Patents

Literature

264results about How to "Easy to productize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

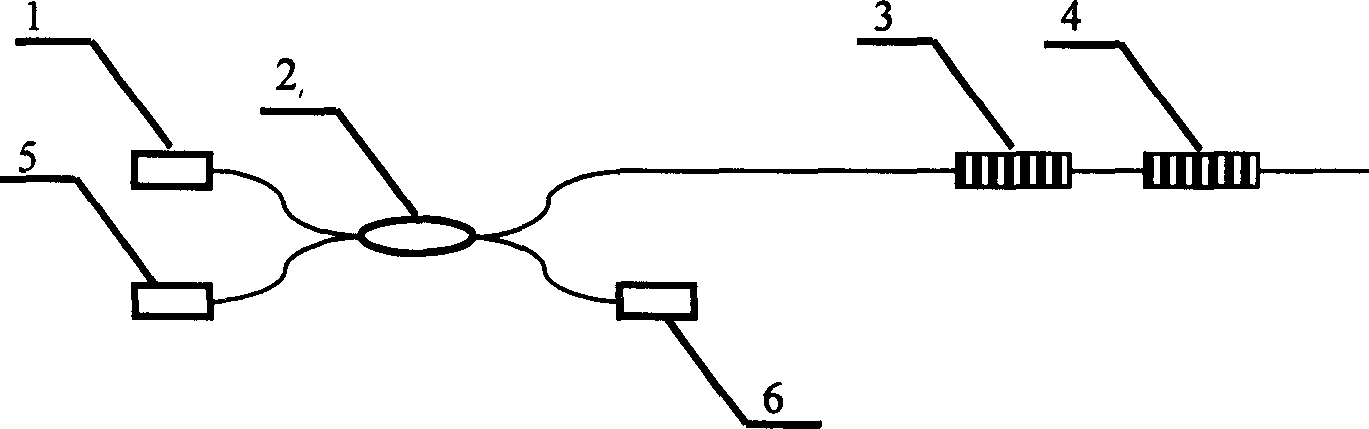

High precision optical fiber grating wave length demodulation system

InactiveCN101586986AAccurately achieve calibrationQuick responseOptical measurementsConverting sensor output opticallyGratingPhotodetector

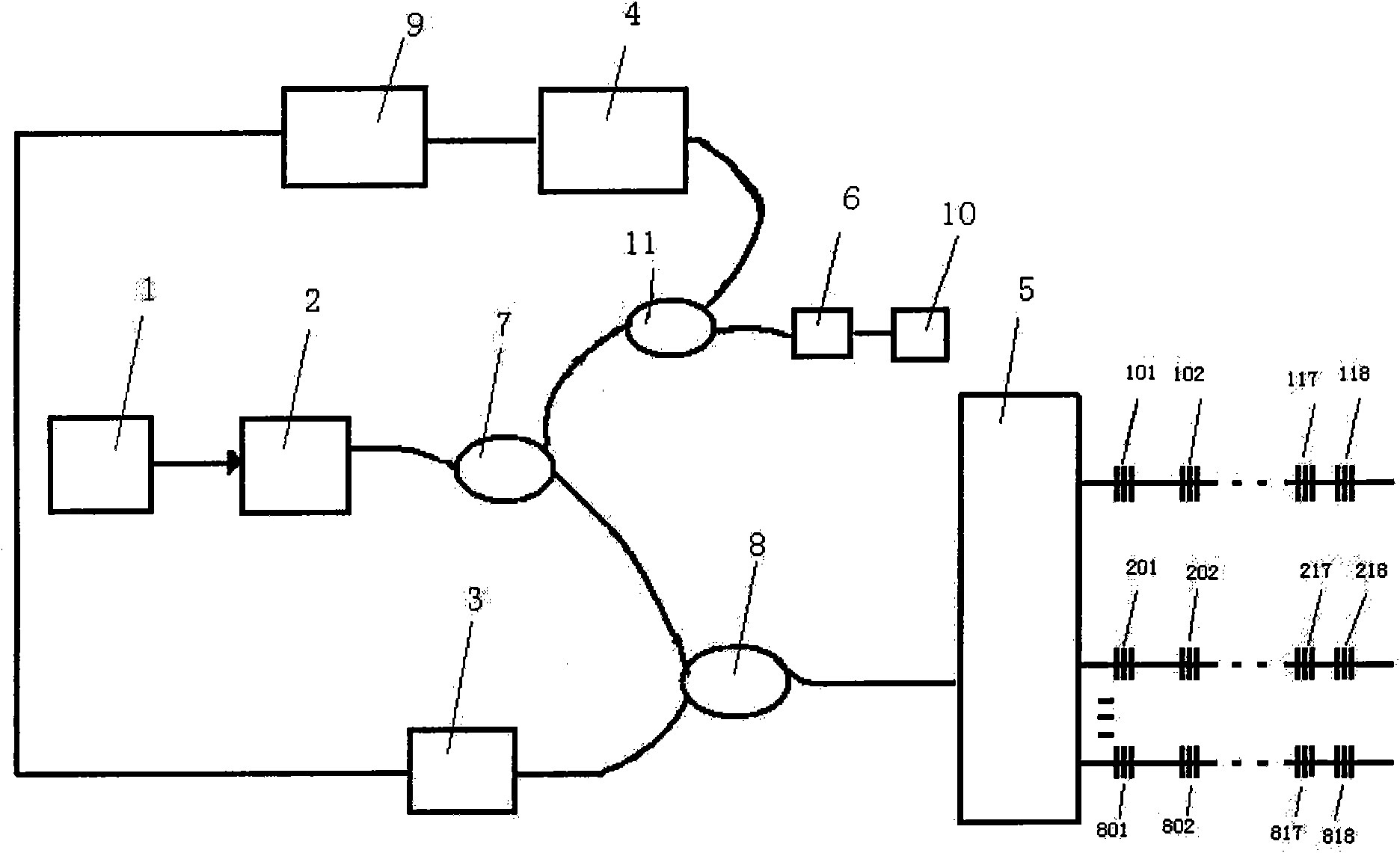

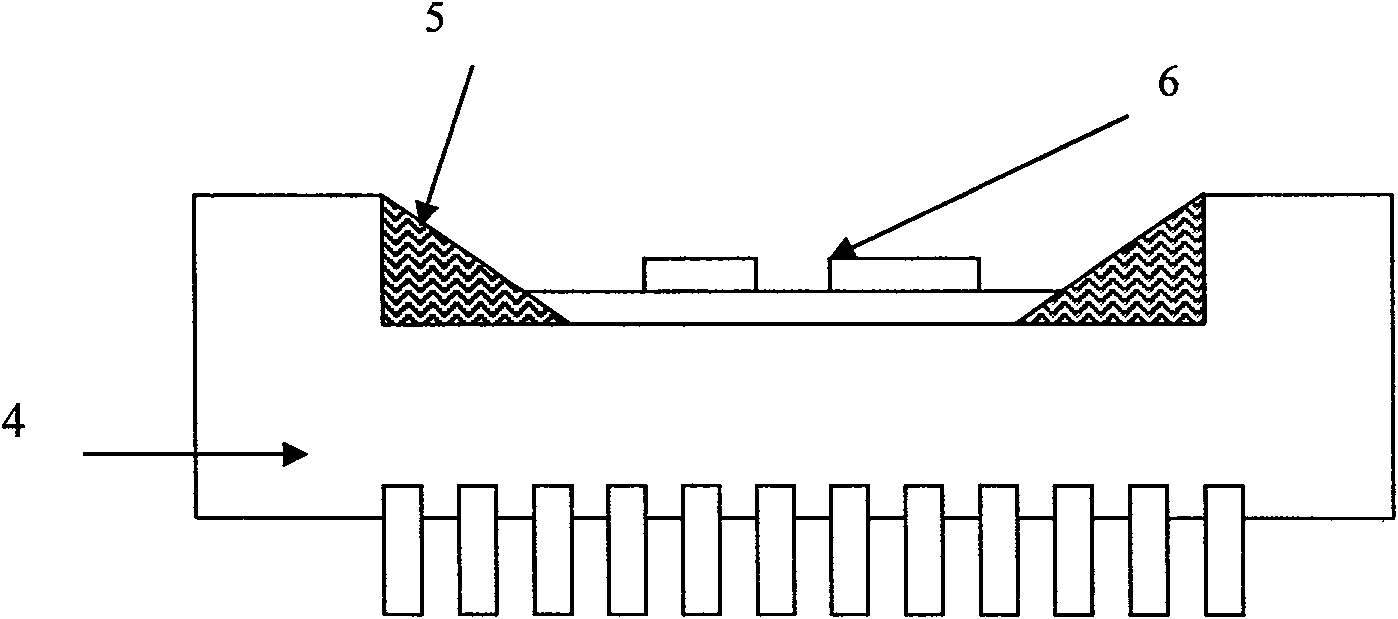

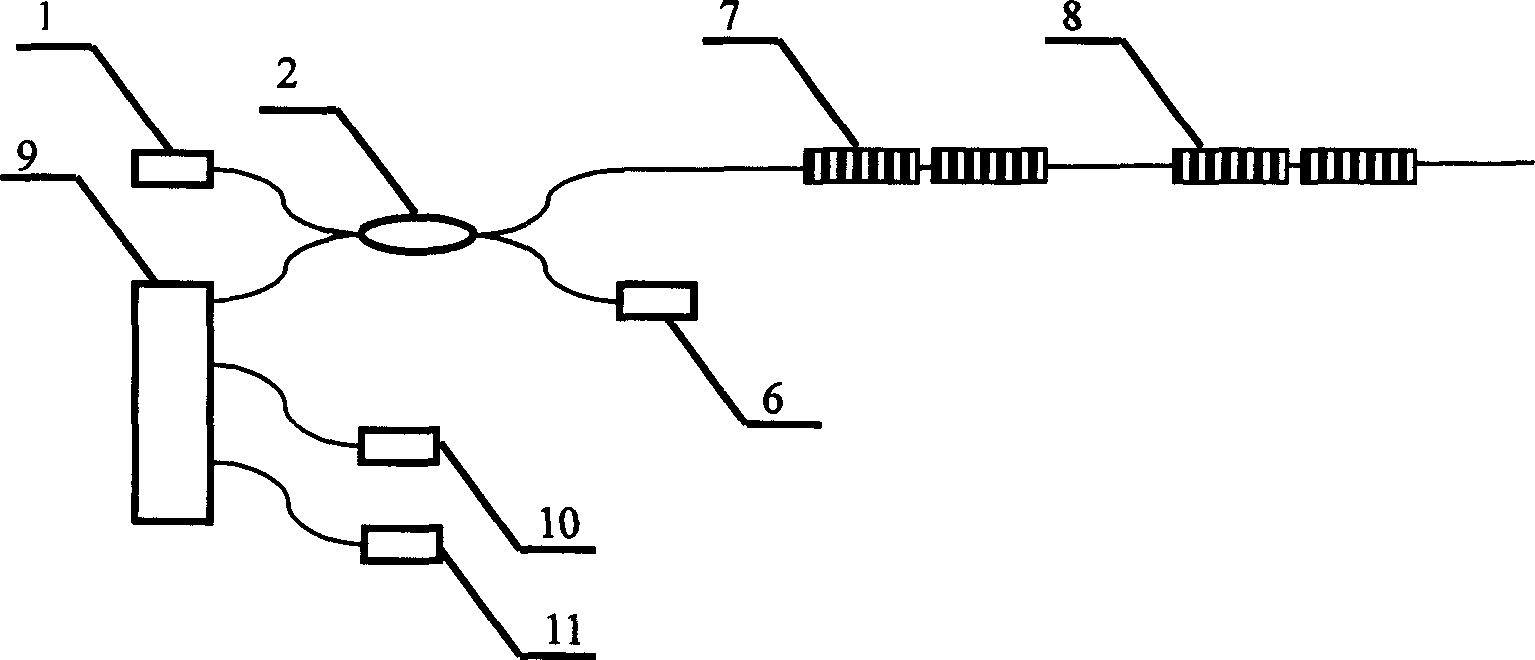

An optical fiber grating wave length demodulation system belongs to the technical field of optical fiber sensing and optical measurement. The demodulation system comprises a broad band light source (1), a tunable filter (2), a 1x2 coupler, a wave length calibration module, a photodetector, a 1xN optical switch (5) and a signal processing system. The inside connection of the wave length calibration module is that: one end of a standard tool filter (6) is connected with an output end of a third 1x2 coupler (11)m the other end of the standard tool filter is connected with a reference grating (10), an input end of the third 1x2 coupler is connected with an output end of a first 1x2 coupler; the other output end of the third 1x2 coupler is connected with a signal processing system (9) by a second photodetector (4) to implement the wave length calibration. The calibration of the reflected optical fiber grating wave length can be implemented rapidly and accurately by the standard tool filter and the reference grating, the signal can be effectively demodulated for high precision. The system also can be used for monitoring temperature and stress and so on physical quantities.

Owner:BEIJING JIAOTONG UNIV

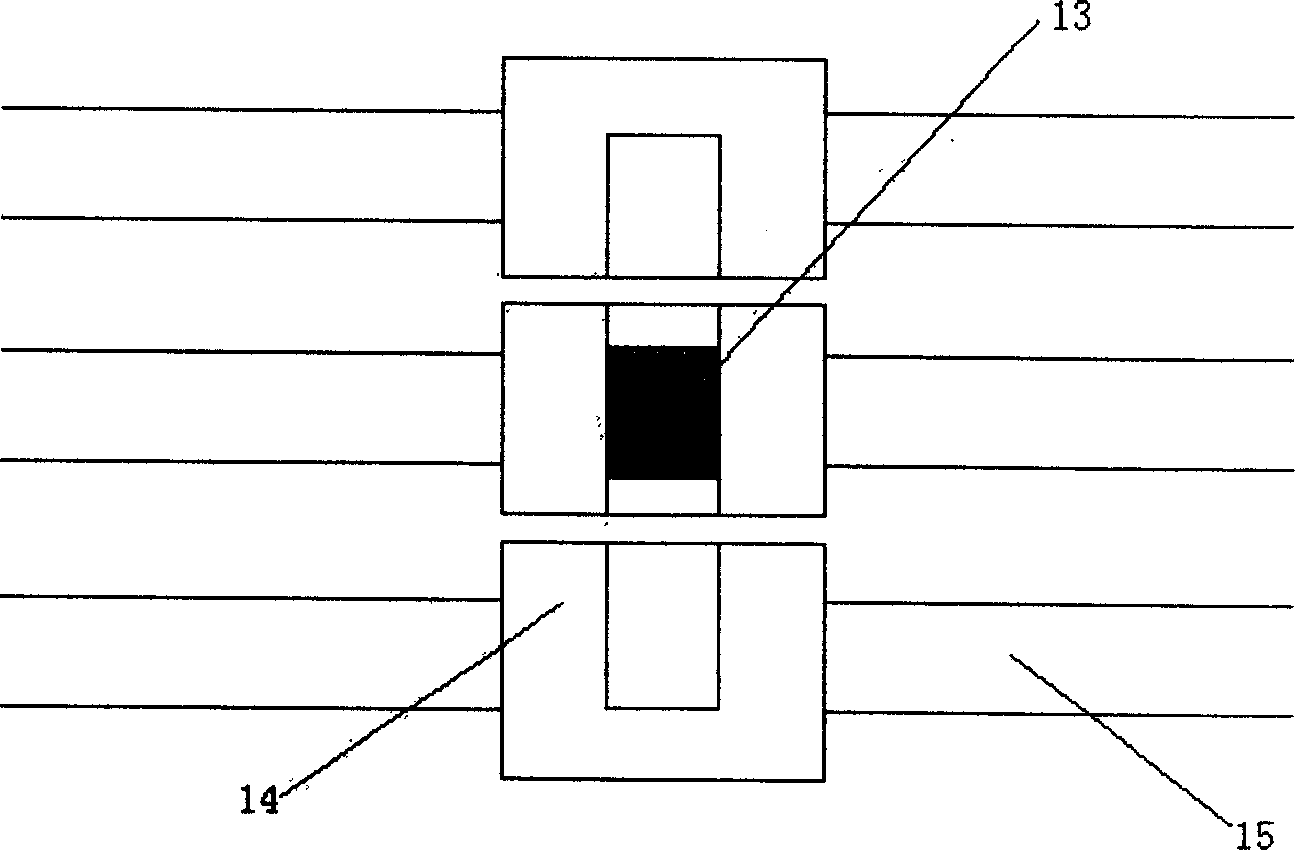

Microelectrode array chip sensor for electrochemical immunological detection

InactiveCN101609063AImprove signal-to-noise ratioImprove stabilityTelevision system detailsImpedence networksPhysicsSignal-to-noise ratio (imaging)

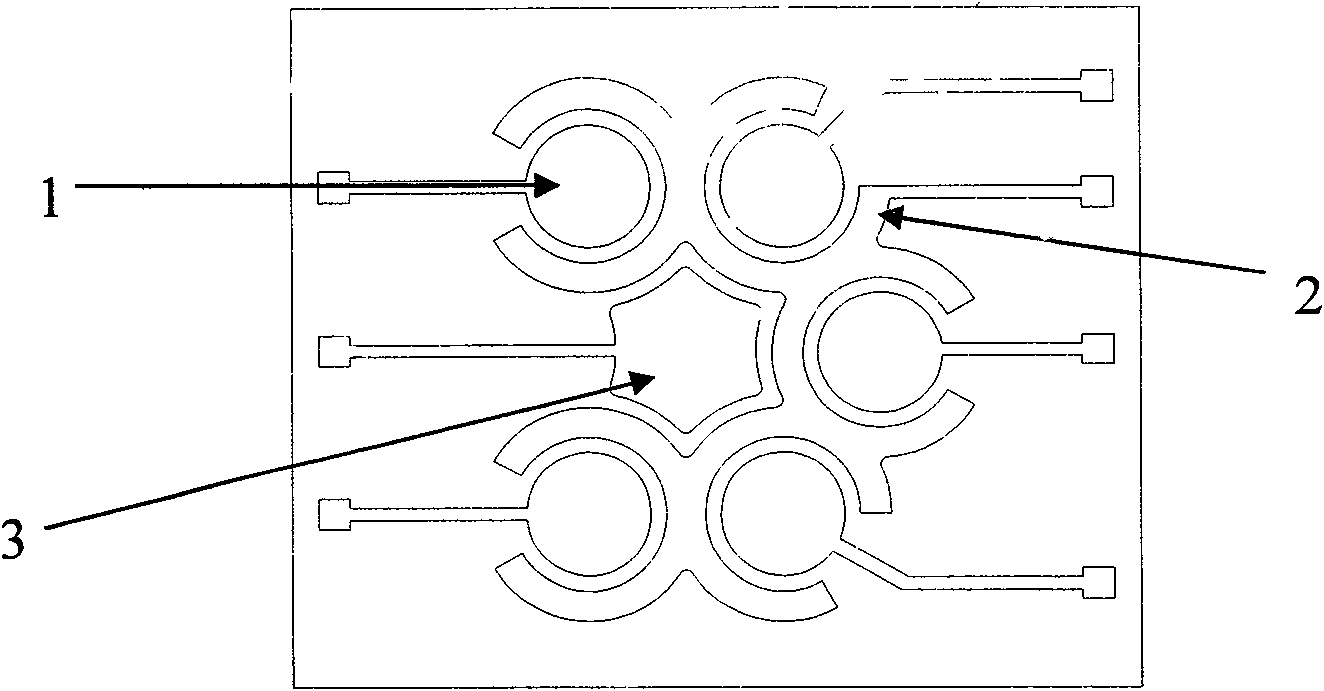

The invention belongs to the technical field of sensors, in particular to a microelectrode array chip sensor for electrochemical immunological detection. The invention uses silicon-based material to carry out manufacturing; and a chip integrates an electrochemical detected working electrode, an auxiliary electrode and a reference electrode, which has a good signal to noise ratio. The auxiliary electrode and the working electrode form a ring-disk structure, and the distance between the auxiliary electrode and the working electrode is small, thereby improving the sensitivity of the electrodes. The array distribution of a plurality of working electrodes can be used for multi-channel detection. The invention can be widely used for detection in various fields such as biological medicine and the like. The sensor is manufactured by using MEMS process, and has simple process and low cost.

Owner:FUDAN UNIV

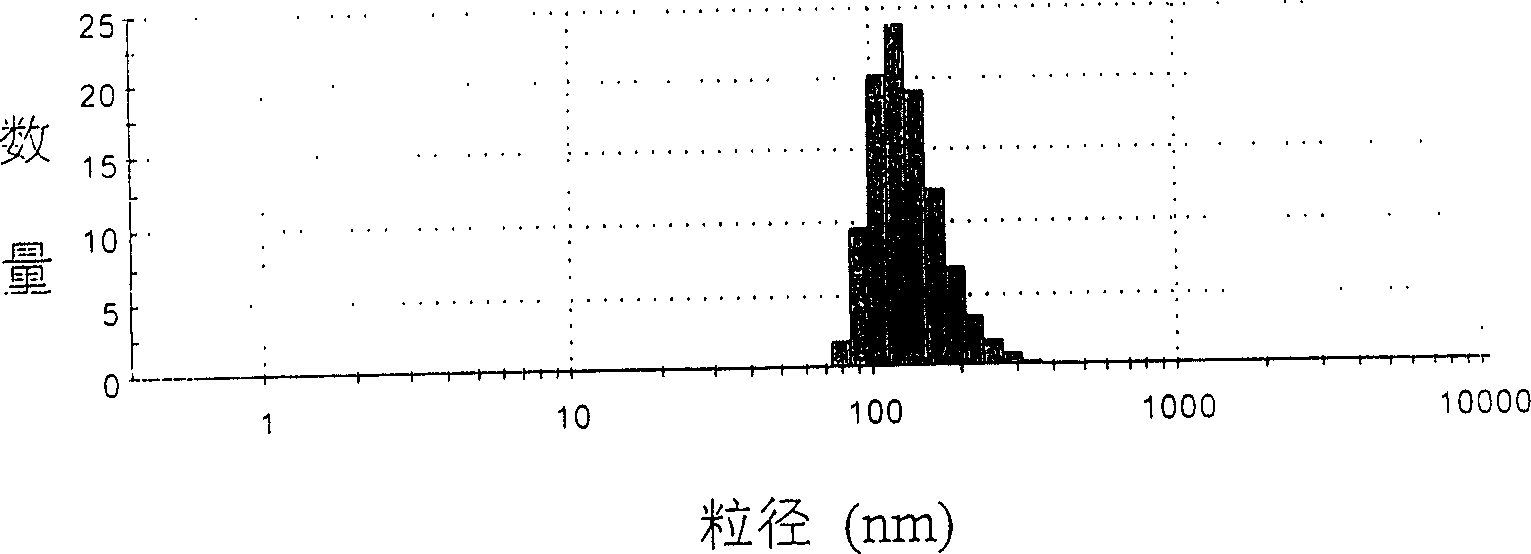

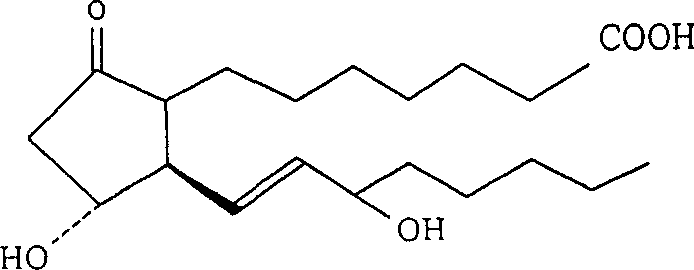

Nano emulsion injection of alprostadil and preparation method

InactiveCN1872072AImprove solubilityImprove stabilityOrganic active ingredientsEmulsion deliveryIsoprostaglandin E1Curative effect

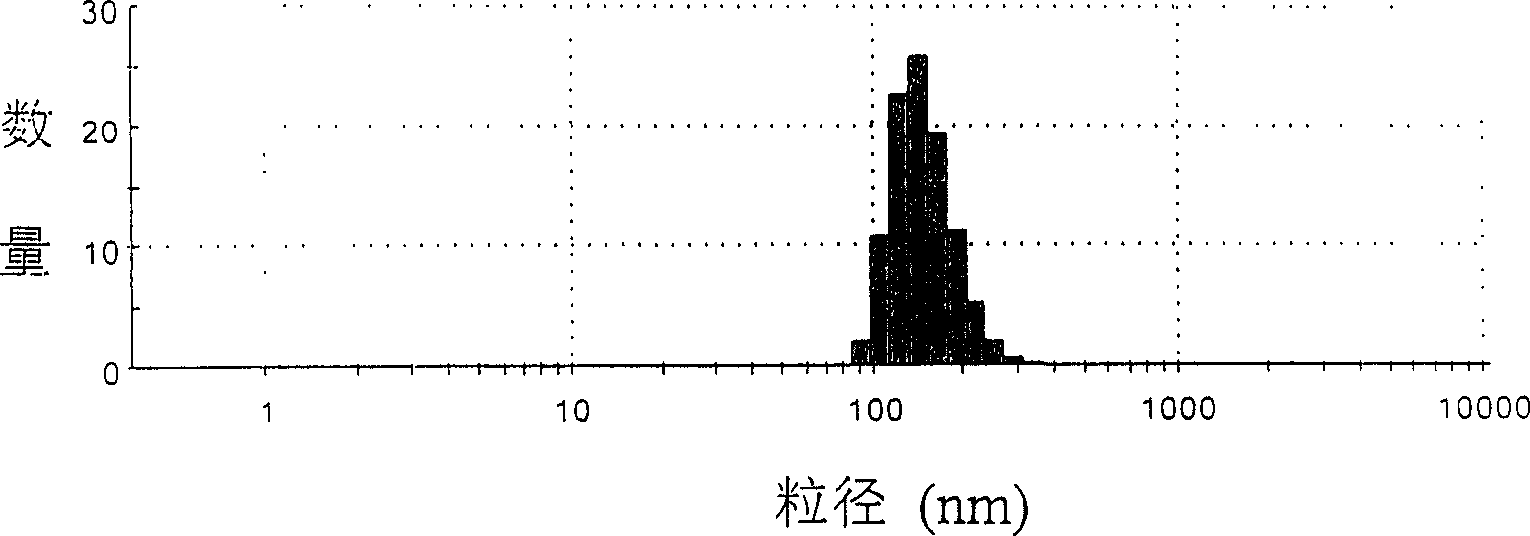

A nano-emulsion injection of prostaglandin E1 contains the nano-emulsion particles of rostaglandin E1, the oil for injection, hydrophilic emulsifier, lipophilic emulsifier, isotonic agent, and stabilizer. Its preparing process and its quality control method are also disclosed.

