Patents

Literature

39 results about "Ethoxyacetic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethoxyacetic acid is found in herbs and spices. Ethoxyacetic acid is a component of perilla leaf extract (Perilla frutescens

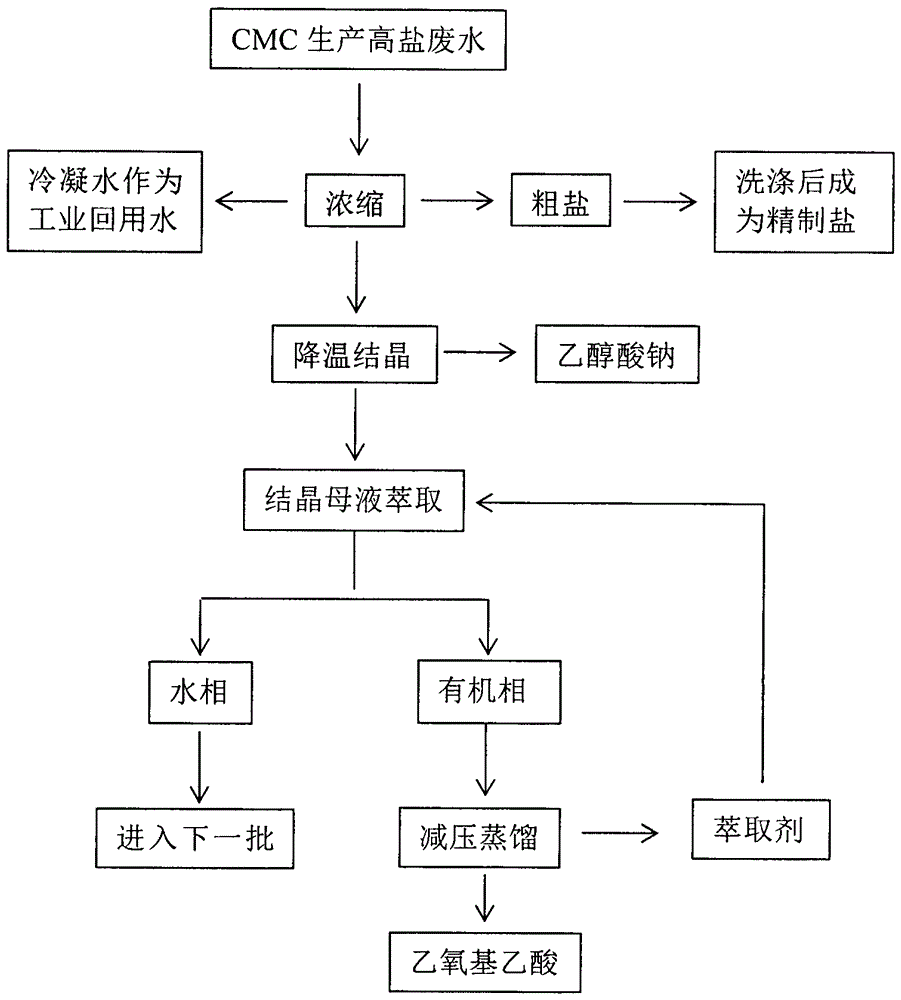

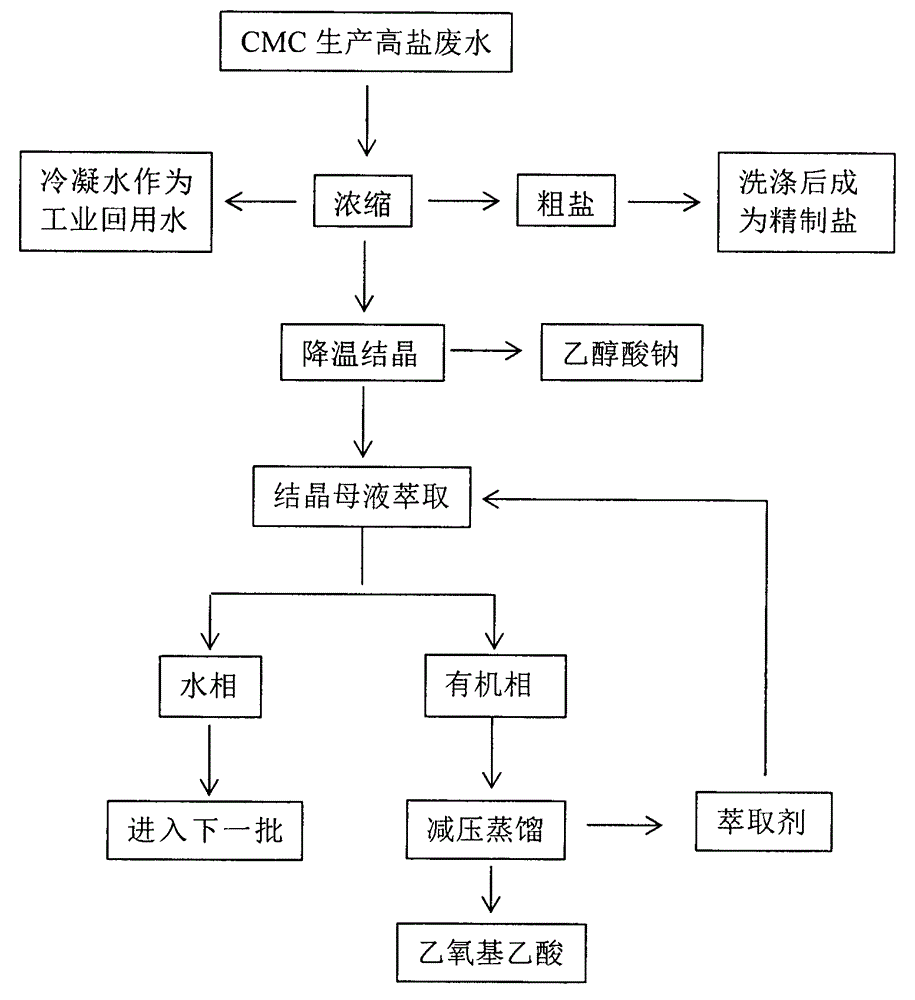

Recycling processing technology for high-salt wastewater during carboxymethyl cellulose production

ActiveCN104370312AAvoid mutual interferenceHigh purityMultistage water/sewage treatmentNature of treatment waterEvaporationEthoxyacetic acid

The invention discloses a recycling processing technology for high-salt wastewater during carboxymethyl cellulose production. The processing technology combines extraction and graded crystallization technologies. In the graded crystalization process, through multi-effect (or mechanical recompression) evaporation crystallization, crude salt is recovered from wastewater and condensate water is evaporated, the condensate water reaches the industrial reuse water standard, and refined salt is prepared from crude salt through washing; and then through cooling crystallization, sodium glycollate crystal is separated out, the crystallization mother liquid is used for a next crystallization process, so that closed cycle is realized. In the above graded crystallization process, ethoxyacetic acid is obtained by performing extraction separation on a concentrated liquid, and the viscosity is reduced. The method is simple in operation, low in cost and high in separation recovery rate. The whole processing technology employs closed cycle, has no pollutants, and is easy for industrialization. The technology helps to solve the high-salt wastewater processing problem in the carboxymethyl cellulose production process, also helps to realize the recycling processing purposes of turning harm into good and changing wastes into valuables, and has substantial economic, social and environment benefit.

Owner:JIANGNAN UNIV

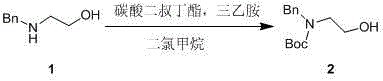

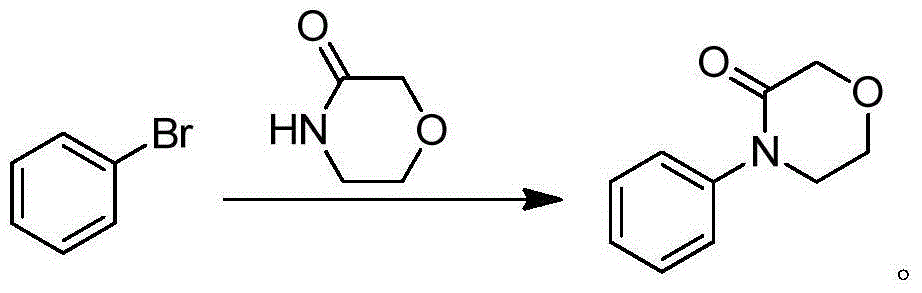

Methods of synthesizing and using derivatives of [2-(2-aminoethoxy)ethoxy] acetic acid

InactiveUS7038078B2Easy to synthesizeImprove featuresOrganic compound preparationCarboxylic preparation by oxidationAcetic acidPolyethylene glycol

A synthetic reaction to produce [2-(2-aminoethoxy)ethoxy] acetic acid (AEEA) derivatives. This synthetic reaction does not require isolation and purification of intermediates. The AEEA derivatives can be used to synthesize high load polystyrene-polyethylene glycol-like resins having excellent swelling characteristics.

