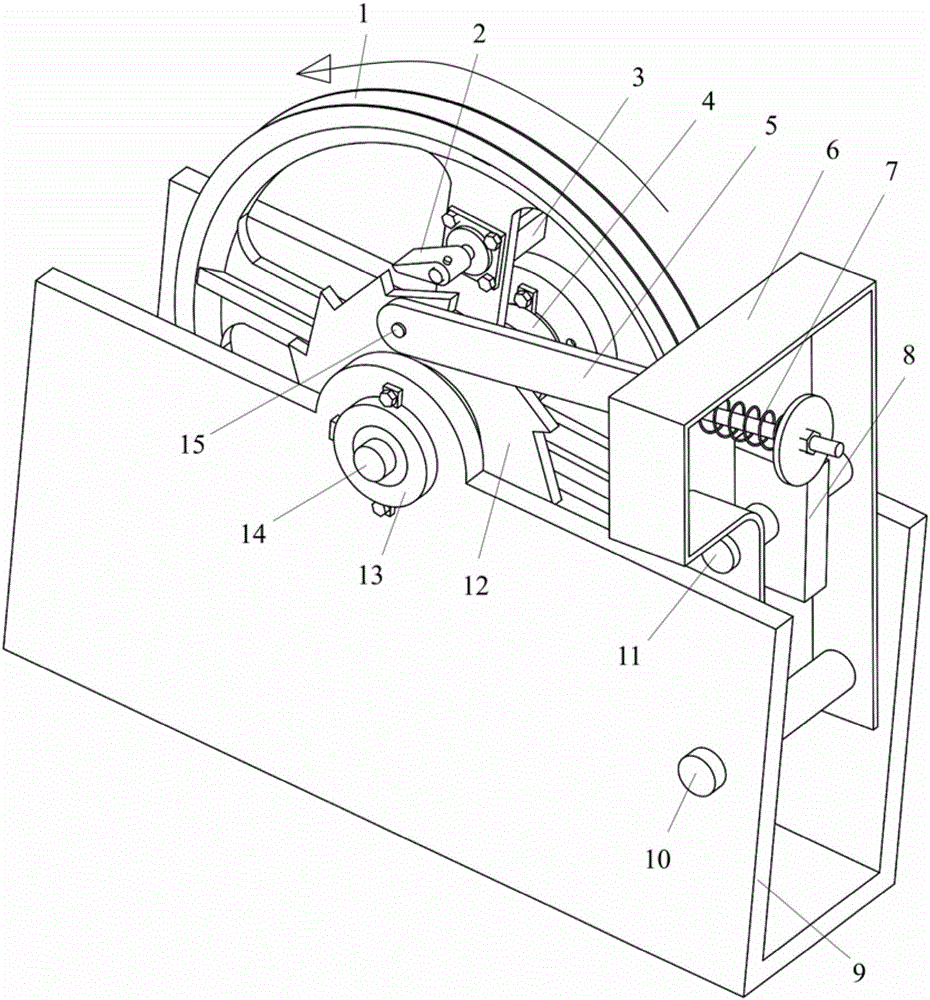

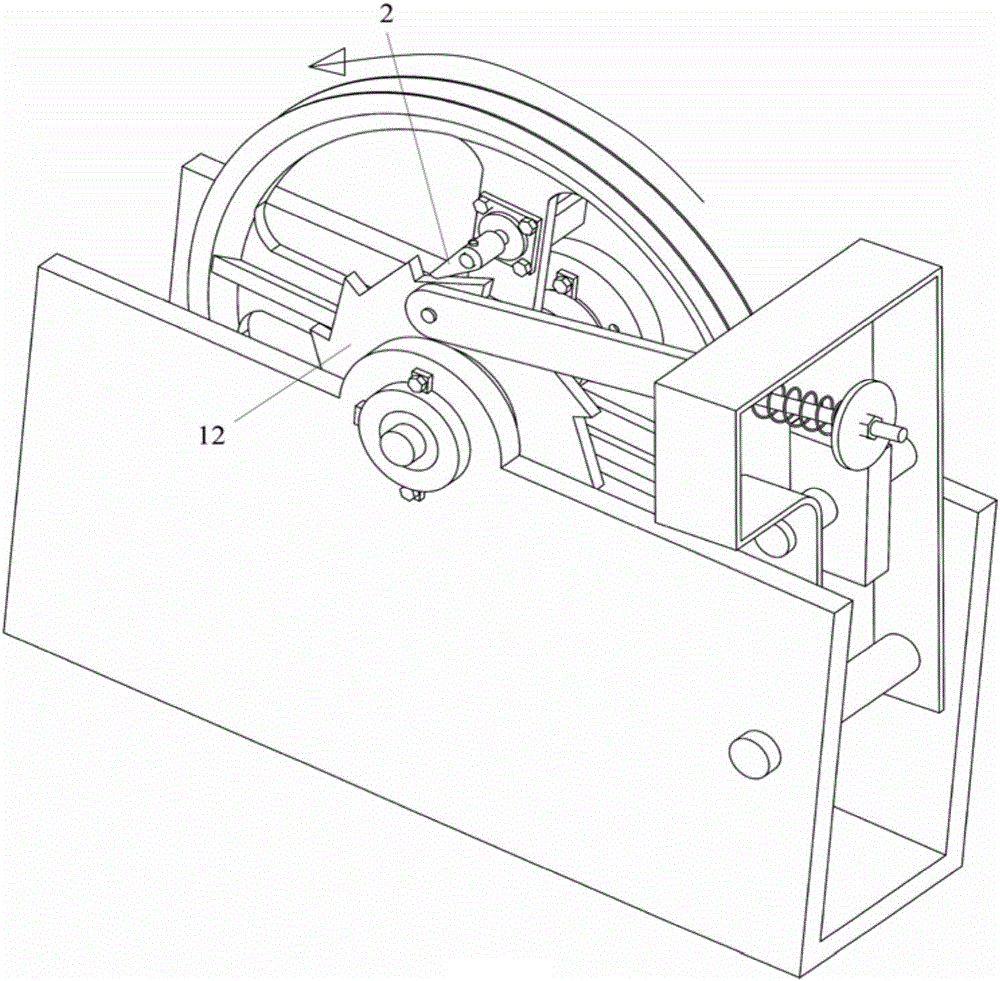

Spherical-wheel mobile robot and speed measuring method thereof

ActiveCN105058398ADoes not affect movementEffective speed measurementManipulatorMobile robotKinematics

The invention provides a spherical-wheel mobile robot and a speed measuring method thereof. The spherical-wheel mobile robot comprises a spherical wheel, a driving mechanism for controlling the spherical wheel to move according to a control signal, a robot body for supporting all structures, a control module and an inertial sensor for obtaining posture data of the robot body; and the spherical-wheel mobile robot further comprises a speed measuring mechanism used for obtaining the speed of the spherical wheel relative to the robot body. The control module obtains the solved speed omega of the spherical wheel through a linear equation based on a kinetic constrained relationship according to the speed, obtained through the speed measuring mechanism, of the spherical wheel relative to the robot body and the posture data, obtained through the inertial sensor, of the robot body, and then the control signal for movement of the spherical-wheel mobile robot is solved through the solved speed of the spherical wheel and the posture data, obtained through the sensor, of the robot body in cooperation with the motion control rule, and the control signal transmitted to the driving mechanism. By means of the spherical-wheel mobile robot and the speed measuring method, the accuracy and the reliability for measuring the spherical speed of the spherical wheel during walking of the robot are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

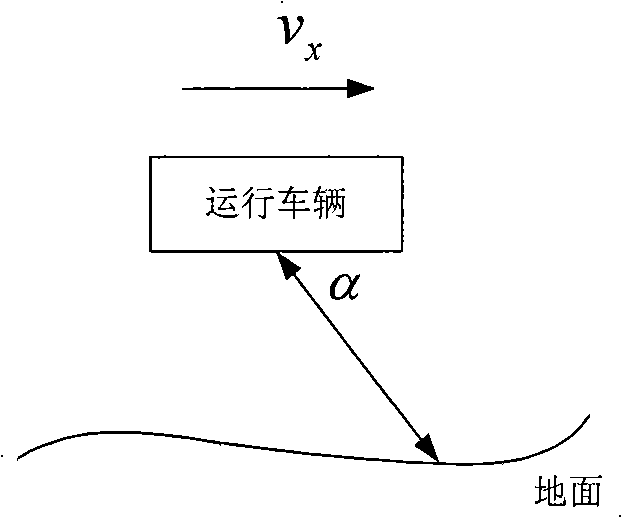

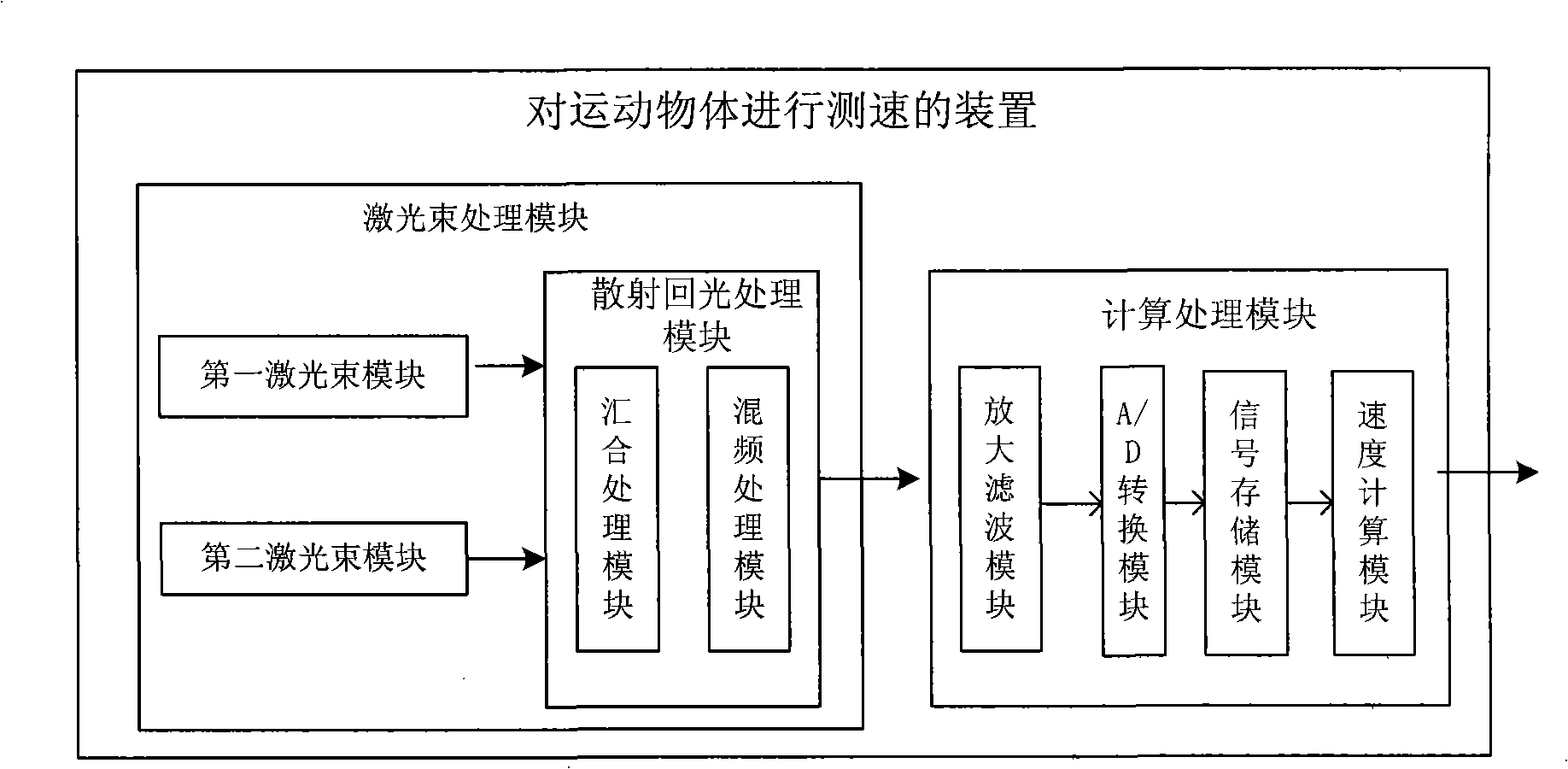

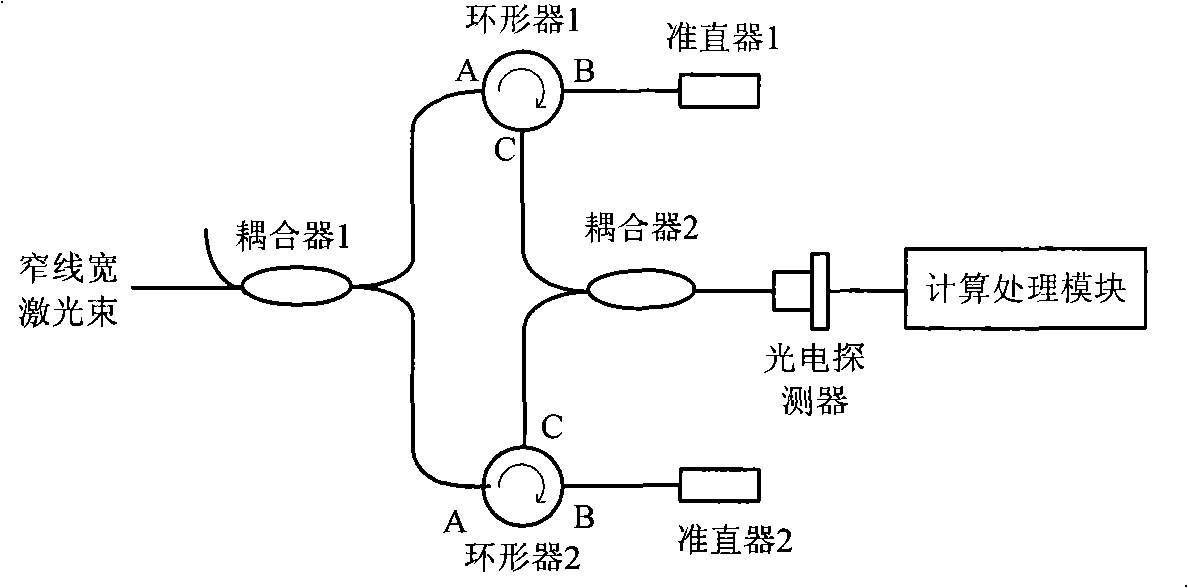

Apparatus and method for measuring speed of mobile

InactiveCN101256238AAccurate speed measurementDevices using optical meansElectromagnetic wave reradiationObject basedMeasurement precision

The invention provides a device and method for measuring speed of running objects. The device main comprises: laser beam processing module for respectively transmitting a first laser beam and second laser beam from running objects of different direction to ground and receiving the scattering return light of the first laser beam returned from the ground and scattering return light of the second laser beam; computation processing module for calculating the doppler frequency difference of the scattering return light of the first laser beam and scattering return light of the second laser beam; obtaining the running speed of the objects based on the doppler frequency difference. The speed of the objects can be accurately measured and the accuracy of measurement is not sensitive to the sway and bump of running objects.

Owner:BEIHANG UNIV

Bicycle speed measurement apparatus

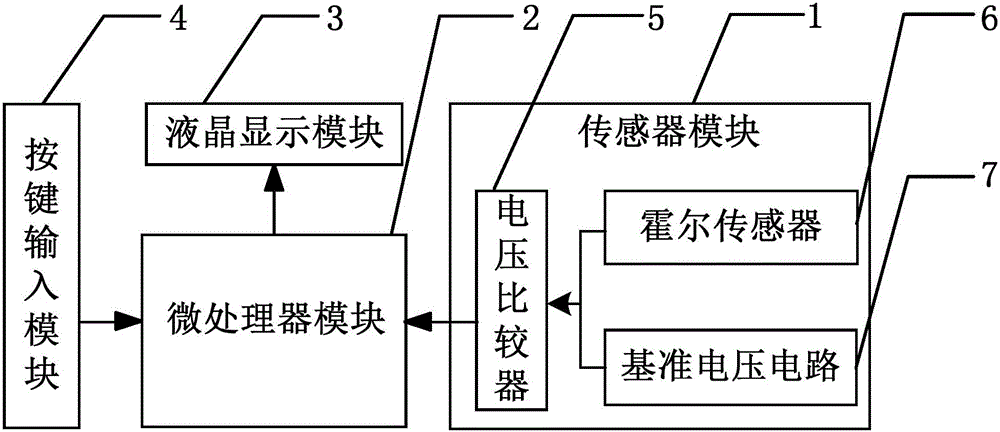

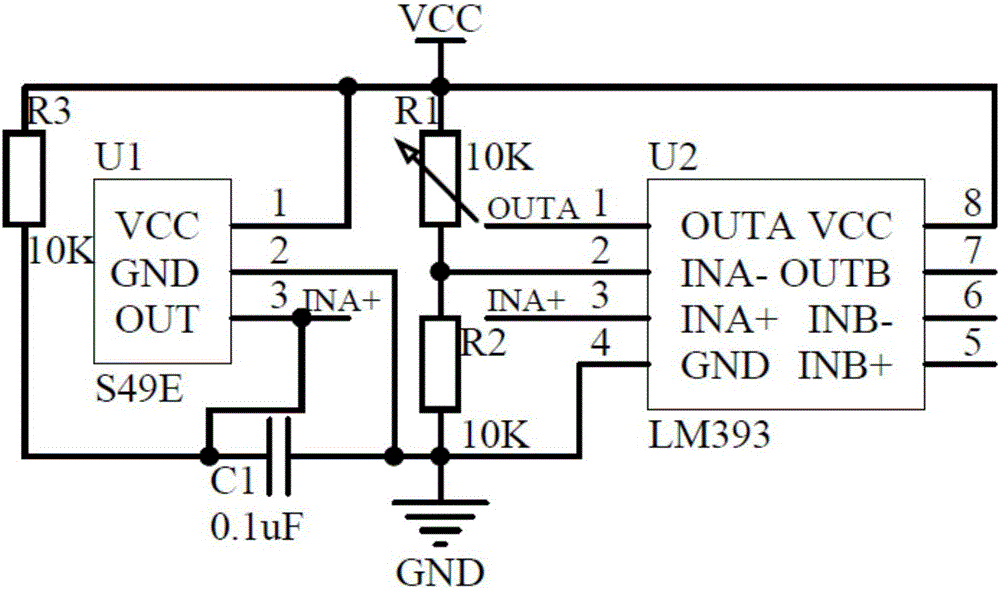

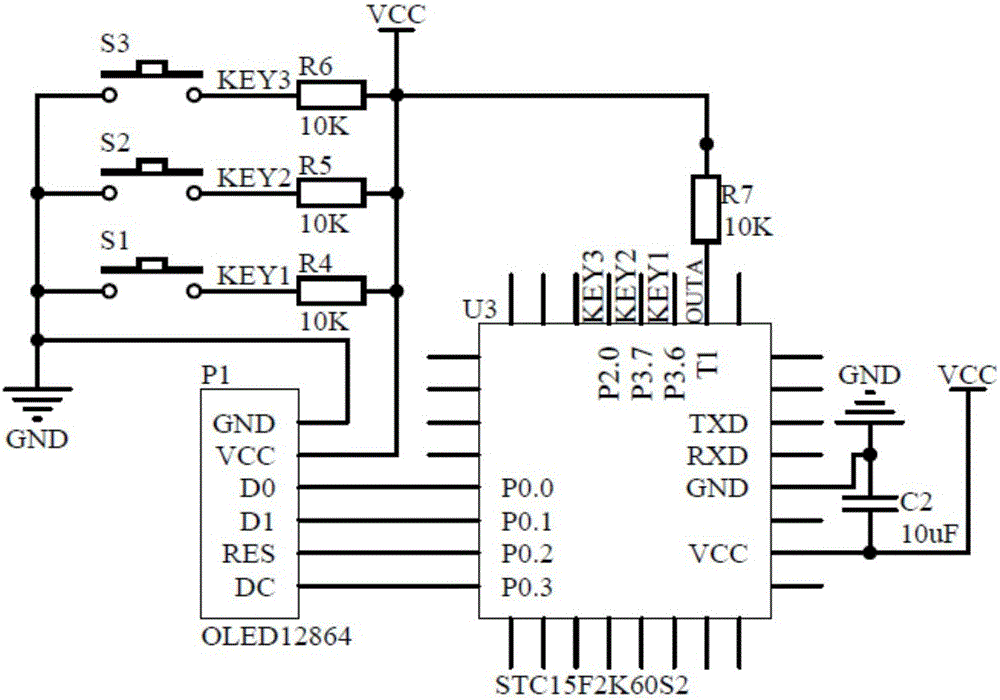

InactiveCN105067007AImprove securityGuaranteed speedNavigation instrumentsIn vehicleSpeed measurement

The present invention discloses a bicycle speed measurement apparatus, which comprises a microprocessor module, a liquid crystal display module, a sensor module and a key input module, wherein the sensor module comprises a Hall sensor, a voltage comparator and a reference voltage circuit, the microprocessor module is connected with the liquid crystal display module, the key input module and the voltage comparator, the voltage comparator is connected with the Hall sensor and the reference voltage circuit, the output terminal of the Hall sensor is connected with the positive input terminal of the voltage comparator, the output terminal of the voltage comparator is connected with the external counter interface of the microprocessor, and the liquid crystal display module and the key input module are connected with the digital I / O port of the microprocessor module. With the bicycle speed measurement apparatus of the present invention, the user can check the time, the bicycle speed, the mileage and other riding data during the riding so as to remind the user to maintain the speed and improve the safety, and the set data can be modified according to the requirement so as to achieve the accurate speed measurement purpose. The bicycle speed measurement apparatus of the present invention can further be used in vehicles, motorcycles, motors and other places requiring rotation speed measurement.

