Patents

Literature

50 results about "Fluid Bed Granulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The process of forming granules involving the addition of liquid to bind particles as they are suspended in a fluidized state by a flowing gas stream, resulting in dry granules suitable for filling or compression.

Technique of preparing amlodipine besylate tablets

ActiveCN101161241AHigh dissolution rateImprove finenessOrganic active ingredientsPill deliverySolubilityAir volume

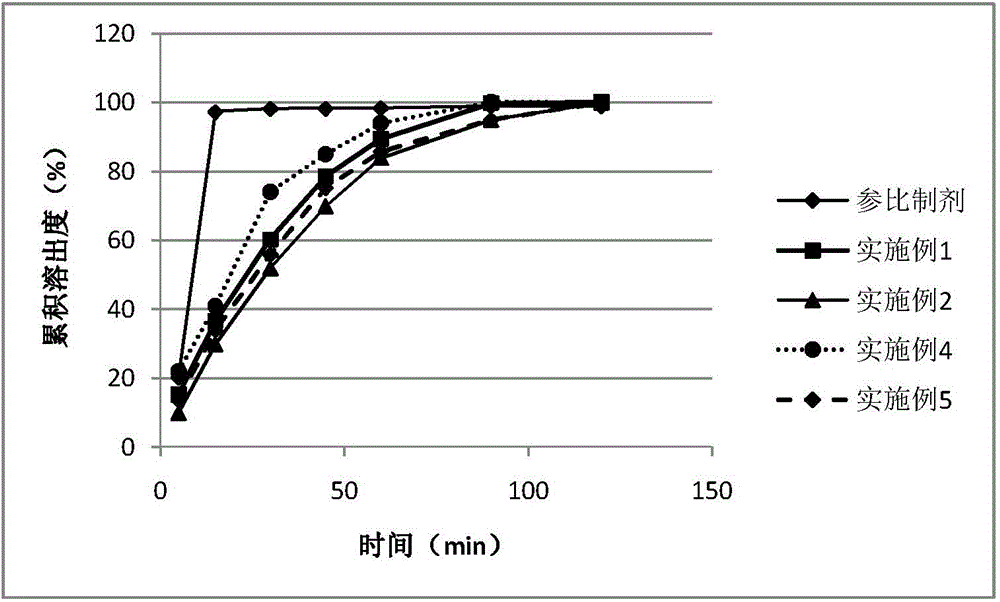

A preparation technology of amlodipine besylate is disclosed in the present invention, the technology is with amlodipine besylate, filler, disintegrating agent, lubricant etc. as main components. By using grinding and sieving; reasonably controlling particle water; repeatedly feeling fluidized bed granulating technology parameter, controlling spraying speed, spraying pressure and air quantity, under the situation of non-affecting tablet content and hardness, increasing the solubility of product greatly, thereby promoting the internal quality and curative effect of the product.

Owner:YANGZIJIANG PHARMA GROUP SHANGHAI HAINI PHARMA

Process for making granular detergent in a fluidized bed granulator having recycling of improperly sized particles

InactiveUS6894018B1Improved solubility and dissolutionConvenient amountDrying solid materials with heatDetergent mixture composition preparationEngineeringSizing

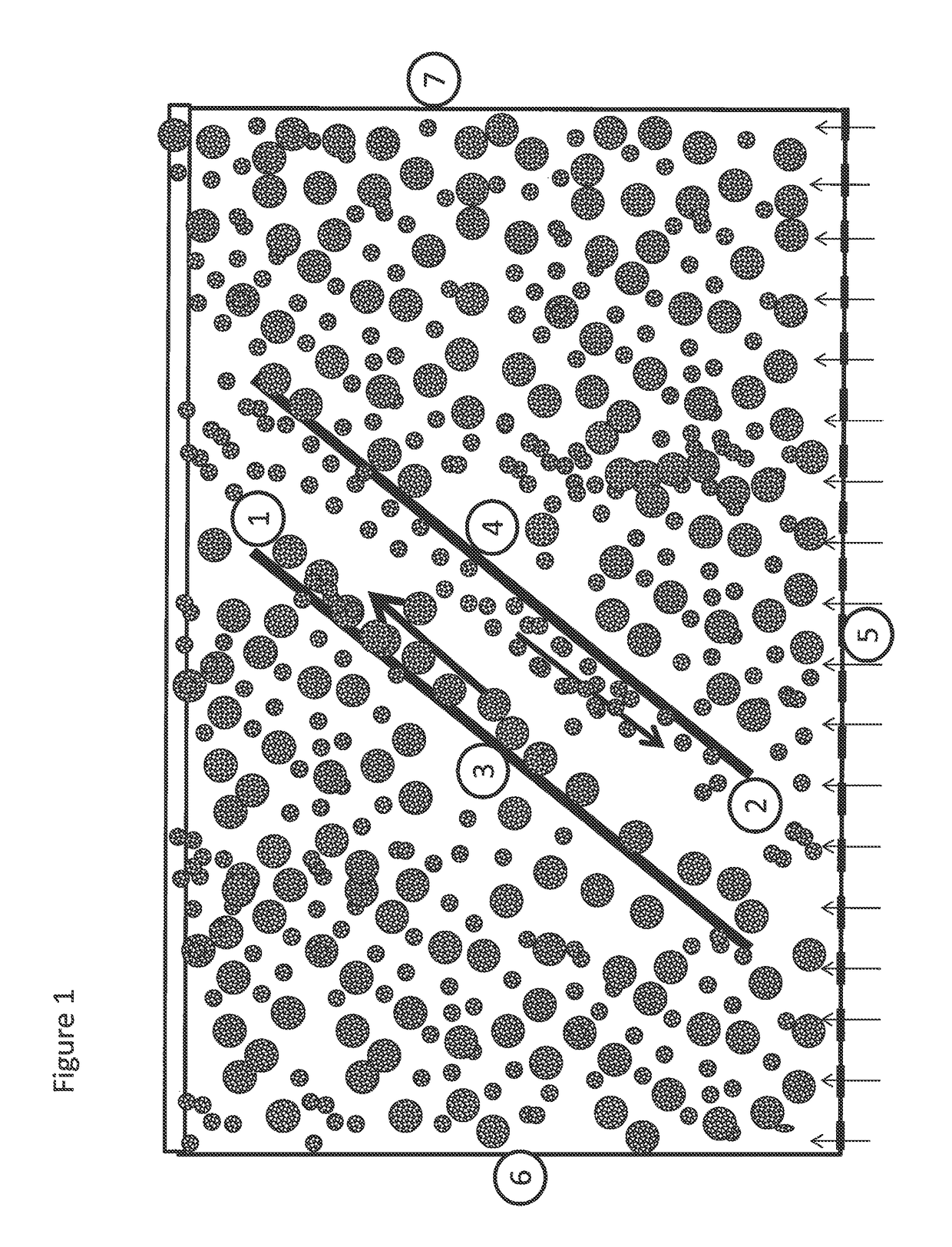

A process for the production of granular detergent compositions is provided wherein fluid bed granulation is employed in conjunction with selected recycle of oversized particles to control the uniformity of the resulting detergent composition. The process comprises feeding starting ingredients into a fluid bed granulator to at least partially granulate the feed material while employing the fluid bed to control undersized particle generation and sizing in conjunction with recycle to control oversized particles.

