Patents

Literature

31results about How to "Precise measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for measuring in-situ stress of rock using thermal crack

InactiveUS20090070043A1Precise measurementEasily measureForce measurementTorque measurementCrazingEnvironmental geology

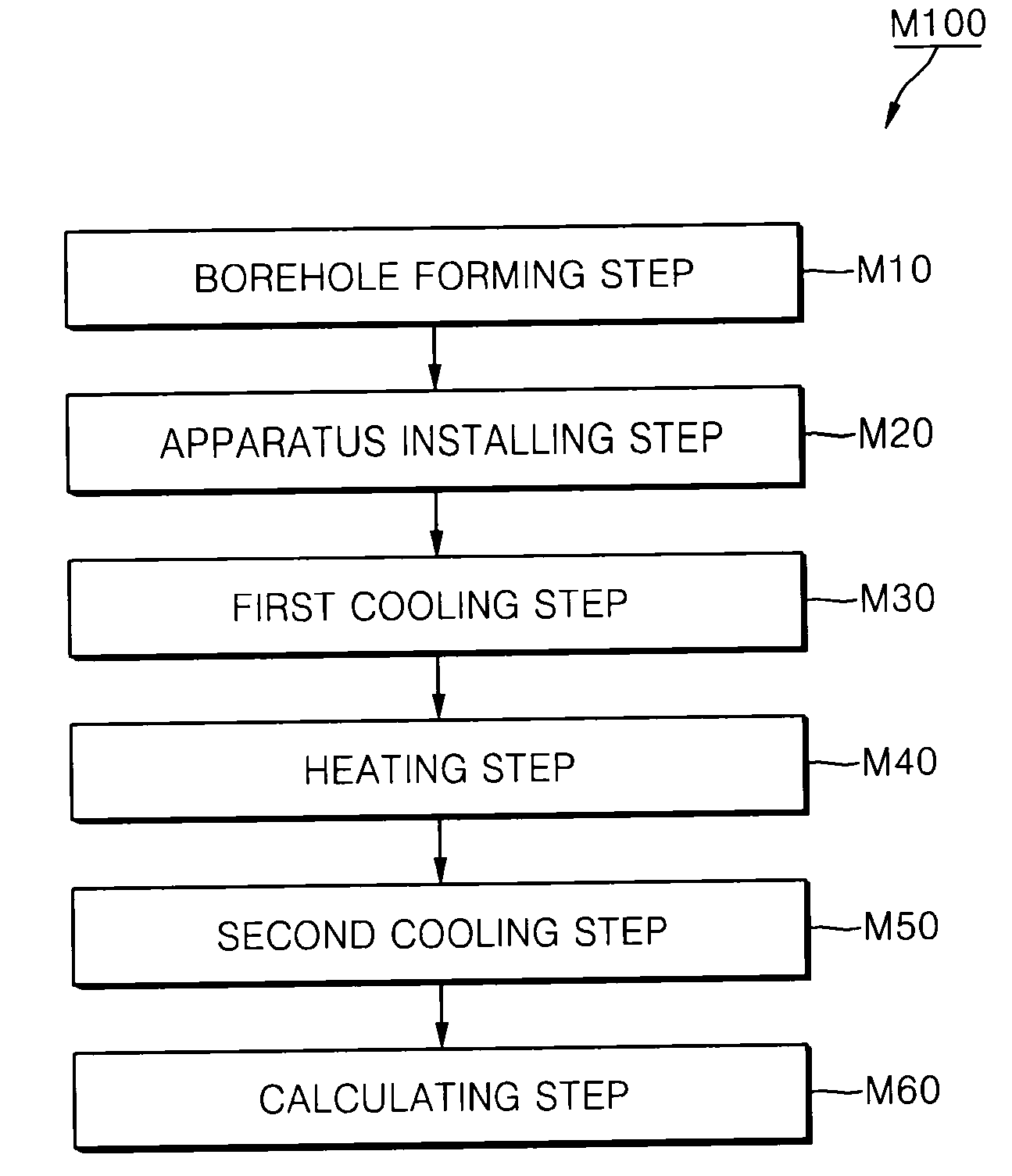

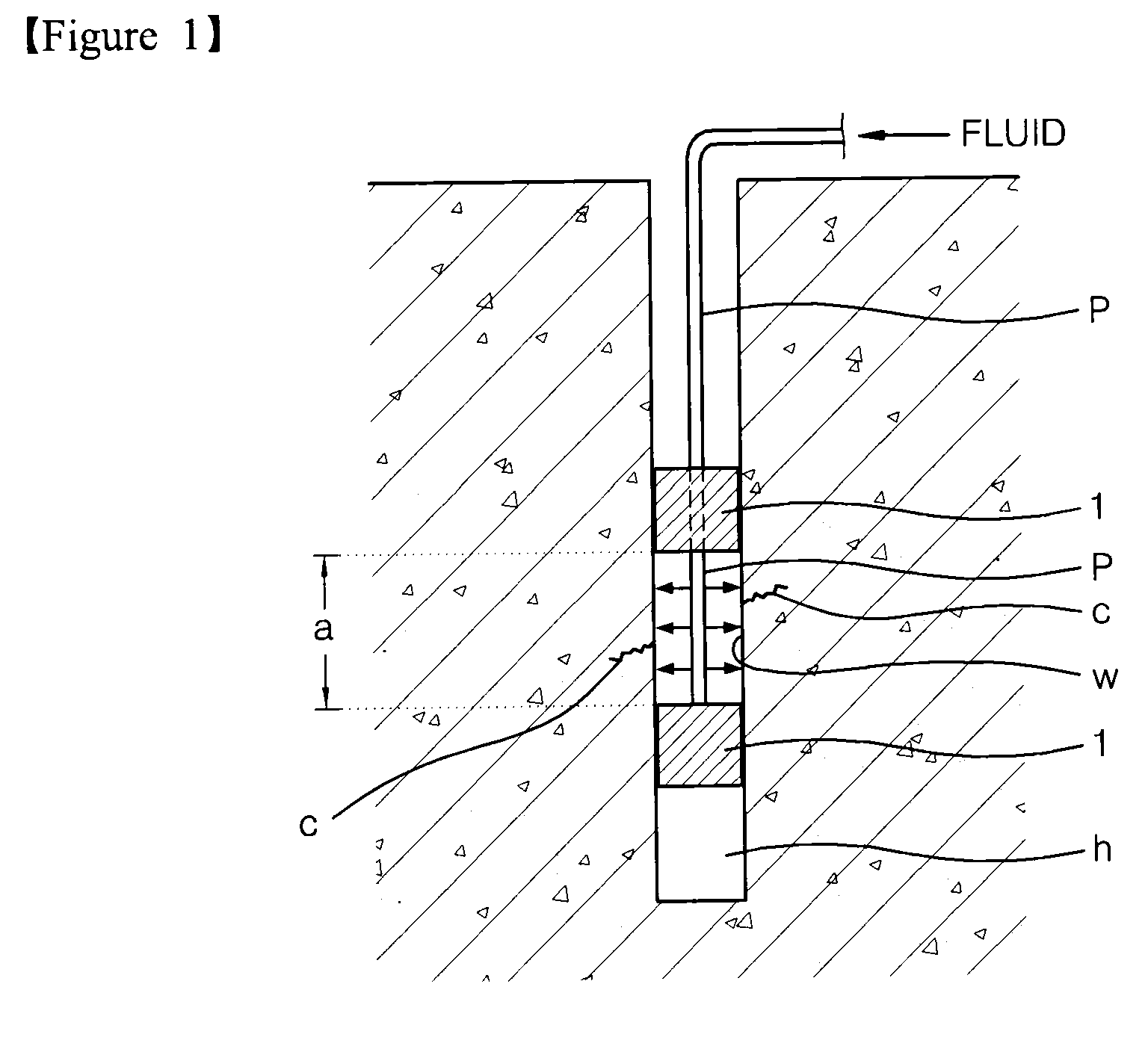

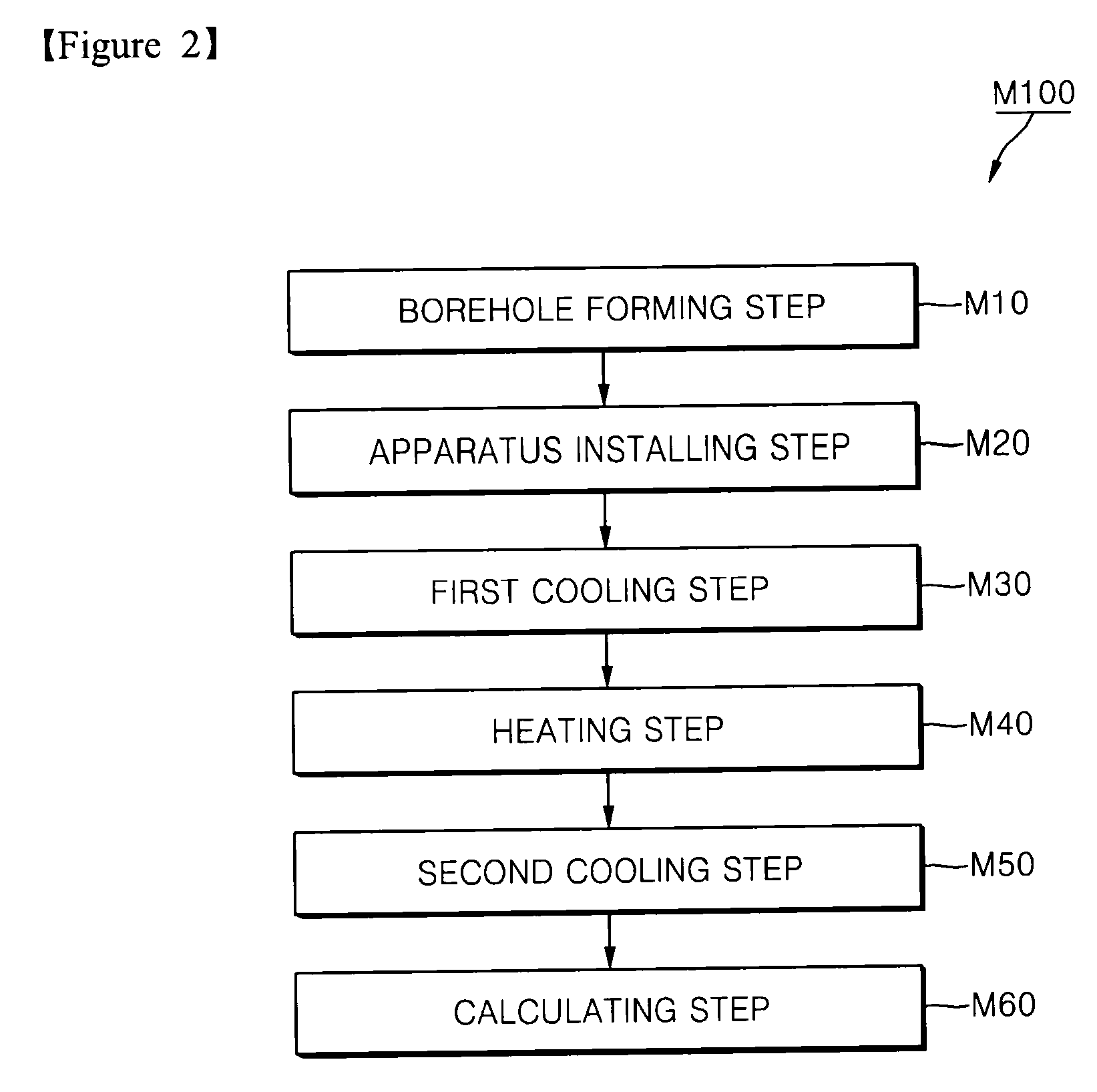

Disclosed is a method and apparatus for measuring in-situ stress in rock using a thermal crack. The method involves forming a borehole, cooling a wall of the borehole, applying tensile thermal stress, forming a crack in the borehole wall, and measuring temperature and cracking point. Afterwards, the borehole wall is heated to close the formed crack, the borehole wall is cooled again to re-open the crack, and temperature is measured when the crack is re-opened. The in-situ stress of the rock is calculated using a first cracking temperature at which the crack is formed and a second cracking temperature at which the crack is re-opened. Further, the apparatus cools, heats and re-cools the borehole wall, thereby measuring the first cracking temperature, the second cracking temperature, and the cracking point.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

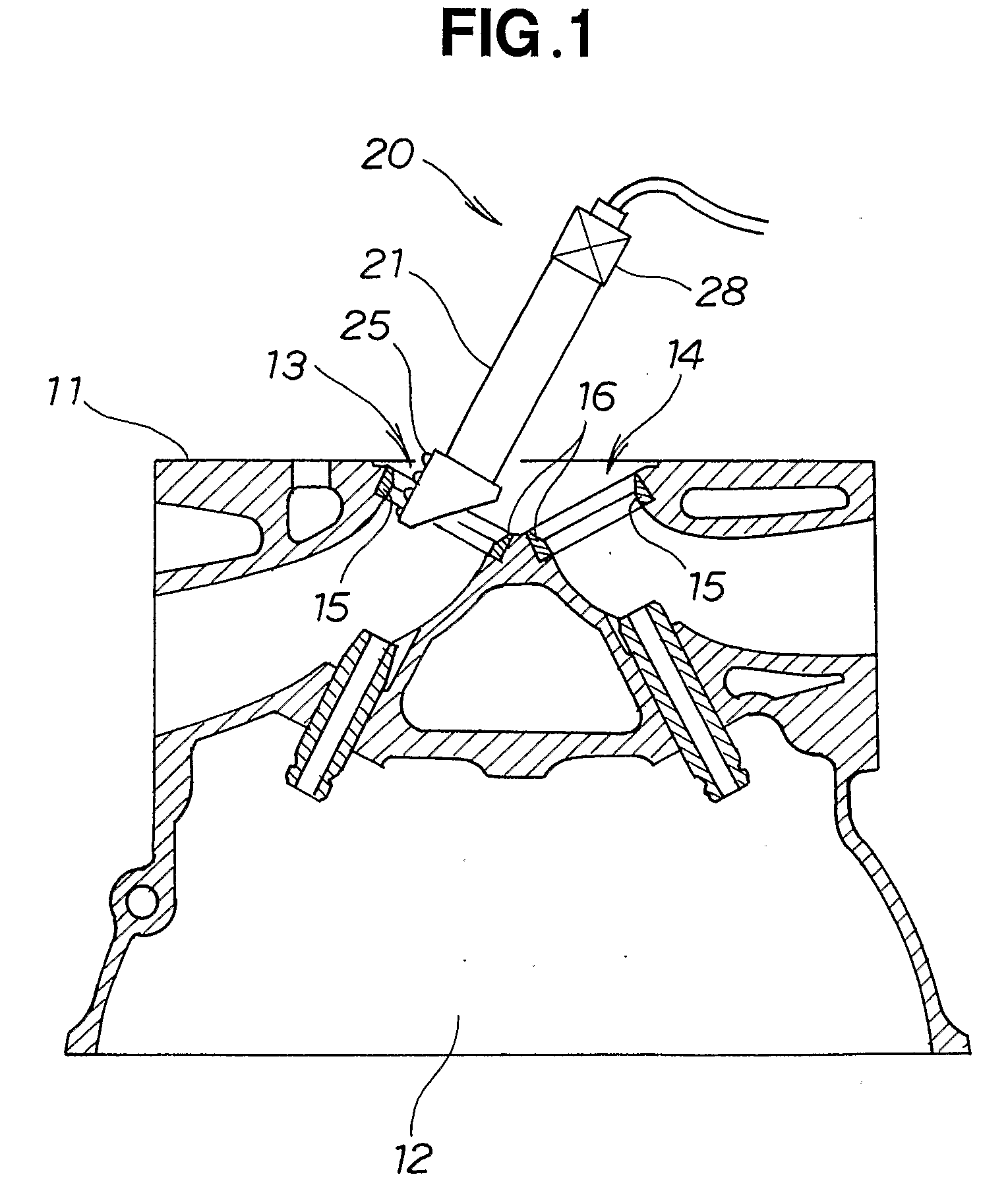

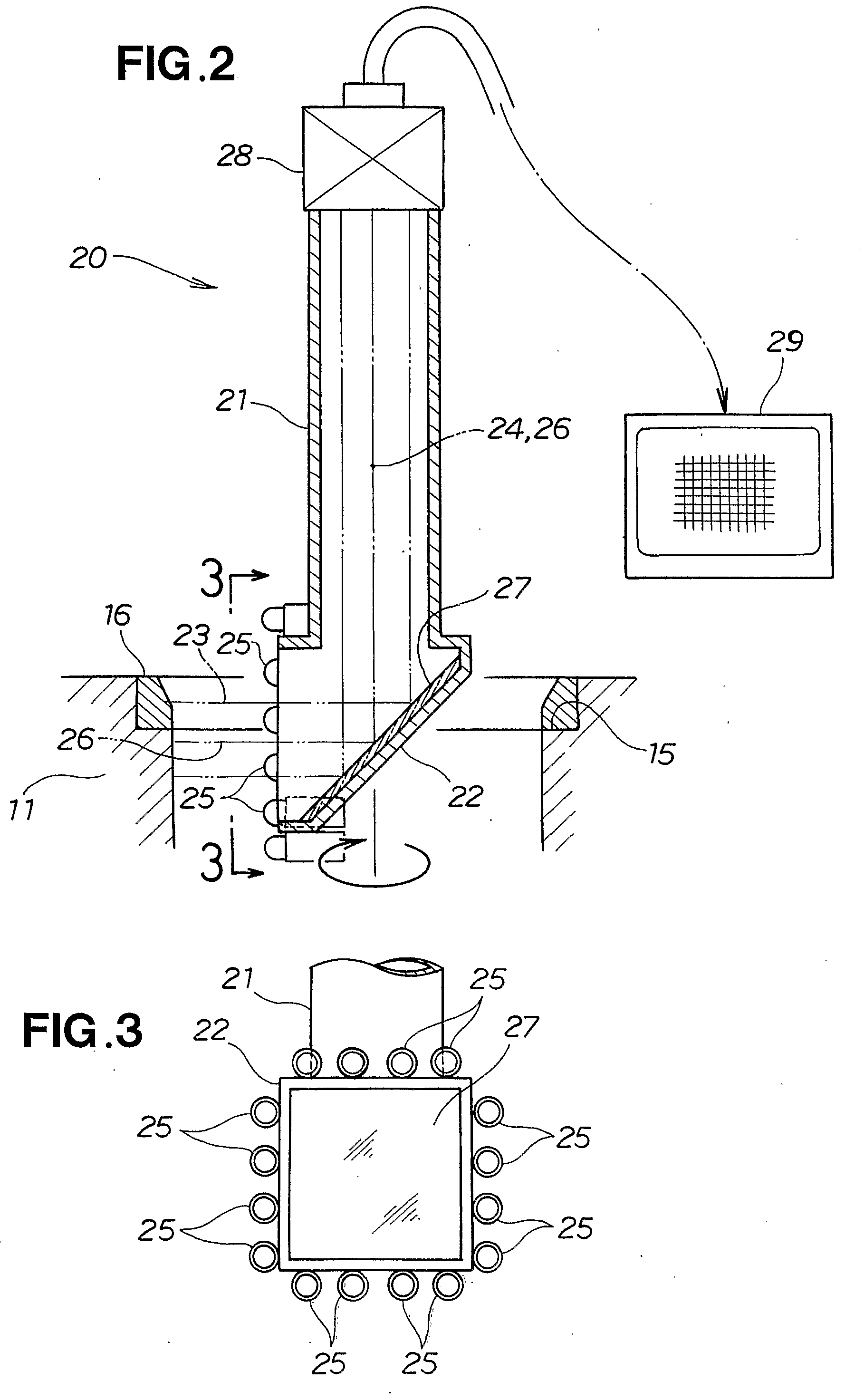

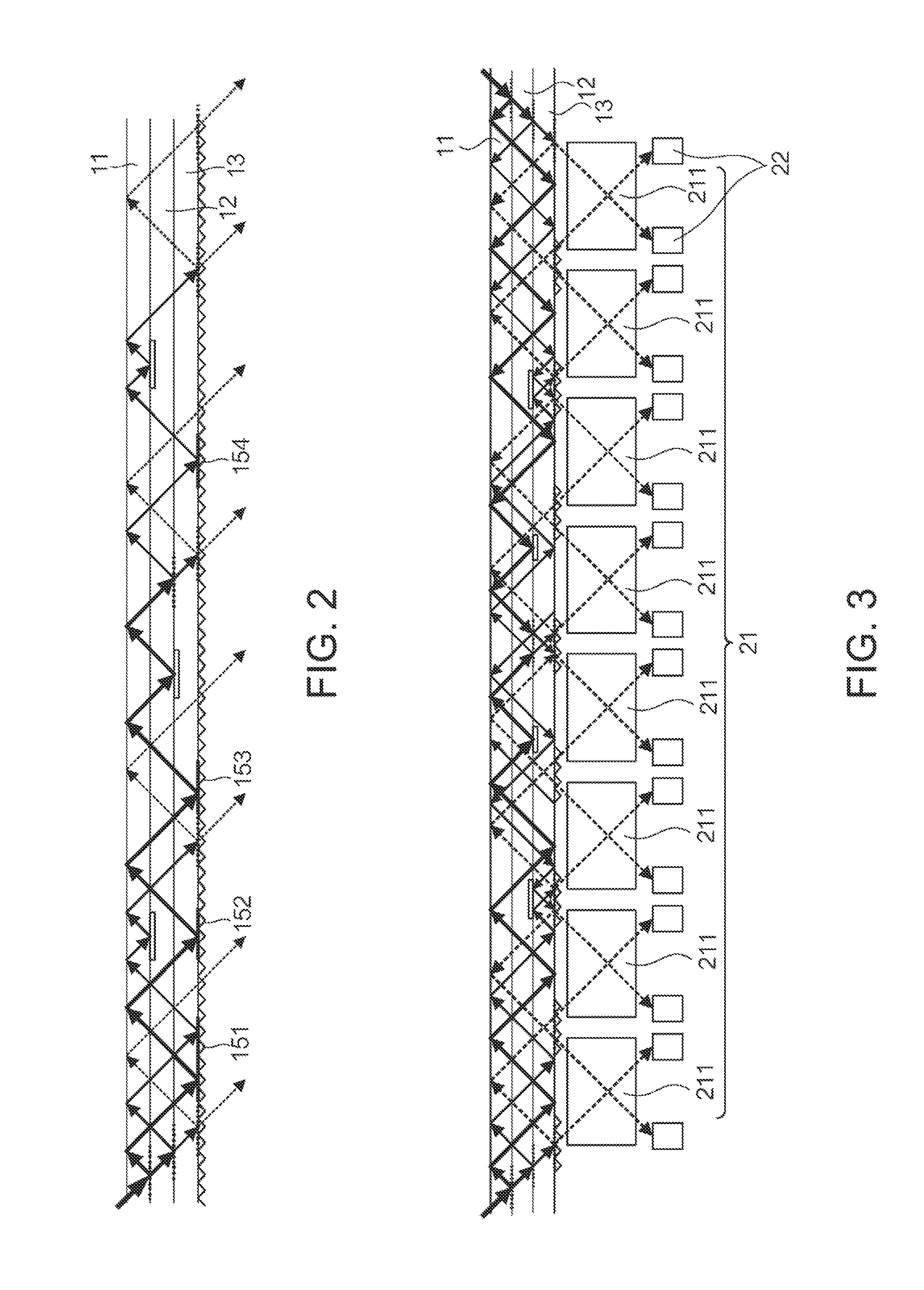

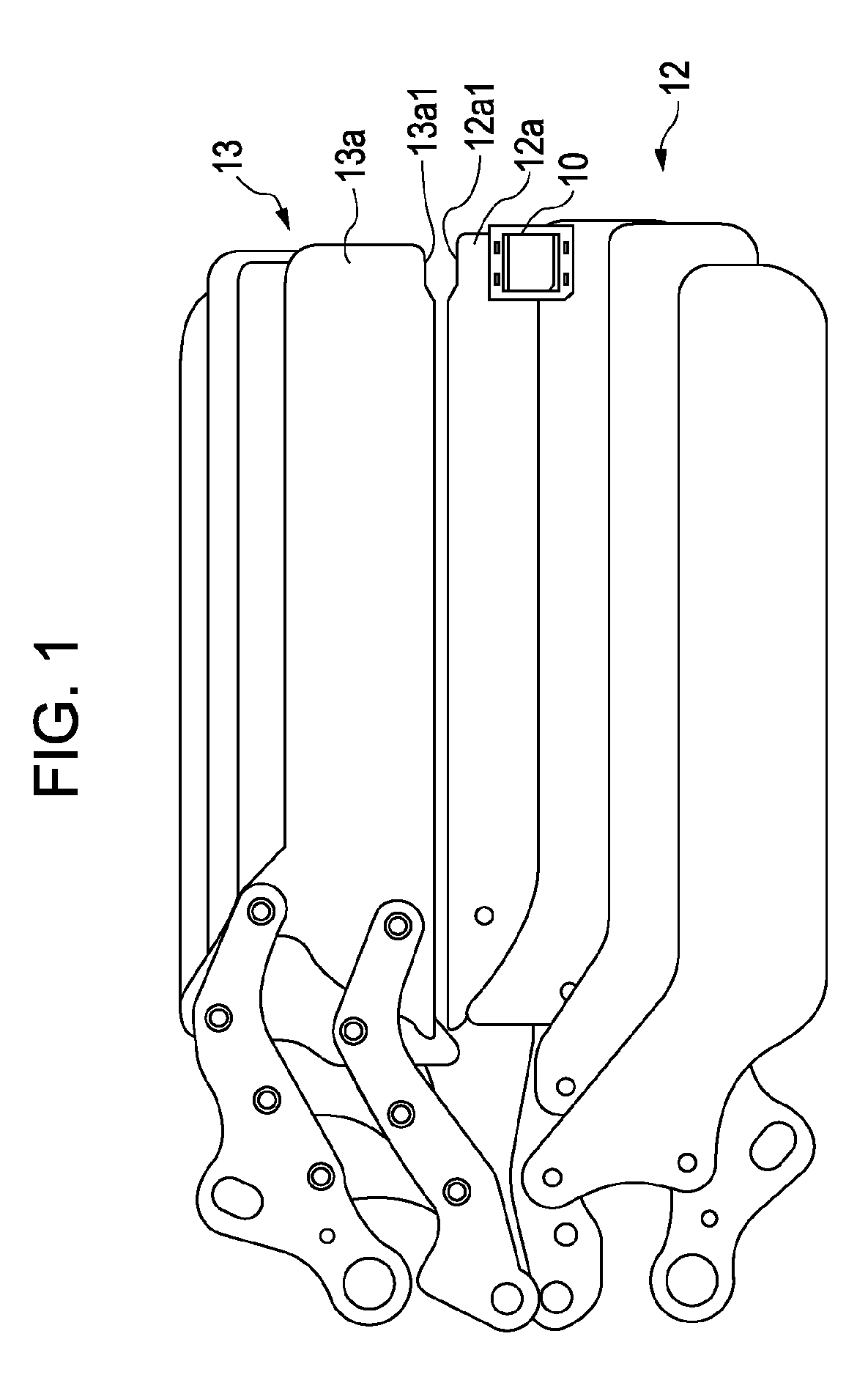

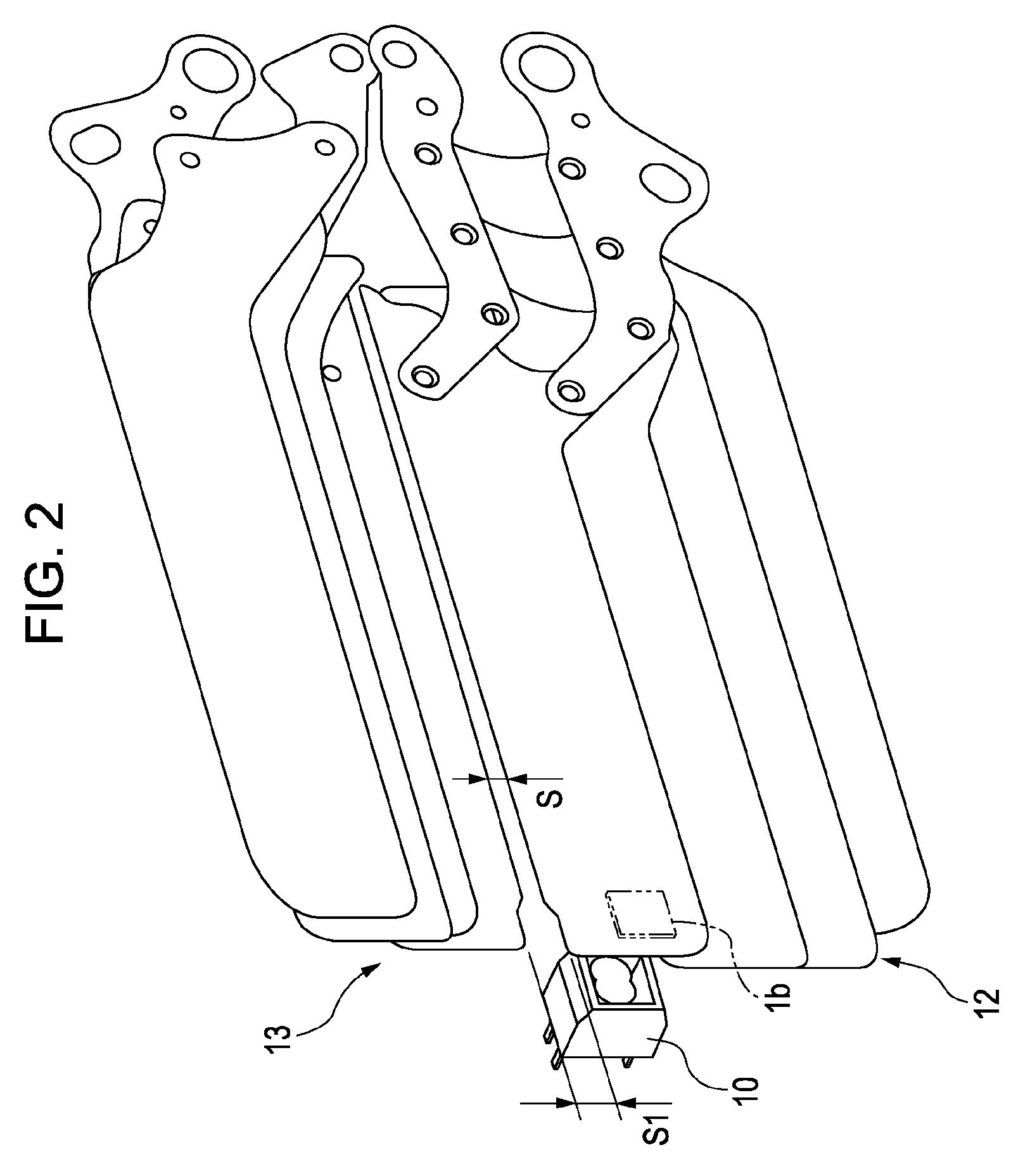

Measurement of gaps between valve seats and attachment parts

InactiveUS20090123032A1Precise measurementLess occurrenceCharacter and pattern recognitionMachines/enginesCcd cameraColor image processing

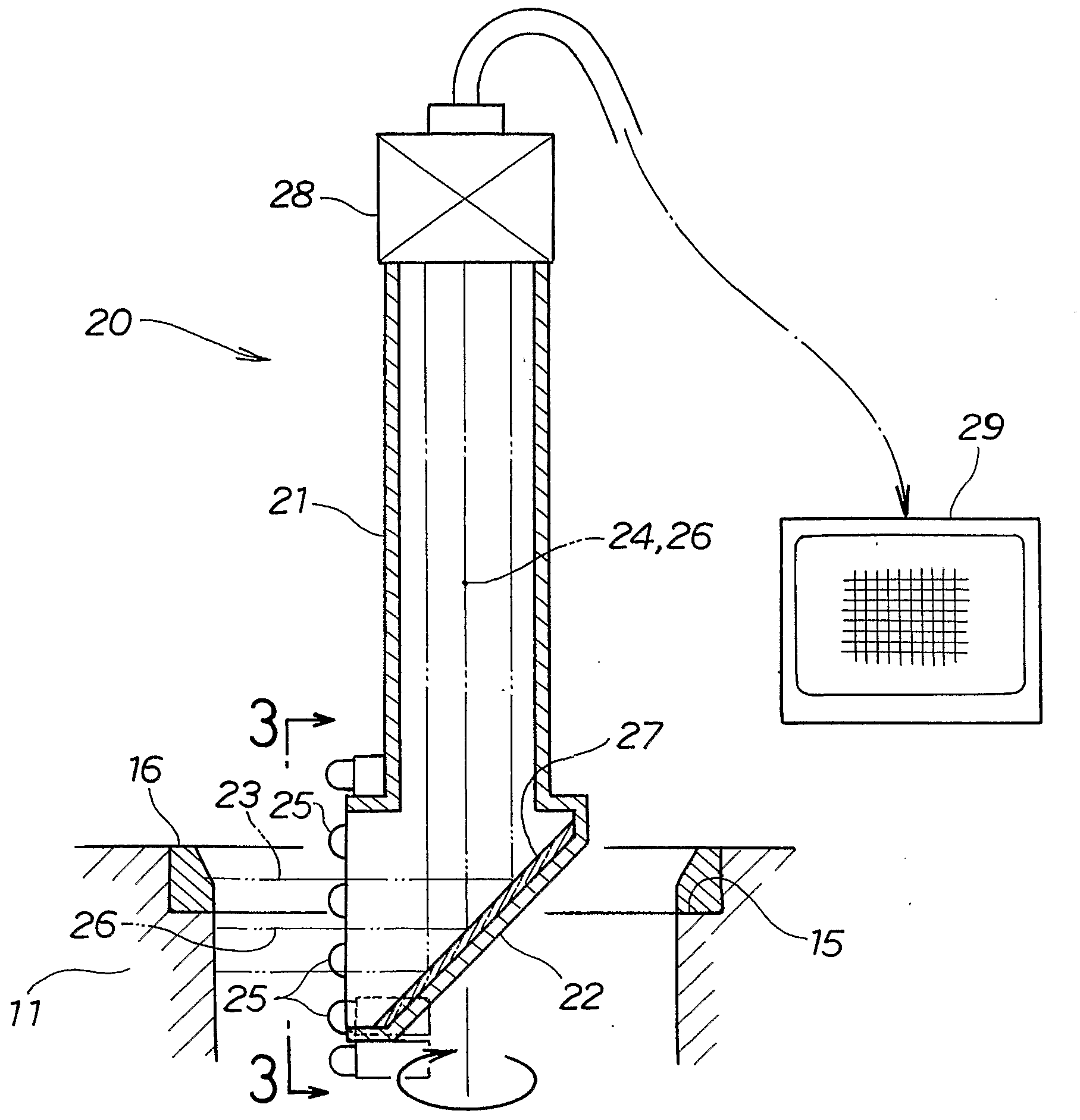

An apparatus for measuring gaps that form between attachment parts (15) in exhaust ports. of an engine, and valve seats (16) provided to the attachment parts. This apparatus comprises, at one end of a cylinder (21), white light-emitting diodes (25) for emitting light orthogonal to a longitudinal axis (24) of the cylinder. An optical axis (26) from the light-emitting diodes is bent by 90° by a mirror (27). Color images obtained by a CCD camera (28) provided at the other end of the cylinder are binarized by a color image processor (29) with a range of hue, a range of chroma, and a range of brightness.

