Patents

Literature

50results about How to "Stable vibration frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

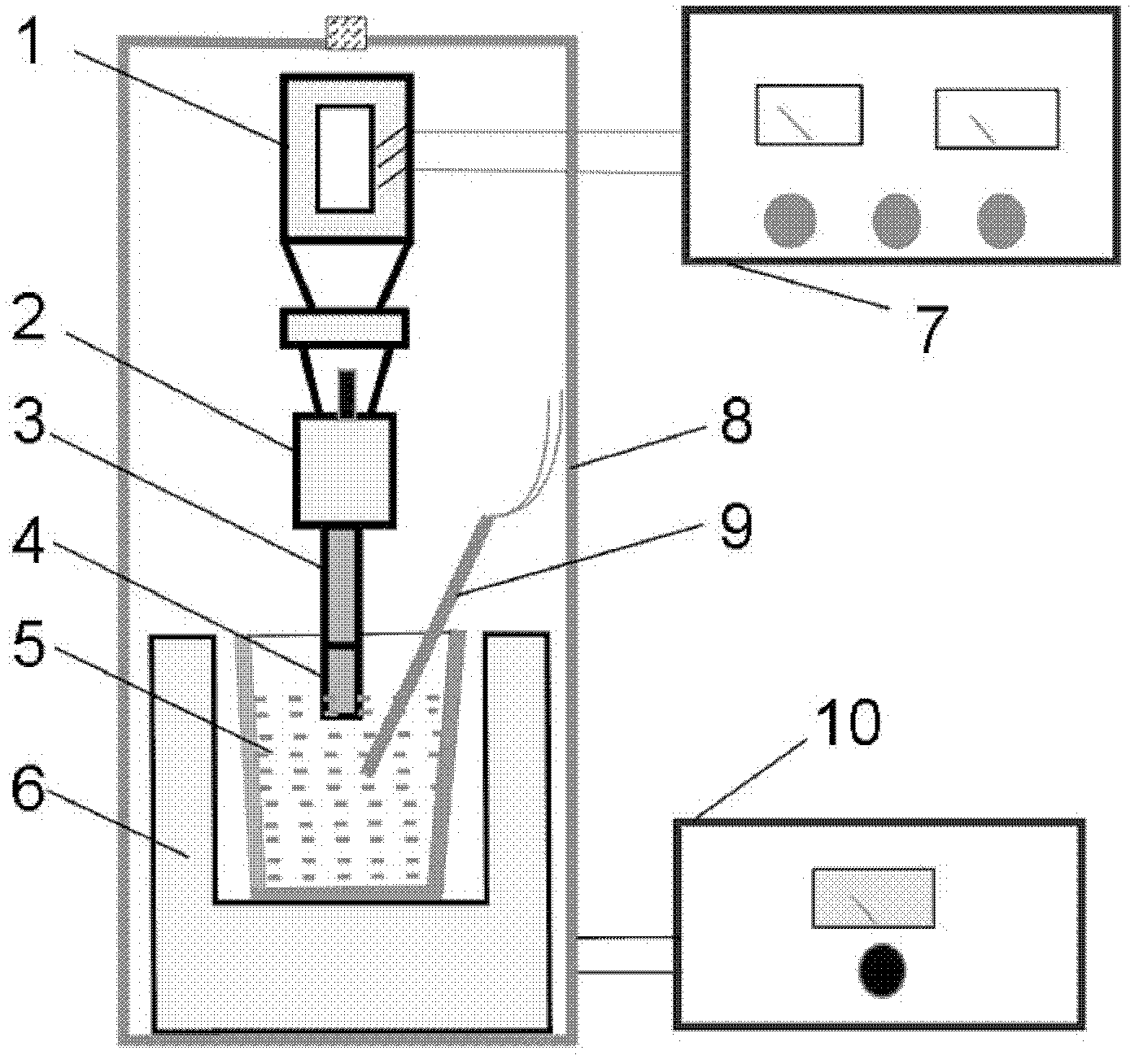

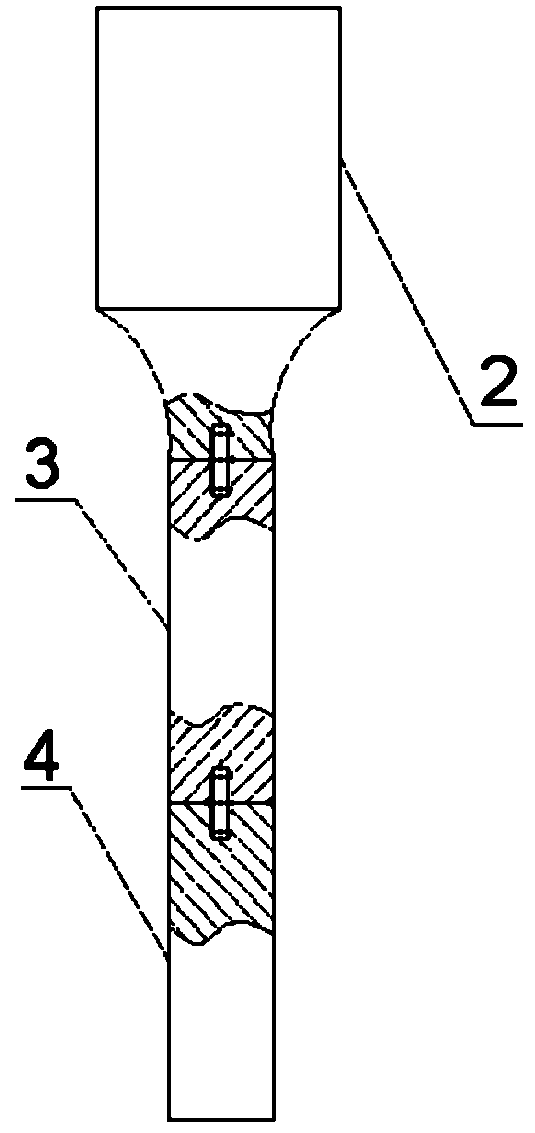

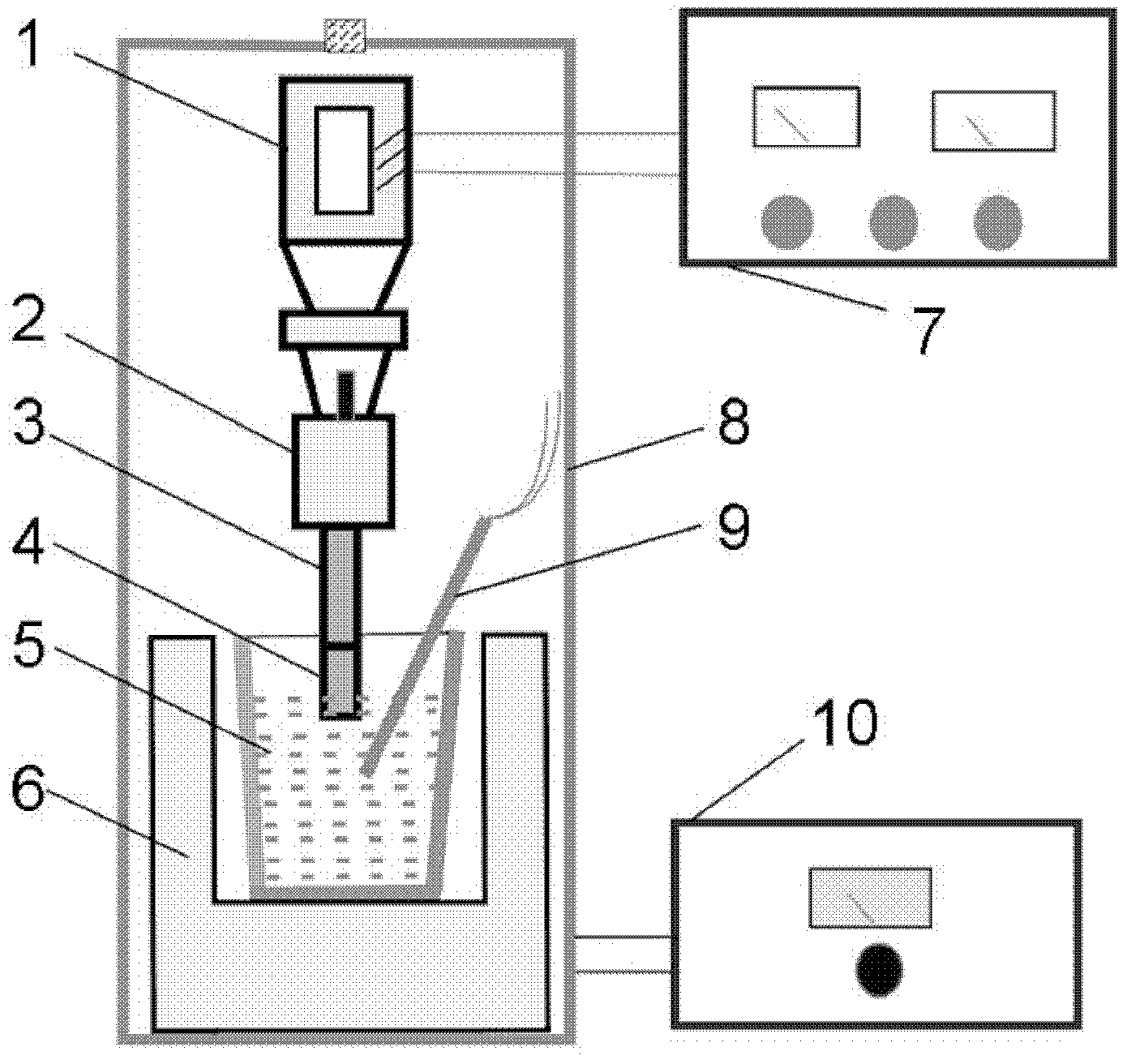

Power ultrasonic device for treating high-temperature metal melt under vacuum state and method thereof

The invention relates to a power ultrasonic device for treating high-temperature metal melt under vacuum state and a method thereof, and belongs to the field of preparation of metal materials. The method has the technical characteristics that the power ultrasonic device is used for treating the high-temperature metal melt under the vacuum state. The power ultrasonic device is characterized in that tantalum with purity being 99.98% is taken as the material of a tool head, and stable and continuous ultrasonic waves can be conducted, and the power ultrasonic device can be prevented from being corroded by high-temperature metal liquid. During the casting process, a vacuum device is adopted for protecting an ultrasonic transducer, alloy to be treated and a temperature preservation device, on one hand, the tantalum tool head can be prevented from being oxidized to deteriorate, one the other hand, the degassing effect of the ultrasonic treatment on the metal melt can be improved by virtue of the vacuum condition. For the produced alloy material, the solidification tissue is fine and compact, the distribution is uniform, and the clarifying effect is good, so that the mechanical property is greatly improved. The invention provides a new technical means for application of ultrasonic treatment of high-temperature melt in industrial production.

Owner:DALIAN UNIV OF TECH

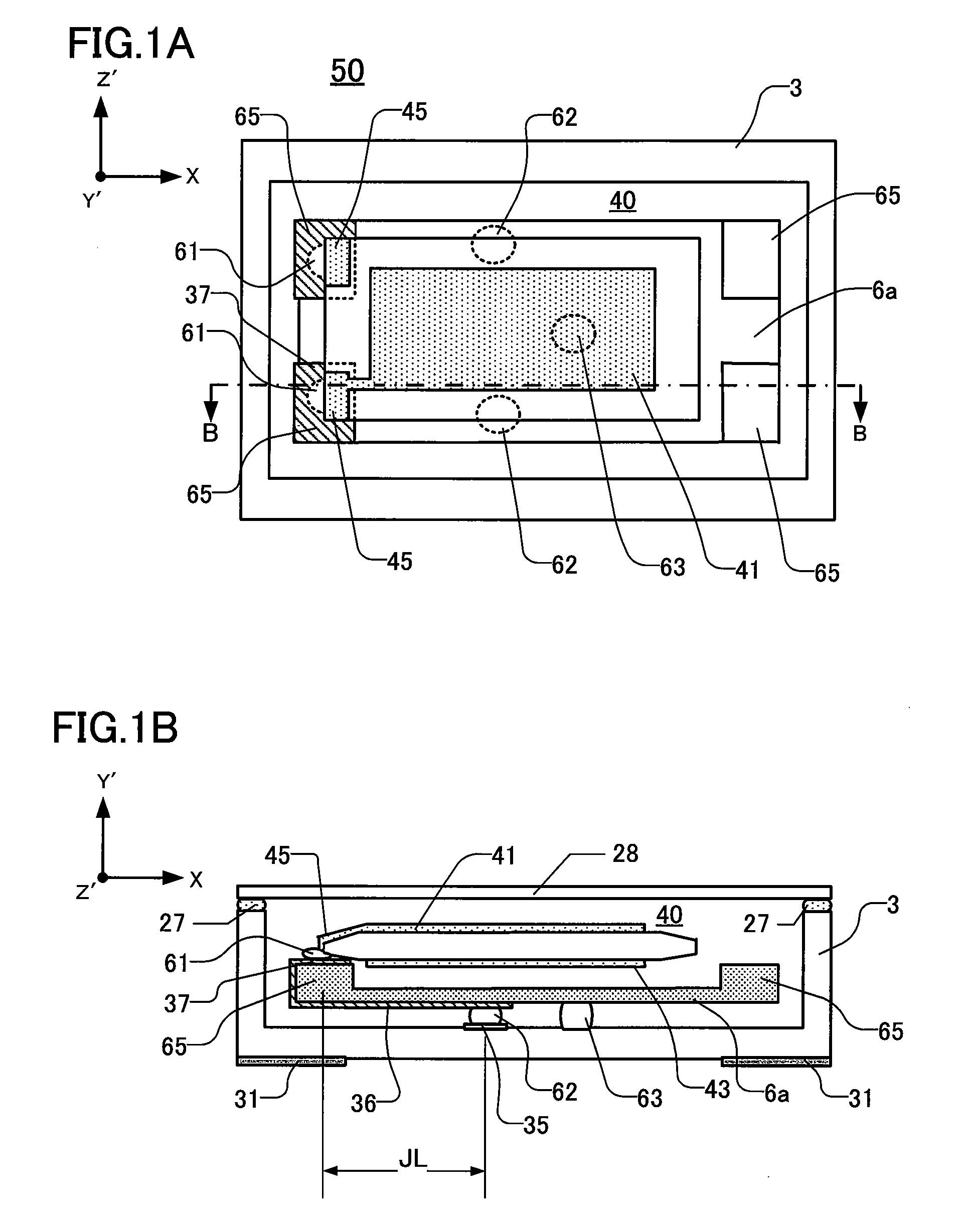

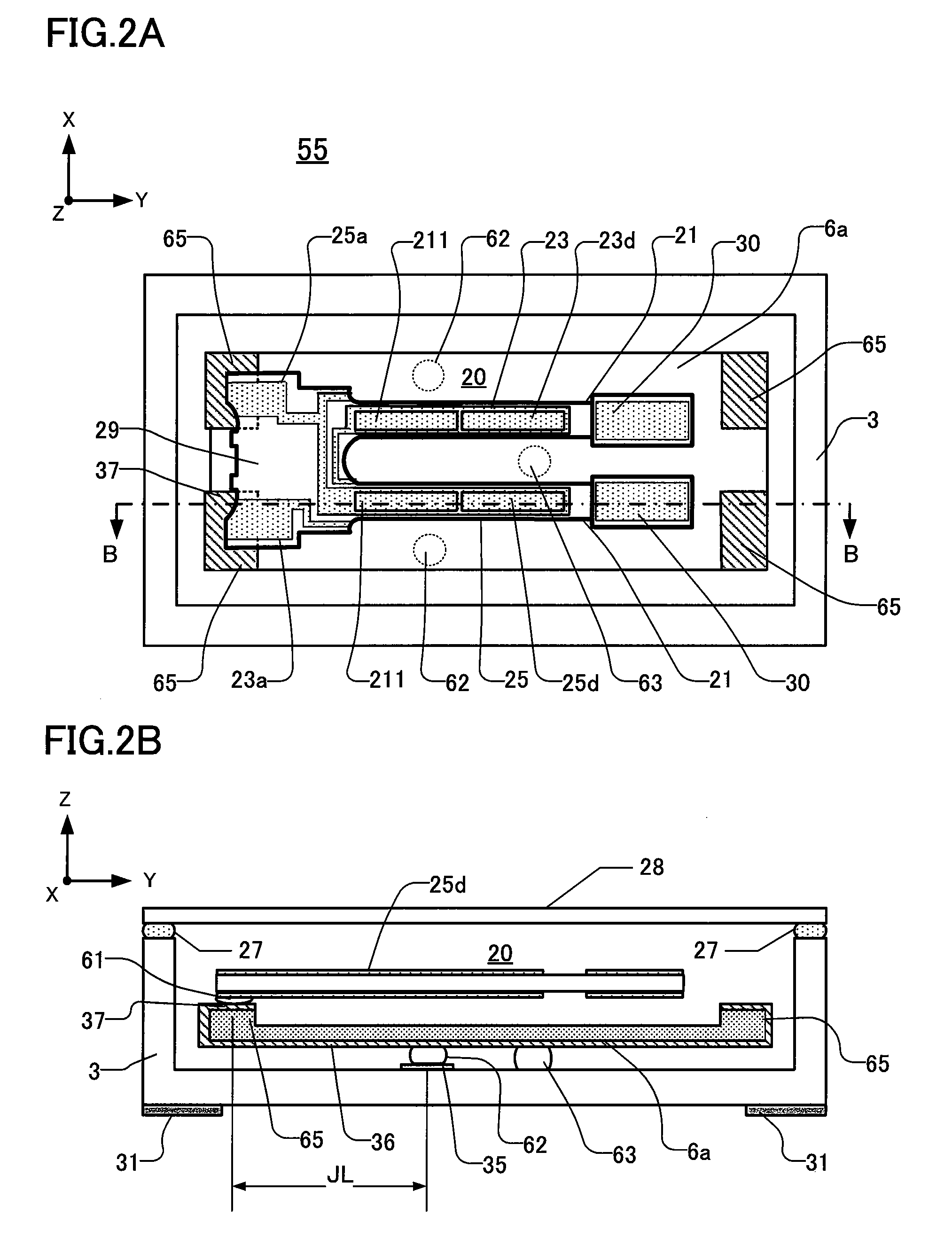

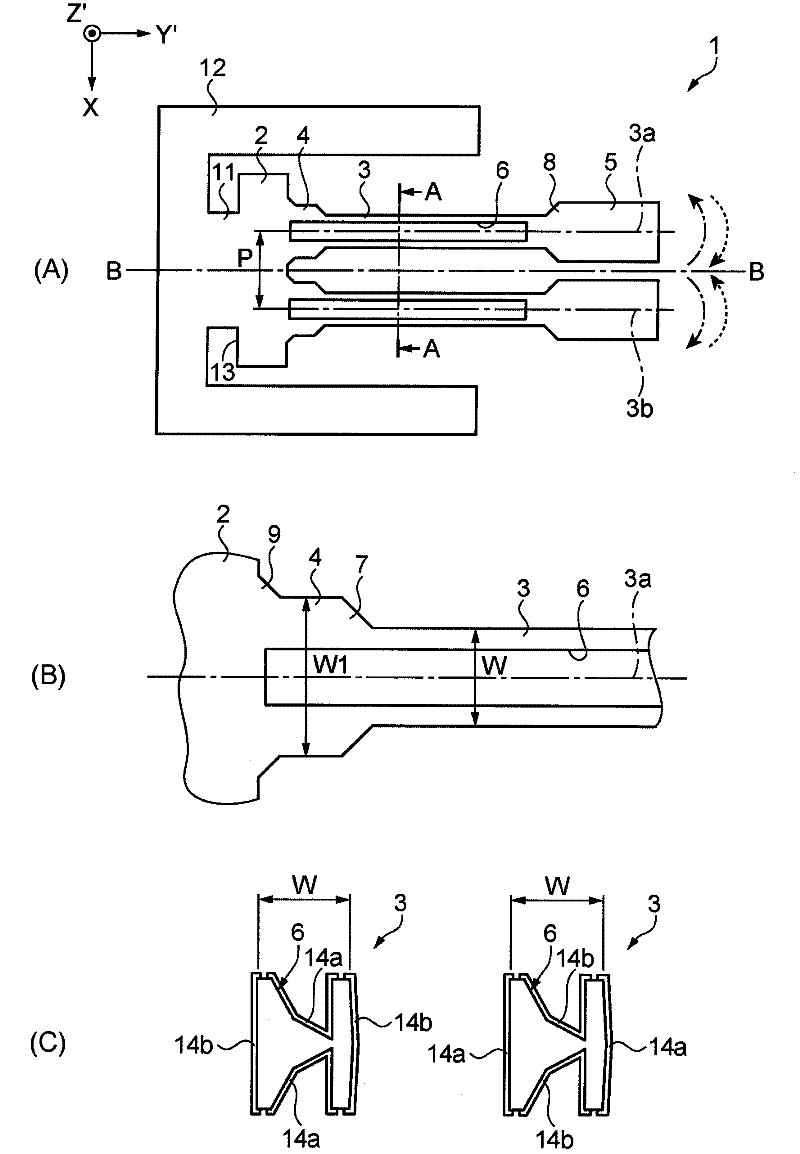

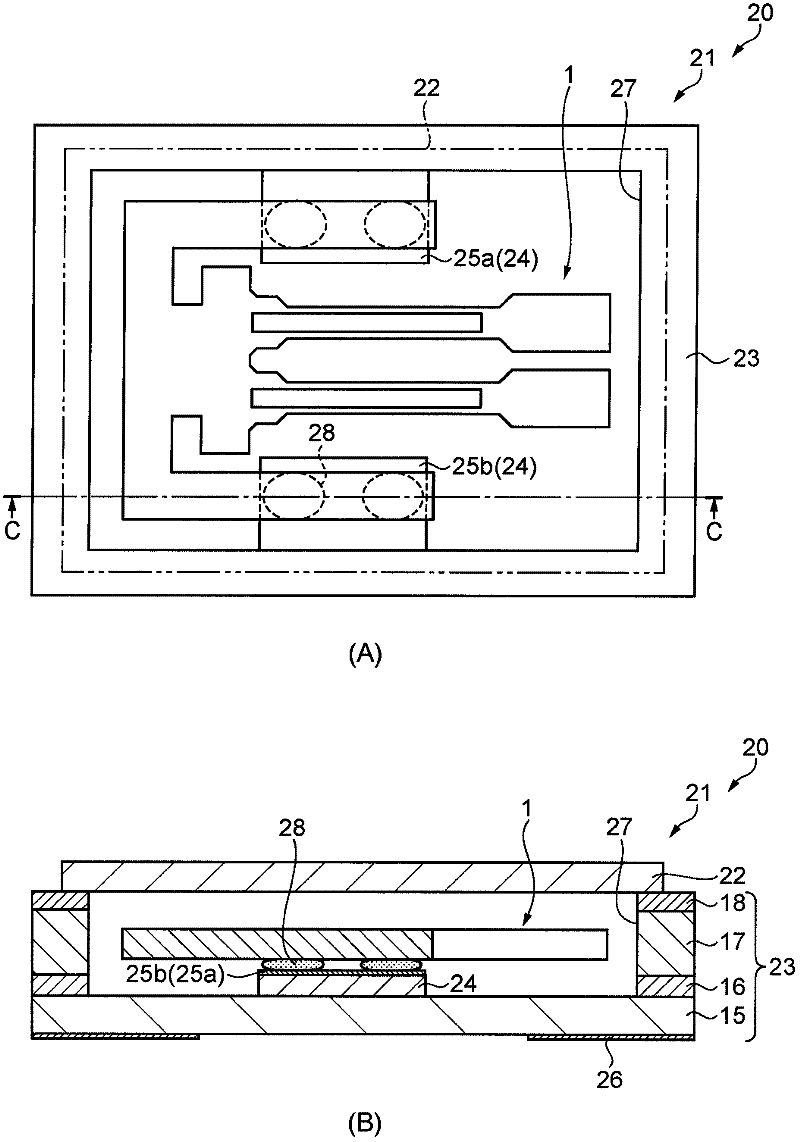

Piezoelectric vibrating devices and methods for manufacturing same

InactiveUS20090256449A1Relieve pressureStable vibration frequencyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesAdhesiveElectrical and Electronics engineering

An exemplary piezoelectric device includes a base having a first connection electrode electrically connected to an external electrode. A second connection electrode is connected to the first connection electrode on a first main surface of a supporting member affixed to the base. A third connection electrode, formed on a second main surface of the supporting member, is electrically connected to the second connection electrode. A piezoelectric vibrating piece is affixed to the supporting member by application of an adhesive applied to the third connection electrode. The piezoelectric vibrating piece and includes excitation electrodes. A convexity is located and extends in a designated direction relative to the third connection electrode to prevent applied adhesive from spreading beyond a designated area of the piezoelectric vibrating piece.

