Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Excellent resistance to organic solvents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PVA alloy capable of being processed with thermoplasticity method and manufacture technology thereof

InactiveCN101845185AImprove liquidityImprove barrier propertiesManufacturing technologyPolyvinyl alcohol

The invention designs a high barrier PVA alloy capable of being processed with a thermoplasticity method. specifically speaking, through various monolayer or multi-layer thermoplasticity processing extrusion processing devices, the alloy is made into various high barrier films containing the alloy comprising a monolayer film, a multi-layer extrusion film, a high temperature retort film, a two-way stretch film and a thermo shrink film, hollow containers comprising a car oil tank, a bottom and a barrel, various tubular products comprising a fuel oil or oil delivery pipe and a gas pipe, various sheets and all high barrier products made from the material. The product made form the material has excellent chemically resistant performance, oil resistance, solvent resistance, transparency, processing stability, high barrier performance for various gases, aroma protection property, tensile strength and elongation at break.

Owner:刘建林

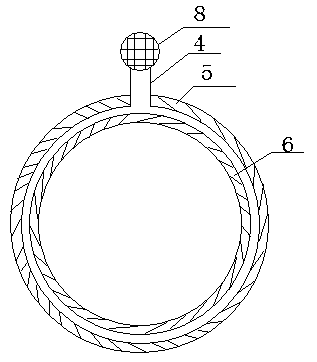

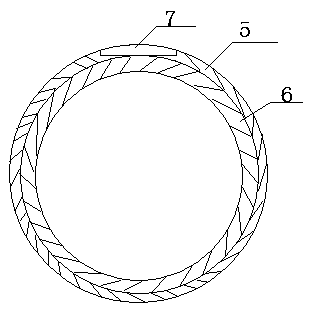

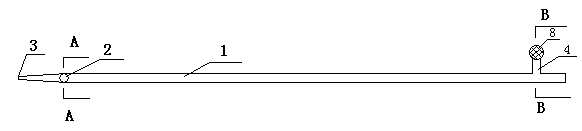

Method for preparing negative photosensitive polyimide based on 2,2-di[4-(2,4-diaminophenyloxy)phenyl]hexafluoropropane

InactiveCN101265328ASmall shrinkageGood dimensional stabilityPhotomechanical apparatusPolymer scienceEnd-group

The invention discloses a method for preparing negative photosensitive polyimide which is based on 2, 2-bis<4-(2, 4-diaminophenoxy) phenyl> hexafluoropropane. The method takes the 2,2-bis<4-(2,4-diaminophenoxy)phenyl> hexafluoropropane and dihydric acid anhydride as raw materials for carrying out the polymerization reaction, hyper-branched fluoride-containing polyamic acid which takes the macromolecular chain end group as the anhydride group is obtained, the hyper-branched fluoride-containing polyamic acid is further reacted with p-hydroxyaniline or m-hydroxyaniline, hyper-branched fluoride-containing polyimide which takes phenolic hydroxyl as the end group by chemical imidization reaction is obtained, phenolic hydroxyl end-blocked fluoride-containing hyper-branched polyimide powder is obtained by precipitation, washing and vacuum drying process, and the hyper-branched fluoride-containing polyimide photosensitive material with the negative photosensitive performance is obtained by undergoing the functionalization after the dissolution. The material has high photosensitive performance, high resolution and excellent process, and the cured product has low water absorption, excellent heat resistance, dielectric performance and mechanical performance, thus having great application prospect in the field of electronic micro-electronics.

Owner:DONGHUA UNIV +1

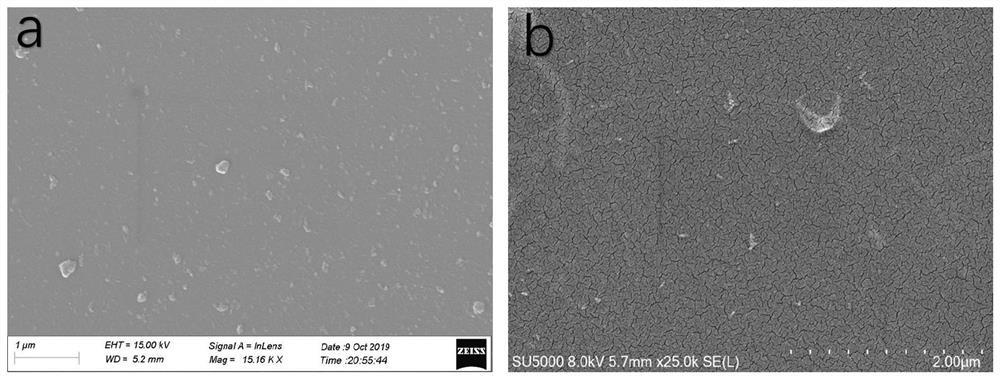

Preparation method for novel anti-pollution polysulfone flat plate ultrafiltration membrane

InactiveCN104667768AEasy to modifyGood acid and alkali resistanceSemi-permeable membranesCross-linkUltrafiltration

The invention discloses a preparation method for a novel anti-pollution polysulfone flat plate ultrafiltration membrane. The preparation method comprises the following steps: adding polysulfone and a pore-forming agent into a solvent; heating, stirring and carrying out micro-pore filtering; then carrying out vacuum de-foaming to obtain a flat plate ultrafiltration membrane casting solution; by taking a non-woven fabric as a supporting layer, and carrying out dry-wet phase changing method scraping by a membrane scraping machine to obtain a uniform flat plate membrane; carrying out grafting, coating and cross-linking on the obtained flat plate membrane by ultraviolet and infrared catalysis manners to realize surface hydrophilic modification, so as to form a stable, durable and good-tolerance hydrophilic protection layer on the surface of the flat plate membrane; and washing and drying to obtain the anti-pollution ultrafiltration membrane. The whole technology has a simple process, raw materials are easily available and industrial automatic production can be realized.

Owner:VONTRON MEMBRANE TECH CO LTD

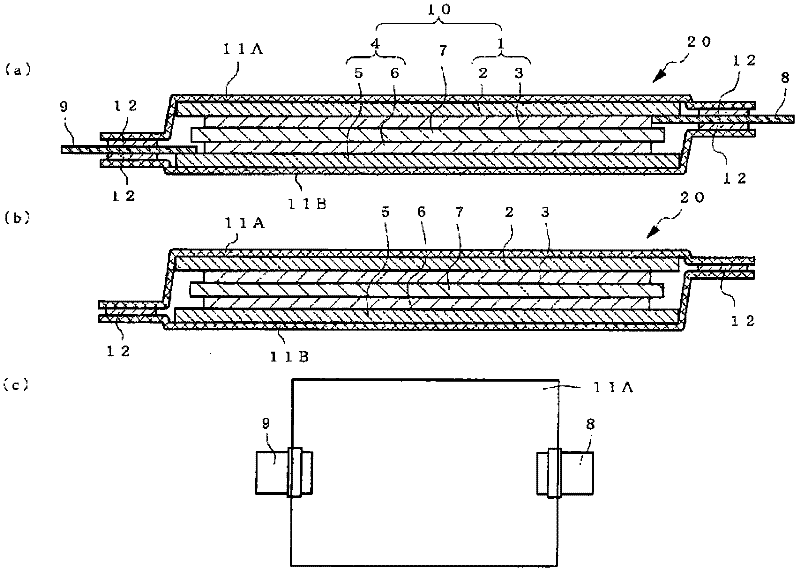

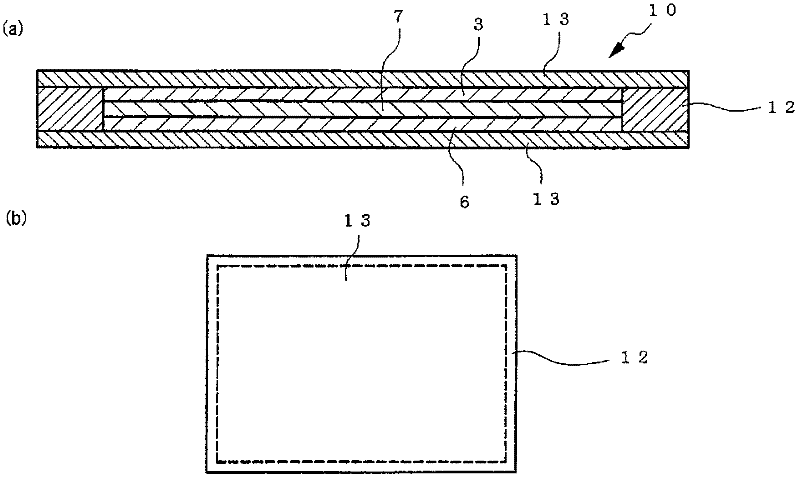

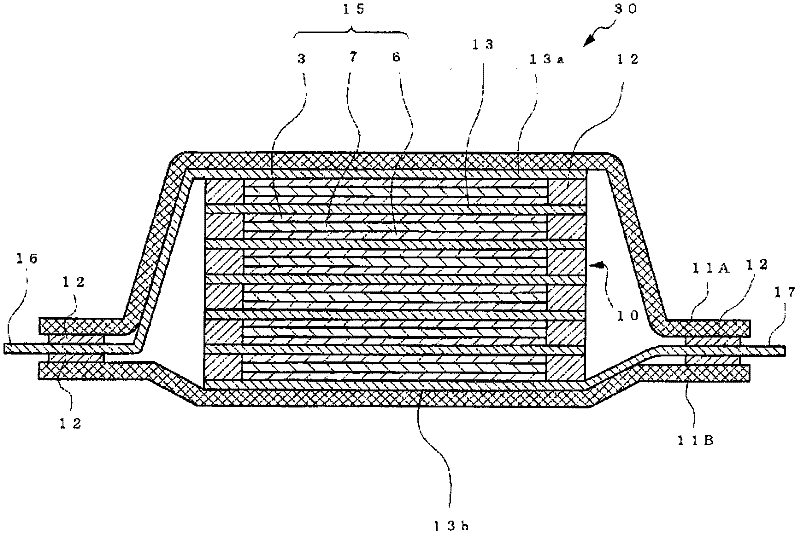

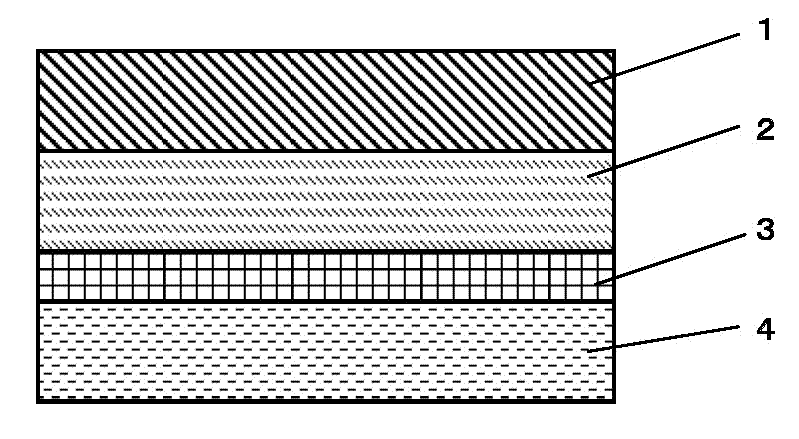

Resin composition and organic-electrolyte battery

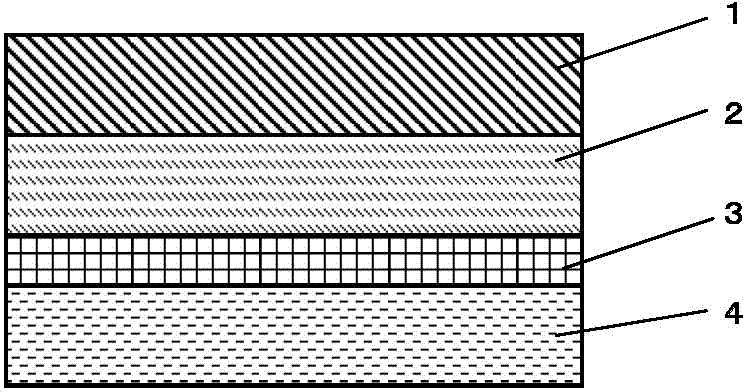

ActiveCN102459395AImprove adhesionExcellent resistance to organic solventsFinal product manufactureSmall-sized cells cases/jacketsHigh resistanceEpoxy

Provided is a resin composition having excellent adhesion to metals and high resistance to organic solvents. In particular, the resin composition is suitable for use as a sealing material for organic-electrolyte batteries which has excellent adhesion to terminals or current collectors constituted of a highly heat-resistant metal such as stainless steel or nickel, is less apt to deteriorate even upon contact with high-temperature organic electrolytes, and is less apt to affect the electrolytes. Also provided is a highly reliable organic-electrolyte battery in which the electrolyte is prevented from oozing out from the electrolyte layer by the action of the resin composition. The resin composition is characterized by comprising an epoxy resin (A) comprising an epoxy resin (E1) having an aromatic ring and an alicyclic skeleton and a latent hardener (B). The organic-electrolyte battery has a positive electrode comprising a current collector (13) and a positive active-material layer (2) electrically bonded to the surface thereof, a negative electrode comprising a current collector (13) and a negative active-material layer (6) electrically bonded to the surface thereof, and an electrolyte layer (7) disposed between the positive electrode and the negative electrode, the battery including a sealing part formed by tightly filling the gap between the peripheral edge parts of the two opposed current collectors (13) with a cured object (12) formed from the resin composition.

Owner:AJINOMOTO CO INC +1

Conductive coating composition and laminate

ActiveCN102559043ASimple and cheap processLower surface resistivityOther chemical processesGlass/slag layered productsOligomerConductive coating

The invention provides a conductive coating composition and a laminate. The conductive coating composition can be used to form an anti-static membrane having advantages of conductivity, high transparence, good attachment to the base material, high rigidity and good chemical resistance. The conductive coating composition comprises the conductive polymer particle having particle diameter D50 under 200nm, adhesive composition ingredient containing the alkoxy silane oligomer. The conductive polymer particle has preferably the particle diameter under 60nm, more preferably 30nm. The conductive polymer particle preferably a composition of Poly (3,4-disubstituted thiophene) and polyanion. By using the conductive coating composition provided in the invention, the normal coating method can be used to coat the cloth base material in low temperature to form the anti-static membrane, and the technology from coating to film forming can be realized with low costs.

