Device for preventing rotating speed measured value from jumping off and method thereof

A speed measurement and speed measurement technology, which is applied in the direction of measuring devices, linear/angular velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problems of inaccurate data, expensive equipment, and small linear error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

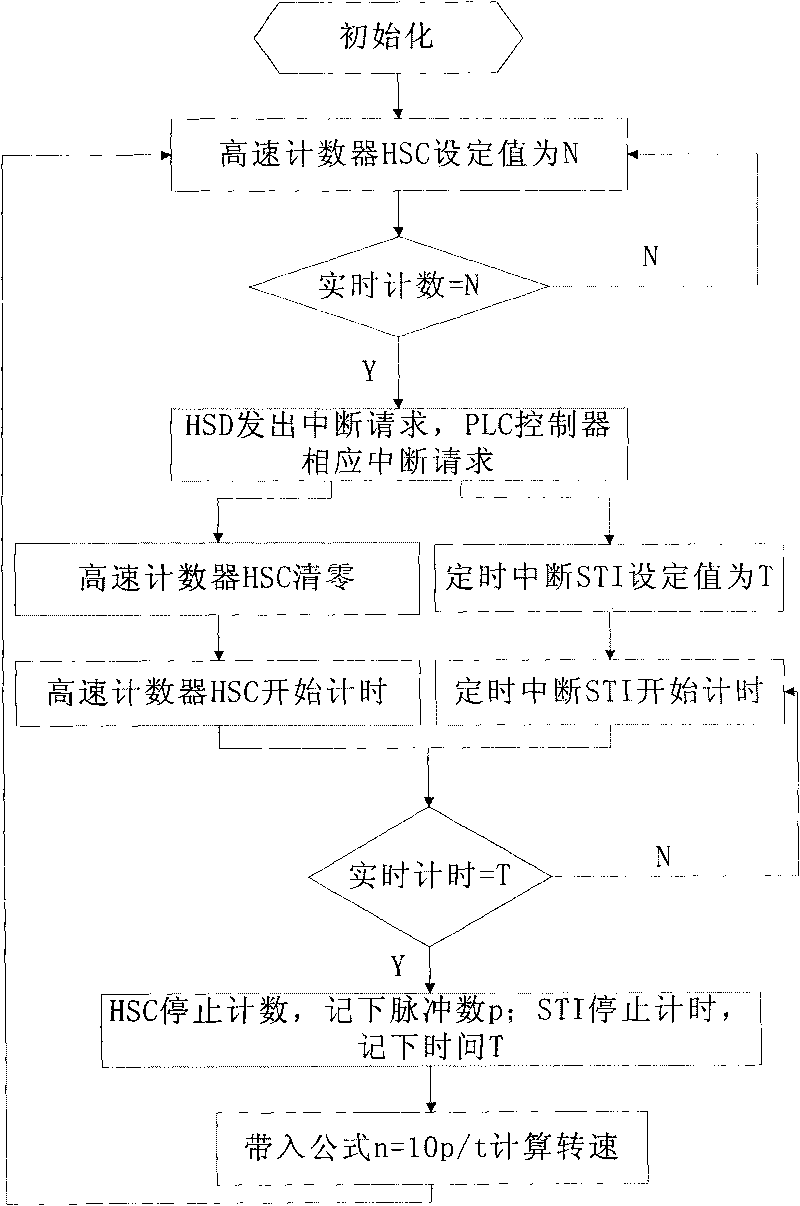

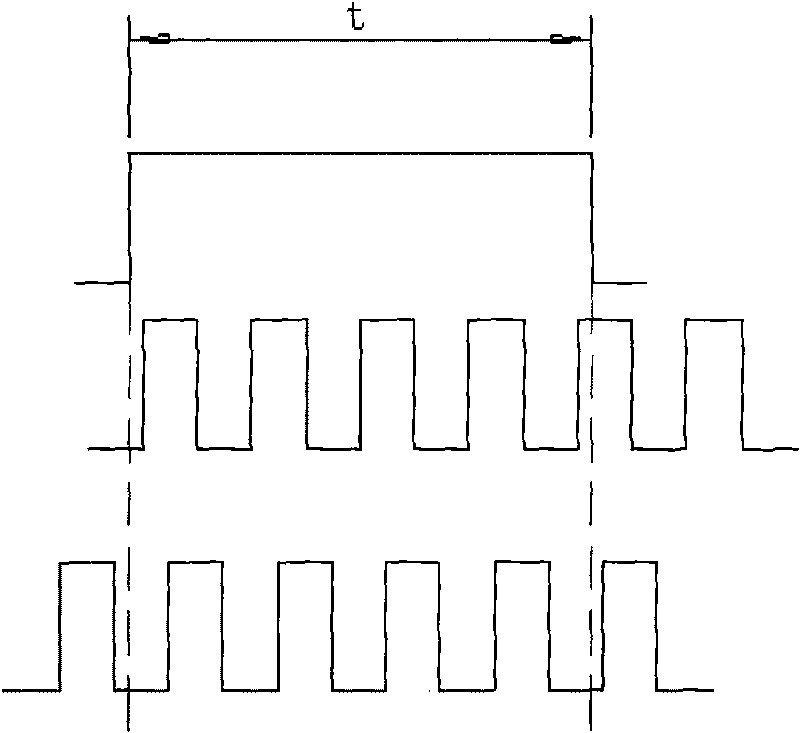

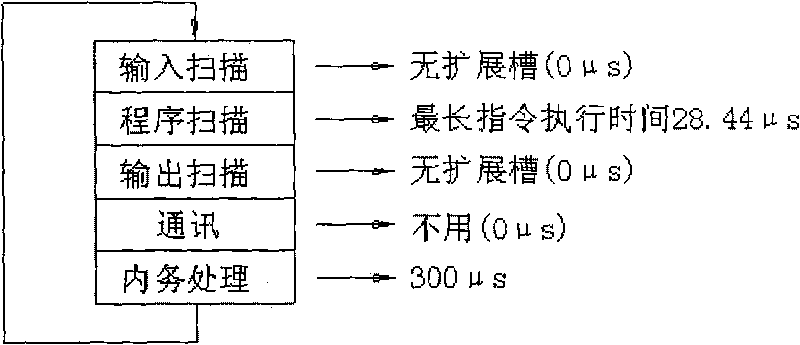

[0020] The basic principle of digital speed measurement: measure the number of pulses input per unit time. Obviously, the higher the pulse frequency, the higher the speed, otherwise the lower the speed.

[0021] Take the speed measurement of LC-6M centrifuge as an example. There is a speed measuring disc on the main shaft of LC-6M centrifuge. There are 6 small magnets evenly distributed on the circumference of the disc. The speed measuring disc rotates with the main shaft of the centrifuge. A Hall element sensor is fixedly installed at a small gap away from the small magnet. When the main shaft rotates, the small magnet passes through the Hall element in turn.

[0022] n = 10 p t ( 1 - 1 )

[0023] The sensor generates 6 pulses per revolution, and the measurement time is represented by t, and the number of pulses corresponding to t is represented...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com