Owner:NIHON DEMPA KOGYO CO LTD

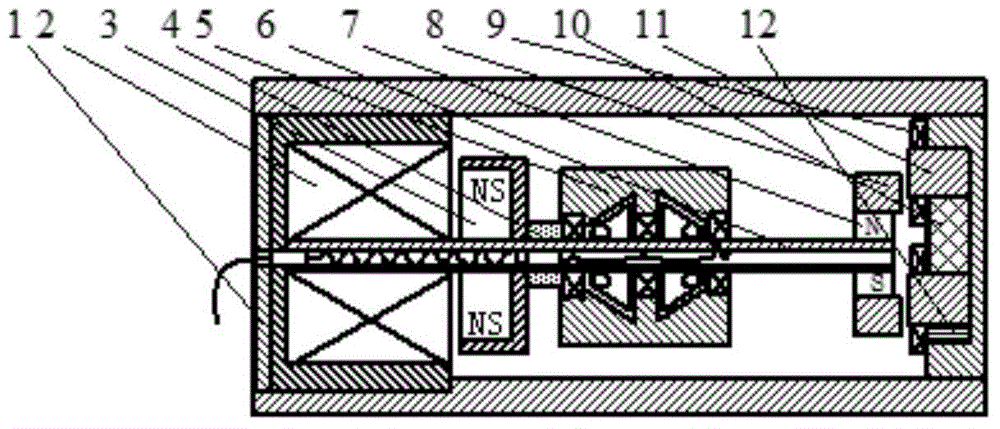

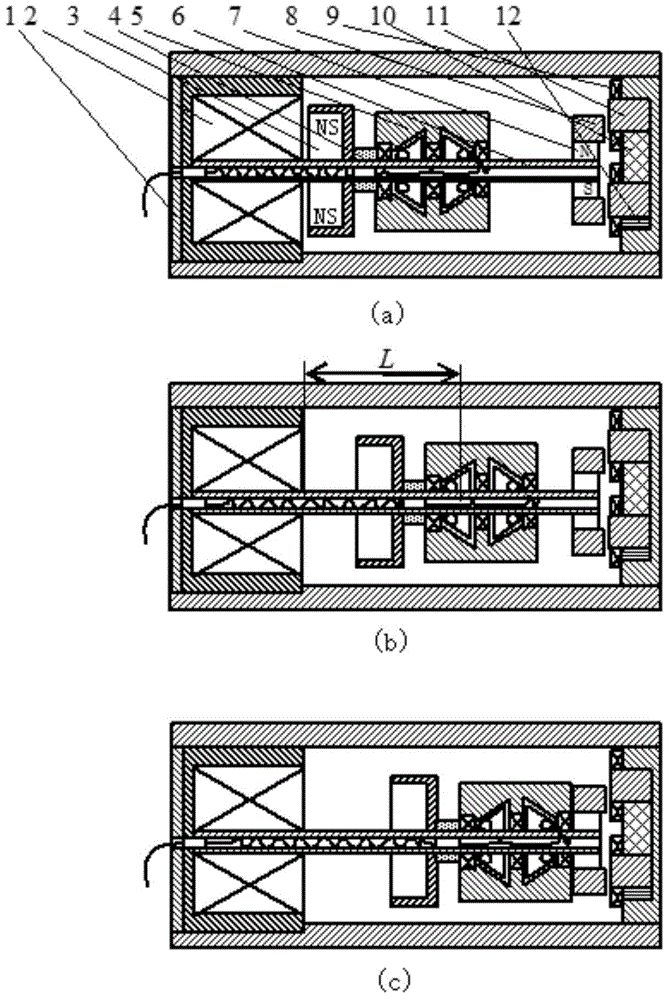

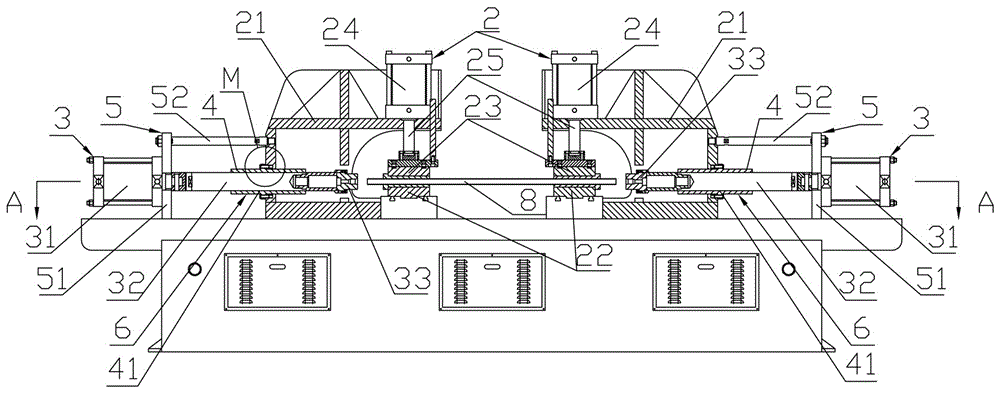

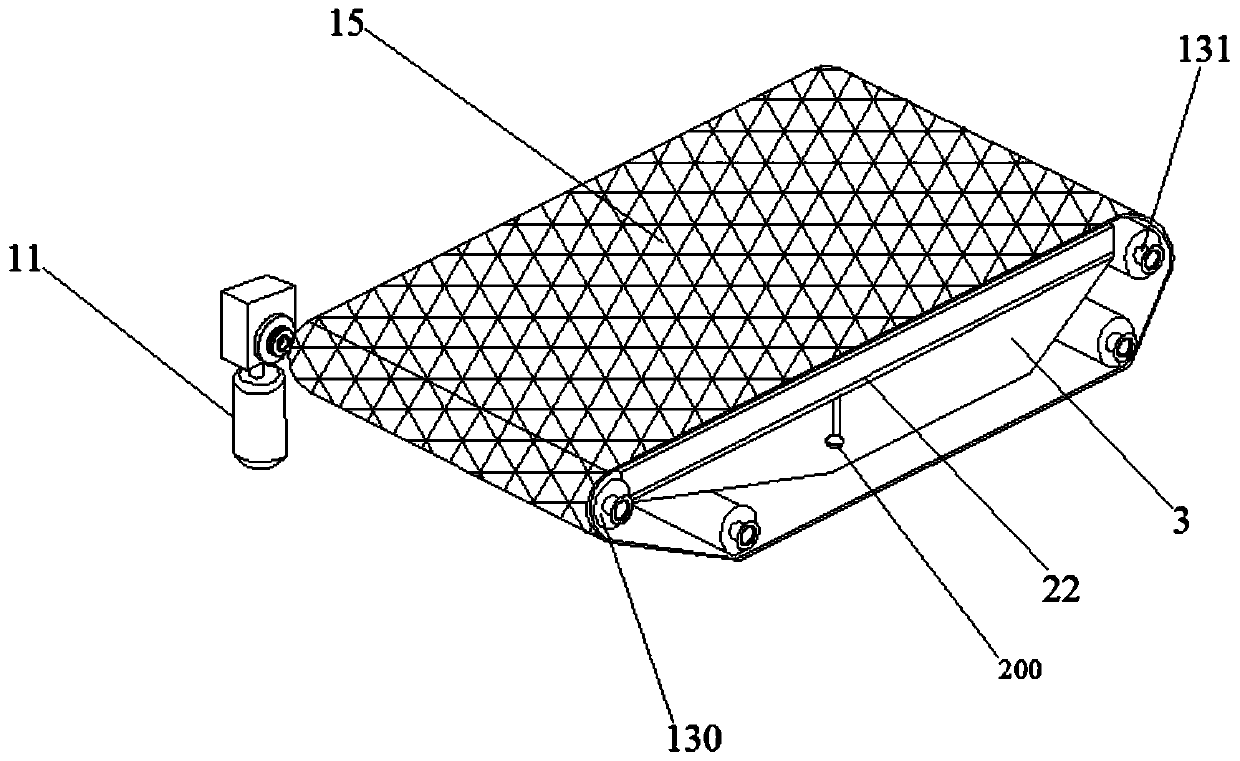

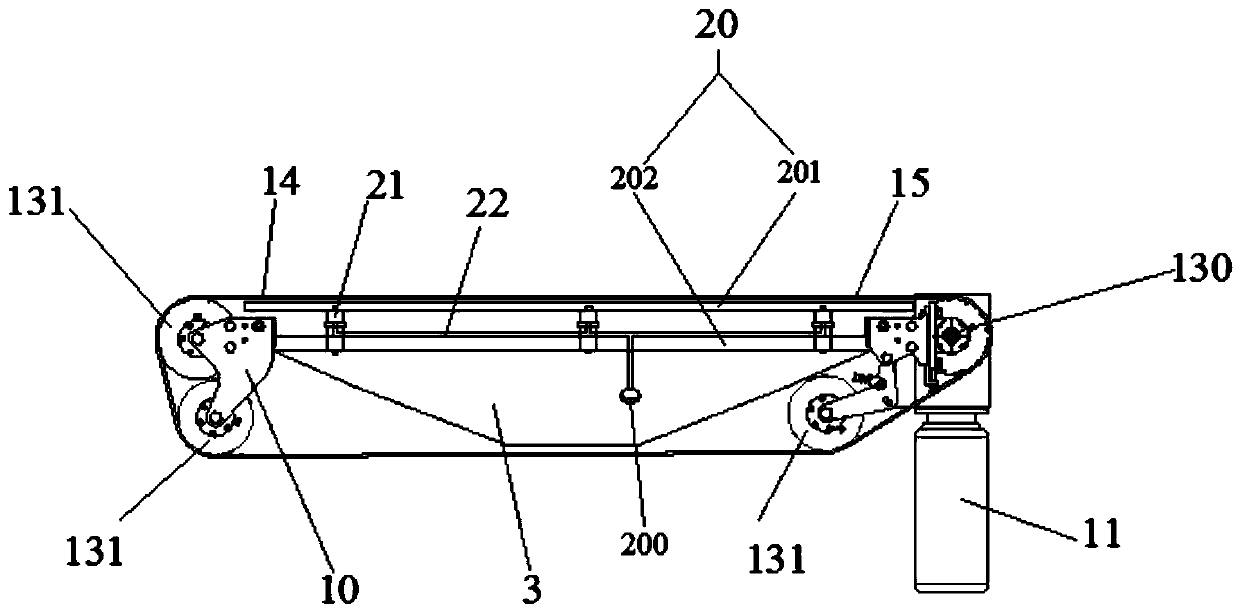

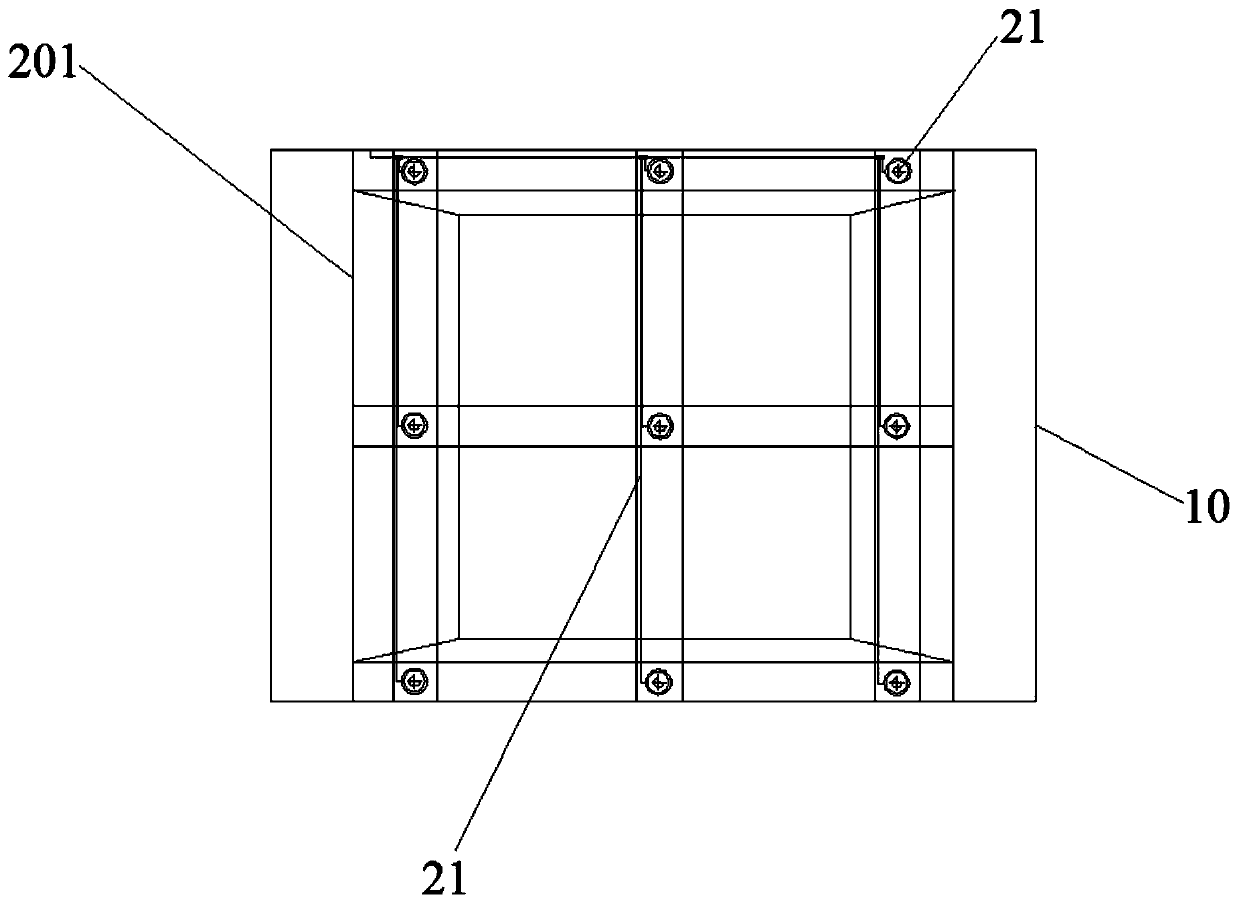

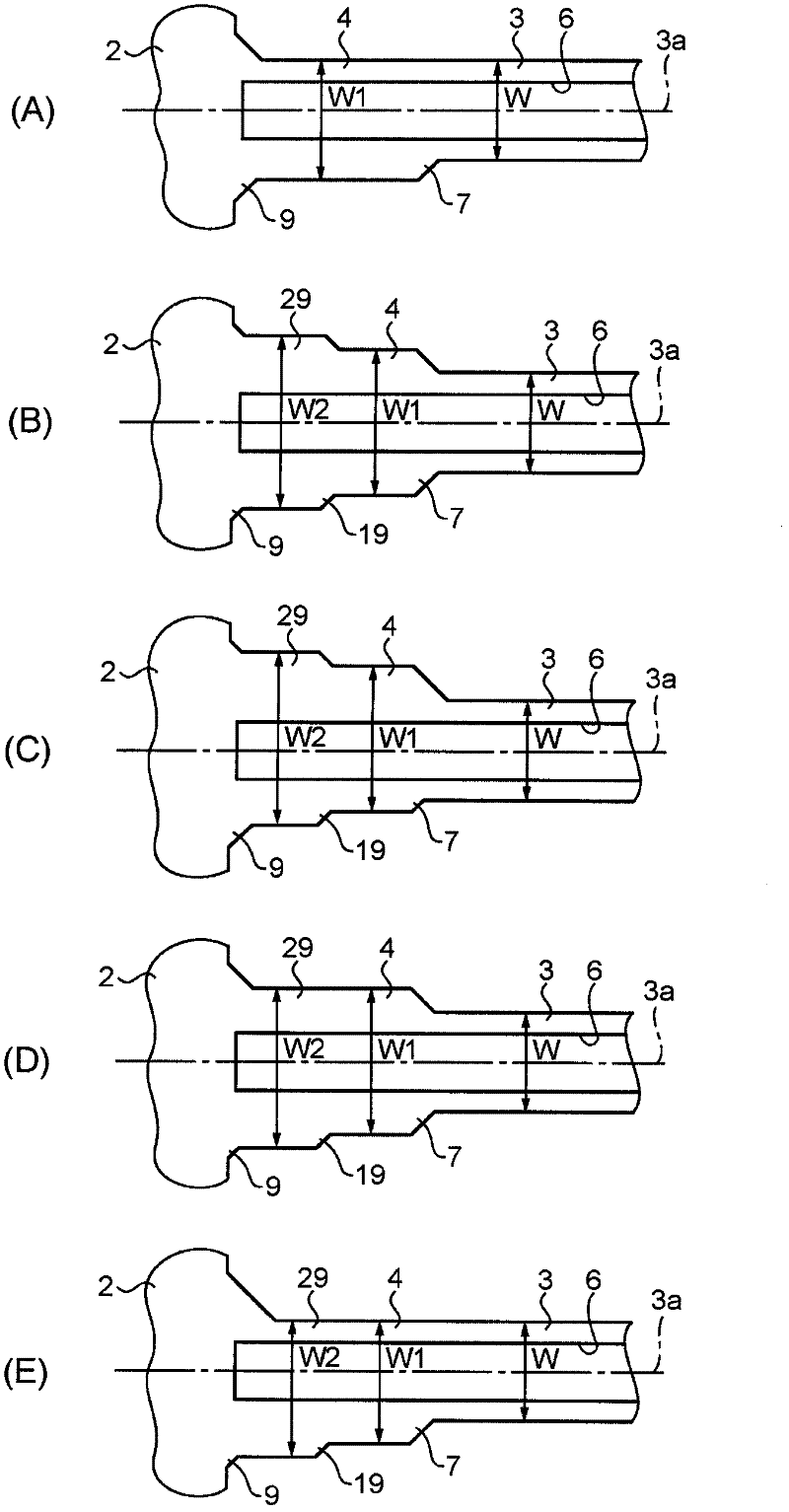

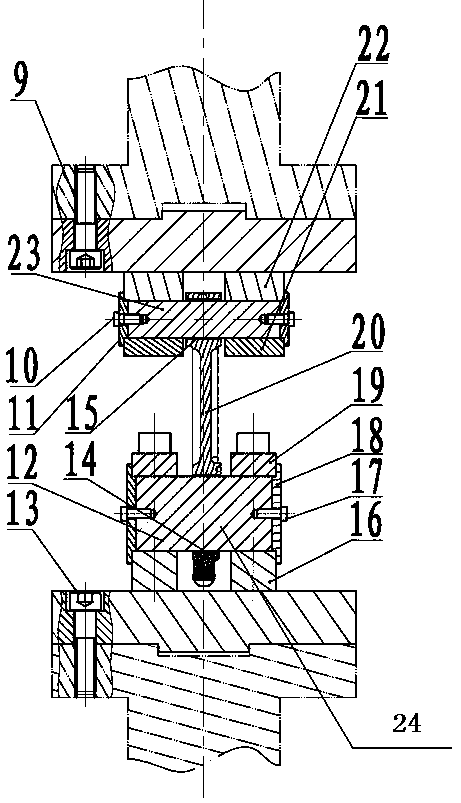

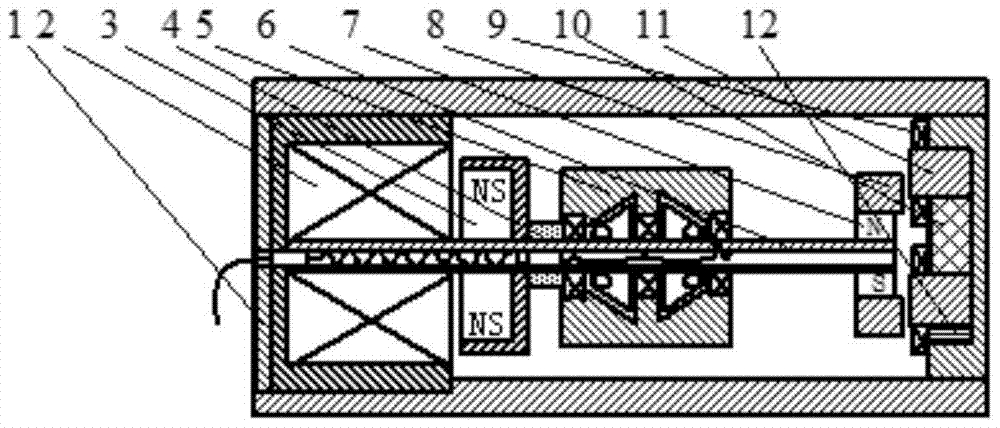

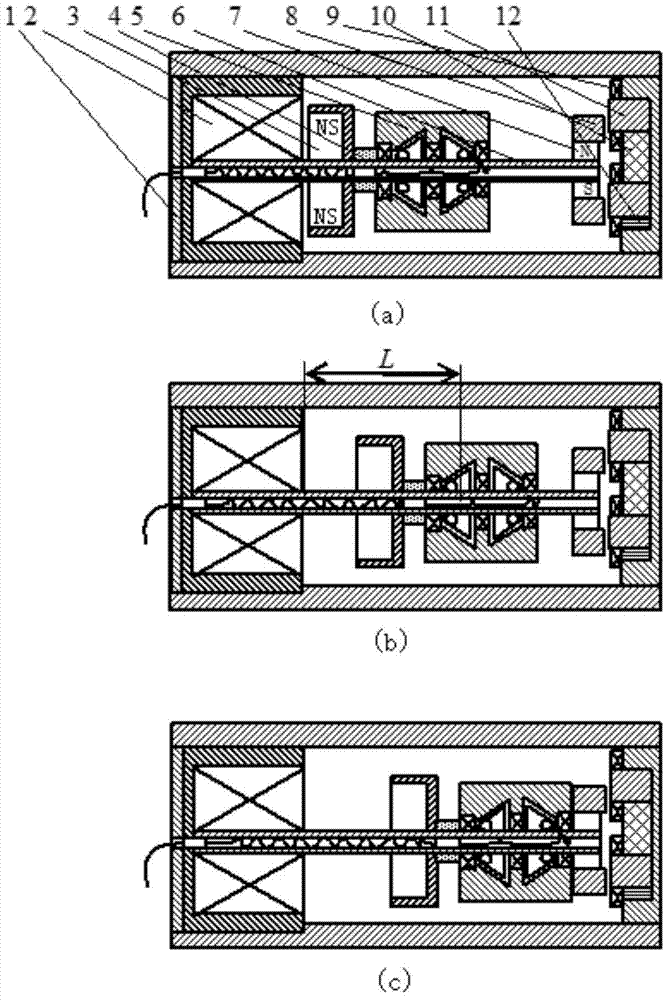

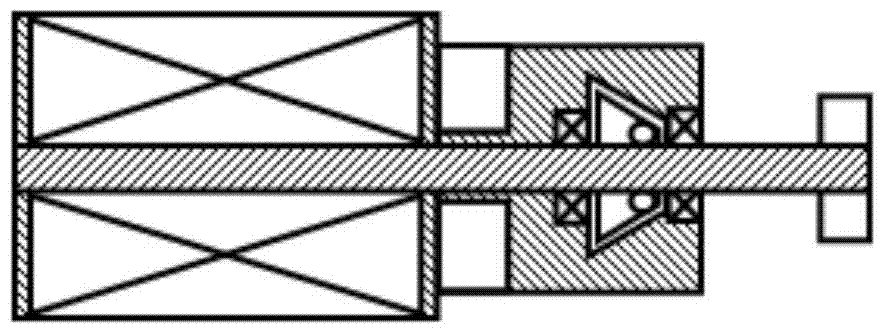

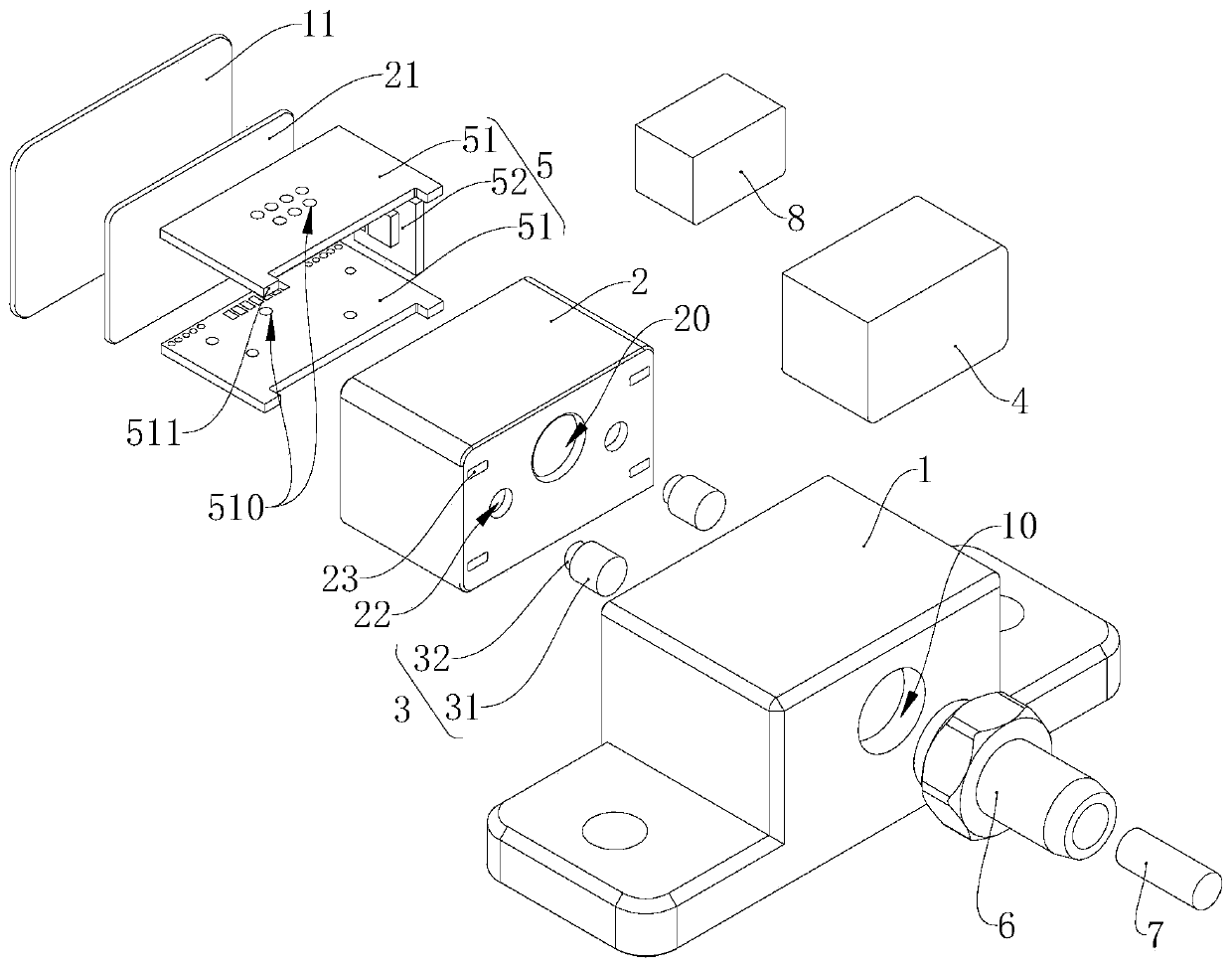

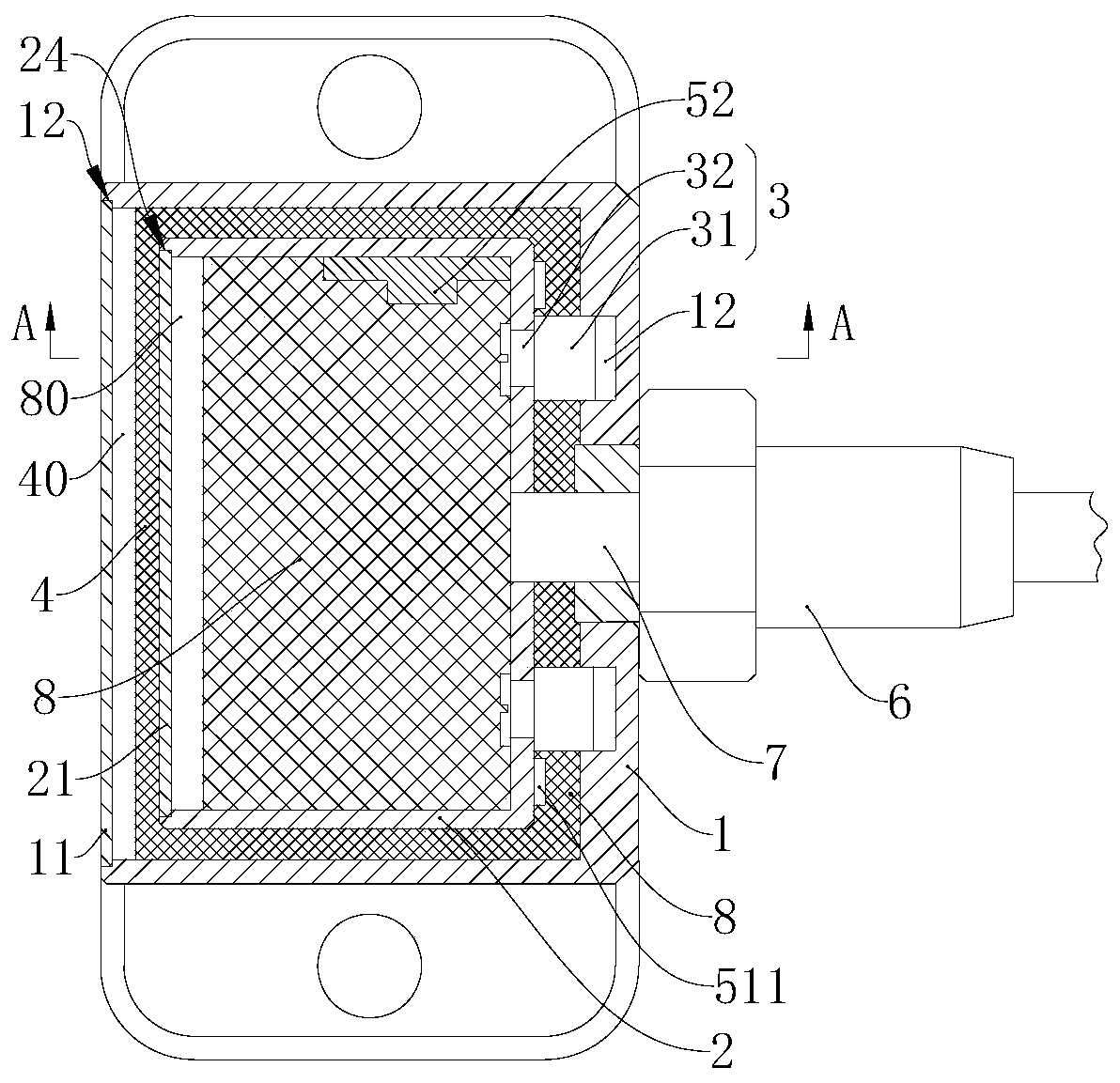

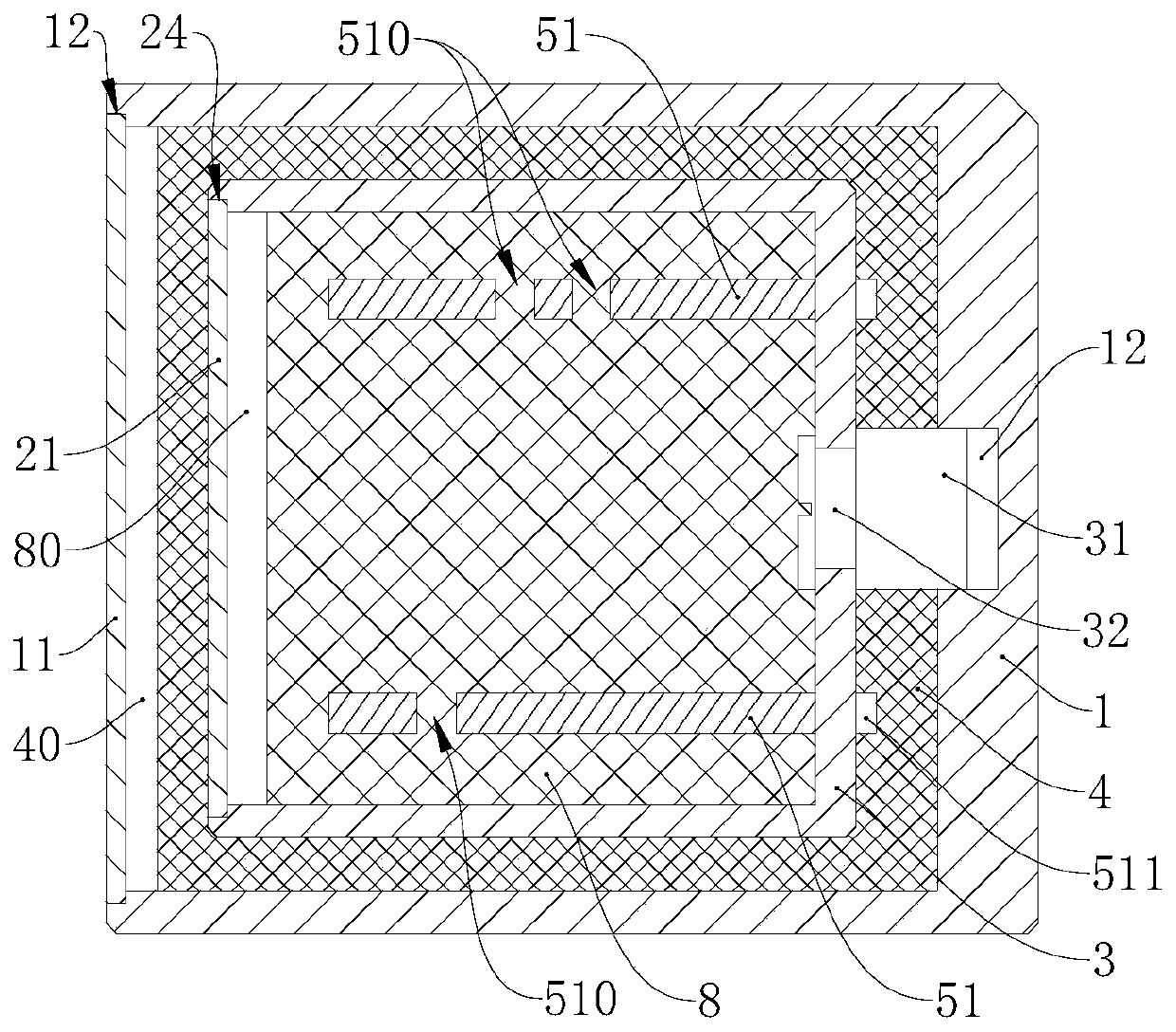

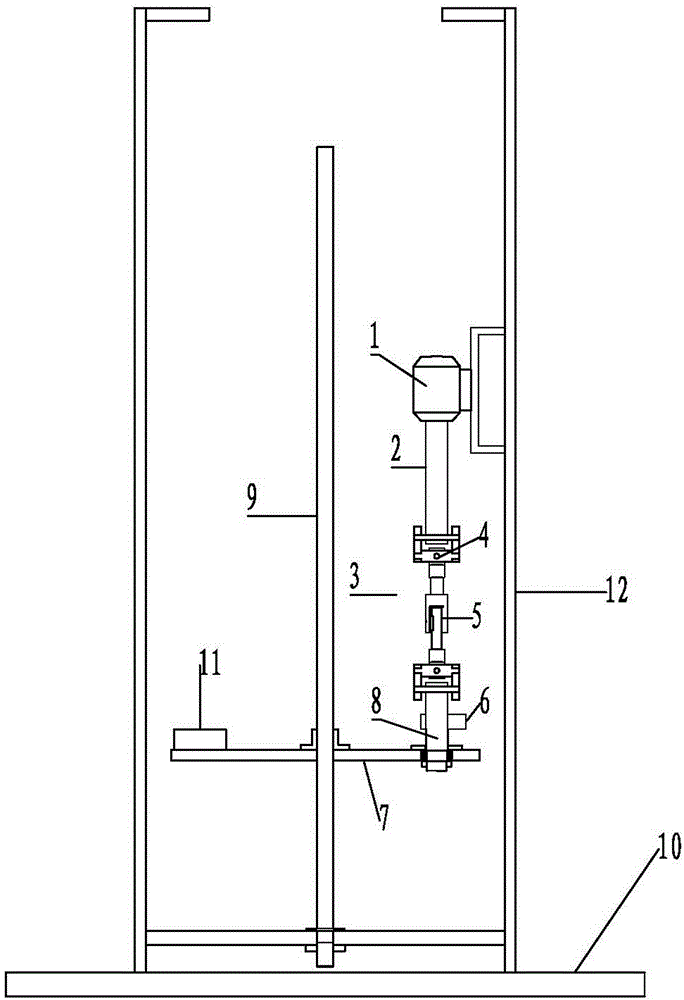

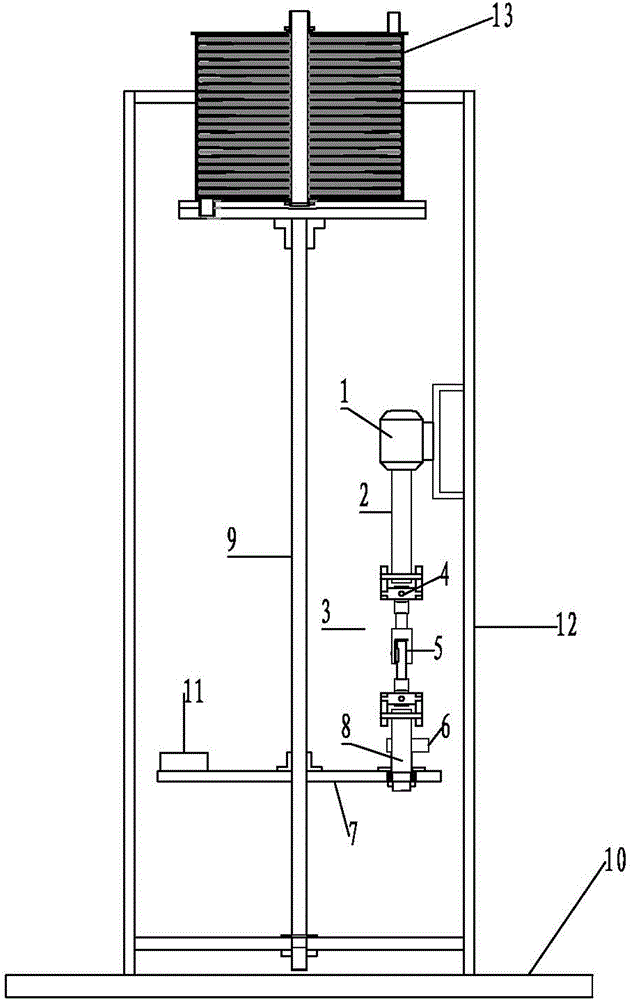

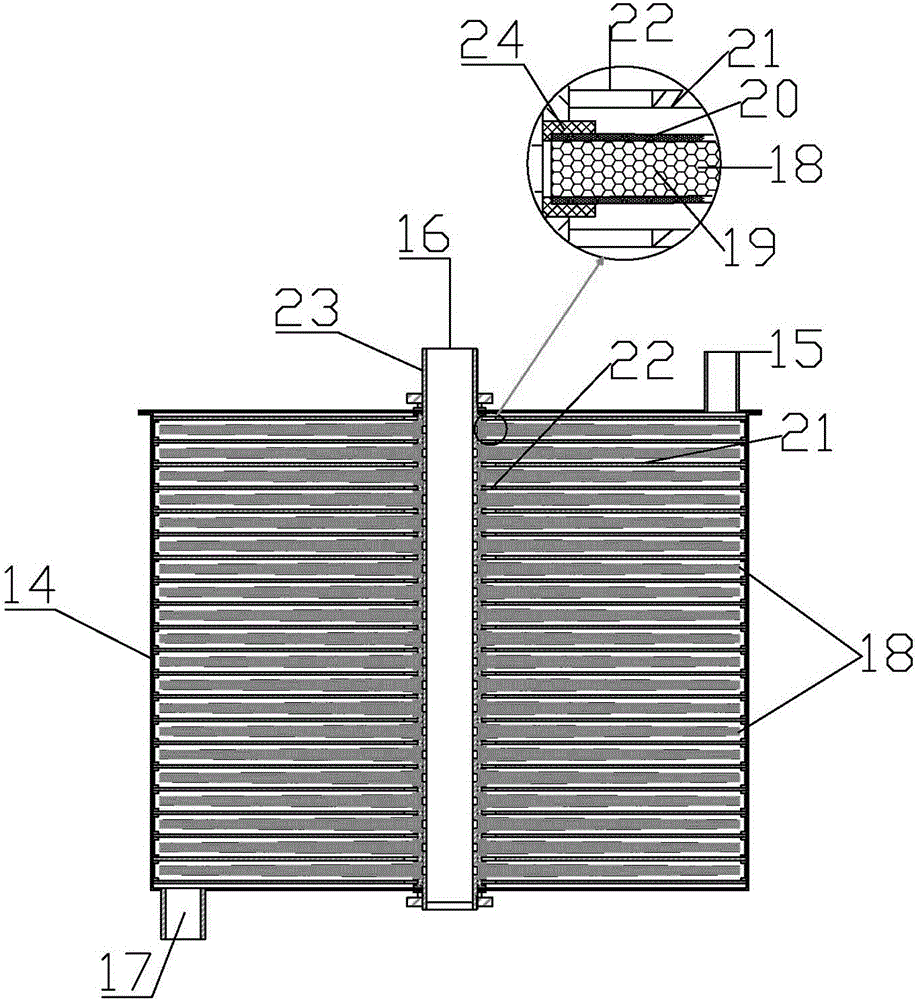

Intelligent self-adaptive vibration absorber, array integrating device and application of intelligent self-adaptive vibration absorber

ActiveCN104806693AAccurately set the natural frequencyReduce vibrationNon-rotating vibration suppressionShock absorbersMulti fieldEngineering

The invention provides an intelligent self-adaptive vibration absorber. The intelligent self-adaptive vibration absorber comprises a driving body, a mass body, an elastic beam, a terminal limiting sensor and a piezoelectric sensor device, wherein the driving body is arranged at one end of the elastic beam; the mass body is movably arranged on the elastic beam, and moves in a reciprocating way along the elastic beam under the driving force of the driving body; the terminal limiting sensor and the piezoelectric sensor device are arranged on the end part of the other end of the elastic beam; self-adaptive control of the inherent frequency of the vibration absorber is realized through adjustment of the length of a cantilever beam formed on the elastic beam by the mass body. Meanwhile, the invention provides an array integrating device based on the intelligent self-adaptive vibration absorber and application of the intelligent self-adaptive vibration absorber. The intelligent self-adaptive vibration absorber is simple in structure, and is suitable for multi-field popularization; precision suppression of single vibration of a controlled object can be realized, precision suppression control can be performed on multi-frequency laminated vibration of the controlled object, and inertial driving and power generation application are realized through structural specificity.

