Measuring device and method of rotating speed of brush motor

A technology for speed measurement and brushed motors, which is applied in measuring devices, linear/angular velocity measurement, speed/acceleration/impact measurement, etc. It can solve the problems of cumbersome, up-and-down fluctuations of motor speed and can not be measured, so as to improve production efficiency and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

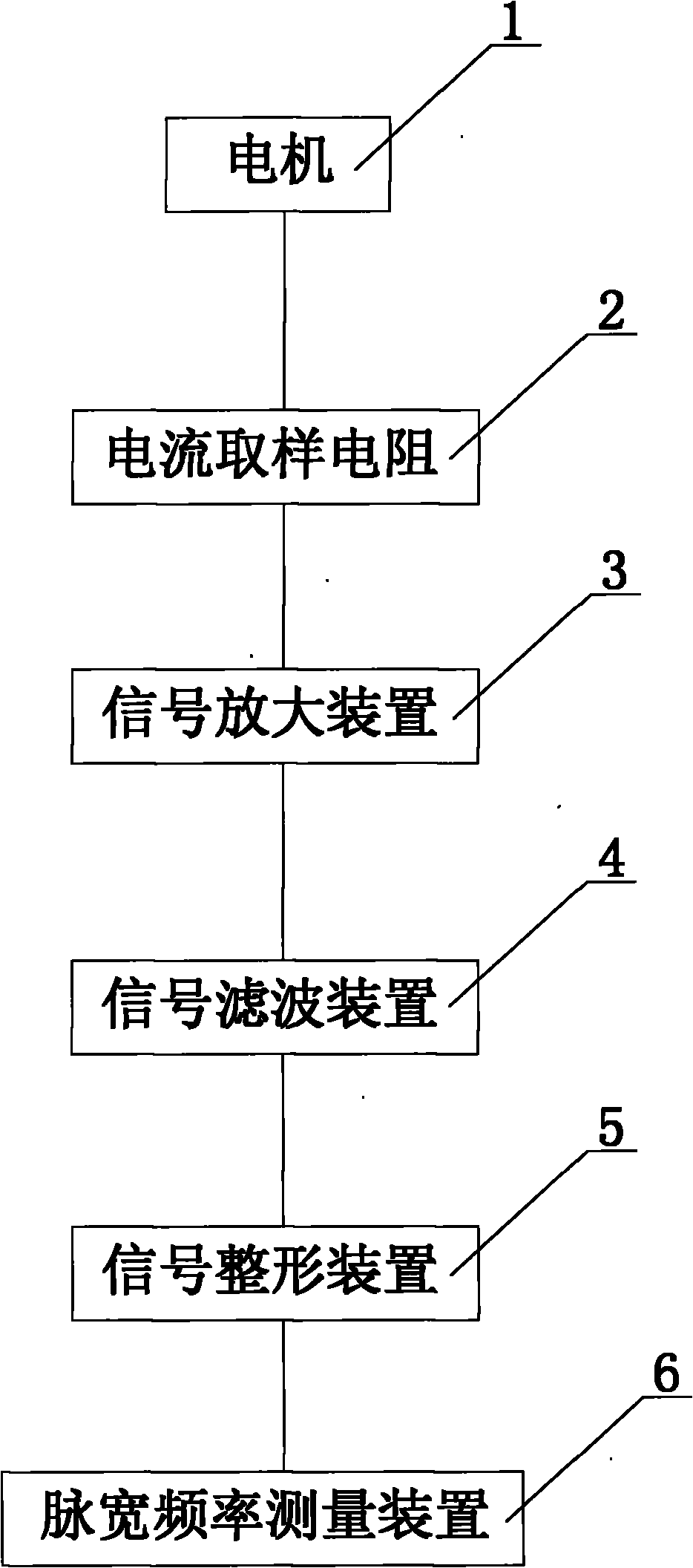

[0016] Such as figure 1 As shown, a brushed motor speed measurement device includes a current sampling resistor 2 connected to the motor 1, a signal amplifying device 3 connected to the current sampling resistor 2, a signal filtering device 4 connected to the signal amplifying device 3, and a signal filtering device A signal shaping device 5 connected to the device 4, and a pulse width frequency measuring device 6 connected to the signal shaping device 5. The signal filtering device 4 adopts a high-order band-pass switched capacitor filter.

[0017] A method for measuring the rotational speed of a brushed motor, comprising the following steps:

[0018] Step 1: When the commutator of motor 1 commutates, a motor current mutation pulse signal is generated, and the motor current mutation pulse signal is converted into a small voltage signal through the current sampling resistor 2;

[0019] Step 2: Amplify the tiny voltage signal into a large voltage signal through the signal amp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com