Owner:UNIV OF MARYLAND BALTIMORE

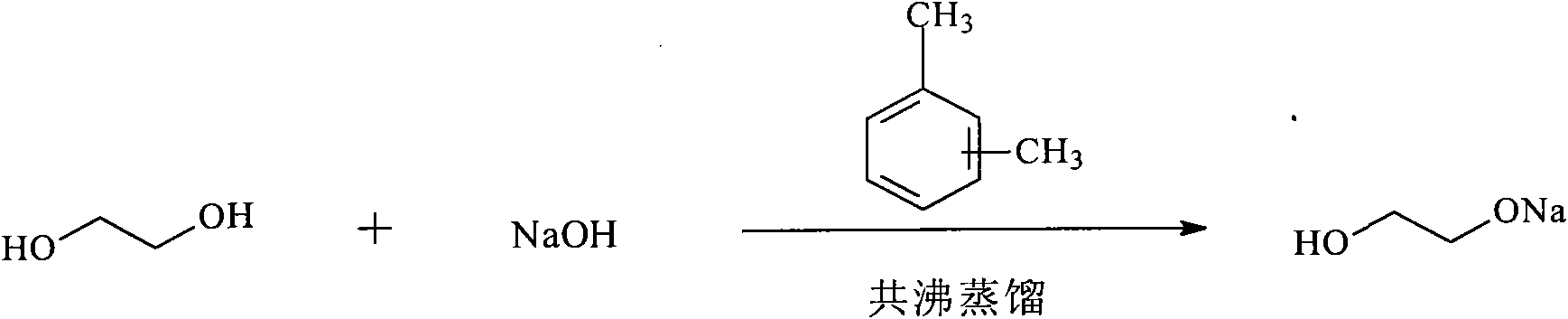

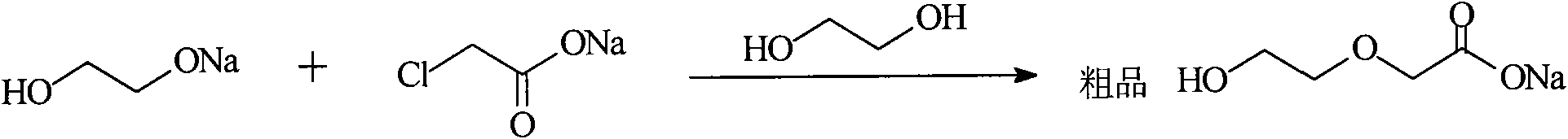

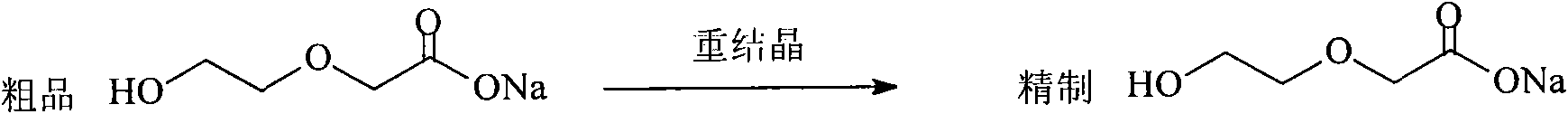

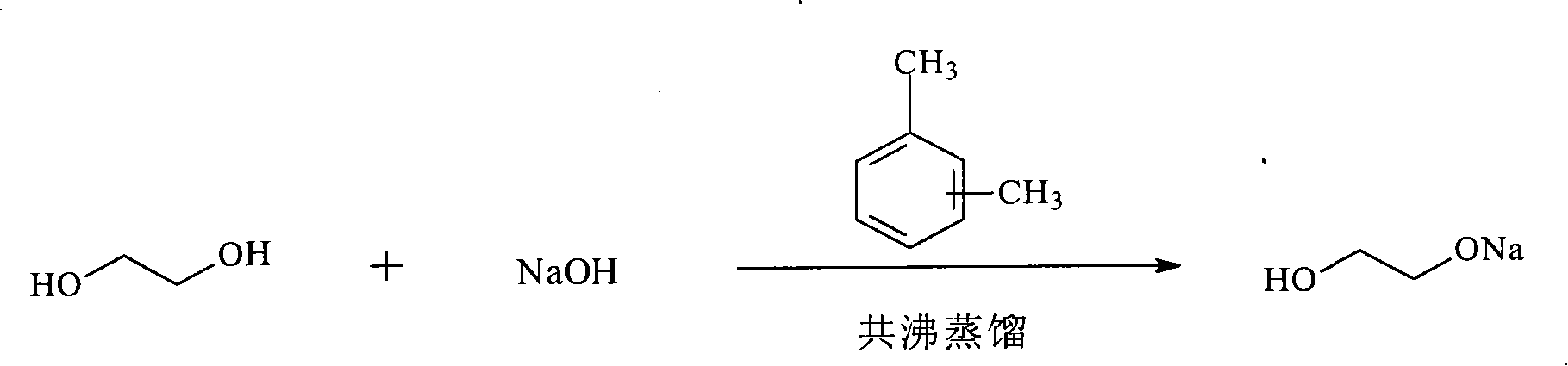

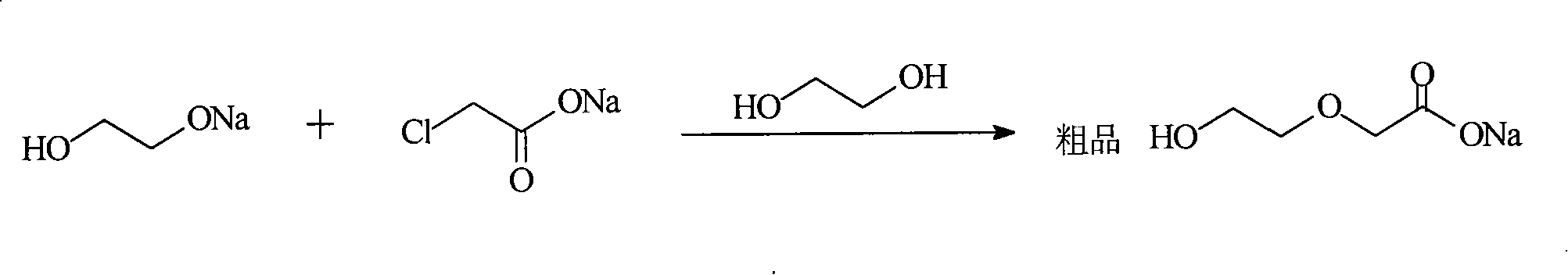

Method for synthesizing 1,4-dioxane-2-ketone by ethylene glycol

The invention discloses a method for synthesizing 1,4-dioxane-2-ketone by ethylene glycol. The method comprises the following steps of: 1, synthesis of ethylene glycol monosodium: mixing a dehydrating agent, ethylene glycol and sodium hydroxide for reaction, cooling down the mixed solution to the room temperature after reaction, standing the mixed solution for demixing to obtain upper-layer liquid, and directly using the upper-layer liquid in the next reaction, wherein the ethylene glycol mixed in the lower-layer ethylene glycol monosodium is unnecessarily separated; 2, synthesis of beta-hydroxyethoxy sodium acetate: mixing ethylene glycol, sodium monochloroacetate and ethylene glycol monosodium for reaction, adding sulfolane to the mixed solution after reaction, recovering ethylene glycol by vacuum distillation, cooling down the mixed solution, then adding acetone to the mixed solution, and obtaining a coarse product of beta-hydroxyethoxy sodium acetate; and 3, synthesis of 1,4-dioxane-2-ketone by ethylene glycol: adding beta-hydroxyethoxy sodium acetate to an oxygen heterocycle containing solvent, slowly adding concentrated sulfuric acid to the mixed solution dropwise when the mixed solution is stirred, and obtaining the finished product of 1,4-dioxane-2-ketone by ethylene glycol. The method takes ethylene glycol as a synthetic raw material, the products are easily separated, and the selectivity is high; and the solvents used in the reaction can be recovered in high efficiency for reutilization, so that the method is environment friendly.

Owner:NANTONG FINC PHARMA CHEM +1

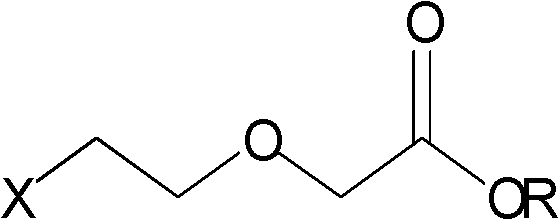

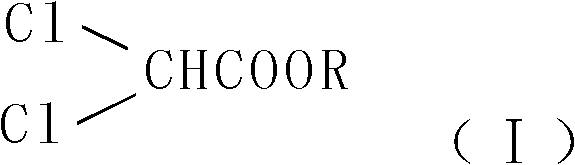

Preparation of haloethoxyacetic acid and esters thereof

ActiveCN102464580AReaction raw materials are cheapReaction raw materials are readily availableOrganic compound preparationCarboxylic acid esters preparationAcetic acidAlcohol

The invention relates to preparation of 2-(2-haloethoxy) acetic acid and esters thereof. The preparation comprises the following steps of: undergoing an oxidation reaction on 2-(2-haloethoxy) ethanol serving as a raw material under the actions of a catalyst and an oxidant at the temperature of 10-50 DEG C to obtain 2-(2-haloethoxy) acetic acid; and undergoing an esterification reaction on the 2-(2-haloethoxy) acetic acid and corresponding alcohols of a target ester under the action of a catalyst to obtain 2-(2-haloethoxy) acetic ester. According to the preparation method disclosed by the invention, a two-step reaction can be undergone with a one-pot process, so that easy operation is achieved. The preparation process disclosed by the invention is safe and environmentally-friendly, has high yield, and is very suitable for industrial production.

Owner:CHONGQING HUABANGSHENGKAI PHARM

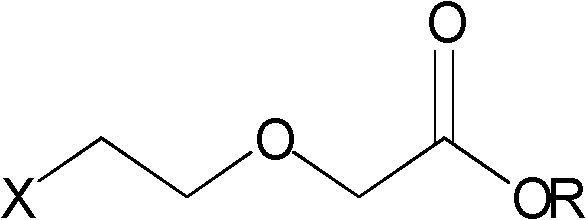

Process for the preparation of esters of [2-[4-[(4-chlorophenyl)phenylmethyl]-1-piperazinyl]-ethoxy]acetic acid

The invention provides a process for the preparation of esters [2-[4-[(4-chlorophenyl)phenylmethyl]-1-piperazinyl]ethoxy]acetic acid, of the formula (I) wherein X represents a halogen atom and R represents a lower alkyl group comprising reacting: (a) a compound of the formula (II) (b) a compound of the formula (III) and (c) a tertiary amine as a solvent and as an acid scavenger at a temperature of at least 100 DEG C., wherein X is a halogen atom, X' is selected from the group consisting of bromine and chlorine and R is a lower alkyl group.

Owner:WAVELENGTH ENTERPRISES LTD

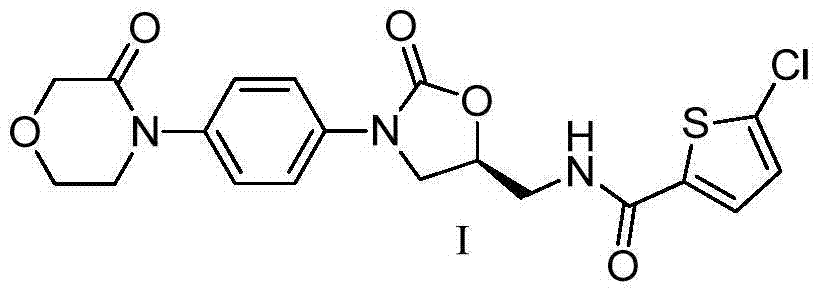

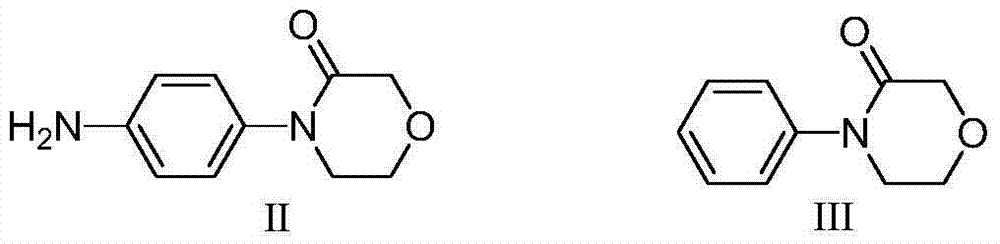

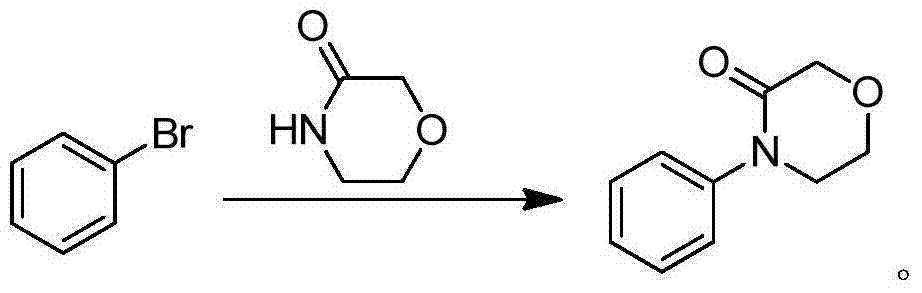

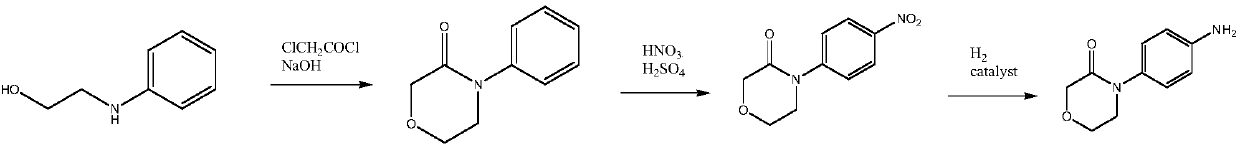

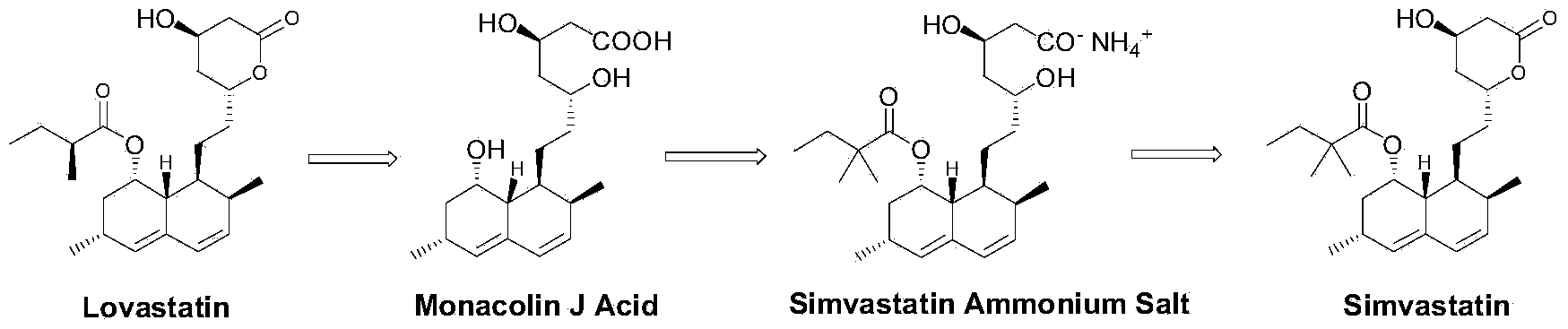

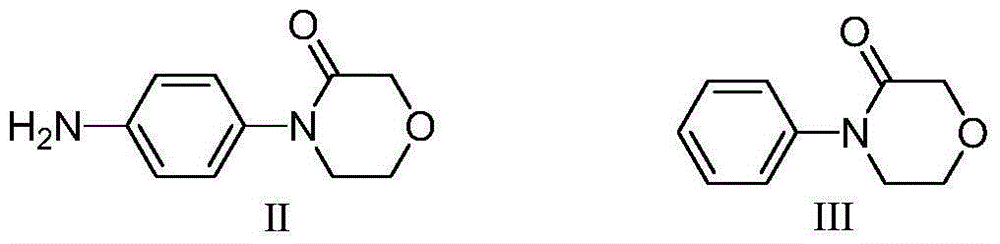

Preparation method of rivaroxaban intermediate

ActiveCN103755657AMild reaction conditionsReaction conditions are easy to controlOrganic chemistrySynthesis methodsRivaroxaban

The invention provides a method for efficiently preparing a key rivaroxaban intermediate, namely, 4-phenylmorpholine-3-ketone, by the one-step process through aniline and halogen ethyl acetate, aiming at solving the technical problems that the conventional synthesis method of 4-phenylmorpholine-3-ketone has a plurality of steps, rigorous requirements on reaction condition, low yield, and complex and complicated product purification. The preparation method has the advantages that the reaction conditions are mild, the yield is high, and industrial production can be carried out. The reaction formula is shown as the description.

