A kind of foamed silicon carbide-based structured catalyst and its application in the preparation of butadiene

A structured catalyst, foamed silicon carbide-based technology, applied in the direction of physical/chemical process catalysts, catalyst carriers, hydrocarbons, etc., can solve the problems of many side reaction products, high energy consumption, high material consumption, catalyst wear and separation, etc. Achieve the effects of increasing productivity, reducing energy consumption, and reducing bed resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

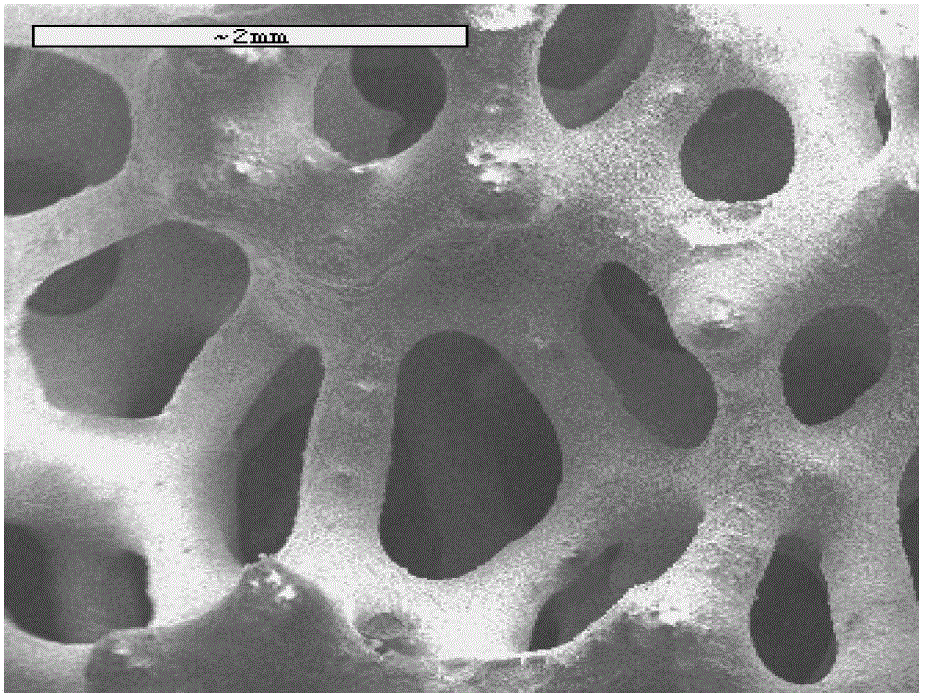

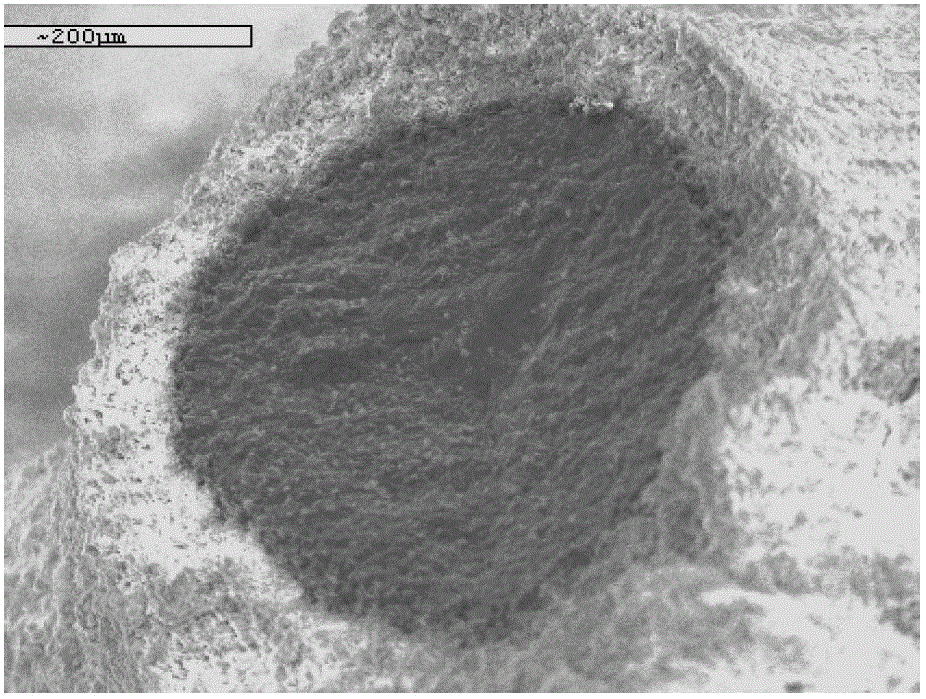

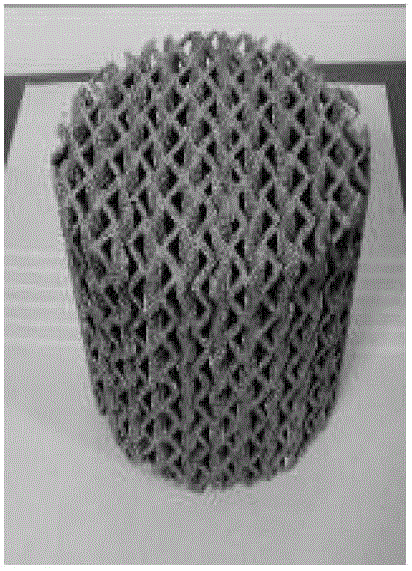

[0030] As shown in Figure 1(a)-Figure 1(b), the catalyst in this example uses silicon carbide foam with the surface modified by Al2O3 as the carrier, the loading of Al2O3 is 20wt%, and the pore volume fraction of the silicon carbide foam is (Porosity) 80%, pore diameter 0.8mm.

[0031] Weigh 20.0 g of Zn(NO 3 ) 2 ·6H 2 O, 35 g Fe(NO 3 ) 2 ·6H 2 O and 5 g Co(NO 3 ) 2 ·6H 2 O, dissolved in a certain amount of water to form a 100 ml solution, then added 28.0 g of citric acid, heated and stirred to dissolve. Add 100ml of foamed silicon carbide carrier to the above solution, soak for half an hour, take it out and dry it, and activate it at 600°C for 1 hour to prepare butadiene foamed silicon carbide-based structured catalyst by oxidative dehydrogenation of butene. Among them, the catalyst active component accounts for 15% of the mass fraction of the entire structured catalyst, the main active component is zinc cobalt ferrite, accounting for 65% of the entire active compone...

Embodiment 2

[0034] The catalyst in this example uses foamed silicon carbide whose surface has been modified with nano-silicon carbide as a carrier, the nano-silicon carbide loading is 30wt%, the foamed silicon carbide has a pore volume fraction of 80%, and a pore diameter of 0.5 mm.