Owner:NAGASE CHEMTEX CORPORATION

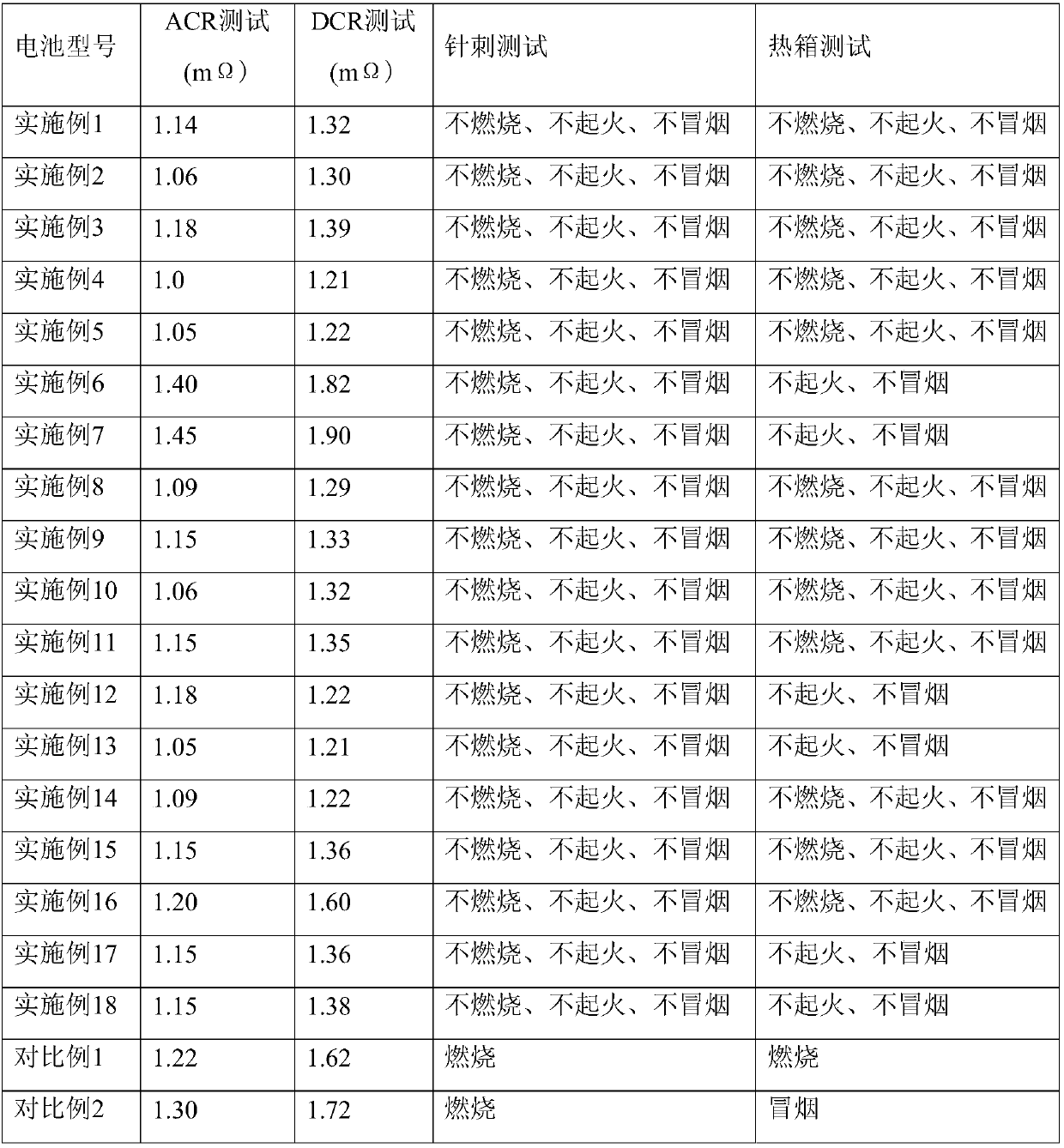

Lithium ion battery safety coating and application thereof as well as lithium ion battery

InactiveCN107623098AHas thermal blocking propertiesImprove thermal stabilityNon-aqueous electrolyte accumulator electrodesCell component detailsMicrosphereSodium-ion battery

The invention discloses a lithium ion battery safety coating. The lithium ion battery safety coating is prepared from a vinyl silane coupling agent, a binder and polyethylene microspheres through thefollowing steps: adding toluene and the vinyl silane coupling agent to the polyethylene microspheres, performing reflux reaction for 20-28 hours, filtering and drying to obtain polyethylene powder, and then mixing the polyethylene powder with the binder, sequentially stirring and dispersing to prepare a safety coating paste, and coating the safety coating paste to form a safety coating. The invention also discloses an application method of the lithium ion battery safety coating and a corresponding lithium ion battery. The safety coating disclosed by the invention has thermal blocking characteristics, can block the transmission of lithium ions in an electrolyte, ensures that side effects of heat production no longer occur, and improves the thermal stability of the battery; the safety coating has excellent organic solvent resistance characteristics and voltage resistance characteristics, and is applicable to the lithium ion battery; and the prepared lithium ion battery has the advantagesof high safety, no smoke, no fire, no combustion and the like.

Owner:WANXIANG 123 CO LTD +1

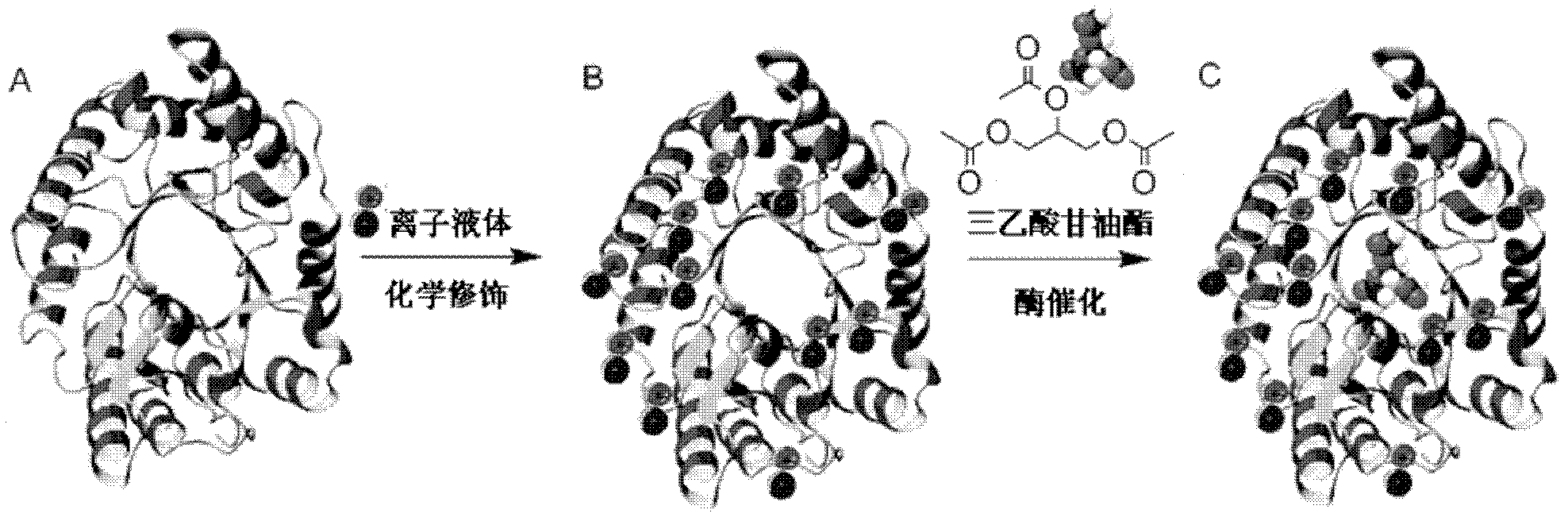

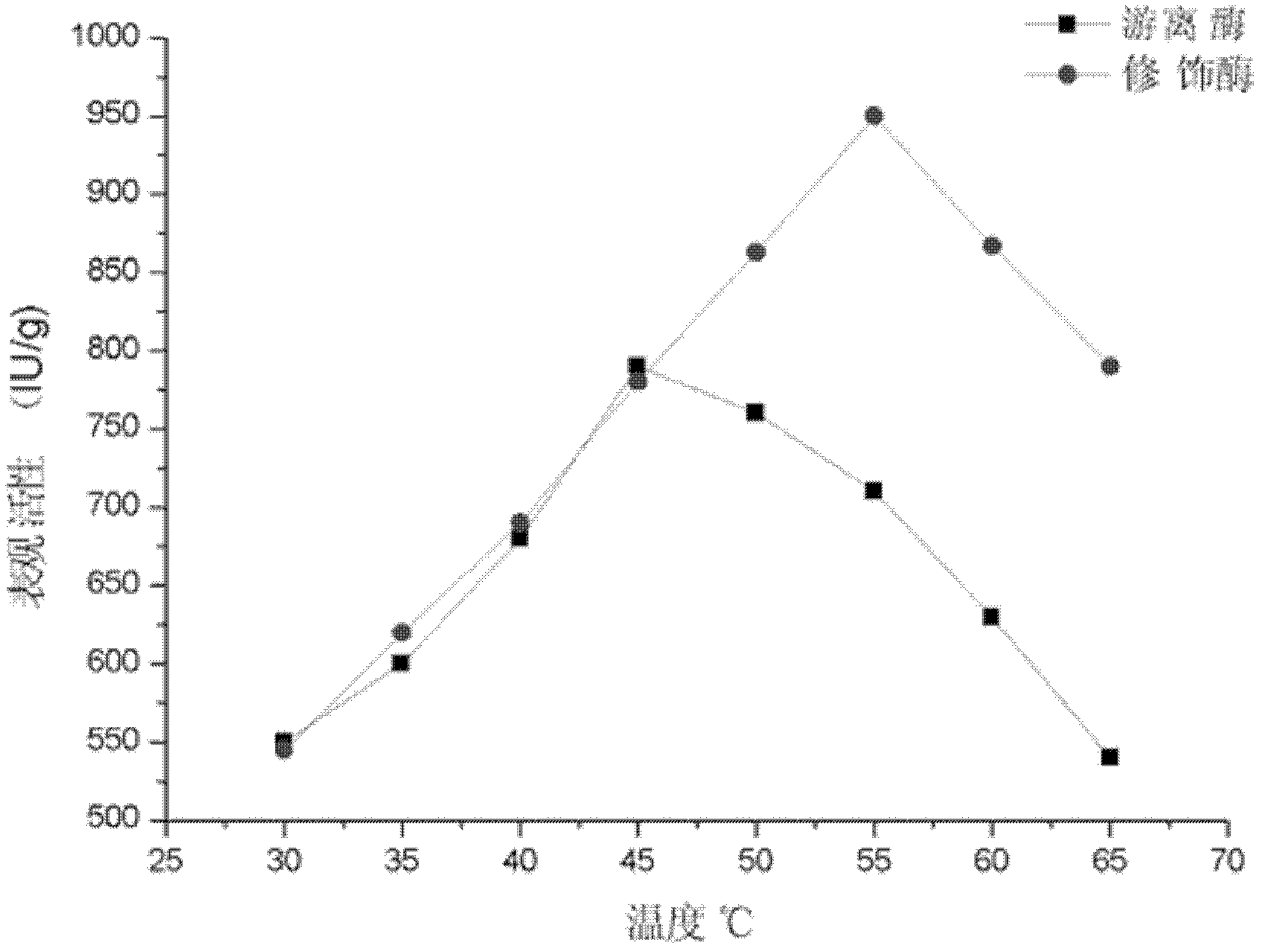

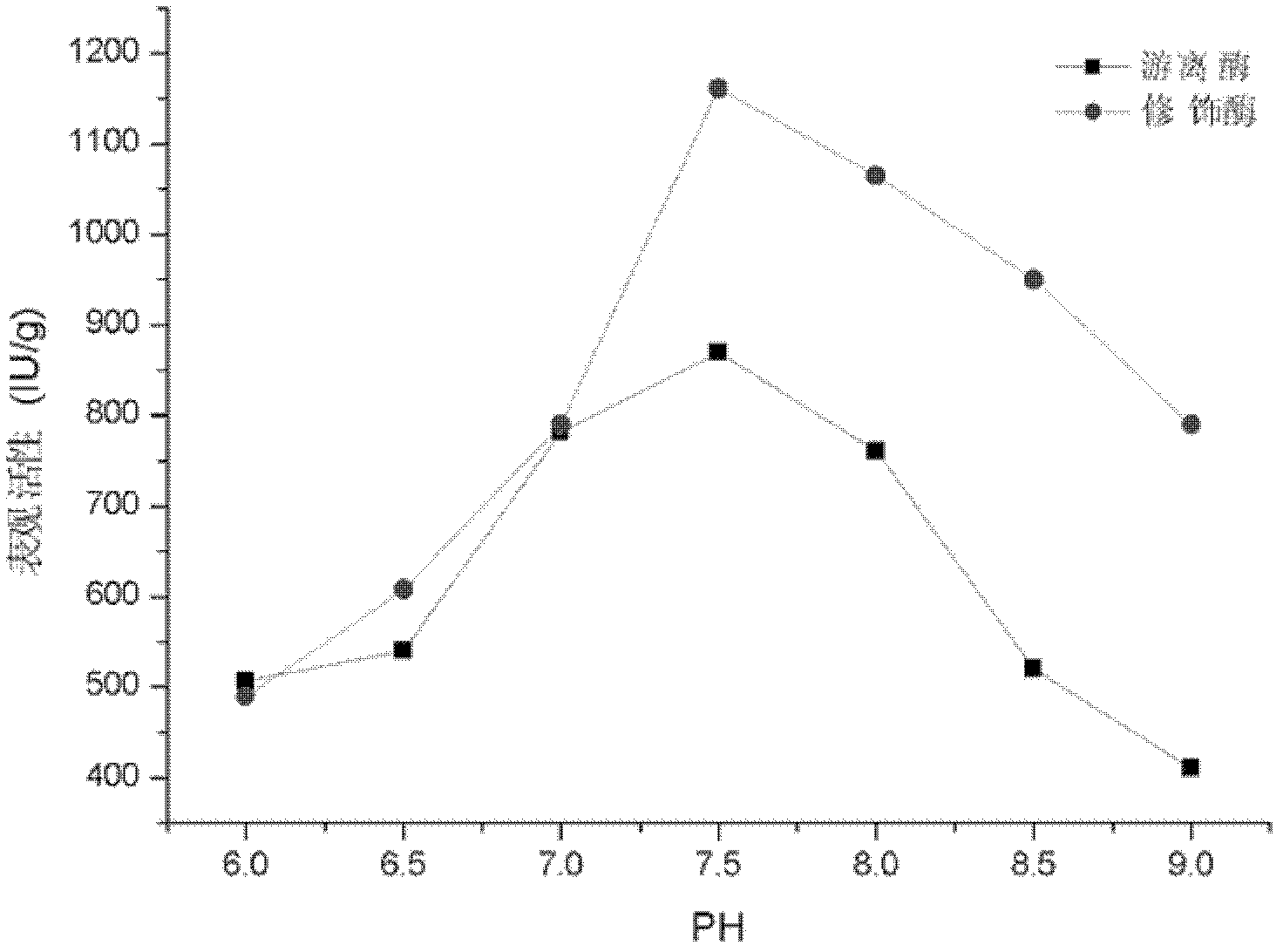

Functional ionic liquid modified lipase and modification method thereof

The invention discloses functional ionic liquid modified lipase and a modification method thereof. The method comprises the following steps of: dissolving functional ionic liquid containing carboxyl, NHS and EDC.HCL in a molar ratio of 1:1:(1-3) in methyl ester sulfonate (MES), reacting at room temperature for 1 to 2 hours for activation, performing hybrid reaction on the activated functional ionic liquid and the lipase in the molar ratio of (200-1,000):1 at the temperature of between 0 and 4 DEG C for 2 to 8 hours; or dissolving the functional ionic liquid containing amino, NHS, EDC.HCL and the lipase in a molar ratio of (100-300):1:(1-3):1 in the MES, and performing hybrid reaction at the temperature of between 0 and 4 DEG C for 3 to 10 hours to obtain the functional ionic liquid modified lipase. The functional ionic liquid with the amino or the carboxyl is introduced into the surface of lipase, and is subjected to covalent binding with the amino acid residues of the lipase molecules, so the space structure of the active center of enzyme is influenced, and the catalytic performance of the lipase is enhanced.

