A disconnection automatic detection device for the production of communication optical fiber and cable

An automatic detection device and technology of communication optical fibers, applied in the field of optical fiber and cable production, can solve the problems of relying on labor, low detection efficiency, low manual detection efficiency, etc., and achieve the effect of high degree of automation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

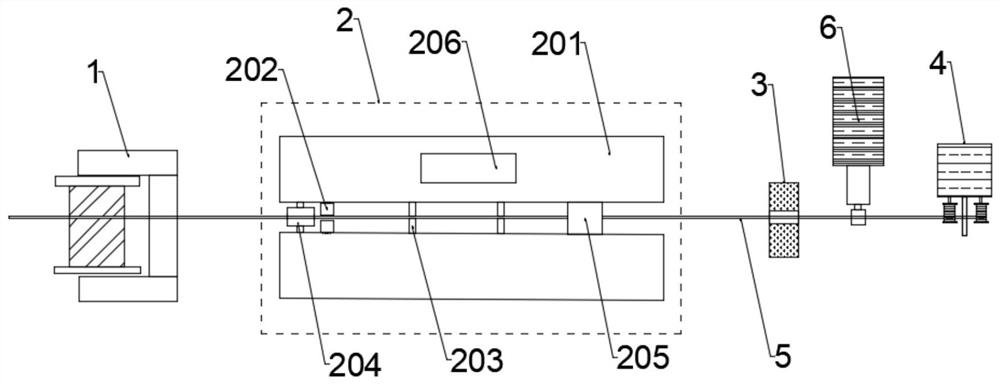

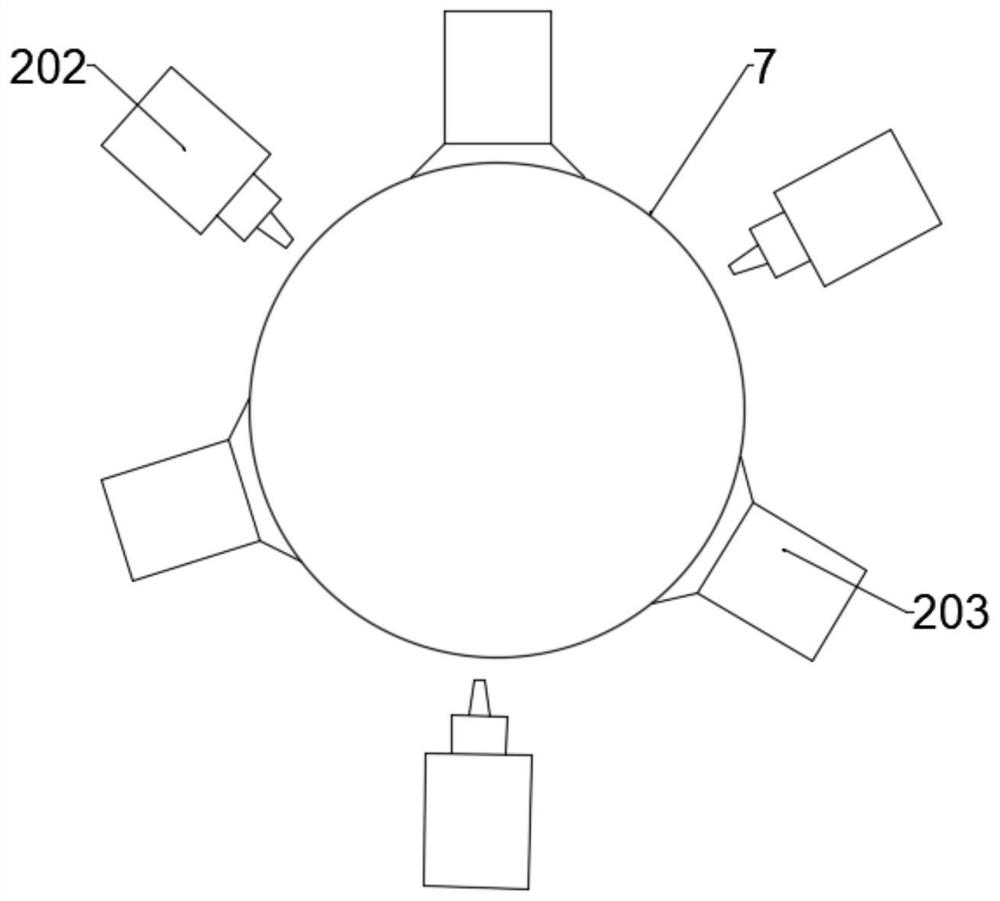

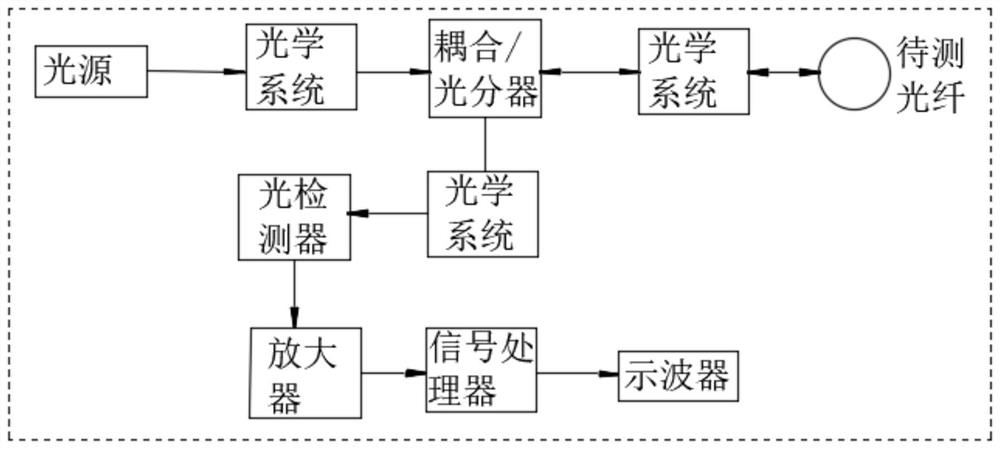

[0028] like figure 1 and figure 2 As shown, the present invention provides a disconnection automatic detection device for the production of communication optical fiber and cable, including a production line platform 5, the leftmost end of the production line platform 5 is provided with a pay-off device 1, and the right side of the pay-off device 1 is provided with There are two-stage optical fiber detection components 2, the right side of the two-stage optical fiber detection component 2 is provided with a caliper 3, the right side of the caliper 3 is provided with a sheath processing device 6, and the uppermost part of the production line platform 5 is A take-up machine 4 is arranged at the right end, and an optical fiber 7 to be tested is arranged above the production line platform 5 .

[0029] The specific embodiment of the present invention is to produce optical fiber cables on the production line platform 5. First, the pay-off device 1 starts to release the optical fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com