Owner:HUBEI UNIV OF ARTS & SCI

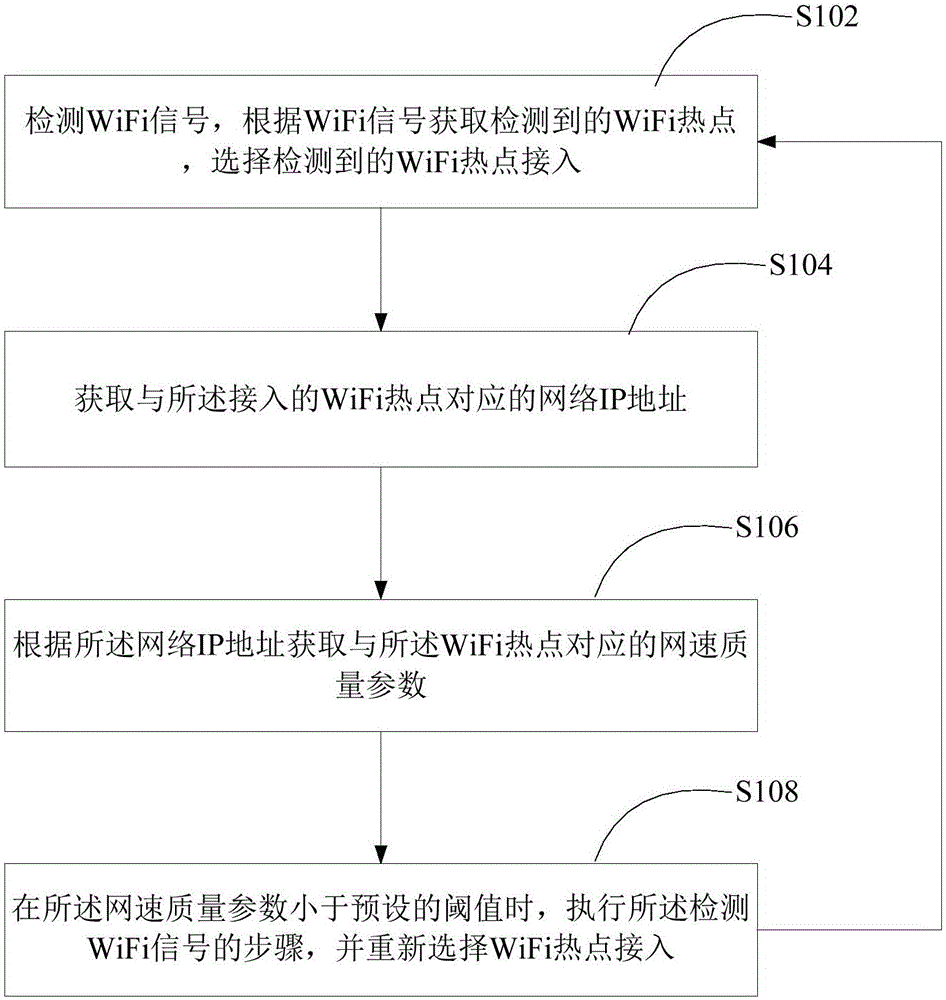

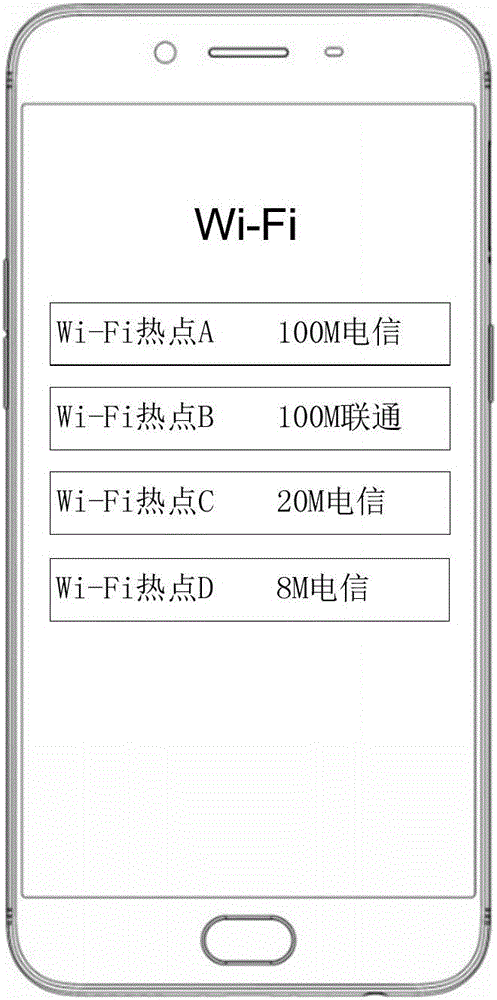

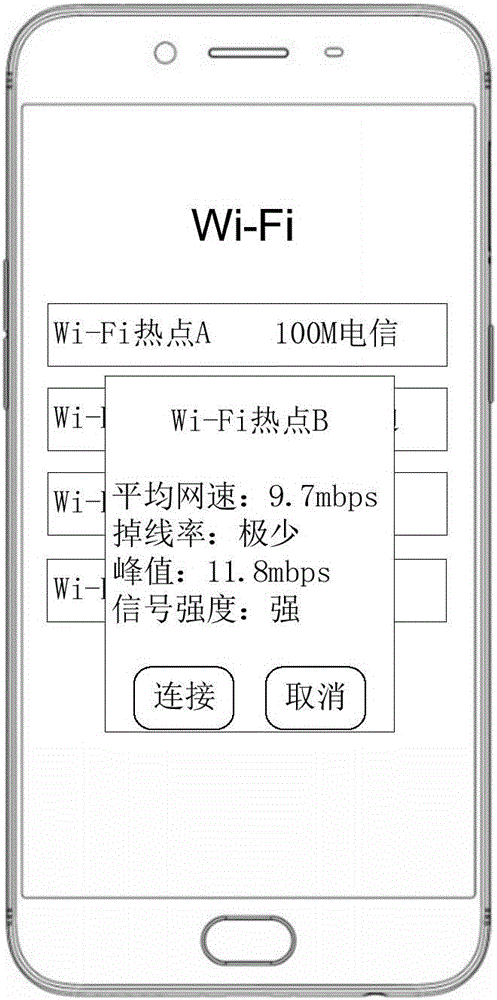

Method and device for connecting WiFi hotspot

InactiveCN106507419AImprove Internet experienceAccurate speed measurementAssess restrictionIp addressThe Internet

The embodiment of the invention discloses a method for detecting the network speed under a WiFi hotspot. The method comprises the following steps of: detecting a WiFi signal, obtaining a detected WiFi hotspot according to the WiFi signal, and selecting the detected WiFi hotspot to access; obtaining a network IP address corresponding to the accessed WiFi hotspot; obtaining a network speed quality parameter corresponding to the WiFi hotspot according to the network IP address; and, when the network speed quality parameter is less than a pre-set threshold value, executing a step of detecting the WiFi signal, and re-selecting the WiFi hotspot to access. The embodiment of the invention further discloses a device for detecting the network speed under the WiFi hotspot. By means of the embodiment of the invention, the internet access speed when a network is accessed by using the WiFi hotspot can be increased.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

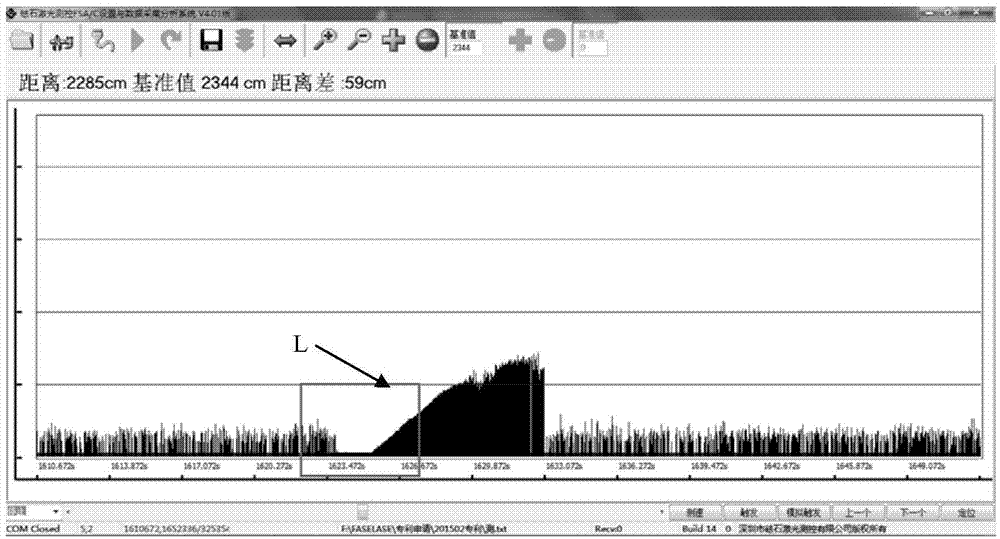

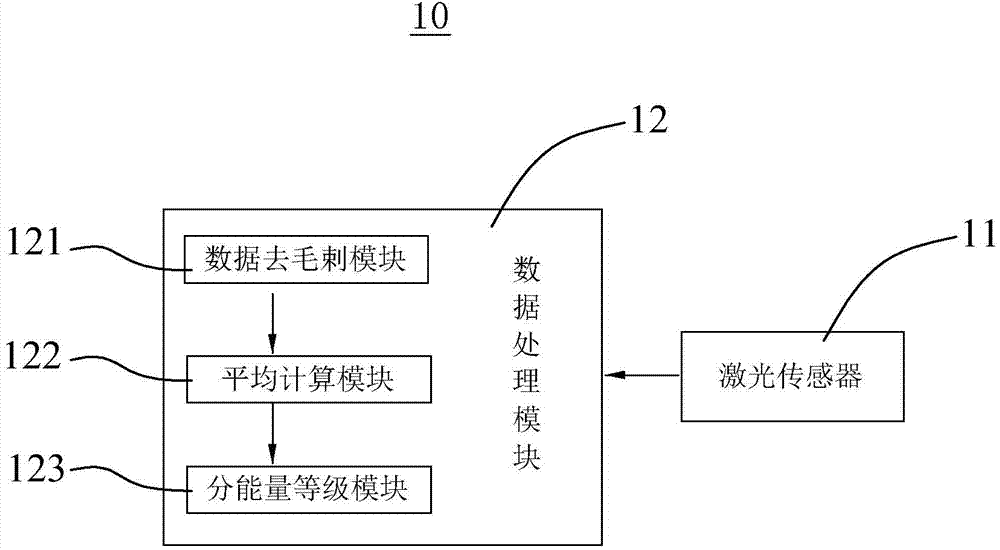

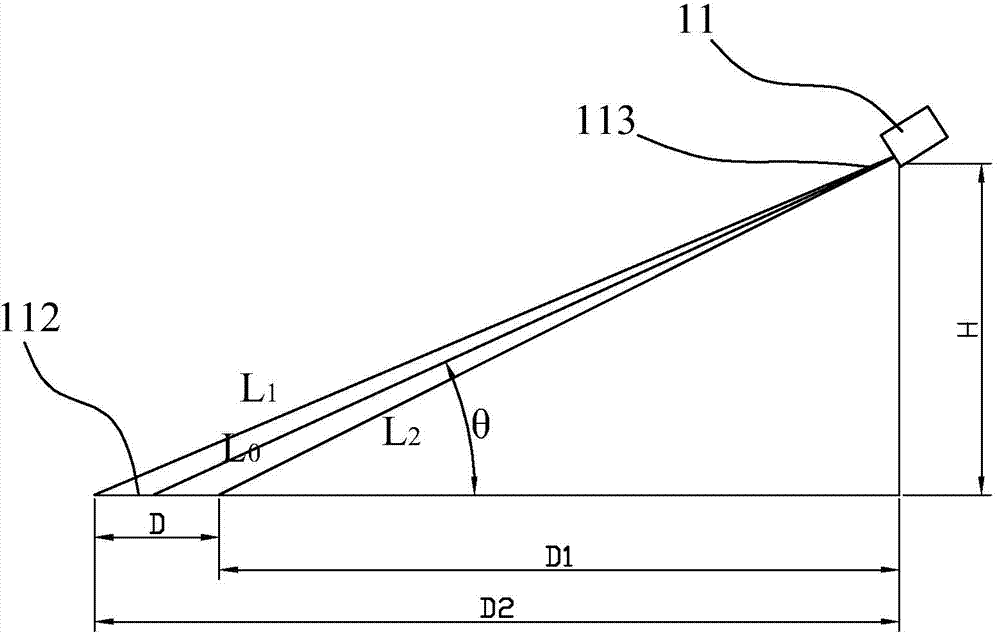

Accurate speed measurement method and system of large laser spot

ActiveCN104751643ASpeed measurement operation is simple and fastAccurate driving distanceRoad vehicles traffic controlDevices using optical meansLight spotTime segment

The invention relates to an accurate speed measurement method and an accurate speed measurement system of a large laser spot. The accurate speed measurement method and the accurate speed measurement system of the large laser spot are used in speed measurement of a vehicle. The accurate speed measurement method of the large laser spot includes following steps: controlling a laser sensor to send out a pulse laser towards a vehicle moving route, and enabling the pulse laser to form the large laser spot above 1m in diameter on the vehicle moving route when no vehicle runs on the vehicle moving route; monitoring situations of a vehicle head when the vehicle head drives into the light spot and moves in the laser spot, obliquely projecting the pulse laser onto the vehicle head, measuring a laser return distance value Ln of the vehicle head at each time point in a moving time segment of the vehicle head in the laser spot, and forming a vehicle head-time pulse waveform map; performing analytical calculation according to the vehicle head-time pulse waveform map, position parameters of the laser sensor and dimension parameters of the light spot so as to obtain speed of the vehicle when the vehicle passes through the laser spot. The accurate speed measurement method of the large laser spot uses the large laser spot to measure the speed, can guarantee that the laser is projected to the same portion of different vehicles, figures out an accurate traveling distance, obtains an accurate speed measurement value, is simple and quick in speed measurement operation, and obtains an accurate and reliable measurement result.

Owner:深圳市砝石激光雷达有限公司

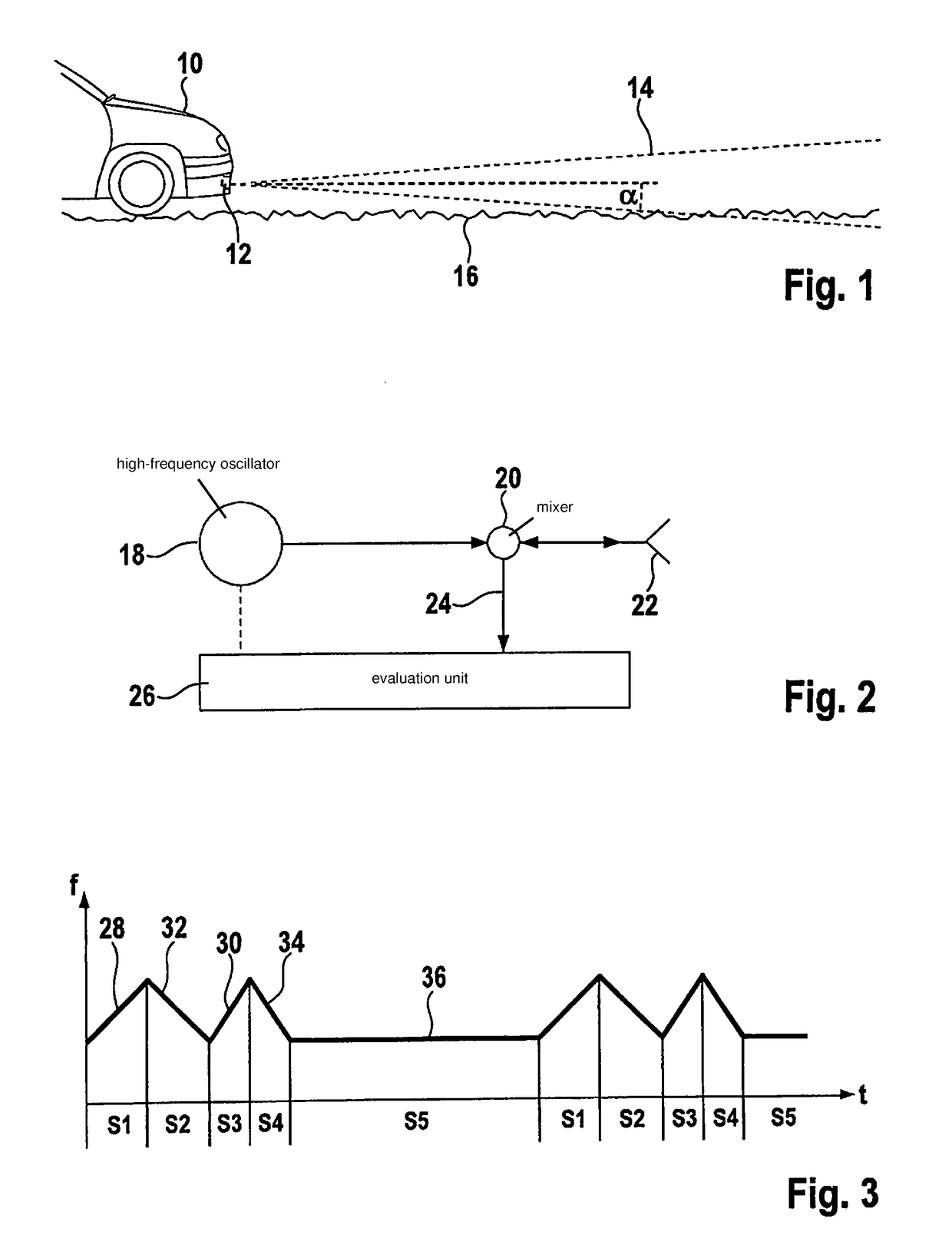

Radar system for motor vehicles

InactiveUS7786926B2Accurate measurementFunction increasePedestrian/occupant safety arrangementRadio wave reradiation/reflectionRadar systemsImpact velocity

