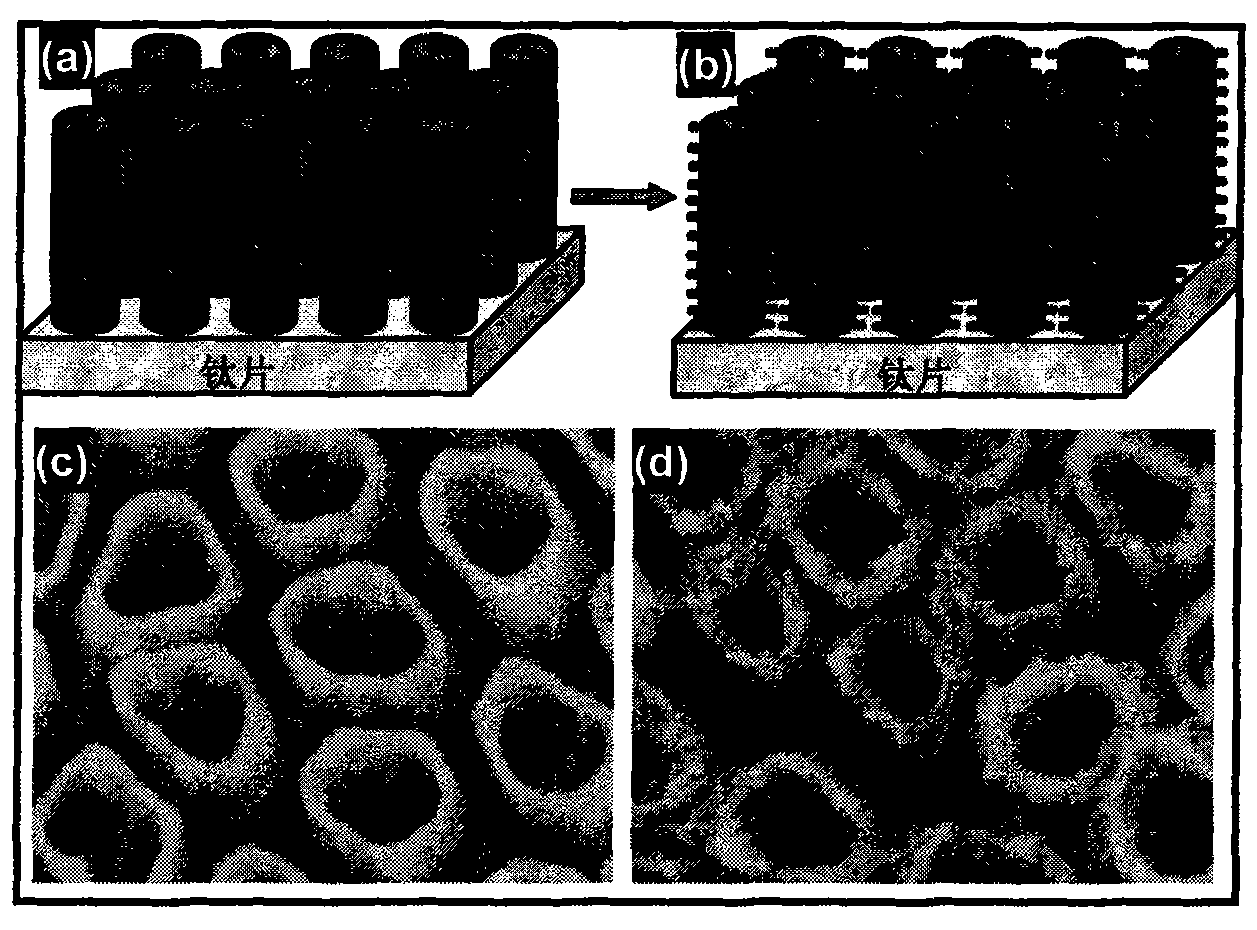

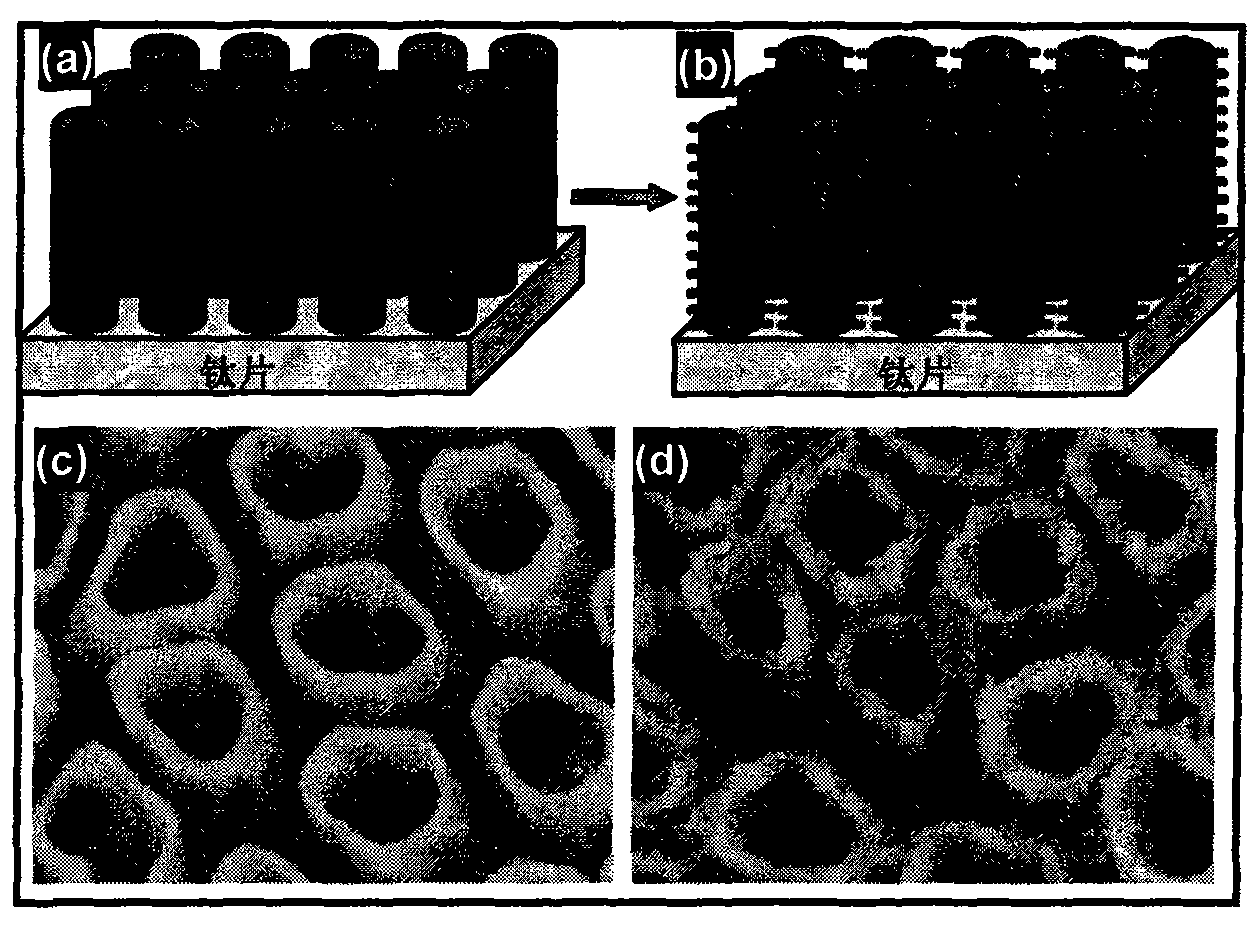

Preparation process of dendritic titanium dioxide nanotube array electrode

A nanotube array, titanium dioxide technology, applied in electrode manufacturing, nanostructure manufacturing, nanotechnology, etc., to achieve the effect of increasing specific surface area, improving performance, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Concrete processing steps of the present invention are as follows:

[0021] ①. Select titanium foil with a thickness of 0.2mm and a purity of 99.99% and cut it into 2×3cm 2 The square, with the diluted hydrofluoric acid and the aqueous solution of nitric acid, has carried out chemical polishing, removes the oxide on the surface, then washes and dries with absolute ethanol and secondary water as standby anode (that is, the preparation of TNTs by anodic oxidation method base material);

[0022] ②. Mix and stir 0.45g of ammonium fluoride and 85ml of lactic acid until fully dissolved, then add 10ml of dimethyl sulfoxide as the electrolyte for preparing TNTs by anodic oxidation;