Owner:广东暨大基因药物工程研究中心有限公司

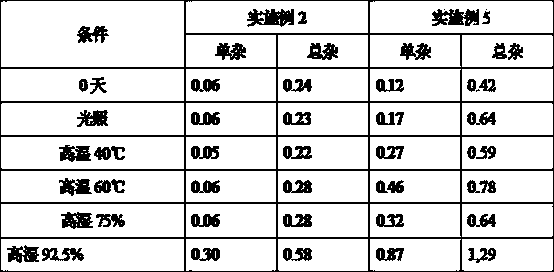

Antiallergic pharmaceutical composition and preparation method thereof

InactiveCN103768031AGuaranteed content uniformityPreparation method is stableOrganic active ingredientsPharmaceutical non-active ingredientsAcetic acidChlorobenzene

The invention belongs to the field of pharmaceutical preparations, and relates to an antiallergic pharmaceutical composition and a preparation method thereof. The preparation is orally disintegrating tablets, and contains an active ingredient with a general formula of (R)-(-)-2-[3-[4-[(4-chlorphenyl)benzyl]-1-piperazinyl]ethoxy]acetic acid dihydrochloride. The preparation of the invention can be rapidly disintegrated in oral cavity, and has the characteristics of no gritty feel, good mouth feel and rapid dissolution.

Owner:BEIJING VENTUREPHARM BIOTECH

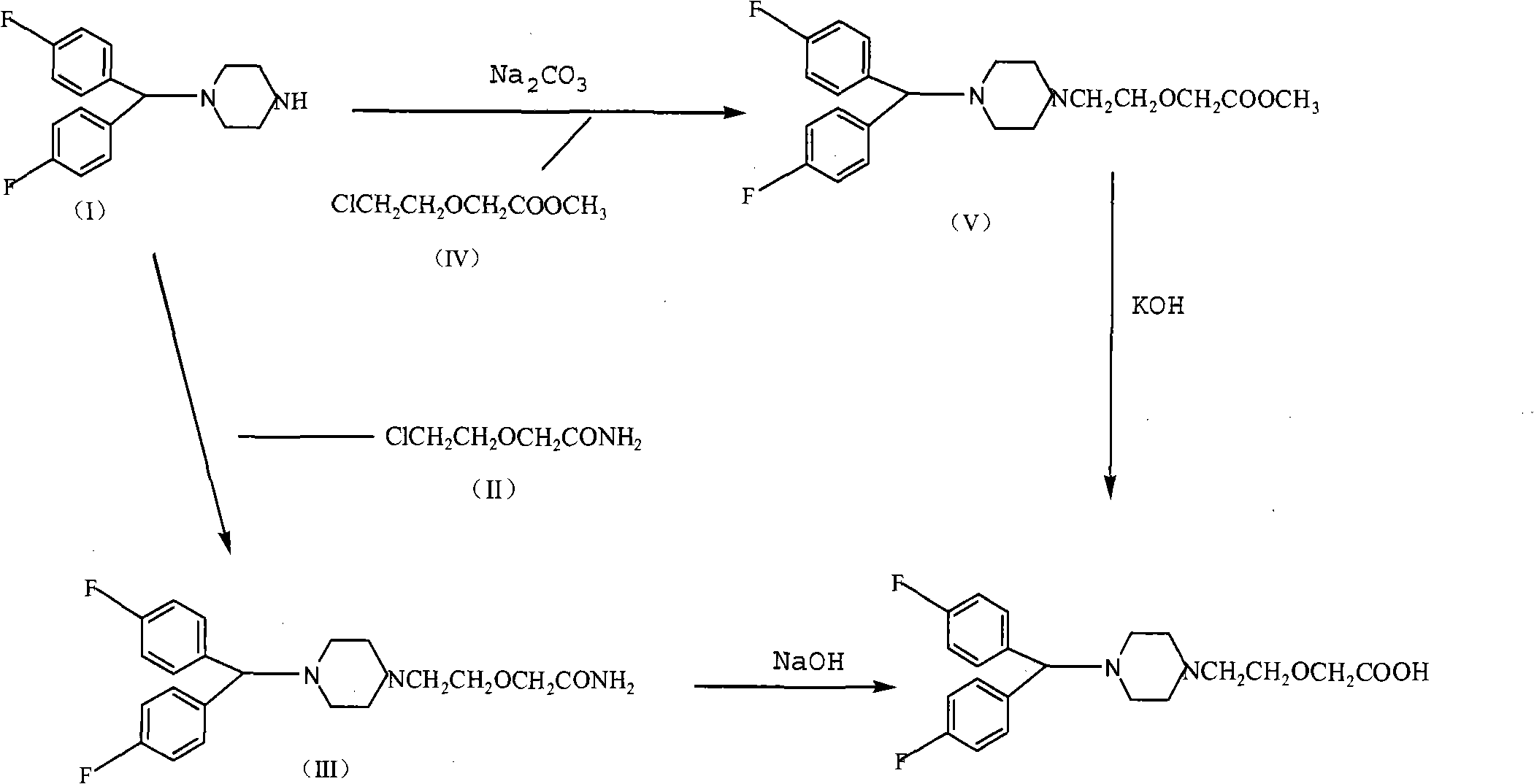

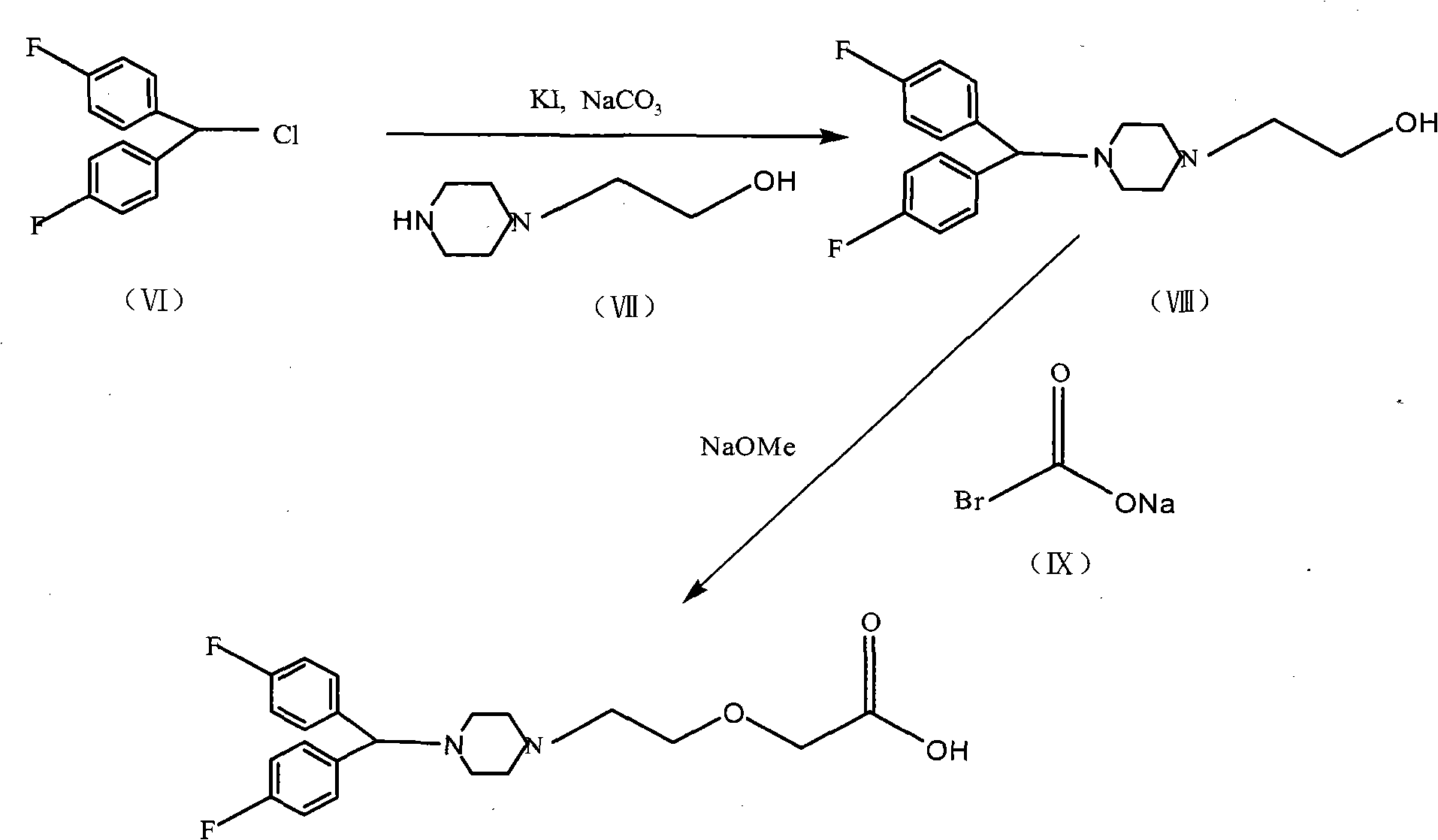

Method for preparing efletirizine dihydrochloride

The invention discloses a method for preparing efletirizine dihydrochloride. 1-bis(4-fluoro phenyl)methyl piperazine and an excessive amount of a chloro(ethoxy)acetic acid derivative are heated to condense in a solvent and in the presence of tertiary amine serving as an acid acceptor and alkali halide or halogenated tetrabutyl ammonium serving as a catalyst to form a [2-[4-[bis(fluorophenyl)methyl]-1-piperazinyl]ethoxy]acetic acid derivative; and the [2-[4-[bis(fluorophenyl)methyl]-1-piperazinyl]ethoxy]acetic acid derivative is hydrolyzed and acidized to form the efletirizine dihydrochloride. The method has the advantages of readily available raw materials, simple and convenient operation, high yield and low cost and is suitable for industrial production.

Owner:SICHUAN UNIV

Resource treatment process of high-salt wastewater in carboxymethyl cellulose production

ActiveCN104370312BHigh viscosityAffect crystallizationMultistage water/sewage treatmentNature of treatment waterEvaporationEthoxyacetic acid

The invention discloses a recycling processing technology for high-salt wastewater during carboxymethyl cellulose production. The processing technology combines extraction and graded crystallization technologies. In the graded crystalization process, through multi-effect (or mechanical recompression) evaporation crystallization, crude salt is recovered from wastewater and condensate water is evaporated, the condensate water reaches the industrial reuse water standard, and refined salt is prepared from crude salt through washing; and then through cooling crystallization, sodium glycollate crystal is separated out, the crystallization mother liquid is used for a next crystallization process, so that closed cycle is realized. In the above graded crystallization process, ethoxyacetic acid is obtained by performing extraction separation on a concentrated liquid, and the viscosity is reduced. The method is simple in operation, low in cost and high in separation recovery rate. The whole processing technology employs closed cycle, has no pollutants, and is easy for industrialization. The technology helps to solve the high-salt wastewater processing problem in the carboxymethyl cellulose production process, also helps to realize the recycling processing purposes of turning harm into good and changing wastes into valuables, and has substantial economic, social and environment benefit.