Owner:HONDA MOTOR CO LTD

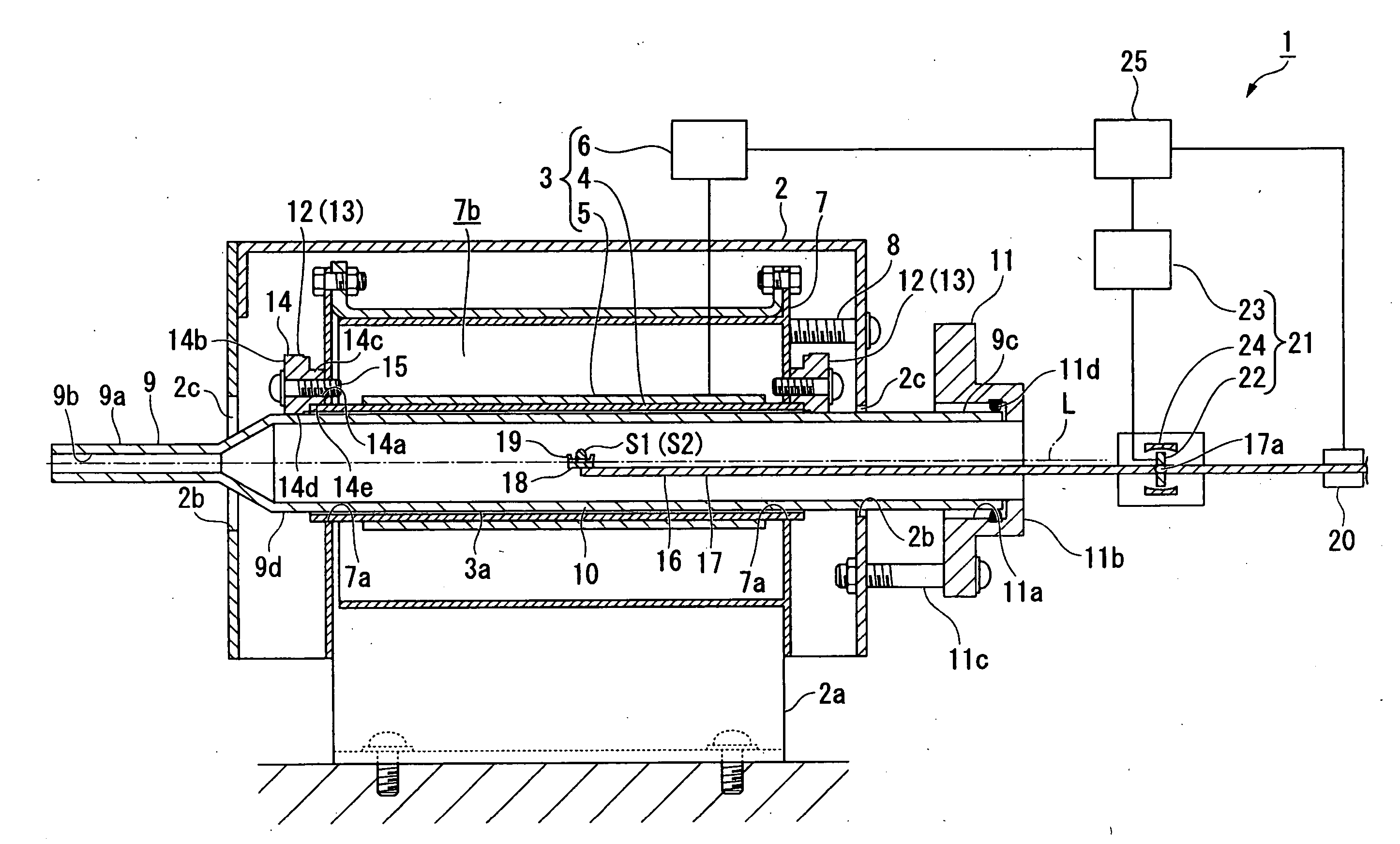

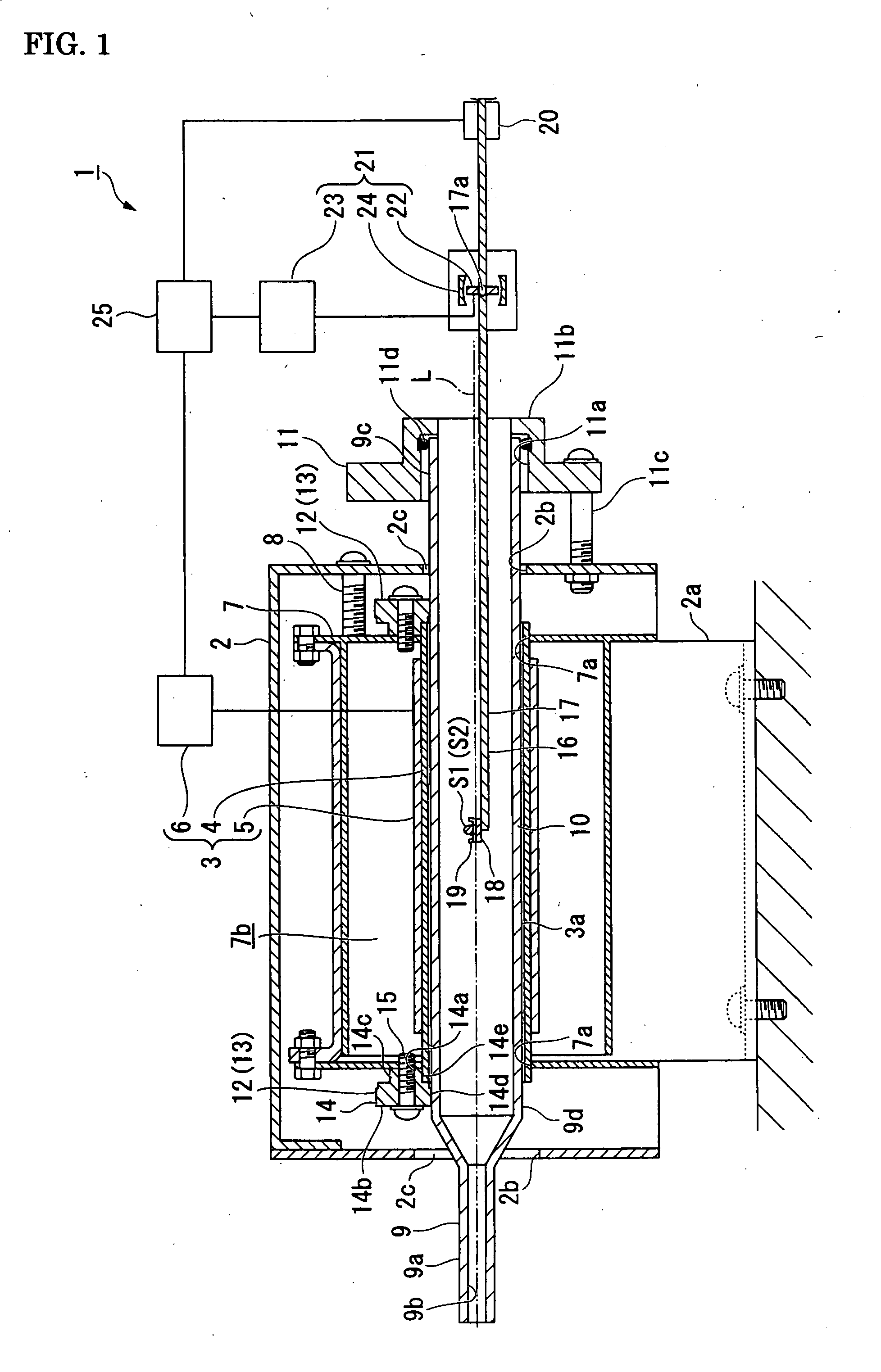

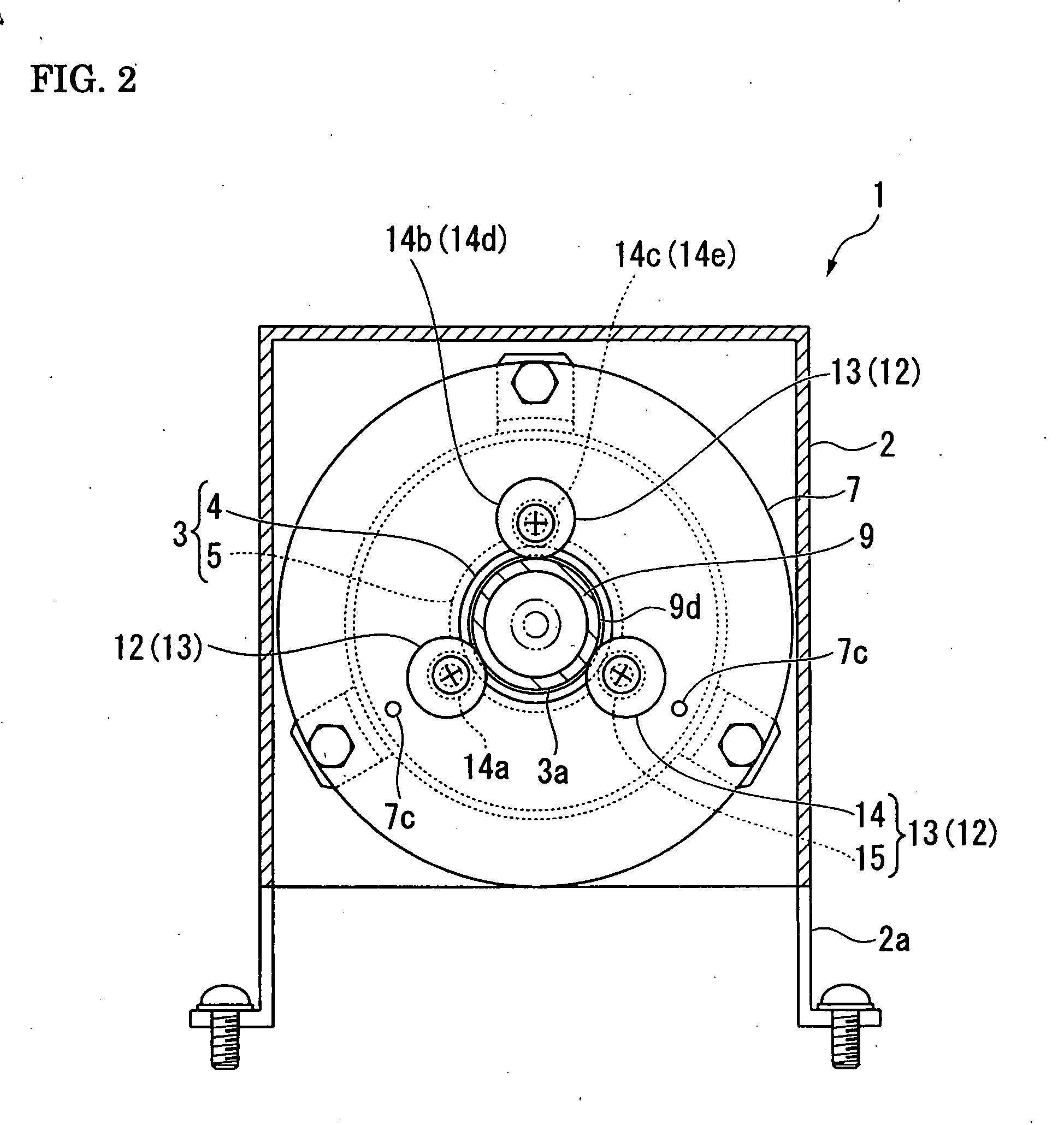

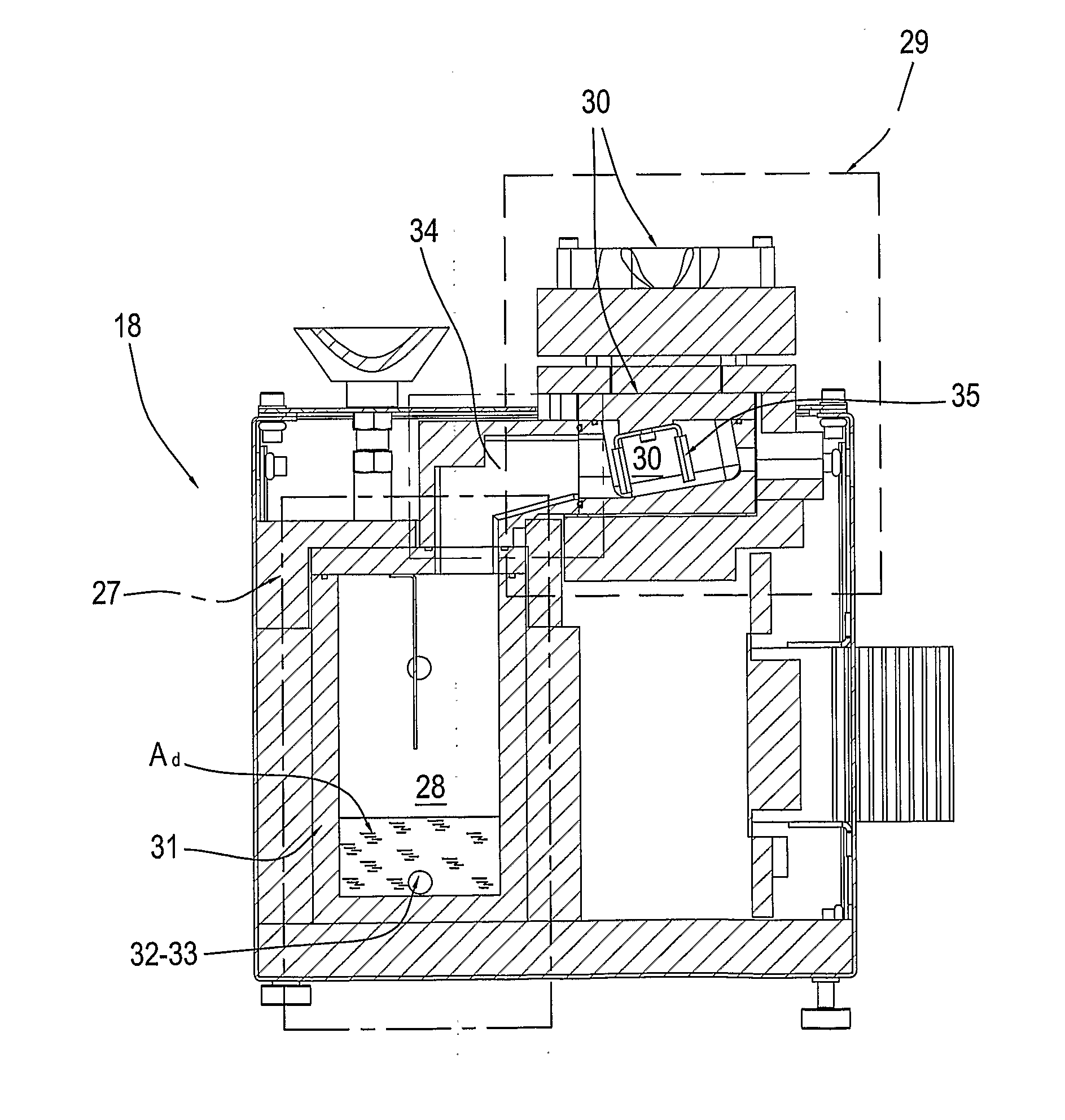

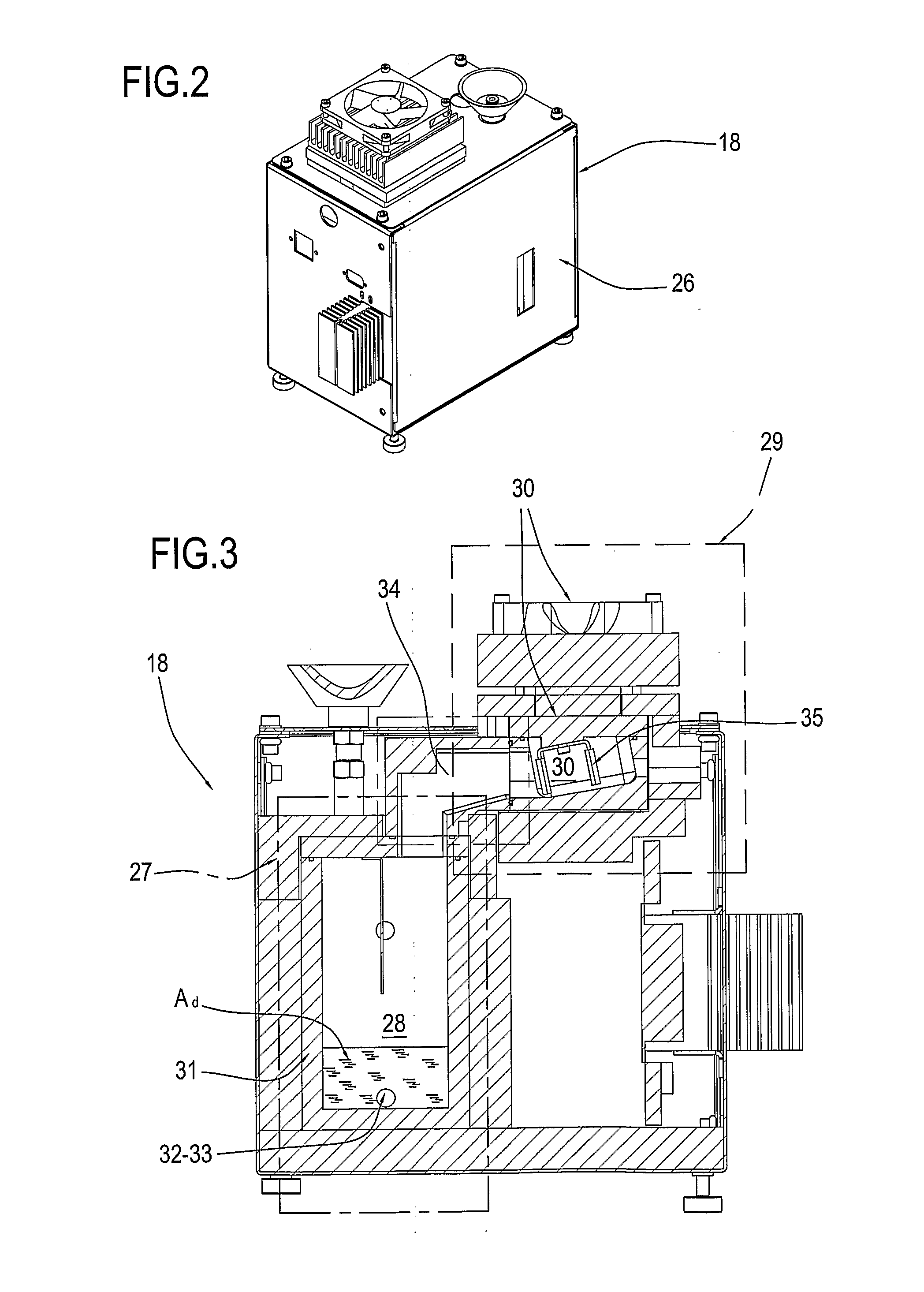

Thermal analysis apparatus

InactiveUS20070201533A1Precise measurementKeep the heatWeighing apparatus using counterbalanceMaterial thermal analysisTemperature measurementEngineering

A thermal analysis apparatus possesses a support base, a heating furnace which is approximately like a cylinder, and whose inside can be raised in its temperature, till a predetermined heating temperature, a heating furnace fixation part fixing the heating furnace to the support base, a furnace tube which is approximately like the cylinder, inserted through the heating furnace while having an interstice, and has been fixed in its base end part to the support base by a fixation member, a fixation means which makes the furnace tube capable of expanding or contracting in an axial direction, and positioning-fixes it in a radial direction, a sample holding means which holds a sample in an inside of a heating part of the furnace tube, that is a range capable of being heated by the heating furnace, and a temperature measurement means measuring a temperature change of the sample.

Owner:SII NANOTECHNOLOGY INC

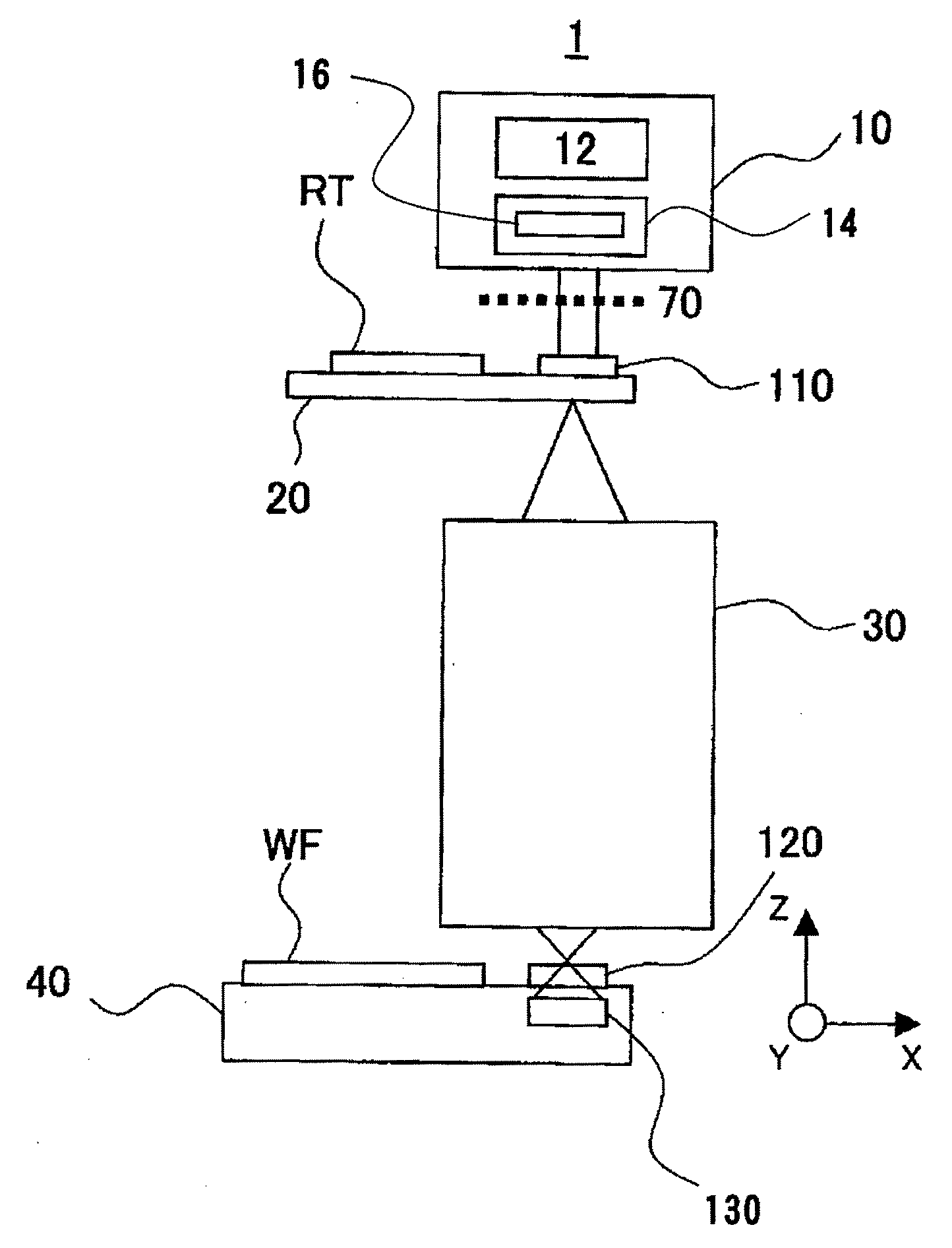

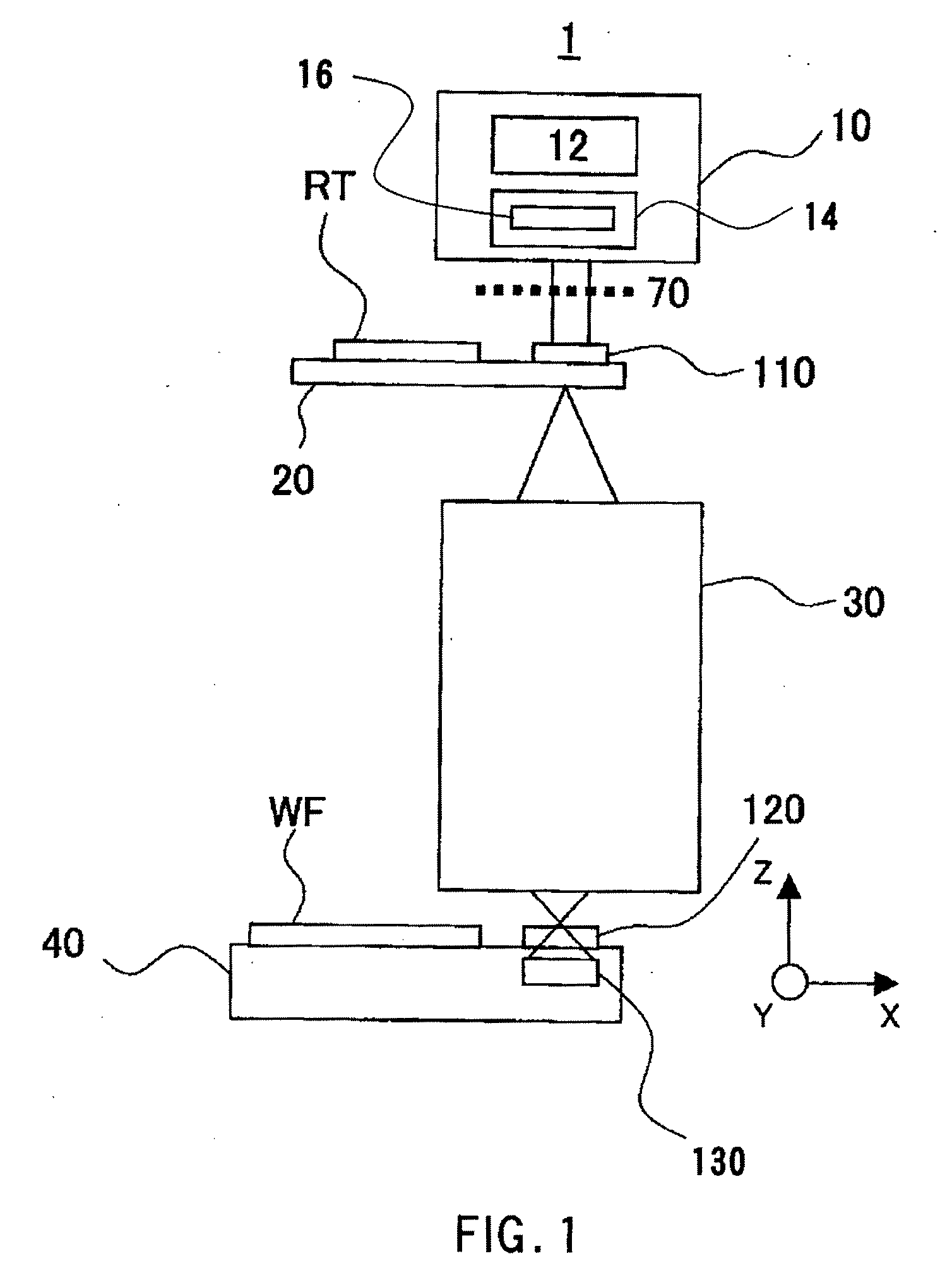

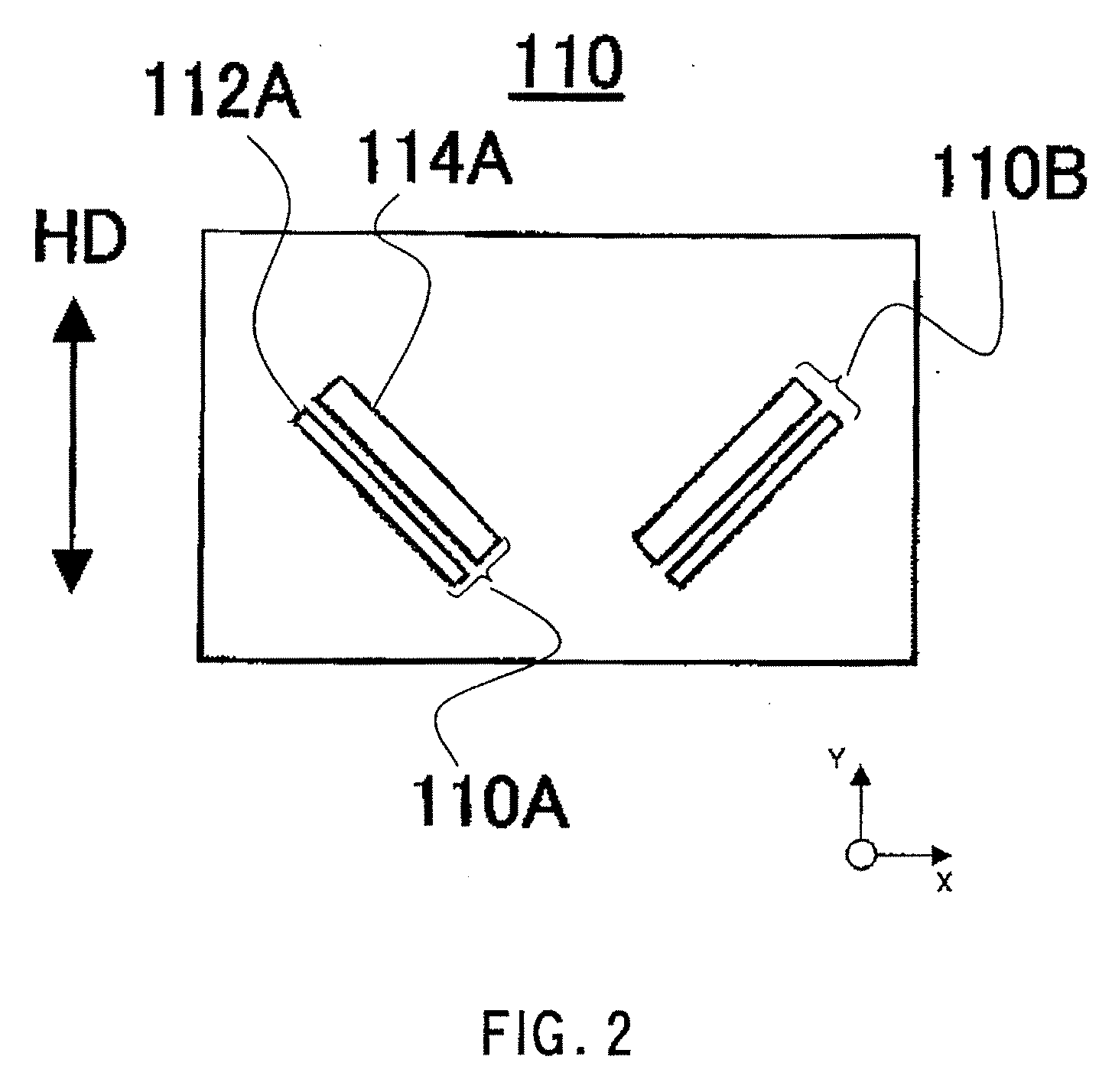

Measurement method and apparatus, exposure apparatus, and device manufacturing method

InactiveUS20070146688A1Precise measurementSimple and small and inexpensiveOptical measurementsPhotomechanical apparatusWavefront aberrationOptical polarization

A measurement method measures a wavefront aberration of a target optical system using an interference pattern formed by lights from first and second image side slits. The first image side slit has a width equal to or smaller than a diffraction limit of the target optical system. The measurement method includes the steps of obtaining a first and second wavefronts having wavefront aberration information of the target optical system in ±45° directions relative to the polarization direction of the light, and calculating wavefront aberration of the target optical system based on the first and second wavefronts of the target optical system obtained by the obtaining step.