Owner:青州市瑞鑫再生资源科技有限公司

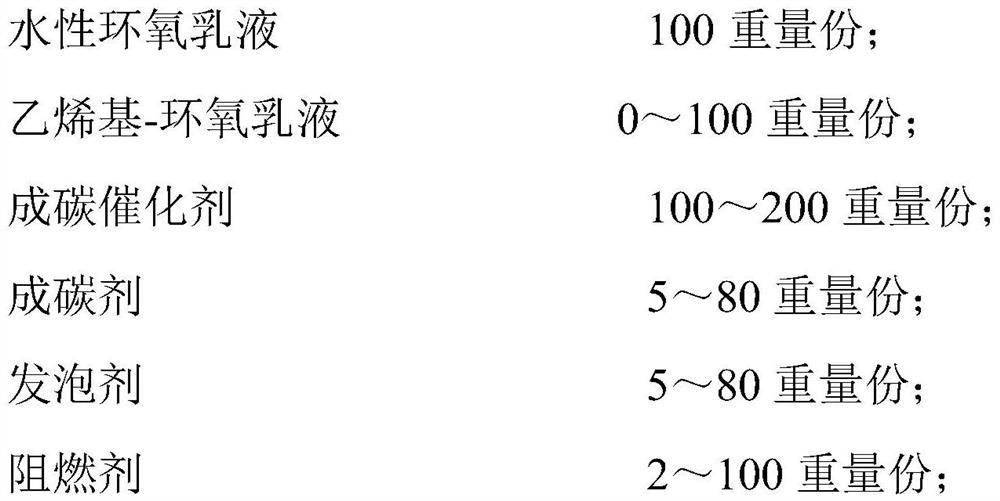

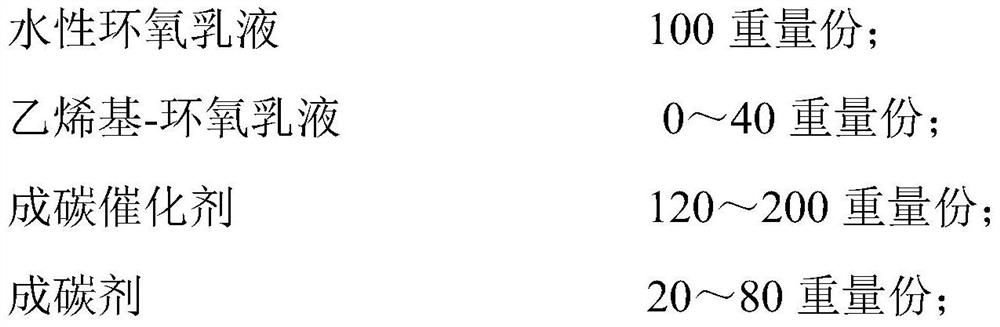

Waterborne epoxy fireproof coating as well as preparation method and application thereof

ActiveCN113444425ANo pollution in the processEasy to operateFireproof paintsAnti-corrosive paintsFiberPolymer science

The invention discloses a waterborne epoxy fireproof coating as well as a preparation method and application thereof. The waterborne epoxy fireproof coating is composed of a component A and a component B. The component A comprises a waterborne epoxy emulsion, a vinyl-epoxy emulsion, a carbon forming catalyst, a carbon forming agent, a foaming agent and a flame retardant; and the component B comprises a curing agent and refractory fibers. The water-based epoxy fireproof coating disclosed by the invention has the same excellent sealing performance as a solvent-free epoxy fireproof coating and a high-solid-content epoxy fireproof coating, has excellent corrosion resistance, UV irradiation resistance, water resistance and organic solvent resistance, and can be used in a severe outdoor environment. According to the fireproof coating, self-made emulsions are preferably selected, the structure of a film forming matter is optimized and adjusted, and fireproof efficiency is high. Meanwhile, water is selected as a diluent, so coating problems of an original epoxy fireproof coating are fundamentally solved, a water-based system is more environmentally friendly, and the coating belongs to a new-generation fireproof coating technology.

Owner:MARINE CHEM RES INST

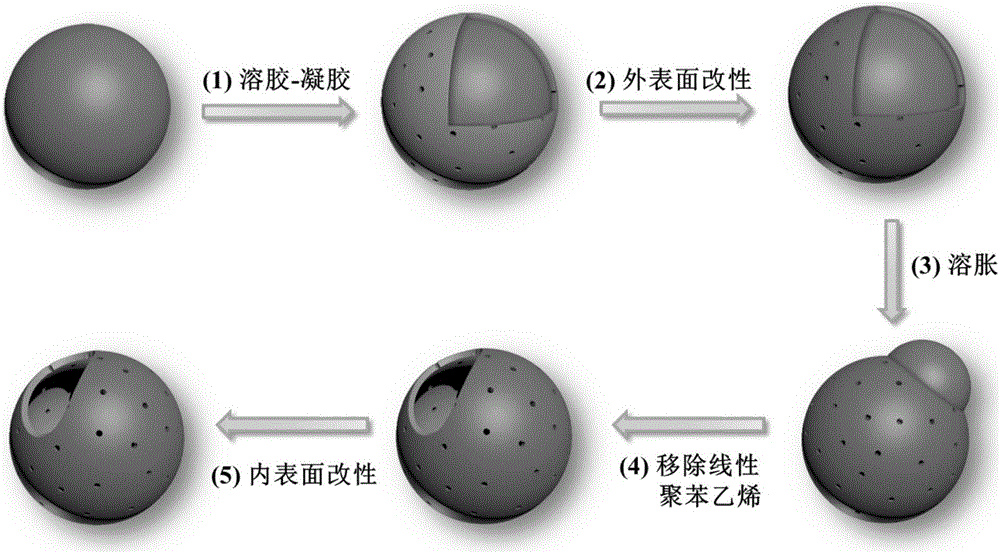

Preparation method of amphiphilic Janus hierarchical pore microcapsule with opening structure

ActiveCN106732221ASimple manufacturing processEasy to scaleMicroballoon preparationMicrocapsule preparationOrganic solventMicrometer

The invention relates to a preparation method of an amphiphilic Janus hierarchical pore microcapsule with an opening structure. The preparation method comprises the following steps of performing occupying modification on the outer surfaces of core / shell composite microspheres; then, swelling the core / shell composite microspheres to form the anisotropic composite microspheres with bulges, and dissolving by a good solvent to remove a template, so as to form a microcapsule with the opening structure; finally, performing different functionalizing on the inner surfaces of the microcapsules, so as to obtain the microcapsule material with the hydrophilic inner surface and the hydrophobic outer surface, or the hydrophobic inner surface and the hydrophilic outer surface. The prepared microcapsule material has excellent biological compatibility, good organic solvent-resistant property, chemical corrosion-resistant property and high mechanical stability, and has huge potential application value in the fields of micrometer-nanometer reactors, load catalyzing and the like.

Owner:HEBEI UNIV OF TECH

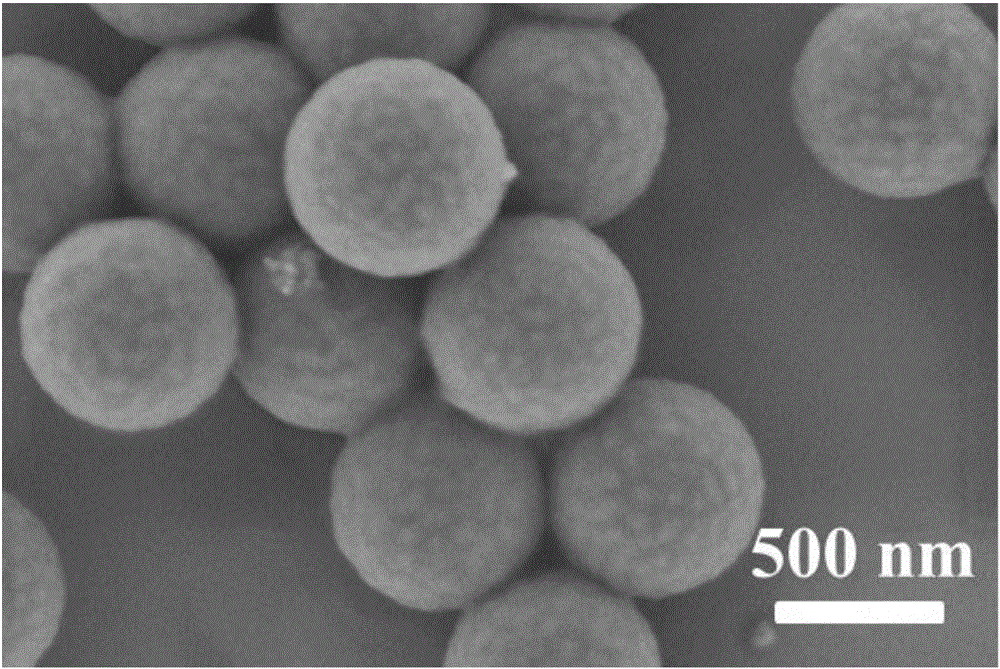

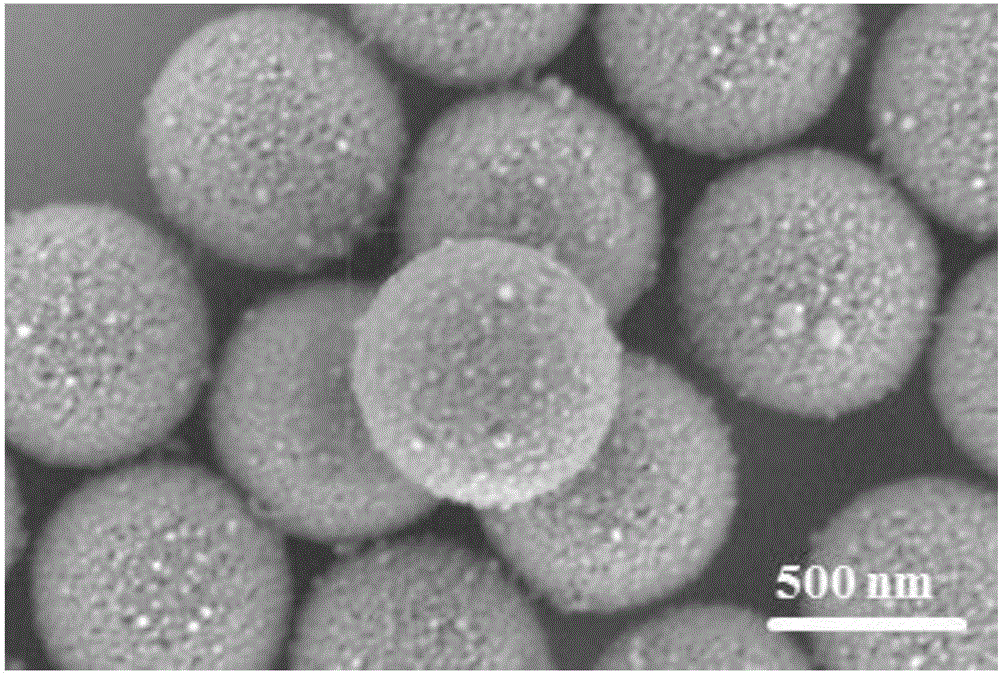

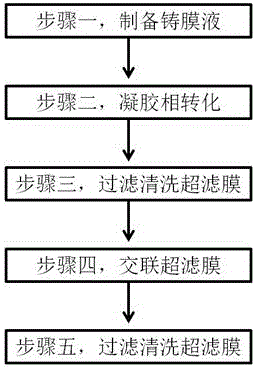

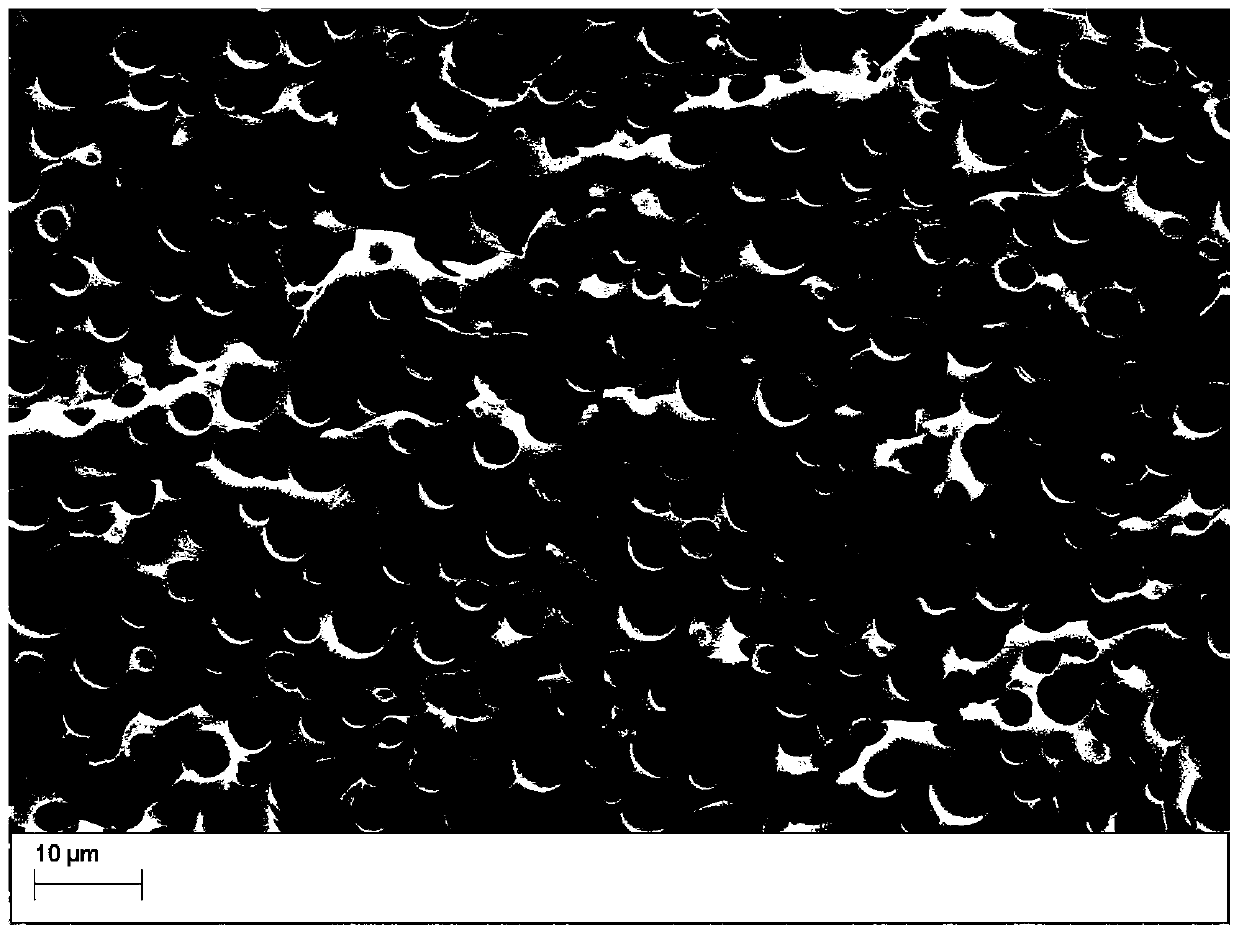

Method for preparing organic-solvent-resistant ultrafiltration membrane, prepared ultrafiltration membrane and application of ultrafiltration membrane

ActiveCN105709616AExcellent resistance to organic solventsHigh water fluxMembranesUltrafiltrationCross-linkOrganic solvent

The invention discloses a method for preparing an organic-solvent-resistant ultrafiltration membrane, the prepared ultrafiltration membrane and application of the ultrafiltration membrane. The method for preparing the organic-solvent-resistant ultrafiltration membrane includes the steps of preparing a membrane casting solution, performing precipitation phase inversion, filtering and cleaning an ultrafiltration membrane for the first time, cross-linking the ultrafiltration membrane and filtering and cleaning the ultrafiltration membrane for the second time. The surface layer of the membrane is cross-linked, and a supporting layer is also cross-linked. According to the method, preparation time is short, the technology is simple, and solvents are saved. The prepared ultrafiltration membrane has the advantage of being resistant to organic solvents and has good application prospects in separation of organic solvent systems.

