Shoulderless and brushless hub motor for electric bicycle

A technology of electric bicycles and wheel brushes, applied in the field of electric motors, can solve the problems of high cost, poor precision and reliability, and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

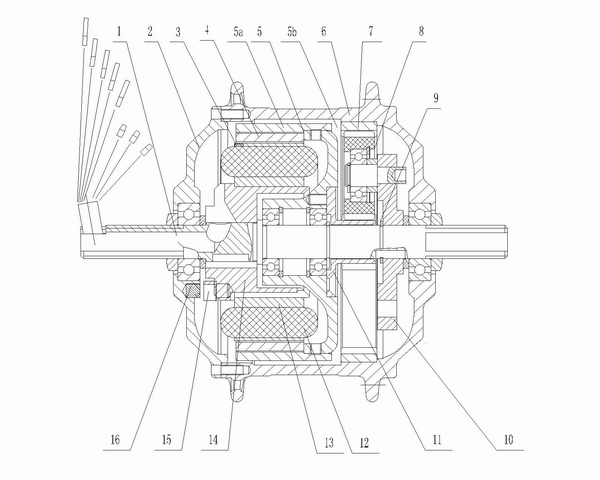

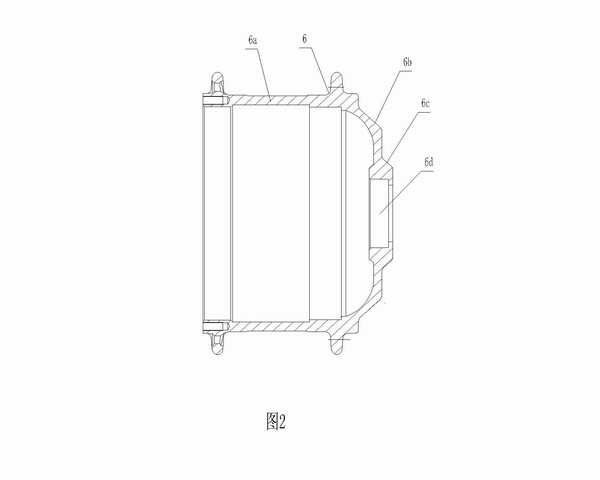

[0018] As shown in the figure, it is a shoulderless brushless hub motor for electric bicycles. The mandrel 1 is a shoulderless structure. The mandrel 1 is sleeved with a conical end cover 2, a conical hub 6, a conical end cap 2, and a conical hub. 6 are fixedly connected by screws to form a motor casing; the conical hub 6 adopts a conical hollow structure, and the bottom end of the mandrel mounting hole 6d is stacked by a small circular platform 6c and a large circular platform 6b to form a conical structure; its cylindrical The inner wall of the section 6a is recessed to form a section of annular concave surface, which constitutes the hollow structure of the conical hub 6; the conical end cover 2 also adopts a conical structure formed by overlapping large and small circular platforms; and in the traditional electric bicycle hub motor, the end cover The end of the hub generally adopts a spherical structure, the ends of the conical end cap 2 and the conical hub 6 adopt a conical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com