Owner:SHANGHAI JIAO TONG UNIV

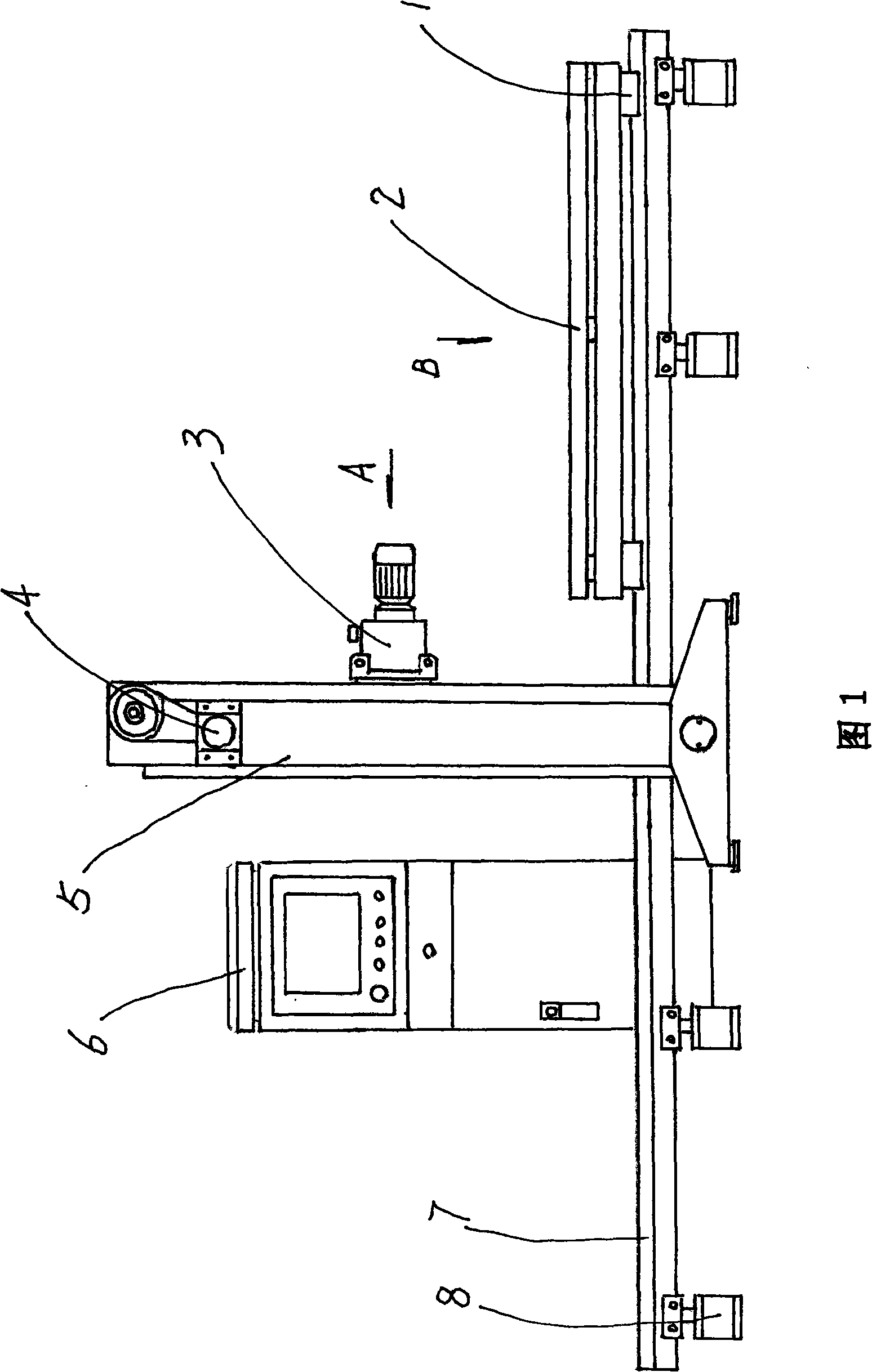

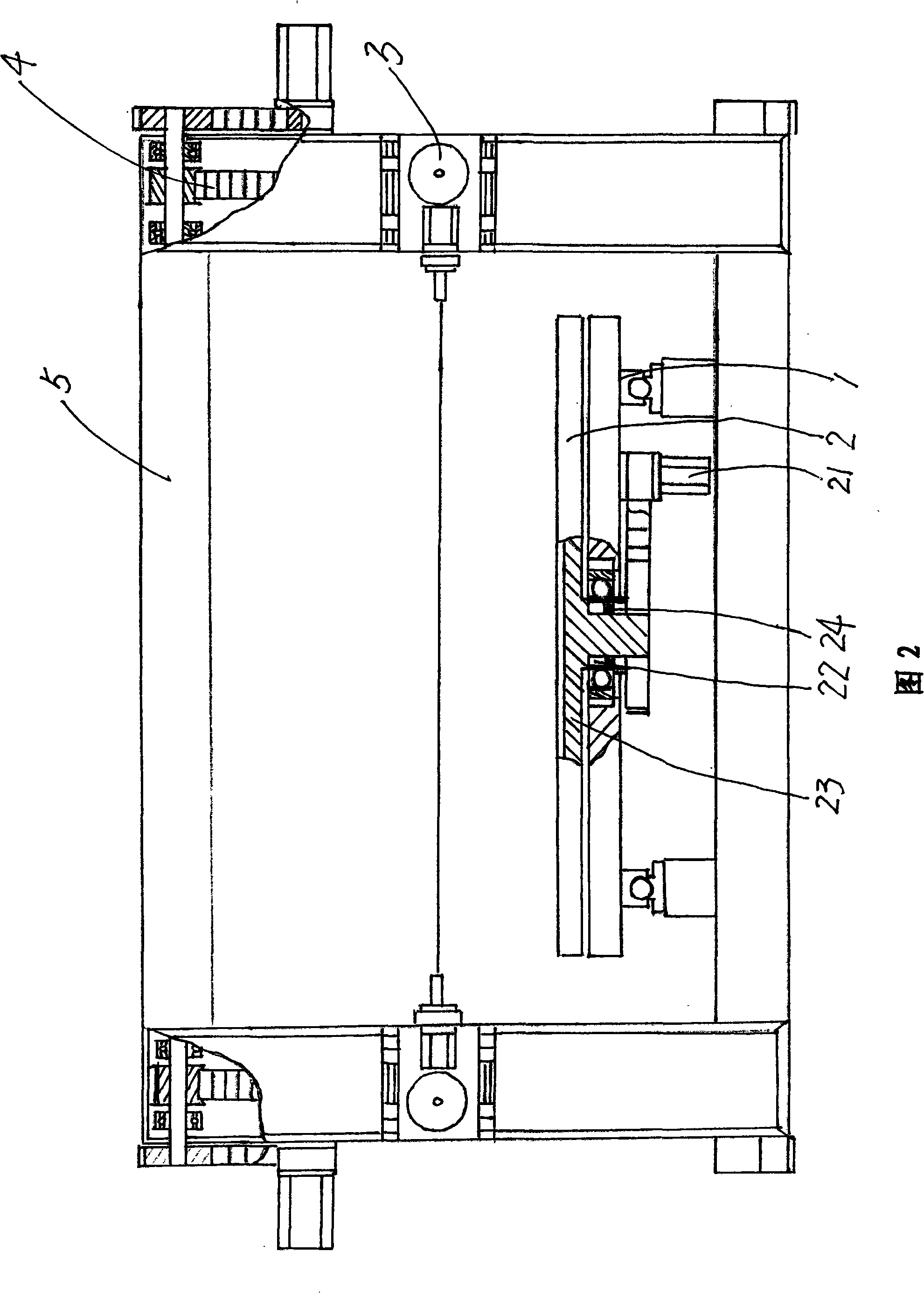

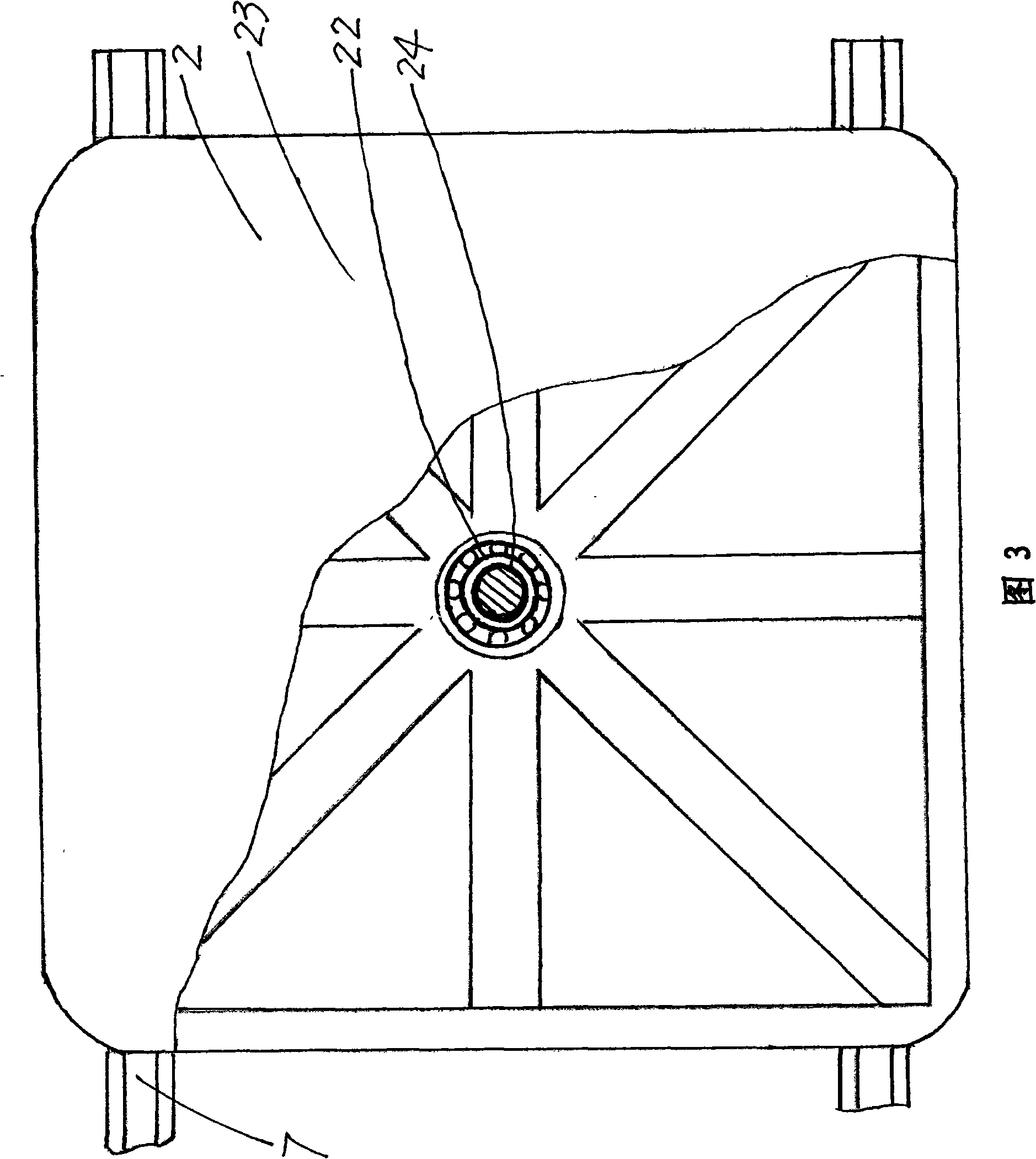

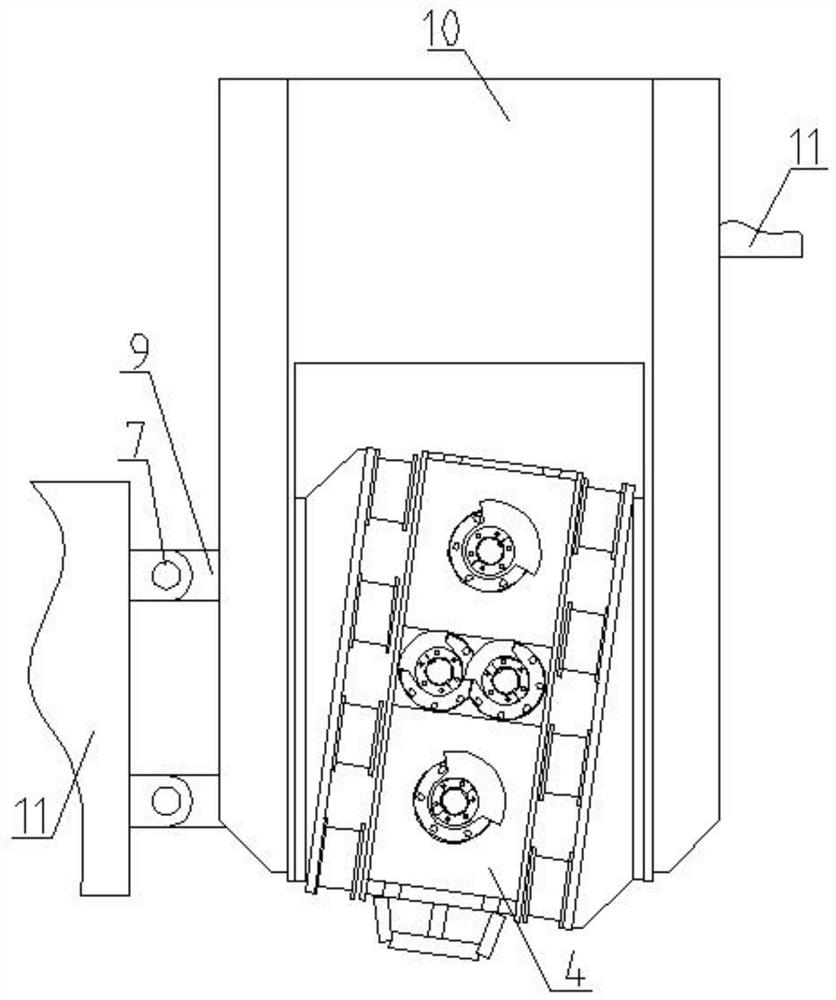

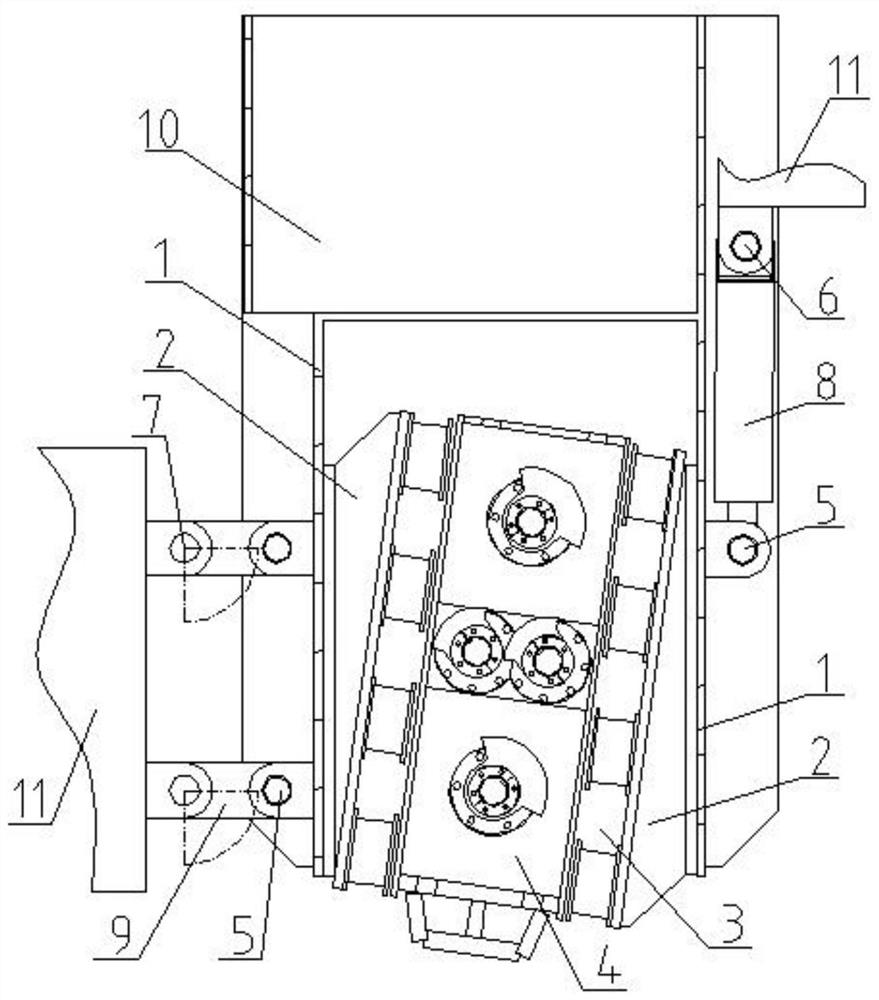

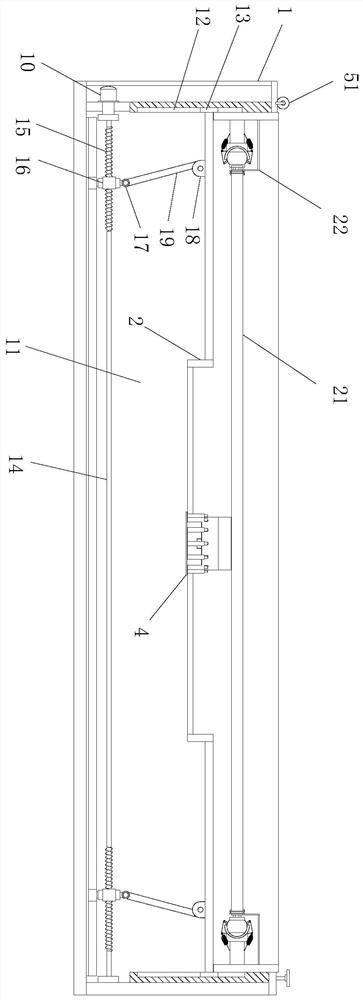

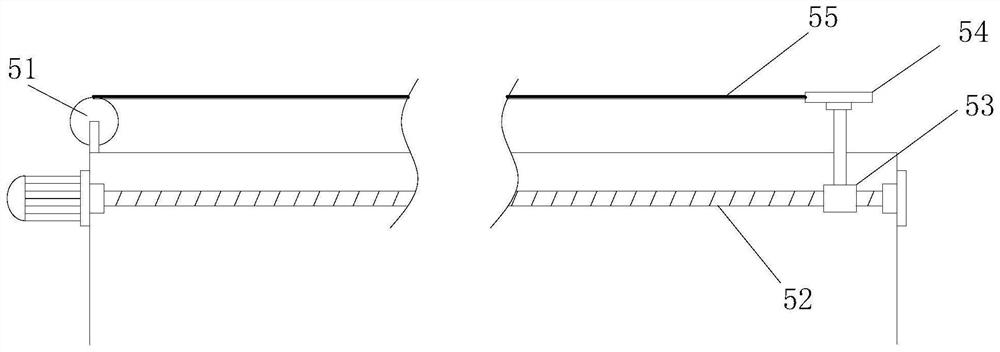

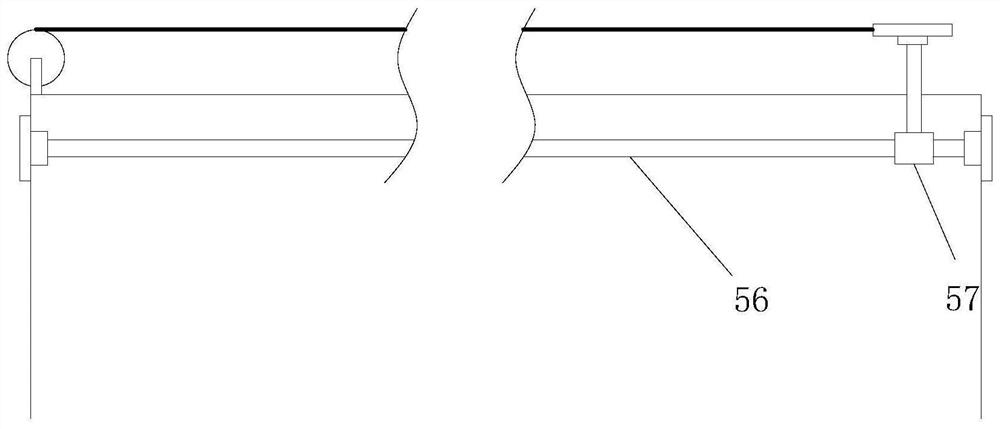

Numerical control sponges cutting machine

ActiveCN101284383AAutomatically adjust the tightnessReliable cuttingMechanical vibrations separationMetal working apparatusControl systemEngineering

The invention relate to a numerical control sponge cutting machine, which comprises a workbench base, a rotary workbench, vibration devices, vertical pulling devices, a gantry, a control part, a horizontal guide rail and a rack. The workbench base is arranged on the horizontal guide rail and the rotary workbench capable of lifting and rotating is arranged on the workbench base; the two vertical pulling devices are arranged on the gantry, and the two vibration devices are respectively arranged on two columns of the gantry; the control part is a numerical control system. Since the two vertical pulling devices are adopted to respectively adjust the height and the position of the two vibration devices, the sponge cutting machine is capable of processing sponge of different heights; since the workbench has a structure capable of lifting and rotating, the sponge cutting machine is capable of processing sponge of various curves; since the combination of adjusting cylinders and dampers is adopted in the vibration devices, the sponge cutting machine has more reliable cutting and the reasonable structure leads to non-environment pollution and high automatization, therefore, the sponge cutting machine is of great utility and popularization value.

Owner:NANTONG MUYE MACHINERY

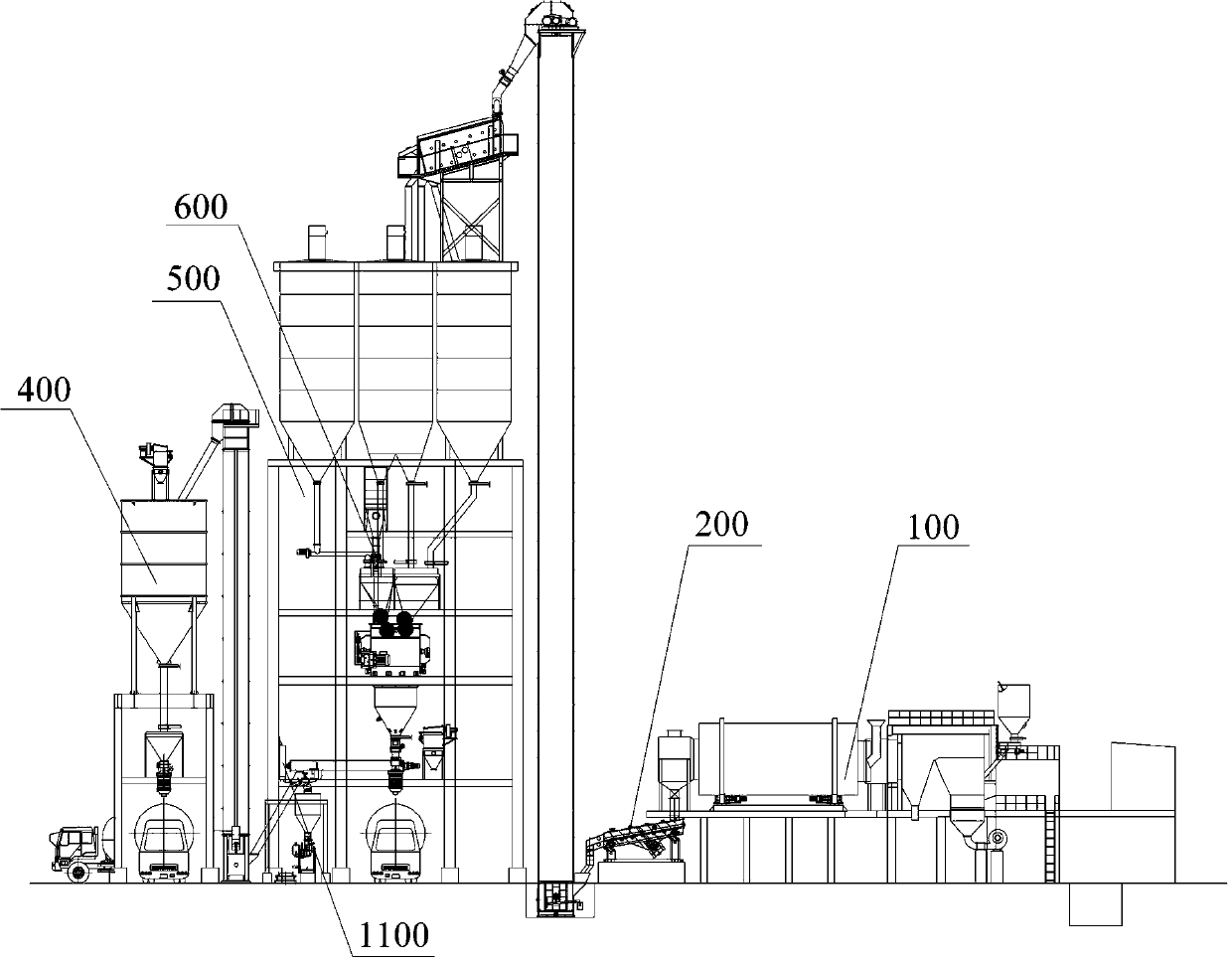

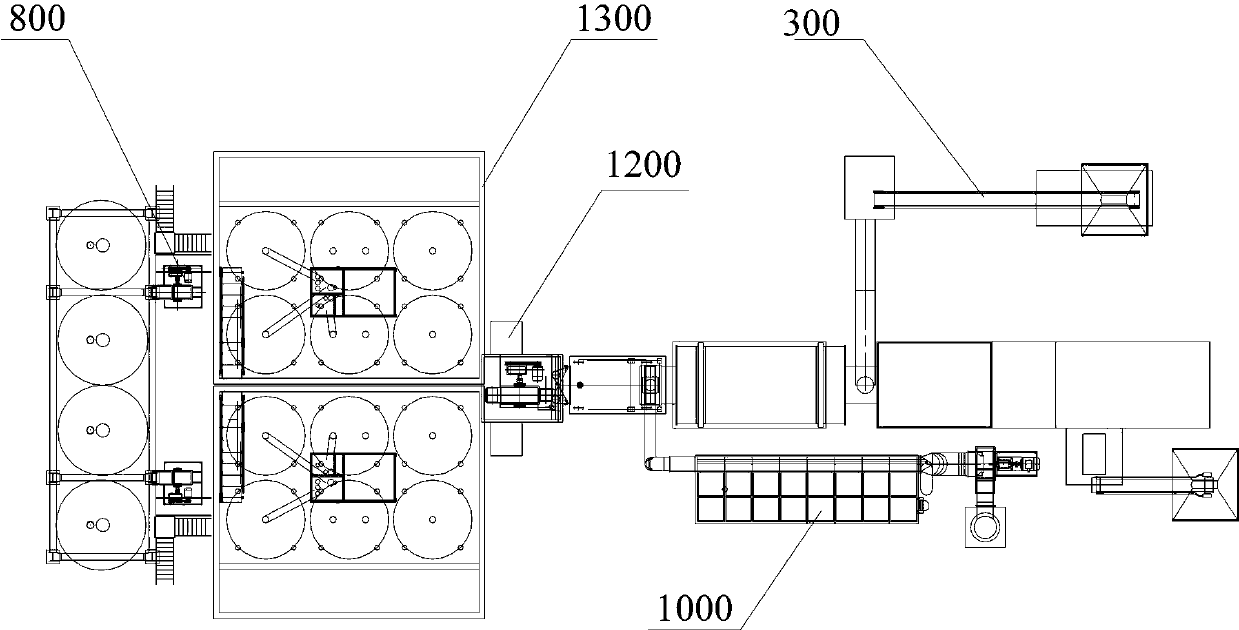

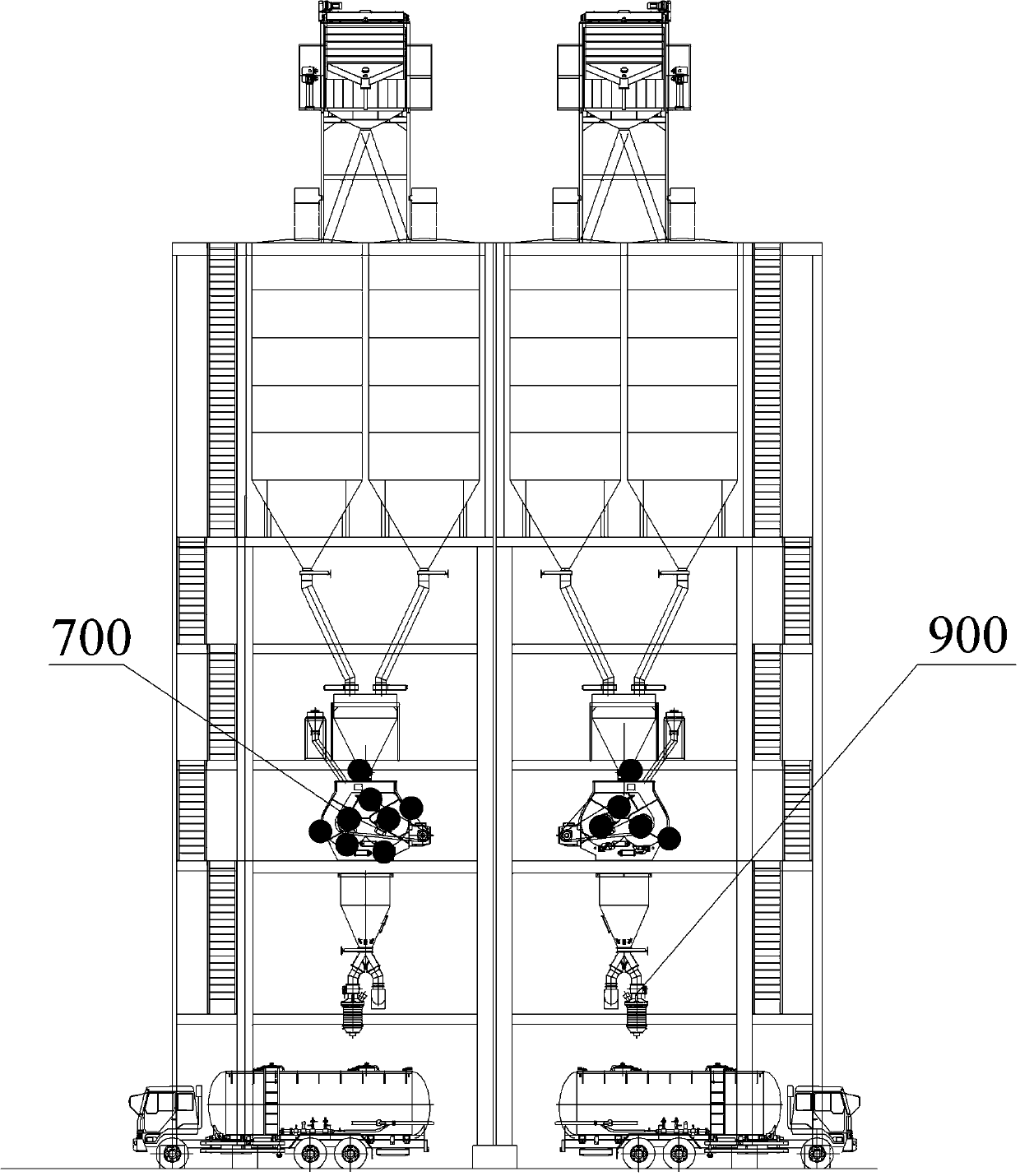

Double-floor type structure dry-mixed mortar station and construction method thereof

InactiveCN103273571AImprove combustion efficiencyRealize stepless speed regulation functionIndustrial buildingsMixing operation plantElastic vibrationSelf locking

The invention provides a double-floor type structure dry-mixed mortar station and a construction method thereof. The double-floor type structure dry-mixed mortar station comprises a drying system, a sieving system, a material supplying system, a storage system, a main body structure, a metering system, a stirring system, a packaging system, a bulking system, a dust-removing system, an electric system, a pneumatic system and an outer packaging system. The double-floor type structure dry-mixed mortar station is characterized in that a variable-frequency feeding device is additionally arranged on a coal cabin charging belt machine in the drying system; aggregates are sieved at a plurality of grades; a primary sieving segregation and sand feeding manner is adopted before bucket lifting; a secondary sieving segregation and sand feeding manner is adopted after the bucket lifting; a sieving machine is provided with an elastic vibration support; a gas tank pulse type automatic dust collector is adopted; a main body adopts a double-floor type structure; two sets of large cubic horizontal double-shaft spiral belt agitating main engines are arranged, one set is standby and the two sets can also be turned on at the same time to use; a multi-finished-product cabin with a manual gate valve and a double-bagging machine are adopted to rapidly bulk and bag to deliver products; and the pneumatic system has bidirectional self-control and self-locking functions so as to guarantee the safety and the reliability of the work of double gas paths and improve the intelligent degree of the whole system.

Owner:上海鸿得利重工有限公司

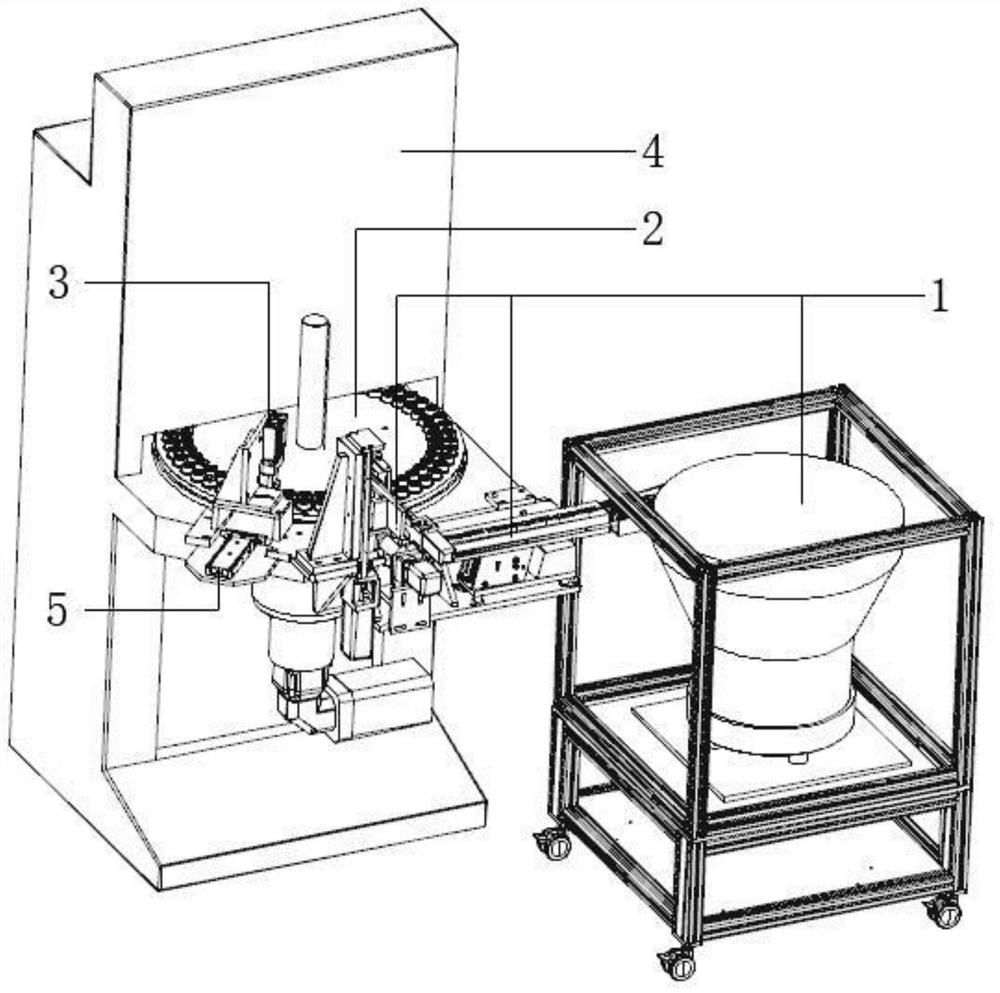

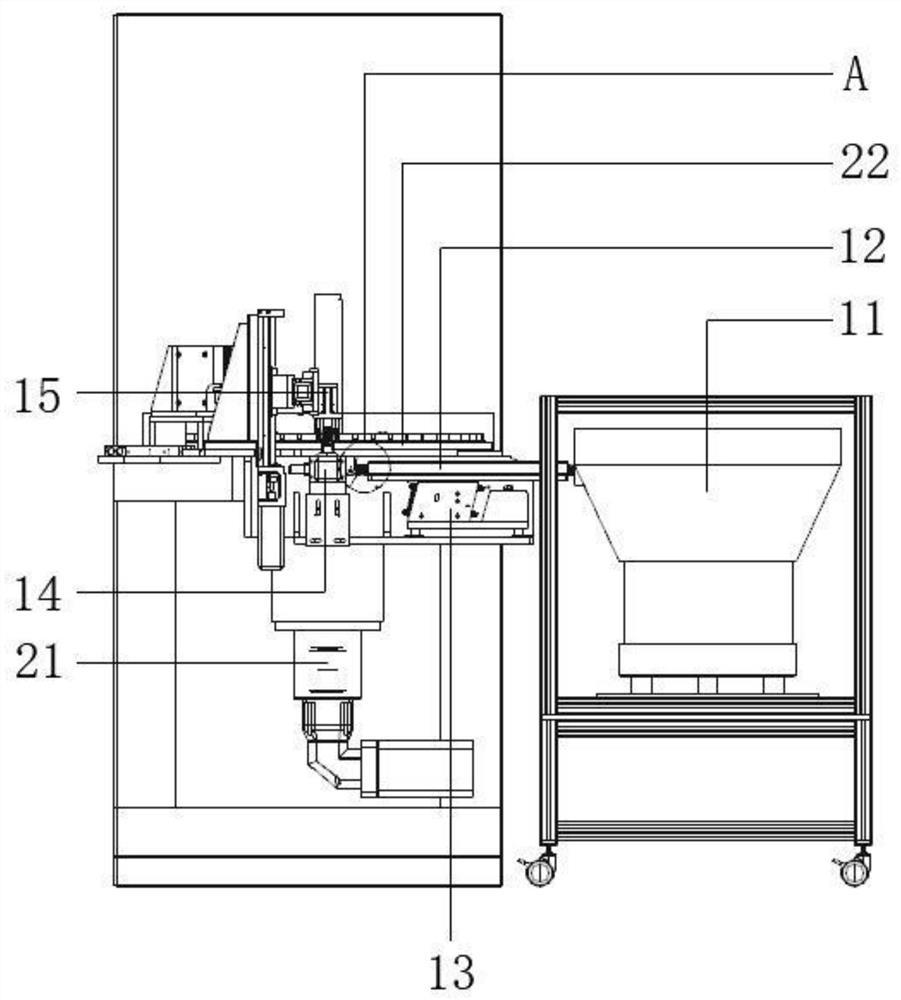

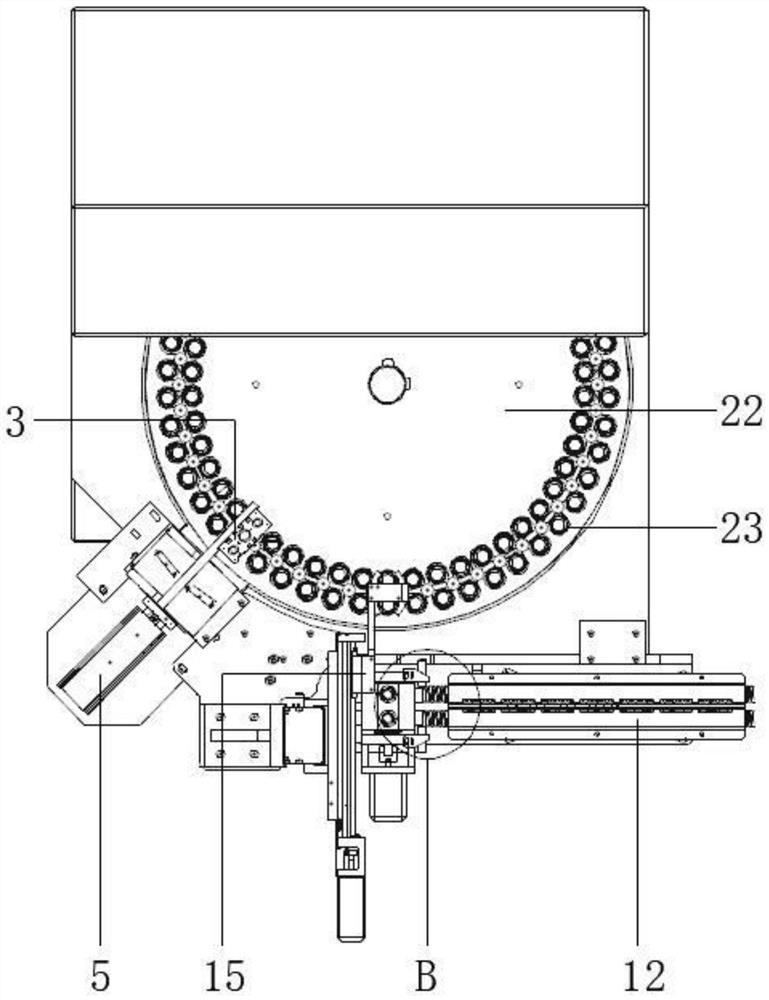

Spring grinder with automatic feeding function

ActiveCN111805324ASolve the technical problem of easy blockage in the delivery hoseSmooth feedingGrinding feedersPlane surface grinding machinesRotating discPhysics

The embodiment of the invention provides a spring grinder with an automatic feeding function, and belongs to the technical field of spring grinders. The spring grinder with the automatic feeding function comprises a spring grinder main body, a conveying mechanism, a spring base, a feeding mechanism, an overturn assembly and a manipulator assembly, wherein the conveying mechanism comprises a rotating disc, and the rotating disc is movably arranged on the spring grinder main body; the spring base is arranged on the rotating disc; the feeding mechanism comprises a vibration plate assembly; the overturn assembly comprises an overturn base, an turnover shaft movably arranged on the turnover base, and a core rod arranged on the turnover shaft; the core rod can penetrate through a spring; and themanipulator assembly is movable and is arranged between the core rod and the spring base. The technical effect of smooth spring feeding is achieved.

