Patents

Literature

34results about How to "Simple and cheap process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for generating linear alpha olefin comonomers

ActiveUS20070185358A1Simple and cheap processSimpler and less-expensive processHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsSolventPolymerization reactor

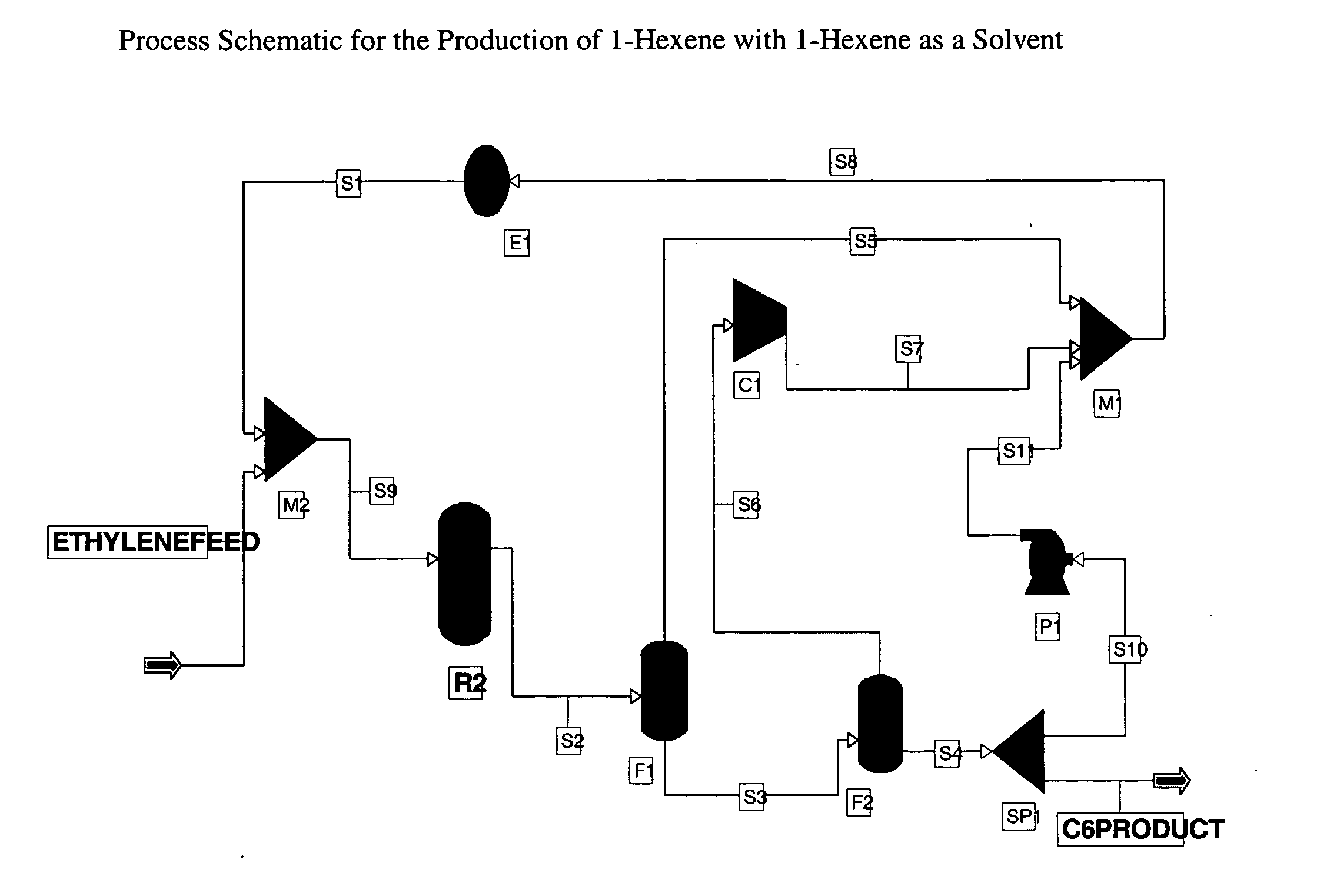

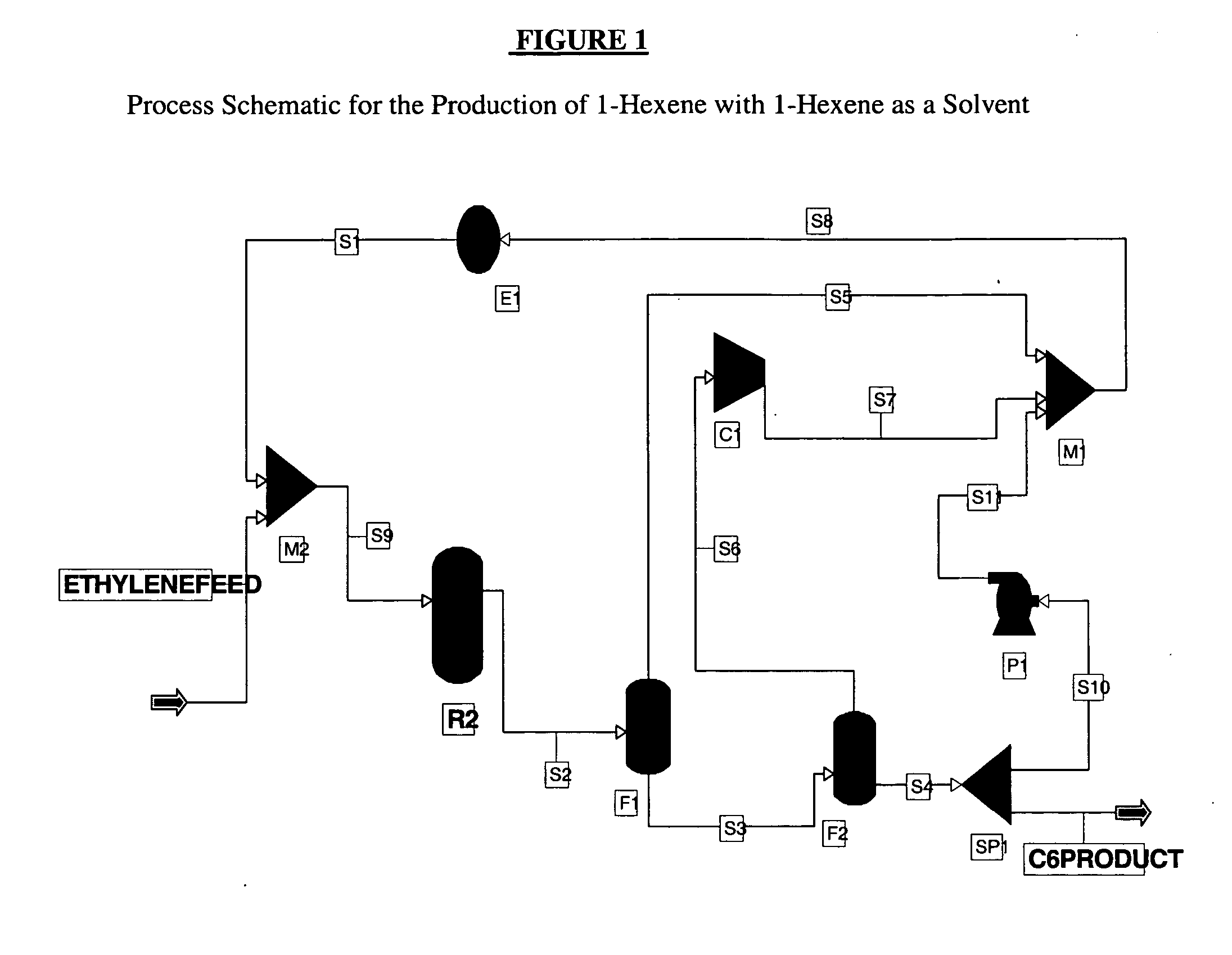

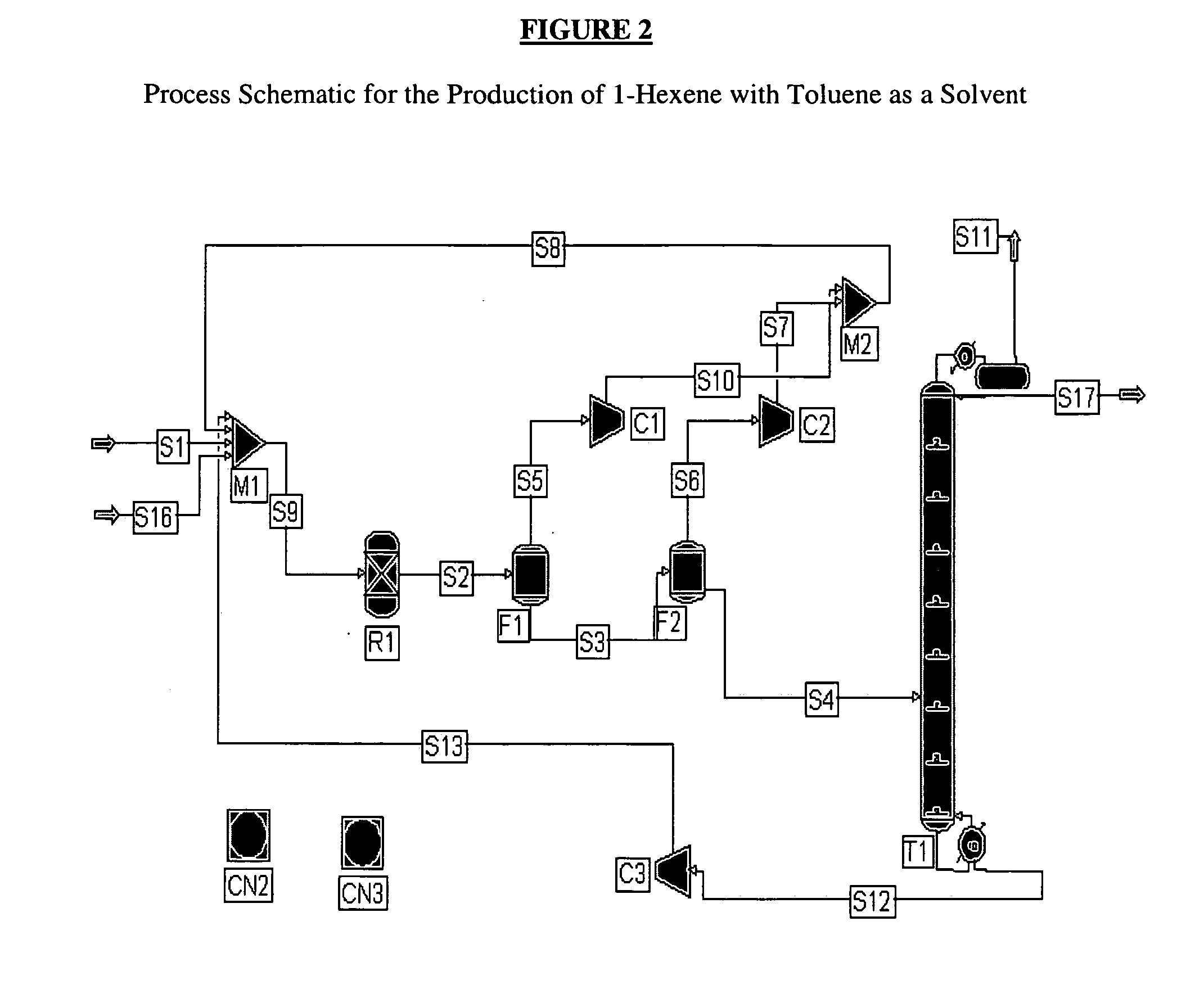

The present invention relates to a method for preparing linear alpha olefin comonomers, such as 1-butene, 1-hexene or 1-octene, from ethylene monomer. The comonomer generated is stored on site for use in a subsequent process, such as a polyethylene polymerization reactor. The method includes the steps of feeding an ethylene monomer, and a catalyst in a solvent to one or more comonomer synthesis reactors; reacting the ethylene monomer and the catalyst in solvent under reaction conditions to produce an effluent stream comprising unreacted ethylene monomer, a catalyst in a solvent, and comonomer; passing the effluent stream to one or more downstream gas / liquid phase separators to form a gas stream of unreacted ethylene monomer, and a liquid stream of comonomer, and catalyst in a solvent; recycling to the one or more comonomer synthesis reactors the unreacted ethylene monomer and a portion of the liquid stream; and storing a remaining portion of said liquid stream for subsequent processing of the comonomer. Some of the benefits of the method include process simplification and reduced capital and operating costs from, inter alia, not having to recover ethylene in high purity nor separate catalyst from comonomer.

Owner:EXXONMOBIL CHEM PAT INC

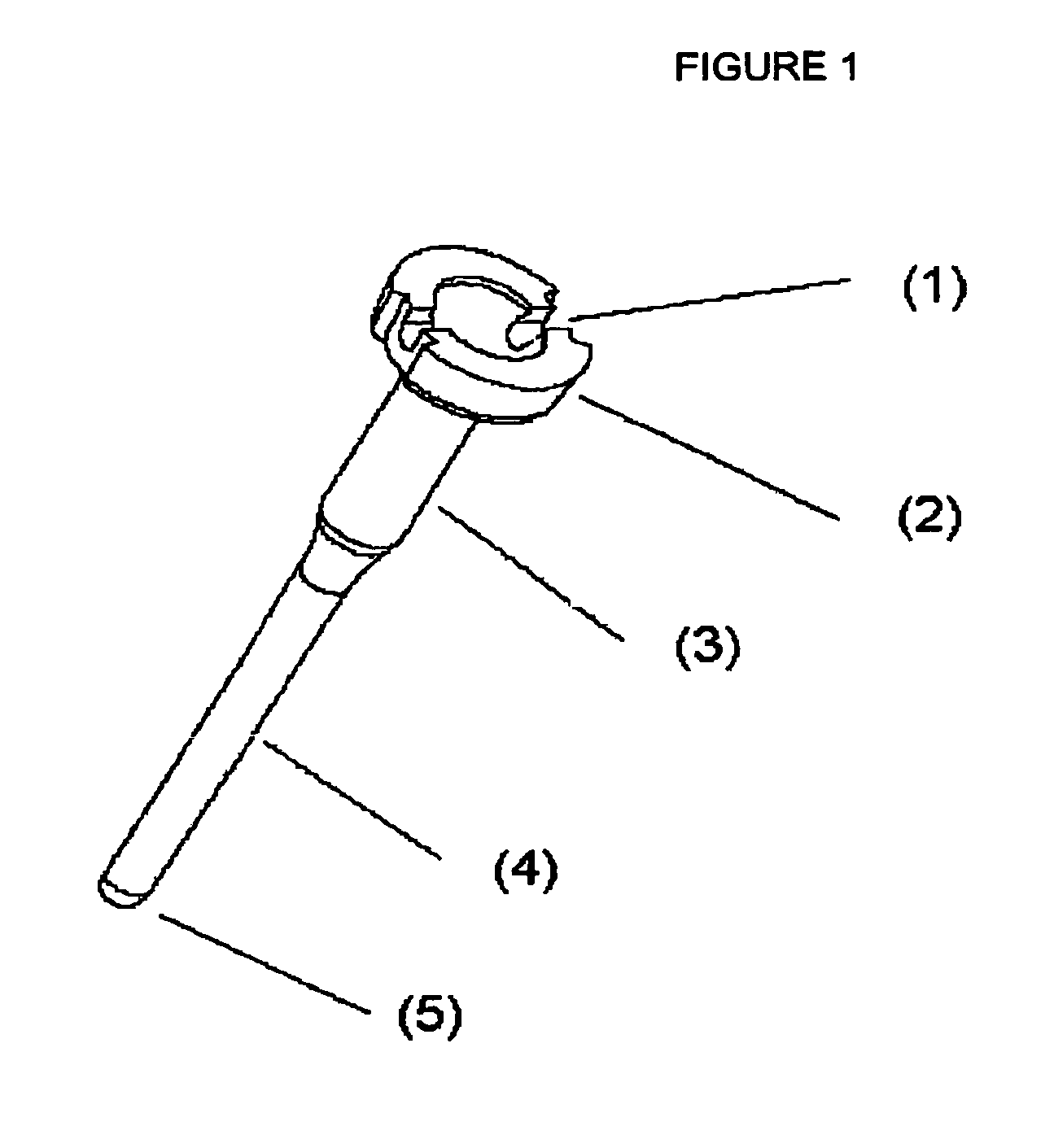

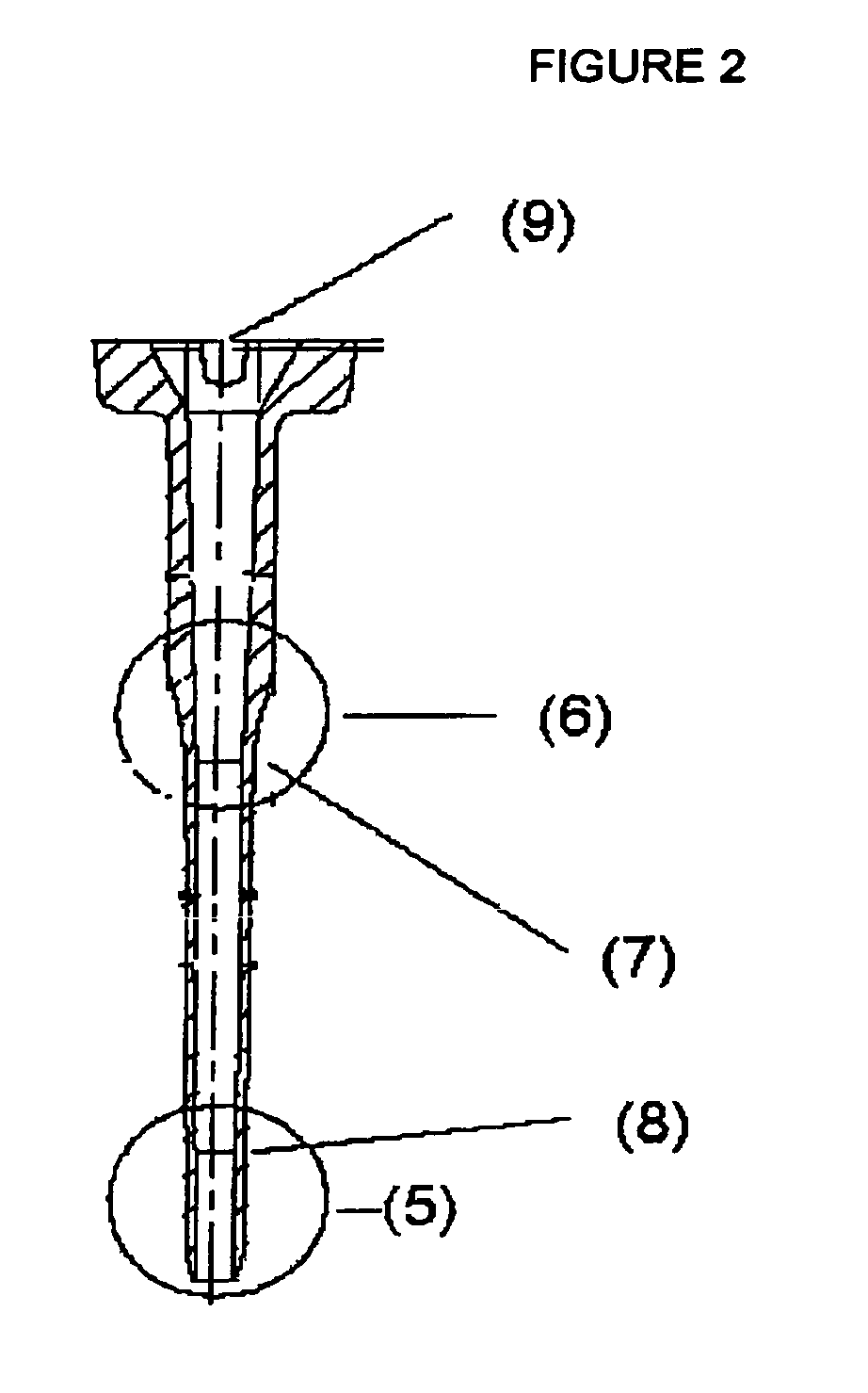

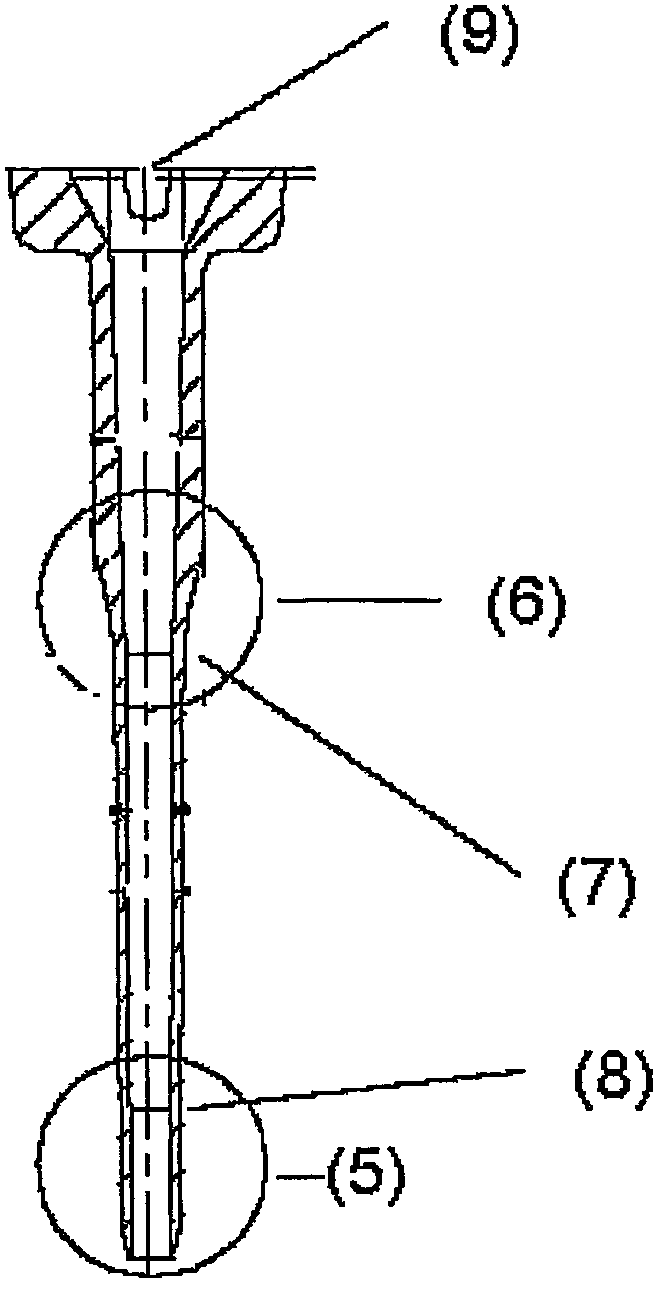

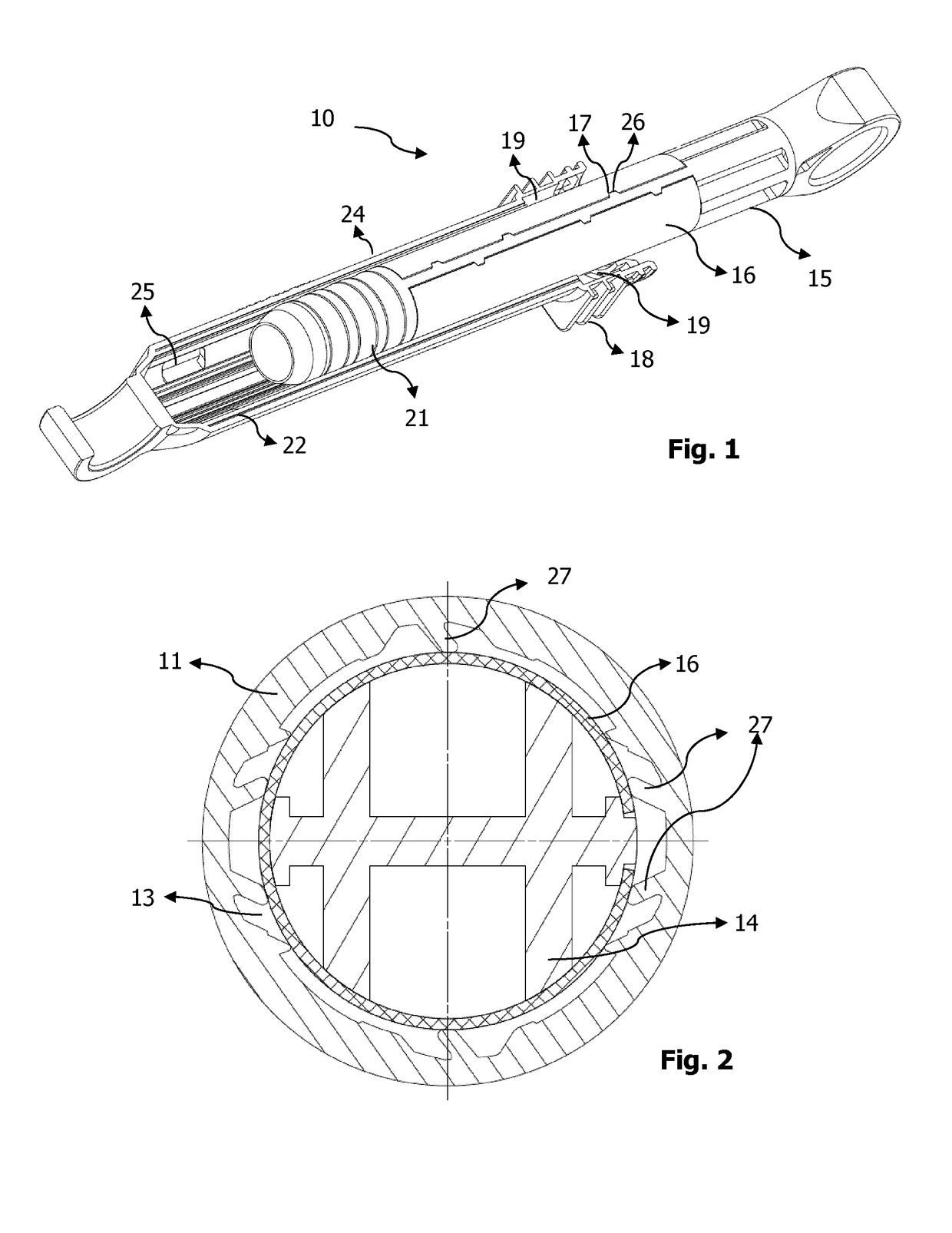

Injection moulding of a catheter

ActiveUS7431876B2Simple and cheap processDischarging arrangementMouldsInjection mouldingNeedle catheter

A method for one-piece injection molding of a soft needle catheter having a hub and a tube-shaped flexible part. According to the method, a molten polymer is fed into a mold which includes a core that is used to form the interior of the catheter, the core defining a hub cavity and a tube-shaped cavity. The hub cavity includes a cone-shaped part and a cylindrical part, with the cone-shaped part extending into the tube-shaped cavity. When the polymer is sufficiently cured, the core is removed from the catheter and the catheter is removed from the mold.

