Full-automatic winding packer

A baler, fully automatic technology, applied in the direction of packaging, transportation and packaging, delivery of filamentous materials, etc., can solve the problems of low production efficiency and the inability of the winding baler to be fully automated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

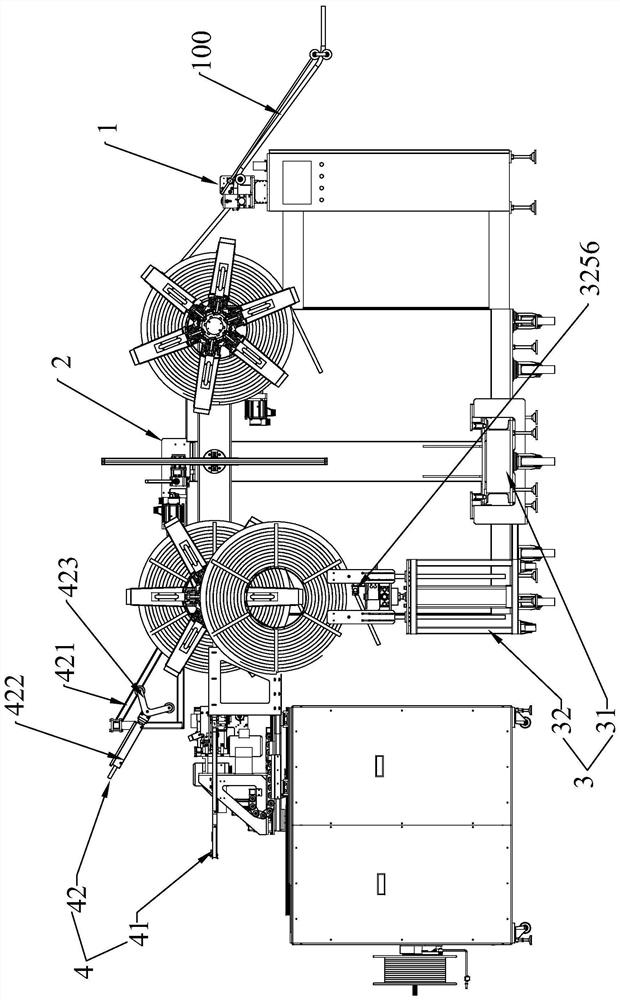

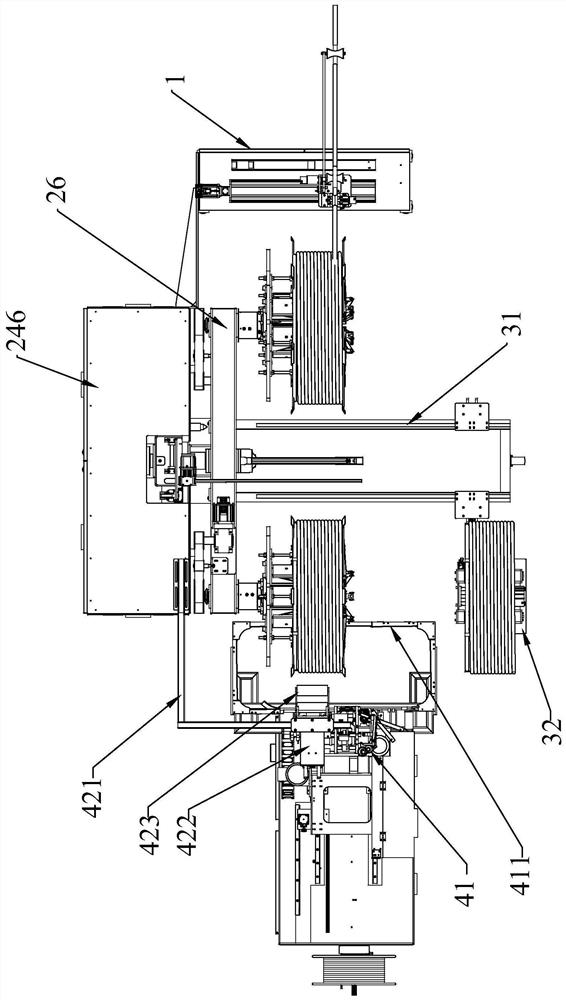

[0067] The preferred embodiment of the fully automatic winding packing machine of the present invention refers to Figure 1-13 As shown, it includes a sorting mechanism 1 , a winding mechanism 2 , an unwinding mechanism 3 and a packing mechanism 4 , and the winding mechanism 2 and the unwinding mechanism 3 are arranged between the sorting mechanism 1 and the packing mechanism 4 . It should be noted that, in actual production, the material 100 on the fully automatic winding and packing machine can be a wire or pipe made of plastic or other materials with a certain degree of softness and length, which can be wound and packed.

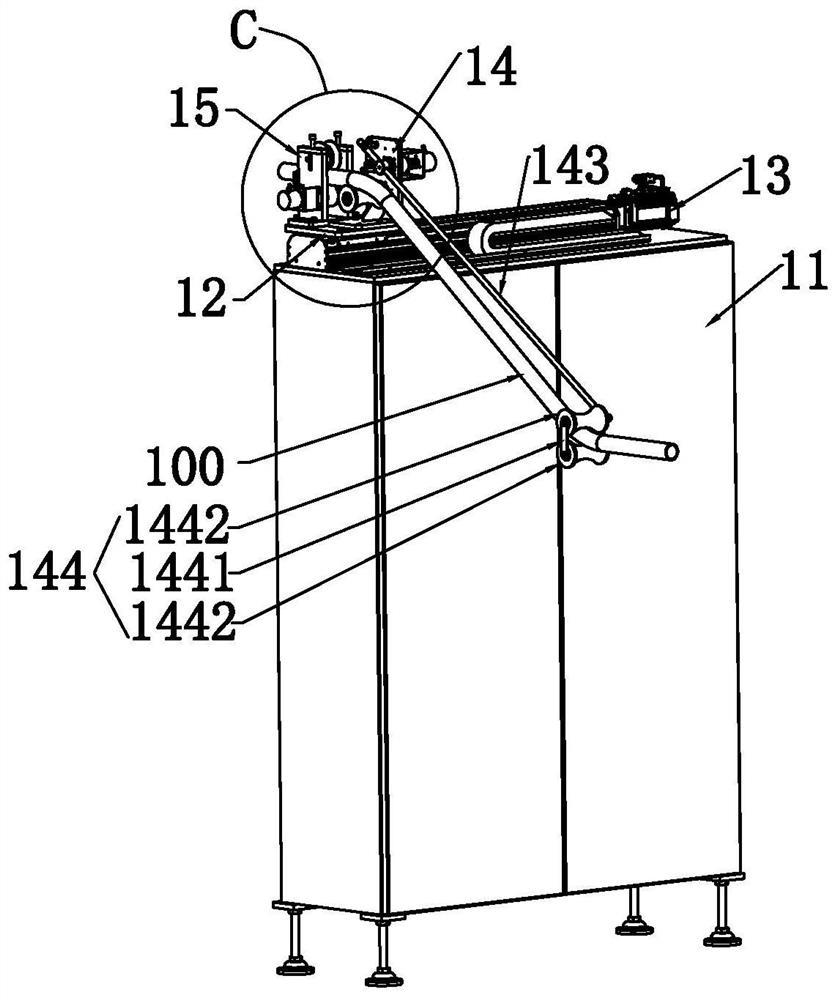

[0068] The sorting mechanism 1 in this embodiment refers to image 3 and 4 As shown, it includes a frame 11, which is sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com