Owner:ROBERT BOSCH GMBH

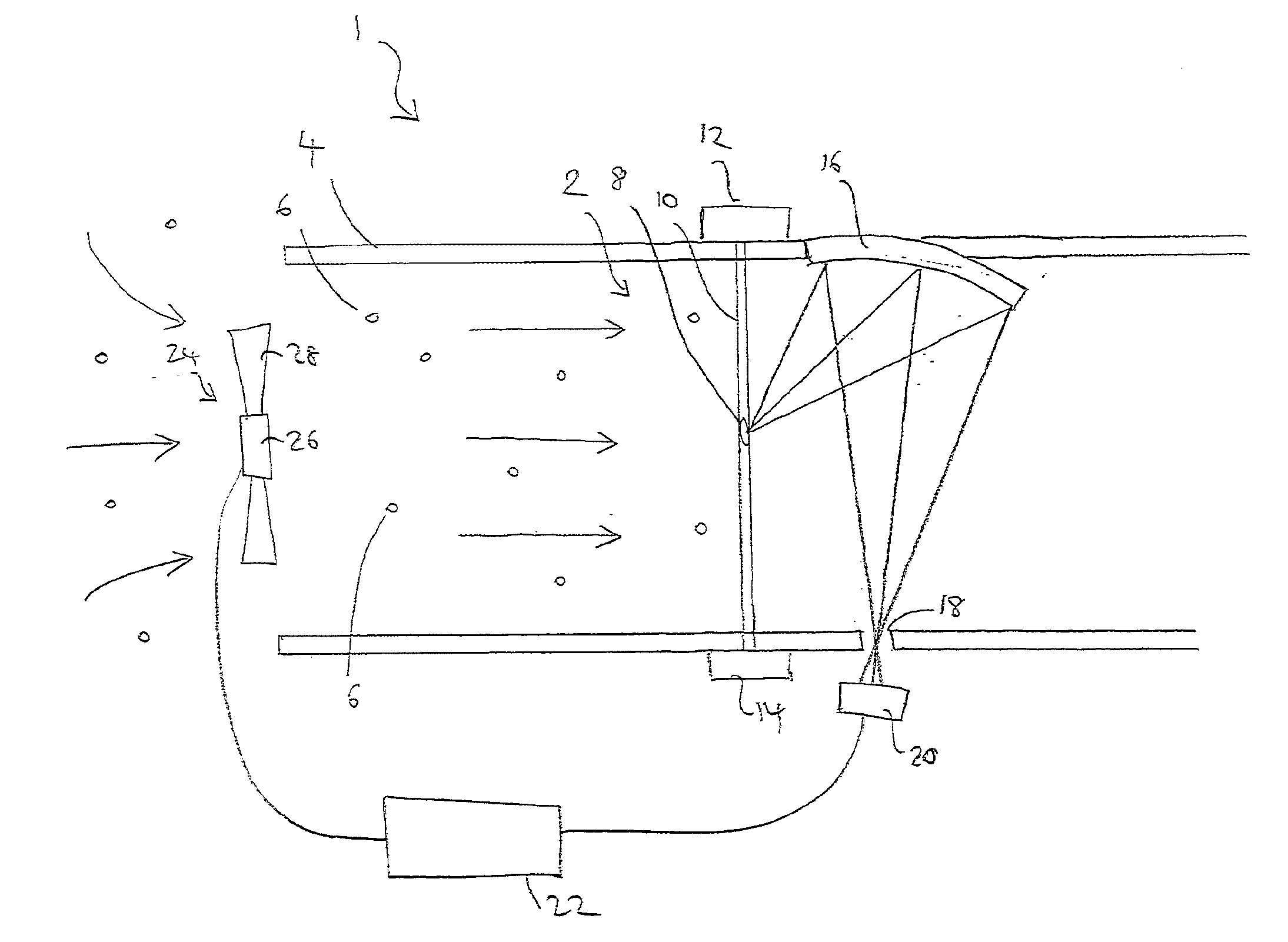

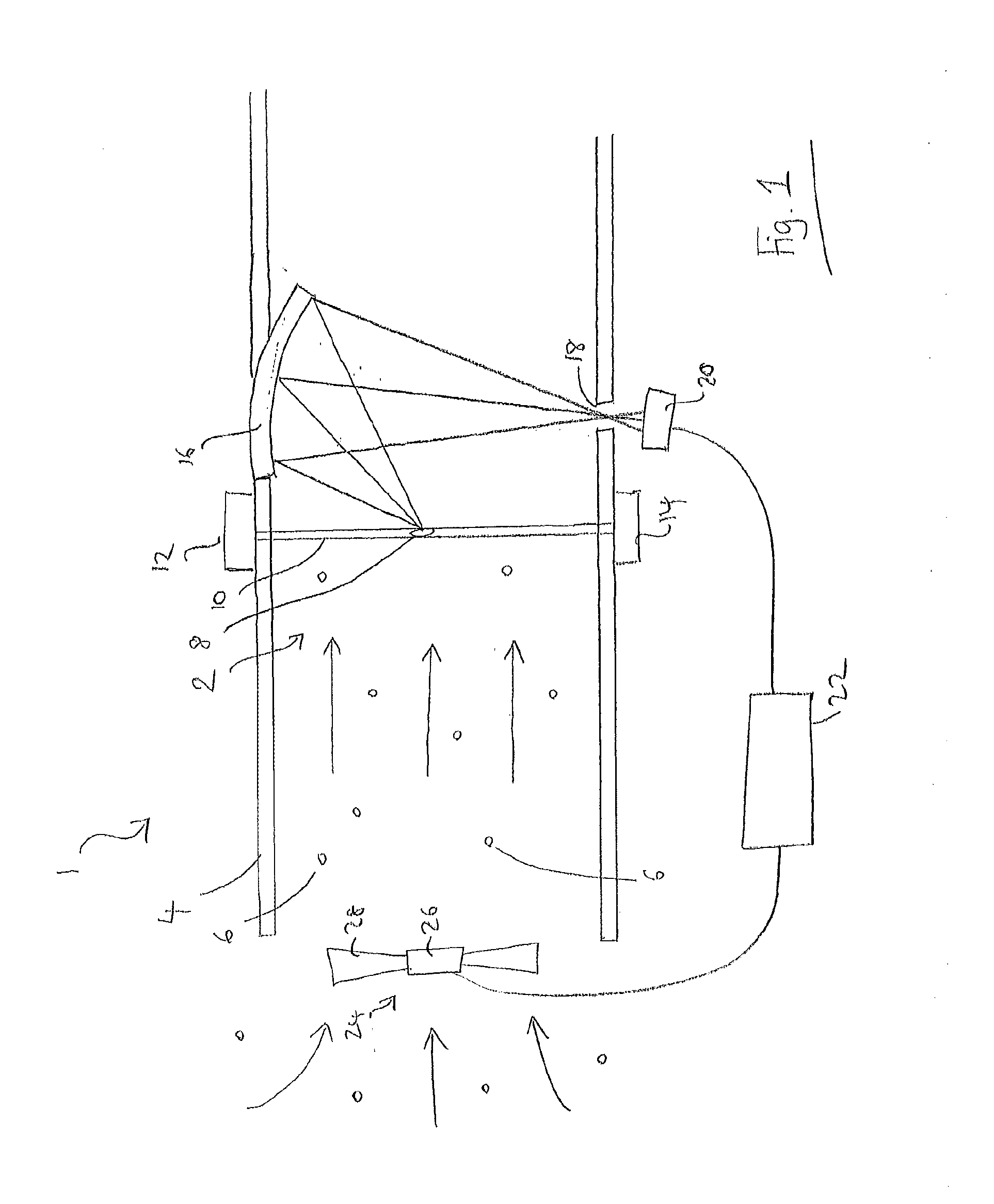

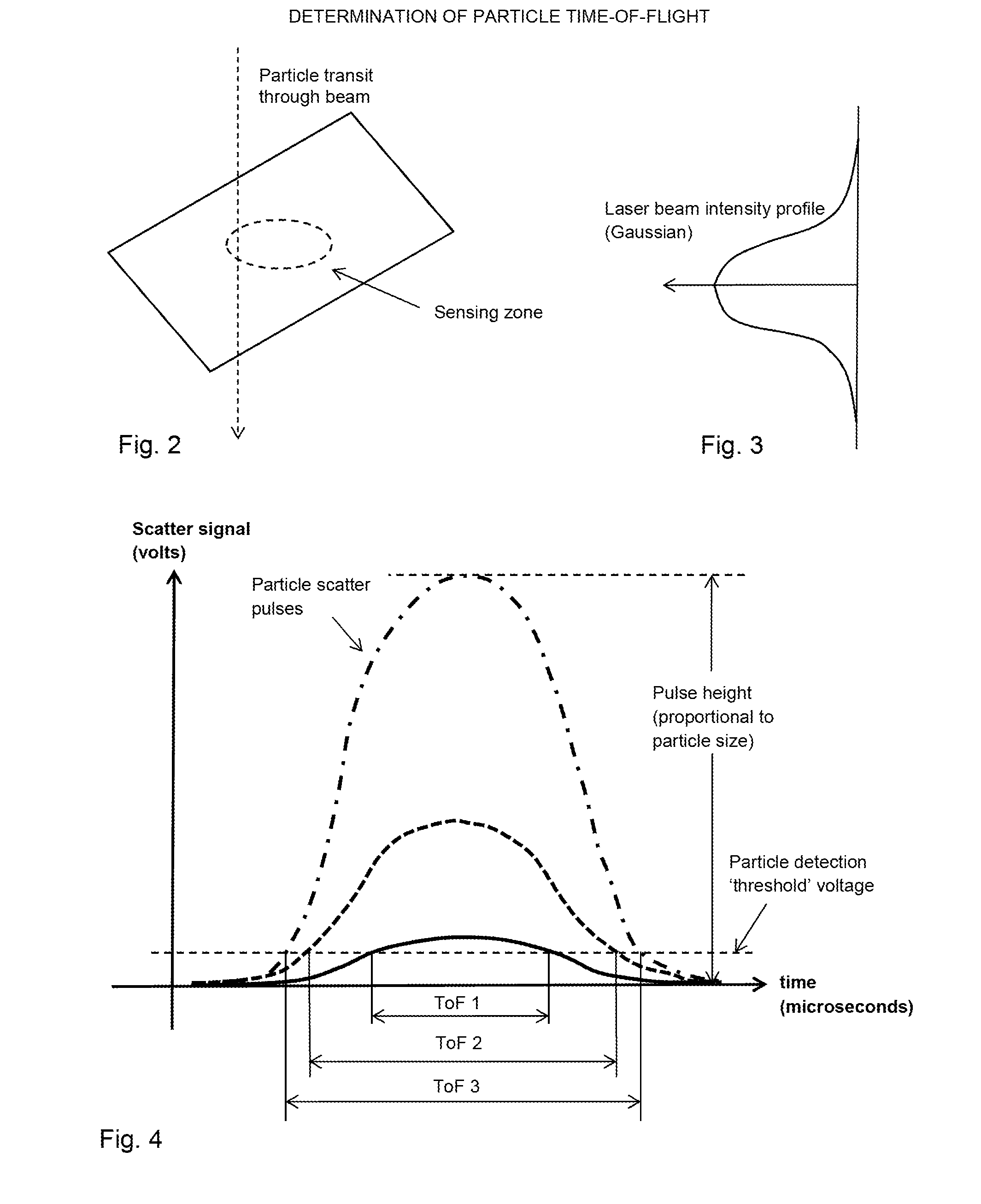

Optical particle counter

ActiveUS20160305872A1Less-accurate measurement of velocityReliable measurementNanoparticle analysisInvestigating moving fluids/granular solidsParticle physicsParticle counter

An optical particle counter determines the velocity of particles passing through a particle detection zone, and thereby the velocity of gas flow, from both the measured time of flight of discrete particles and also the size of intensity peaks of scattered light. This is used to determine particle concentration and may be used to control an optional fan.