Owner:UNOMEDICAL AS

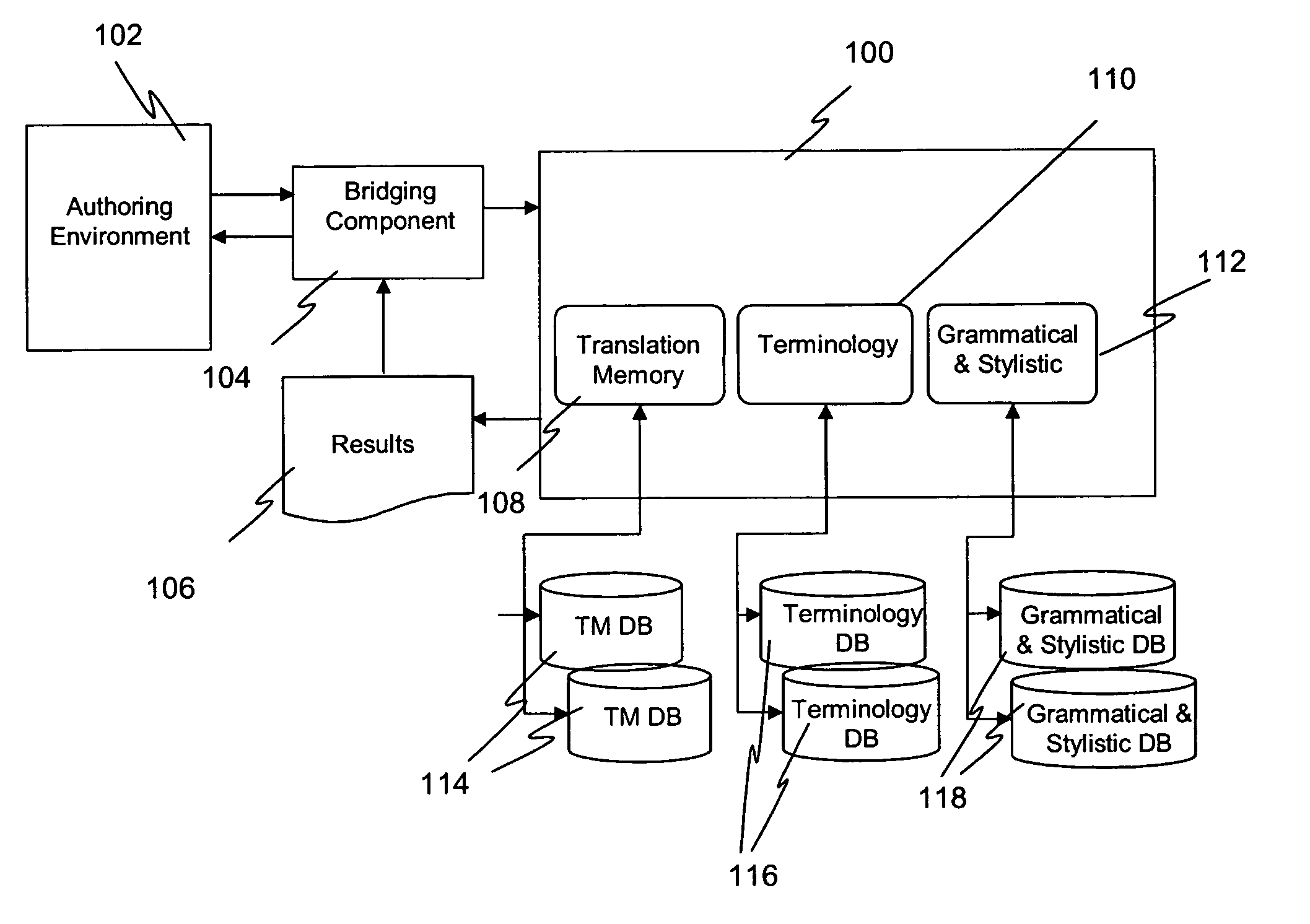

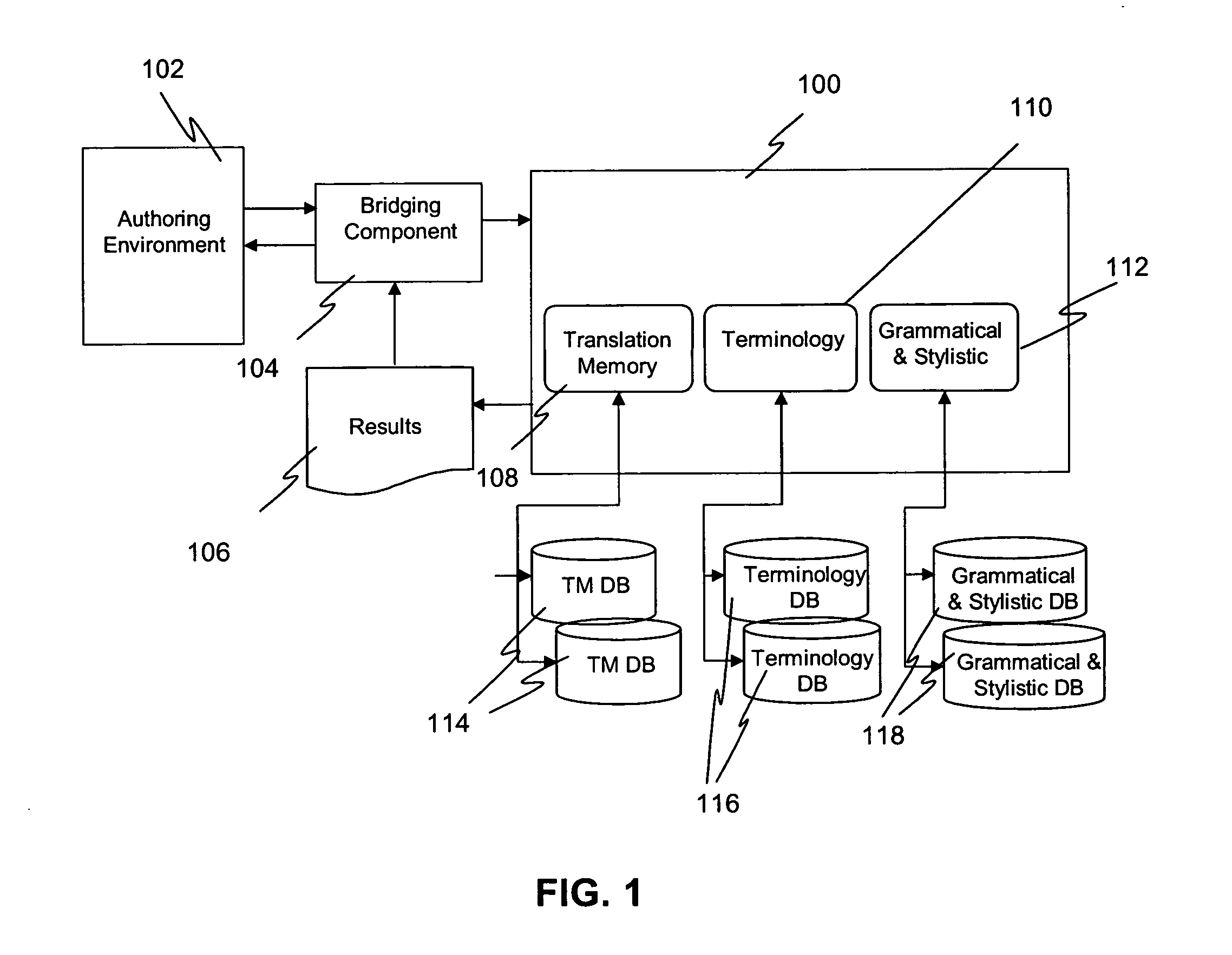

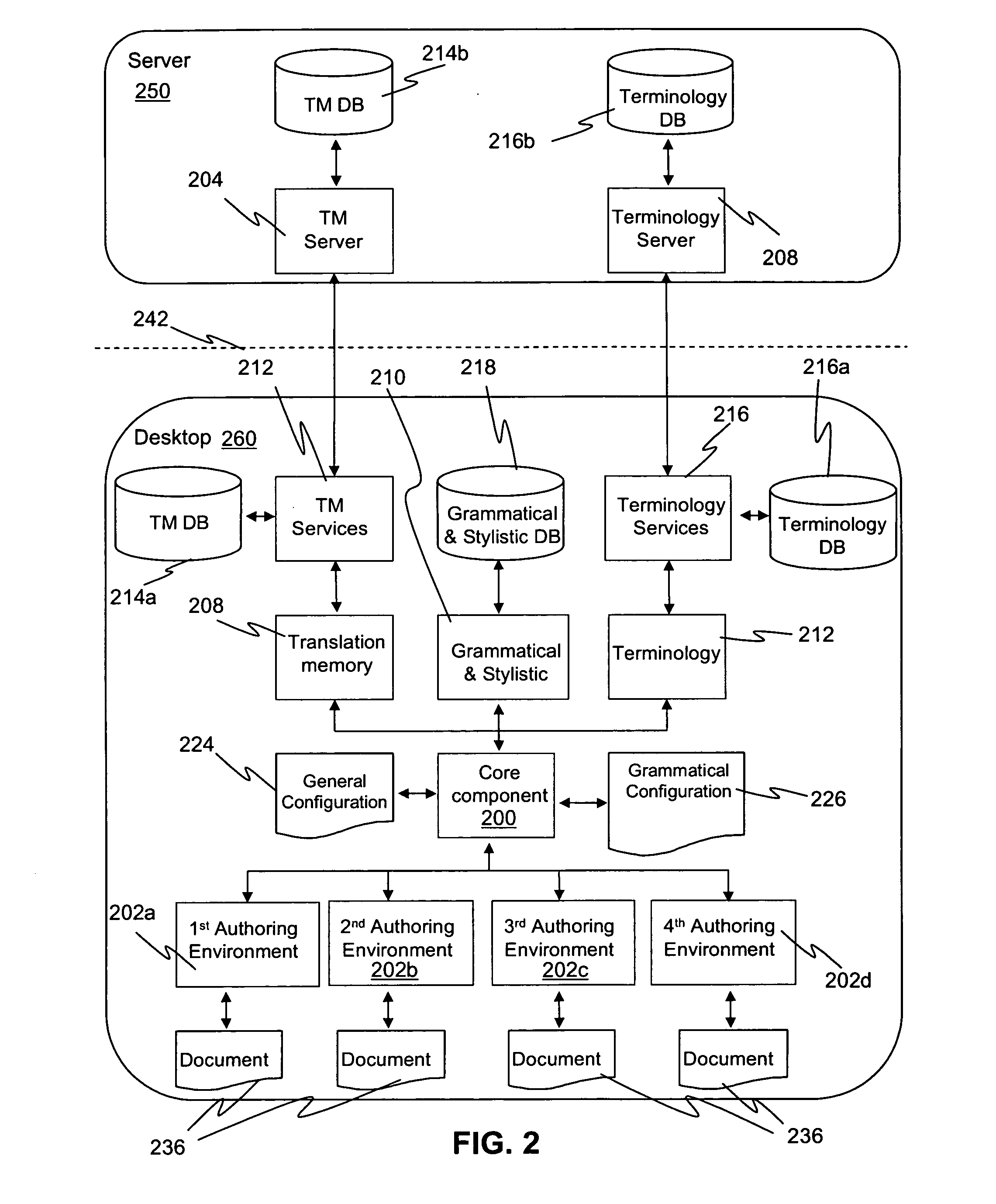

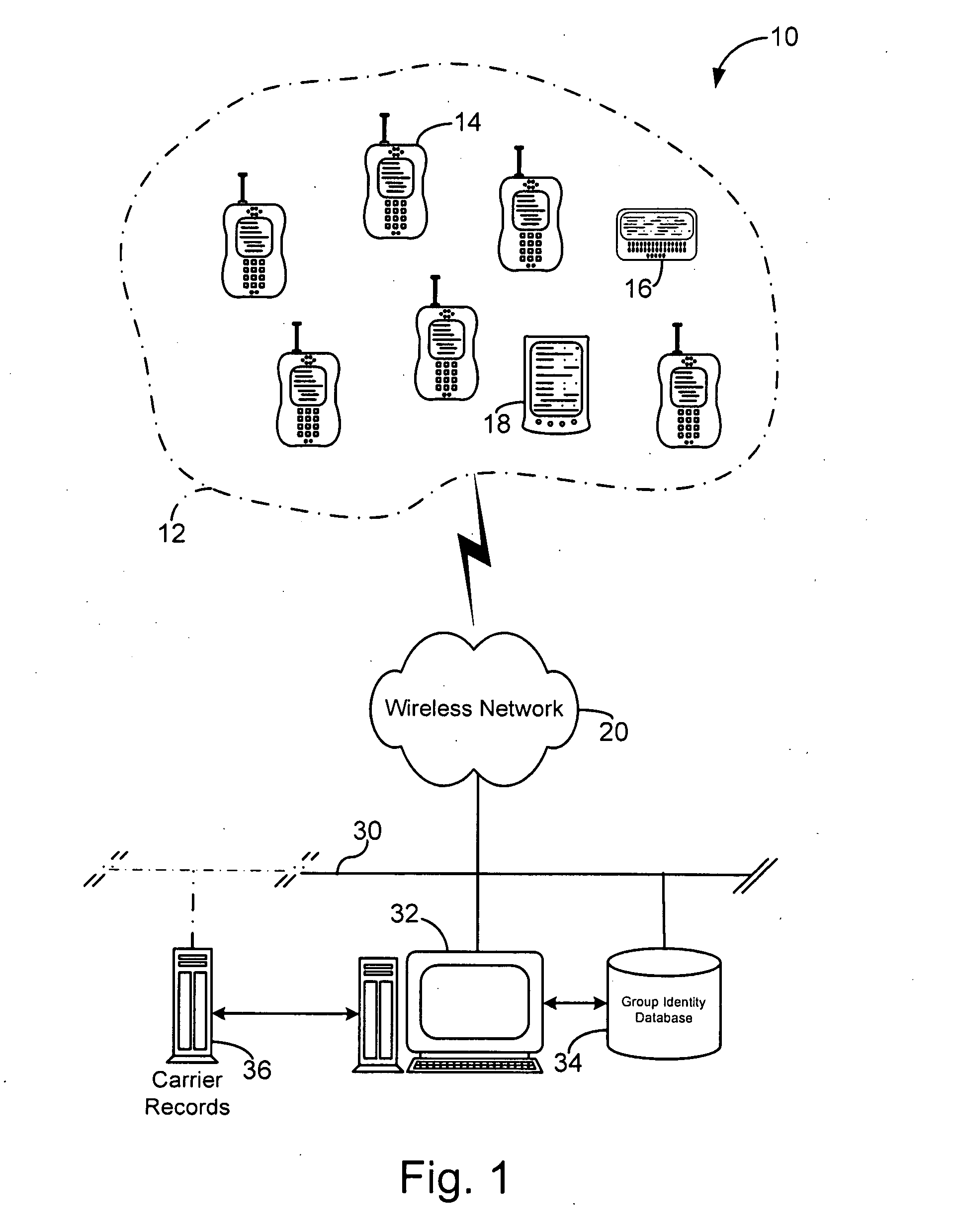

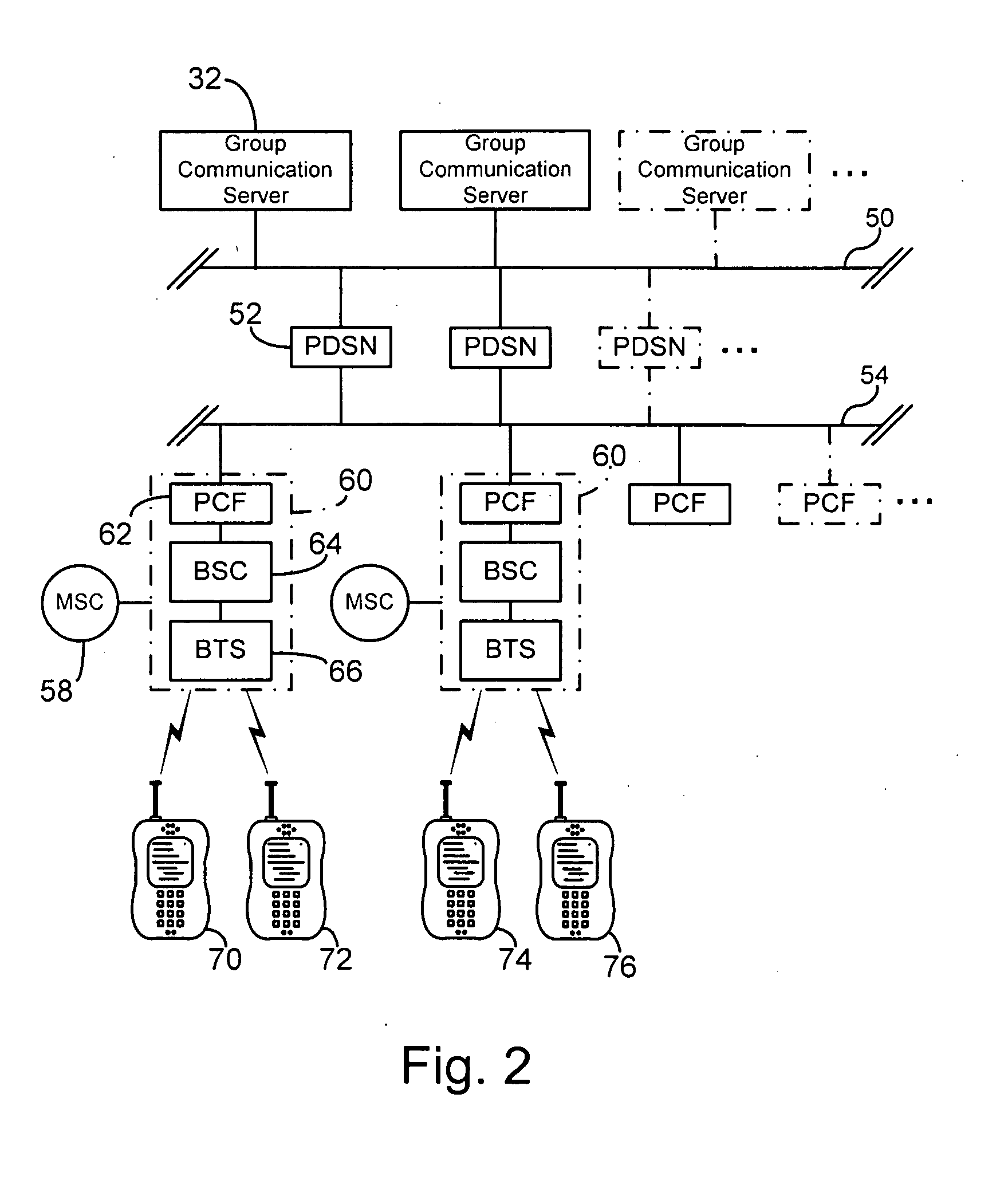

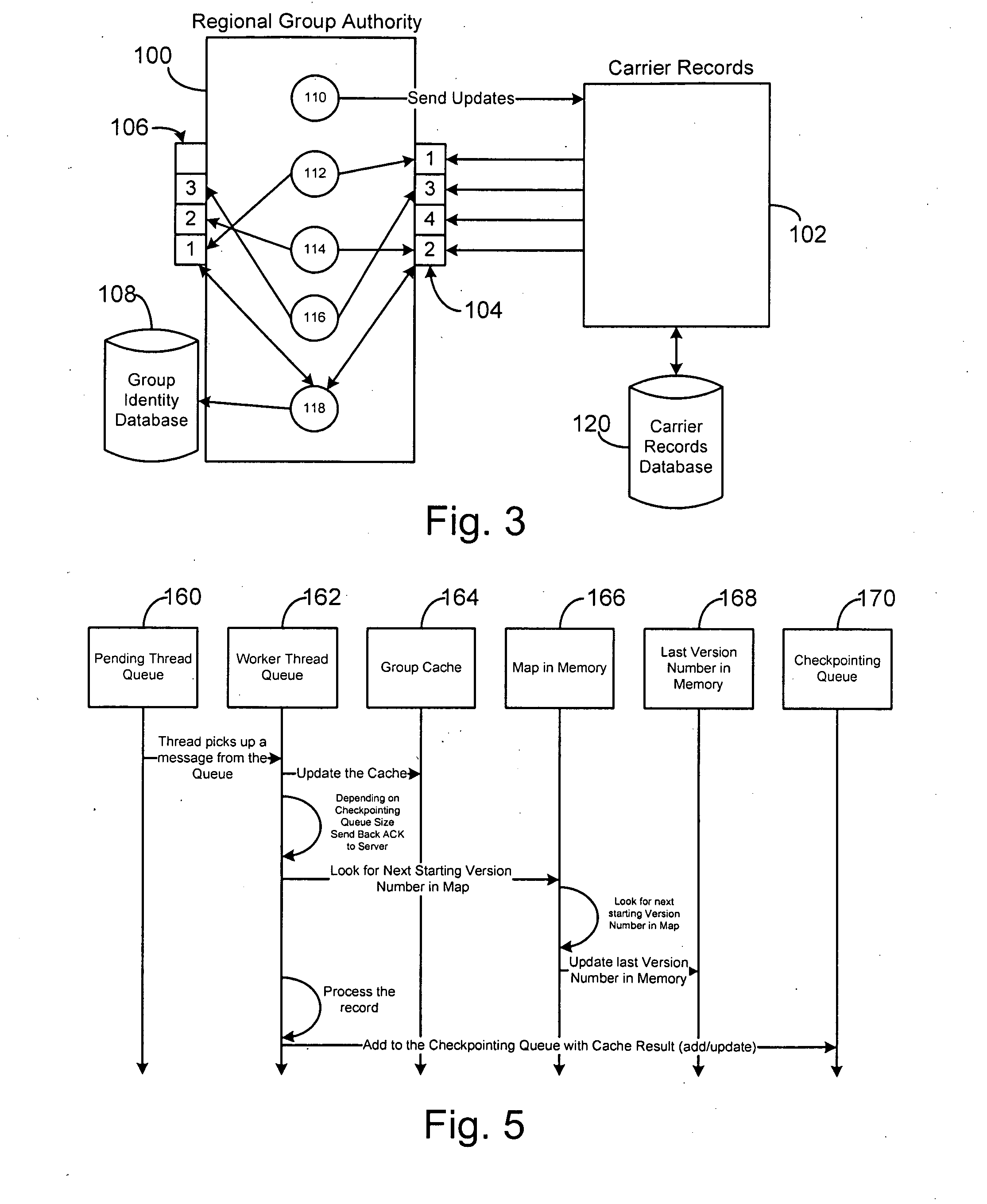

Computer-implemented method, computer software and apparatus for use in a translation system

ActiveUS20080077395A1Simple and cheap processImprove consistencyNatural language translationSpecial data processing applicationsSource materialComputer software

A computer-implemented method for use in natural language translation comprises performing in software processes, the steps of: comparing source material with stored material in a first natural language, said stored material having previously been translated from said first natural language to at least a second natural language, identifying at least a part of said source material which has a relationship with at least a part of said stored material, outputting said identified part of source material and said identified part of stored material in a form suitable for review by a user, and replacing said identified part of source material with said identified part of stored material to assist full translation of said source material from said first natural language to at least said second natural language.

Owner:SDL LTD

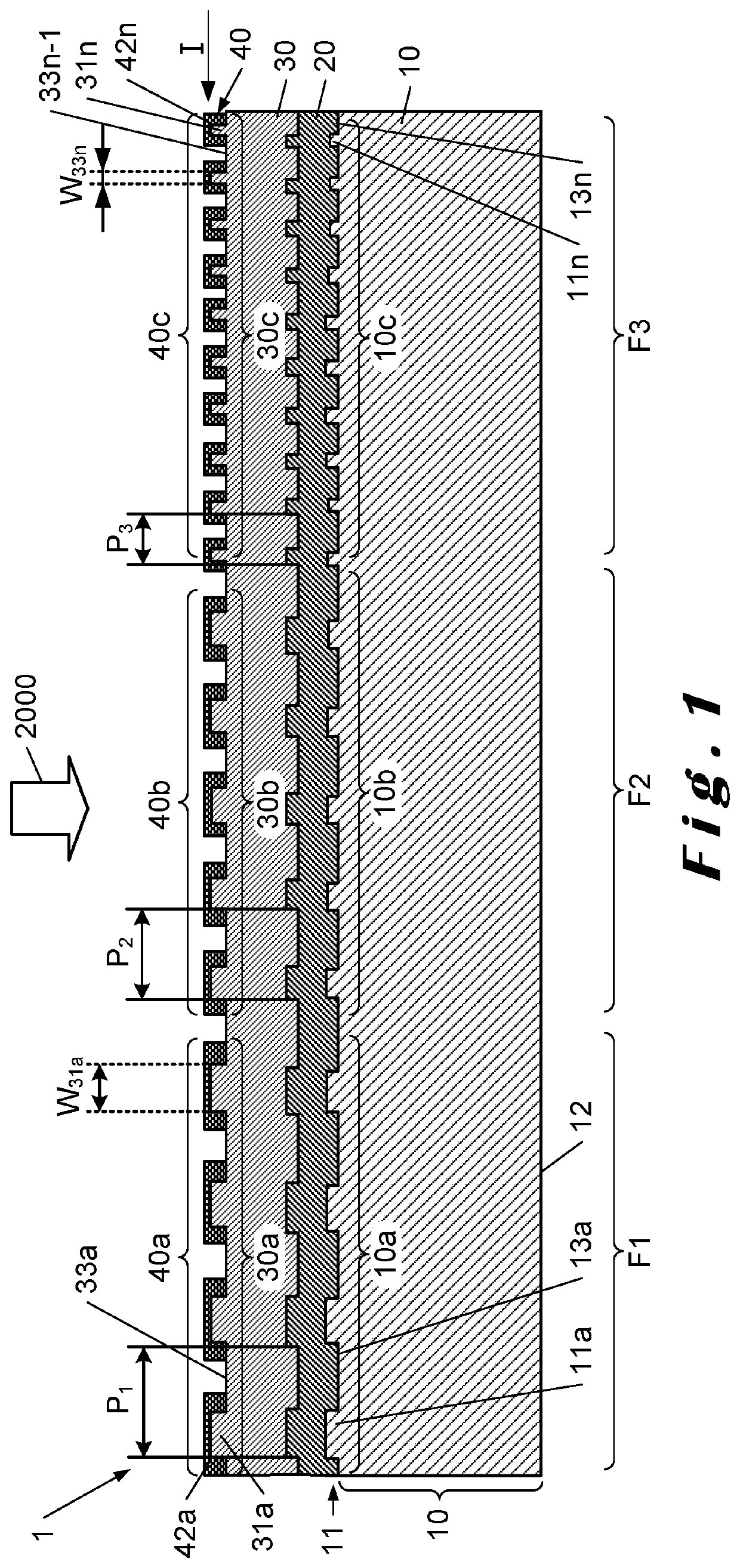

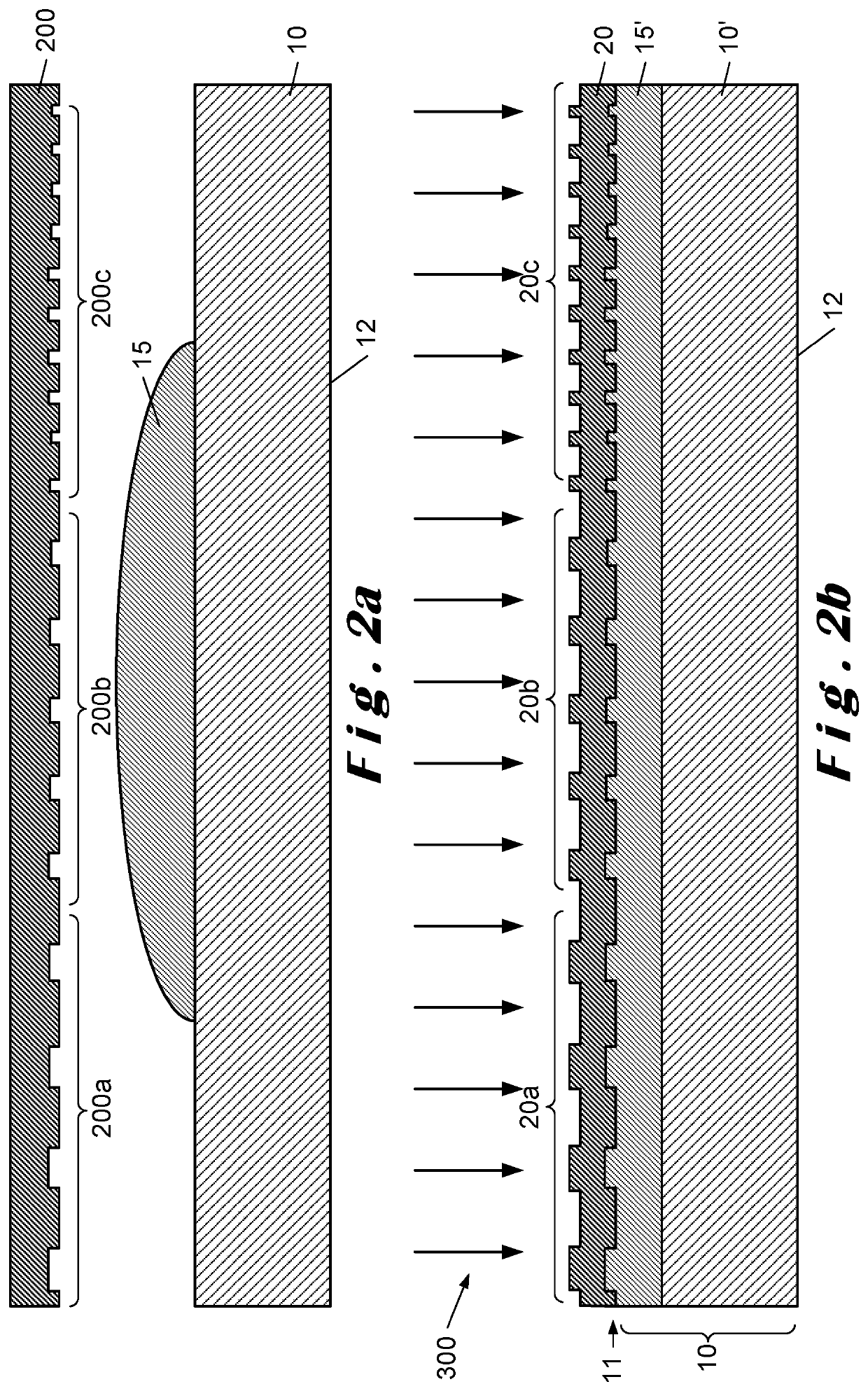

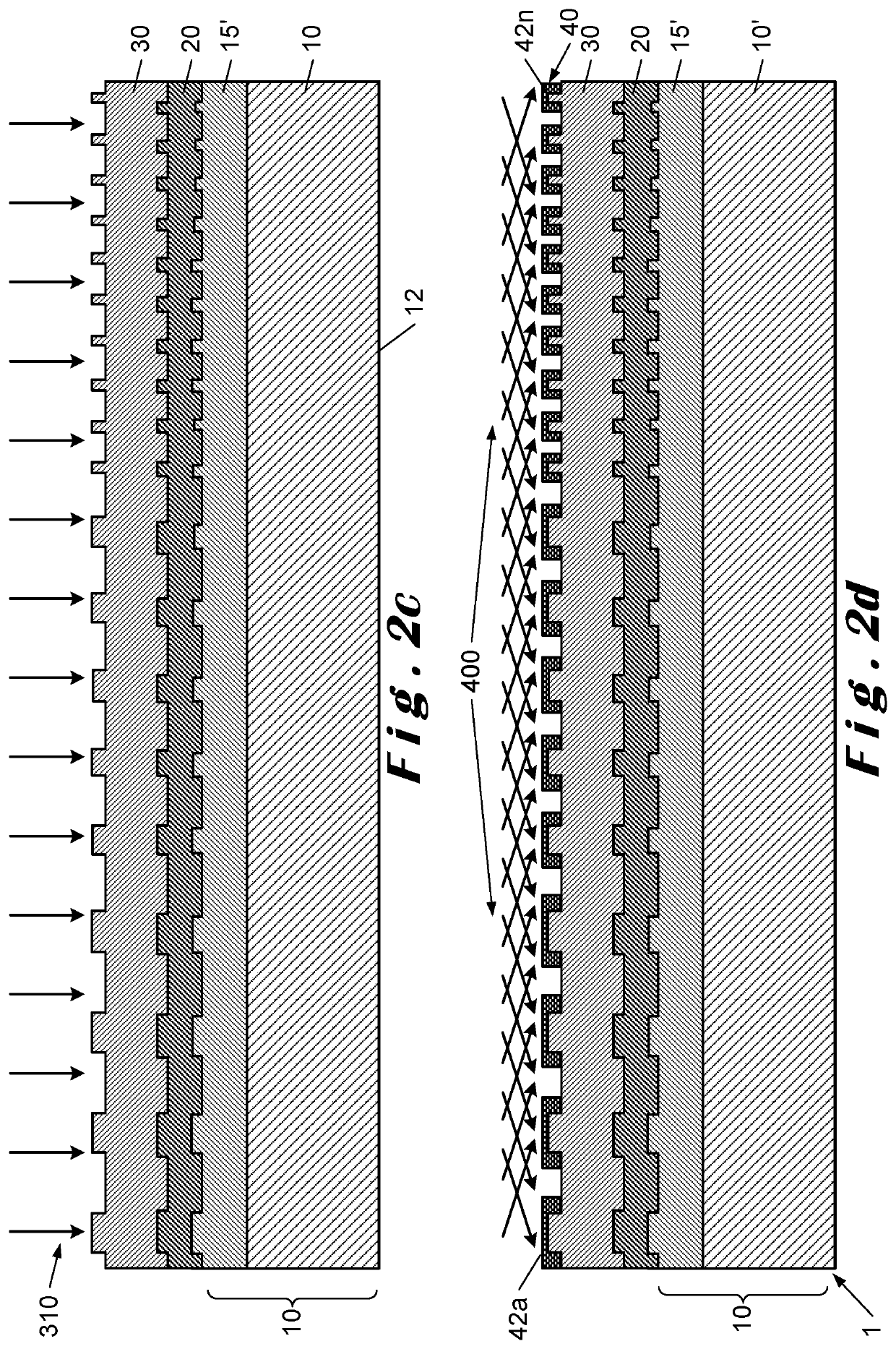

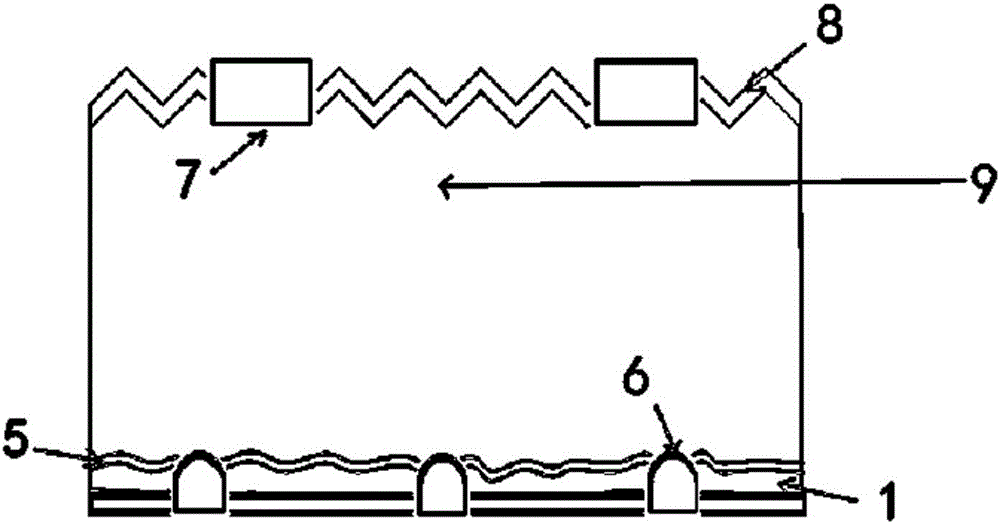

Optical filter, optical filter system, spectrometer and method of fabrication thereof

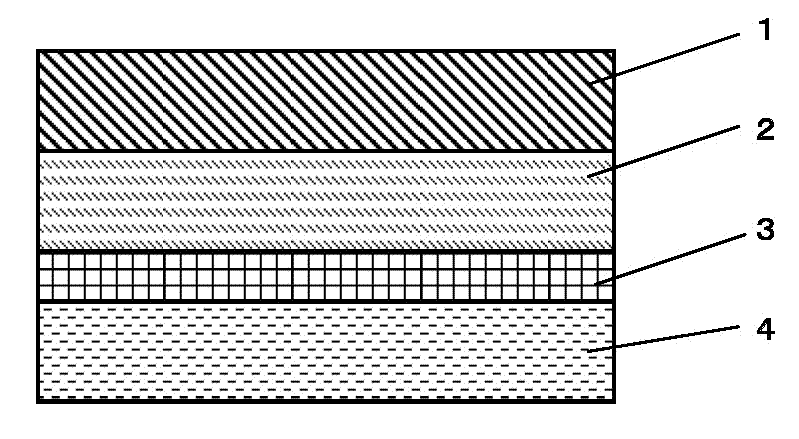

ActiveUS20200064195A1Simple processEasy to manufactureSpectrum investigationOptical filtersDetector arrayRefractive index

A nano-structured optical wavelength transmission filter is provided. The optical filter includes a patterned substrate on which a high refractive index dielectric waveguide is arranged. A low index dielectric layer is arranged on the high refractive index dielectric waveguide, on which an array of metallic nanostructures is arranged. The layers of the optical filter have conformal shapes defined by a patterned surface of the substrate. An optical filter system includes the optical transmission filter and a detector array fixed to the substrate. A spectrometer includes at least one optical transmission filter and / or at least one said optical transmission filter system, and has a spectral resolution of lower than 30 nm for incident light having a wavelength between 300 nm and 790 nm. A method of fabrication of an optical filter, an optical filter system and a spectrometer is also described.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

Method for recycling valuable metals from spent batteries

InactiveUS20170170532A1Cheap and simpleEliminate needElectrolysis componentsPhotography auxillary processesElectrolysisFiltration

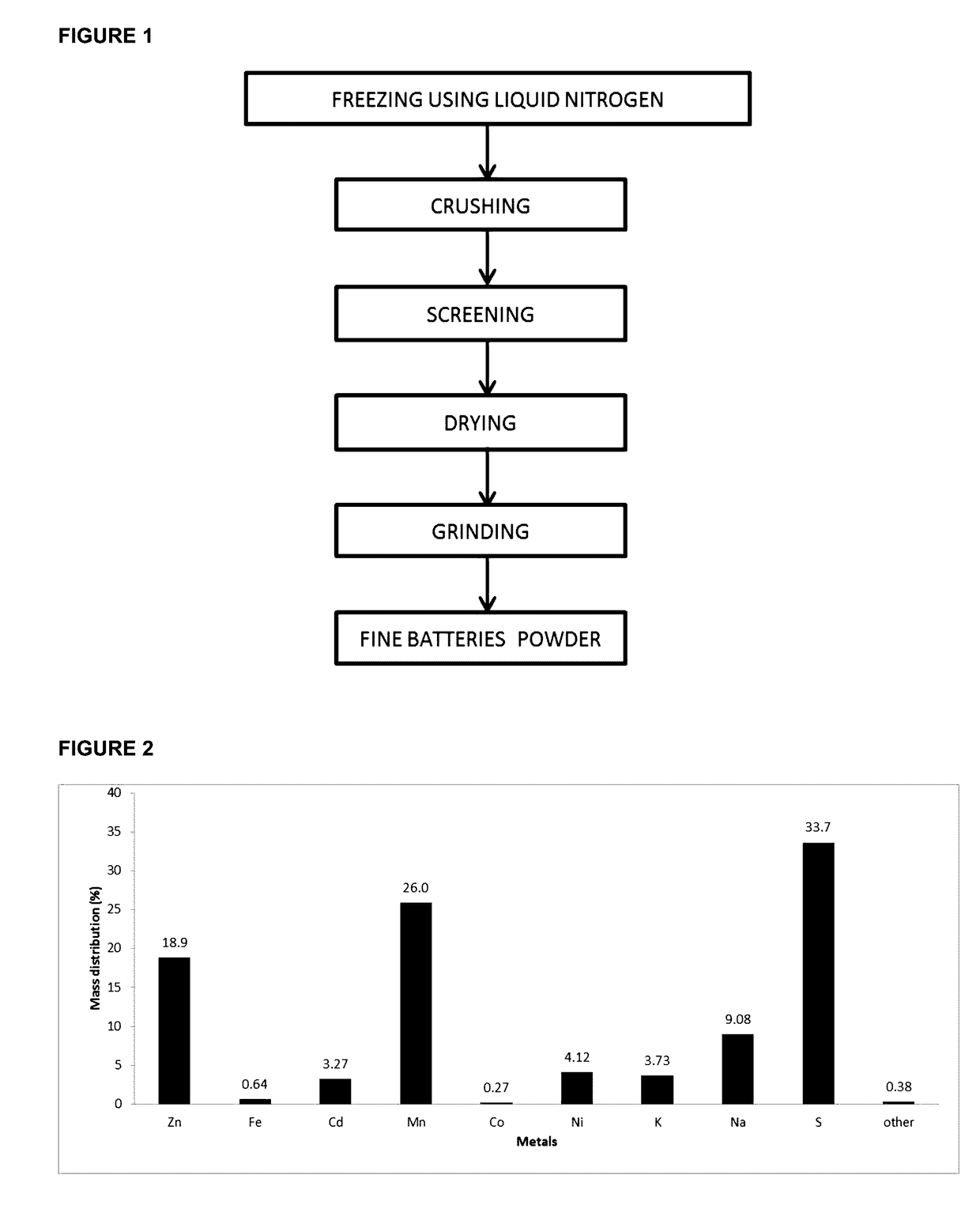

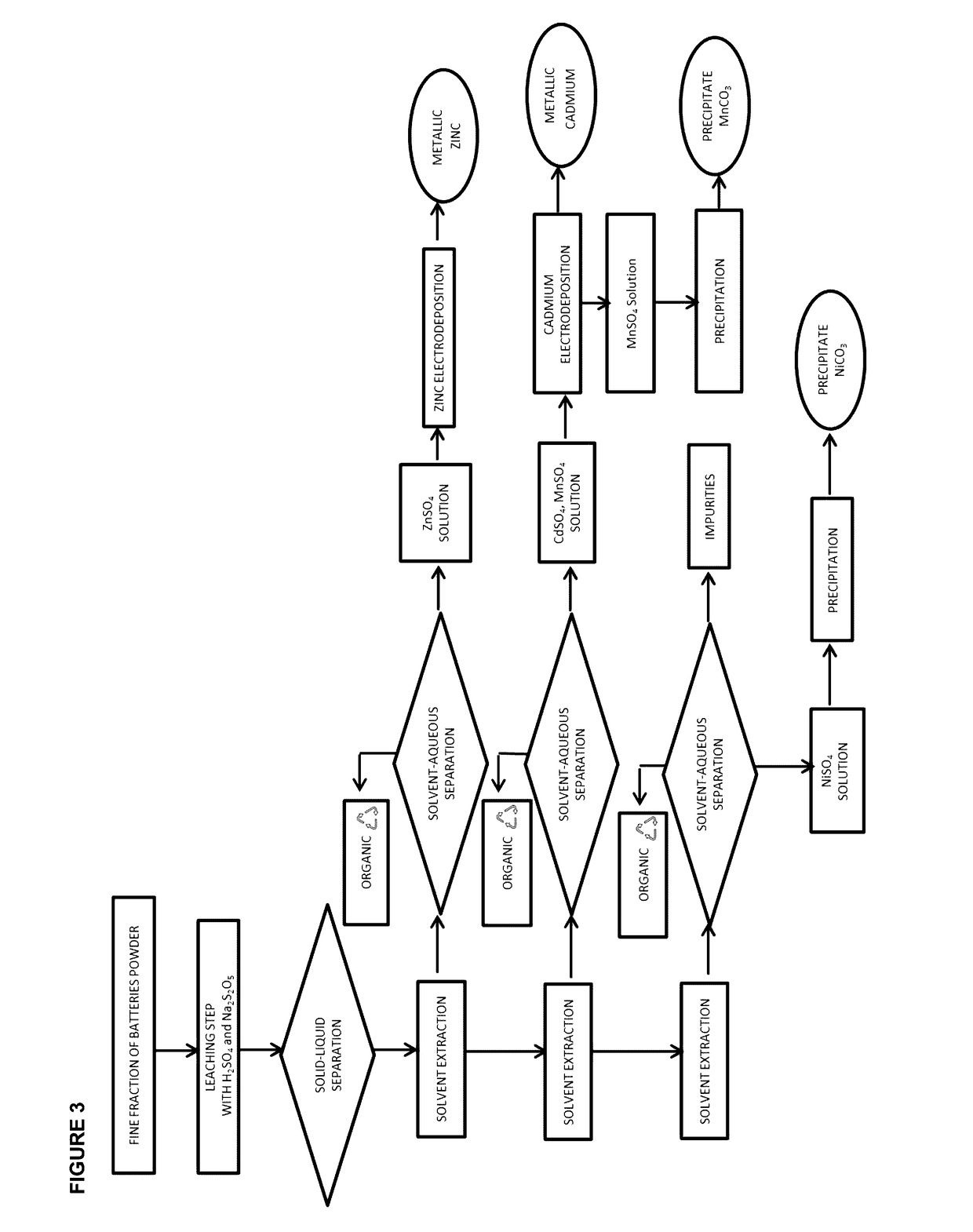

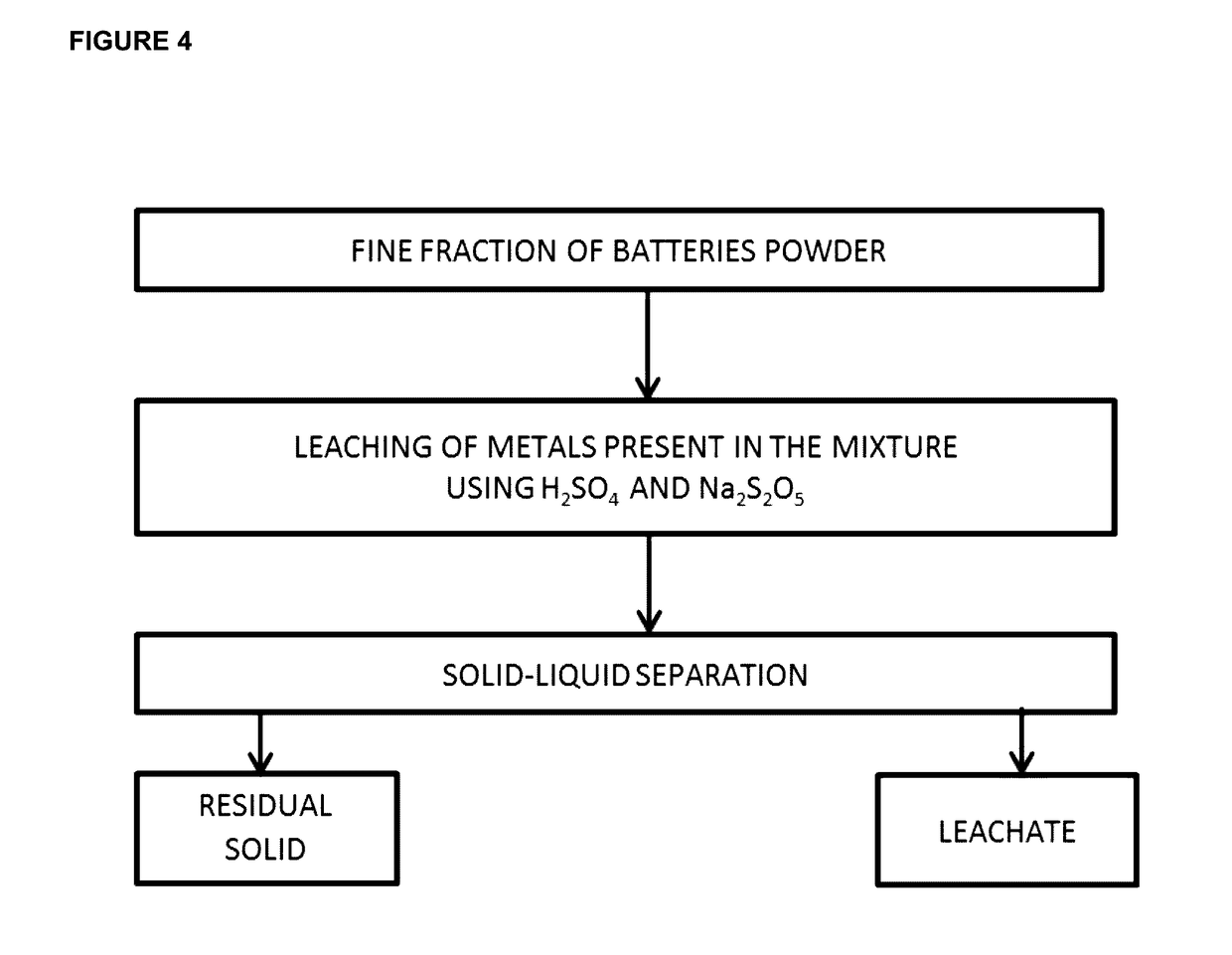

A process has been developed in order to recover and recycle the metals present in spent batteries, including alkaline spent batteries alone or mixed with other types of spent batteries. This method shows a good potential in terms of metals recoveries efficiencies and economic feasibility. Firstly, the spent batteries are crushed (optionally after having been frozen in the case of spent batteries of mixed types). Then, the undesirable parts (plastics, steel cases, papers, etc.) are removed by screening. The collected powder, containing the metals, is mixed with a solution of sulfuric acid in the presence of a reducing agent. The solid / liquid separation is carried out by filtration and the leachate is purified in order to selectively recover the metals. The purification steps consist of: a) recovering Zn by solvent extraction followed by an electrowinning process; b) simultaneously recovering Mn and Cd by solvent extraction process; c) selectively recovering Cd from the mixture solution of Cd and Mn by electrowinning process; d) precipitating Mn from a pure solution of MnSO4 in a carbonate form; e) removing the impurities present in the effluent by solvent extraction in order to obtain a pure NiSO4 solution; f) precipitating Ni from a NiSO4 solution in a carbonate form.