Owner:CANON KK

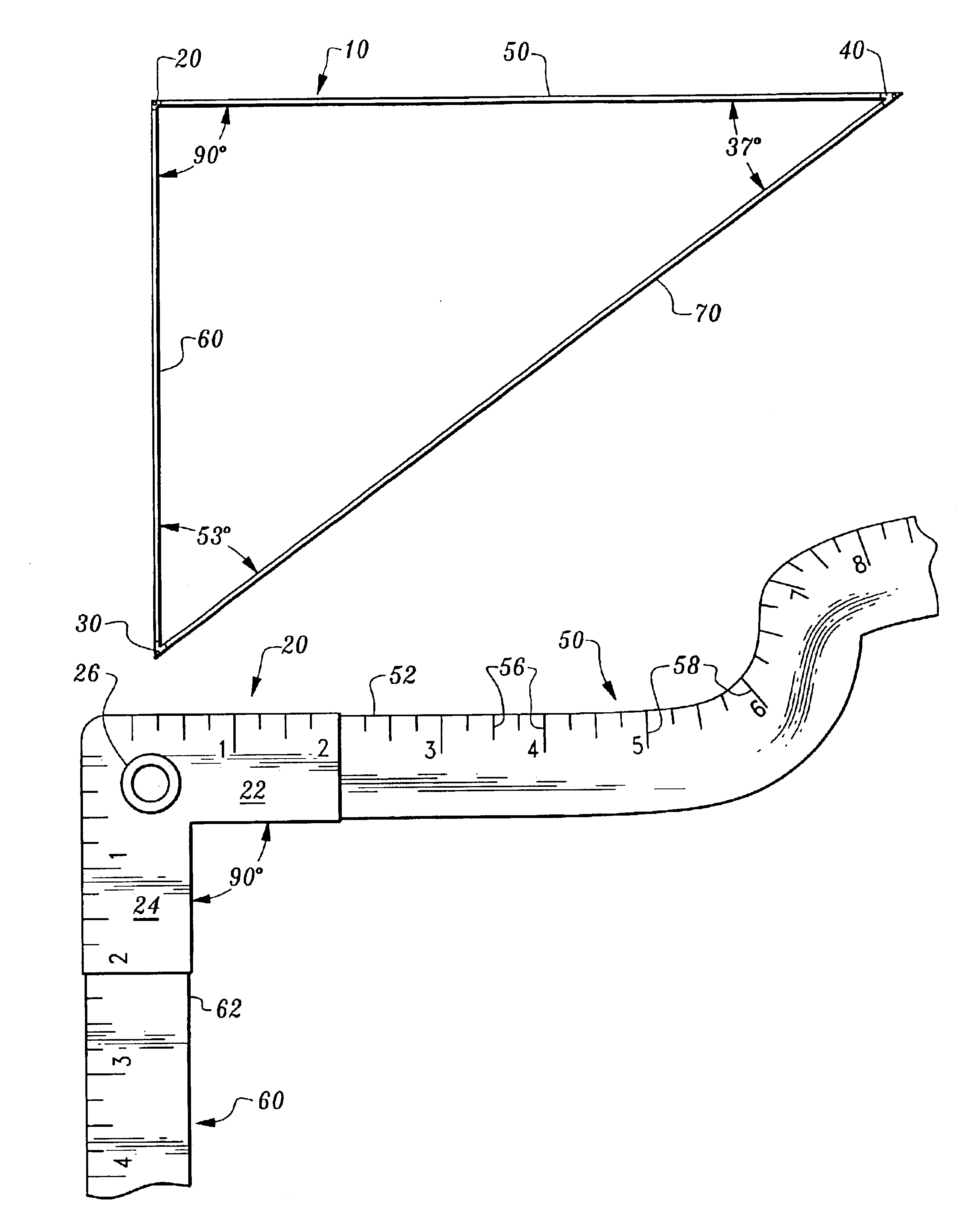

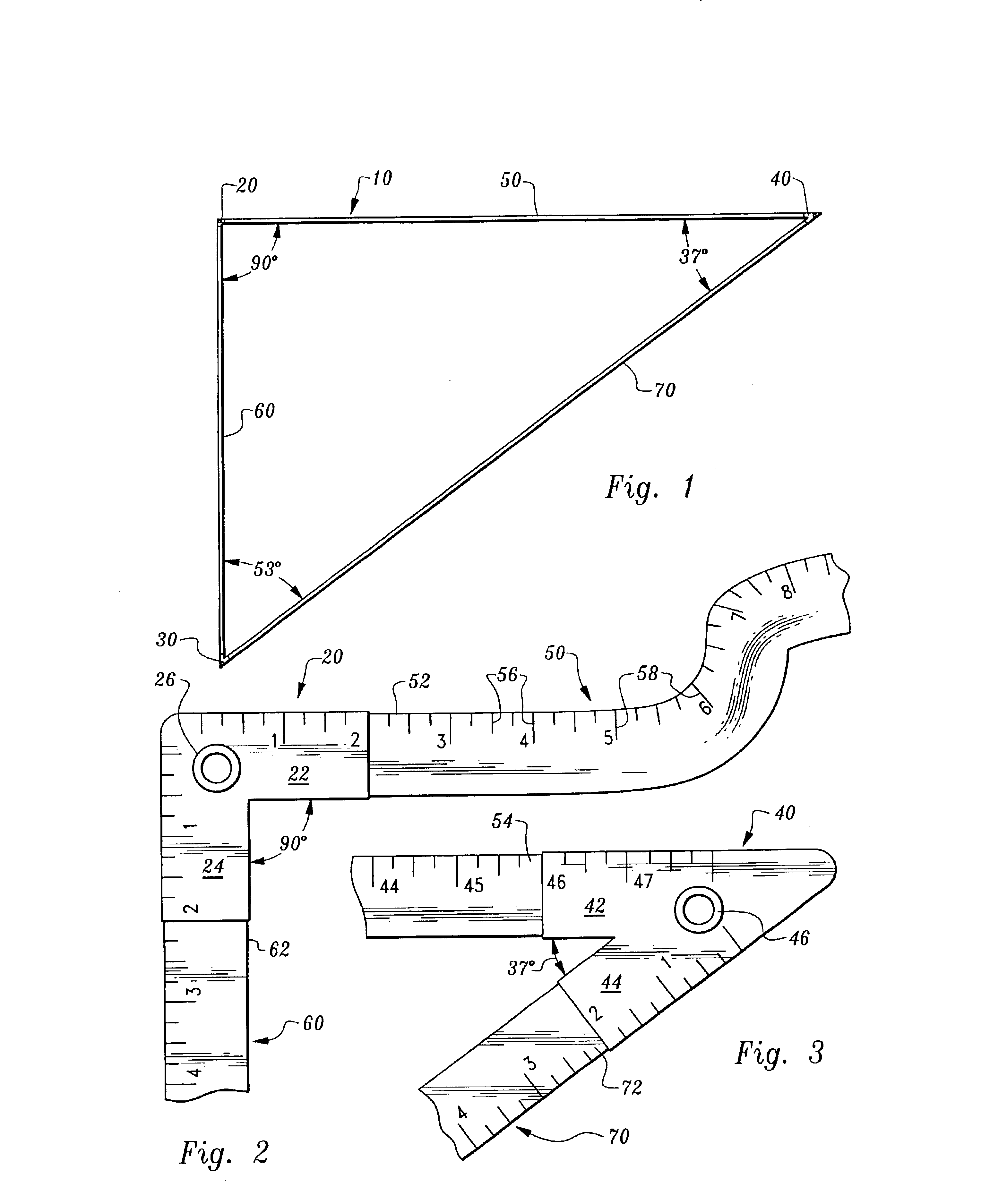

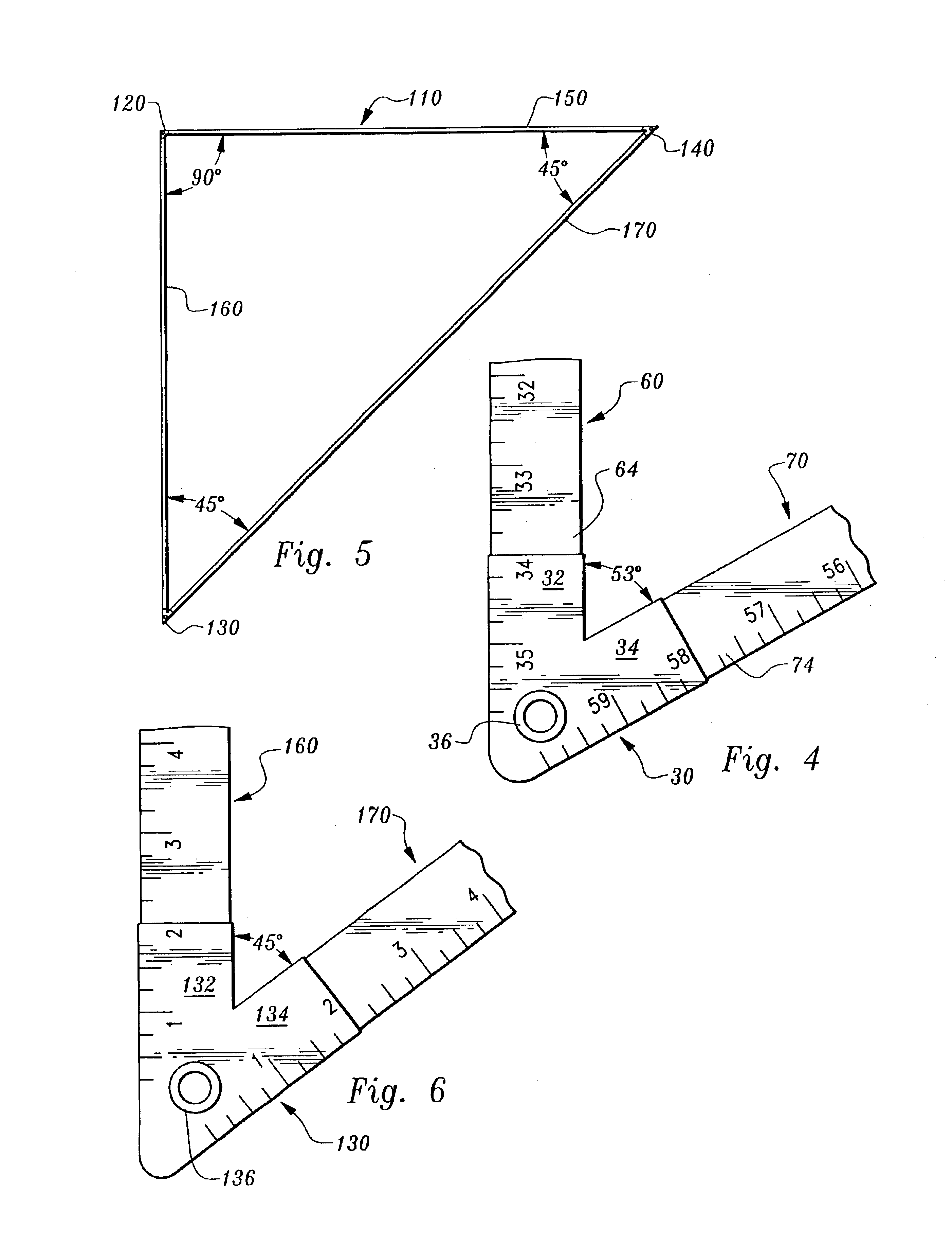

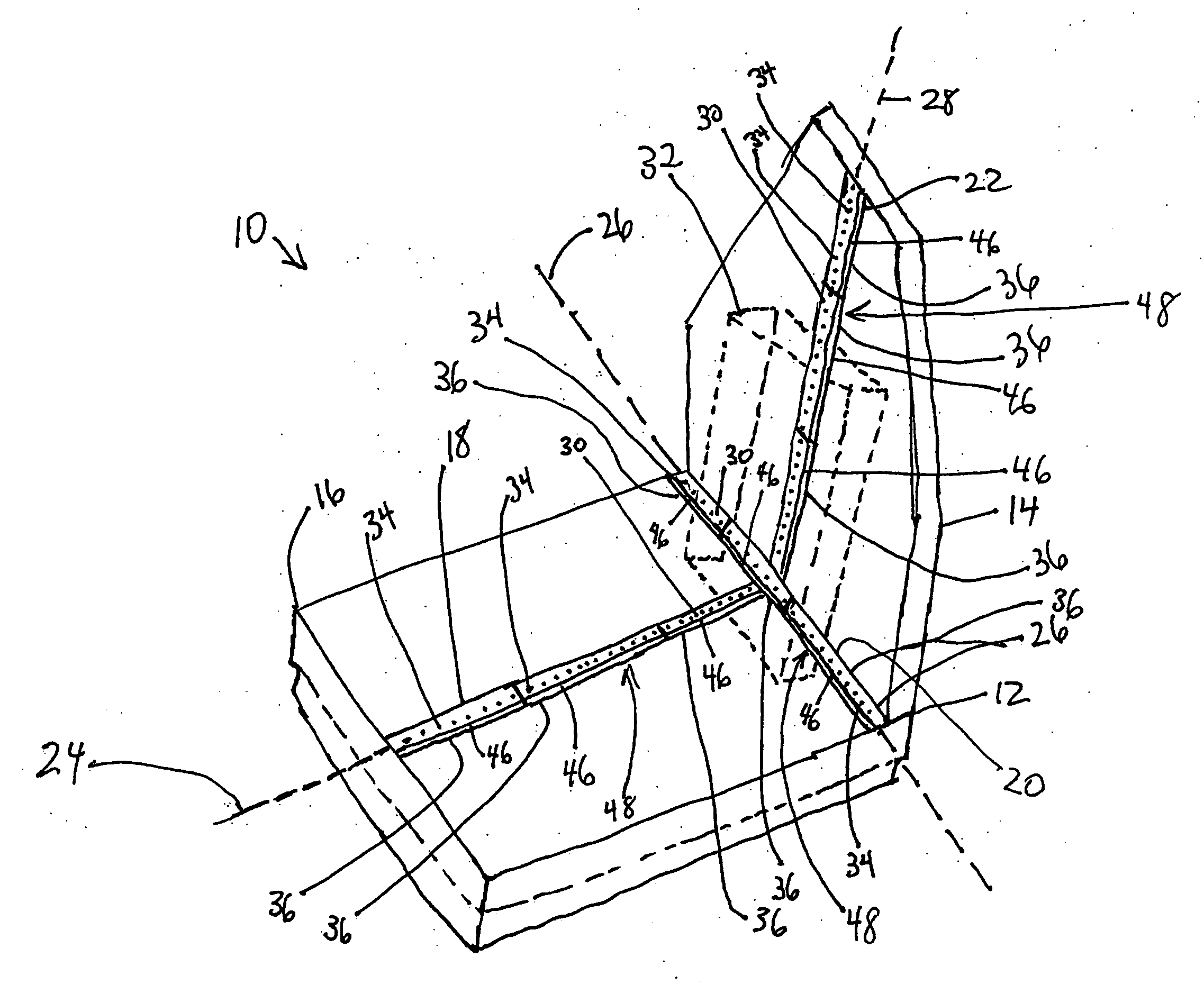

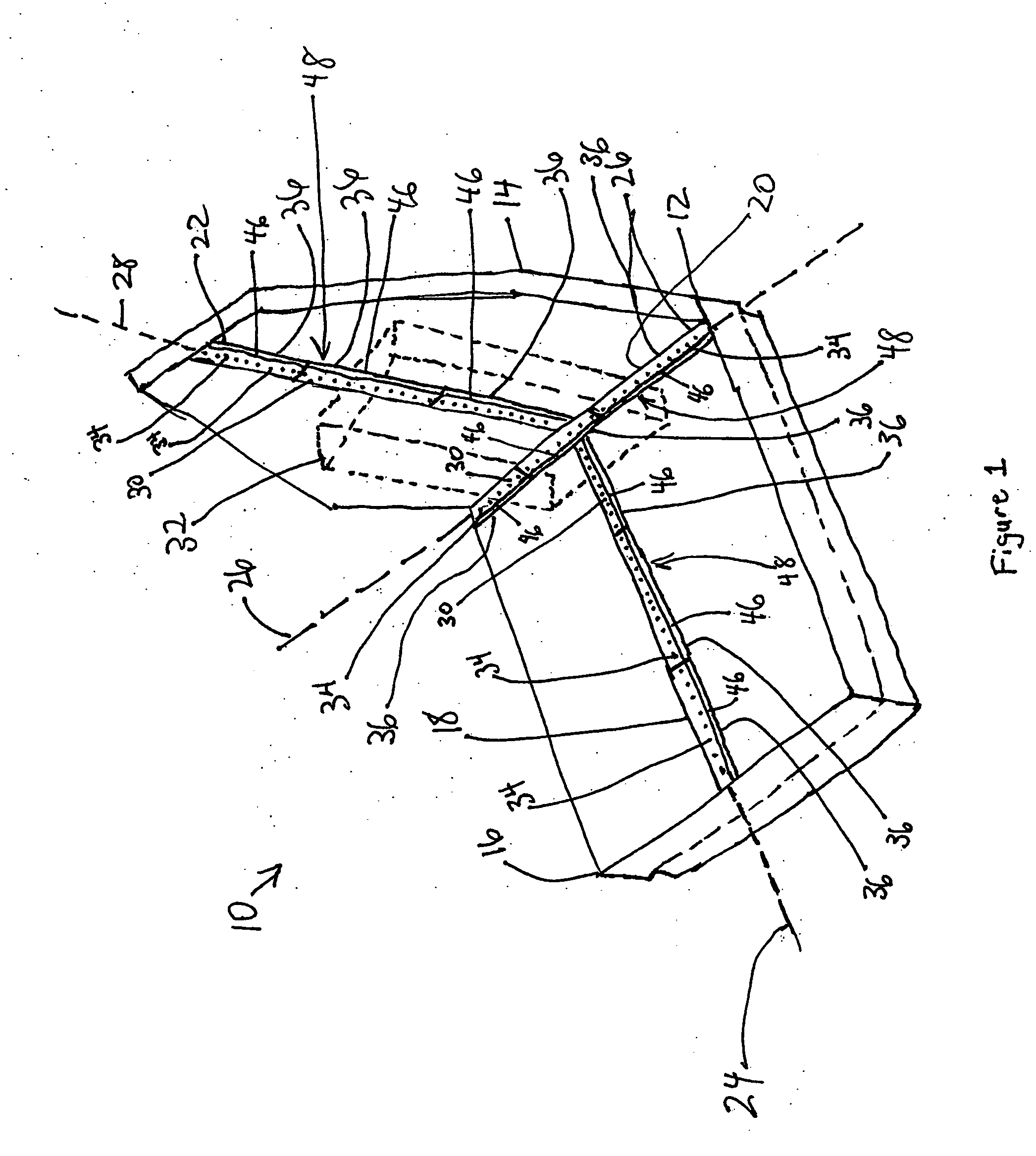

Flexible and collapsible construction geometry tool

InactiveUS6880261B1Precise measurementPrecise distance measurementLiquid surface applicatorsOther artistic work equipmentsEngineeringBuilding construction

Owner:ABBEY JOHN D

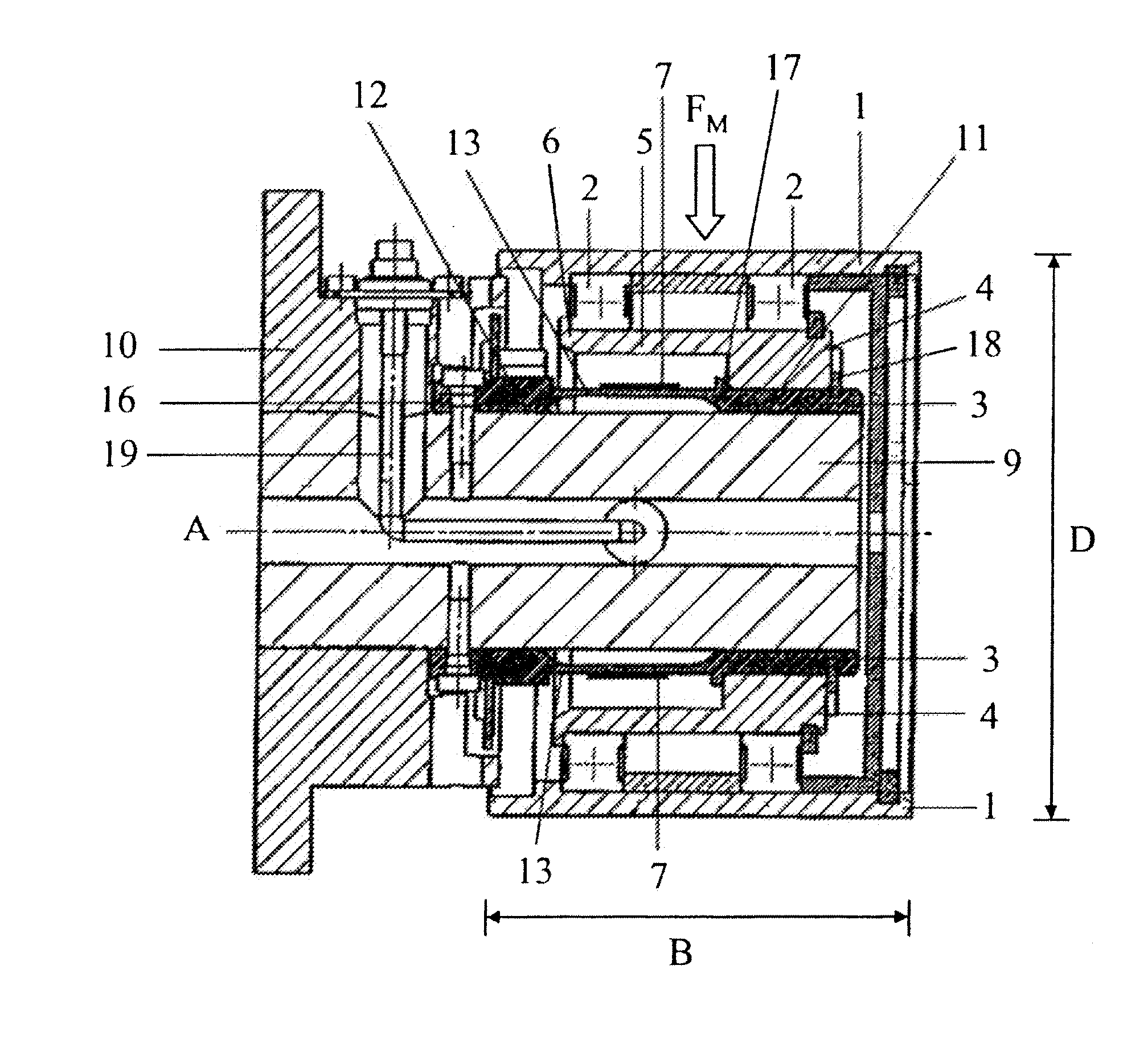

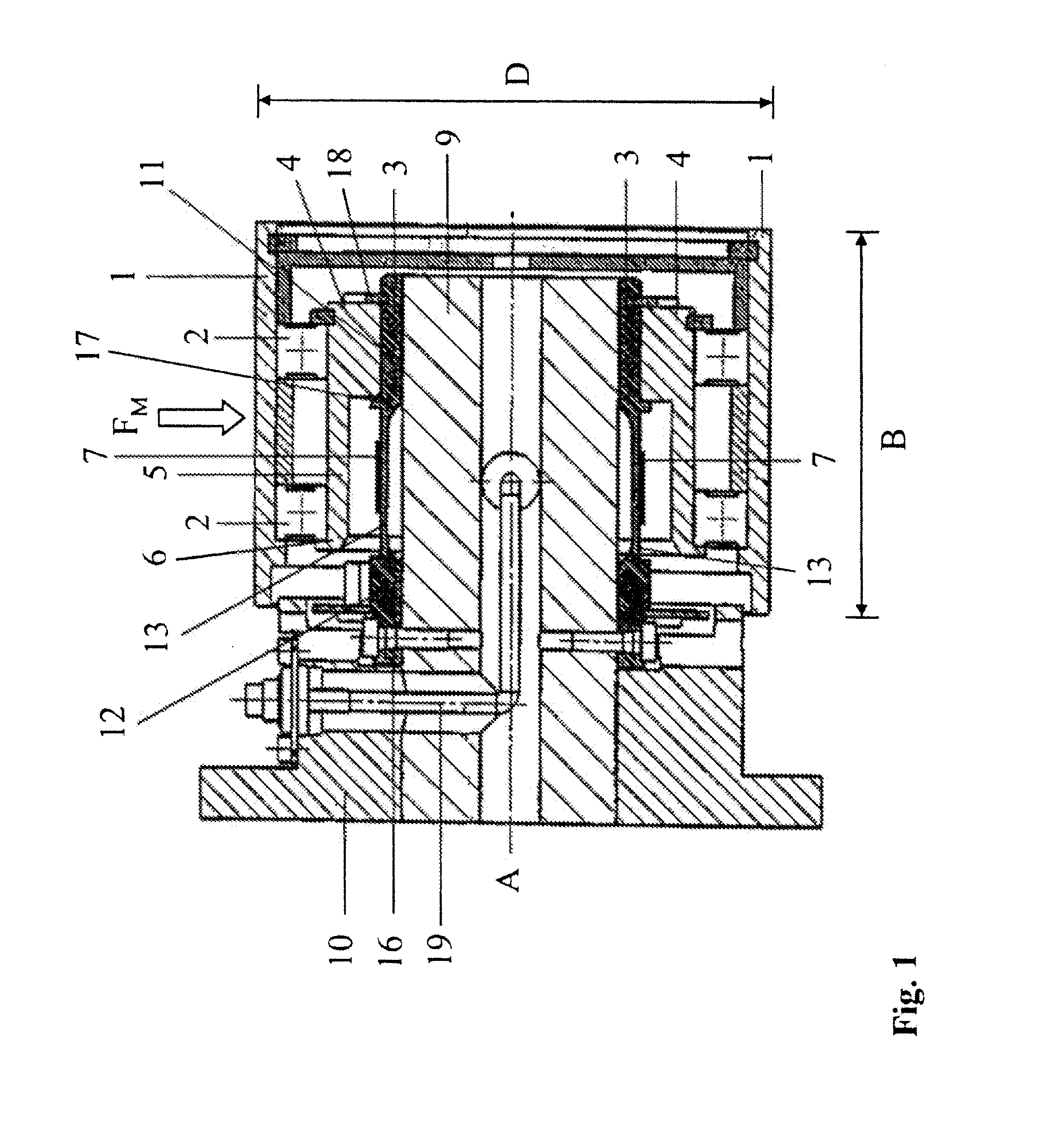

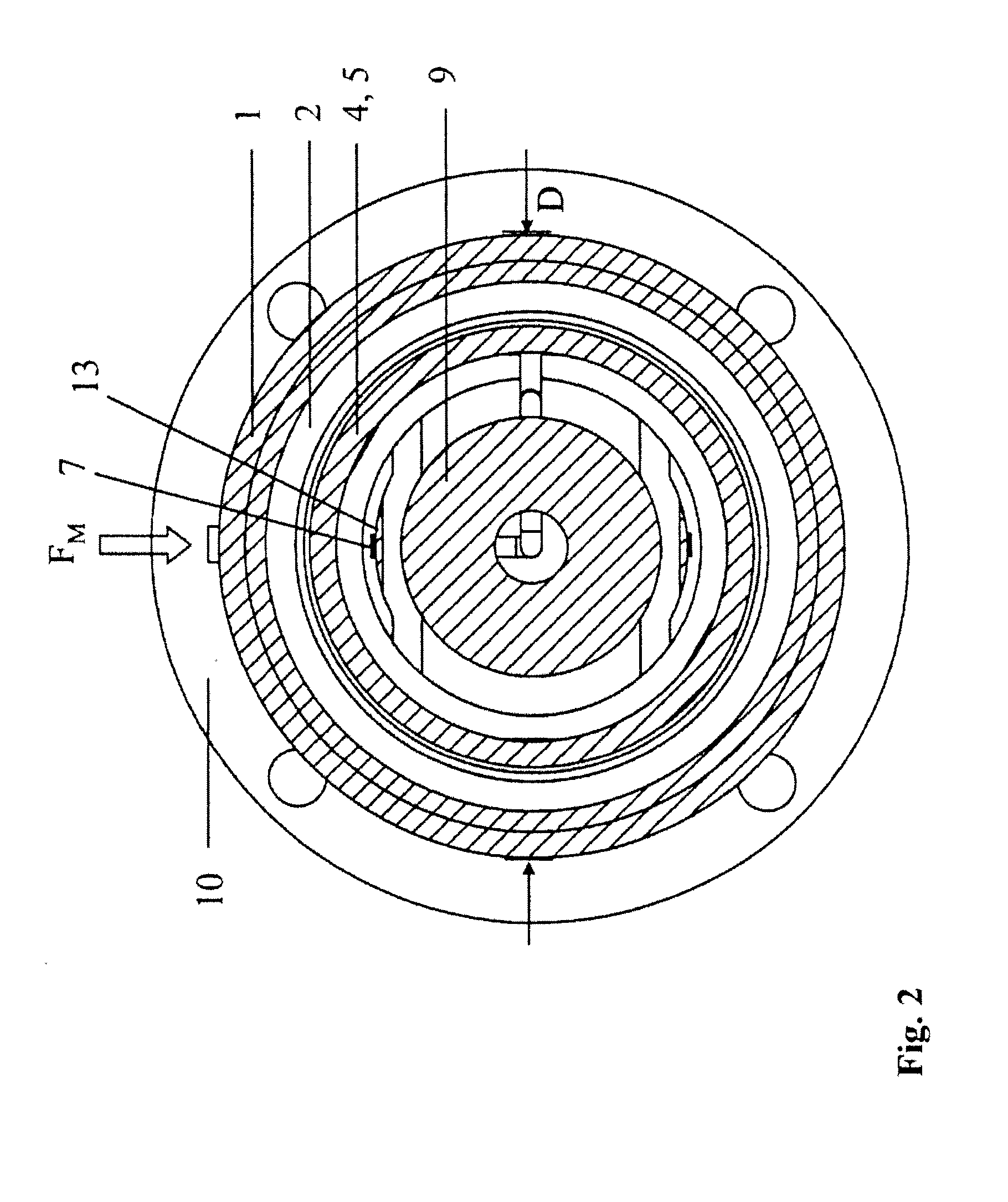

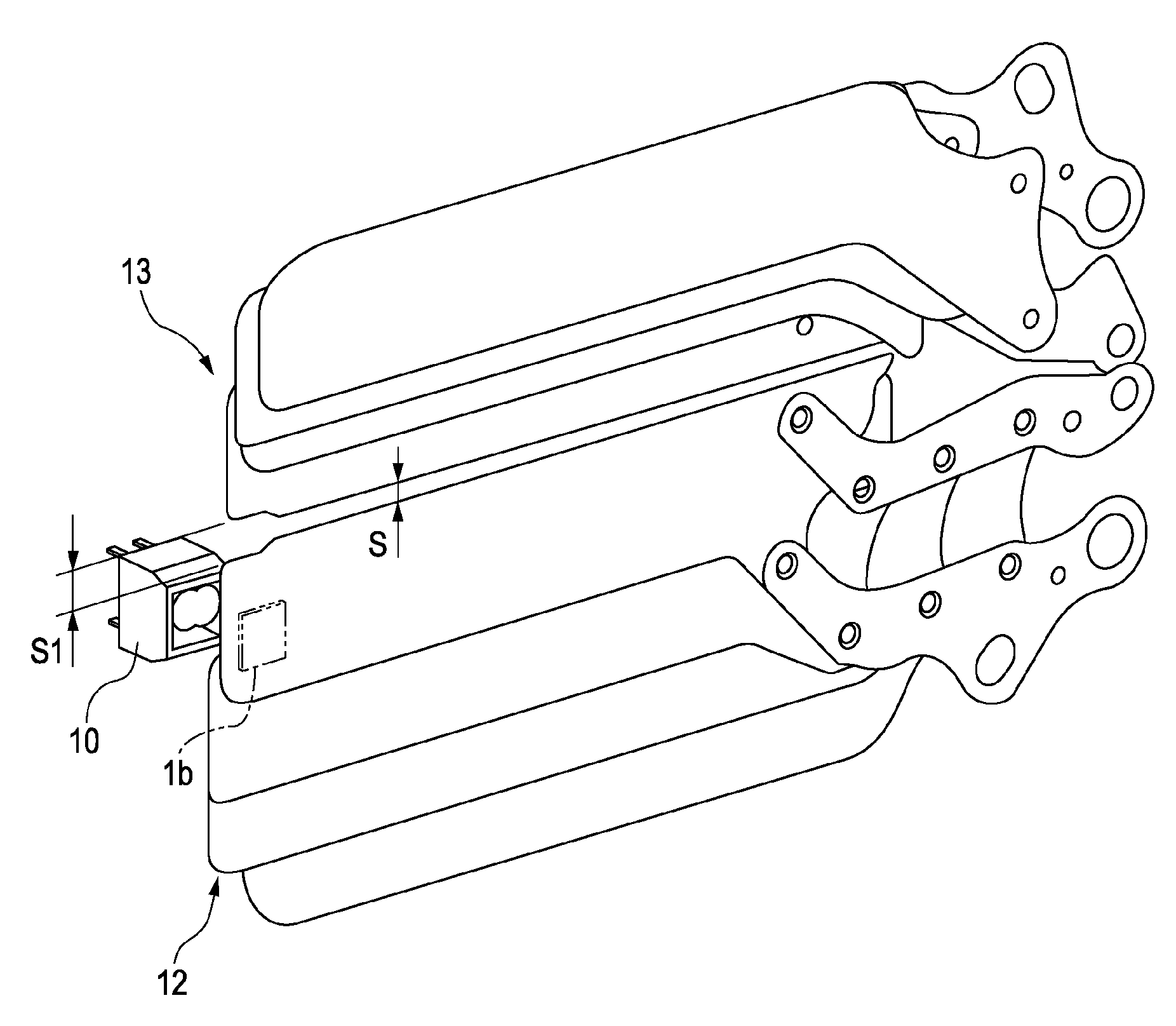

Measuring a Tensile Force

ActiveUS20080115590A1Force be absorbPrecise measurementTension measurementForce measurement by elastic gauge deformationPull forceEngineering

Owner:TEXMAG GMBH VERTRIEBS

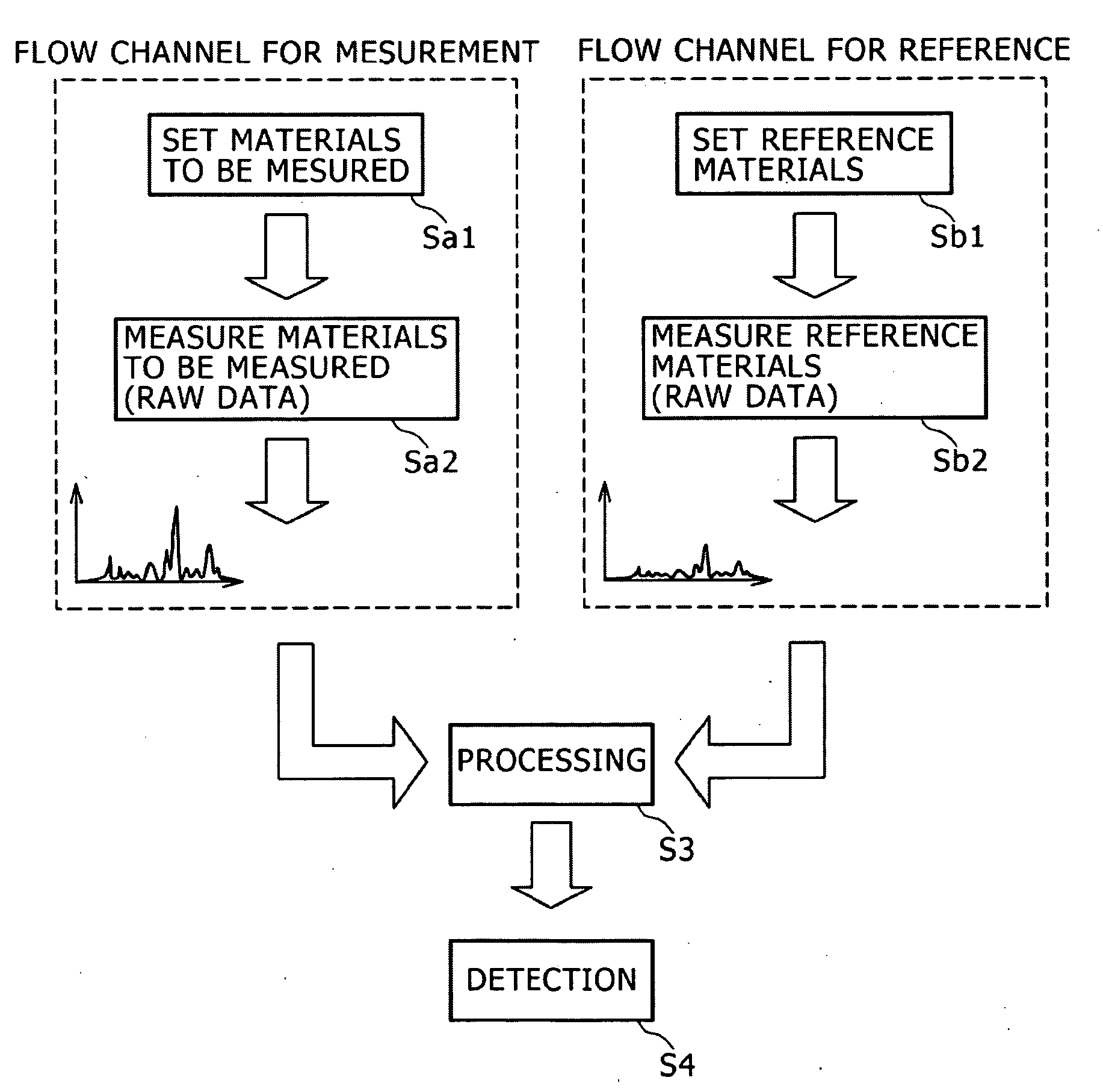

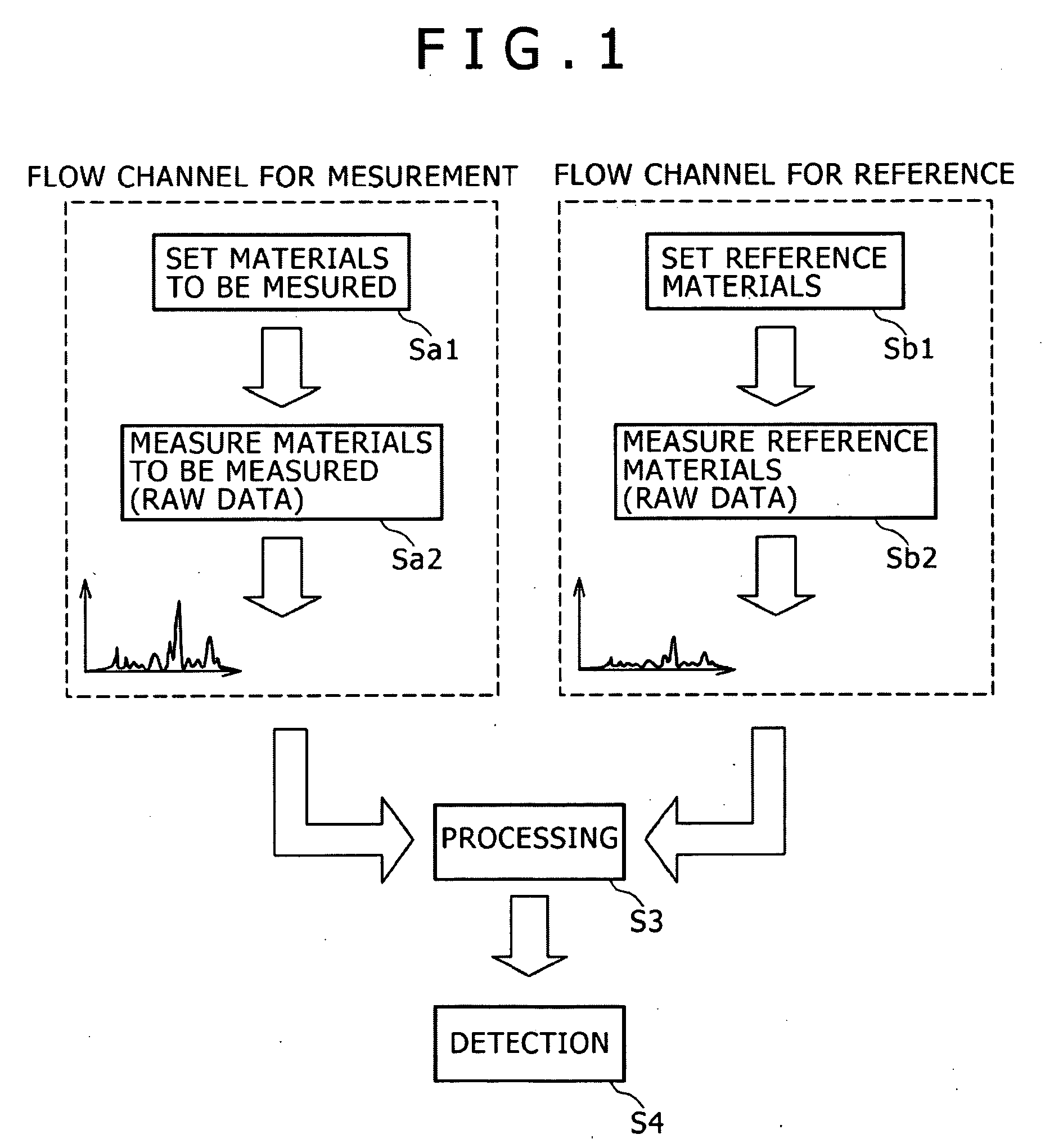

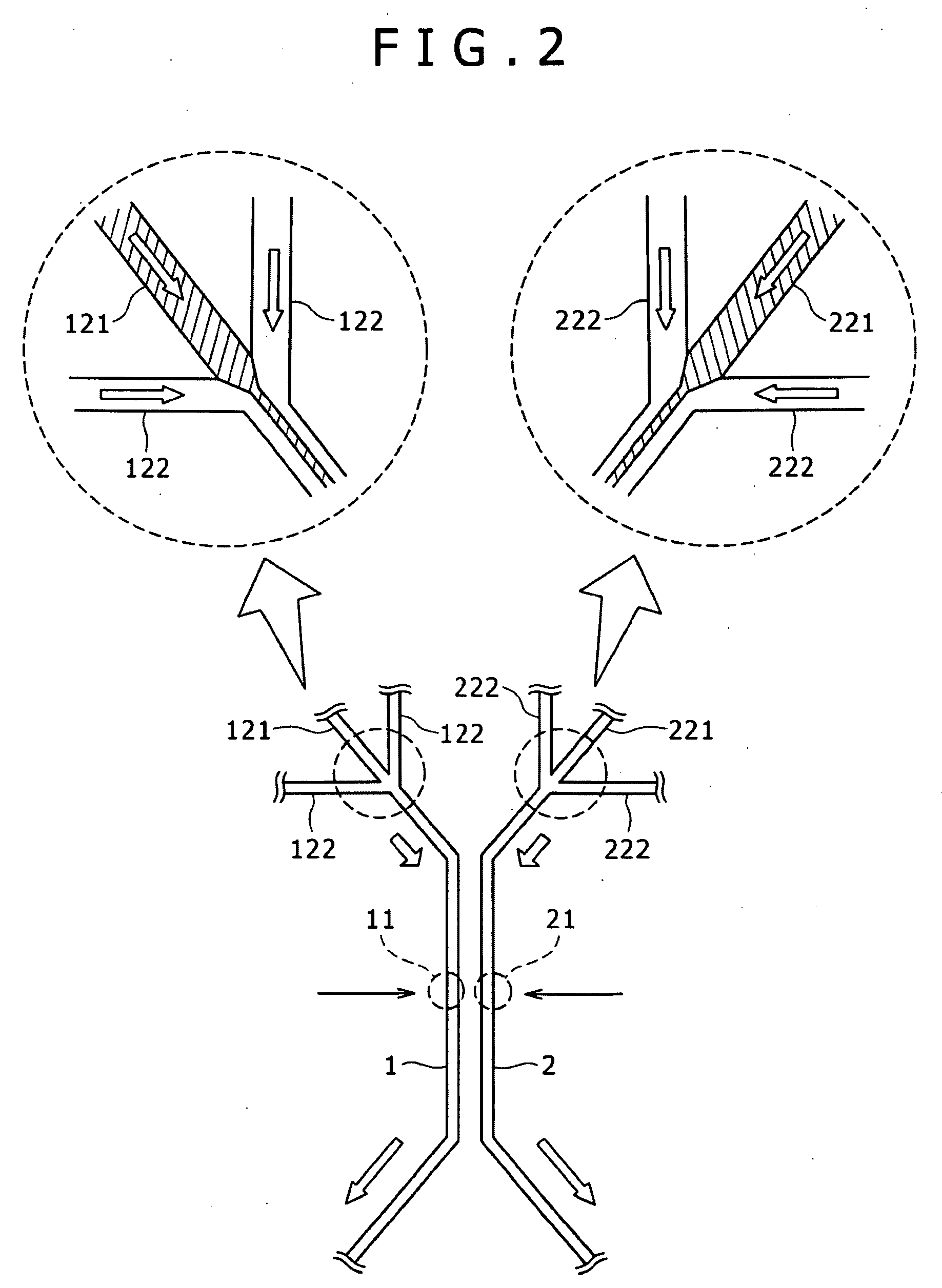

Method for measuring micro-particle

InactiveUS20090109436A1Precise measurementAccurate measurementMaterial analysis by optical meansEngineeringMicro particles

A method for measuring a micro-particle caused to flow through a flow channel, includes the steps of: measuring a property of a material to be measured as a micro-particle in a predetermined position of a flow channel for measurement, and measuring properties of one or more reference materials in a predetermined position of a flow channel for reference while the material to be measured is caused to flow through the flow channel for measurement, and the one or more reference materials are caused to flow through the flow channel for reference; and processing a result of the measurement of the material to be measured in accordance with a result of the measurements of the one or more reference materials.

Owner:SONY CORP

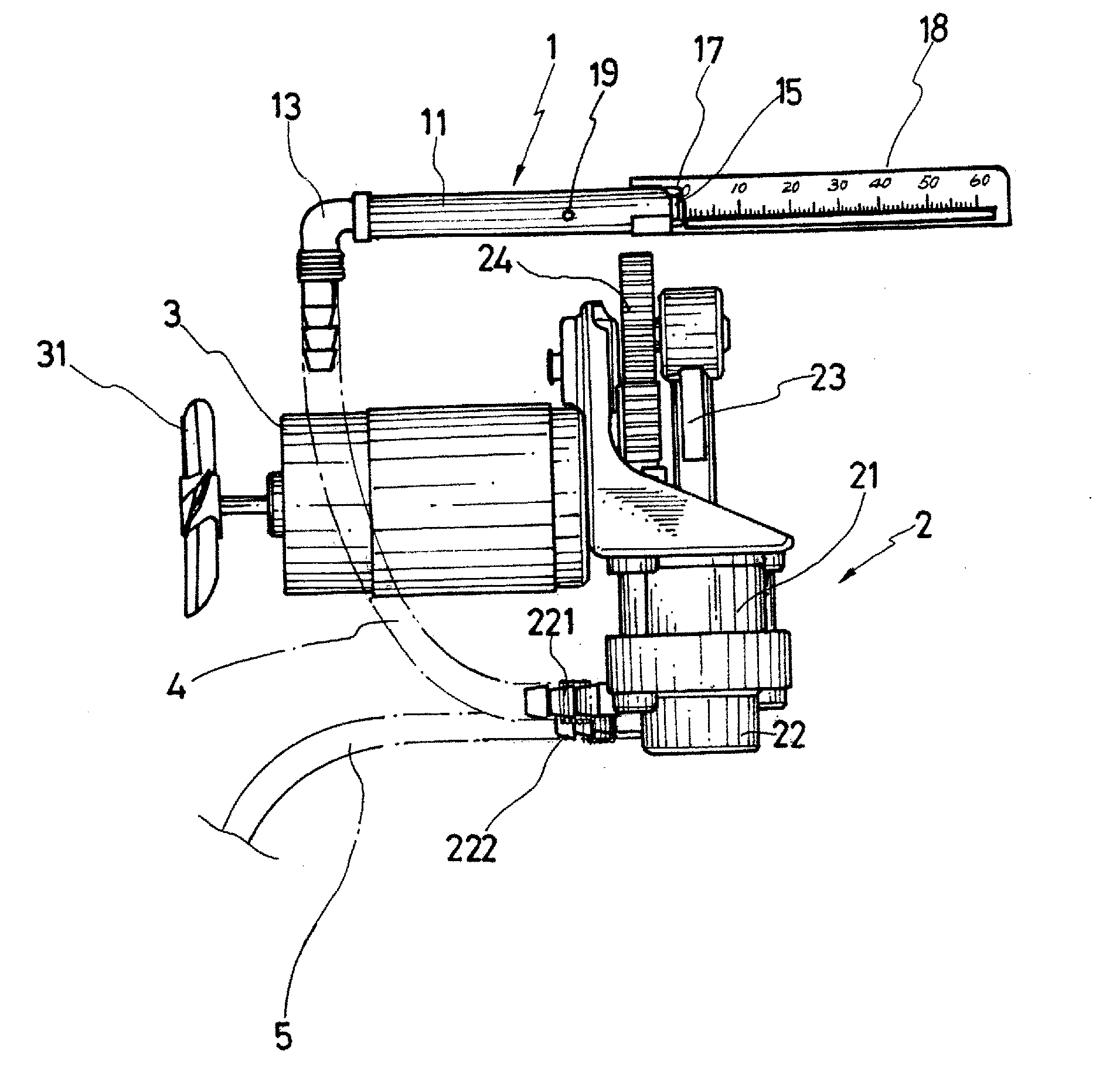

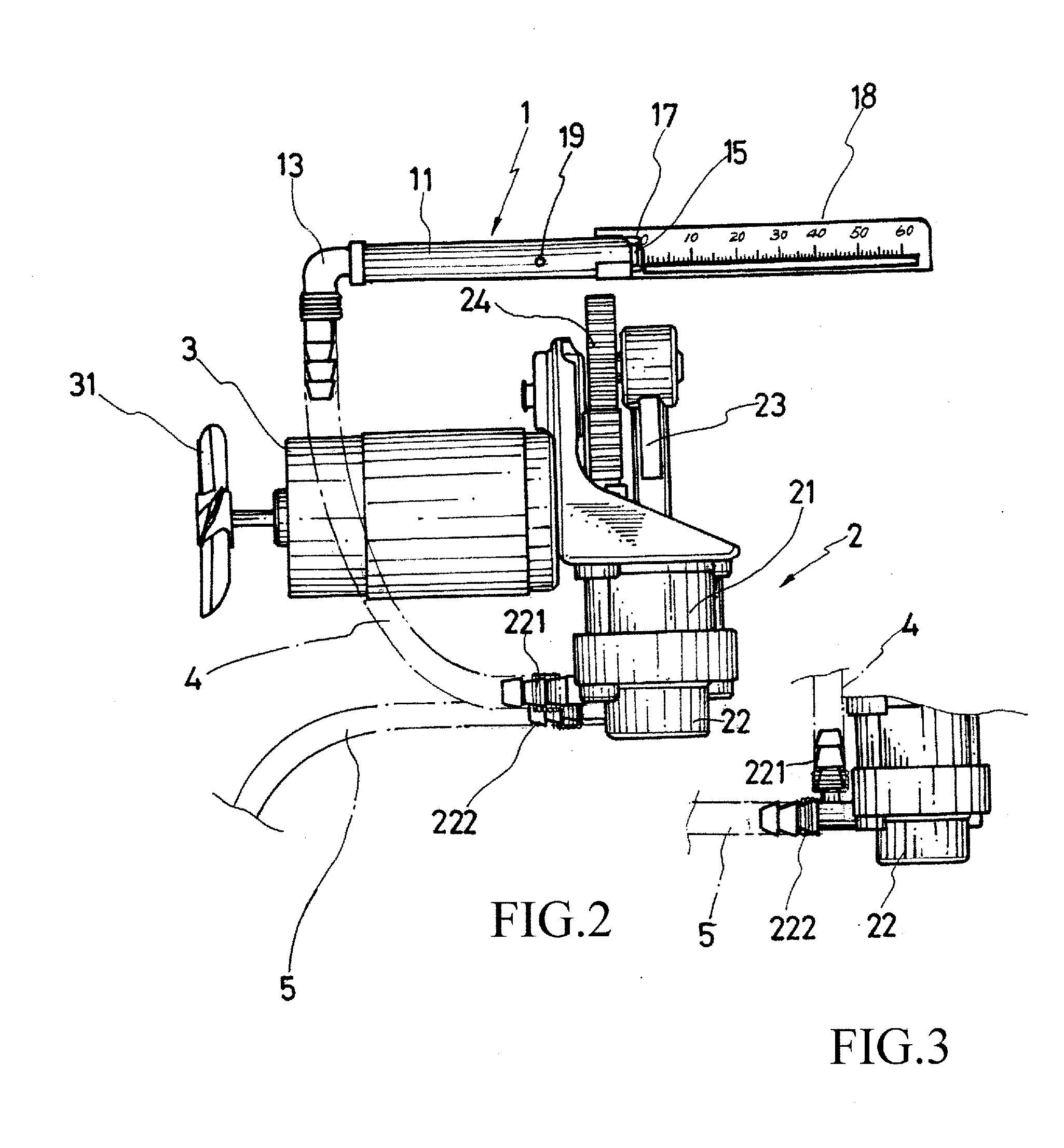

Pressure indication device of inflation machine with safety pressure relief

ActiveUS20140318260A1Precise measurementDurableInflated body pressure measurementFluid pressure measurement using elastically-deformable gaugesPressure levelEngineering

A pressure indication device is provided to connect to an inflation mechanism of an inflation machine. The pressure indication device includes a hollow tubular body in which a push bock is received in a manner of being movable by a pressure conducted into the hollow tubular body and connected to a linearly movable plate and biased by an elastic element. The hollow tubular body has a tubular wall forming a pressure relief hole at a preset position corresponding to a maximum allowable pressure level. A scale bar having graduations is provided along a moving path of the plate. The elastic force of compression of the elastic element serves as a reaction force (restoration and returning force) for the linear movement of the plate. A pressure conducted into the hollow tubular body from the inflation machine drives the plate to move and thus indicates the pressure level.