Owner:诸暨迈思特自动化科技有限公司

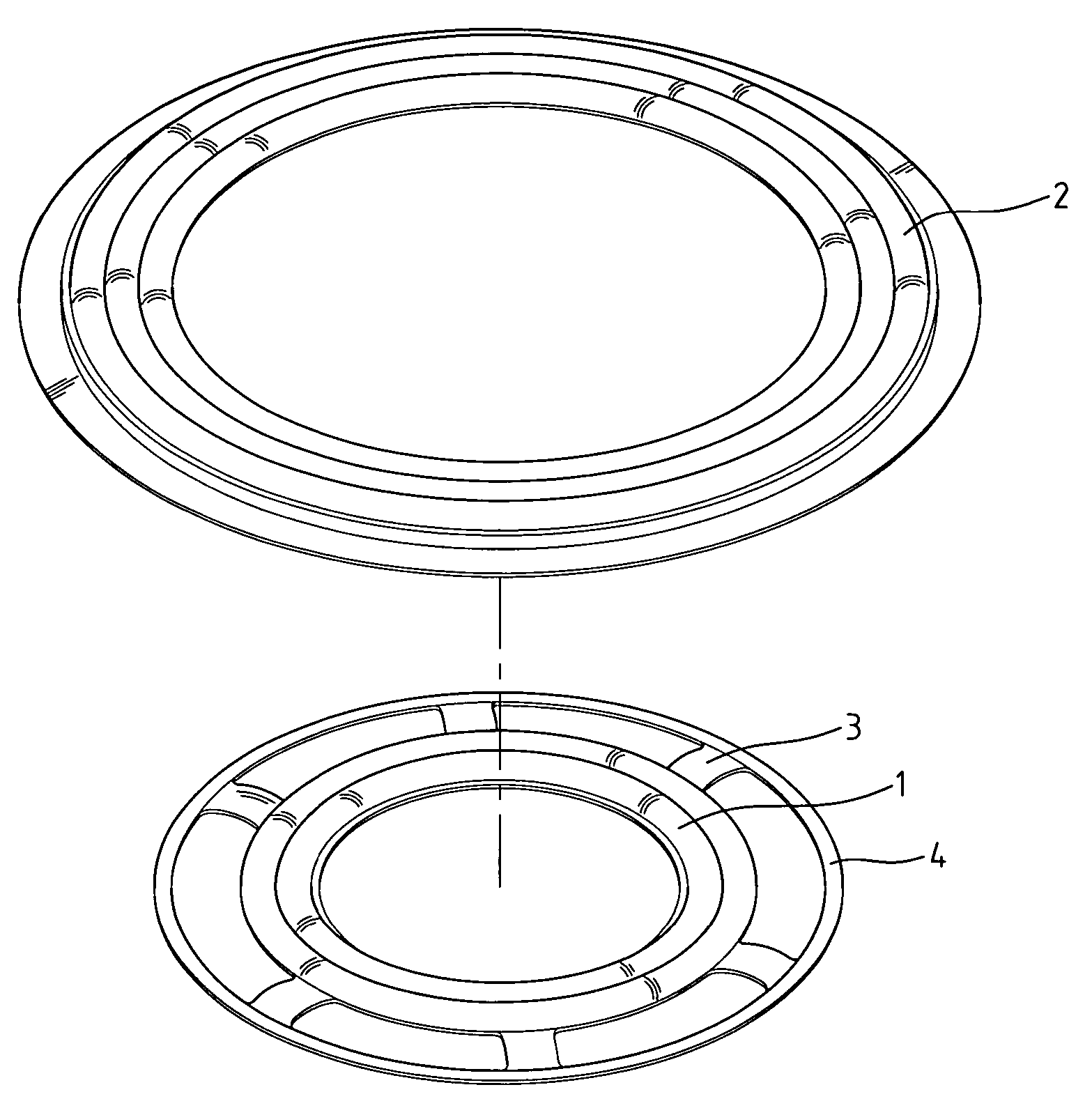

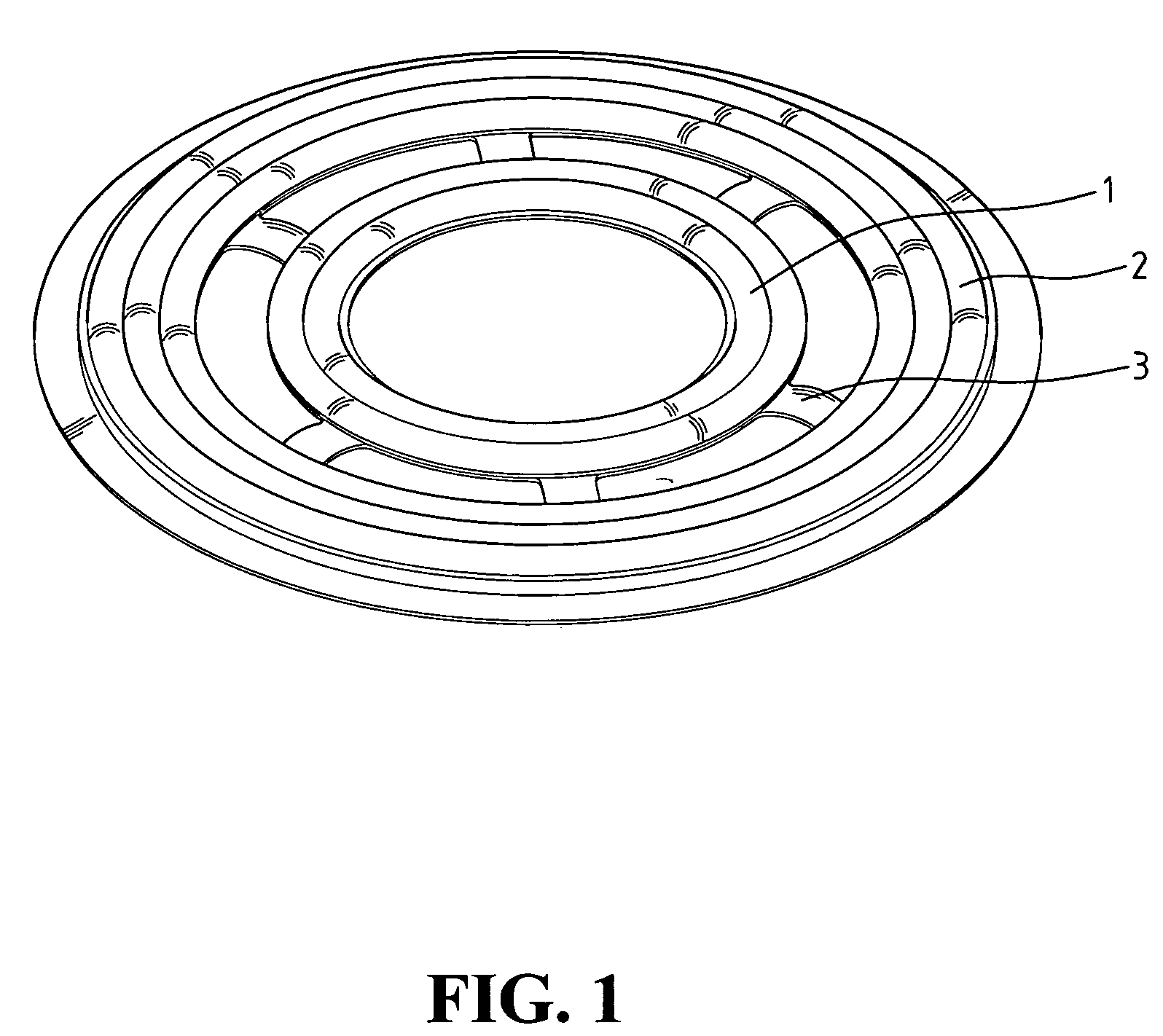

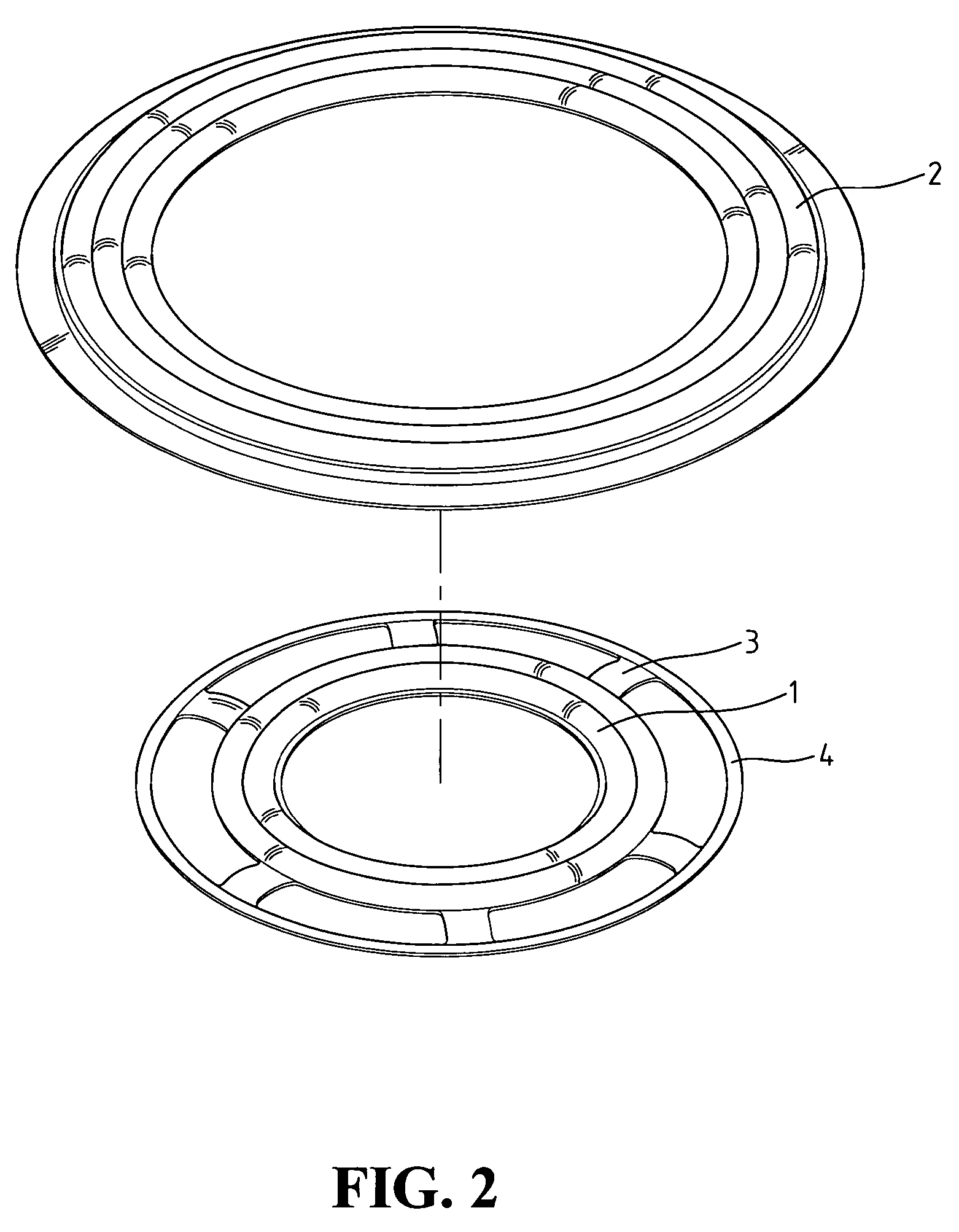

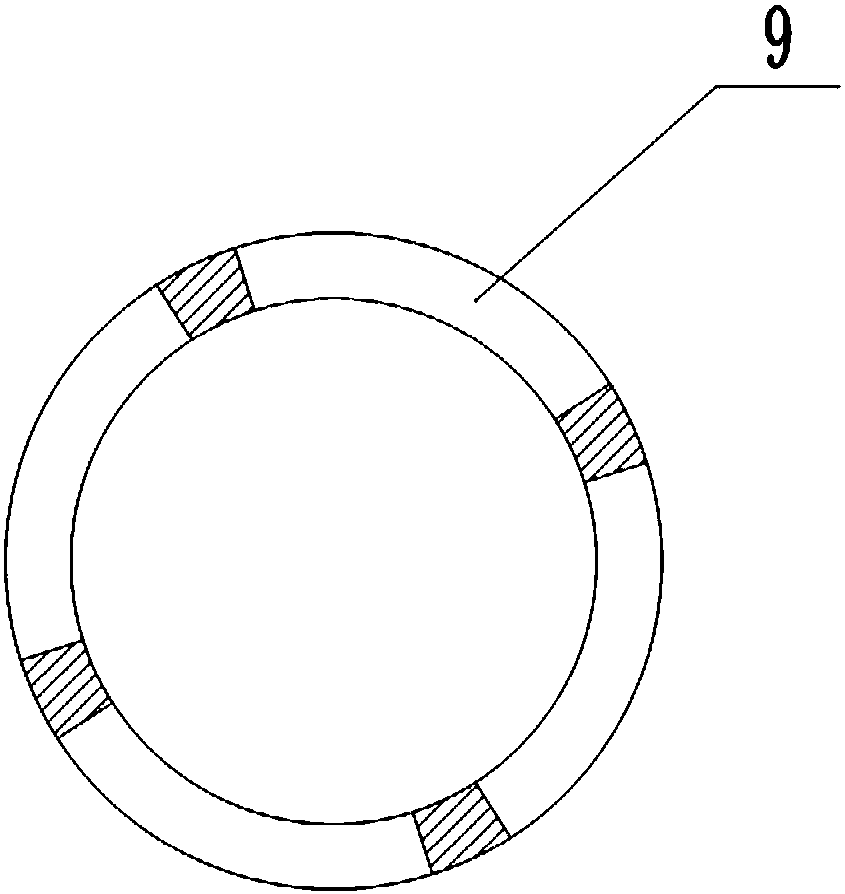

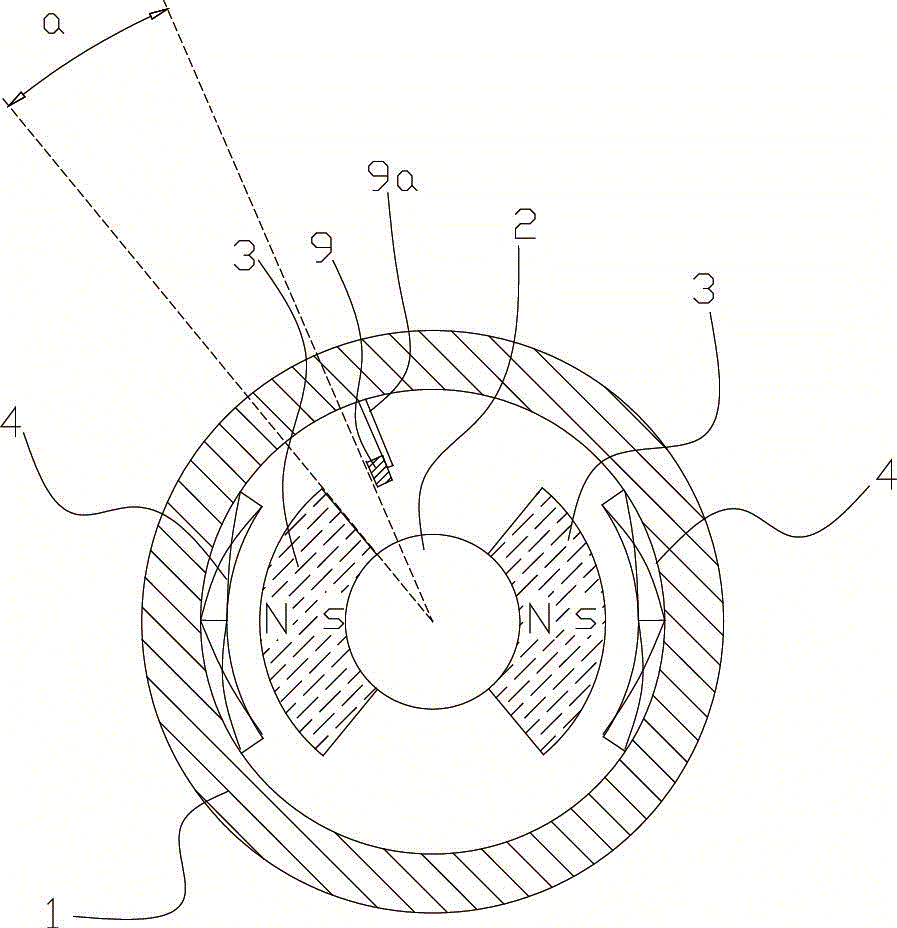

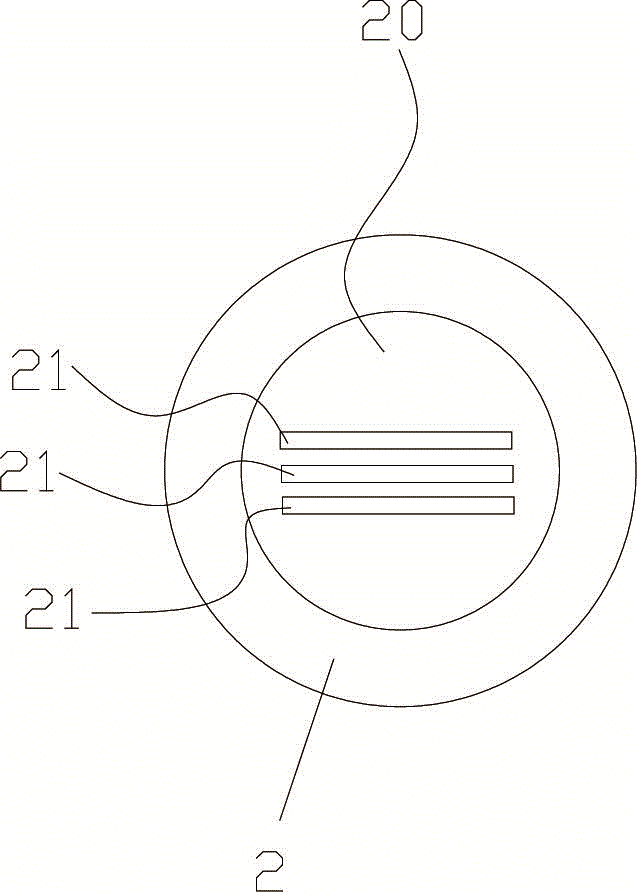

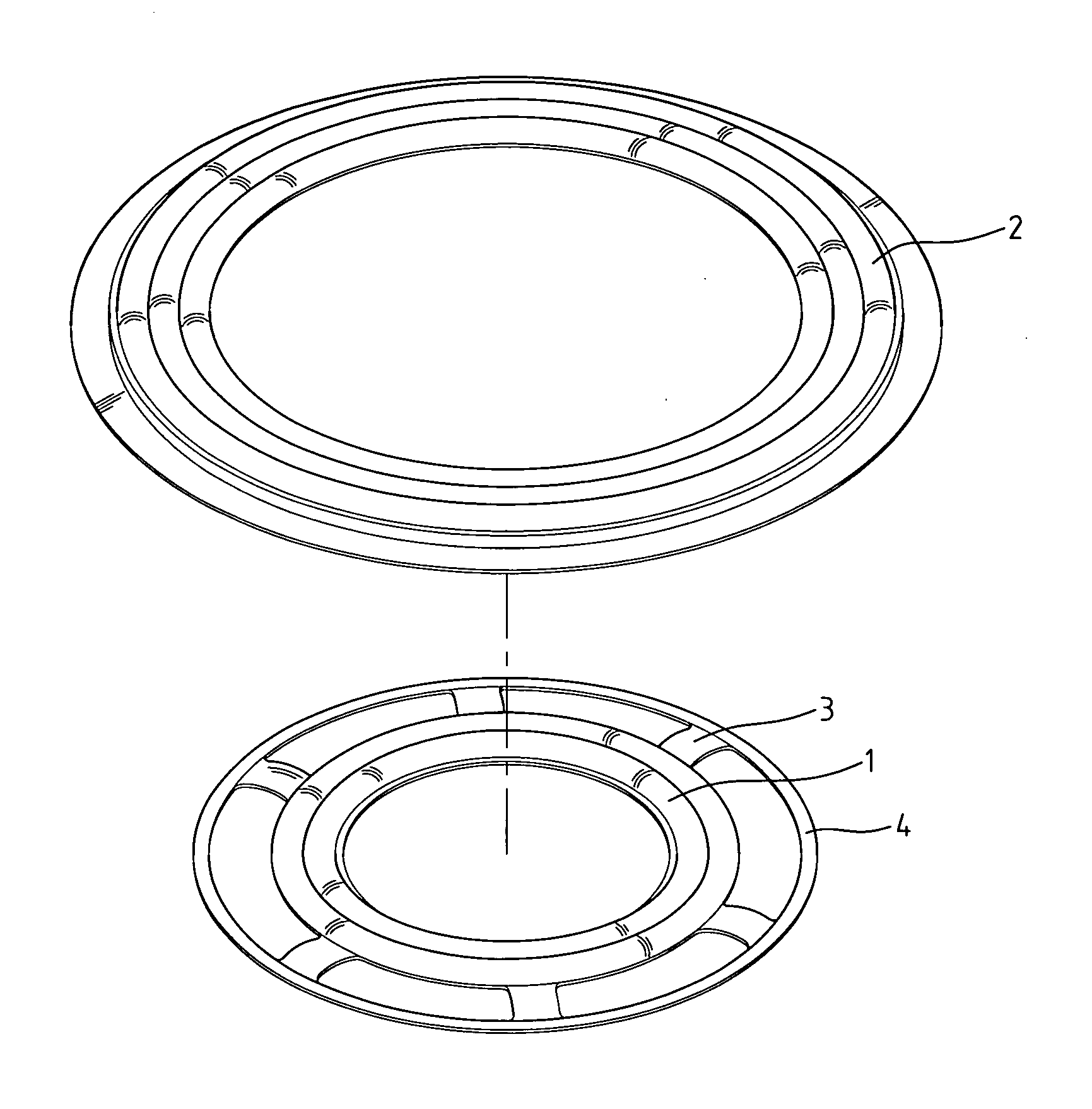

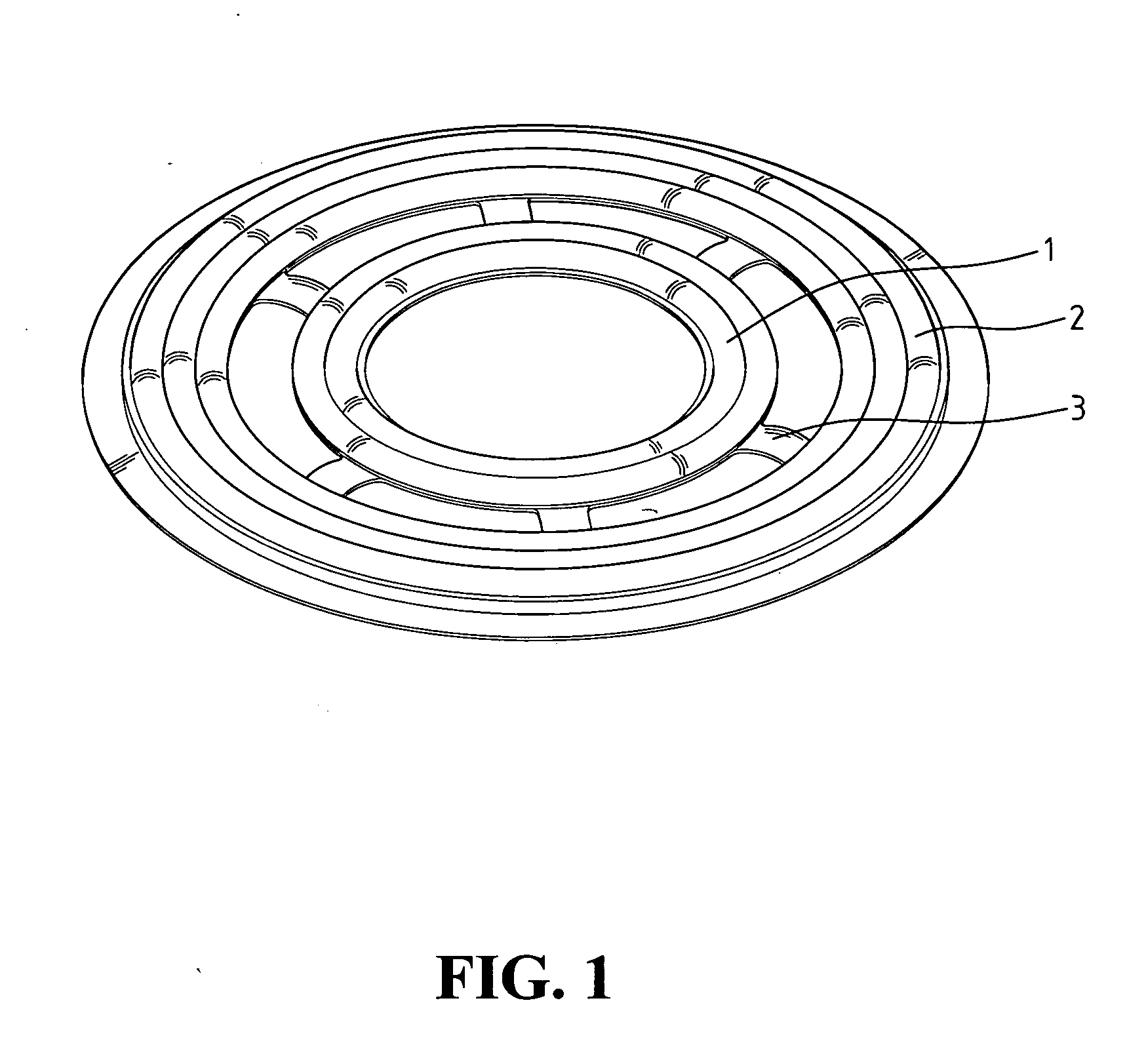

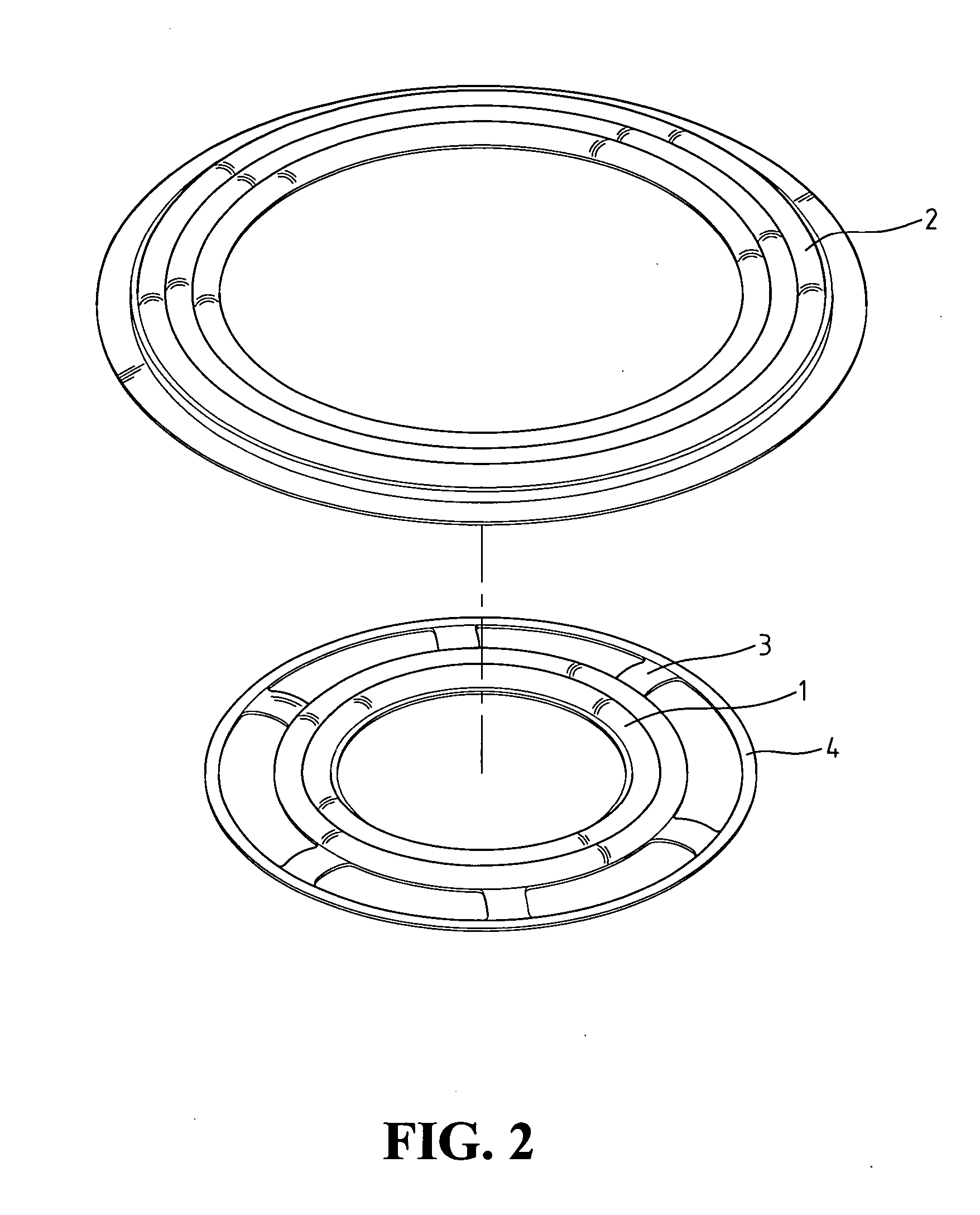

Composite damper for speaker

ActiveUS7724913B2Increase elasticitySimple manufacturing processTransducer casings/cabinets/supportsDeaf-aid setsEngineeringSnubber

A composite damper for a speaker comprises an inner ring surface material, an outer ring surface material, and a plurality of ribs connected between the inner ring surface material and the outer ring surface material. The inner ring surface material and the outer ring surface material have a plurality of alternating concentric peaks and valleys; thereby when it is coupled with a periphery of a voice coil of the speaker, it has a more stable vibration frequency.