Owner:JIANGNAN UNIV

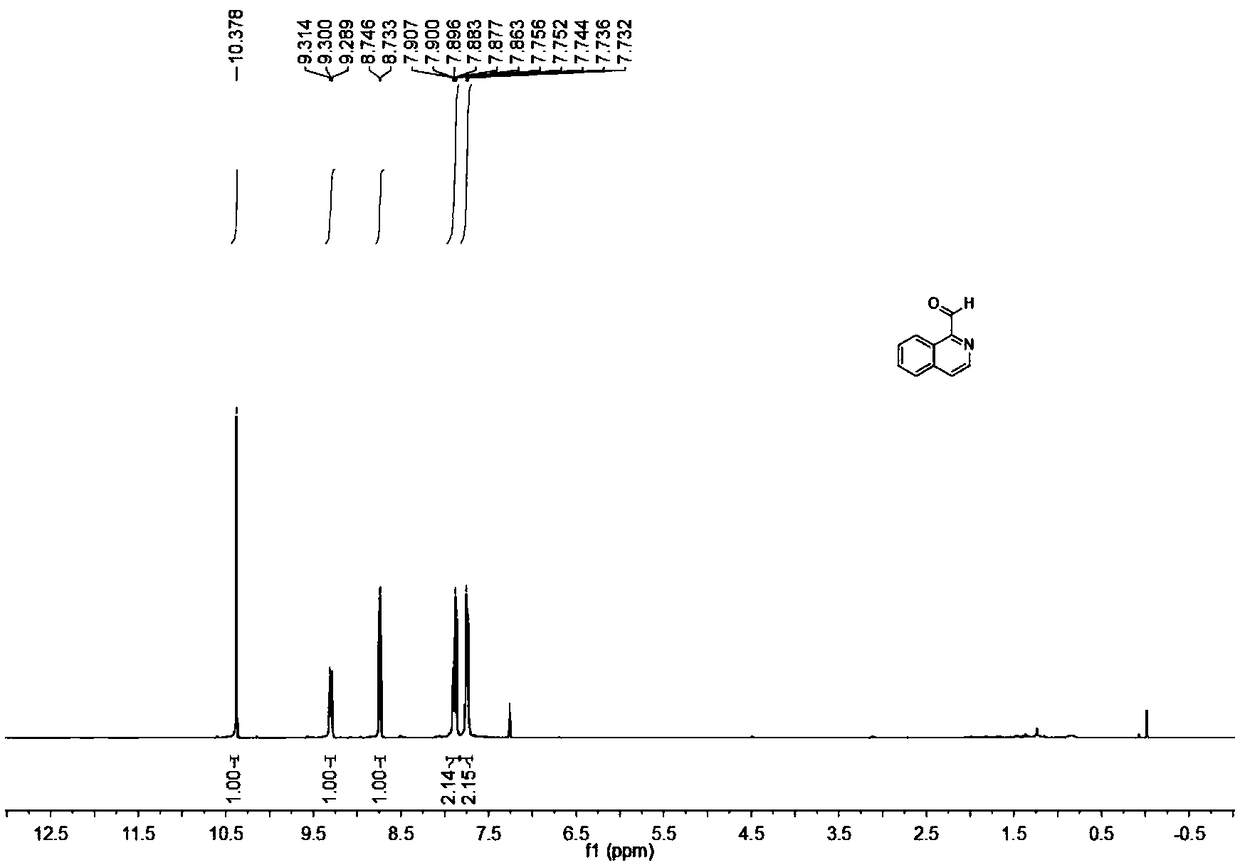

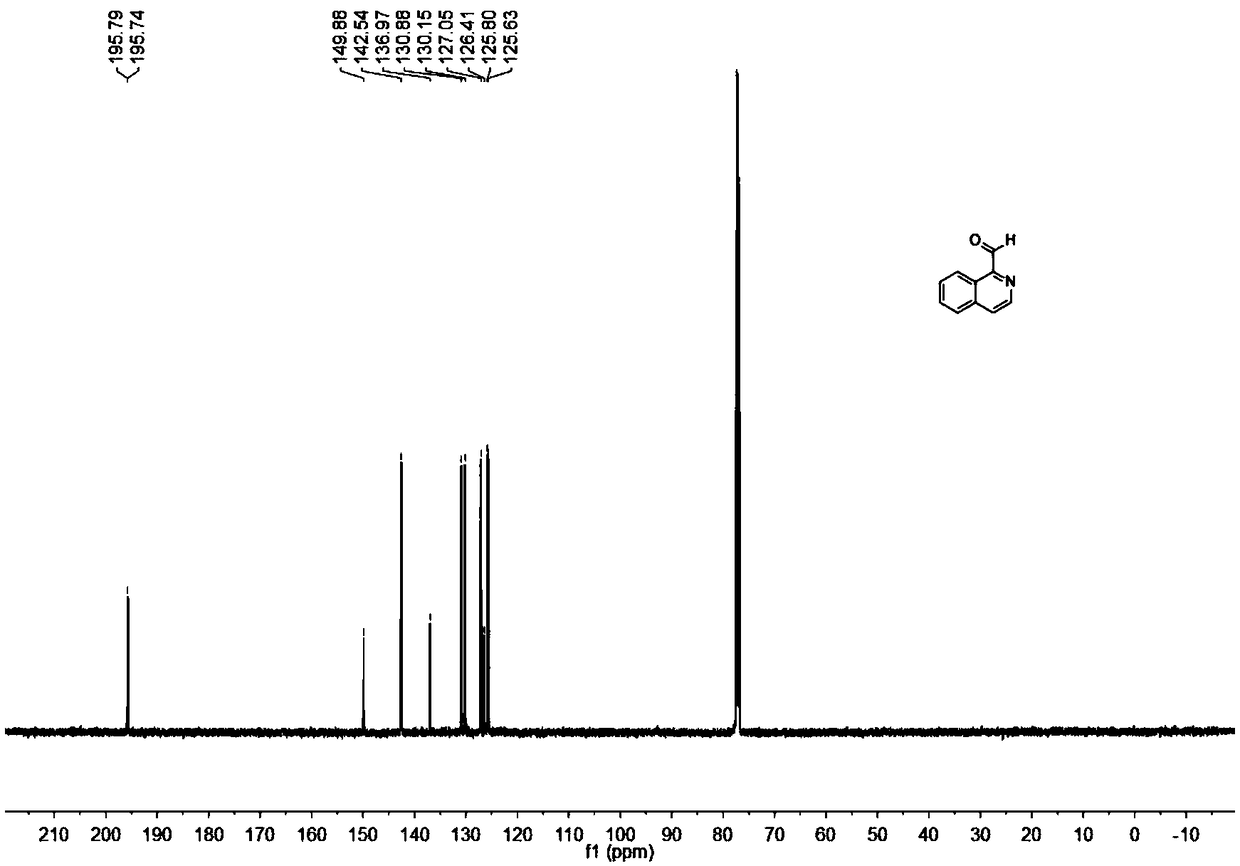

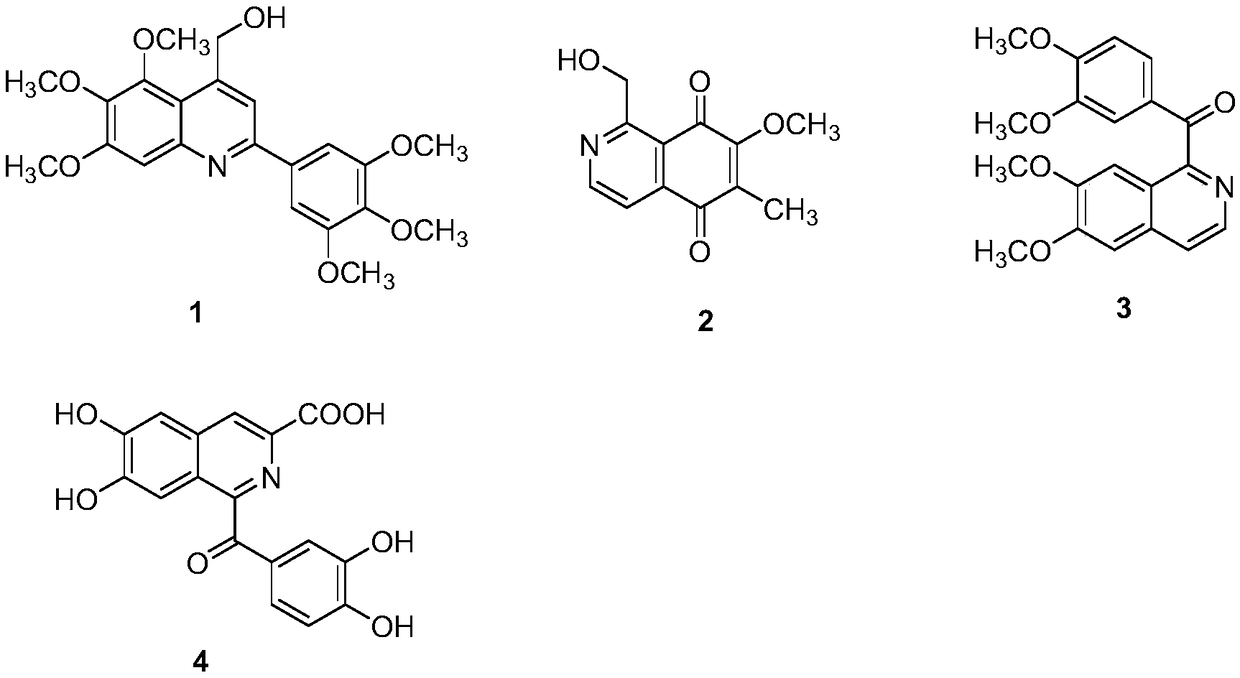

Preparation method for formylated heterocyclic derivative

ActiveCN108640807APotential application value is goodVarious conversion pathwaysCarbonyl group formation/introductionOrganic synthesisMixed materials

The invention discloses a preparation method for a formylated heterocyclic derivative, and relates to the preparation method for the formylated heterocyclic derivative. The purpose of the invention isto solve the problems that current synthesis of a formylated heterocyclic derivative requires a high-temperature heating system, energy consumption is high, conditions are harsh, requirements on equipment are high, and a yield is low. The method comprises the following steps: dissolving a heterocyclic derivative, 2,2-ethoxyacetic acid, an oxidant and an alkali into an organic solvent at room temperature, performing uniform mixing, introducing a nitrogen gas for 25-35 min, placing the mixed material under a blue LED lamp, performing a complete illumination reaction, adding an acid, performingcatalytic hydrolysis, adjusting the pH to be neutral, and performing chromatography separation and purification by using a silica gel column, so as to obtain the formylated heterocyclic derivative. According to the method disclosed by the invention, the reaction can be performed at normal temperature and normal pressure, the reaction conditions are mild, the yield can reach 80%, and the method hasthe advantages of simple operation, no pollution, safety, environmental protection and low costs; and the method is used in the field of organic synthesis.