Owner:THE PROCTER & GAMBLE COMPANY

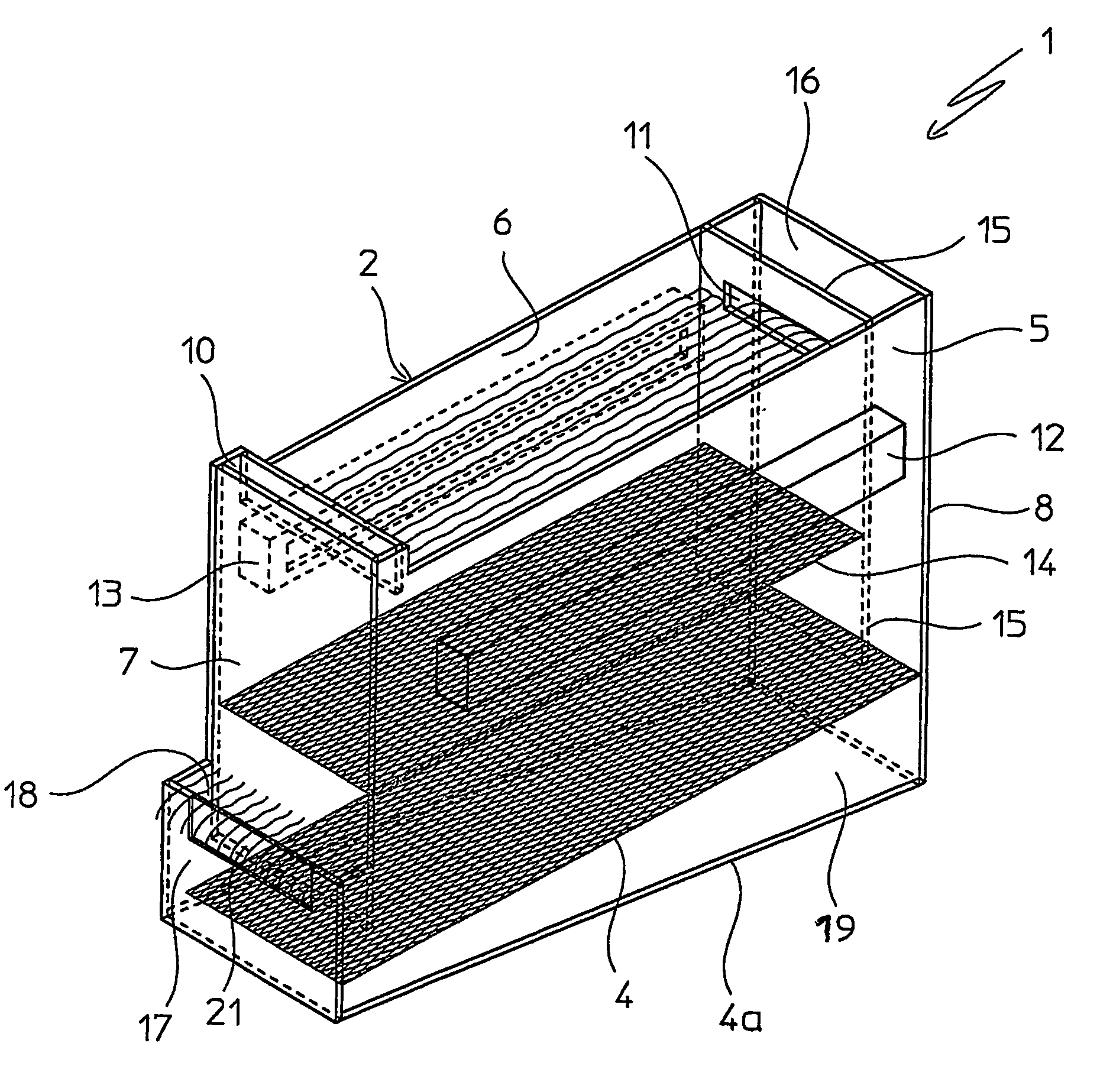

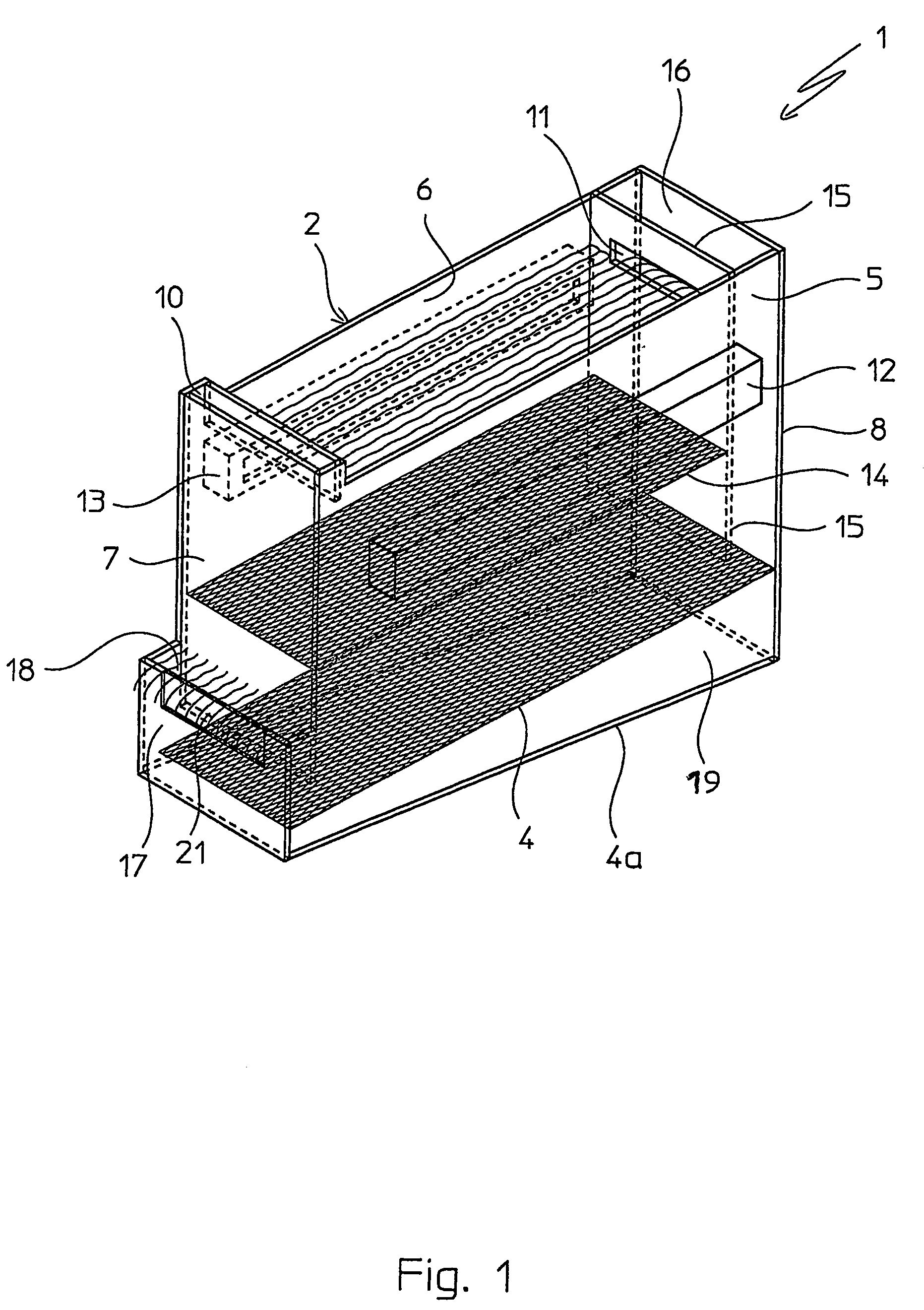

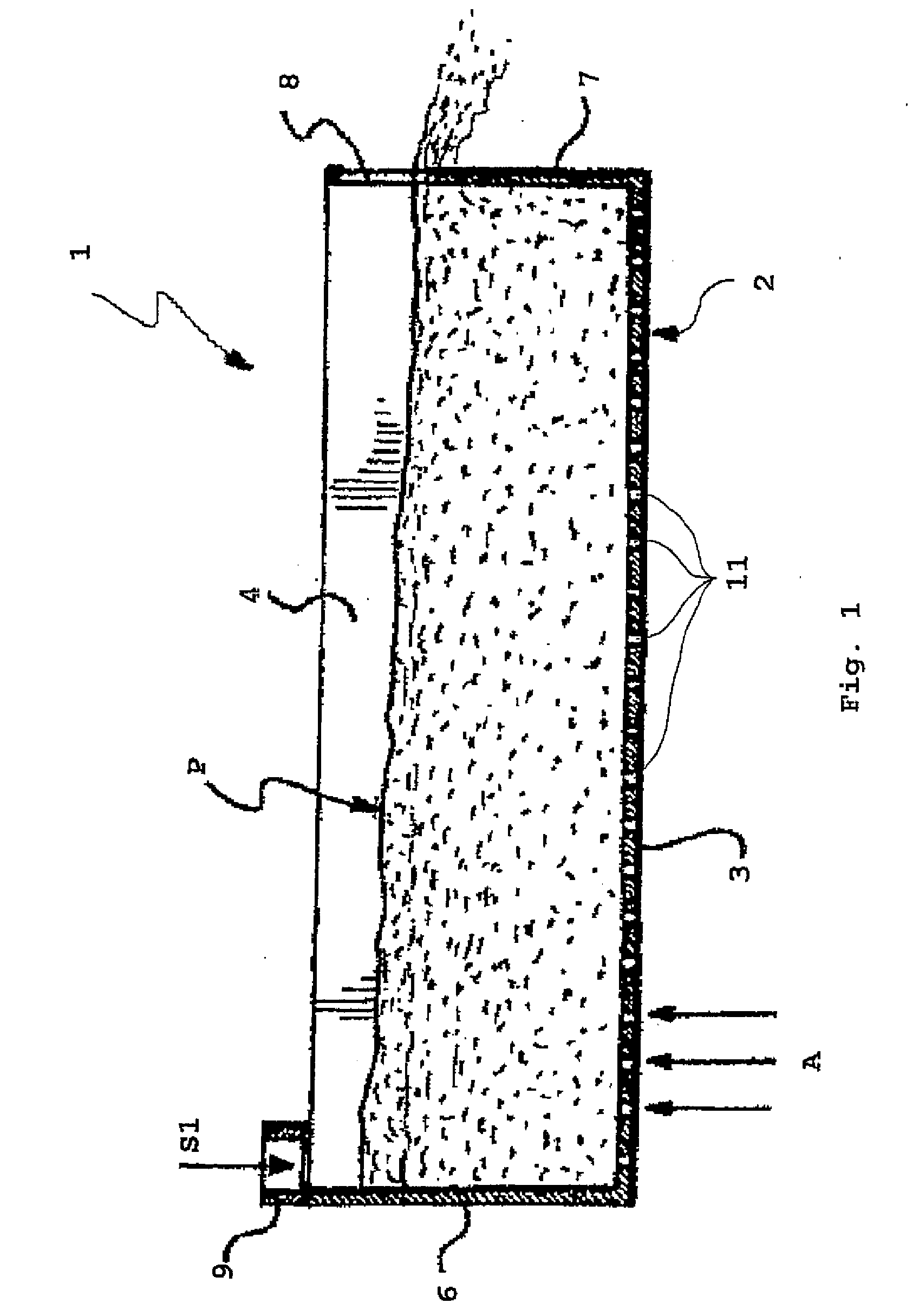

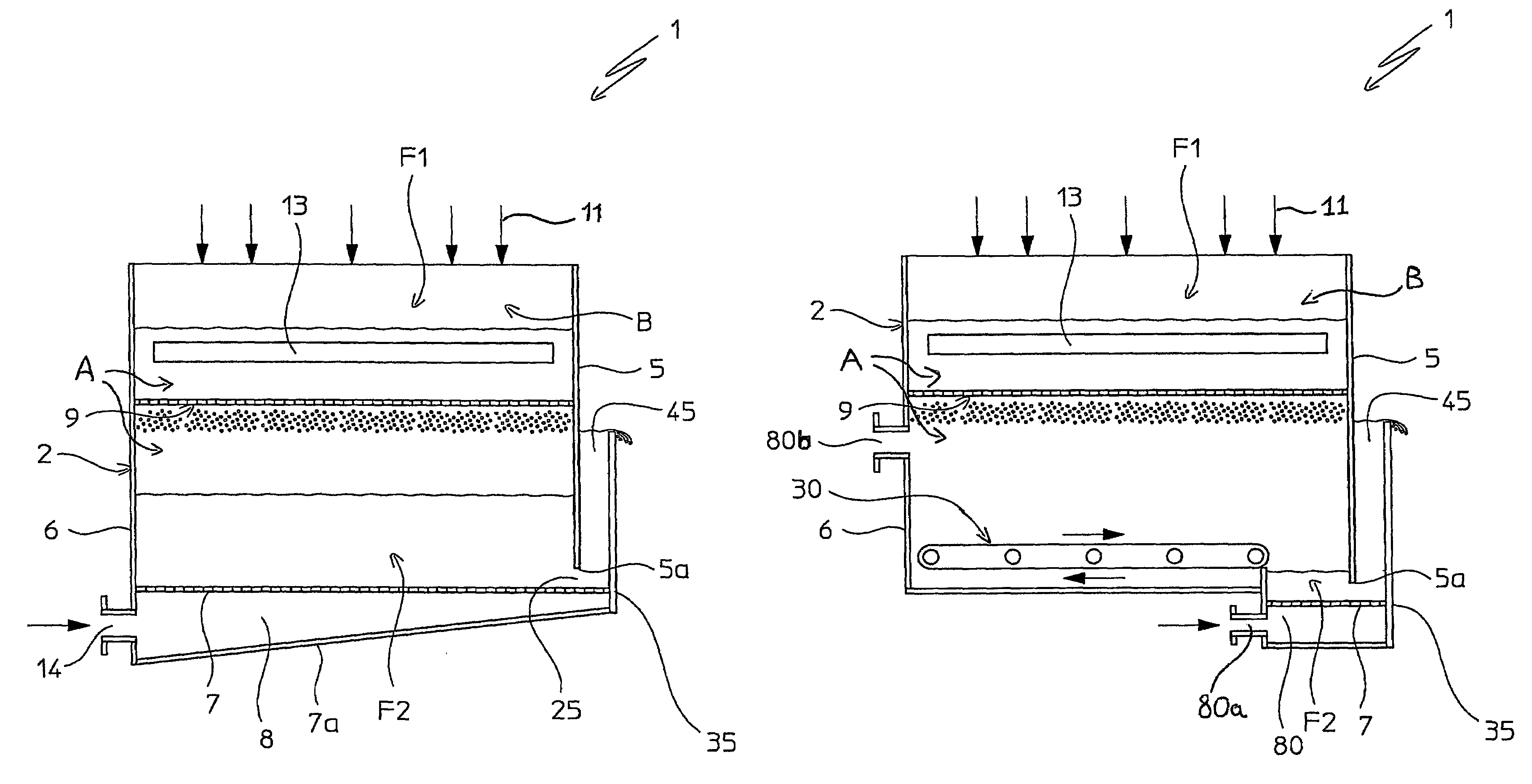

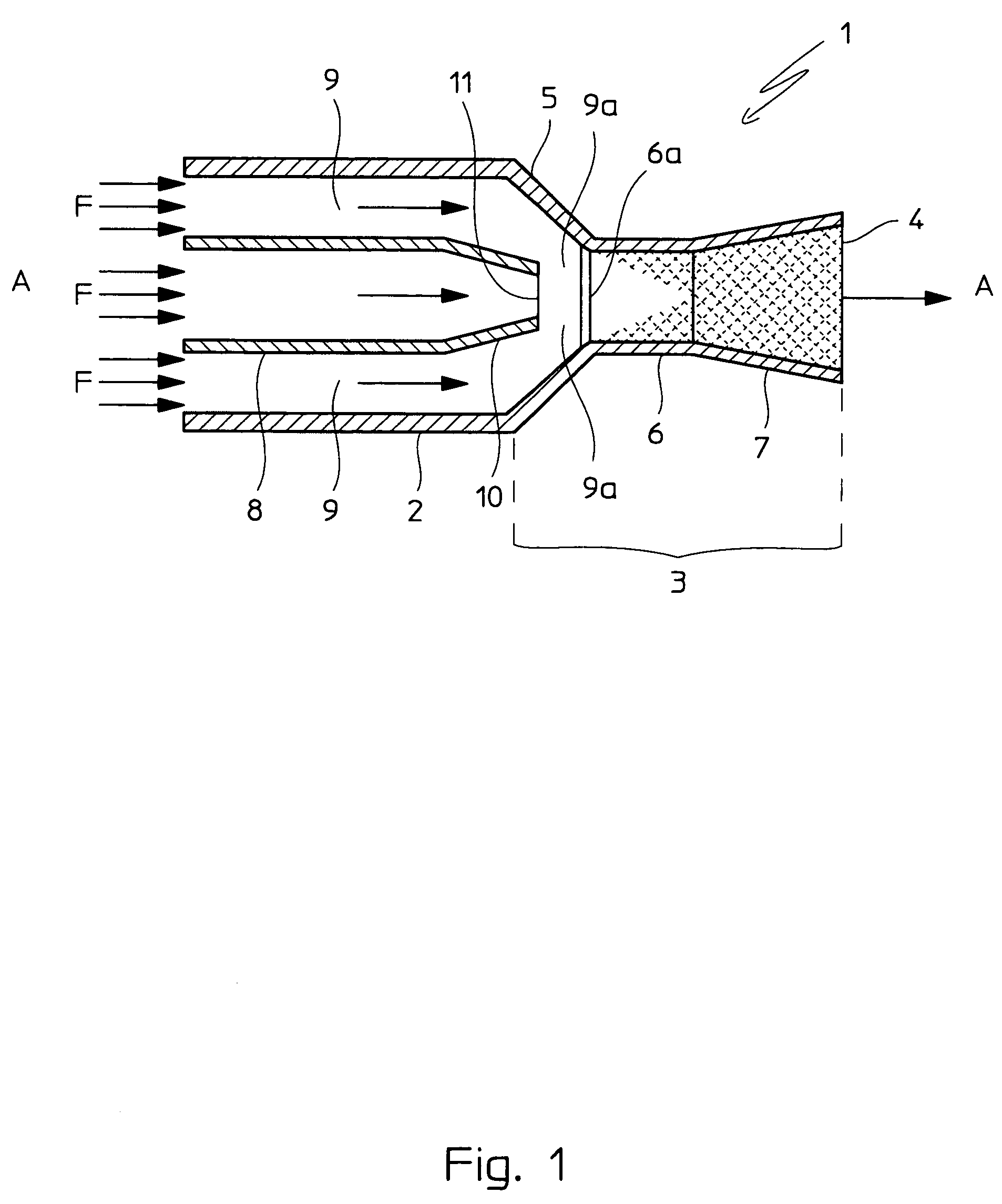

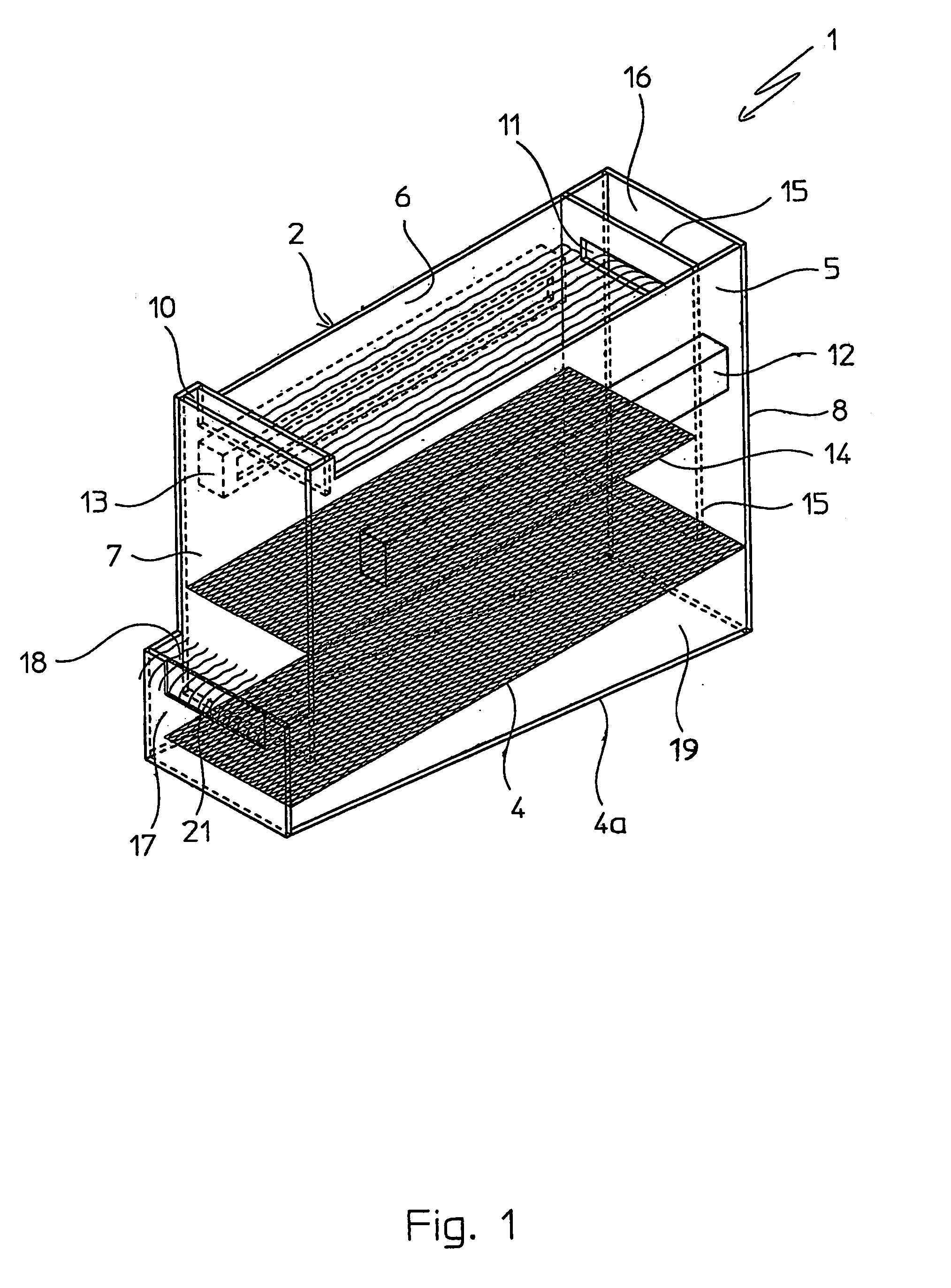

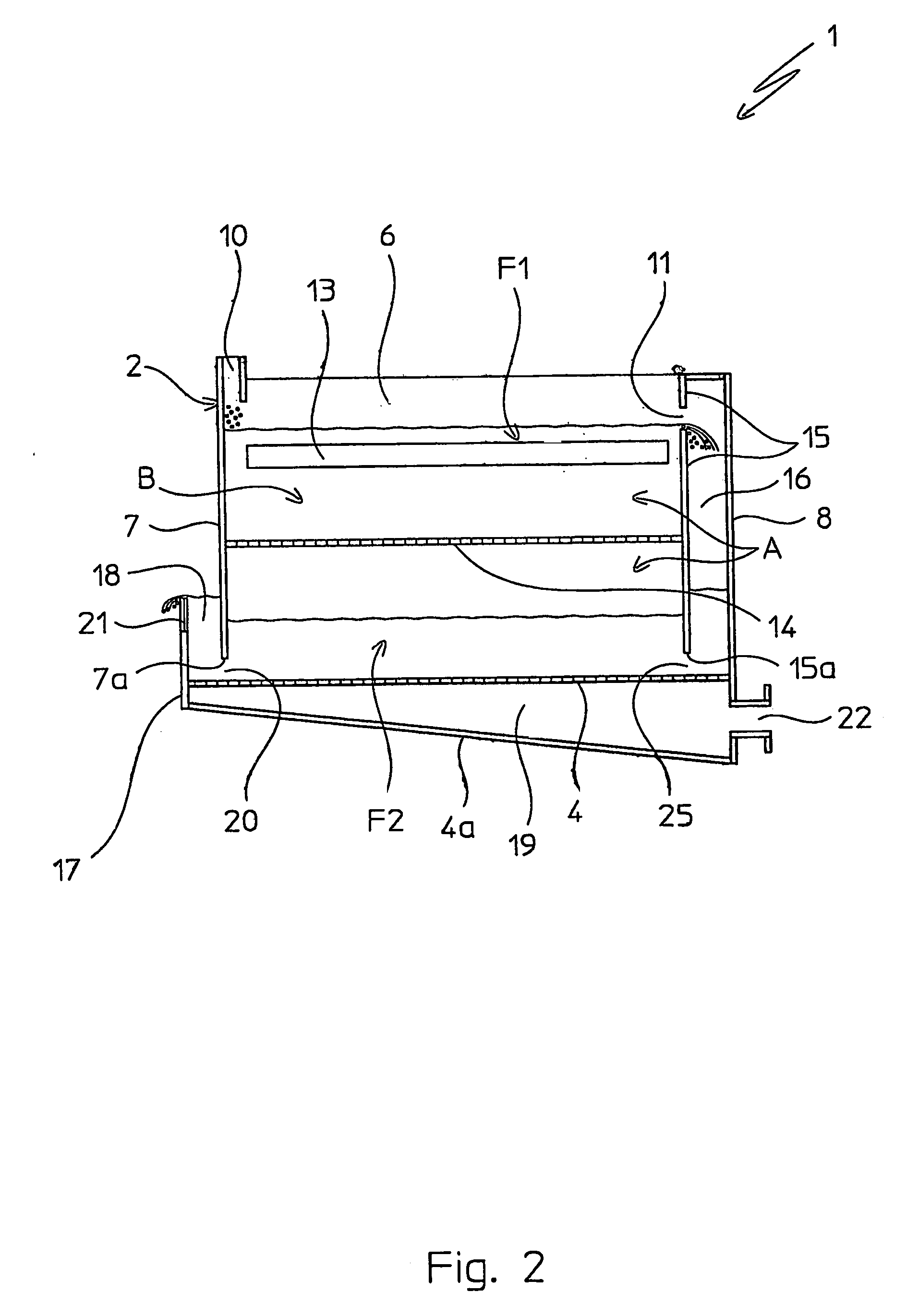

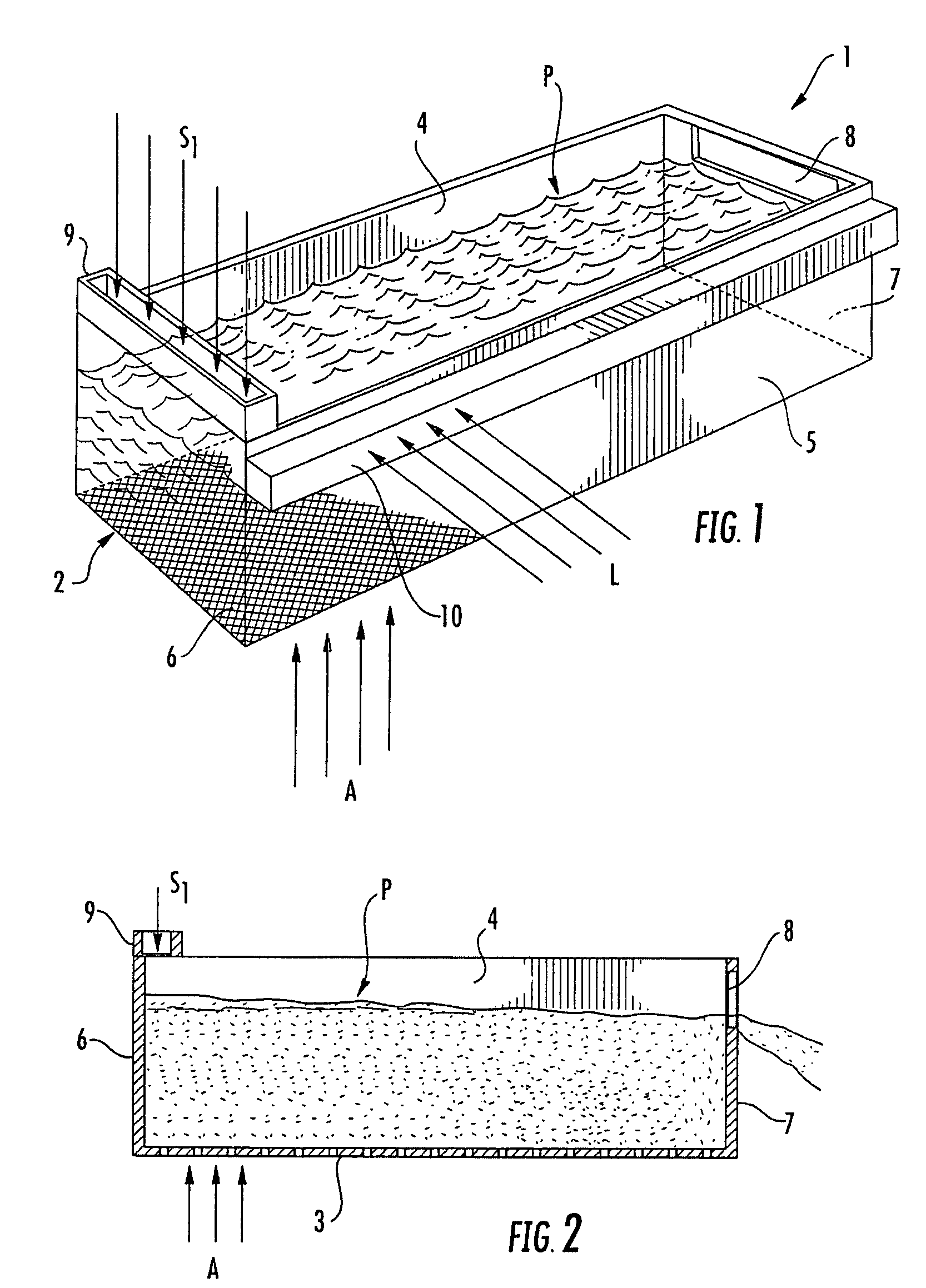