[0035] Weigh 20.0 g of Zn(NO 3 ) 2 ·6H 2 O, 35 g Fe(NO 3 ) 2 ·6H 2 O was dissolved in a certain amount of water to form a 100 ml solution, then 23.0 g of citric acid was added, heated and stirred to dissolve. Add 100ml of foamed silicon carbide carrier to the above solution, soak for half an hour, take it out and dry it, activate it at 500°C for 2 hours to make butadiene foamed silicon carbide-based structured catalyst by oxidative dehydrogenation of butene. Among them, the catalyst active component accounts for 25% of the mass fraction of the entire structured catalyst, the main active component is zinc ferrite, accounting for 60% of the entire active component mass fraction; the secondary active compo...

Embodiment 3

[0038] The catalyst in this example uses silicon carbide foam whose surface has been modified with titania as a carrier, the loading of titania is 30wt%, the pore volume fraction of the silicon carbide foam is 75%, and the pore diameter is 0.5mm.

[0039] Weigh 20.0 g of Zn(NO 3 ) 2 ·6H 2 O, 35 g Fe(NO 3 ) 2 ·6H 2 O and 5 grams of Cr(NO 3 ) 2 ·6H 2 O, dissolve in a certain amount of water to make 100 milliliters of solution, then add 25.0 grams of citric acid, heat and stir to dissolve. Add 100ml of foamed silicon carbide carrier to the above solution, soak for half an hour, take it out and dry it, activate it at 500°C for 2 hours to make butadiene foamed silicon carbide-based structured catalyst by oxidative dehydrogenation of butene. Among them, the active component of the catalyst accounts for 21% of the mass fraction of the entire structured catalyst, the main active component is zinc iron chromate, accounting for 60% of the mass fraction of the entire active compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com