Owner:ANHUI FUYANG FENGJINBA MASCH & ELECTRIC CO LTD

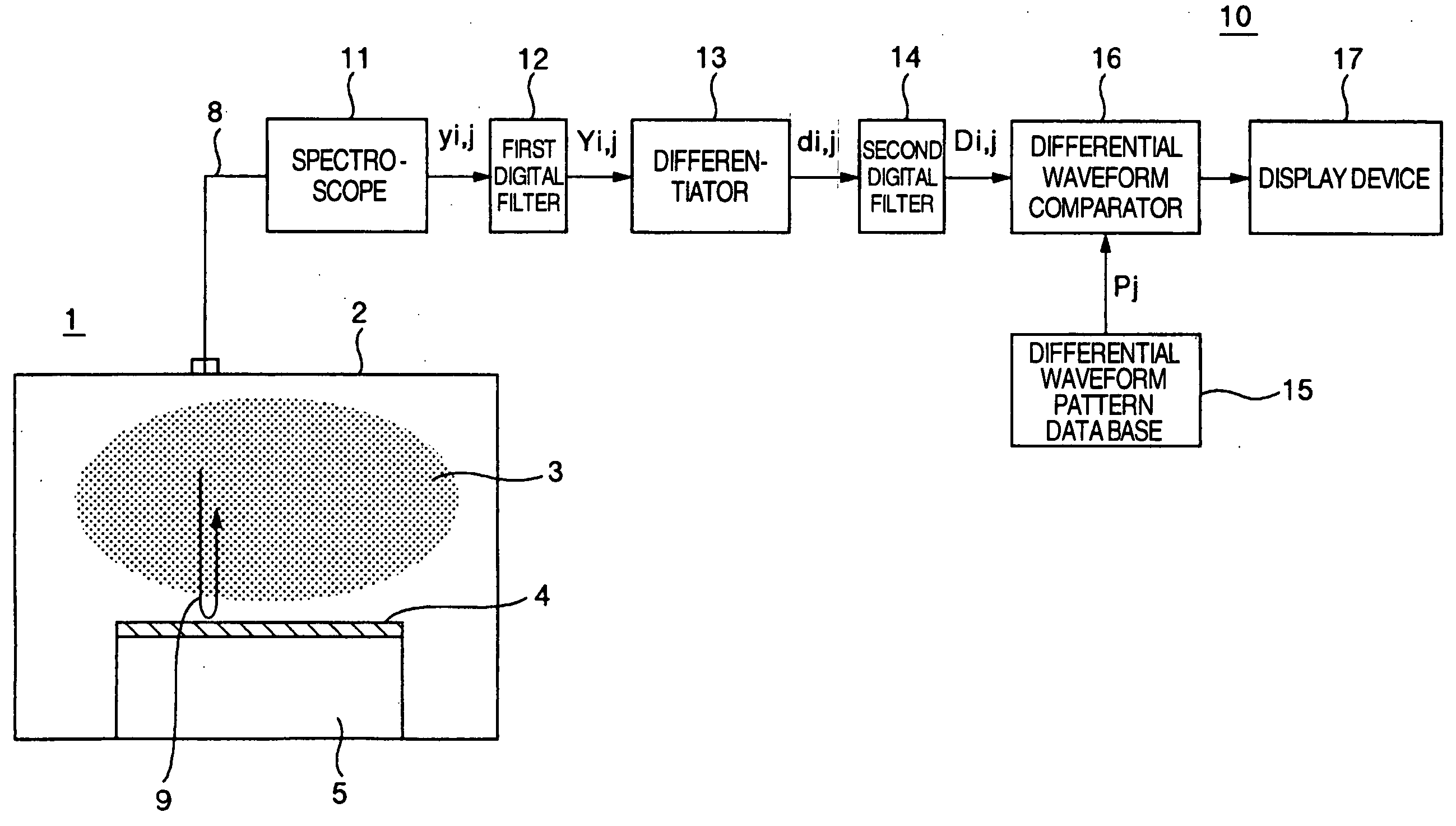

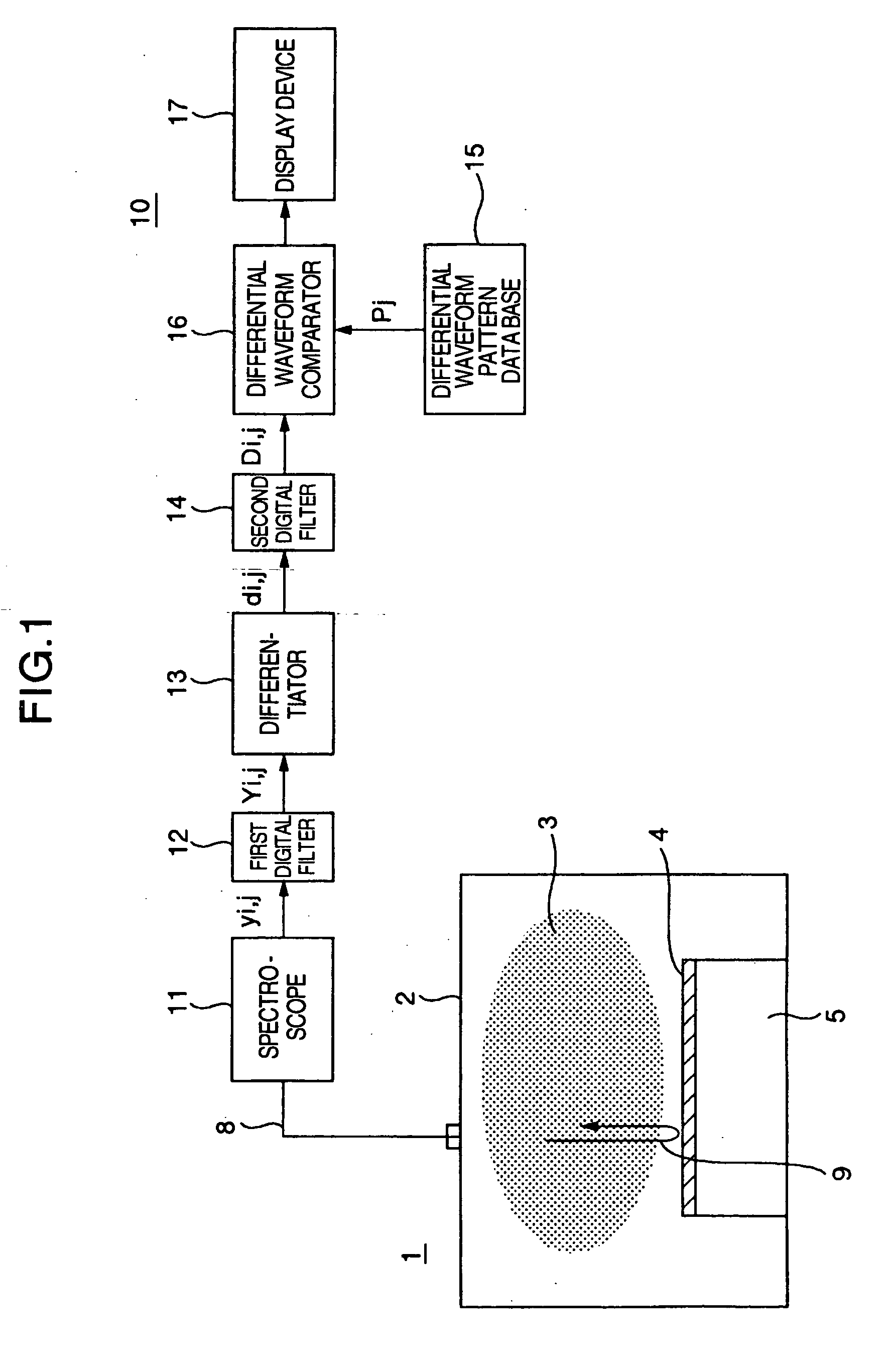

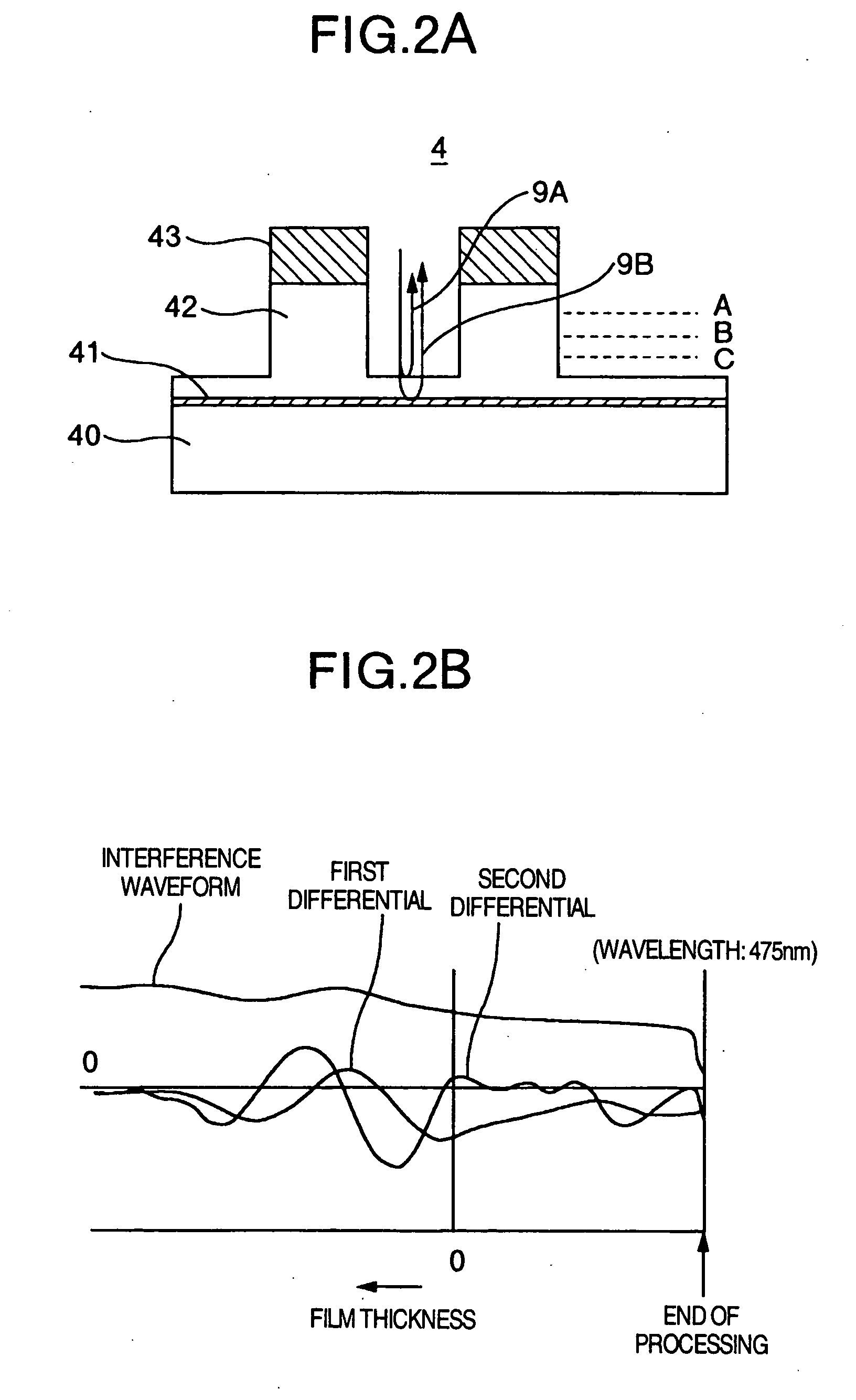

Film thickness measuring method of member to be processed using emission spectroscopy and processing method of the member using the measuring method

InactiveUS20050018207A1Precise measurementInterference of lightRadiation pyrometryInterferometric spectrometryPhysicsSpectroscopy

A standard pattern of a differential value of an interference light is set with respect to a predetermined film thickness of a first member to be processed. The standard pattern uses a wavelength as a parameter. Then, an intensity of an interference light of a second member to be processed, composed just like the first member, is measured with respect to each of a plurality of wavelengths so as to obtain a real pattern of an differential value of the measured interference light intensity. The real pattern also uses a wavelength as a parameter. Then, the film thickness of the second member is obtained according to the standard pattern and the real pattern of the differential value.

Owner:OPNEXT JAPAN INC

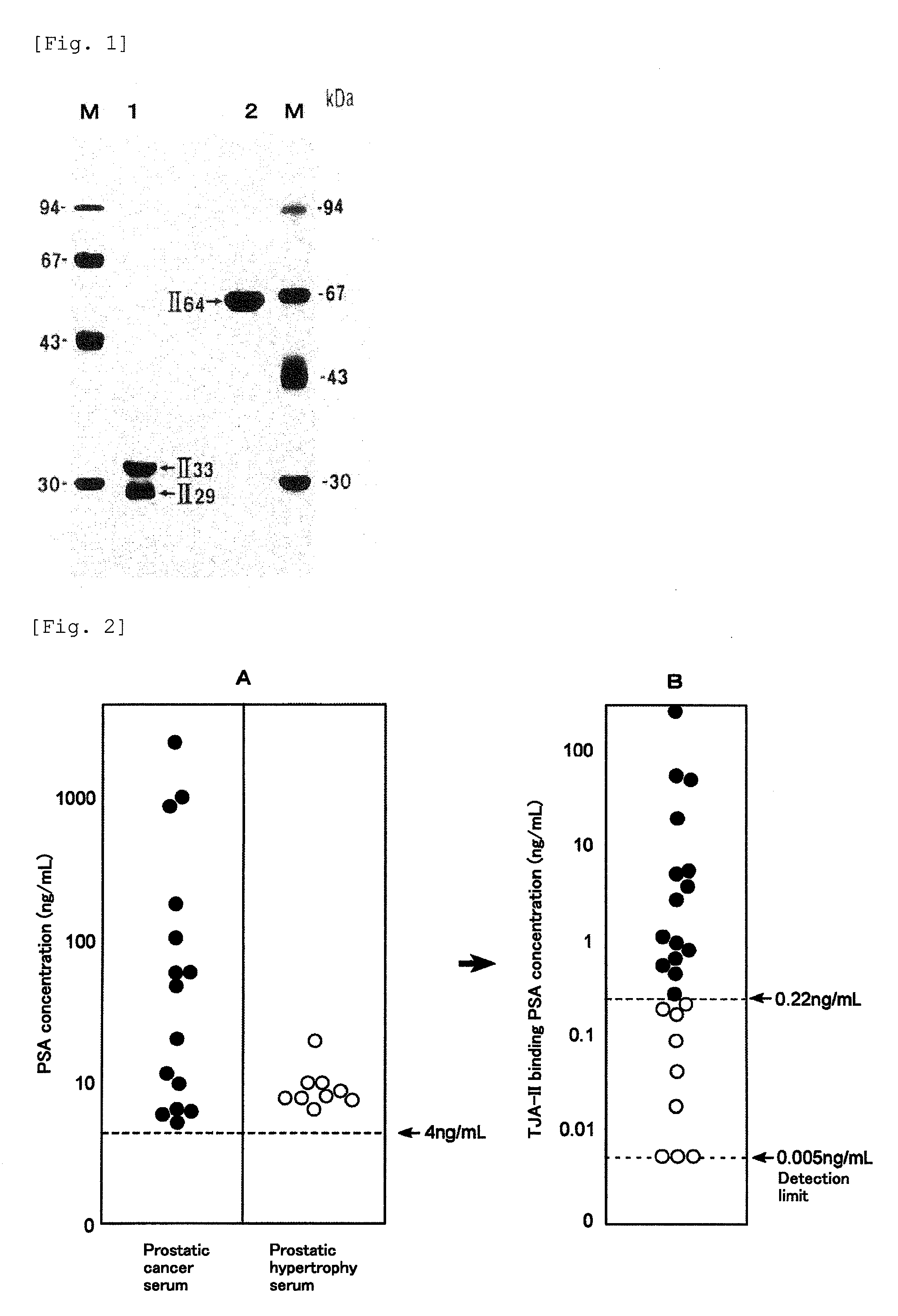

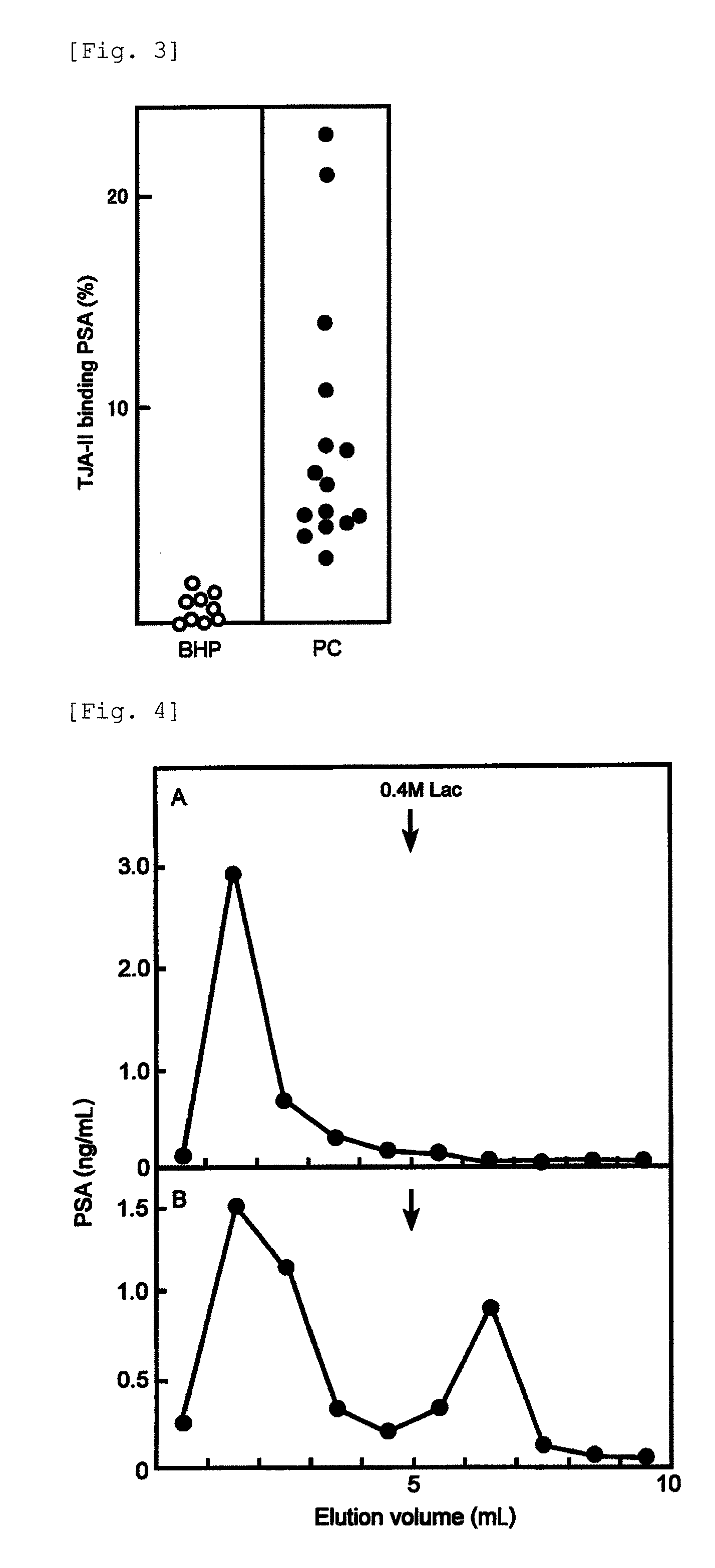

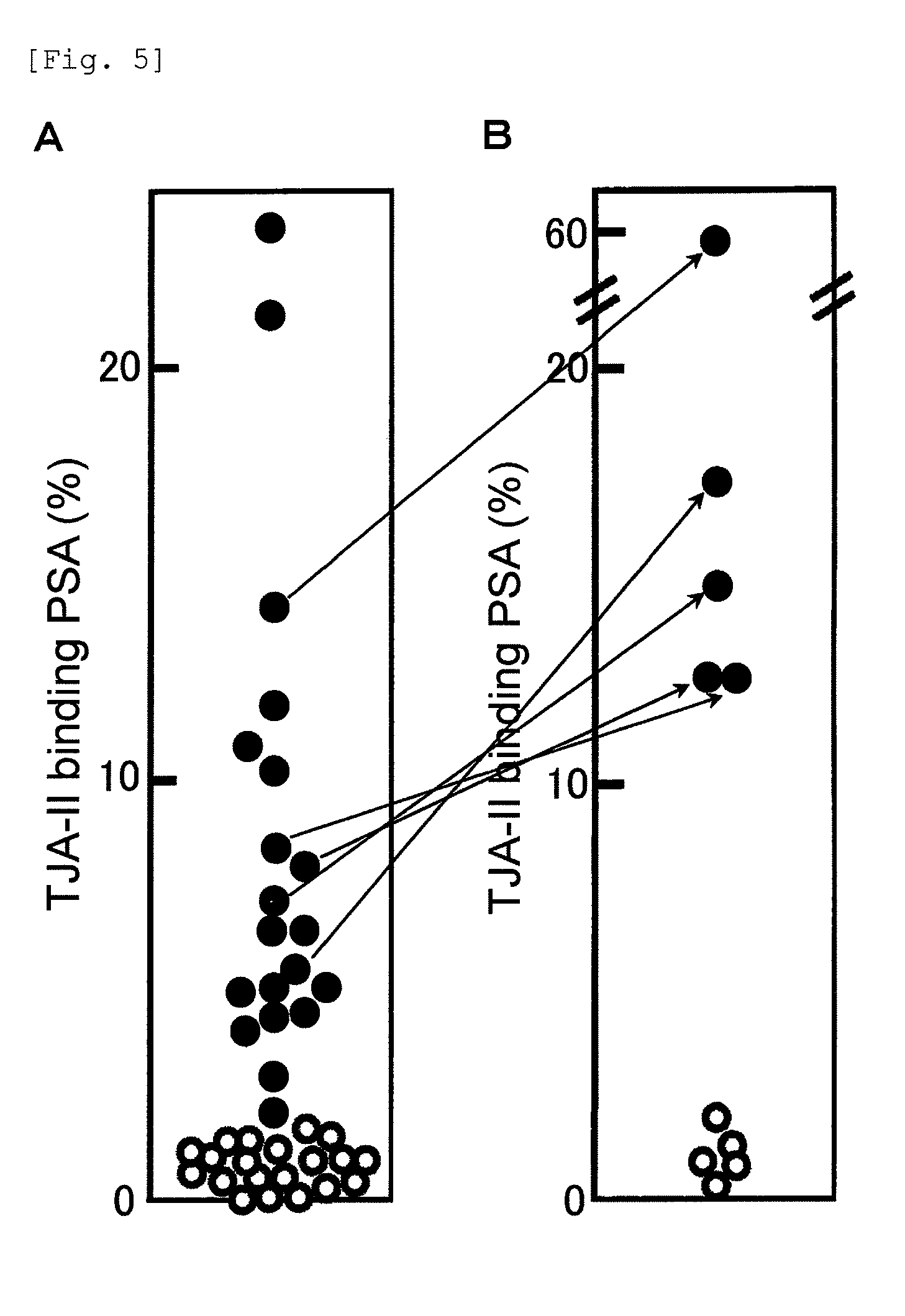

Method for analyzing psa, and a method for distinguishing prostate cancer from prostatic hypertrophy using that method for analyzing psa

ActiveUS20120282612A1Precise measurementDistinguish clearlySugar derivativesMicrobiological testing/measurementUrologyEccentric hypertrophy

A method for distinguishing prostate cancer from prostatic hypertrophy using the method for analyzing PSA and an analysis kit of PSA are provided.An object of the present invention can be solved by being brought into contact a lectin having an affinity for β-N-acetylgalactosamine residues with a sample possibly containing PSA, to determine an amount of PSA having an affinity for the lectin. A method for distinguishing prostate cancer from prostatic hypertrophy can be provided by this method.

Owner:OTSUKA PHARM CO LTD +1

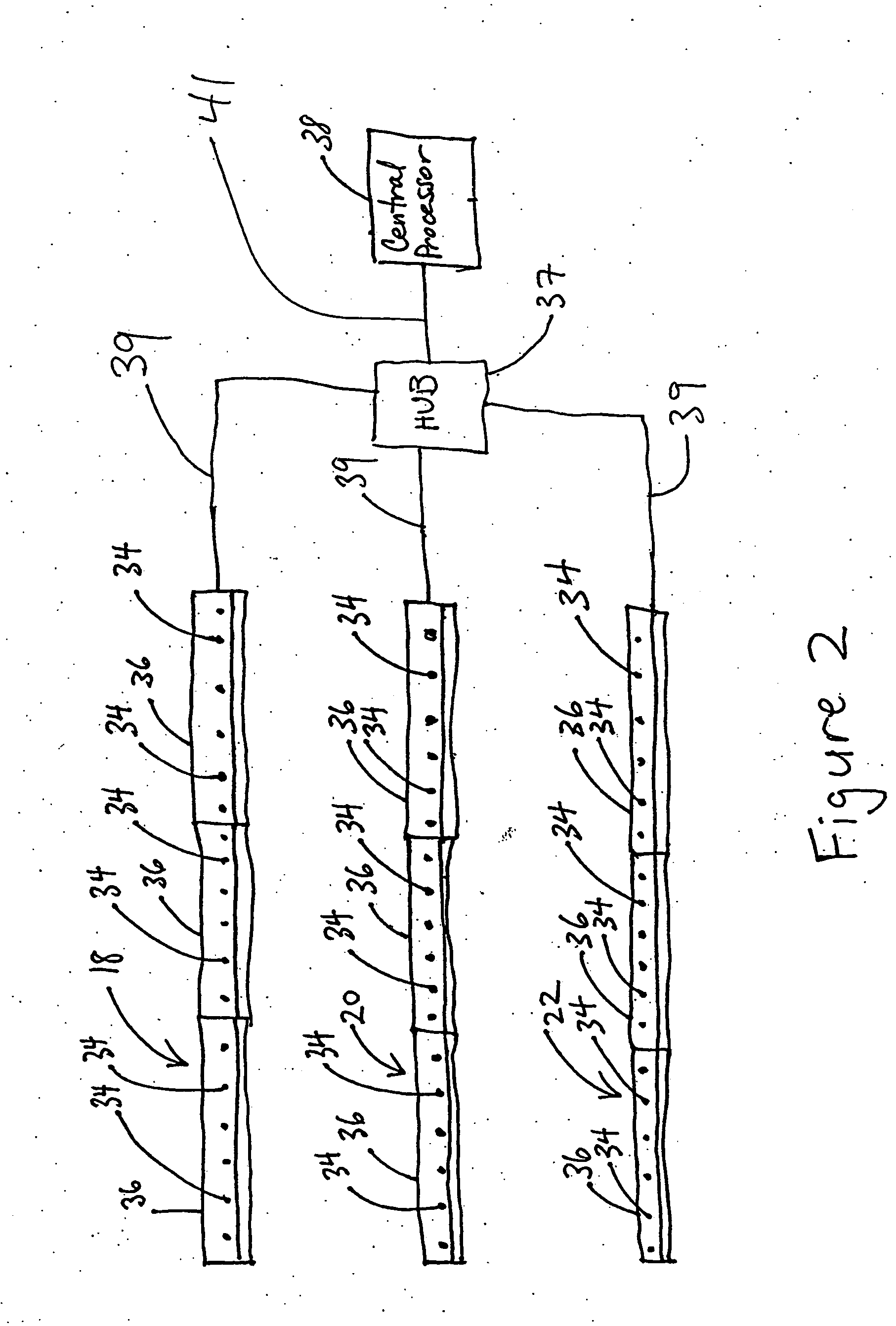

Device for measuring package size

ActiveUS20070261255A1Precise measurementEase and efficiency of useWalking sticksMechanical area measurementsMeasurement deviceEnergy source

A package measurement apparatus comprising three measurement devices, one for each dimension. Each measurement device comprises a plurality of signal receptor modules. Each module comprises a row of signal receptor, and a signal energy source. In a first calibration step, the outputs of each receptor are standardized to reference maximums and minimums. In a second calibration step, calibration sets of receptor outputs are created and recorded. During measurement, a measurement set of receptor outputs is obtained and matched with a calibration set of receptor outputs to determine the dimension of an object.

Owner:GLOBAL SENSOR SYST

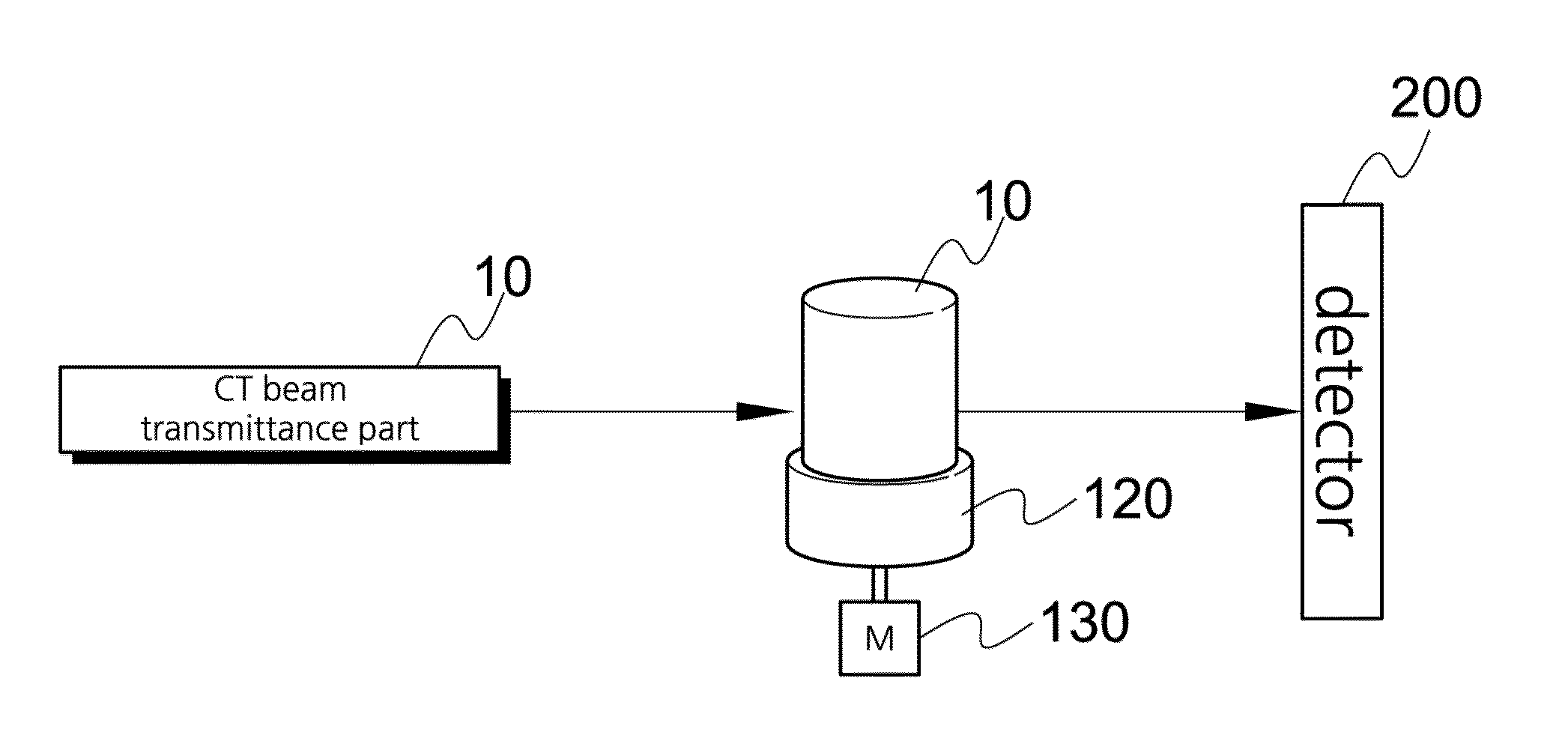

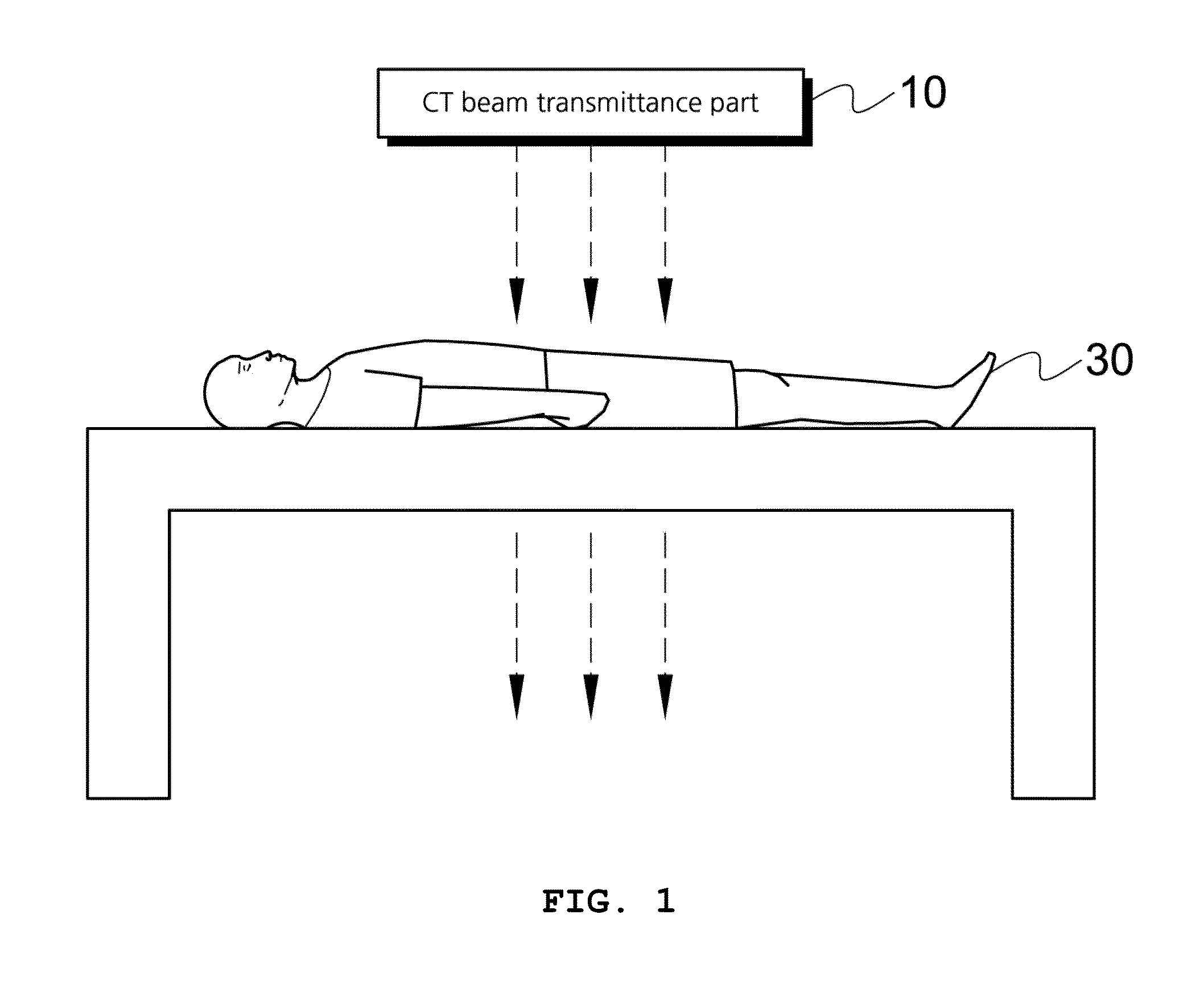

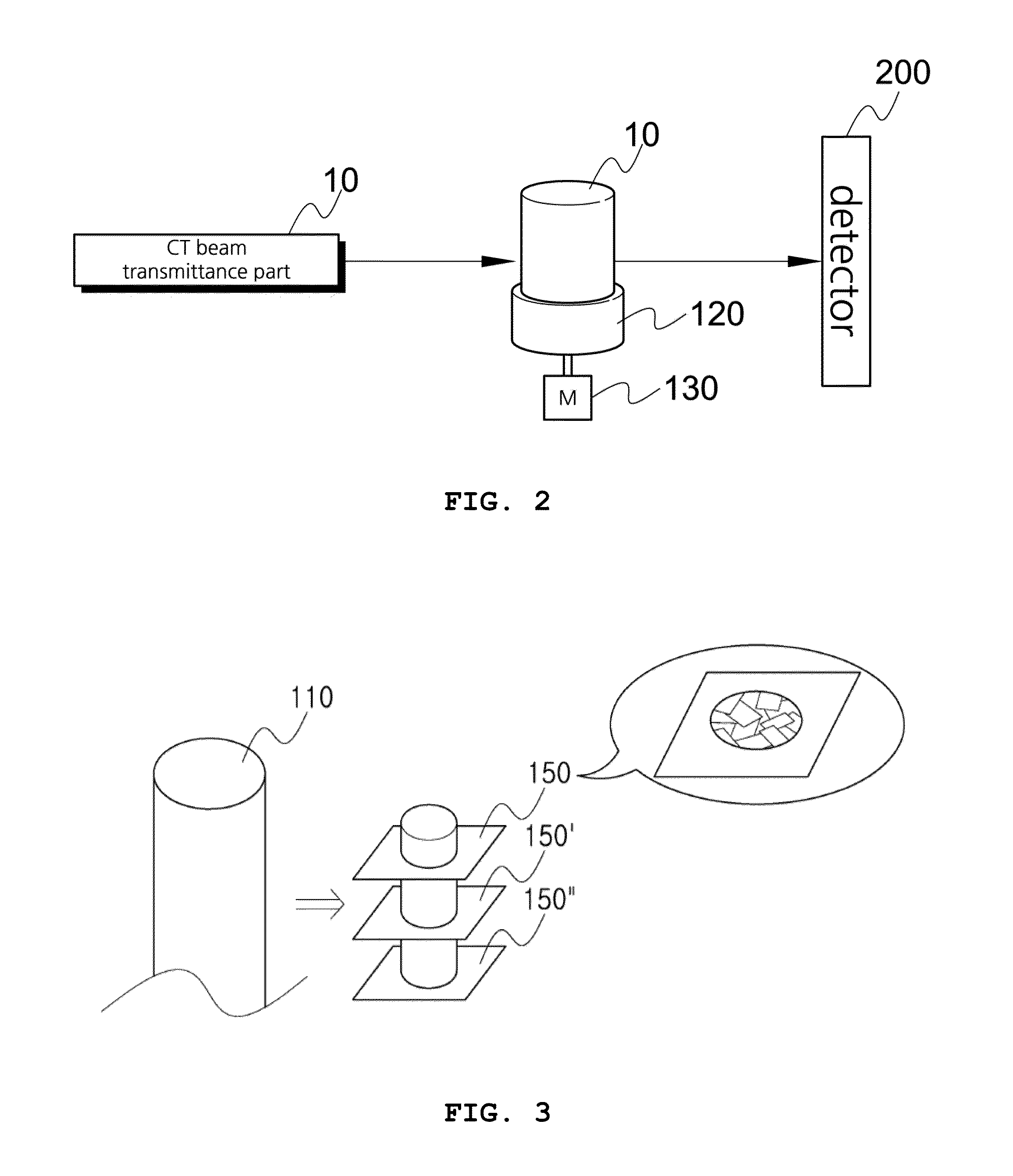

Apparatus for detecting volume of foreign substance existed in core of geological sample using computer tomography apparatus and method thereof