Owner:INSTITUT NATIONAL DE LA RECHERCHE SCIENTIFIQUE

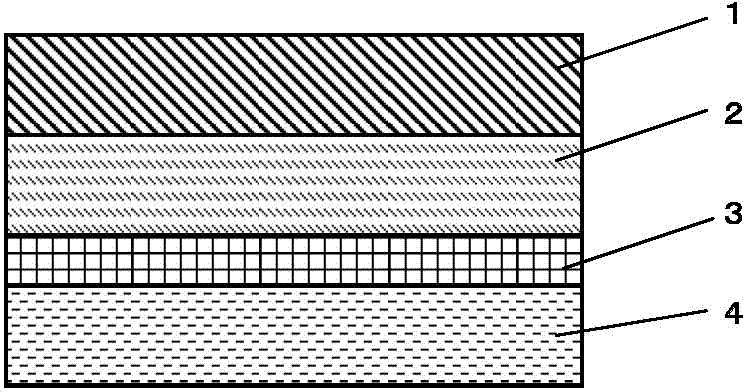

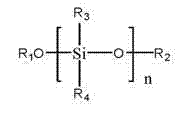

Conductive coating composition and laminate

ActiveCN102559043ASimple and cheap processLower surface resistivityOther chemical processesGlass/slag layered productsOligomerConductive coating

The invention provides a conductive coating composition and a laminate. The conductive coating composition can be used to form an anti-static membrane having advantages of conductivity, high transparence, good attachment to the base material, high rigidity and good chemical resistance. The conductive coating composition comprises the conductive polymer particle having particle diameter D50 under 200nm, adhesive composition ingredient containing the alkoxy silane oligomer. The conductive polymer particle has preferably the particle diameter under 60nm, more preferably 30nm. The conductive polymer particle preferably a composition of Poly (3,4-disubstituted thiophene) and polyanion. By using the conductive coating composition provided in the invention, the normal coating method can be used to coat the cloth base material in low temperature to form the anti-static membrane, and the technology from coating to film forming can be realized with low costs.

Owner:NAGASE CHEMTEX CORPORATION

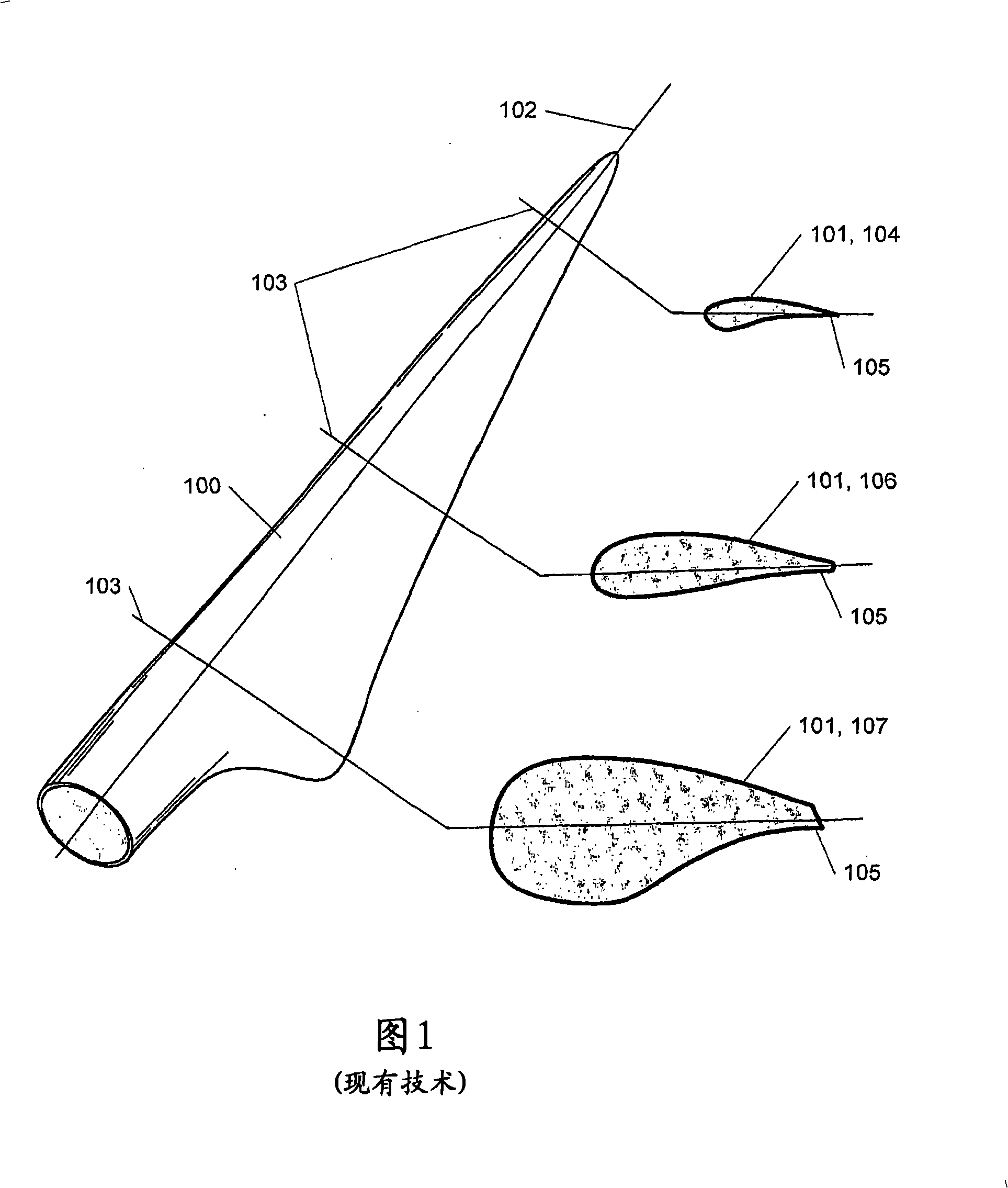

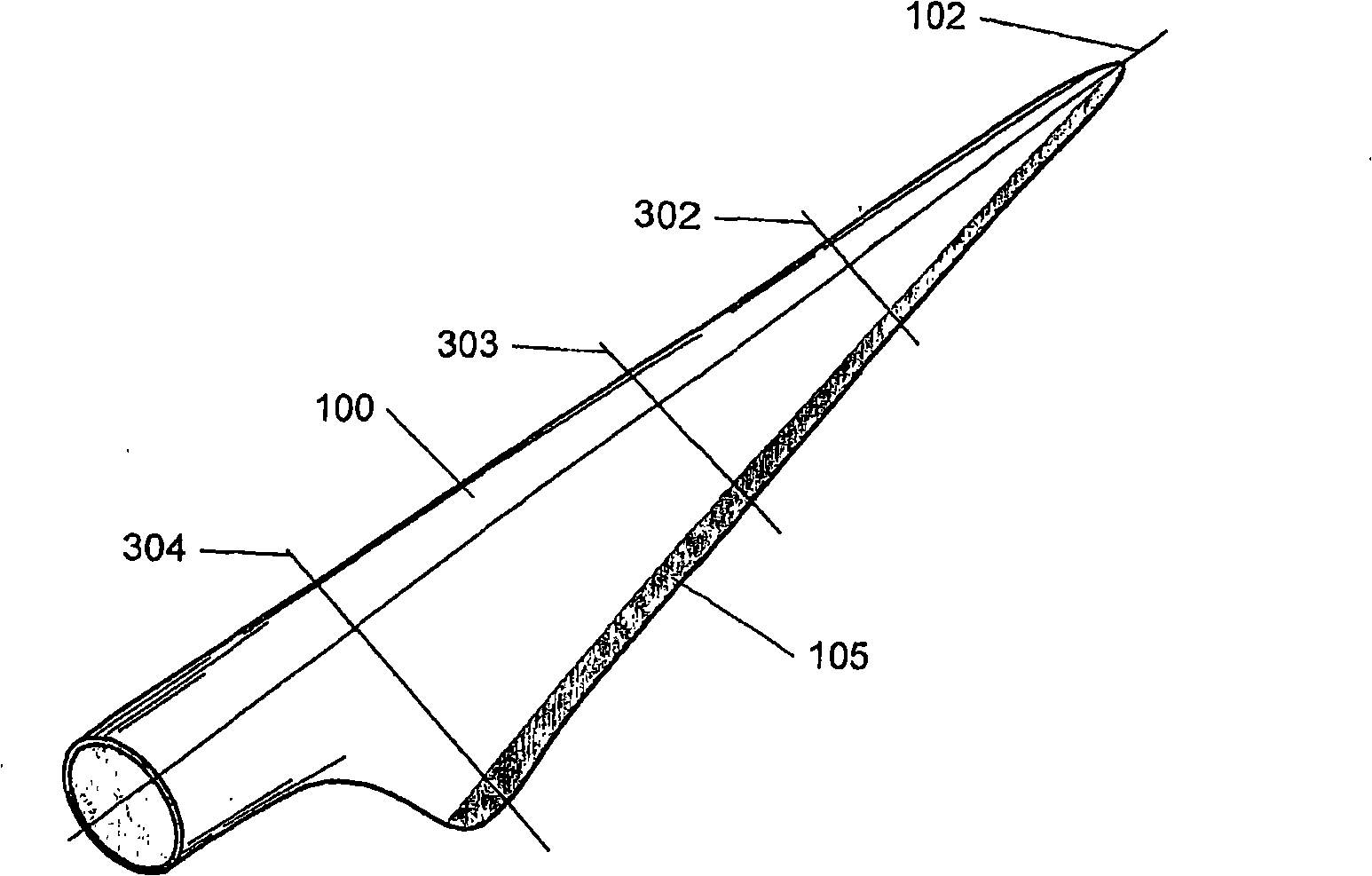

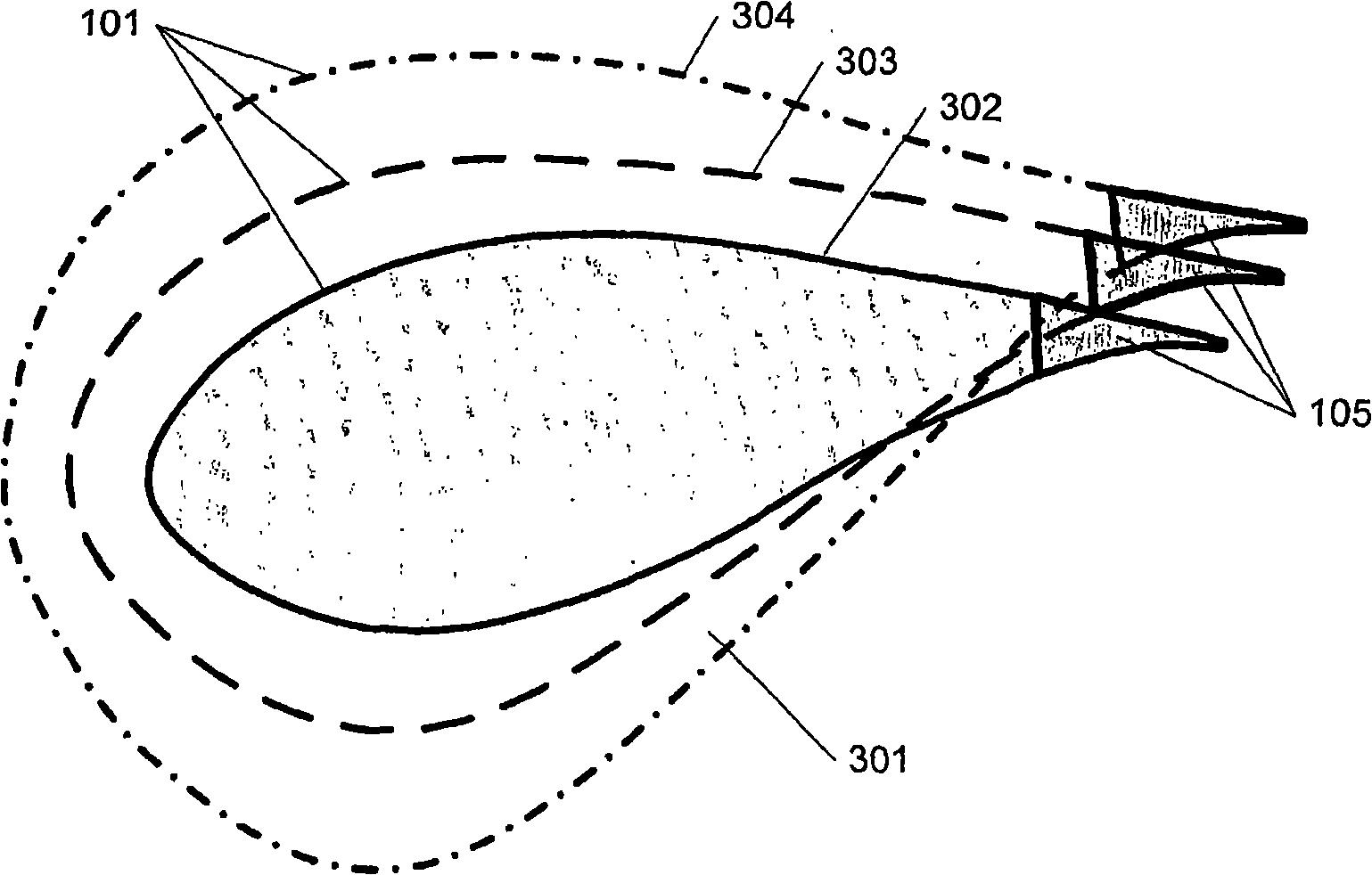

Wind turbine rotor blade comprising a trailing edge section of constant cross section

A wind turbine rotor blade comprising a series of profiles is presented, which series of profiles comprises a number of profiles describing the outline of the blade transversally of its longitudinal axis, wherein some of the profiles of the series of profiles comprise approximately the same profile rear edge which describes at least a portion of the rear edge of the blade. The rear edge of the blade is configured in one piece and / or of a flexible material. Moreover a method of designing a series of profiles for a wind turbine rotor blade is presented.

Owner:LM GLASSFIBER

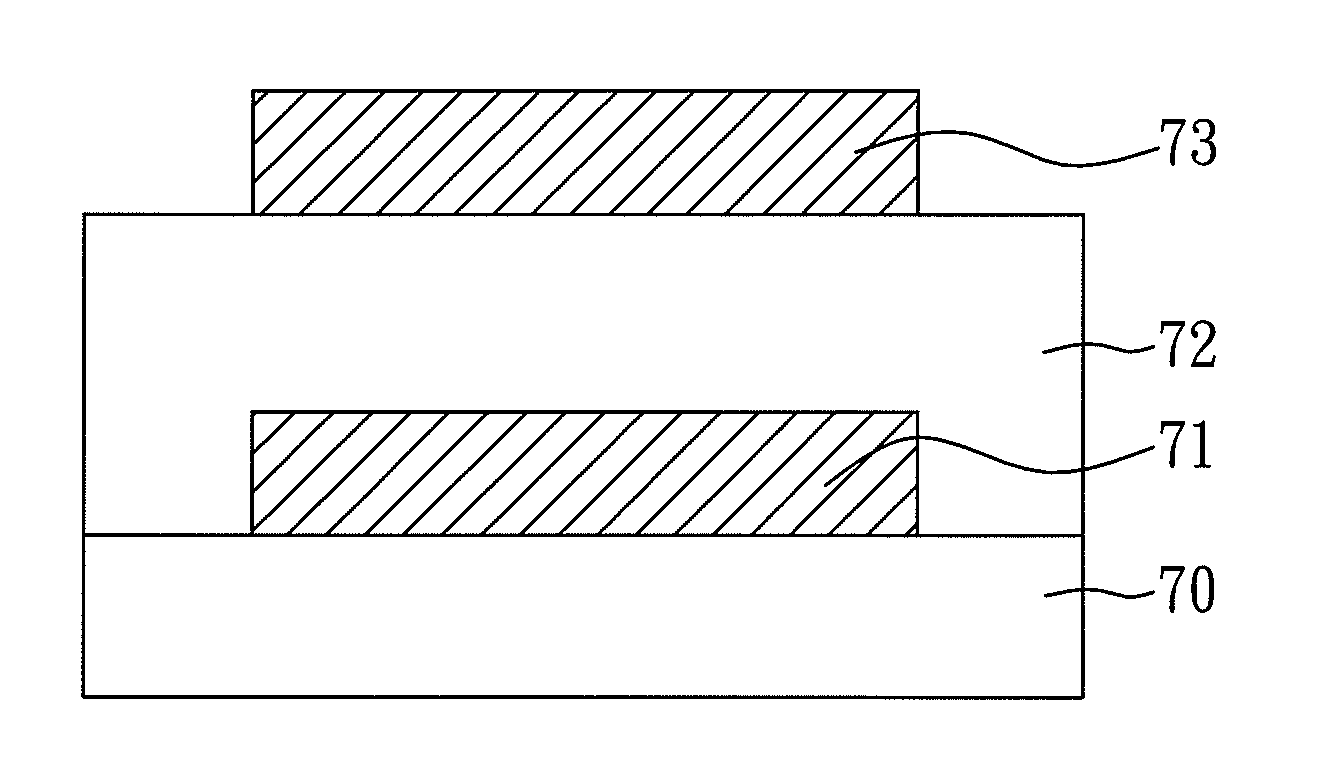

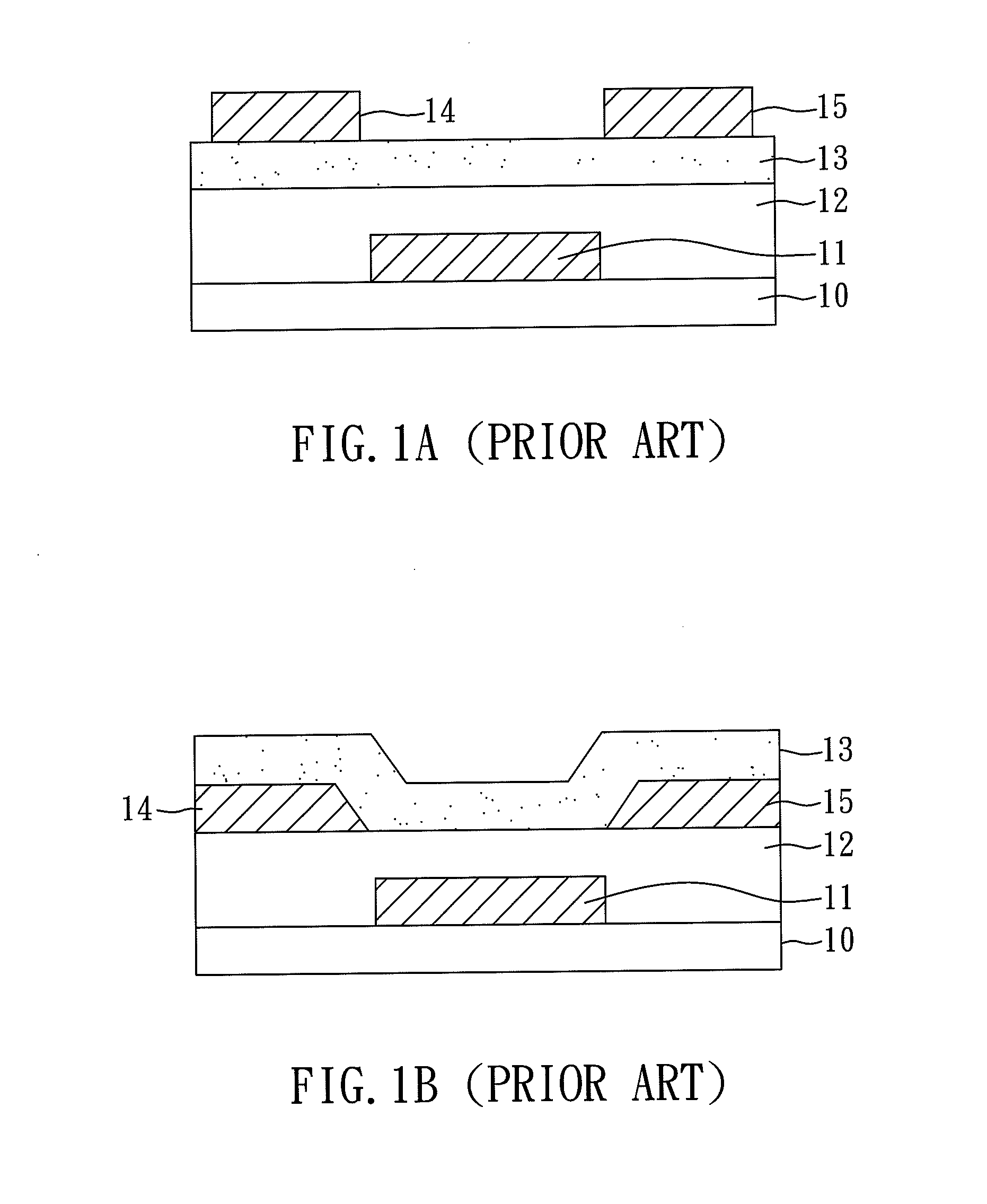

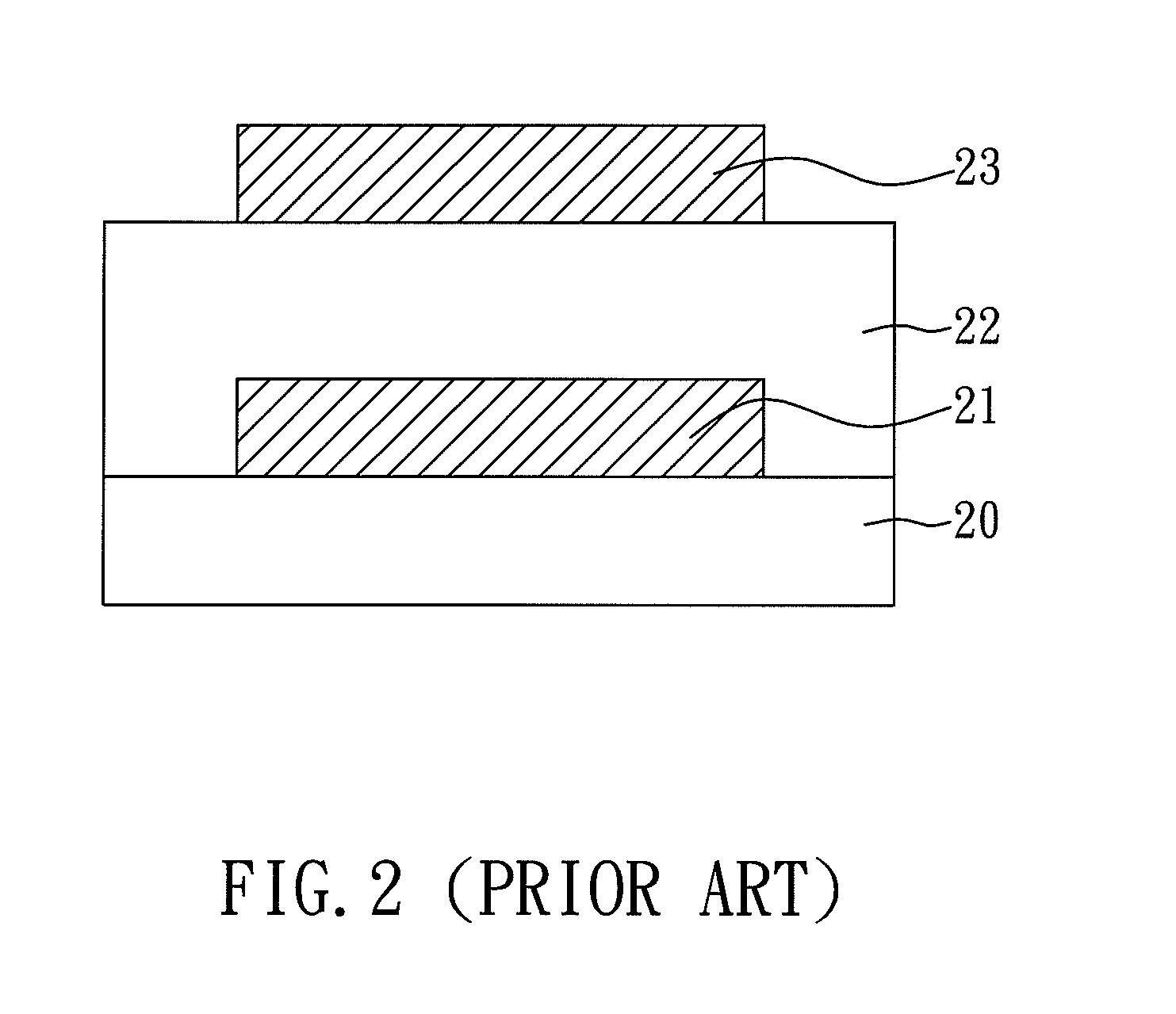

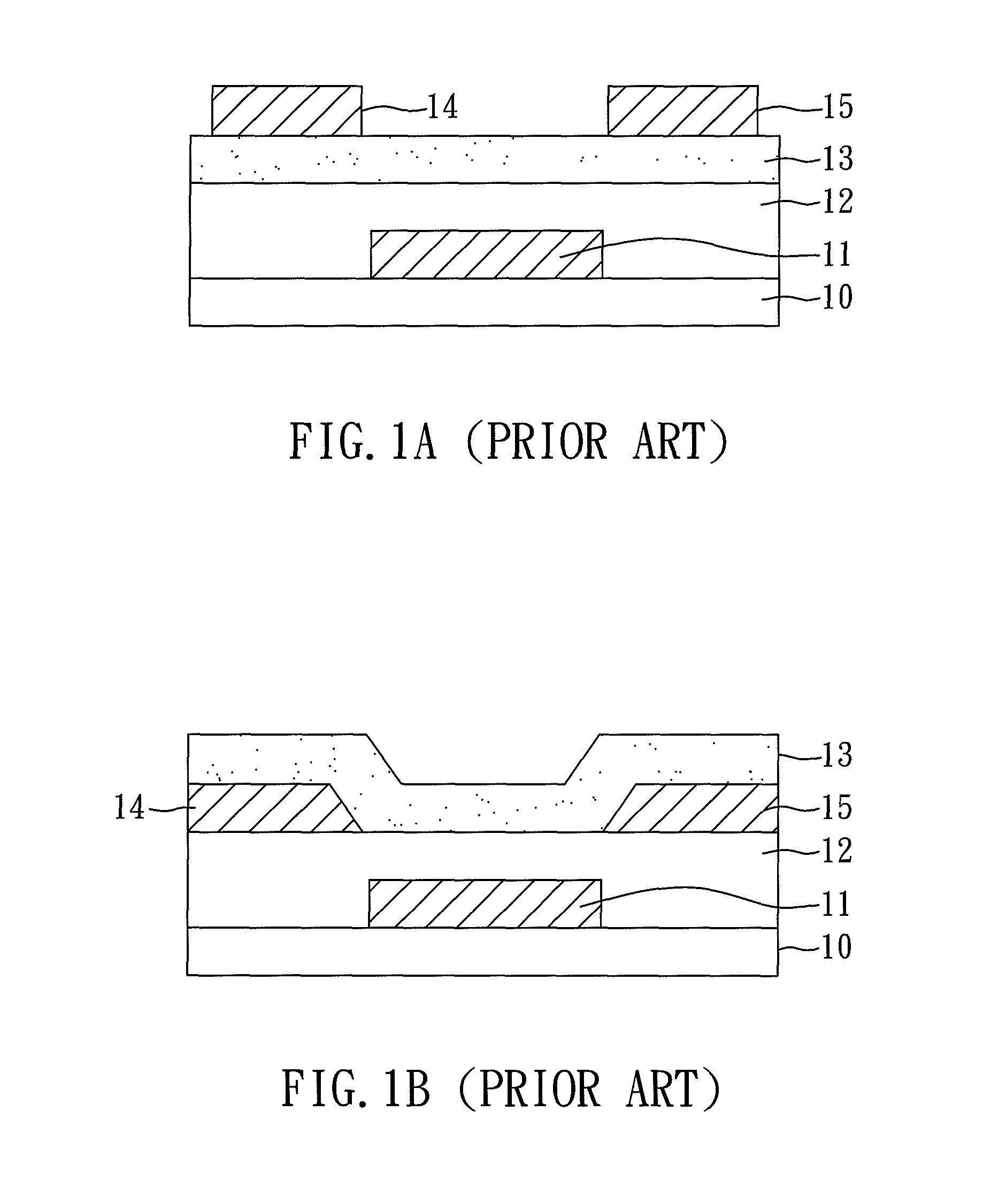

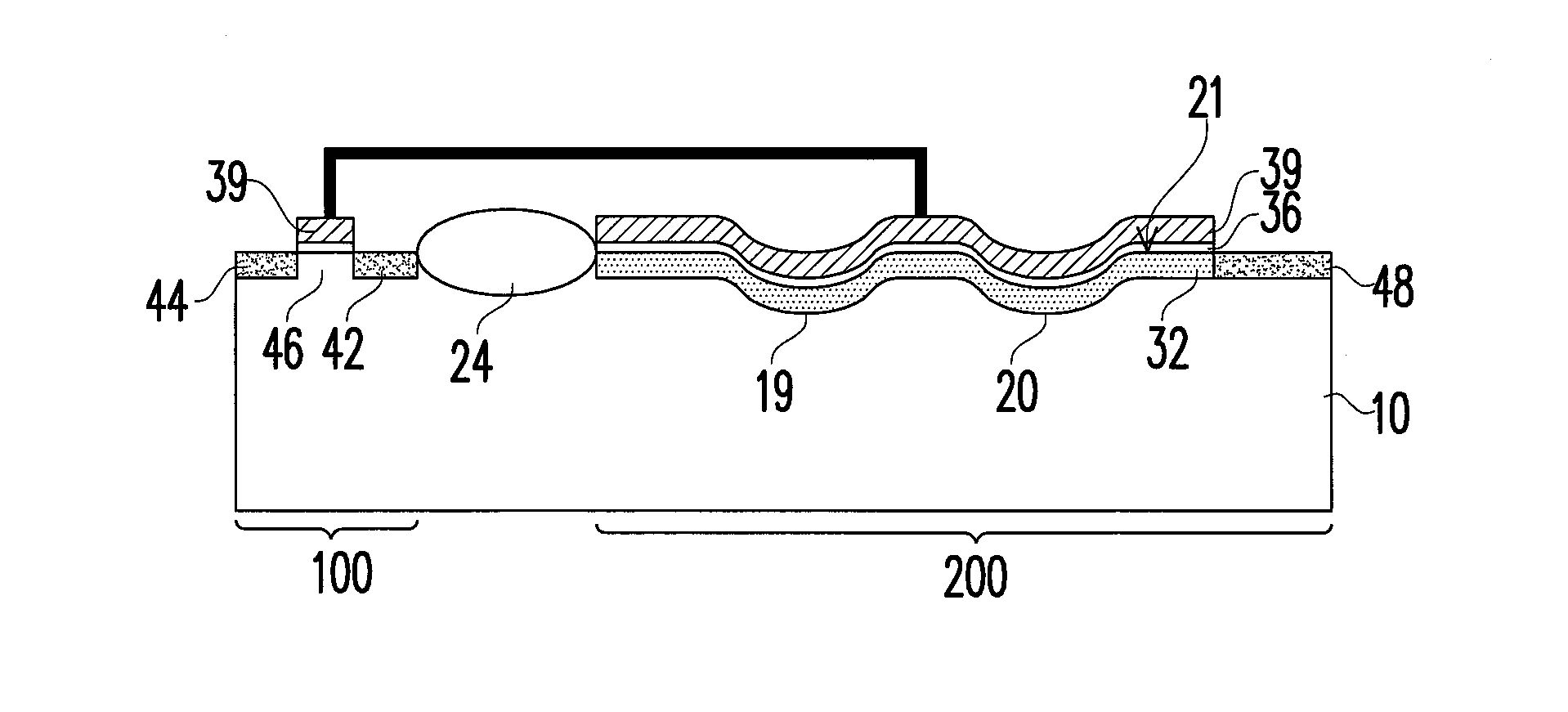

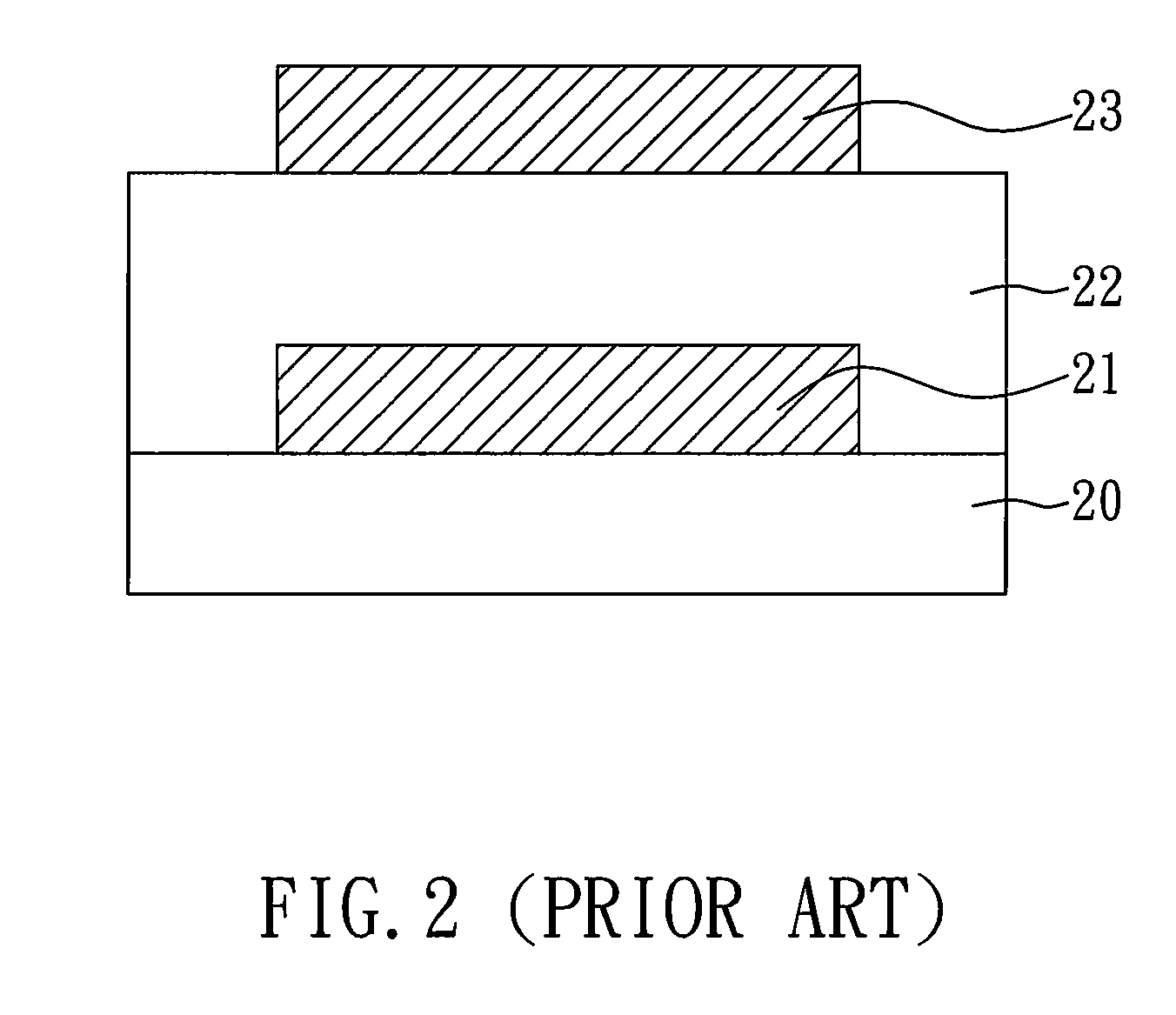

OTFT and MIM Capacitor Using Silk Protein as Dielectric Material and Methods for Manufacturing the Same

InactiveUS20110227046A1Improve efficiencySimple and cheap processFixed capacitor dielectricNanoinformaticsMetal-insulator-metalEngineering

An organic thin film transistor (OTFT) and a metal-insulator-metal (MIM) capacitor using silk protein as a dielectric material, and methods for manufacturing the same are disclosed. The OTFT of the present invention comprises: a substrate; a gate electrode disposed on the substrate; a gate insulating layer containing silk protein, which is disposed on the substrate and covers the gate electrode; an organic semiconductor layer; and a source electrode and a drain electrode, wherein the organic semiconductor layer, the source electrode and the drain electrode are disposed over the gate insulating layer.