Owner:ALPHASENSE LTD

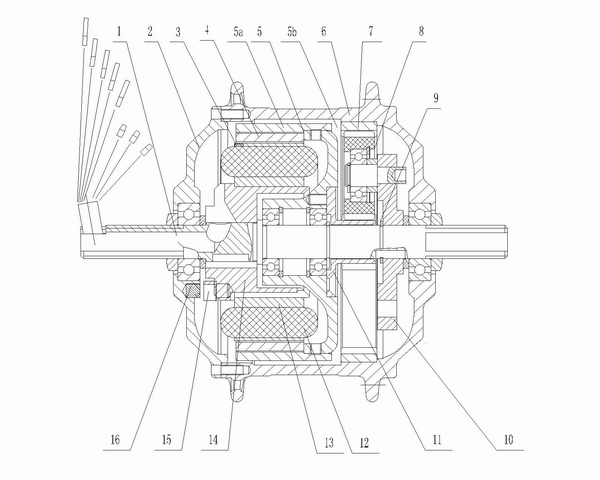

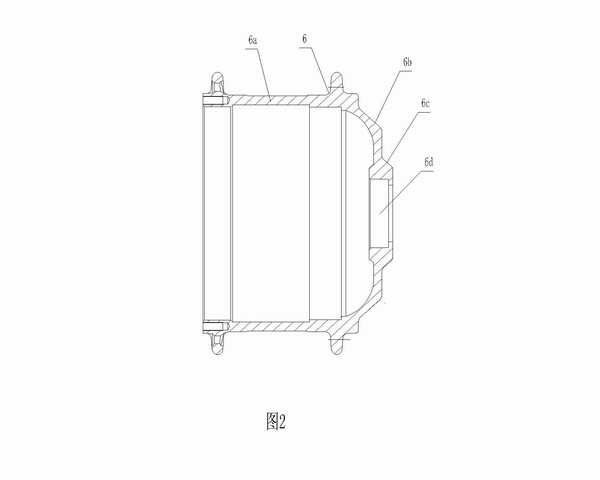

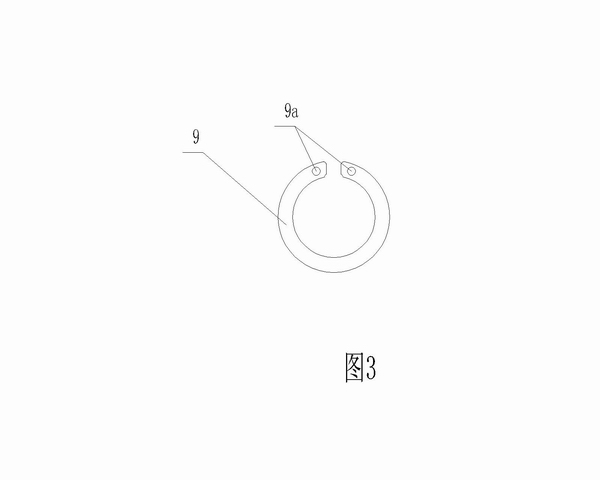

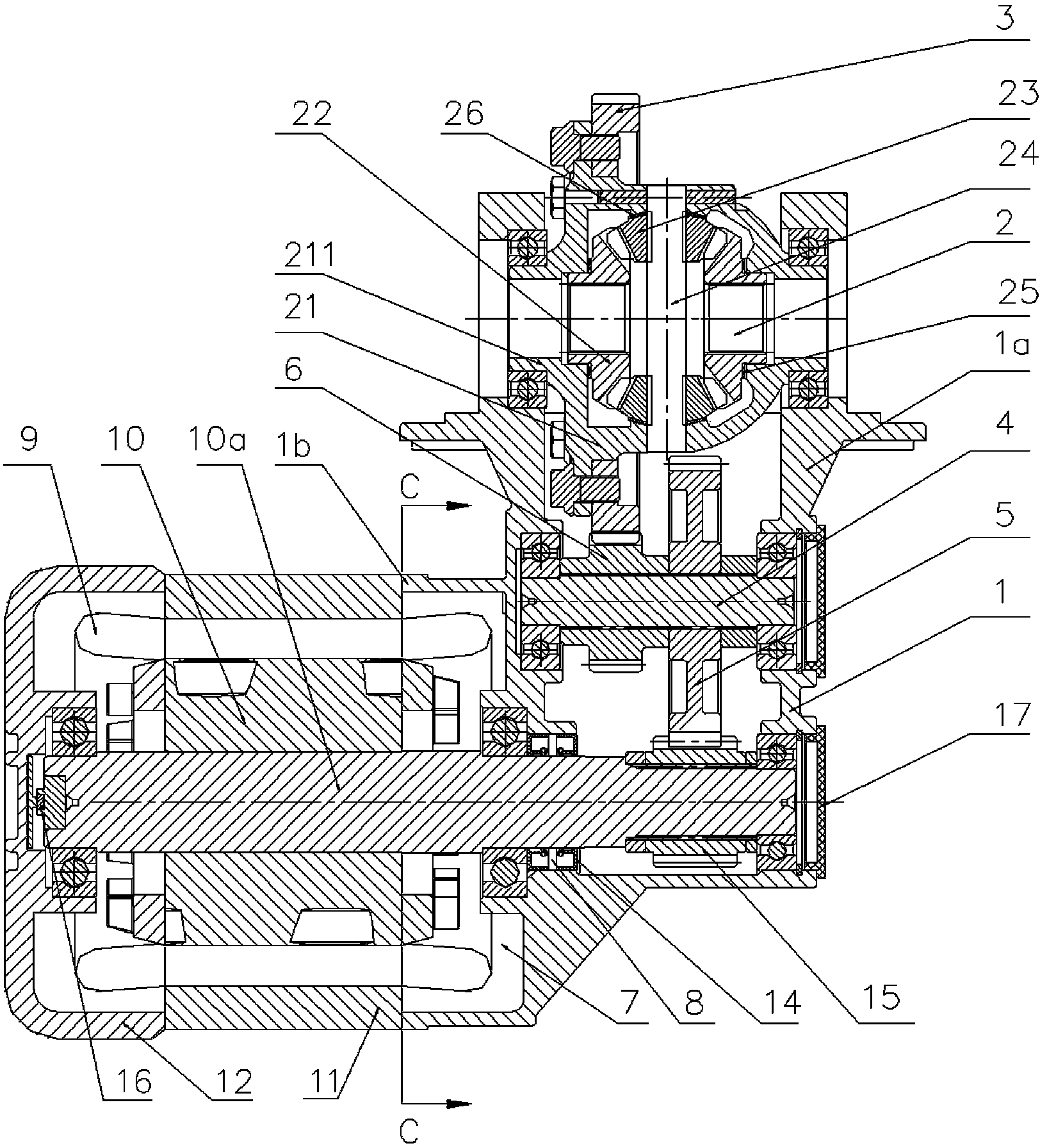

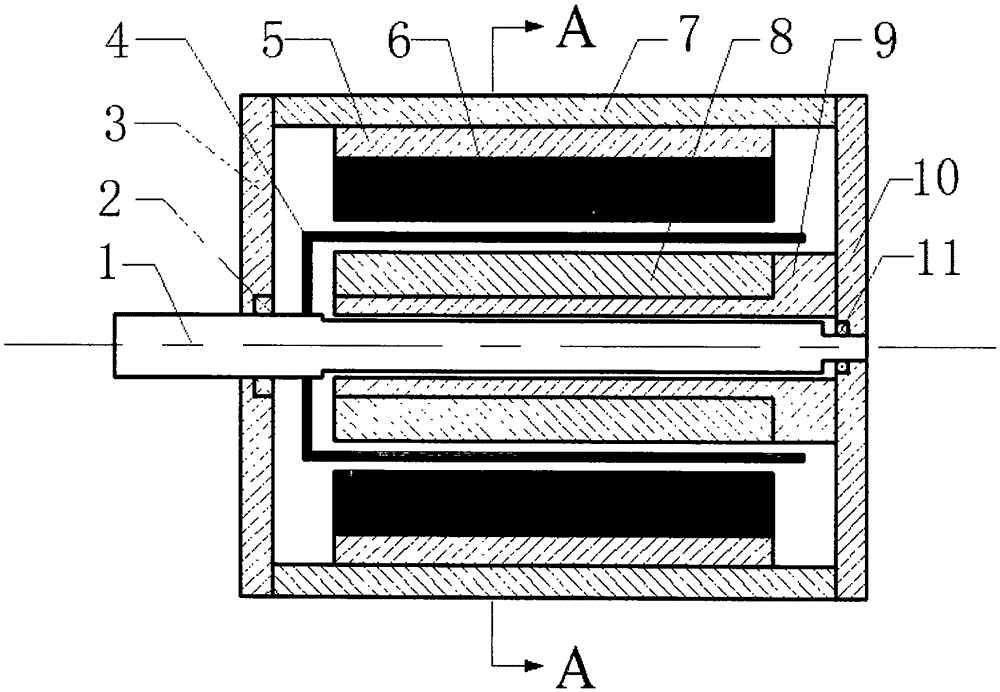

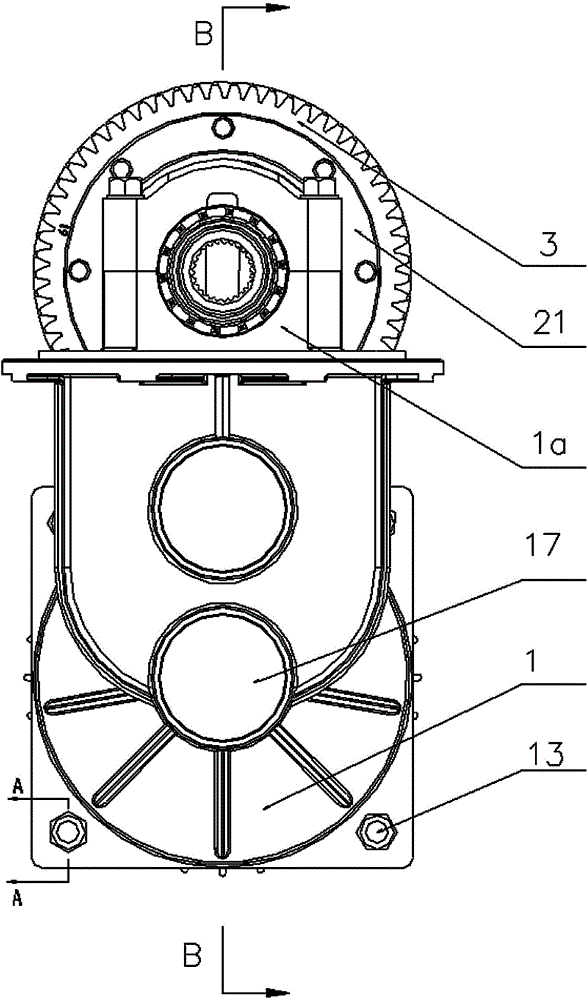

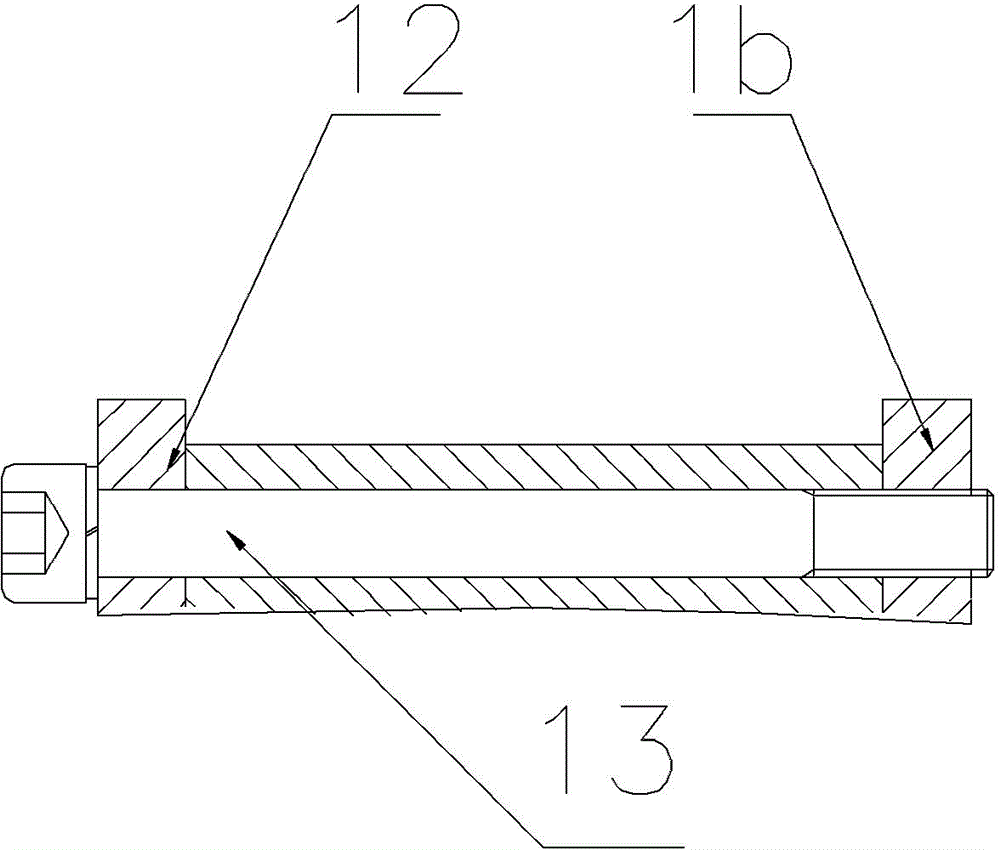

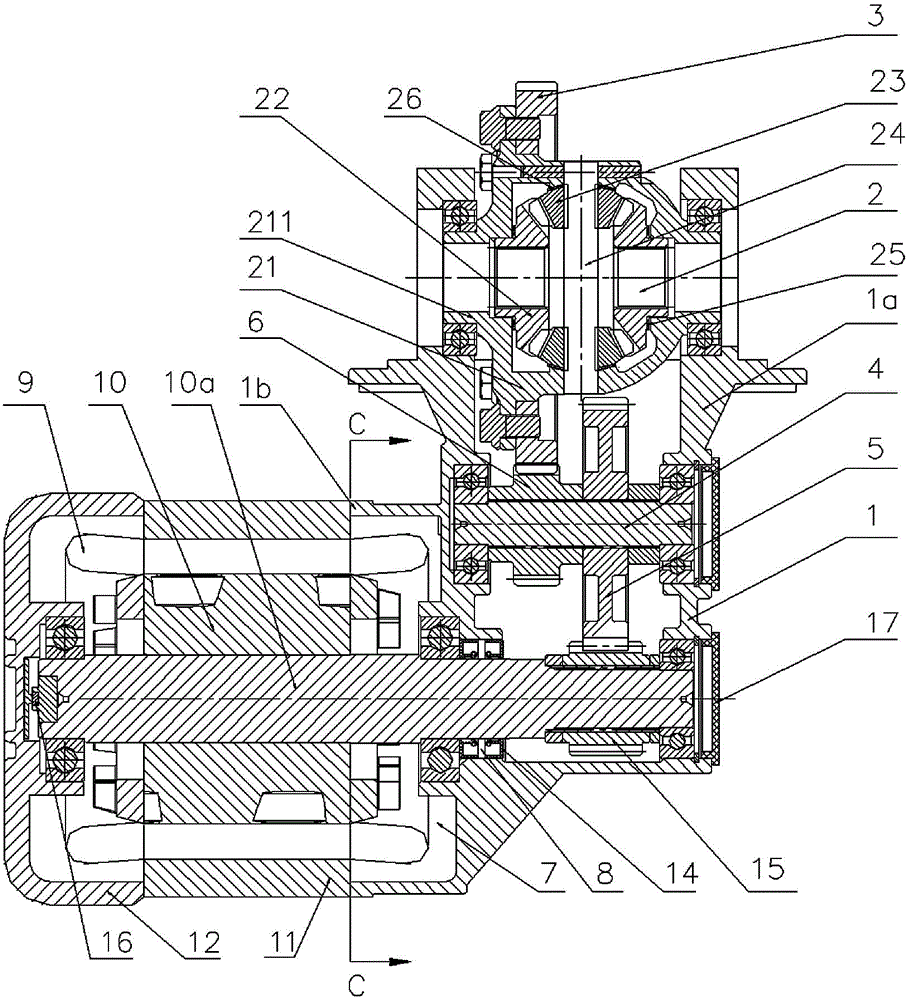

Shoulderless and brushless hub motor for electric bicycle

InactiveCN101989801ANovel structureReasonable structureMechanical energy handlingCurrent electricGear wheel

The invention relates to a shoulderless and brushless hub motor for an electric bicycle, belonging to the technical field of a motor for a direct-current electric bicycle. The invention is characterized in that the mandrel of the motor is in a shoulderless structure; a clamp spring for a lugless shaft, which is butted and matched with the inner end of a clutch, is clamped on the mandrel; a conical hub with a conical open structure is sleeved on the mandrel; the conical hub is connected with a conical end cover to form a shell; the conical hub is in clearance fit with a built-in magnetic yoke assembly and is in transmission fit with a built-in three-planetary gear mechanism; a Hall speed measuring sensor is matched and arranged on a stator bracket; and a signal magnetic sheet is arranged at a position, which is opposite to the Hall speed measuring sensor, on the inner side of the conical end cover. The invention furthest has the advantages that the inner cavity space of the hub is increased through the shoulderless structure of the mandrel and the open structure of the conical hub, and a built-in speed measuring mechanism is adopted; and the hub motor provided by the invention has the characteristics of novel and reasonable structure, reliable efficacy, light weight, small volume, low cost and the like, is accurate in speed measurement, and is an ideal front-end driving device for the electric bicycle, thereby filling the blank of built-in electronic digital speed measurement of the hub motor at home.

Owner:郑国明

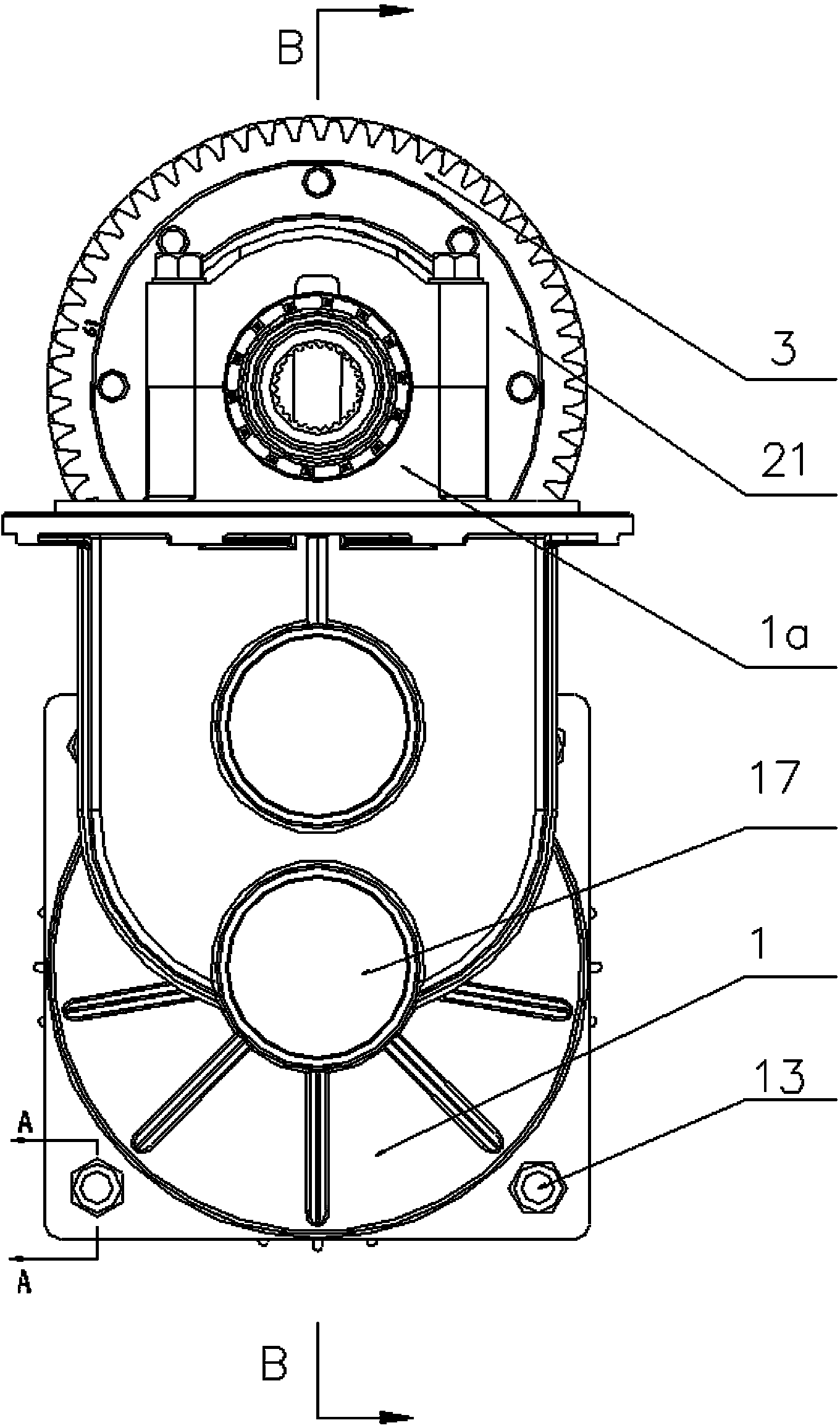

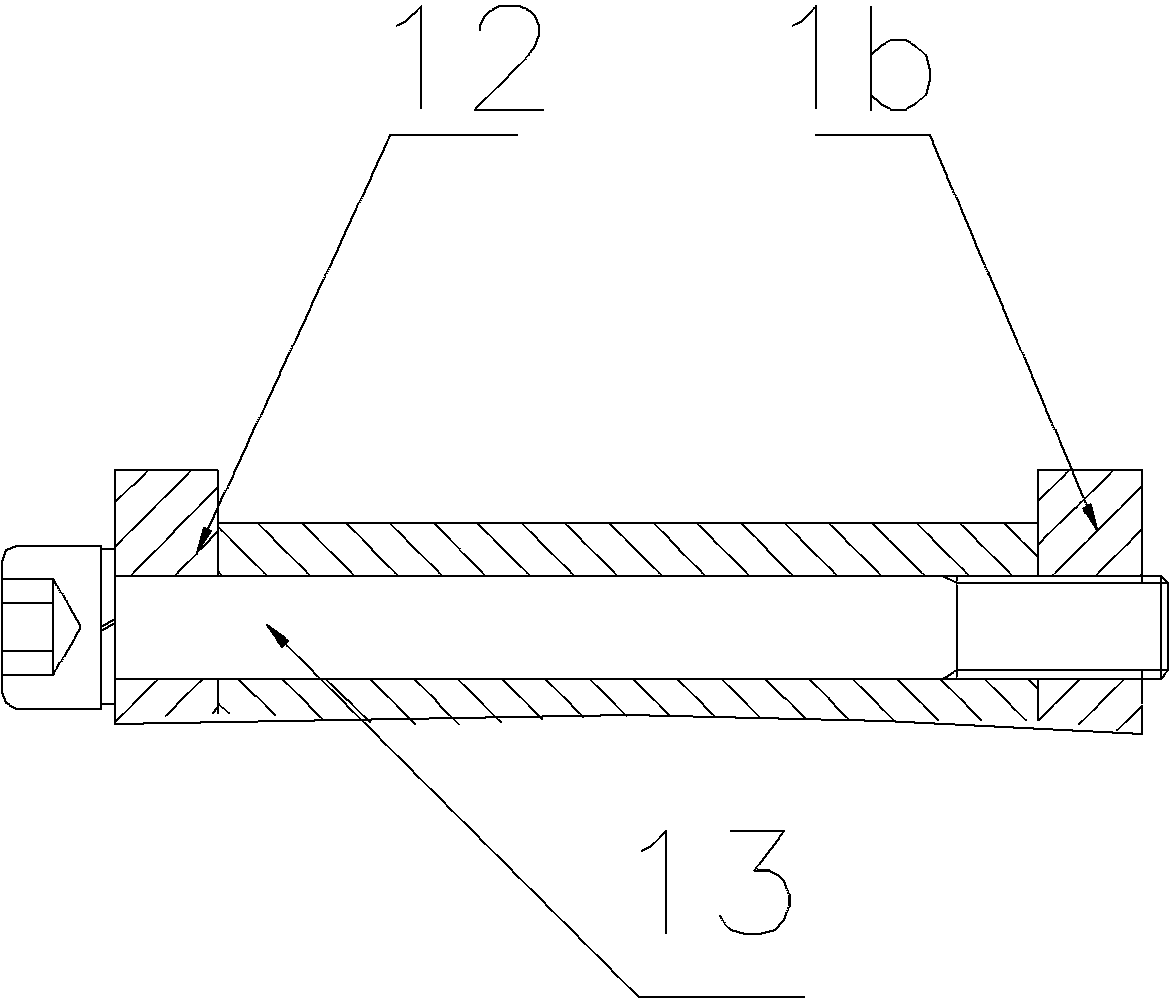

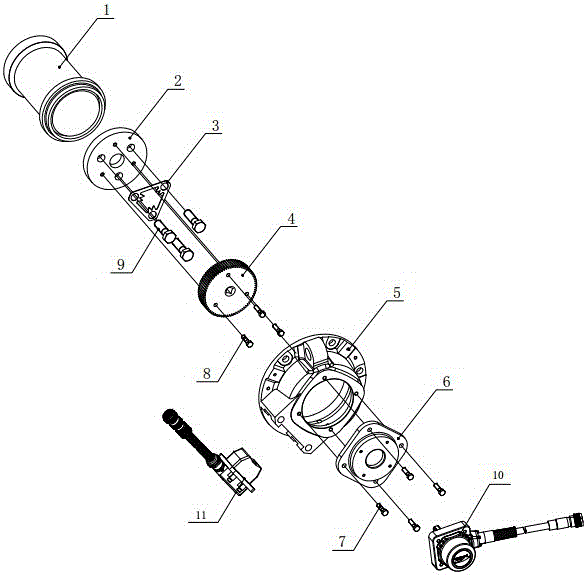

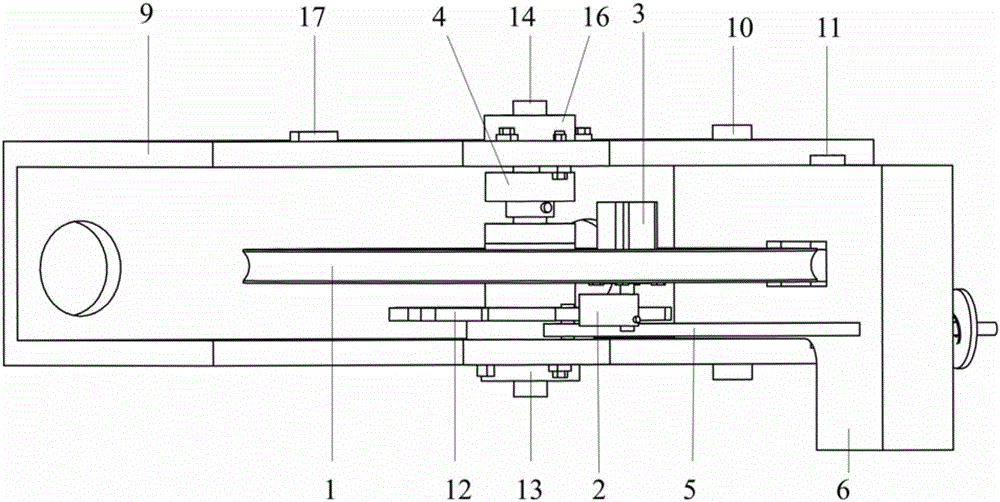

Rear axle electrodynamic force drive device of electric vehicle

The invention discloses a rear axle electrodynamic force drive device of an electric vehicle. The drive device comprises a reducer shell, wherein the reducer shell is provided with two supports, the two supports support a differential shell, a second driven gear is fixed on the differential shell, a transmission shaft is arranged in the differential shell, a first driven gear and a second drive gear are fixed on the periphery of the transmission shaft, the second drive gear is meshed with the second driven gear, the reducer shell is provided with an end face, a cavity is formed on the end face, a shaft hole is formed in the bottom of the cavity, one end of an alternating current motor stator core is connected with the end face, the other end of the alternating current motor stator core is connected with a rear end cover, the rear end cover, the alternating current motor stator core and the reducer shell are fixed through bolts, one end of a rotor shaft of an alternating current motor supports on the rear end cover, the other end of the rotor shaft of the alternating current motor penetrates through the shaft hole to support on the reducer shell, the first drive gear is fixed on the rotor shaft of the alternating current motor, and the first drive gear is meshed with the first driven gear. The electrodynamic force drive device realizes stepless speed regulation, shifting impact is eliminated, and the heat dissipation of a drive motor is ensured.

Owner:CHONGQING DONGBA TECH

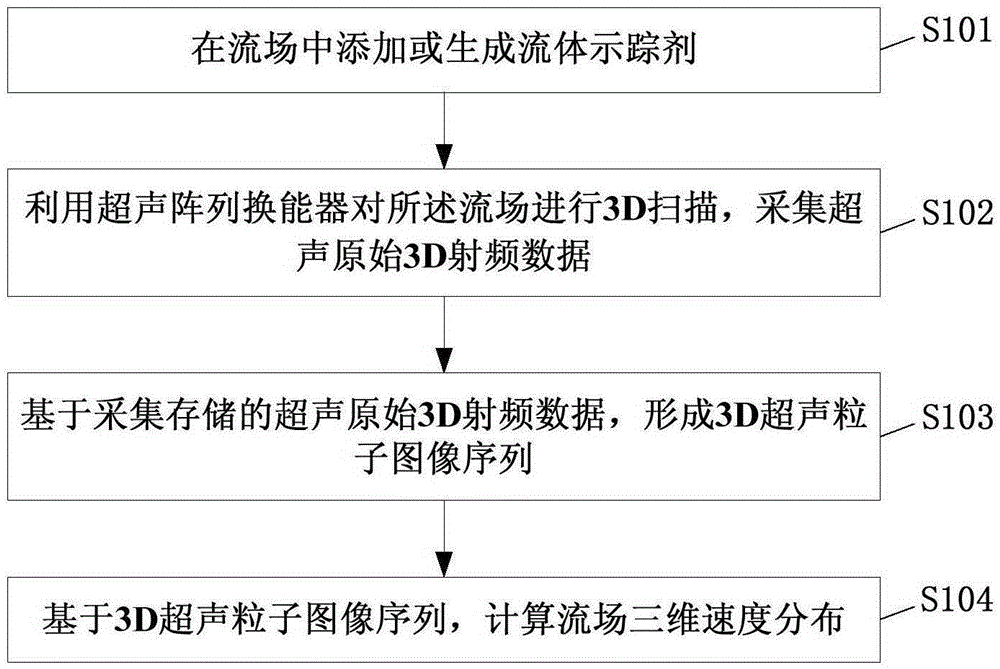

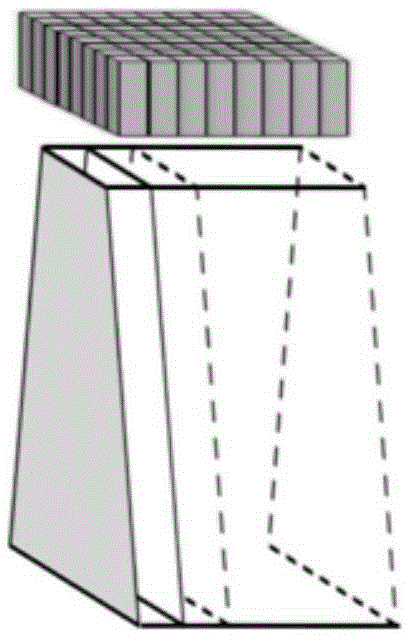

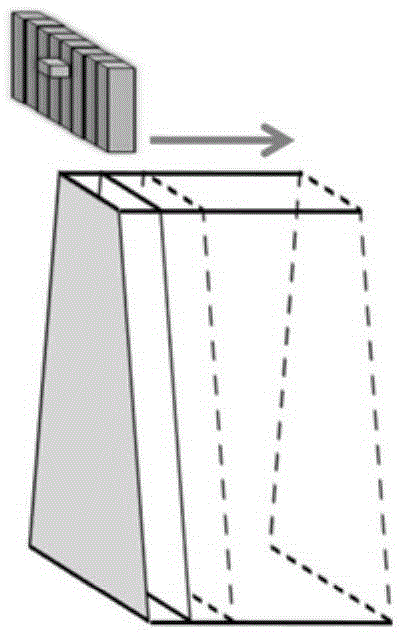

Ultrasonic three-dimensional fluid imaging and speed measuring method

ActiveCN105411624AStrong penetrating powerAccurate speed measurementBlood flow measurement devicesInfrasonic diagnosticsRadio frequencyFluid field

The invention discloses an ultrasonic three-dimensional fluid imaging and speed measuring method. The method comprises the steps that 1, a fluid tracer is added or generated in a flow fluid; 2, an ultrasonic array energy converter is utilized for conducting 3D scanning on the flow fluid, and ultrasonic original 3D radio frequency data are collected; 3, on the basis of the collected and stored ultrasonic original 3D radio frequency data, a 3D ultrasonic particle picture sequence is formed; 4, on the basis of the 3D ultrasonic particle picture sequence, three-dimensional speed distribution of the flow fluid is calculated.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

