Preparation method for formylated heterocyclic derivative

A derivative and formylation technology, which is applied in the field of preparation of formylated heterocyclic derivatives, can solve the problems of large equipment requirements, harsh conditions, high energy consumption, etc., and achieve short reaction time, mild conditions and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

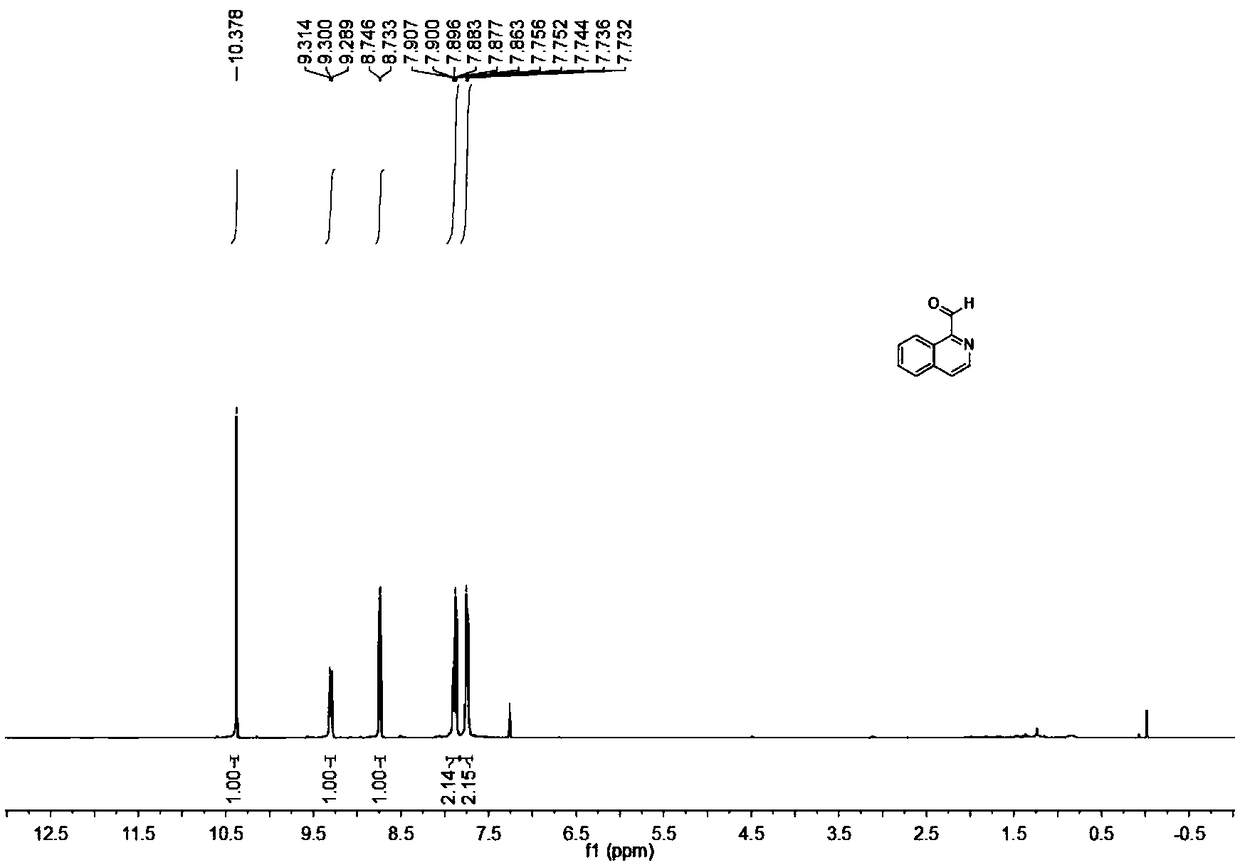

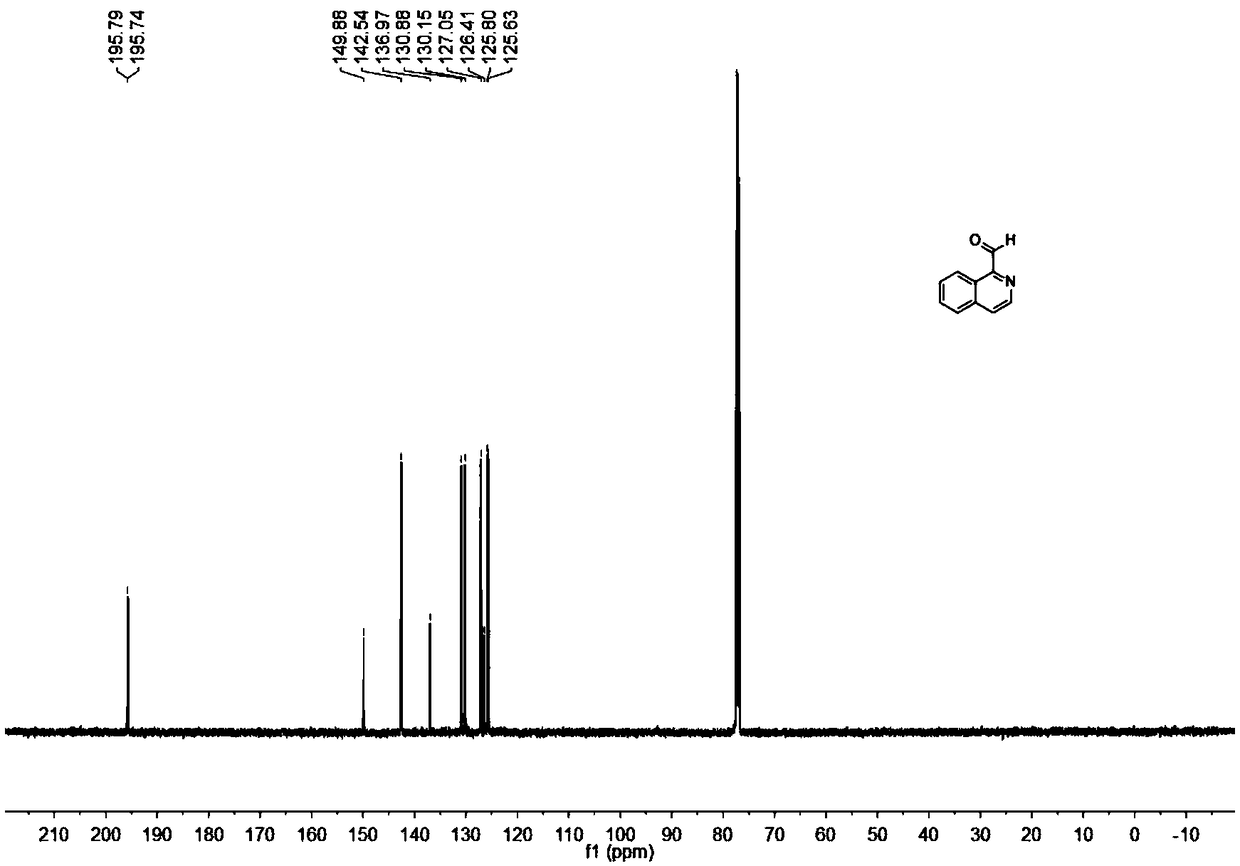

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment 1: The preparation method of a formylated heterocyclic derivative in this embodiment is to dissolve the heterocyclic derivative, 2,2-ethoxyacetic acid, oxidizing agent and alkali in an organic solvent at room temperature, mix Uniform, then pass nitrogen gas for 25-35min, and then put it under the light of blue LEDs light to complete the reaction, then add acid to catalyze hydrolysis, adjust the pH to neutral, and then separate and purify through silica gel column chromatography to obtain the