Rear axle electric power drive for electric vehicles

A driving device, electric power technology, applied in the control device, vehicle parts, transportation and packaging, etc., can solve the problems of power consumption, complex structure, large transmission loss, etc., to reduce space occupation, simple and compact structure, improve heat dissipation efficacy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

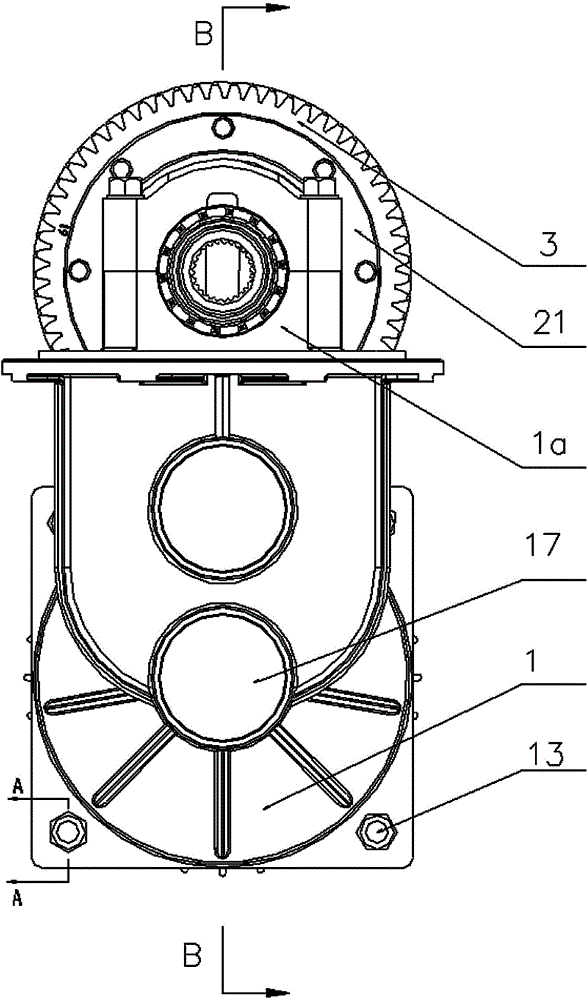

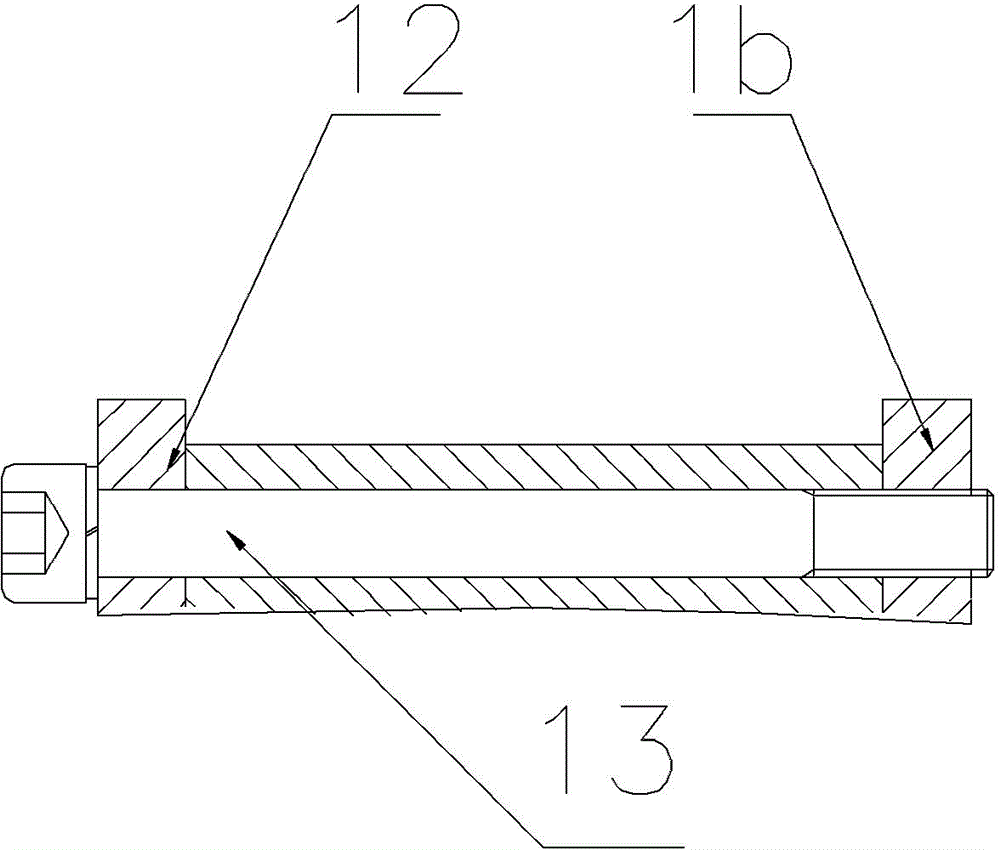

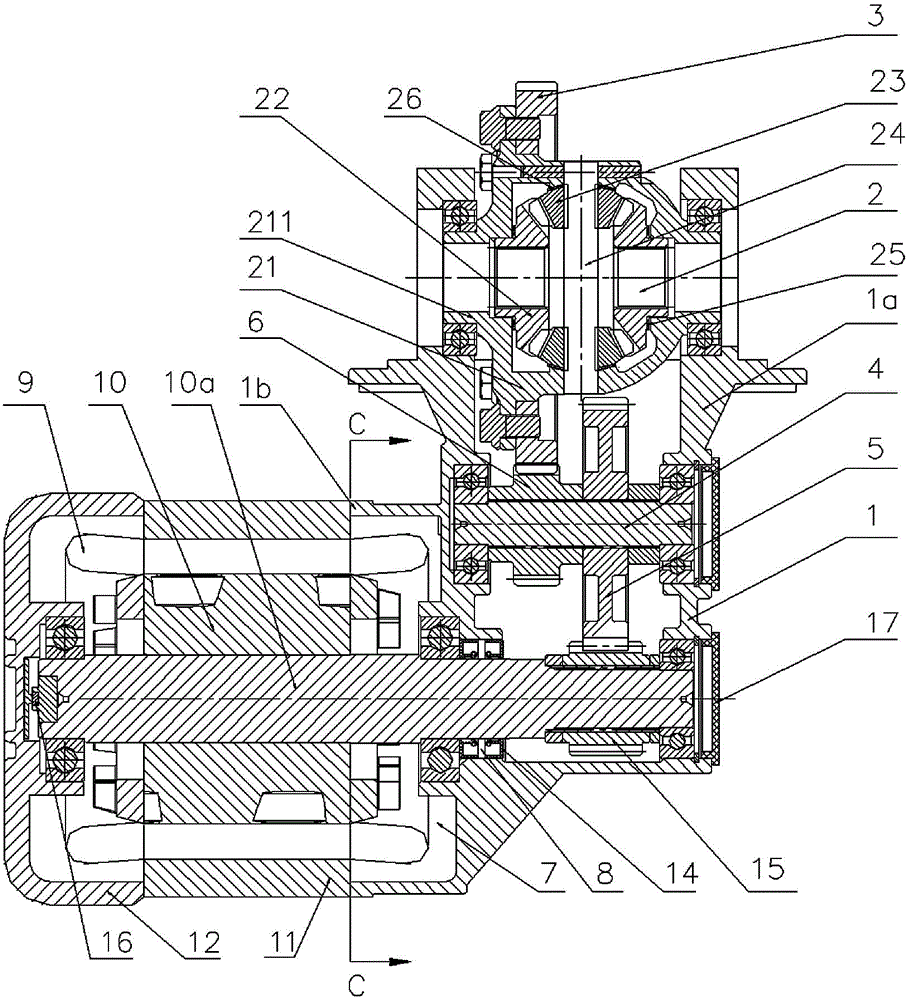

[0023] see Figure 1 ~ Figure 4 , is an embodiment of the rear axle electric power drive device of an electric vehicle, including a reducer housing 1, and the reducer housing 1 is provided with two supports 1a for installing the differential 2, and the rear end of the support There is a flange for fixed connection with the rear axle, and the two supports are integrally cast with the reducer housing. The two supports are symmetrically located on the left and right sides of one end of the reducer housing, the differential 2 is located between the two supports 1a, and the case of the differential 2 is rotatably supported on the two supports 1a.

[0024] The reducer housing has a cavity for installing the reducer, the second driven gear 3 is circumferentially fixed on the differential 2 housing, and the second driven gear can be bolted, riveted or welded to the differential On the housing, in this embodiment, the second driven gear is bolted to the reducer housing for easy mainte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com