Owner:OCEAN UNIV OF CHINA

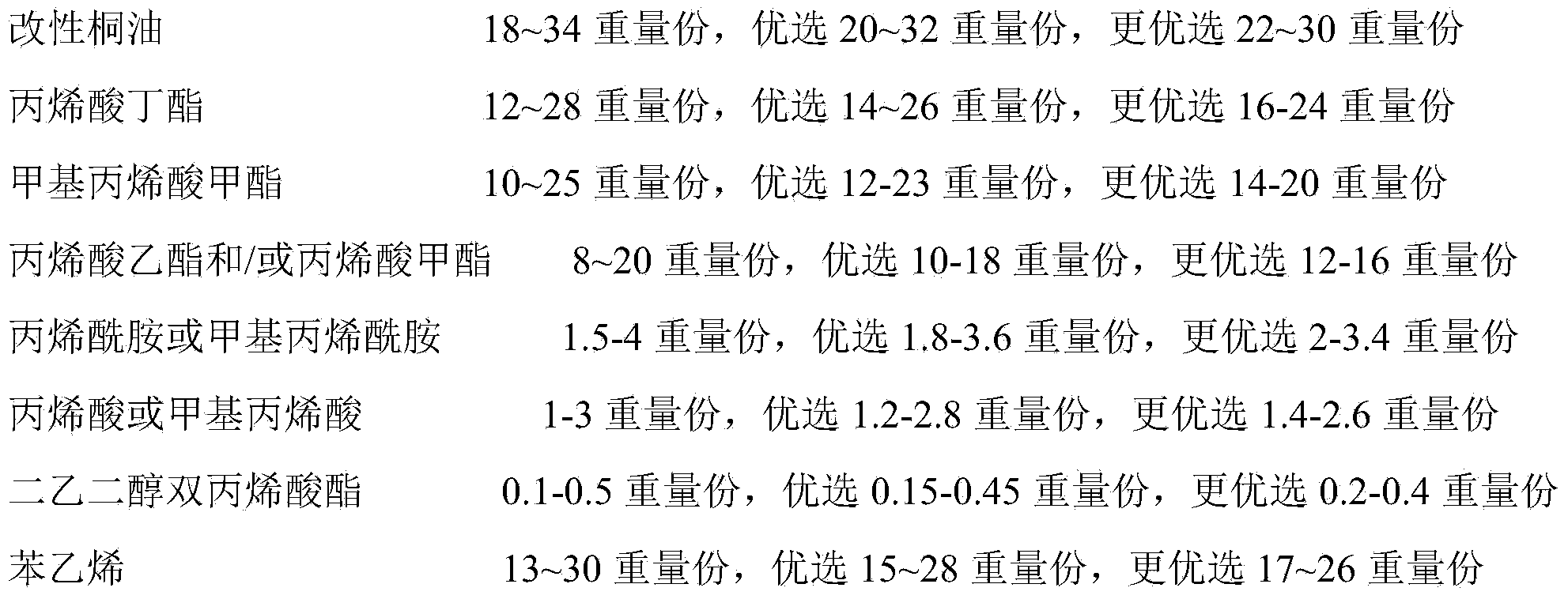

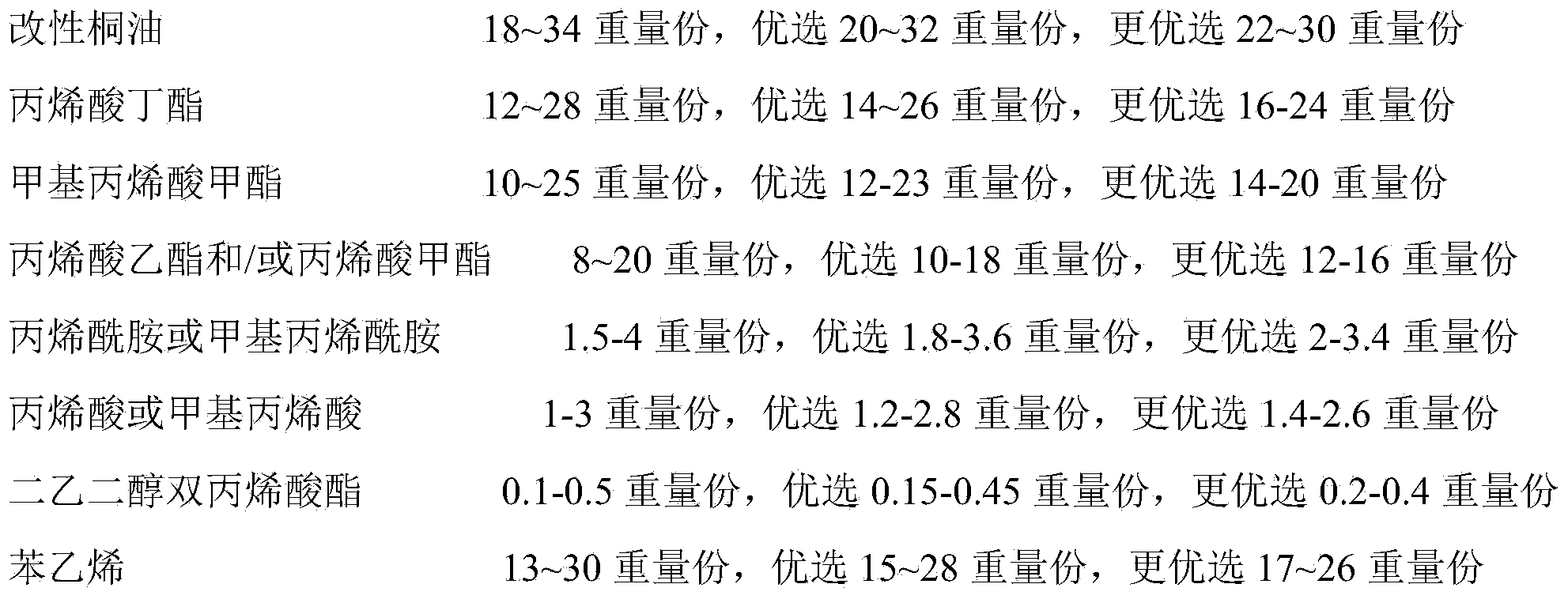

Paint composition containing modified tung oil and preparation method thereof

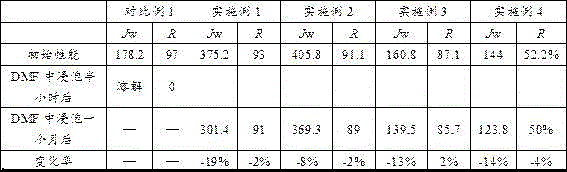

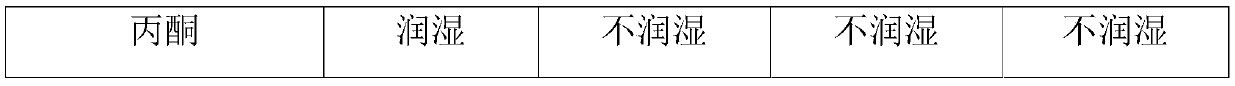

The invention discloses a modified tung oil-acrylate copolymer emulsion which is prepared by carrying out free radical emulsion polymerization reaction on modified tung oil, acrylate monomer, styrene and crosslinking monomer as monomer components and adding a diamidohydrazine or polyhydrazide crosslinking agent, wherein the modified tung oil is an addition reaction product prepared from tung oil and an alkene unsaturated surfactant with the molecular weight of 100-500 in a weight ratio of 100:(50-150). The invention also discloses a paint composition using the emulsion. The paint composition can be used for coating metals and plastics.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

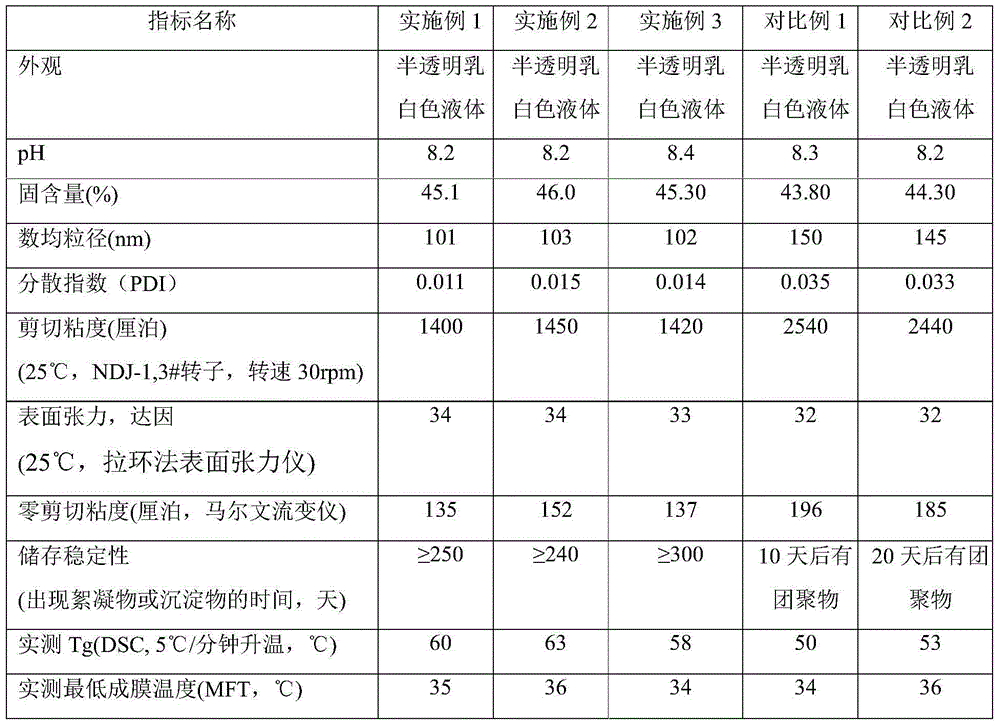

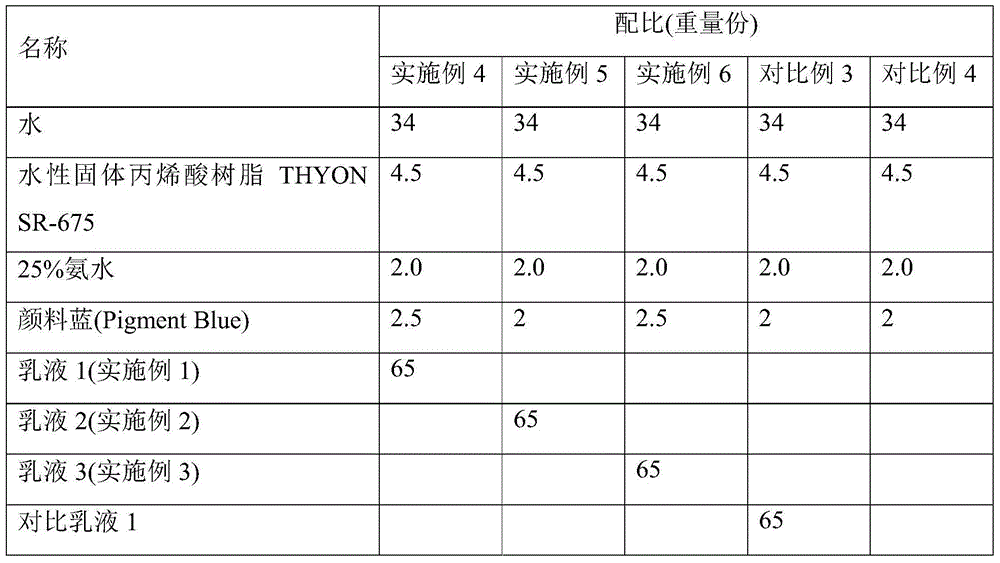

Aqueous coating composition and preparation method thereof

The invention discloses a modified tung oil-acrylic ester copolymer emulsion which contains a small quantity of acrylamide and acrylic monomer units. A preparation method of the emulsion comprises the following steps: carrying out free radical emulsion polymerization by taking modified tung oil, acrylic ester monomers, acrylamide, acrylic acid, styrene and cross-linking monomer as components of monomers, and then adding hydrazide or polyhydrazide cross-linking agents to prepare the emulsion, wherein the modified tung oil is a product of addition reaction between the tung oil and an olefinic unsaturated surfactant with molecular weight being 100-500 according to a weight ratio of 100 to (50-150). The invention also discloses an aqueous coating composition which uses the emulsion and aqueous acrylic resin containing acrylamide. Compared with the pigment, the coating composition has improved dispersion, is excellent in storage stability and can be used for coating metals and plastics.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Light-sensitive polymer composition not easy to change color and application thereof

InactiveCN101281366AExcellent water resistanceExcellent water and solvent resistancePhotosensitive materials for photomechanical apparatusWater dispersibleChemistry

The invention relates to a phototonus resin composite unlikely to change colors and its application. The composite comprises a 0.1 to 50 wt percent water dispersible polymer, 0.1 to 50 wt percent water solubility bond polymer, 0.1 to 50 wt percent photocureable compound, 0.5 to 40 wt percent thermosetting compound, 0.1 to 10 wt percent diazonium resin or bichromate and proper additive. Compared with the prior art, the invention has the characteristic of unlikely to change colors in the producing art of rotary silk screen after being exposed and dried on the basis of keeping organic solvent resistance.

Owner:MURAKAMI MURAKAMI PRECISION STENCIL (KUNSHAN) CO LTDSTENCIL (KUNSHAN)

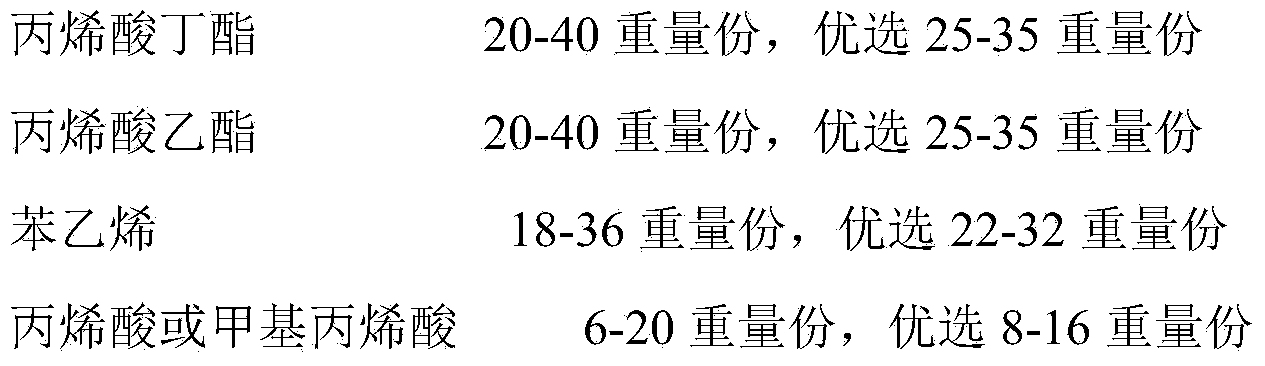

Corrosion-resistant waterborne conductive paint and preparation method thereof

ActiveCN103436060AStrong adhesionGood physical propertiesAnti-corrosive paintsElectrically-conductive paintsCalcium silicateMeth-

The invention provides a waterborne conductive paint, particularly relates to a corrosion-resistant conductive paint and a preparation method thereof, and belongs to the technical field of paints. The corrosion-resistant conductive paint comprises the following components in parts by weight: silver powder, graphite, copper powder, epoxy resin E-51, organic silicon resin, benzyl dimethyl ketal, phenyl ethyl acrylic ester, 1,6-hexanediol acrylic ester, stearyl amine, diethylene glycol hexyl ether, polyoxy propylene triol, cetyl trimethyl ammonium bromide, isooctyl oleic ester, calcium silicate, bentonite, polyvinyl alcohol aqueous solution, ammonia water, preservative, ammonium dodecylbenzenesulphonate, hydroxymethyl cellulose and water. The corrosion-resistant conductive paint has the advantages that the adhesive force is good and can be up to 95%, other physical properties are superior to like products, the salt spray resistance property can be more than 280 hours, the organic solvent resistance property is excellent, and the conductibility is high.