Owner:NATIONAL TSING HUA UNIVERSITY

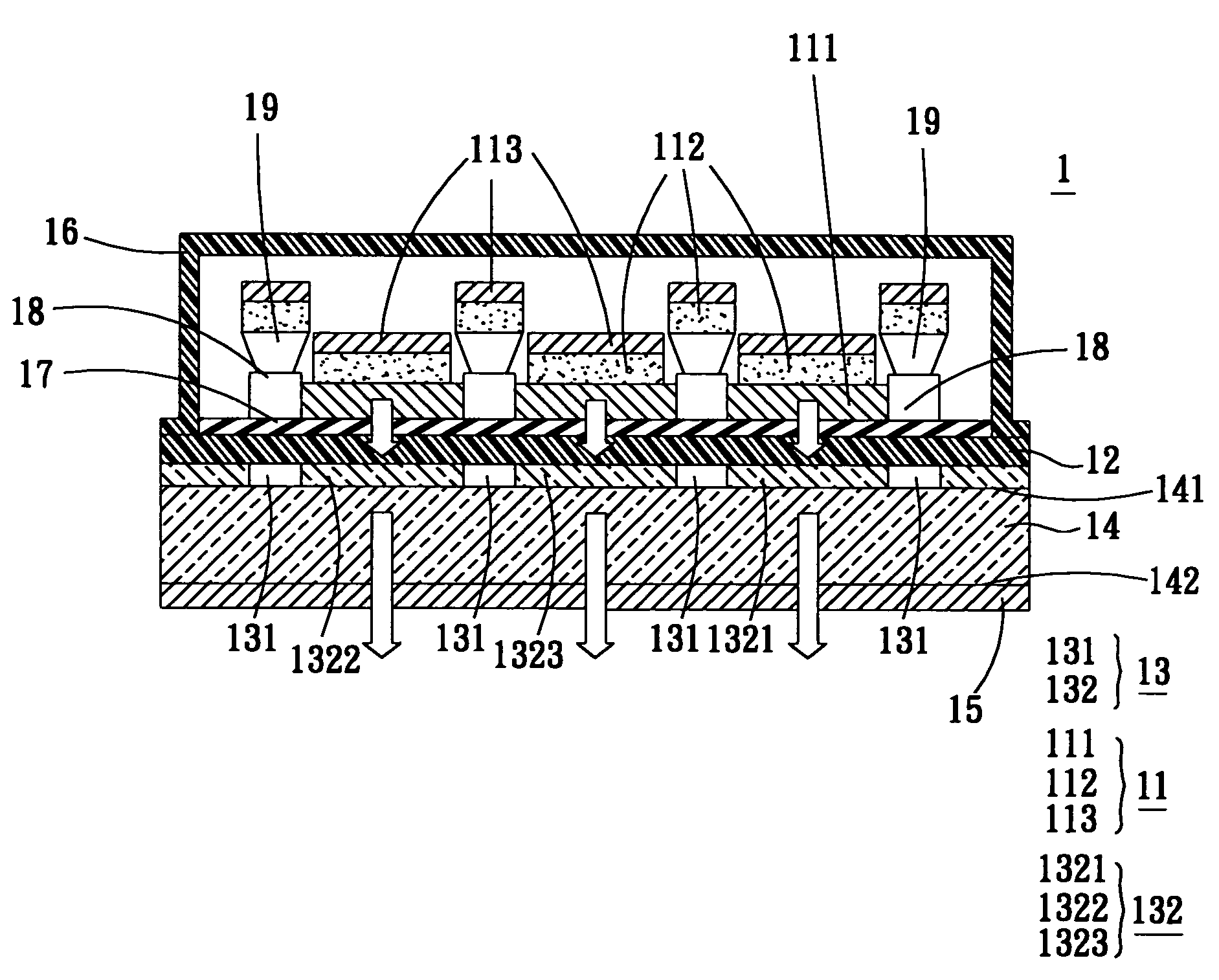

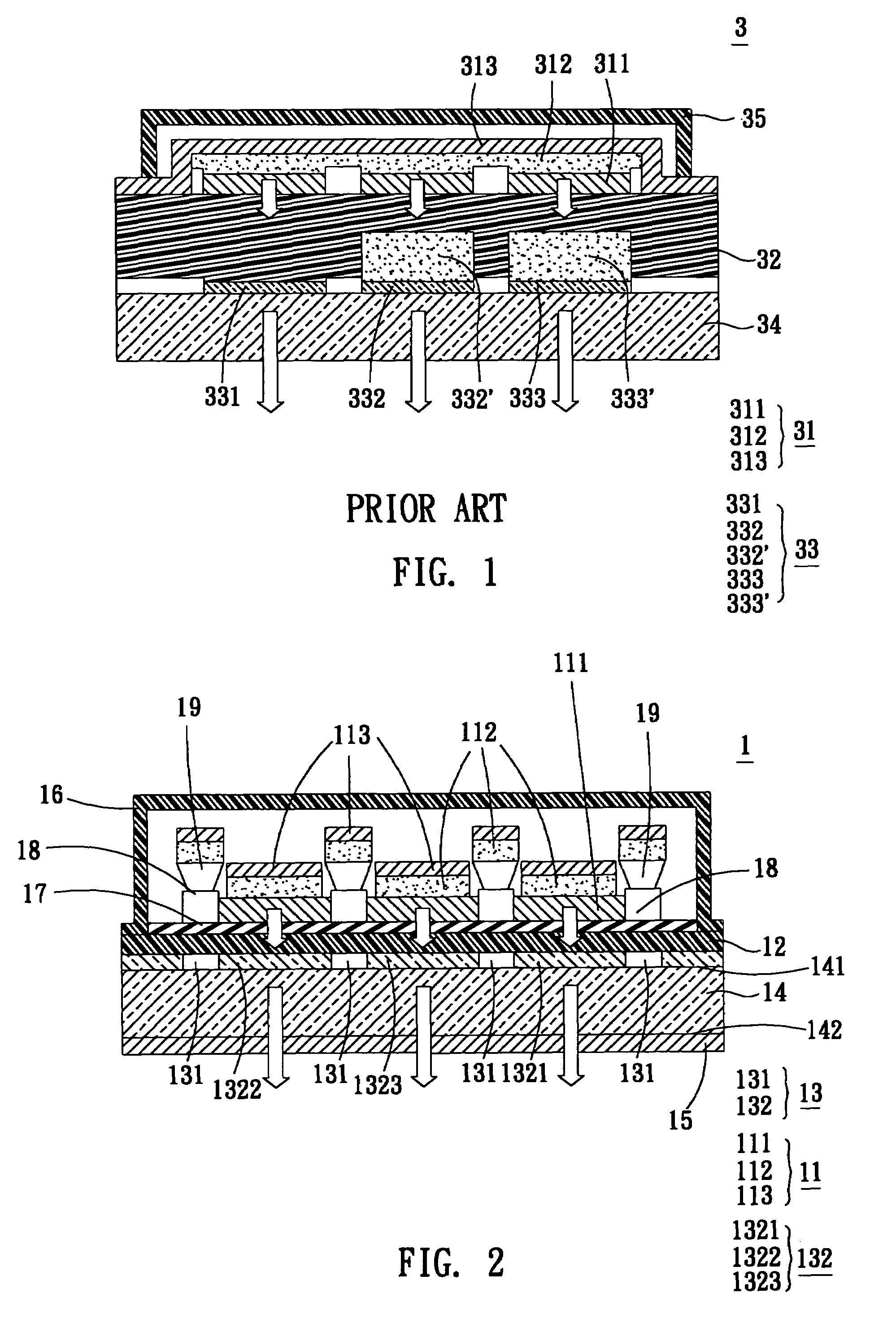

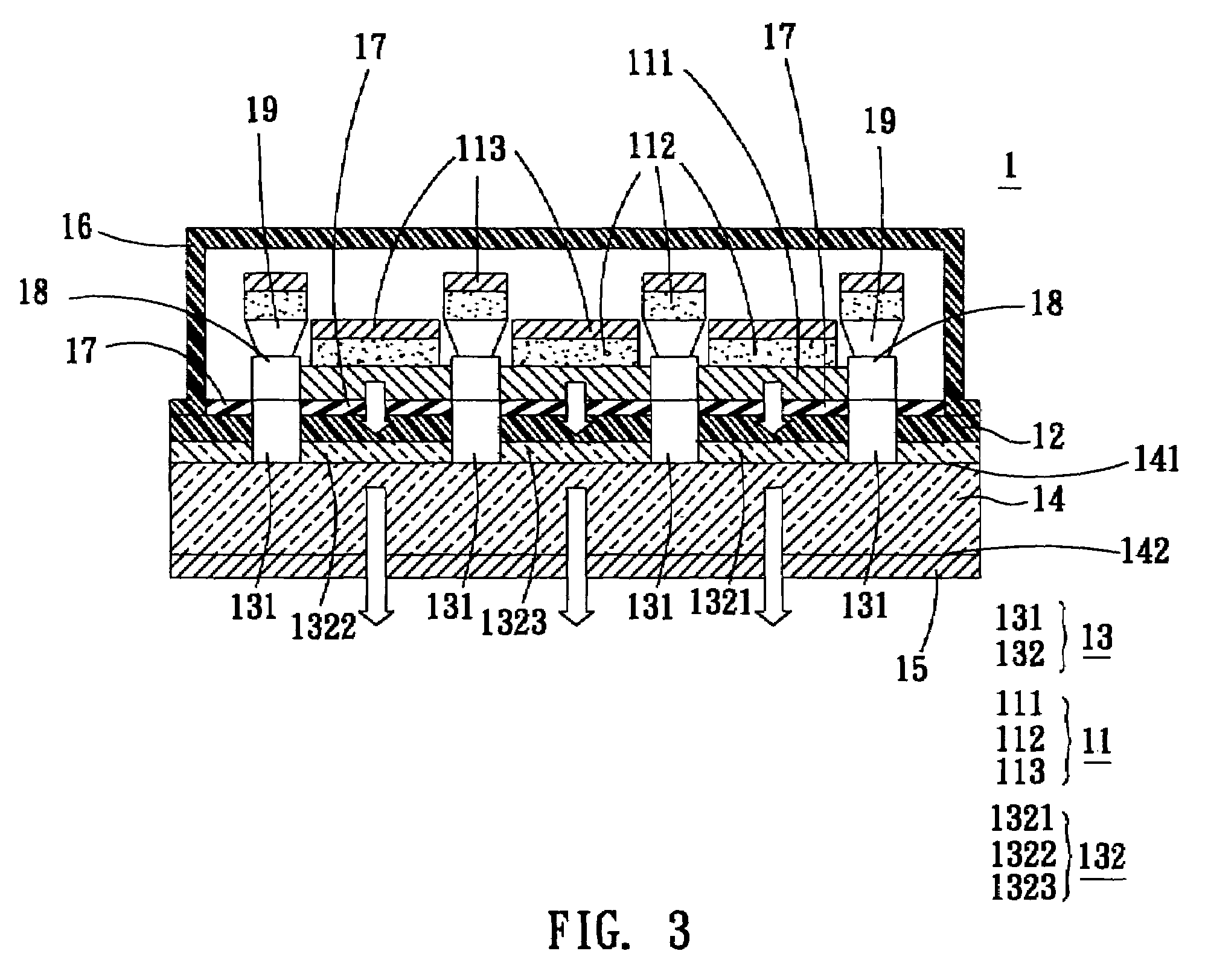

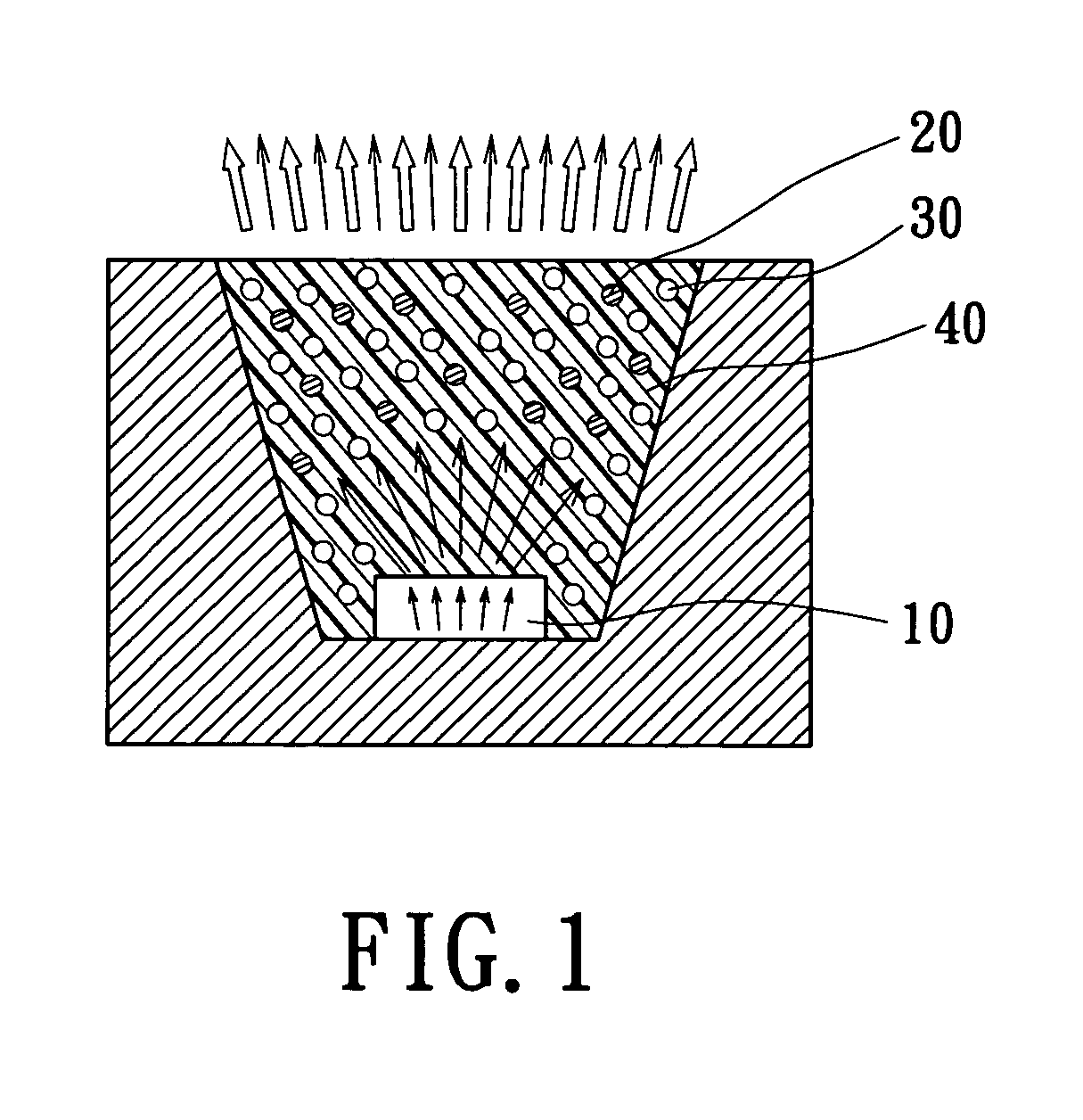

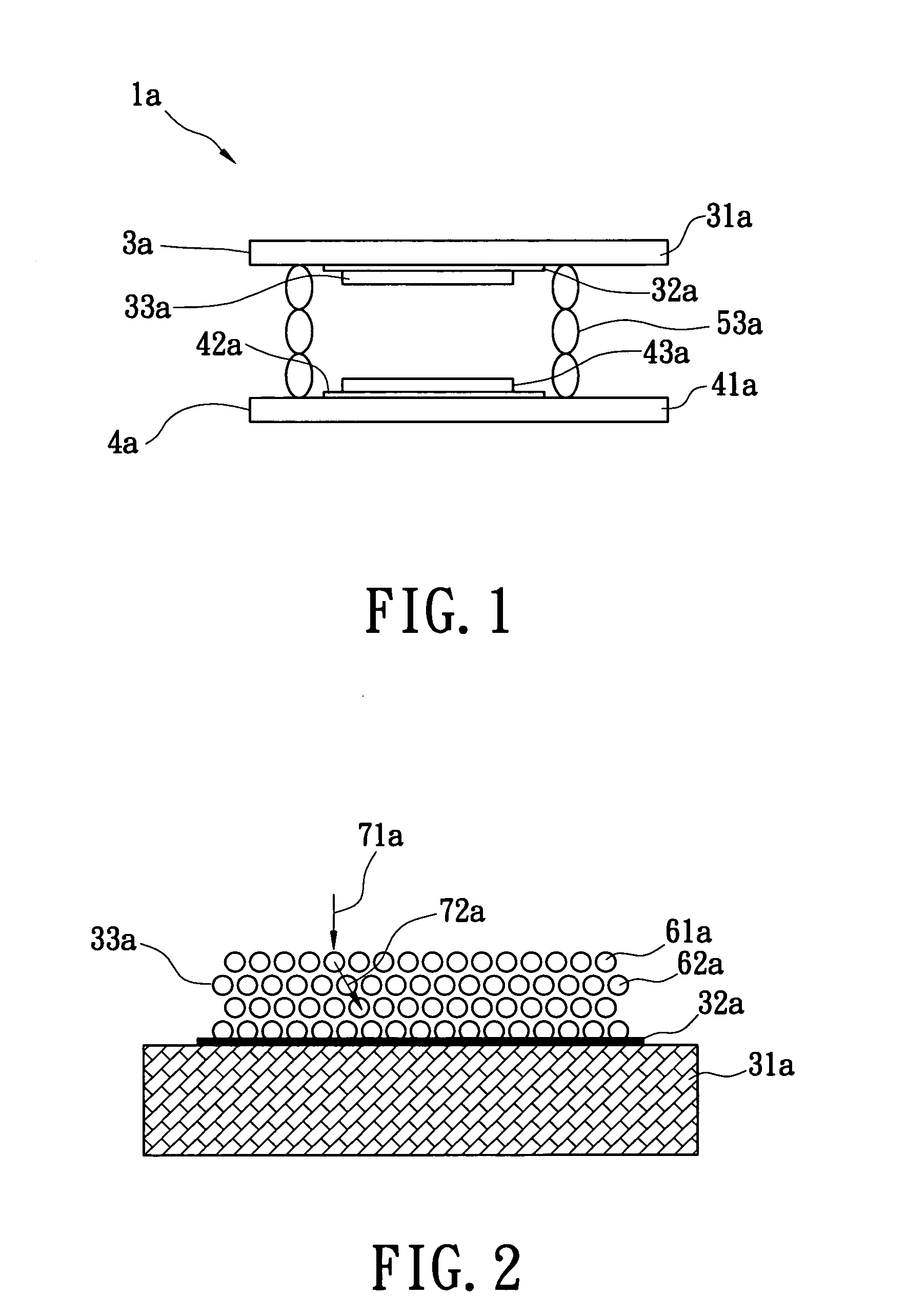

Full color display panel with mirror function

InactiveUS7067975B2High purityImprove luminous efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesReflective layerComputer science

A full color display panel with a mirror function comprises an organic light-emitting area, a spectrum-modulation layer, a color-separating layer, a transparent substrate and a semi-reflecting layer. The organic light-emitting area includes a plurality of pixels for emitting white light. The spectrum-modulation layer is doped with a fluorescent material and / or a phosphorescent material in a transparent protecting medium. The color-separating layer includes a light-shielding frame and a plurality of color filters. The light-shielding frame is disposed around the peripheral of the color filters. The transparent substrate has a first surface and a second surface opposite to the first surface. The color-separating layer is disposed above the first surface of the transparent substrate. The spectrum-modulation layer is disposed above the color-separating layer. The organic light-emitting area is disposed above the spectrum-modulation layer. The semi-reflecting layer is disposed between the first surface and color-separating layer or on the second surface.

Owner:RITDISPLAY

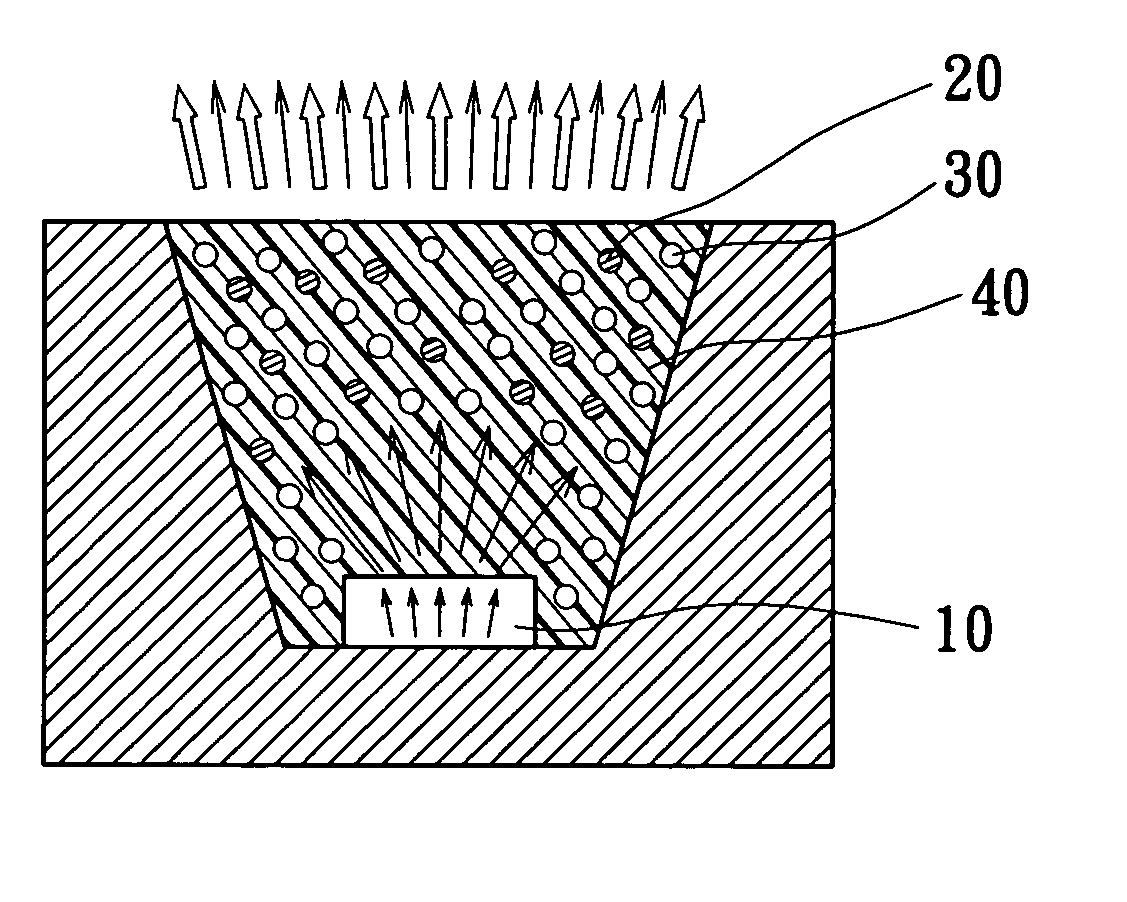

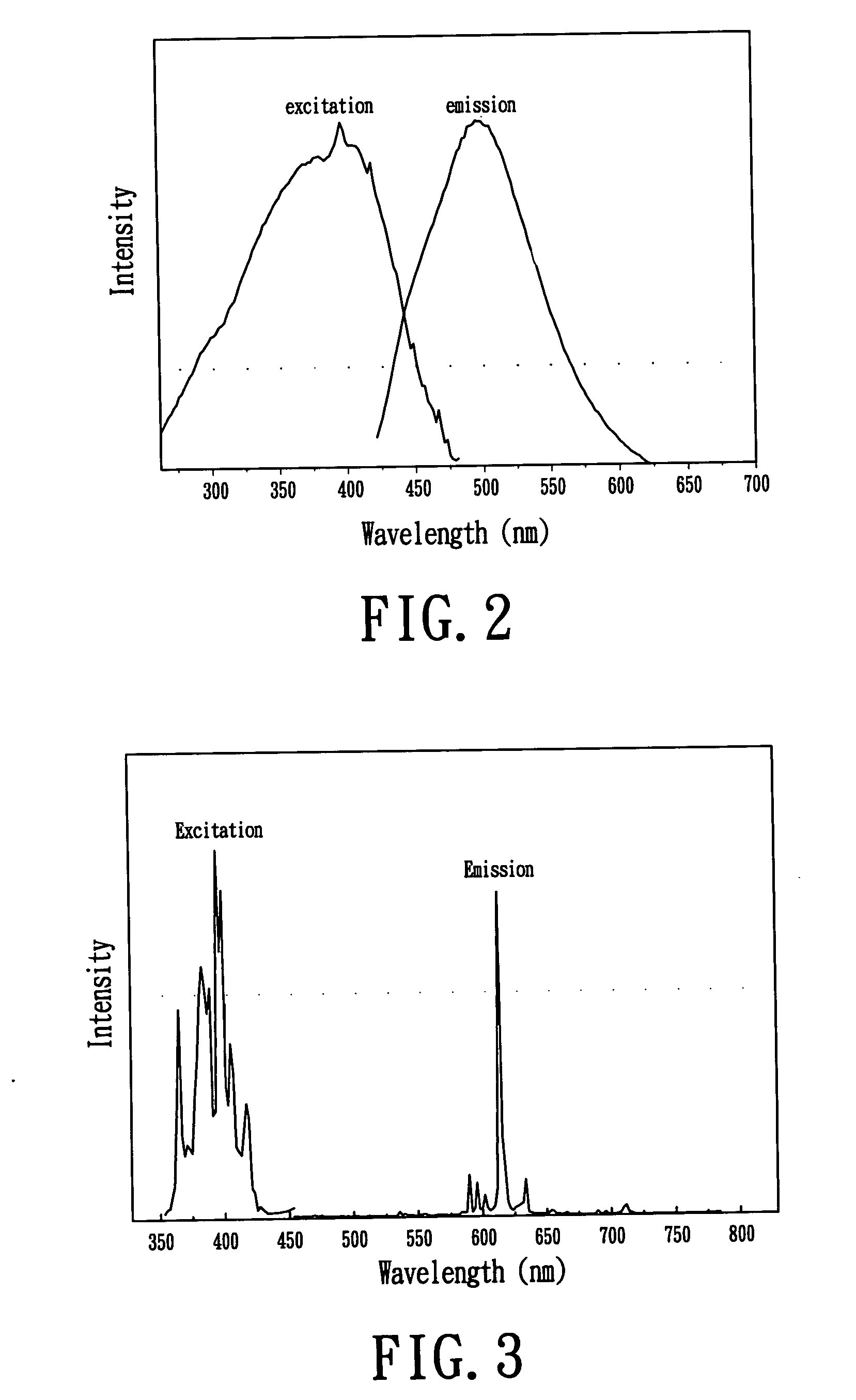

White light-emitting device

InactiveUS20050247953A1High illuminationHigh propertyElectroluminescent light sourcesGas discharge lamp usagePhosphorHigh color

A white light-emitting device has a semiconductor light-emitting chip, a blue-green phosphor and a red phosphor for emitting blue-green light and red light, respectively. The blue-green phosphor and the red phosphor absorb light emitted from the semiconductor light-emitting chip to excite blue-green light and red light that are mixed into white light with improved illumination efficiency, and a high color-rendering property. The white light-emitting device is cheaply and simply manufactured.

Owner:LITE ON TECH CORP

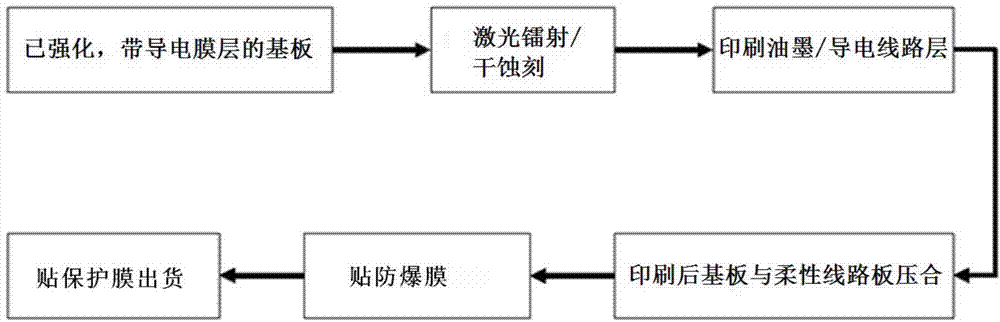

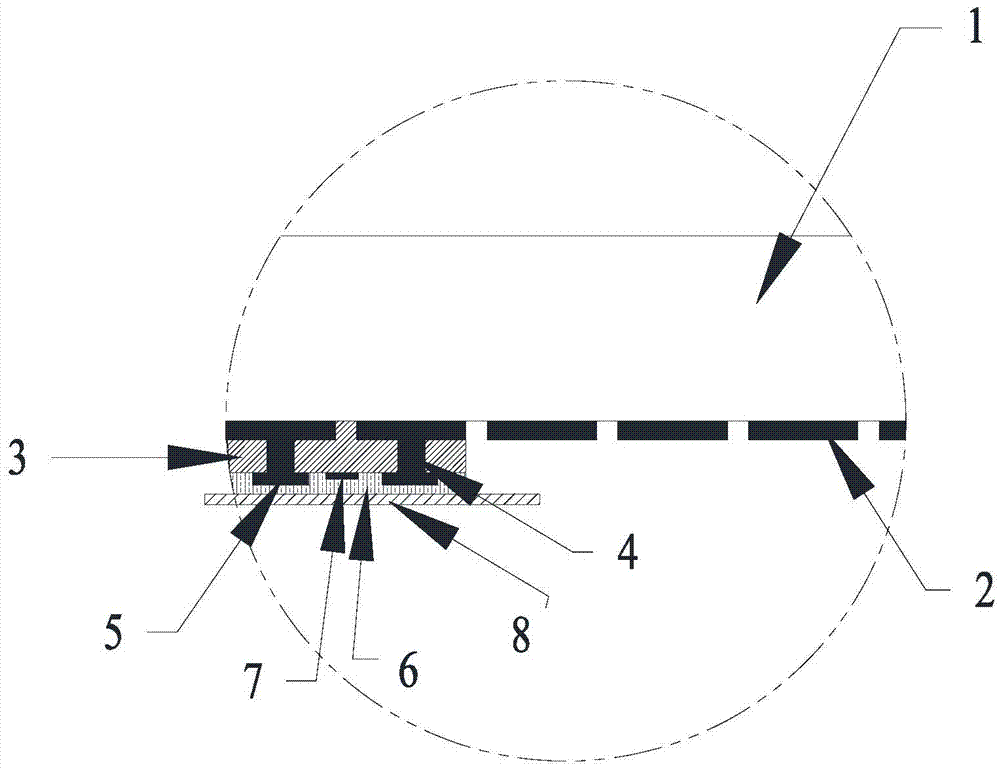

Production process of super-thin touch screen

ActiveCN103488367AThin structureReduce the number of layersInput/output processes for data processingFlexible circuitsMegasonic cleaning

The invention provides a production process of a super-thin touch screen. The production process includes the following steps that (1) ultrasonic cleaning is carried out on a substrate which is reinforced and plated with a conductive membrane layer in an ultrasonic washing unit; (2) the substrate undergoes laser or dry-etching operation through a laser cutting machine or a printer; (3) two layer of printing ink, including a colored insulating printing ink layer and a colored conductive printing ink layer, are printed on the substrate which is qualified in function; (4) a flexible circuit board and the printed substrate are pre-pressed through a pre-pressing machine so as to be basically connected, then bonding pressing operations are carried out on the flexible circuit board and the printed substrate through a main-bonder cog so that the flexible circuit and the printed substrate are connected; (5) an anti-explosion membrane is attached to the product, and a bubble removing machine is used so that bubbles can be removed after the anti-explosion membrane is attached. Compared with the prior art, the layers of the touch screen can be reduced, the structure is lighter and thinner, the process is simple and low in price, materials are reduced, loss and pollution are lower, working procedures are reduced, and labor cost is reduced.

Owner:广东金龙机电有限公司

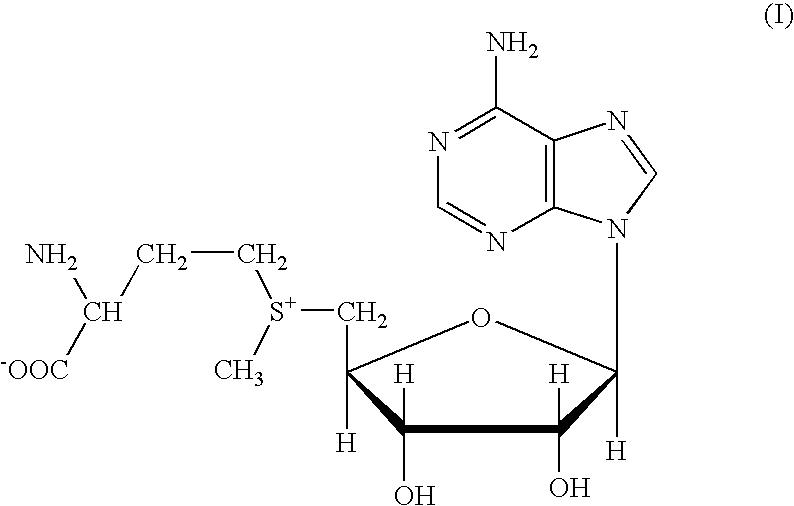

Stable granulates containing S-adenosylmethionine and process for the preparation thereof

InactiveUS7048948B2Low costShorten the timeBiocideOrganic active ingredientsS-Adenosyl methionineS-Adenosyl-l-methionine

A fluid bed granulation process for manufacturing non-hygroscopic, stable granulates containing a water-soluble salt of S-adenosylmethionine is described. Said process comprises:a) the simultaneous, sequential or alternate dispersion of at least a solution of a water-soluble salt of SAMe (A) and of a solution of a coating agent (B), on a fluid bed granulation carrier (C) andb) the fluid bed granulation of the mixture.Granulates obtainable by said process and solid oral pharmaceutical forms obtainable by said granulates are disclosed.

