Rotational speed sensor device

A technology of speed sensor and detection sensor, applied in the field of speed sensor device and double row rolling bearing, can solve the problem of not considering the temperature measurement of double row rolling bearing 1, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

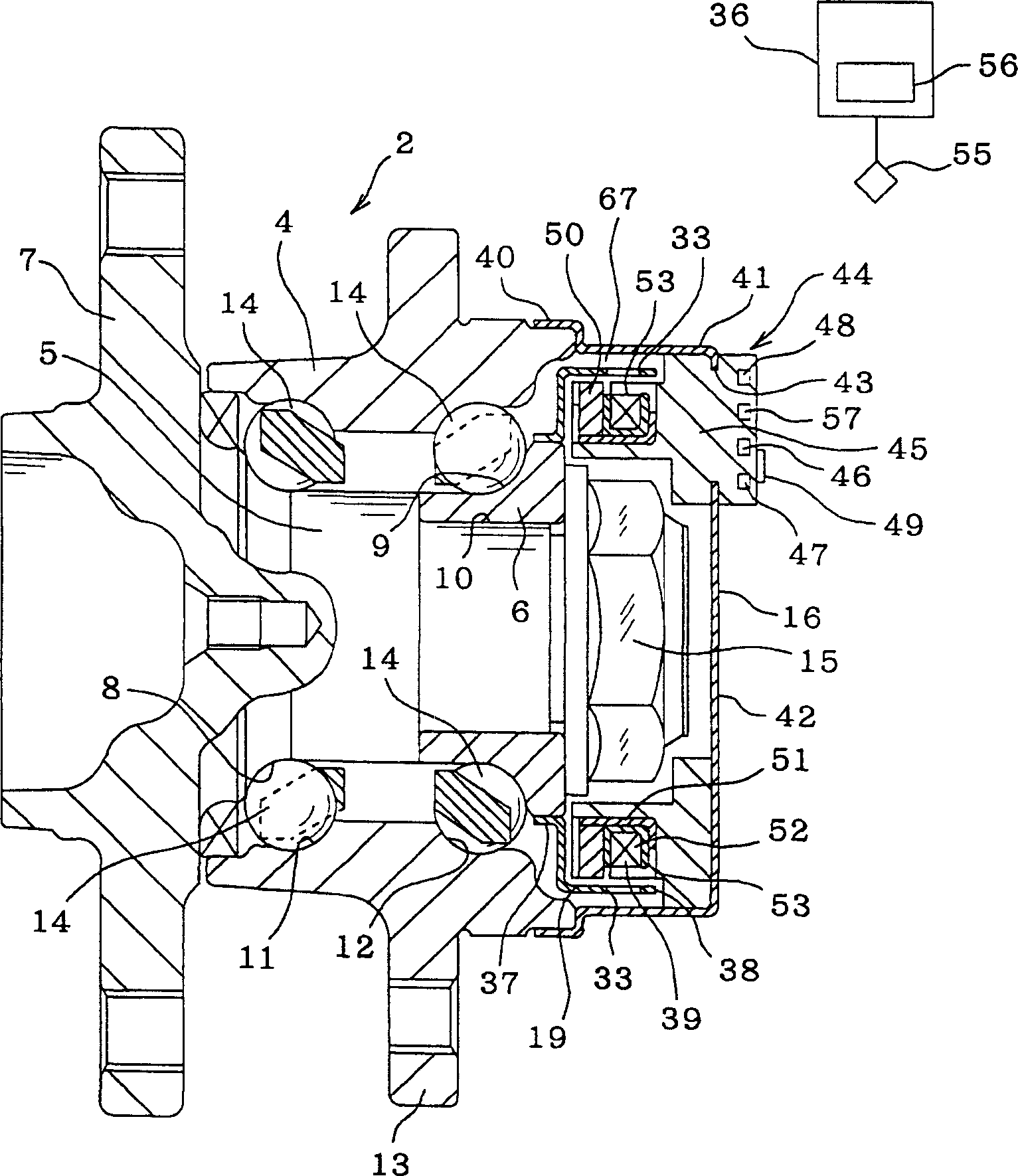

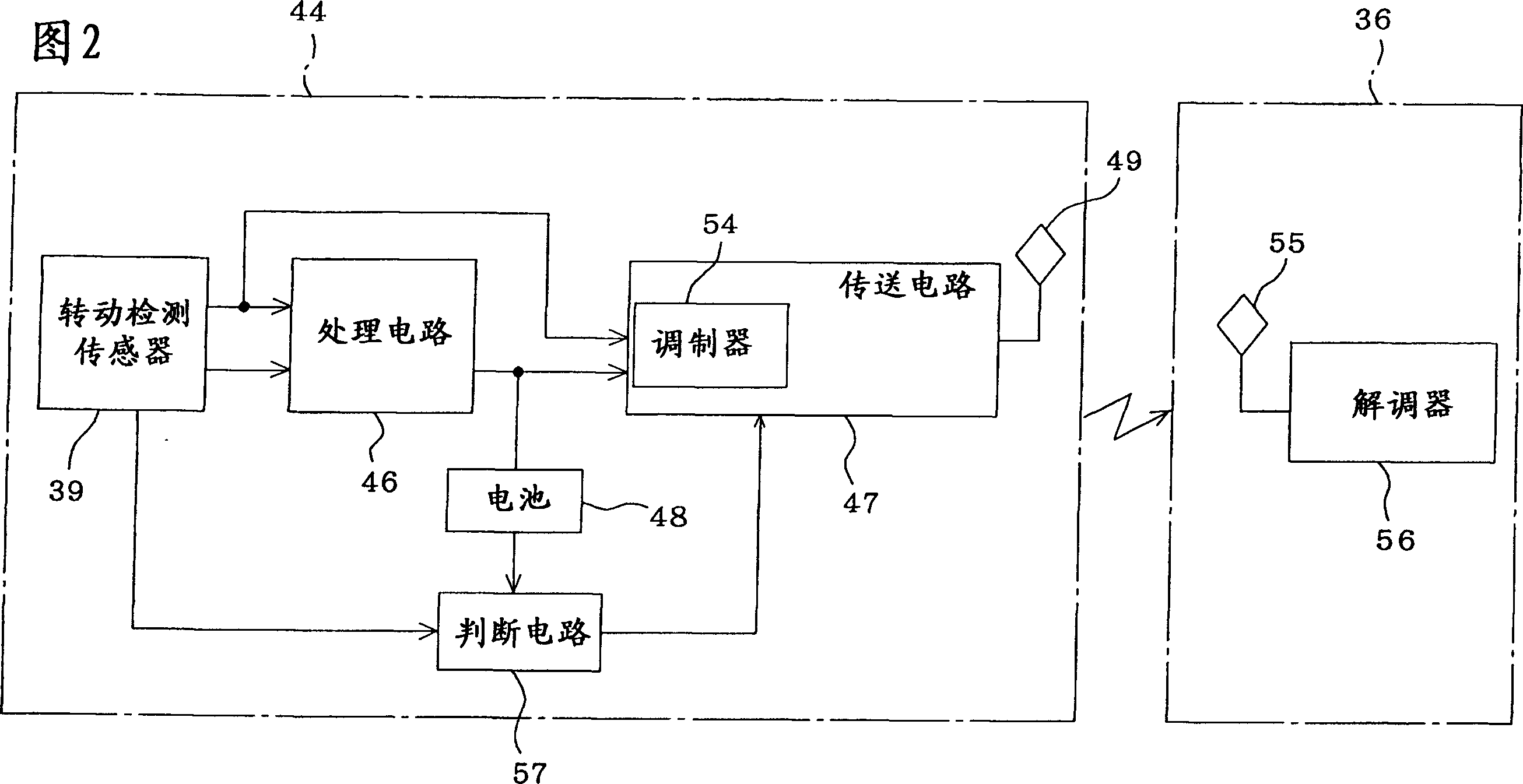

[0079] Similar to the conventional rotational speed sensor device as described above, the rotational speed sensor device of the present invention includes an encoder supported by a rotating sleeve for supporting a rolling bearing unit of a wheel concentric with the rotating sleeve so that the characteristic of the detected part or the encoder Alternating in the circumferential direction, and a rotation detection sensor supported by a non-rotating part so that its detection part surface faces the detected part or the encoder. The detection signal of the rotation detection sensor is sent to the controller installed on the chassis side by wireless transmission.