InactiveUS20130083888A1Precise measurementAccurate measurementRadiation/particle handlingX-ray apparatusTomographyPhysics

An apparatus for detecting a volume of a foreign substance existed in a core of a geological sample using a computer tomography apparatus and a method thereof, more particularly an apparatus for detecting a volume of a foreign substance existed in a core of a geological sample using a computer tomography apparatus and a method thereof capable of calculating a volume of any one object among the foreign substance existed in the core.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

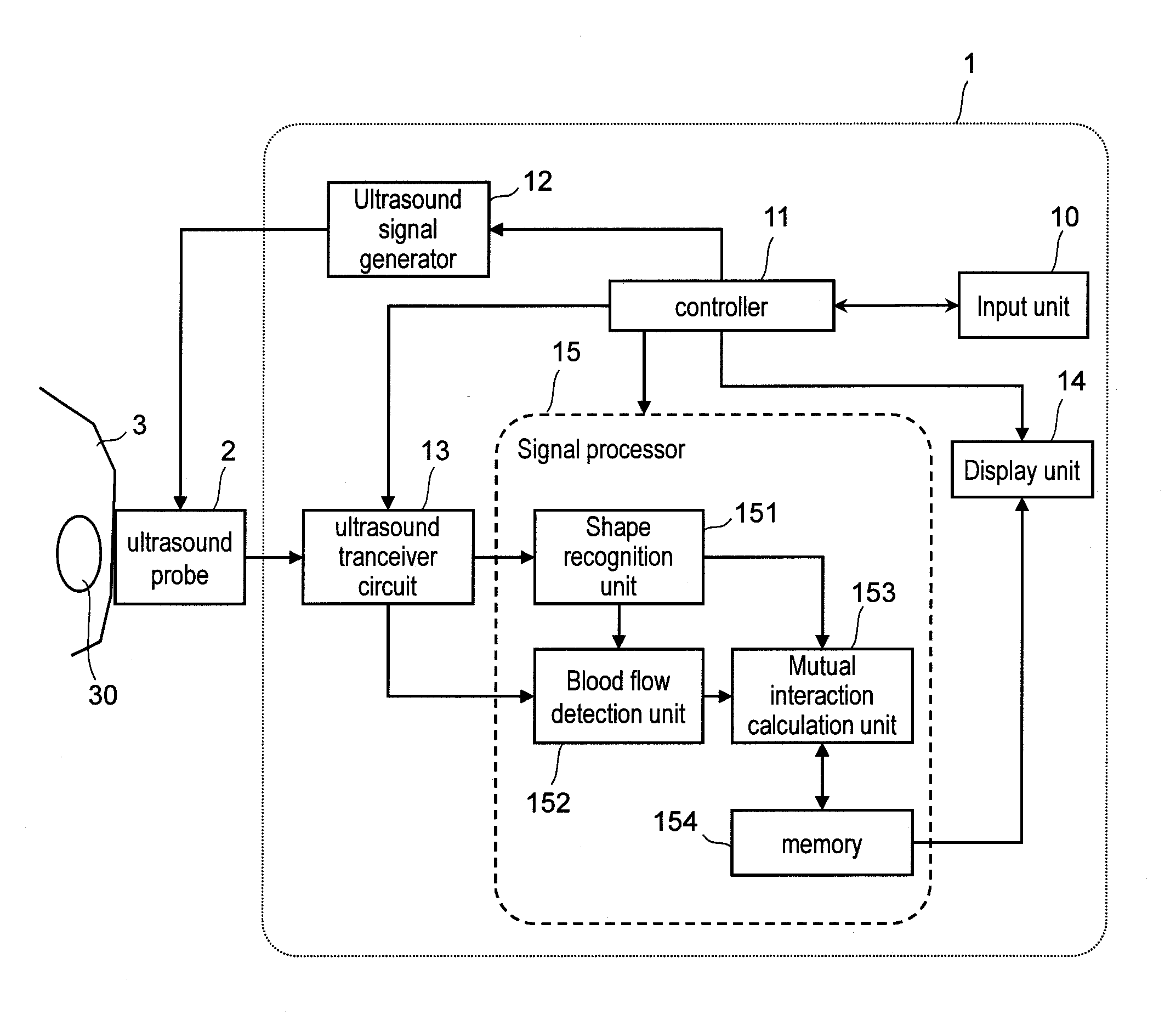

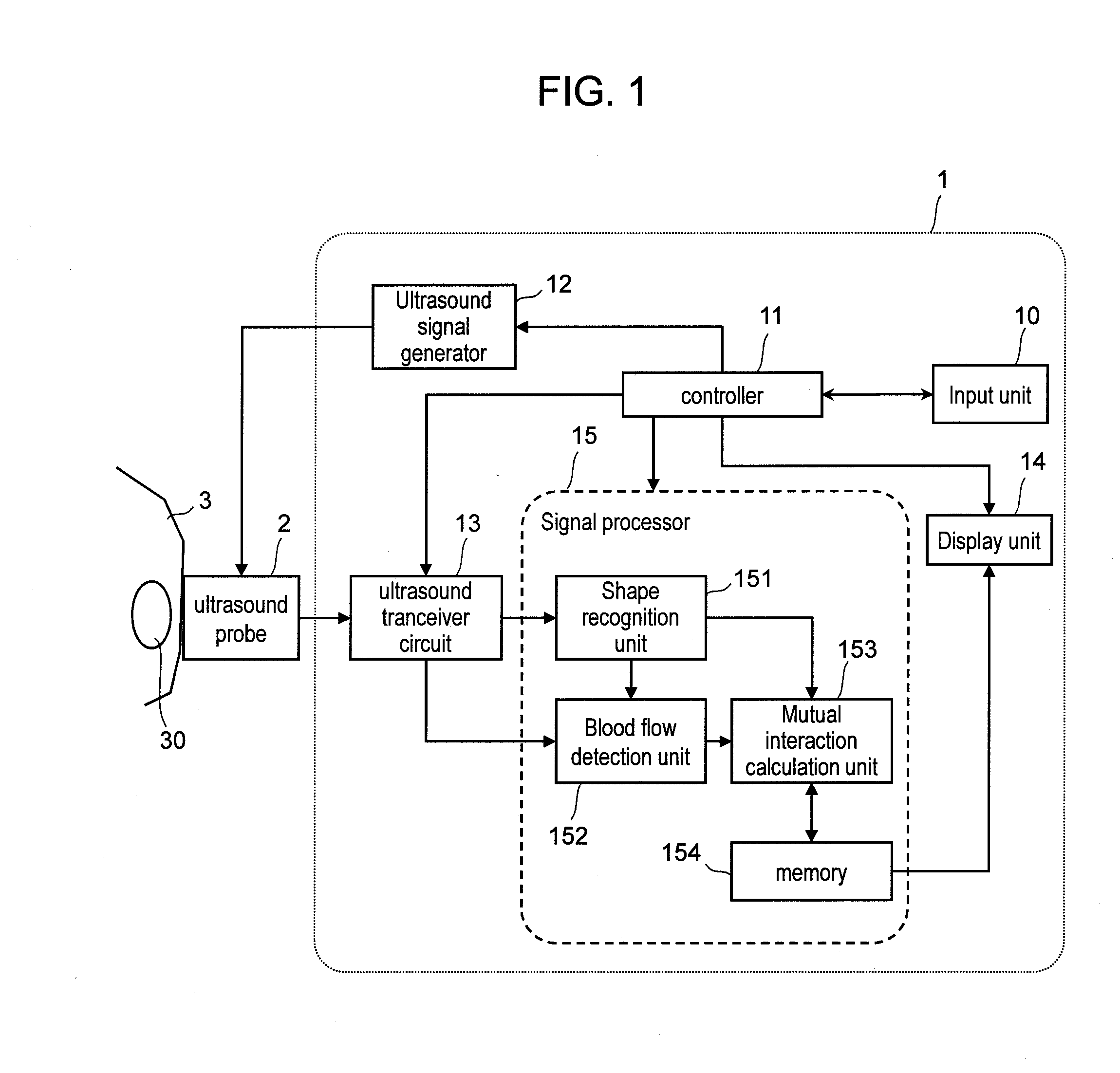

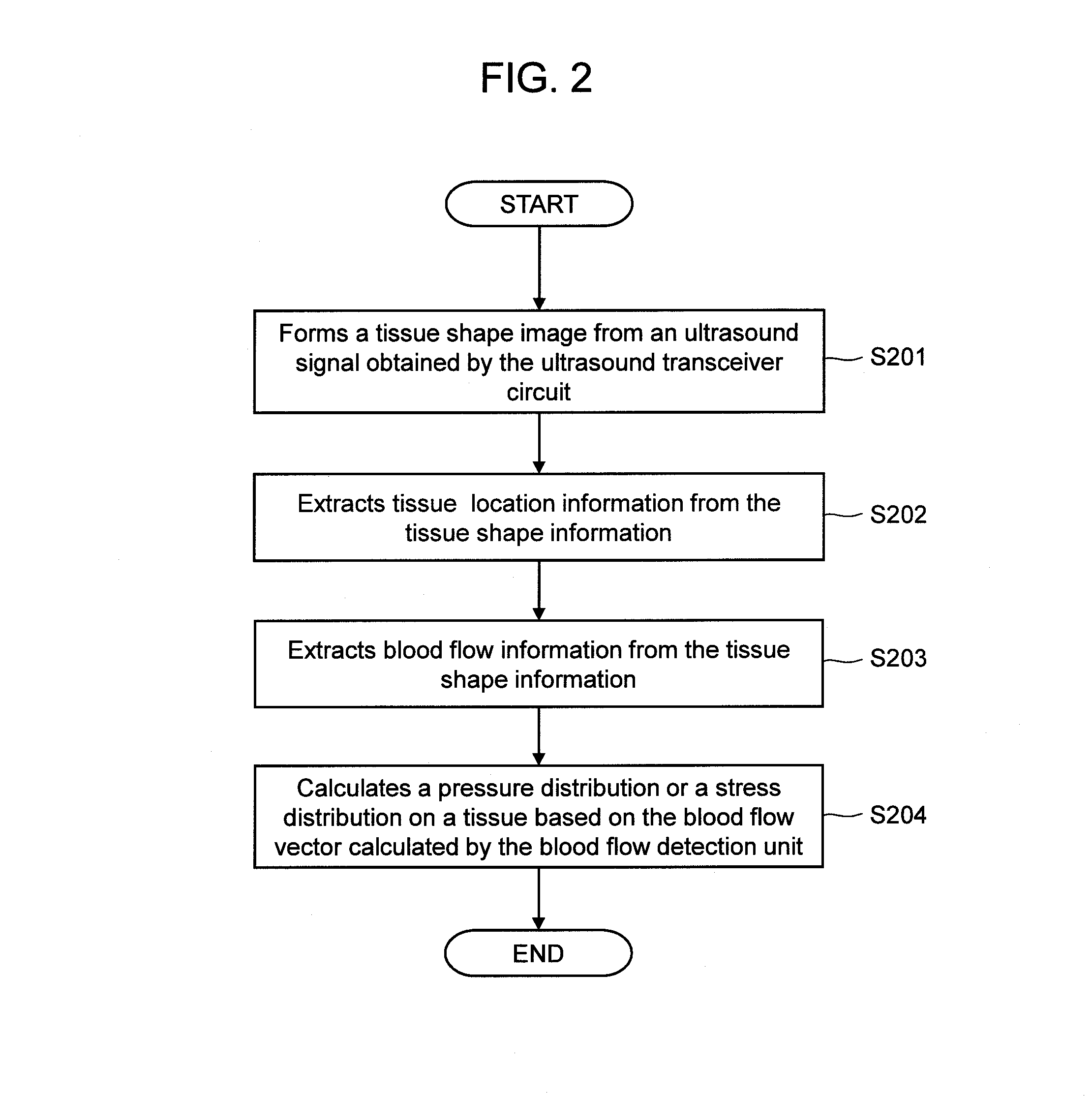

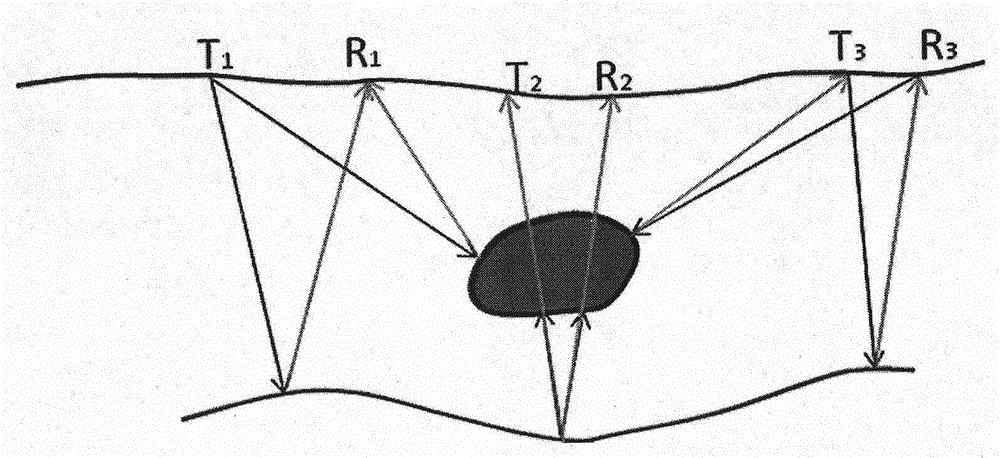

Ultrasound image capture device, ultrasound image capture method, ultrasound image capture program

ActiveUS20130289408A1Precise measurementFlow of bloodBlood flow measurement devicesInfrasonic diagnosticsUltrasound imageSonification

Provided is a technology which quantitatively measures blood flow in the vicinity of circulatory organs. An ultrasound image capture device according to the present invention removes an image portion corresponding to an organ shape by taking the difference of a multi-frame ultrasound image, and thereafter computes a measured value of a blood flow velocity vector on the basis of a plurality of images at different timings (as per FIG. 3).

Owner:FUJIFILM HEALTHCARE CORP

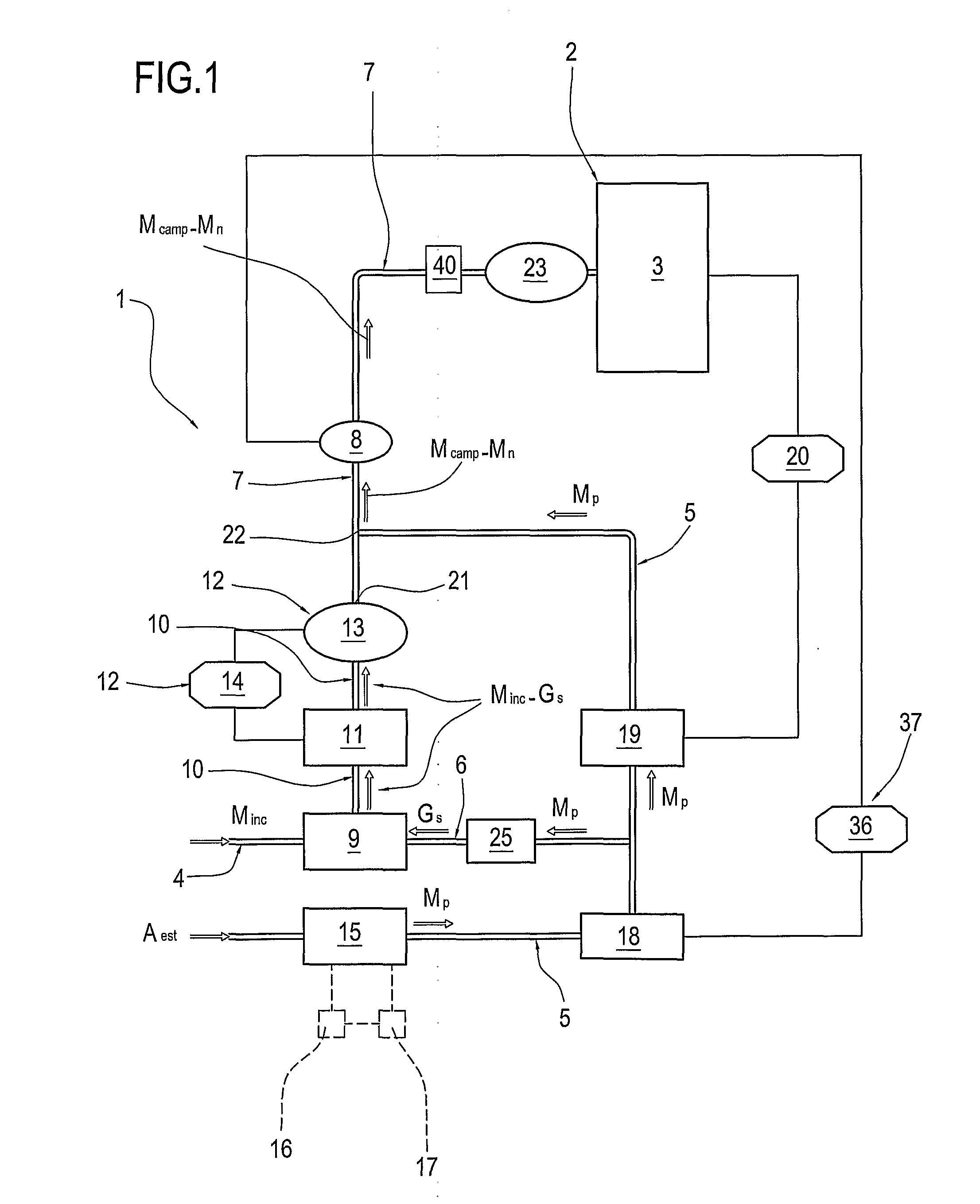

Method and device for detecting the composition of gas mixtures

ActiveUS20100300180A1Economical and reliablePrecise measurementUsing mechanical meansGas analyser calibrationPhysical chemistry

A method for detecting the composition of an unknown gas mixture (Minc) through an electronic nose (2) equipped with a measuring chamber (3) that houses at least one sensor comprises the steps of: calibrating a sensor by feeding a known gas mixture (Mn) into the measuring chamber (3); feeding the unknown gas mixture (Minc) into the chamber (3), while keeping the unknown gas mixture (Mine) in a predetermined desired state; and detecting the composition of the unknown gas mixture (Minc) by means of the sensor.

Owner:SACMI COOP MECCANICI IMOLA S C R L

Tree root system detection method taking ground penetrating radar as tool

InactiveCN104570133ASolve the problem that the distribution cannot be accurately measuredAvoid damageDetection using electromagnetic wavesTree rootEstimation methods

The invention discloses an estimation method for measuring accumulation and biomass of a tree root system with a ground penetrating radar. The method is characterized by comprising the steps of detecting around a tree root with the ground penetrating radar, detecting a distribution form of the tree root system via a received radar echo signal, and estimating the biomass of the underground tree root system by establishing a relationship between a radar detection signal and a measured characteristic of the tree root system.

Owner:BEIJING FORESTRY UNIVERSITY

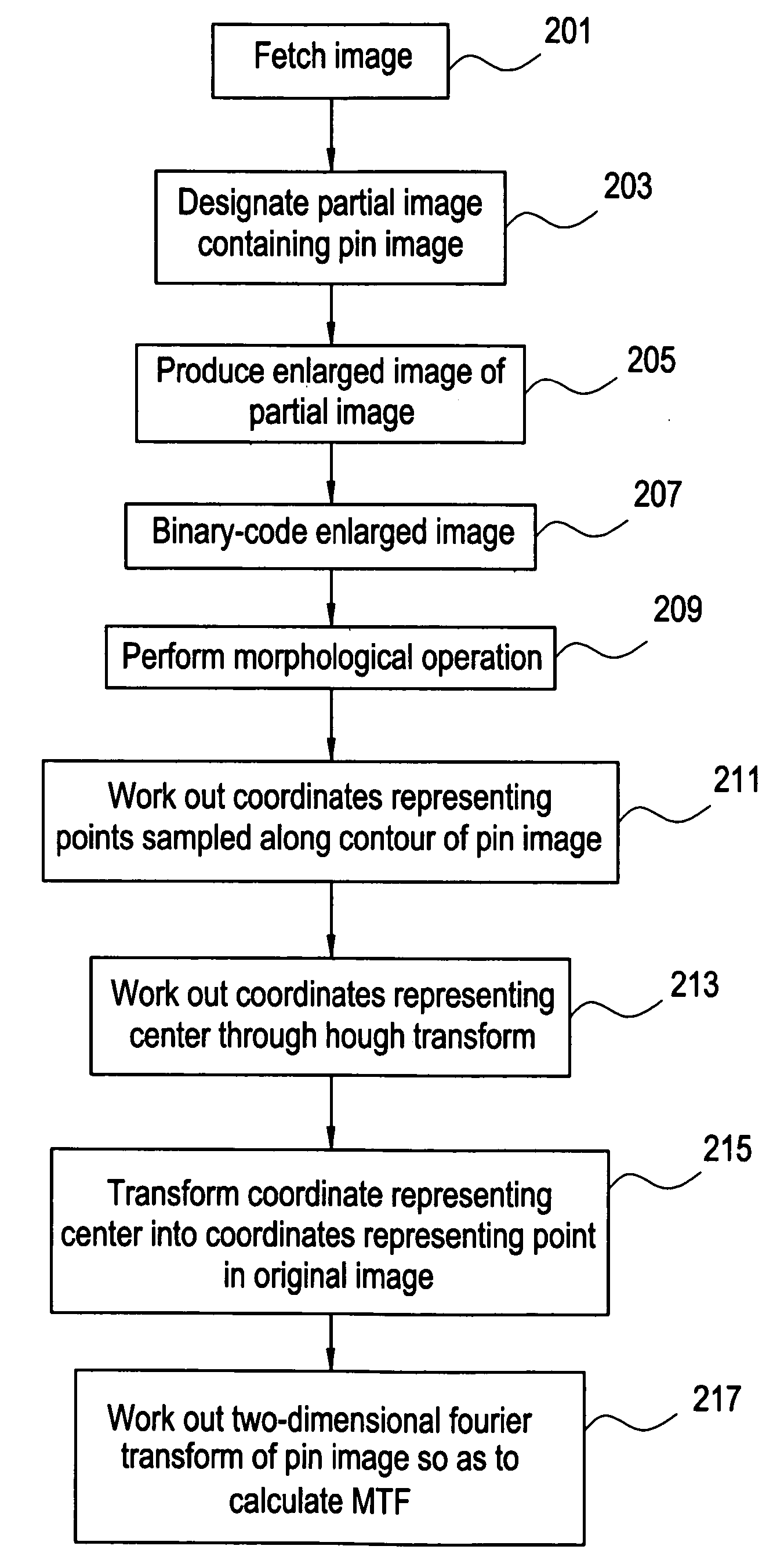

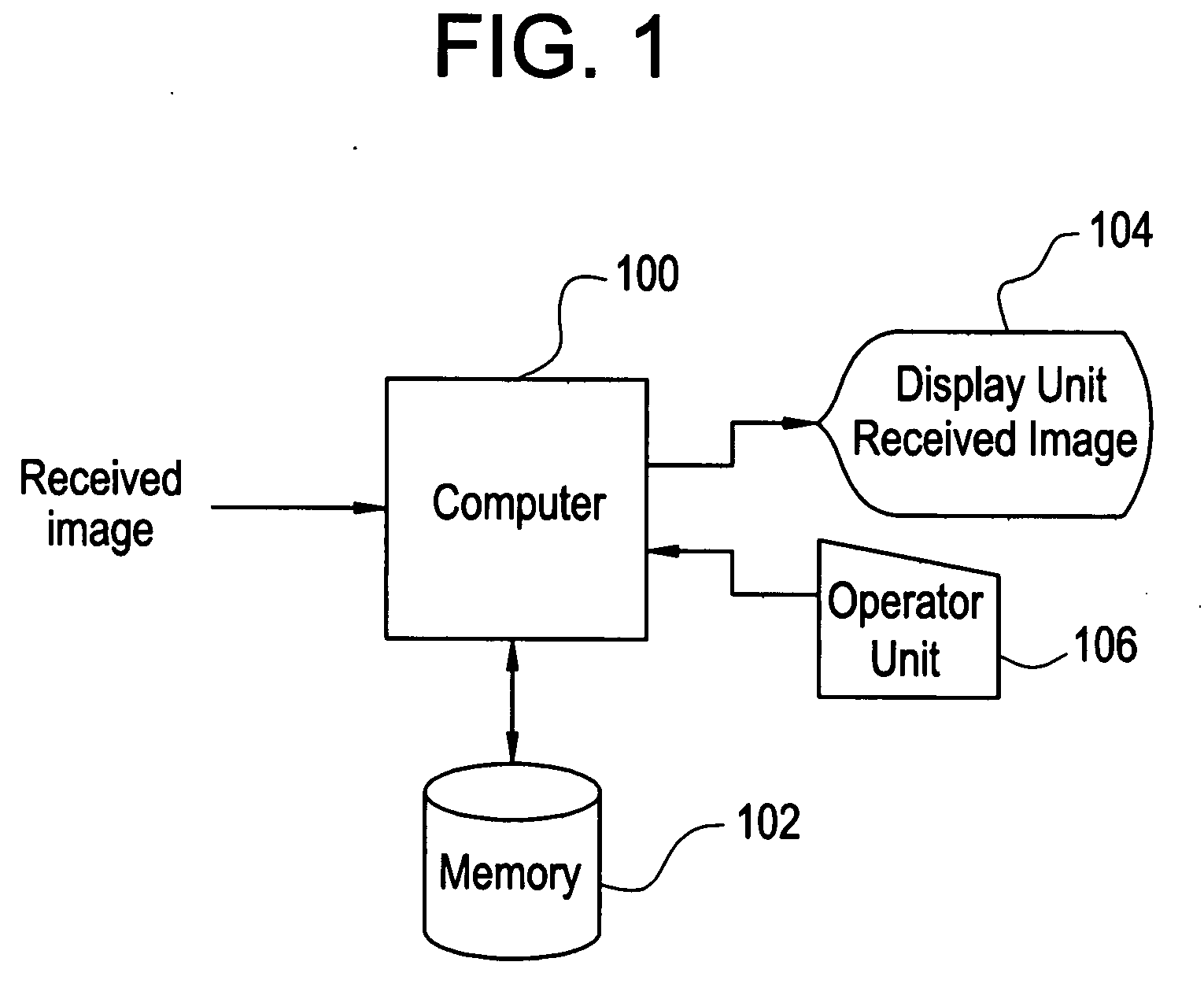

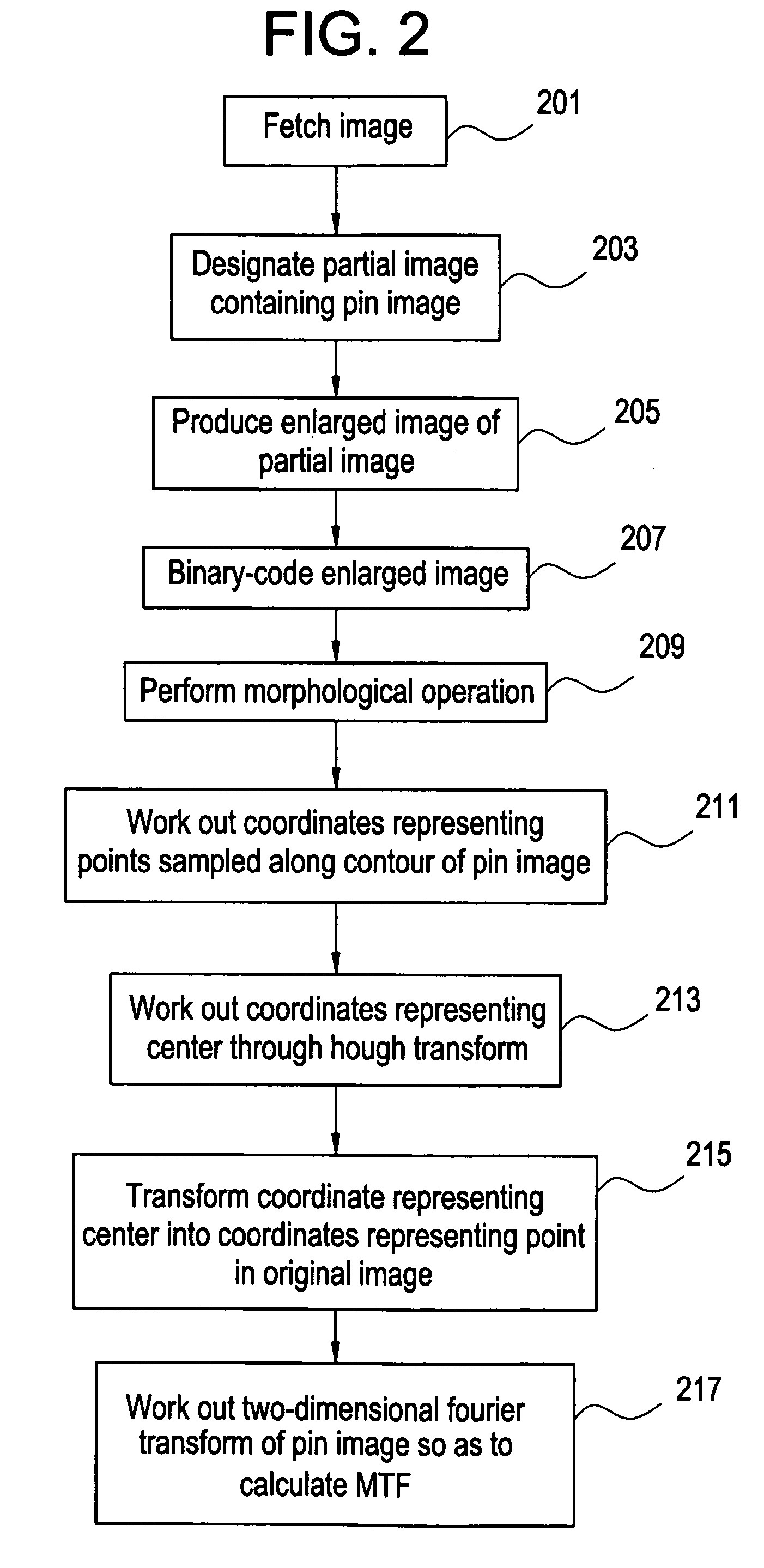

MTF measuring method and system

ActiveUS20050100244A1Precise measurementHigh precision measurementImage analysisCharacter and pattern recognitionLine Spread FunctionBinary encoding

A method of measuring a modulation transfer function (MTF) includes detecting the center of a line spread function (LSF) image in order to calculate an MTF. For this purpose, an enlarged image of a portion of an image containing the LSF image is created, and binary-coded based on a threshold. A morphological operation is performed on the binary-coded image. Coordinates representing points that define the contour of the resultant image are sampled, and used to work out coordinates representing the center of a circle through Hough transform. The coordinates representing the center are transformed into coordinates representing a point in an original image.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

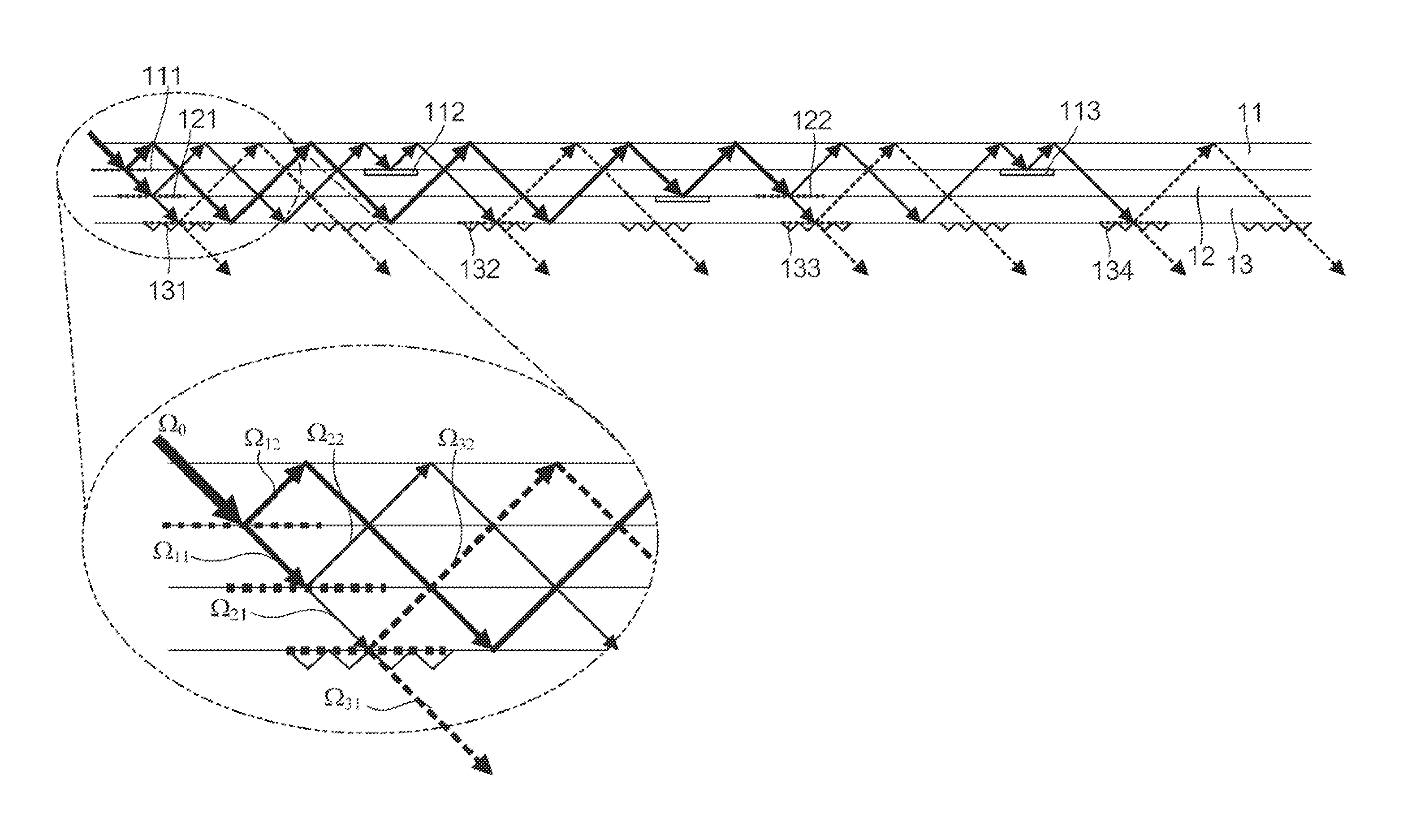

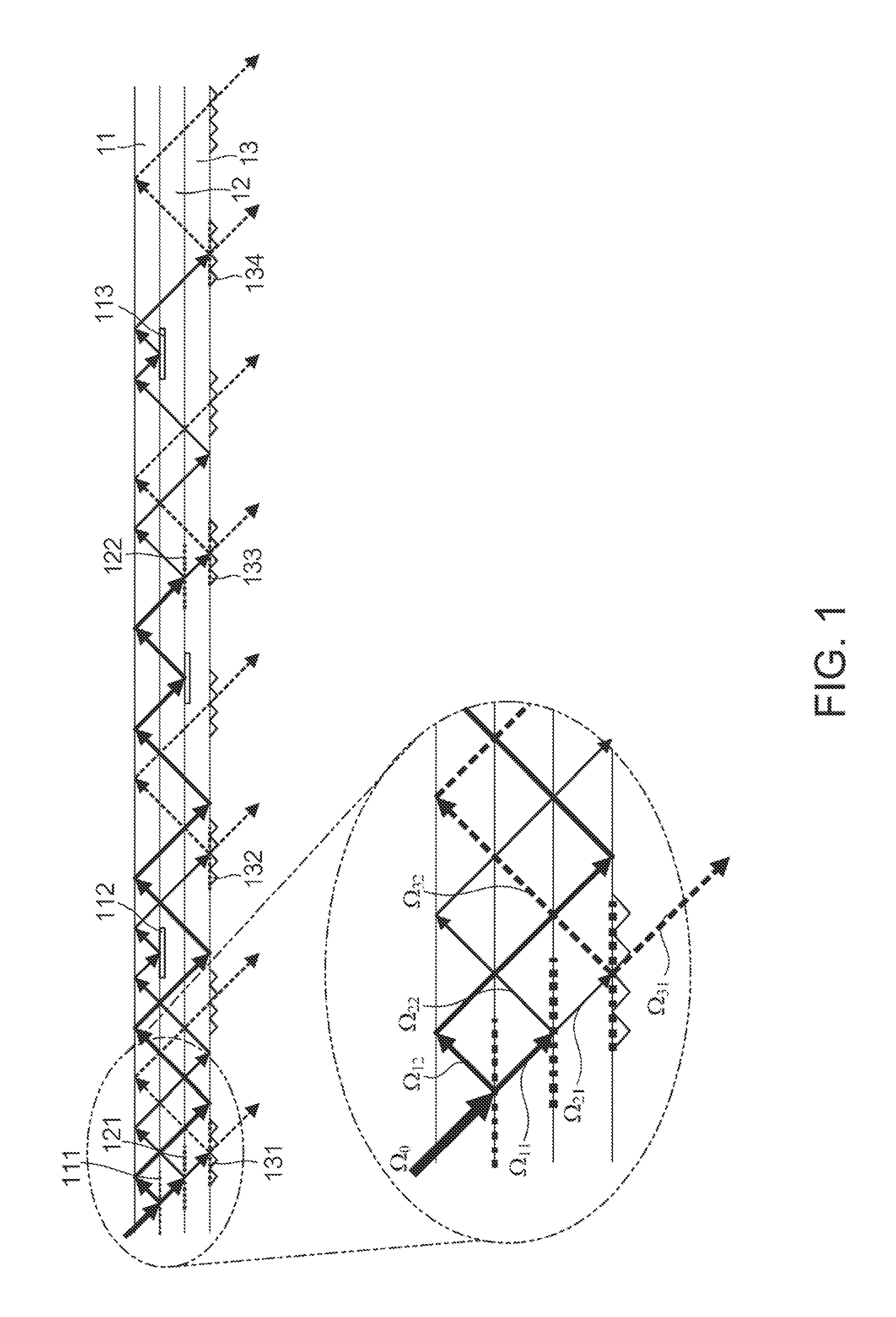

Light divider and magnetism measurement apparatus

ActiveUS20150123653A1Precise measurementUniform dividedCoupling light guidesMagnetic field measurement using magneto-optic devicesLuminous fluxOptoelectronics

A light divider includes a light guide having a first surface and a second surface that reflect light incident on the light guide, the light guide causing the light to propagate through a portion between the first surface and the second surface, light dividing films that are provided in the light guide and so characterized that the light dividing films not only reflect but also transmit the light, and a plurality of light extracting portions that are provided on the first surface and allow light fluxes that the light dividing films have transmitted to exit through the first surface.