Owner:嵊州市睿新材料科技研发中心

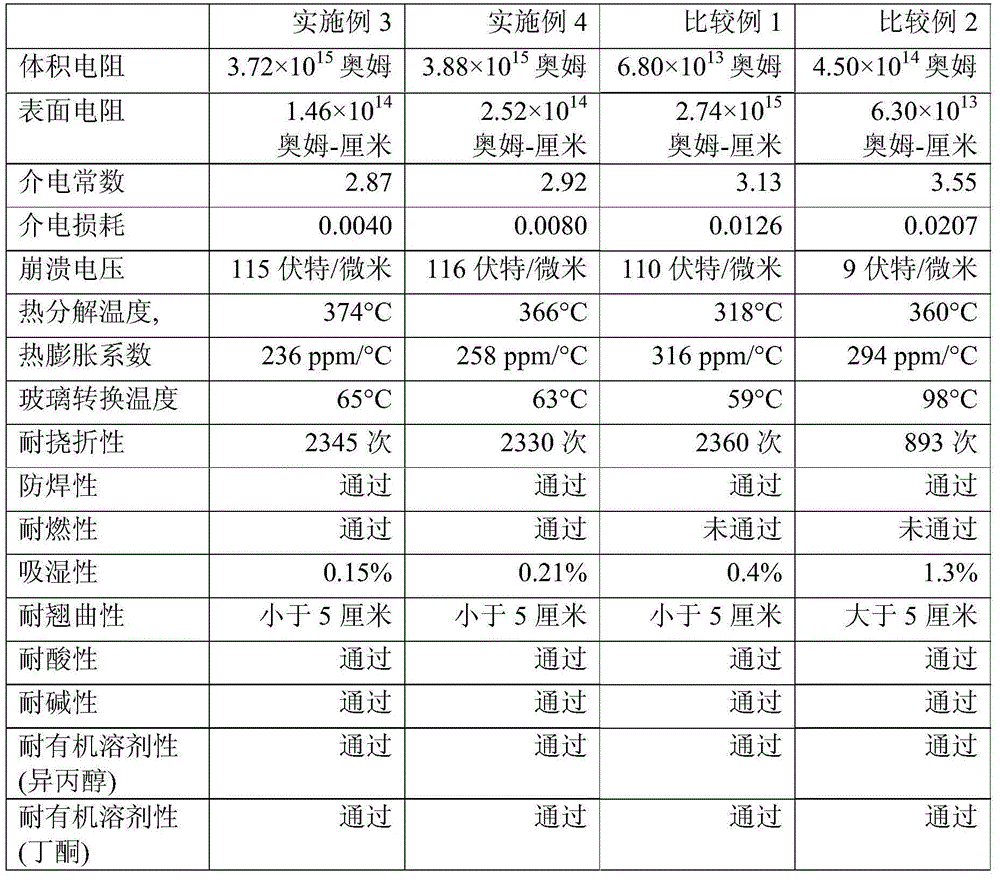

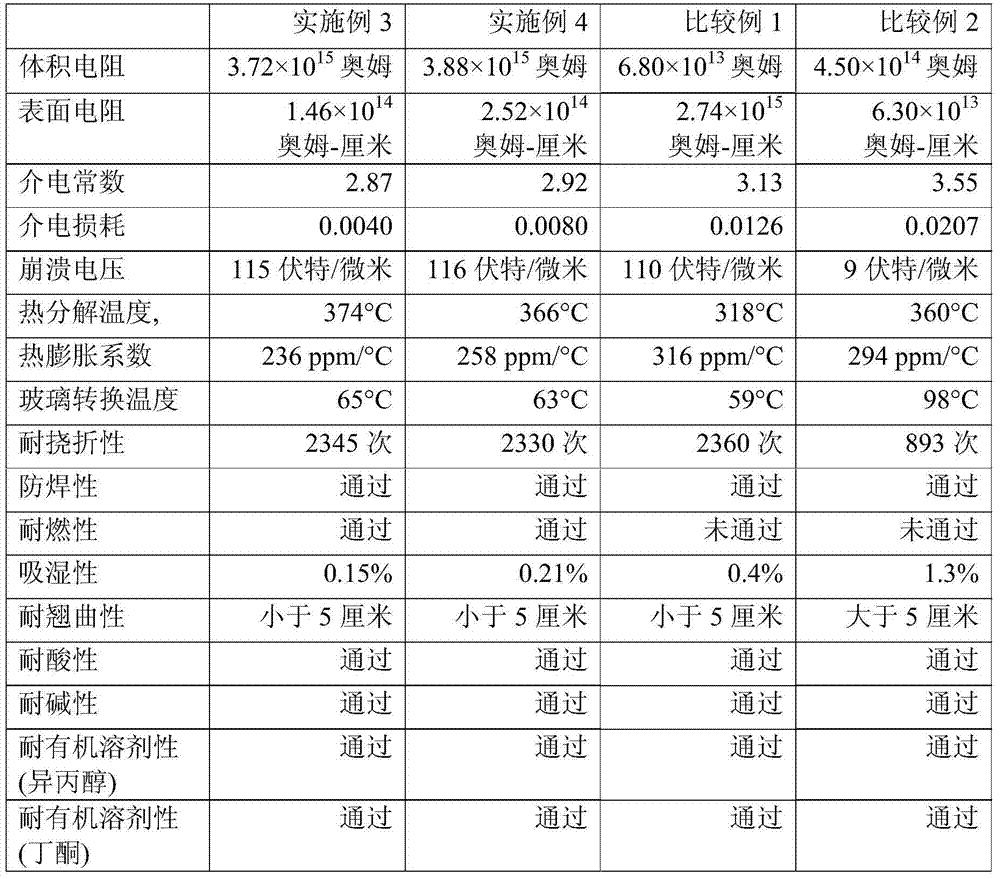

Thermosetting anti-welding printing ink with low dielectric constant and dielectric loss and preparation method of thermosetting anti-welding printing ink

The invention provides thermosetting anti-welding printing ink with low dielectric constant and dielectric loss and a preparation method of thermosetting anti-welding printing ink. The preparation method comprises the steps of reacting by virtue of long-carbon-chain aliphatic diamine monomers, aromatic diamine monomers with acid groups, aromatic dianhydride monomers with the acid groups and mono-anhydride monomers with the acid groups, cyclizing polyamide acid to obtain modified polyimide, and finally crosslinking modified polyimide with a hardening agent, so as to prepare the thermosetting anti-welding printing ink, wherein the dielectric constant of the thermosetting anti-welding printing ink is less than 3, the dielectric loss of the thermosetting anti-welding printing ink is less than 0.01, and the thermosetting anti-welding printing ink is applicable to high-frequency electronic equipment. Besides, tests show that the thermosetting anti-welding printing ink prepared by virtue of the preparation method has the characteristics of good electrical property, rupture resistance, welding resistance, warping resistance, flame resistance, acid resistance, alkali resistance and organic solvent resistance, low moisture rate and the like.

Owner:TAIFLEX SCI

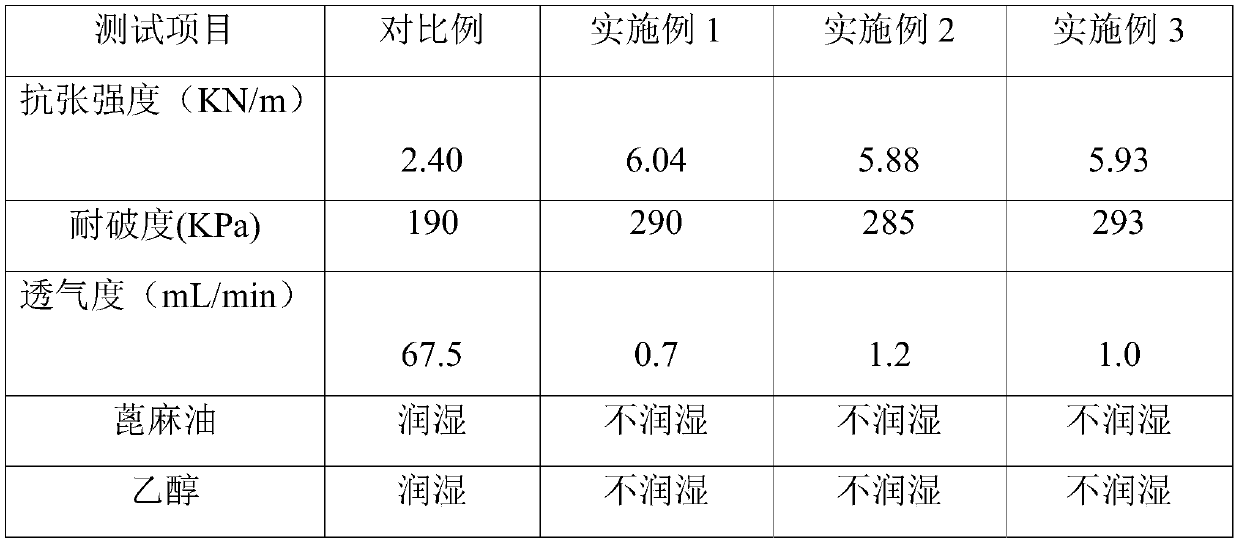

Fluoride-free oil-proof paper as well as preparation method and application thereof

The invention belongs to the technical field of oil-proof paper, and discloses fluoride-free oil-proof paper as well as a preparation method and an application thereof. The preparation method of the oil-proof paper comprises the following steps: putting a sodium hydroxide / urea / water solution into a refrigerator for precooling, moving out the mixed solution, adding dissolved pulp, stirring the mixture at room temperature, and then placing the mixture into the refrigerator for freezing treatment; moving out the mixture after a period of time, and unfreezing the mixture at room temperature; carrying out centrifugal treatment, and collecting supernate to obtain a transparent cellulose coating; coating paper with the obtained cellulose coating, then soaking the paper in a coagulating bath, andcoagulating the coating for a period of time at a certain temperature; and drying the paper to obtain the fluoride-free oil-proof paper. According to the invention, a cellulose regeneration method isadopted to cover the surface of the paper, so that hydrogen bonds among cellulose are rearranged, pores are reduced, and the paper has good barrier property on grease, organic solvents, water vapor and the like. The fluoride-free oil-proof paper provided by the invention can be used in the field of food packaging, and has a good application prospect in preparation of disposable tableware.

Owner:SOUTH CHINA UNIV OF TECH

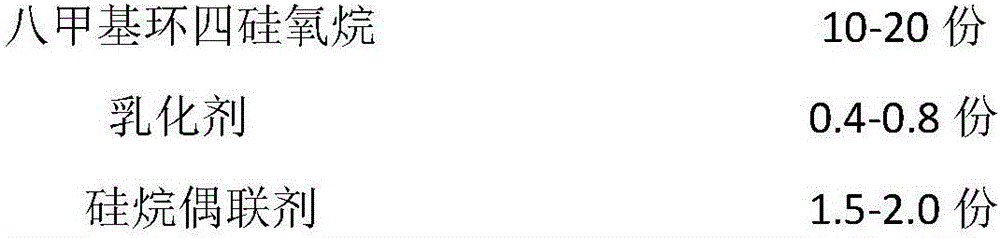

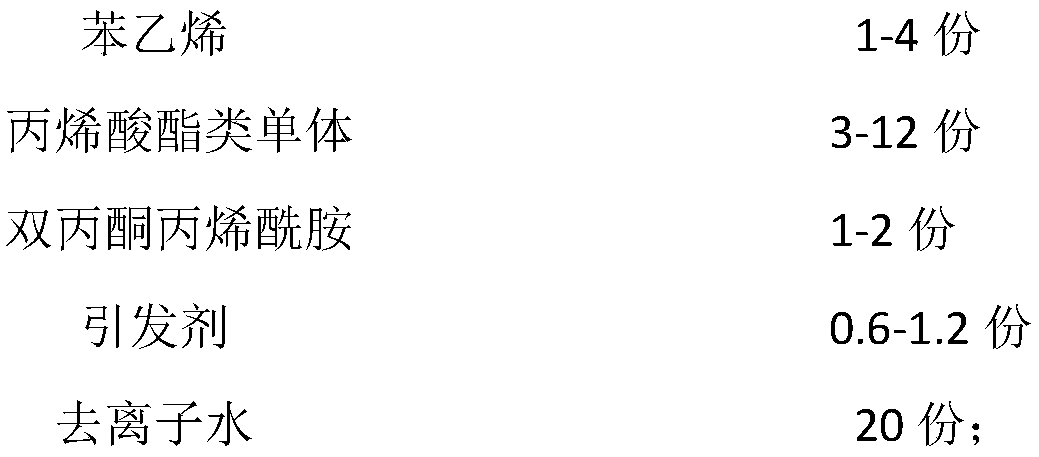

Aqueous polysiloxane resin and preparation method thereof

The invention discloses aqueous polysiloxane resin and a preparation method thereof. The aqueous polysiloxane resin is prepared from a pre-emulsion A, an emulsion B and a solution C as raw materials. The preparation method comprises the following steps: 1) preparing the pre-emulsion A; 2) preparing the emulsion B; 3) preparing the solution C; 4) pouring a part of the pre-emulsion A into a reaction container, dripping a part of the emulsion B, and at the same time heating the reaction container to 55-65 DEG C to react for 0.5-1 hour so as to prepare a light blue fluorescent seed emulsion; 5) simultaneously dripping the rest pre-emulsion A and the emulsion B into the fluorescent seed emulsion, heating to 55-65 DEG C to react for 2-3 hours, after the reaction is completed, cooling to the room temperature, adjusting the pH value to be 7-8, dripping the solution C, stirring for 10-30 minutes, and filtering, thereby obtaining a filtrate, that is, the aqueous polysiloxane resin. The aqueous polysiloxane resin is good in storage stability and flexibility, good in adhesion property, high in hardness and good in impact resistance, water resistance, salt water resistance, artificial aging resistance and chemical corrosion resistance. The aqueous polysiloxane resin is simple in preparation method, gentle in reaction condition and stable in process procedure.

Owner:WUHAN HOSTS COATING MATERIAL CO LTD

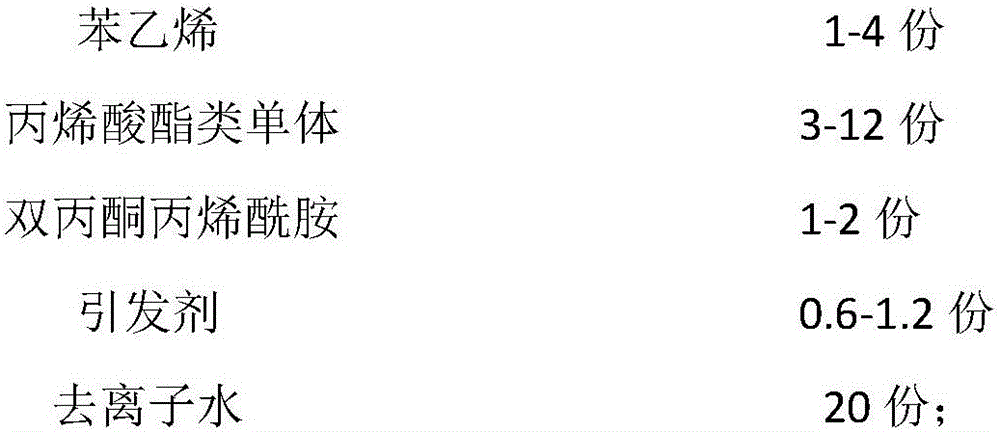

Processing method of molybdenum mineral dressing waste water

InactiveCN109179762AEfficient removalReduce problem sizeWater treatment parameter controlSludge treatmentParticulatesSludge

The invention discloses a processing method of molybdenum mineral dressing waste water. The processing method comprises following steps: 1, molybdenum mineral dressing waste water is introduced into apre-precipitation pool for precipitation so as to obtain pre-precipitation pool bottom sludge and a pre-precipitation pool supernatant; 2, the pre-precipitation pool supernatant is introduced into aflat ceramic membrane pool, and a flat ceramic membrane assembly is adopted for purifying to remove small particles and reduce the turbidity of produced water; 3, unfiltered waste water in the flat ceramic membrane pool is introduced into a reaction pool through a pipeline for reaction; and 4, waste water from the reaction pool is introduced into a precipitation pool for precipitation so as to obtain a precipitation supernatant and a precipitation pool bottom sludge. According to the processing method, the flat ceramic membrane is adopted for processing of molybdenum mineral dressing waste water, so that small particles can be removed with high efficiency, the turbidity of produced water is low, the technology is stable, waste water amount is reduced greatly, the adding amount of medicinesis low, operation cost is reduced greatly, precipitation pool equipment size and occupied land area are reduced at the same time, and investment cost is reduced.