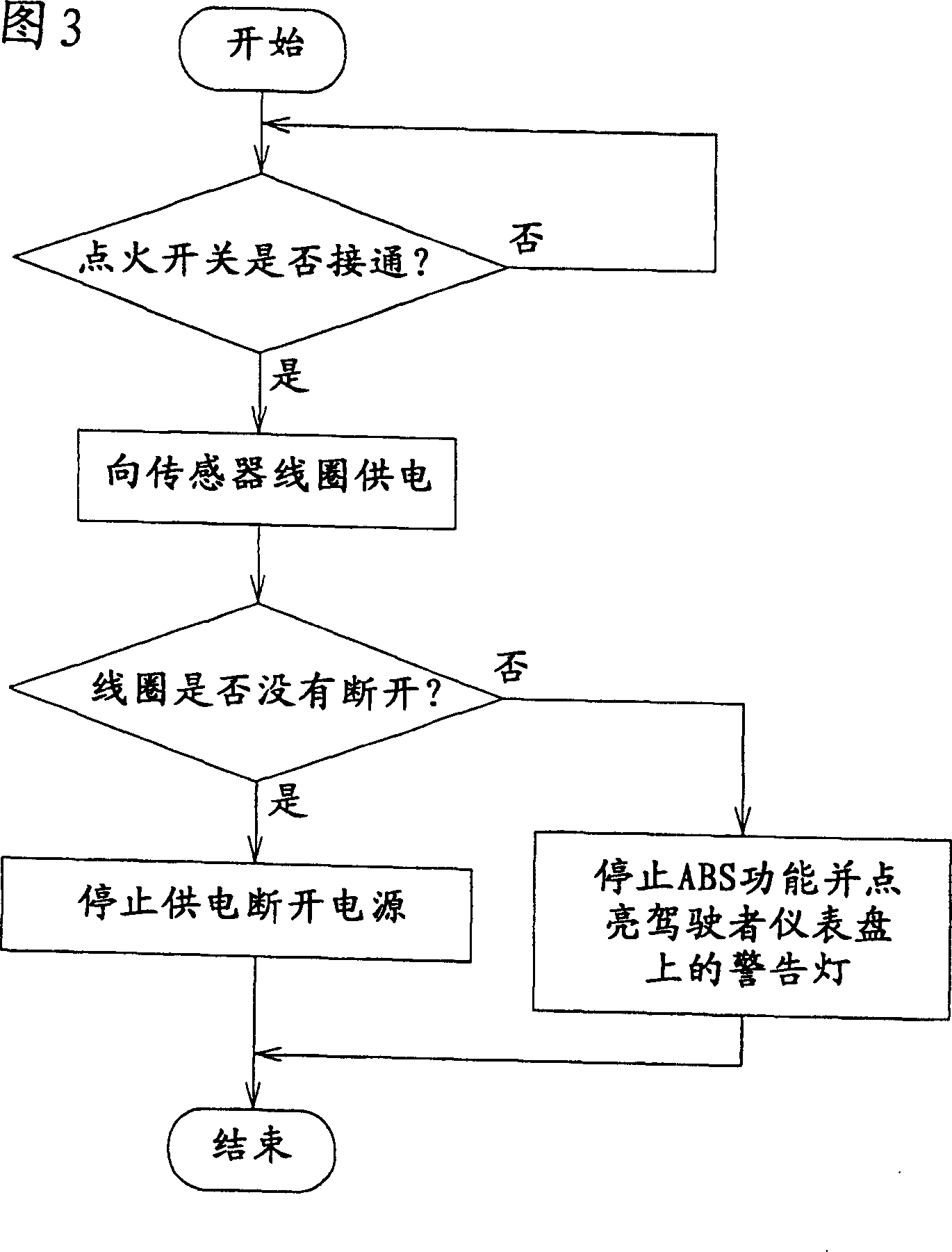

[0080] In particular, the rotational speed sensor device according to the present invention is equipped with a self-diagnostic circuit to determine whether there is any problem or abnormality in detecting the rotational speed.

[0081] Using the rotational speed sensor of the present invention, the function of detecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com