Owner:COLUMBIA PEAK VENTURES LLC

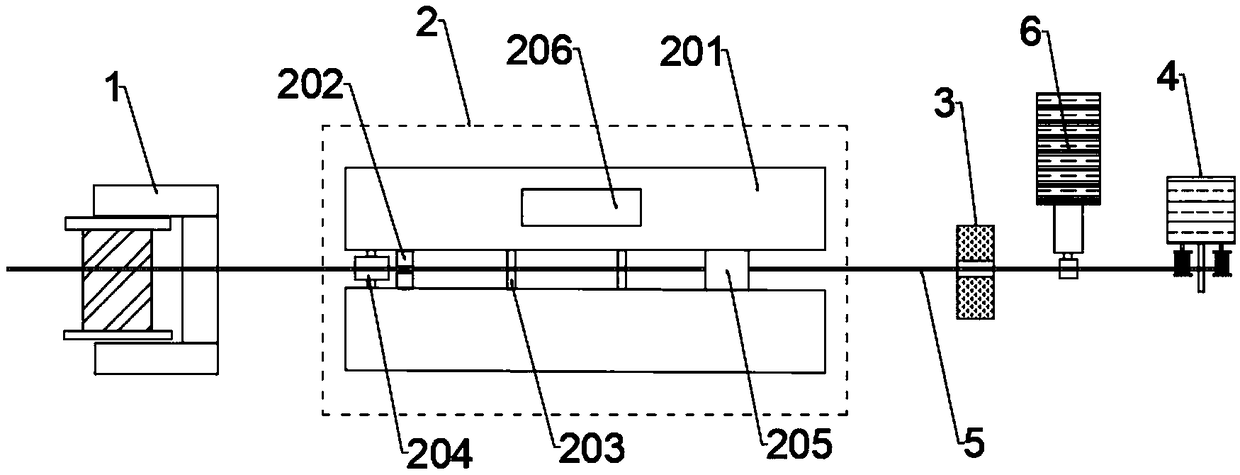

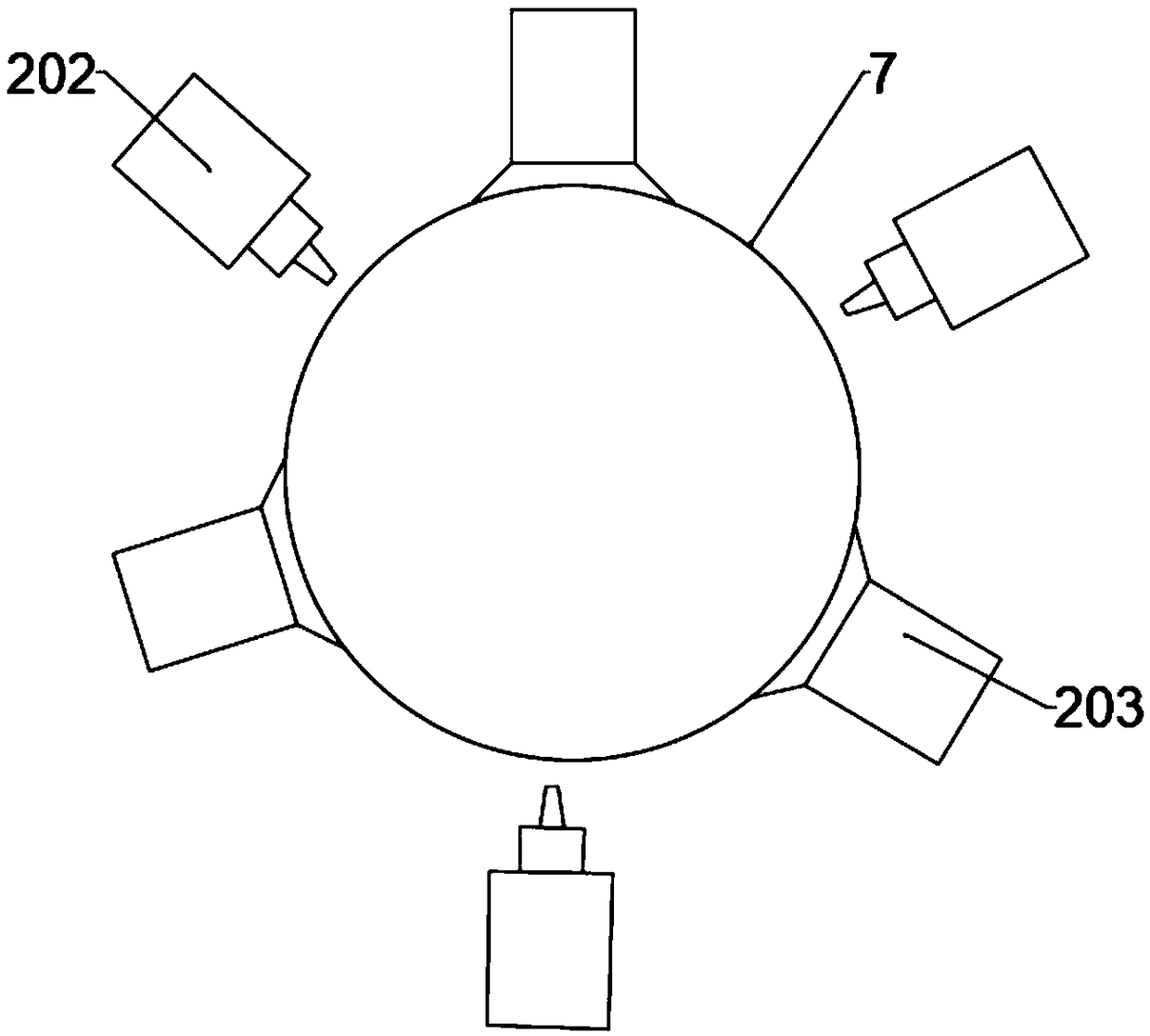

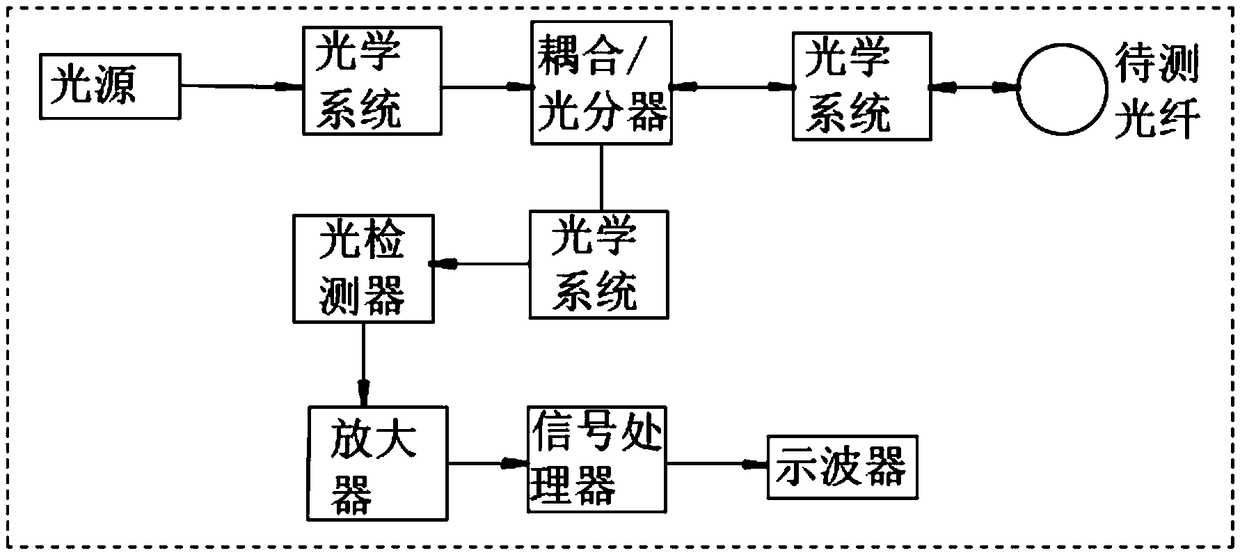

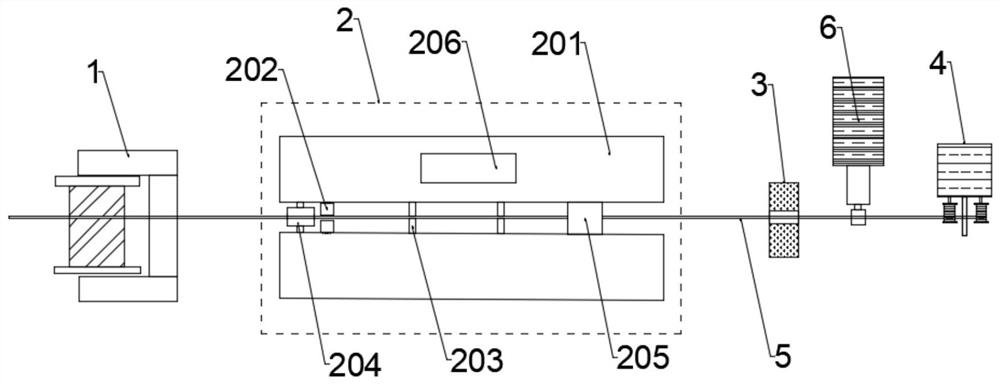

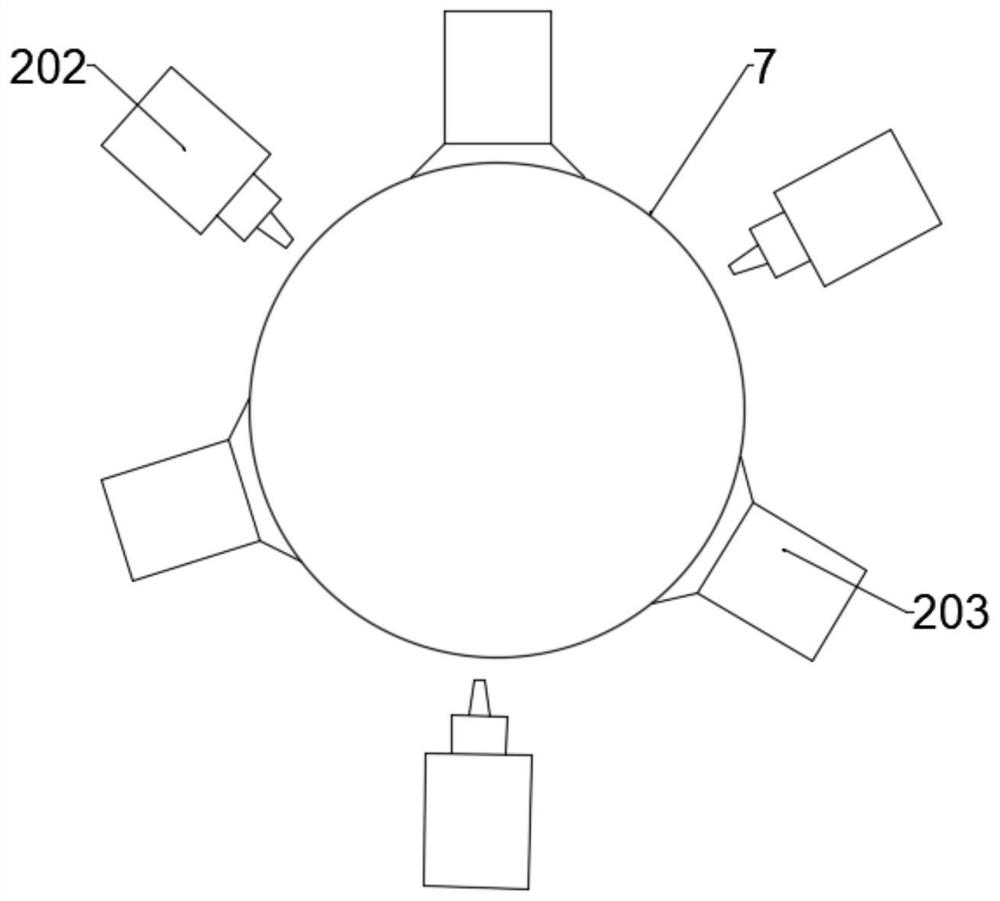

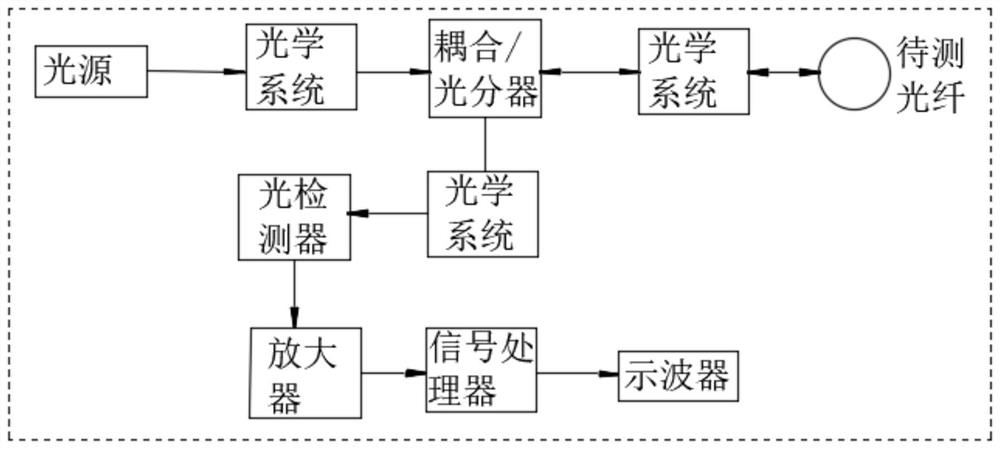

Line breakage automatic testing device for production of communication optical fiber cable

ActiveCN108957209AImprove quality requirementsDetect disconnectionScattering properties measurementsElectrical testingFiberProduction line

The invention discloses a line breakage automatic testing device for production of a communication optical fiber cable. The device comprises a production line platform. The leftmost end of the production line platform is provided with a pay-off device. The right side of the pay-off device is provided with a two-stage optical fiber detecting assembly. The right side of the two-stage optical fiber detecting assembly is provided with a diameter measuring instrument. The right side of the diameter measuring instrument is provided with a sheath processing device. The rightmost end of a production line platform is provided with a wire winding machine. A to-be-tested optical fiber is arranged above the production line platform. According to the line breakage automatic detecting device, a two-stage optical fiber testing assembly is utilized; and measurement is performed according to a comparison method in which a returning signal is received by means of a backward scattering method and a manner of utilizing optical-magnetic modulation and converting modulated light to an electric signal. Because the measuring facility for the electric signal is more accurate, the breakage condition of theoptical fiber cable can be accurately tested. Furthermore the line breakage automatic testing device can perform comprehensive testing on signal damping and signal transmission capability of the optical fiber and fills a gap of testing line breakage in the optical fiber production process in prior art, thereby realizing high popularization value.

Owner:四川特旺通信科技有限公司

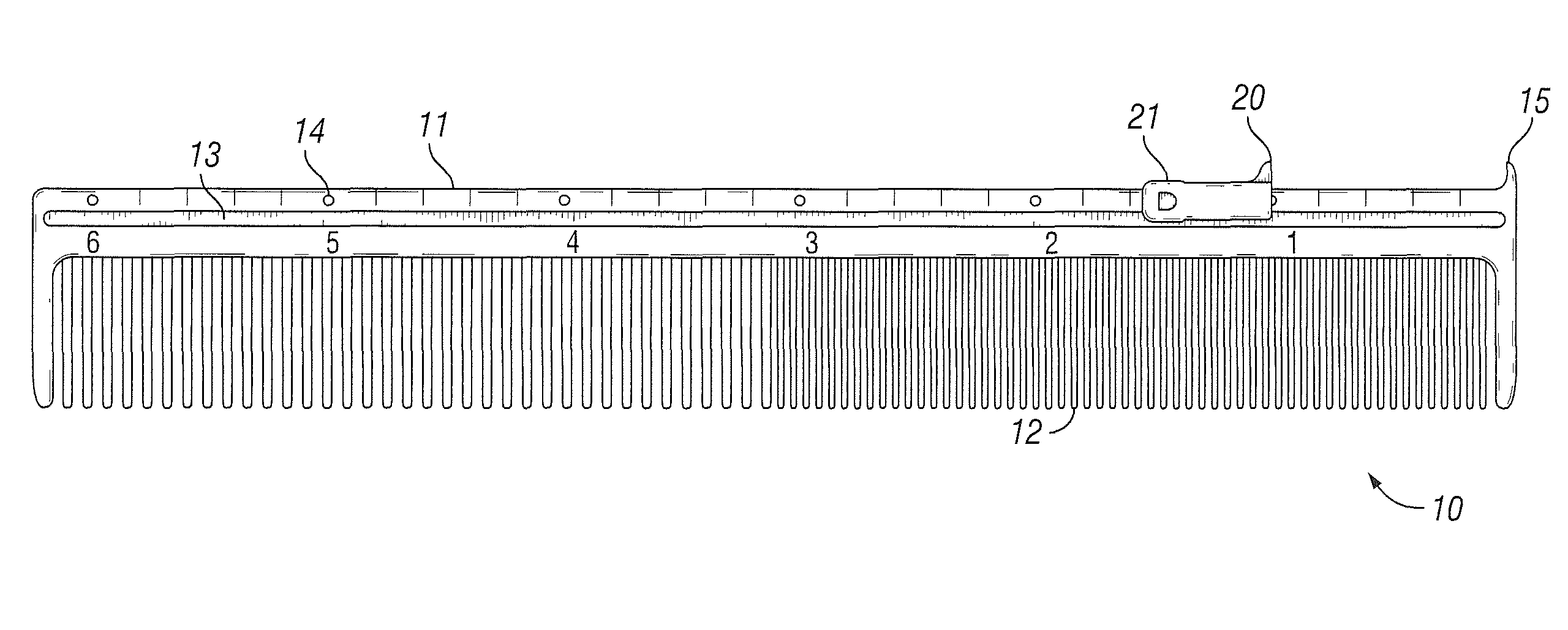

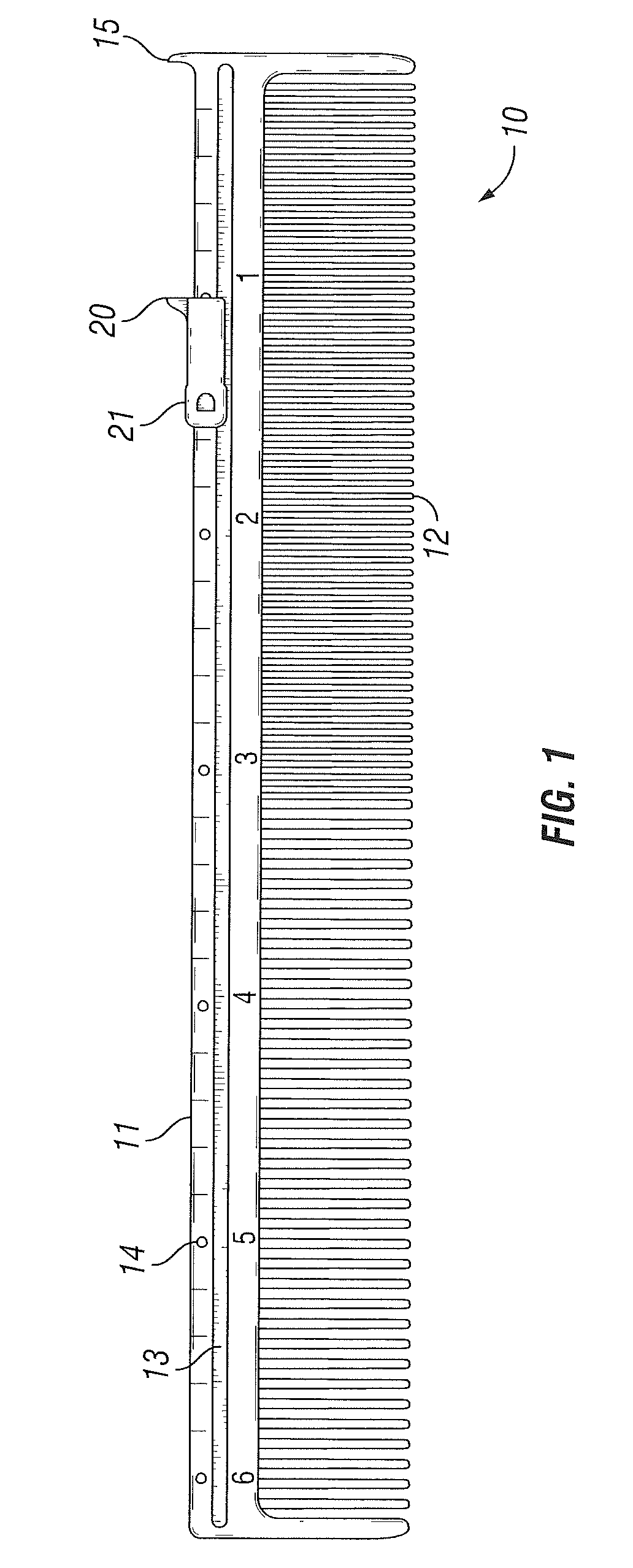

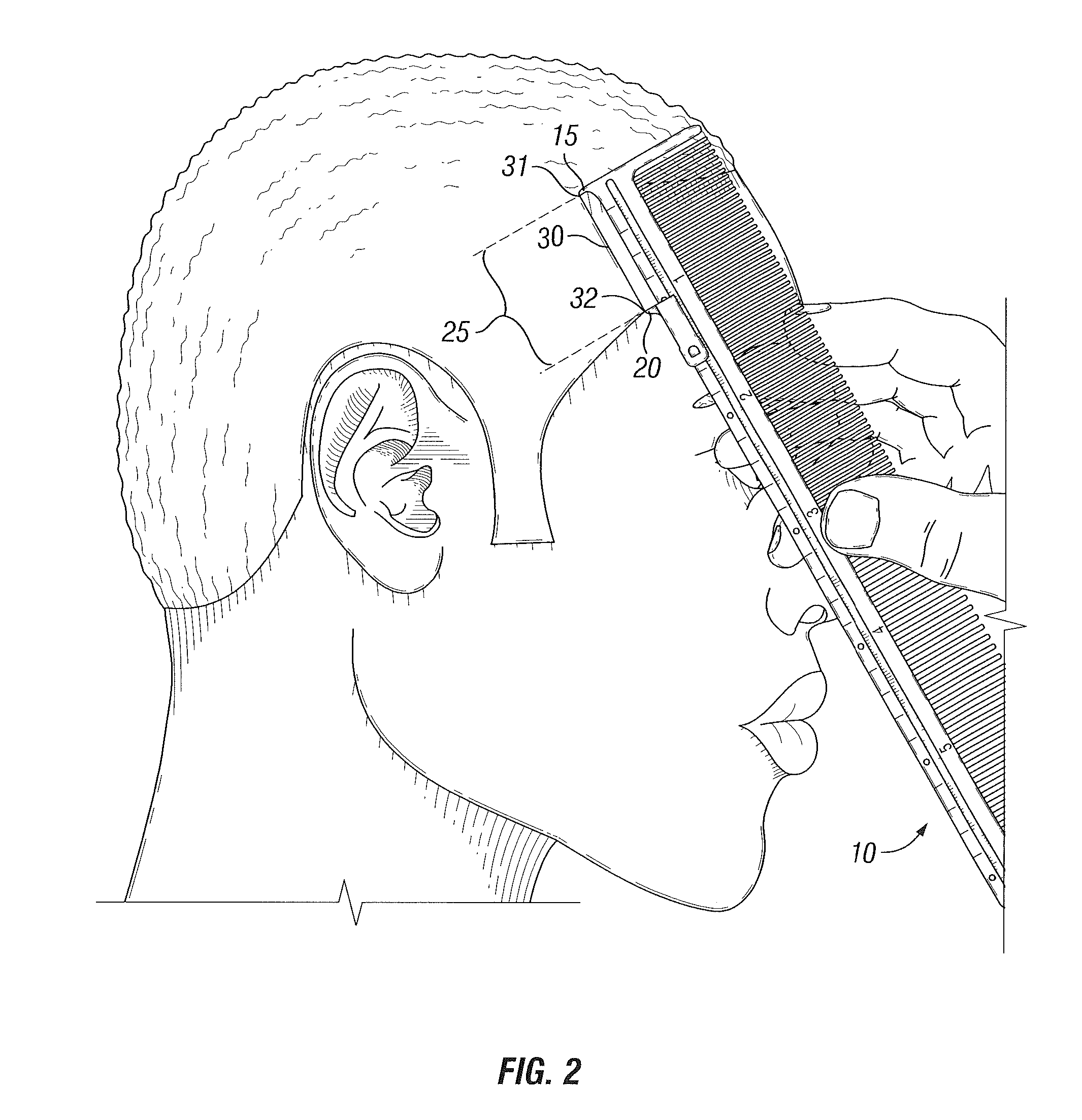

Fixed point barber comb and methods of use

The present invention provides a barber instrumentality useful for accurate and reproducible hair styling. In particular, methods are provided herein for the use of the instrumentality wherein precise measurements can be taken to reproduce certain styles within a haircut, including cutting with reference to the outline of the hair on the head (the hairline), especially around the temple.

Owner:HODGE MORONO

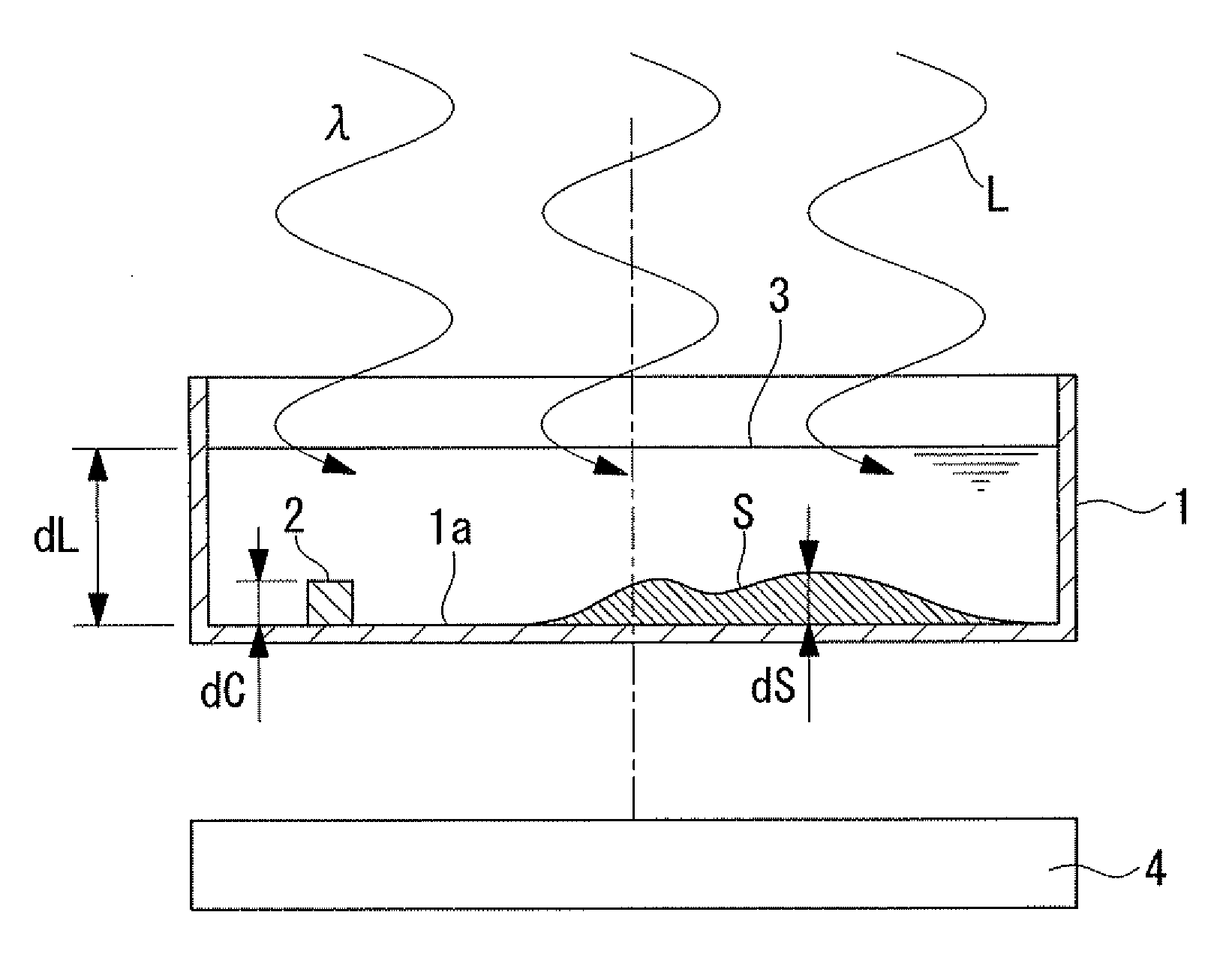

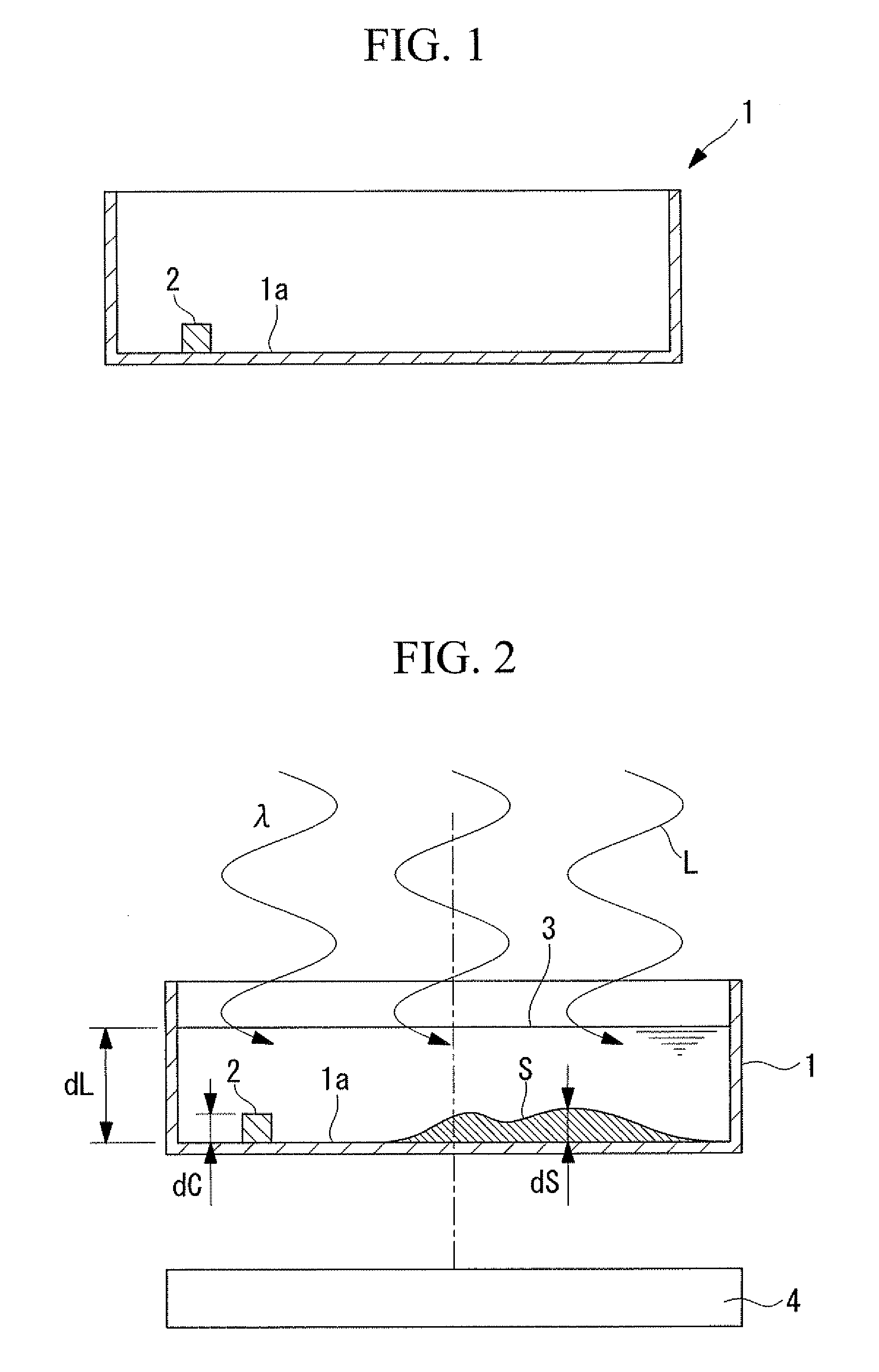

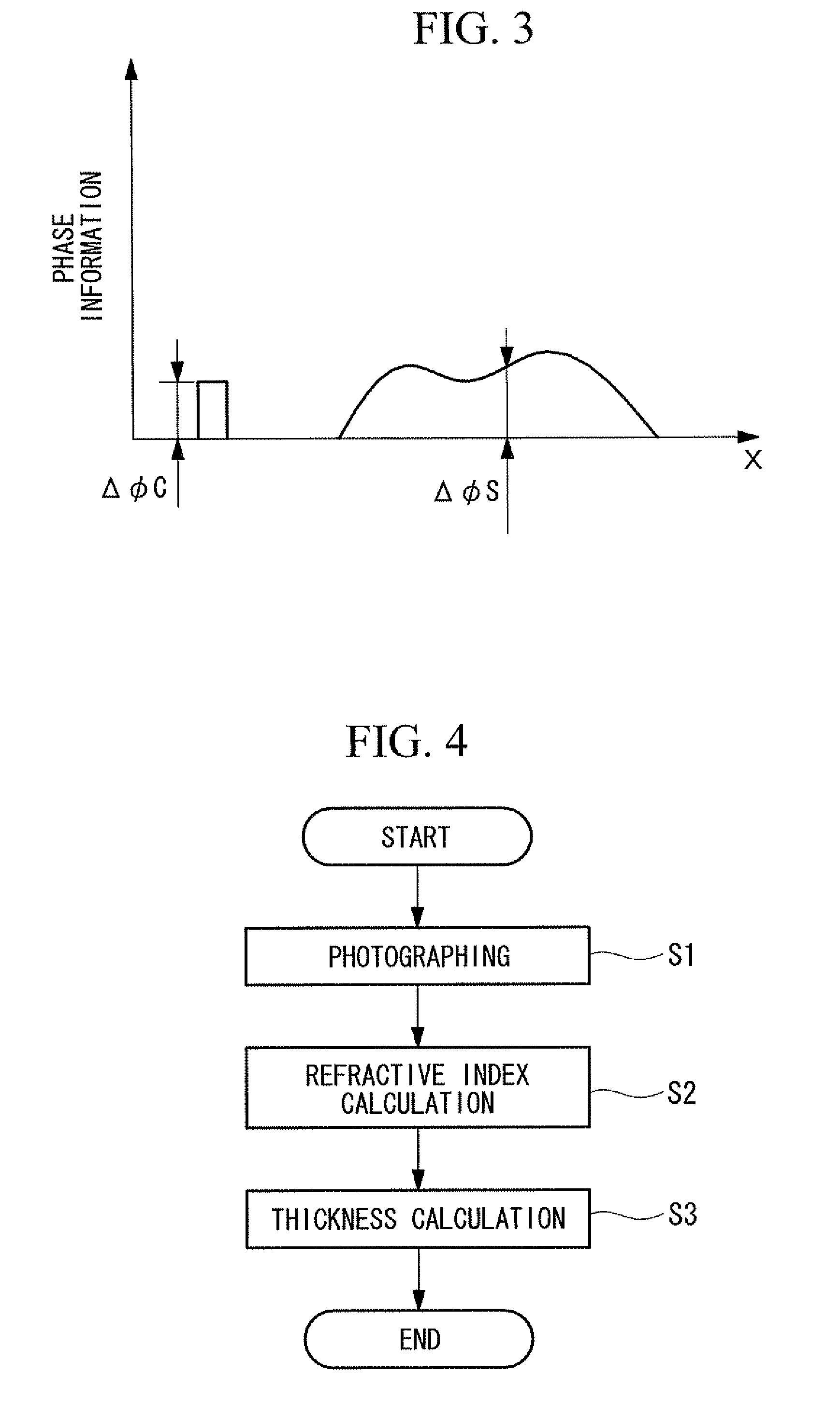

Culture vessel and cellular thickness measurement method

InactiveUS20090097016A1Precise measurementAccurate measurementPhase-affecting property measurementsBiochemistry apparatusCulture vesselCulture cell

To enable precise measurement of a cellular thickness distribution regardless of changes in the refractive index of a culture solution with the progress of culture. There is provides a culture vessel made of a transparent material with a culture surface capable of culturing cells in an adhesive manner on the bottom face, wherein a reference substance having an already known refractive index and an already known thickness dimension is fixed to a part of the culture surface.