Owner:OHARA HIROSHI

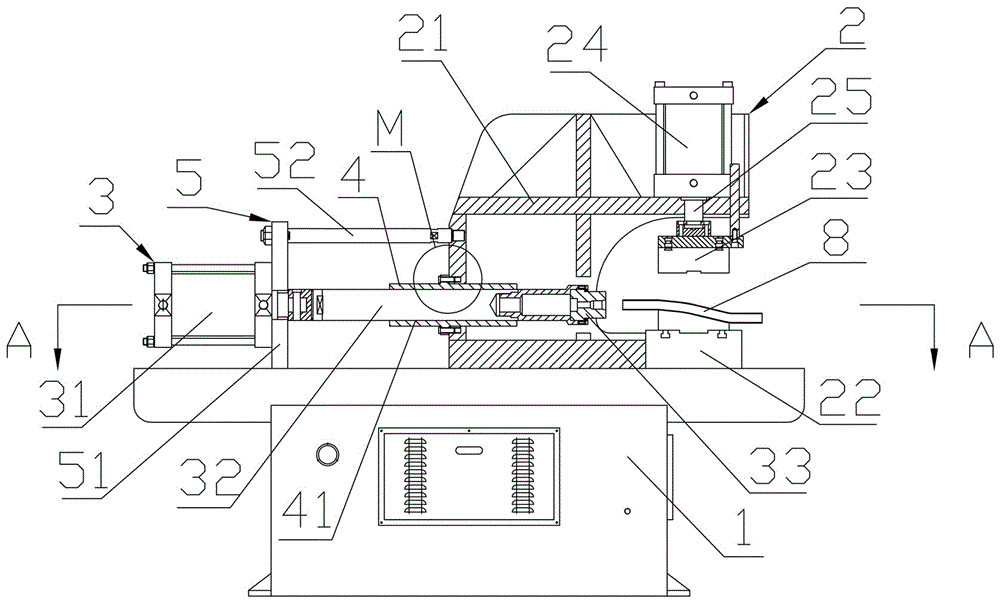

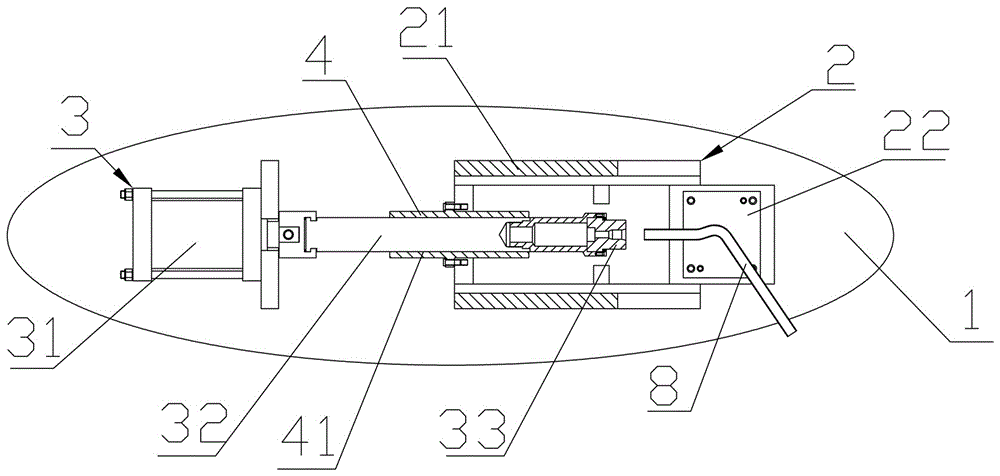

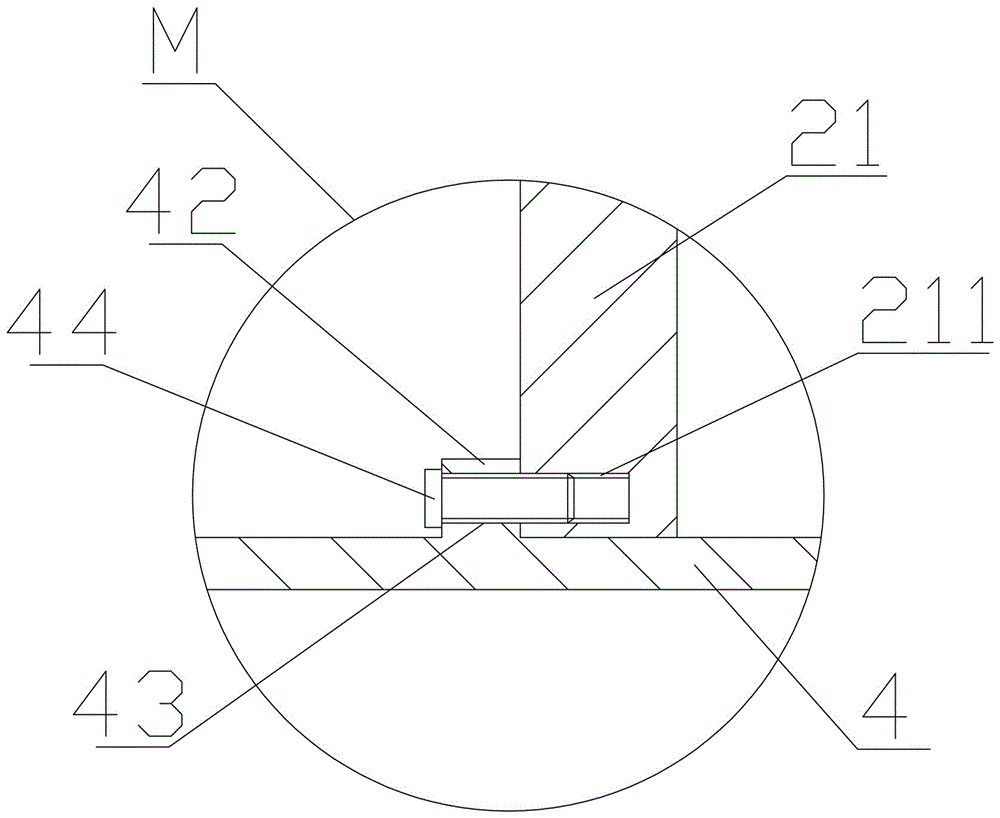

Pipe end forming machine

InactiveCN105964750ALess interferenceStable vibration frequencyMetal-working feeding devicesPositioning devicesEngineeringOpen structure

The invention discloses a pipe end forming machine in the field of pipe machining equipment. The pipe end forming machine comprises a rack, wherein a clamping mechanism is arranged on the rack, a forming mechanism is arranged at one side of the clamping mechanism, the clamping mechanism comprises a clamping frame; one end, far away from the forming mechanism, of the clamping frame sinks inwards to form a clamping notch; gaps are respectively formed in side walls at two sides of the clamping notch, so that the clamping notch in the clamping frame is of a front and back through open structure; a lower clamping die is arranged at the bottom of the clamping notch, an upper clamping die is arranged above the lower clamping die, a clamping cylinder is fixedly arranged on the clamping frame, and under the action of the clamping cylinder, the upper clamping die can achieve die assembly or separation with the lower clamping die; the forming mechanism comprises a forming cylinder, a piston rod of the forming cylinder can extend to the direction of the clamping notch and is movably supported in the clamping frame; and a forming die is arranged at an end part of the piston rod of the forming cylinder. The pipe end forming machine has the advantages of being high in machining precision and capable of avoiding interference between a bent pipe and a machining bench.

Owner:和和机械(张家港)有限公司

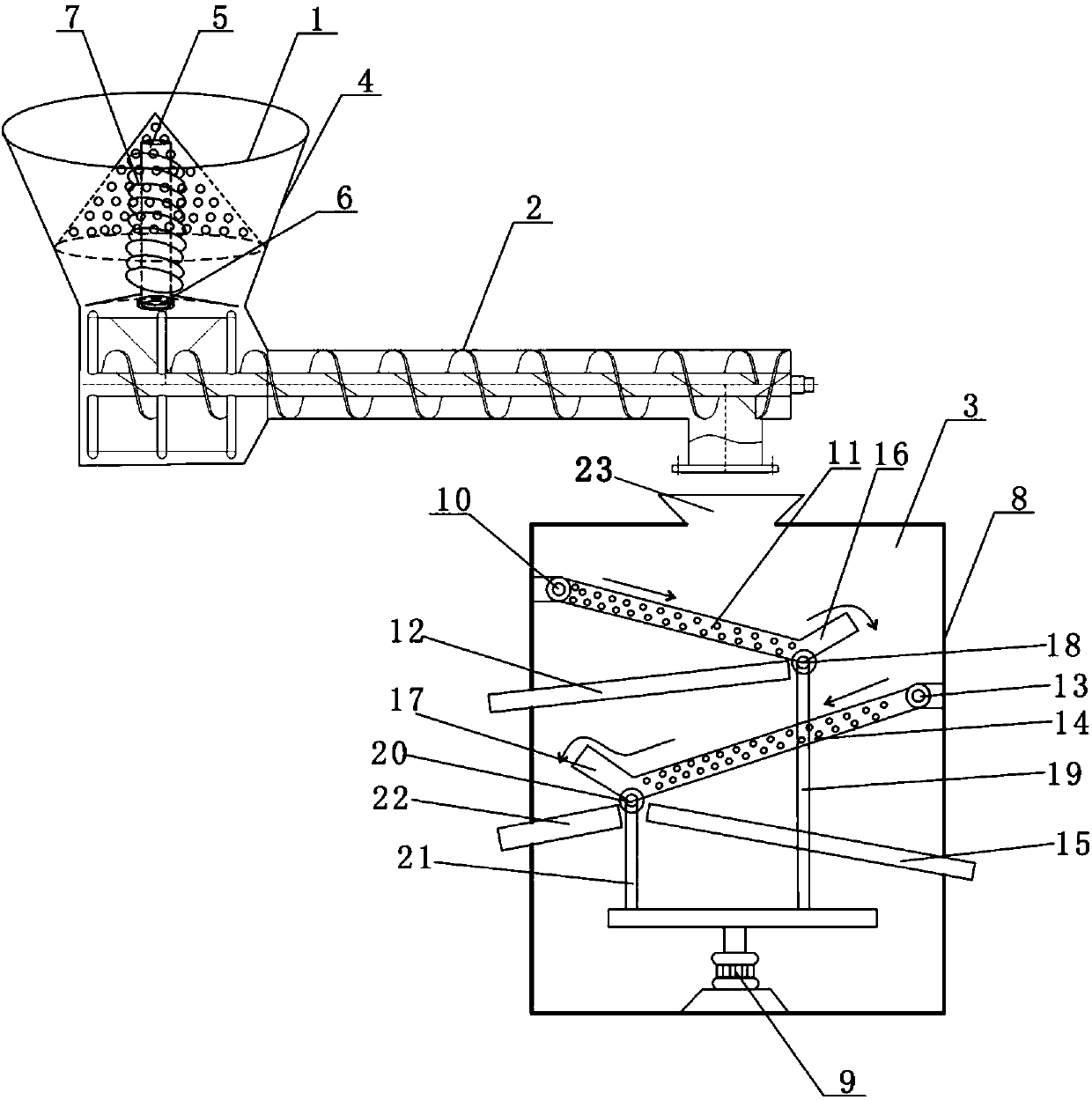

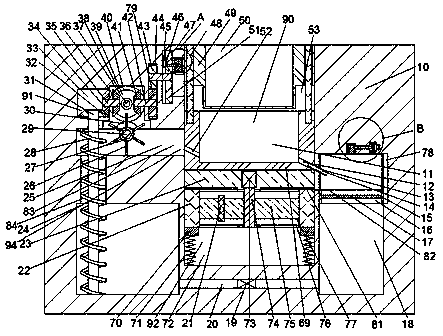

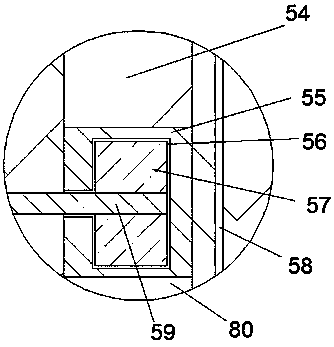

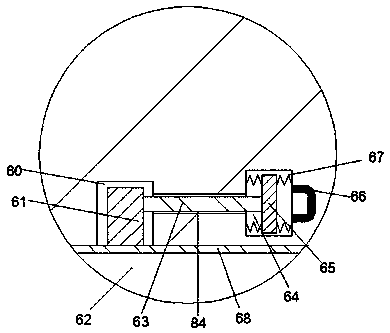

Granulated feed drying and sorting integrated device

The invention provides a granulated feed drying and sorting integrated device. The granulated feed drying and sorting integrated device comprises a drying mechanism, a screw conveyer and a sorting mechanism, wherein the drying mechanism is connected with the sorting mechanism, the sorting mechanism is arranged below the discharging end of the screw conveyer, the drying mechanism comprises a dryinghopper, and a taper hopper provided with hollowed-out meshes is sleeved with the drying hopper; a vertical shaft is arranged in the drying hopper, a rotating disc is connected to the bottom end of the vertical shaft, and a hollow screw heating coiled tube is fixed to the vertical shaft. The sorting mechanism comprises a sorting case, an upper-layer vibrating sieve is installed on one side of thesorting case, and an upper-layer chute is arranged below the upper-layer vibrating sieve. A lower-layer vibrating sieve is installed on the other side of the sorting case, and a lower-layer chute is arranged below the lower-layer vibrating sieve. Granulated feed which is sorted through the upper-layer vibrating sieve enters the lower-layer vibrating sieve, and a vibrating motor is connected with the upper-layer vibrating sieve and the lower-layer vibrating sieve. According to the granulated feed drying and sorting integrated device, granulated feed drying and sorting are integrated, and the granulated feed drying and sorting integrated device has the advantages of being good in drying and sorting effect.

Owner:宜昌市昌伟饲料科技有限公司

Metal rust-removal device

InactiveCN109352506ASimple device structureEasy to operateEdge grinding machinesPolishing machinesFan bladeMetal

The invention discloses a metal rust-removal device. The metal rust-removal device comprises a rust-removal rack, wherein a processing cavity is arranged in the rust-removal rack; a rust-removal mechanism is arranged in the processing cavity; the rust-removal mechanism comprises a guide rail rod and a sand loading disc; the guide rail rod slides up and down in the space; the sand loading disc canvibrate; the left side of the processing cavity is equipped with a rotary disc cavity; and a transmission mechanism is arranged in the rotary disc cavity. In a using process, the device drives an eccentric fan blade to rotate through a motor, so that vibrating frequency is more stable; and in the rust-removal process, the integral process is generated inside the device, so that the environmental pollution problem or the personnel health problem caused by splash of fine sand flying up in the air can be effectively prevented. Meanwhile, a sand clearing device is used to perform simple physical filtration on sand, so that the service life of the sand can be effectively prolonged, and secondary rusting due to a fact that rust is attached on a metal part can be prevented, and therefore, the processed metal part is longer in service life.

Owner:金华瑞慈科技有限公司

Supporting device for billboard

The invention discloses a supporting device for a billboard. The supporting device comprises a display table, a base, an inflating pump, a first turbine, a second turbine and a negative pressure vane.The inner bottom wall of the base is vertically connected with a first rotating shaft. The top of the first rotating shaft is fixedly connected with the bottom of the display table. The first turbineis located in the base and fixed to the first rotating shaft. The inflating end of the inflating pump communicates with a cavity of the base. The base is provided with a sleeve. The display table islocated in the sleeve. The two sides of the sleeve are provided with outer layer openings correspondingly. A pipeline communicates with the position between the base and one of the outer layer openings. A plurality of inner layer openings are formed in the circumferential direction of the display table. The display table is internally provided with a sealing piece. The sealing piece is rotationally connected with a second rotating shaft. The end, close to the sleeve, of the second rotating shaft is connected with the second turbine. The other end of the second rotating shaft is connected withthe negative pressure vane. The display table is provided with a plurality of adsorption holes. The upper end surface of the display table is provided with a plurality of exhaust holes. Thus the problem that an advertising cloth is prone to loosening and falling off when fixed to the billboard is solved.

