fpc four-opening vacuum air bag fast pressing machine

A pressing machine and vacuum technology, applied in the direction of electrical components, multi-layer circuit manufacturing, printed circuit, etc., can solve problems such as poor pressing effect, hand pressing accidents, poor safety, etc., to improve efficiency, improve safety, and smooth high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

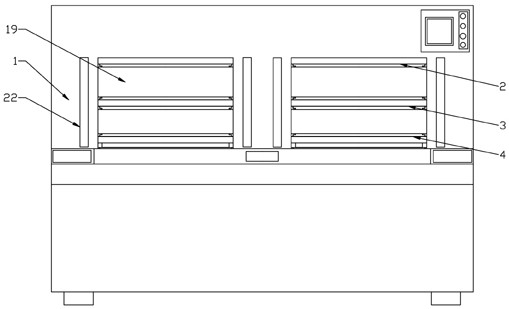

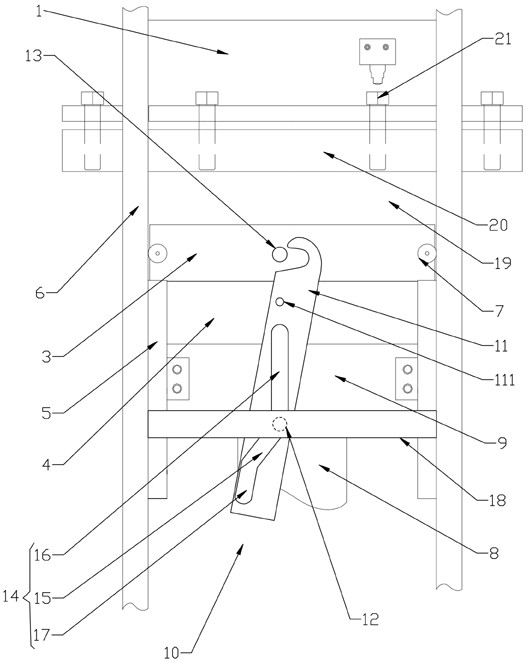

[0025] Embodiment 1: as Figure 1 to Figure 3 As shown, the present invention includes a casing 1, two sets of pressing assemblies arranged symmetrically on both sides of the casing 1, each set of pressing assemblies includes an upper fixing plate 2, a middle plate 3 and a lower pressing plate 4, Both the inside of the upper fixing plate 2 and the inside of the middle plate 3 are provided with vacuum chambers, and the lower surface of the upper fixing plate 2 and the lower surface of the middle plate 3 are provided with corresponding vacuum chambers. The airbag cavity is connected with an elastic sealing pressure film, and the casing 1 is provided with a position-limiting module 5 matched with the middle plate 3 in the middle. In the present invention, the middle plate 3 divides the pressing area between the upper fixing plate 2 and the lower pressing plate 4 into two, and the present invention has two sets of pressing assemblies, thus forming a four-opening structure, which c...

Embodiment approach

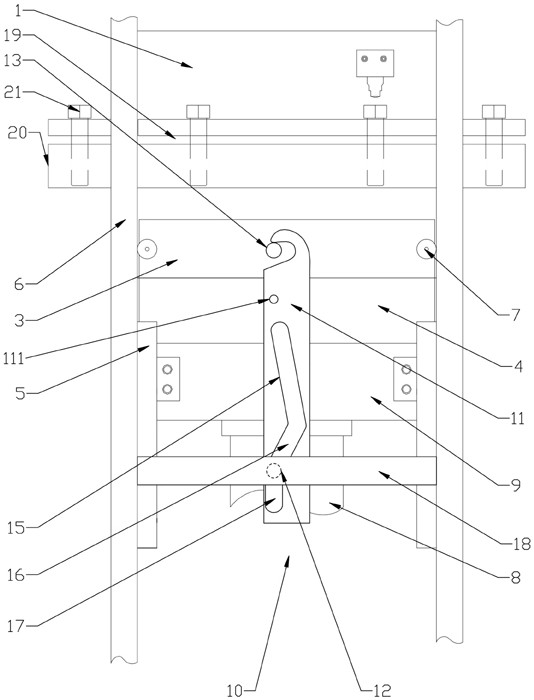

[0028]A hook device 10 is provided on the outer side of the lower platen 4, and the hook device 10 includes a rotating hook block 11 and a fixed path guide column 12, and a hook point 13 is provided on the side of the middle plate 3 , the rotating shaft 111 of the rotating hook block 11 is arranged on the side of the lower platen 4, the surface of the rotating hook block 11 is provided with a path through groove 14 matching with the path guide column 12, and the path The guide post 12 is inserted into the path through groove 14, and the path through groove 14 includes a section of inner turn structure 15, and the path guide post 12 is guided at the inner turn structure 15 during the upward movement of the lower pressing plate 4. The rotating hook block 11 rotates inwards so that the rotating hook block 11 hooks the hook point 13 . In the present invention, the hook device 10 is used to pull down the middle plate 3 through the hook point 13 when the lower platen 4 goes down, so...

Embodiment 2

[0034] Embodiment 2: Different from Embodiment 1, the upper fixing plate 2 is fixedly arranged on the upper end surface of the cavity 19, and both sides of the middle plate 3 are provided with The card position bump. The clamping projection plays the role of contacting and going up the buffer frame 20, which is similar to the effect of the limit projection 7; the middle plate 3 contacts the buffer frame 20 and is integrated with the buffer frame 20. The gaps between the shells 1 provide buffer spaces.

[0035] The invention can be used in the technical field of fast presses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com