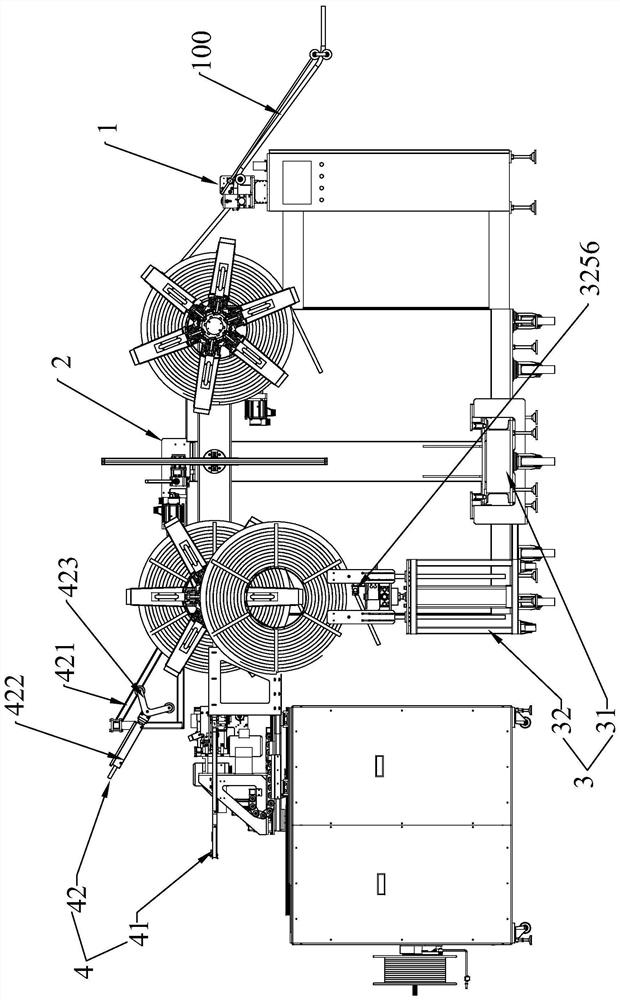

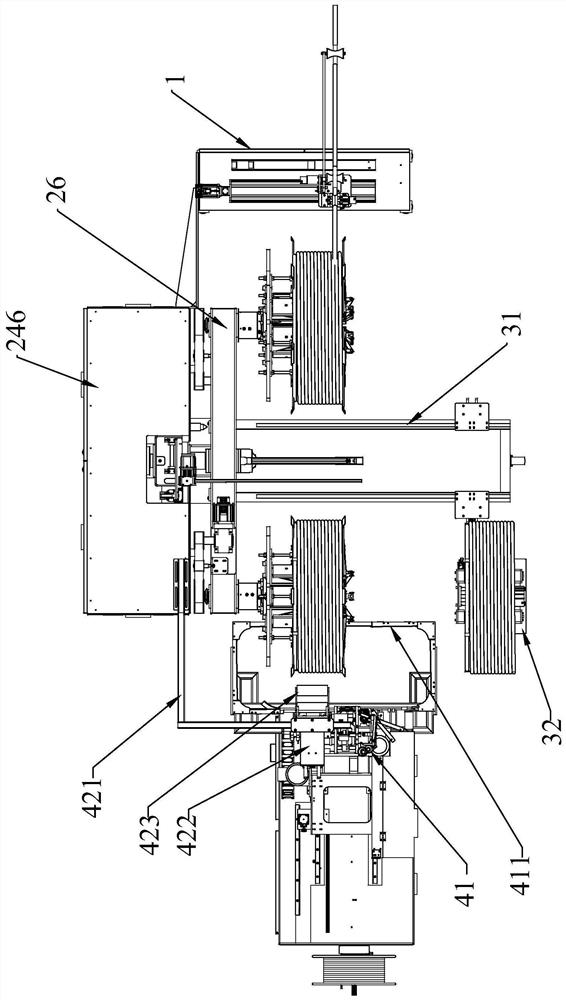

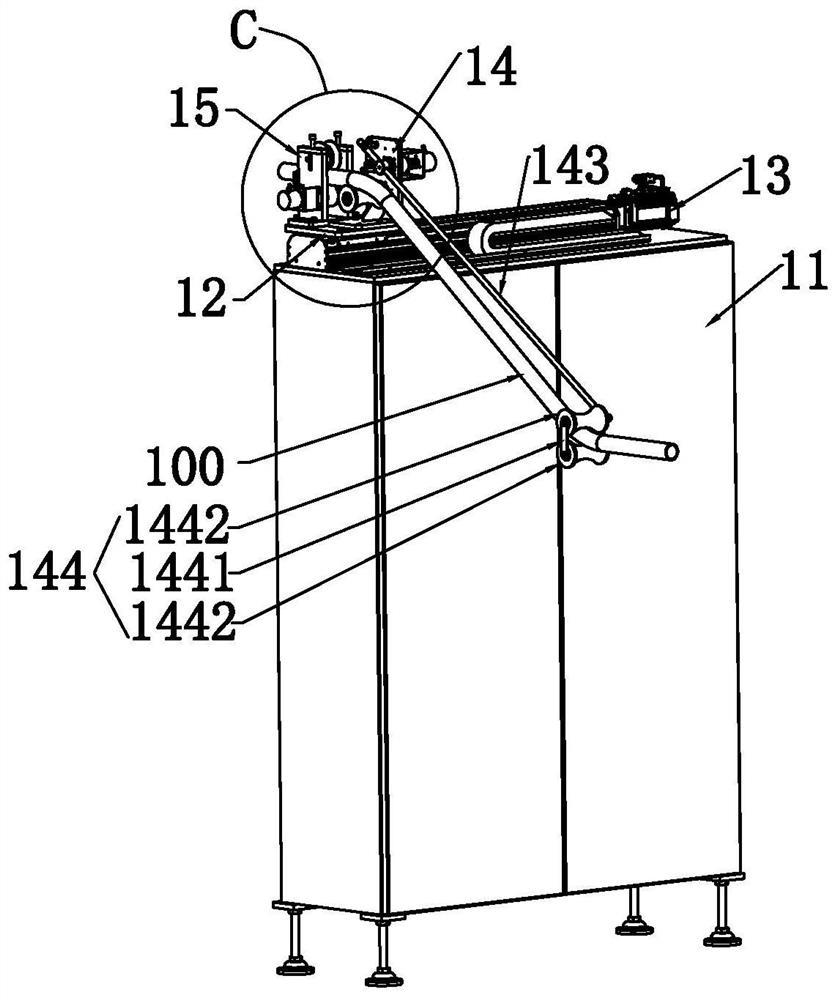

Full-automatic winding packer

ActiveCN111874739AIncrease productivitySimple structureFilament handlingPackagingWire rodProcess engineering

The invention discloses a full-automatic winding packer which comprises a sequencing mechanism, a winding mechanism, a coil discharging mechanism and a packing mechanism. The winding mechanism and thecoil discharging mechanism are arranged between the sequencing mechanism and the packing mechanism. The full-automatic winding packer comprises the sequencing mechanism, the winding mechanism, the coil discharging mechanism and the packaging mechanism, so that the full-automatic winding packer can be applied to various pipes or wires capable of being wound, completes the links of sequencing, winding, coil changing, packaging and coil discharging under the condition without human assistance, achieves comprehensive and automatic material packaging, and greatly improves the production efficiency; and meanwhile, the sequencing mechanism detects the tension of material pieces through a tension detection device and detects the running states of the material pieces through a speed measurement device. The full-automatic winding packer has the advantages of being simple in structure and accurate in speed measurement, can effectively avoid the problem of winding creases, reduces the reject ratio of products, and saves the production cost.

Owner:大连银路电控设备有限公司

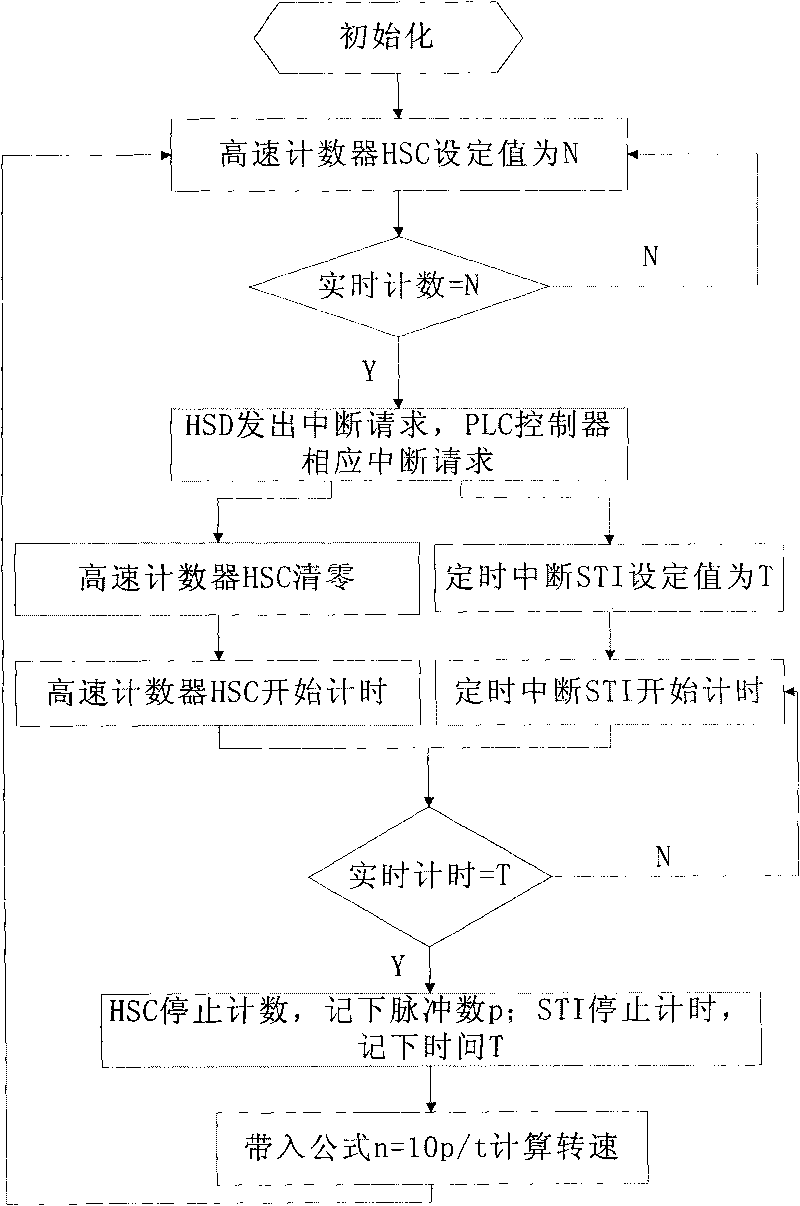

Device for preventing rotating speed measured value from jumping off and method thereof

InactiveCN101726625APrevent jumpingAccurate speed measurementLinear/angular speed measurementHall elementVelocity measurement

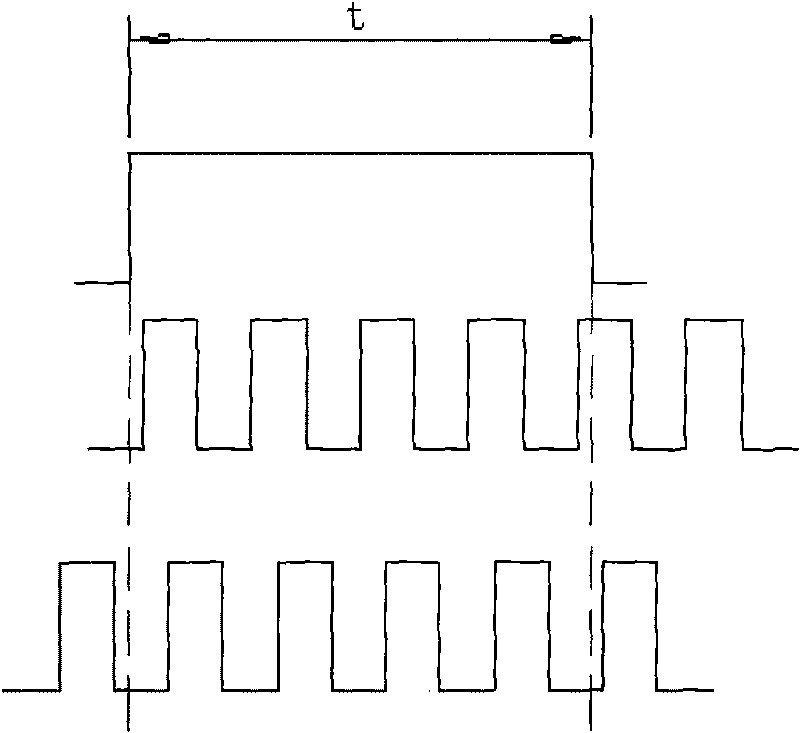

The invention relates to a device for preventing rotating speed measured value from fluctuating and a method thereof. The device comprises a centrifugal machine principal axis, a tachometer disc and a tachogenerator which are arranged on the principal axis and rotate with the principal axis synchronously; the tachogenerator is assembled by the following parts: n little magnets which are arranged on the tachometer disc and distributed evenly, and a Hall element sensor is firmly arranged near the little magnets; and the invention is characterized in that the Hall element sensor is connected with a PLC controller, the controller provides a high-speed counter (HSC) and a set time interrupter (STI) which have interruption function. Basically, the rising edge of measurement time t at every turn is aligned with that of the pulse to be tested, namely, timing begins from the rising edge of the pulse to be tested, so that the numbers of pulses measured in the measurement time t at every turn are basically equivalent, the velocity measurement is precise, and the fluctuating of the rotating speed measured value is avoided.

Owner:SHANGHAI CENTRIFUGE INST

Alternating current/direct current tachogenerator

Owner:绵阳赛恩新能源科技有限公司

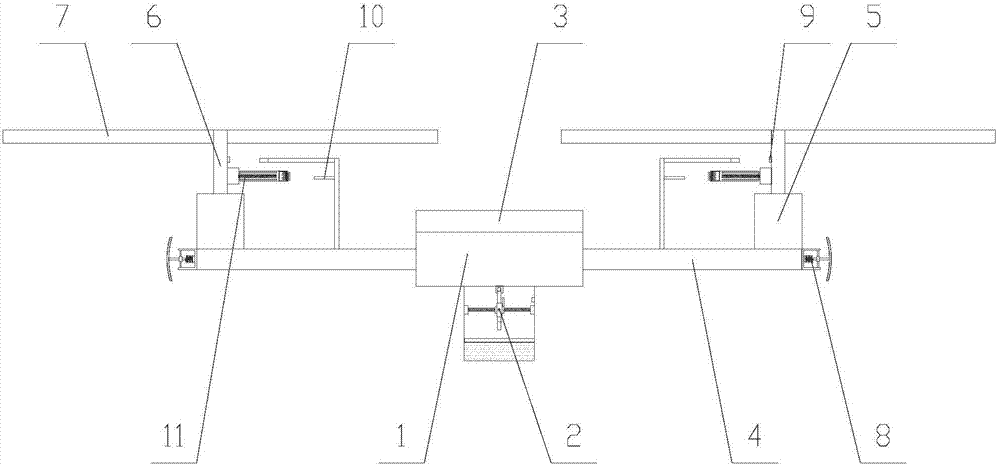

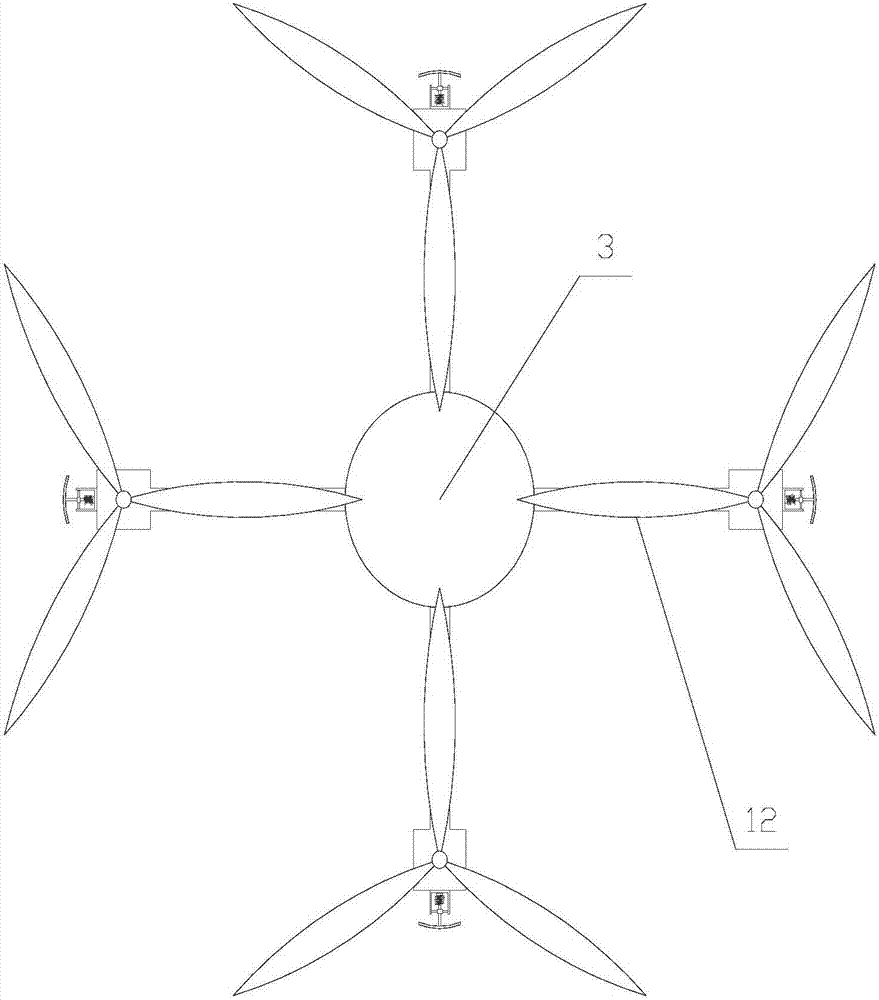

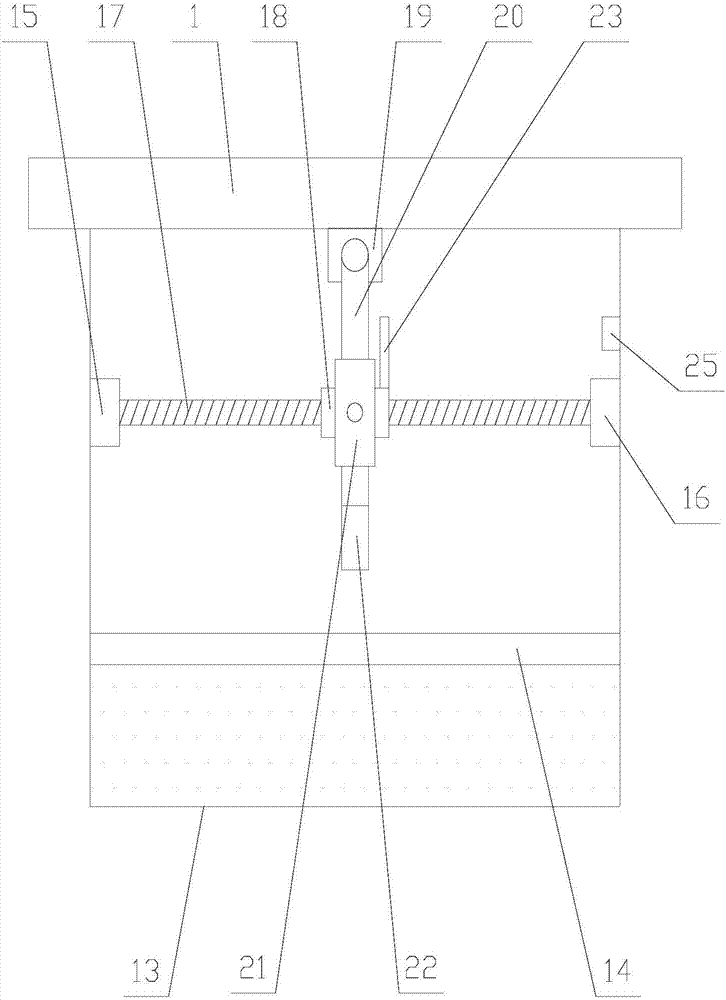

Precisely controlled intelligent four-rotor unmanned aerial vehicle

InactiveCN106882364AAccurate speed measurementAccurate operationAircraft controlRotocraftUncrewed vehicleEngineering

The invention relates to a precisely controlled intelligent four-rotor unmanned aerial vehicle. The precisely controlled intelligent four-rotor unmanned aerial vehicle comprises a deflection measuring mechanism and a plurality of flight units; the deflection measuring mechanism comprises a light reflecting plate and a deflection measuring assembly; the deflection measuring assembly comprises a driving unit, a moving block, a hinge block, a rotating rod, a sleeve and a first photoelectric sensor; each flight unit comprises an auxiliary speed measurement unit on a side rod and a speed reducing unit on a first driving shaft; each auxiliary speed measurement unit comprises a supporting rod, a resistance rod, a transverse rod and a second photoelectric sensor; according to the precisely controlled intelligent four-rotor unmanned aerial vehicle, the inclination degree of an unmanned aerial vehicle is accurately controlled through the deflection measuring mechanism, the rotating speed of the first driving shaft in each flight unit is detected through the corresponding auxiliary speed measurement unit, and a speed is reduced to different degrees by utilizing the speed reducing unit, so that each flight unit is regulated to keep the unmanned aerial vehicle horizontal; the wind strength in each direction is detected through a wind detecting unit; the rotating speed of paddles in each flight unit is regulated again; therefore, precise operation of the unmanned aerial vehicle is realized.