Owner:HARBIN INST OF TECH

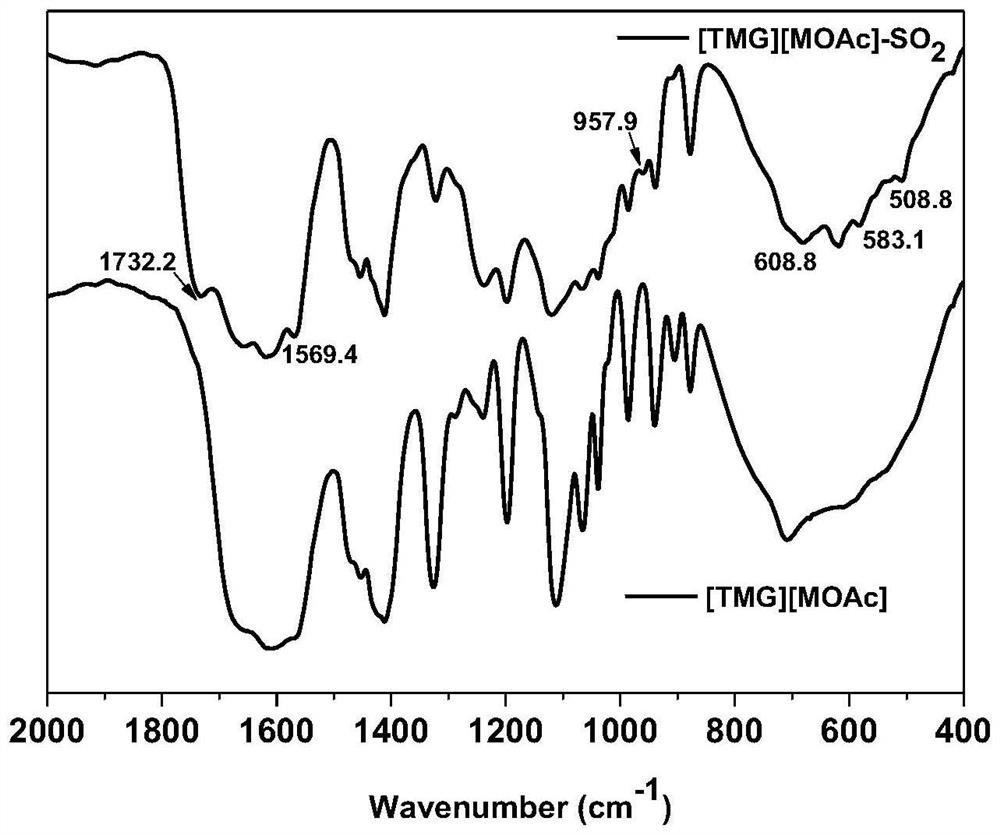

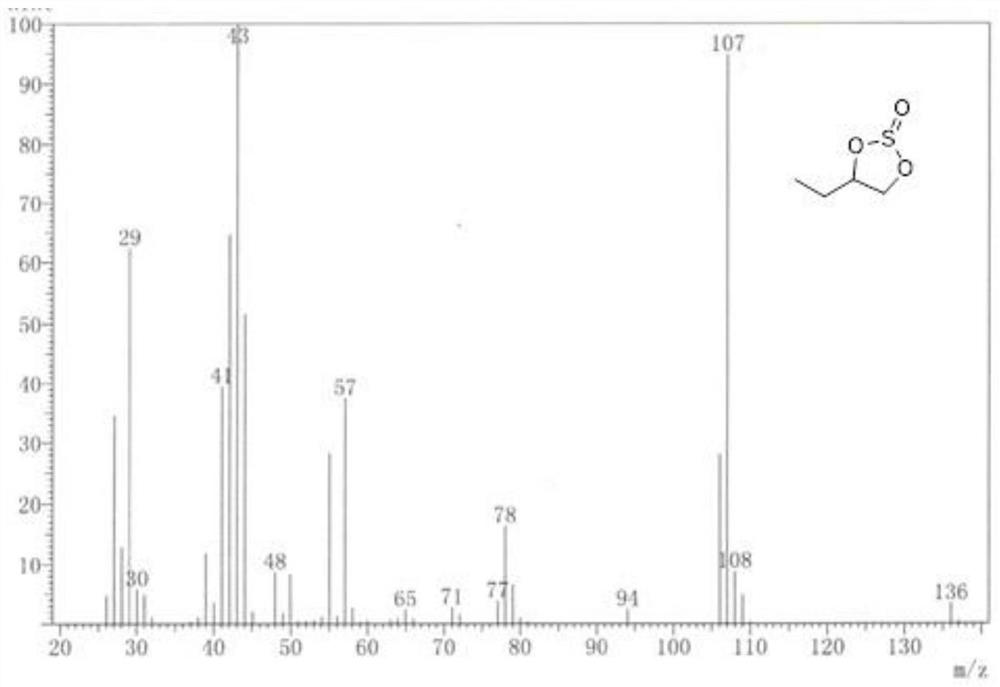

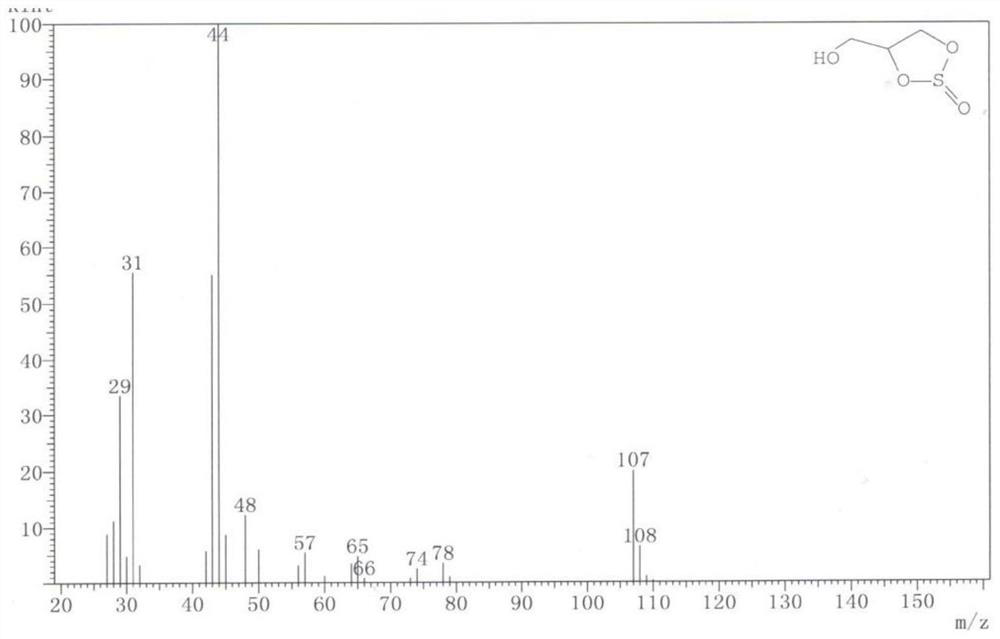

Guanidyl functionalized ionic liquid as well as preparation method and application thereof

PendingCN113861081ARapid responseHigh yieldGas treatmentOrganic compound preparationMethoxyacetic acidPtru catalyst

The invention discloses guanidyl functionalized ionic liquid as well as a preparation method and application thereof. Cations of the ionic liquid are 1,1,3,3-tetramethylguanidine cations, and anions are methoxyacetic acid anions or ethoxyacetic acid anions. The preparation method comprises the following steps: adding 1,1,3,3-tetramethylguanidine into absolute ethyl alcohol, slowly dropwise adding methoxyacetic acid or ethoxyacetic acid in an ice bath environment, carrying out stirring reaction, carrying out rotary evaporation to remove absolute ethyl alcohol and water to obtain an ionic liquid primary product containing trace water, and carrying out vacuum drying to obtain the guanidyl functionalized ionic liquid. When the guanidyl-containing ionic liquid is used for trapping sulfur dioxide, the guanidyl-containing ionic liquid has the advantages of high absorption capacity, reusability and the like, can promote effective conversion of SO2 under low-temperature and solvent-free conditions, and can be used as an effective absorbent for flue gas desulfurization and a catalyst for cycloaddition reaction of SO2 and an epoxy compound.

Owner:CHINA PHARM UNIV

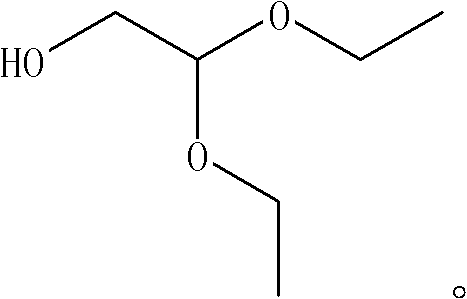

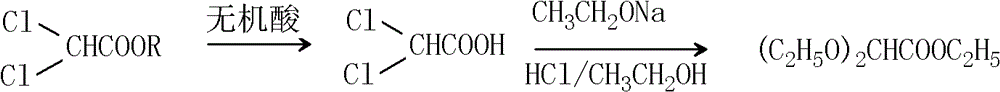

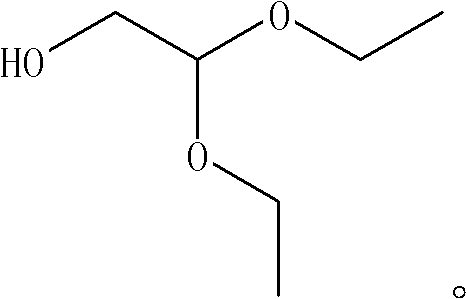

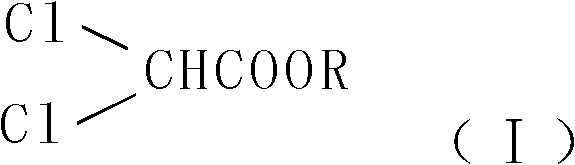

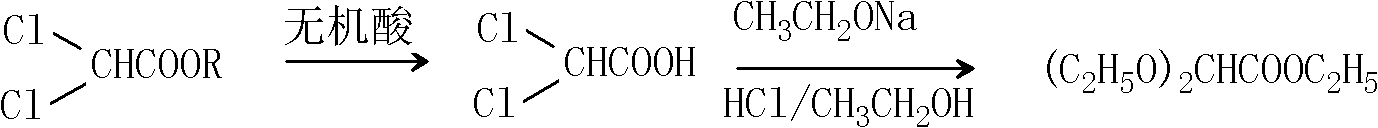

Synthesis method of 2, 2-ethoxyethanol

InactiveCN102115431BEasy to operateSimple processOrganic chemistryOrganic compound preparationChemical industrySynthesis methods

The invention relates to a synthesis method of 2, 2-ethoxyethanol, belonging to the technical field of medicine and chemical industry. The method comprises the steps of: taking compound of a formula (I) as a raw material, and hydrolytically reacting the raw material with inorganic acid to obtain dichloroacetic acid; reacting the obtained dichloroacetic acid with caustic alcohol in absolute ethyl alcohol in a backflow way, adding hydrochloric acid ethanol solution in a cooling way after the reaction, adjusting PH value, filtering and distilling to obtain 2, 2-ethyl diethoxyacetate; and reacting the 2, 2-ethyl diethoxyacetate obtained in step b with KBH4 and inorganic catalyst in inorganic catalyst in a backflow way to obtain the 2, 2-ethoxyethanol. The synthesis method has the advantages that the raw material is easily obtained, the technical process is simple, the reaction condition is stable, the reaction can be performed without high pressure, and the synthesis method is suitable for the industrial production on a large scale. The solvent ethanol can be recovered and used mechanically, the atom economy is good, the cost is low, the product yield is high, and the product quality is more than 98%.

Owner:TAIZHOU UNIV

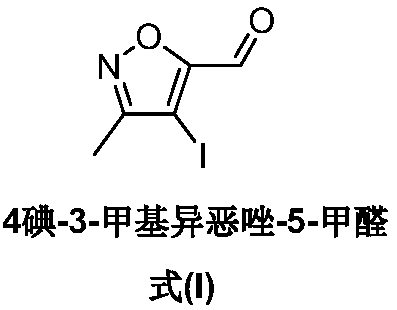

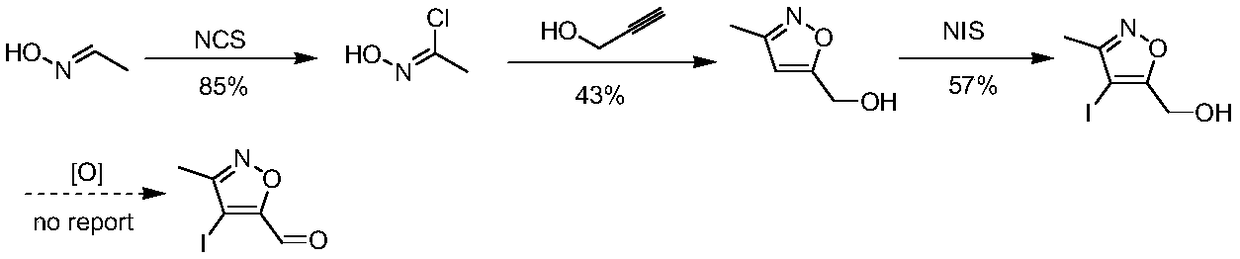

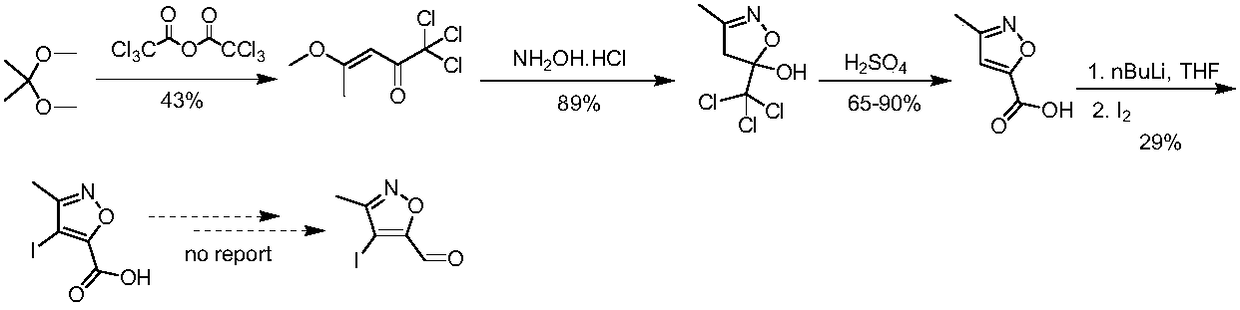

Synthesizing method of 4-iodo-methylisoxazole-5-formaldehyde

The invention belongs to the technical field of organic synthesis and provides a synthesizing method of 4-iodo-methylisoxazole-5-formaldehyde. The synthesizing method of the 4-iodo-methylisoxazole-5-formaldehyde comprises (1) condensation reaction including condensing the raw material of acetone oxime with 2, 2-ethyl diethoxyacetate to obtain 5-(diethoxymethyl)-3-methyl-4, 5-dihydroisoxazole-5-alcohol, (2) acylation reaction including aromatizing the 5-(diethoxymethyl)-3-methyl-4, 5-dihydroisoxazole-5-alcohol through methylsulfonyl chloride to obtain 5-(diethoxymethyl)-3-methylisoxazole, (3) iodination reaction including iodinating the 5-(diethoxymethyl)-3-methylisoxazole in acetonitrile through iodosuccinimide to obtain the 4-iodo-methylisoxazole-5-formaldehyde. The preparation method ofthe 4-iodo-methylisoxazole-5-formaldehyde is short in reaction path, low in costs of raw materials, simple in operation and applicable large-scale industrial production.

