A Time Grating Linear Displacement Sensor

A linear displacement and sensor technology, applied in the direction of instruments, measuring devices, electrical devices, etc., can solve problems affecting the measurement accuracy of sensors, complex sensor structures, and complicated winding methods, and achieve simple structure, easy productization, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

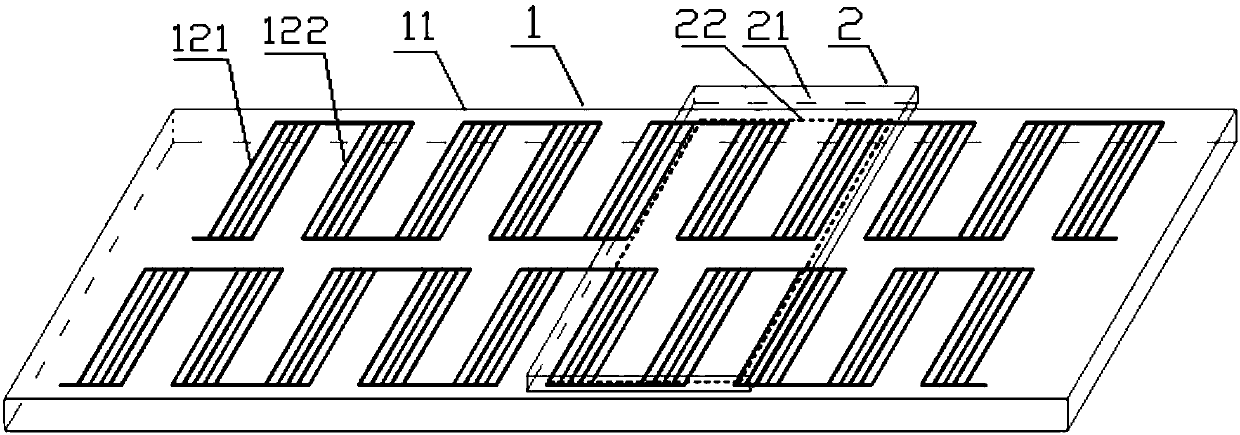

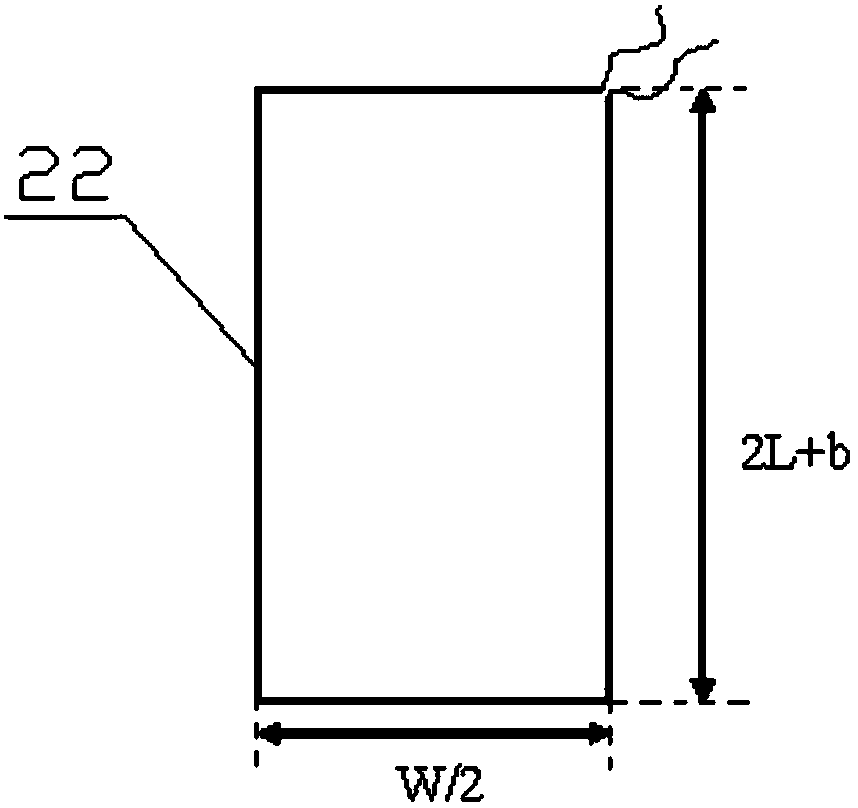

[0039] Embodiment 1: as figure 1 , figure 2 , image 3 The time grating linear displacement sensor shown includes a fixed scale 1 and a moving scale 2, and the moving scale 2 is directly opposite to the fixed scale 1 in parallel with a gap of 0.1 mm.

