Nano-sensing method and device based on contact/non-contact composite principle

A sensing method, non-contact technology, applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problem of not giving the mechanical structure of the probe, signal transmission shielding interference, and the inability to realize the actual engineering measurement of large aspect ratio structures, Problems such as inability to measure non-conductor DUTs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

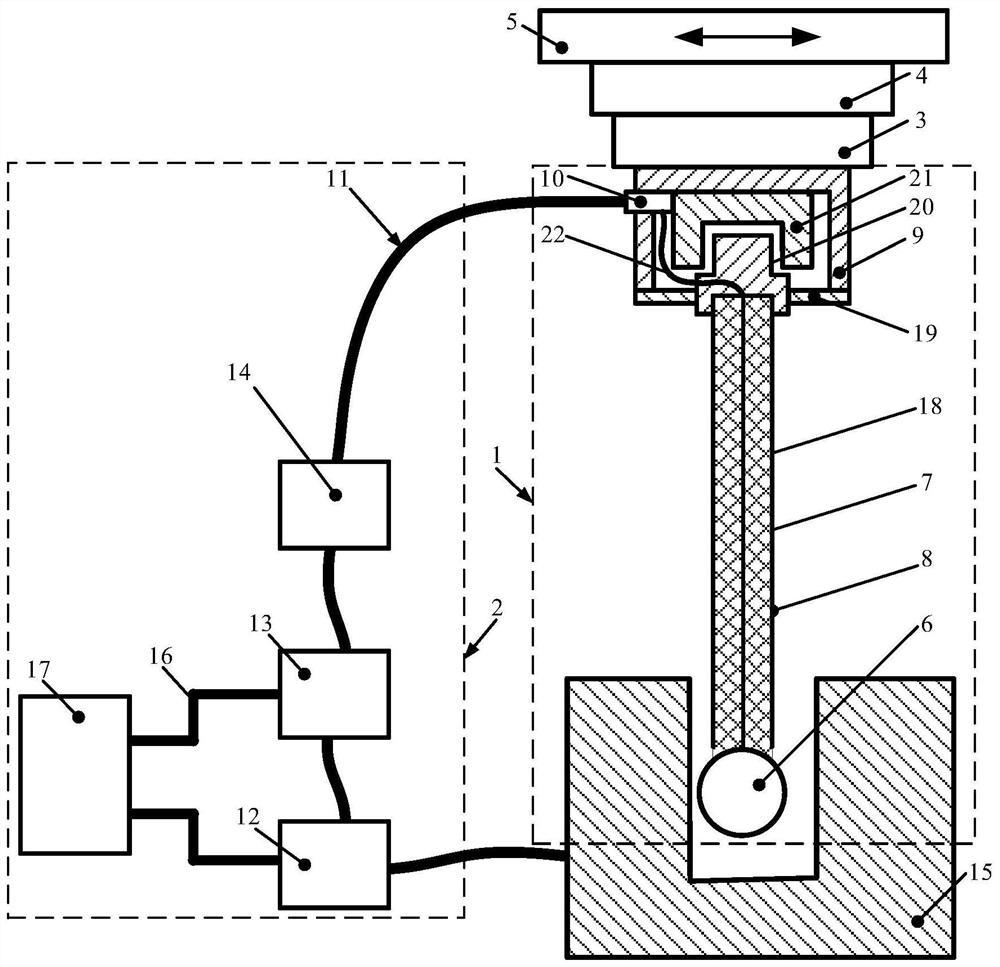

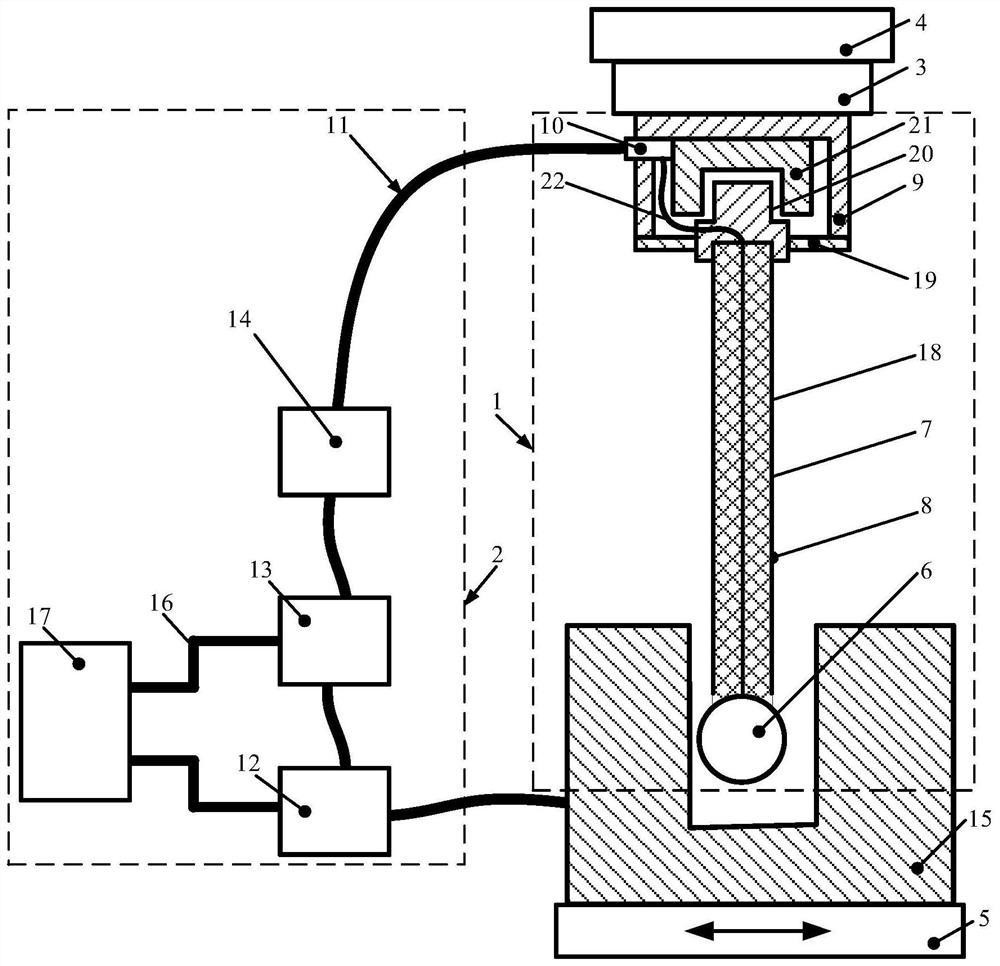

[0038] figure 2 As another embodiment of the present invention, the measurement drive mechanism 5 drives the object under test 15 . Fix the test piece 15 on the measurement drive mechanism 5, and the test drive mechanism 5 drives the test piece 15 close to the micro-probe 6 of the composite principle probe 1 to complete the measurement. The composite principle probe 1 is connected and fixed with the probe attitude adjustment mechanism 3 and the anti-collision safety protection mechanism 4, and can be installed on the Z-axis motion mechanism of the coordinate machine for easy measurement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com