Owner:OLYMPUS CORP

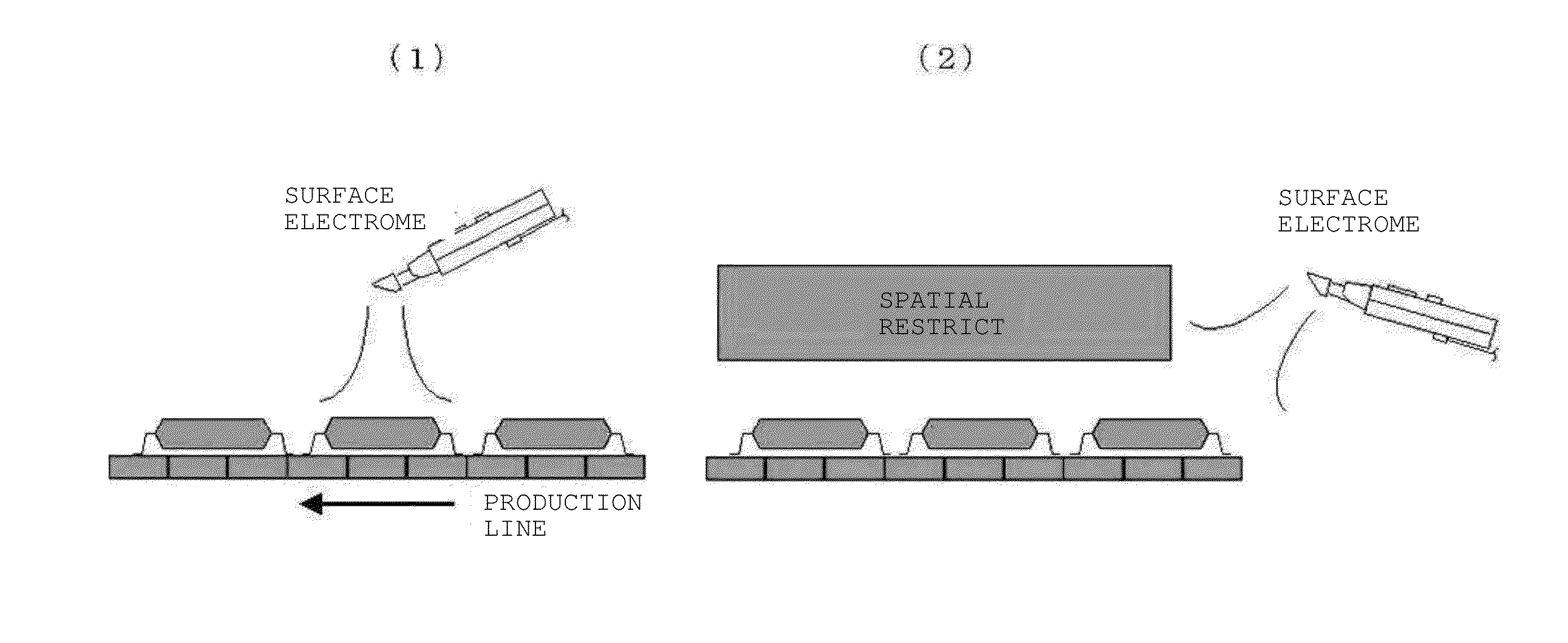

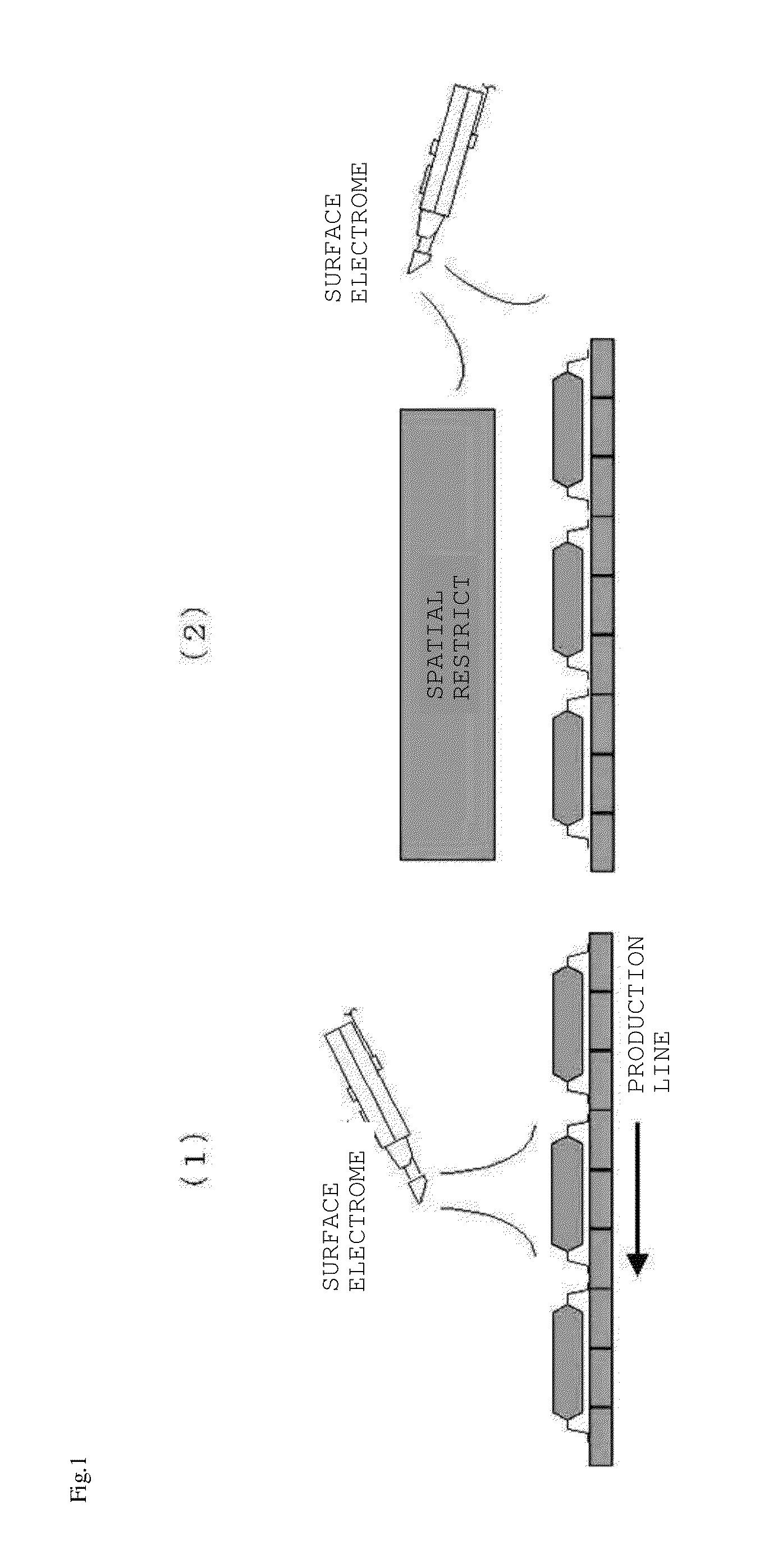

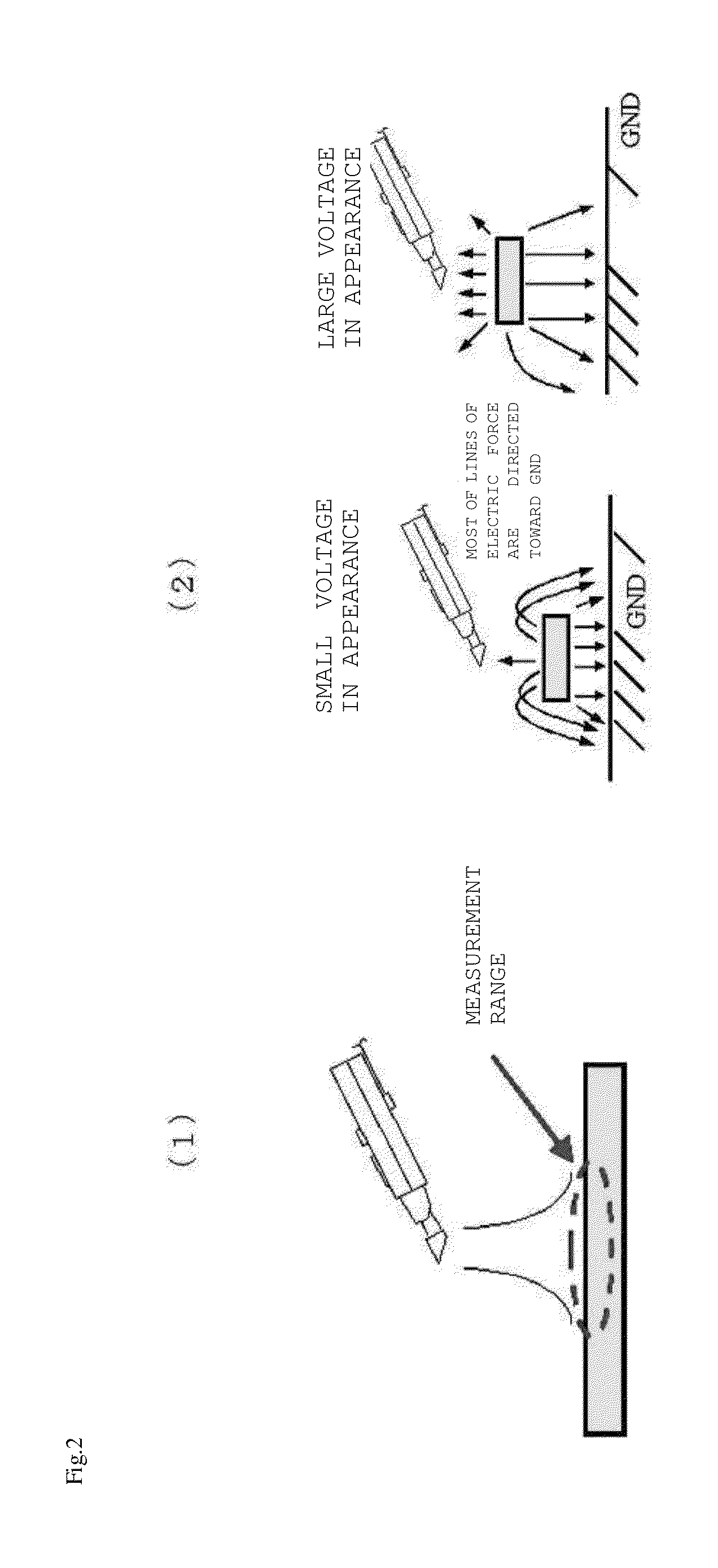

Static-electricity electrification measurement method and apparatus

InactiveUS20130307552A1Precise measurementAccurate measurementSemiconductor/solid-state device testing/measurementSolid-state devicesEnvironmental effectObject based

[Problem to be Solved] A static-electricity electrification measurement method and apparatus that satisfy, at the same time, three conditions: (1) to measure static-electricity electrification non-destructively, (2) to reduce environmental influence of a measured object wherein metals and insulators are mixed to measure the static-electricity electrification, and (3) to measure the static-electricity electrification without getting close thereto is provided.[Solution] A static-electricity electrification measurement method of the present invention includes: an adding step of adding vibrations having a vibration frequency and an amplitude selected in advance to a measured object; an intensity measuring step of measuring intensity of electromagnetic waves generated along with the vibrations of the measured object; and a state measuring step of measuring a static-electricity electrification state of the measured object based on intensity of the electromagnetic waves measured in the measuring step.

Owner:NAT INST OF ADVANCED IND SCI & TECH

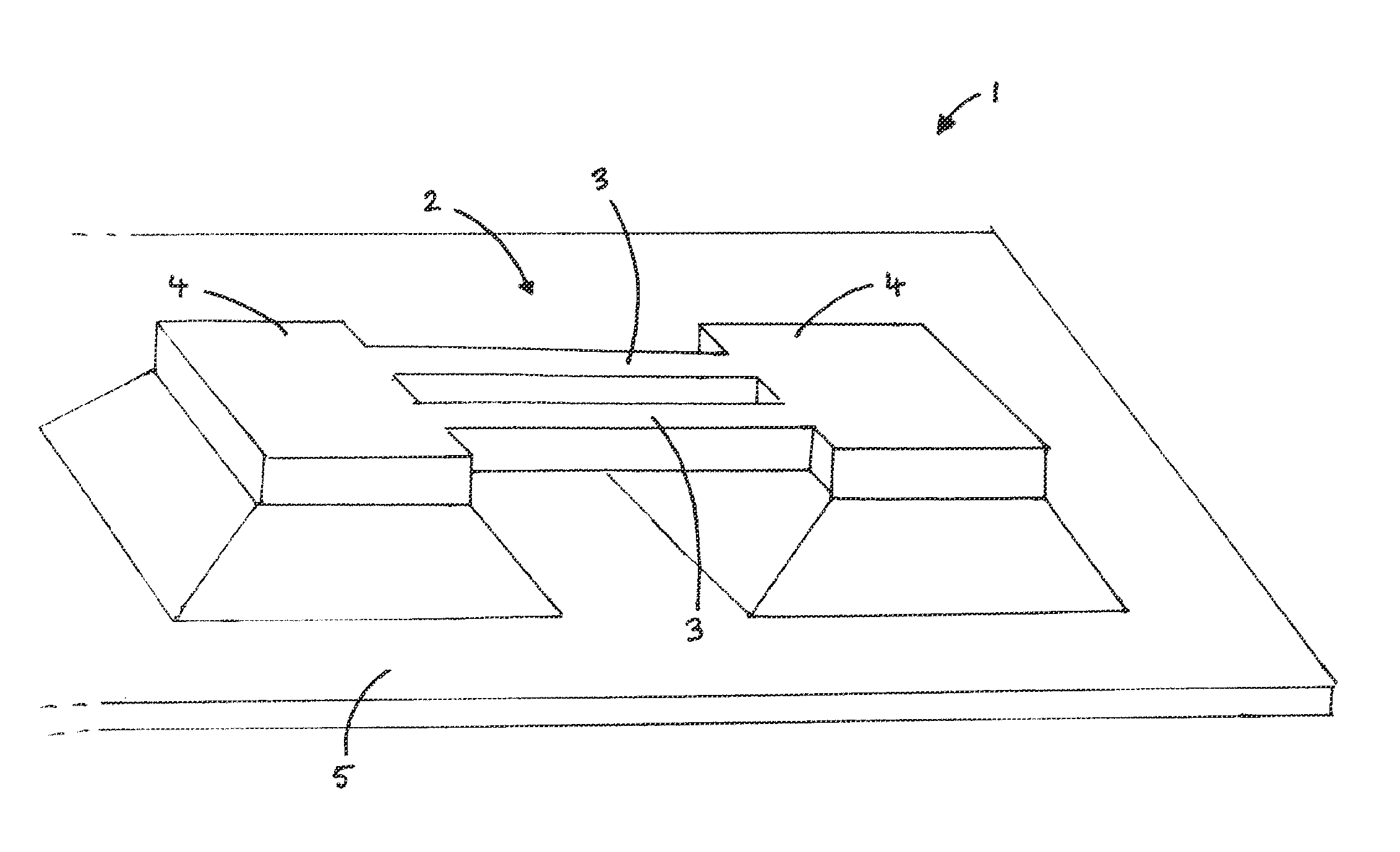

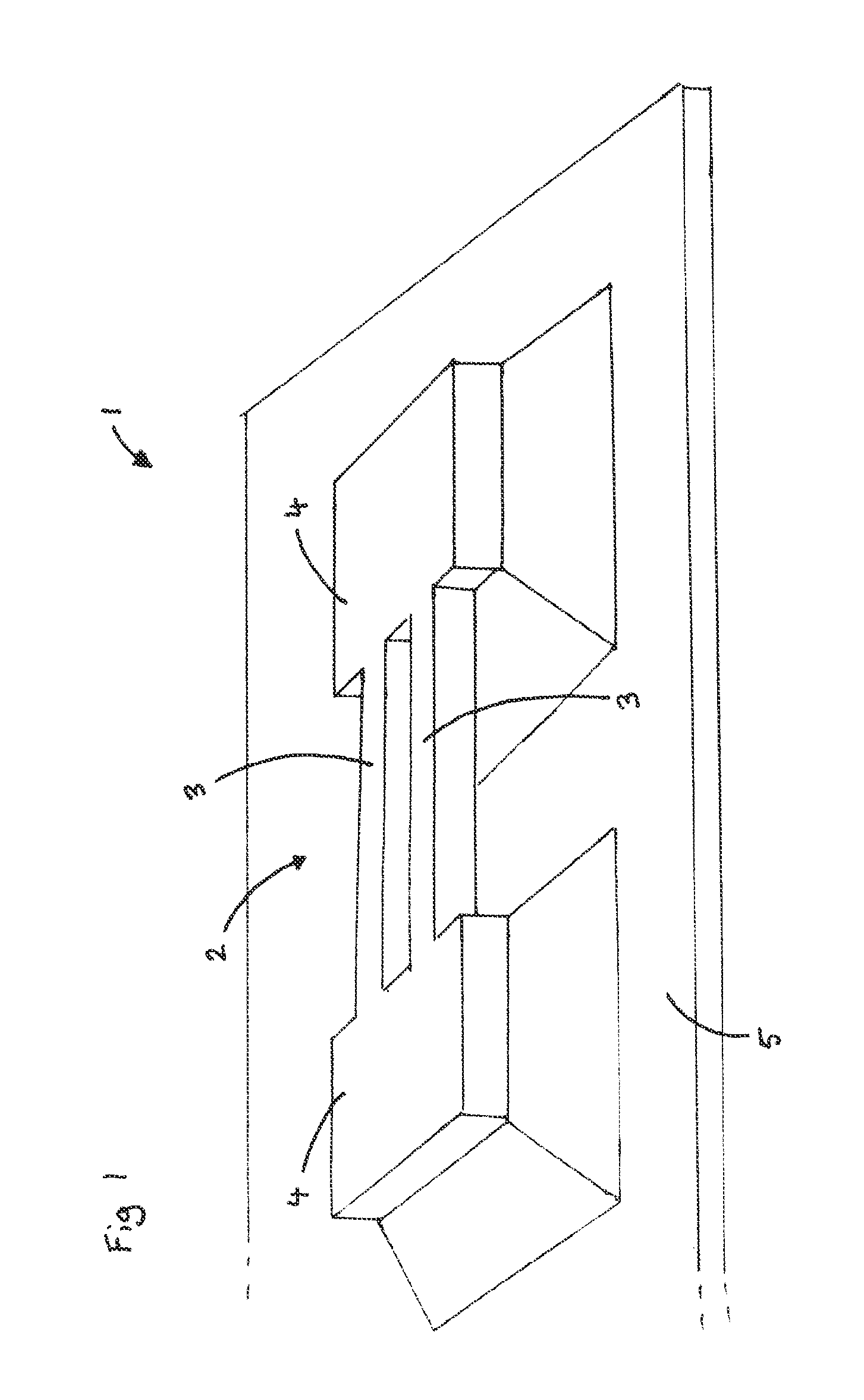

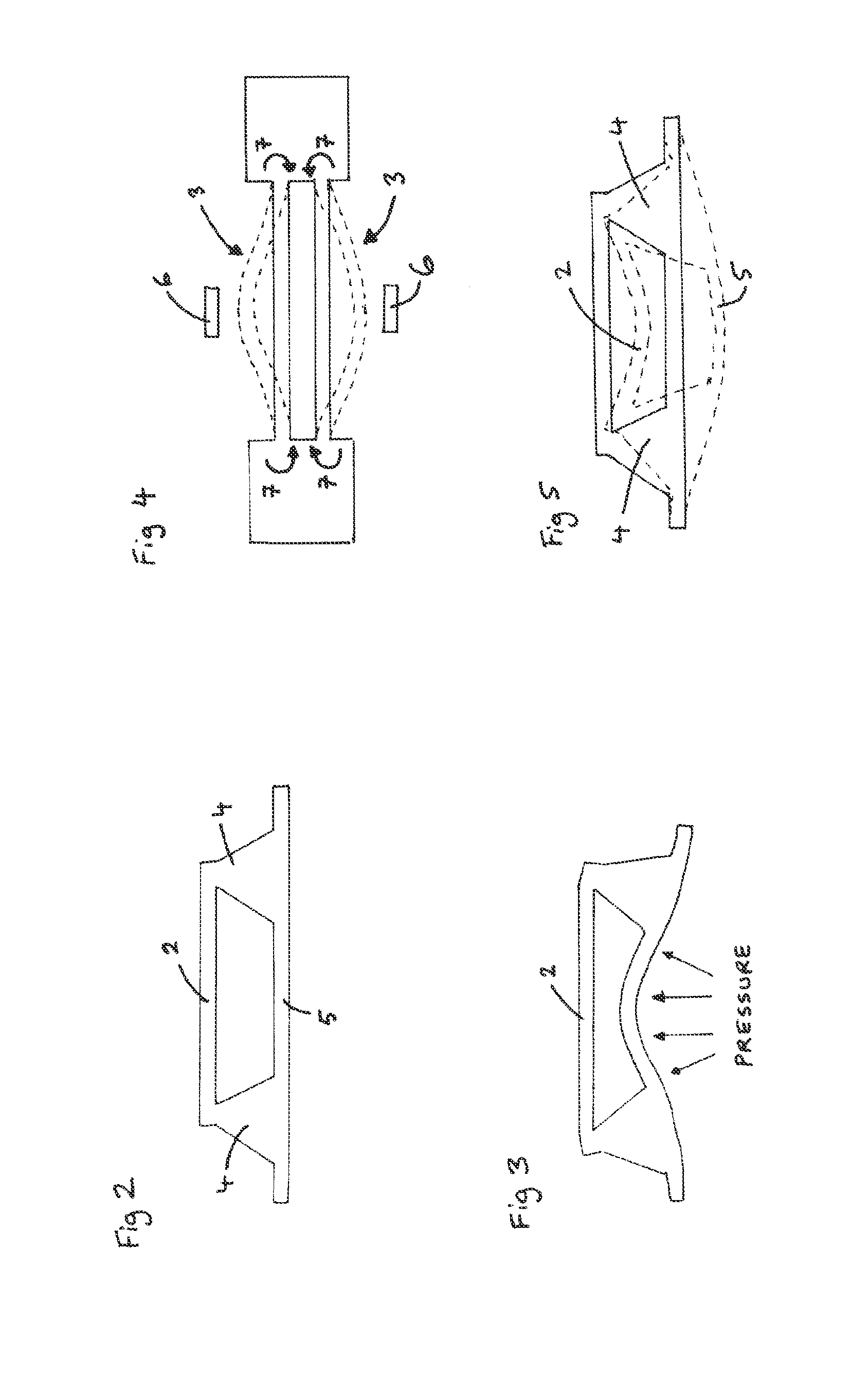

Sensor

ActiveUS20120060617A1Precise measurementAccurate measurementFluid pressure measurement by electric/magnetic elementsDistortionEngineering

A resonant sensor is disclosed which may be arranged to measure the pressure of a fluid. The resonant sensor comprises a diaphragm which may be exposed to a fluid; two supports provided on the diaphragm and a resonator having at least two beams with each beam being suspended between the two supports. The ends of each beam are attached to a corresponding support at more than one point. By attaching each end of the beams to a support at more than one point, the moments and reaction forces to which the support is subjected may be balanced so that distortion of the support and diaphragm due to vibration of the resonator beams is reduced. Consequently, the resonant sensor is able to provide more precise measurements.

Owner:GE INFRASTRUCTURE SENSING

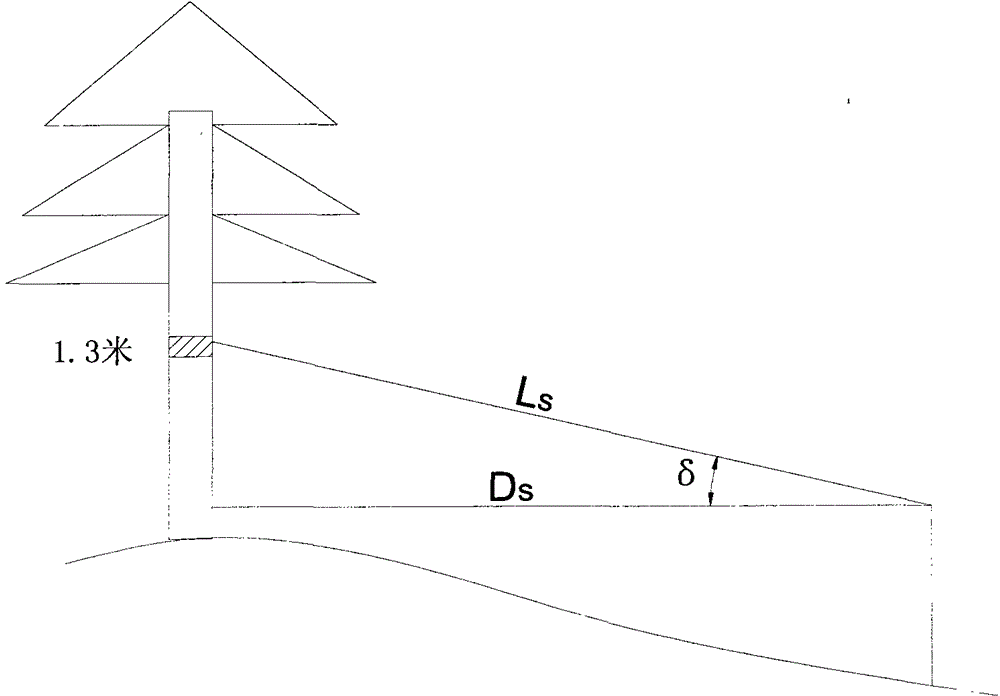

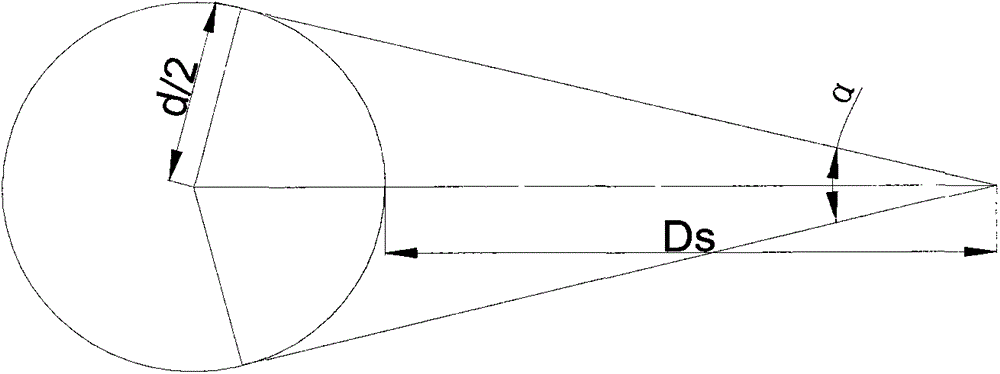

A Method for Measuring Tree Diameter with Fixed Angle and Ranging

ActiveCN103471551BSolving DBH MeasurementsImprove measurement efficiencyMeasurement devicesTerrainRange tree

The invention discloses a method for measuring the tree diameter through a constant angle. The distance and slant angle of a stand tree are measured through the certain constant angle, and the diameter of the stand tree is measured through calculation. By means of the method, the diameter of the stand tree can be measured under the conditions that the terrain is complex and the stand tree is difficult to get close to, the problem that the diameter at the breast height of stand trees with a large diameter class is inconvenient to measure can be solved effectively, intensity of measurement operation is relieved to some extent, and efficient and accurate measurement of forest resources is achieved.

Owner:BEIJING FORESTRY UNIVERSITY

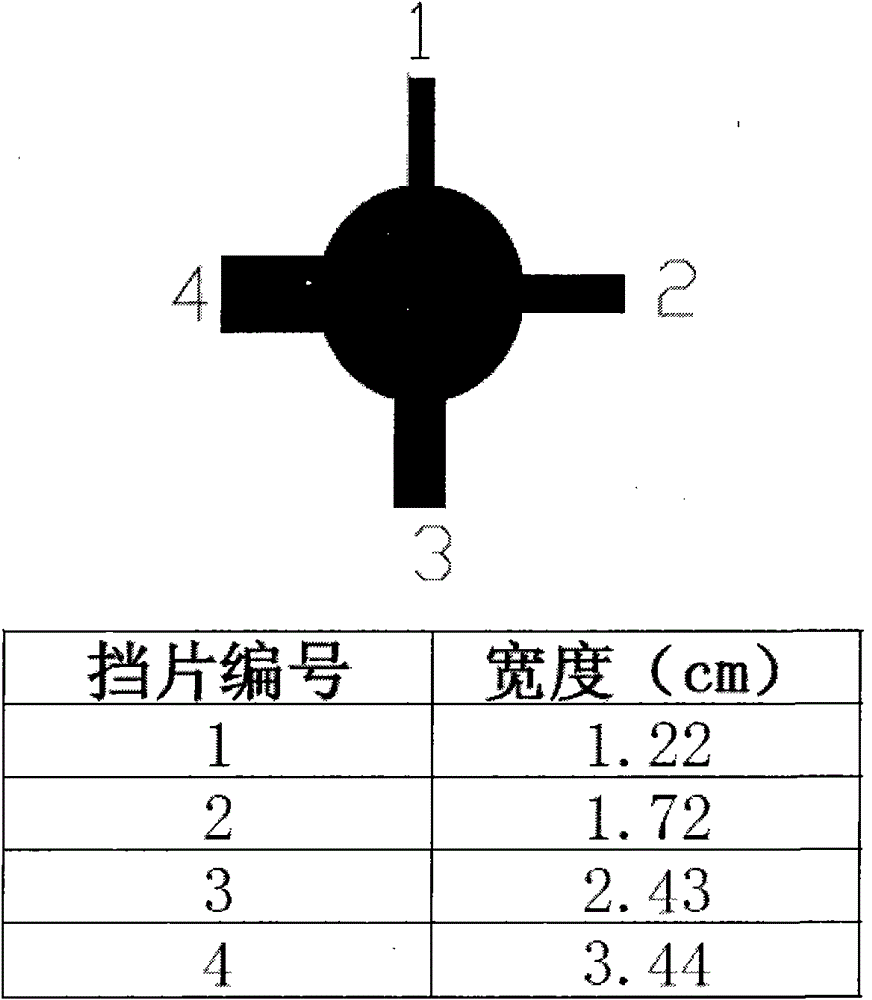

Shutter device and image pickup apparatus

A shutter device includes a blade member and a detecting unit. The blade member includes a first blade, a second blade, a detection portion, and a limiting portion. The blade member controls a time of exposure, performed on a recording medium, on the basis of a magnitude of a width of a slit. The slit includes slit portions and is provided when the first and second blades travel. The slit portions are provided at the detection portion and limiting portion, respectively. The detecting unit detects a state of the slit width. A cut-away portion is provided at the blade member so that a width of the slit portion at the detection portion is greater than a width of the slit portion at the limiting portion. The detection portion is detected by the detecting unit. The limiting portion limits the exposure time.

Owner:CANON KK

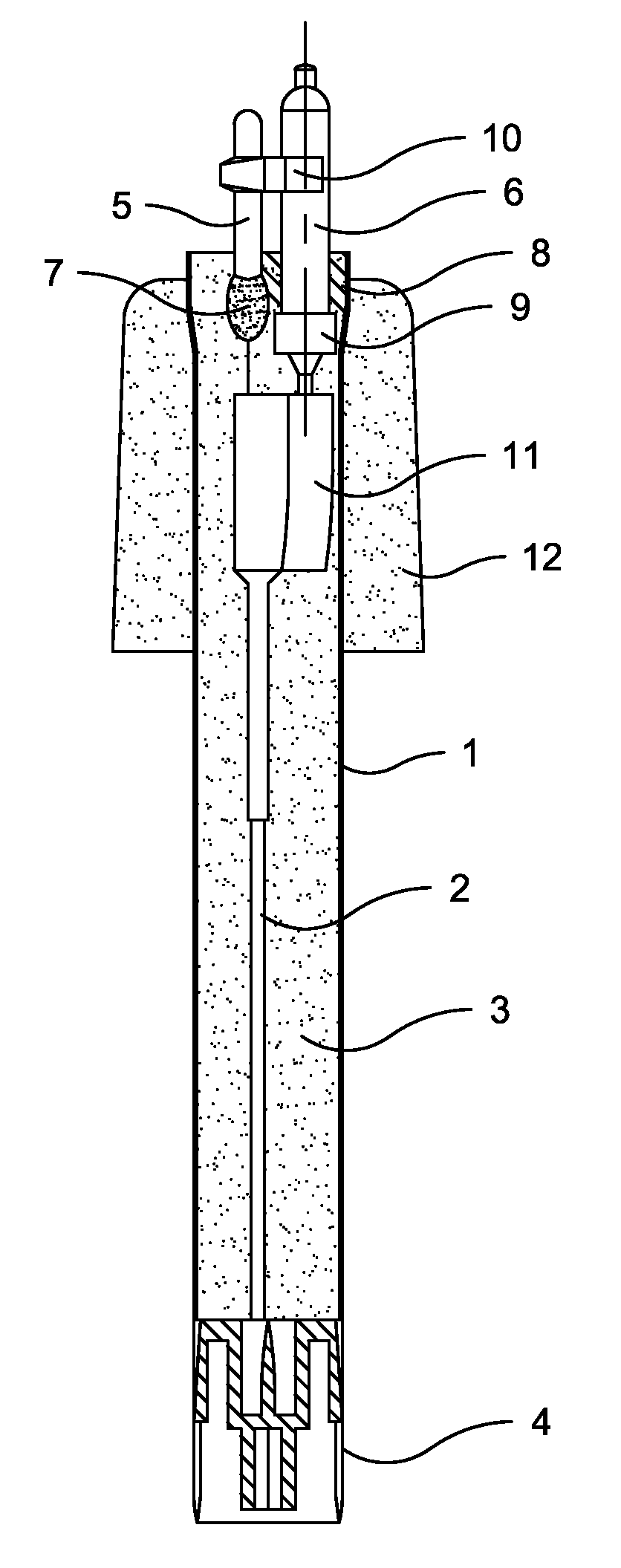

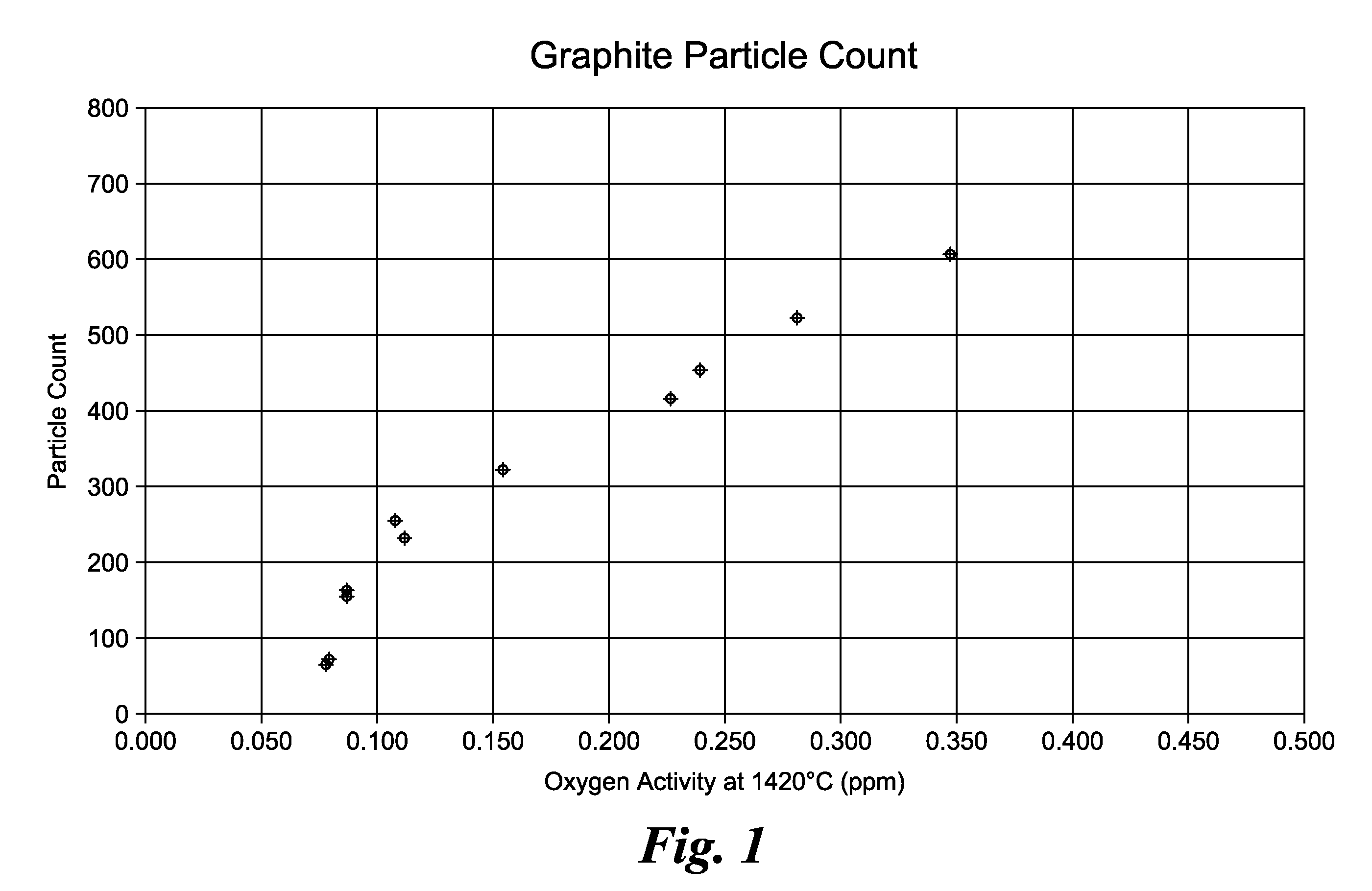

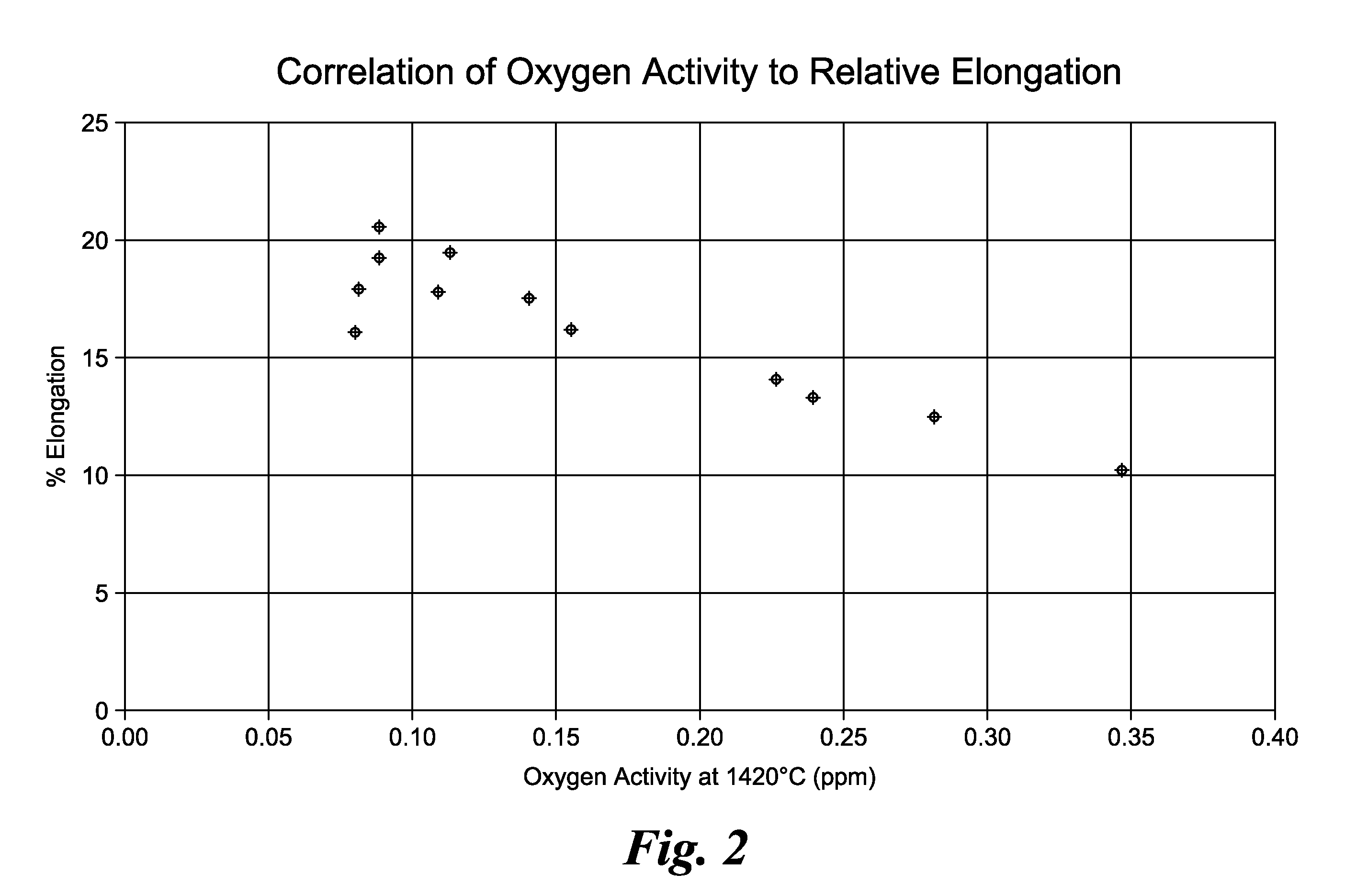

Method for Influencing the Properties of Cast Iron, and Oxygen Sensor

ActiveUS20100018348A1Elongation decreasePrecise measurementFurnace componentsMolten spray coatingCast ironMagnesium

A method is provided for influencing the properties of cast iron by adding magnesium to the cast iron melt and measuring the oxygen content of the cast iron melt. Magnesium is added to the cast iron melt until the oxygen content of the cast iron melt is approximately 0.005 to 0.2 ppm at a temperature of approximately 1,420° C. A sensor for measuring the oxygen content in cast iron melts contains an electrochemical measuring cell containing a solid electrolyte tube.