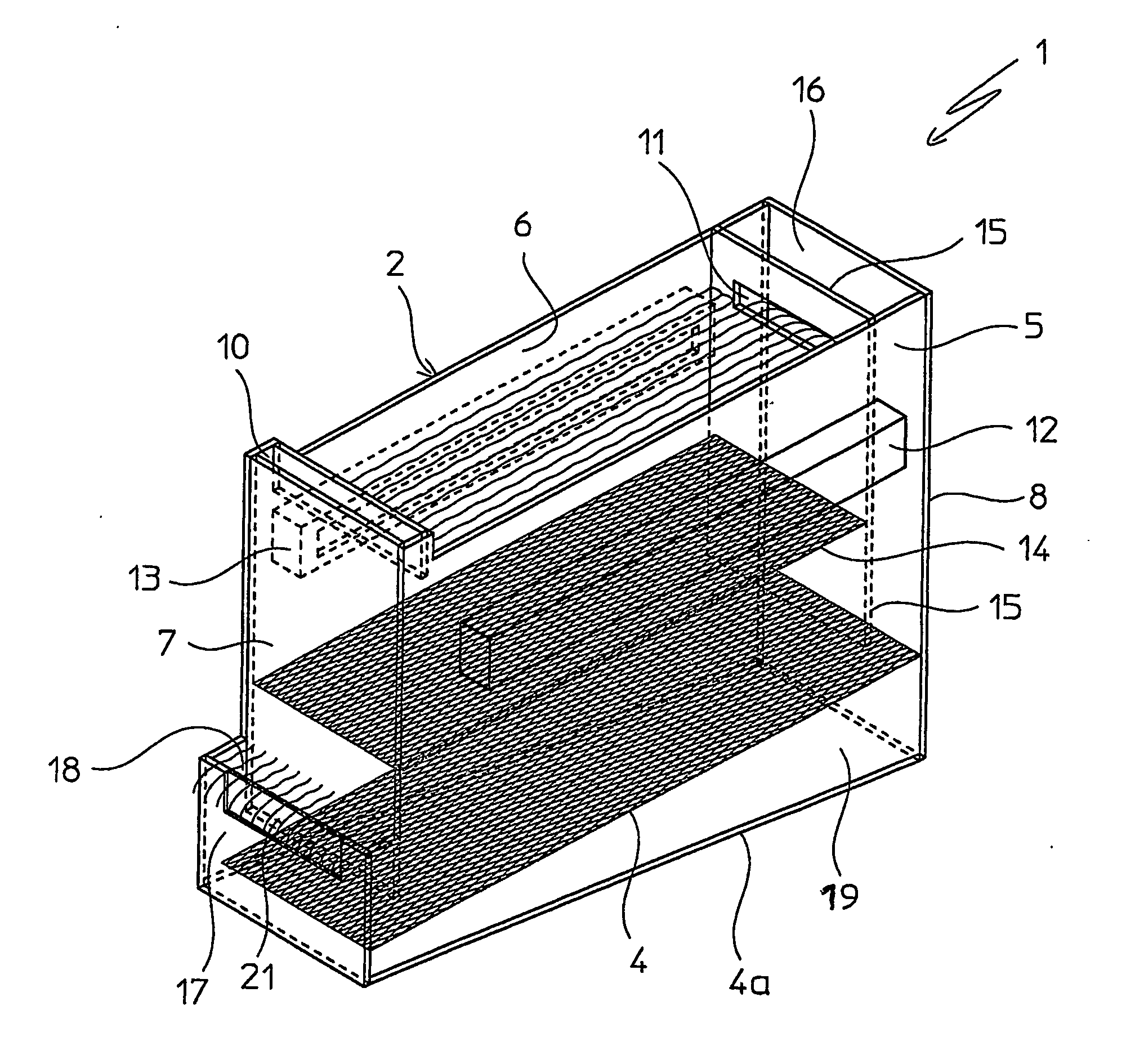

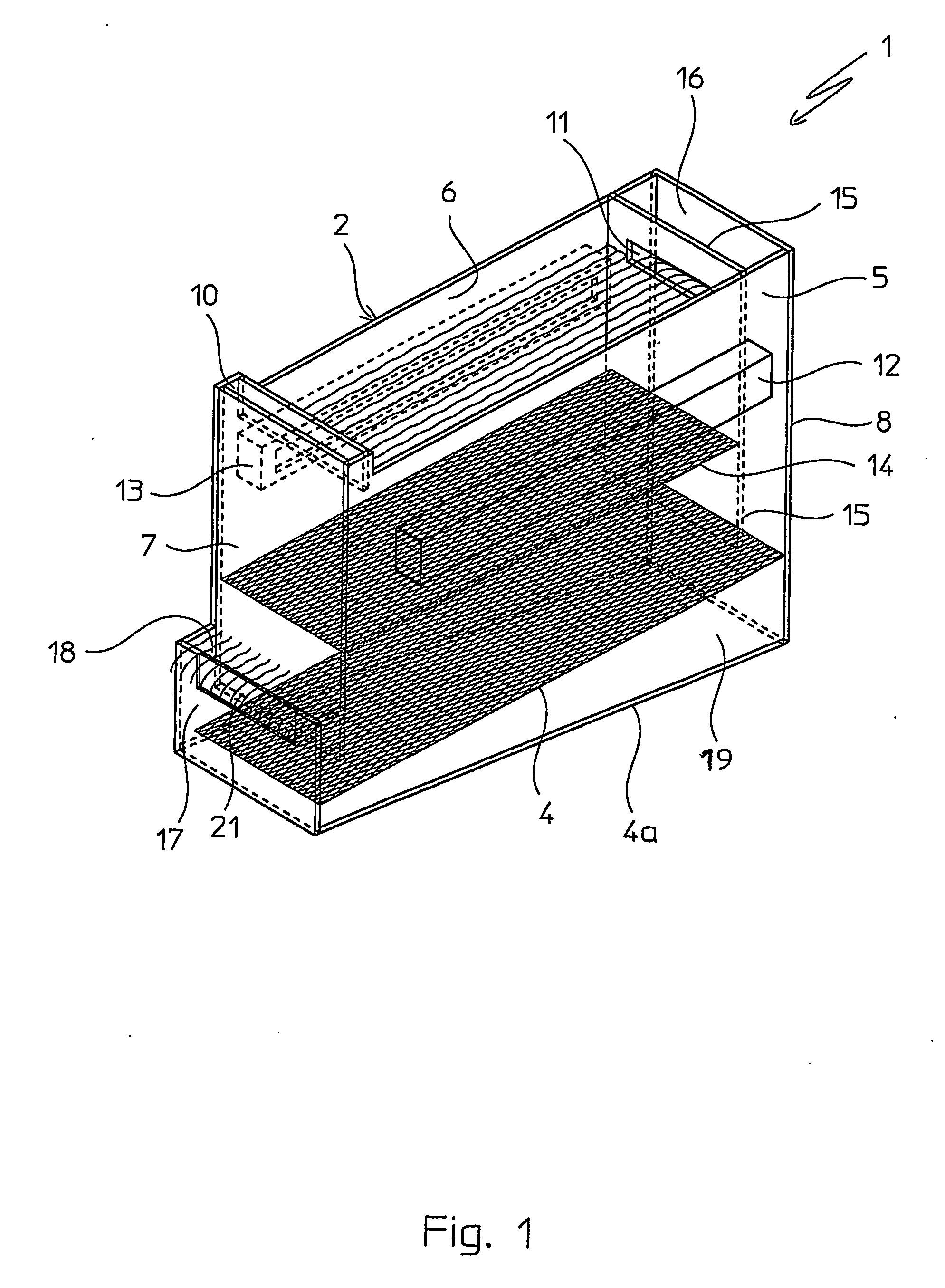

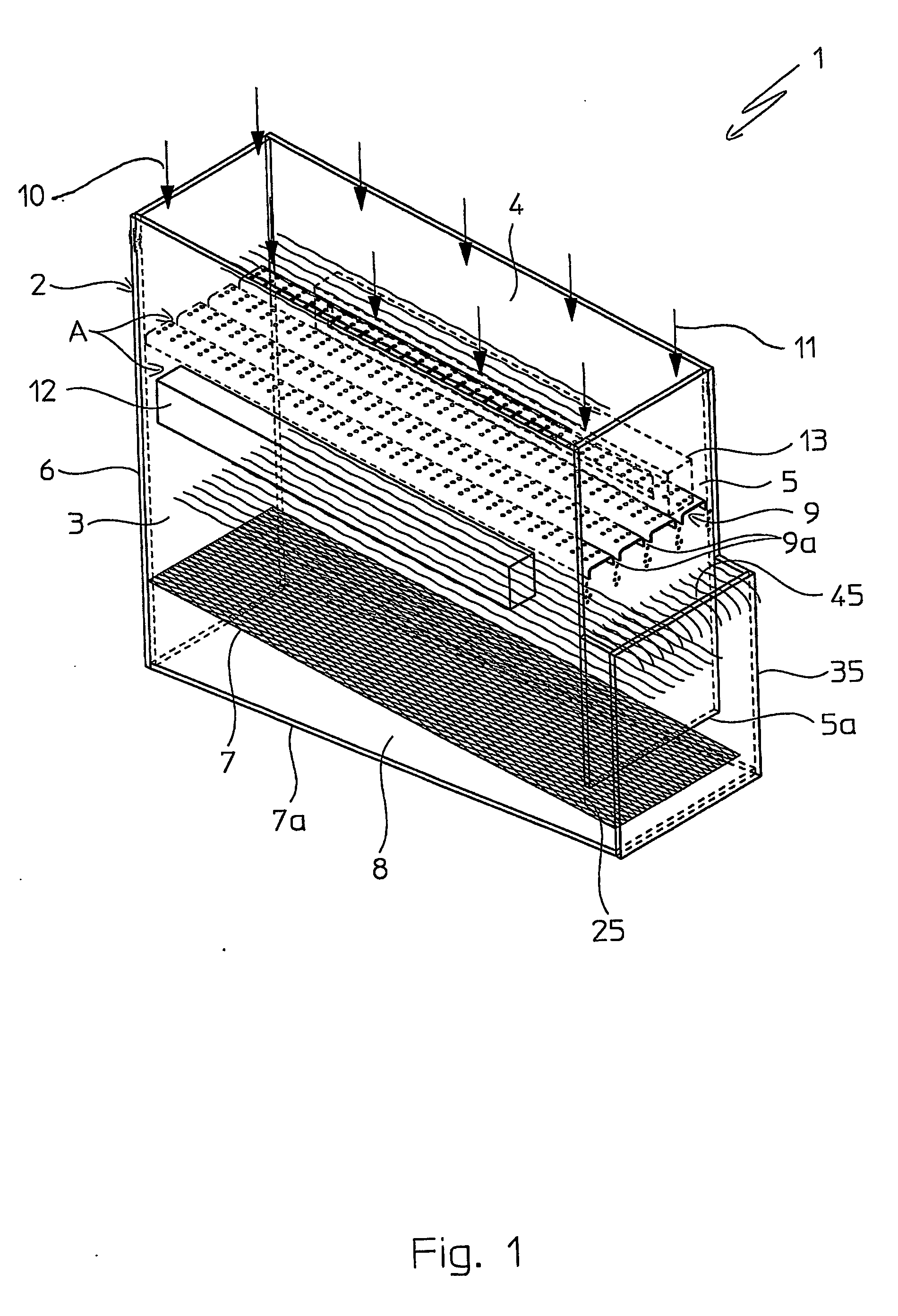

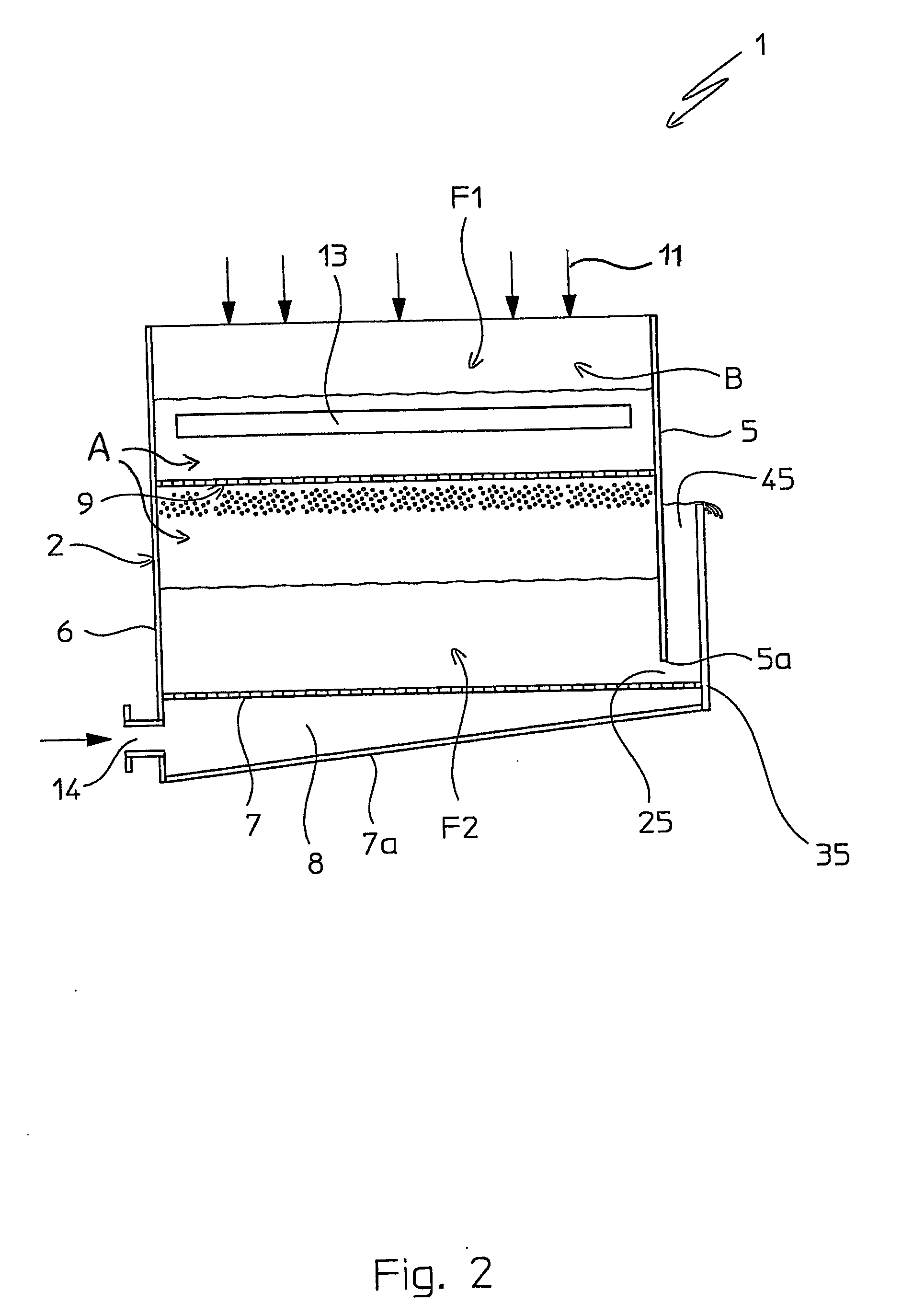

Fluid bed granulation process and apparatus

ActiveUS7966745B2Fully processedDrying using combination processesLiquid surface applicatorsEngineeringCooling fluid