Owner:SANDA FILM SCI & TECH XIAMEN

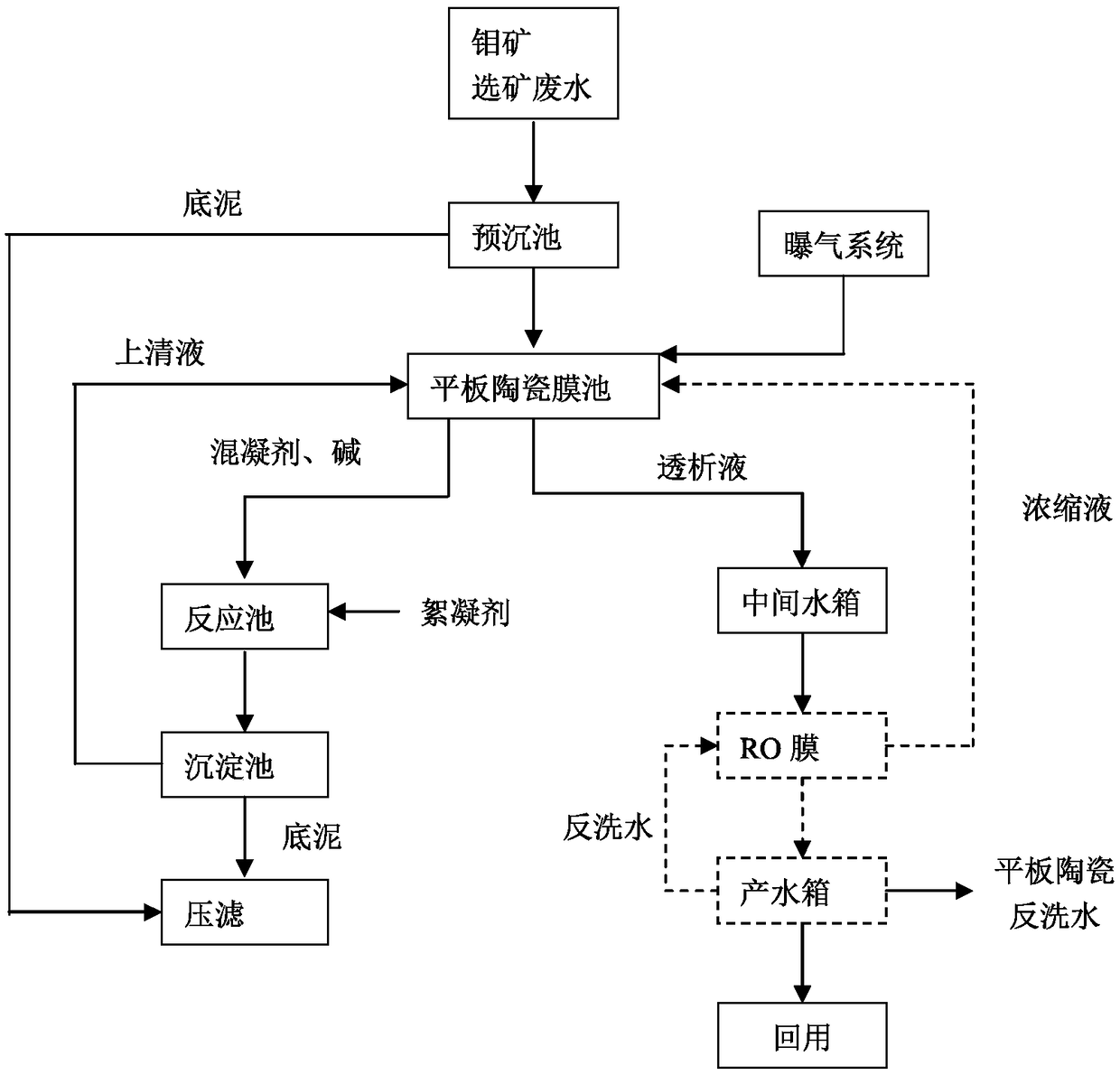

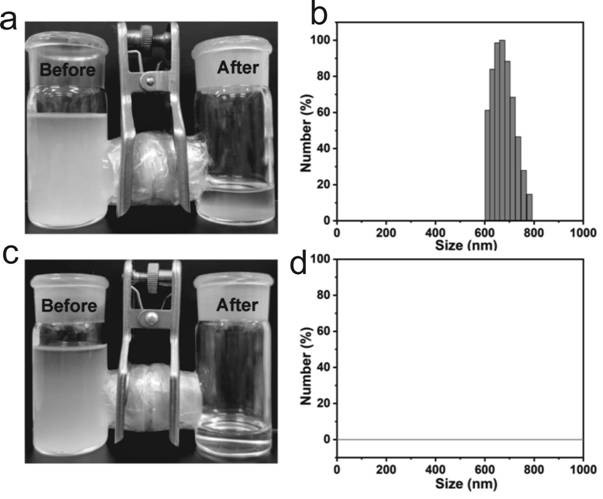

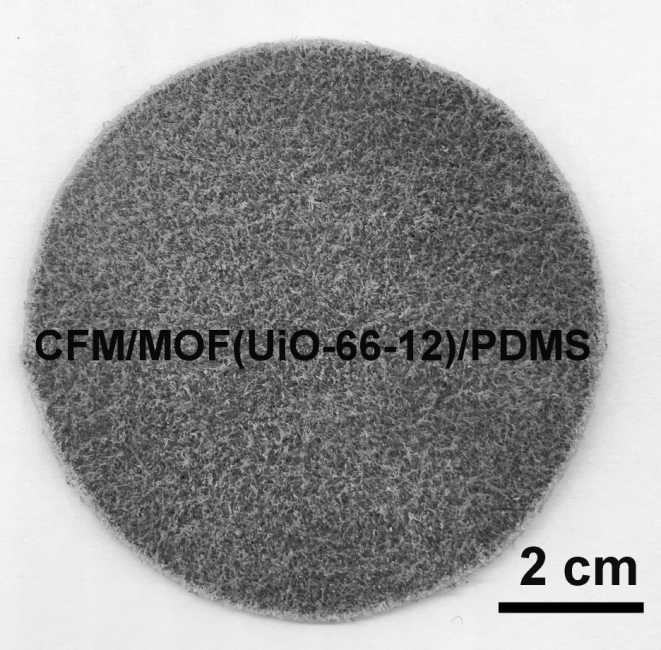

Preparation and application of durable high-flux emulsion separation membrane material

ActiveCN113244793APromote formationRealize demulsification separationSemi-permeable membranesNon-miscible liquid separationOrganic solventOil emulsion

The invention discloses preparation and application of a durable high-flux emulsion separation membrane material. Firstly, a metal organic framework (MOF) material is loaded on a leather collagen fiber membrane; then the leather collagen fiber membrane loaded with the MOF is soaked in a precursor solution for growing the MOF for standing reaction for secondary growth of the MOF, and the screening demulsification performance of the MOF loaded on the leather collagen fiber membrane is regulated and controlled by controlling secondary growth conditions; and then the MOF modified leather collagen fiber membrane is subjected to surface hydrophobic treatment by using a low-surface-energy substance, so that the durable high-flux emulsion separation membrane material is obtained. The durable high-flux emulsion separation membrane material provided by the invention can be used for high-flux separation of a water-in-oil emulsion stabilized by a compound surfactant, has excellent chemical stability such as organic solvent resistance, acid and alkali resistance, and ultraviolet resistance, and still has excellent separation performance on the water-in-oil emulsion after being worn.

Owner:SICHUAN UNIV

EVOH-NCC-SO3Li single ion polymer

InactiveCN108767172AHigh porosityImprove mechanical propertiesCell component detailsPhysical chemistrySingle ion

The invention discloses a preparation method of a novel EVOH-NCC-SO3Li single ion polymer. The method comprises the following steps of 1 activating NCC (nano-crystalline cellulose); 2 grafting EVOH (ethylene-vinyl alcohol copolymer) to NCC; 3 preparing an EVOH-NCC-SO3Li solid; and 4 preparing an electrospun EVOH-NCC-SO3Li nano non-woven fabric. In this way, the novel EVOH-NCC-SO3Li single ion polymer lithium battery diaphragm with the high performance can be prepared.