Owner:HERALUS ELECTRO NITE INT NV

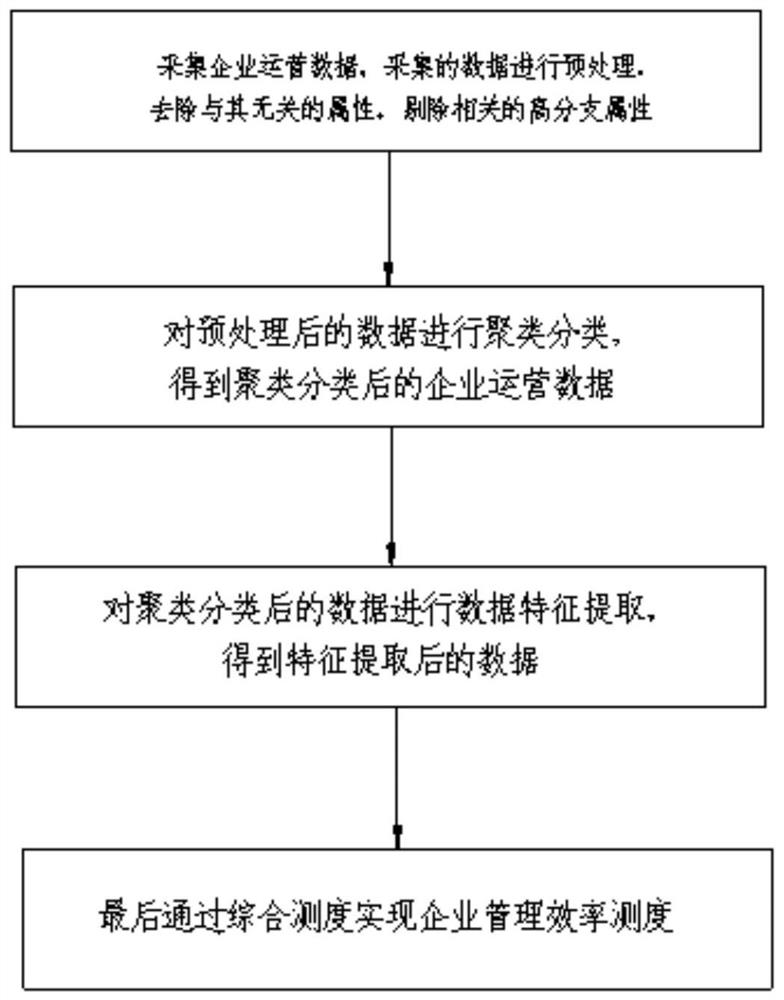

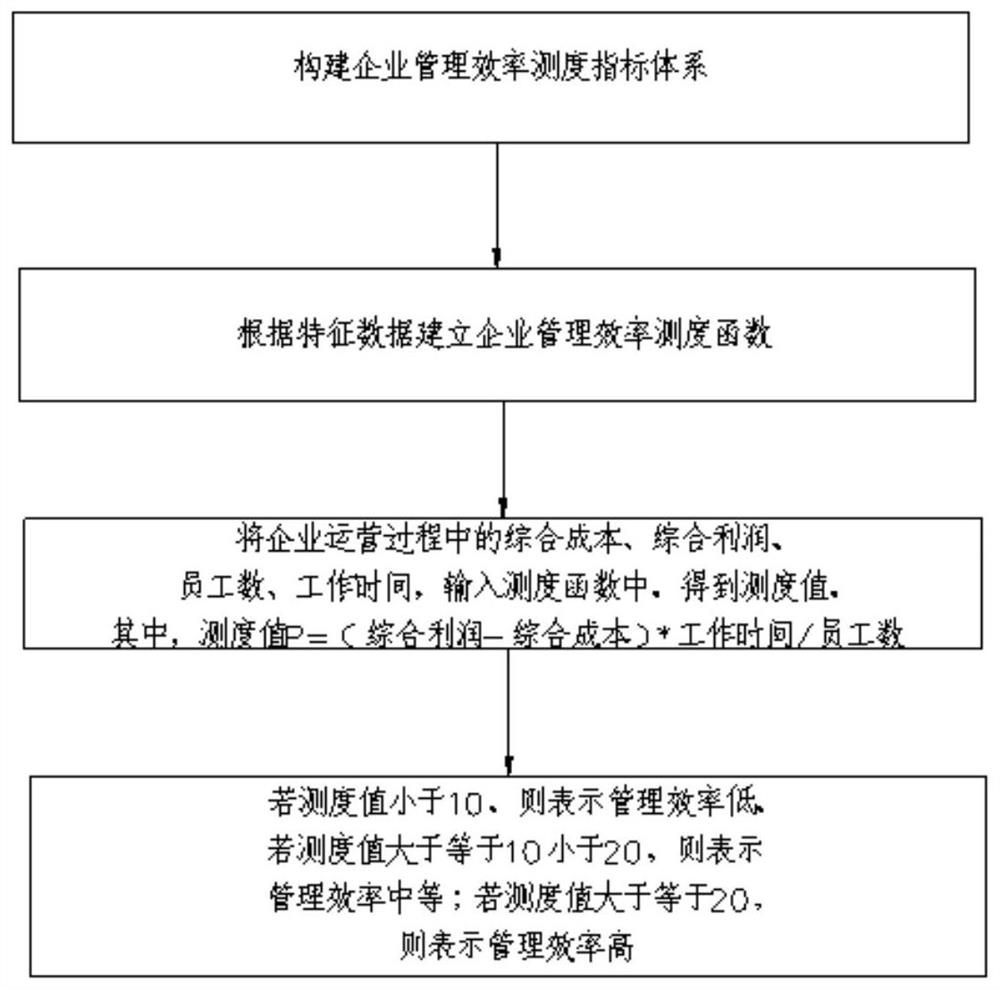

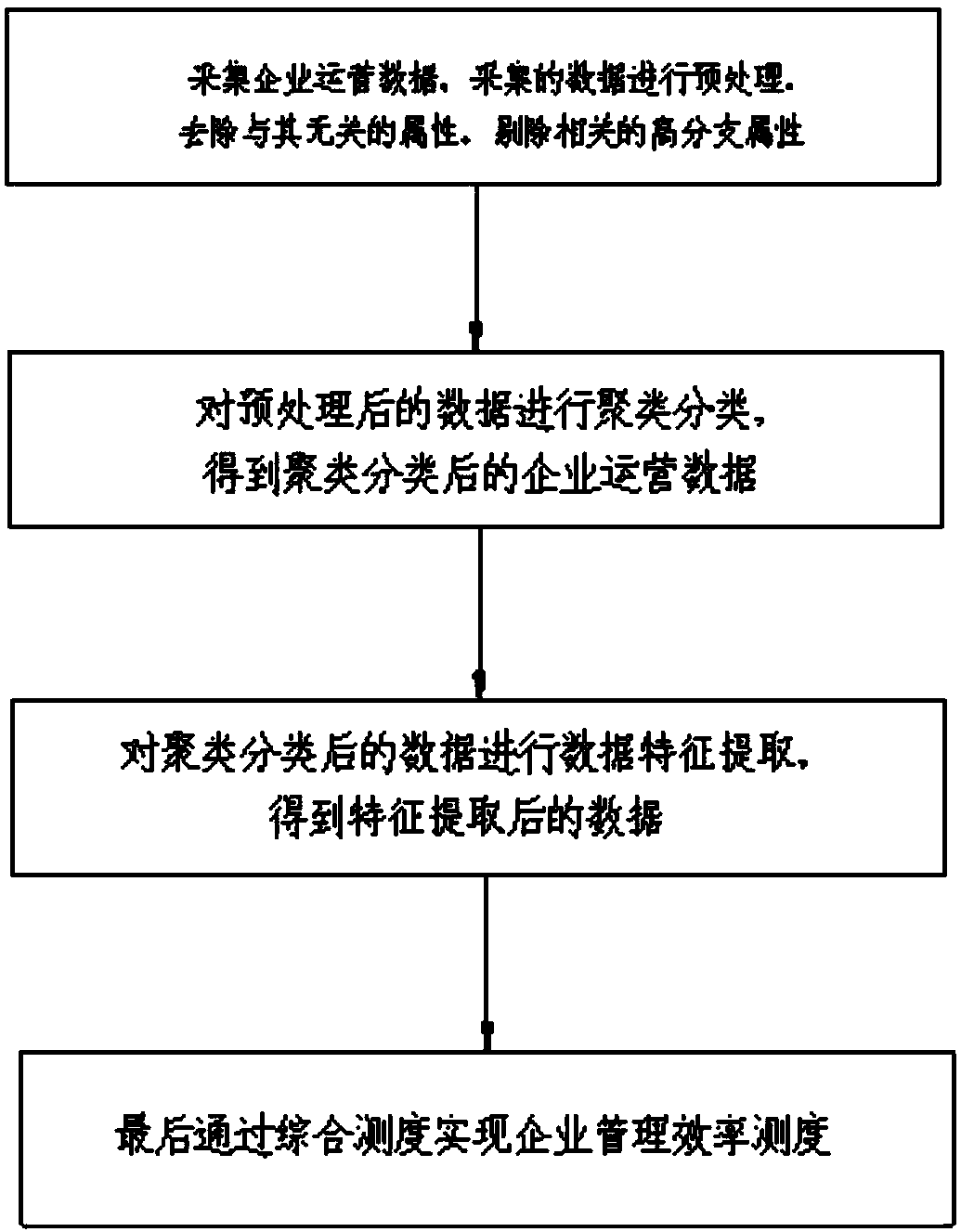

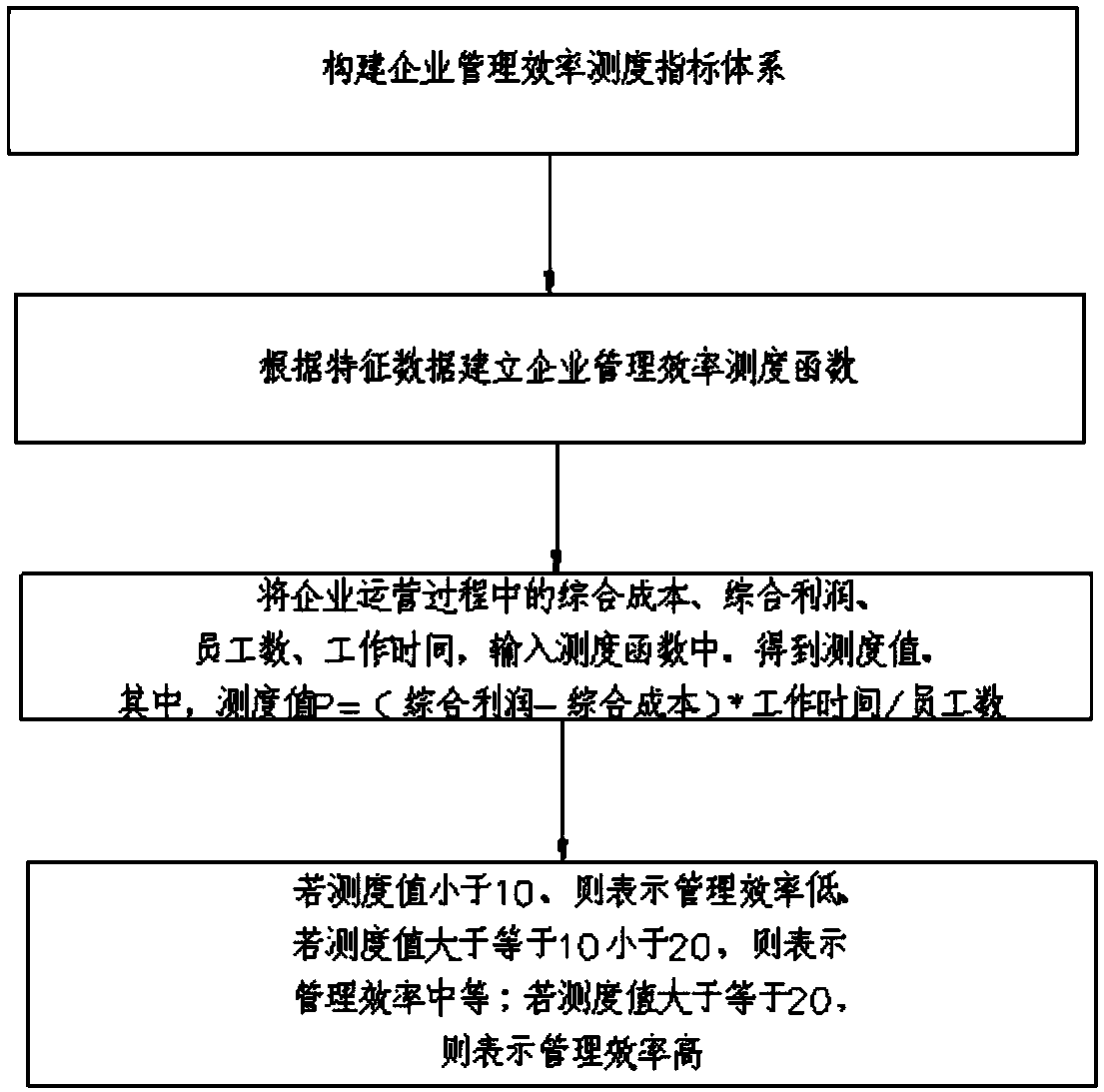

A Method for Measuring Enterprise Management Efficiency Based on Compound Optimization Analysis

ActiveCN109508358BEasy to operateImprove measurement efficiencyResourcesDatabase modelsData setClassification methods

The invention discloses a method for measuring enterprise management efficiency based on compound optimization analysis, comprising the following steps: A. collecting enterprise operation data, performing preprocessing on the collected data, removing irrelevant attributes, and eliminating relevant high-branch attributes; B. Cluster and classify the preprocessed data to obtain the enterprise operation data after clustering and classification; C. Extract data features from the data after clustering and classification to obtain the data after feature extraction; D. Finally, realize the enterprise operation data through comprehensive measurement Measures of management efficiency. The measurement method of the present invention is simple to operate, has high measurement efficiency, and improves enterprise management efficiency; among them, the data clustering and classification method adopted reduces the time spent on manual labeling of data sets, makes data classification more accurate, and improves data efficiency. Utilization rate; the data feature extraction method adopted can effectively extract the characteristics of enterprise data, which is convenient for subsequent comprehensive measurement.

Owner:HUNAN INST OF TECH

A disconnection automatic detection device for the production of communication optical fiber and cable

ActiveCN108957209BImprove quality requirementsDetect disconnectionScattering properties measurementsContinuity testingWinding machineProduction line

The invention discloses a line breakage automatic testing device for production of a communication optical fiber cable. The device comprises a production line platform. The leftmost end of the production line platform is provided with a pay-off device. The right side of the pay-off device is provided with a two-stage optical fiber detecting assembly. The right side of the two-stage optical fiber detecting assembly is provided with a diameter measuring instrument. The right side of the diameter measuring instrument is provided with a sheath processing device. The rightmost end of a production line platform is provided with a wire winding machine. A to-be-tested optical fiber is arranged above the production line platform. According to the line breakage automatic detecting device, a two-stage optical fiber testing assembly is utilized; and measurement is performed according to a comparison method in which a returning signal is received by means of a backward scattering method and a manner of utilizing optical-magnetic modulation and converting modulated light to an electric signal. Because the measuring facility for the electric signal is more accurate, the breakage condition of theoptical fiber cable can be accurately tested. Furthermore the line breakage automatic testing device can perform comprehensive testing on signal damping and signal transmission capability of the optical fiber and fills a gap of testing line breakage in the optical fiber production process in prior art, thereby realizing high popularization value.

Owner:四川特旺通信科技有限公司

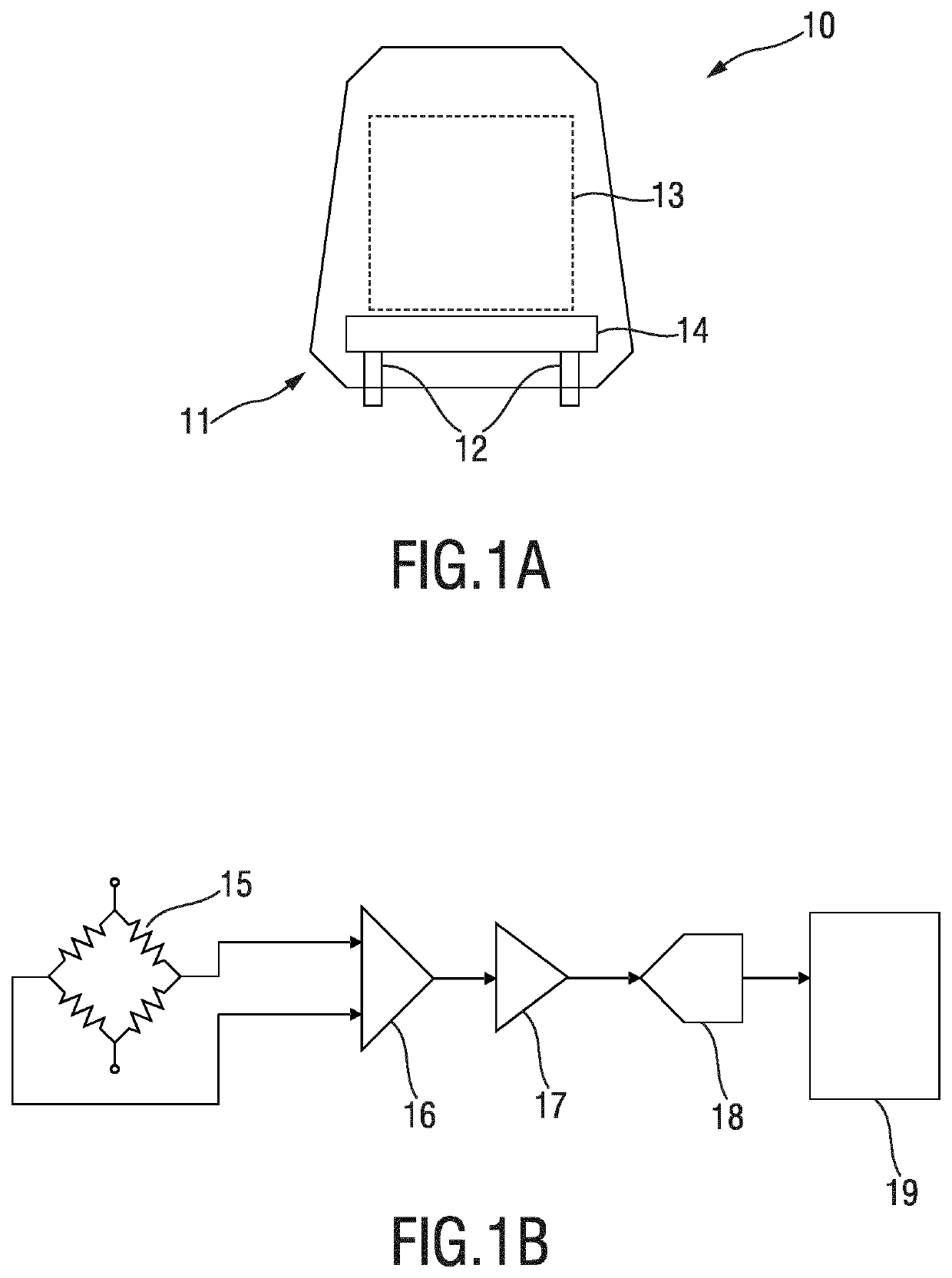

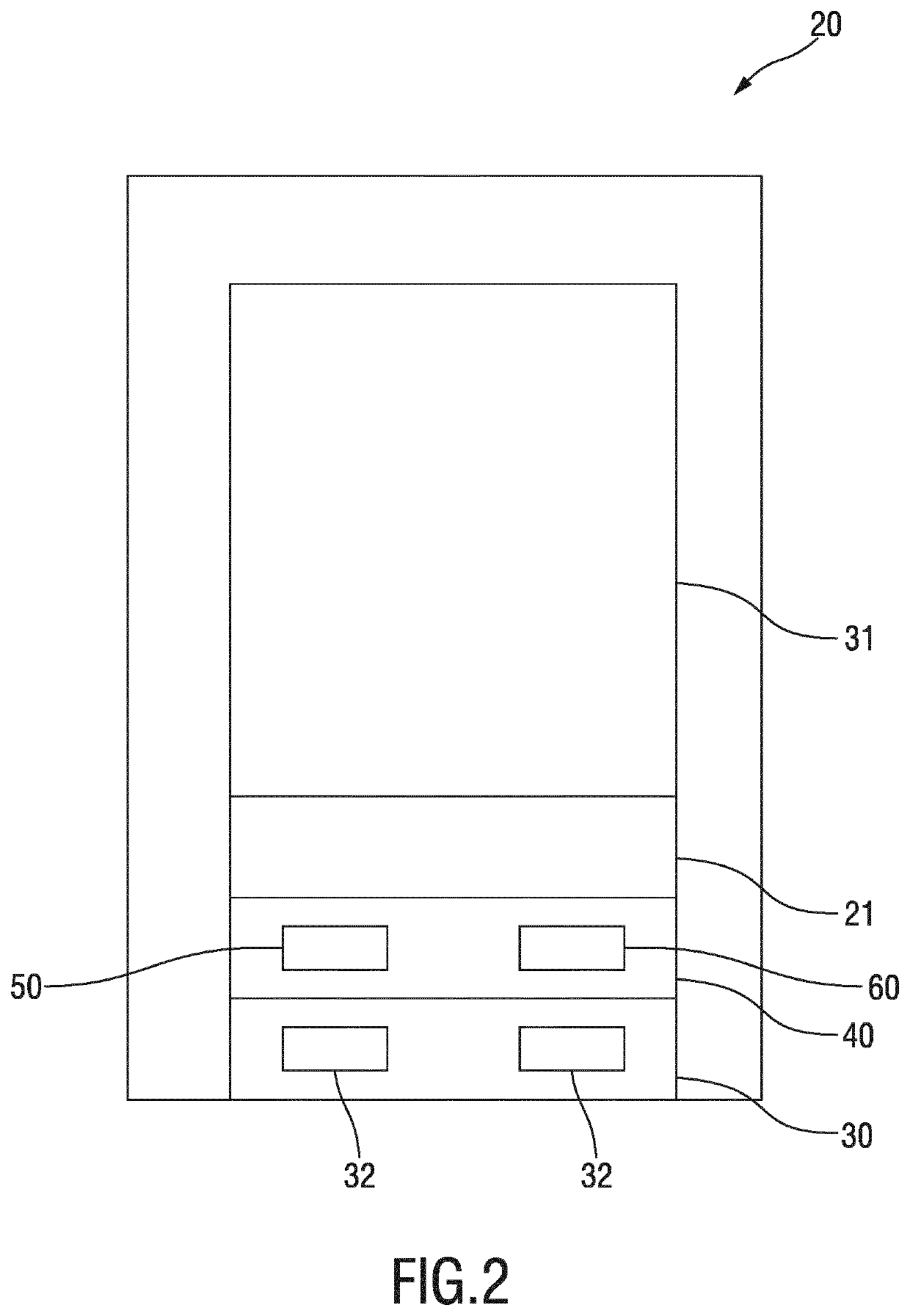

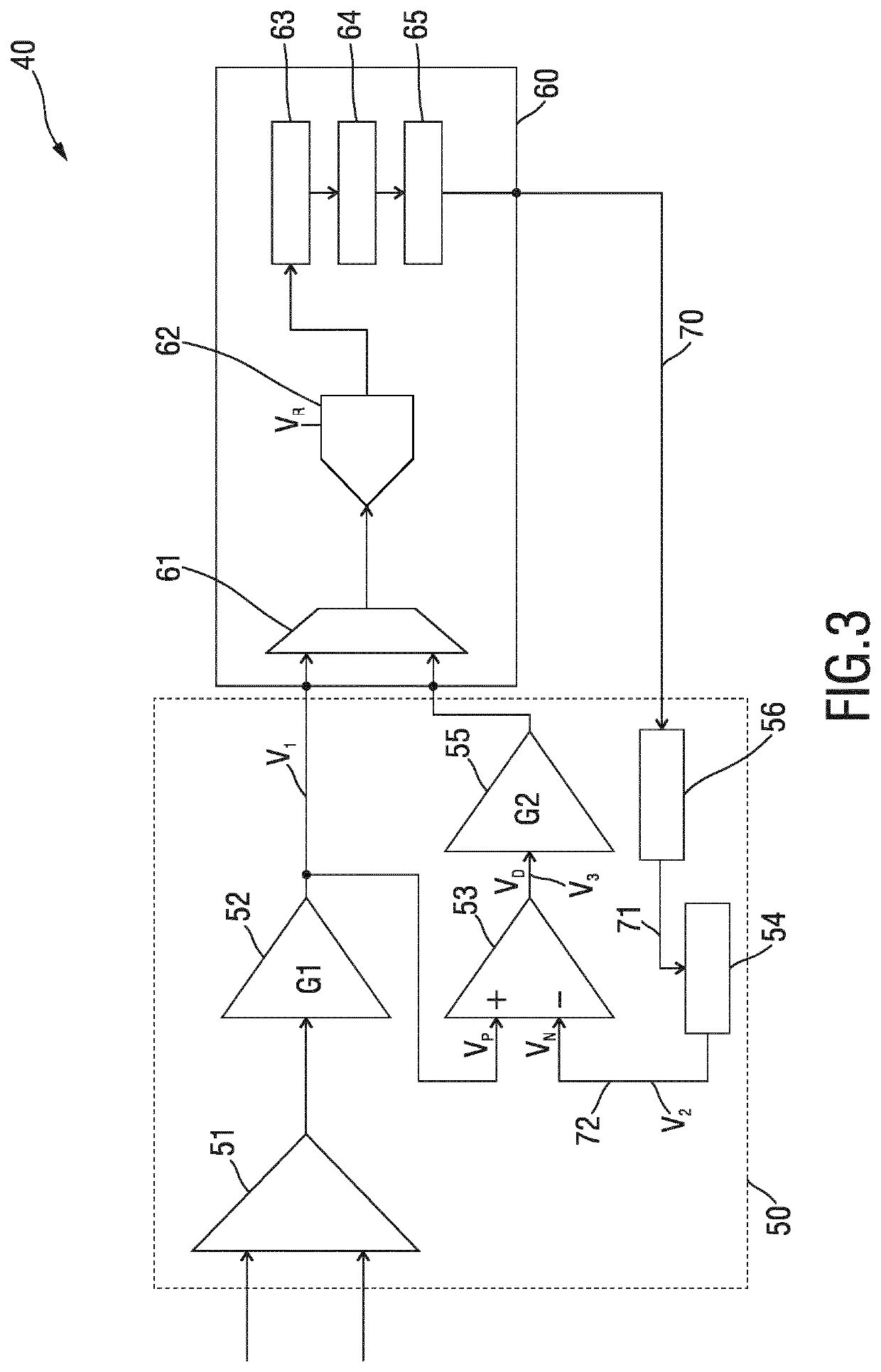

Sensing and control device and method for a weight measurement device

PendingUS20200033184A1Low costPrecise measurementWeighing apparatus using elastically-deformable membersWeighing auxillary devicesPhysicsPulse width modulated

The present invention relates to a sensing and control device (40) and method for a weight measurement device (30) comprising a load unit for loading material to be weighted. To enable precise measurement with less expensive components, said sensing and control device comprises analog circuitry (50) configured to receive a weight measurement signal, convert the received weight measurement signal into a first voltage signal, subtract a second voltage signal representing the weight of at least the load unit without being loaded with material to be weighted from the first voltage signal when the load unit is loaded with material to be weighted to generate a third voltage signal representing the weight of the material to be weighted, and control circuitry (60) configured to receive the first voltage signal while the load unit is not loaded with material to be weighted, convert the first voltage signal into a first digital signal, and generate a pulse width modulated, PWM, signal having a pulse width representing the weight measured by the load unit while not being loaded with material to be weighted, and further configured to convert the third voltage signal into a second digital signal representing the weight measurement of the material to be weighted. The analog circuitry (50) is configured to generate the second voltage signal from the PWM signal generated by the control circuitry, wherein the voltage level of the second voltage signal is proportional to the pulse width of the PWM signal.

Owner:KONINKLJIJKE PHILIPS NV

Method for measuring enterprise management efficiency based on compound optimization analysis

ActiveCN109508358AEasy to operateHigh measurement efficiencyResourcesDatabase modelsManagement efficiencyData mining

The invention discloses a method for measuring enterprise management efficiency based on compound optimization analysis, comprising the following steps: A, collecting enterprise operation data, preprocessing the collected data, removing attributes irrelevant to the data, and removing related high branch attributes; B, clustering and classifying the pre-processed data to obtain the enterprise operation data after clustering and classifying; C, extracting data features from the data after clustering and classification to obtain the data after feature extraction; D, finally, measuring that management efficiency of the enterprise through the comprehensive measurement. The measuring method of the invention has the advantages of simple operation, high measuring efficiency and improved enterprisemanagement efficiency. Among them, the method of data clustering and classification reduces the time consuming to label the data set manually, which makes the classification of data more accurate andimproves the utilization rate of data. The adopted data feature extraction method can effectively extract the characteristics of enterprise data, which is convenient for the subsequent comprehensivemeasurement.

Owner:HUNAN INST OF TECH

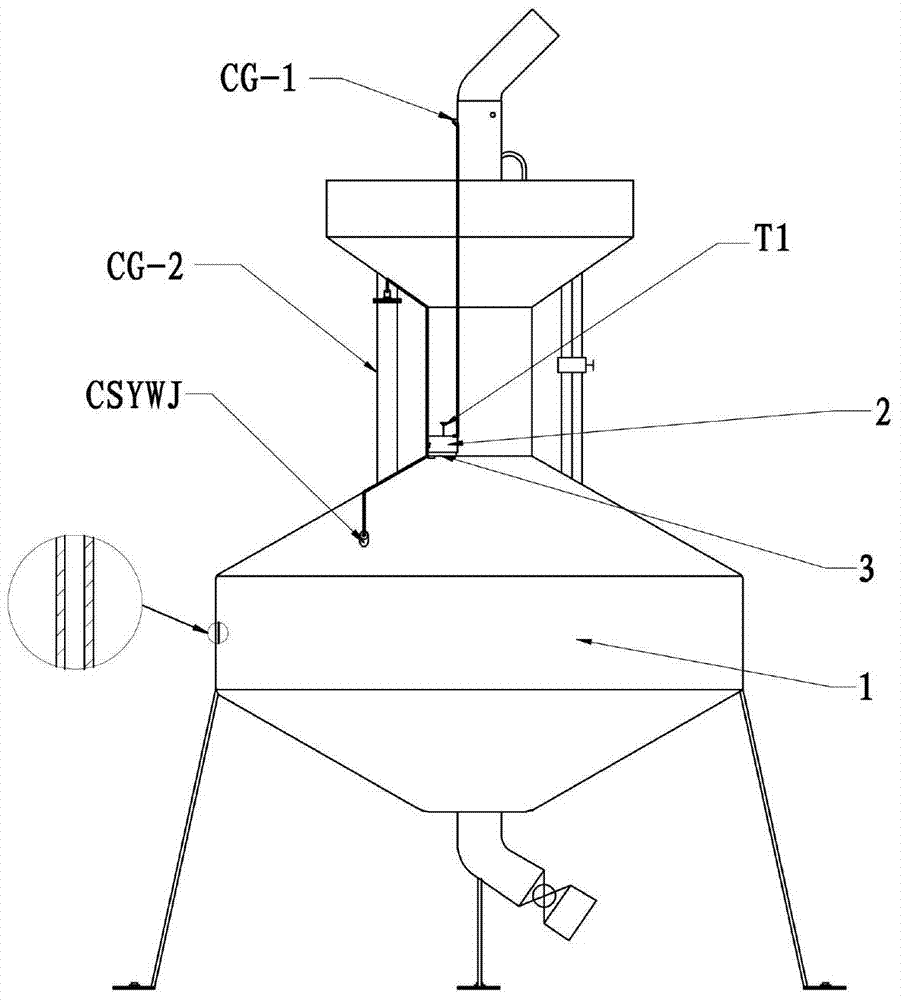

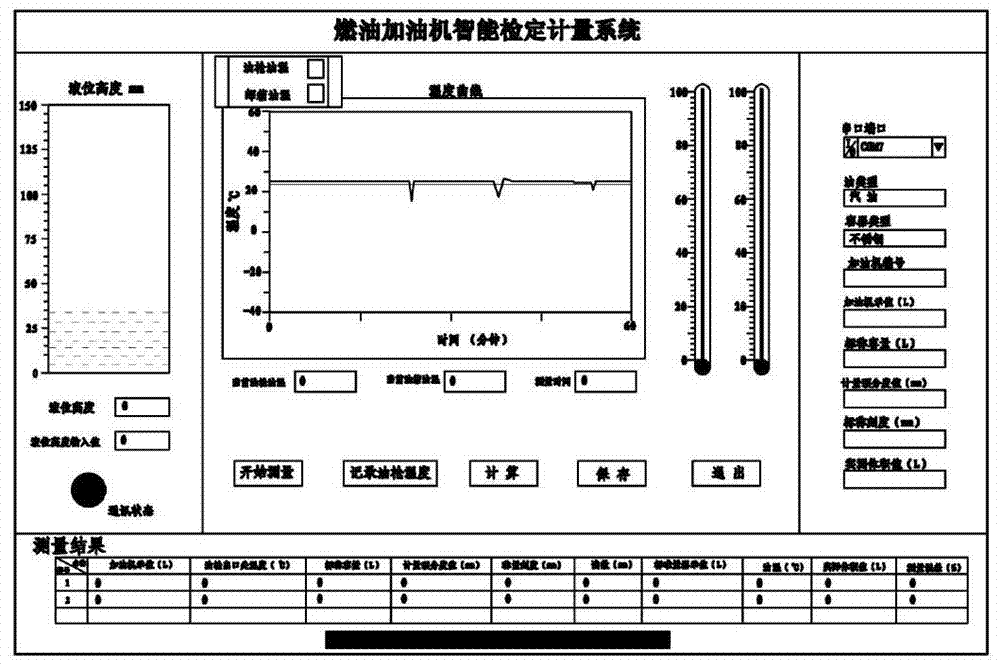

Wireless automatic verification device for tanker capacity of vacuum insulation standard metal gauge

ActiveCN104019869BSolve the problem of material lossSolve the easy lossTesting/calibration apparatusComputer monitorAutomatic test equipment

Owner:海兴县顺达计量仪器厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com