Hyperboloidal inner bore and transmission mechanism using same

A gear transmission mechanism, hyperboloid technology, applied in transmissions, differential transmissions, mechanical equipment, etc., can solve the problems of gear meshing accuracy and life impact, and achieve the effect of avoiding tooth flank contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

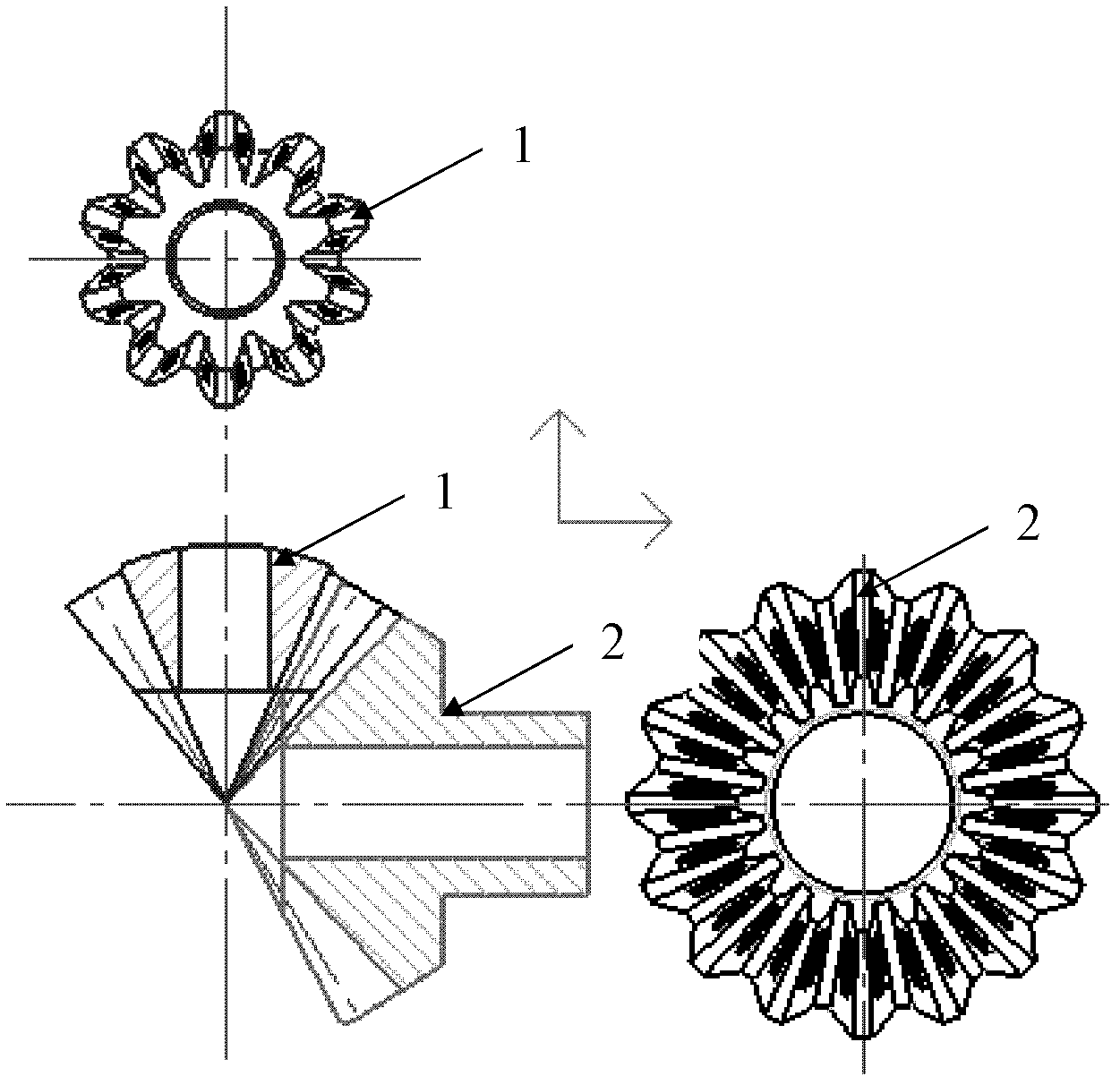

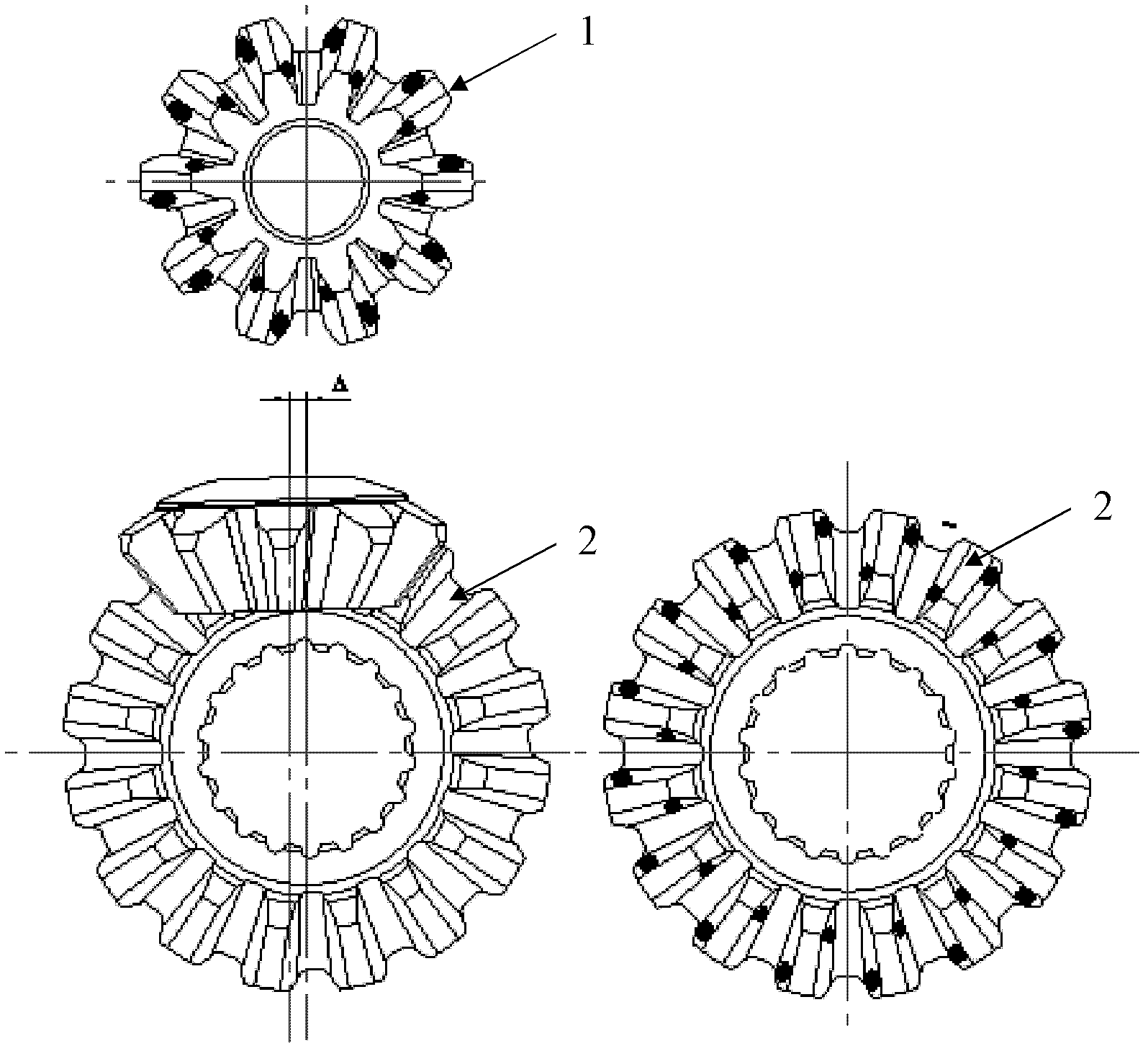

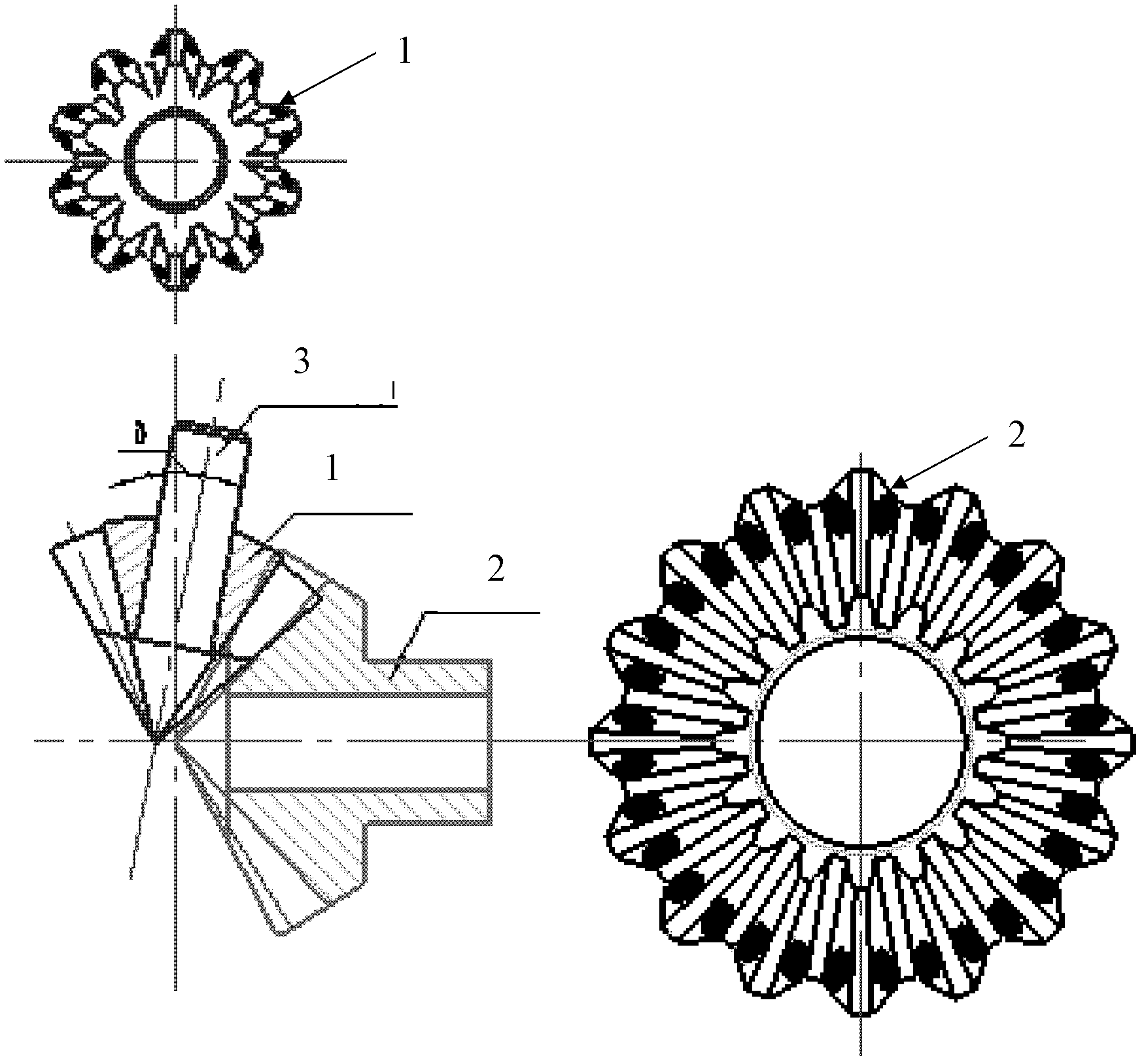

[0017] The formation principle of the hyperboloid inner hole is: an arbitrary straight line rotates around another central axis that is different from it, and the spatial shape obtained. Such as Figure three shown.

[0018] If the planetary gear shaft hole is processed into the shape shown in the figure, it will normally cooperate with the normal planetary gear shaft according to the minimum diameter of the middle part. When meshing with the side gear, if the cone top of the planetary bevel gear has a certain slight displacement, the planetary gear can swing and automatically adjust the contact to ensure normal meshing with the side gear. In this way, the above-mentioned Figure three As shown, the case of tooth flank contact when the bevel gear meshes.

[0019] According to the above, the formation principle of the inner hole of the hyperboloid is the same as that of a general cylinder. The hyperboloid is also formed by a generatrix rotating around a cylindrical surface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com