Solid-liquid separator

A technology of solid-liquid separator and transmission, which is applied in the direction of filtration separation, separation method, wellbore/well parts, etc., which can solve the problems of out-of-synchronization of plane vibration and large noise of sieve plugging screen, and achieve enhanced screening effect, Reduce working noise and prevent screen blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

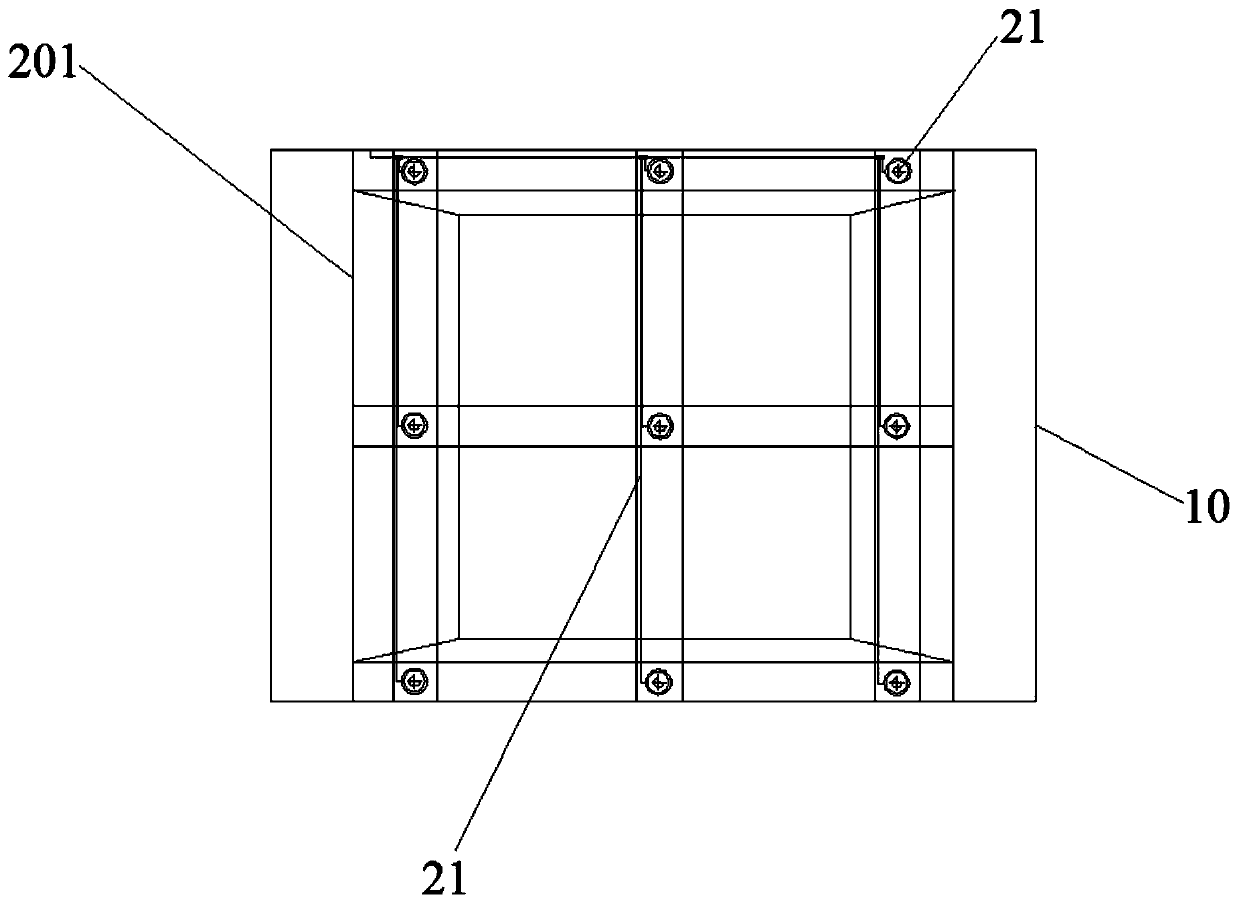

[0015] Embodiment 1 provides a solid-liquid separator in which pneumatic vibrators are arranged in a nine-square pattern, and its structure will be described in detail below.