Owner:日照新睿招商发展有限公司

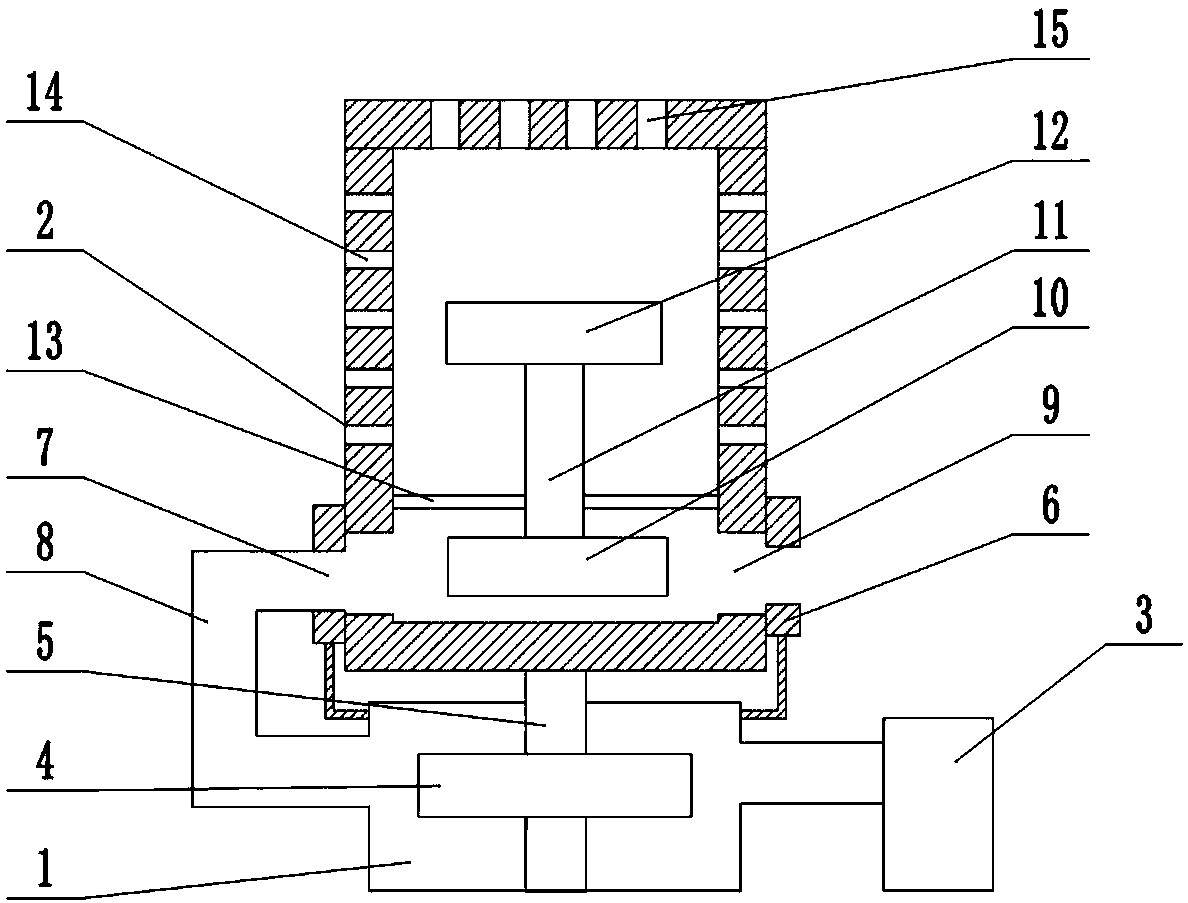

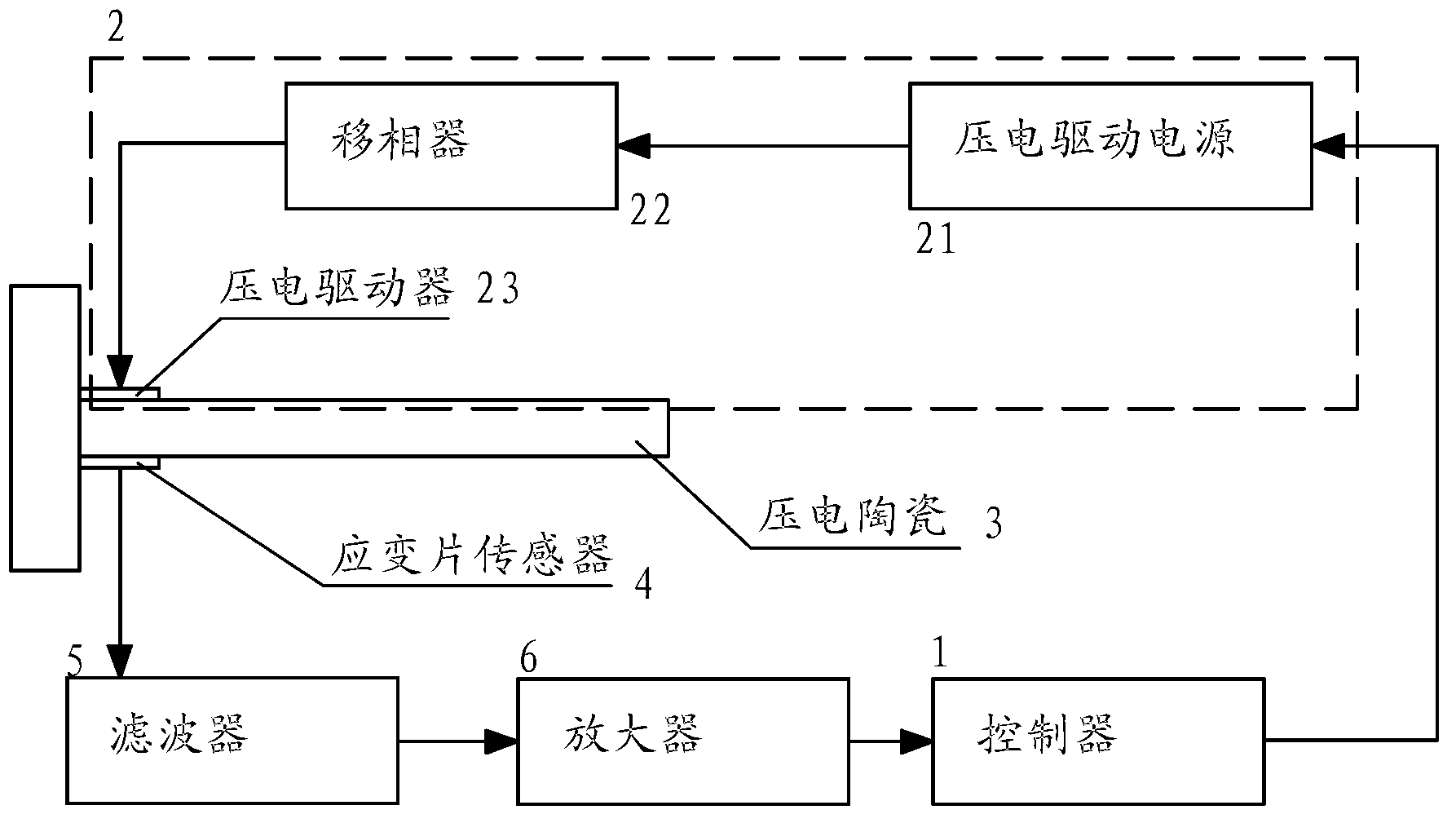

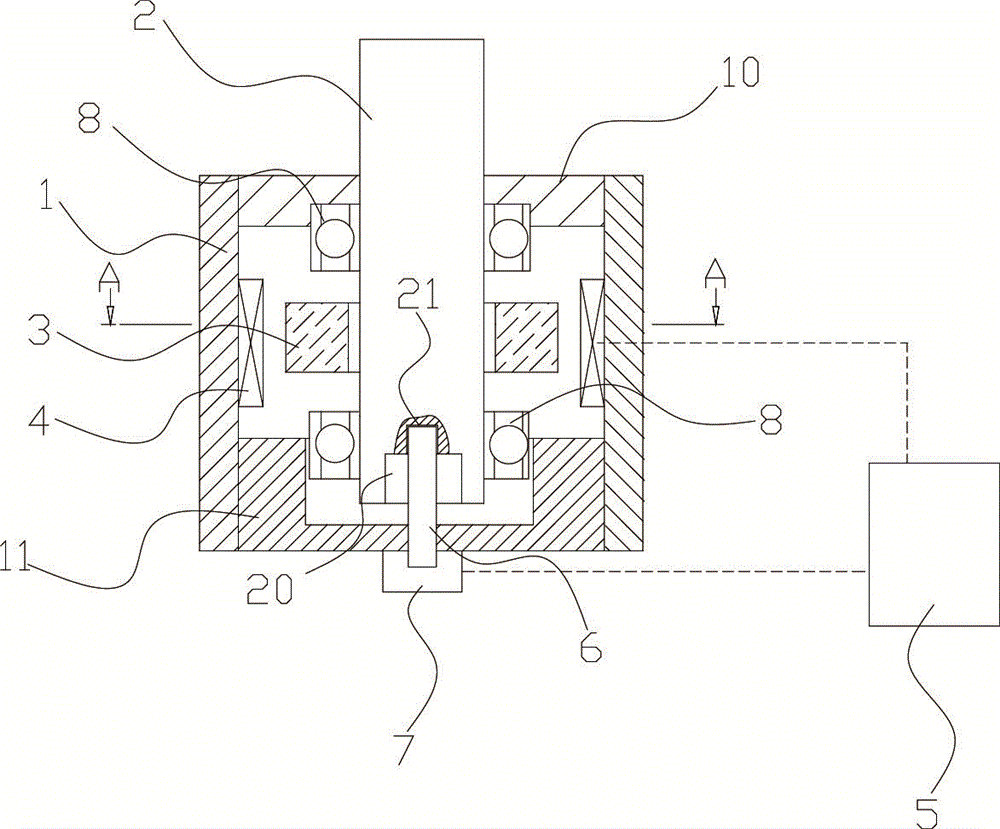

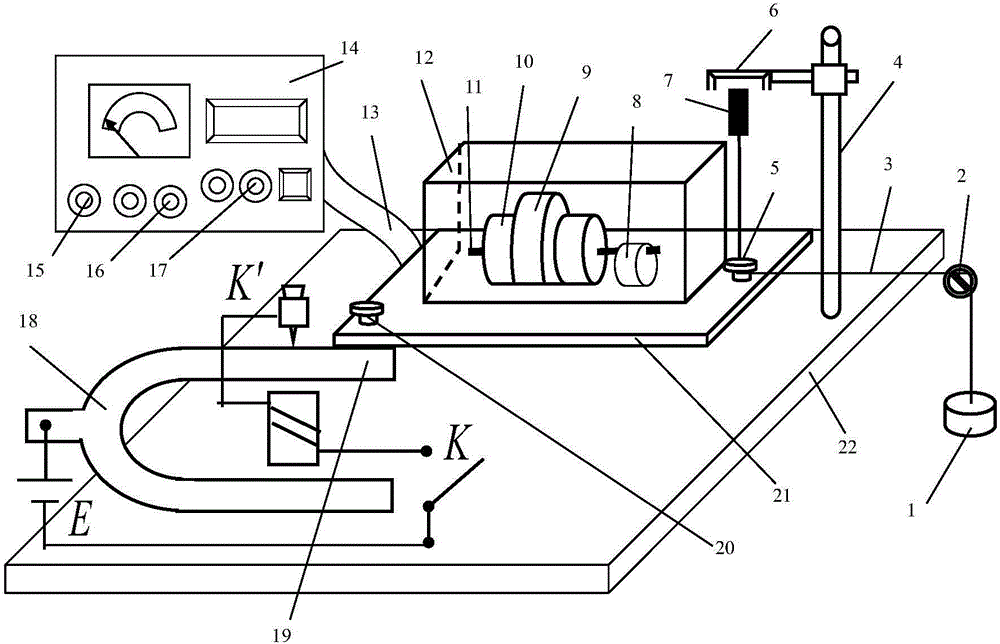

Closed loop control system of ultrasonic separator

The invention discloses a closed loop control system of an ultrasonic separator. A controller is connected with a piezoelectric driving power source of a piezoelectric driving unit; a piezoelectric driver of the piezoelectric driving unit is mounted on a piezoelectric ceramic upper surface; a strain sheet sensor connected with a filter is arranged on a piezoelectric ceramic lower surface; the filter is connected with an amplifier; the amplifier is connected with a controller; the piezoelectric driving unit comprises the piezoelectric driving and is connected with a phase shifter; and the phase shifter is connected with the piezoelectric driver. With the adoption of the manner, the closed loop control system provided by the invention can be used for effectively detecting a vibration frequency and adjusting the vibration frequency by using feedback, so that the vibration frequency of the system can be kept stable. Therefore, the optimal separation effect can be realized.

Owner:SUZHOU VOCATIONAL UNIV

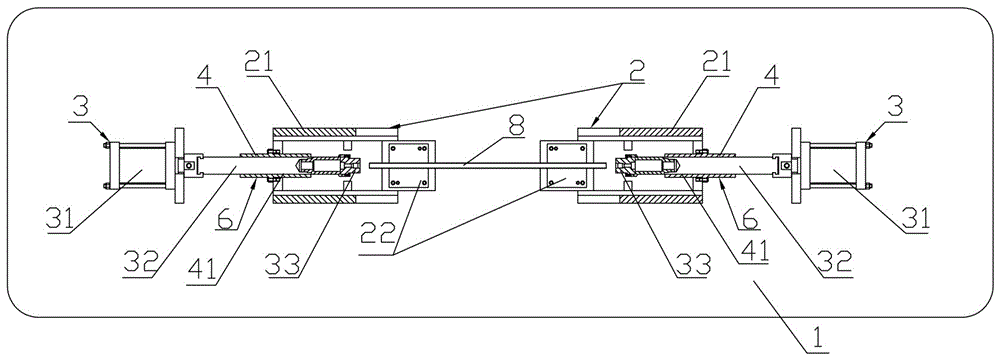

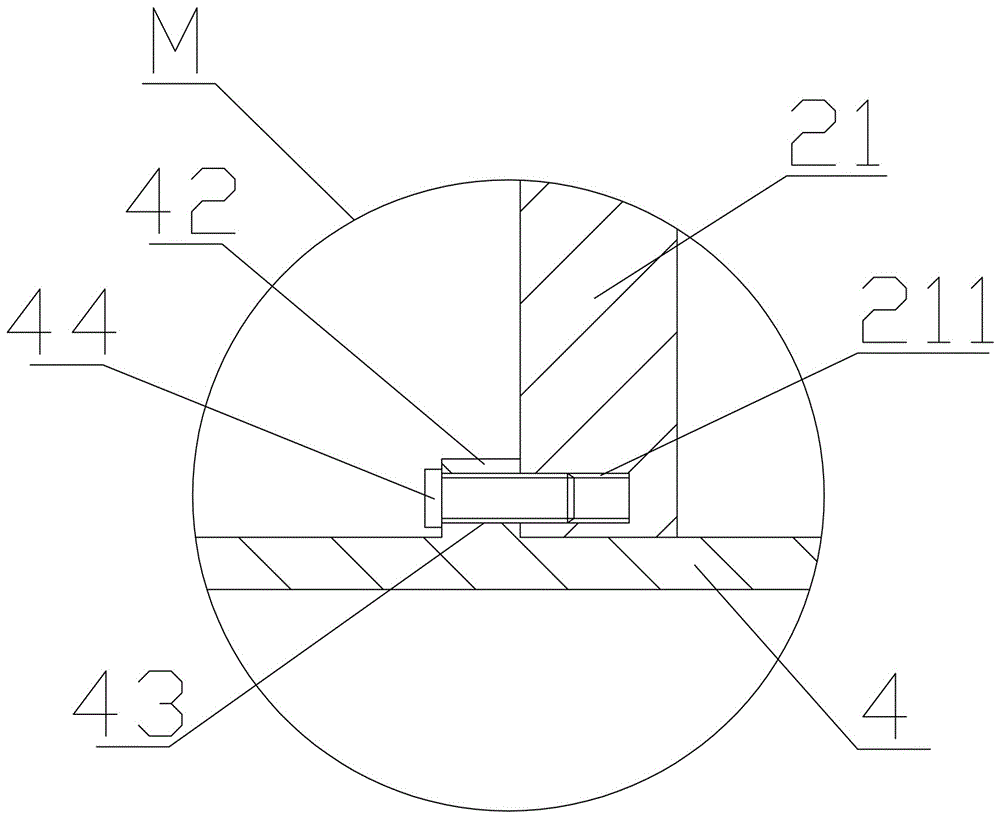

Double-head pipe end forming machine

ActiveCN105935712AIncrease contact areaImprove stabilityMetal-working feeding devicesPositioning devicesPistonMechanical engineering

The present invention discloses a double-head pipe end forming machine which belongs to the field of pipe processing equipment. The forming machine comprises a rack, and the rack is provided with a pair of clamping mechanisms and a pair of forming mechanisms disposed symmetrically at two sides of the clamping mechanisms. Each clamping mechanism comprises a clamping support, the clamping support is internally provided with a clamping gap, a lower clamping die is disposed at the bottom part of the clamping gap, an upper clamping die is installed above the lower clamping die, a clamping oil cylinder is installed on the clamping support, a piston rod of the clamping oil cylinder penetrates through a top part of the clamping support and then is fixedly connected with the upper clamping die, and under a driving action of the clamping oil cylinder, the upper clamping die and the lower clamping die are clamped together or separated from each other. Each forming mechanism comprises a forming oil cylinder, a piston rod of the forming oil cylinder enters into the adjacent clamping support and stretches towards the clamping gap of the clamping support, and an end part of the piston rod of the forming oil cylinder is provided with a forming die. Both of the two clamping supports are provided with guiding mechanisms, and the piston rods of the forming oil cylinders enter into the clamping supports through the guiding mechanisms. The double-head pipe end forming machine provided by the present invention has the advantages of high machining precision.

Owner:和和机械(张家港)有限公司

Vibration motor

ActiveCN104617703AGuaranteed output frequencyConsistent frequencyAssociation with control/drive circuitsMechanical energy handlingEngineeringAlternating current

The invention discloses a vibration motor. The vibration motor comprises a housing, and further comprises a gear switch used for controlling the frequency of an alternating-current power supply, and an elastic insertion piece, wherein an output shaft is rotationally arranged in the housing; two opposite coils are arranged on a side wall of the housing; an armature part in response to the coils is fixedly arranged on the output shaft; a slot is formed in the bottom of the output shaft; an insertion slot allowing the elastic insertion piece to insert is formed in a bottom end of the slot; a drive mechanism pushing the elastic insertion piece is arranged at one end of the elastic insertion piece. Compared with the prior art, the slot allowing the elastic insertion piece to insert is formed in the bottom of the output shaft and the drive mechanism pushing a spring leaf is arranged, so that when the gear switch performs switching among gears at different vibration frequencies, the spring leaf is inserted into the slot of the output shaft through the drive mechanism to change an elastic deformation coefficient of the spring leaf, and the coil output frequency can be guaranteed to be the same as the frequency of the output shaft of the vibration motor when a maintenance tool is switched among the gears at different frequencies.

Owner:东莞市富泰电机有限公司

Solid-liquid separator

PendingCN110469279AConsistent amplitudeStable vibration frequencyFlushingMoving filtering element filtersScreening effectSolid particle

The invention discloses a solid-liquid separator. The solid-liquid separator comprises a transmission mechanism, a vibration mechanism and a charging box. The horizontal displacement is provided by the transmission mechanism to realize the movement of a solid-liquid mixture in the horizontal direction; the vertical displacement is provided by the vibration mechanism, a vibration bracket is fixedlyarranged on the transmission mechanism, a pneumatic exciter is arranged on the vibration bracket, the pneumatic exciter is ventilated by an air path pipeline, and the vibration of the solid-liquid mixture in the vertical direction is realized; and finally, a liquid phase enters the charging box, and solid particles continue to move forwards with a screen and finally fall into the material pickingend. According to the solid-liquid separator, the structural stability and the consistency of the amplitude and vibration frequency are effectively kept, and it is further ensured that the amplitudeand vibration frequency of each area of the screen are consistent, the working noises are reduced, the screen is effectively prevented from blocking, and the screening effect is enhanced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Composite damper for speaker

ActiveUS20070223712A1Increase elasticitySimple manufacturing processTransducer casings/cabinets/supportsTransducer circuitsEngineeringLoudspeaker

A composite damper for a speaker comprises an inner ring surface material, an outer ring surface material, and a plurality of ribs connected between the inner ring surface material and the outer ring surface material. The inner ring surface material and the outer ring surface material have a plurality of alternating concentric peaks and valleys; thereby when it is coupled with a periphery of a voice coil of the speaker, it has a more stable vibration frequency.

Owner:OHARA HIROSHI

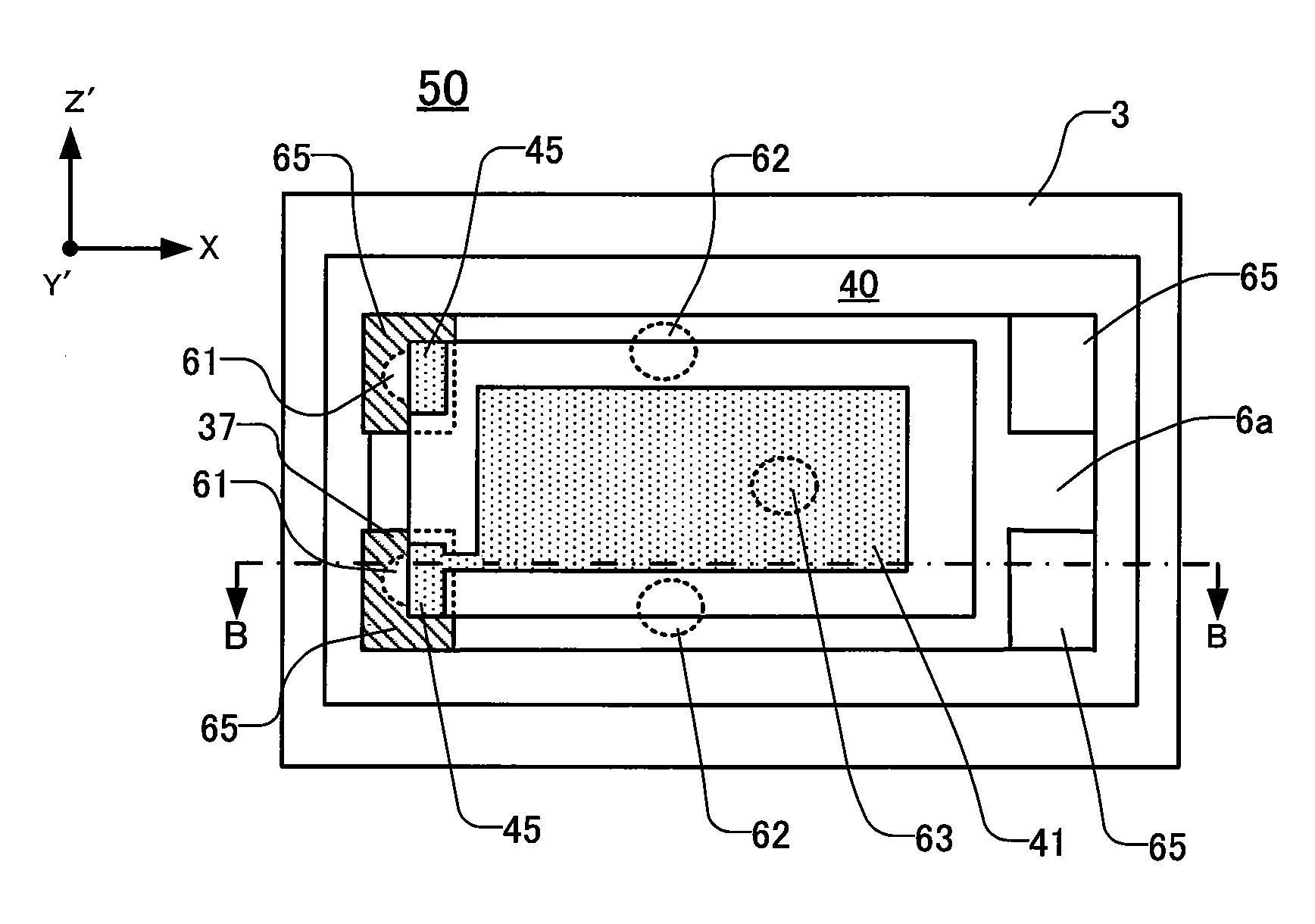

Piezoelectric resonator element, piezoelectric device, and electronic apparatus

InactiveCN102195609AStable vibration frequencyStable electrical characteristicsImpedence networksQuartz crystal resonatorEngineering

A piezoelectric resonator element and a piezoelectric device, which prevent the vibration of the resonating arm section from leaking to the side of the base portion and stabilize the vibration of the resonating arm section, and an electronic apparatus using these devices are obtained. The quartz crystal resonator element as the piezoelectric resonator element is provided with a base portion formed of a piezoelectric material, a plurality of resonating arm sections each extending from the base portion via an arm base section, and an elongated groove section formed along a longitudinal direction of the resonating arm section, and the arm base section has an arm width, which is larger than an arm width of the resonating arm section and smaller than a distance between imaginary centerlines of the respective resonating arm sections in a width direction of the resonating arm section.

Owner:SEIKO EPSON CORP

Integral welding-free forming process for belled mouth and body of brass instrument

InactiveCN1357421APronunciation uniform stress in the bodyUniform stressEngineeringForming processes

The key point of the present invention is to form belled mouth and main body of brass instrument through stepped drawing process. Before each drawing, the workpiece is annealed. From the second drawing on, one certain height is remained depending on the drawn area. The drawn belled mouth and main body is then further processed with a steel spindle, rolling pole similar tool. The brass instrument thus produced has homogeneous stress, stable vibration frequency, round and accurate tone quality.

Owner:史占秋

Pneumatic rammer

InactiveCN105297701AEasy to operateStable vibration frequencySoil preservationAir compressionEngineering

The invention relates to a pneumatic rammer which comprises a rammer head, a sealing nut, a cylinder body, a cylinder body nut, an air rod, an air inlet control valve, a handle, an air pipe connector and a piston rod. The rammer head is welded to the front end of the piston rod. The sealing nut is arranged at the joint of the cylinder body and a piston. The cylinder body is installed on the air rod through the cylinder body nut. The handle is arranged on the air rod. The air inlet control valve is arranged on the handle. The air pipe connector is installed at the end of the air rod. The air pipe connector is connected with air compression equipment through a high-pressure pneumatic pipe. A semispherical component is arranged on the rammer head. The pneumatic rammer has the beneficial effects that the semispherical component is welded to the rammer head, operation is convenient and fast, the vibration frequency is stable, the vibration strength is uniform, and the rammering effect is excellent.

Owner:青海省建筑建材科学研究院有限责任公司 +1

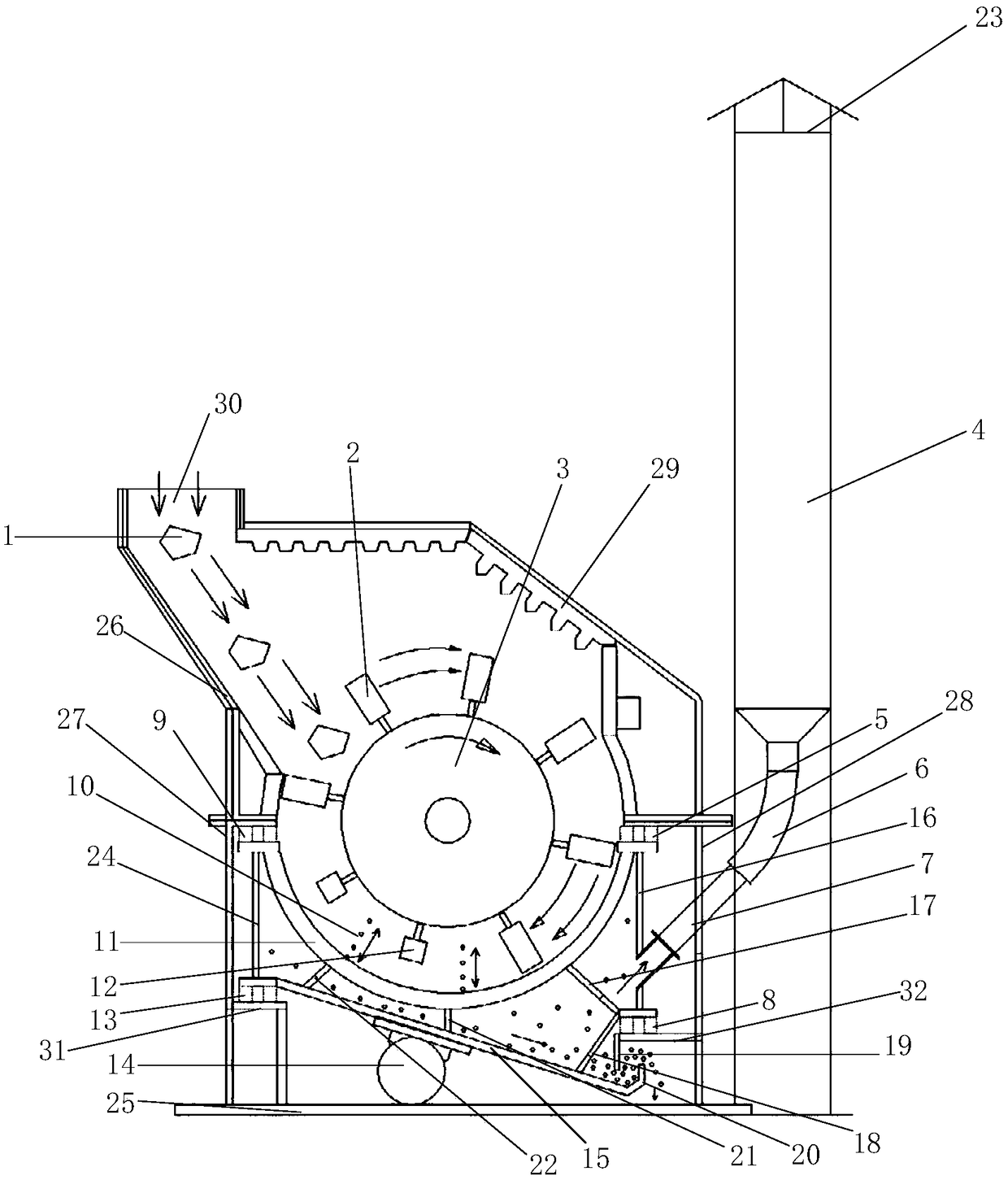

Environment-friendly sand making machine

The invention belongs to the technical field of sand making machines, and discloses an environment-friendly sand making machine which comprises a feeding cabin and a rotary sand hammering mechanism arranged in the feeding cabin. The feeding cabin is composed of an upper feeding cabin and a lower feeding cabin elastically connected with the upper feeding cabin. The lower feeding cabin is an arc-shaped screening plate which is connected with the upper feeding cabin in a sealed mode through an elastic connecting piece. A sand discharging bin is arranged below the arc-shaped screening plate and isconnected with the lower side of the arc-shaped screening plate in a sealed mode through an elastic connecting piece. A vibrating device is arranged on the sand discharging cabin which is further provided with a dust-raising preventing mechanism. The environment-friendly sand making machine has the characteristics of low abrasion loss, high productivity and dust-raising prevention.

Owner:四川绿矿环保科技有限公司

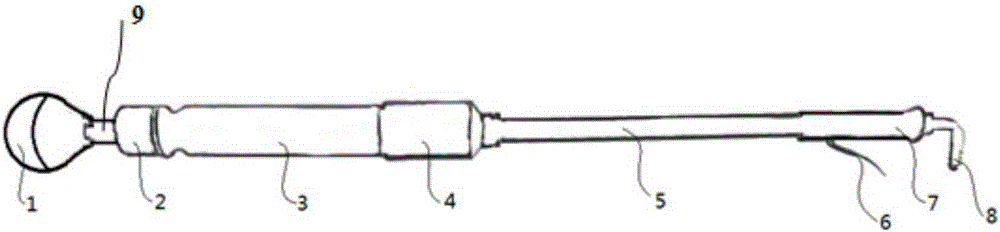

String vibration period experiment instrument with vibration motor and electric vibration tuning fork as double vibration wave sources

InactiveCN104318825AChange vibration frequencyImprove vibrationEducational modelsElectricityTuning fork

The invention provides a string vibration period experiment instrument with a vibration motor and an electric vibration tuning fork as double vibration wave sources. The string vibration period experiment instrument with the vibration motor and the electric vibration tuning fork as the double vibration wave sources aims to the solve the technical problems that an existing string vibration experiment instrument is complicated in equipment structure, a dead zone exists during an experiment, and the demonstration effect is poor. The string vibration period experiment instrument comprises an experiment instrument body. A base is arranged at the bottom of the experiment instrument body, and a vibration motor assembly is installed on the experiment instrument body. The vibration motor assembly is installed on the head portion of the electric vibration tuning fork through a fixing flat plate. The vibration motor is installed in the vibration motor assembly. An eccentric block is installed on the right side of an outer rotating shaft of the vibration motor. A direct-current power source frequency measurement instrument is installed on the left side of the base. A voltage adjusting and frequency adjusting power source and a vibration motor frequency measurement instrument are installed on the direct-current power source frequency measurement instrument. The voltage adjusting and frequency adjusting power source is provided with a voltage adjustment and frequency adjustment alternation switch, a power switch and the like. The vibration motor frequency measurement instrument is provided with a power supply switch, a frequency switch and the like. When the string vibration period experiment instrument is used, through the steps of power source connection, voltage adjustment and the like, the string vibration frequency is obtained by measuring the vibration frequency with the vibration motor as the wave source finally. The double vibration wave sources can be mutually checked and compared. The string vibration period experiment instrument with the vibration motor and the electric vibration tuning fork as the double vibration wave sources has the advantages that the structure is reasonable, an operation method is easy to implement, and the demonstration effect is remarkable.

Owner:SHENYANG NORMAL UNIV

Connecting rod fatigue test device with high reliability

PendingCN108776016AImprove reliabilityImprove fatigue strengthMachine gearing/transmission testingDrive shaftEngineering

The invention belongs to the technical field of machines, and provides a diesel engine connecting rod fatigue test device. The connecting rod fatigue test device with high reliability is provided withan adapter flange I connected to the lower end of a main drive shaft I and an adapter flange II connected to the upper end of the main drive shaft II; the adapter flange I and the main drive shaft Iare in clearance fit and are fixedly connected into a whole; the adapter flange II and the main drive shaft II are in clearance fit and are fixedly connected into a whole; the structures of the adapter flange I and the adapter flange II are the same, and the central axis of the adapter flange I, the central axis of the adapter flange II, the central axis of the main drive shaft I and the central axis of the main drive shaft II are located on a same axis; the lower end of the adapter flange I is fixedly connected with a connecting rod small end fixture; the lower end of the adapter flange II isfixedly connected with the main drive shaft II; and the upper end is fixedly connected with the connecting rod large end fixture. According to the invention, the vibration frequency of a connecting rod and the vibration frequency of the connecting rod fatigue test device tend to be consistent, so that the connection between the connecting rod and the test device is firm, and the looseness prevention performance is good.

