Wireless automatic verification device for tanker capacity of vacuum insulation standard metal gauge

A standard metal gauge and vacuum insulation technology, applied in measuring devices, testing/calibrating devices, instruments, etc., can solve the problems of easy loss of cable materials, etc., and achieve the effect of simple and practical overall structure, accurate measurement and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

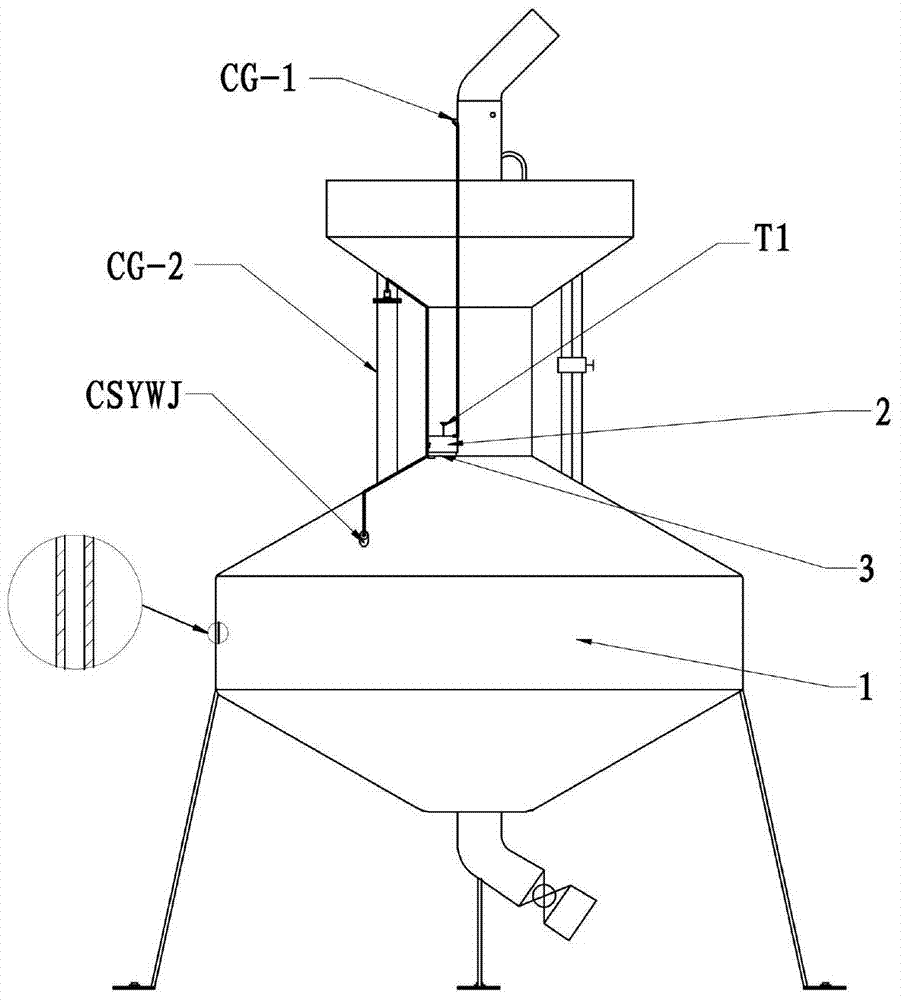

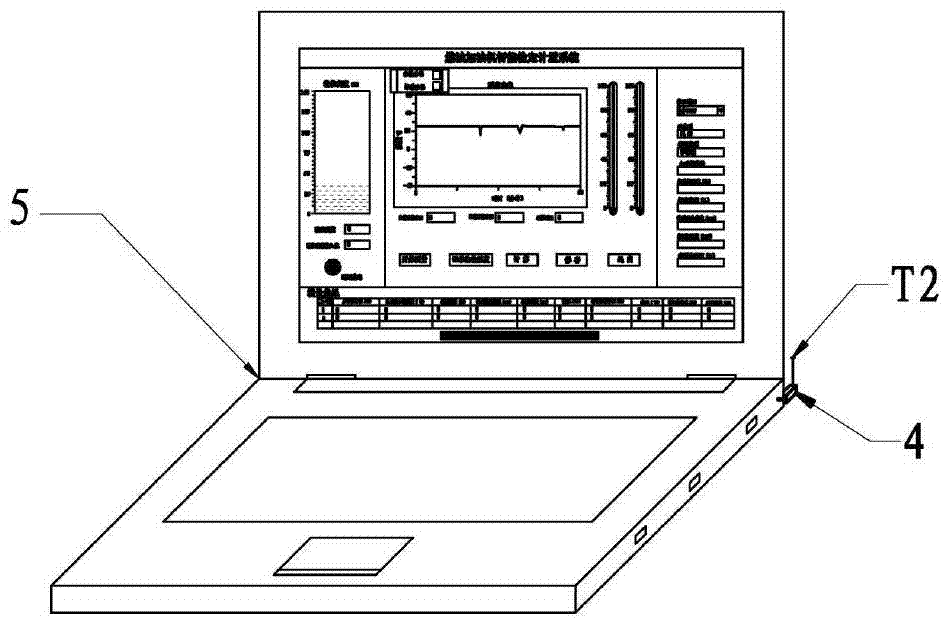

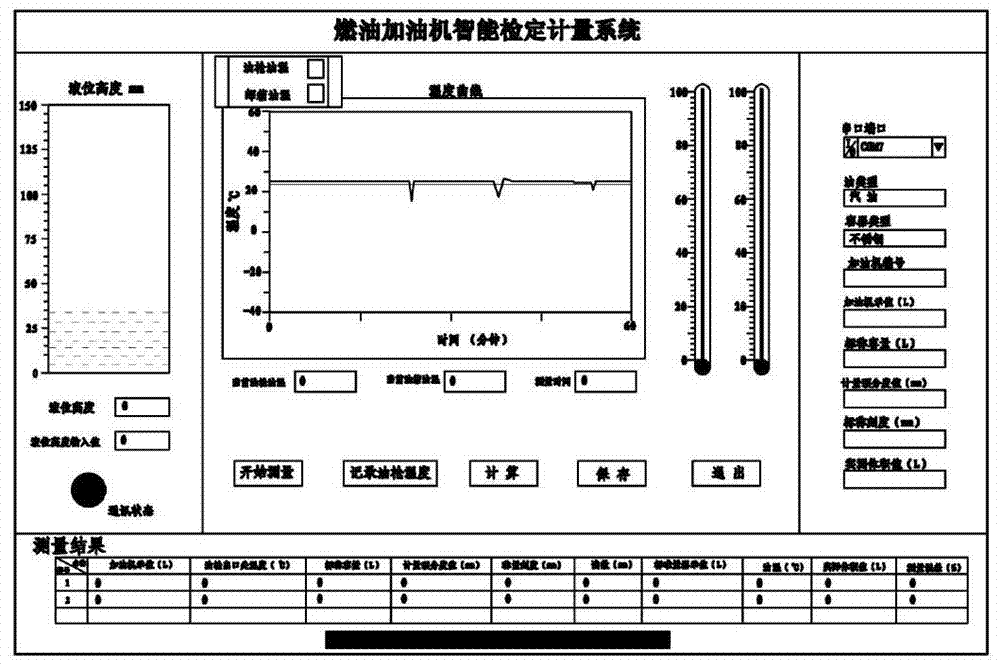

[0024] as attached Figure 1-4 In the shown embodiment, the present invention is provided with: a vacuum heat preservation standard metal measuring instrument main body 1, a data acquisition wireless transmitter 2, a wireless receiver 4, and a monitoring computer 5, and the data acquisition wireless transmitter 2 is connected to the vacuum heat preservation unit by a connecting seat 3 On the main body 1 of the standard metal gauge, the liquid level indicator installed on the main body 1 of the vacuum insulation standard metal gauge is a magnetic hysteresis telescopic liquid level gauge CSYWJ. The temperature sensor CG-1, the oil temperature sensor CG-2 of the main body of the gauge, the data acquisition circuit, and the wireless transmission module, the data acquisition circuit and the wireless transmission module are sealed in the explosion-proof shell of the transmitter, and the gun outlet connected to the input end of the data acquisition circuit The oil temperature sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com