Owner:江西中轻智能设备有限公司

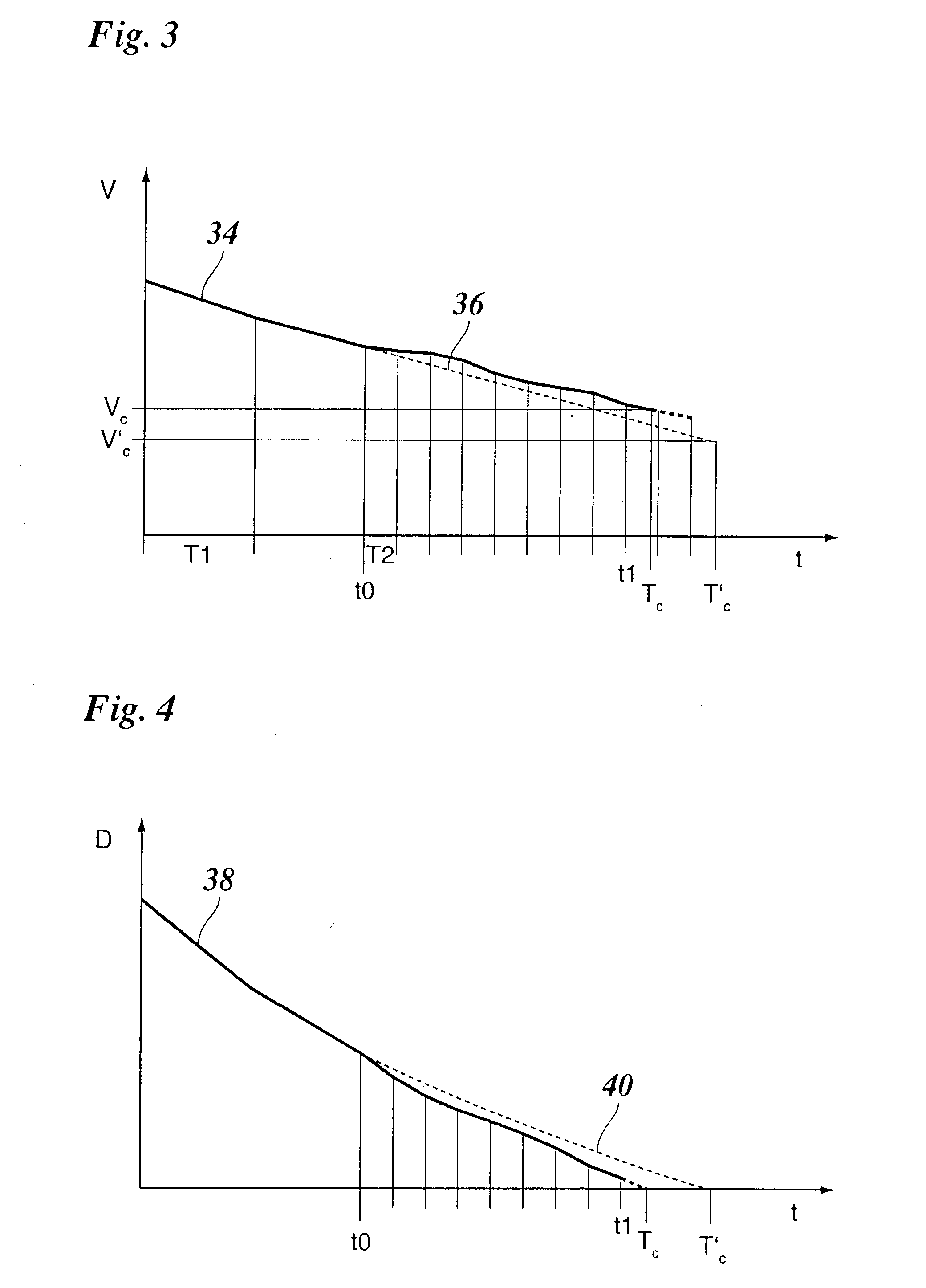

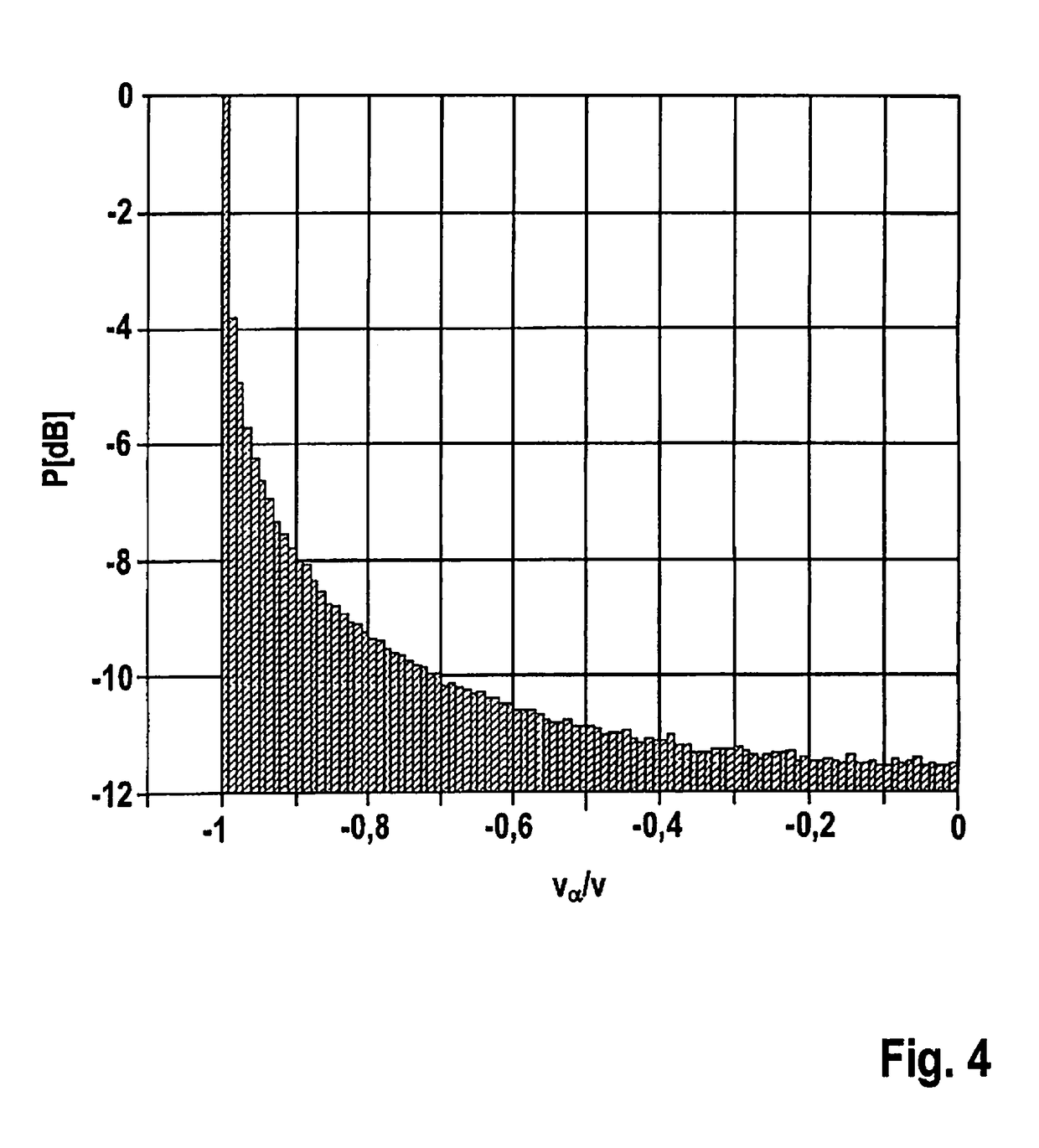

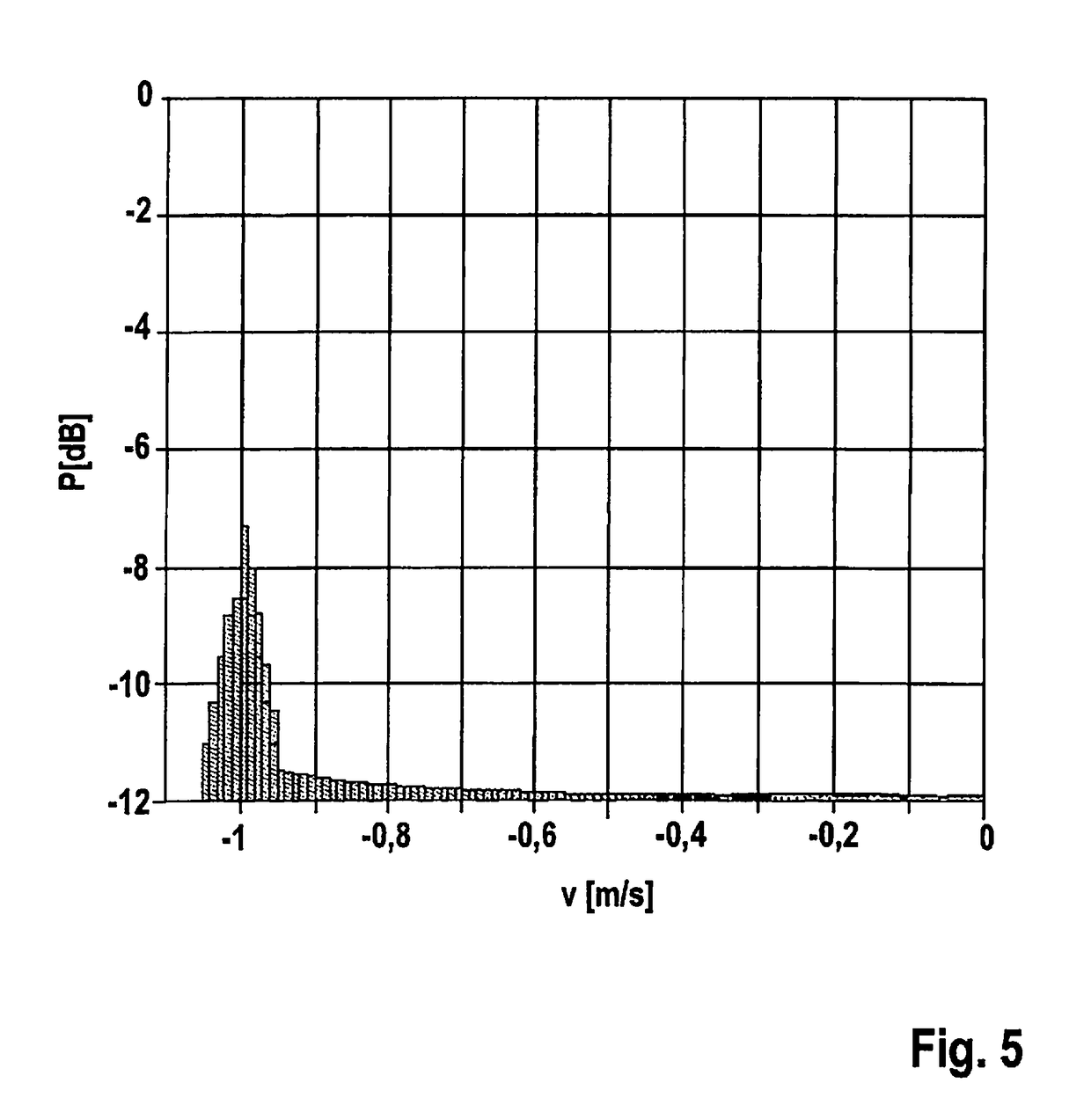

Fmcw radar sensor for motor vehicles

ActiveUS20180356511A1Simple and precise mannerHighly accurate mannerRadio wave reradiation/reflectionModulation patternRadar

An FMWC radar sensor for motor vehicles, having a high-frequency oscillator, which is developed to generate a frequency-modulated transmit signal that has a periodically repeating series of modulation sequences having different modulation patterns, and having an evaluation device for evaluating the received radar echo according to the FMCW principle, wherein the series of the modulation sequences includes a special class of modulation sequences whose duration is longer than that of any other modulation sequence not belonging to this class and whose frequency swing is smaller than that of any other modulation sequence, and the evaluation device is developed to carry out a measurement of the ego velocity of the vehicle on the basis of a radar echo that is received from non-moving objects during the modulation sequences that belong to the special class.

Owner:ROBERT BOSCH GMBH

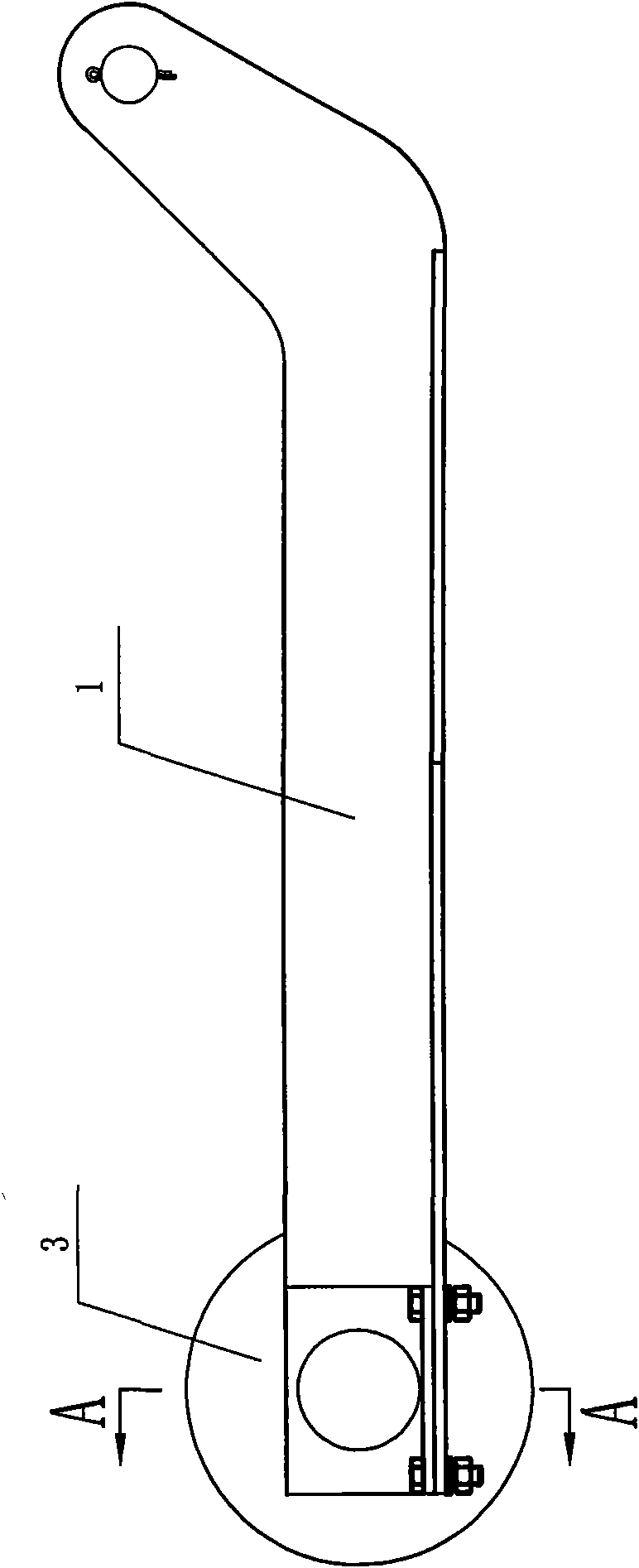

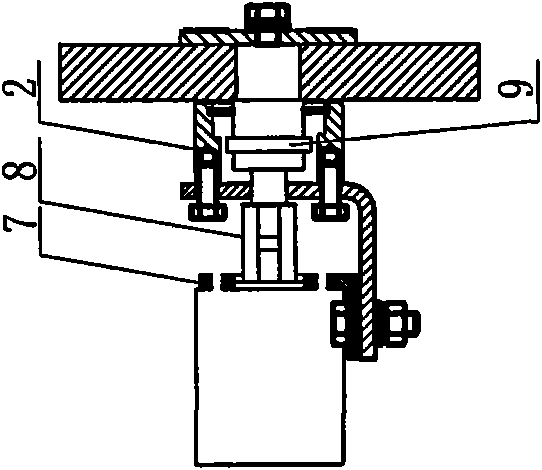

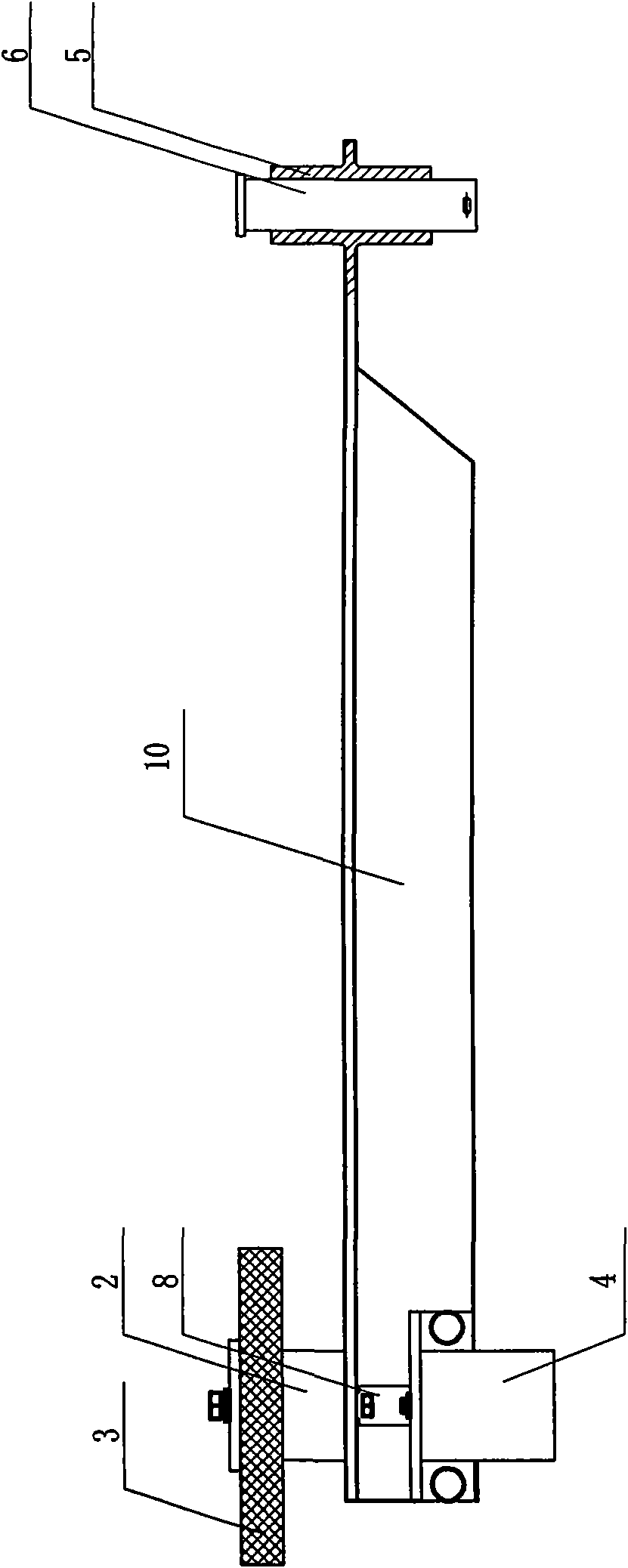

Locomotive axle end structure on which six-channel Hall speed sensor can be additionally mounted

ActiveCN106218321ASolve the problem that it cannot be installed on the axle end of the locomotiveOvercome inherent shortcomingsAxle unitsDevices using electric/magnetic meansEngineering

A locomotive axle end structure on which a six-channel Hall speed sensor can be additionally mounted comprises an axle, an axle end gland, a gear plate, a front cover and a back cover. A through hole used for positioning the gear plate is distributed in the middle of the axle end gland, an axle positioning hole in which an axle is positioned is bored in the back of the axle end gland, and the axle end gland and the axle are fixed together; a square hole allowing the installation of a square falcon component is formed in the center of the front of the gear plate, the center of the back of the gear plate is arranged to extend to form a section of positioning shaft for the axle end gland, and the positioning shaft is matched with the positioning through hole in the gear plate on the axle end gland, to position the gear plate; mounting holes for the six-channel Hall speed sensor are formed in the side of the front cover, and the distance between the mounting surface of the mounting holes and the central axis of the front cover not only guarantees the effective induction distance of the six-channel Hall speed sensor, but also can avoid the interference of the sensor and the gear plate; the square falcon component of the six-channel Hall speed sensor is fixed into the square hole of the gear plate when the six-channel Hall speed sensor is fixed on the front of the front cover.