Owner:HENAN DIESEL ENGINE IND

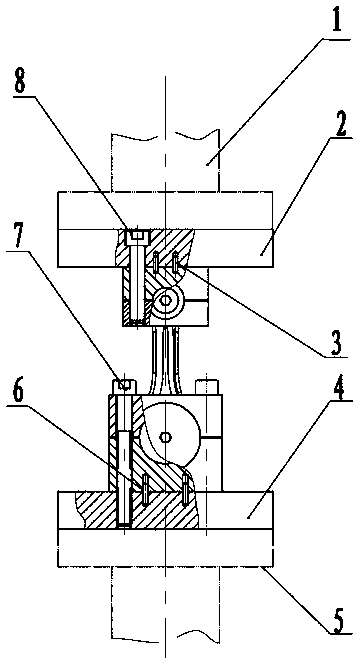

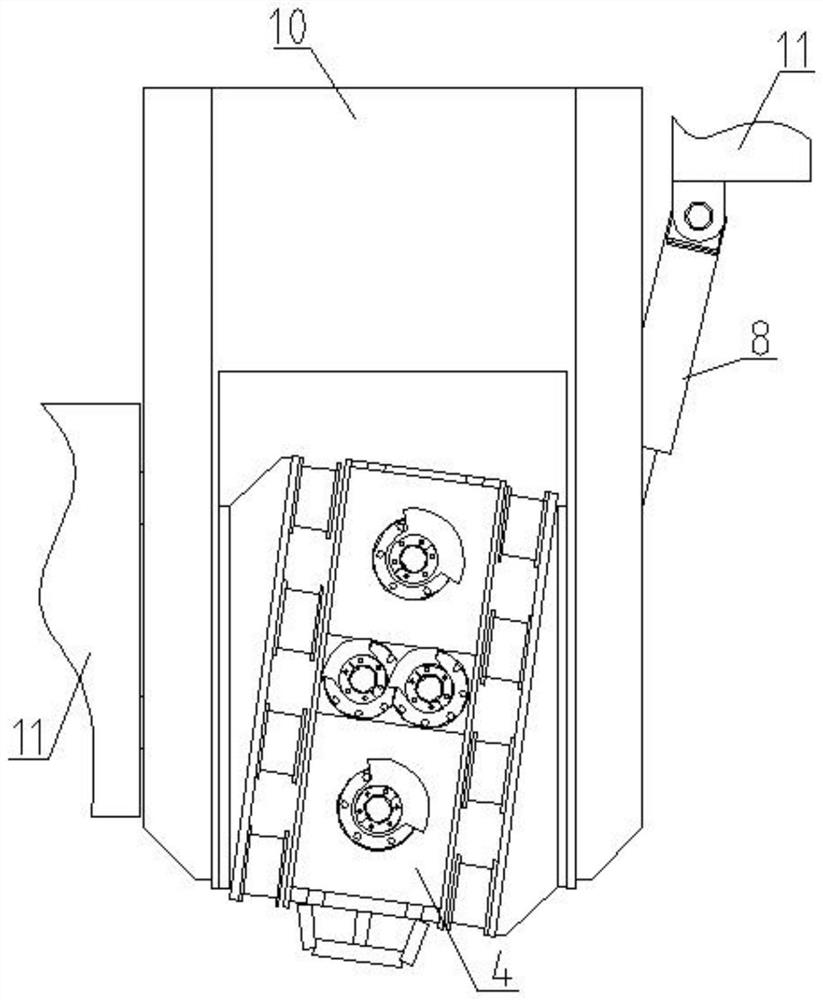

A vibration device for a resonance crusher

ActiveCN111749108BHeight adjustableImprove construction efficiencyRoads maintainenceControl theoryMechanical engineering

The invention discloses a vibrating device for a resonance crusher, which comprises a mounting bracket and a vibrating unit; the mounting bracket includes two vertically arranged bracket poles, and hinge shaft earrings are arranged on the outside of the bracket poles; one side of the crushing locomotive There is a front hinge seat on the body, and an oil cylinder is connected to the front hinge seat, and the free end of the oil cylinder is connected to the hinge earring on the support pole; on the other side, there are two or more rear hinge seats horizontally on the crusher body. , the central connection line of the rear hinge seat is parallel to the support vertical rod, the rear hinge seat is connected to the hinge earring on the support vertical rod through the connecting rod, the central connection line of the rear hinge seat, the connecting rod and the adjacent support vertical rod form Parallelogram structure, by adjusting the length of the oil cylinder to change the shape of the parallelogram structure, thereby adjusting the height of the vibration unit from the ground, the position of the vibration unit can be adjusted in a large space, the angle of the hammer head remains unchanged during the up and down movement, the connecting rod bears the main reaction force, and the oil cylinder The force is relatively small, prolonging the service life of the entire device.

Owner:武汉海德力液压技术有限公司

Intelligent Adaptive Vibration Absorber, Array Integration Device and Its Application

ActiveCN104806693BAccurately set the natural frequencyReduce vibrationNon-rotating vibration suppressionShock absorbersCantilevered beamMulti field

The invention provides an intelligent self-adaptive vibration absorber. The intelligent self-adaptive vibration absorber comprises a driving body, a mass body, an elastic beam, a terminal limiting sensor and a piezoelectric sensor device, wherein the driving body is arranged at one end of the elastic beam; the mass body is movably arranged on the elastic beam, and moves in a reciprocating way along the elastic beam under the driving force of the driving body; the terminal limiting sensor and the piezoelectric sensor device are arranged on the end part of the other end of the elastic beam; self-adaptive control of the inherent frequency of the vibration absorber is realized through adjustment of the length of a cantilever beam formed on the elastic beam by the mass body. Meanwhile, the invention provides an array integrating device based on the intelligent self-adaptive vibration absorber and application of the intelligent self-adaptive vibration absorber. The intelligent self-adaptive vibration absorber is simple in structure, and is suitable for multi-field popularization; precision suppression of single vibration of a controlled object can be realized, precision suppression control can be performed on multi-frequency laminated vibration of the controlled object, and inertial driving and power generation application are realized through structural specificity.

Owner:SHANGHAI JIAOTONG UNIV

Agricultural seed sun-bathing device capable of preventing damp

InactiveCN111854382ALift controlQuick storageSeed and root treatmentDrying machines with non-progressive movementsAgricultural scienceAgricultural engineering

The invention relates to the agricultural technical field, in particular to an agricultural seed sun-bathing device capable of preventing damp. The agricultural seed sun-bathing device capable of preventing damp comprises a seed sun-bathing box, wherein an inner accommodating cavity is arranged in the seed sun-bathing box; a bearing frame is arranged inside the inner accommodating cavity; the bottom of the inner accommodating cavity is transversely equipped with a transmission rod; outer threaded regions are arranged on areas at left and right ends of the transmission rod; thread directions ofthe outer threaded regions at left and right sides are reverse; transmission sleeves are mounted on the outer threaded regions through threaded connection; the transmission sleeves are externally connected and equipped with fixed bolts; bottoms of two sides of the bearing frame are equipped with supporting bolts; supporting connecting rods are mounted between the fixed bolts and the supporting bolts; the sun-bathing plate is mounted on the bearing frame; and the bottom of the middle area of the bearing frame is of a concave structure, and is equipped with a vibrating frame. On rainy days, theagricultural seed sun-bathing device also can be quickly stored for a time being. The device is matched with a rainproof curtain for expanding and paving, so that the rainproof effect can be effectively achieved.

Owner:佟月菊

Instability detection sensor and packaging method

ActiveCN110849400AReliable deliveryImprove electromagnetic compatibilityMeasurement apparatus housingsMetallic enclosureElectrical connection

The invention provides an instability detection sensor and a packaging method, which belong to the technical field of sensors. The instability detection sensor comprises a metal outer shell, a metal inner shell and a circuit unit, wherein a first opening is formed in one side surface of the metal outer shell, and the side surface is connected with a first sealing cover used for packaging the firstopening; the metal inner shell is arranged in the metal outer shell, and a preset gap is formed between the metal inner shell and the metal outer shell; a second opening is formed in the side surface, facing the first sealing cover, of the metal inner shell, and the side surface is connected with a second sealing cover used for packaging the second opening; the circuit unit is fixedly connected to the inner wall of the metal inner shell and provided with a signal cable sequentially penetrating through the side wall of the metal inner shell and the side wall of the metal outer shell outwards,and the signal cable is used for being electrically connected with a signal processor; and when the second sealing cover packages the second opening and the first opening is upward, the preset gap isfilled with liquid first silicone rubber, and the first silicone rubber is used for completely wrapping the metal inner shell and supporting the metal inner shell in the metal outer shell in an insulating mode after being cured.

Owner:MT MICROSYST

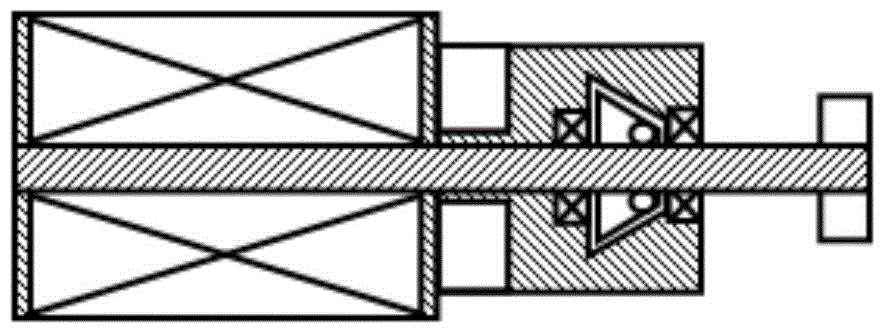

A vibrating device with an Oldham coupling and a membrane processing system using the same

InactiveCN103817066BRelative Angle Change Compensation AdjustmentAvoid shortened service lifeSemi-permeable membranesMechanical vibrations separationCouplingClassical mechanics

The invention discloses a vibrating device with an Oldham coupling, which comprises a motor and is provided with an output rotating shaft; The Oldham coupling at one end of the Oldham coupling is connected to the output shaft, the other end of the Oldham coupling is connected to the eccentric shaft, and the output shaft is suitable for The eccentric shaft rotates eccentrically through the Oldham coupling group; the adjacent Oldham couplings are connected by key sleeves, and the adjacent Oldham couplings are suitable for relative sliding along the axial direction while being unable to relatively rotate. On this basis, the present invention also provides a membrane treatment system using the above vibration device. The vibration device mentioned above is suitable for preventing the membrane filtration system from being polluted by impurities while prolonging the service life of the motor equipment.

Owner:连力生

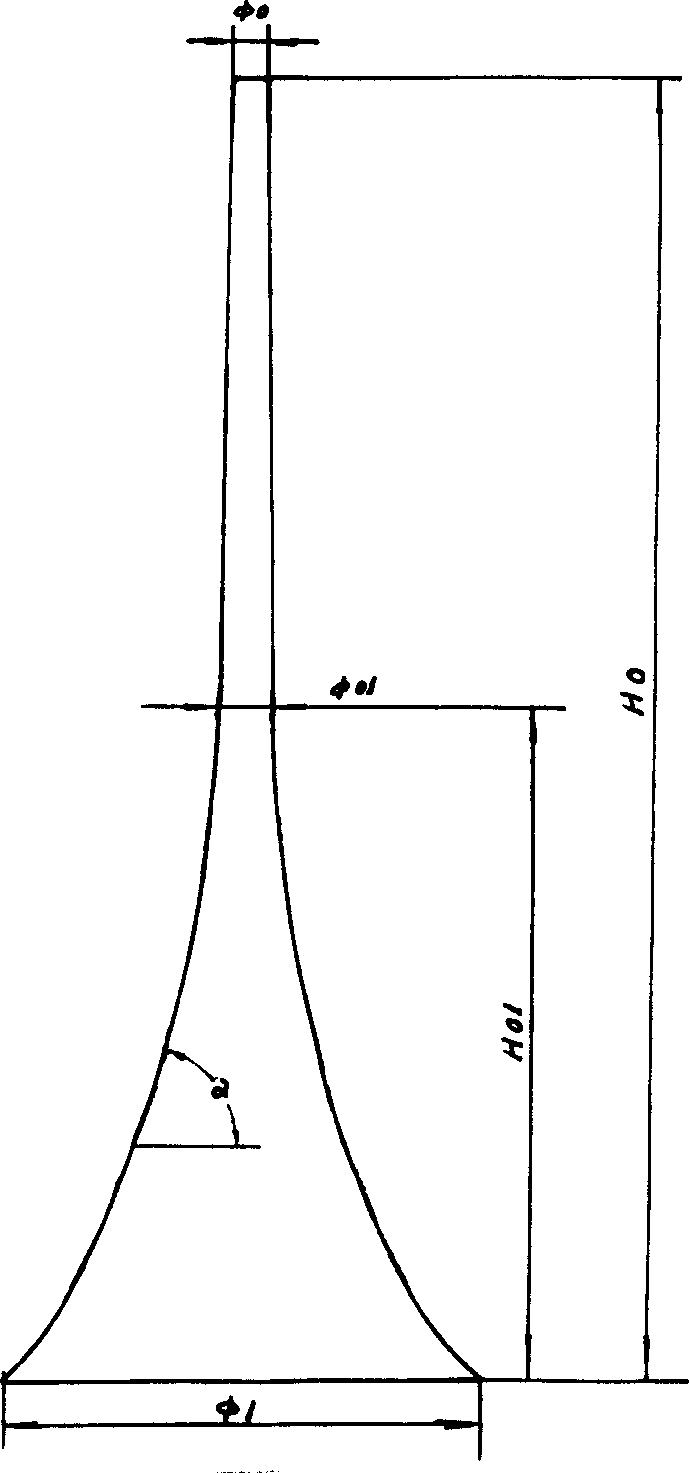

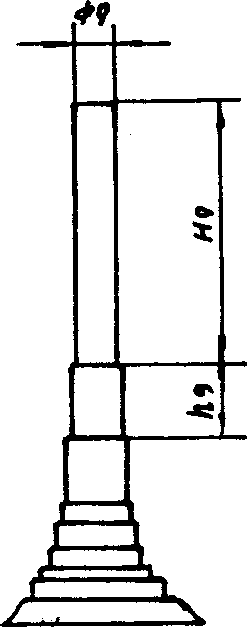

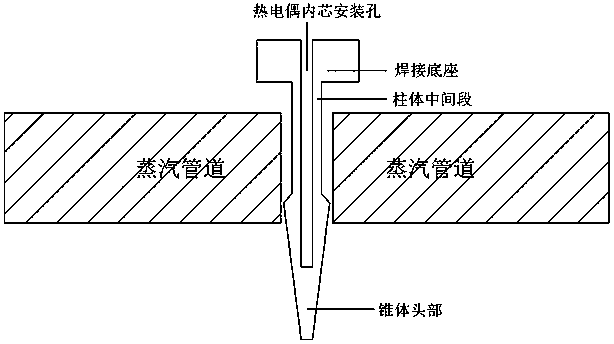

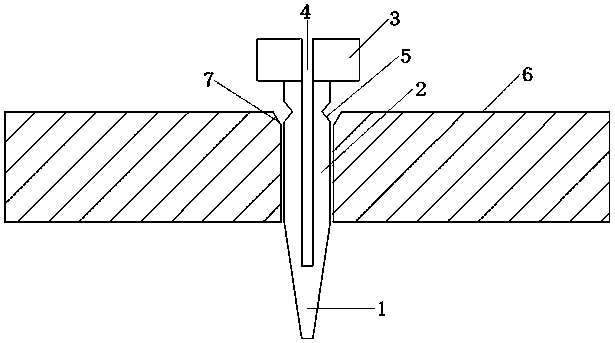

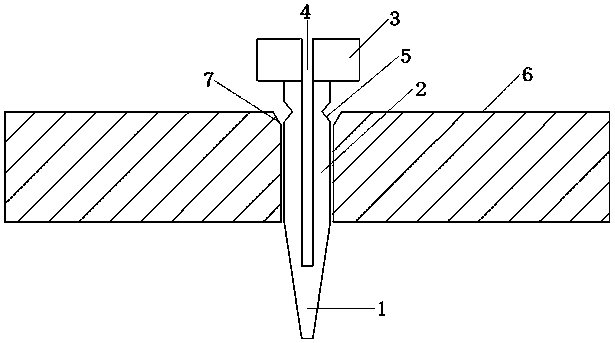

High-temperature high-pressure anti-vibration anti-scouring thermocouple outer sleeve and installation method thereof

PendingCN111141403AAvoid crackingReduce vibration amplitudeThermometer detailsThermometers using electric/magnetic elementsPhysicsSteel columns

The invention discloses a high-temperature high-pressure anti-vibration anti-scouring thermocouple outer sleeve and an installation method thereof, and belongs to the field of temperature measurementcontrol of high-temperature high-pressure high-speed flowing steam in a boiler steam pipeline. The problems that an existing thermocouple measurement outer sleeve is prone to abrasion and breakage, and measurement reliability is affected are solved. The sleeve comprises a conical head, a cylindrical middle section and a base, the conical head, the cylindrical middle section and the base are formedby machining a solid special round steel column made of the same material, the conical head is connected with the cylindrical middle section, the cylindrical middle section is connected with the base, and the conical head, the cylindrical middle section and the base are made of the same material; a mounting hole is formed in the thermocouple outer sleeve and used for mounting a thermocouple innercore, the mounting hole sequentially penetrates through the base and the cylindrical middle section and extends into the conical head, and a V-shaped wedge groove is formed in the end, connected withthe base, of the cylindrical middle section along an outer wall face. The thermocouple outer sleeve is simple in structural design and can effectively improve the reliability of boiler high-temperature high-pressure high-speed flowing steam temperature measurement.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

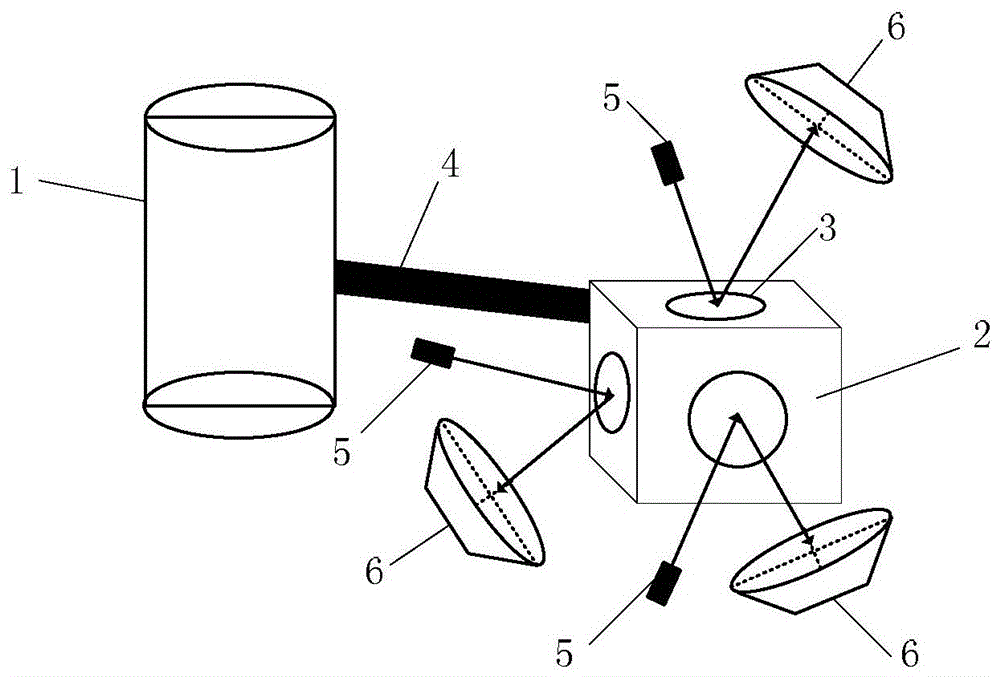

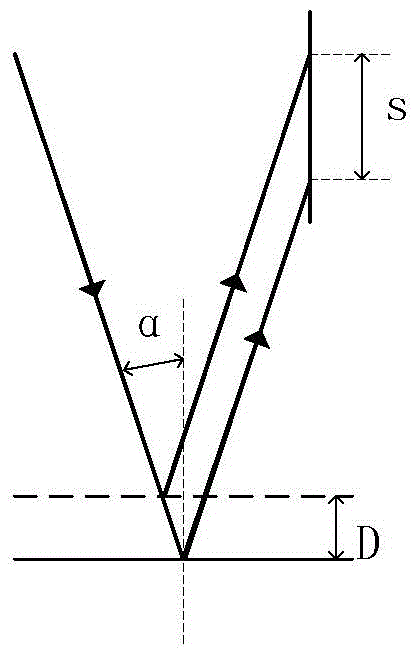

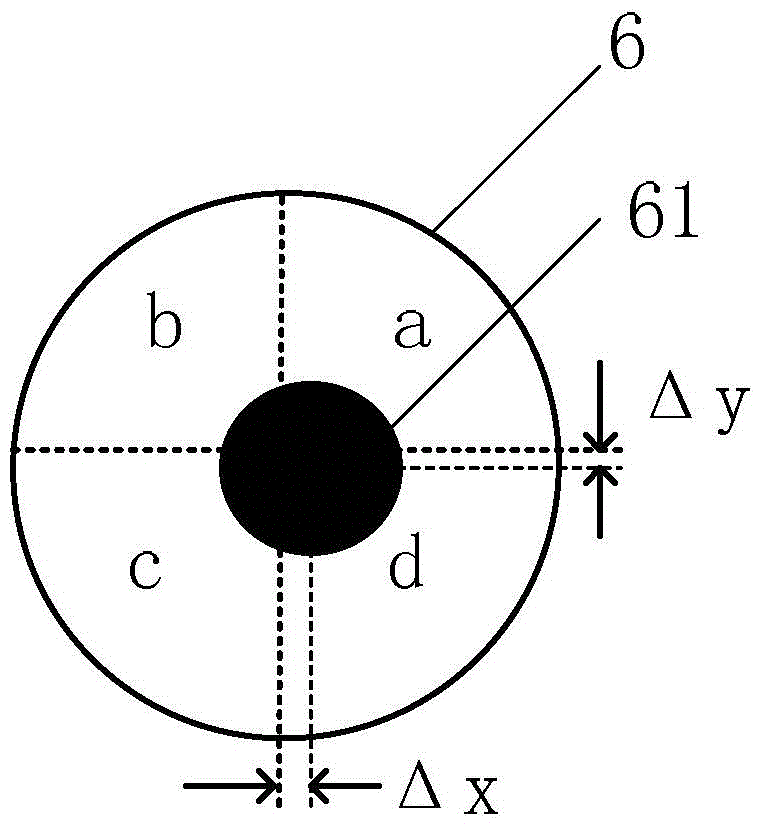

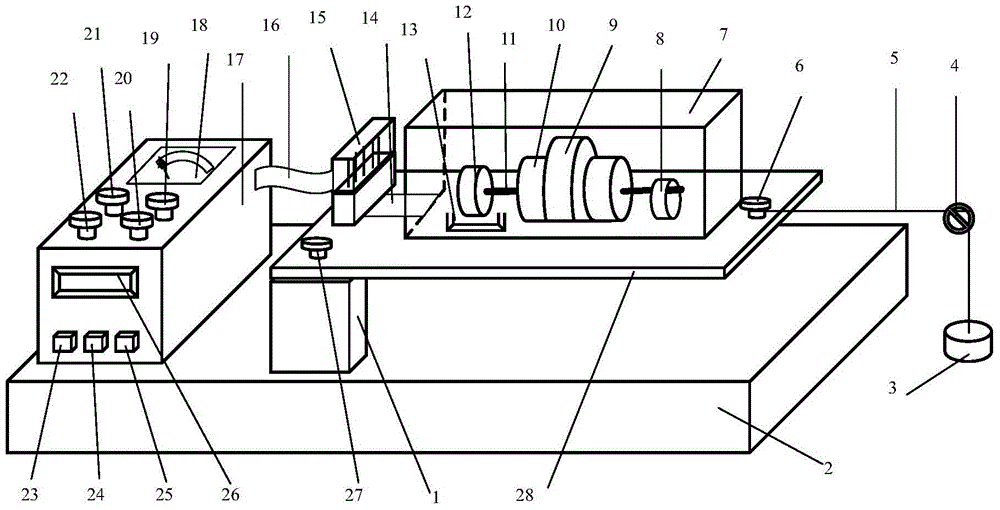

Device and method for detecting vibration performance parameters of a curtain wall panel earthquake simulation system

ActiveCN103822767BStable vibration frequencyEasy to measureVibration testingFour quadrantsComputer module

The invention relates to a curtain wall panel earthquake simulation system vibration performance parameter detection device and a method thereof. The detection device includes a vibration table, a fixing base, three laser light sources and three four-quadrant laser detectors, three sets of current and voltage conversion modules, three sets of computation modules, three sets of analog-to-digital converters and a micro controller; a motor is arranged inside the vibration table; the fixing base is in the shape of a cube; three surfaces of the fixing base which are perpendicular to an X axis, a Y axis and a Z axis are provided with a light reflecting plate respectively; the fixing base is in rigid connection with the vibration table through a connection rod; the three laser light sources are arranged above and opposite to the light reflecting plates respectively; and the three four-quadrant laser detectors are respectively arranged above and are opposite to the light reflecting plates. With the curtain wall panel earthquake simulation system vibration performance parameter detection device and the method thereof of the invention adopted, fast and accurate detection of vibration table high-frequency vibration performance parameters can be realized, and therefore, the problem of insufficient detection accuracy is high frequency vibration in an earthquake simulation system can be solved.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +2

String Vibration Velocity Tester Using Vibration Motor as Wave Source and Its Operation Method

InactiveCN104318824BChange vibration frequencyImprove vibrationEducational modelsElectricityMotor speed

The invention provides a string vibration speed measurement experiment instrument with a vibration motor as a wave source. The string vibration speed measurement experiment instrument with the vibration motor as the wave source aims to solve the technical problems that according to an existing string vibration experiment instrument, an equipment structure is complicated, manufacturing cost is high, a dead zone exists during an experiment, the experiment efficiency is low, and the demonstration effect is poor. The string vibration speed measurement experiment instrument comprises an experiment instrument body. A base is arranged at the bottom of the experiment instrument body, and a vibration motor assembly is installed on the experiment instrument body. The vibration motor assembly is installed on a supporting stand column through a fixing flat plate. The vibration motor is installed in the vibration motor assembly. An eccentric block is installed on the right side of an outer rotating shaft of the vibration motor. A speed measurement disk and a photoelectric door are installed on the left side of the outer rotating shaft of the vibration motor. A direct-current power source speed measurement instrument is installed on the right side of the base. A voltage adjusting and frequency adjusting power source and a motor speed measurement instrument are installed on the direct-current power source speed measurement instrument. The voltage adjusting and frequency adjusting power source is provided with a voltage adjustment and frequency adjustment alternation switch, a power switch and the like. The motor speed measurement instrument is provided with a power supply switch, a frequency switch and the like. When the string vibration speed measurement experiment instrument is used, through the steps of power source connection, voltage adjustment and the like, the string vibration frequency is obtained by measuring the vibration frequency with the vibration motor as the wave source finally. According to the string vibration speed measurement experiment instrument with the vibration motor as the wave source, the structure is reasonable, and an operation method is easy to grasp.

Owner:SHENYANG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com