Owner:广州中大创新药物研究与开发中心有限公司

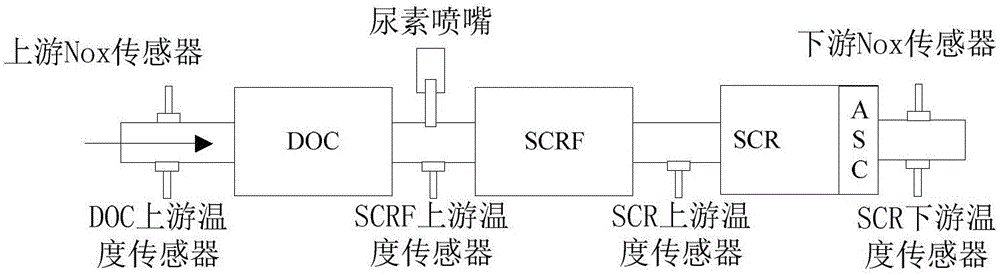

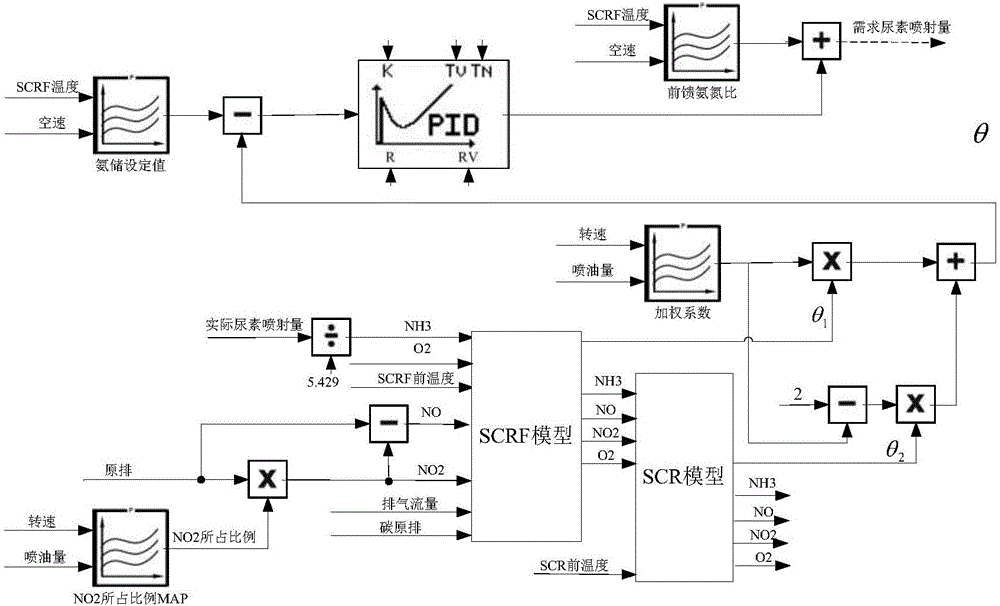

Model-based urea emitting amount control method and aftertreatment control system

ActiveCN106837480AJet Precise ControlStrong control adaptabilityInternal combustion piston enginesExhaust apparatusCycle controlAmmonia storage

The invention relates to a model-based urea emitting amount control method. The method includes the following steps that S1, according to the actual urea emitting amount, based on an SCRF model, a first ammonia storage value in an SCRF is calculated; S2, based on an SCR model, a second ammonia storage value in an SCR is calculated; S3, the first ammonia storage value obtained in the step S1 and the second ammonia storage value obtained in the step S2 are subject to weighted treatment to obtain an actual ammonia storage value; S4, a difference is obtained from the actual ammonia storage value obtained in the step S3 and an actual storage setting value, and a closed-cycle correction ammonia nitrogen ratio is obtained through a PID controller; and S5, the sum of the closed-cycle correction ammonia nitrogen ratio obtained in the step S4 and a feedforward ammonia nitrogen ratio is obtained to be finally converted into the needed urea emitting amount. According to the model-based urea emitting amount control method, a model-based closed-cycle control strategy is adopted, accurate control over urea emitting can be achieved, the engine emission requirements can be met, standardization work can be reduced, and the problem about crystallization can be solved.

Owner:WEICHAI POWER CO LTD

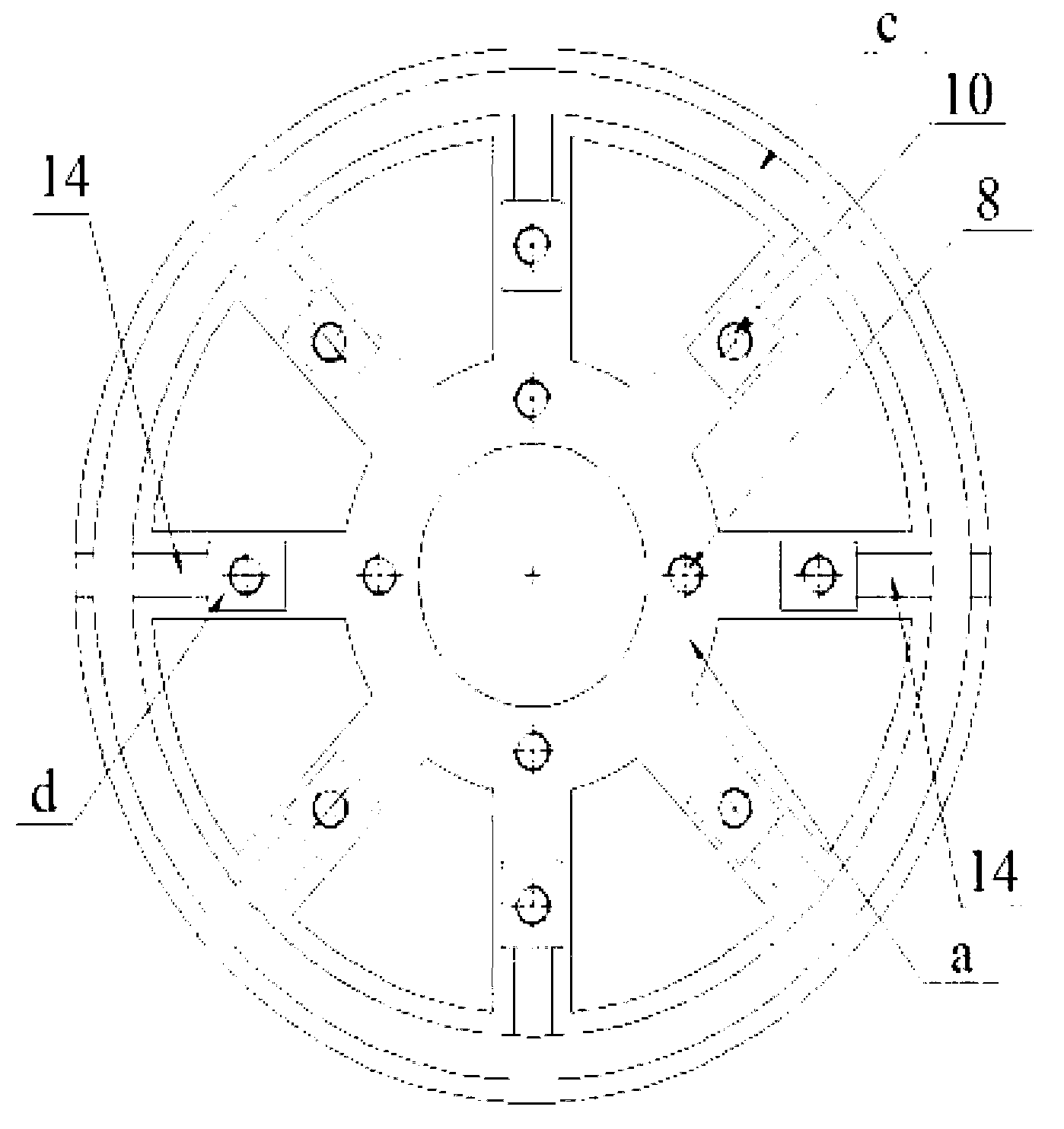

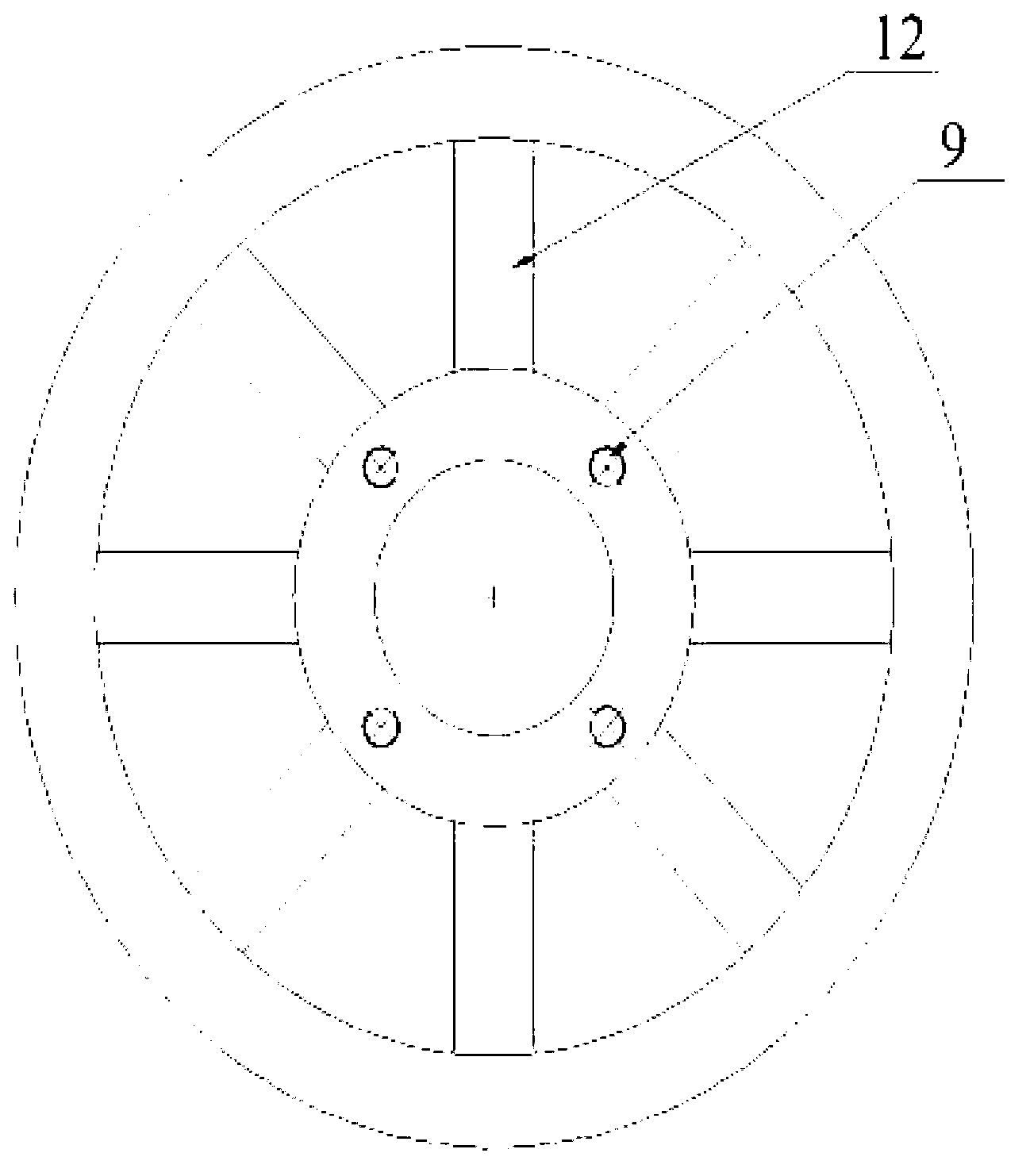

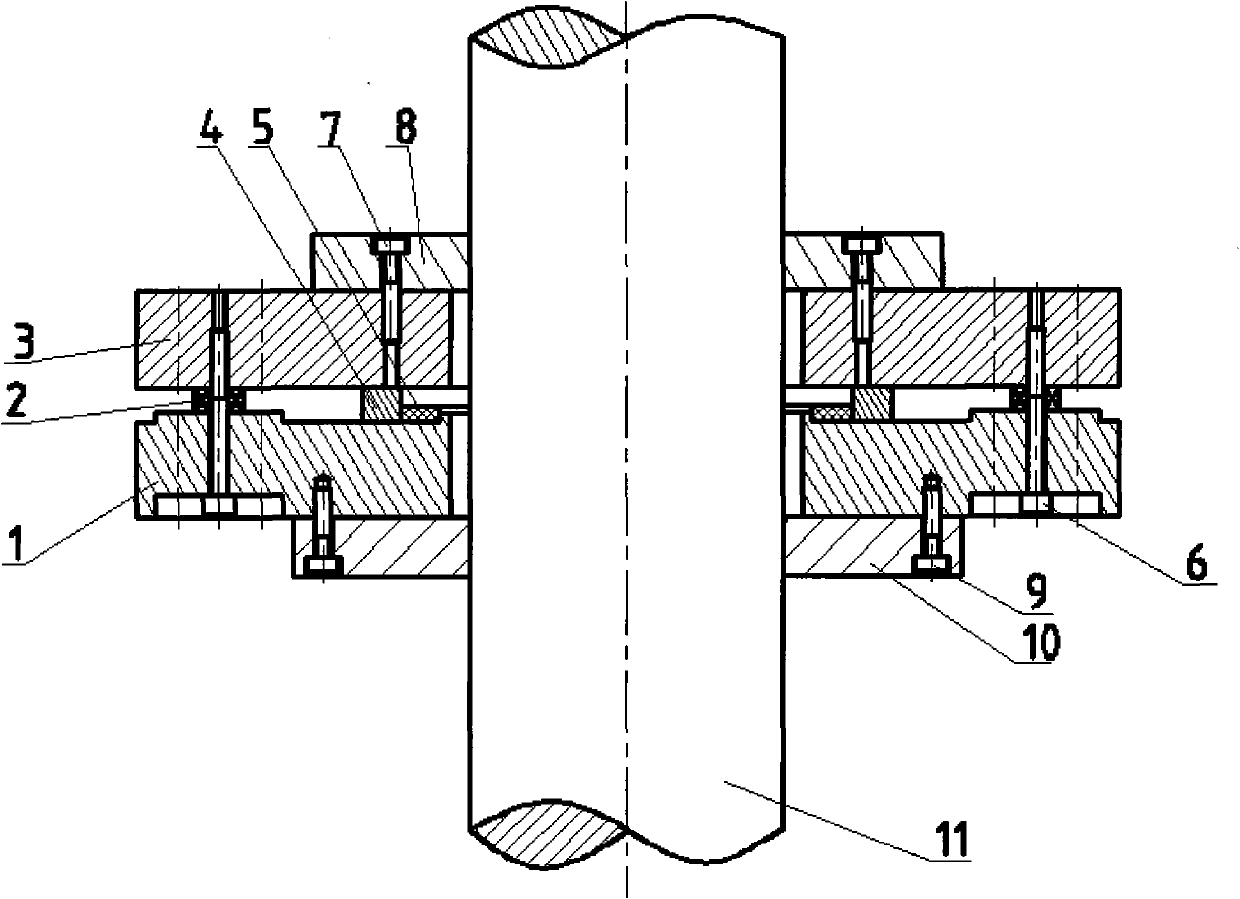

Spoke type parallel piezoelectricity six-dimensional force sensor and measuring method

InactiveCN103196594ASimple structureLow costForce measurement using piezo-electric devicesMeasurement of force componentsEngineeringForce sensor

The invention discloses a spoke type parallel piezoelectricity six-dimensional force sensor and a measuring method. The spoke type parallel piezoelectricity six-dimensional force sensor comprises an upper cover and a lower cover. The spoke type parallel piezoelectricity six-dimensional force sensor is characterized in that a first annular groove is formed in the lower surface of the upper cover, symmetrical wire guiding holes are formed in the lower surface of the upper cover, eight groups of first spokes are evenly distributed on the upper cover in a concentric mode, a second square groove is formed in the lower surface of each spoke, eight groups of second spokes are evenly distributed on the lower cover in a concentric mode, a third groove symmetrical with each corresponding second square groove is formed in the upper surface of each second spoke, a force sensitive element is arranged on the upper surface of each third groove, the upper surface of each force sensitive element is in contact with the surface of each corresponding second square groove, a hollow screw is installed in each wire guiding hole, four first screw holes are evenly formed in the upper cover in a symmetrical and concentric mode, four first screw holes are evenly formed in the lower cover in a symmetrical and concentric mode, and the upper cover, the force sensitive elements and the lower cover are fit together after four pre-tightening screws penetrate through the first screw holes. The spoke type parallel piezoelectricity six-dimensional force sensor is good in manufacturability and stability, easy to manufacture, long in service life, simple in operation, convenient to use, and low in cost.