Owner:NINGBO CRRC TIMES TRANSDUCER TECH CO LTD

Control method of elevator speed limiter

Owner:HEFEI UNIV OF TECH

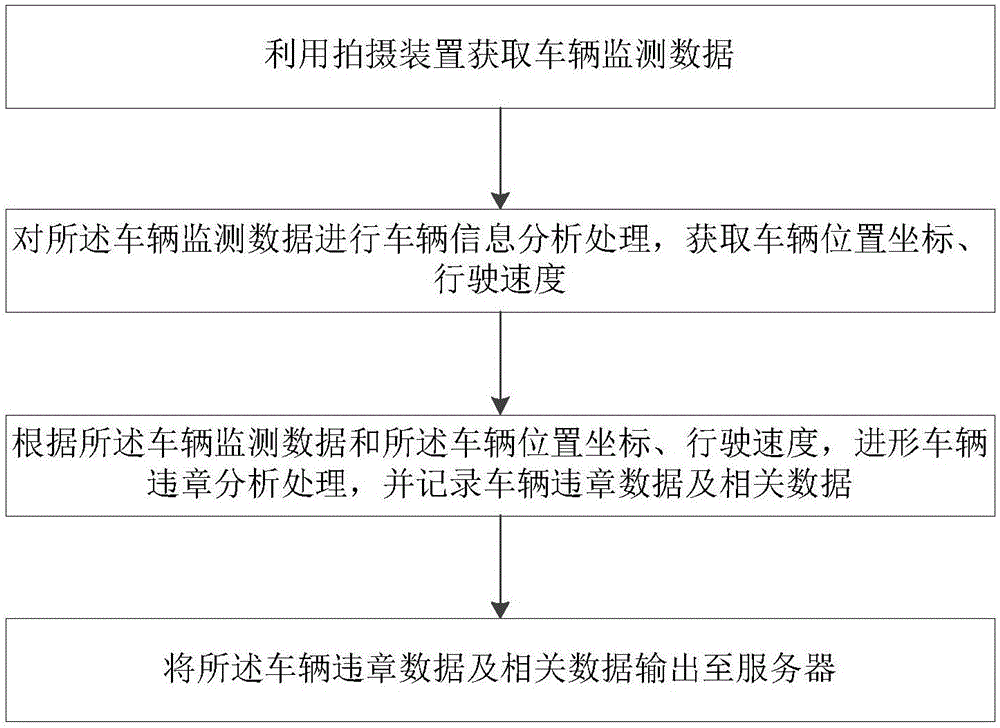

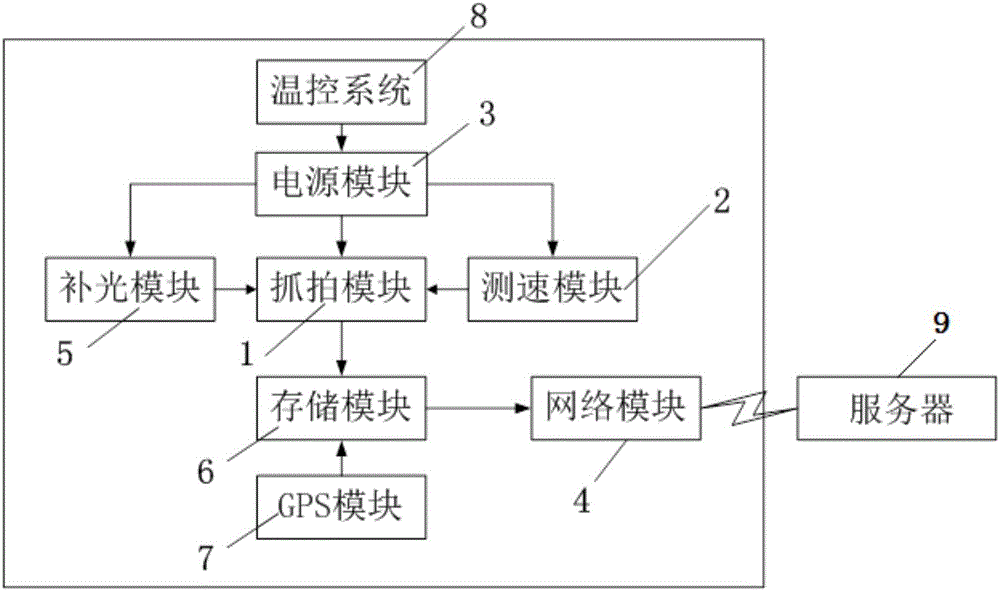

Method and device for detecting rule and regulation-breaking behaviors of vehicles

InactiveCN106384516AIncrease driving speedHigh Accuracy Travel SpeedDetection of traffic movementHardware structureInformation analysis

The invention relates to a method and device for detecting the rule and regulation-breaking behaviors of vehicles. The method includes the following steps that: the monitoring data of the vehicles are acquired by using a photographing device; vehicle information analysis processing is performed on the monitoring data of the vehicles, so that the position coordinates and running speed of the vehicles can be acquired; and rule and regulation breaking analysis processing is performed on the vehicles according to the monitoring data of the vehicles as well as the position coordinates and running speed of the vehicles, and the rule and regulation breaking data and related data of the vehicles are recorded; and the rule and regulation breaking data and related data of the vehicles are outputted to a server. According to the method and device of the invention, the vehicles of a plurality of lanes are detected in real time, high-accuracy vehicle running speed is provided, and speed measurement is accurate and is not affected by the weather and environment; and the internal hardware structure of the device is integrated, so that external connection interfaces of the device can be decreased, and the engineering construction of the device is simple and convenient, and the installation modes of the device are diversified.

Owner:BEIJING SIGNALWAY TECH

Belt speed measuring device

InactiveCN101526546AAuto Adjust ContactCan detect real speedLinear/angular speed measurementWeighing apparatus detailsCouplingBelt speed

The invention disclose a belt speed measuring device, which comprises a main shaft; wherein, the main shaft is provided with a coupling which is flexible connection, one side of the coupling is connected with a roller and the other side is provided with a speed measuring coder, the main shaft is also provided with a sleeve, the interior of which is provided with a pin roll, the surface of the roller is provided with a flower groove or an adhesive layer; the belt speed measuring device is mainly applied in the positions of an electronic belt scale, a constant weight feeder and the like which need real time speed measuring, can automatically adjust the slope angle with the belt, depends on self gravity to contact with the belt; the roller is provided with the flower groove or the adhesive layer, which can effectively prevent slipping and detects the true velocity of the belt; the flexible connection is adopted between the speed measuring coder and the roller, which guarantees the speed measuring coder not to be damaged, simultaneously ensures the synchronization with the roller and the accuracy and reliability of the speed measuring; the belt speed measuring device outputs standard pulse signals, can be switched in different control instruments or systems, is convenient to be installed, has high cost performance and accurate speed measuring and parts thereof do not need to be maintained.

Owner:HENAN FENGBO AUTOMATION CO LTD

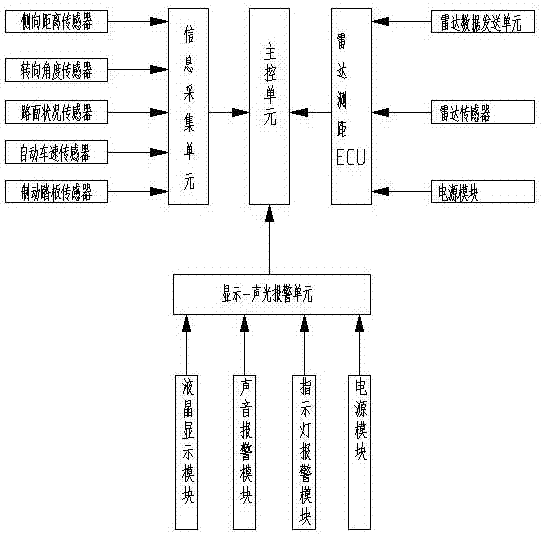

Vehicle braking rear-end collision pre-warning method based on CAN bus

InactiveCN107985297AFull reaction timeImprove practicalityElectric/fluid circuitBrake safety systemsCommunication interfaceRear-end collision

The invention discloses a vehicle braking rear-end collision pre-warning method based on a CAN bus. In the driving of vehicles in China, a driver carries out the response in dependence on observing the circumstance of a front vehicle only, but the driver has the response time. The method comprises the following steps: (1) measuring a distance and a relative speed from a front target object in realtime by a radar sensor installed on a front bumper of the vehicle; (2) measuring vehicle signals by an automatic vehicle speed sensor, a lateral distance sensor, a steering angle sensor, a pavement condition sensor and a brake pedal sensor which are installed on the vehicle and sending to an information collecting unit; (3) transmitting the processed signal measured by the radar sensor and the signals in the information collecting unit to a main control unit through a CAN bus communication interface; and (4) according to the obtained data, judging the driving safety by the main control unit,and sending to a displaying-sound-light alarm unit, displaying the speed and distance and alarming in real time. The method is used for the vehicle braking rear-end collision pre-warning based on theCAN bus.

Owner:NORTHEAST FORESTRY UNIVERSITY

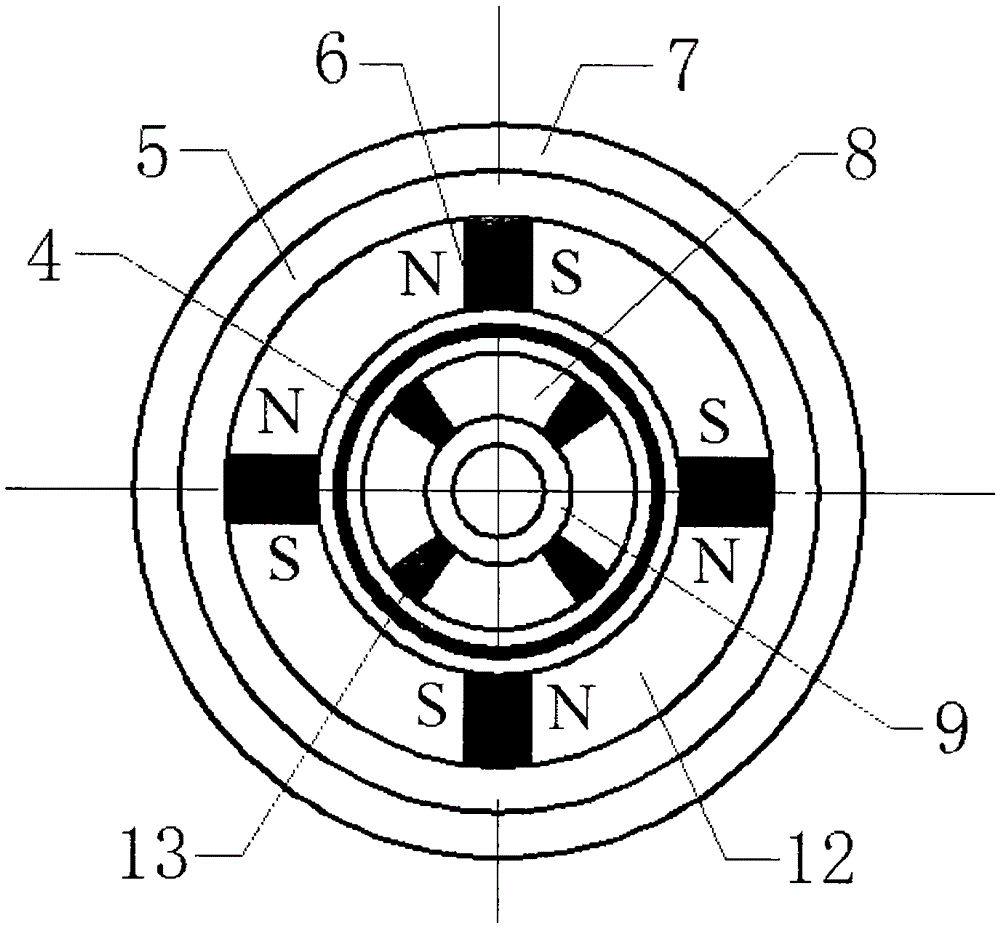

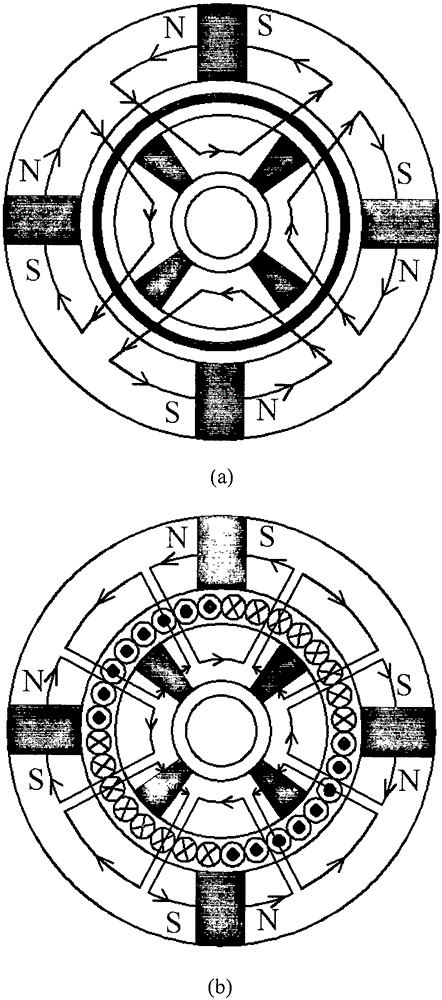

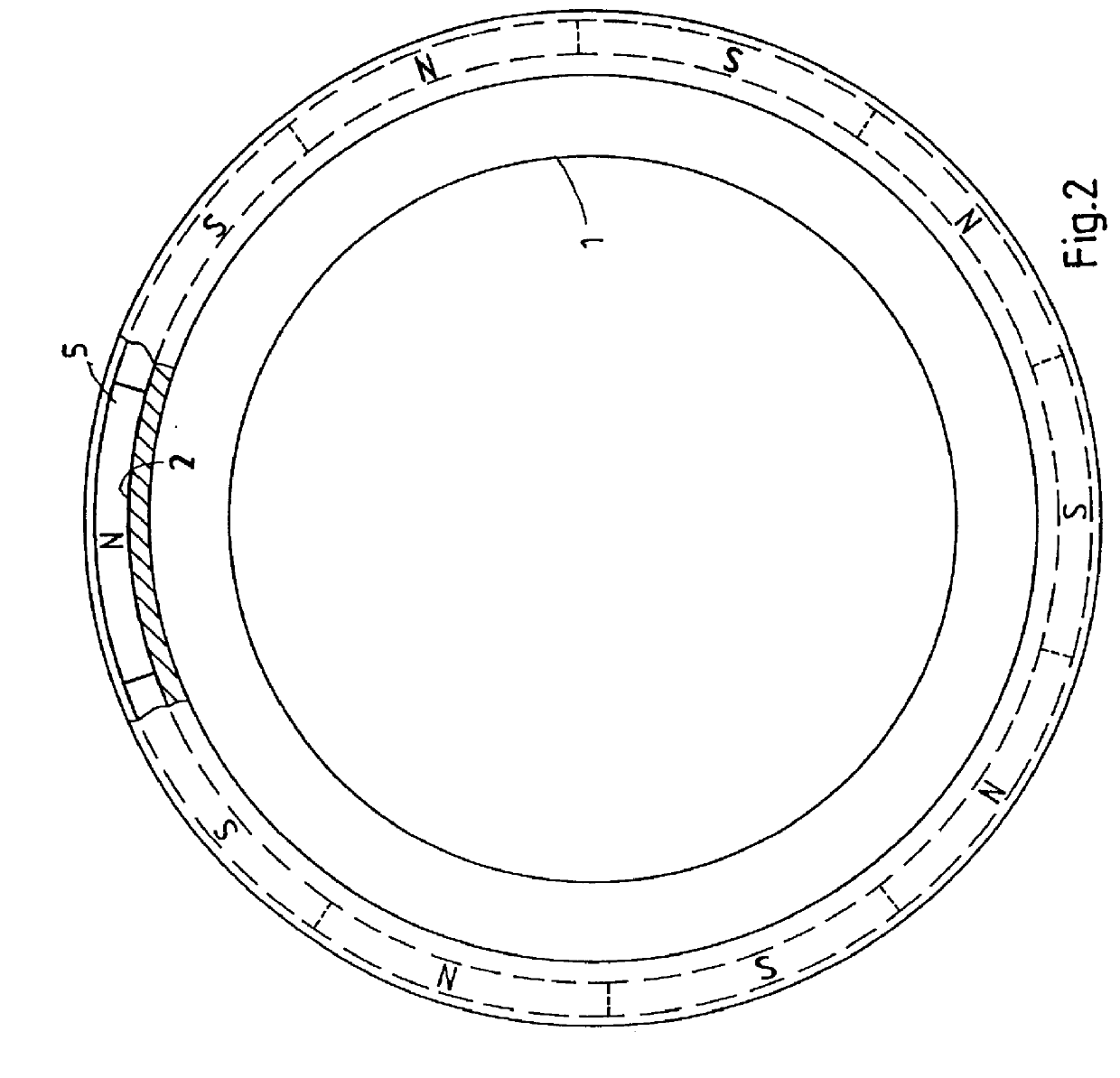

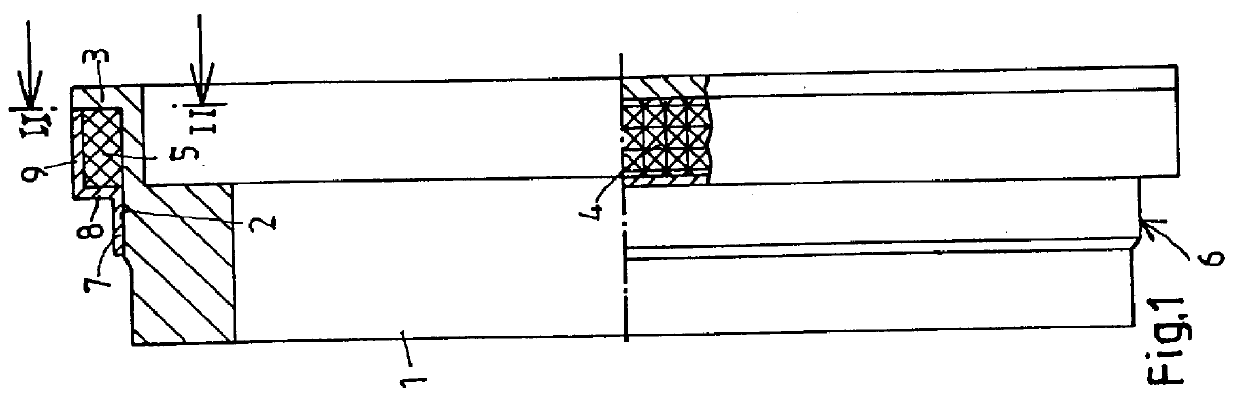

Magnetic pole rotor for revolution counting

InactiveUS6087748AAccurate speed measurementMagnetic circuit characterised by insulating materialsDevices using electric/magnetic meansMagnetic polesOperating temperature

PCT No. PCT / EP97 / 00152 Sec. 371 Date Jun. 2, 1998 Sec. 102(e) Date Jun. 2, 1998 PCT Filed Jan. 15, 1997 PCT Pub. No. WO97 / 26543 PCT Pub. Date Jul. 24, 1997A magnetic pole rotor having a plurality of magnetic poles which are arranged on a base ring. The technical problem is to construct the magnetic pole gear such that a non-rotational connection to the shaft remains assured, even at high operating temperatures. A plastics ring (5) surrounding the magnetic poles is pressed onto a cylindrical surface (2) of the base ring (1) and a cage ring (6) covers the plastics ring (5).