formylated hetero Ring derivatives; the molar ratio of heterocyclic derivatives, 2,2-ethoxyacetic acid, oxidizing agent and base is 1:5-8:2:2, and the molar volume ratio of heterocyclic derivatives and organic solvents is 1mmol: 10 -20mL;

[0015] Wherein the structural formula of the heterocyclic compound containing N structure is:

[0016] The structural formula of 2,2-ethoxyacetic acid is:

[0017] This embodiment is a one-step method for synthesizing di...

specific Embodiment approach 2

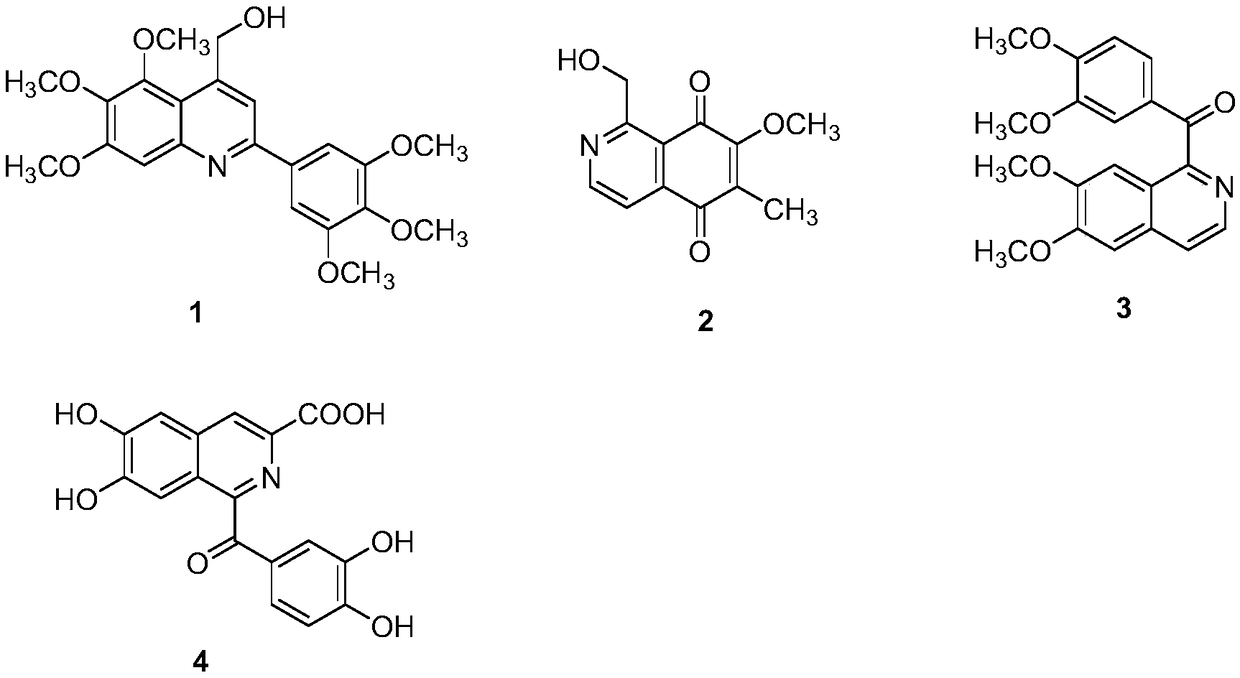

[0018] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the heterocyclic derivatives are quinoline compounds, isoquinoline compounds, quinoxaline compounds, pyridine compounds, imidazole compounds, benzimidazole compounds, Benzothiazole compounds, phenanthridine compounds, or natural product caffeine. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the organic solvent is dichloromethane, acetonitrile, tetrahydrofuran or dimethyl sulfoxide. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com