Owner:HARBIN UNIV OF SCI & TECH

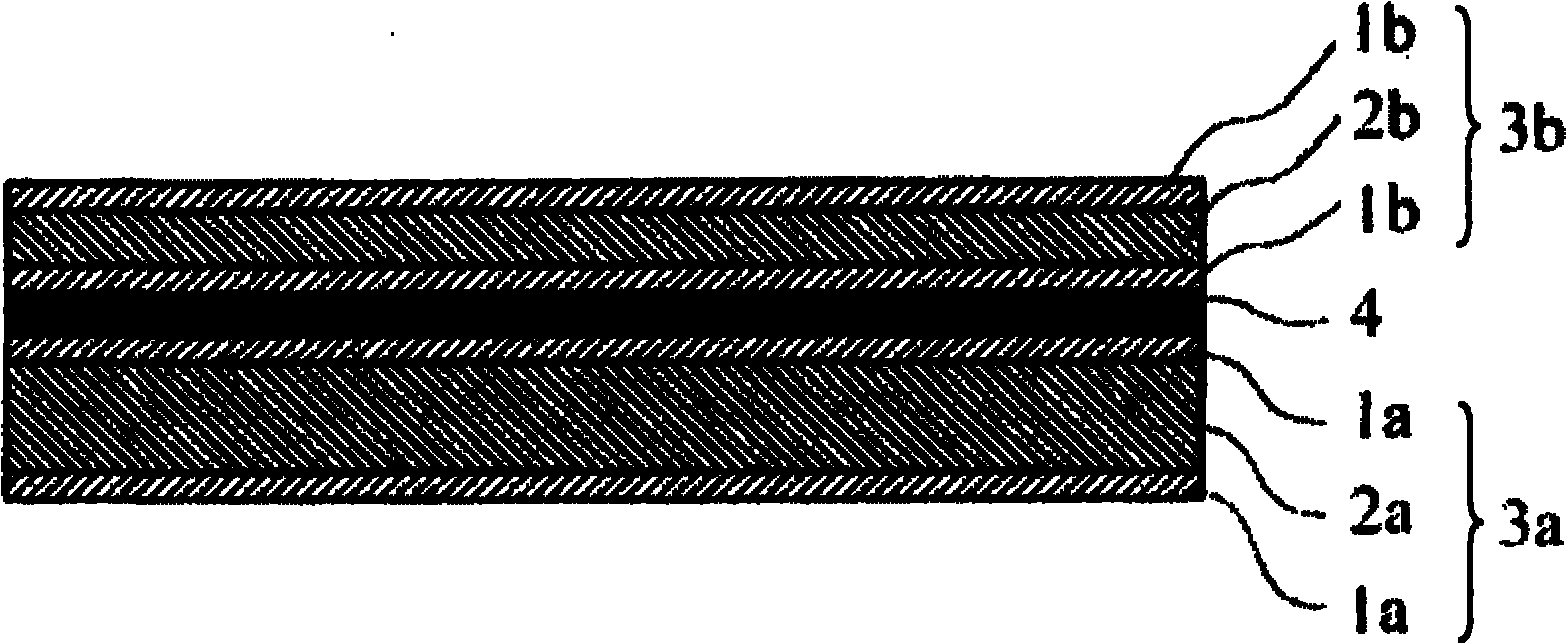

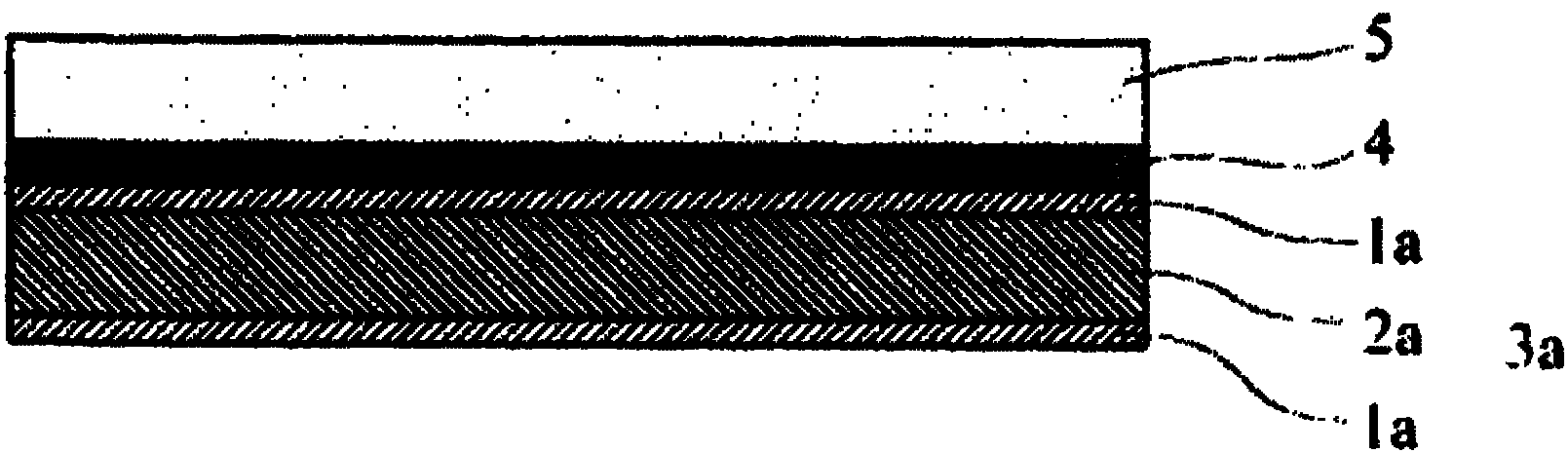

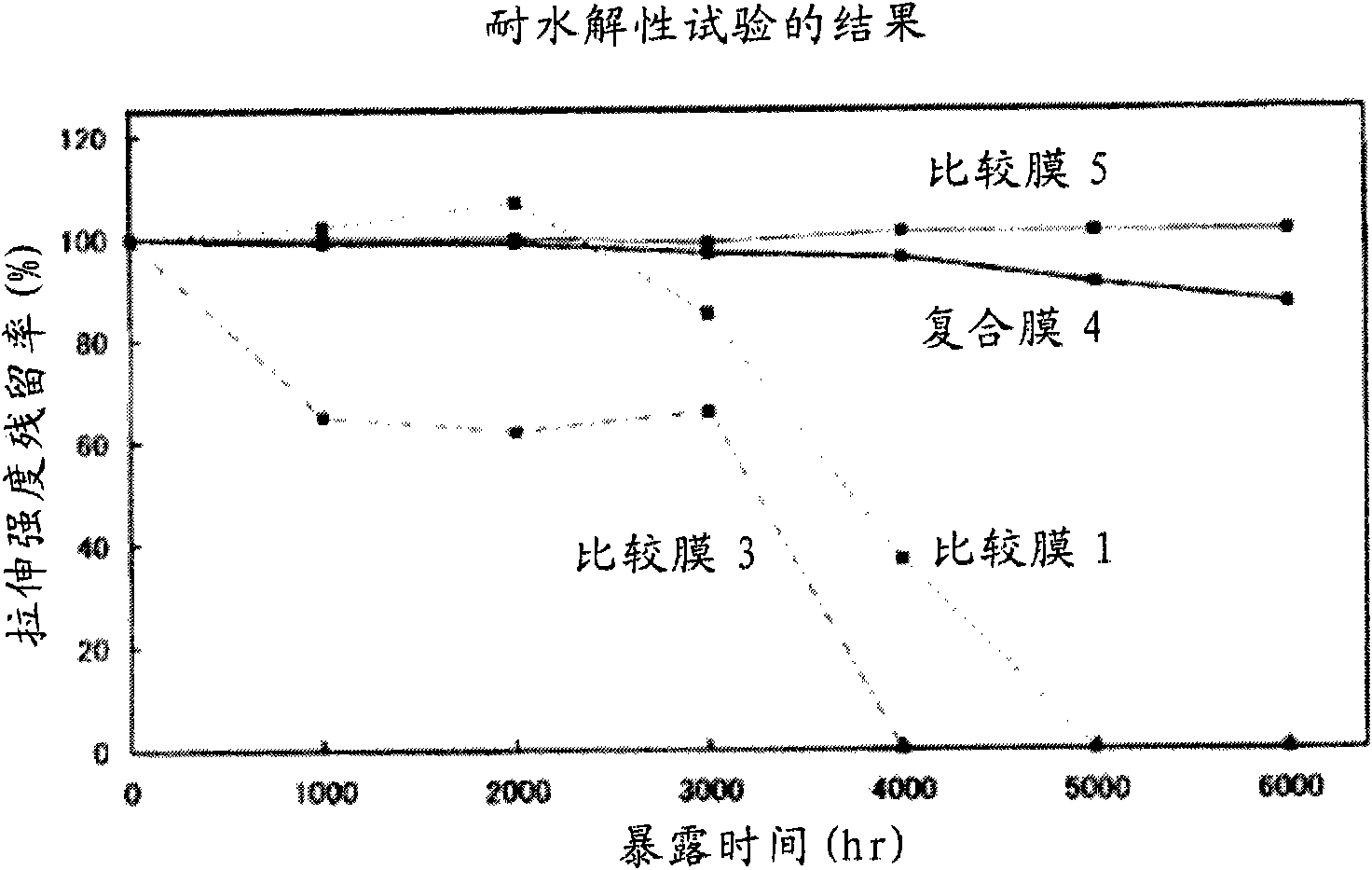

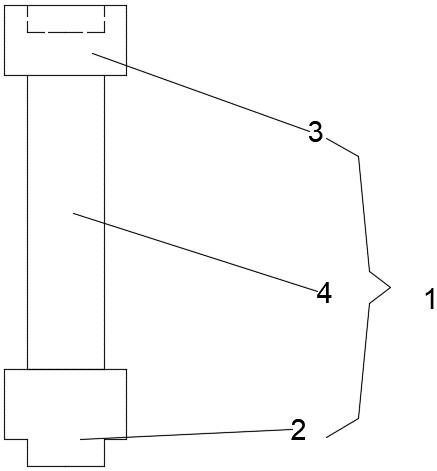

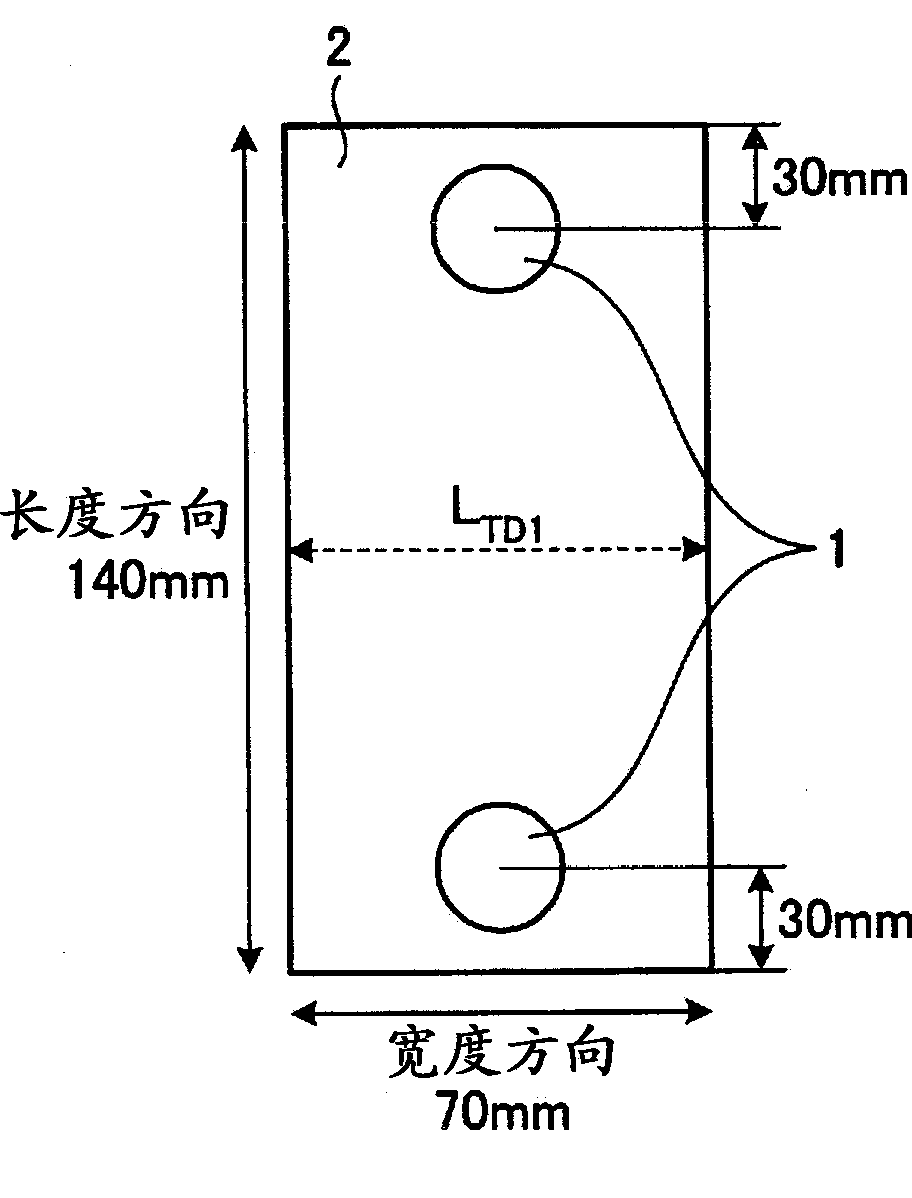

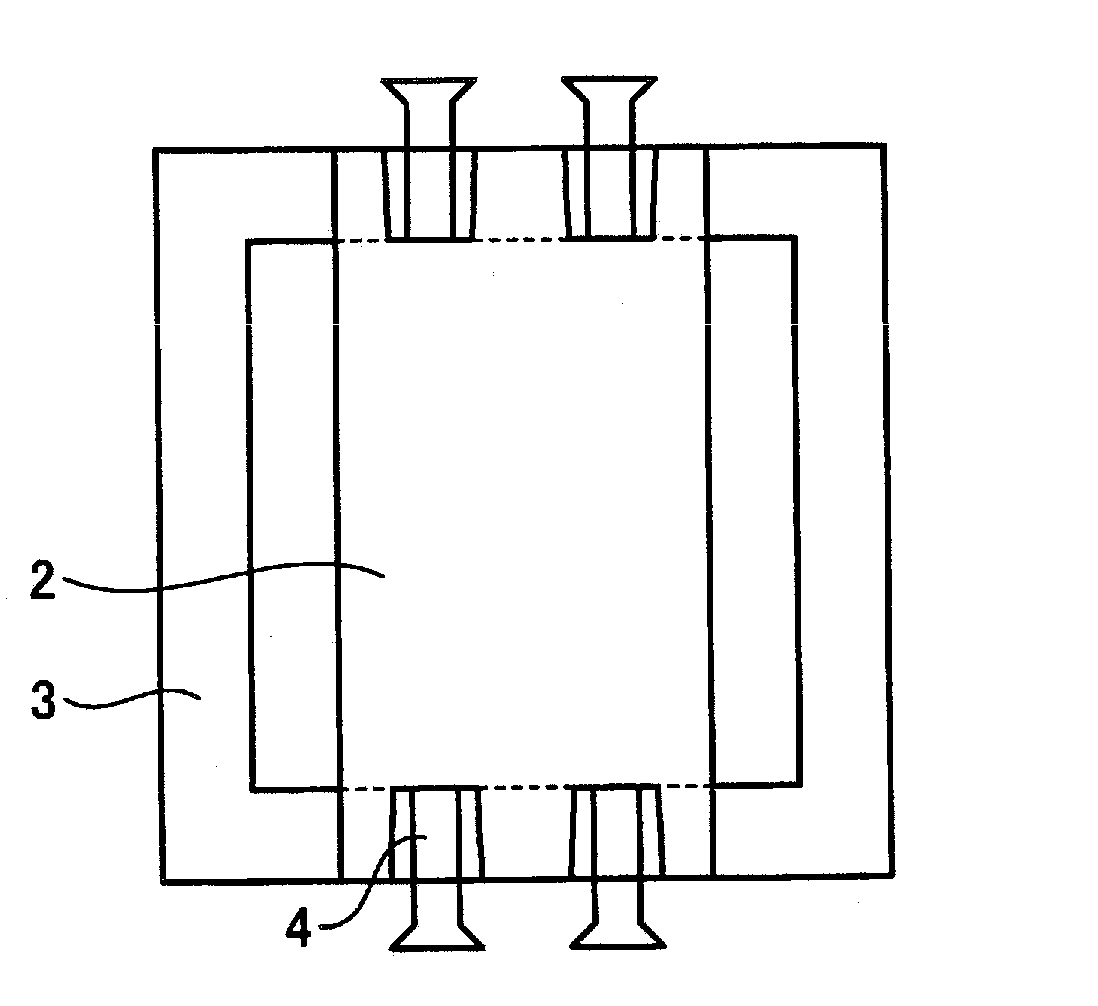

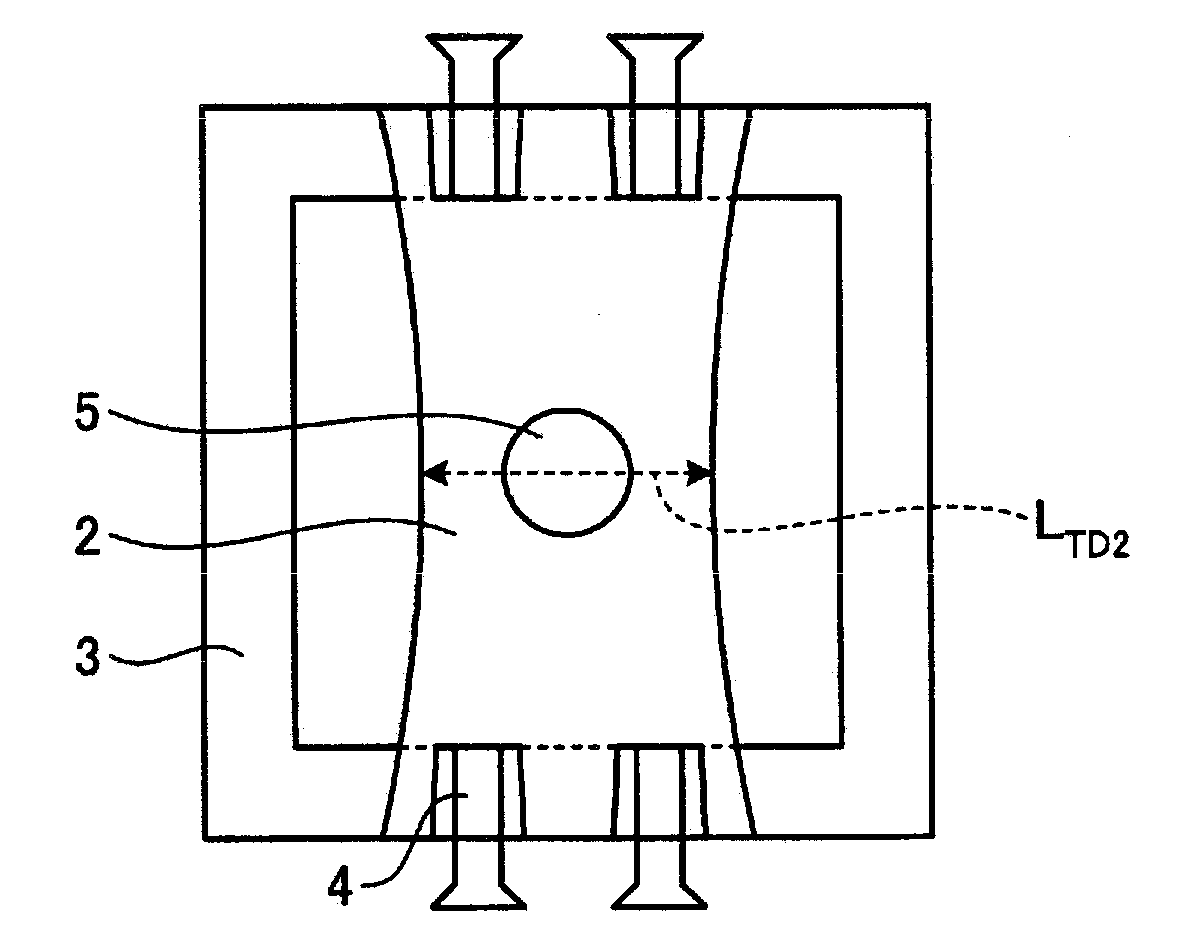

Rear surface protection sheet for solar cell module and solar cell module protected by such protection sheet

InactiveCN101861657AGood weather resistanceImprove water resistanceSynthetic resin layered productsElectrical equipmentPolytetramethylene terephthalateElectrical battery

Provided is a rear surface protection sheet for a solar cell module. The sheet is composed of a pair of polybutylene terephthalate outer layers (1a, 1a), a three-layer composite film (3a) composed of a polycarbonate core layer (2a) arranged between the outer layers, and a moisture proof layer (4) laminated on the composite film. In the solar cell module, a solar cell element is protected by the protection sheet. The composite film having a three-layer structure is formed by coextrusion.

Owner:OKURA IND

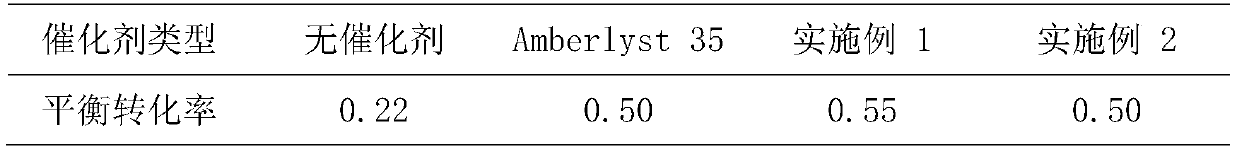

Supported catalytic filler and preparation method and application thereof

ActiveCN111013173AAvoid abnormal operating conditionsImprove bindingChemical/physical processesFractional distillationPolymer scienceAdhesive

The invention discloses a supported catalytic filler and a preparation method and application thereof, belonging to supported catalytic fillers. The supported catalytic filler is provided with a filler carrier, a porous adhesive layer and a catalytic active component, and the catalytic active component fills in the pores of the porous adhesive layer or combined with the surface of the porous adhesive layer. The preparation method comprises the following steps: dissolving a porous structure medium in a pore-forming agent, adding a cross-linking agent to form an adhesive solution, dipping the filler carrier in the adhesive solution, taking out the filler carrier for curing to obtain a filler carrier containing a cured adhesive layer, removing the pore-forming agent in the adhesive layer, andcarrying out vacuum drying to obtain the filler carrier with a porous adhesive layer; and putting the filler carrier with the porous adhesive layer into a coupling agent solution, then putting the filler carrier with the porous adhesive layer into an aqueous PSS-Na solution, enabling PSS-Na to infiltrate into the micropores of the adhesive layer and to react with resin for combination, then putting the filler carrier into a dilute sulfuric acid solution for acidification, carrying out washing with water to remove residual acid, and carrying out vacuum drying to obtain the supported catalyticfiller. The prepared supported catalytic filler can be applied to a reaction separation process.

Owner:XIAMEN UNIV

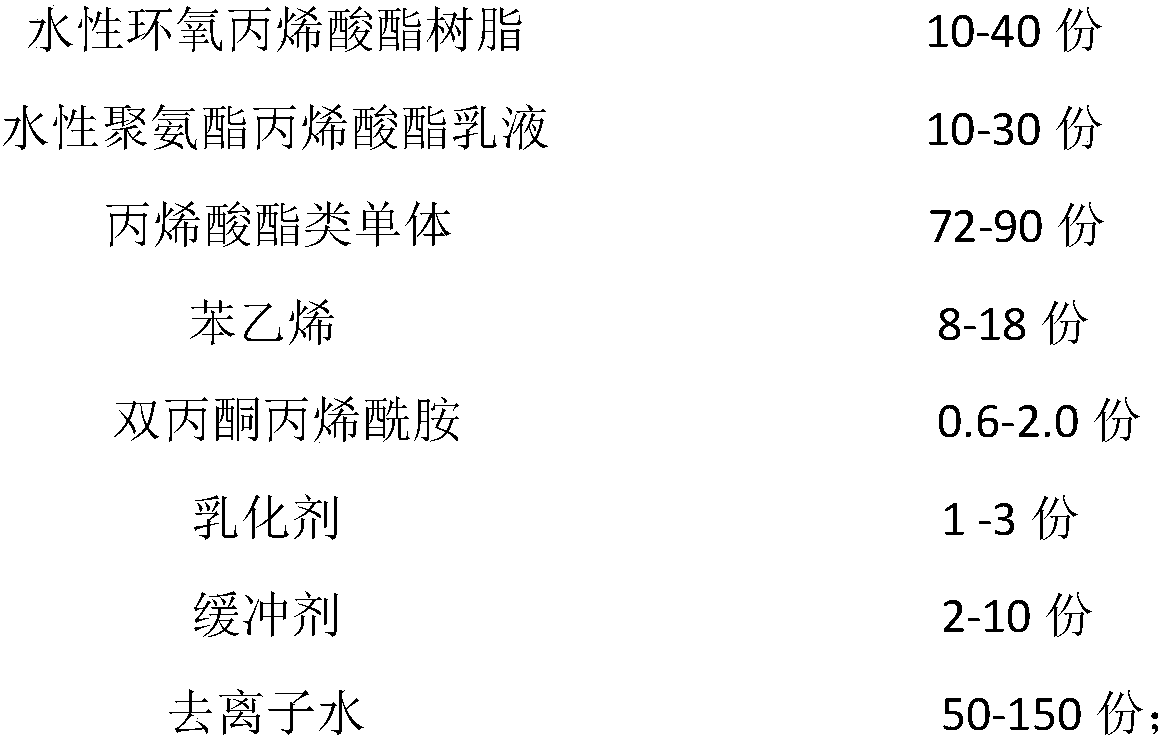

Preparation method of antibacterial water-borne wood composite coating

InactiveCN112625487AExcellent resistance to organic solventsSmall particle sizeWax coatingsAntifouling/underwater paintsPolymer scienceA-DNA

The invention relates to a preparation method of an antibacterial waterborne wood composite coating, and belongs to the technical field of wood coatings. The antibacterial waterborne wood composite coating is prepared by taking the waterborne polyurethane emulsion as a matrix emulsion and adding the nano-silver sol and the modified nano-zinc oxide, wherein a coating film formed by the waterborne polyurethane emulsion has good physical and mechanical properties, cold resistance and organic solvent resistance, a silver element and a zinc element have a micro-power effect, and the antibacterial waterborne wood composite coating has good antibacterial property. According to the method, bacteria can lose division and proliferation capacity and die by virtue of reservoir enterprise force, nano-silver can play a role of a catalytic active center, under the action of light, silver and water or air act, and generated active oxygen ion free radicals and hydroxyl free radicals have extremely high chemical activity and can react with the bacteria to destroy a DNA double-helix structure, so that the DNA double-helix structure is damaged, metabolism is disordered, and the effect of inhibiting or killing bacteria is achieved.

