Locomotive axle end structure on which six-channel Hall speed sensor can be additionally mounted

A hall speed, six-channel technology, applied in axles, wheels, vehicle parts, etc., can solve problems such as lower reliability, overload, dirt entry, product failure, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

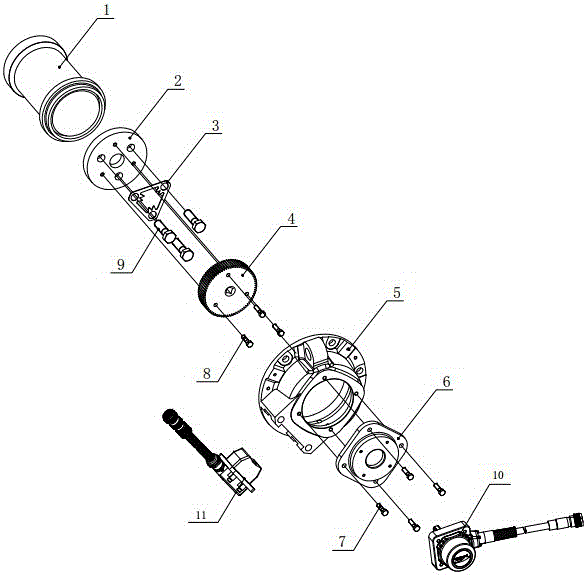

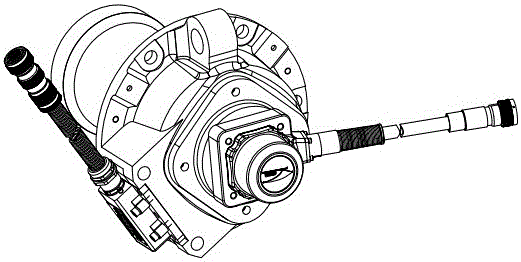

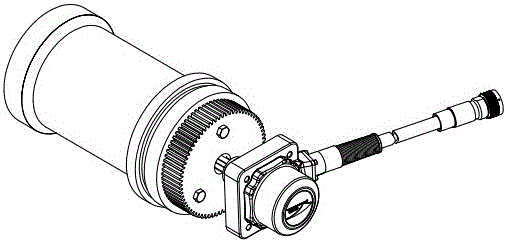

[0021] Such as figure 1 , 2 , 3, the locomotive shaft end structure that can be equipped with a six-channel Hall speed sensor includes an axle shaft 1, a shaft end gland 2, a gear plate 4, a front cover 5, and a rear cover 6.

[0022] The structure of the above-mentioned shaft end gland 2 is as follows: Figure 4 , 5 As shown, a through hole 21 is distributed in the middle, which is used for the positioning of the gear plate 4. Three hexagon head bolt mounting holes 22 and threaded holes 23 have the same diameter and are evenly distributed on the inner circumference of the shaft end gland 2. The shaft end gland 2 An axle locating hole 24 is sunk in the back, and the axle locating hole 24 is used for positioning between the axle end gland 2 and the axle 1, and the axle 1 is placed in the axle locating hole 24.

[0023] The structure of above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com