Owner:成都道合尔医药技术有限公司

Pipeline deodorization and dredging agent composition and preparation method thereof

InactiveCN107974370AAvoid secondary pollutionFast descalingSurface-active non-soap compounds and soap mixture detergentsDeodrantsEthylenediamineHexamethylenetetramine

The invention relates to a deodorization and dredging cleaning product for kitchen and bathroom sewer pipelines and catering public sewage pipelines and in particular relates to a pipeline deodorization and dredging agent composition. The pipeline deodorization and dredging agent composition is prepared from the following raw materials in parts by weight: 5 to 8 parts of urotropine, 3 to 6 parts of sodium citrate, 10 to 15 parts of sodium carbonate, 2 to 4 parts of sodium silicate, 9 to 11 parts of sodium ethoxide, 2 to 5 parts of potassium oxalate, 3 to 5 parts of polyethylene glycol, 2 to 4parts of sodium propoxide, 5 to 8 parts of sodium ethoxyacetate, 3 to 6 parts of sulfosuccinic acid, 1 to 3 parts of sodium methacrylate, 6 to 9 parts of lauryl amine,5 to 8 parts of lauryl alcohol, 2to 4 parts of hydroxyethyl ethylenediamine, 4 to 6 parts of hydroxysuccinic acid and 0.1 to 0.3 part of lipase. The invention further relates to a preparation method of the pipeline deodorization anddredging agent composition. The deodorization and dredging agent provided by the invention can be used for eliminating odor of the sewer pipelines within a few minutes and completely cleaning obstructions in the sewer pipelines within ten minutes; the pipeline deodorization and dredging agent composition has no toxin and no odor and can be used for rapidly deodorizing and dredging the sewer pipelines.

Owner:GANSU HEIMA PETROCHEM ENG

Synthesis method of 2, 2-ethoxyethanol

InactiveCN102115431AEase of industrial productionSimple processOrganic chemistryOrganic compound preparationChemical industrySynthesis methods

The invention relates to a synthesis method of 2, 2-ethoxyethanol, belonging to the technical field of medicine and chemical industry. The method comprises the steps of: taking compound of a formula (I) as a raw material, and hydrolytically reacting the raw material with inorganic acid to obtain dichloroacetic acid; reacting the obtained dichloroacetic acid with caustic alcohol in absolute ethyl alcohol in a backflow way, adding hydrochloric acid ethanol solution in a cooling way after the reaction, adjusting PH value, filtering and distilling to obtain 2, 2-ethyl diethoxyacetate; and reacting the 2, 2-ethyl diethoxyacetate obtained in step b with KBH4 and inorganic catalyst in inorganic catalyst in a backflow way to obtain the 2, 2-ethoxyethanol. The synthesis method has the advantages that the raw material is easily obtained, the technical process is simple, the reaction condition is stable, the reaction can be performed without high pressure, and the synthesis method is suitable for the industrial production on a large scale. The solvent ethanol can be recovered and used mechanically, the atom economy is good, the cost is low, the product yield is high, and the product quality is more than 98%.

Owner:TAIZHOU UNIV

Deodorization degradation treatment agent composition for landfill leachate and preparation method thereof

ActiveCN107986343AAvoid secondary pollutionProcessing speedSpecific water treatment objectivesWater contaminantsEthylenediaminePotassium persulfate

The invention provides a deodorization degradation treatment agent composition for landfill leachate in municipal waste landfills and waste power plants. The composition is prepared from the followingraw materials in parts by weight: 6-9 parts of ammonium persulfate, 4-7 parts of potassium persulfate, 11-16 parts of potassium carbonate, 2-4 parts of sodium silicate, 8-10 parts of potassium oxalate, 3-5 parts of polyglycol ether, 2-4 parts of sodium propoxide, 6-9 parts of potassium ethoxy acetate, 3-6 parts of decyl dimethylamine, 1-3 parts of sodium methacrylate, 8-11 parts of laurylamine, 5-8 parts of sulfosuccinic acid, 2-4 parts of hydroxyethyl ethylenediamine and 0.1-0.3 part of lipase. By utilizing the composition, the foul smell of the landfill leachate can be eliminated in severalseconds to several minutes in the treatment process, and the ammonia nitrogen content in the landfill leachate can be reduced by above 50% within ten minutes, so that time and fund can be saved for the next biochemical treatment of the waste, the landfill leachate is non-toxic and odorless, and rapid deodorization and rapid degradation of the landfill leachate can be realized. The invention further provides a preparation method of the deodorization degradation treatment agent composition.

Owner:GANSU HEIMA PETROCHEM ENG

A method for recovering ethoxyacetic acid from sodium carboxymethylcellulose production wastewater

ActiveCN104140366BEasy to operateLow costPreparation from carboxylic acid saltsMultistage water/sewage treatmentRecovery methodAcetic acid

A method for recycling ethoxyacetic acid from sodium carboxymethylcellulose industrial wastewater comprises the following steps that (1), the pH value of the sodium carboxymethylcellulose industrial wastewater is adjusted to 11.0-12.0, and then the wastewater is subjected to decompression and distillation to obtain a white solid; (2) the white solid obtained in the step (1) is eluted by concentrated hydrochloric acid, the obtained hydrochloric acid solution is extracted for 3 times by an organic solvent, and organic phases are separated out for standby application; (3), the organic phases obtained in the step (2) are subjected to decompression and distillation to obtain ethoxyacetic acid products. According to the method for recycling the ethoxyacetic acid from the sodium carboxymethylcellulose industrial wastewater, operation is convenient, the cost is low, and recycling and reusing of resources are achieved.

Owner:SHANGHAI UNIV OF ENG SCI +1

Method for recycling ethoxyacetic acid from sodium carboxymethylcellulose industrial wastewater

ActiveCN104140366AEasy to operateLow costPreparation from carboxylic acid saltsMultistage water/sewage treatmentOrganic solventDistillation

A method for recycling ethoxyacetic acid from sodium carboxymethylcellulose industrial wastewater comprises the following steps that (1), the pH value of the sodium carboxymethylcellulose industrial wastewater is adjusted to 11.0-12.0, and then the wastewater is subjected to decompression and distillation to obtain a white solid; (2) the white solid obtained in the step (1) is eluted by concentrated hydrochloric acid, the obtained hydrochloric acid solution is extracted for 3 times by an organic solvent, and organic phases are separated out for standby application; (3), the organic phases obtained in the step (2) are subjected to decompression and distillation to obtain ethoxyacetic acid products. According to the method for recycling the ethoxyacetic acid from the sodium carboxymethylcellulose industrial wastewater, operation is convenient, the cost is low, and recycling and reusing of resources are achieved.

