Full-automatic rubber covered grinding machine actuating mechanism

An actuator, fully automatic technology, used in grinding machines, machine tools designed for grinding workpiece rotating surfaces, grinding workpiece supports, etc., can solve the waste of productivity, the dust on the surface of the roller shaft cannot be removed in time, and the surface of the rubber roller. slippage etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

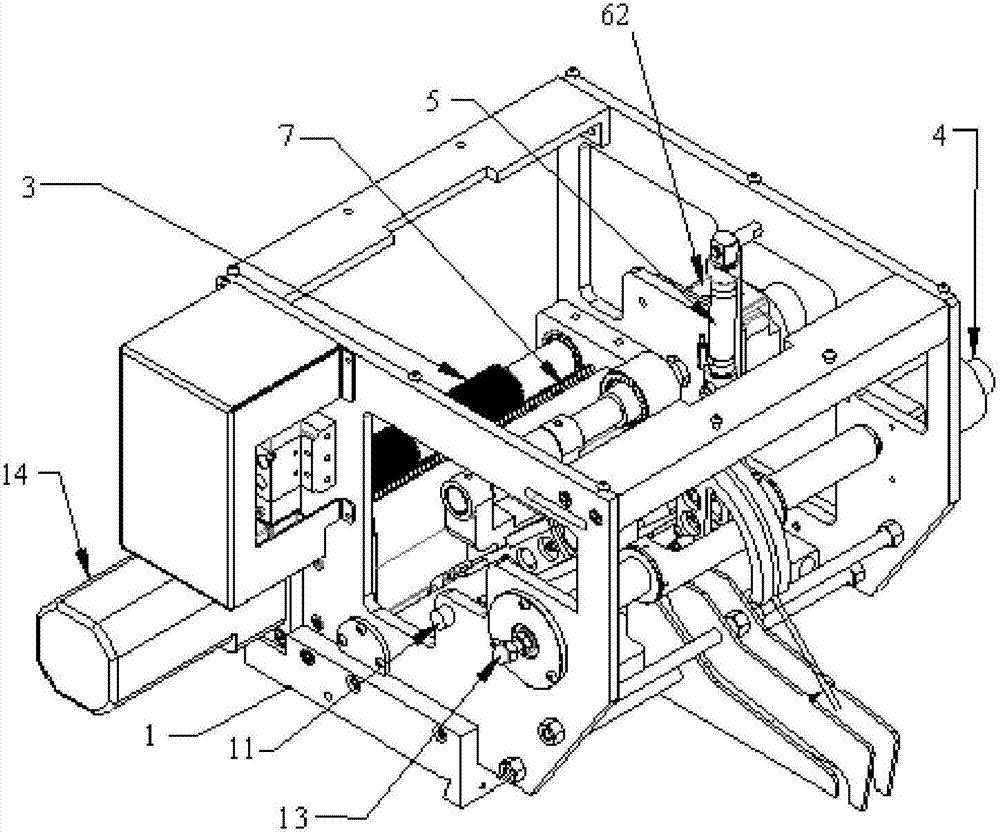

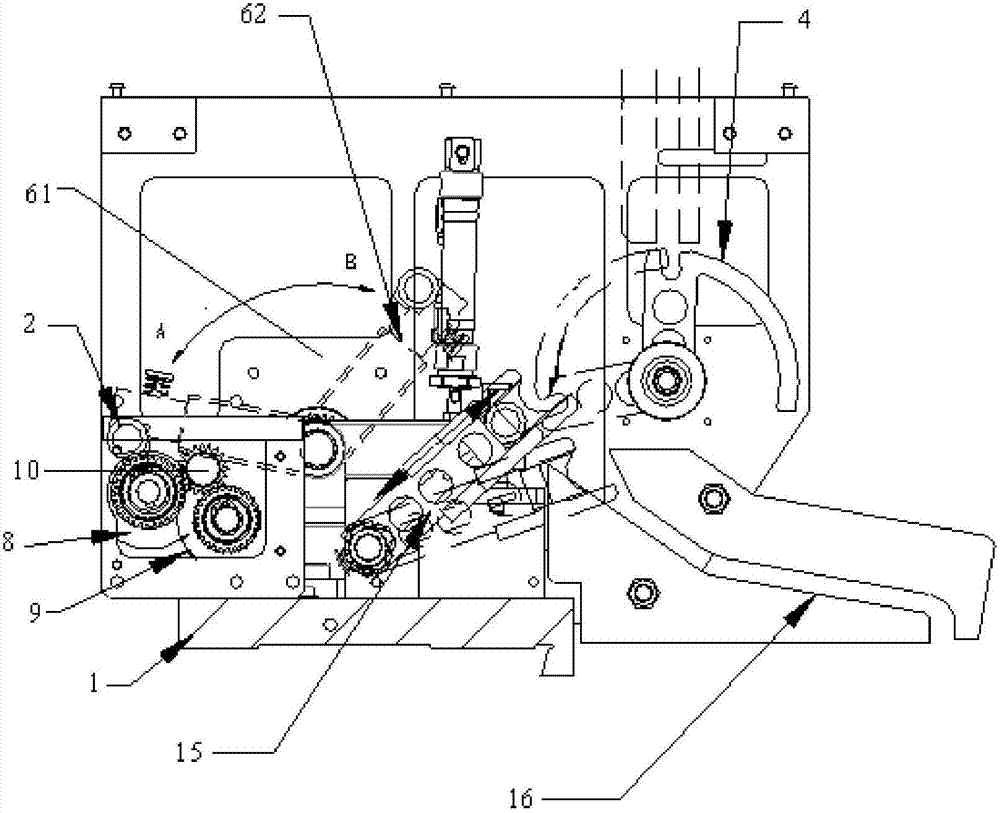

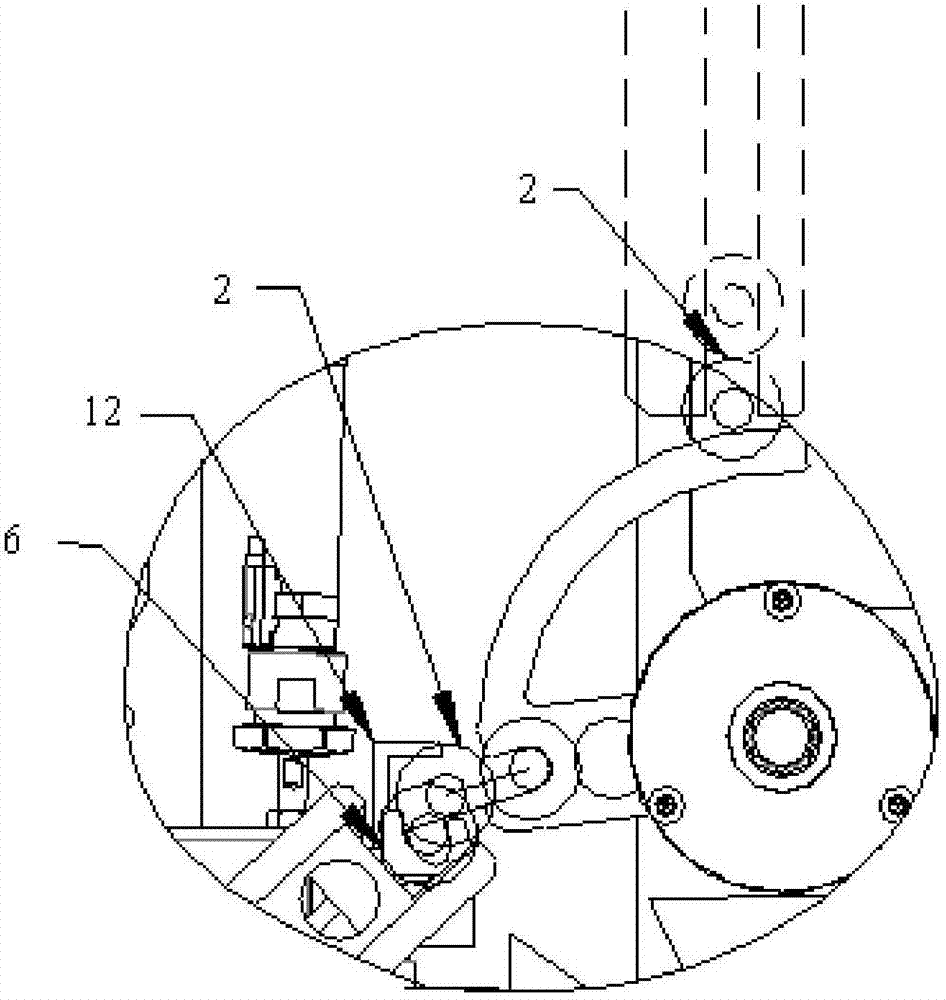

[0026] Please refer to figure 1 , figure 2 and image 3 , a fully automatic rubber roller 2 grinder actuator provided by the present invention is installed on the fuselage of the rubber roller 2 grinder through the bottom plate 1, including the rubber roller 2, the roller shaft 3, the manipulator 4, the cylinder 5 and the clamp 6, the The rubber roller 2 falls into the clamp groove 61 of the clamp 6 after the manipulator 4 is driven from the waiting position to the feeding position by the air cylinder 5 .

[0027] Please refer to figure 1 , figure 2 and image 3 , the clamp 6 further includes a clamp swing arm 62 , the clamp swing arm 62 is hole-connected to the clamp 6 , and the clamp swing arm 62 has the function of lateral fine adjustment.

[0028] Please refer to figure 1 , figure 2 and image 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com