Square-prism-reinforced pipe pile and machining method thereof

A technology of reinforced and tubular piles, which is applied in the processing of tubular piles and the field of reinforced square-edged tubular piles, which can solve the design problems of small pile side friction force, small pile side friction coefficient, and failure to meet both bearing capacity and shear resistance Requirements and other issues, to achieve the effect of improving the bearing capacity of the pile tip, improving the friction force of the pile side, and high pullout resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

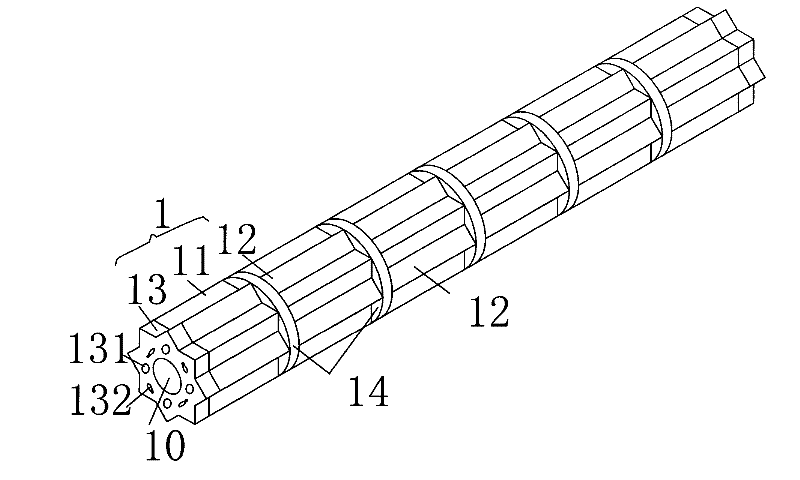

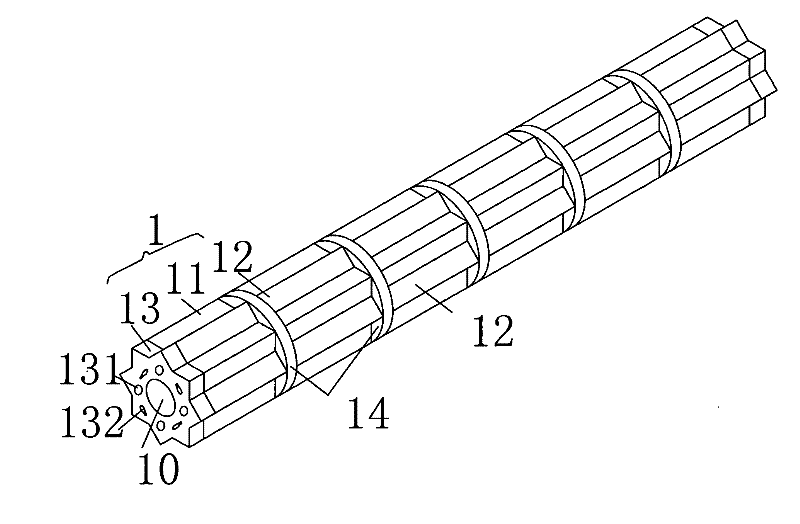

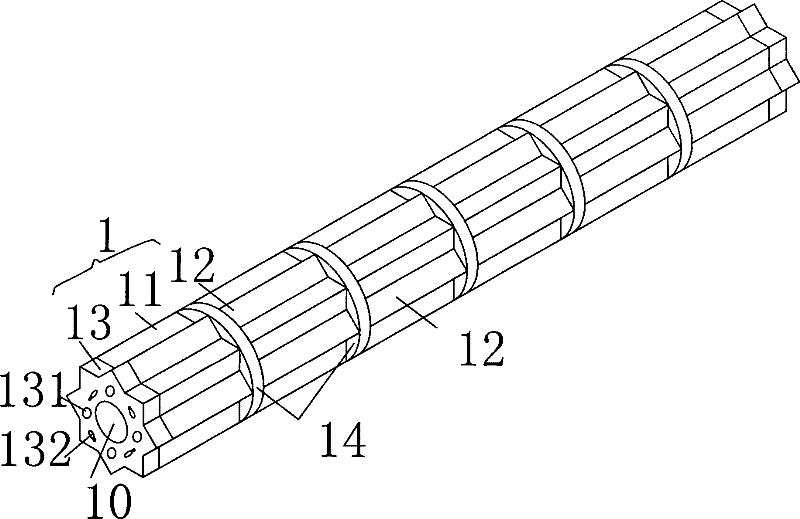

[0025] like figure 1 As shown, in an embodiment of the square edge reinforced pipe pile 1 of the present invention, comprise square pile body 11, square pile body 11 is the prefabricated concrete part of a quadrilateral, is provided with reinforcement cage (not shown in the figure) ).

[0026] The outer surface of each side of the square pile body 11 is provided with a prismatic outer surface 12, so a total of four prismatic outer surfaces 12 are arranged on the outer surfaces of its four sides, which increases the side friction of the pipe pile.

[0027] Reinforcing ribs 14 are also arranged on the outer surface of the square pile body 11 . In this embodiment, a plurality of reinforcing ribs 14 are arranged on the outer surface of the square pile body 11 at intervals.

[0028] The present invention also increases the pile end bearing capacity of the pipe pile due to the above-mentioned four prismatic outer surfaces 12 being provided.

[0029] Further, connector structures 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com