Owner:UNIV OF JINAN

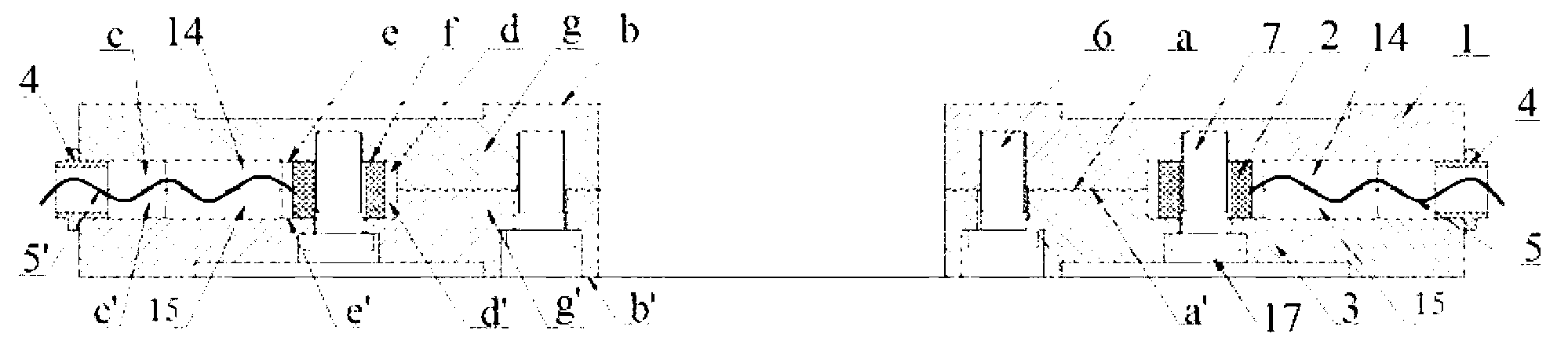

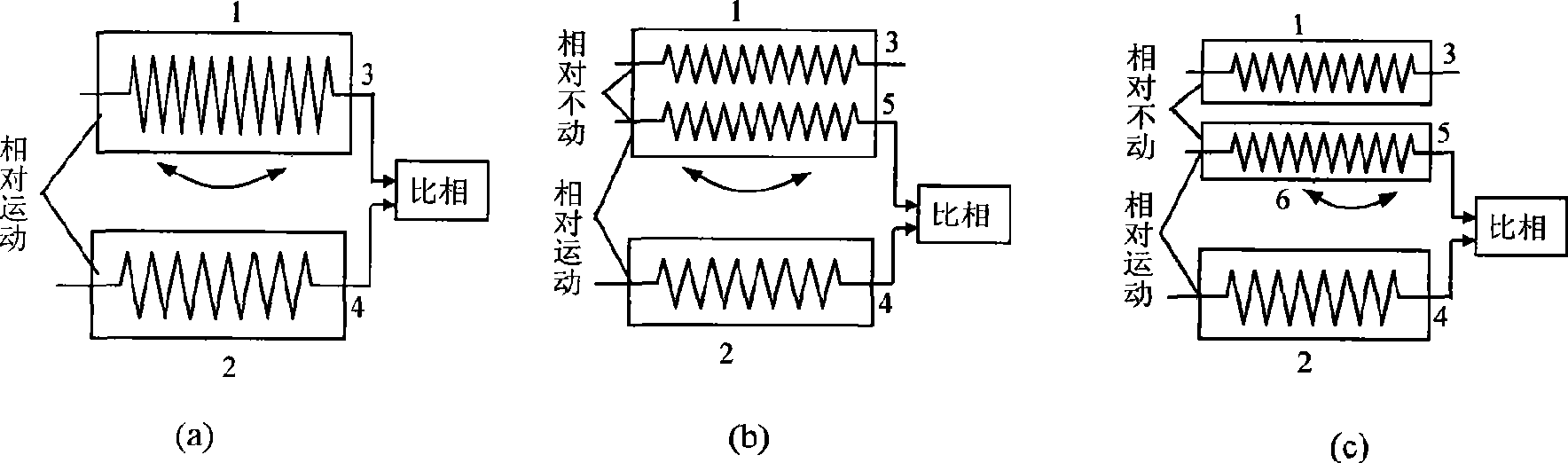

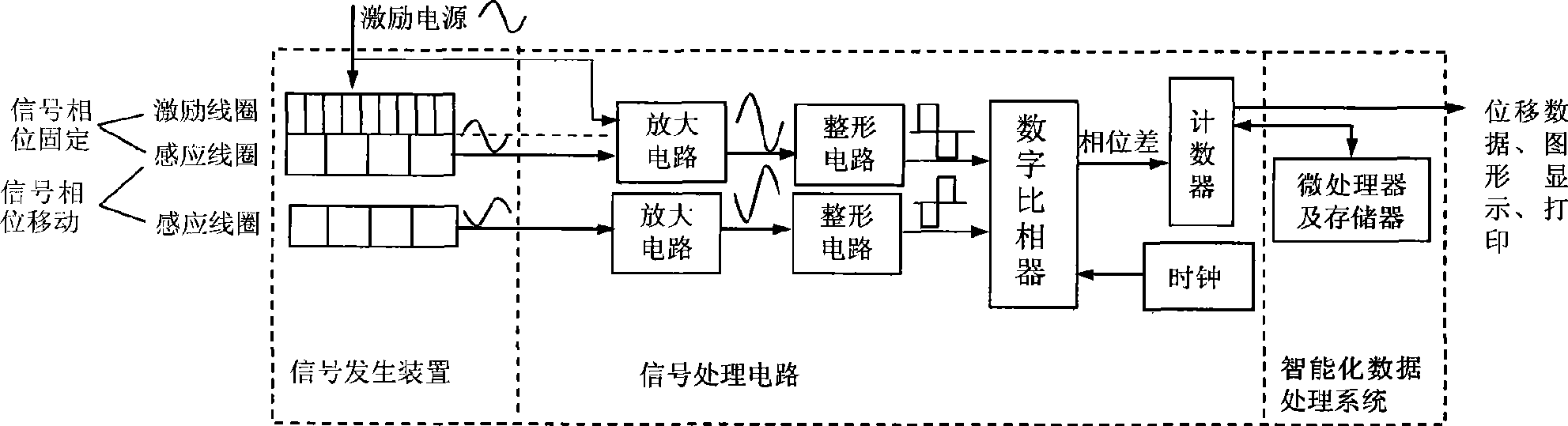

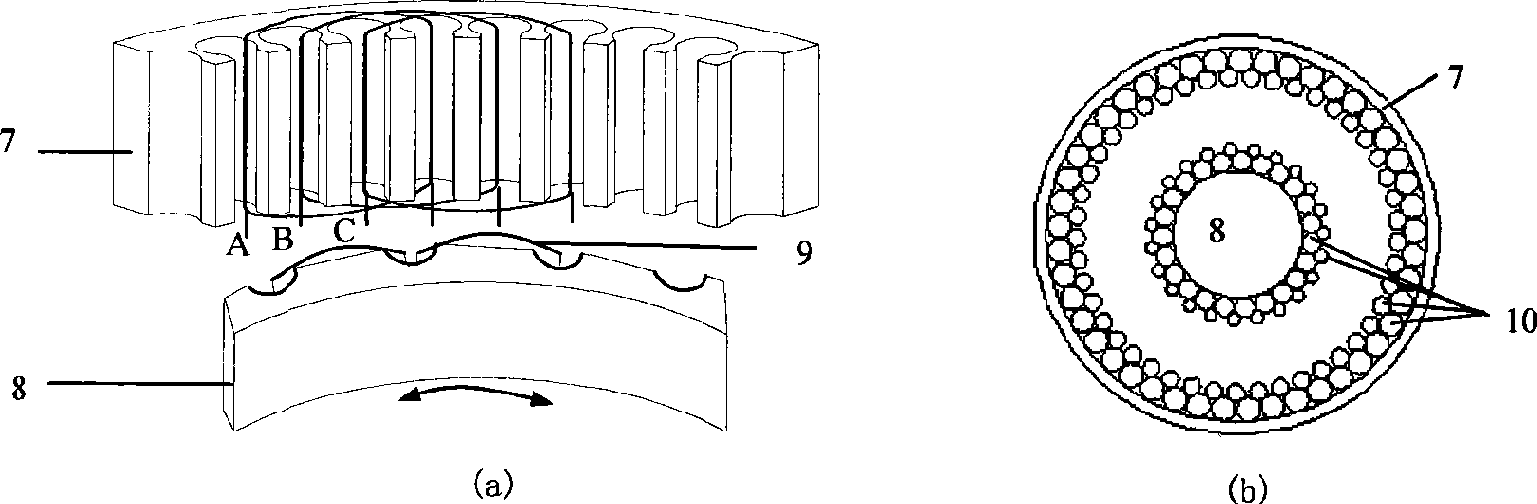

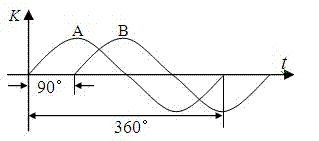

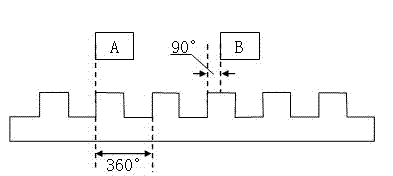

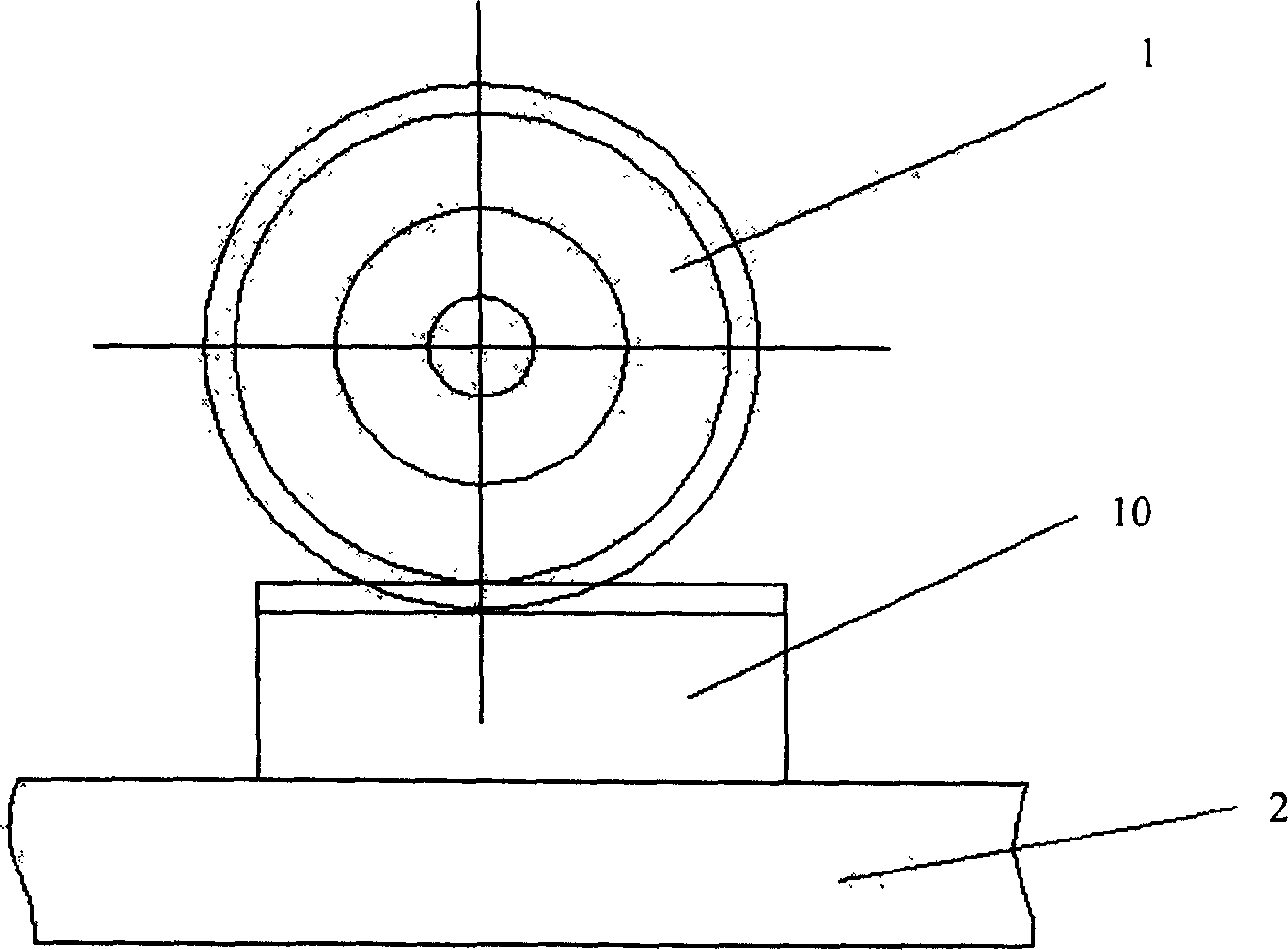

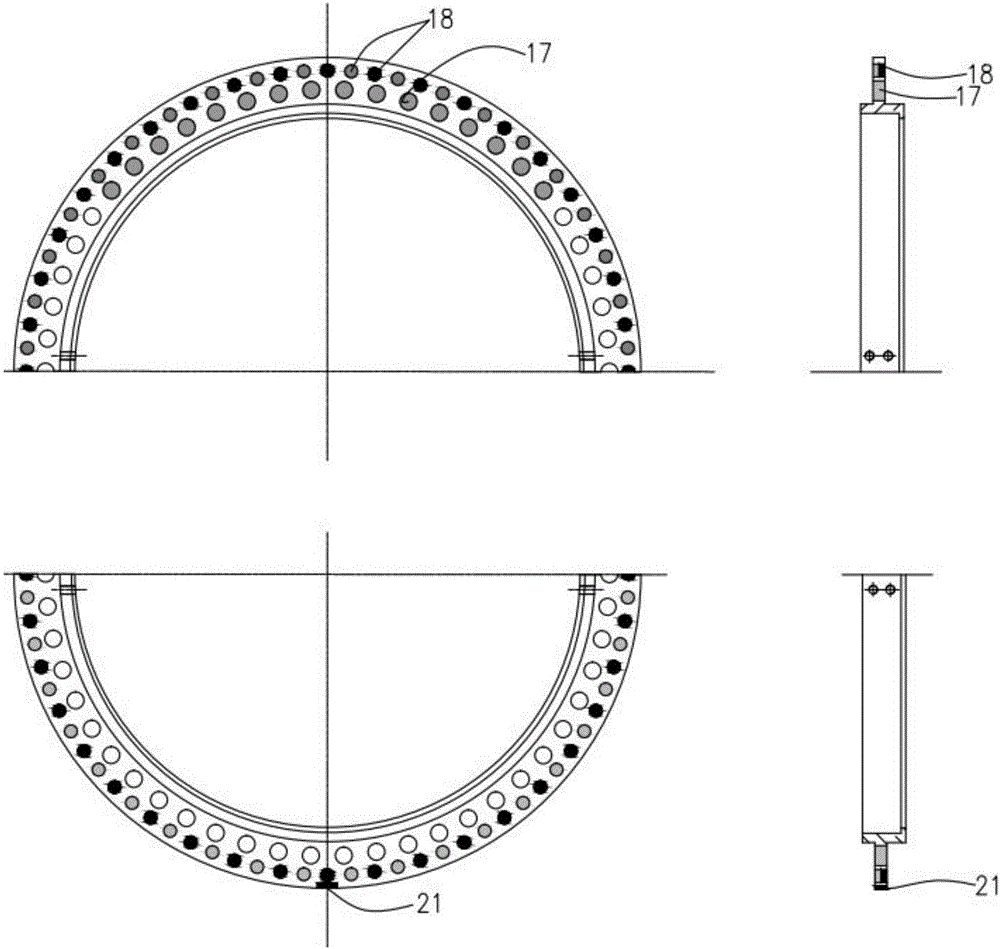

Time gating angular displacement sensor

ActiveCN101363709ASimple structureLow costUsing electrical meansConverting sensor outputTime gatingPhase difference

The invention provides a time grating angular displacement sensor which belongs to displacement precise measuring devices. The sensor comprises a frame which is used for winding a coil and composed of an outer circle matrix and an inner circle matrix; and slots are formed on the inner peripheral wall of the outer circle matrix and the outer peripheral wall of the inner circle matrix at equal intervals. The sensor is characterized in that the excitation coil is wound on the matrix, and the induction coil is wound on the other matrix; the induction coil and the excitation coil carry out the relative motion; the excitation coil is connected with an excitation power supply, an excitation signal and an electric signal which is output by the induction coil are respectively connected to an amplification circuit and subjected to the phase comparison by a digital phase comparator after the shaping by a shaping circuit; and the phase difference of the two signals is represented by the number of interpolated clock pulses, further converted to the angular displacement value and directly or indirectly displayed as the angular displacement data after the treatment by a microprocessor and a memory. The sensor has the advantages of simple structure, low cost, high resolution, strong anti-interference ability and easy productization.

Owner:CHONGQING UNIV OF TECH

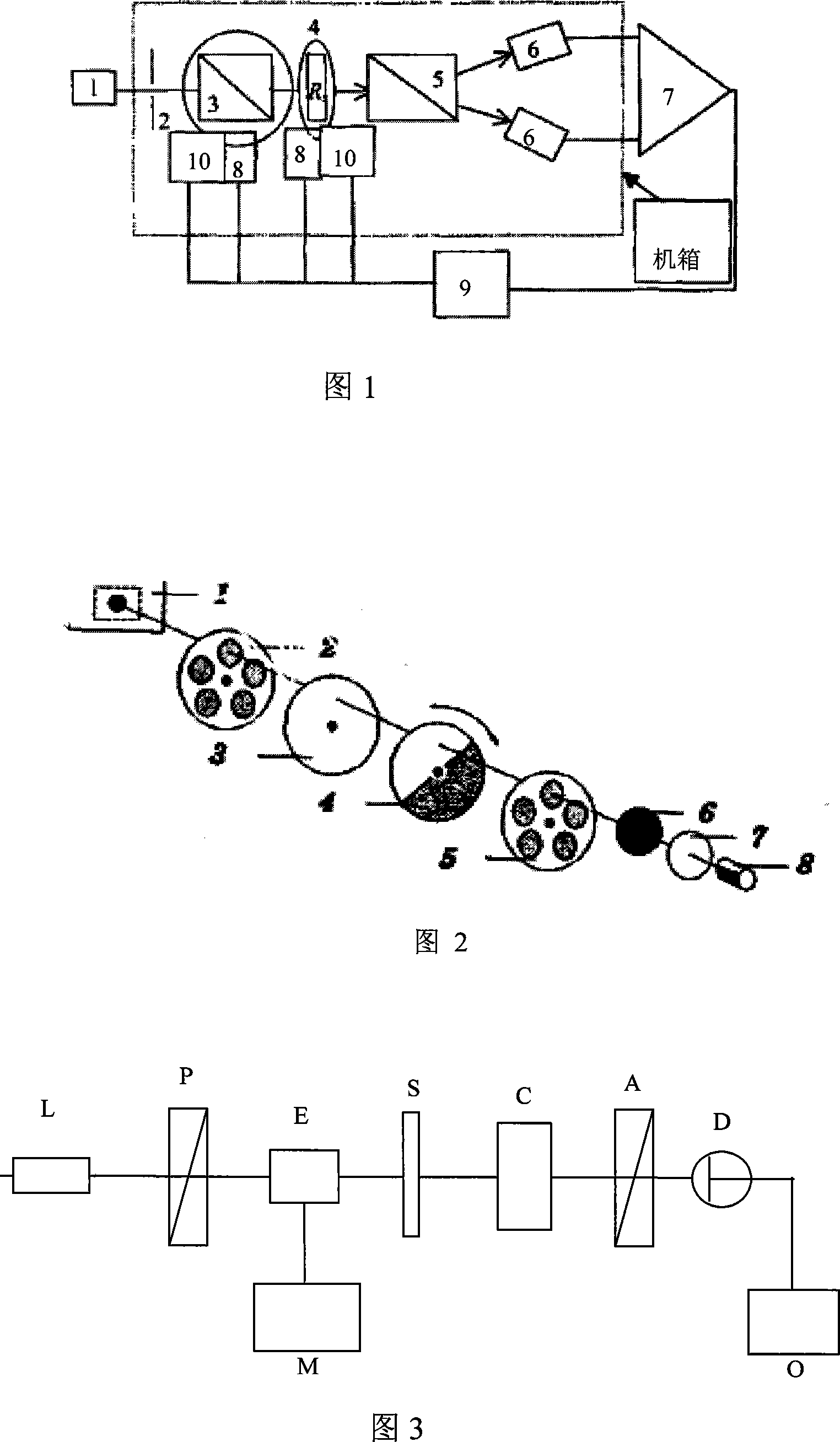

Optical phase put-off precision measurement method and system thereof

InactiveCN101183043AAdvantages of measurement accuracyEliminate unstable measurement resultsTesting optical propertiesPolarizerOptical path

The invention discloses an optical phase delay precision measuring method and a system thereof. The system of the invention comprises a laser, a polarizer, a photo-modulator, a modulation signal source, a measuring phase retarder, a phase compensator, a polarization analyzer, an optical detector and a result output unit. The method of the invention is as follows that the optical modulator is added into a light path for optical modulation of detection polarized light and then modulation polarized light is generated; a result display unit realizes conversion from measurement of direct current zero point to measurement of alternate current zero point after conducting filtering process of the received signal, therefore, the position of an extreme point can be determined accurately and the measuring precision can be improved. The measurement of the invention is simple and convenient and the result is accurate and reliable, meanwhile, the precision is up to lambada / 300; the invention is suitable for production of a wave plate and other optical delay devices and detection of the product in the sales department.

Owner:大恒新纪元科技股份有限公司北京光电技术研究所

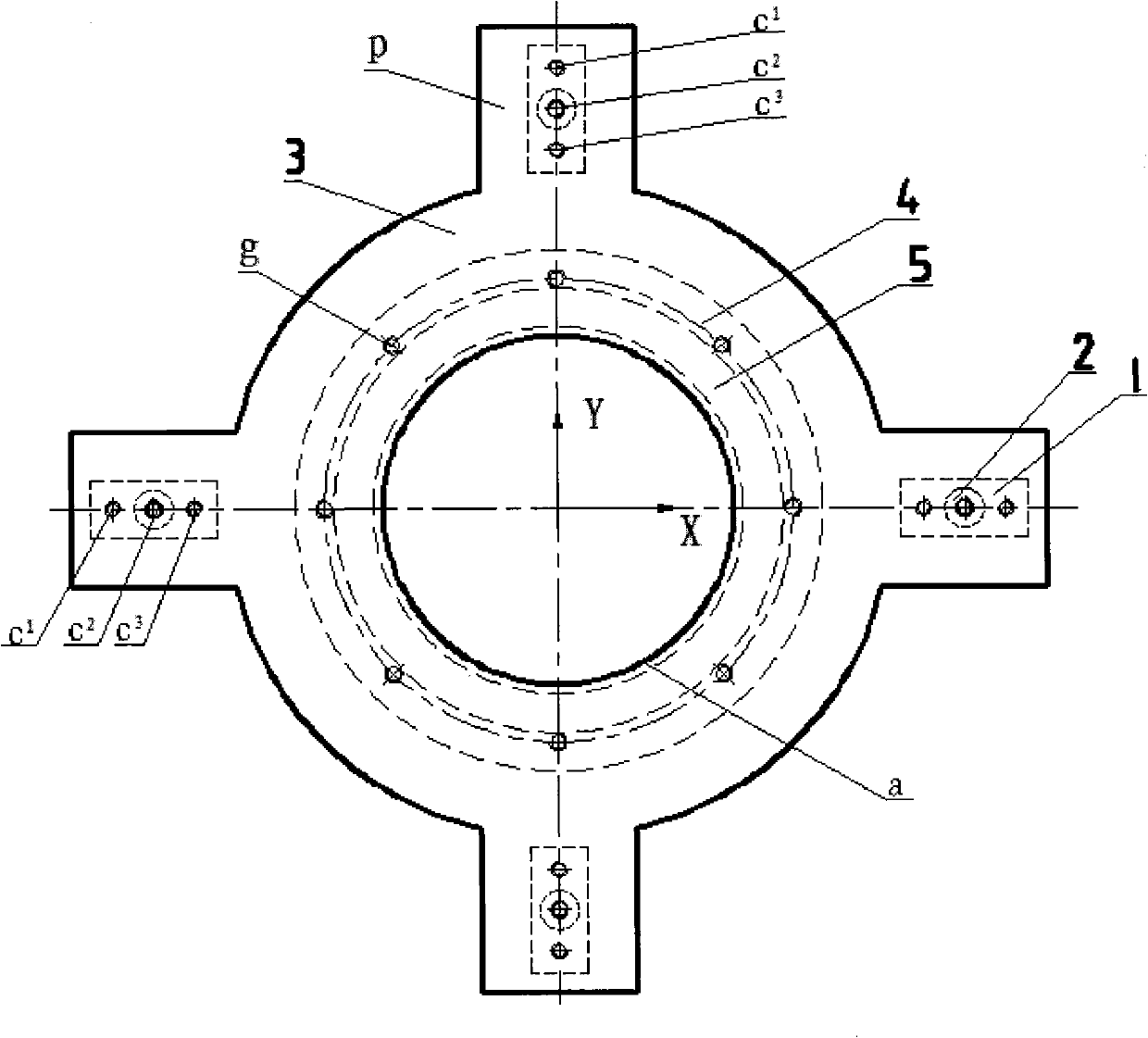

Piezoelectric type six-dimensional force sensor with adjustable load sharing ratio and test method thereof

ActiveCN101793574ALight structureSimple structureFluid pressure measurement by electric/magnetic elementsWork measurementEngineeringForce sensor

The invention discloses a piezoelectric type six-dimensional force sensor with an adjustable load sharing ratio and a test method thereof, which belongs to the field of sensors and measurement and control thereof. The invention particularly relates to the measurement of six-dimensional force on a shaft in different measuring ranges. The six-dimensional force sensor comprises an upper cover, four force sensing elements for sealing and leading out conducting wires, a lower body, load sharing rings, positioning rings and four pre-tightening screws. The adopted test method adjusts the ratio of the summation of stresses on the four force sensing elements to the stress on a tested shaft by adjusting the mounting positions of the four force sensing elements and selecting a series of modularized load sharing rings and positioning rings. The piezoelectric type six-dimensional force sensor adjusts the load sharing ratio to achieve the aim that the same sensor measures the six-dimensional force with different measuring ranges on the shaft in a certain shaft diameter range; and the piezoelectric type six-dimensional force sensor has good rigidity, high sensibility, a low cost and easy commercialization, and the test method is simple to operate, is convenient to use and is safe and reliable.

Owner:DALIAN UNIV OF TECH

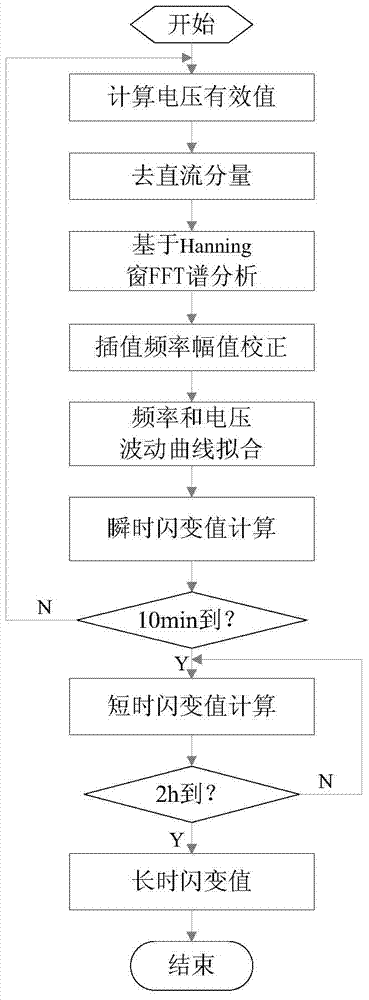

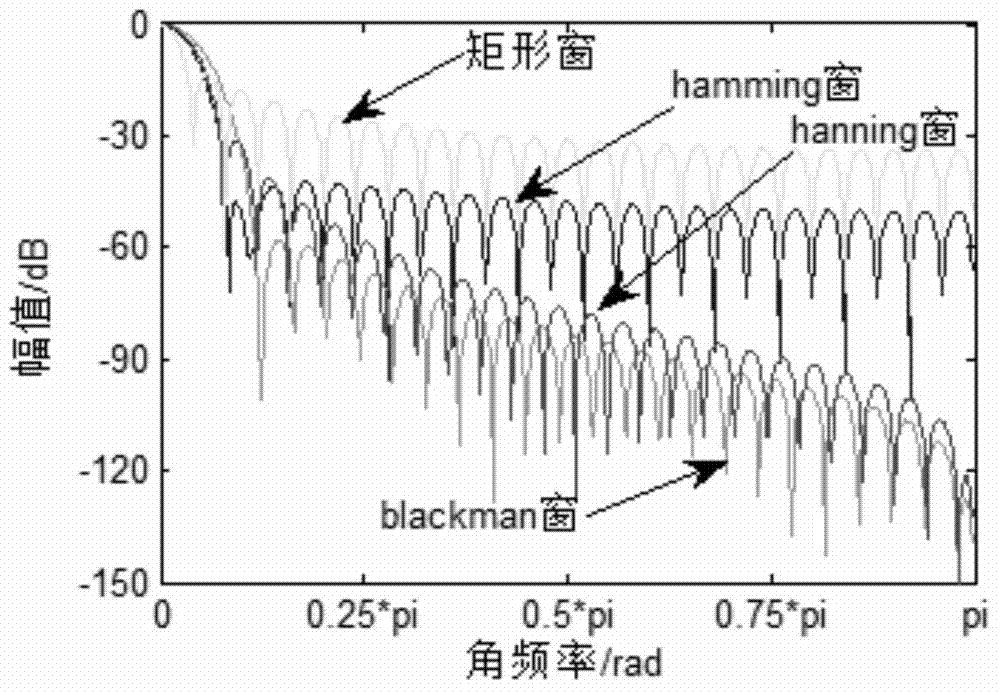

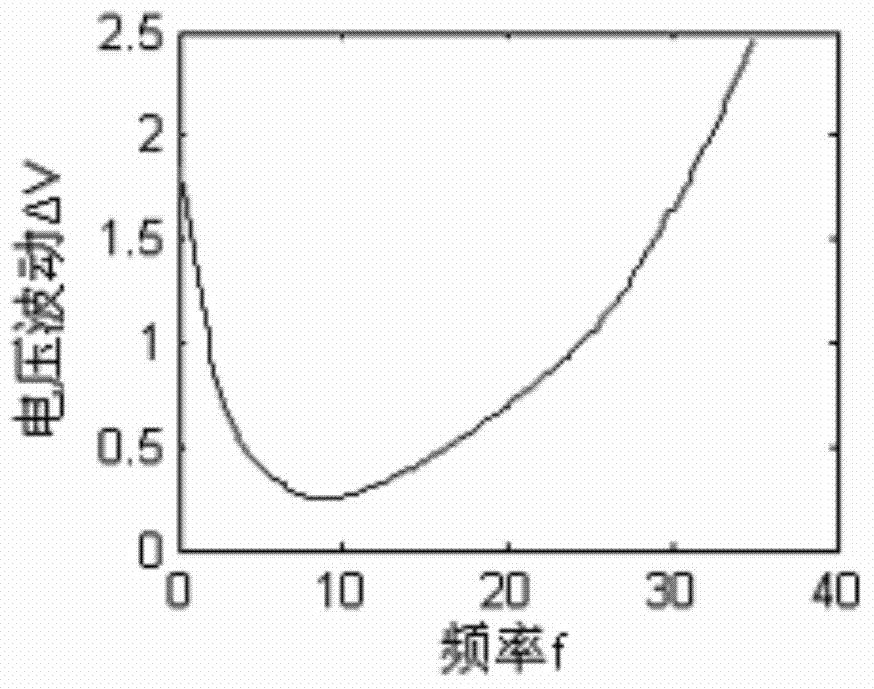

Flicker value calculation method based on improved FFT and inverter

ActiveCN103926456AImprove accuracySimplify the flicker measurement processSpectral/fourier analysisSingle network parallel feeding arrangementsSEMI-CIRCLECurve fitting

The invention relates to a flicker value calculation method based on improved FFT and an inverter. In order to solve the technical problems, the flicker value calculation method based on the improved FFT and the inverter are provided, and high-precision flicker value calculation is achieved. According to the technical scheme, the method includes the steps that (1), all phases of voltage signals are sampled to obtain a voltage sampled sequence; (2), a voltage root-mean-square value is calculated according to sampling length per semi-circle wave, so that a voltage root-mean-square value sequence is obtained; (3), the average value of the voltage root-mean-square value sequence is calculated, and the average value is subtracted from each voltage root-mean-square value, so that a new voltage root-mean-square value sequence is obtained; the new voltage root-mean-square value sequence is windowed, FFT is performed, and amplitude frequency is corrected through double spectrum line interpolation operation; (5), curve fitting is performed on voltage fluctuation and fluctuation frequency discrete points; (6), please see the formula in the specification, a transient flicker value P is calculated; (7), the steps from one to six are repeated, all transient flicker values P within ten minutes are calculated, and according to the formula in the specification, a short-time flicker value Pst is calculated. The flicker value calculation method and inverter are used for the field of electric power technologies.

