Conductive coating composition and laminate

A conductive polymer and conductive technology, applied in the direction of conductive coatings, coatings, layered products, etc., can solve the problems of insufficient chemical resistance, insufficient film hardness, and easy scratches on the surface, achieving high conductivity, Good adhesion and small difference in refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

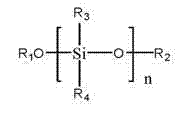

[0090] Use the following reagents to prepare a homogeneous aqueous dispersion: Baytron PH500 (H.C. Starck Co. Production) 100 parts (including 1.1 parts of the conductive polymer and 98.9 parts of ion-exchanged water. When the conductive polymer is 100 parts, the ion-exchanged water is 8991 parts), as a binder alkoxy 24 parts of silane oligomer MS-51 (produced by Mitsubishi Chemical Corporation) (2165 parts when the conductive polymer is 100 parts), N-methylformamide (NACALAI TESQUE company (NACALAI TESQUE company) ), reagent) 19 parts (1730 parts when the conductive polymer is 100 parts), ethanol (manufactured by NACALAI TESQUE, reagent) 514 parts (46727 parts when the conductive polymer is 100 parts), ion-exchanged water 48 parts (4364 parts for 100 parts of conductive polymer).

[0091] Next, the above-mentioned dispersion liquid was coated on an alkali-free glass plate, and heated in an oven at 130° C. for 30 minutes to form a film to obtain a test piece with an antistati...

Embodiment 2)

[0094] Instead of Baytron PH500 (manufactured by H.C. STARCK) in Example 1, Baytron PH1000 (manufactured by H.C. STARCK, D50 of 52 nm, containing 1.1 parts of the conductive polymer) was used to obtain a test piece similarly to Example 1.

Embodiment 3)

[0096] Instead of Baytron PH500 (manufactured by H.C. STARCK Company) in Example 1, Baytron P (manufactured by H.C. STARCK Company, D50 of 140 nm, containing 1.1 parts of the conductive polymer) was used to obtain a test piece similarly to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com