Owner:成都萃匀离环保科技有限公司

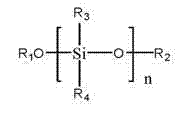

A kind of aqueous polysiloxane resin and preparation method thereof

The invention discloses aqueous polysiloxane resin and a preparation method thereof. The aqueous polysiloxane resin is prepared from a pre-emulsion A, an emulsion B and a solution C as raw materials. The preparation method comprises the following steps: 1) preparing the pre-emulsion A; 2) preparing the emulsion B; 3) preparing the solution C; 4) pouring a part of the pre-emulsion A into a reaction container, dripping a part of the emulsion B, and at the same time heating the reaction container to 55-65 DEG C to react for 0.5-1 hour so as to prepare a light blue fluorescent seed emulsion; 5) simultaneously dripping the rest pre-emulsion A and the emulsion B into the fluorescent seed emulsion, heating to 55-65 DEG C to react for 2-3 hours, after the reaction is completed, cooling to the room temperature, adjusting the pH value to be 7-8, dripping the solution C, stirring for 10-30 minutes, and filtering, thereby obtaining a filtrate, that is, the aqueous polysiloxane resin. The aqueous polysiloxane resin is good in storage stability and flexibility, good in adhesion property, high in hardness and good in impact resistance, water resistance, salt water resistance, artificial aging resistance and chemical corrosion resistance. The aqueous polysiloxane resin is simple in preparation method, gentle in reaction condition and stable in process procedure.

Owner:WUHAN HOSTS COATING MATERIAL CO LTD

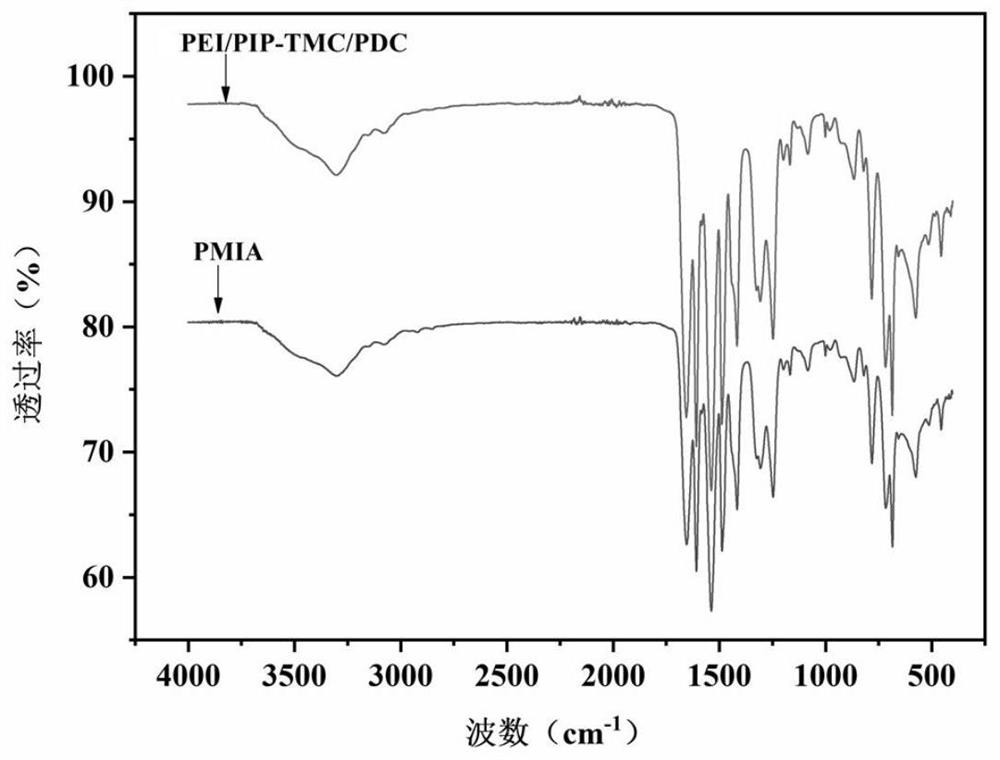

Method for preparing polyamide composite nanofiltration membrane based on green and environment-friendly ionic liquid

InactiveCN112934005AExcellent resistance to organic solventsImprove pressure resistanceReverse osmosisCongo redVitamin B12

The invention discloses a method for preparing a polyamide composite nanofiltration membrane based on a green and environment-friendly ionic liquid, which comprises the following steps: dissolving a polymer (poly (m-phenylene isophthalamide)) by using the green and environment-friendly ionic liquid (1-ethyl-3-methylimidazole acetate) to prepare a porous base membrane; and using another green and environment-friendly ionic liquid (1-butyl-3-methylimidazole bis (trifluoromethanesulfonyl) imide salt) as an oil phase for interfacial polymerization on the surface of the base membrane to prepare a polyamide selection layer under the condition that both the ionic liquid phase and the water phase adopt mixed monomers, so that the polyamide composite nanofiltration membrane with high separation performance is obtained. The process is low in cost, safe, green and environment-friendly. The polyamide composite nanofiltration membrane prepared by the process has an excellent separation effect on organic solutions containing Congo red, acid red 94, solvent red, brilliant blue R, amaranth red, rhodamine B, vitamin B12 and other dyes (or drugs).

Owner:HUAQIAO UNIVERSITY

Thermosetting solder resist ink with low dielectric constant and low dielectric loss and its preparation method

The invention provides a thermosetting solder resist ink with low dielectric constant and low dielectric loss and its preparation method, in which long carbon chain aliphatic diamine monomers and aromatic diamine monomers with acid groups The polyamic acid is obtained after reacting the monomer with the aromatic dianhydride monomer and the monoanhydride monomer with an acid group, and then the polyamic acid is cyclized to obtain a modified polyimide, and finally the modified polyimide is After cross-linking with the hardener, a thermosetting solder resist ink with a dielectric constant of less than 3 and a dielectric loss of less than 0.01 can be prepared, which is suitable for high-frequency electronic equipment. In addition, after testing, the thermosetting solder resist ink prepared by the method of the present invention also has good electrical properties, flex resistance, solder resistance, warpage resistance, flame resistance, acid resistance, and alkali resistance. , resistance to organic solvents and low moisture absorption.

Owner:TAIFLEX SCI

High-temperature-resistant coated sucker rod

ActiveCN112227965AImprove compactnessEasy to takeDrilling rodsMolybdeum compoundsEngineeringSucker rod

The invention relates to the field of sucker rods, in particular to a high-temperature-resistant coated sucker rod. The sucker rod is composed of at least one sucker rod unit section. Each sucker rodunit section comprises a convex port, a concave port and a cylindrical rod, wherein the convex port and the concave port are fixedly arranged at the two ends of the cylindrical rod correspondingly. Ahigh-temperature-resistant layer is arranged on the outer surface of each sucker rod unit section. The high-temperature-resistant layers are prepared from modified polyimide. The problem that the surface of the sucker rod is hot in long-time work is solved. The high-temperature-resistant coated sucker rod has the following advantages that (1) the sucker rod is composed of the at least one sucker rod unit section, and pipe connecting and dismounting are convenient; and (2) the high-temperature-resistant layers are arranged, high temperature can be isolated outside the sucker rod, and the situation that the sucker rod deforms or influences the oil pumping quality due to accumulation of a large amount of heat during use is avoided.

Owner:DONGYING JINYILAI PETROLEUM MACHINERY

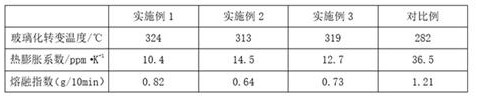

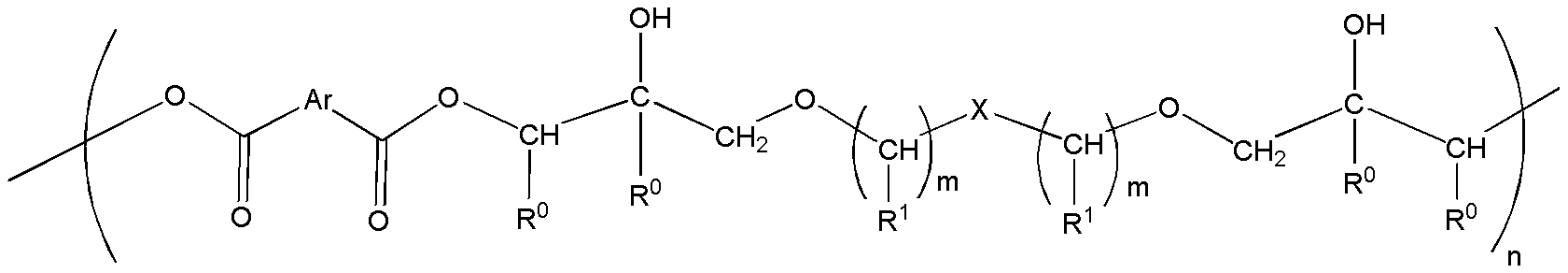

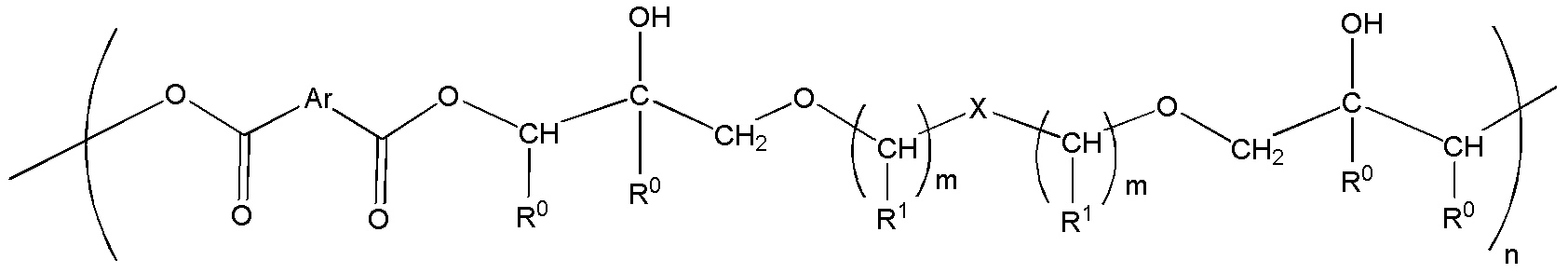

Coating compositions

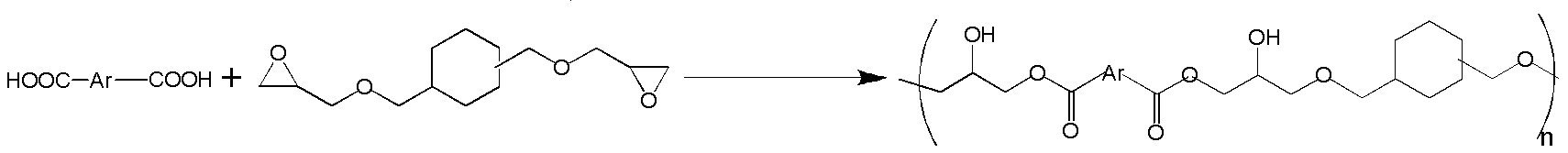

InactiveCN103154071AImprove flexibilityGood resistance to distillationEpoxy resin coatingsPolyester coatingsEpoxyChemical structure

A curable coating composition comprising an advanced poly epoxy ester resin polymeric composition having the following chemical structure: where n is a number from 1 to about 3000; each m independently has a value of 0 or 1; each R0 is independently -H or -CH3; each R1 is independently -H or a C1 to C6 alkylene radical (saturated divalent aliphatic hydrocarbon radical); Ar is a divalent aromatic fused -ring moiety, which is most preferably a divalent naphthalene group, substituted divalent naphthalene group, where the substitute groups include an alkyl, cycloalkyl, an aryl or an aralkyl group or other substituent; and X is cycloalkylene group, including substituted cycloalkylene group, where the substitute group include an alkyl, cycloalkyl, an aryl or an aralkyl group or other substitute group, for example, a halogen, a nitro, a blocked isocyanate, or an alkyloxy group; the combination of cycloalkylene and alkylene groups and the combination of alkylene and cycloalkylene group with a bridging moiety in between.

Owner:BLUE CUBE IP

Porous polypropylene film, layered porous film, and electricity-storage device

InactiveCN103890062AExcellent resistance to organic solventsImprove breathabilityHybrid capacitor separatorsElectrolytic capacitorsElectricityOrganic solvent

Provided are: a porous polypropylene film that exhibits excellent gas permeability and resistance to organic solvents, wherein when said film is coated with a functional layer such as a heat-resistance layer, the physical properties of said film do not change much; a layered porous film; and an electricity-storage device. Said porous polypropylene film, which contains a polypropylene resin that can form a beta crystal structure, is characterized by a gas permeation resistance of 1,000 sec / 100 ml or less and further characterized in that an acetone-immersion treatment changes the thickness of the porous polypropylene film by no more than 20%.

Owner:TORAY IND INC

Expansion type cardiovascular piezometry catheter

InactiveCN103284711AAvoid blockingNo pollution in the processCatheterAngiographyAcid corrosionCatheter

An expansion type cardiovascular piezometry catheter comprises a catheter body and an expansion sac, one end of the catheter body is provided with a conical port, and the other end of catheter body is provided with an inflating connector, the expansion sac is arranged on the body of one end of the catheter body close to the conical port, and the inflating connector is communicated with the expansion sac. No bubbles are generated in the catheter, resonance and attenuation are not caused during monitoring, and occlusion caused by blood clotting during monitoring can be well avoided. Monitoring results are accurate, and accurate pressure values can be obtained without time delay and extra steps. Besides, the expansion type cardiovascular piezometry catheter is resistant to alkali and acid corrosion, has the advantages of excellent organic solvent resistance, is non-toxic and pollution-free and can be widely used to substitute for existing materials on and on.

Owner:陈绍良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing negative photosensitive polyimide based on 2,2-di[4-(2,4-diaminophenyloxy)phenyl]hexafluoropropane Method for preparing negative photosensitive polyimide based on 2,2-di[4-(2,4-diaminophenyloxy)phenyl]hexafluoropropane](https://images-eureka.patsnap.com/patent_img/fa404351-10dd-49df-9e89-119ad27fa20f/a20081003650500221.PNG)

![Method for preparing negative photosensitive polyimide based on 2,2-di[4-(2,4-diaminophenyloxy)phenyl]hexafluoropropane Method for preparing negative photosensitive polyimide based on 2,2-di[4-(2,4-diaminophenyloxy)phenyl]hexafluoropropane](https://images-eureka.patsnap.com/patent_img/fa404351-10dd-49df-9e89-119ad27fa20f/a20081003650500041.PNG)

![Method for preparing negative photosensitive polyimide based on 2,2-di[4-(2,4-diaminophenyloxy)phenyl]hexafluoropropane Method for preparing negative photosensitive polyimide based on 2,2-di[4-(2,4-diaminophenyloxy)phenyl]hexafluoropropane](https://images-eureka.patsnap.com/patent_img/fa404351-10dd-49df-9e89-119ad27fa20f/a20081003650500051.PNG)