Owner:NINGBO HENGLIDA TECH

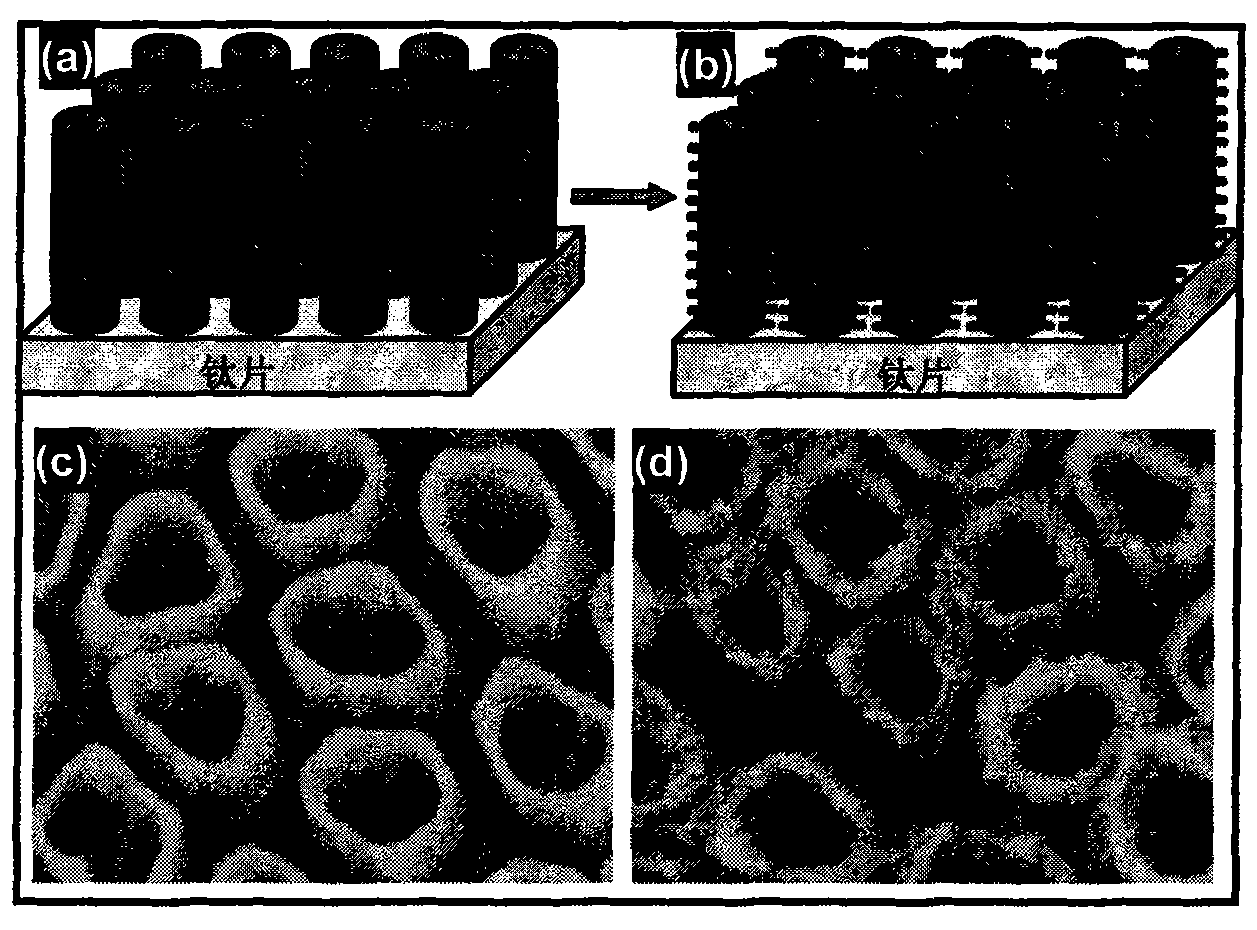

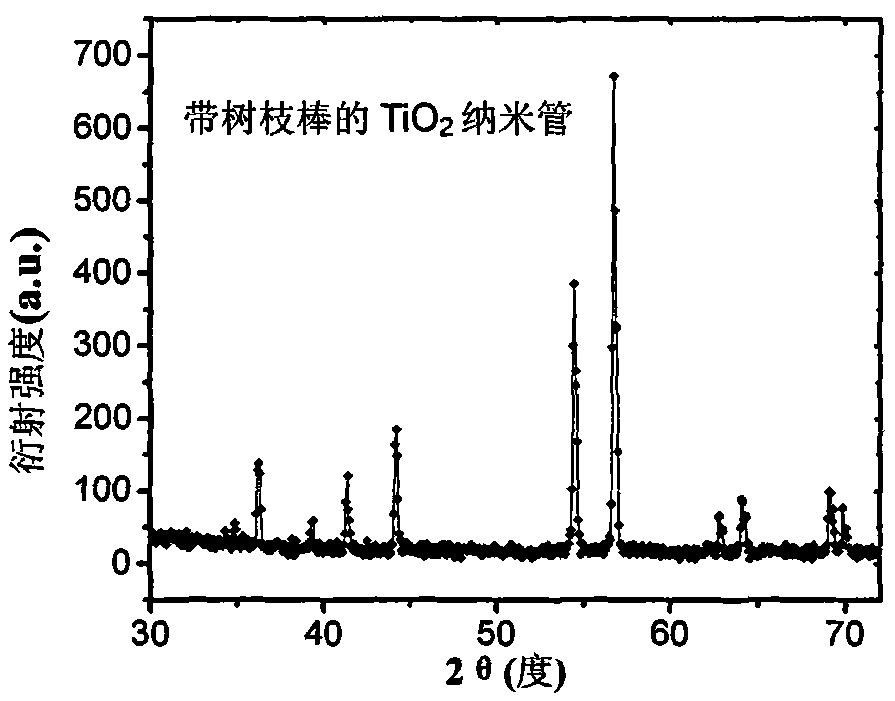

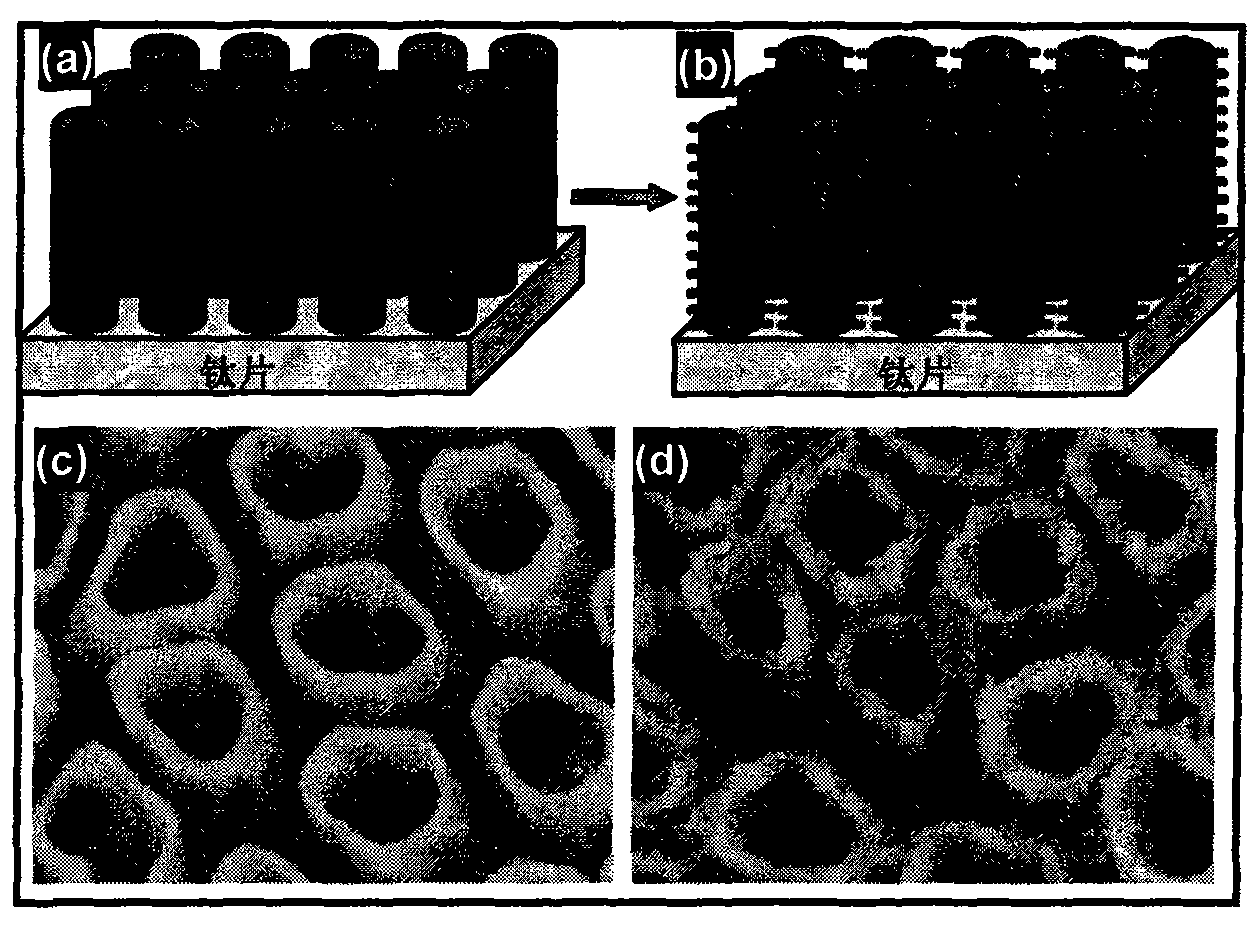

Preparation process of dendritic titanium dioxide nanotube array electrode

InactiveCN101969109ALarge specific surface areaLow manufacturing process costNanostructure manufactureLight-sensitive devicesTio2 nanotubeSolar cell

The invention provides a preparation process of a dendritic titanium dioxide nanotube array electrode, which comprises: firstly, pre-preparing a titanium dioxide nanotube array by using an anodizing method and by using pure titanium foil as an anode and mixed solution of ammonium fluoride, lactic acid and dimethyl sulphoxide as electrolyte; secondly, growing nanorods with dendritic titanium dioxide on the pre-prepared titanium dioxide nanotubes serving as a host skeleton by using a low-temperature liquid-phase method and by using aqueous solution of hydrochloric acid and TTIP as growing solution, and thus obtaining the required dendritic titanium dioxide nanotube array; and finally, using the dendritic titanium dioxide nanotube array as a material to assemble the working electrodes of dye-sensitized solar cells, photoelectrochemical cells, photocatalysis devices and the like. The dendritic titanium dioxide nanotube array can improve the conversion efficiency of the cells and the efficiency of the photocatalytic pollutant degradation considerably; and the preparation process is low in cost, simple in process and easy in production.

Owner:XIANGFAN UNIVERSITY

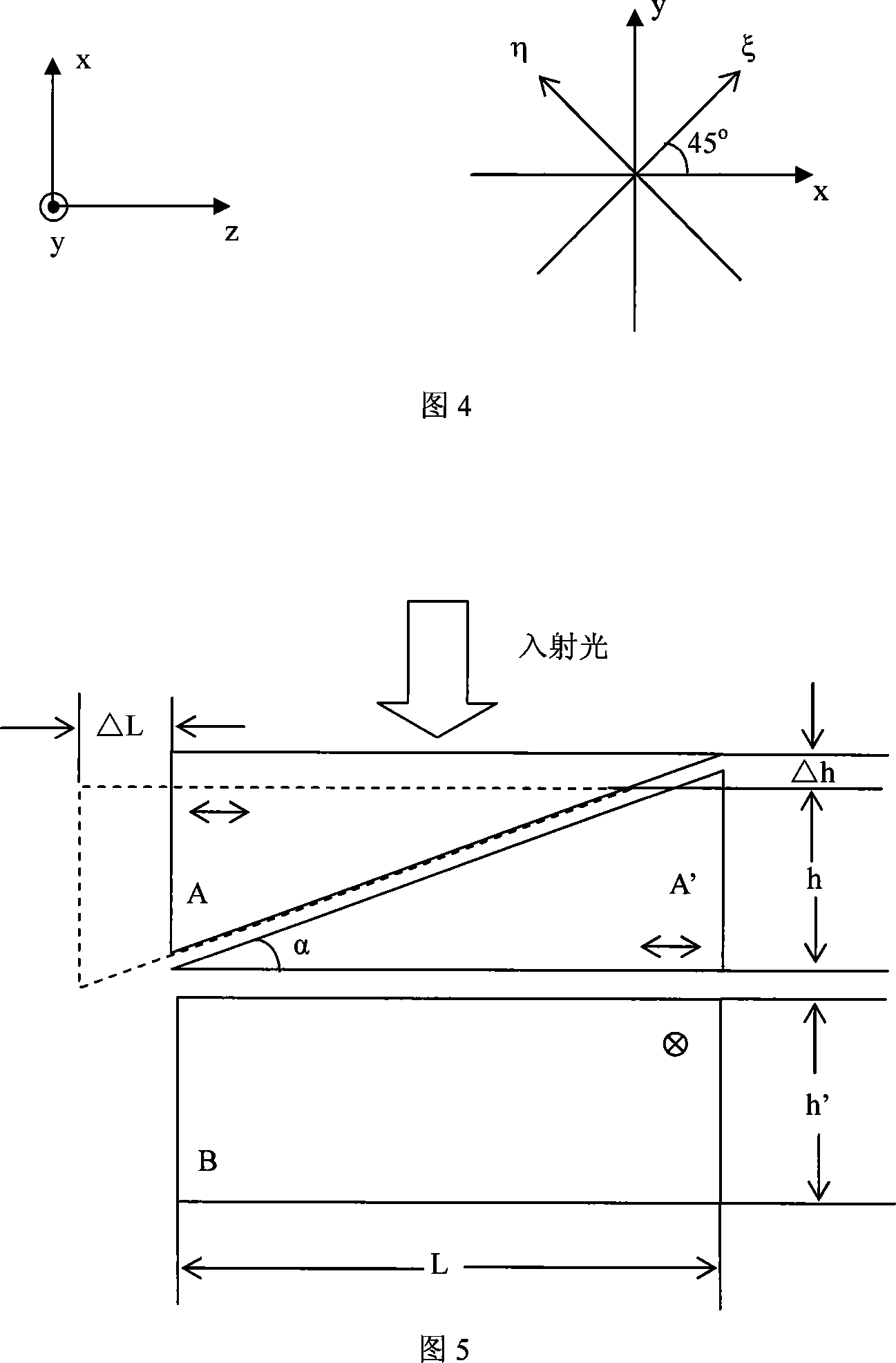

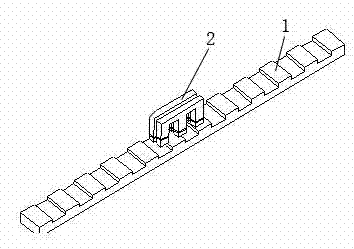

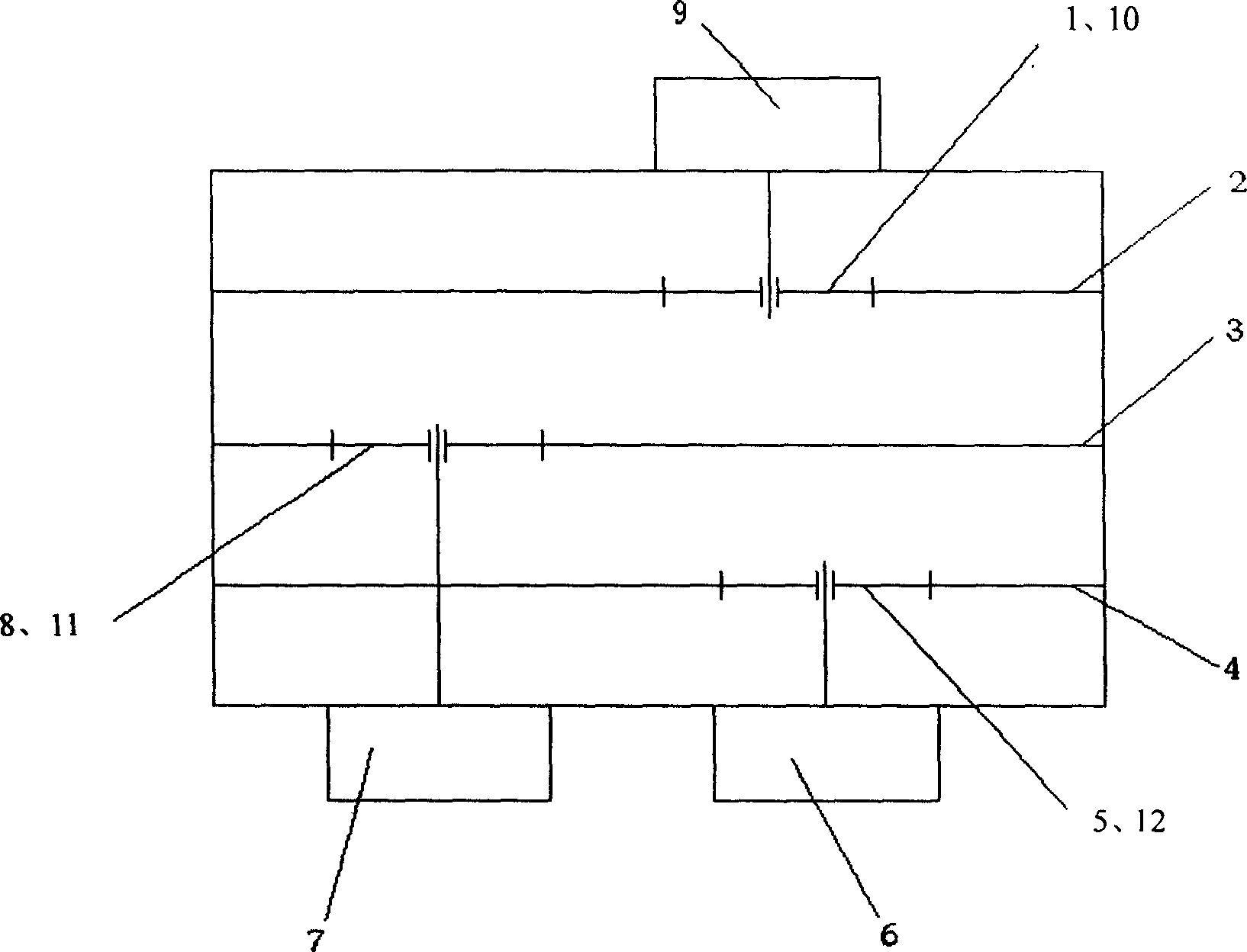

Linear displacement sensor

InactiveCN102359753ASimple structureLow costUsing electrical meansData displaySignal processing circuits

The invention provides a linear displacement sensor, and belongs to the field of accurate displacement measurement. The sensor consists of two substrates, namely a long ruler and a short ruler, wherein an excitation coil and an induction coil are simultaneously wound on one ruler substrate; a row of magnetizers are arranged on the other ruler substrate at equal intervals and are unwound; the excitation coil is connected with an excitation power supply; an induction signal is generated on the induction coil; when the short ruler and the long ruler do relative motion, the amplitude of the induction signal is changed due to the change of magnetic flux; and electric signals output by the excitation coil and the induction coil are connected to a conditioning circuit to be processed, the processed signals are sent to a signal processing circuit to be subjected to amplitude and phase discrimination, an amplitude difference or a phase difference of the signals is expressed by the number of interpolated clock pulses and is converted into a linear displacement value, and the linear displacement value is directly used as linear displacement data to be displayed or output or is subjected to error correction and the like by a microprocessor and a memory and used as the linear displacement data to be displayed or output.

