Battery pack preheating method and system thereof

A battery pack and preheating technology, which is applied in the field of power electronics, can solve the problems of reducing the mass/volume ratio energy and mass/volume ratio power of the battery pack, local temperature fine-tuning, and complex design, etc., so as to be beneficial to engineering and product The effects of modernization, reliable and practical use value, and shortened heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The drawings show by way of illustrations specific details in which the invention may be practiced. These embodiments are described in sufficient detail to enable those skilled in the art to practice the invention. These embodiments may be practiced with a lesser degree of these specific details, and structural, logical, and functional changes may be made in these embodiments without departing from the scope of the present invention. These embodiments are not necessarily mutually exclusive, as, depending on the particular application, features of one embodiment can be combined with features of another embodiment to form new embodiments. In the following description, for the sake of brevity, only elements / components closely related to the present invention are described.

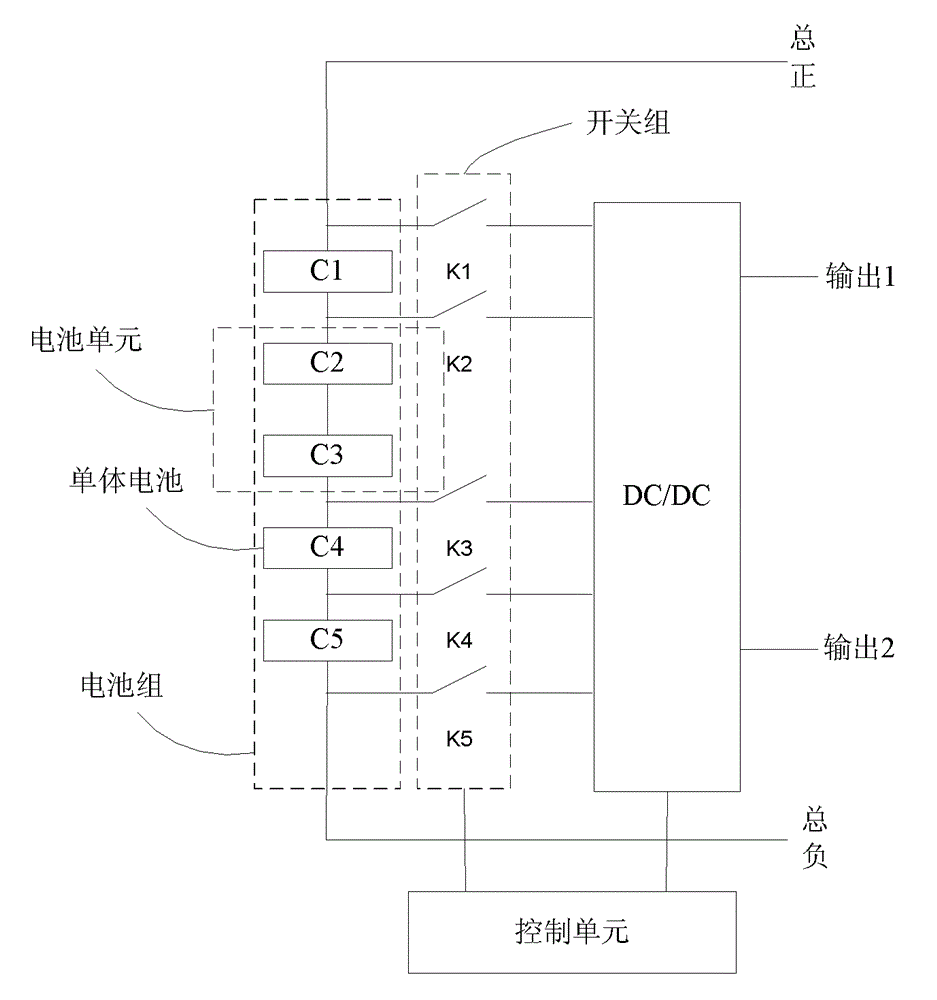

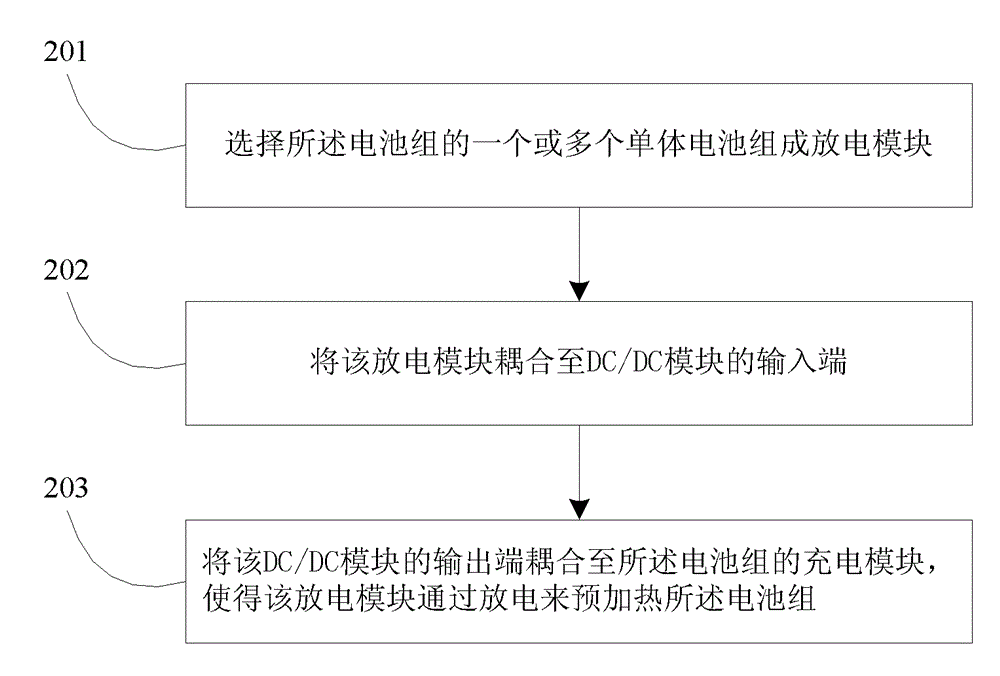

[0012] figure 1 is a schematic diagram of a system for preheating a battery pack according to an embodiment of the present invention. As shown in the figure, the battery pack is composed of single c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com