Preparation method of amphiphilic Janus hierarchical pore microcapsule with opening structure

A technology of open structure and graded pores, applied in the field of organic, inorganic and polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

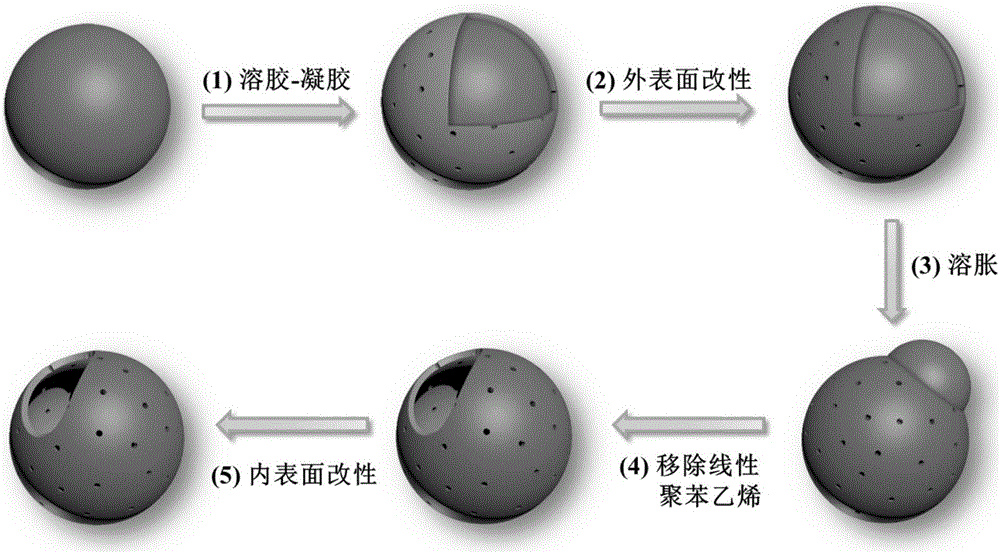

[0064] The preparation process of the present invention is as attached figure 1 As shown, (1) by preparing linear polystyrene (LPS) template microspheres functionalized with PVP or sulfonic acid groups, and preparing core / shell composite microspheres on the surface of polystyrene by sol-gel process, (2 ) Hydrophobic and hydrophilic modification of the outer surface of the core / shell composite microspheres with a silane coupling agent, (3) obtaining anisotropic composite microspheres by swelling, (4) removing the LPS template with a good solvent to obtain The outer surface functionalized Janus hierarchical porous microcapsules with open structure, (5) use silane coupling agent to carry out hydrophobic and hydrophilic modification on the inner surface of the microcapsules with functionalized outer surface to prepare an amphiphilic microcapsule with open structure Janus graded pore microcapsules.

[0065] The preparation process of the invention is simple, the reaction condition...

Embodiment 1

[0069] (1) Preparation of 800nm PVP functionalized linear polystyrene template microspheres

[0070] Take 90mL of water and 0.025g of polyvinylpyrrolidone (PVP) into a 500mL three-necked flask, stir for 10min, blow in argon, drop 10mL of styrene monomer into the reaction system, emulsify for 30min, and at the same time The temperature rises to 70°C, dissolve 0.1g of potassium persulfate in 10mL of water, add the potassium persulfate solution dropwise into the reaction system over 30 minutes, control the stirring speed at 180r / min, stop the reaction after 13 hours of reaction, and centrifuge the material Settling, obtaining linear polystyrene template microspheres with an average particle diameter of 800nm after vacuum drying;