Owner:CHONGQING UNIV OF TECH

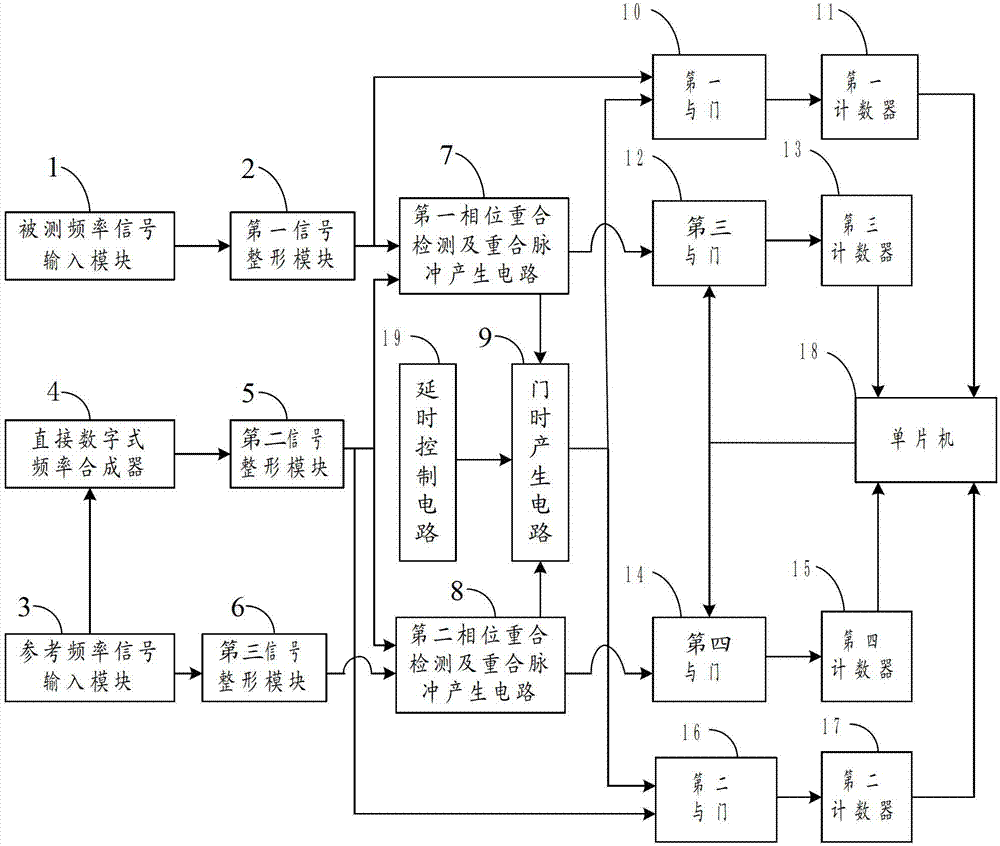

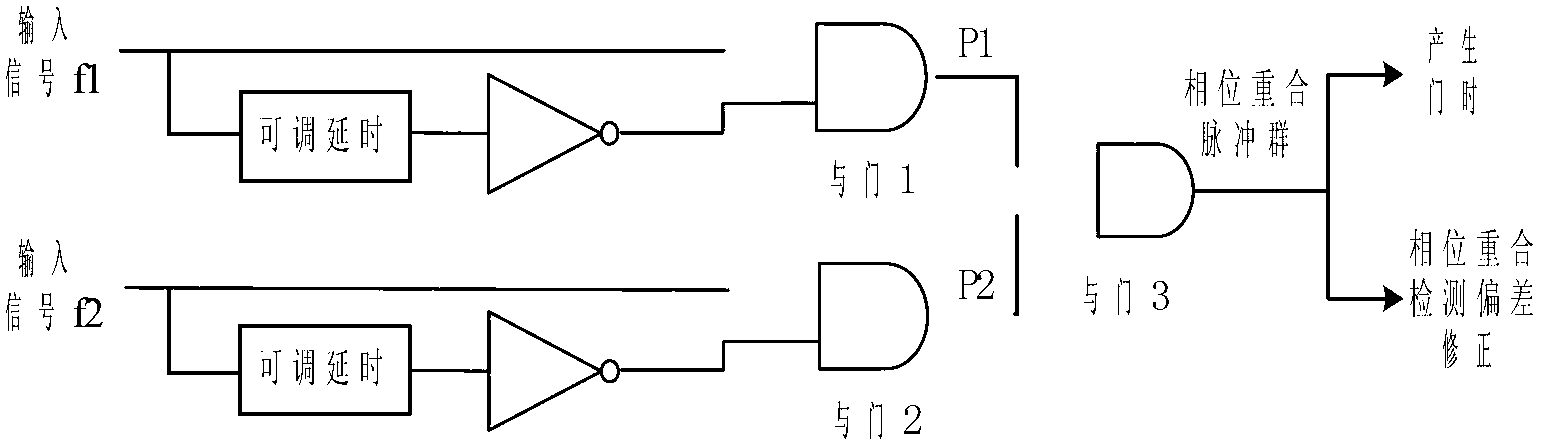

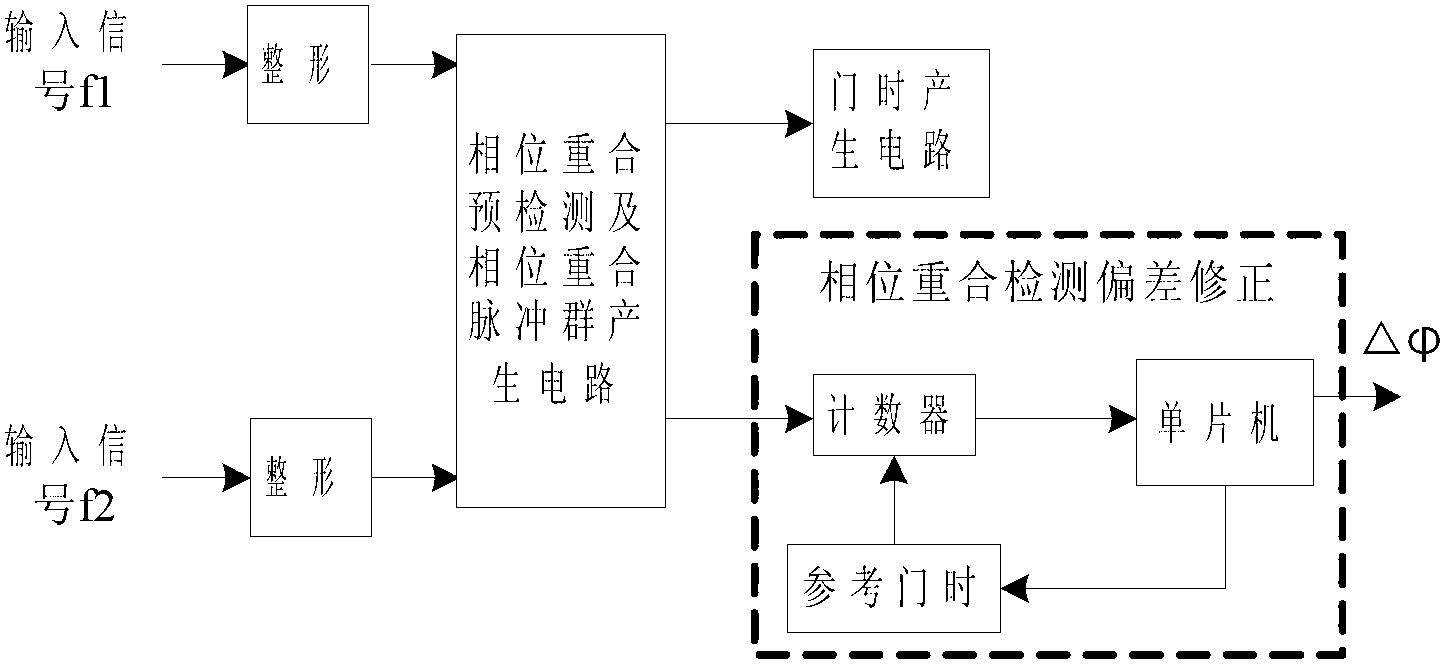

Method and system of ultrahigh resolution phase difference measurement

InactiveCN103197145ASimple structureEliminate counting errorsVoltage-current phase angleTime driftPhysics

The invention discloses a method and a system of ultrahigh resolution phase difference measurement with phase difference correction function and based on double-coincidence detection. The method includes the steps that: a. a measurement gate is formed by means of double phase coincidence detection between two pilot frequency signals, a first phase coincidence detection and coincidence pulse generating circuit conducts phase coincidence detection to a detected frequency signal and a public frequency signal and generates coincidence pulse; b. a second phase coincidence detection and coincidence pulse generating circuit conducts phase coincidence detection to a reference frequency signal and the public frequency signal and generates coincidence pulse; c. a gate-time generating circuit generates a gate-time signal according to a received enabling signal and a received closing signal, and a single chip computer obtains phase difference of the detected frequency signal and the reference frequency signal according to count data; and d. the coincidence pulse is counted within the time range near the enabling time and closing time of the measurement gate and a corrected value of the phase difference is obtained. Lastly, the ultrahigh resolution phase difference measurement is accomplished. By means of the method and the system of ultrahigh resolution phase difference measurement, counting error is eliminated, measuring resolution ration is high, and long time drift distance is small.

Owner:XIDIAN UNIV

Hydroxy camptothecin emulsion and its preparation method

InactiveCN1493289AChange distributionTissue-targetedOrganic active ingredientsEmulsion deliveryCurative effectTG - Triglyceride

A hydroxycamptothecin emulsion is prepared from hydroxycamptothecin 0.01-2.2 %, emulsifier 0.3-8%, triglyceride 2-30%, glycerine for injection 2.0-3.0 % and water for injection through dissolving the 10-hydroxycamptothecin in the oil phase containing triglyceride and emulsifier, adding water phase, mixing, and ultrasonic or homogeneous emulsifying. Its advantages are high curative effect and stability, and good target to tissue.

Owner:曹永强 +1

Method and system for pilot frequency bi-phase coincidence detection based on coincidence pulse counting

InactiveCN103176045ASimple structureHigh-resolutionVoltage-current phase angleFrequency to pulse train conversionPhase noisePhase difference

The invention discloses a system and a method for pilot frequency bi-phase coincidence detection based on coincidence pulse counting. The system comprises a pilot frequency signal phase coincidence pre-detection and phase coincidence pulse group generation circuit, a bi-phase coincidence detection phase deviation correction circuit and a gate delay generation circuit. By utilizing a group phase coincidence principle among pilot frequency signals and by combining the phase coincidence pre-detection and phase coincidence pulse group generation circuit and coincidence pulse counting, gate information needed by measurement comparison is given, and a phase coincidence detection deviation value can be resolved by the aid of a coincidence pulse count value so as to correct a final measurement result. By the method, influences of phase noise and trigger error on phase coincidence detection are eliminated, and the realized phase difference coincidence detection can reach measurement resolution superior to picosecond. Besides, the method is capable of improving precision of phase coincidence detection and measurement resolution, and a circuit is simple in structure and easy for integration and productization.

Owner:XIDIAN UNIV

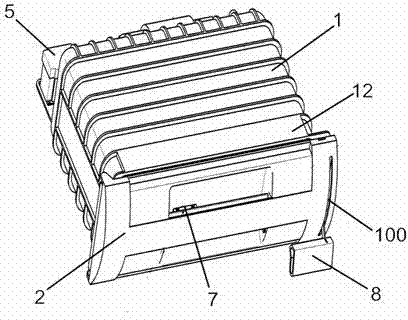

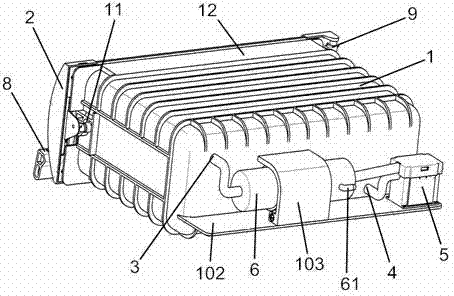

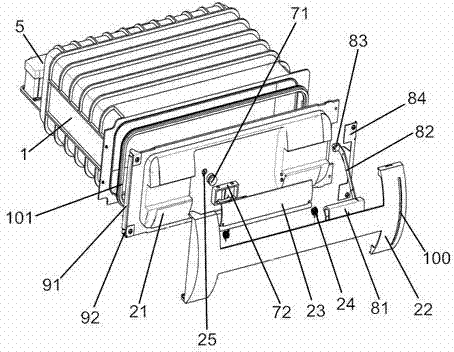

Nitrogen freshness preservation drawer

InactiveCN103575050AImprove deformation resistanceAvoid damageLighting and heating apparatusCooling fluid circulationEngineeringRefrigeration

The invention relates to the field of domestic refrigeration equipment, in particular to a nitrogen freshness preservation drawer used in the inside of a freezer. The nitrogen freshness preservation drawer comprises a drawer cavity, a drawer cover part, an air inlet, an air extraction opening and an air extractor, wherein the air inlet and the air extraction opening are formed in the drawer cavity. The air extraction end of the air extractor is connected with an air extraction opening pipeline, an air separating device is arranged on the drawer cavity, the air feeding end of the air separating device is connected with an air inlet pipeline, and the air inlet end of the air separating device is connected with an air outlet end pipeline of the air extractor. A pressure release part is arranged on the drawer cover part, and a locking component is arranged between the drawer cavity and the drawer cover part. According to the nitrogen freshness preservation drawer, the drawer cavity can be independently formed in the freezer, the original structure of the freezer is basically not affected, the structure is simple through a nitrogen separating mode, a pressure release mode and a locking mode, and using is convenient.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

Optical fibre grating wavelength demodulating method

A method for demodulating grating wavelength of optical fibre includes using wideband optical source and a pair of optical fibre connected in series with one as reference and the other as measurement, measuring return power of this pair of optical fibre to obtain reflecting wavelength variation of reference fibre to measurement fibre for achieving wavelength modulation.

Owner:DALIAN UNIV OF TECH

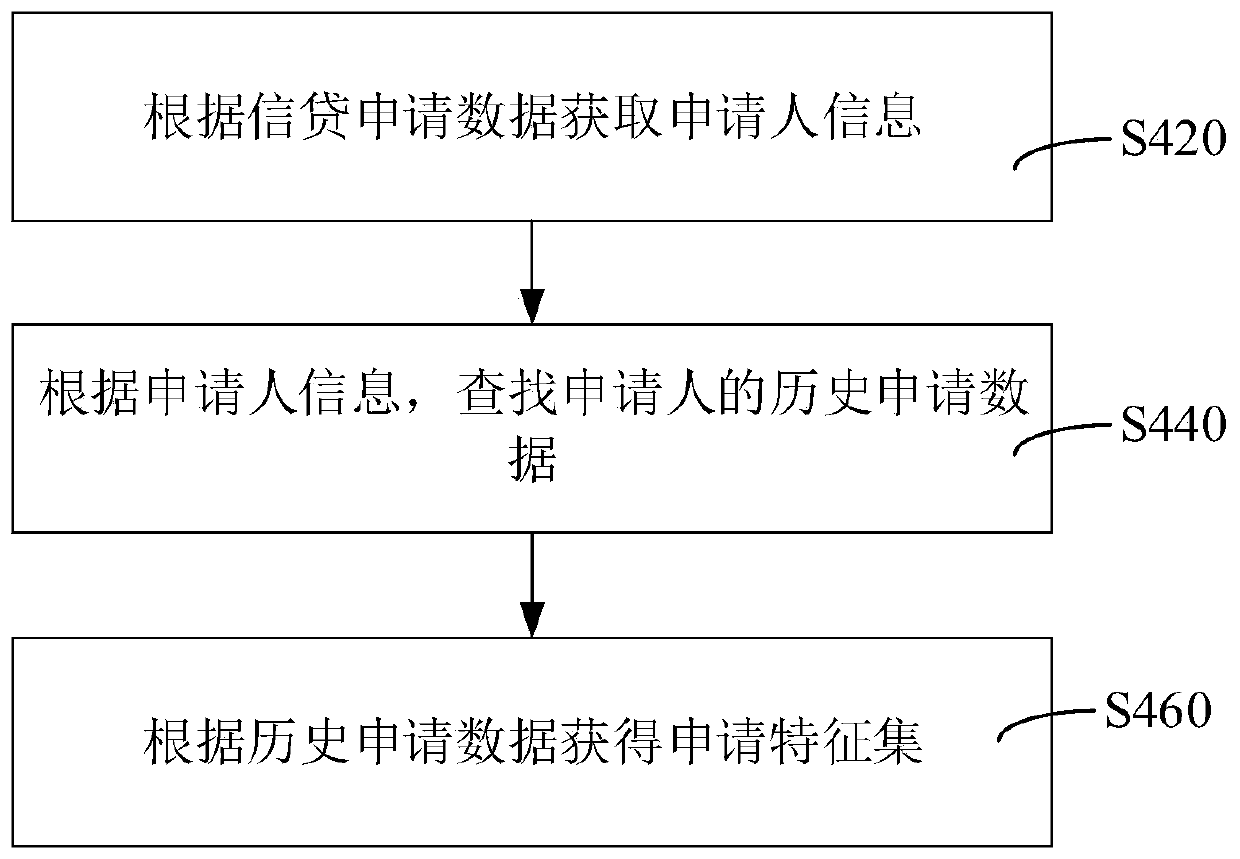

Abnormal application detection method and device, computer device and storage medium

PendingCN109859029AImprove practicalityEasy for customers to understand and productizeFinanceCharacter and pattern recognitionFeature setComputer device

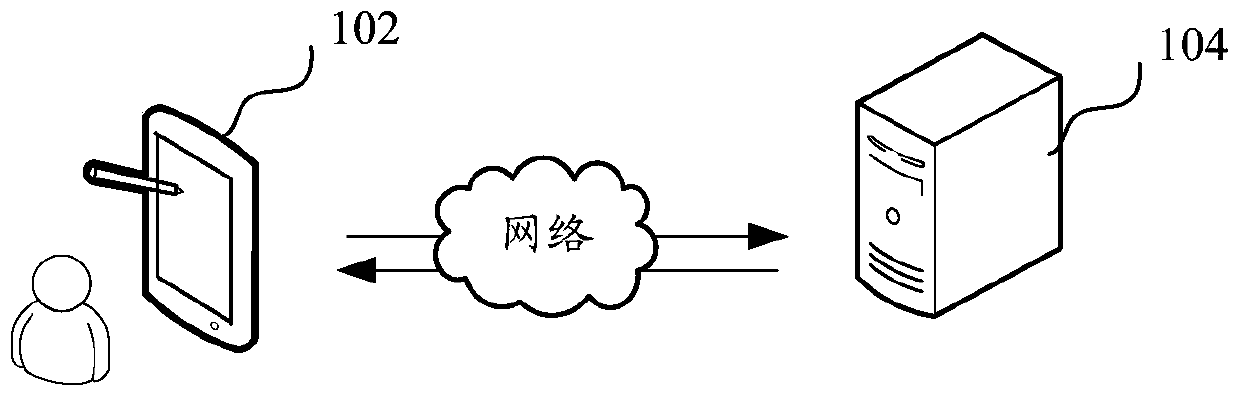

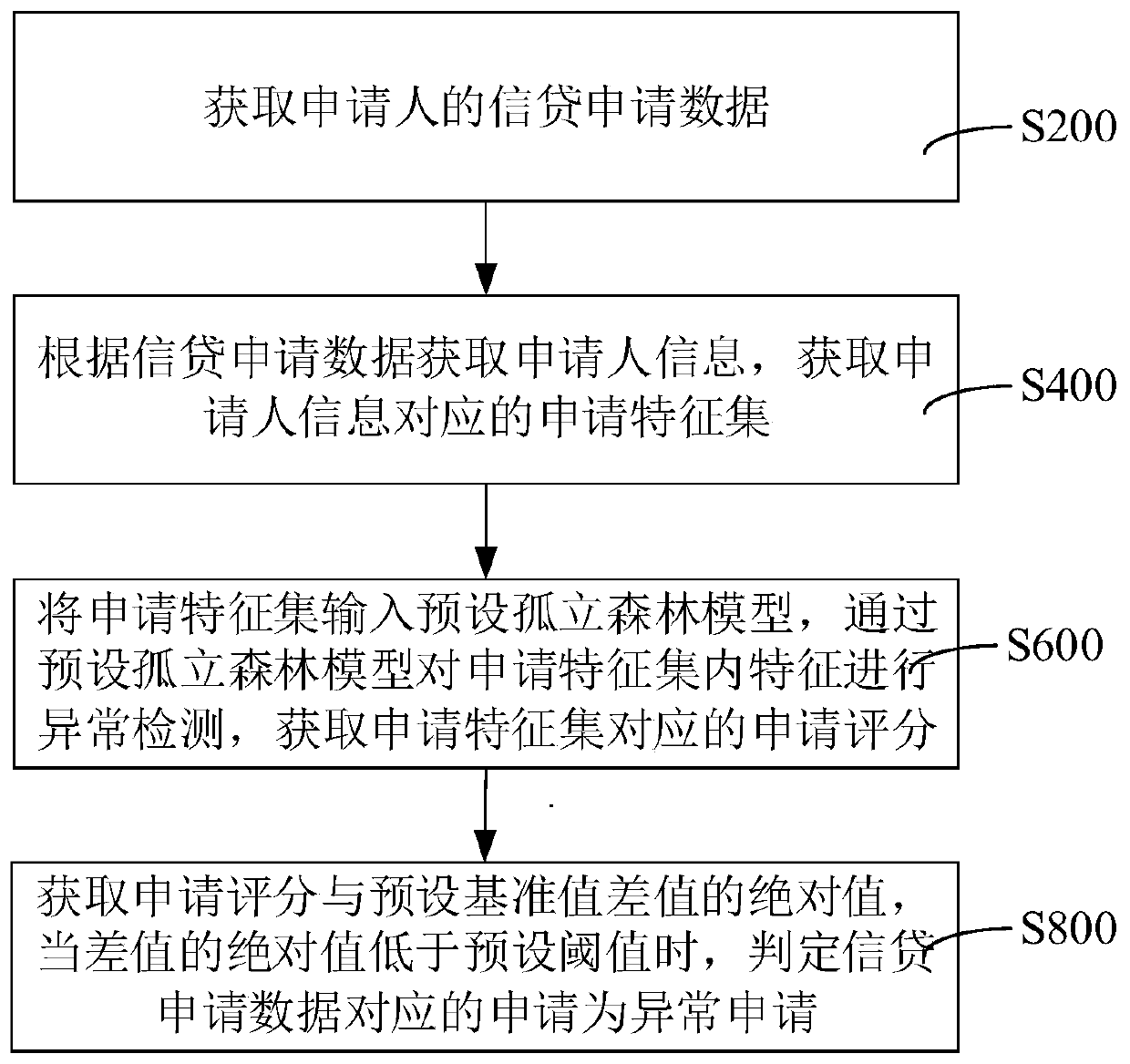

The invention relates to the field of artificial intelligence classification models, and specifically relates to an abnormal application detection method and device, a computer device and a storage medium. The method comprises the steps of obtaining credit application data of an applicant; obtaining applicant information and an application feature set corresponding to the applicant information according to the credit application data; inputting the application feature set into a preset isolated forest model, obtaining an application score corresponding to the application feature set, and constructing the preset isolated forest model based on an unmarked training feature set; and judging whether an application corresponding to the credit application data belongs to an abnormal application or not according to the application score. The credit application is scored by adopting the preset isolated forest model obtained by unsupervised learning, no label is needed for training, the practicability of the abnormal application scoring system is greatly improved, variable fraud and unseen fraud can be recognized, the abnormal degree of the abnormal application scoring system is output in ascoring mode, and the abnormal degree of the abnormal application scoring system is reflected, so that clients can understand and productize the abnormal application conveniently.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

Electronic control electromechanical gear shifting system for automatic transmission

InactiveCN1635289AShorten shift timeSimple structureGearing controlControl devicesAutomatic transmissionControl system

This invention relates to an electric controlled mechanic automatic speed variator shift system, which comprises shift execution structure and shift control system, wherein the said execution structure is composed of independent each shift fork current motor, shift gear, and shift gear bars, that is, each direct current motor is connected to one shift gear fixed on each fork axis shift gear bar and shift gear and each direct current motor is separately connected to the said shift control system.

Owner:JILIN UNIV

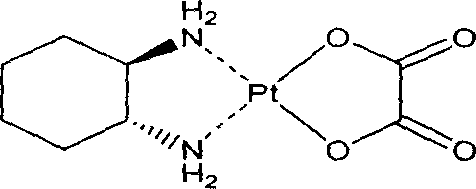

Intravenous nanometer suspension injection contg. oxaliplatin platinum phospholipid compound

InactiveCN1868455AHigh drug loadingImprove stabilityAntineoplastic agentsOil/fats/waxes non-active ingredientsFreeze-dryingPhospholipid complex

A nano-class suspension injection of oxaliplatin-phoshpatide composition for intravenous injection is proportionally prepared from oxaliplatin, surfactant, pH regulator, isotonic agent, antioxidant, water for injection, and optional excipient (for the freeze-dried powder injection).