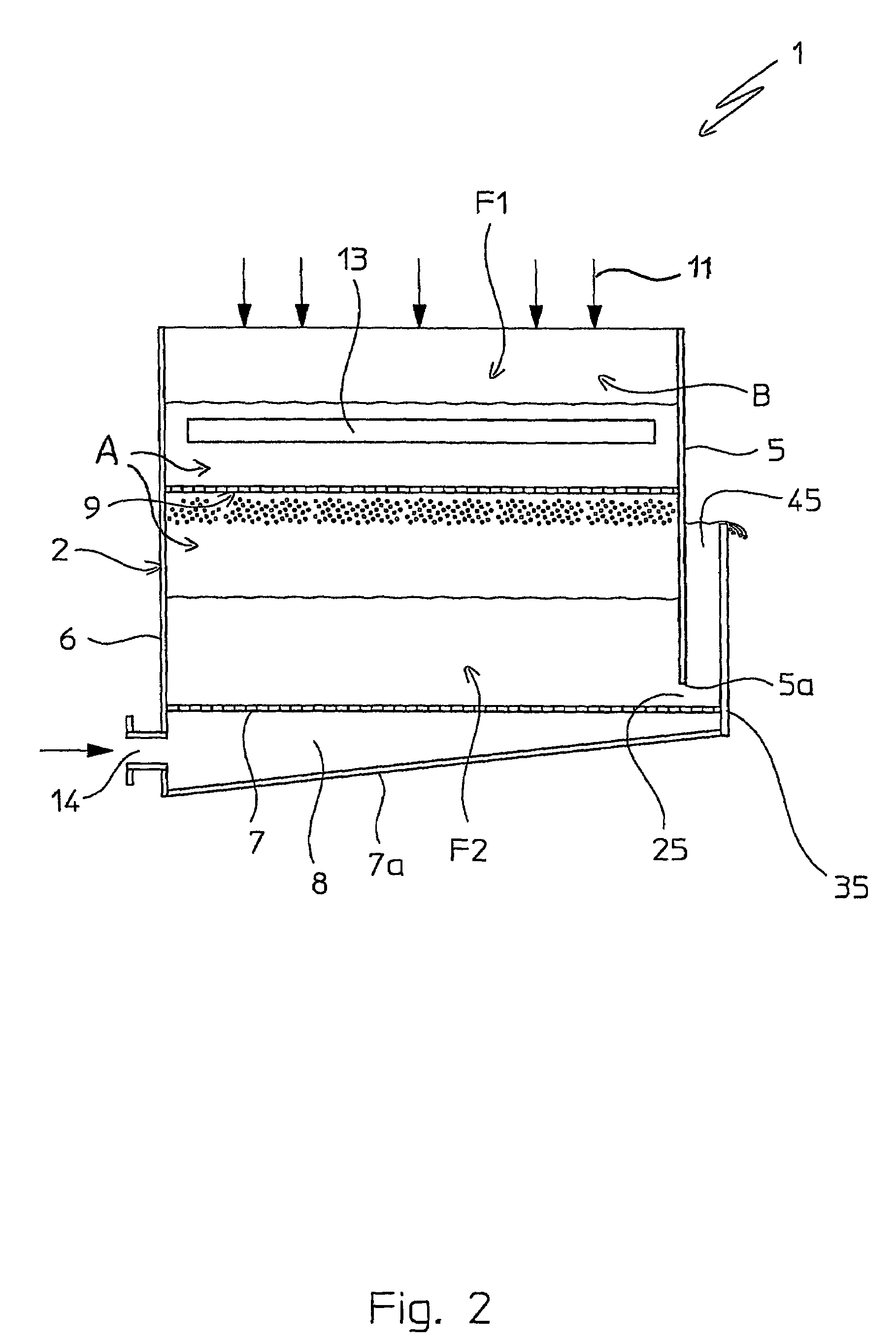

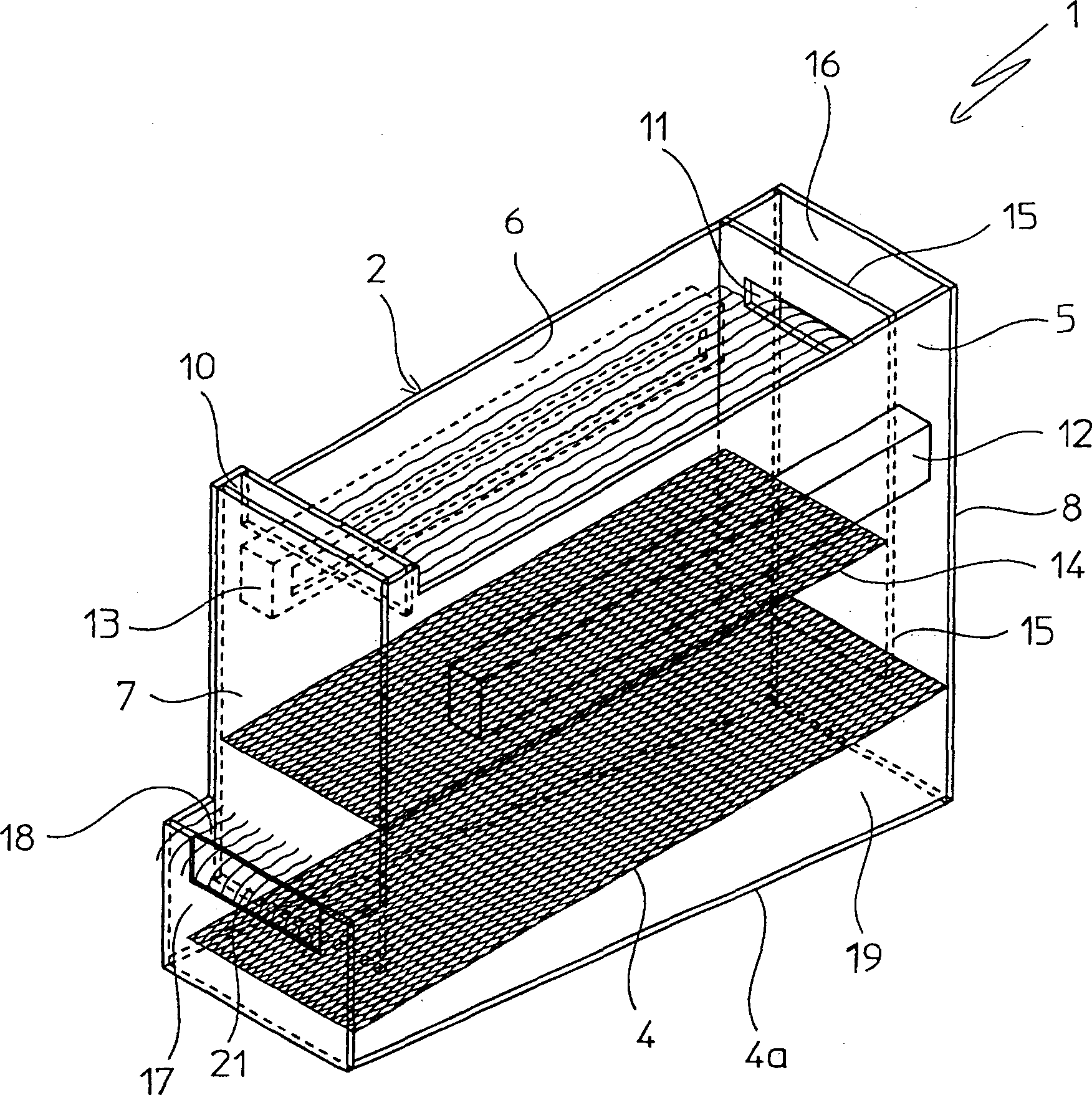

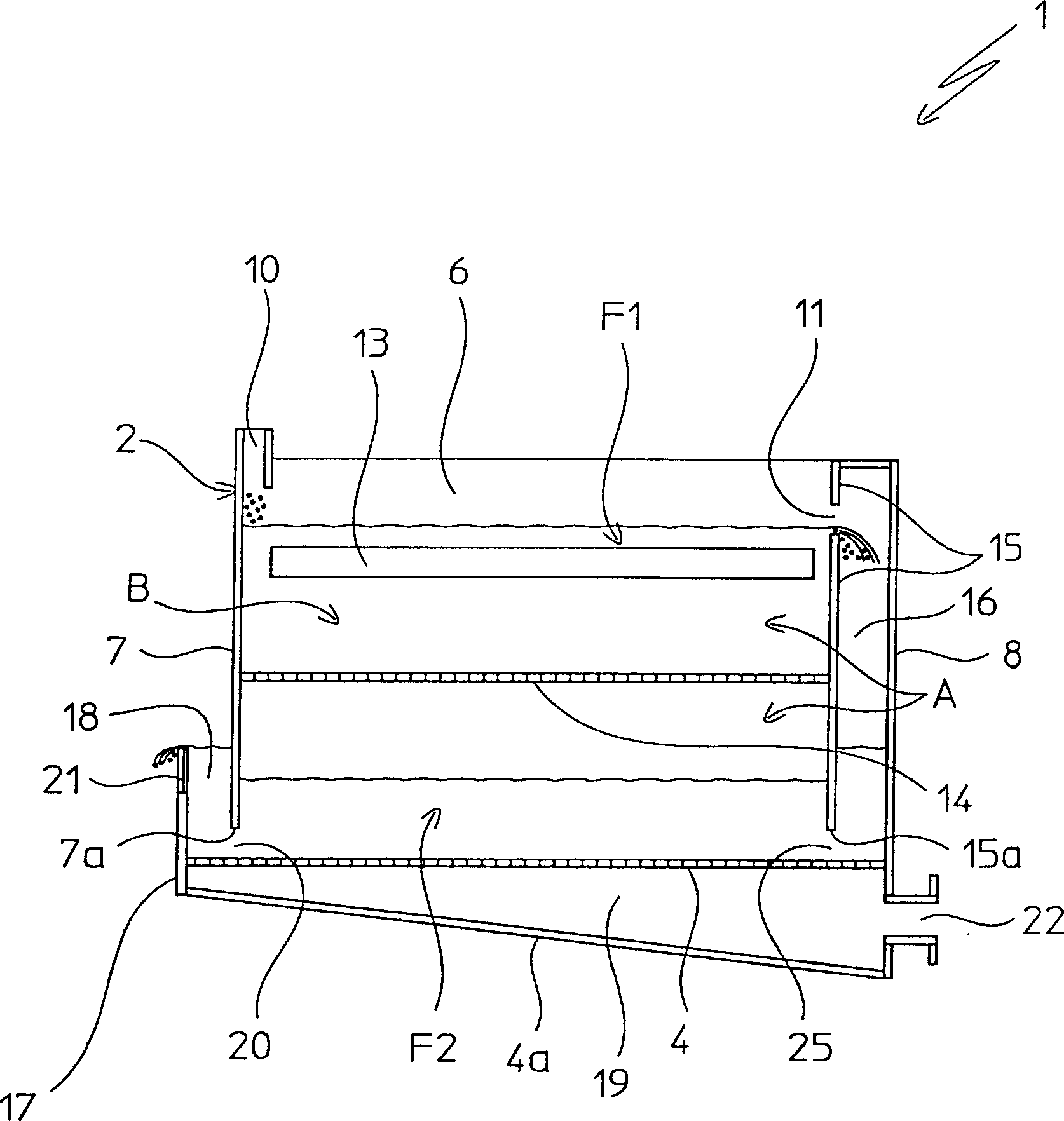

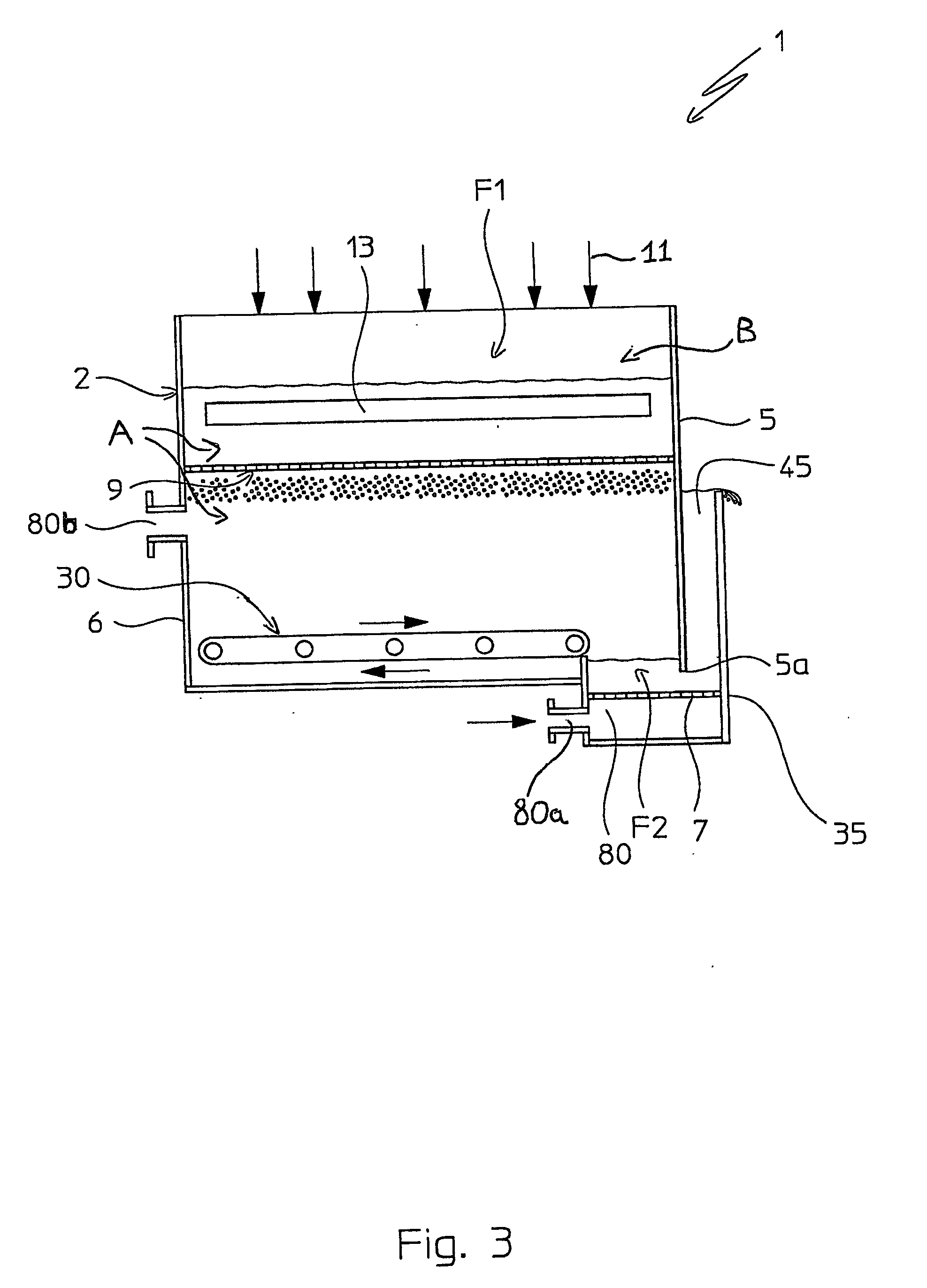

Fluid bed granulation process comprising the step of cooling the granules in a cooling fluid bed (F2). At least part of the fluidizing air coming out from said cooling fluid bed (F2) is fed into the granulation fluid bed (F1).

Owner:CASALE SA

Fluid Bed Granulation Process

InactiveUS20080299305A1Strict controlReduce formationLiquid surface applicatorsLiquid spraying apparatusContinuous flowEngineering

A fluid bed granulation process of a predetermined substance comprises the steps of: forming, through a fluidification. air flow of predetermined flow rate, a fluid bed of granules of said substance to be granulated fed to it in the form of seeds, —feeding said fluid bed with a continuous flow of a growth substance (or liquid).

Owner:CASALE SA

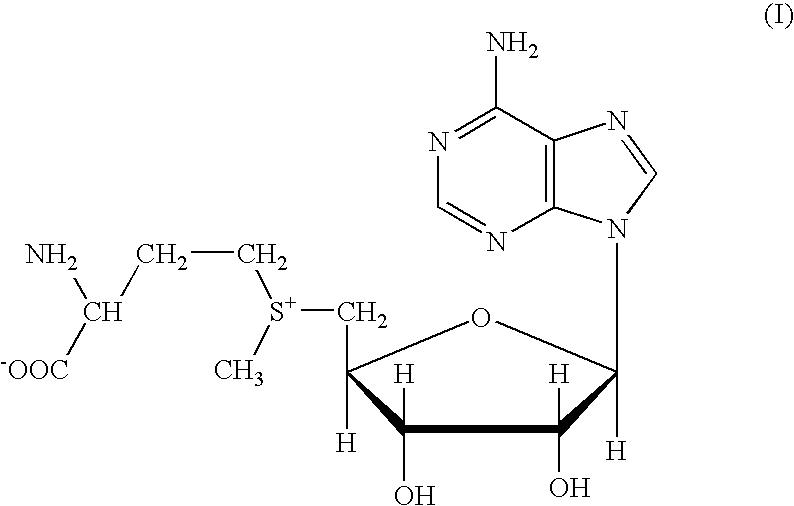

Stable granulates containing S-adenosylmethionine and process for the preparation thereof

InactiveUS7048948B2Low costShorten the timeBiocideOrganic active ingredientsS-Adenosyl methionineS-Adenosyl-l-methionine

A fluid bed granulation process for manufacturing non-hygroscopic, stable granulates containing a water-soluble salt of S-adenosylmethionine is described. Said process comprises:a) the simultaneous, sequential or alternate dispersion of at least a solution of a water-soluble salt of SAMe (A) and of a solution of a coating agent (B), on a fluid bed granulation carrier (C) andb) the fluid bed granulation of the mixture.Granulates obtainable by said process and solid oral pharmaceutical forms obtainable by said granulates are disclosed.

Owner:CHEM & HEALTH INT

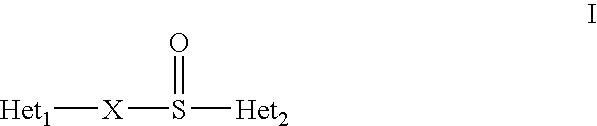

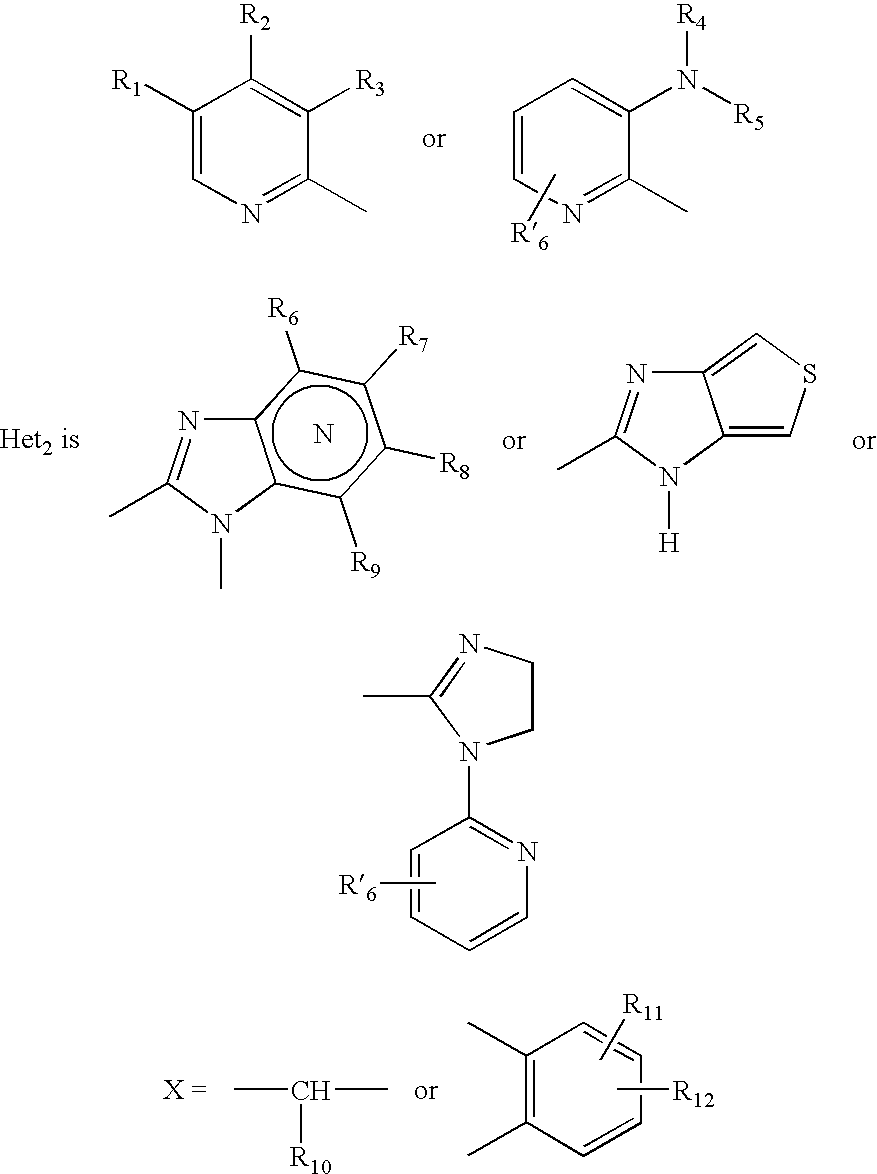

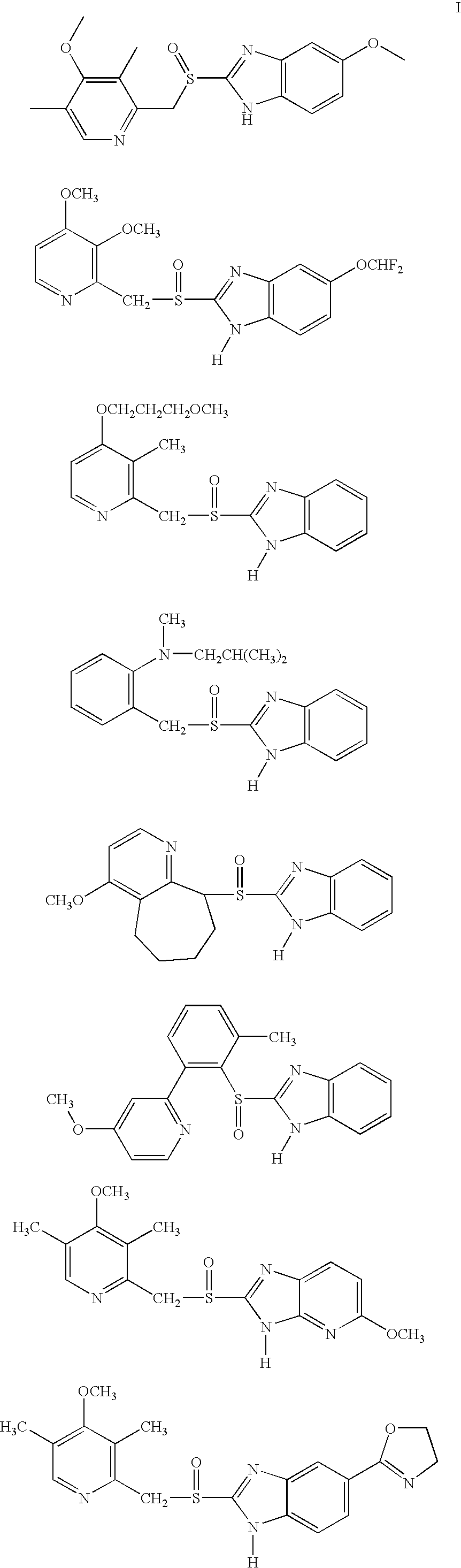

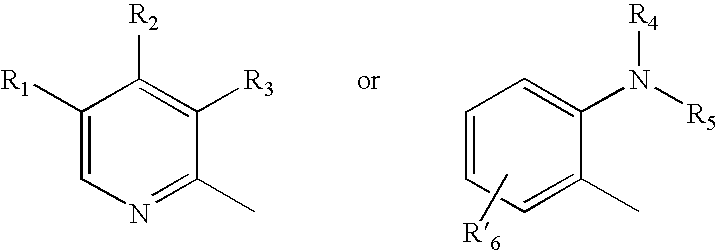

Mehtod to obtain microparticles containing a h+ k+ atp-ase inhibitor

InactiveUS20040101565A1Reduce brittlenessHigh mechanical strengthPowder deliveryOrganic active ingredientsMicroparticleBiochemistry

A method for the preparation of homogenous microparticles containing a H<+>, K<+>-ATP-ase inhibitor using a fluid-bed granulation technique. The microparticles that have a desired size distribution are selected. At least 80% of the microparticle based on its dry weight content is the acid labile H<+>, K<+>-ATP-ase inhibitor.

Owner:ASTRAZENECA AB

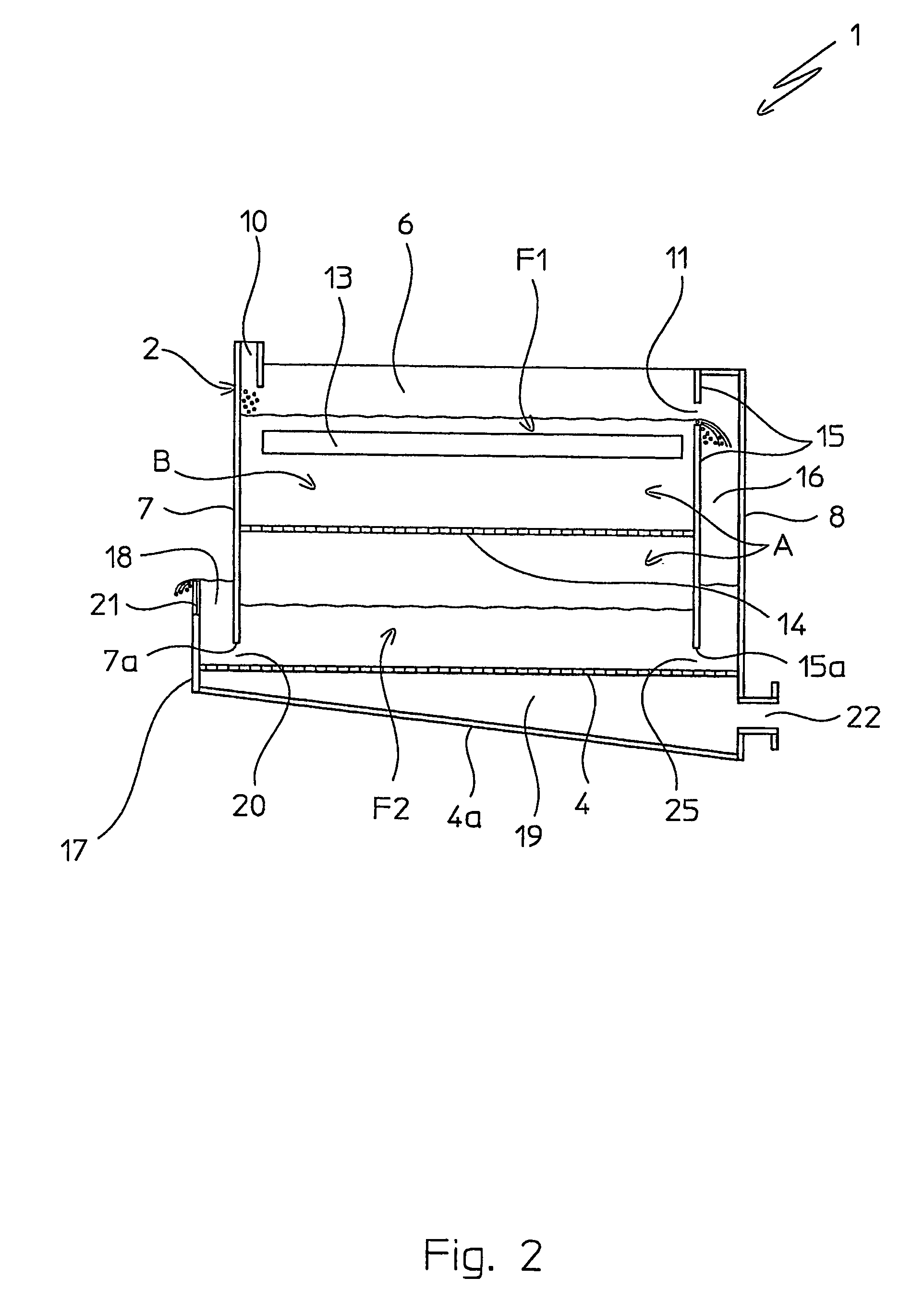

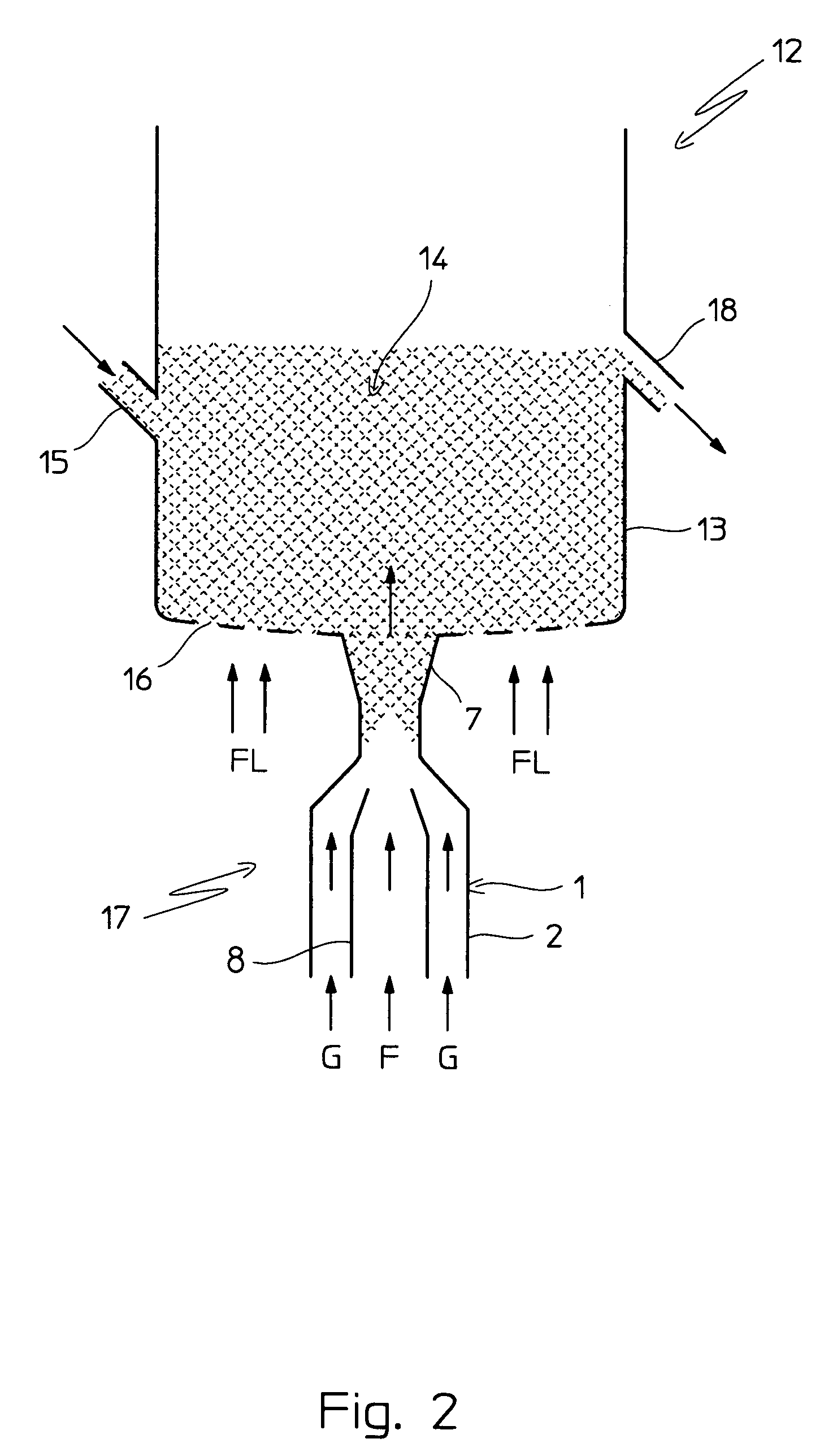

Fluid bed granulation process and apparatus

ActiveUS7637966B2Easy to carryReliable recoveryDrying solid materials with heatDetergent mixture composition preparationVertical growthRecovery phase