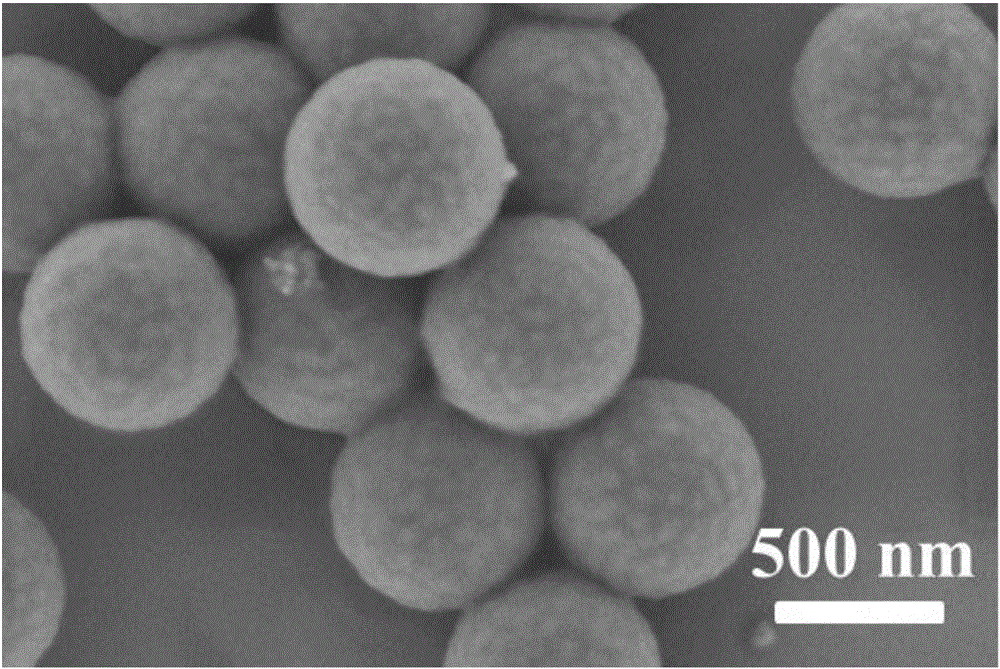

[0071] attached figure 2 It is an SEM photo obtained by scanning linear polystyrene template microspheres with a FEI Nano SEM 450 scanning electron microscope. It can be seen from the figure that the linear polystyrene template microspheres prepar...

Embodiment 2

[0089] (1) Preparation of linear polystyrene template microspheres with 500nm sodium dodecylsulfonate as emulsifier

[0090] Add 240mL of water, 0.2g of sodium bicarbonate, and 0.075g of SDS into the reactor, stir for 10min, add 40mL of styrene monomer into the reaction system under the protection of argon, emulsify for 30min, raise the temperature of the system to 70°C, Dissolve 0.32g of potassium persulfate (KPS) in 60mL of water, add potassium persulfate solution dropwise into the reaction system over 30 minutes, control the stirring speed at 180r / min, stop the reaction after 13 hours of reaction, centrifugally settle the material, and vacuum dry Obtain 500nm monodisperse linear polystyrene template microspheres;

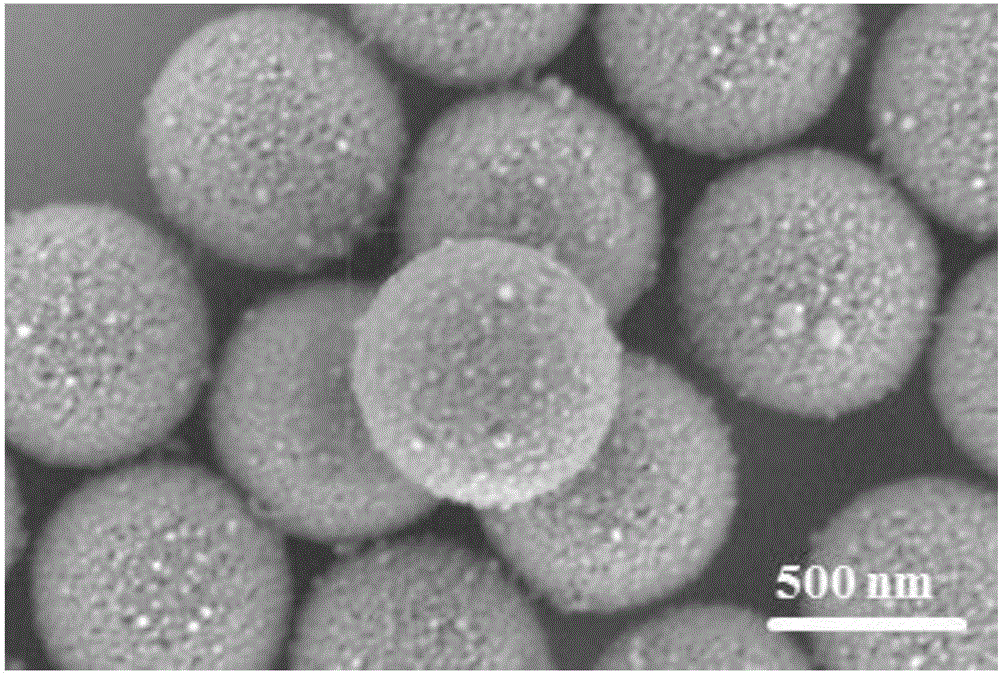

[0091] (2)LPS@SiO 2 Preparation of core / shell composite microspheres

[0092]At room temperature (25°C), soak 1g of linear polystyrene template microspheres obtained in the dry step (1) method 2 in 60mL of concentrated sulfuric acid (98Wt%) for 10min, then plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com