[0040] The fixed length 1 is made up of the fixed length base 11 and the excitation unit fixed on the surface of the fixed length base 11. The fixed length base 11 is a rectangular parallelepiped magnetic material base, and the long side direction of the fixed length base 11 is the measurement direction (i.e. The direction of motion of the ruler), the excitation unit is a printed circuit board with two insulating layers and an excitation coil layer, the surface area of the fixed-length substrate 11 is greater than the coverage area of the excitation coil layer, and there is a margin in four directions.

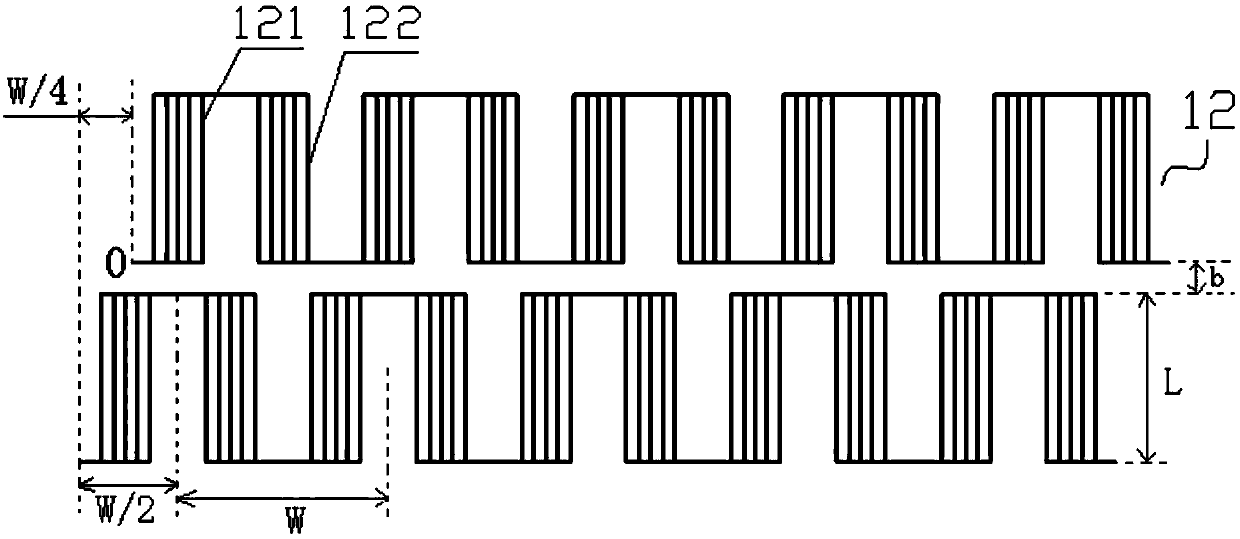

[0041] Such as figure 2 As shown, the excitation coil layer is composed of two identical and parallel excitation coil...

Embodiment 2

[0050] Embodiment 2: Most of the structures of the time grating linear displacement sensor in this embodiment are the same as in Embodiment 1, except that the excitation unit is a printed circuit board with 4 insulating layers and 3 above-mentioned excitation coil layers, 4 An insulating layer and three excitation coil layers are arranged at intervals along the direction perpendicular to the surface of the fixed-length substrate 11, and the three excitation coil layers are connected in parallel with each other through via hole wiring, which improves the magnetic field strength of the fixed length; the induction unit has A printed circuit board with 4 insulating layers and 3 above-mentioned induction coil layers, the 4 insulating layers and 3 induction coil layers are arranged at intervals along the direction perpendicular to the surface of the moving scale base 21, and the 3 induction coil layers are connected through via holes The way of connecting each other in series improve...

Embodiment 3

[0051] Embodiment 3: as Figure 4 As shown, most of the structures of the time grating linear displacement sensor in this embodiment are the same as in Embodiment 1, the difference is that the induction coil layer is composed of a first induction coil line array arranged on a printed circuit board, and the first induction coil An induction coil line array is composed of two identical second rectangular coils 23 connected in series along the measuring direction. The width of each second rectangular coil 23 along the measuring direction is W / 2-c, and the length perpendicular to the measuring direction is 2L+ b, two second rectangular coils 23 are located on one wiring layer, the center distance is W / 2 and the winding direction is opposite, and the lead-out wires of the two second rectangular coils 23 are located on another wiring layer, where c represents two adjacent Minute spacing between the second rectangular coils 23 .

[0052] The two excitation coil arrays 12 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com