Owner:SHENYANG PHARMA UNIVERSITY

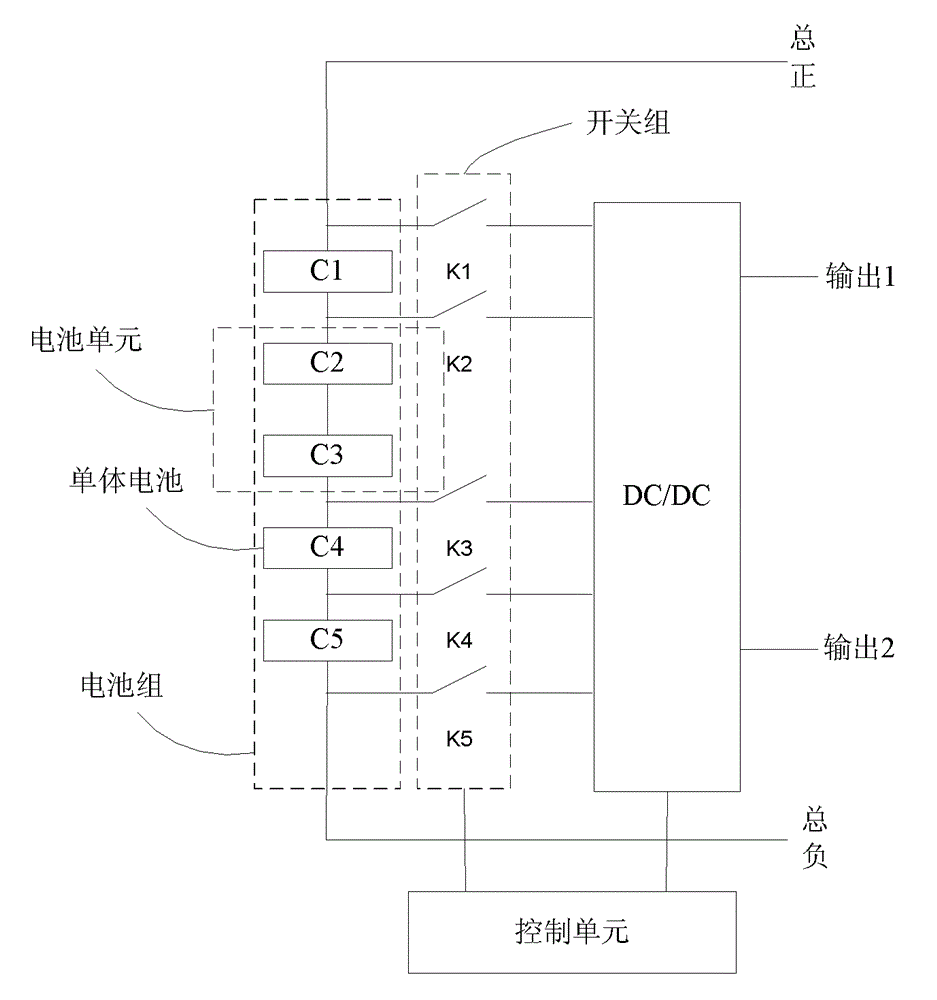

Battery pack preheating method and system thereof

ActiveCN105356007AWill not affect normal cycle lifeEasy to engineerBatteries circuit arrangementsSecondary cells charging/dischargingProcess engineeringBattery cell

The invention provides a batter pack preheating method and a system thereof. According to an embodiment of the invention, the battery pack preheating method comprises the following steps: one or more single cells of a battery pack is / are selected to form a discharging module; the discharging module is coupled to an input end of a DC / DC module; and an output end of the DC / DC module is coupled to a charging module of the battery pack, and the charging module preheats the battery pack through discharging.

Owner:SAIC GENERAL MOTORS +1

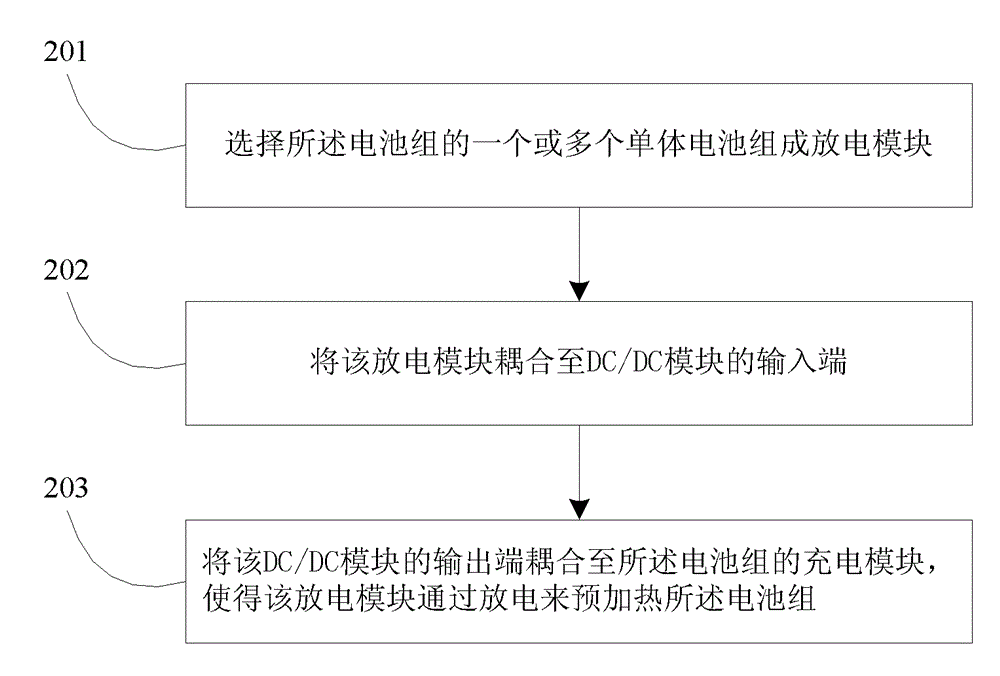

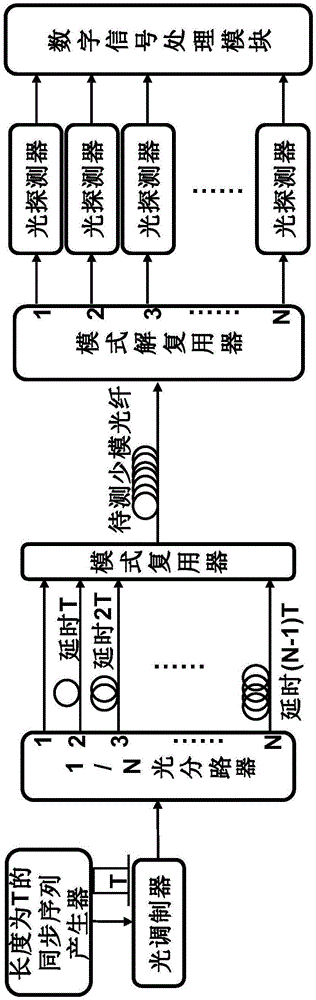

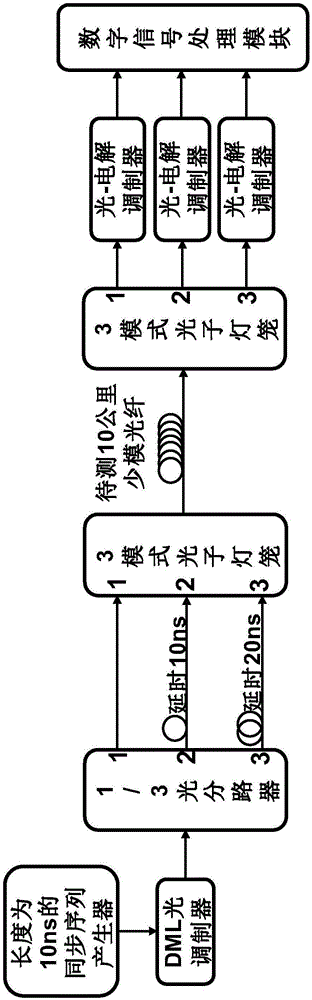

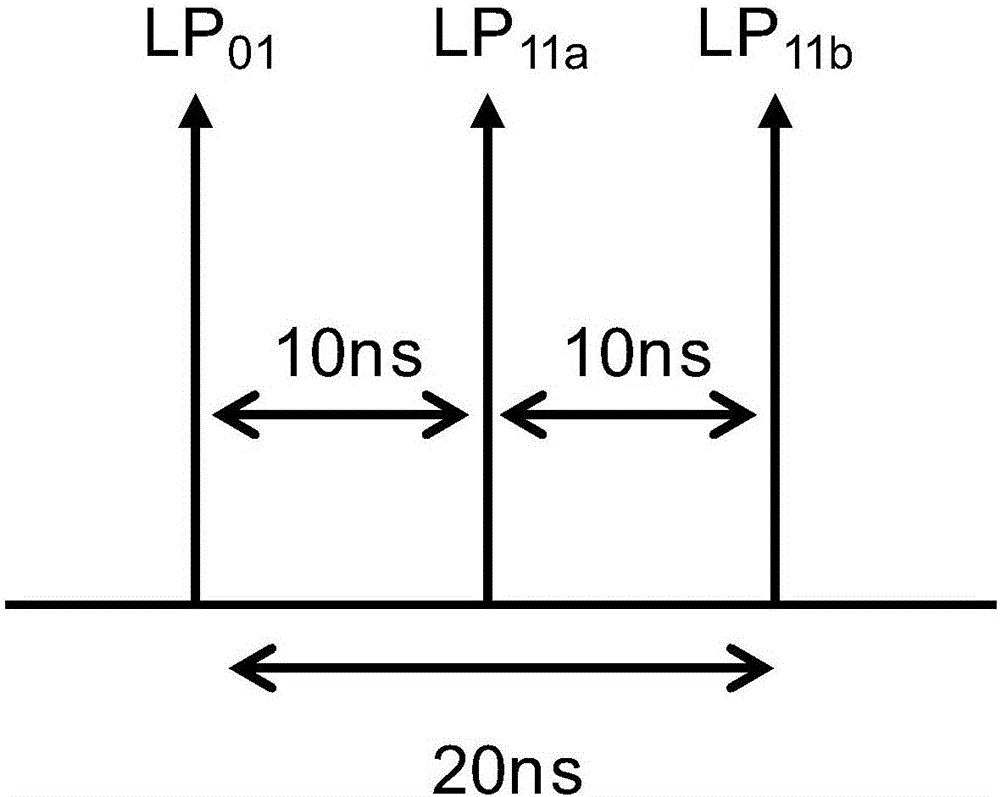

Synchronous-sequence-based few-mode fiber mode-mode delay measurement system and method

ActiveCN106788704ALow costThe principle is simpleElectromagnetic transmissionVIT signalsDigital signal processing

The invention discloses a synchronous-sequence-based few-mode fiber mode-mode delay measurement system and method, and relates to the field of optical communication. The method comprises the following steps: at a transmitting end, generating a group of synchronous sequences, modulating the synchronous sequences to optical carriers, dividing the synchronous sequences into N-path single-mode optical signals, performing different delays on the N-path single-mode optical signals, coupling the delayed N-path single-mode optical signals to form one-path N-mode multiplexed optical signals, and inputting the one-path N-mode multiplexed optical signals into a to-be-measured few-mode fiber; at a receiving end, demultiplexing the received one-path N-mode multiplexed optical signals so as to obtain N-path single-mode optical signals, and recovering synchronous sequence information of the N-path single-mode optical signals; by a digital signal processing module, determining relative start time positions of the received N-path synchronous sequences, comparing the determined relative start time positions of the received N-path synchronous sequences with the relative start time positions of the N-path synchronous sequences at the transmitting end so as to obtain a relative delay between any two modes, and by combining with the length of the to-be-measured few-mode fiber, computing an mode-mode delay parameter of the to-be-measured few-mode fiber between the any two modes. The synchronous-sequence-based few-mode fiber mode-mode delay measurement system and method have remarkably reduced costs and are suitable for future large-scale applications under engineering conditions.

Owner:WUHAN POST & TELECOMM RES INST CO LTD

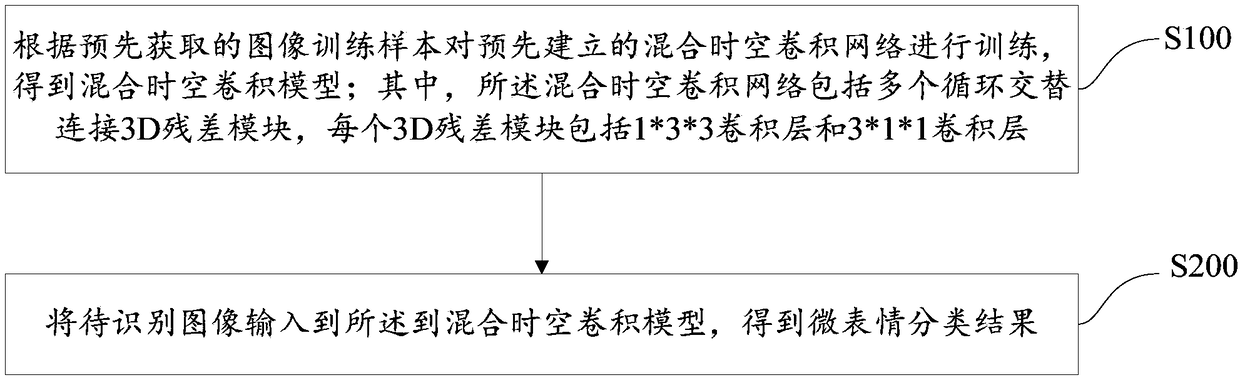

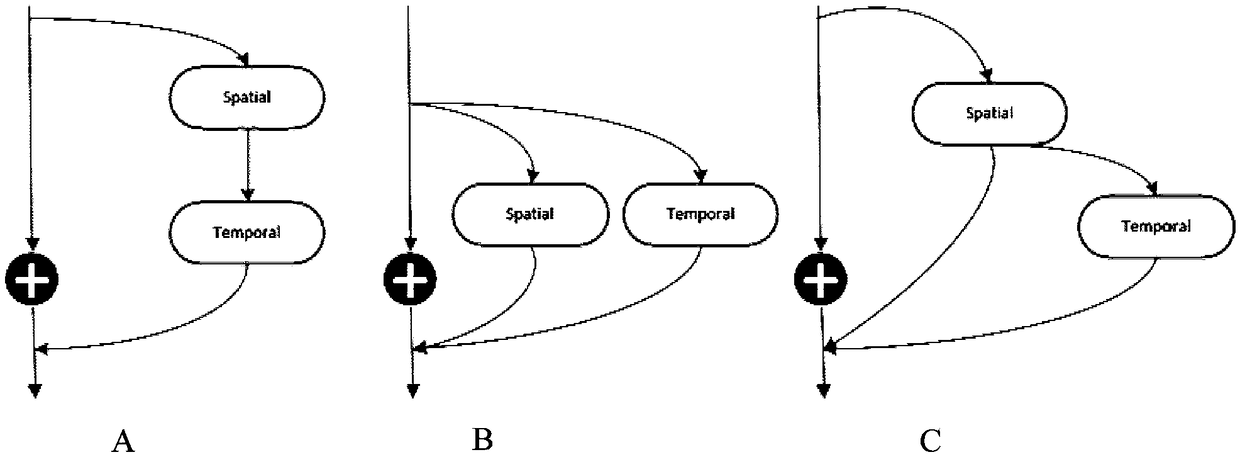

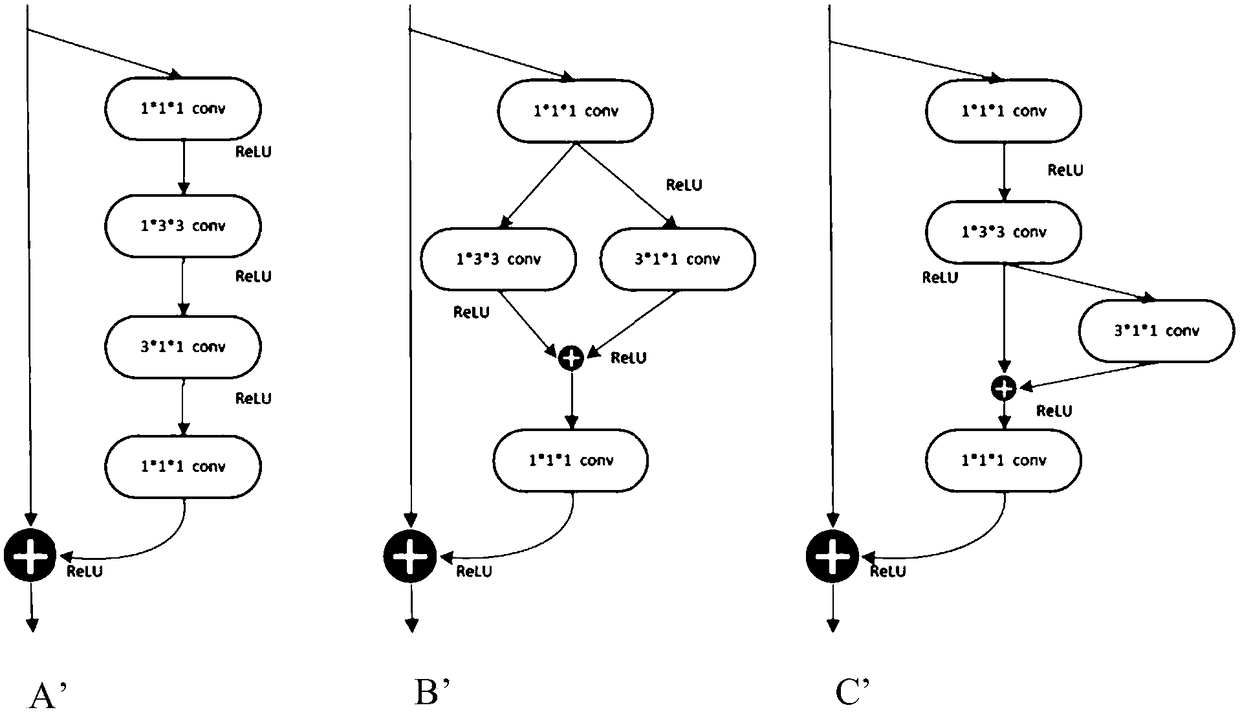

Method and apparatus for micro-expression recognition based on hybrid spatio-temporal convolution model

ActiveCN109389045ARich and authentic inner emotionsAdd categoryAcquiring/recognising facial featuresComputation complexityMicroexpression

The invention provides a micro-expression recognition method and a device based on a mixed spatio-temporal convolution model. The method comprises the following steps: training a mixed spatio-temporalconvolution network established in advance according to a pre-acquired image training sample to obtain a mixed spatio-temporal convolution model; Wherein the hybrid spatio-temporal convolution network comprises a plurality of cyclically alternately connected 3D residual modules, each 3D residual module comprising a 1*3*3 convolution layer and a 3*1*1 convolution layer; An image to be recognized is input to the mixed spatio-temporal convolution model to obtain a microexpression classification result. The mixed 1*3*3 convolution (2D) +3*1*1 convolution (1D) is used for convolution calculation,on the one hand, the invention guarantees the precision requirement of 3D CNN in micro expression recognition; on the other hand, the invention adopts the mixed 1*3*3 convolution (2D) +3*1*1 convolution (1D) to perform convolution calculation. On the other hand, it greatly reduces the computational complexity, and reduces the requirement of computer hardware, which is more conducive to the production.