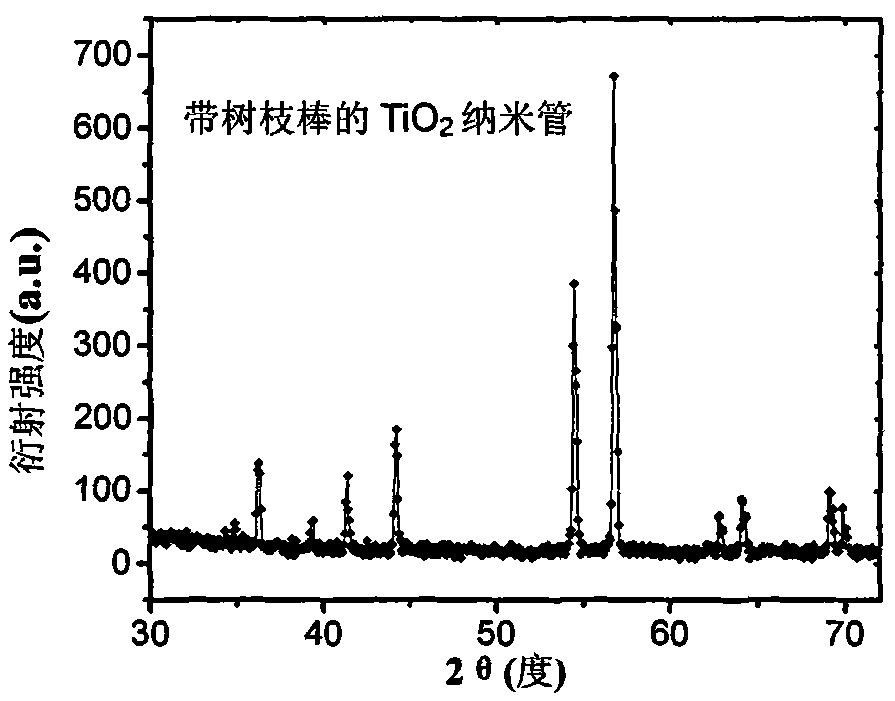

[0023] ③.Using carbon rods as cathodes, making an anodic oxidation tank, titanium foils as anodes, adding the prepared electrolyte, and applying a DC voltage of 50V under laboratory temperature conditions for 9 hours to obtain TNTs with an amorphous structure; then , and annealed at 400°C for 1 h...

Embodiment 2

[0029] Concrete processing steps of the present invention are as follows:

[0030] ①. Use titanium foil with a thickness of 0.2mm and a purity of 99.99% and cut it into 2×3cm 2 The square, with the diluted hydrofluoric acid and the aqueous solution of nitric acid, has carried out chemical polishing, removes the oxide on the surface, then washes and dries with absolute ethanol and secondary water as standby anode (that is, the preparation of TNTs by anodic oxidation method base material);

[0031] ②. Mix and stir 0.41g of ammonium fluoride and 90ml of lactic acid until fully dissolved, then add 9ml of dimethyl sulfoxide as the electrolyte for preparing TNTs by anodic oxidation;

[0032] ③.Using carbon rods as cathodes, making an anodic oxidation tank, titanium foils as anodes, adding the prepared electrolyte, and applying a DC voltage of 50V under laboratory temperature conditions for 9 hours to obtain TNTs with an amorphous structure; then , and annealed at 400°C for 1 hour ...

Embodiment 3

[0037] Concrete processing steps of the present invention are as follows:

[0038] ①. Select titanium foil with a thickness of 0.2mm and a purity of 99.99% and cut it into 2×3cm 2 The square, with the diluted hydrofluoric acid and the aqueous solution of nitric acid, has carried out chemical polishing, removes the oxide on the surface, then washes and dries with absolute ethanol and secondary water as standby anode (that is, the preparation of TNTs by anodic oxidation method base material);

[0039] ②. Mix and stir 0.4g ammonium fluoride and 87ml lactic acid until fully dissolved, then add 8ml dimethyl sulfoxide as the electrolyte for preparing TNTs by anodic oxidation;

[0040] ③.Using carbon rods as cathodes, making an anodic oxidation tank, titanium foils as anodes, adding the prepared electrolyte, and applying a DC voltage of 50V under laboratory temperature conditions for 9 hours to obtain TNTs with an amorphous structure; then , and annealed at 400°C for 1 hour to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com