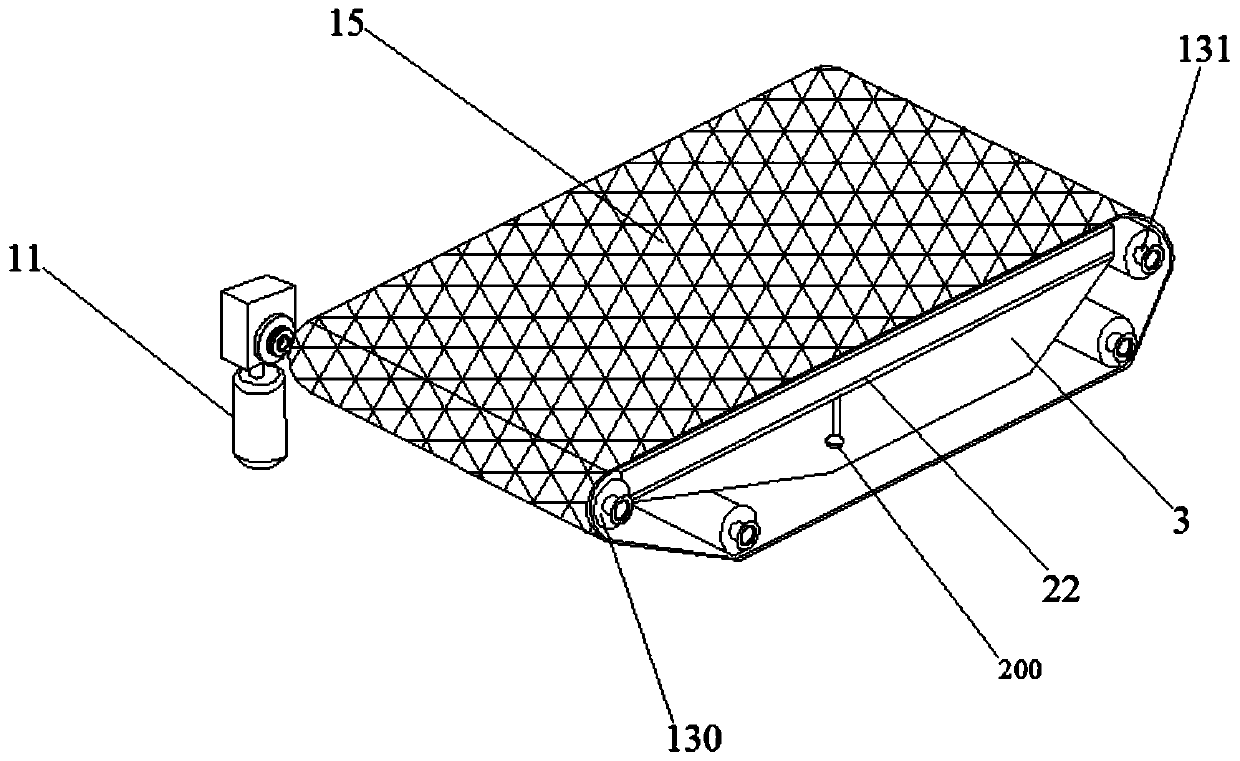

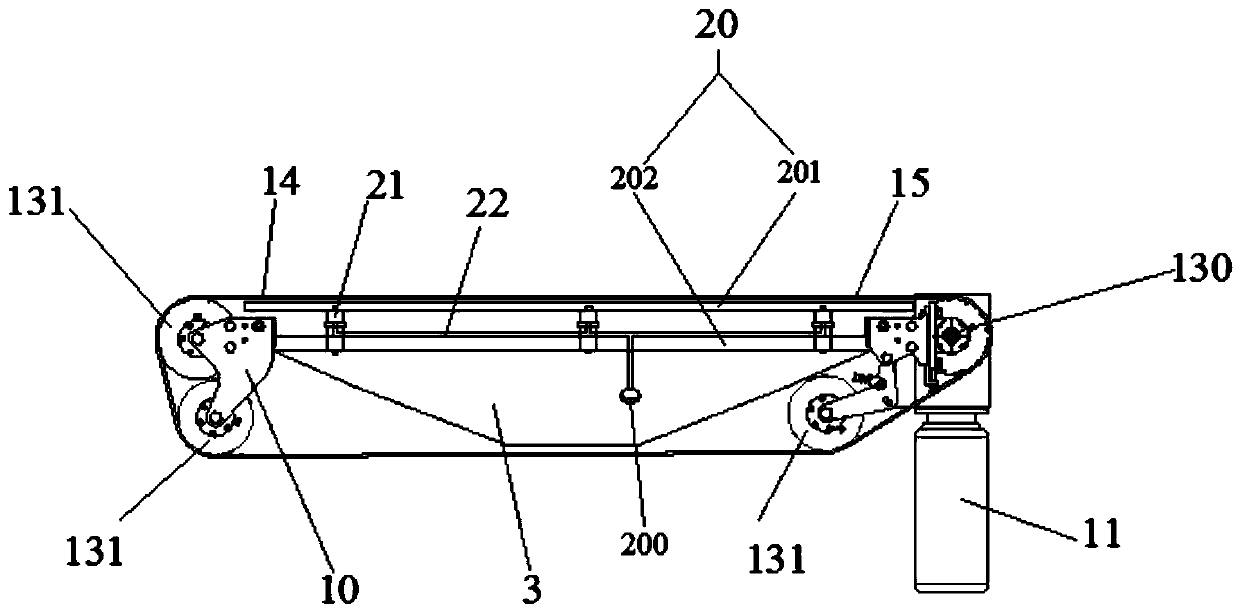

[0016] refer to figure 1 and figure 2 , the solid-liquid separator includes a transmission mechanism, a vibration mechanism and a charging box 3.

[0017] The transmission mechanism comprises a transmission case 10, a drive motor 11, a main rotating roller 130, three auxiliary rotating rollers 131, a transmission belt 14 and a screen cloth 15,

[0018] The main rotating roller 130 and the three auxiliary rotating rollers 131 are arranged horizontally at the four corners of the transmission case 10 respectively, and the four points of the vertical section are connected from head to tail in order to form a trapezoid with the upper bottom facing downward and the lower bottom facing upward.

[0019] The output shaft of the driving motor 11 is provided with a bevel gear, and the main rotating roller 130 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com