Owner:GCI SCI & TECH +1

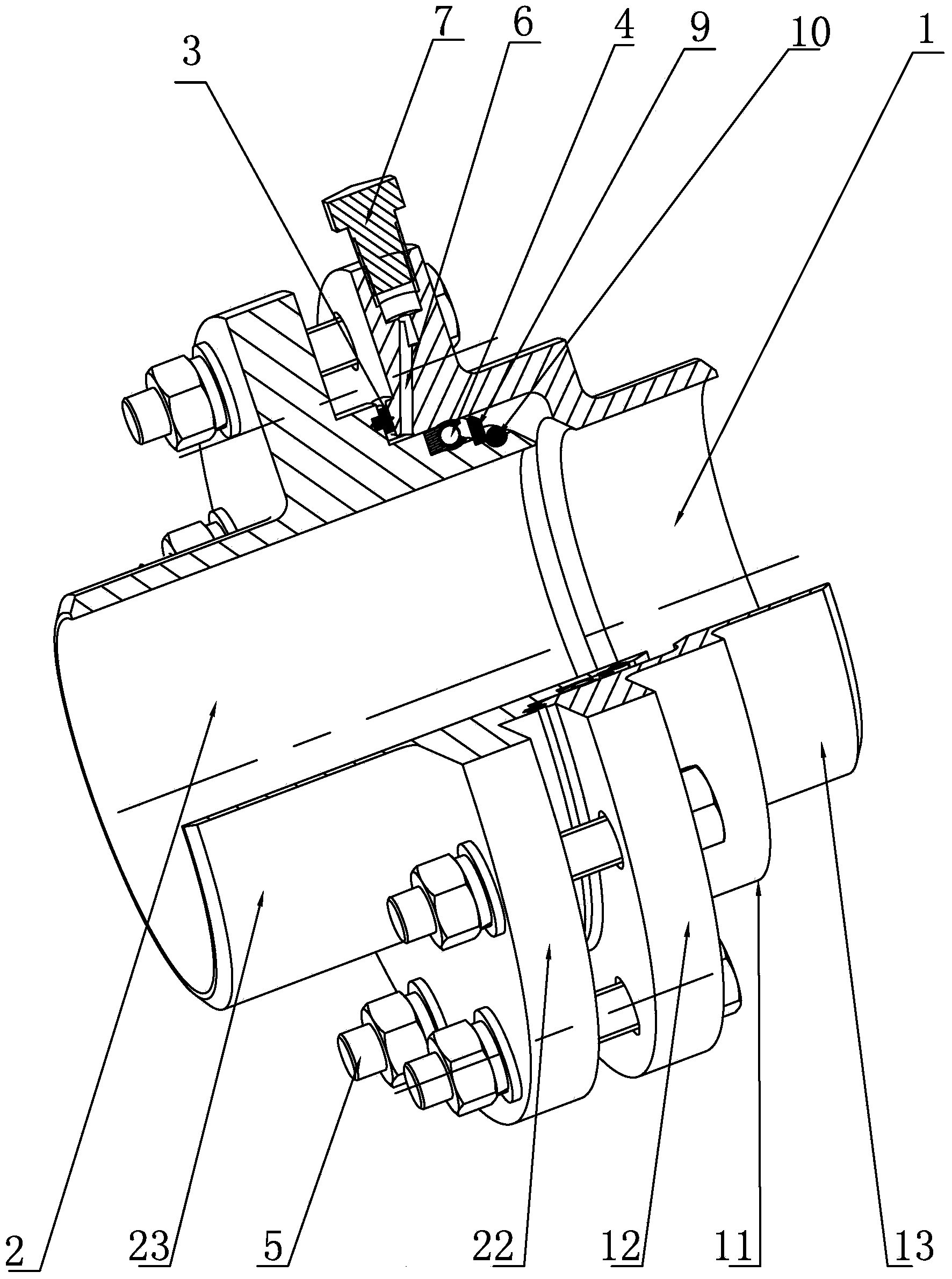

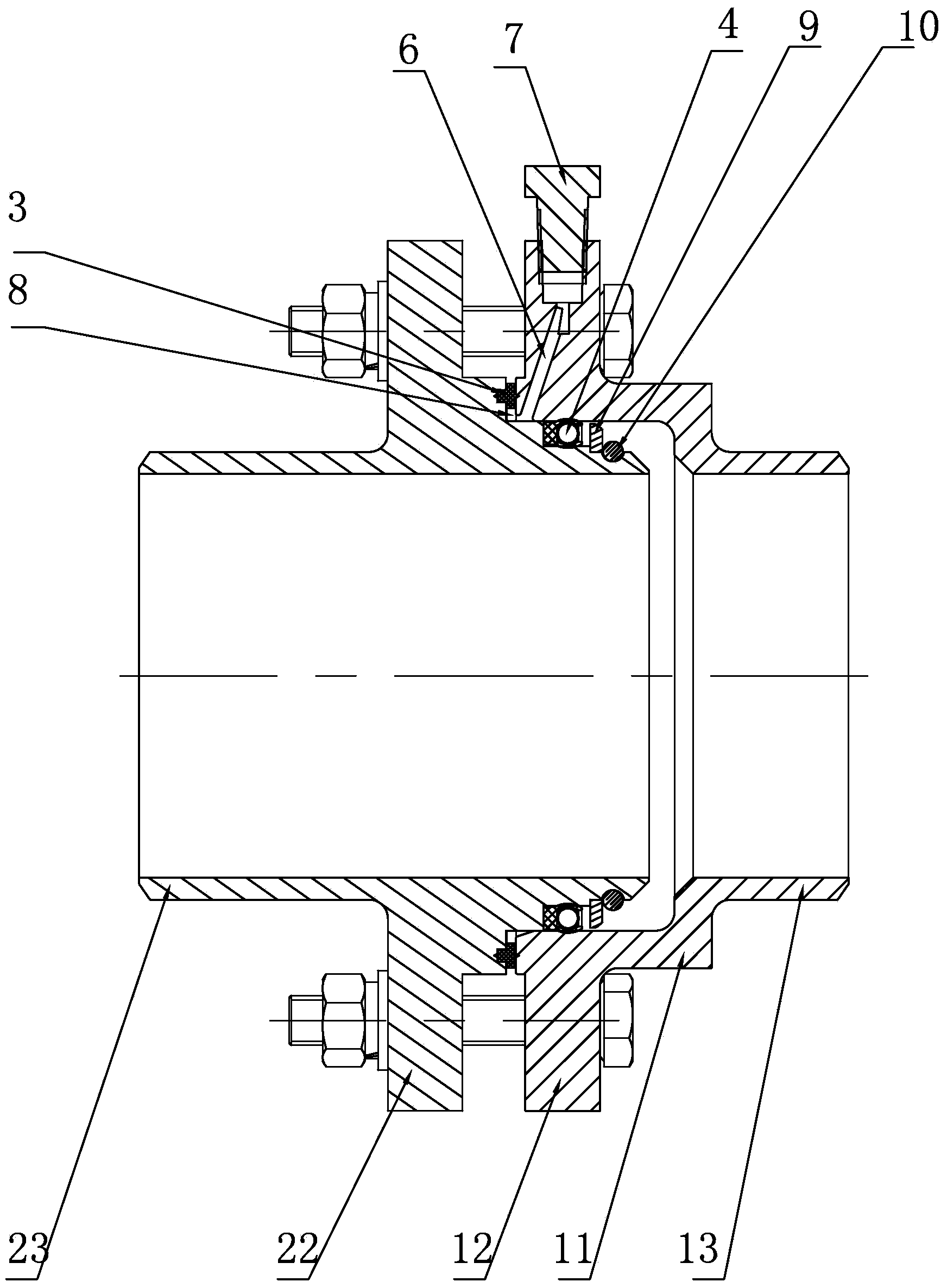

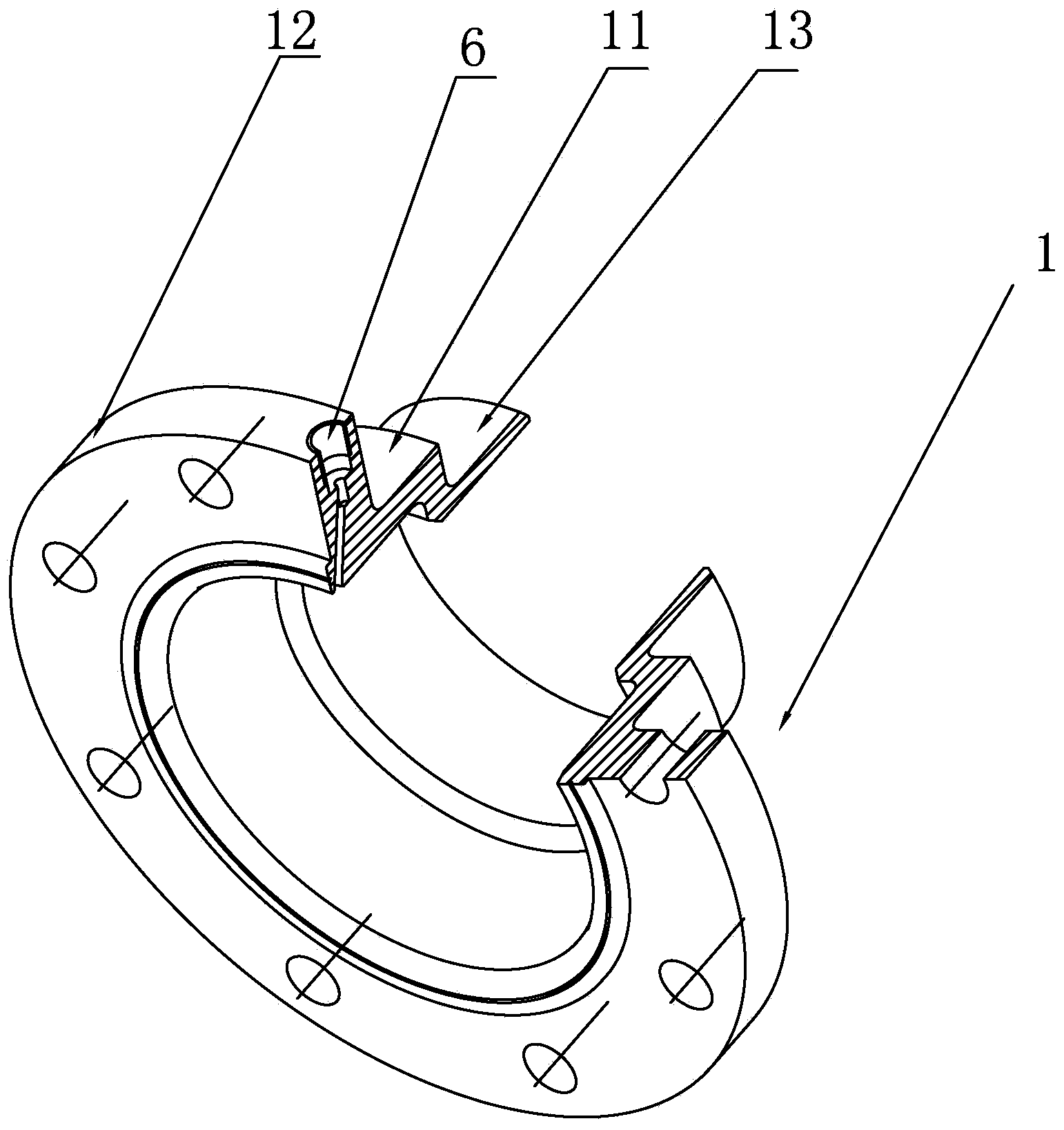

Redundant seal pipeline connector

ActiveCN104048124AEffective Radial Sealing EffectRealize online detectionDetection of fluid at leakage pointFlanged jointsButt jointFlange

The invention relates to a pipeline connector used for a filling system with higher sealing requirements, and aims to provide a redundant seal pipeline connector which has a simple structure, is reliable to seal, simple and convenient to operate, and can carry out the on-line detection on the sealing effect of the pipeline connector at the same time. The redundant seal pipeline connector comprises a seal receptacle, a seal cone, end surface sealing pieces, radial sealing pieces and fastening pieces, wherein the seal receptacle comprises a first axial bulge, a first annular flange and a first welding end, which are manufactured integrally; the seal cone comprises a second axial bulge, a second annular flange and a second welding end, which are manufactured integrally; the end surface of the second axial bulge is in butt joint with the end surface of the first annular flange; the end surface sealing pieces are positioned on the butt-joint matched surfaces; the front end of the second axial bulge is sleeved with the first annular flange; the radial sealing pieces are positioned in the radial matched surfaces; the fastening pieces are used for fixedly connecting the seal receptacle with the seal cone; a pressure measuring channel is arranged on the first annular flange; an air outlet end port of the pressure measuring channel is connected with a seal cap.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

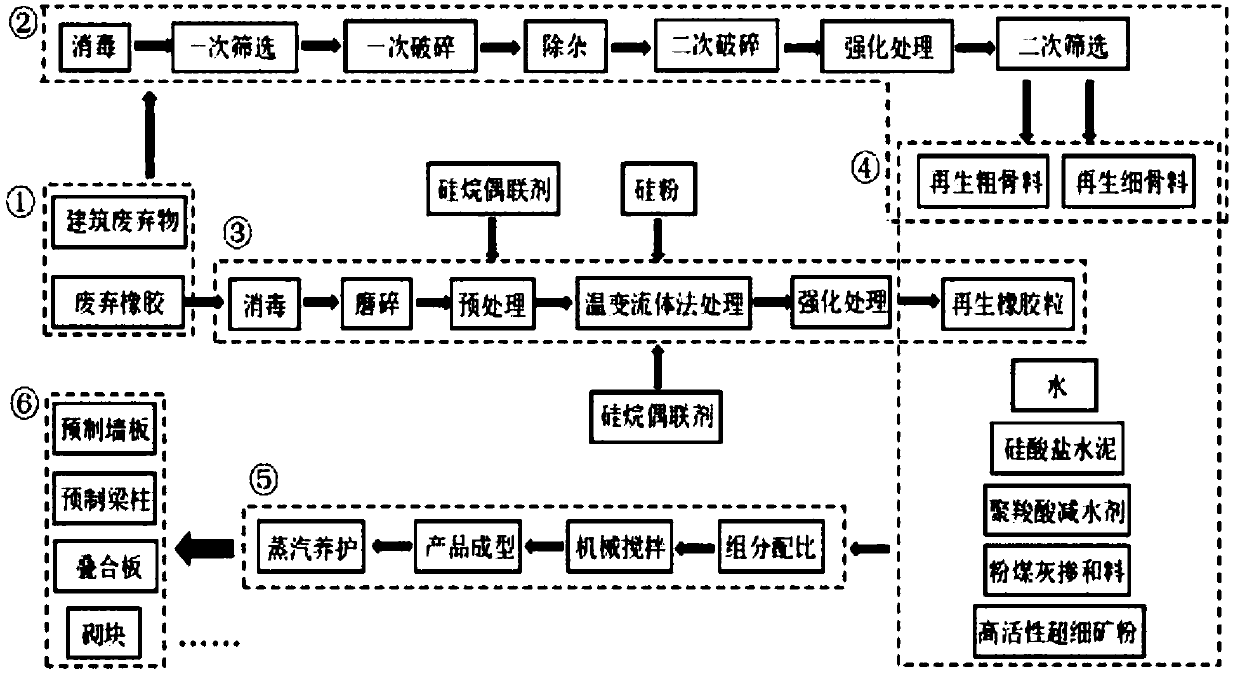

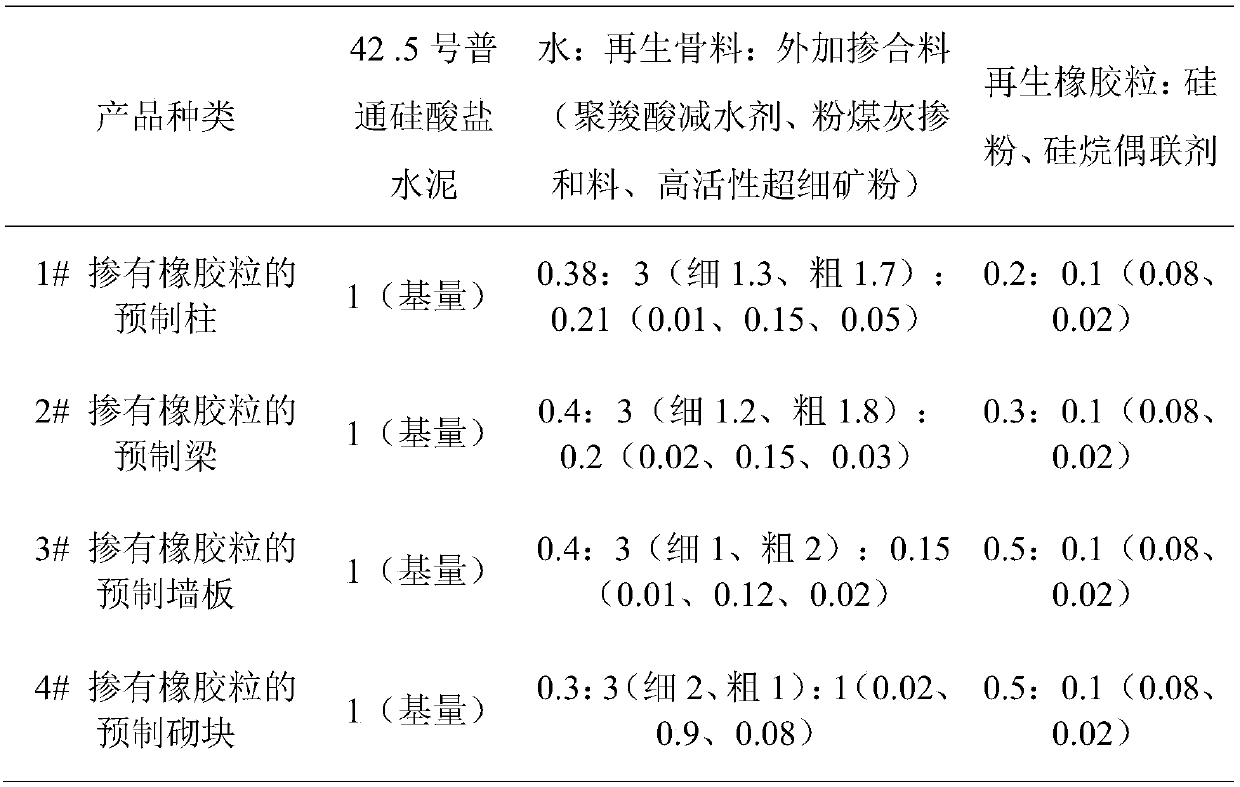

Recycled concrete doped with rubber particles as well as preparation method and application thereof

The invention provides recycled concrete doped with rubber particles as well as a preparation method and application thereof. Construction garbage is disinfected, broken, decontaminated, sieved, strengthened and the like to prepare recycled aggregates; abandoned rubber tyres and the like are used for preparing rubber particles through technologies including disinfection, breaking, preprocessing, temperature change fluid method processing, strengthening processing and the like; the obtained recycled composite aggregates, silicate cement, water and other mineral admixture are mixed to prepare different concrete products, including recycled concrete prefabricated wall panels, building blocks and the like doped with rubber particles, through a subsequent technology by controlling different proportions. The concrete prepared with the method has the advantages of environment protection, low price, stable mechanical property, good durability and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

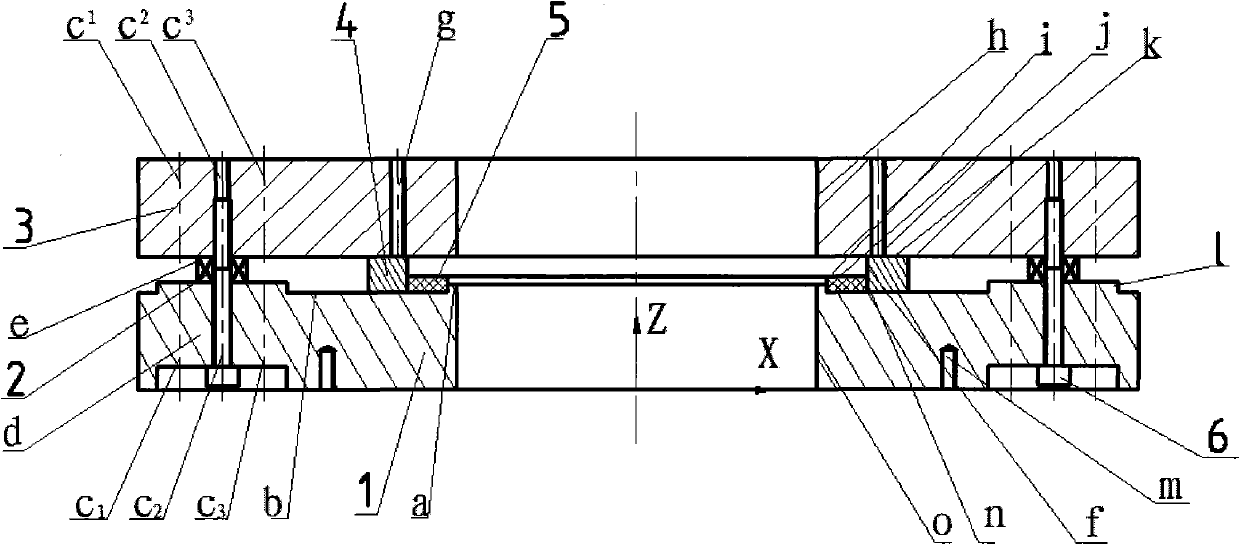

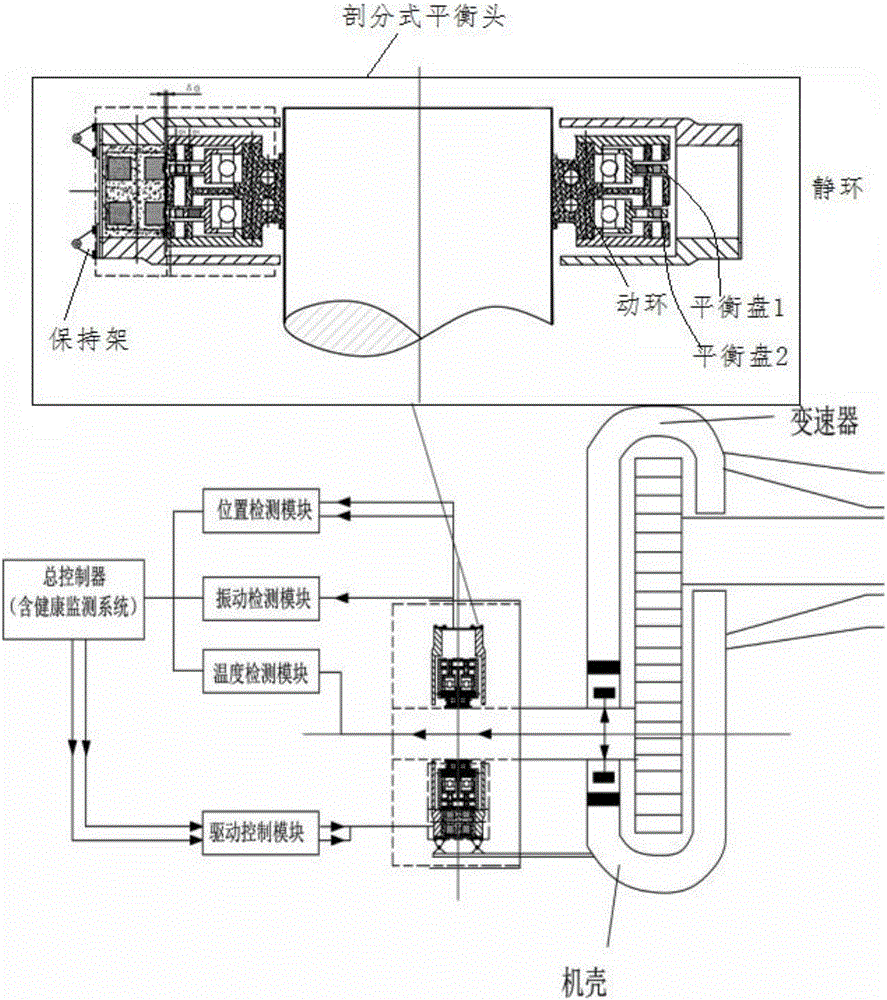

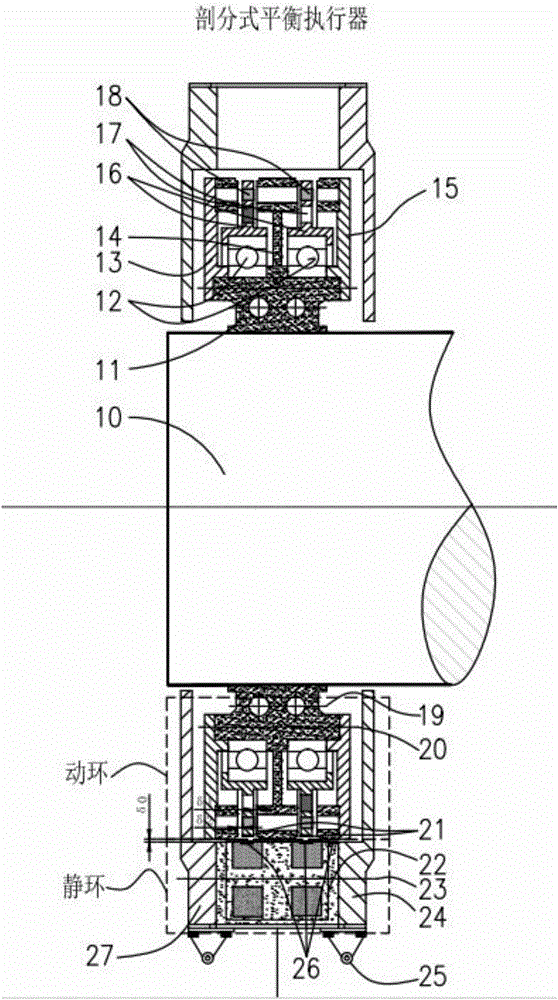

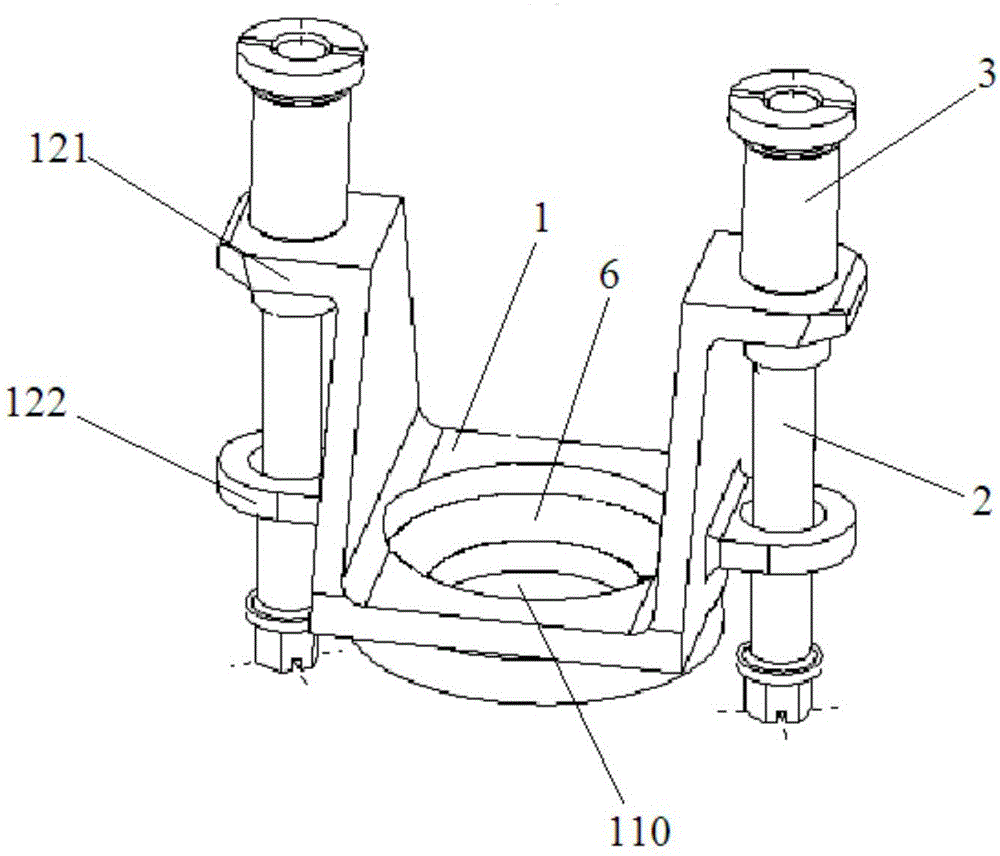

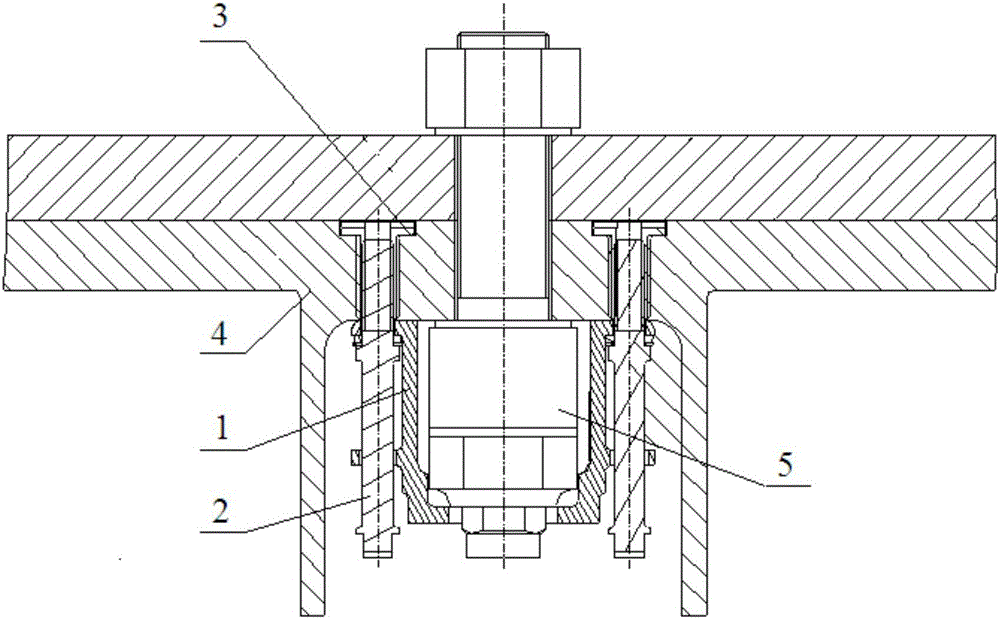

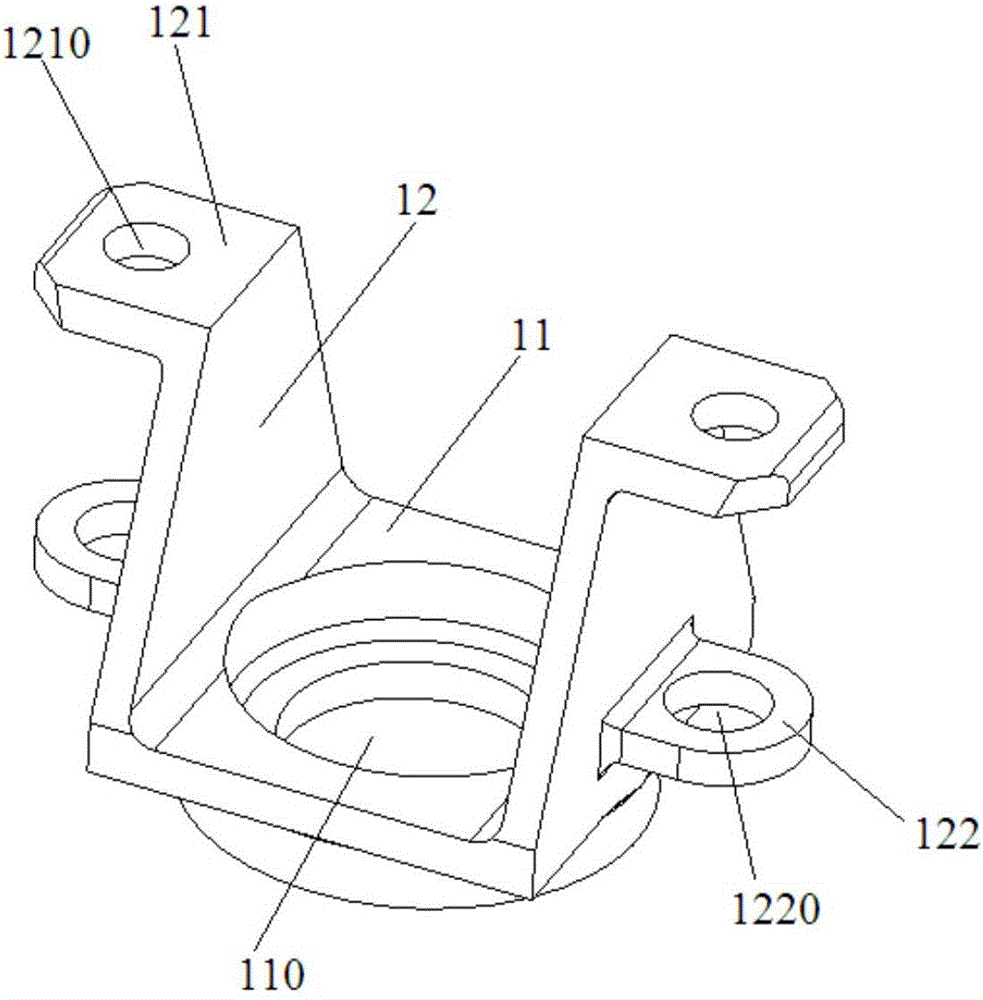

Split type automatic balancing device for realizing on-line automatic balance of rotating machine

ActiveCN106768642AImprove the installation effectSave assembly timeStatic/dynamic balance measurementEngineeringOriginal Device

The invention discloses a mechanical device for realizing the on-line automatic balance of a rotating machine. The device is of a split type structure, and comprises two parts of a split type moving ring and a split type stationary ring, wherein a split type transitional sleeve is connected with a rotating main shaft and the moving ring, and plays a role of supporting the moving ring; the series mounting and fixation are realized for all split components of the stationary ring in the axial direction through stationary ring set bolts; a split structure is adopted by the stationary ring; the stationary ring enwraps the moving ring in the circumferential direction; the split surfaces of all the split components of the moving ring are connected respectively by adopting ways of a bolt, a plug-in type, a connecting piece and the like; all the split components of the moving ring are subjected to the series mounting and fixation in the axial direction through moving ring set bolts. By using the split type structure of the mechanical device, an automatic balancing device is enabled to not only be applicable to the development of a novel product but also be applicable to an in-service rotating appliance; the simplification and the convenience of an automatic balancing head in mounting and disassembly processes are promoted greatly; the assembly and the disassembly of the automatic balancing device can be completed without needing to disassemble an original device; the application and popularization of the automatic balancing device are facilitated.