Owner:CHEM & HEALTH INT

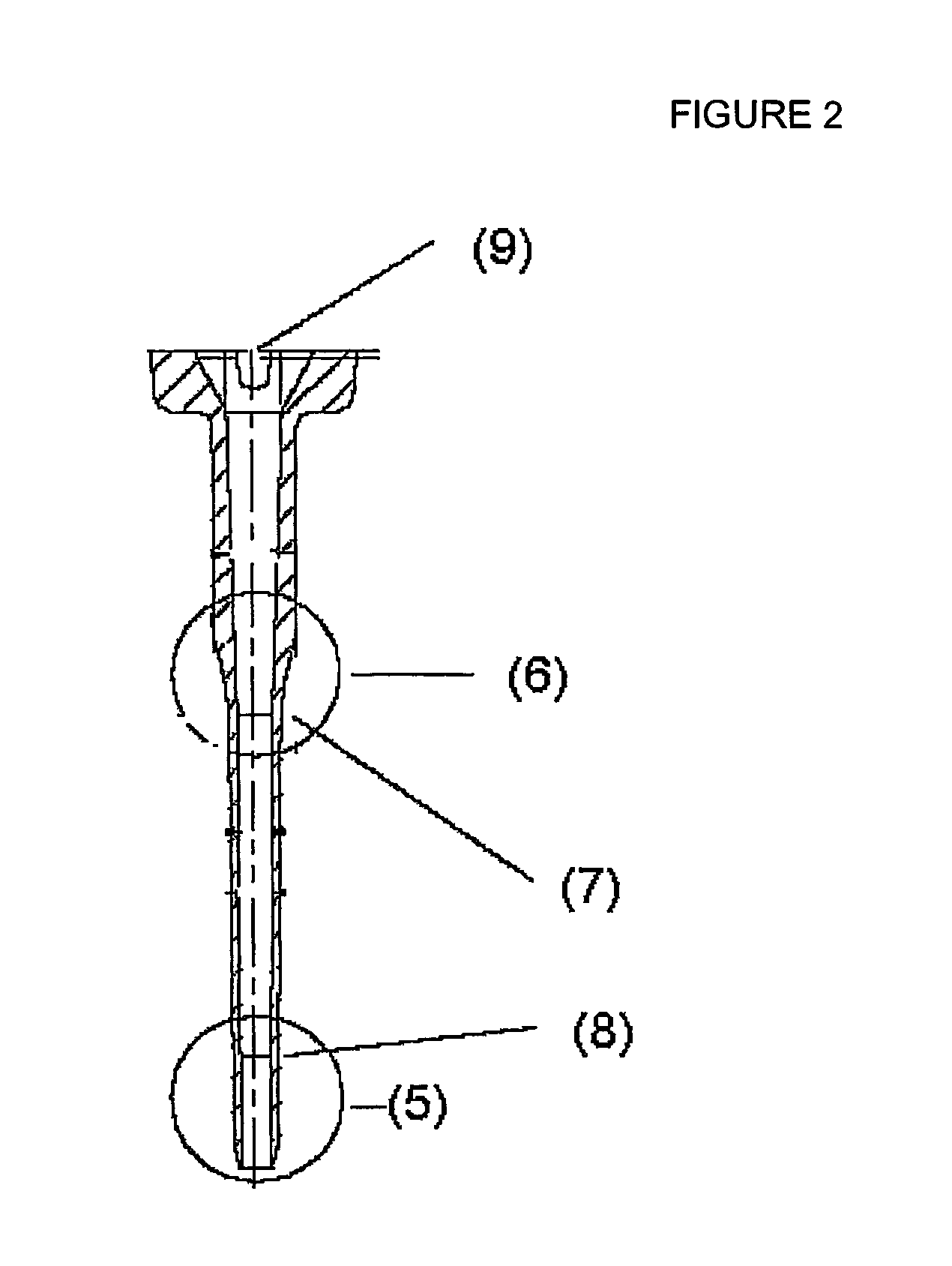

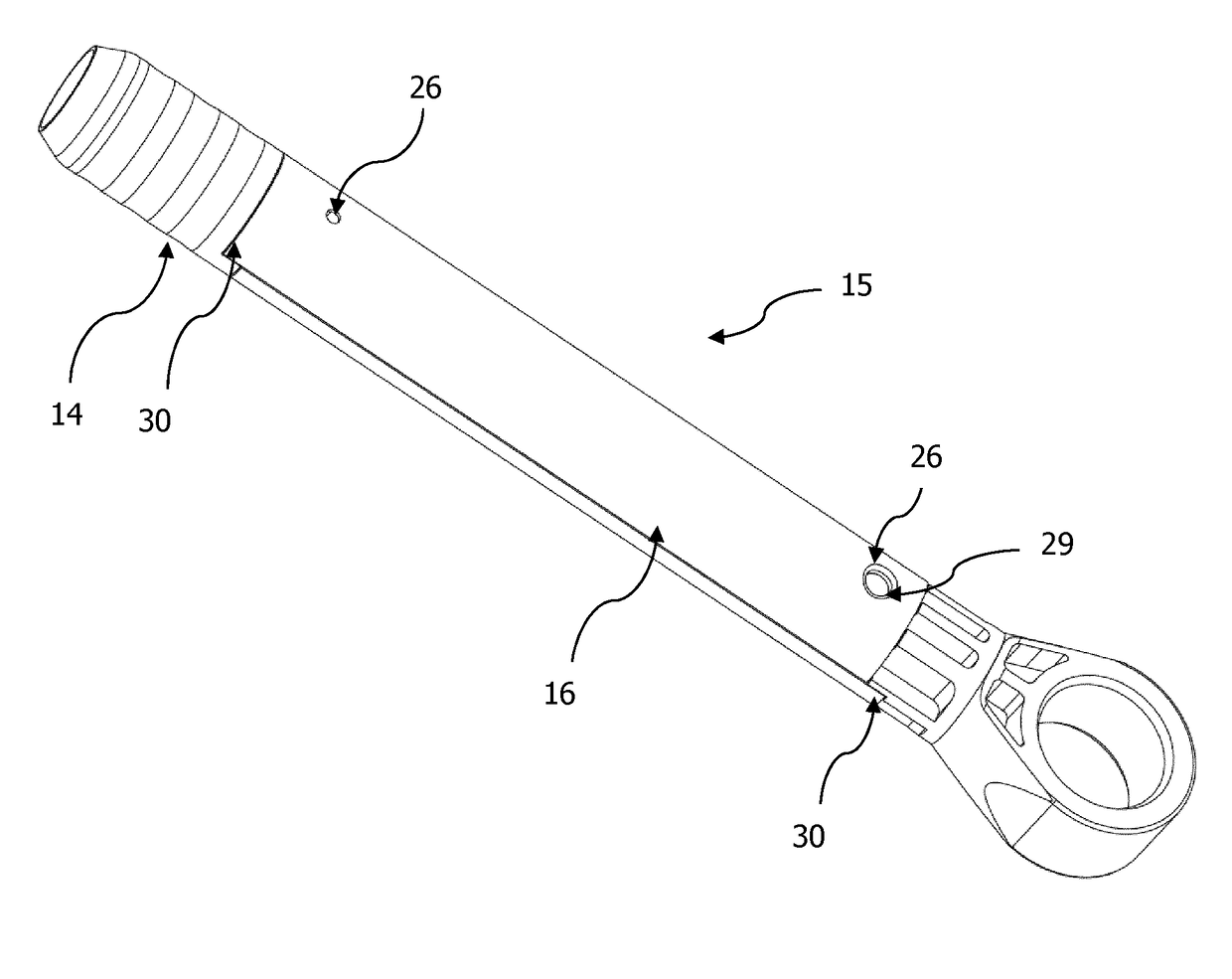

Injection moulding of a catheter

ActiveUS7887737B2Simple and cheap processDischarging arrangementMouldsInjection mouldingCatheter device

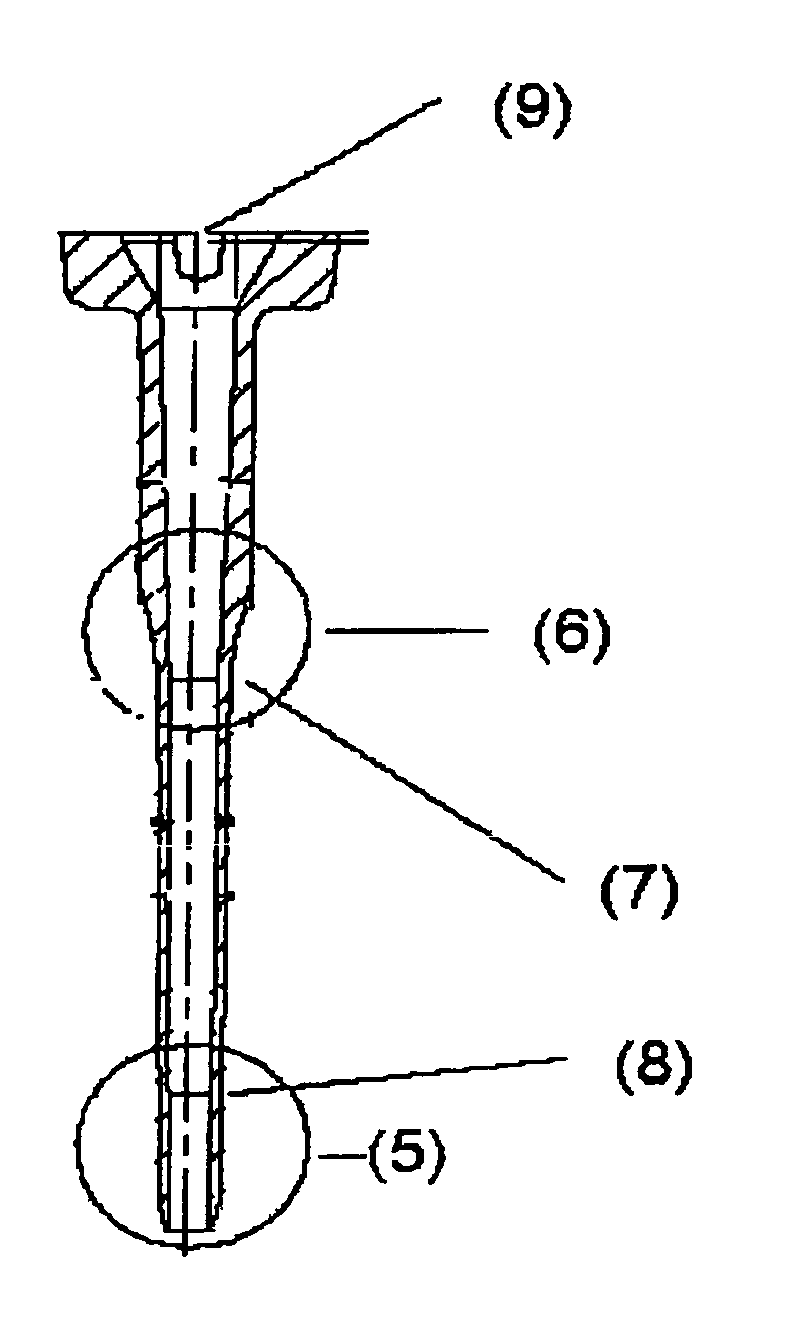

A method for producing a one-piece catheter comprising a hub (3) and a tube-shaped flexible part (4) wherein the tube shaped flexible part (4) has an interior which is divided in two region one being cone-shaped (7-8) and one being cylindrical (5). A one-piece catheter of the above mentioned kind and a mould for moulding such catheter.

Owner:UNOMEDICAL AS

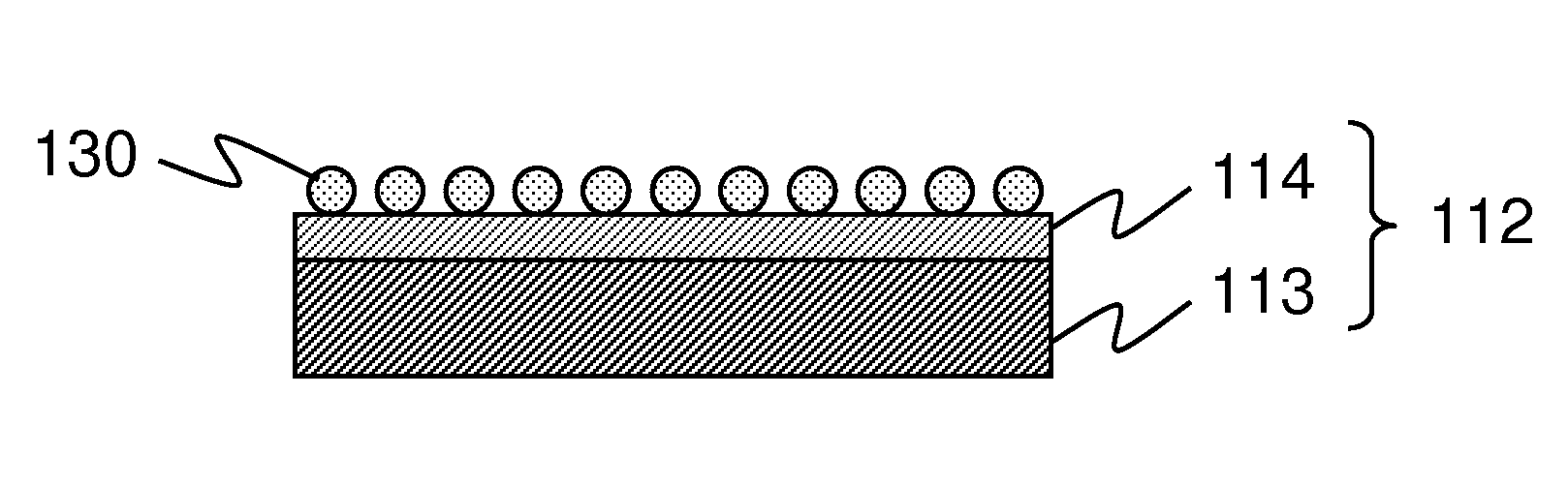

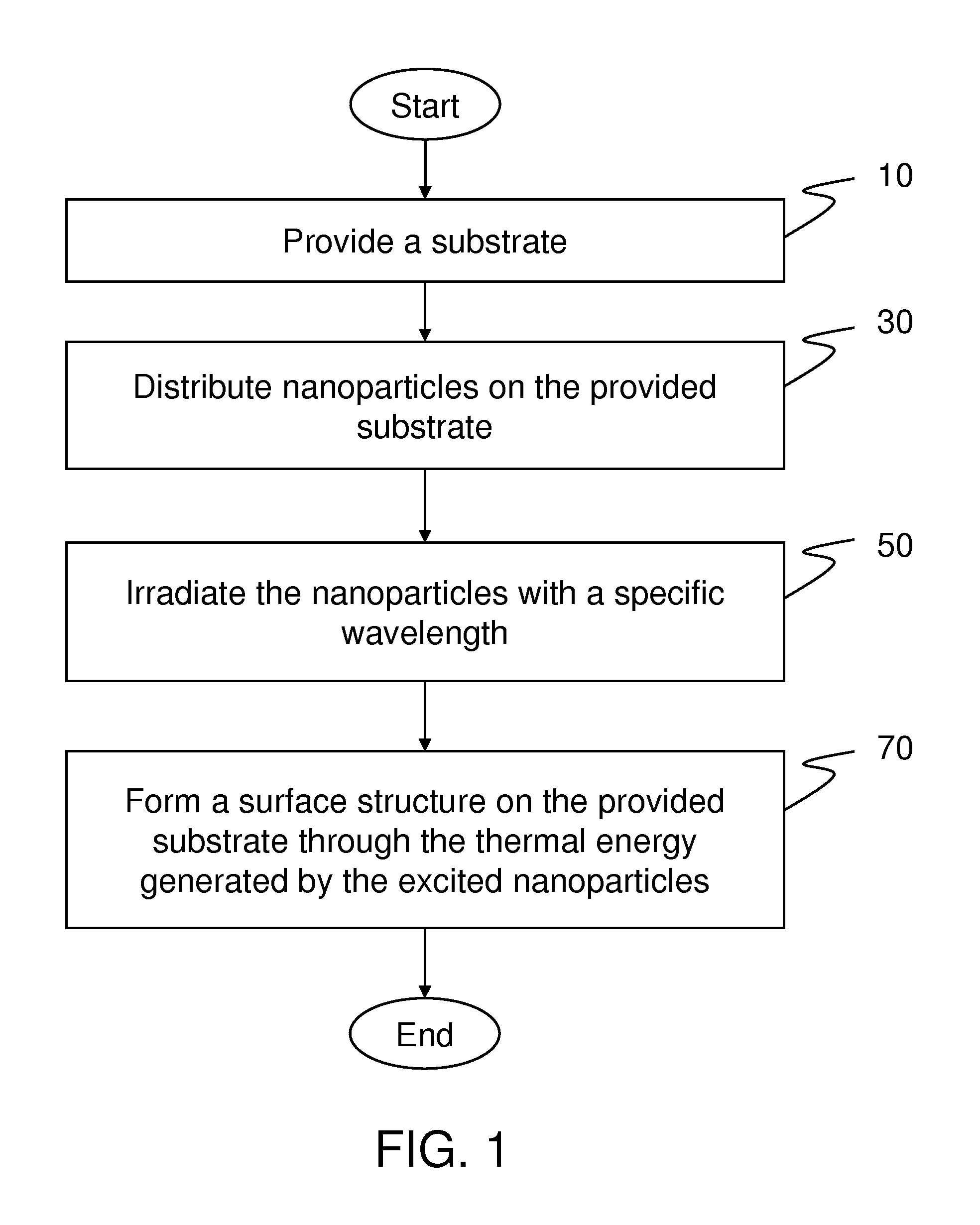

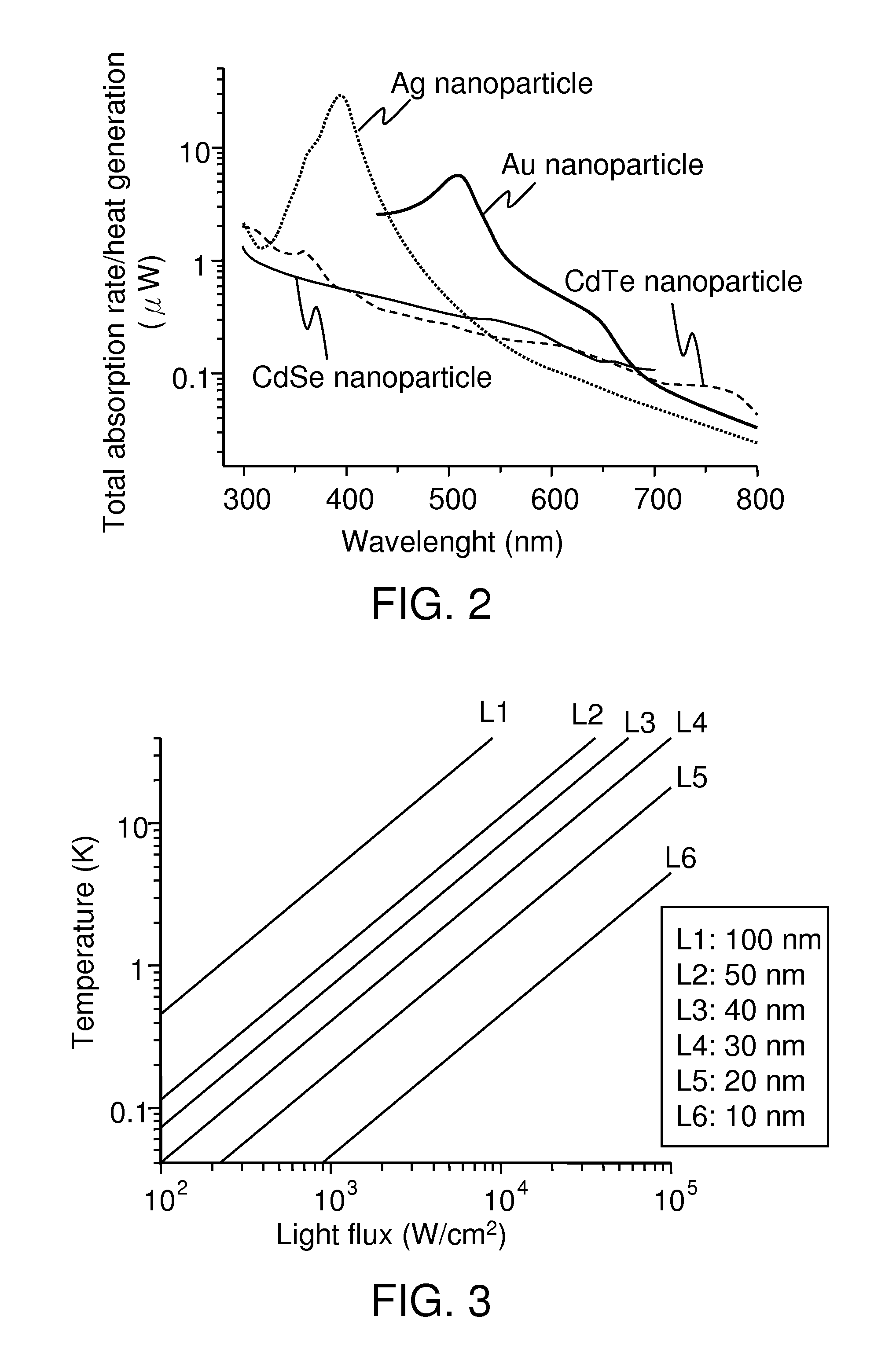

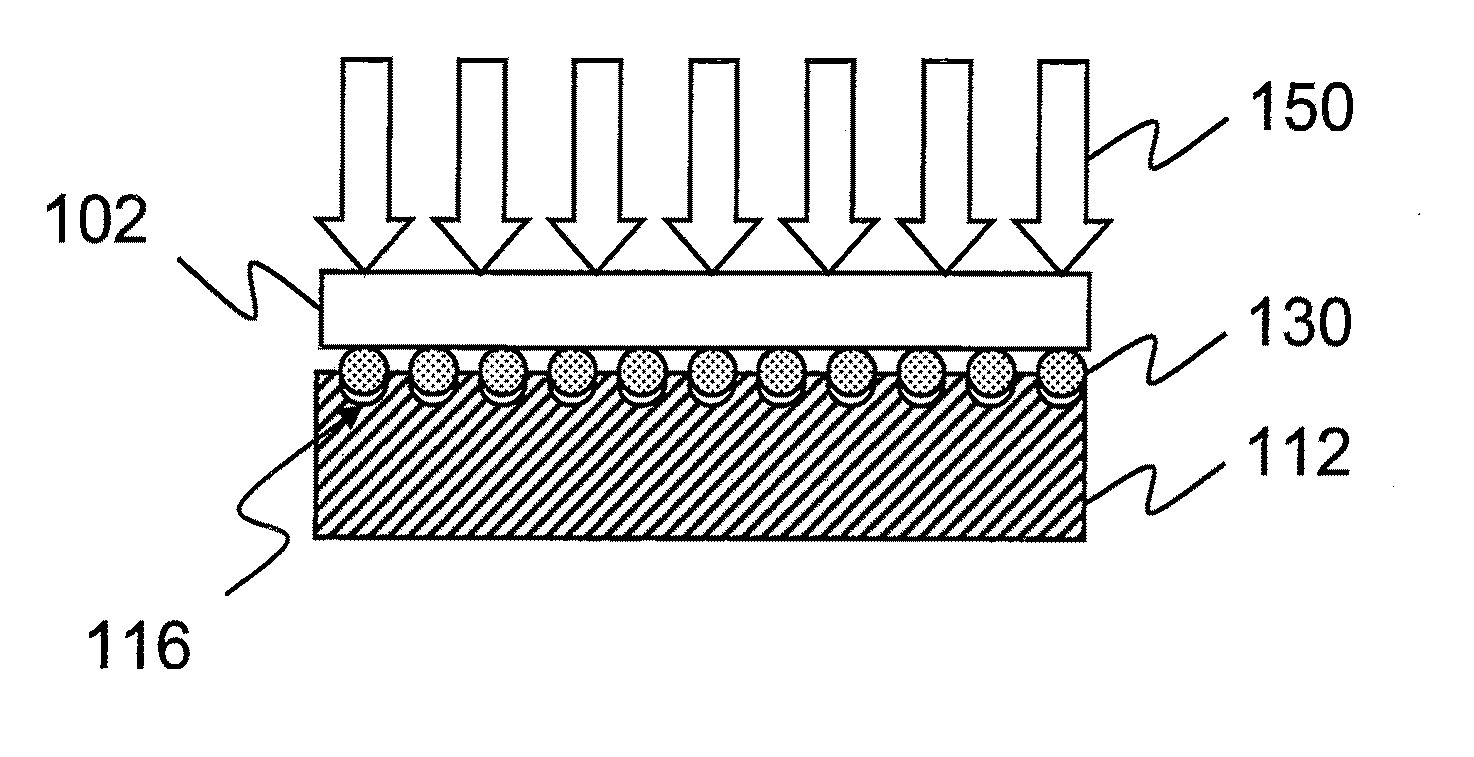

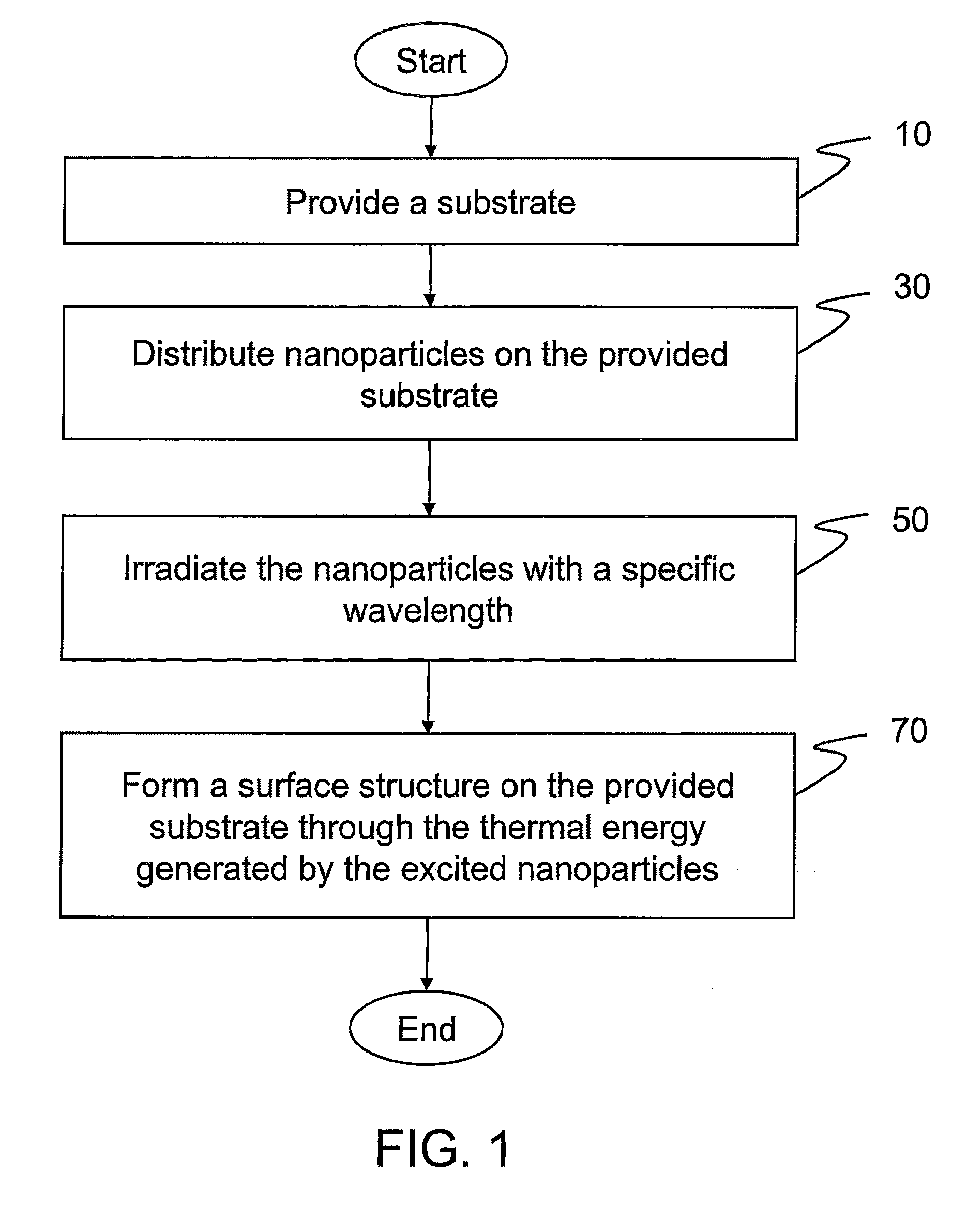

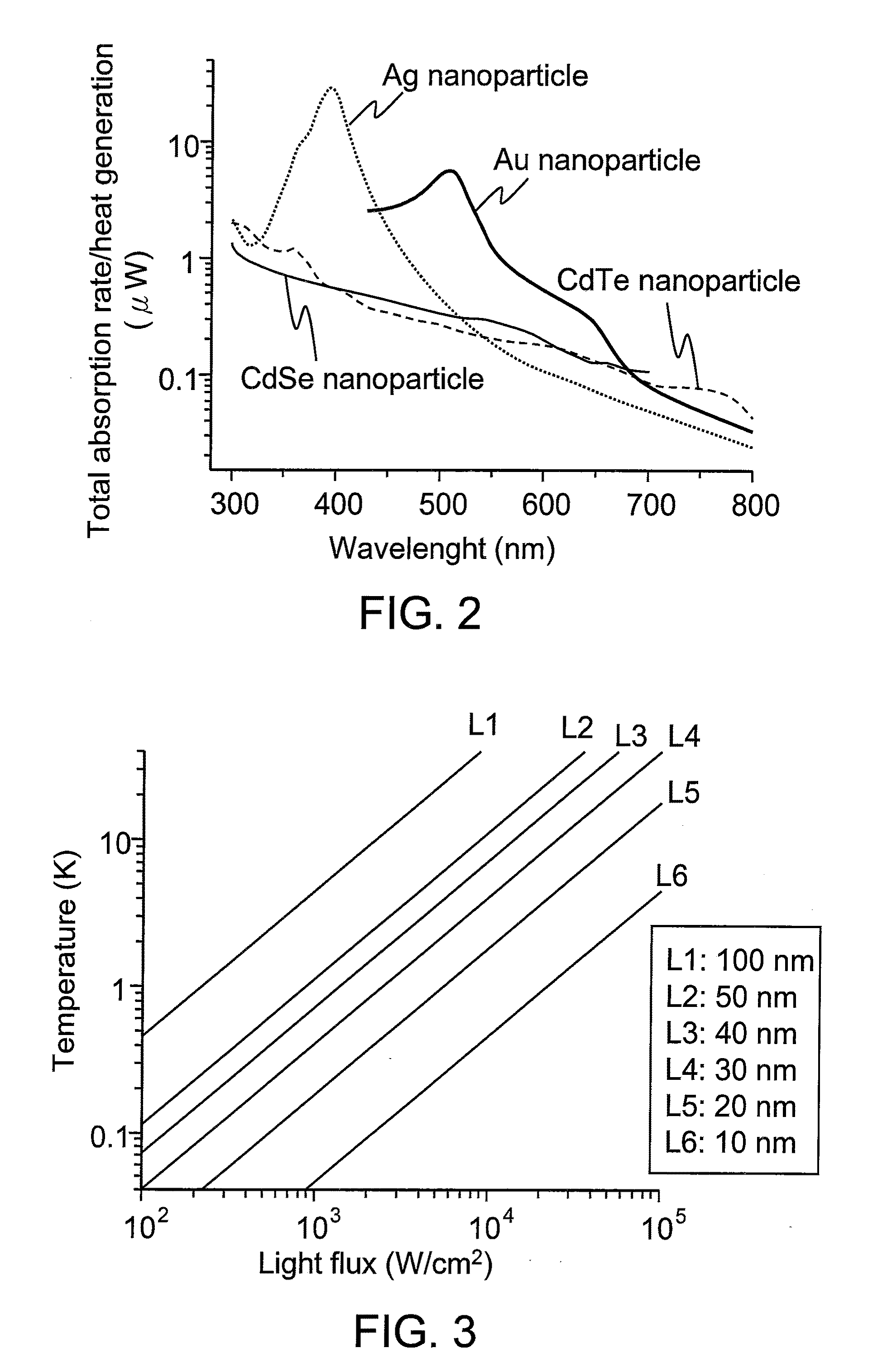

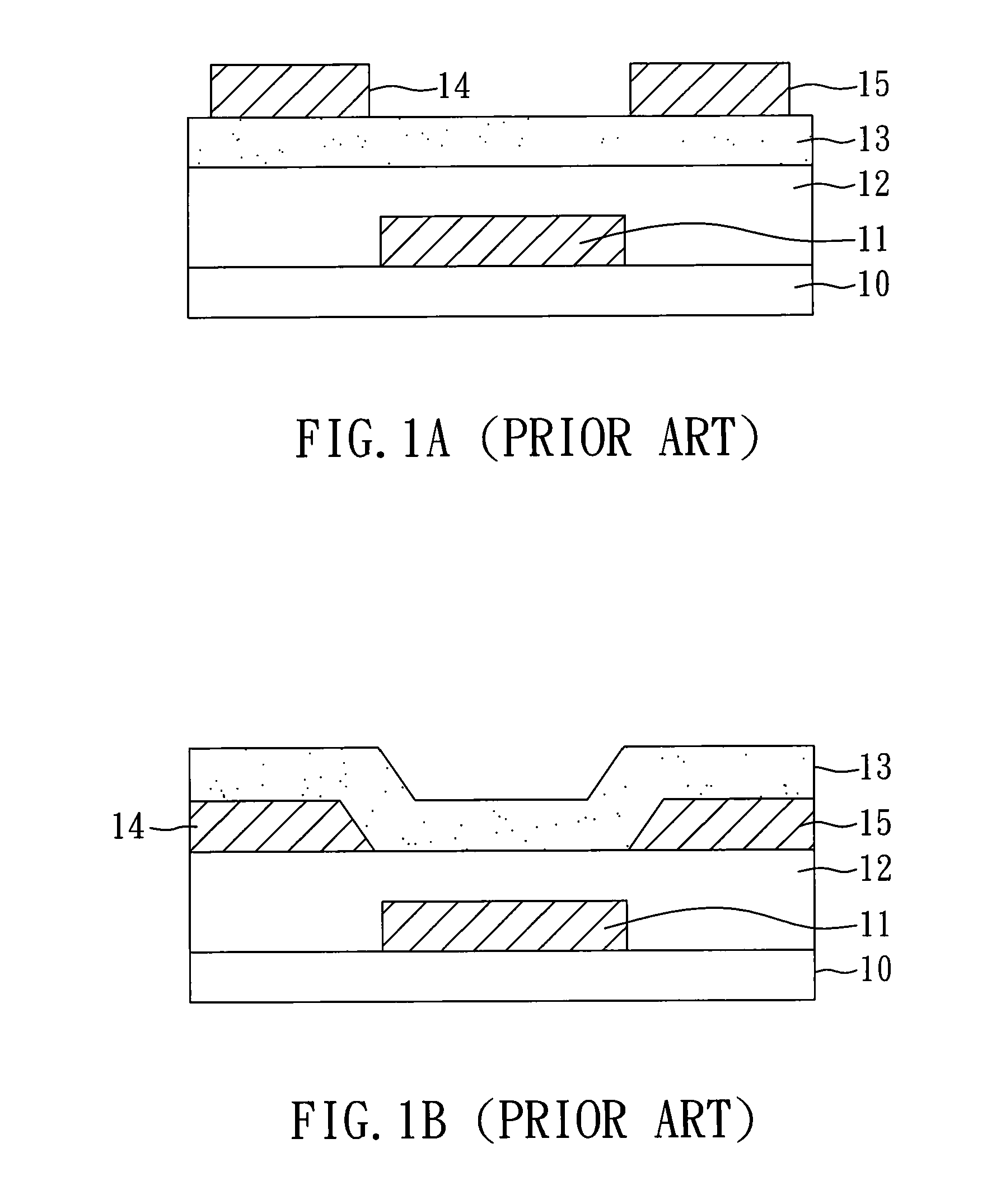

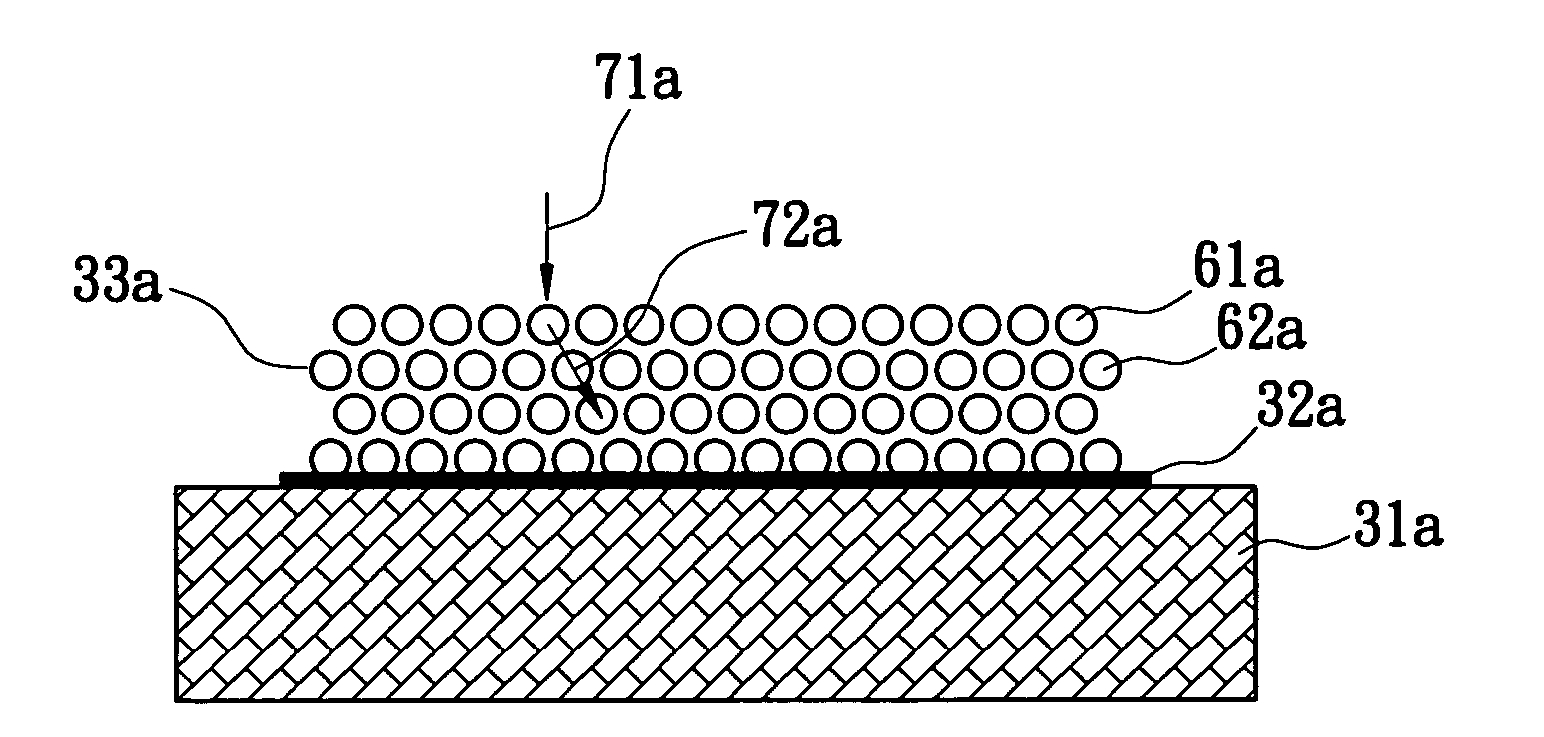

Method for manufacturing a substrate with surface structure by employing photothermal effect

InactiveUS20120009353A1Simple and cheap processIncrease the areaNanoinformaticsPhotomechanical apparatusThermal energyLight energy

A manufacturing method for manufacturing a substrate with a surface substrate by employing photothermal effect is described. Nanoparticles on the surface of the substrate excited by a beam convert light energy to thermal energy. The surface structure on the substrate is formed through the thermal energy generated by the excited nanoparticles. The substrate with a layer of the predetermined pattern is thus formed.

