Square cylindrical corrugated tube pile and processing method thereof

A corrugated tube, cylindrical technology, applied in the field of foundation piles, can solve the problems of small pile side friction coefficient, unable to meet the design requirements of bearing capacity and shear resistance at the same time, small pile side friction force, etc. Friction, high pull-out resistance, and the effect of improving the bearing capacity of pile ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

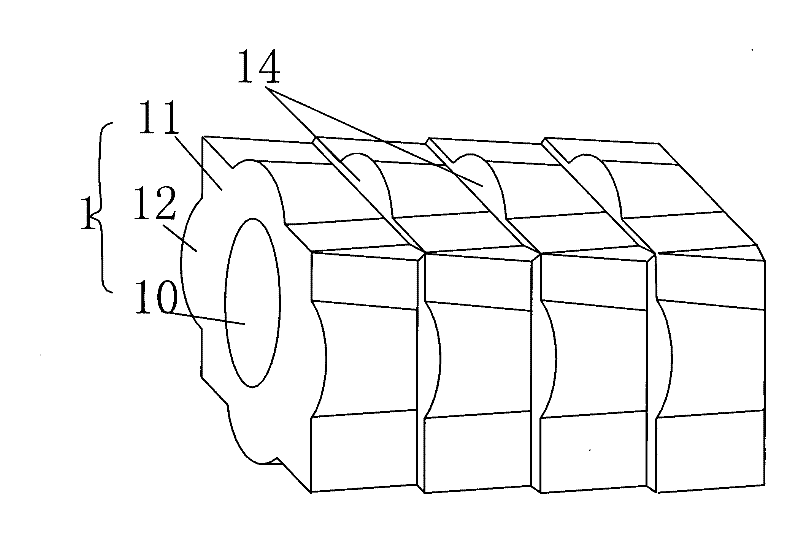

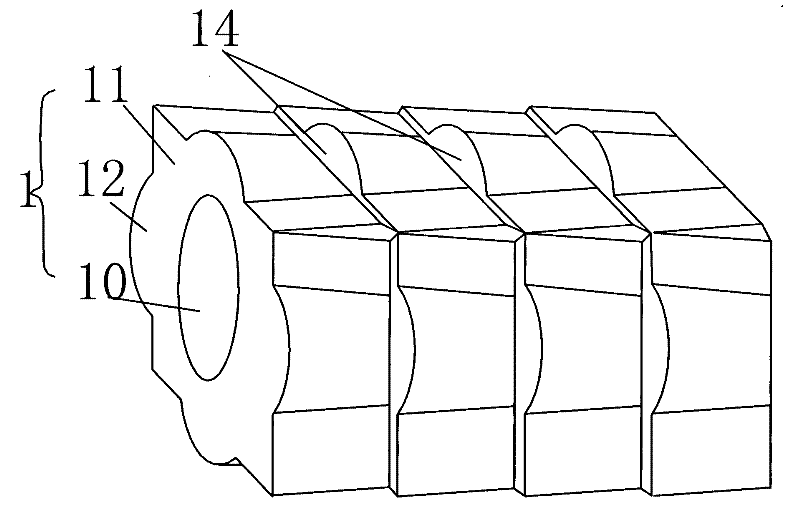

[0024] Such as figure 1 As shown, in the embodiment of the square-cylindrical corrugated pipe pile 1 of the present invention, the square-cylindrical pile body 11 is included, and the square-cylindrical pile body 11 is a prefabricated concrete part composed of a square and four semicircular arcs 12 , the inside is provided with a reinforcement cage (not shown in the figure).

[0025] The outer surface of each side of the square cylindrical pile body 11 is a nodular shape, forming a boss 14, so a plurality of bosses 14 are arranged on the outer surface of its four sides, which increases the pile side friction of the pipe pile.

[0026] The present invention also increases the pile end bearing capacity of the pipe pile due to the above-mentioned boss 14 being provided.

[0027] Further, connector structures (not shown in the figure) are respectively fixedly connected to the two ends of the square cylindrical pile body 11 . The connecting head structure is a steel structural me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com