Owner:DONNER MICHAEL

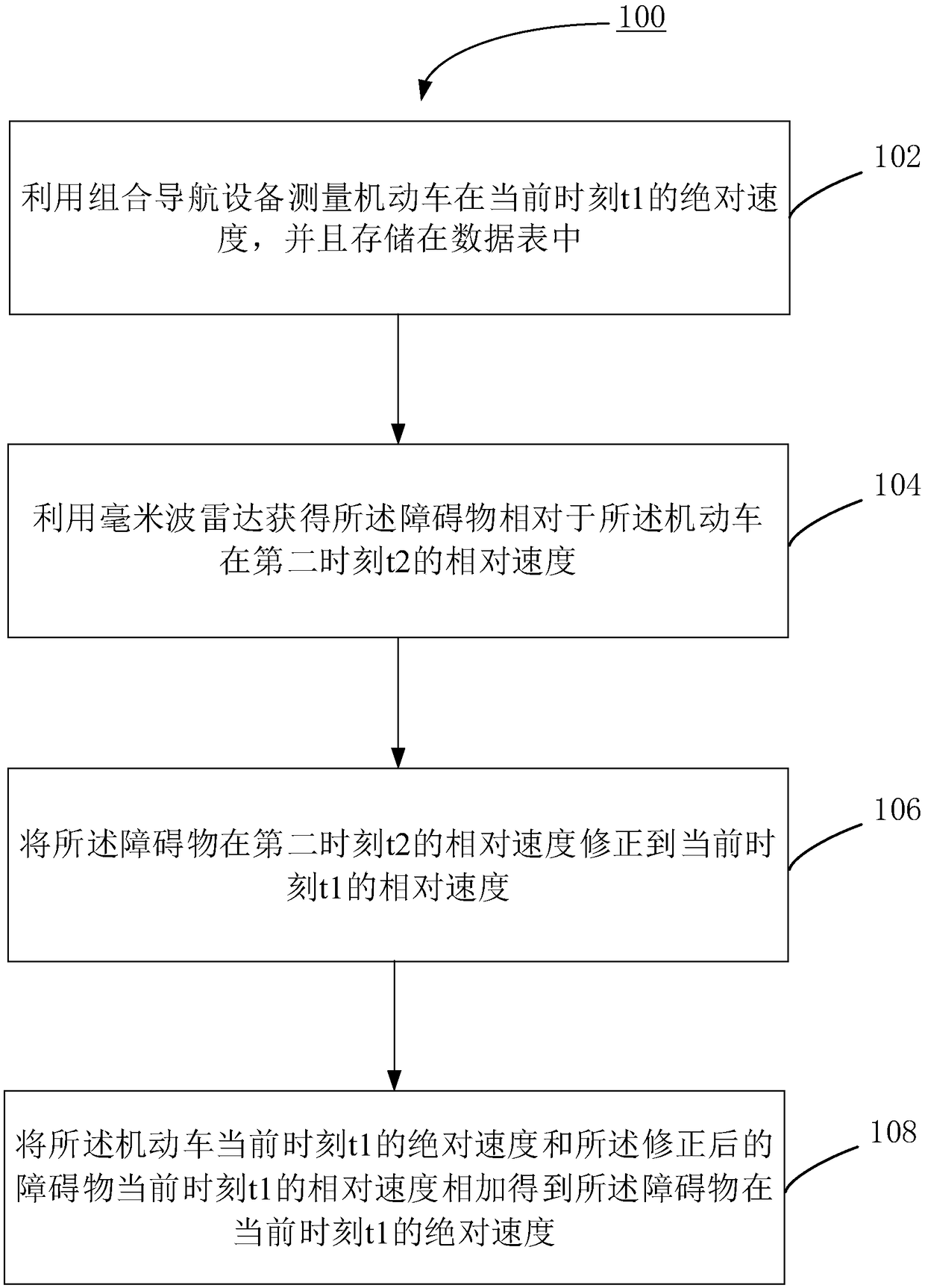

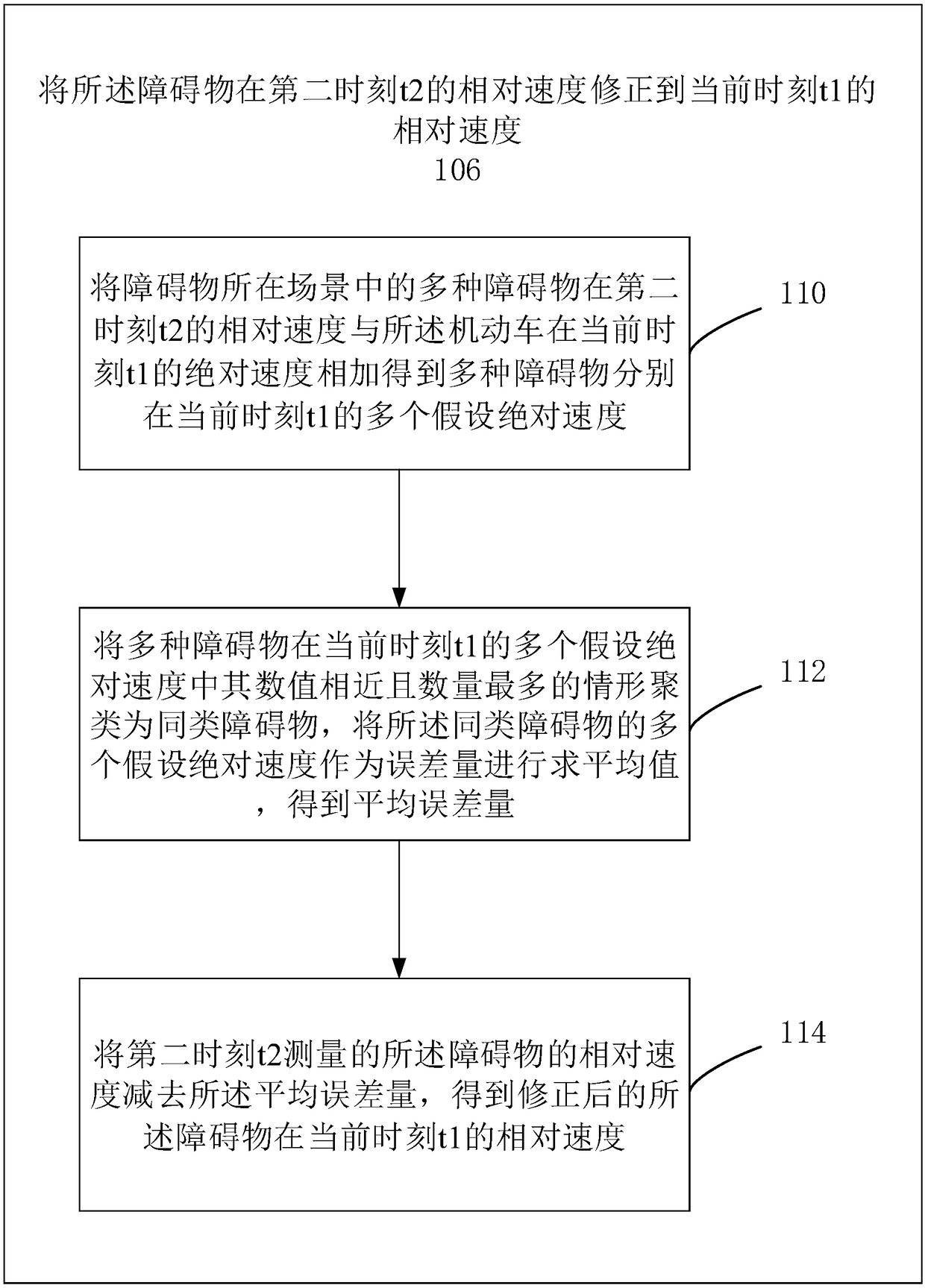

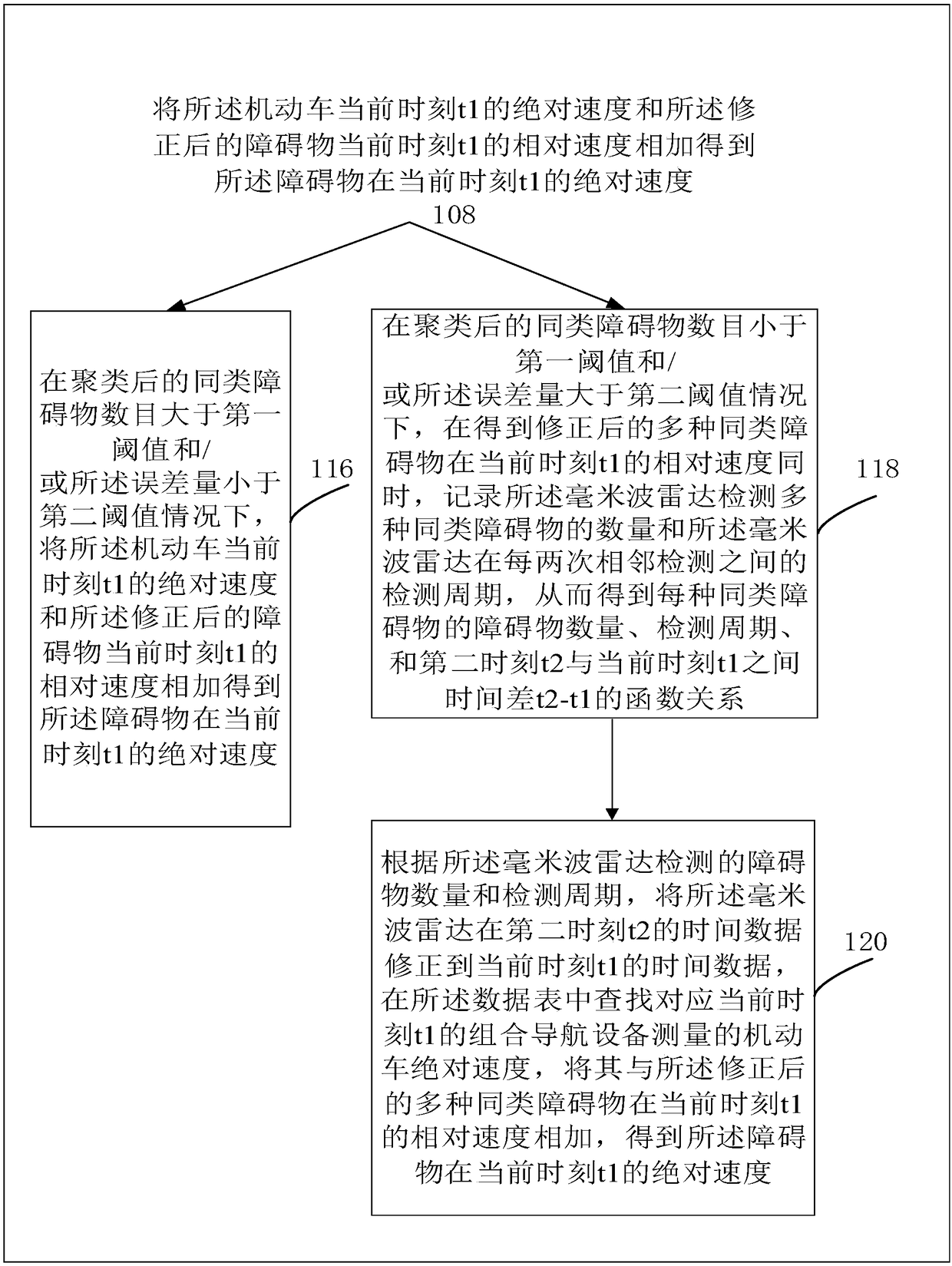

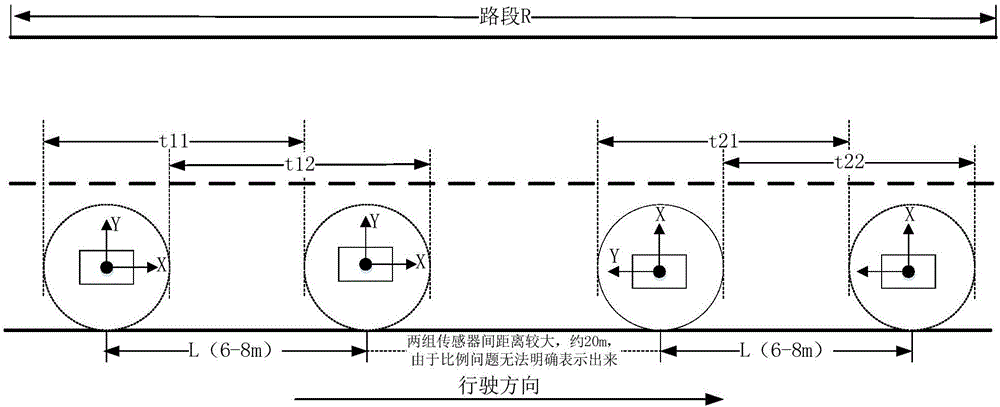

Estimation method and estimation system for absolute speed of obstacle, computer equipment and storage medium

ActiveCN109143242AAccurate measurementAccurate speed measurementRadio wave reradiation/reflectionEstimation methodsEngineering

Embodiments of the invention provide an estimation method and an estimation system for absolute speed of an obstacle, computer equipment and a storage medium. The estimation method for the absolute speed of the obstacle can include the following steps: measuring the absolute speed of a motor vehicle at a current time t1 by utilizing integrated navigation equipment, and storing the absolute speed in a data table; obtaining the relative speed of the obstacle relative to the motor vehicle at a second time t2 by utilizing a millimeter wave radar; correcting the relative speed at the second time t2to the relative speed at the current time t1; and adding the absolute speed of the motor vehicle at the current time t1 and the relative speed at the corrected current time t1 of the obstacle to obtain the absolute speed of the obstacle at the current time t1. By means of the technical solution of the method and the system, measurement of the speed of the obstacle is more accurate.

Owner:APOLLO INTELLIGENT DRIVING (BEIJING) TECHNOLOGY CO LTD

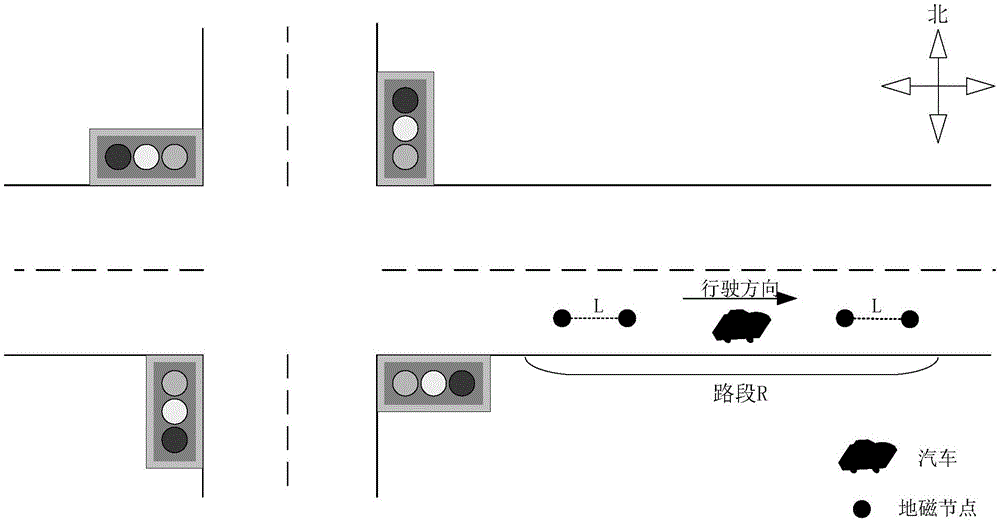

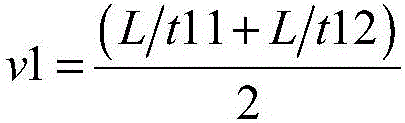

Intelligent traffic congestion drainage method based on geomagnetic information

InactiveCN106530759AHigh sensitivityAccurate speed measurementControlling traffic signalsTraffic congestionNormal conditions

The invention discloses an intelligent traffic congestion drainage method based on geomagnetic information. The method comprises the following steps: 1, measuring an average driving speed vR of an automobile in a road R by use of a geometric sensor; 2, sending the measured average vehicle speed vR in the road R to a signal lamp controller of an upstream crossroad through a wireless sensing network; and 3, assuming that a vehicle average driving speed on the road R in one day under a normal condition is v, the signal lamp controller adjusting a signal lamp of the upstream crossroad through comparing vR with v so as to realize traffic congestion drainage. According to the invention, the method can improve city traffic conditions and avoid traffic congestion and road obstruction, improves the pass capability and the operation efficiency of a road network and promotes coordinated development between city traffic and city construction.

Owner:NANJING UNIV OF SCI & TECH +1

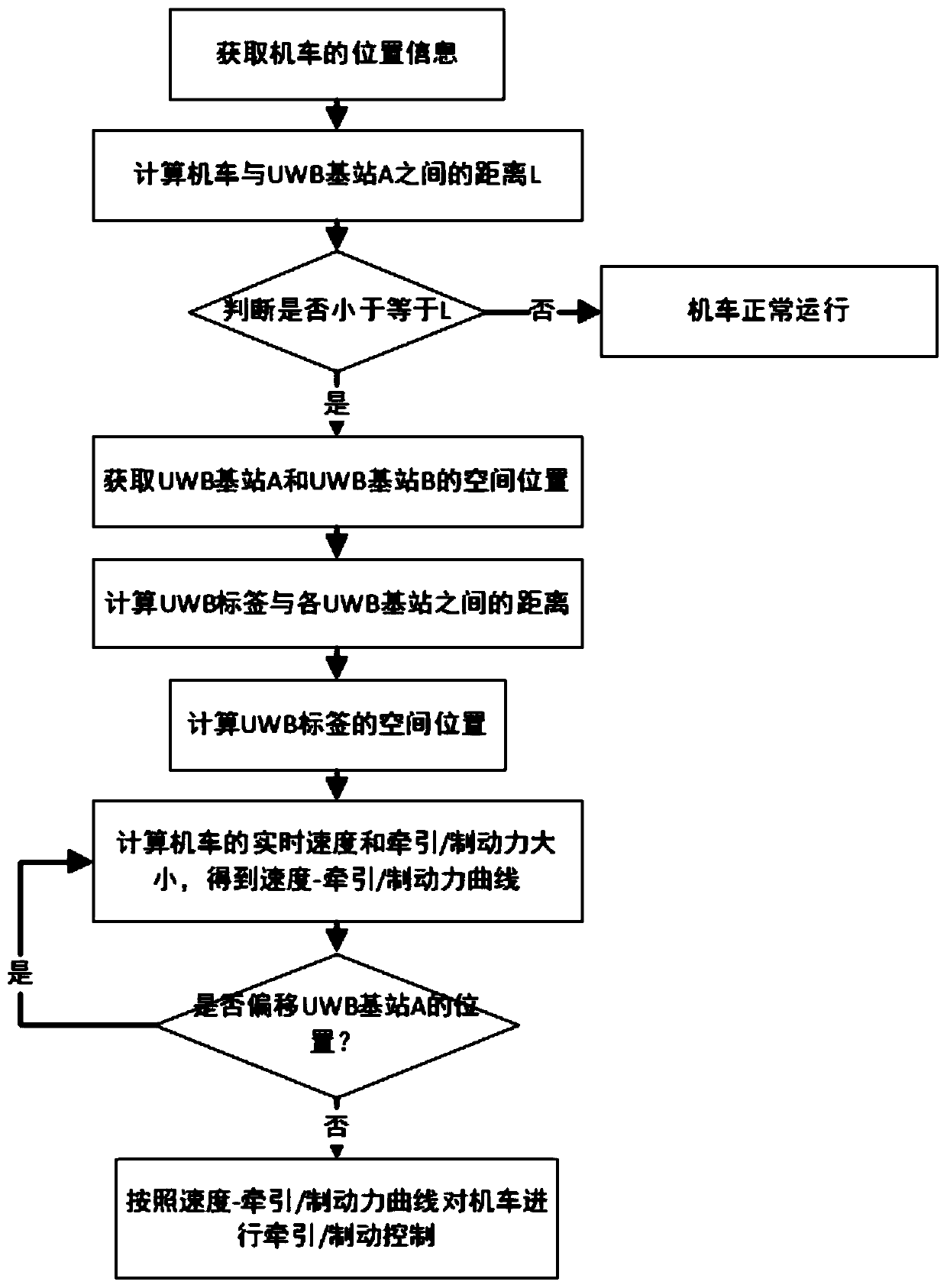

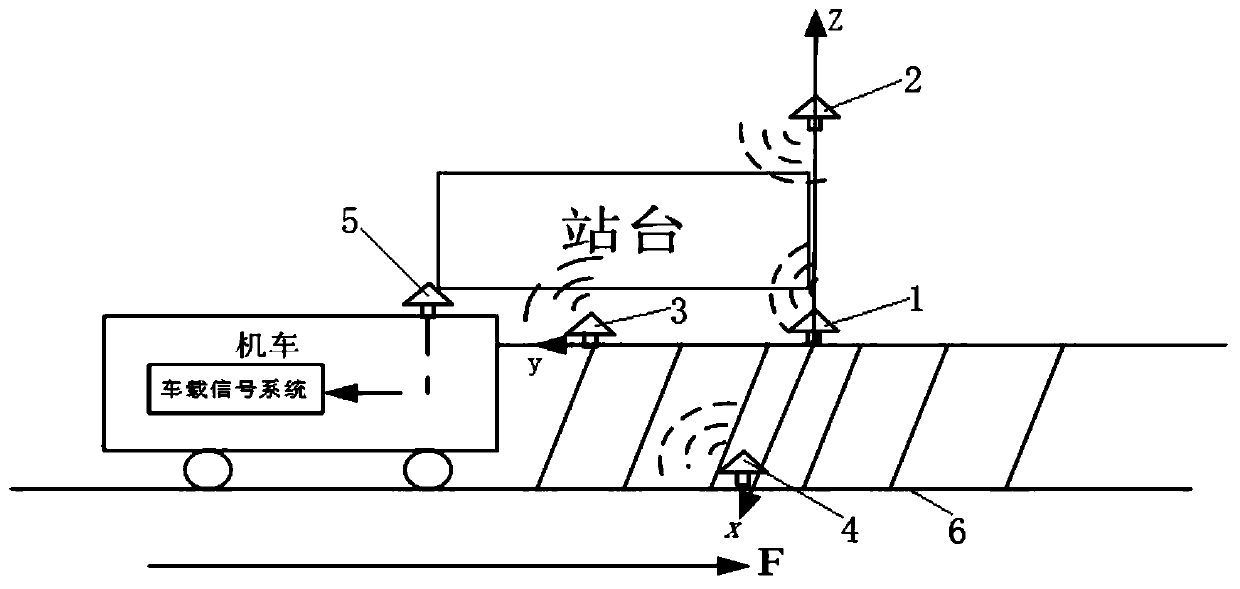

Locomotive benchmarking method and system based on UWB positioning

PendingCN111559412AAccurate parkingPrecise benchmarking and parkingPosition fixationDevices using time traversedSpeed measurementBrake control

The invention discloses a locomotive benchmarking method and system based on UWB positioning. According to position information of a UWB base stations and a real-time distance between a UWB label andeach UWB base station, the real-time spatial position of the UWB label under a WGS coordinate system or a three-dimensional coordinate system can be obtained. The real-time speed of a locomotive can be obtained according to a sampling period and the real-time spatial position of the UWB label, and finally a traction / braking force required for locomotive pull-in benchmarking is calculated accordingto the real-time spatial position of the UWB label and the real-time speed of the locomotive, so that traction / braking control over the locomotive is realized, and accurate benchmarking parking is realized; for locomotives, especially locomotives running on curved tracks, the benchmarking method can more accurately obtain the spatial position information of the UWB labels under a WGS coordinate system or a three-dimensional coordinate system, and more accurately realize positioning and speed measurement of the locomotives, thereby realizing one-time accurate benchmarking and parking of the locomotives.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Rear axle electric power drive for electric vehicles

The invention discloses a rear axle electrodynamic force drive device of an electric vehicle. The drive device comprises a reducer shell, wherein the reducer shell is provided with two supports, the two supports support a differential shell, a second driven gear is fixed on the differential shell, a transmission shaft is arranged in the differential shell, a first driven gear and a second drive gear are fixed on the periphery of the transmission shaft, the second drive gear is meshed with the second driven gear, the reducer shell is provided with an end face, a cavity is formed on the end face, a shaft hole is formed in the bottom of the cavity, one end of an alternating current motor stator core is connected with the end face, the other end of the alternating current motor stator core is connected with a rear end cover, the rear end cover, the alternating current motor stator core and the reducer shell are fixed through bolts, one end of a rotor shaft of an alternating current motor supports on the rear end cover, the other end of the rotor shaft of the alternating current motor penetrates through the shaft hole to support on the reducer shell, the first drive gear is fixed on the rotor shaft of the alternating current motor, and the first drive gear is meshed with the first driven gear. The electrodynamic force drive device realizes stepless speed regulation, shifting impact is eliminated, and the heat dissipation of a drive motor is ensured.

Owner:CHONGQING DONGBA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com