Owner:IND TECH RES INST

Method for manufacturing a substrate with surface structure by employing photothermal effect

InactiveUS20090269505A1Low costSimple methodNanoinformaticsPretreated surfacesThermal energyLight energy

A method for manufacturing a substrate with a surface substrate by employing photothermal effect is described. Nanoparticles on the surface of the substrate excited by a beam convert light energy to thermal energy. The surface structure on the substrate is formed through the thermal energy generated by the excited nanoparticles. The substrate with a layer of the predetermined pattern is thus formed.

Owner:IND TECH RES INST

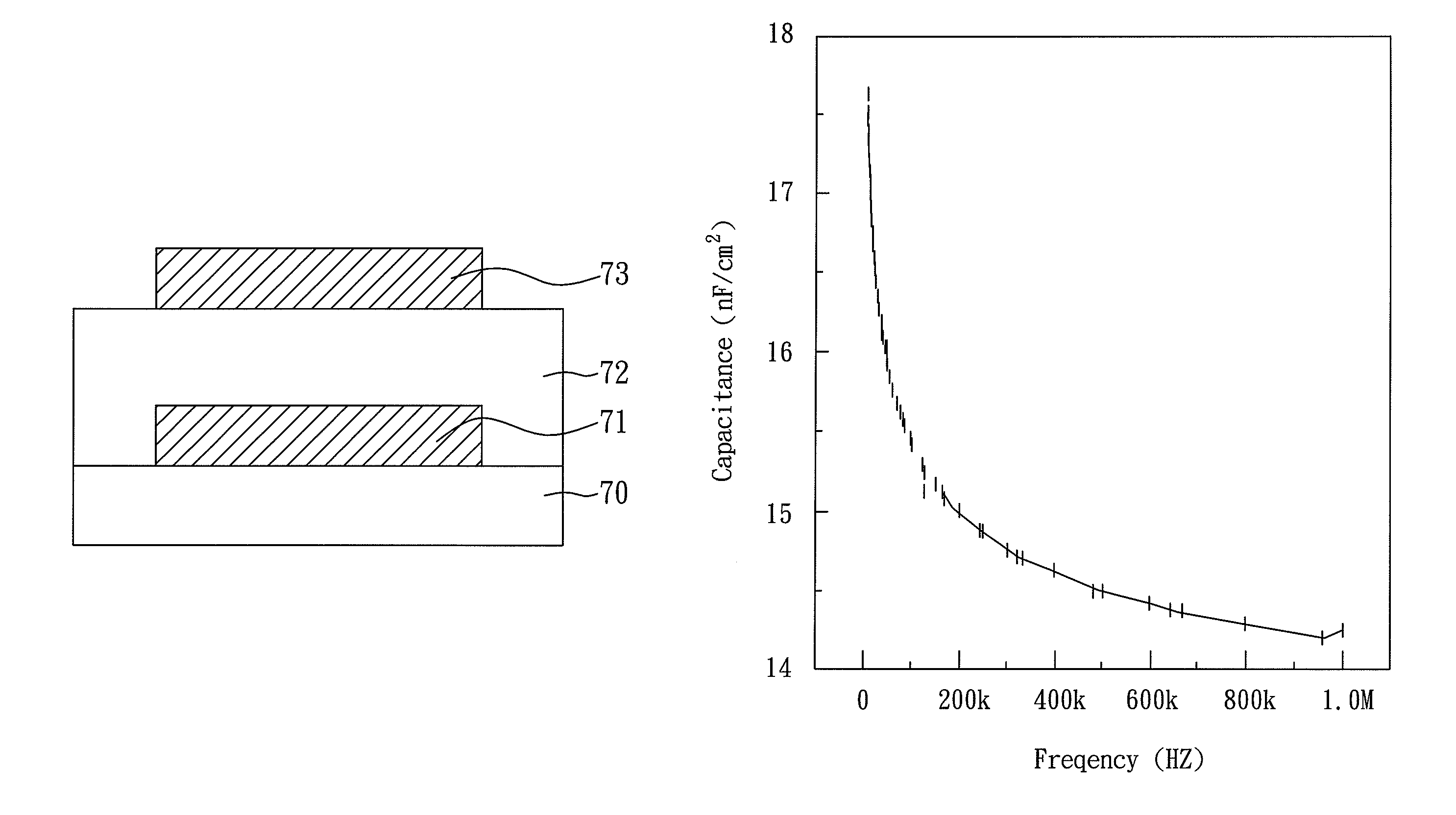

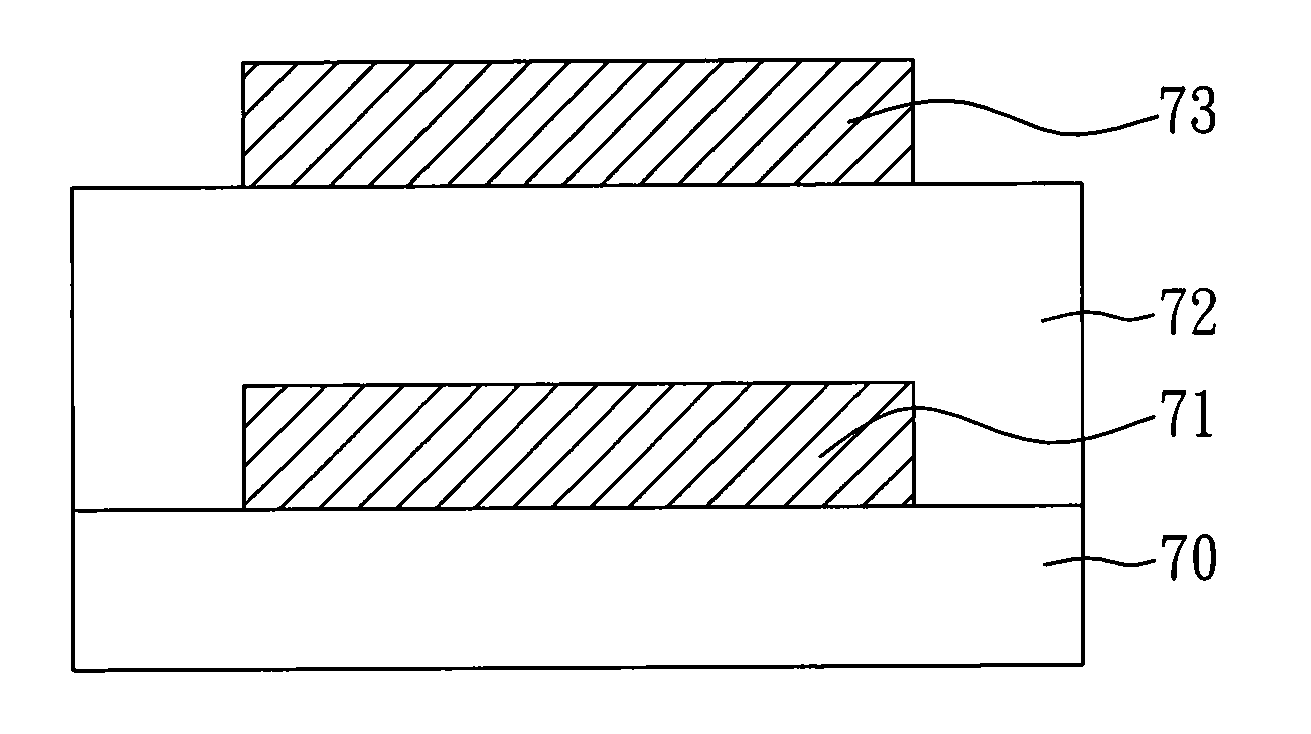

OTFT and MIM capacitor using silk protein as dielectric material and methods for manufacturing the same

InactiveUS8129716B2Improve efficiencySimple and cheap processNanoinformaticsSolid-state devicesMetal-insulator-metalEngineering

An organic thin film transistor (OTFT) and a metal-insulator-metal (MIM) capacitor using silk protein as a dielectric material, and methods for manufacturing the same are disclosed. The OTFT of the present invention comprises: a substrate; a gate electrode disposed on the substrate; a gate insulating layer containing silk protein, which is disposed on the substrate and covers the gate electrode; an organic semiconductor layer; and a source electrode and a drain electrode, wherein the organic semiconductor layer, the source electrode and the drain electrode are disposed over the gate insulating layer.

Owner:NATIONAL TSING HUA UNIVERSITY

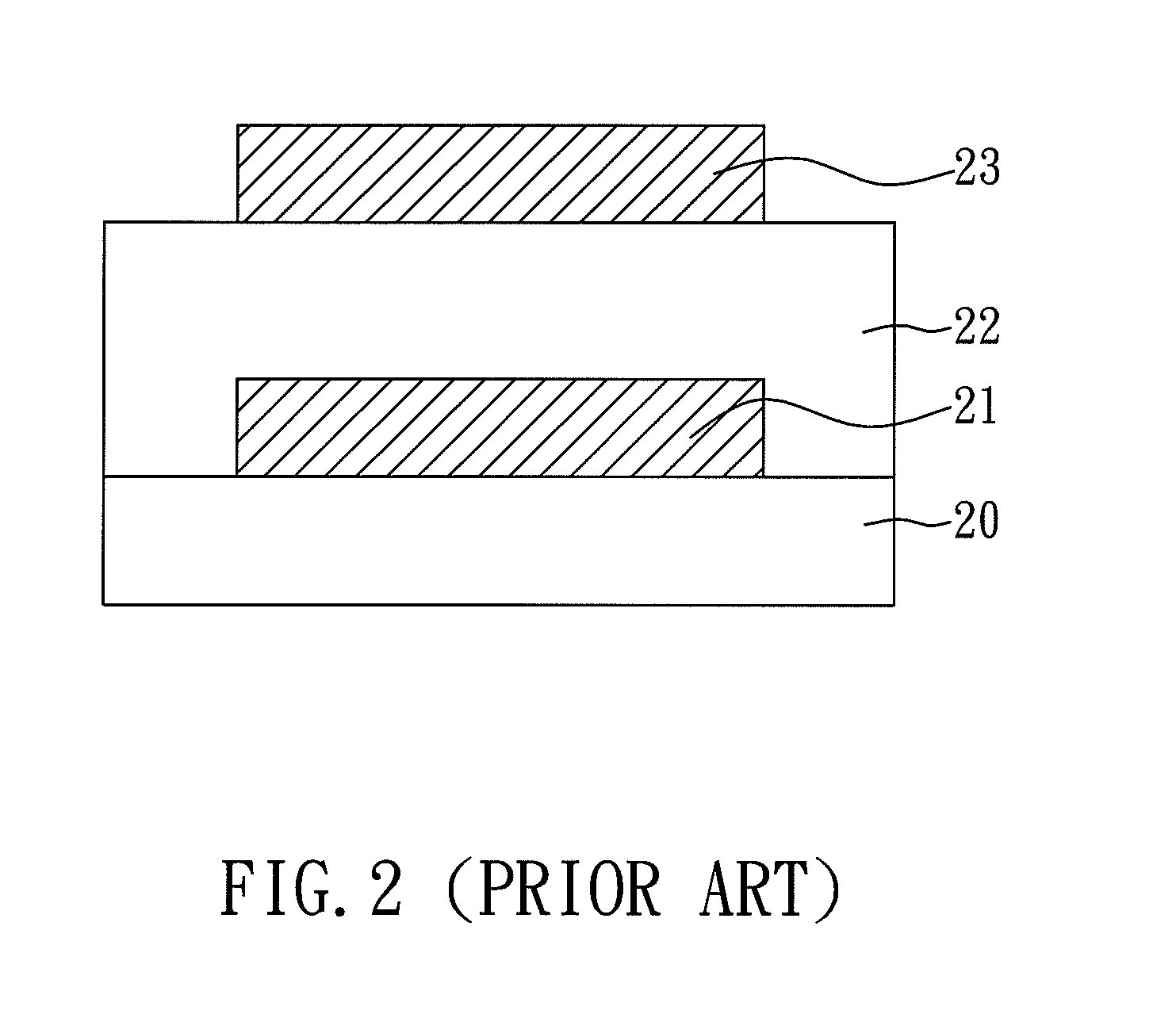

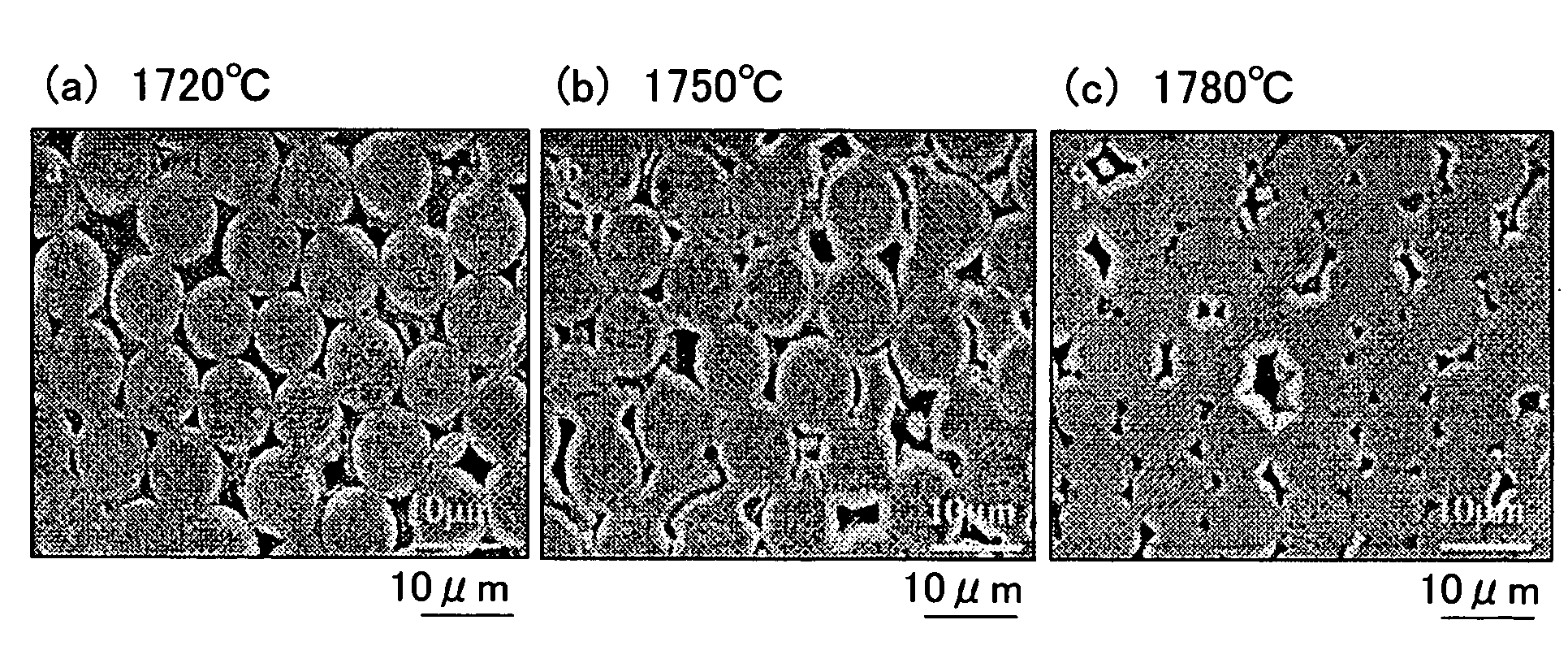

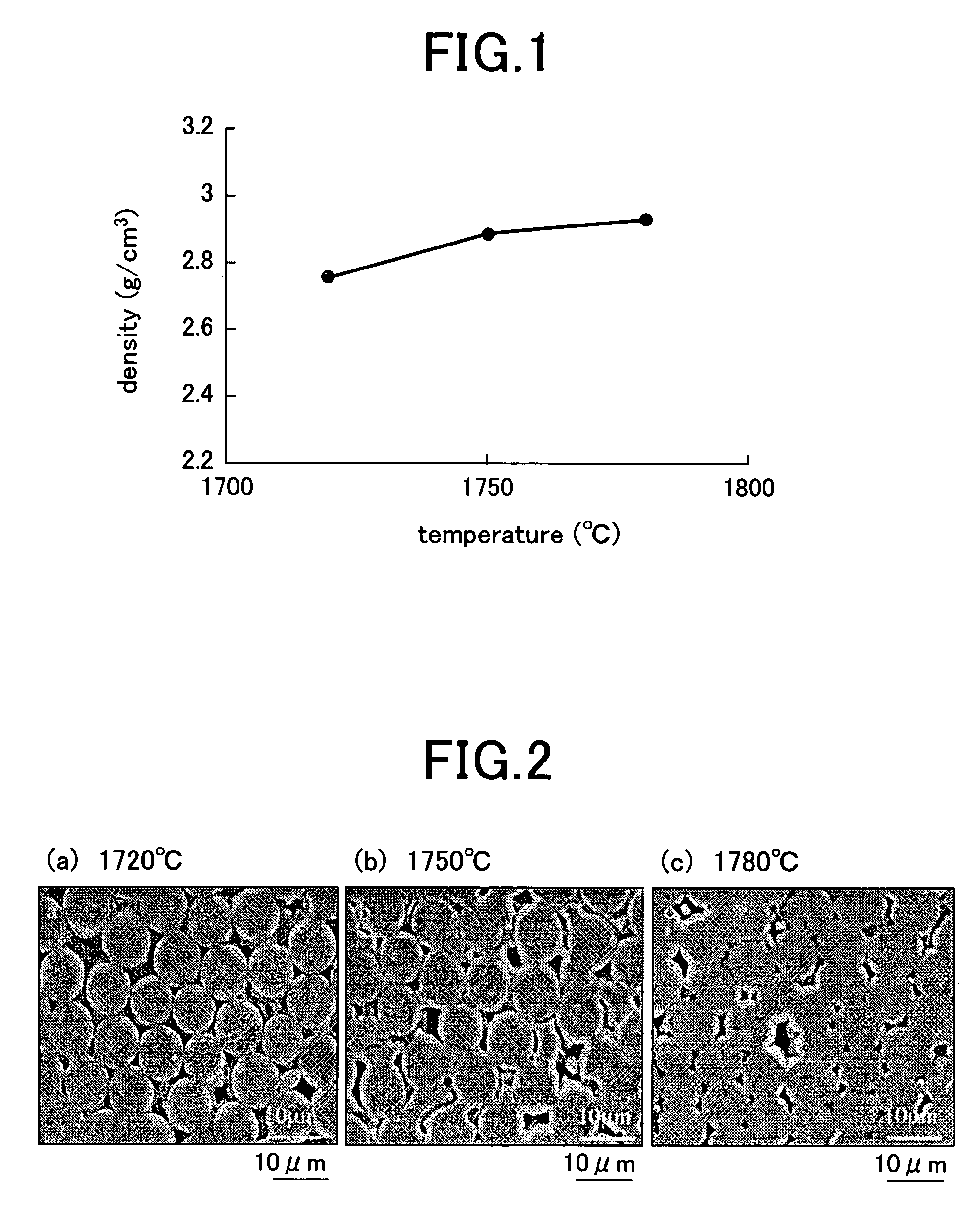

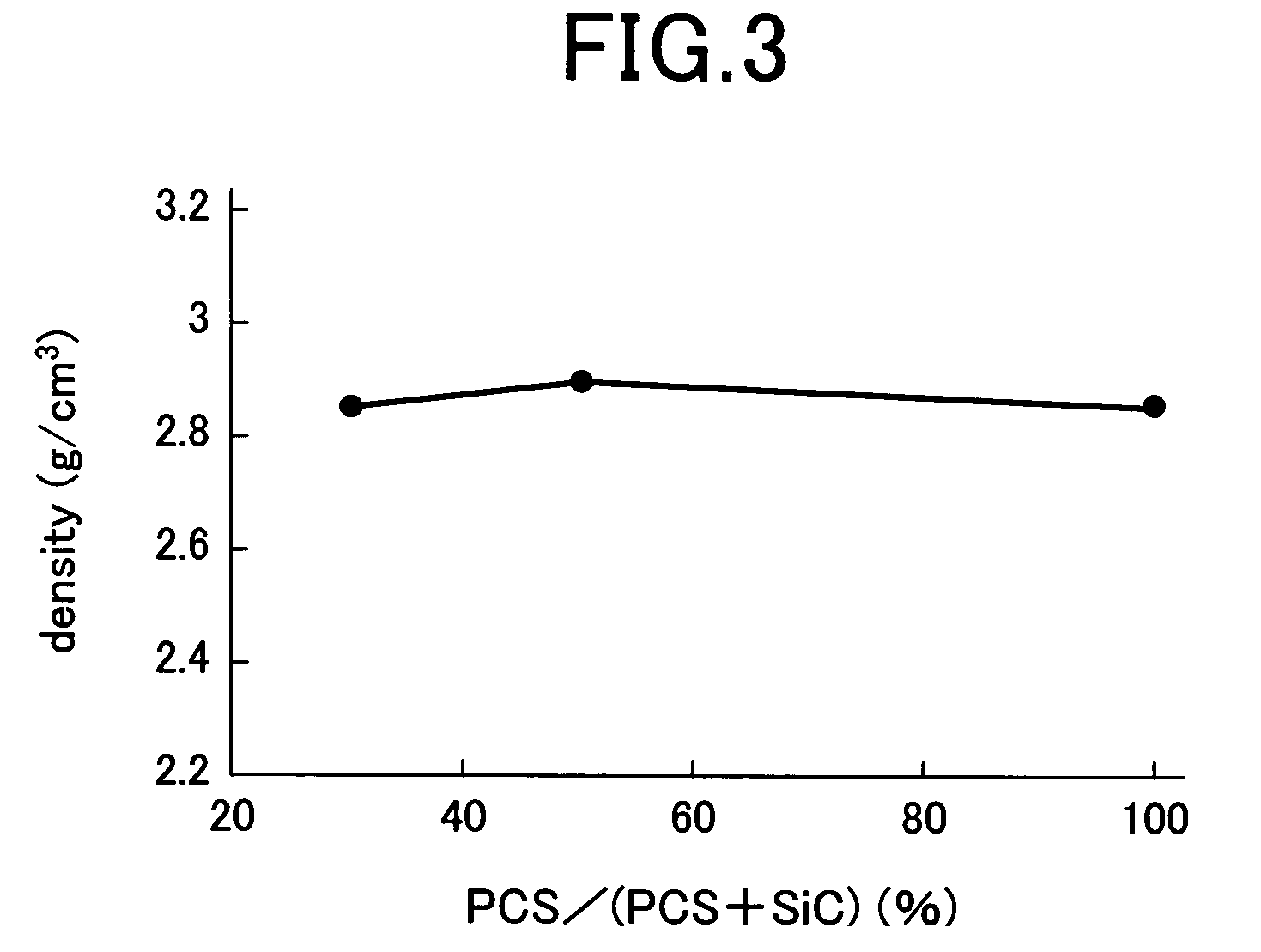

Method for producing SiC fiber-reinforced SiC composite material by means of hot press

InactiveUS7404922B2Improve mechanical propertiesSimple and cheap hot-pressing processMaterial nanotechnologyCeramic shaping apparatusPowder mixtureSlurry

A powdery mixture of fine SiC powder with one or more oxide sintering additives of Al2O3, Y2O3, SiO2 and CaO is blended and uniformly dispersed in a polymeric SiC precursor to prepare a matrix-forming polymeric slurry. A preform of SiC fiber, which has quasi-stoichiometric composition with high crystallinity, is impregnated with the polymeric slurry and then hot-pressed at a temperature of 1600° C. or higher in presence of a liquid phase. Since the heat-resistant SiC fiber is used as strengthening fiber, the prepreg is sintered to a dense SiC composite excellent in mechanical properties by one-step hot-pressing.

Owner:JAPAN SCI & TECH CORP

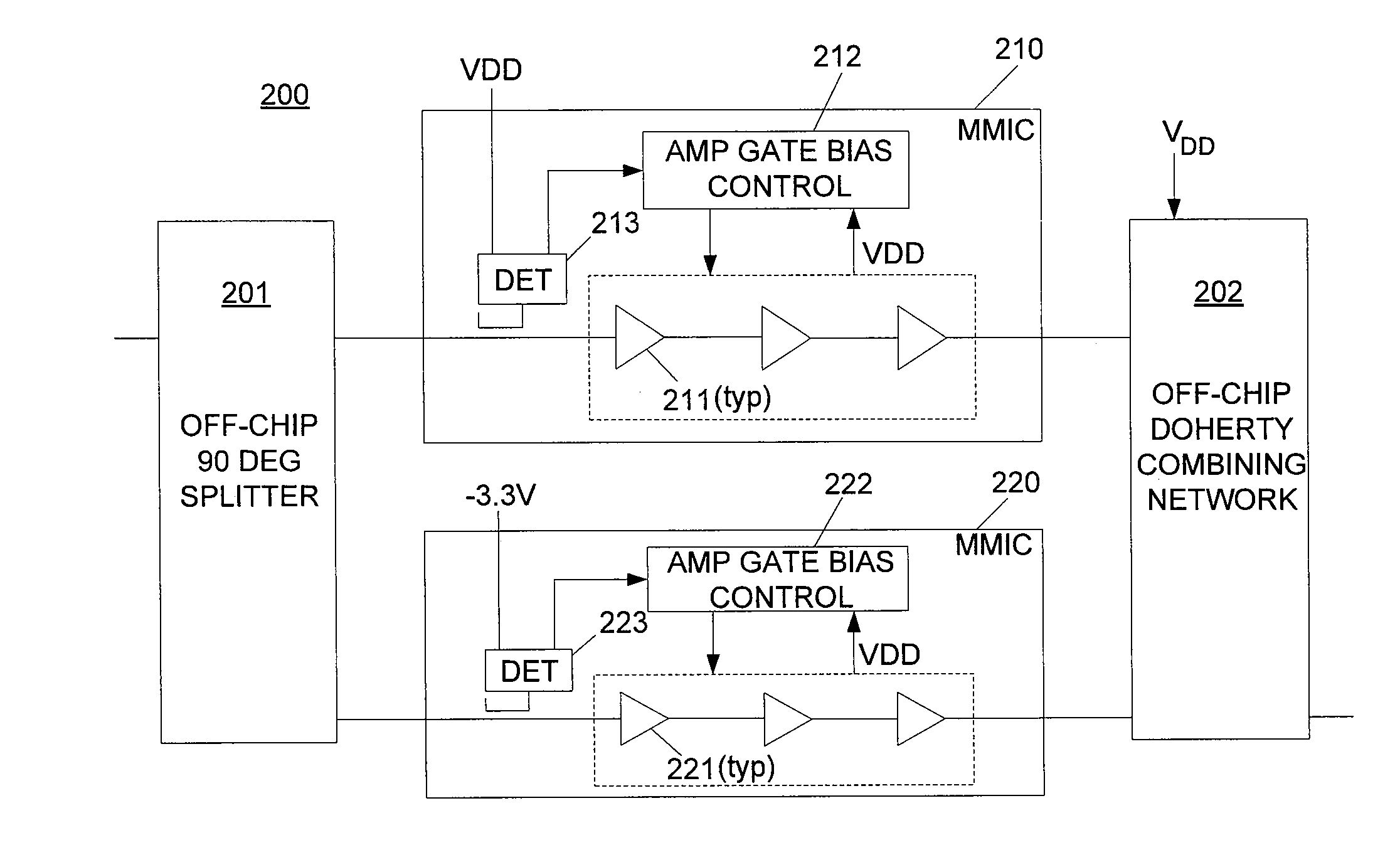

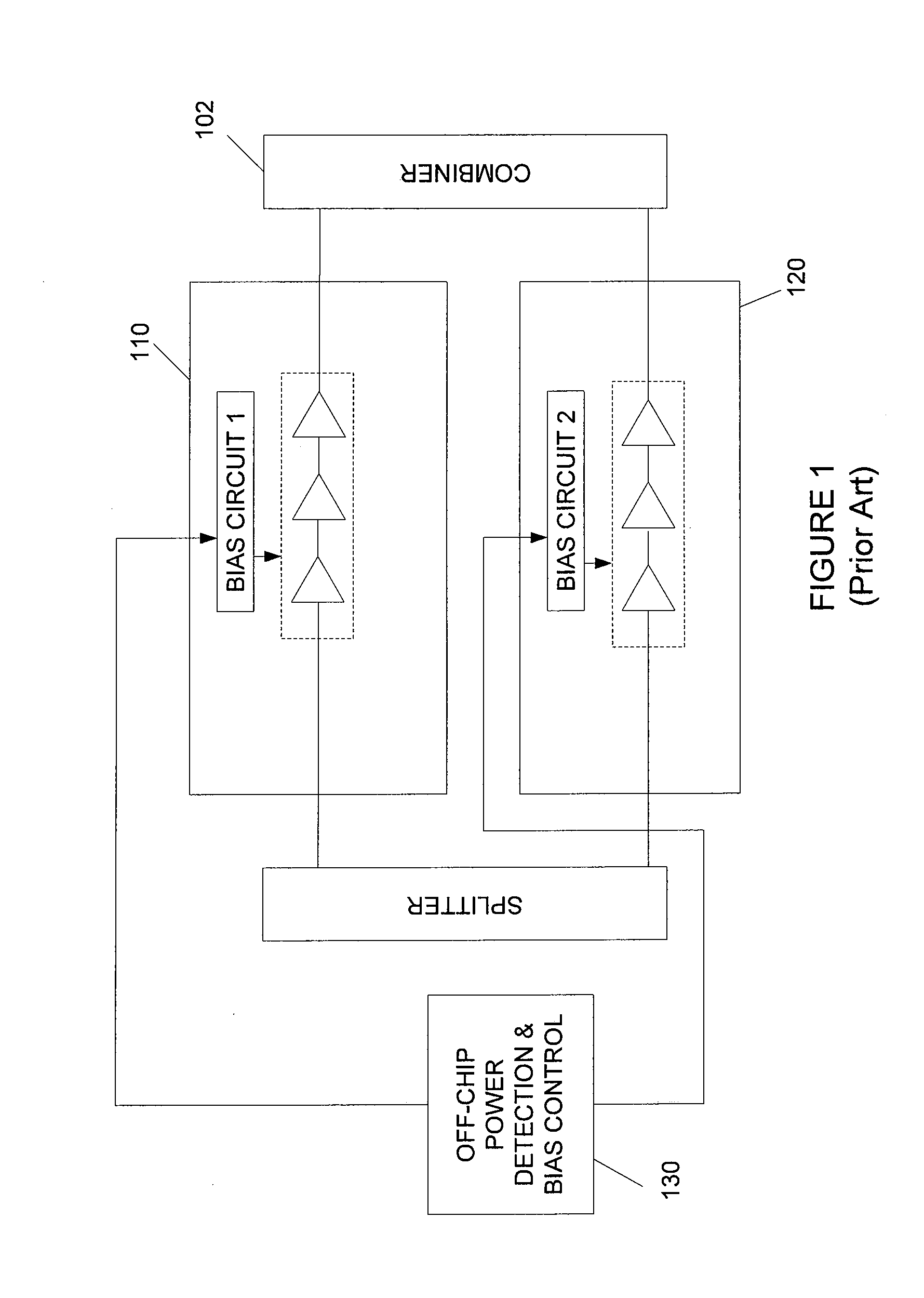

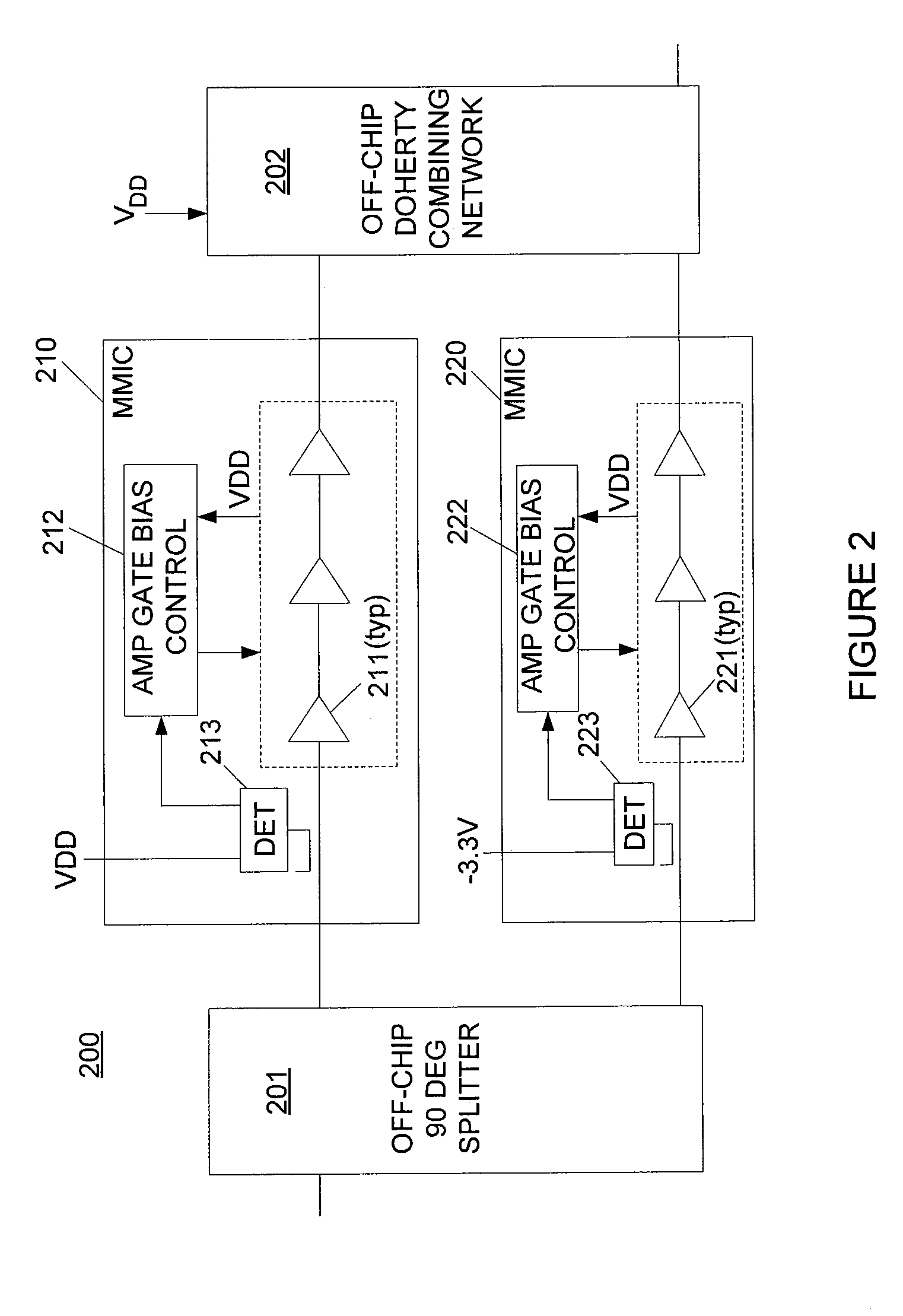

Multi-chip doherty amplifier with integrated power detection

ActiveUS20110248784A1Simple and cheap processSave design cost and production costAmplifier combinationsAmplifier detailsRadio frequencyDoherty amplifier

In accordance with an exemplary embodiment of the present invention, a Doherty amplifier is provided for applications in radio frequency, microwave, and other electronic systems. An exemplary Doherty amplifier comprises a first MMIC having a first power detector, and a second MMIC having a second power detector. The first MMIC and the second MMIC are structurally identical. Furthermore, the first MMIC is configured as a carrier amplifier and the second MMIC is configured as a peaking amplifier. In the exemplary embodiment, an amplifier control bias of the carrier amplifier is a function of the power detected by the first power detector and an amplifier control bias of the peaking amplifier is a function of the power detected by the second power detector. The ability to assemble a Doherty amplifier using a single MMIC product results in a simple and less expensive manufacturing process.