Owner:BEIJING UNIV OF CHEM TECH

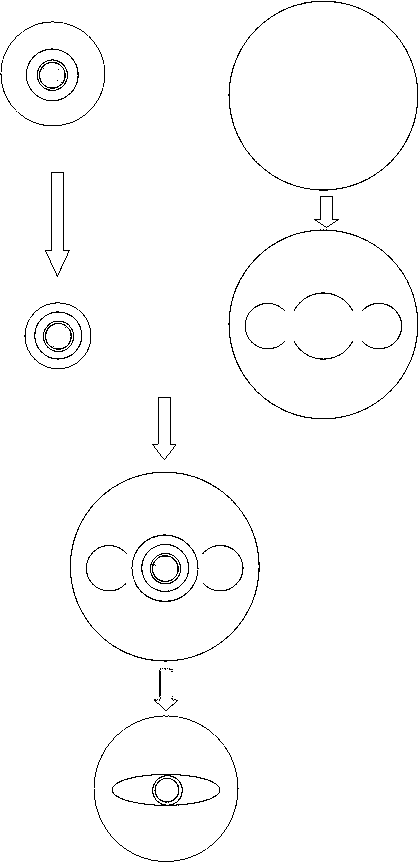

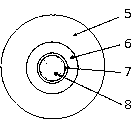

Manufacture method of elliptical stressed zone type polarization maintaining fiber

ActiveCN103253860ASimple processEasy to productizeGlass making apparatusOptical fibre with polarisationOvalityCore (optical fiber)

The invention discloses a manufacture method of elliptical stressed zone type polarization maintaining fiber, which comprises the following steps: producing a prefabricated rod to be processed with a stressed zone using MCVD technology; fixing the prefabricated rod to be processed on a grinding machine, grinding the external diameter to an appropriate dimension, and obtaining a core rod of the fiber prefabricated rod; drilling three apertures on the transverse plane of a quartz rod, obtaining a quartz coating member; inserting the core rod into a central aperture of the quartz coating member, obtaining a formal fiber prefabricated rod; fixing the fiber prefabricated rod on an optical fiber drawing tower and drawing into an elliptical stressed zone type polarization maintaining fiber. The cross section structure of the elliptical stressed zone type polarization maintaining fiber comprises from outside to inside in order: an outer cladding (1), a stressed zone (2), an inner cladding (3) and a core layer (4), which is characterized in that the stressed zone (2) is in elliptical shape, and the ovality is above 2.5:1. The invention has the advantages that the outer coating member is made of high purity quartz with low cost, and the production cost is reduced; the process flow is simple, and the repeatability is high, and the circular hole interior surface has a high fineness and good symmetry, and method improves the processing efficiency, and the optical performance and reliability of the polarization maintaining fiber are substantially improved.

Owner:北京玻璃研究院有限公司 +1

Explosive bolt acquirer

InactiveCN106403733AGuaranteed impact resistanceEasy to installSelf-propelled projectilesHigh volume manufacturingEngineering

The invention relates to the technical field of projectile body structural design, in particular to an explosive bolt acquirer. The explosive bolt acquirer comprises a support and an installation bolt, the support is in an inversed-n shape and comprises a base plate and two side plates, the side plates and the two ends of the base plate are integrally molded, the upper ends of the side plates extend to the outer sides to be provided with end edges, and installation holes are formed in the end edges; the installation bolt penetrates the installation holes to be connected with a shell end frame so that the support can be fixed to the lower surface of the shell end frame, the base plate is provided with a buffer hole, and a bolt head of an explosive bolt is located between the two side plates and is embedded into the buffer hole. Compared with a traditional explosive bolt acquiring structure, the explosive bolt acquirer is convenient and rapid to install, the design, analyzing and testing cost is reduced, projectile body structural design quick response and cost reduction are achieved, material selecting and machining can be separated from material selecting and machining of a projectile body overall bin, the machining difficulty is reduced, selectable materials are many, the production efficiency is improved, productization is facilitated, and the large-batch production efficiency is high.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

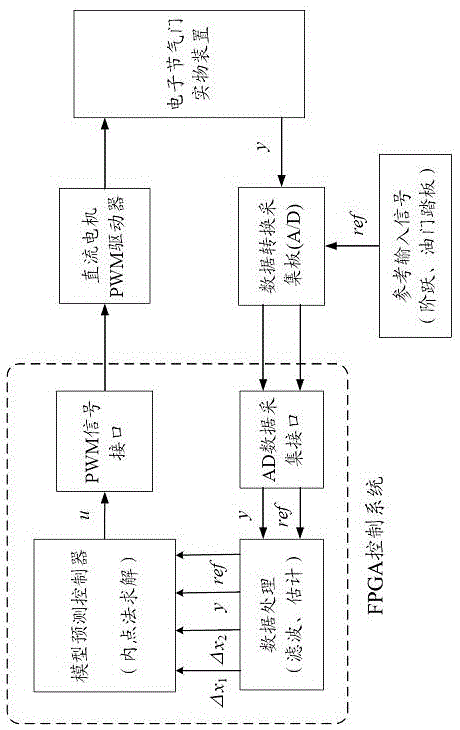

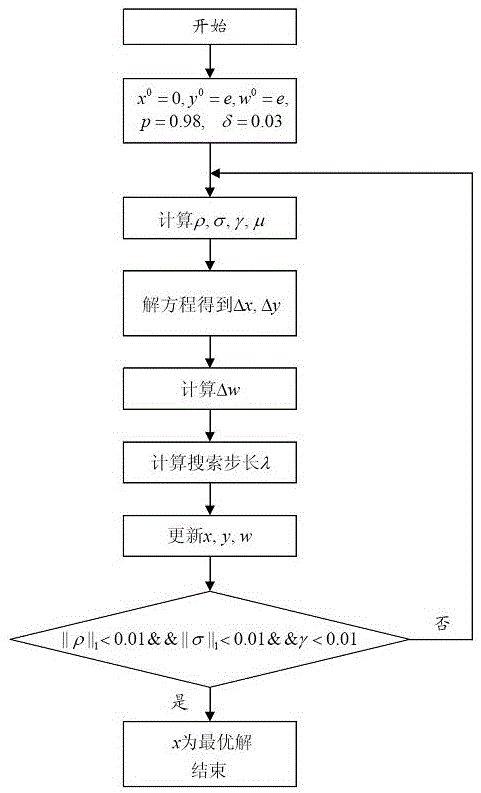

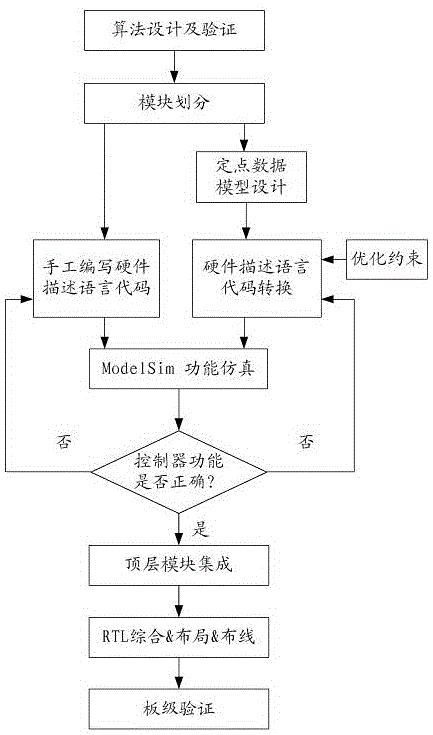

Model prediction control system for electronic throttle valve based on FPGA

InactiveCN105114189ASolving multi-objective constrained control problemsImprove anti-interference abilityEngine controllersMachines/enginesFpga implementationsConstraint control

The invention provides a model prediction control system for an electronic throttle valve based on FPGA, and belongs to the field of automotive electronic technology. The purpose of the invention is to provide a model prediction control system for an electronic throttle valve based on FPGA, wherein the model prediction control system can well meet control demands of a throttle valve, can be flexibly to reduce, expand and upgrade on line, and overcome shortages of an electronic control system of a present electronic throttle valve. The method of the system comprises designing a model prediction controller and implementing a control system through FPGA. The invention designs an advanced model prediction controller of a throttle valve, constraint optimization is successful, multi-target constraint control can be achieved because the throttle valve can quickly and accurately track, a good control effect is achieved. The model prediction control system for the electronic throttle valve based on the FPGA can be conveniently to upgrade, expand and maintain, the service life of a product can be prolonged, and costs of development and maintenance are reduced. Compared with a control system based on a single chip microcomputer or the like, the control system based on the FPGA is strong in anti-interference, productization is easier, and design on a special control chip can be achieved.

Owner:JILIN UNIV

Light source and setting method thereof, and optical detection method and system

PendingCN113155845AHigh strengthAvoid saturationElectrical apparatusOptically investigating flaws/contaminationLuminous intensityGray level

The invention discloses a light source and a setting method thereof, and an optical detection method and system. The method comprises the following steps: acquiring image gray level distribution characteristic data of a standard sample in a camera view field range; adjusting the light-emitting intensity distribution of a light source according to the image gray level distribution characteristic data, wherein the light source is an area array light-emitting device, and the area array light-emitting device comprises a light-emitting unit with controllable light-emitting intensity; and using an adjusted light source to illuminate a detected product, adjusting the luminous intensity distribution of an area array illumination light source, feeding back the compensated brightness distribution to the light source, and carrying out illumination for compensating the brightness distribution. Image saturation of a high-reflection area is avoided, and meanwhile the image brightness of a low-reflection area is improved. Therefore, the detection precision of the detected object irradiated by the light source is improved.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD +1

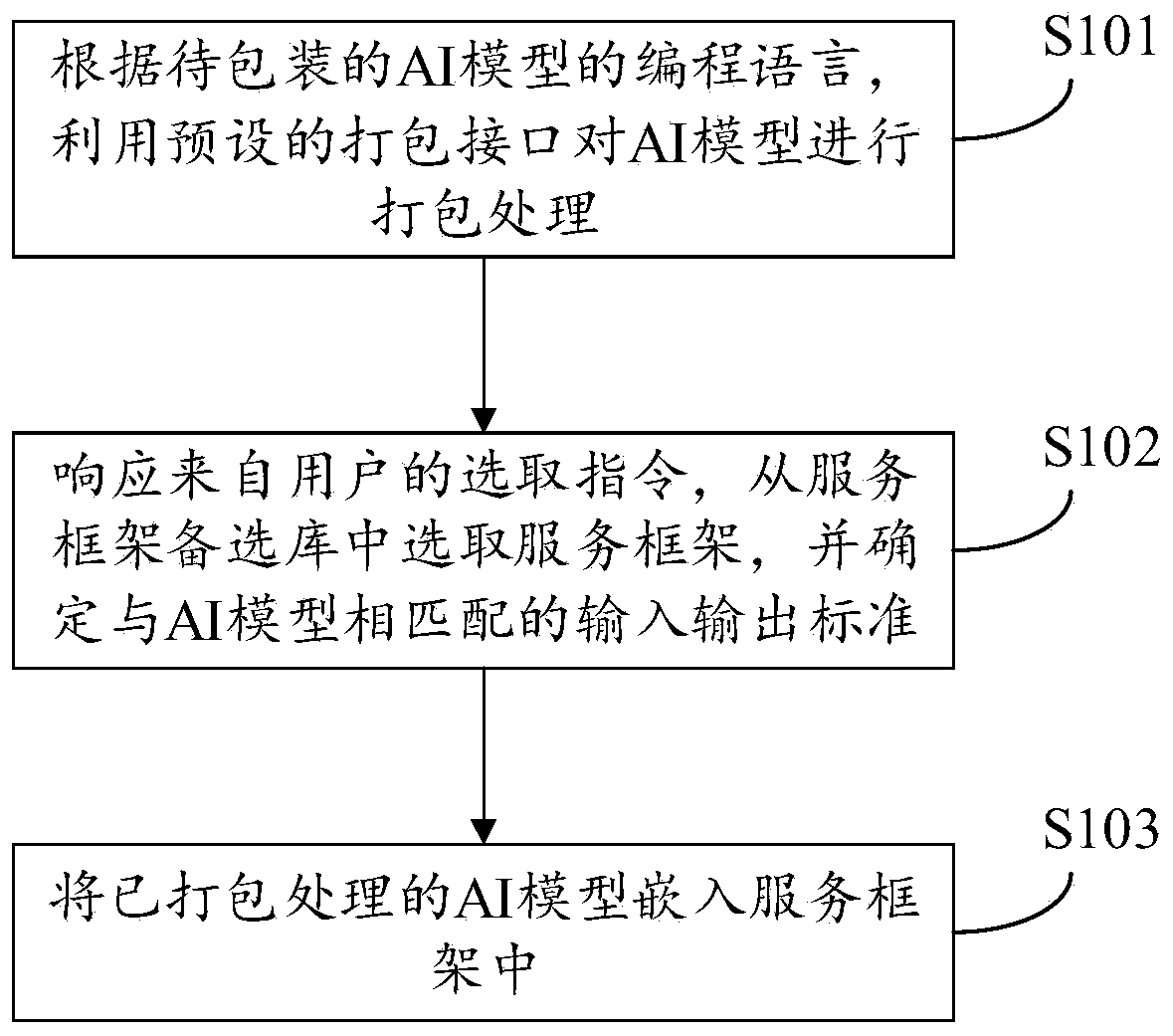

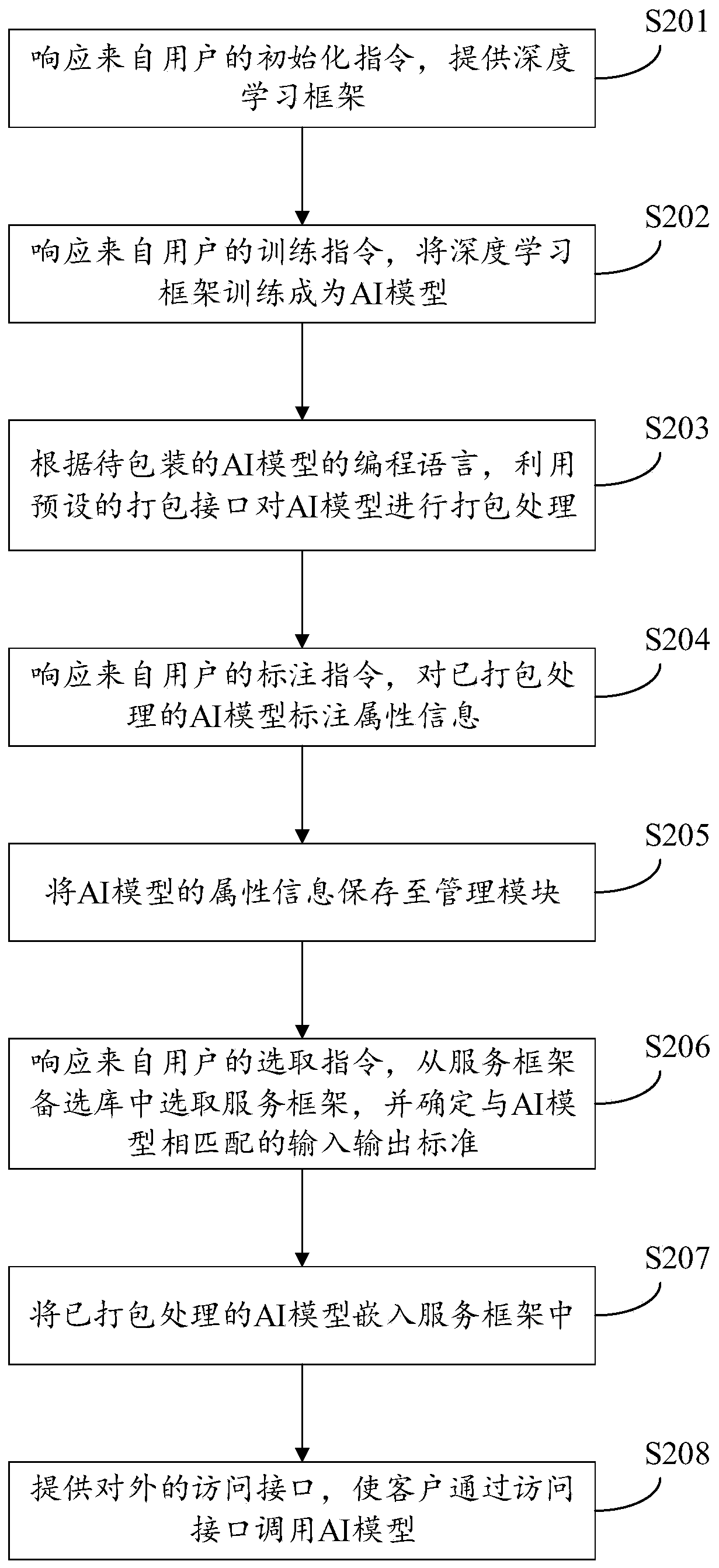

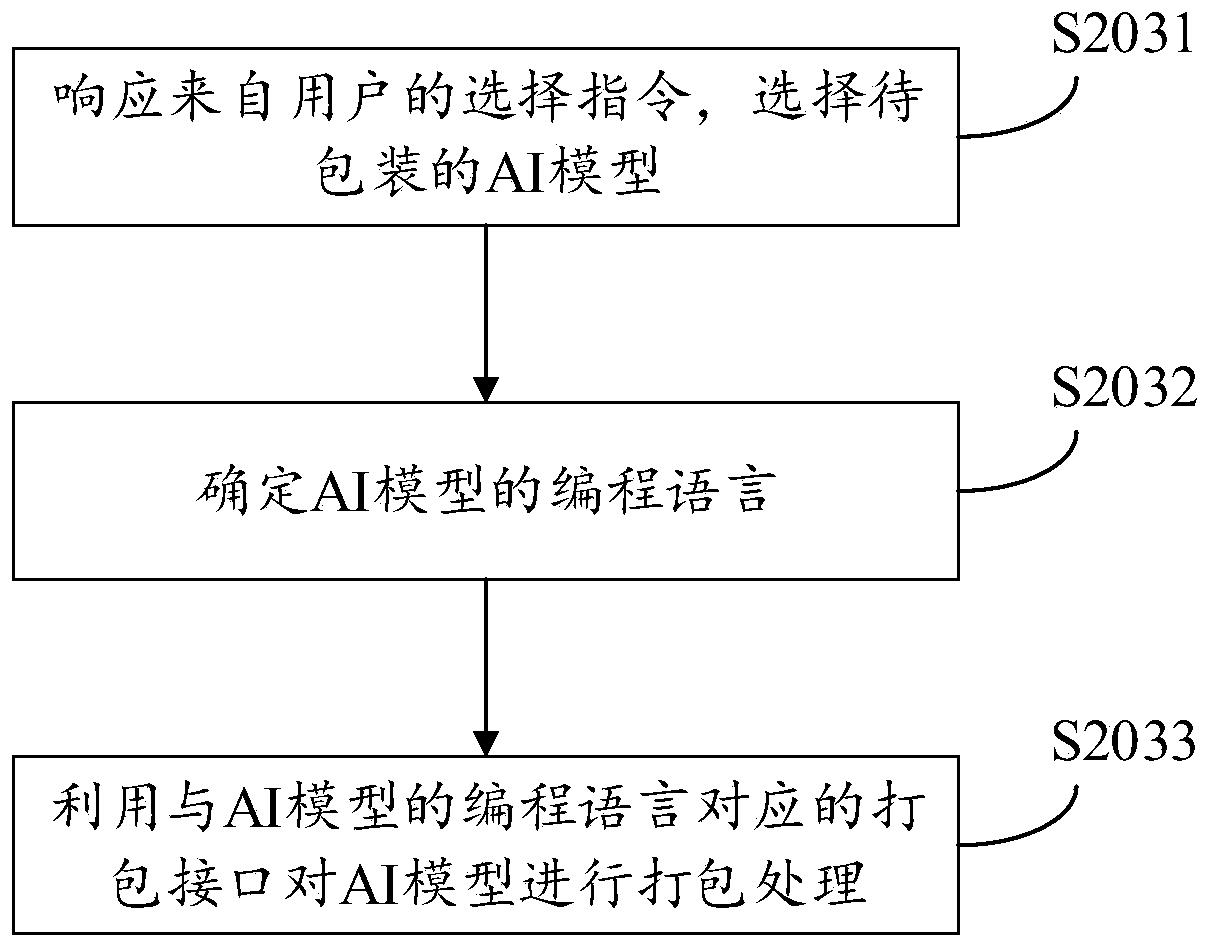

AI model packaging method and platform and electronic equipment

PendingCN111290778AEasy to productizeProductizationVersion controlSoftware simulation/interpretation/emulationSoftware engineeringArtificial intelligence

The invention provides an AI model packaging method and platform and electronic equipment, and relates to the technical field of artificial intelligence. The AI model packaging method comprises the steps of according to the programming language of an AI model to be packaged, using a preset packaging interface for packaging the AI model; in response to a selection instruction from a user, selectinga service framework from a service framework alternative library, and determining an input and output standard matched with the AI model; and embedding the packaged AI model into the service framework. According to the AI model packaging method and platform and the electronic equipment provided by the invention, the learning cost of an AI algorithm researcher is reduced, and the productization speed of the AI model is increased.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com