Owner:SHANGHAI UNIV OF ENG SCI +1

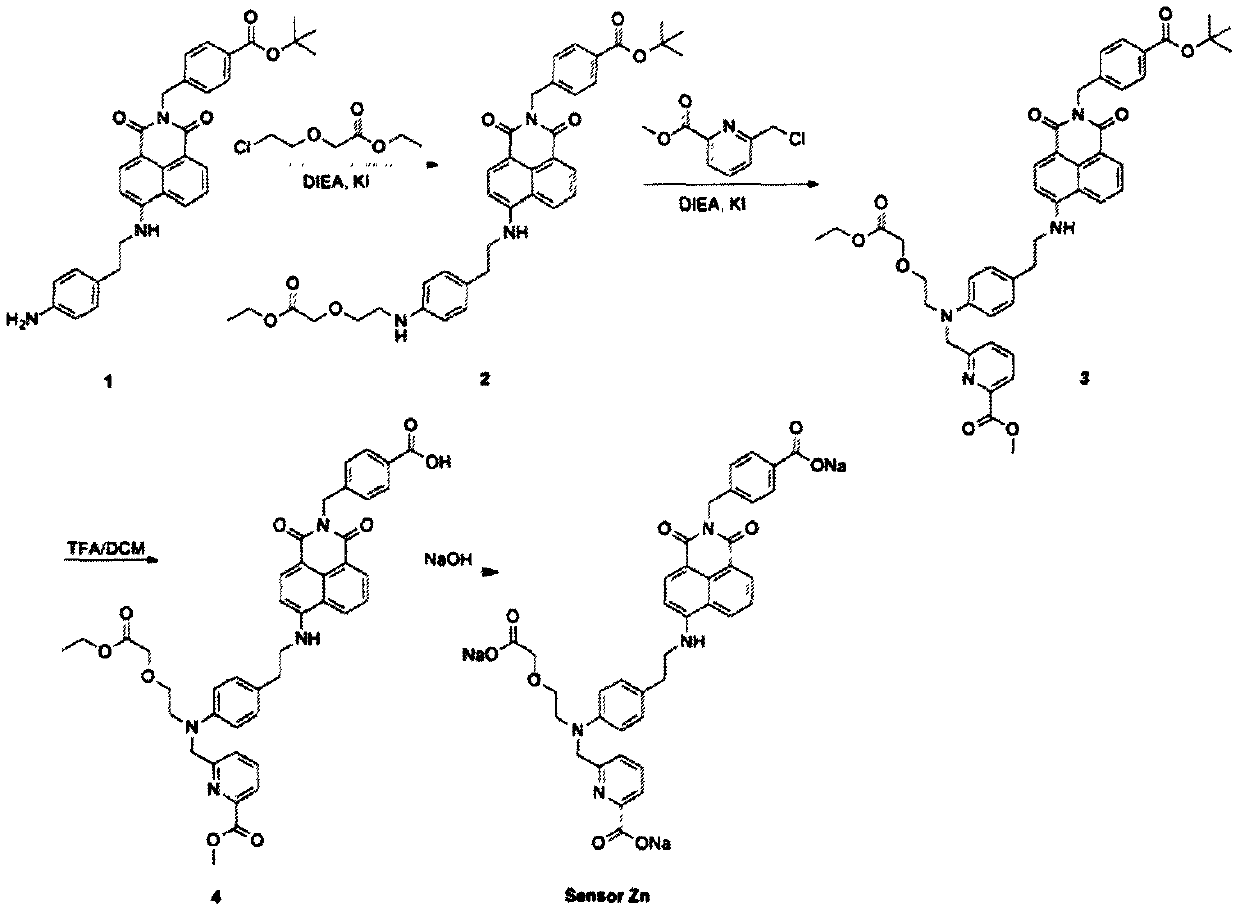

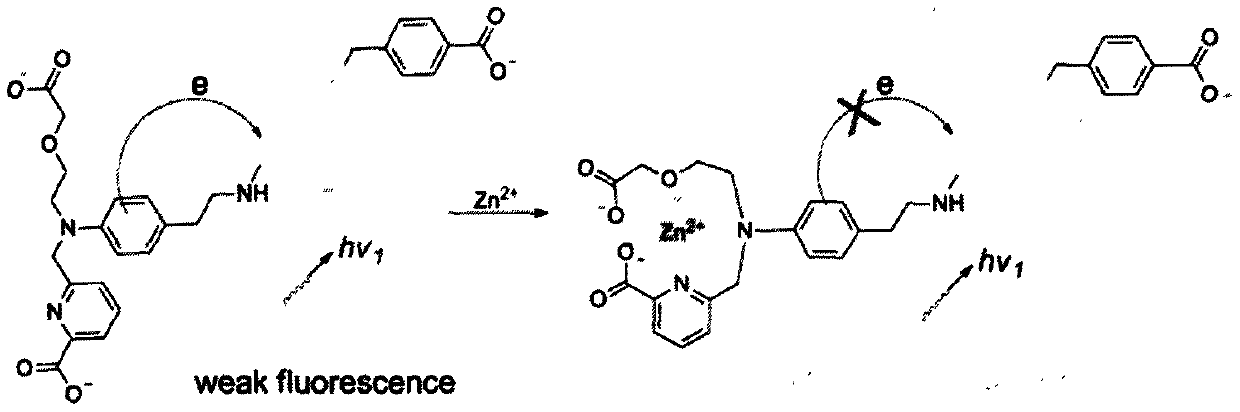

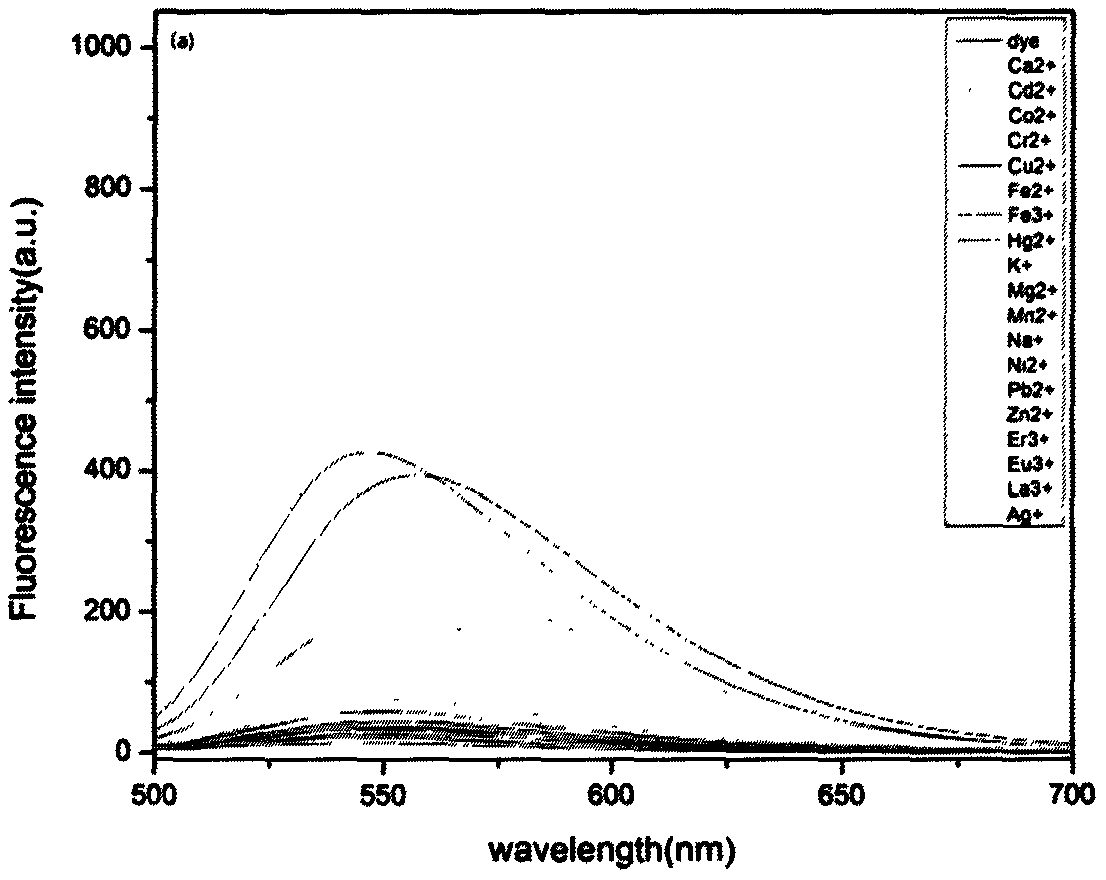

Compound for detecting content of metal ions in water and application thereof

InactiveCN110003175AMild reaction conditionsSafe reaction conditionsGroup 3/13 element organic compoundsFluorescence/phosphorescenceChemical compoundZinc ion

The invention discloses an organic compound for detecting content of metal ions. The organic compound for detecting the content of the metal ions uses N-ethoxyacetic acid-N-methyl pyridine aniline asa metal ion complex; a chromophore or fluorophore is introduced into a molecule of the compound to generate a color indicator or a fluorescence indicator of metal ions, particularly zinc ions. The organic compound for detecting the content of the metal ions, disclosed by the invention, has the advantages that the compound can also be fixed on a hydrophilic polymer; by using the chromophore or thefluorophore, the compound can be prepared into a reversible metal ion fluorescent probe capable of being used for multiple times; the compound can be suitable for continuous detection of metal ion concentration in various environments, particularly for continuous detection of zinc ion concentration in the water.

Owner:TIANJIN AGRICULTURE COLLEGE

Pencil handwriting eliminating liquid

InactiveCN103525156ANo smellGood effect in erasing handwritingChemical paints/ink removersHandwritingEther

The invention provides a pencil handwriting eliminating liquid which is characterized in that the formula comprises materials in parts by weight as follows: 10-30 parts of ethoxy ethyl acetate, 5-10 parts of dihydroxyethyl amine ether acetic ester and 40-50 parts of triethylene glycol methyl ether acetic ester. The preparation process comprises the steps as follows: the ethoxy ethyl acetate, the dihydroxyethyl amine ether acetic ester and the triethylene glycol methyl ether acetic ester are mixed uniformly, so that the product is obtained. The pencil handwriting eliminating liquid has the advantages that the raw materials are easy to obtain, the cost is low, the liquid is environment-friendly and free from peculiar odor, and the paper surface is not damaged when the handwriting is eliminated.

Owner:韦谷林

Garbage leachate deodorization degradation treatment agent composition and preparation method thereof

ActiveCN107986343BProduct raw materials are green and environmentally friendlySpecific water treatment objectivesWater contaminantsPotassium persulfateEthylenediamine

The invention provides a deodorization and degradation treatment agent composition for treating municipal waste landfills and refuse power plant leachate, which is made of the following raw materials in parts by weight: 6-9 parts of ammonium persulfate, persulfuric acid 4-7 parts of potassium, 11-16 parts of potassium carbonate, 2-4 parts of sodium silicate, 8-10 parts of potassium oxalate, 3-5 parts of polyethylene glycol ether, 2-4 parts of sodium propoxide, ethoxylate Potassium glycolate 6-9 parts, decyldimethylamine 3-6 parts, sodium methacrylate 1-3 parts, laurylamine 8-11 parts, sulfosuccinic acid 5-8 parts, hydroxyethylethylenediamine 2 to 4 parts, 0.1 to 0.3 parts of lipase. During the treatment process, it only eliminates the odor of the landfill leachate within a few seconds to a few minutes, and reduces the ammonia nitrogen content in the landfill leachate by more than 50% within ten minutes, saving time and money for the next biochemical treatment of waste, reaching Non-toxic and tasteless, rapid deodorization and degradation of landfill leachate purposes. The invention also provides a preparation method of the deodorizing degradation treatment agent composition.

Owner:GANSU HEIMA PETROCHEM ENG

Pipeline dredging deodorant and preparation method thereof

InactiveCN108048243AProduct raw materials are green and environmentally friendlyAvoid secondary pollutionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium acetateButanedioic acid

The invention discloses a pipeline dredging deodorant which is prepared from the following raw materials in parts by weight: 6 to 9 parts of sodium persulfate, 4 to 7 parts of potassium citrate, 10 to14 parts of potassium carbonate, 3 to 5 parts of sodium silicate, 8 to 10 parts of potassium ethoxide, 2 to 5 parts of stearyl alcohol sodium sulfovinate, 3 to 5 parts of polypropylene glycol, 2 to 4parts of oleyl alcohol sodium sulfovinate, 6 to 9 parts of ethyoxyl sodium acetate, 3 to 6 parts of alkylphenol polyoxyethylene ether, 2 to 5 parts of di-lauroyl tartaric acid ester, 6 to 9 parts ofpolyethylene glycol, 10 to 15 parts of potassium carboxylate, 3 to 6 parts of sodium n-alkyl sulfate and 5 to 8 parts of hydroxy-butanedioic acid. The dredging deodorant disclosed by the invention caneliminate odor of a sewer line in several minutes in the kitchen and bathroom and catering industries, completely clear obstructions in the sewer line within ten minutes, fulfills the aims of havingno toxicity or odor and rapidly removing odor and dredging the sewer line, and is poisonless and harmless for an operator and the kitchen and bathroom environment. The invention further discloses a preparation method of the pipeline dredging deodorant.

Owner:刘音希

Method for synthesizing 1,4-dioxane-2-ketone by ethylene glycol

Owner:NANTONG FINC PHARMA CHEM +1

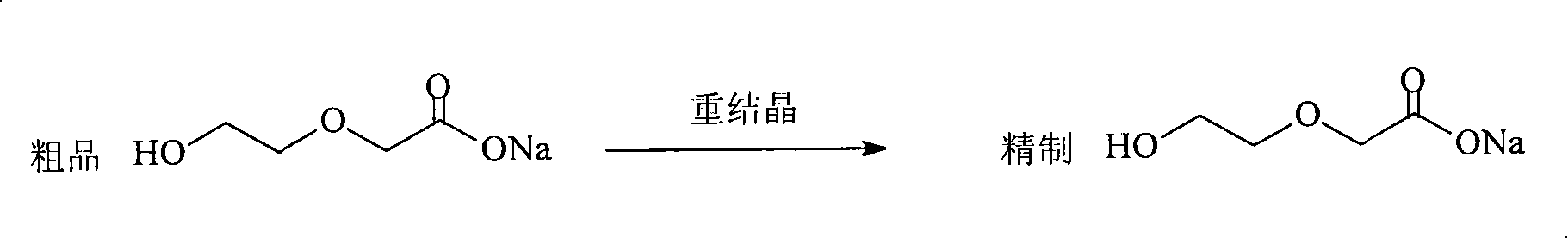

Catalyst for synthesizing ethyl ethoxyacetate through hydrogenation of diethyl oxalate and preparation method and application of catalyst

ActiveCN105854880ASimple manufacturing methodSufficient raw materialsOrganic compound preparationCarboxylic acid esters preparationActive componentDiethyl oxalate

A catalyst for synthesizing ethyl ethoxyacetate through hydrogenation of diethyl oxalate is prepared from, by mass, 2.0-65.0wt% of CuO serving as a main active component and 3.5-98.0wt% of Al2O3 serving as a carrier. The catalyst for synthesizing ethyl ethoxyacetate through hydrogenation of diethyl oxalate has the advantages of being high in selectivity, good in stability and suitable for industrial production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

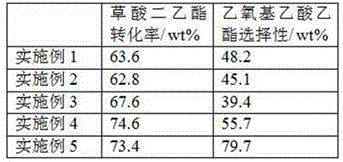

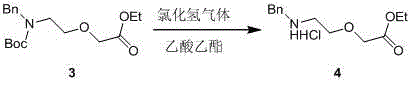

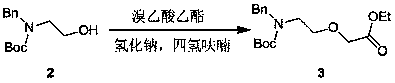

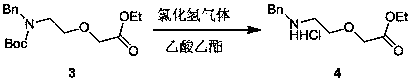

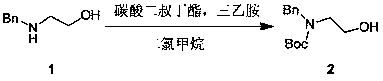

Synthesis method of 4-tert-butyl-5-ethyl-6-oxo-1, 4-oxyaza-4, 5-dicarboxylic acid

ActiveCN105693652AReasonable reaction process designSave raw materialsOrganic chemistryBulk chemical productionCarbamateEthyl group

The invention relates to a synthesis method of 4-tert-butyl-5-ethyl-6-oxo-1, 4-oxyaza-4, 5-dicarboxylic acid, and solves the technical problems of difficult synthesis operation and expensive raw materials in existing methods. The method includes: reacting 2-benzylaminoethanol as the starting raw material with t-butyloxycarboryl to protect amino to obtain tert-butylbenzyl(2-hydroxyethyl)carbamate, reacting the product with sodium hydride in ice bath, then reacting the reaction product with ethyl bromoacetate to obtain ethyl 2-(2-(benzyl)t-butyloxycarboryl)amine)ethoxy)acetic acid, then removing Boc with a hydrochloric acid ethyl acetate solution to obtain ethyl 2-(2-(benzylamine)ethoxy)acetic acid hydrochloride, and then in the presence of alkali, reacting the ethyl 2-(2-(benzylamine)ethoxy)acetic acid hydrochloride with ethyl bromoacetate to obtain ethyl 2-(benzyl(2-(2-ethoxy-2-oxoethoxy)ethyl)amino)acetic acid, using palladium hydroxide as the catalyst, in the presence of di-tert-butyl carbonate, removing Boc from benzyl with hydrogen to obtain ethyl 2-((t-butyloxycarboryl)(2-(2-ethoxy-2-oxoethoxy)ethyl)amino)acetic acid, and finally under a potassium tert-butoxide alkaline condition and with toluene as the solvent, conducting backflow and ring closing so as to obtain a final compound.