A process for obtaining finished granules of a predetermined substance in a granulation fluid bed (F1) of the so-called vertical growth type, the bed being formed and maintained by a respective flow of fluidification air, comprises a transfer phase by falling of the finished granules in a pressurized space below the granulation bed and a recovery phase of the finished granules from the pressurized space.

Owner:CASALE SA

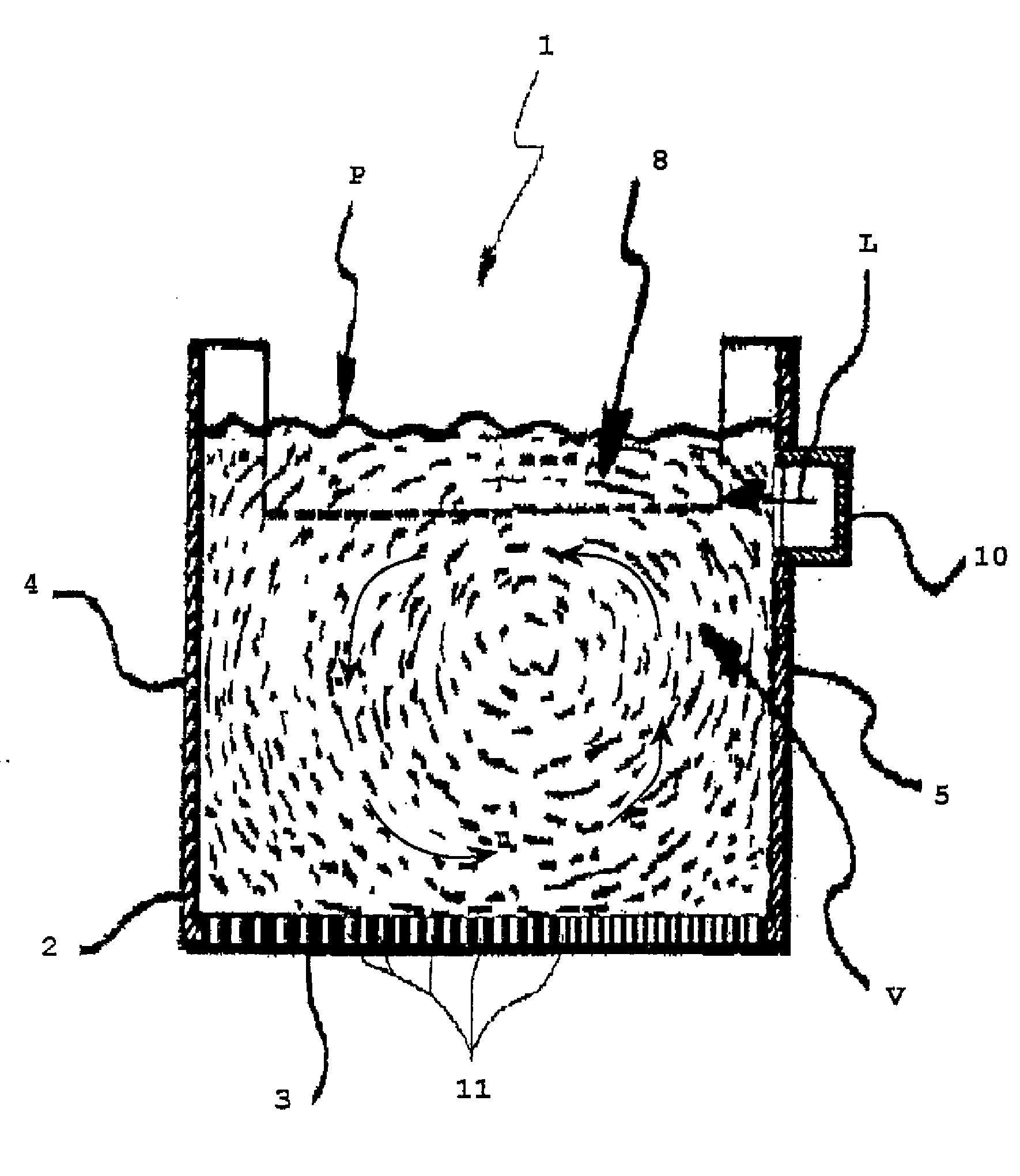

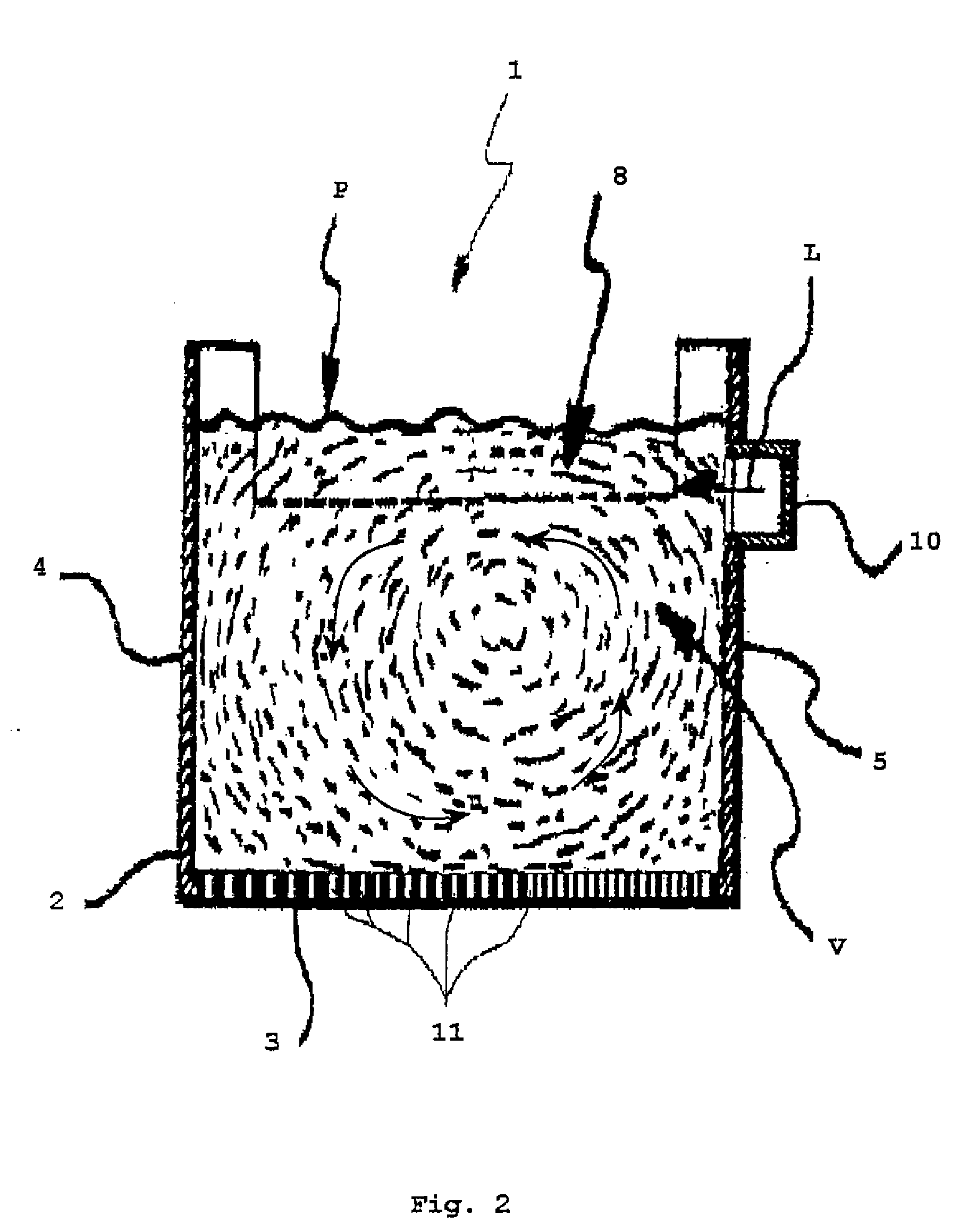

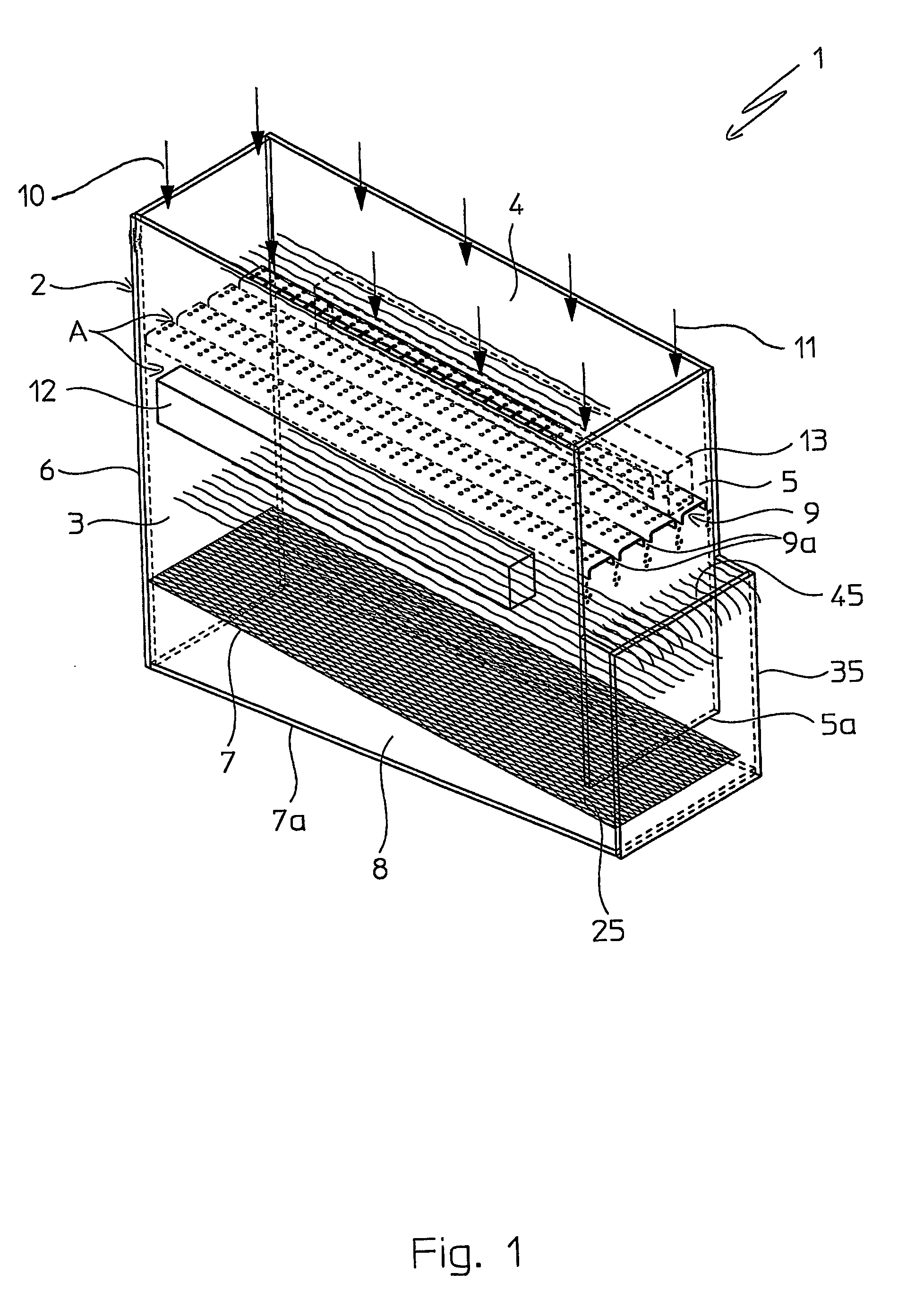

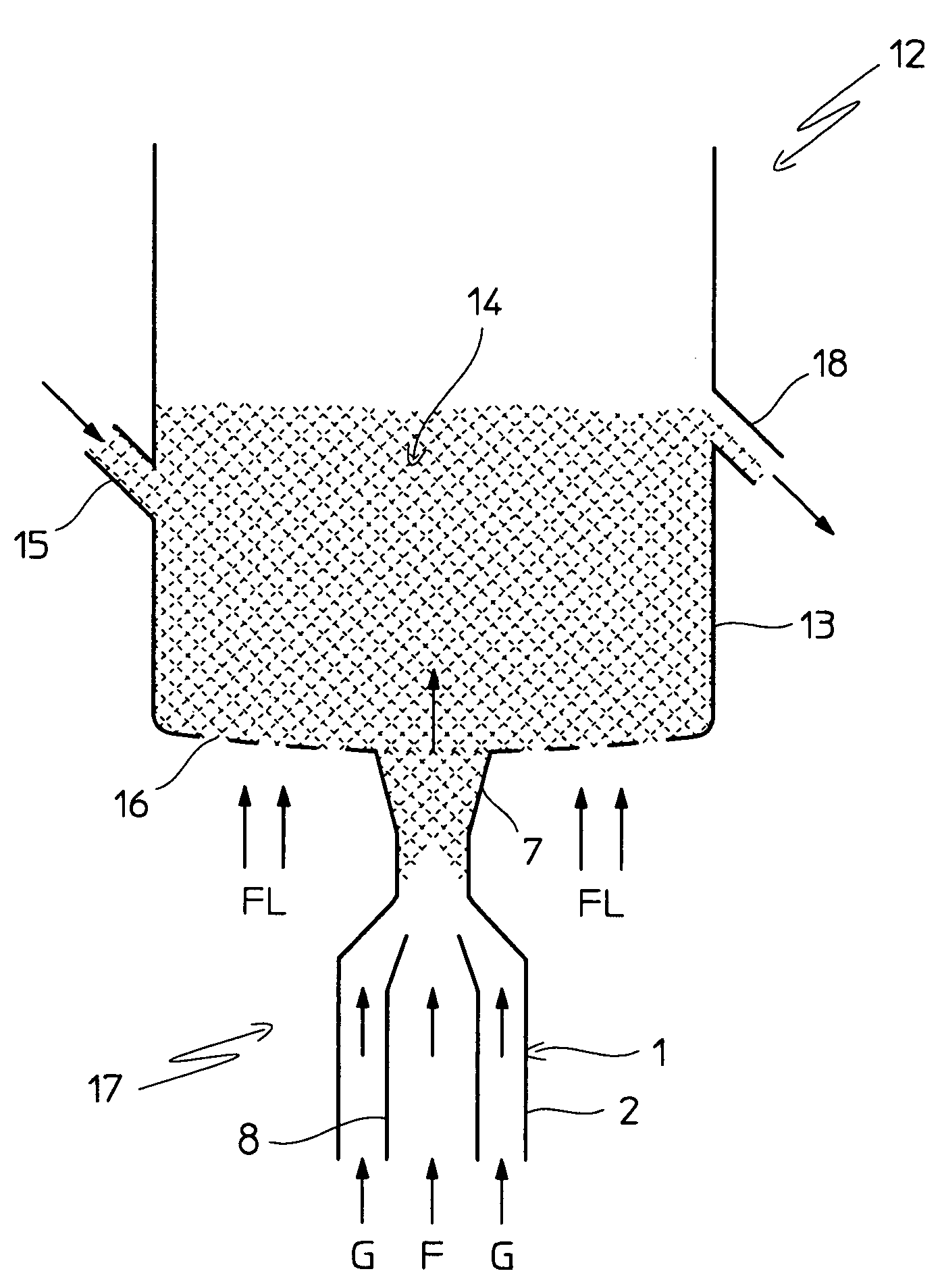

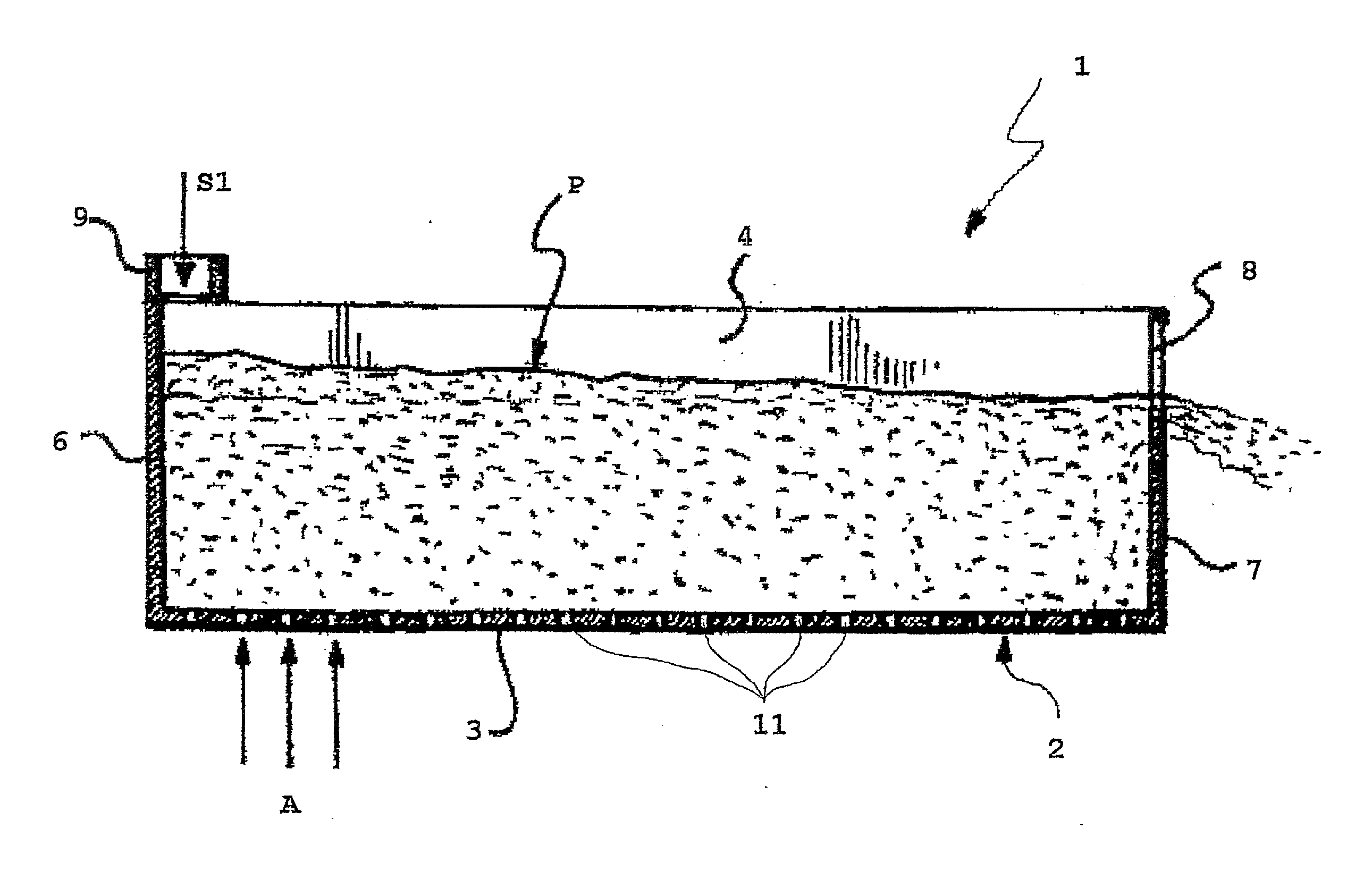

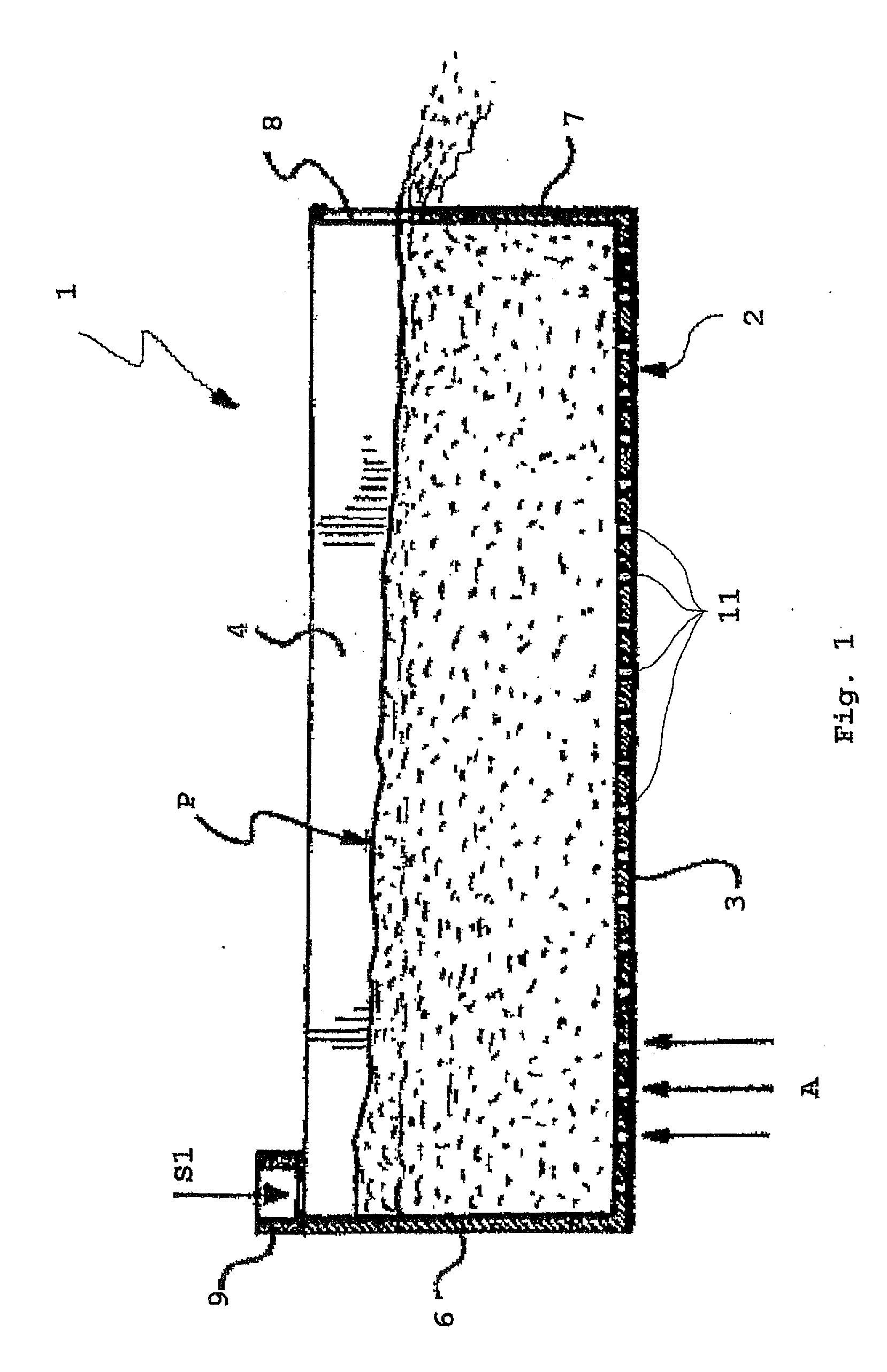

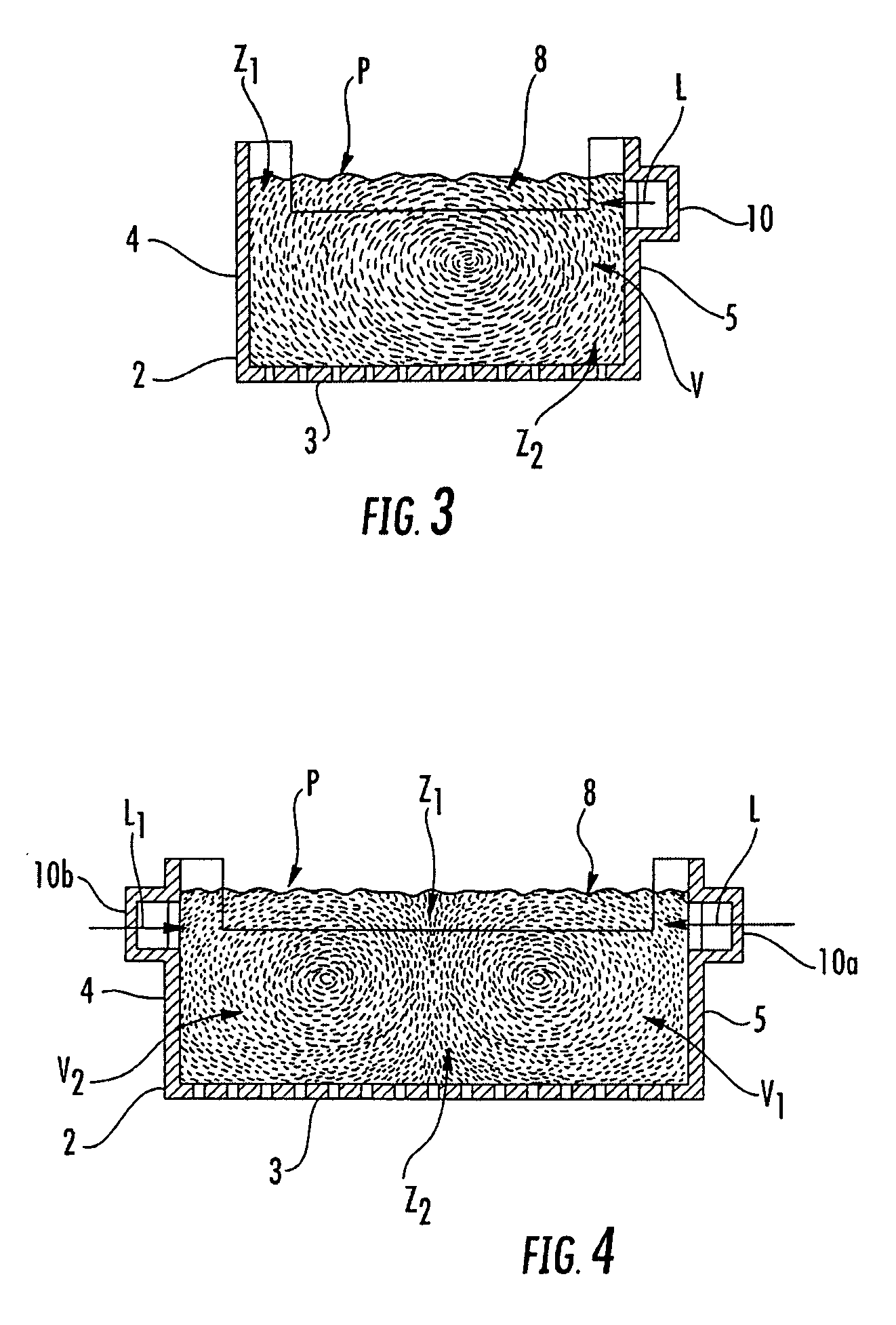

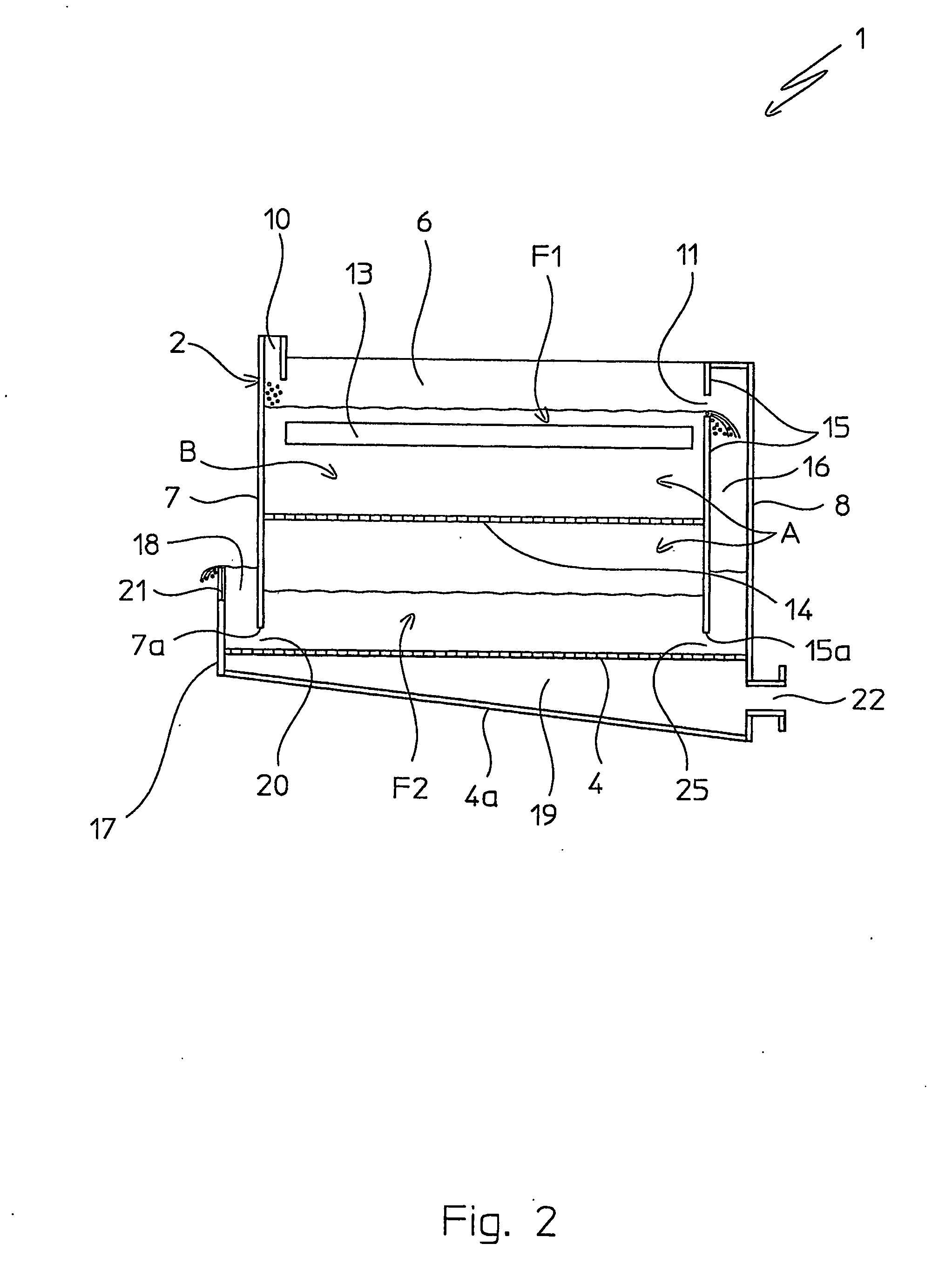

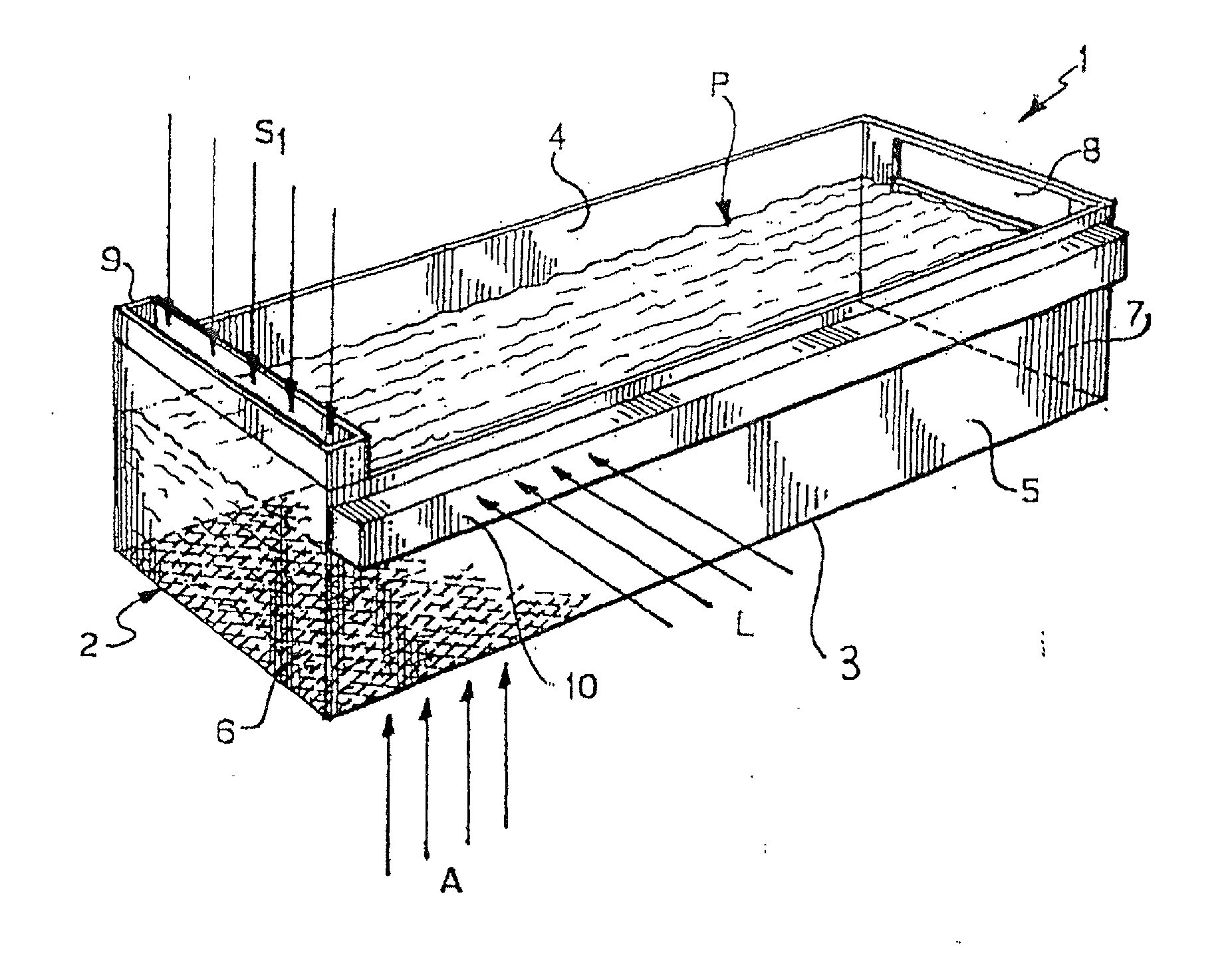

