Recycling processing technology for high-salt wastewater during carboxymethyl cellulose production

A technology of carboxymethyl cellulose and treatment process, which is applied in the field of high-salt refractory organic wastewater, can solve the problems of reaction principle and reaction substances without much change, and achieve less difficulty in operation and management, improved purity, and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

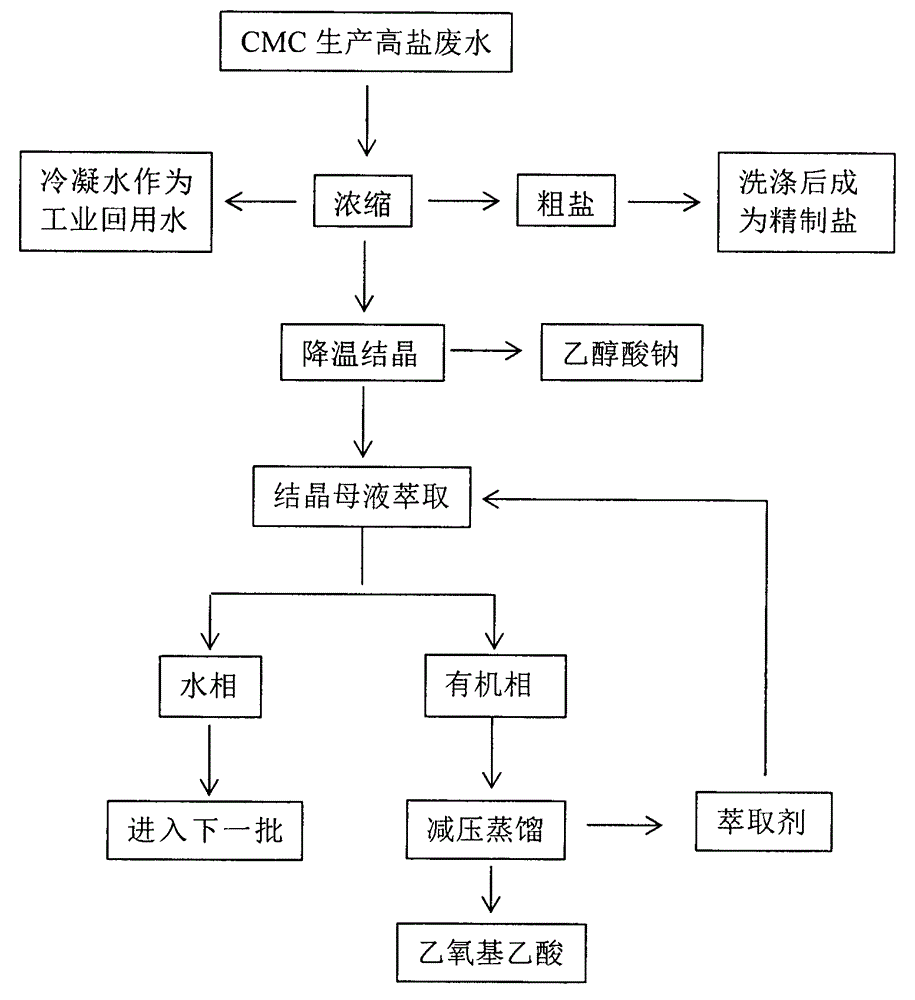

Method used

Image

Examples

Embodiment approach 1

[0034] (1) Take 2L of waste water provided by a CMC manufacturer in Jiangsu. After measuring its solid content of 200g / L, add 1% diatomite to the waste water, and obtain a clearer filtrate by suction filtration, and control the vacuum degree to -0.08Mpa , Concentrate the filtrate under the condition of about 80°C, and filter the concentrate while it is hot. The filter cake is sodium chloride, and the purity is about 96%. The filtrate was collected for the second concentration.

[0035] (2) by step (1) processing gained filtrate is wherein the concentration of sodium glycolate is 227g / L after measuring, and this filtrate is-0.08Mpa in vacuum tightness, carry out secondary concentration under 80 ℃ of conditions, filter concentrated solution while hot, Glycolic acid concentration is 373g / L in the filtrate.

[0036] (3) The pH value of the filtrate obtained in step (2) is adjusted to 10 with sodium hydroxide, and sodium glycolate is crystallized by means of temperature programmin...

Embodiment approach 2

[0040] (1) Take 2L of waste water provided by a CMC manufacturer in Jiangsu. After measuring its solid content of 200g / L, add 1% diatomite to the waste water, and obtain a clearer filtrate by suction filtration, and control the vacuum degree to -0.08Mpa , Concentrate the filtrate under the condition of about 80°C, and filter the concentrate while it is hot. The filter cake is sodium chloride, and the purity is about 96%.

[0041] (2) The concentration of glycolic acid in the obtained filtrate from step (1) is 218g / L. Add hydrochloric acid to adjust the pH to 1, filter, add extractant to obtain aqueous phase and organic phase, and the organic phase is distilled under reduced pressure to recover and extract agent to obtain ethoxyacetic acid at the same time.

[0042](3) The water phase obtained in step (2) was mixed with the water phase in step (5) in embodiment 1, and the pH value was adjusted to 10 with sodium hydroxide, and the sodium glycolate was crystallized by means of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com