Owner:CHANGZHOU HEQUAN PHARMA CO LTD +2

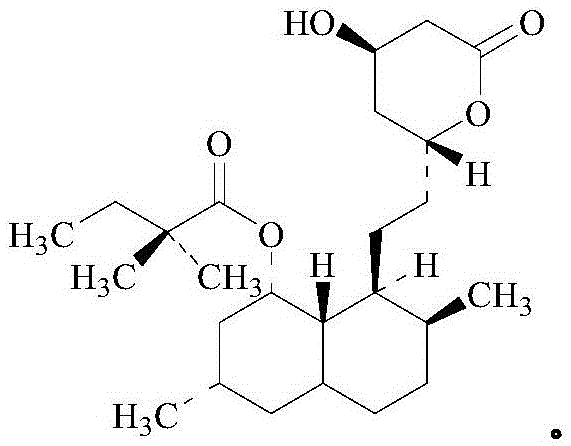

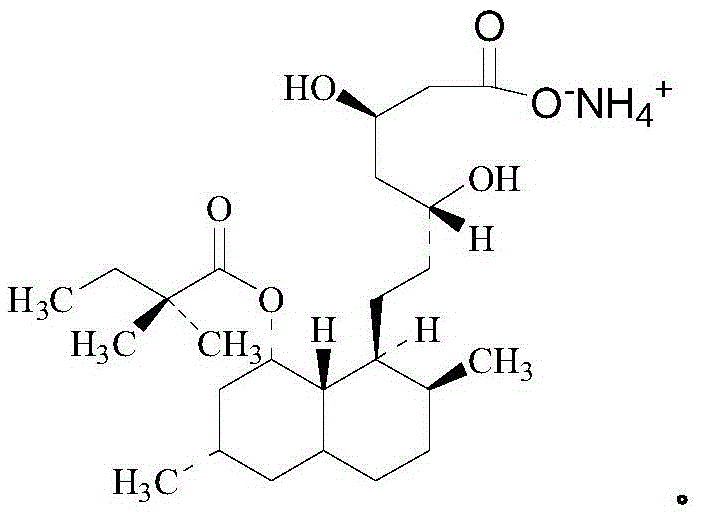

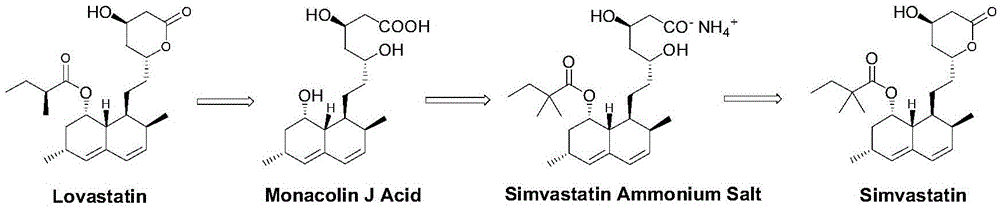

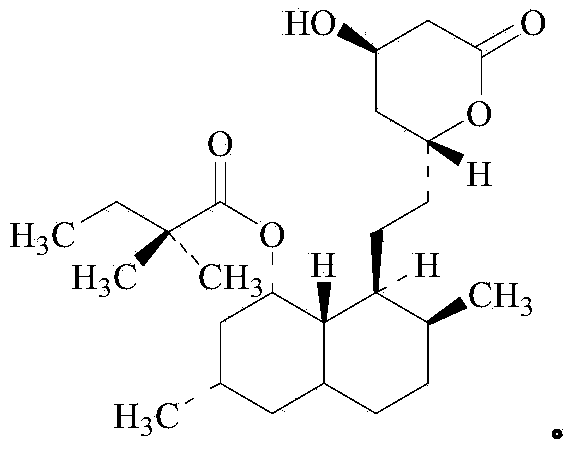

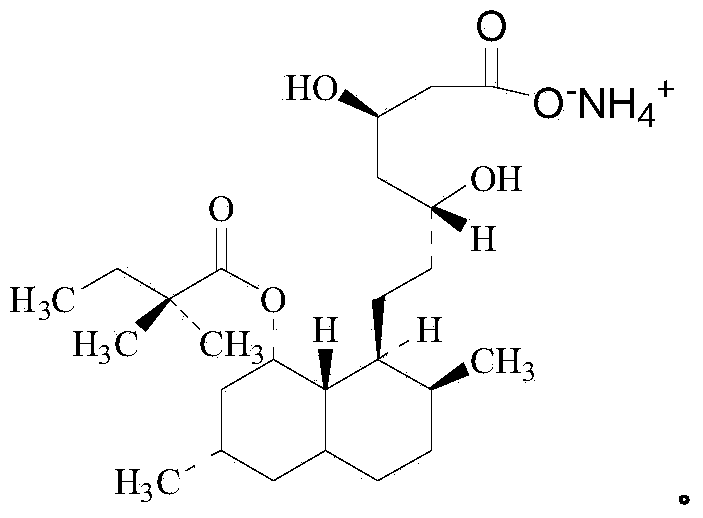

A kind of preparation method of simvastatin ammonium salt

ActiveCN103725727BReduce the amount of feedThe synthesis process is simpleFermentationSal ammoniacSide chain

The invention relates to a preparation method of a simvastatin ammonium salt. A substrate monacolin J acid, 2,2-dimethylbutyric acid-2-sulfhydrylethoxyacetate and ammonia water react under the pH value of 8.5-10 under the action of recombinant acyltransferase to generate the simvastatin ammonium salt, wherein the mass ratio of the monacolin J acid to the 2,2-dimethylbutyric acid-2-sulfhydrylethoxyacetate is 1:(0.6-1). The 2,2-dimethylbutyric acid-2-sulfhydrylethoxyacetate, which has the advantages of low addition amount and cheap synthesis raw material and is easy to synthesize, is used as an acyl donor for synthesizing the simvastatin side chain, so the method obviously lowers the production cost and has important use value.

Owner:ENZYMEWORKS

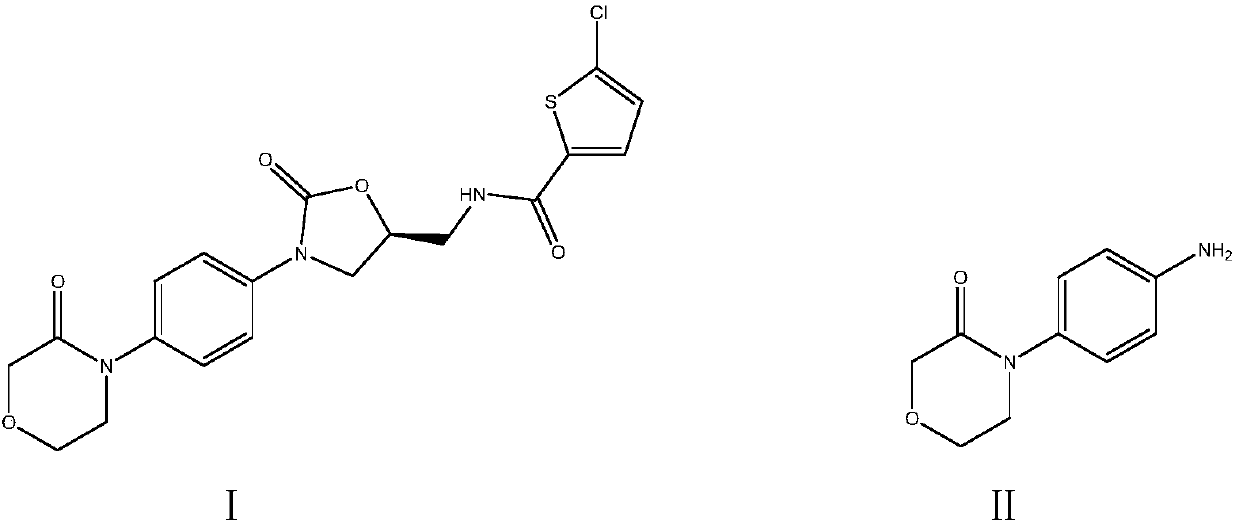

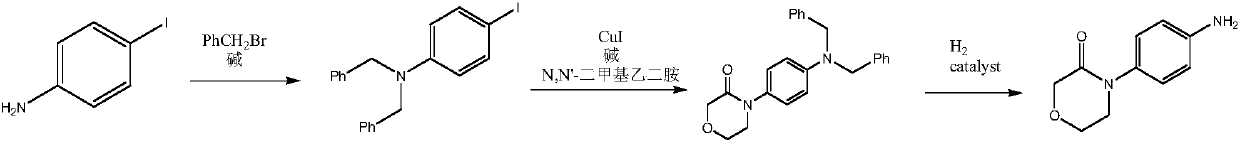

Synthetic method of high-selectivity 4-(4-aminophenyl) morpholine-3-one

ActiveCN109651286AReduce manufacturing costHigh yieldOrganic chemistryChemical recyclingAlcoholMorpholine

The invention relates to a synthetic method of high-selectivity 4-(4-aminophenyl) morpholine-3-one; according to the method, by condensation of p-nitrohalobenzene and 2-aminoethoxy acetate in the presence of an alkali, 2-(4-nitrophenyl) aminoethoxy acetate is obtained, by hydrogenation reduction under the action of a solvent and a hydrogenation catalyst, 2-(4-aminophenyl) aminoethoxy acetate is obtained, and the 4-(4-aminophenyl) morpholine-3-one is obtained by intramolecular dealcoholization cyclization. The reaction route disclosed by the invention is high in reaction selectivity, the reaction selectivity of each step reaches more than 99.0%, and the total yield is up to 96.0%. The raw materials are cheap and easy to obtain, the separation process is few, the process route is concise, and the method is low in wastewater quantity, high in reaction atom economy, green and environment-friendly in process.

Owner:XINFA PHARMA

Preparation method of simvastatin ammonium salt

ActiveCN103725727AReduce the amount of feedThe synthesis process is simpleFermentationSide chainAmmonia

The invention relates to a preparation method of a simvastatin ammonium salt. A substrate monacolin J acid, 2,2-dimethylbutyric acid-2-sulfhydrylethoxyacetate and ammonia water react under the pH value of 8.5-10 under the action of recombinant acyltransferase to generate the simvastatin ammonium salt, wherein the mass ratio of the monacolin J acid to the 2,2-dimethylbutyric acid-2-sulfhydrylethoxyacetate is 1:(0.6-1). The 2,2-dimethylbutyric acid-2-sulfhydrylethoxyacetate, which has the advantages of low addition amount and cheap synthesis raw material and is easy to synthesize, is used as an acyl donor for synthesizing the simvastatin side chain, so the method obviously lowers the production cost and has important use value.

Owner:ENZYMEWORKS

A kind of preparation method of rivaroxaban intermediate

ActiveCN103755657BSimple stepsRaw materials are easy to getOrganic chemistrySynthesis methodsRivaroxaban

The invention provides a method for efficiently preparing a key rivaroxaban intermediate, namely, 4-phenylmorpholine-3-ketone, by the one-step process through aniline and halogen ethyl acetate, aiming at solving the technical problems that the conventional synthesis method of 4-phenylmorpholine-3-ketone has a plurality of steps, rigorous requirements on reaction condition, low yield, and complex and complicated product purification. The preparation method has the advantages that the reaction conditions are mild, the yield is high, and industrial production can be carried out. The reaction formula is shown as the description.

Owner:广东暨大基因药物工程研究中心有限公司

A kind of synthetic method of 4-tert-butyl-5-ethyl-6-oxyethylene-1,4-oxazepane-4,5-dicarboxylate

ActiveCN105693652BReasonable reaction process designSave raw materialsOrganic chemistryBulk chemical productionCarbamatePtru catalyst

The invention relates to a synthesis method of 4-tert-butyl-5-ethyl-6-oxo-1, 4-oxyaza-4, 5-dicarboxylic acid, and solves the technical problems of difficult synthesis operation and expensive raw materials in existing methods. The method includes: reacting 2-benzylaminoethanol as the starting raw material with t-butyloxycarboryl to protect amino to obtain tert-butylbenzyl(2-hydroxyethyl)carbamate, reacting the product with sodium hydride in ice bath, then reacting the reaction product with ethyl bromoacetate to obtain ethyl 2-(2-(benzyl)t-butyloxycarboryl)amine)ethoxy)acetic acid, then removing Boc with a hydrochloric acid ethyl acetate solution to obtain ethyl 2-(2-(benzylamine)ethoxy)acetic acid hydrochloride, and then in the presence of alkali, reacting the ethyl 2-(2-(benzylamine)ethoxy)acetic acid hydrochloride with ethyl bromoacetate to obtain ethyl 2-(benzyl(2-(2-ethoxy-2-oxoethoxy)ethyl)amino)acetic acid, using palladium hydroxide as the catalyst, in the presence of di-tert-butyl carbonate, removing Boc from benzyl with hydrogen to obtain ethyl 2-((t-butyloxycarboryl)(2-(2-ethoxy-2-oxoethoxy)ethyl)amino)acetic acid, and finally under a potassium tert-butoxide alkaline condition and with toluene as the solvent, conducting backflow and ring closing so as to obtain a final compound.

Owner:CHANGZHOU HEQUAN PHARMA CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Methods of synthesizing and using derivatives of [2-(2-aminoethoxy)ethoxy] acetic acid Methods of synthesizing and using derivatives of [2-(2-aminoethoxy)ethoxy] acetic acid](https://images-eureka.patsnap.com/patent_img/5a7d00d6-c614-43e9-b7b1-d48e7b988c33/US07038078-20060502-D00001.png)

![Methods of synthesizing and using derivatives of [2-(2-aminoethoxy)ethoxy] acetic acid Methods of synthesizing and using derivatives of [2-(2-aminoethoxy)ethoxy] acetic acid](https://images-eureka.patsnap.com/patent_img/5a7d00d6-c614-43e9-b7b1-d48e7b988c33/US07038078-20060502-C00001.png)

![Methods of synthesizing and using derivatives of [2-(2-aminoethoxy)ethoxy] acetic acid Methods of synthesizing and using derivatives of [2-(2-aminoethoxy)ethoxy] acetic acid](https://images-eureka.patsnap.com/patent_img/5a7d00d6-c614-43e9-b7b1-d48e7b988c33/US07038078-20060502-C00002.png)