Belt speed measuring device

A speed measuring device, belt technology, applied in measuring device, linear/angular velocity measurement, speed/acceleration/impact measurement, etc., can solve the problems of inability to measure speed, inaccurate speed measurement, loss of data, etc., to achieve accurate and reliable speed measurement, protection from Damage, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

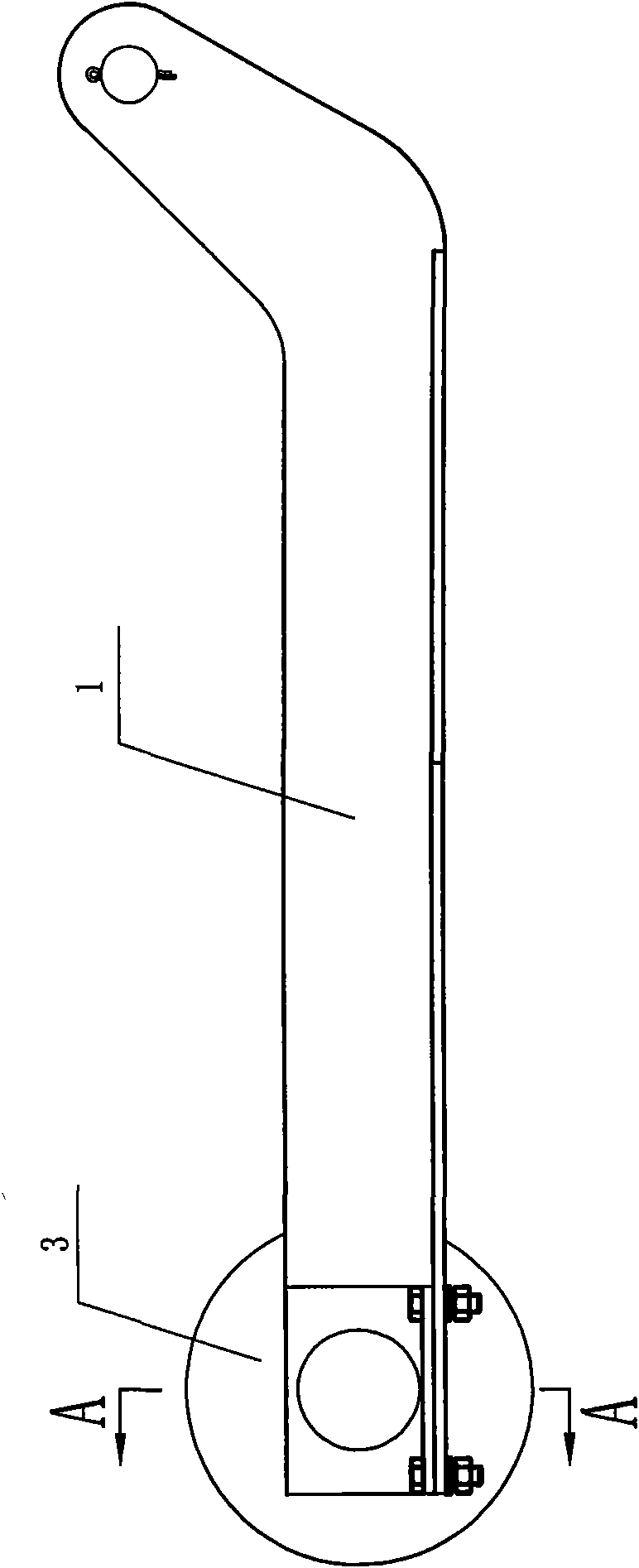

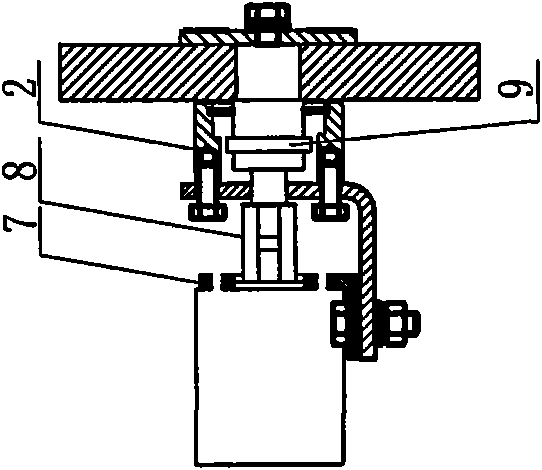

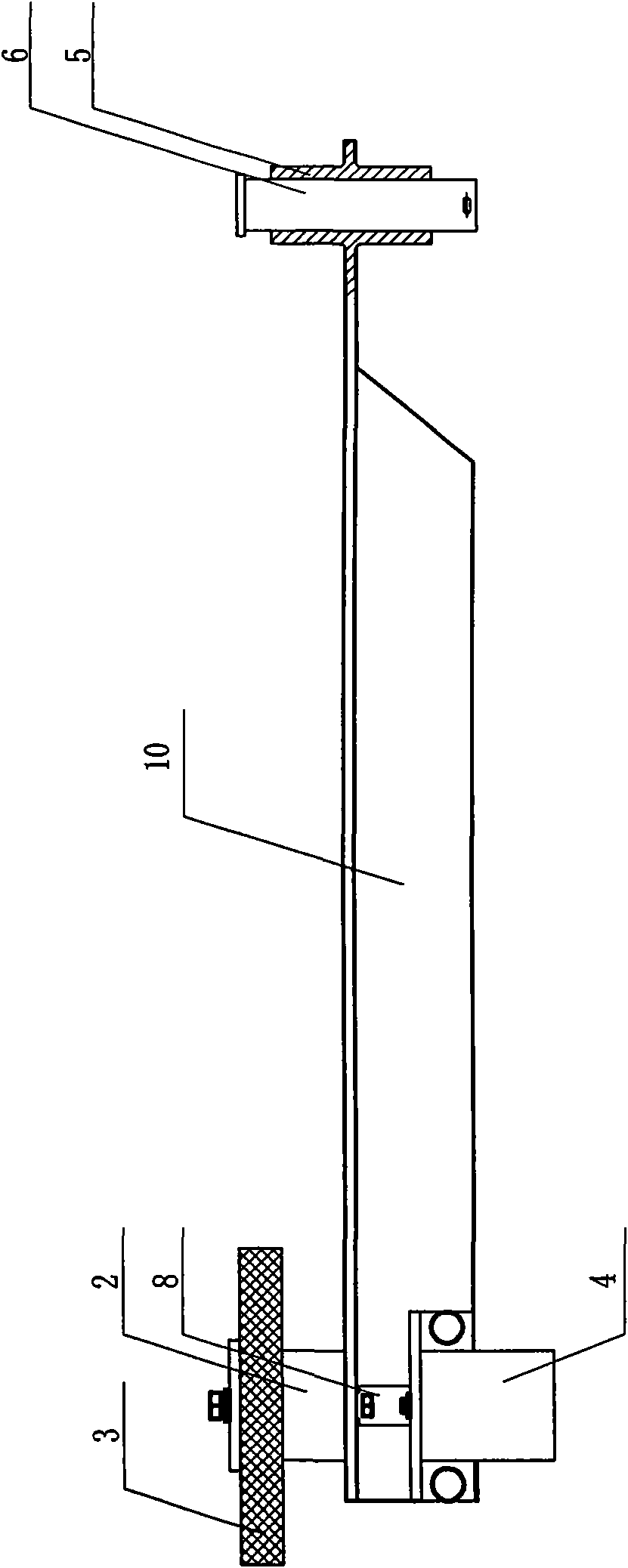

[0022] Depend on figure 1 with figure 2 It can be seen that the belt speed measuring device includes a bracket 1, and a bent plate body 10 is provided on one side of the bracket 1, wherein, one end of the bracket 1 is provided with a crank arm, and the crank arm is bent upward, and the crank arm is provided with a sleeve 5, A pin shaft 6 is installed inside the sleeve 5, and the sleeve 5 and the pin shaft 6 constitute an installation device. The other end of the bracket 1 is provided with a wheel 2, and the wheel 2 is provided with a roller 3, which passes through a flexible connector 8 It is connected with the speed measuring encoder 4 installed on the bent plate body 10 , the flexible connector 8 is a rubber bushing, one end is sleeved on the axle of the roller 3 , and the other end is sleeved on the rotating shaft of the speed measuring encoder 4 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com