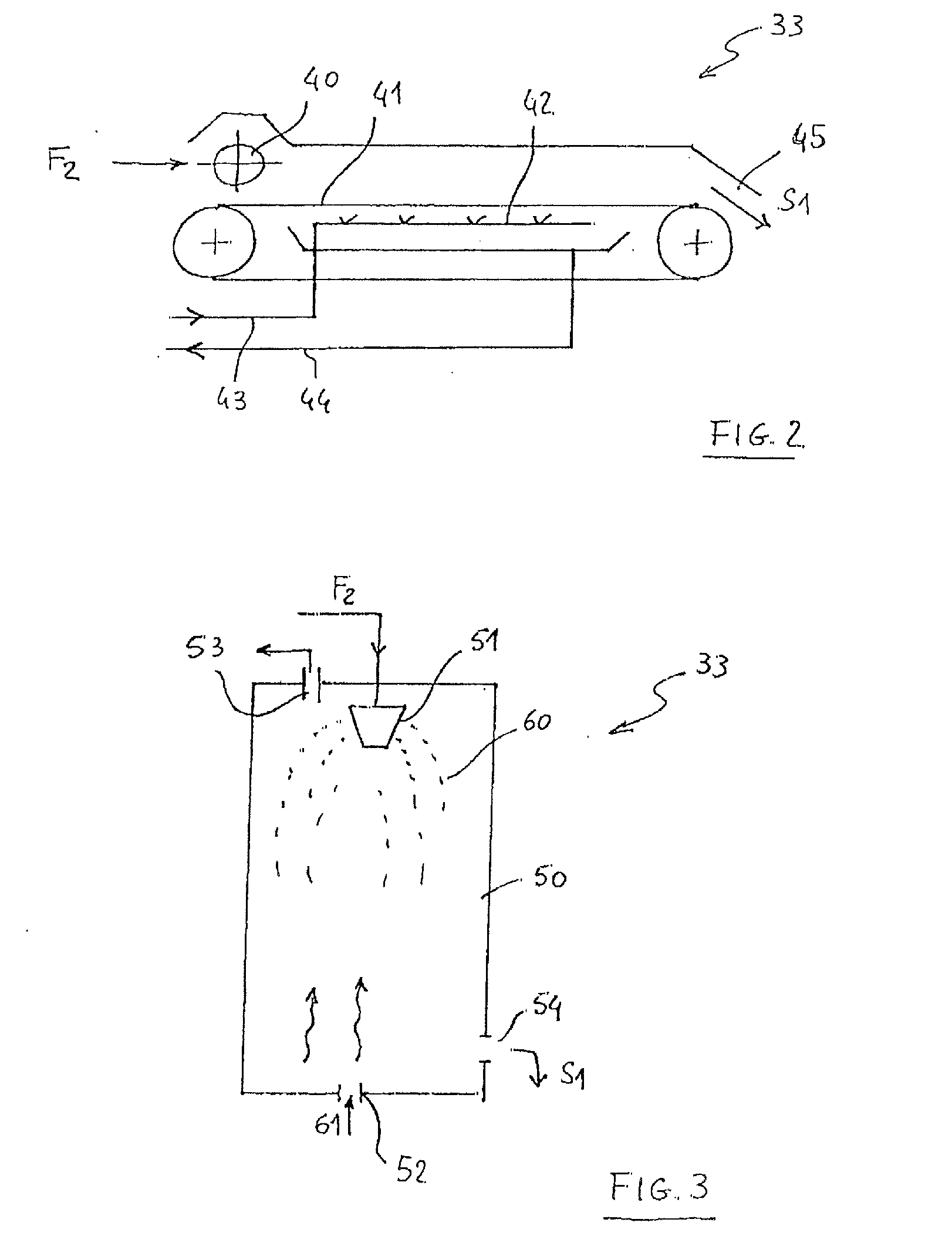

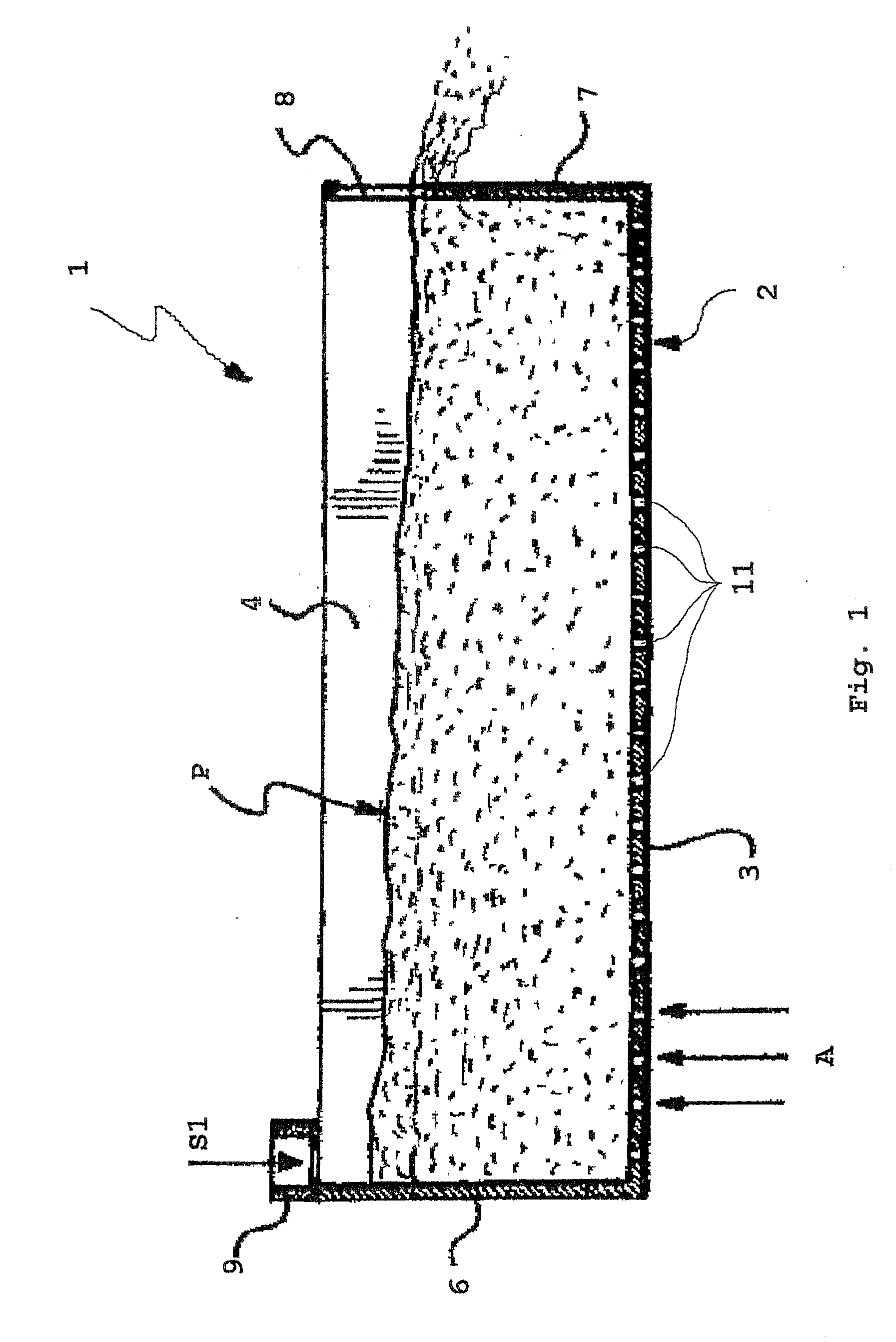

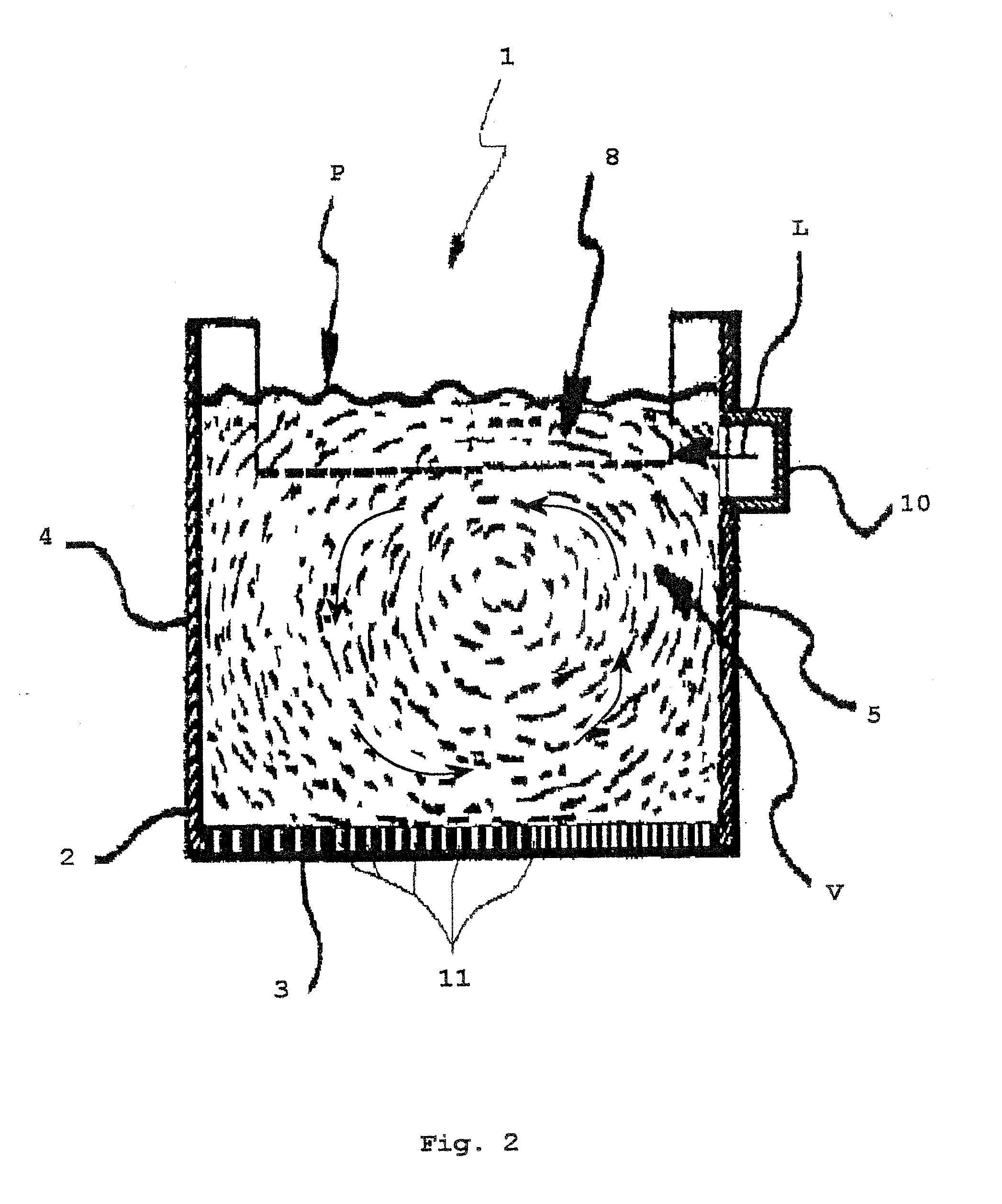

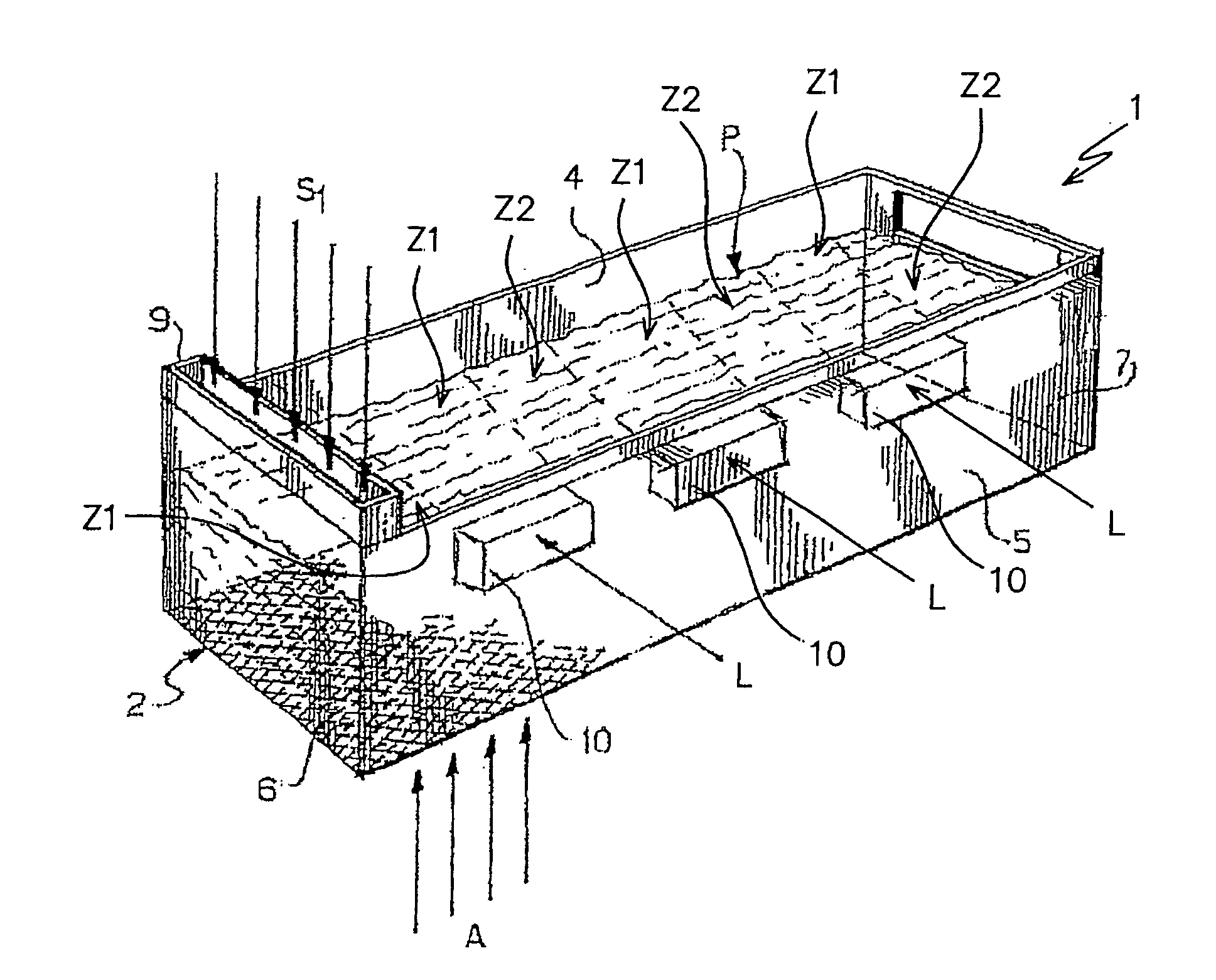

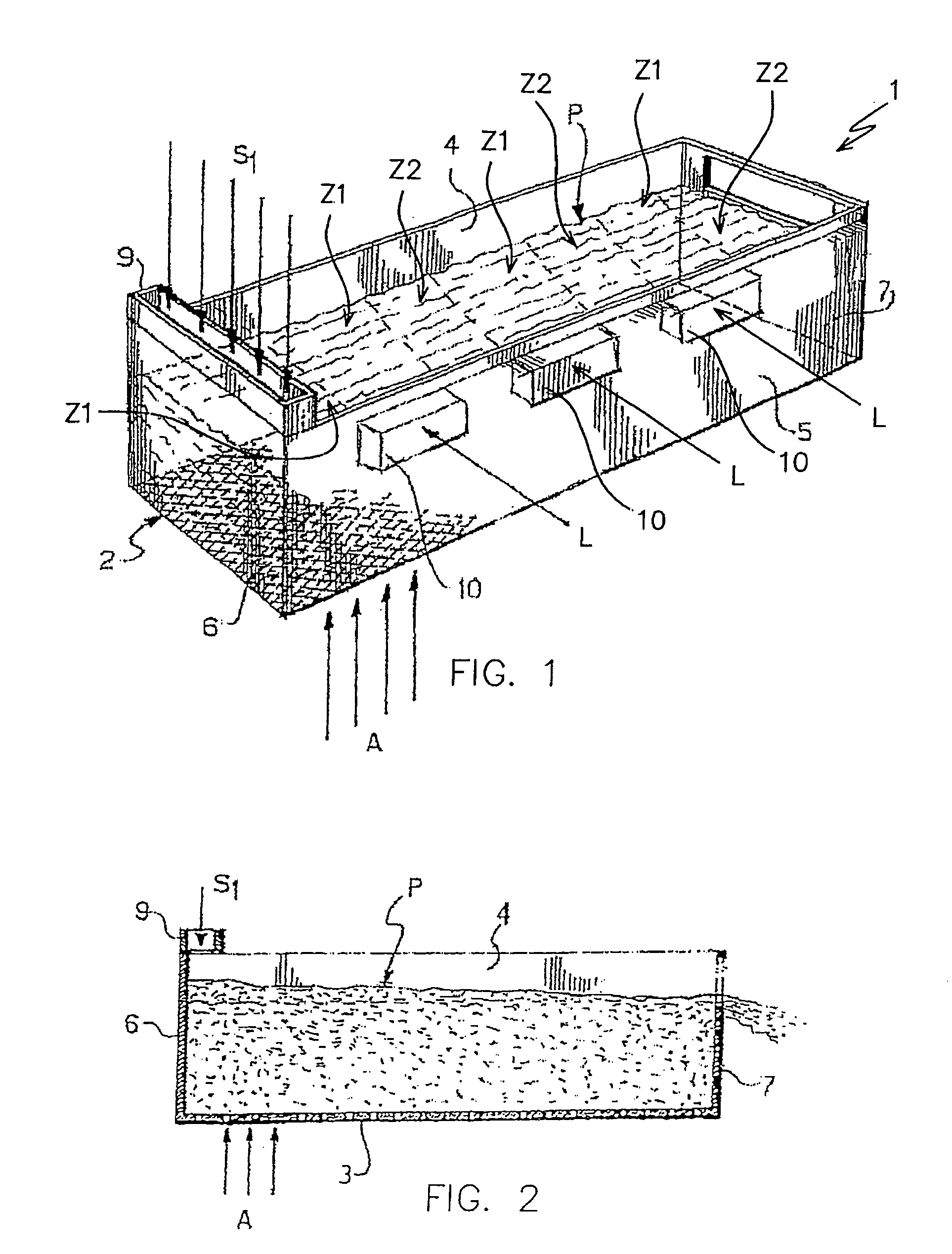

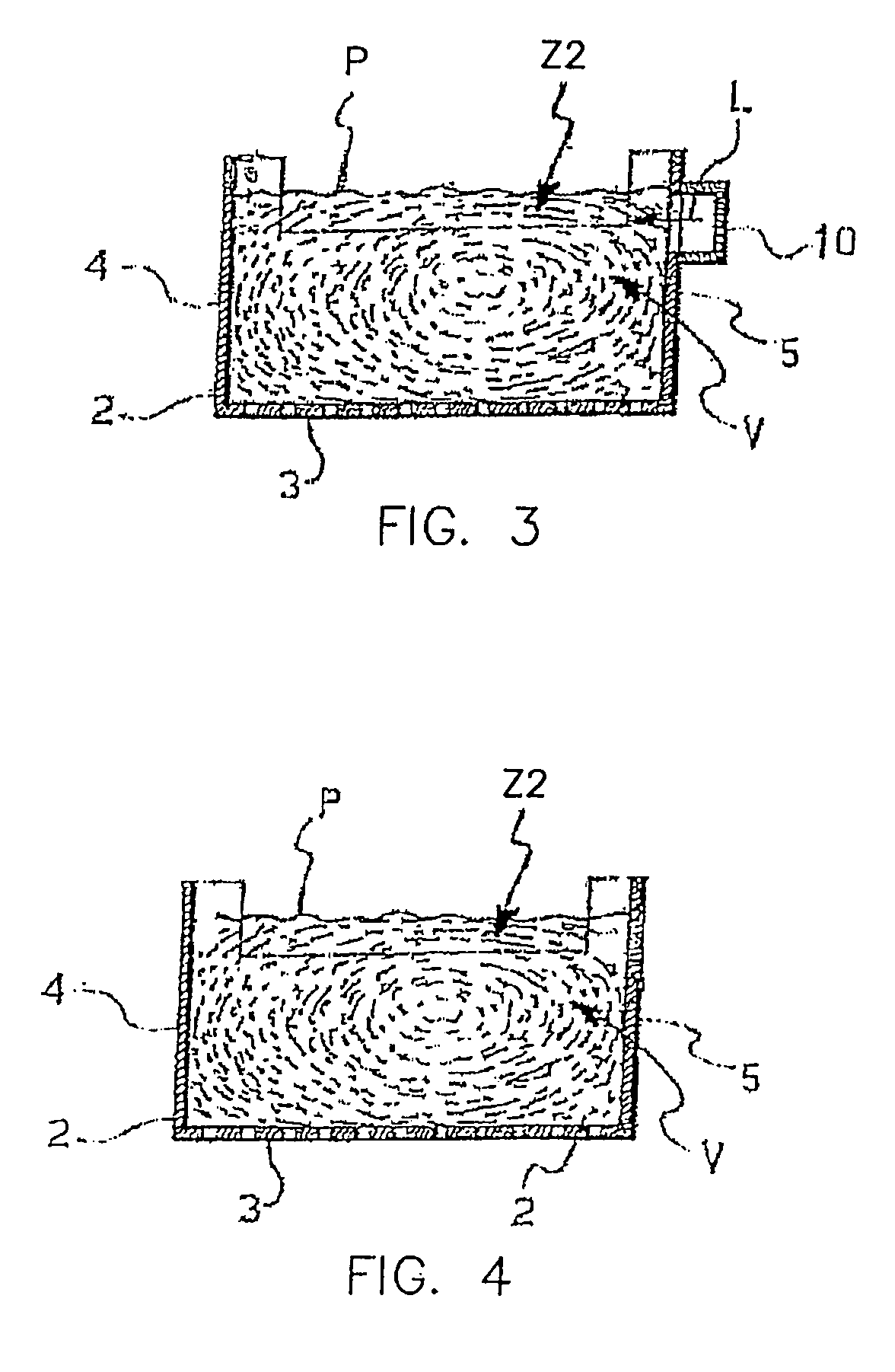

Fluid bed granulation process

ActiveUS7438729B2Drying solid materials with heatGranulation by powder suspensionHorizontal axisEvaporation