Owner:VIASAT INC

Coating composition and uses thereof

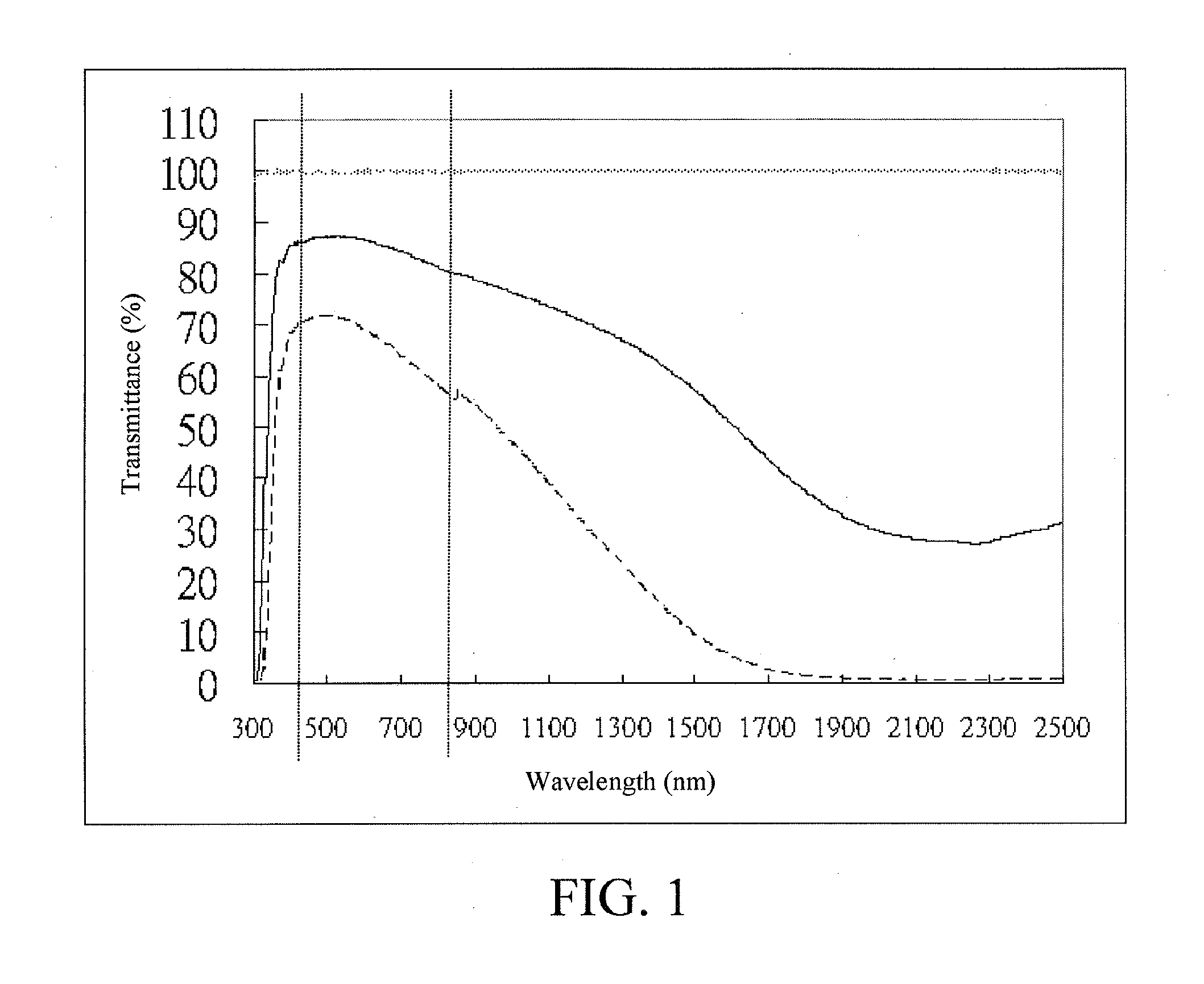

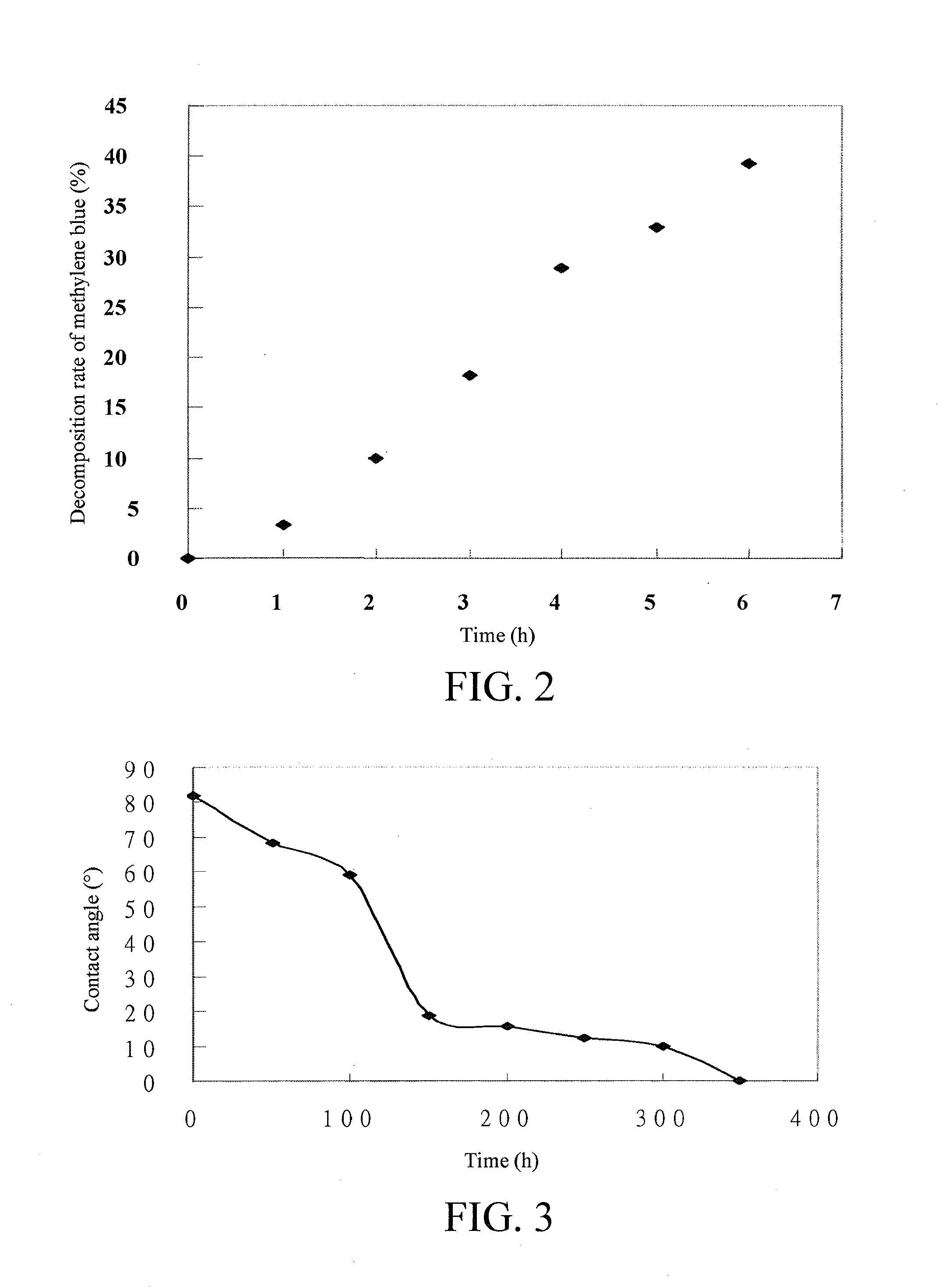

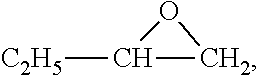

InactiveUS20120168666A1Reduce transmittanceSimple and cheap processClimate change adaptationChemical industryUltraviolet lightsCompound s

A coating composition comprising a photocatalyst composite and a silicone resin is provided, in which the content of the photocatalyst composite ranges from about 1% to about 70% by weight (wt %), based on the total weight of the coating composition, and the photocatalyst composite contains a heat insulation material and a photocatalyst material. An energy-saving material is further provided, which includes a substrate and a film formed from the coating composition of the present invention on at least one of the surfaces of the substrate. The energy-saving material is capable of effectively shielding off infrared (IR) light, substantially decreasing indoor temperature, and reducing power consumption. In addition, in the presence of the photocatalyst which can absorb ultraviolet light, the material also exhibits good superhydrophilic and self-cleaning properties and provides antimicrobial and deodorization effects.

Owner:ETERNAL MATERIALS CO LTD

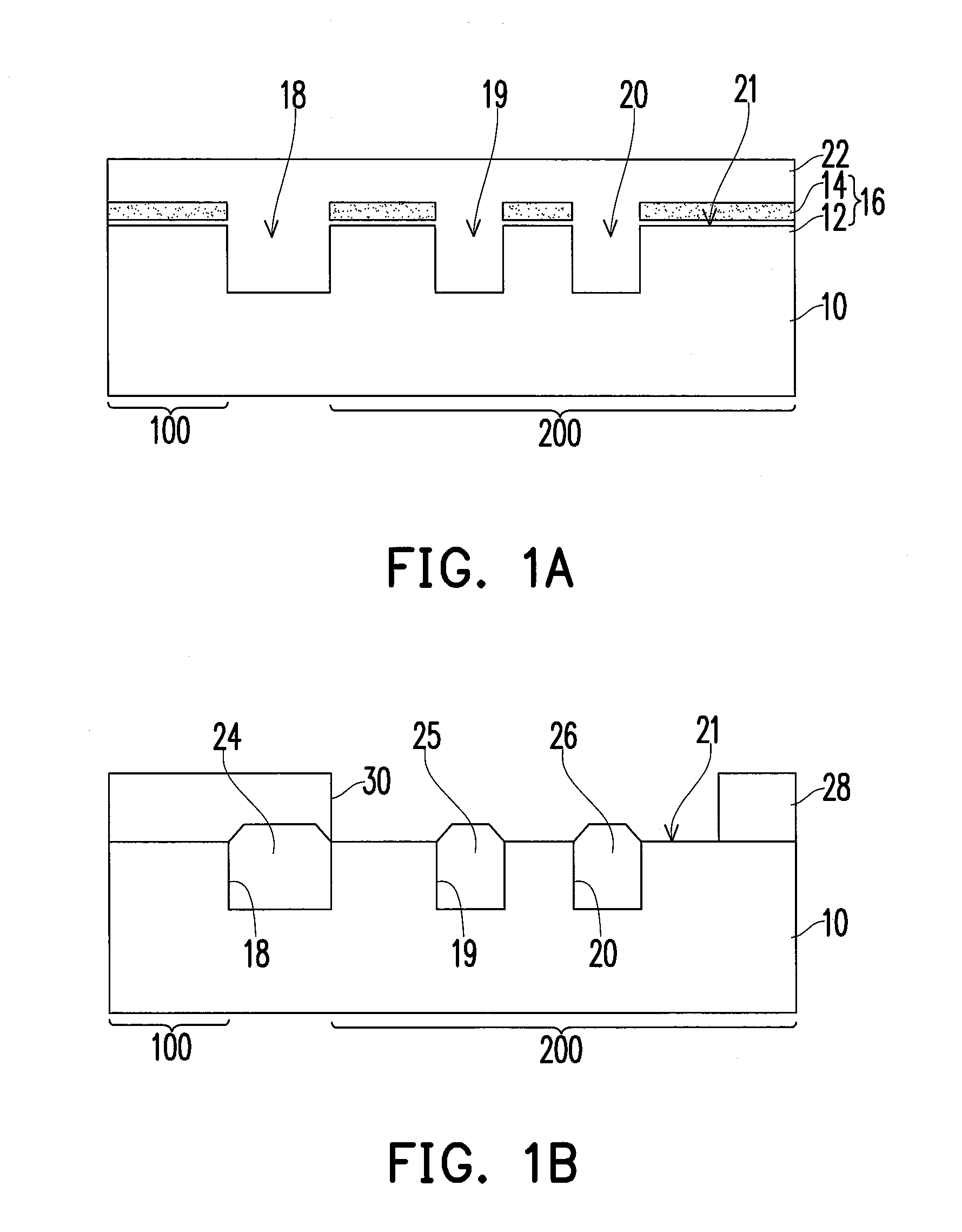

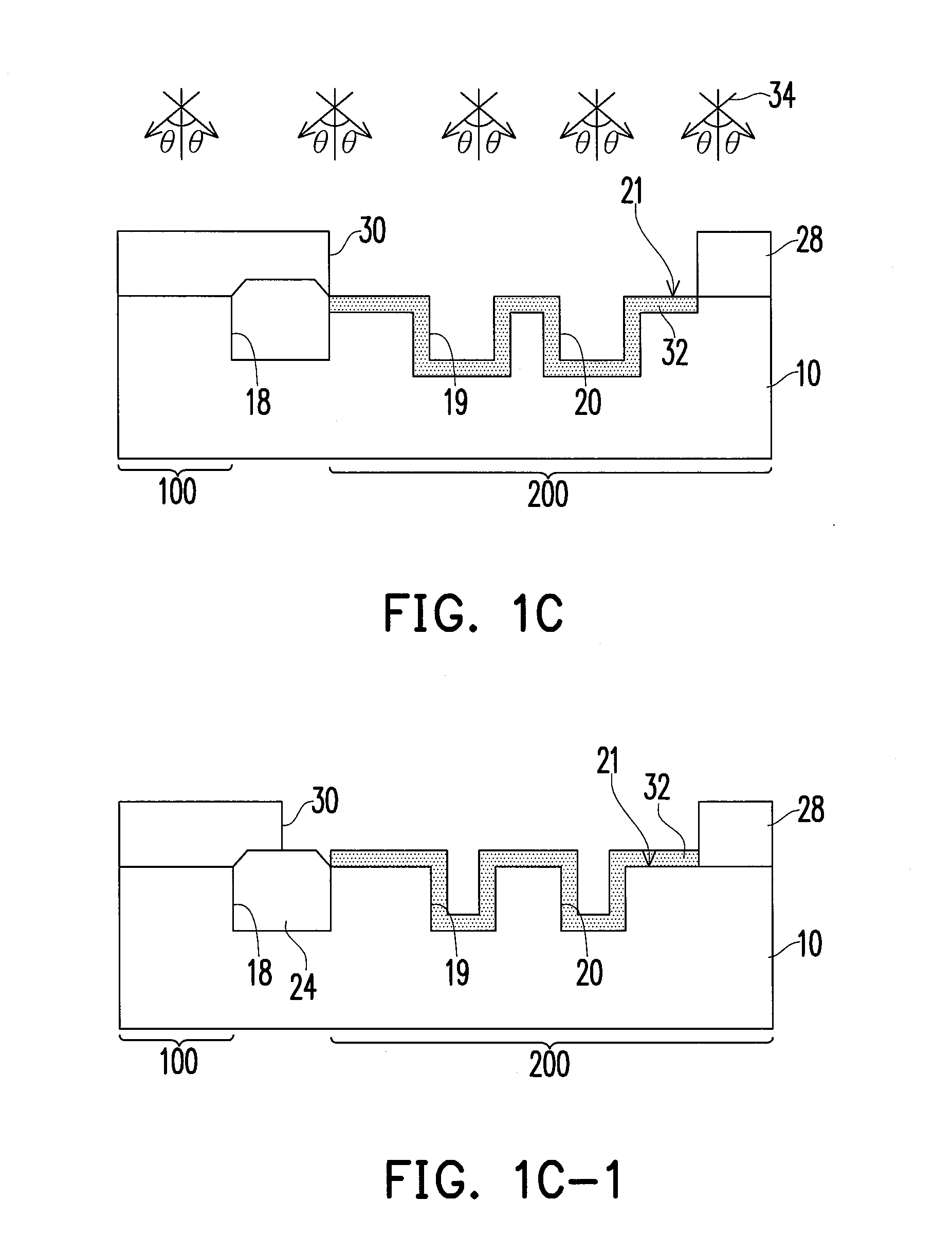

Method of fabricating non-volatile memory device

InactiveUS20120264264A1Coupling efficiency is improvedSimple and cheap processSolid-state devicesSemiconductor/solid-state device manufacturingDielectric layerVolatile memory

A method of fabricating a non-volatile memory device is provided. A substrate including a first region and a second region is provided. Then, an uneven surface is formed on the substrate in the second region. Thereafter, a doped layer is formed in the substrate in the second region, and the doped layer is served as a control gate. Afterward, a dielectric layer is formed on the substrate in the first region and on the uneven surface of the substrate in the second region. Next, a floating gate is formed on the dielectric layer, and the floating gate is extended from the first region to the second region. Source and drain regions are formed in the substrate at opposite sides of the floating gate in the first region.

Owner:MAXCHIP ELECTRONICS CORP

Electronic grade silk solution, otft and MIM capacitor with silk protein as insulating material and methods for manufacturing the same

InactiveUS20110253984A1Improve performanceSimple and cheap processPeptide/protein ingredientsFixed capacitor dielectricCapacitanceEngineering

An electronic grade silk solution, an organic thin film transistor (OTFT) and a metal-insulator-metal capacitor with silk protein as the insulating material manufactured by use of the silk solution, and methods for manufacturing the same are disclosed. The OTFT of the present invention comprises: a substrate; a gate disposed on the substrate; a gate insulating layer containing silk protein, which is disposed on the substrate and covers the gate; an organic semiconductor layer; and a source and a drain, wherein the organic semiconductor layer, the source and the drain are disposed over the gate insulating layer.

Owner:NATIONAL TSING HUA UNIVERSITY

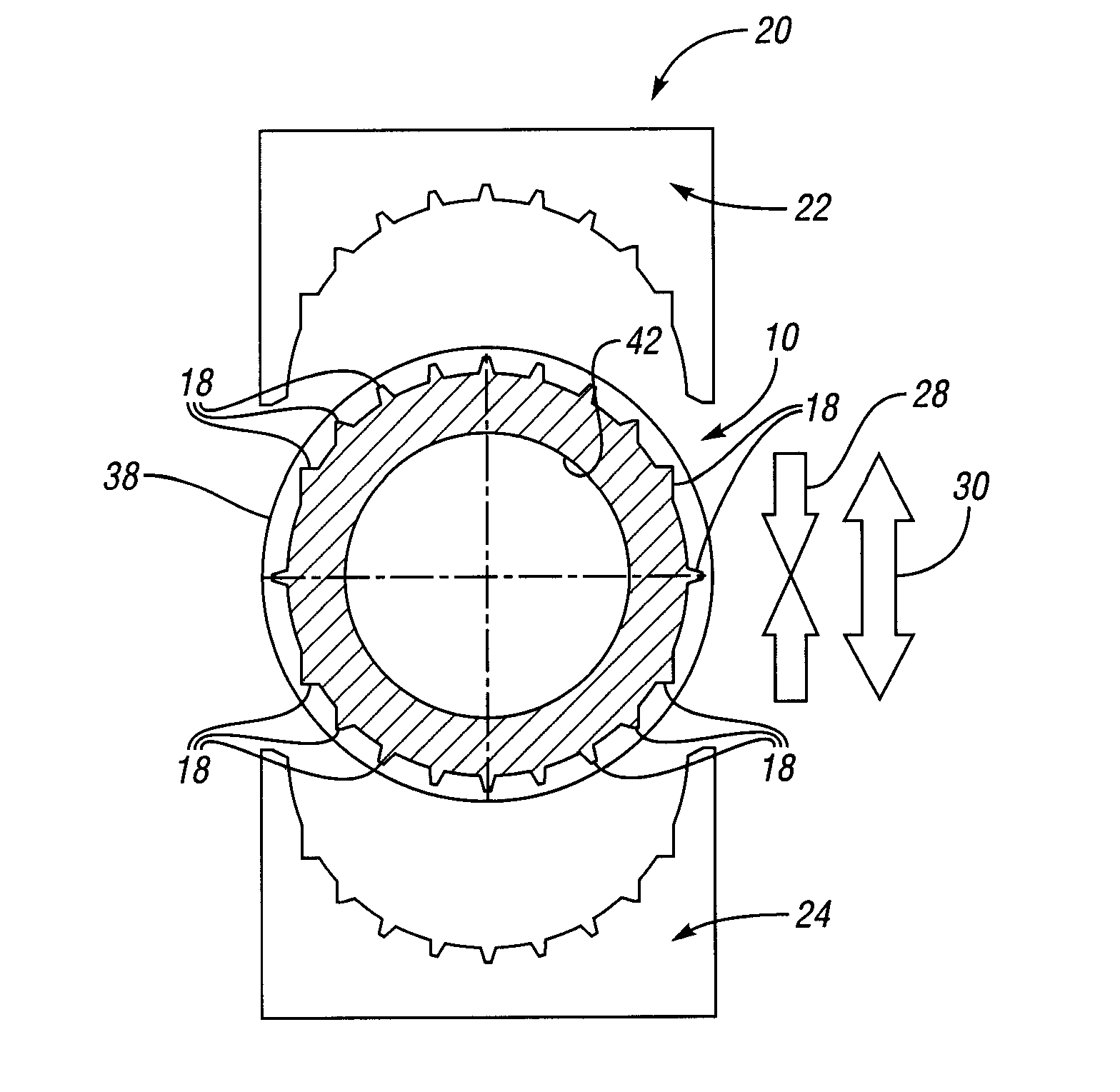

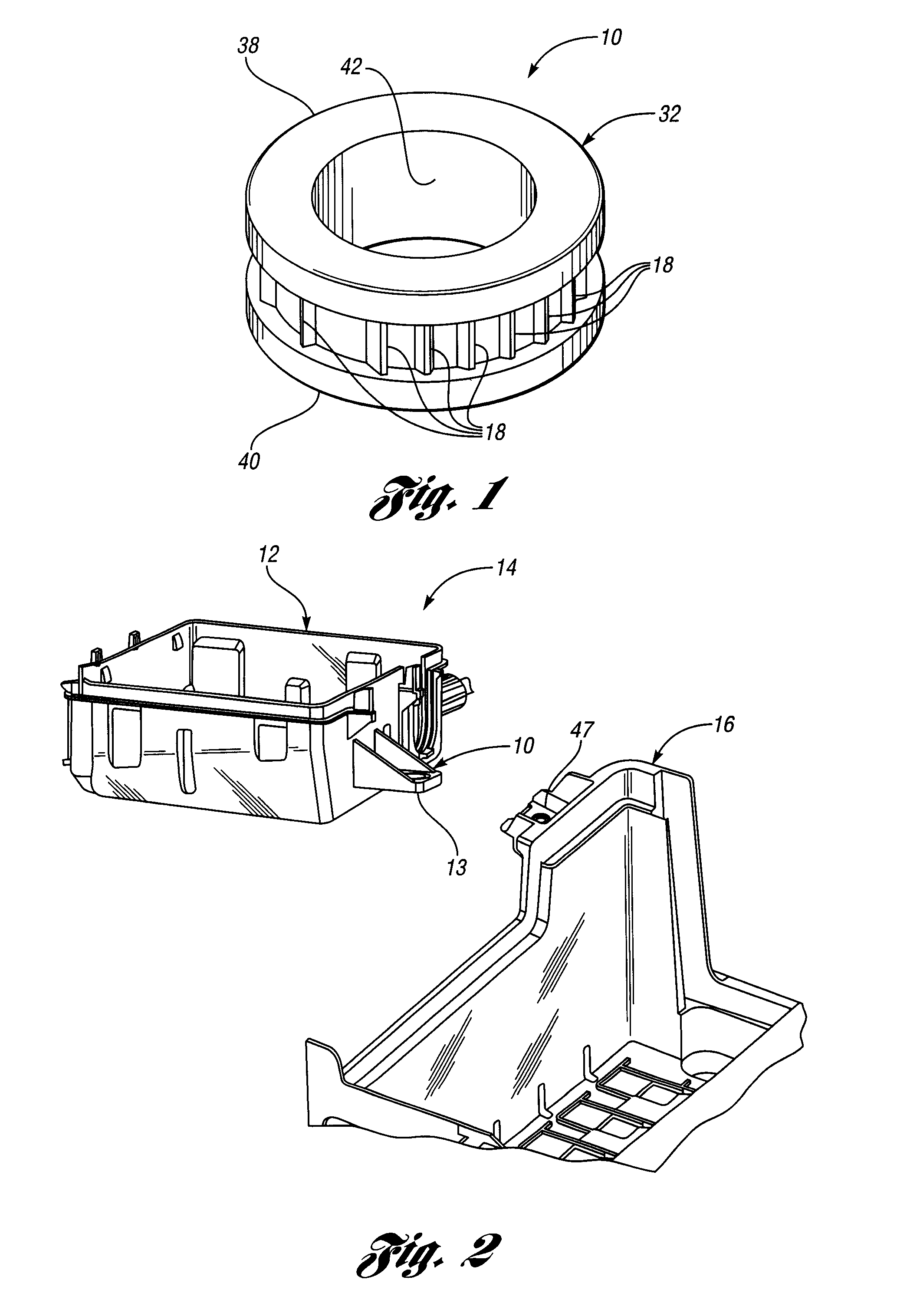

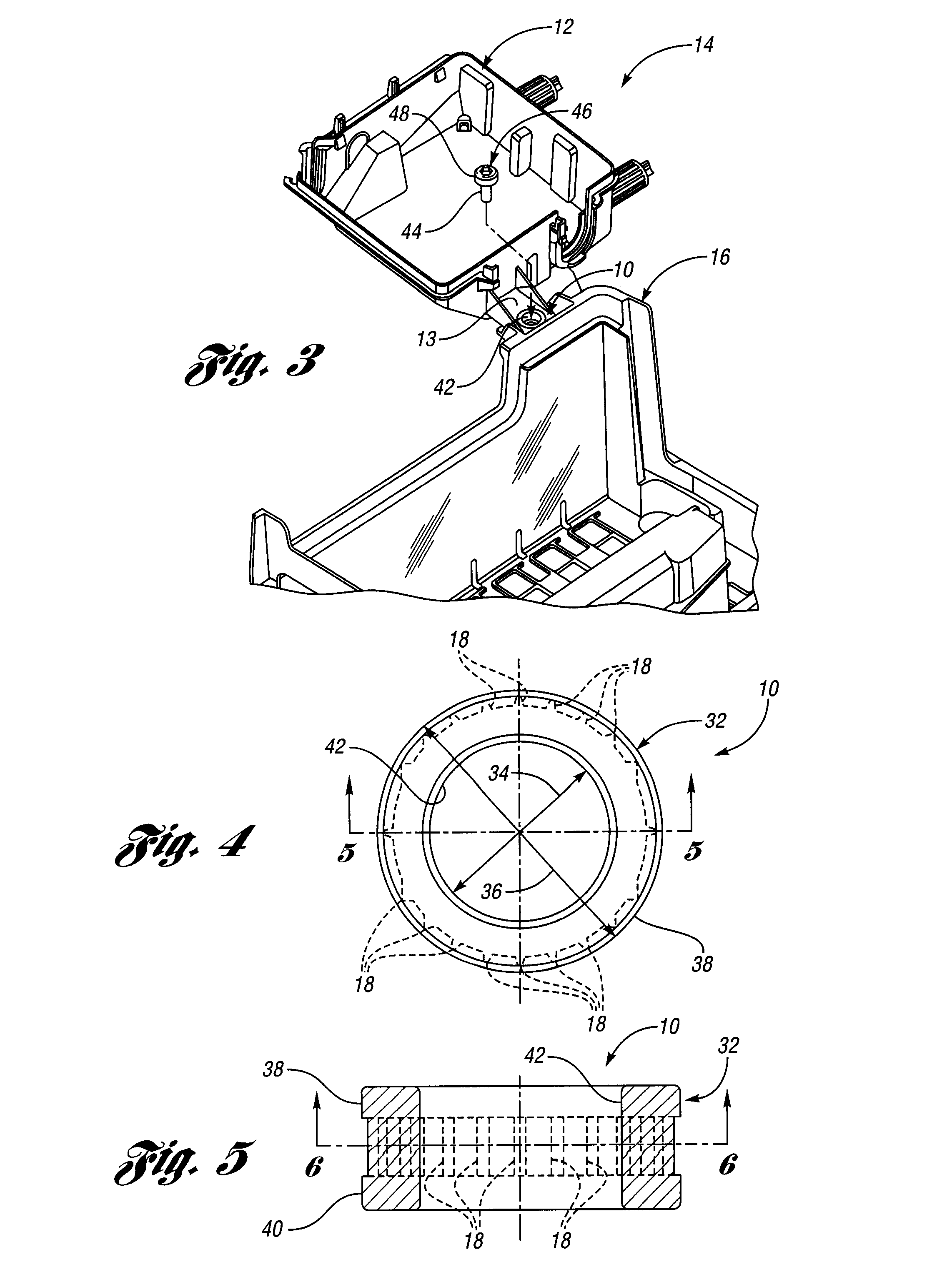

Insert, plastic part assembly utilizing same and die-casting mold for making the insert

ActiveUS8561742B2Simple and cheap processElectric/fluid circuitPropulsion coolingDie castingEngineering

A molded metal insert and plastic part integrally formed therewith form an assembly wherein the insert is provided with anti-rotation, die-cast teeth. The insert is adapted to attach and fix the plastic part to a vehicle structure in combination with a threaded fastener. The insert includes a cylindrical metal body having inner and outer diameters and upper and lower end portions. The inner diameter defines a passageway sized to allow an externally threaded portion of the fastener to extend through the passage and below the lower end portion for threaded attachment to the vehicle structure. The upper end portion provides a seat for a head of the fastener. The anti-rotation metal teeth are integrally molded with and extend radially outwardly from the cylindrical metal body between the inner and outer diameters and between the upper and lower end portions wherein the upper and lower end portions protect the teeth. A die-casting mold for forming the insert is also provided.

Owner:LEAR CORP

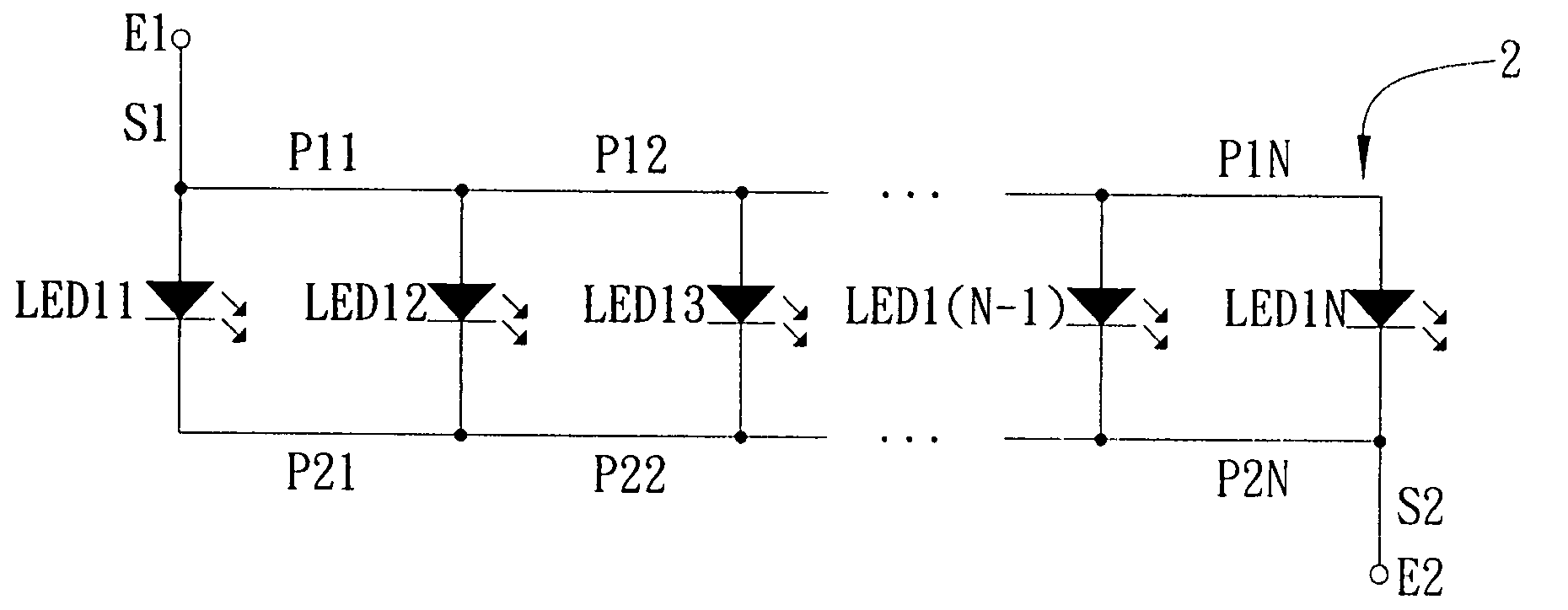

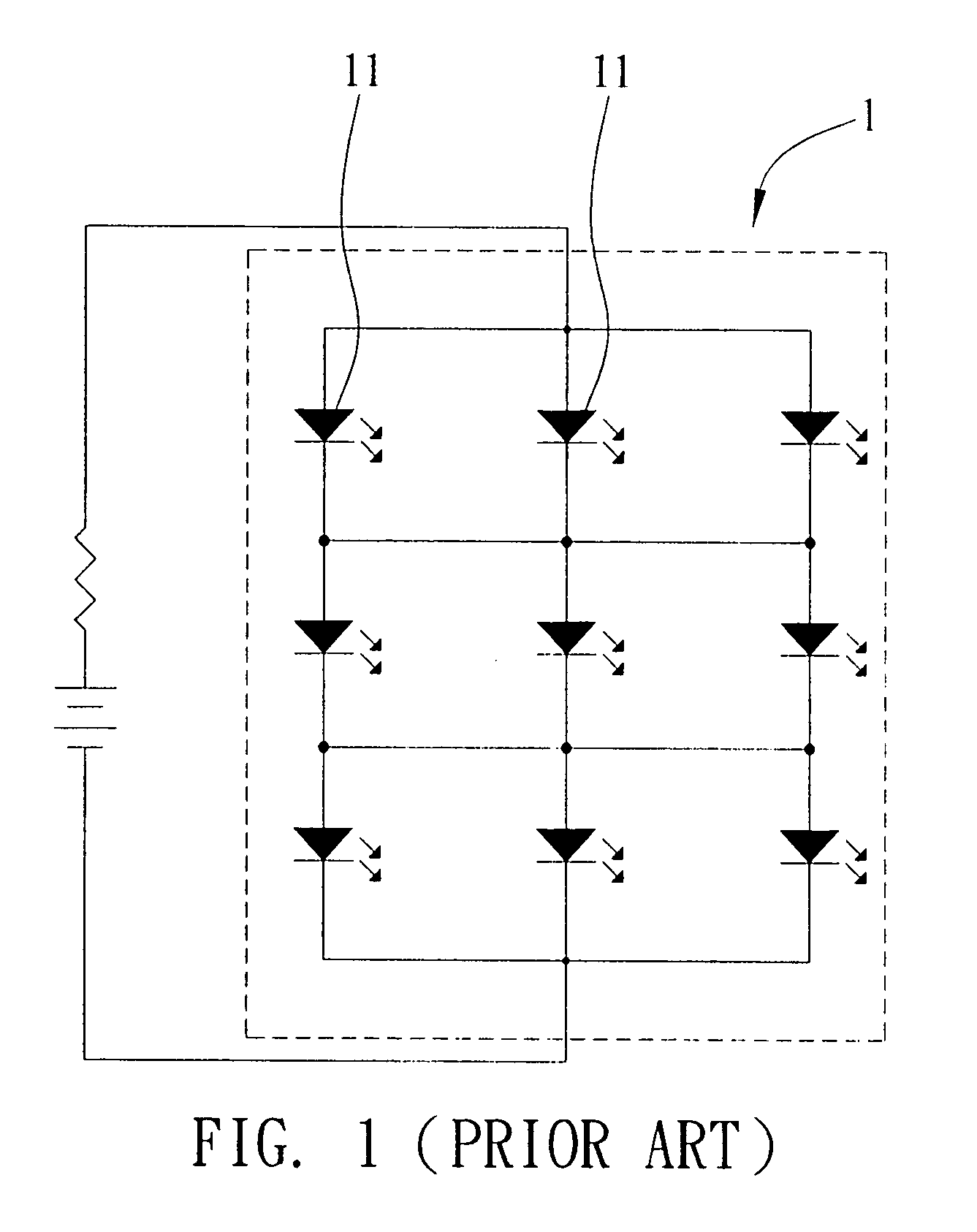

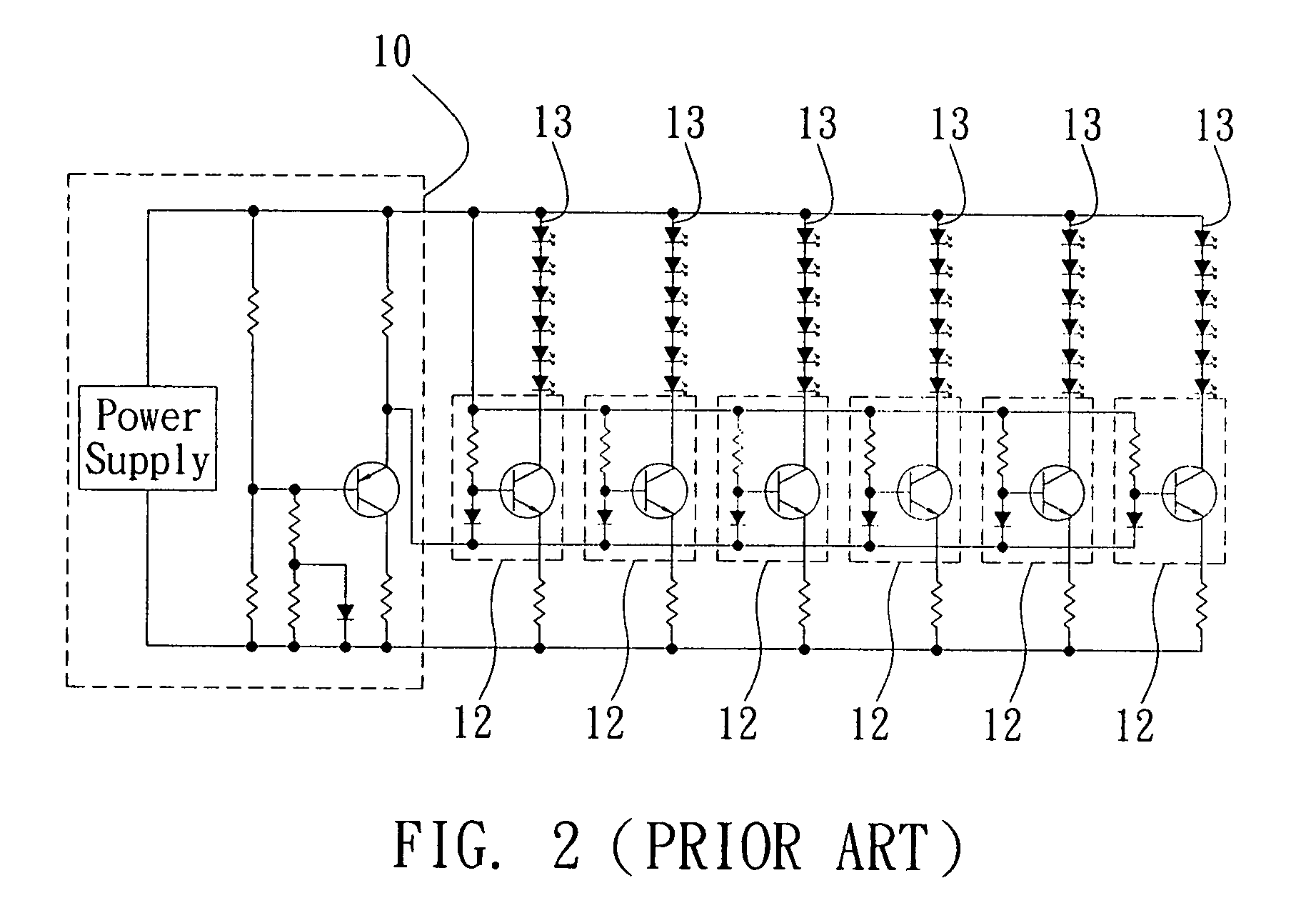

Resistance balance circuit

InactiveUS20080211750A1Improve homogeneityLack of homogeneityStatic indicating devicesElectroluminescent light sourcesElectrical resistance and conductanceEngineering

Owner:IND TECH RES INST

Developable phosphor coating mixture solution and method for manufacturing anodic phosphor layer

InactiveUS20060013944A1High bonding strengthSimple and cheap processBleaching apparatusElectrostatic spraying apparatusScreen printingManufacturing technology

A developable phosphor coating mixture solution and its manufacturing technique on anodic phosphor layers are described. The anodic phosphor layer of the field emission display is achieved through a silkscreen-printing method copulated with exposure procedure. The process is a simple silkscreen-printing method on an anodic glass substrate. Material features are combined with the manufacturing process to increase the adhesion ability of the phosphor powder on the anodic laminate. The exposure procedure develops high-resolution photography. The simple process and low cost coating can be used in manufacturing glass substrates.

Owner:TECO NANOTECH CO LTD

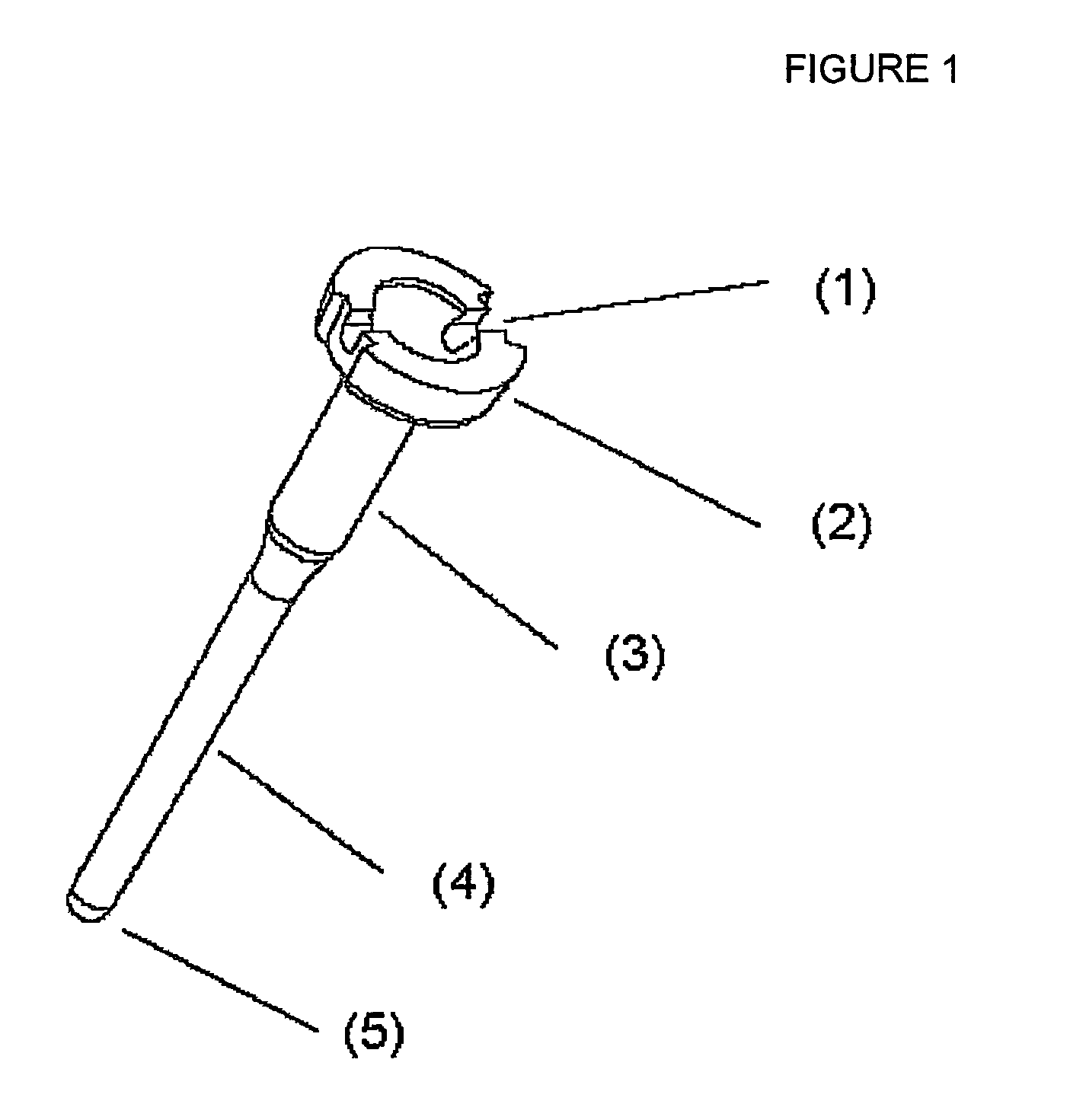

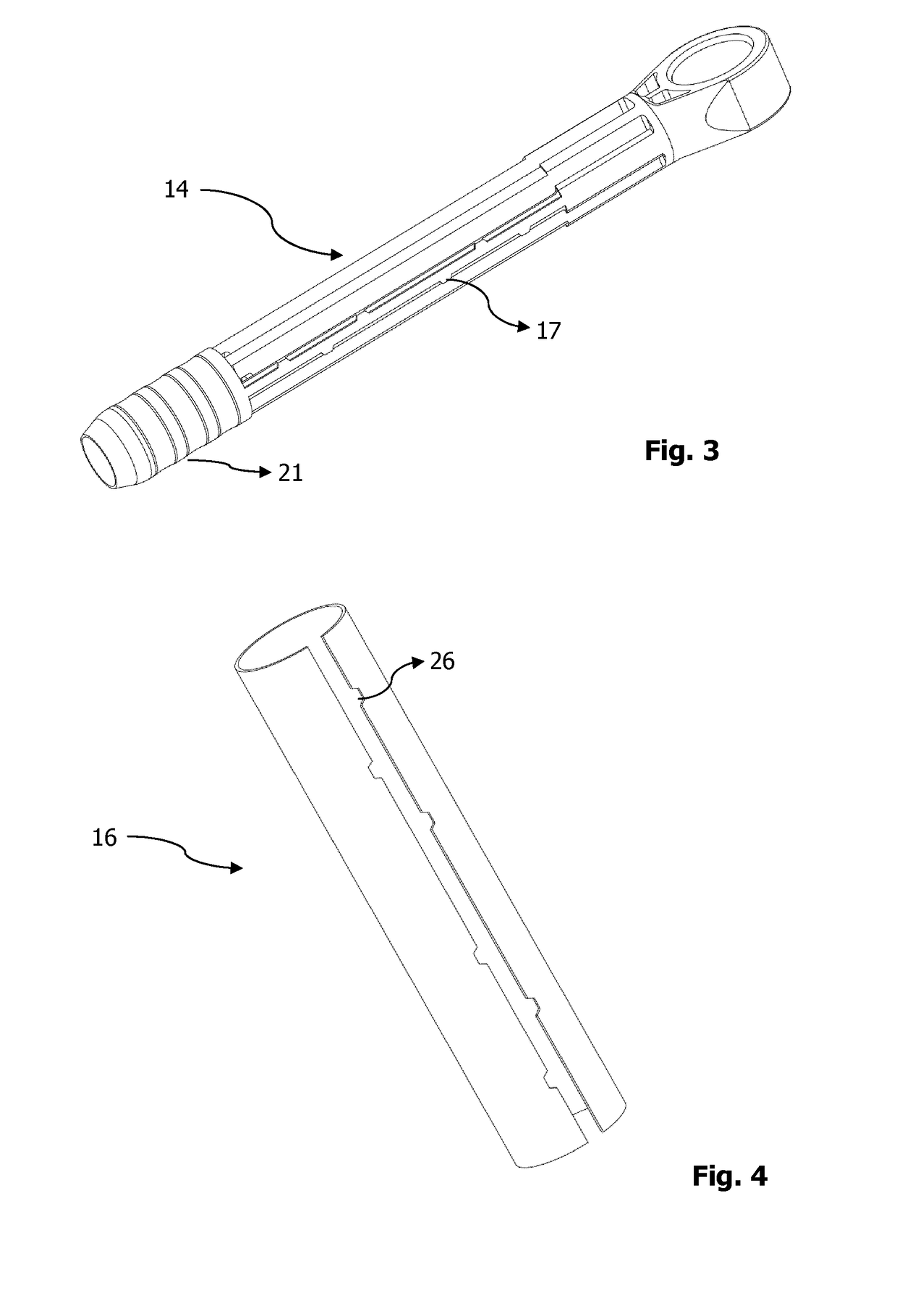

Frictional vibration damper

ActiveUS9732458B2Simple and cheap processImprove integritySpringsOther washing machinesPiston rodVibration damper

A frictional vibration damper for washing machines is disclosed. The damper comprises a piston body and a piston rod which adapted to move along the primary axis of said piston body. A friction element is located in between the piston rod and the piston body. The piston rod and piston body is equipped with joint at one of their ends for connection to the frame and the drum of the washing machine. The piston rod comprises a tubular body which is made of sheet material and which is fixedly rolled around a carrier piece. The frictional damper according to the present invention preferentially comprises, on one or both sides of the tubular body, with connection elements in the longitudinal direction for engaging to corresponding connection elements located on the carrier piece.

Owner:AKSISTEM ELEKTROMEKANIK SANAYI & TICARET LTD STI

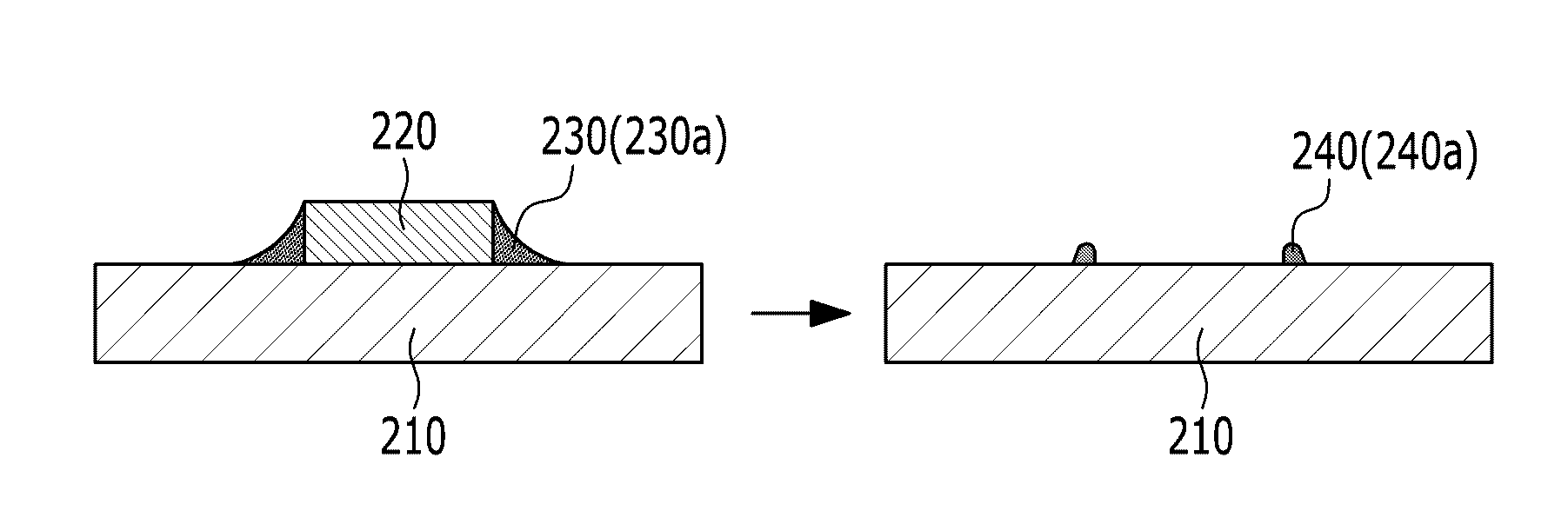

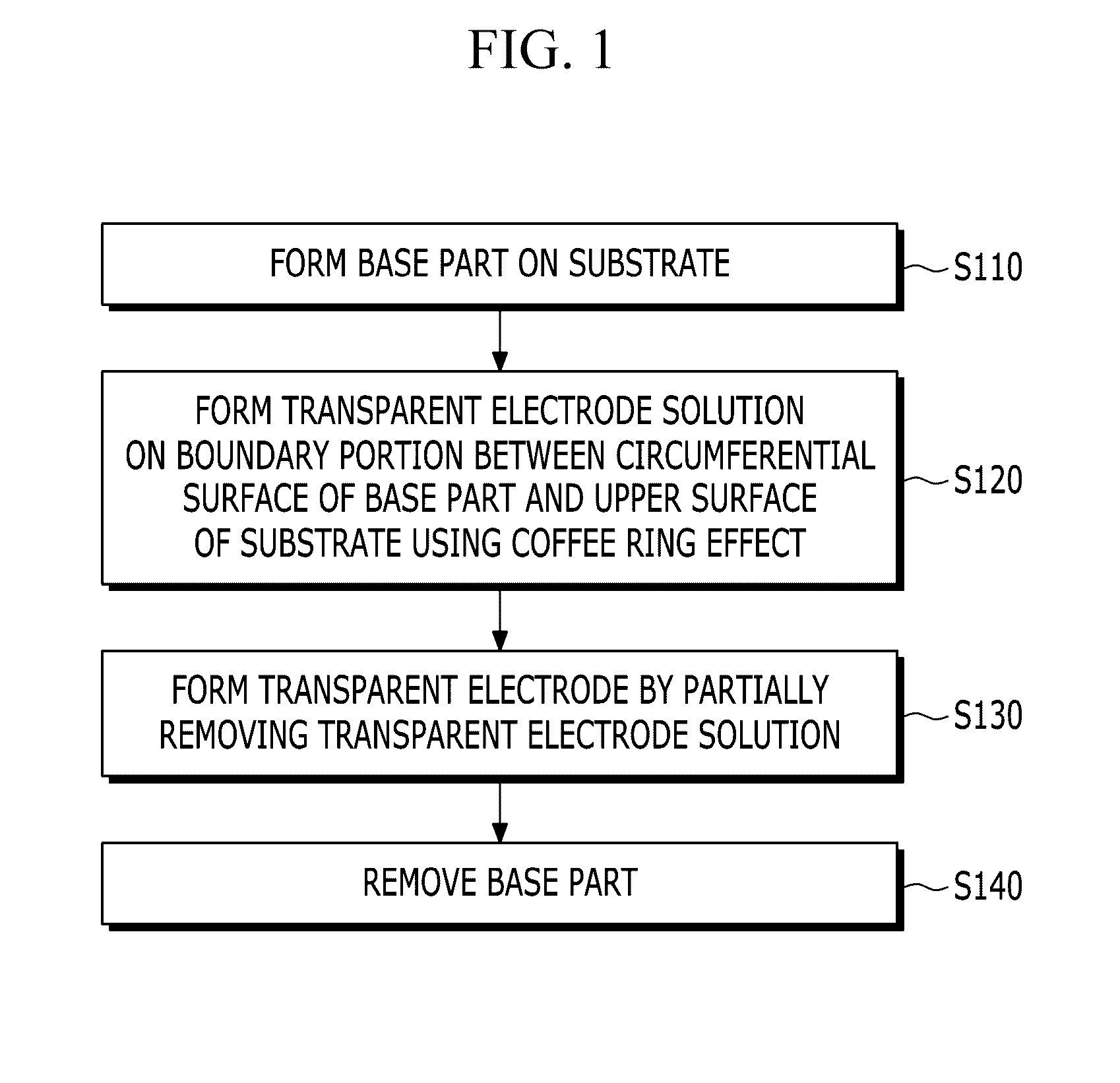

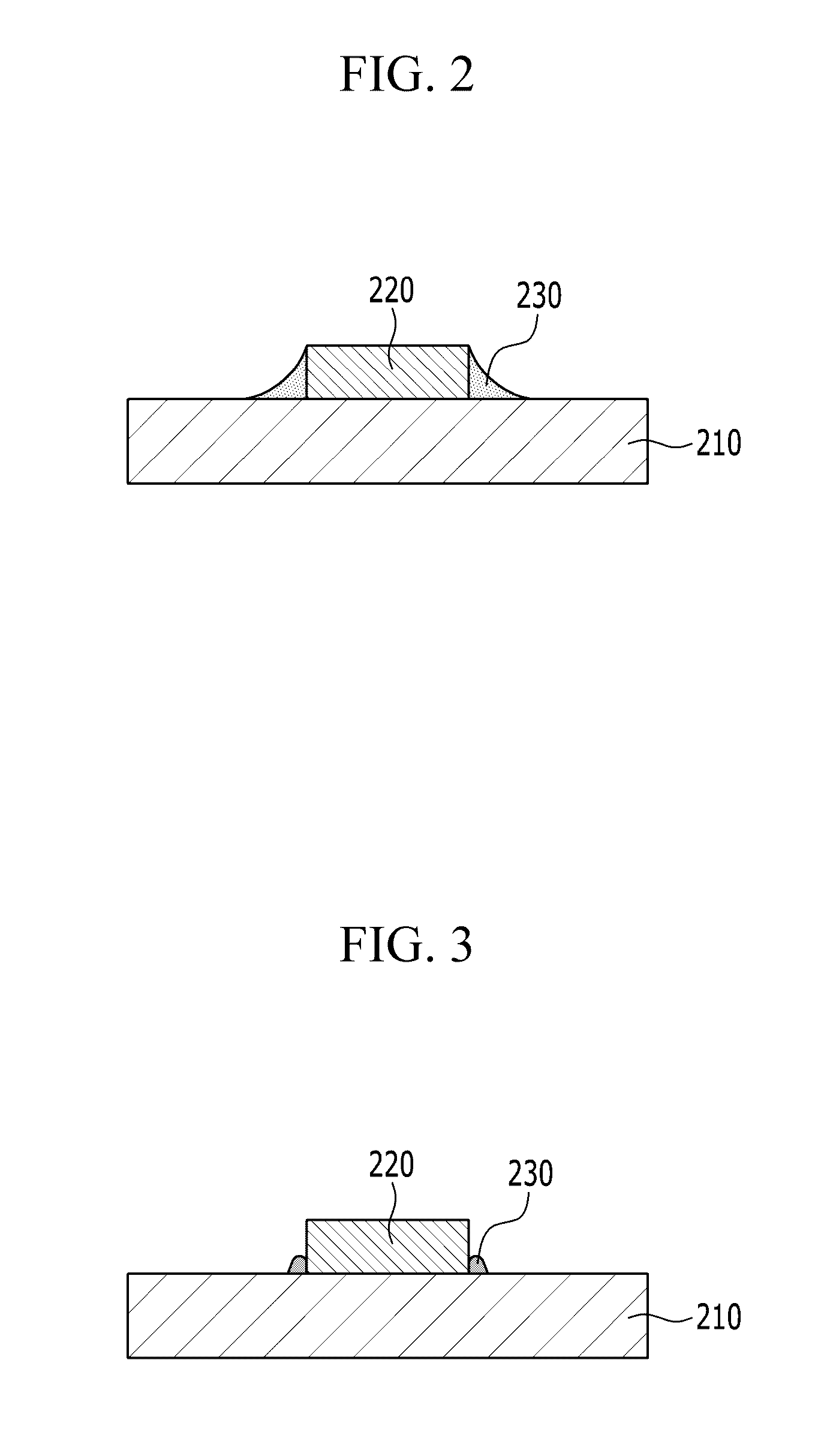

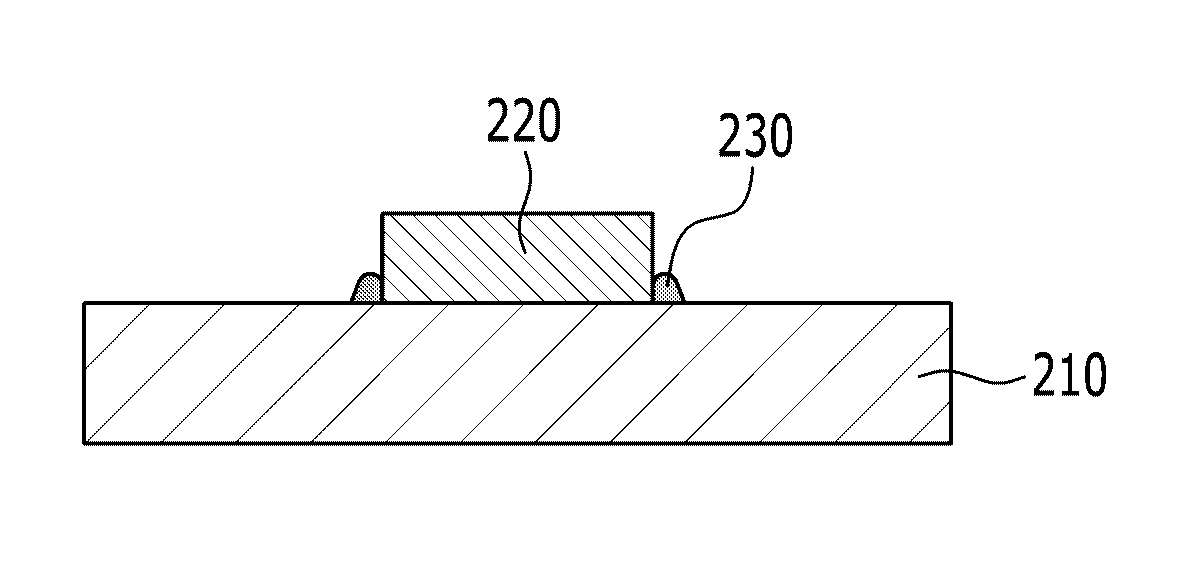

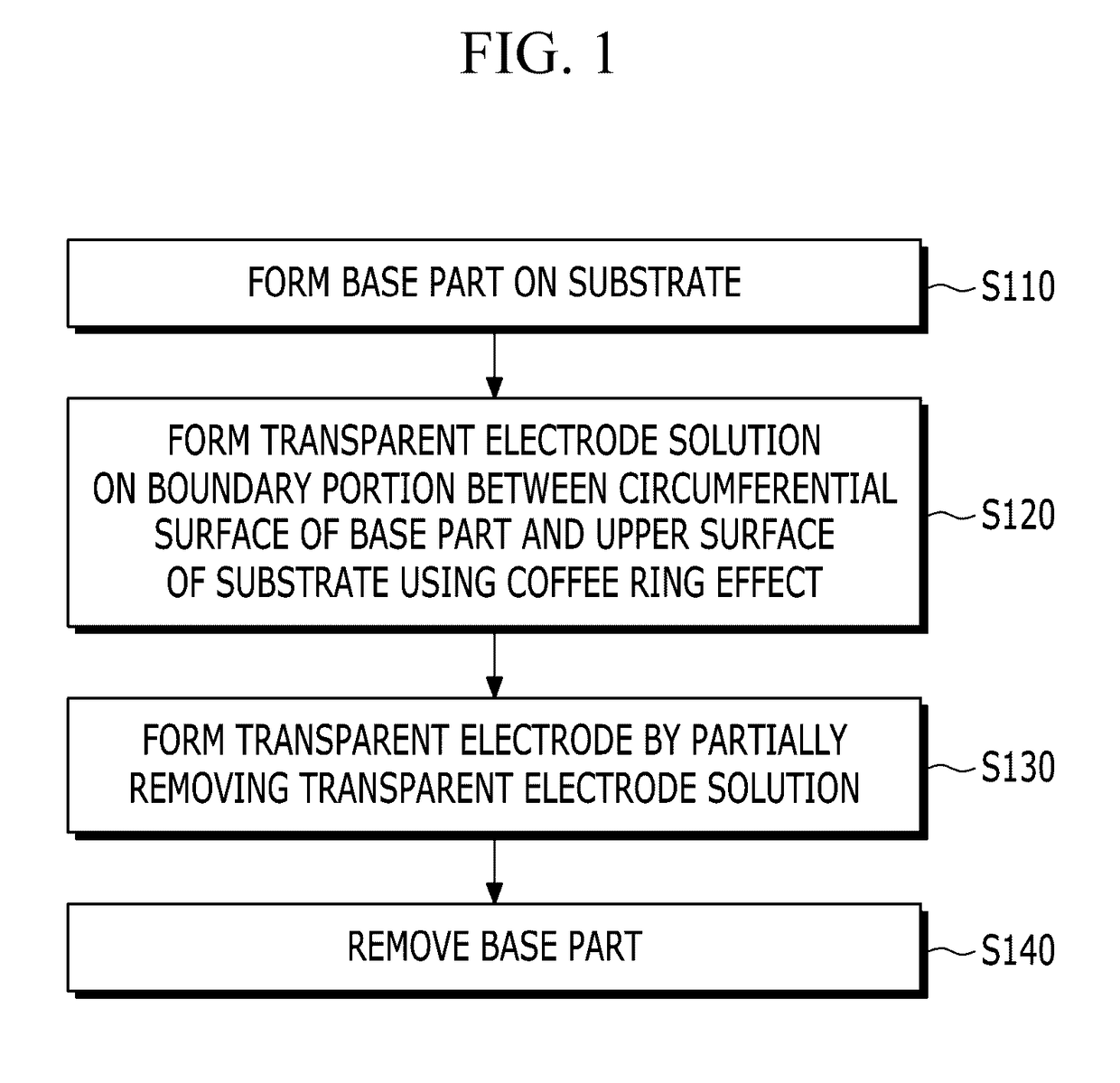

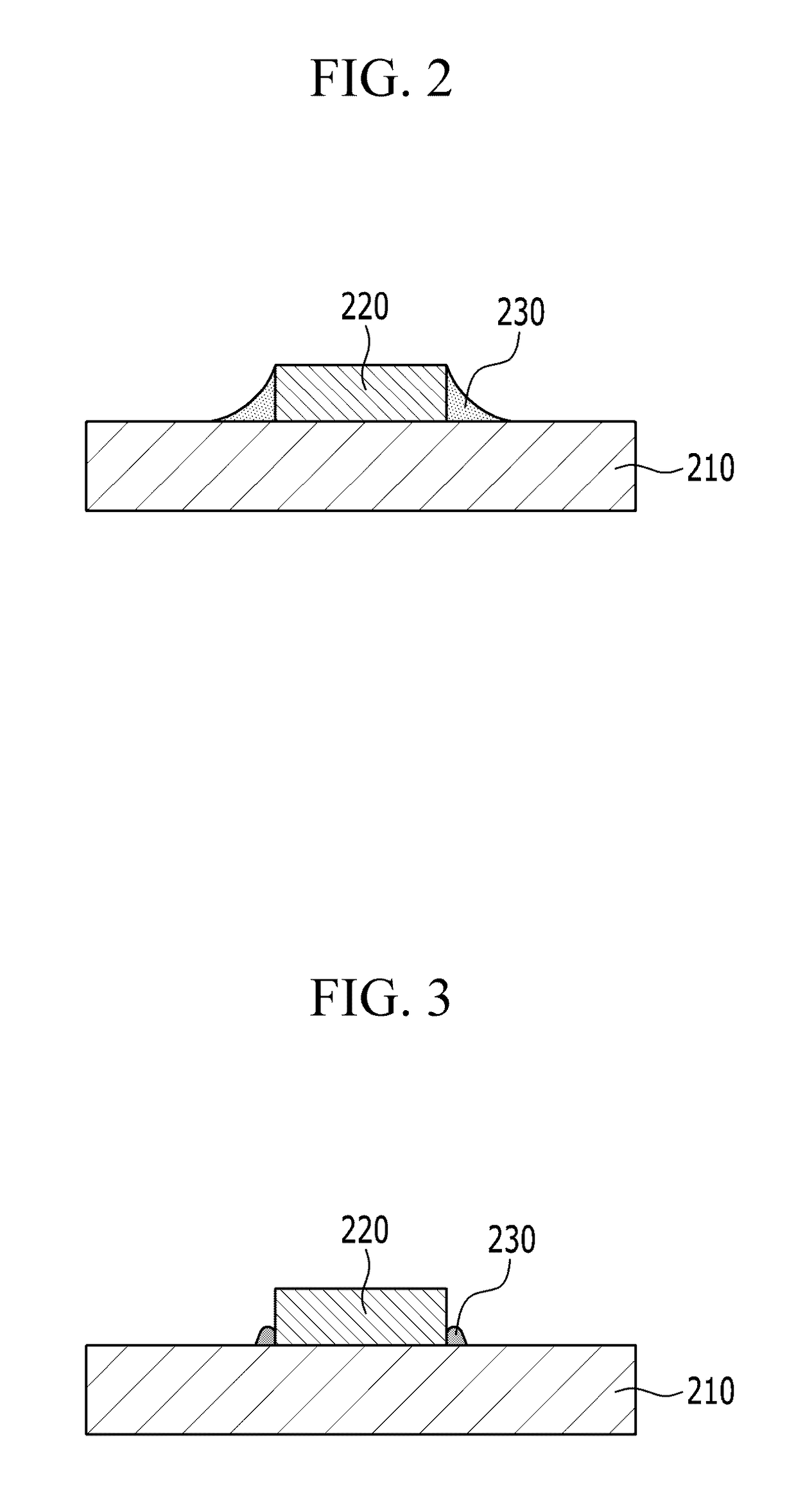

Method of forming fine electrode for flat panel display

InactiveUS20160323999A1Simple and cheap processFinely formResist detailsPrinted circuit aspectsFlat panel displayDisplay device

A method of forming a fine electrode, including: forming a base part on a substrate; disposing a transparent electrode solution at a boundary portion between a circumferential surface of the base part and an upper surface of the substrate; forming a transparent electrode by partially removing the transparent electrode solution; and removing the base part from the substrate.

Owner:SAMSUNG DISPLAY CO LTD

A kind of preparation method of novel solar cell

InactiveCN105762228BImprove performanceGood electrode metallizationFinal product manufacturePhotovoltaic energy generationPicosecond laserPurification methods

The invention relates to a novel solar cell preparation method. In order to reduce the manufacturing cost of a solar cell and improve the conversion efficiency, the method comprises the steps: manufacturing a substrate silicon wafer through employing a physical purification method; preparing a silicon nitride film through employing a plasma enhanced chemical vapor deposition method; preparing a polycrystalline silicon film through employing a graphite sucking disc dipping method; opening a hole on the back surface of the solar cell through employing a picosecond laser after the annealing processing of the solar cell; and finally completing the preparation of the solar cell through employing a conventional solar cell PN node, anti-reflection film and electrode manufacturing method. The method does not need ingot casting and slicing, is safe, has no pollution, is simple in technology, and can enable the production cost of the solar cell to be greatly reduced. In addition, the method improves the conversion efficiency of the solar cell through combining a PERC solar cell preparation method, can achieves the industrialized large-scale production of low-cost and high-efficiency solar cells.

Owner:HUANGHUAI UNIV

Stable Granulates Containing S-adenosylmethionine and Process for Preparation Thereof

InactiveUS20080274997A1Increase production costSimple and cheap processPowder deliveryBiocideS-Adenosyl methionineS-Adenosyl-l-methionine

A fluid bed granulation process for manufacturing non-hygroscopic, stable granulates containing a water-soluble salt of S-adenosylmethionine is described. Said process comprises:a) the simultaneous, sequential or alternate dispersion of at least a solution of a water-soluble salt of SAMe (A) and of a solution of a coating agent (B), on a fluid bed granulation carrier (C) andb) the fluid bed granulation of the mixture.Granulates obtainable by said process and solid oral pharmaceutical forms obtainable by said granulates are disclosed.

Owner:CHEM & HEALTH INT

Method of forming fine electrode for flat panel display

InactiveUS9674951B2Simple and cheap processResist detailsPrinted circuit aspectsDisplay deviceFlat panel display

A method of forming a fine electrode, including: forming a base part on a substrate; disposing a transparent electrode solution at a boundary portion between a circumferential surface of the base part and an upper surface of the substrate; forming a transparent electrode by partially removing the transparent electrode solution; and removing the base part from the substrate.

Owner:SAMSUNG DISPLAY CO LTD

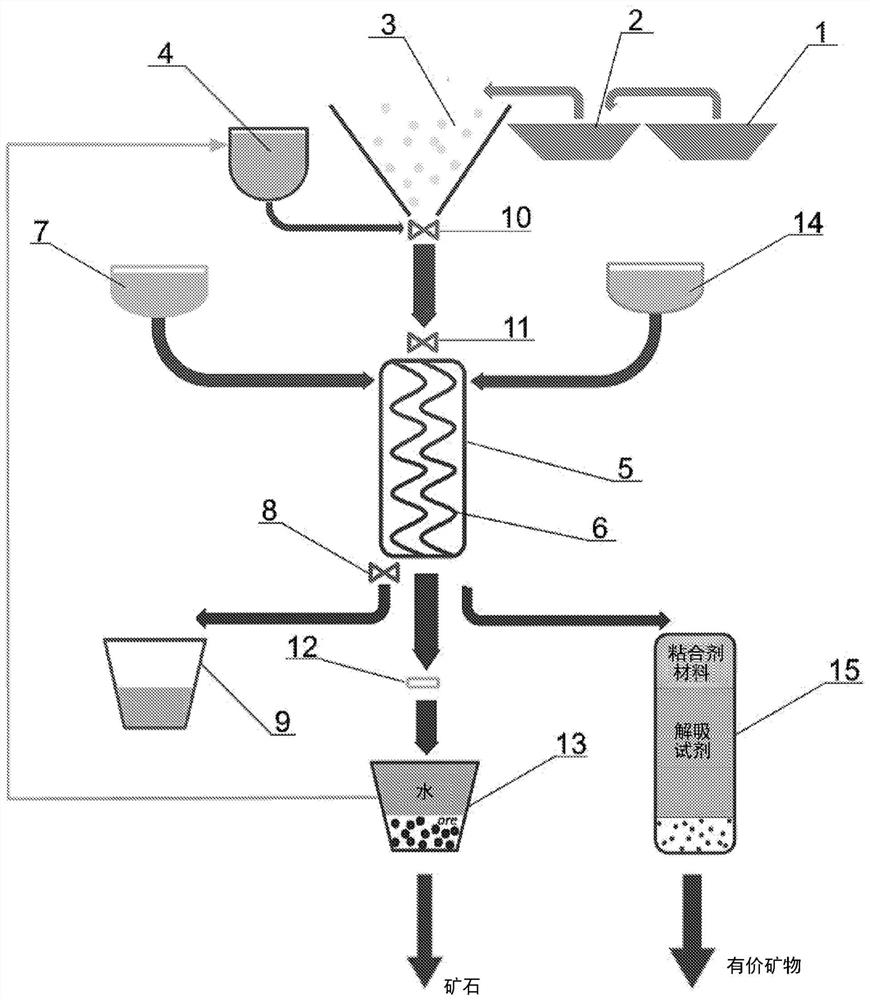

Method for separating particles of valuable minerals, precious metals, rare earth metals, gemstones and sub-gemstones from natural ores by adhesion in aqueous environment

PendingCN114302973ASimple and cheap processEliminate Technical DefectsOther chemical processesProcess efficiency improvementMining engineeringGemstone

Process for separating particles of valuable minerals, precious metals, rare earth metals, gemstones and sub-gemstones from natural ores by adhesion phenomena in an aqueous environment, consecutively encompassing a number of known stages, such as:-a preliminary separation; comprising screening up to 5000 [mu] m fractions from alluvial (macadam) ore or crushing native (rock) ore into fractions such that valuable minerals are separated from gangue and, if appropriate, ferromagnets are separated from the ore by known methods; forming a suspension by mixing the preliminarily separated ore fraction with a liquid; -adsorption of valuable minerals from the suspension on the binder coating and also recovery of water from the process; -desorbing particles of valuable minerals from the binder coating according to the invention, characterized in that lanolin or a mixture thereof with additives is used to form the binder coating in the separator, the content of lanolin in the mixture may be no less than 80%.

Owner:安杰伊·切丘尔斯基

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com