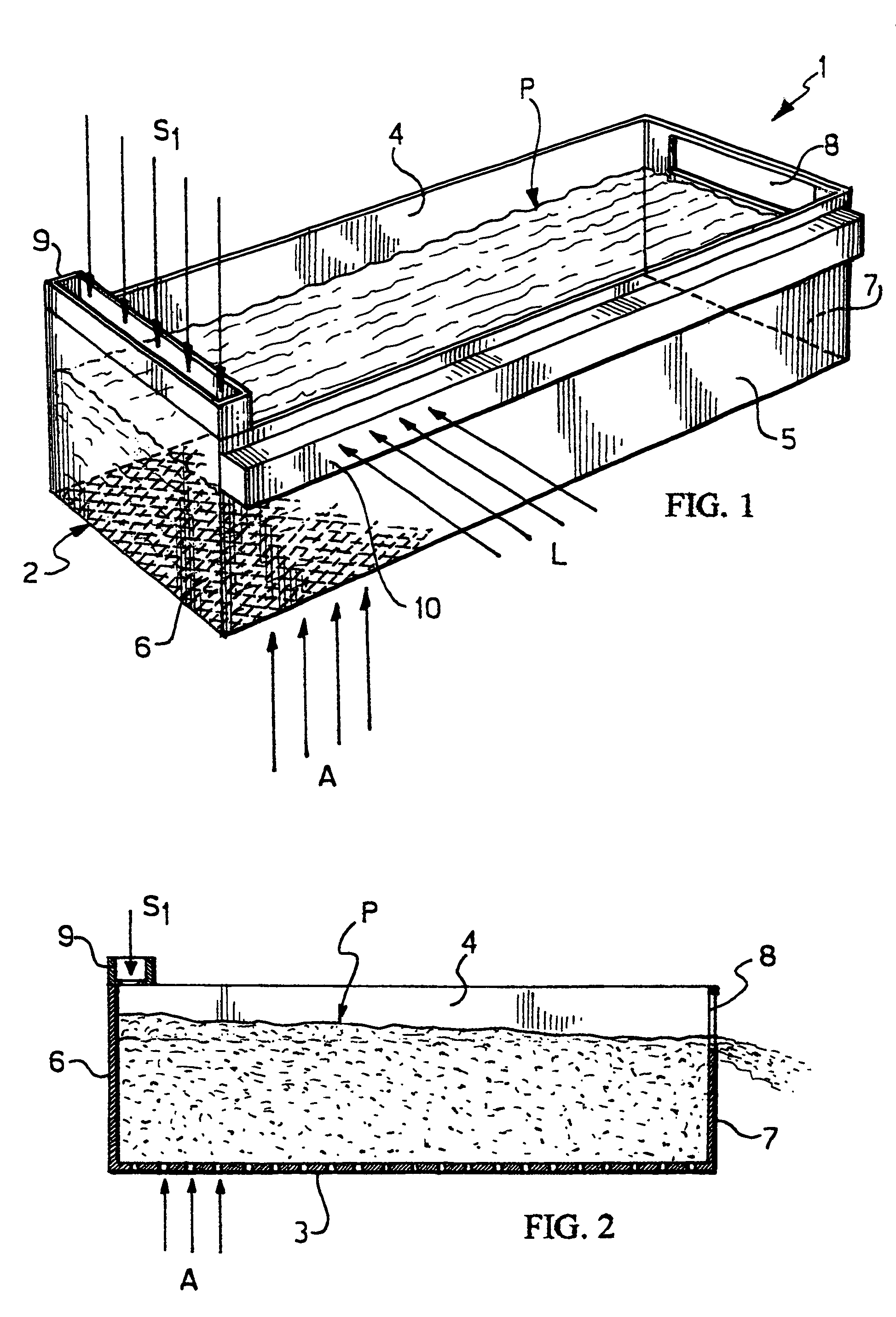

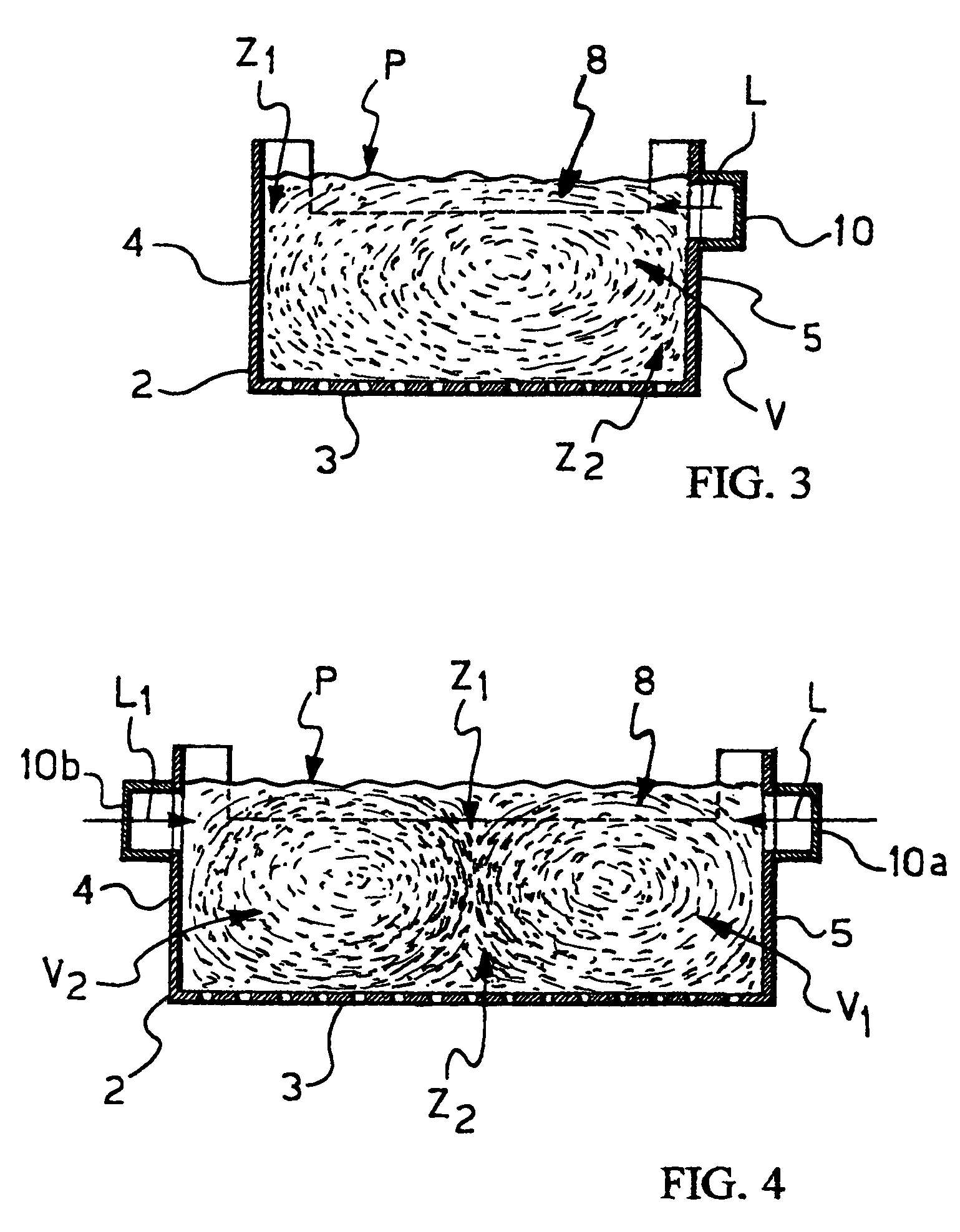

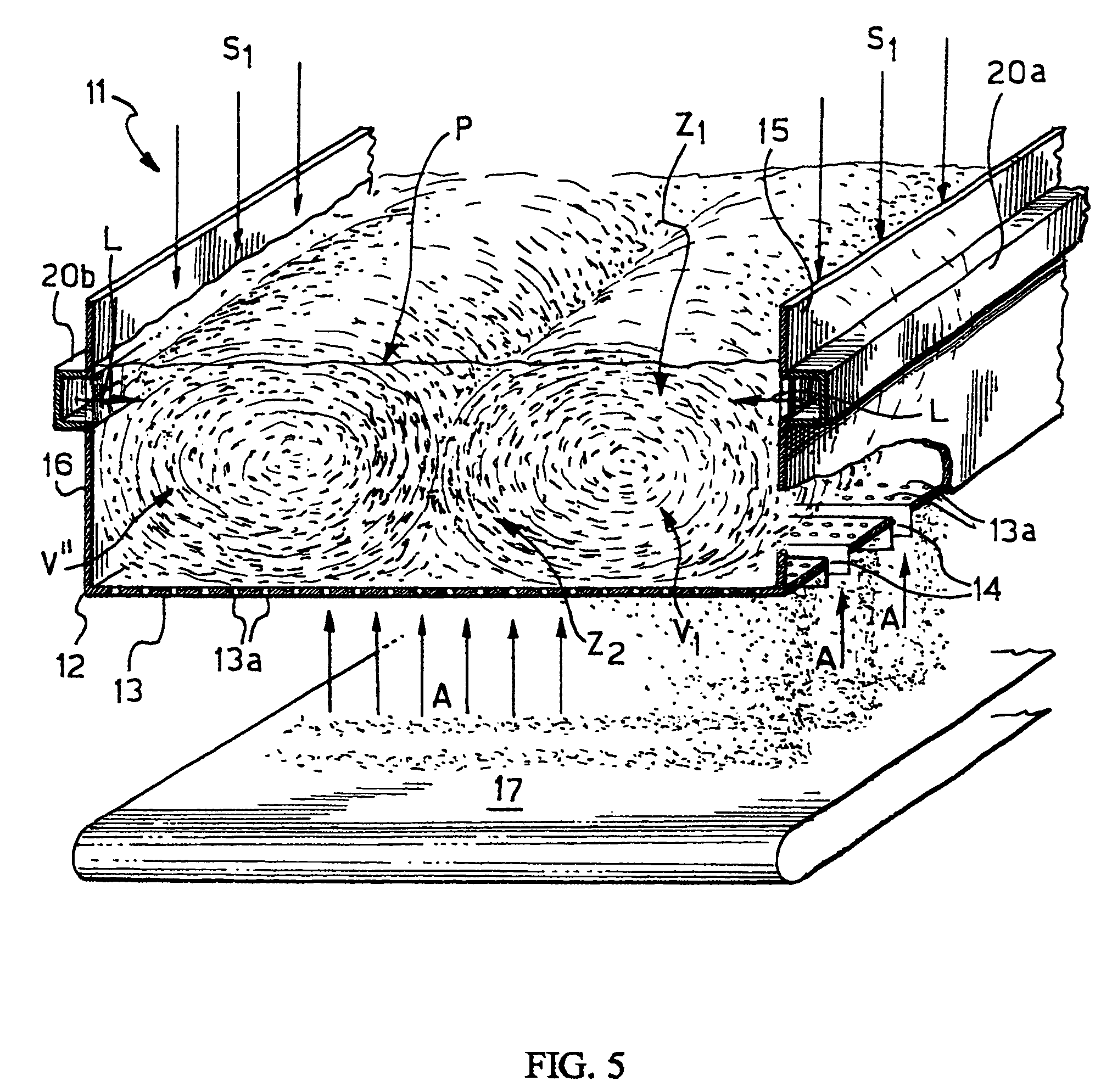

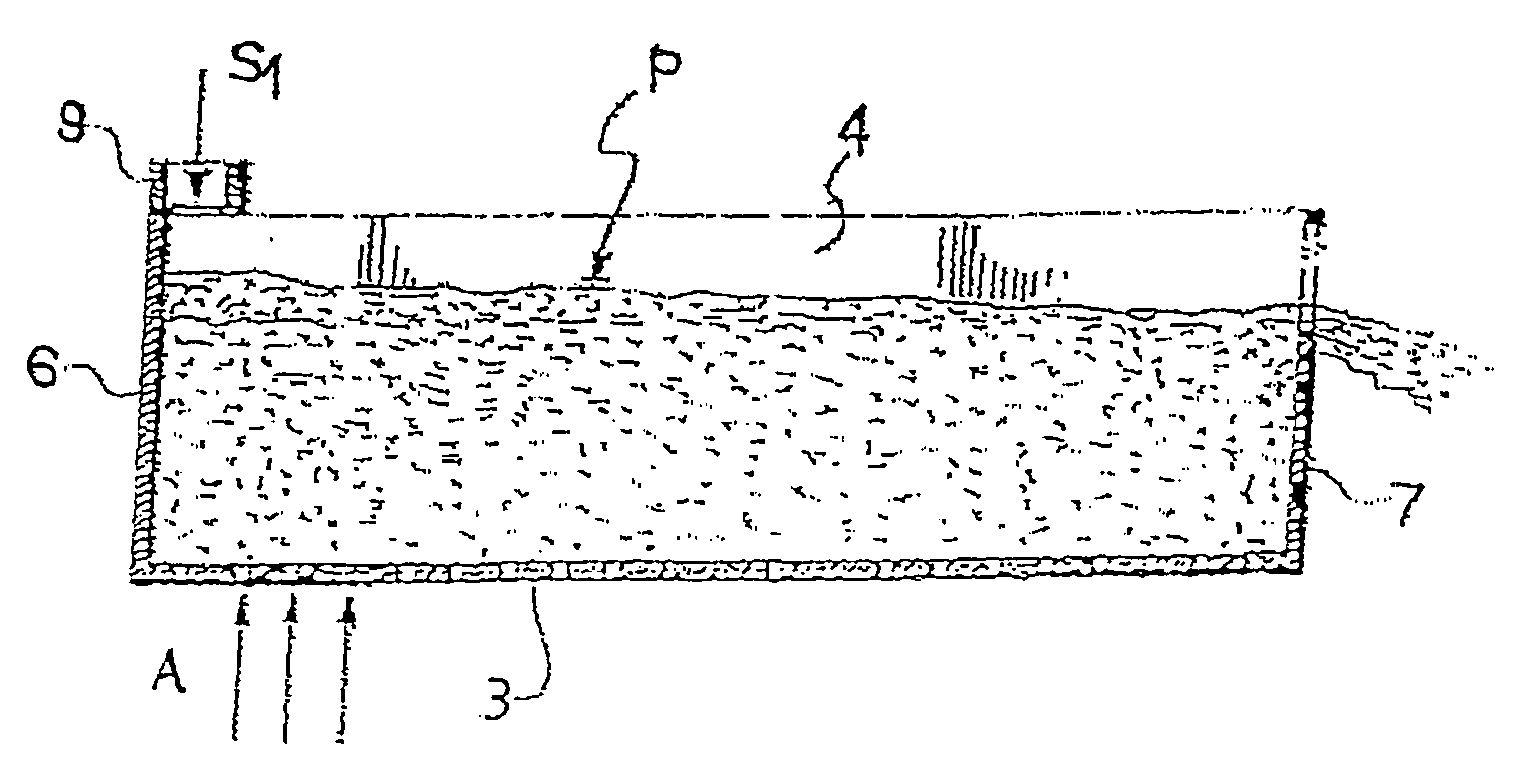

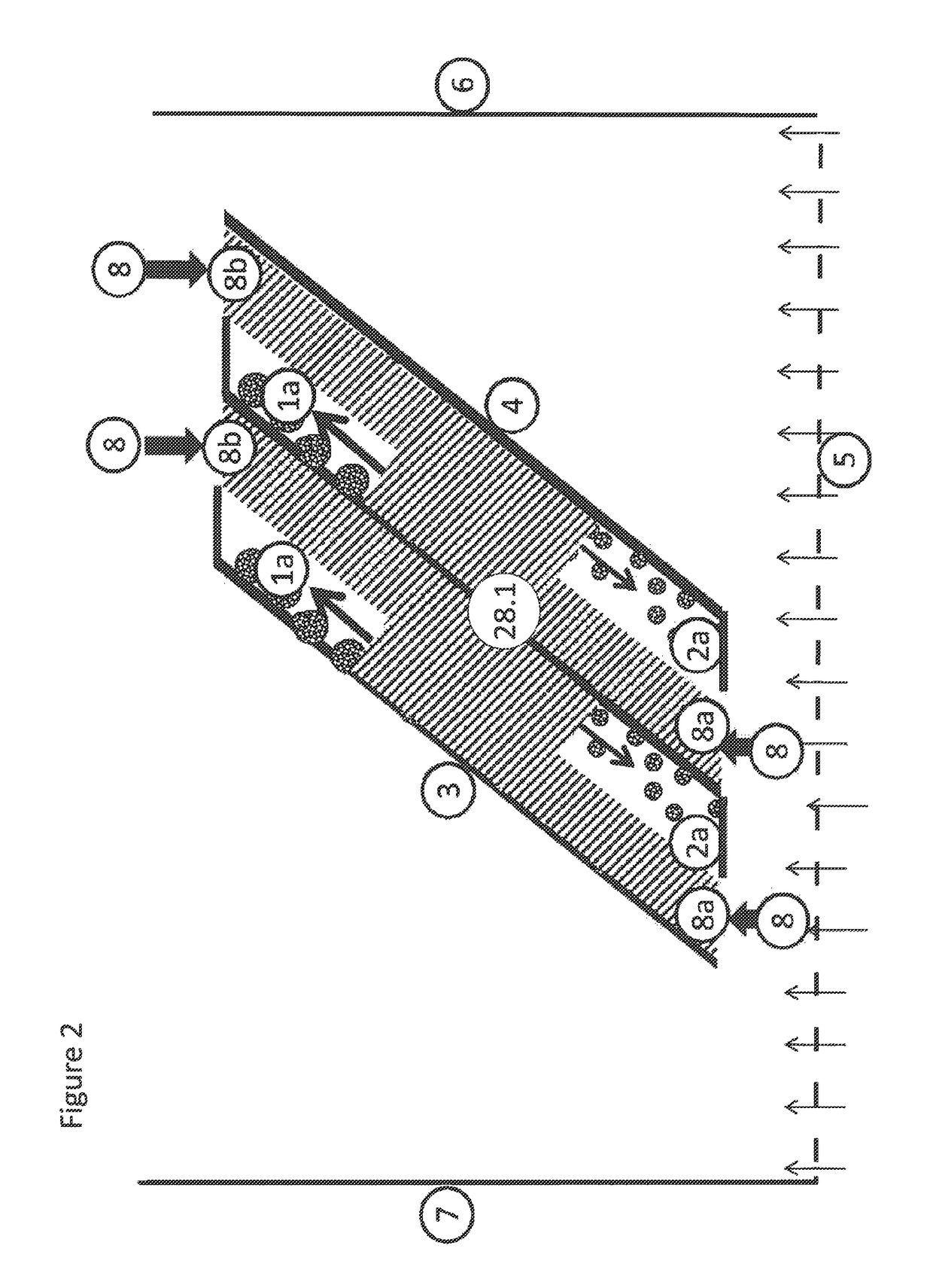

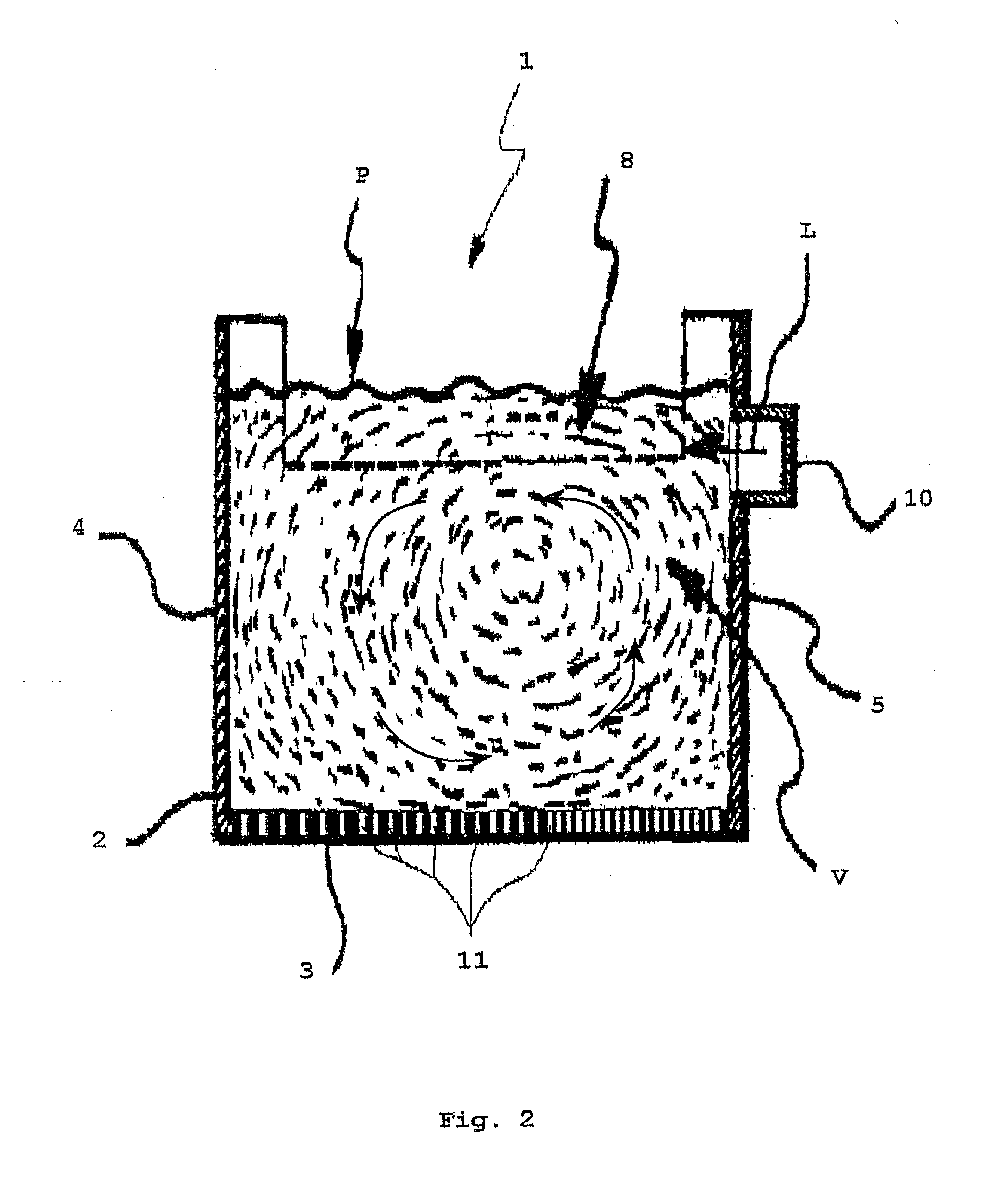

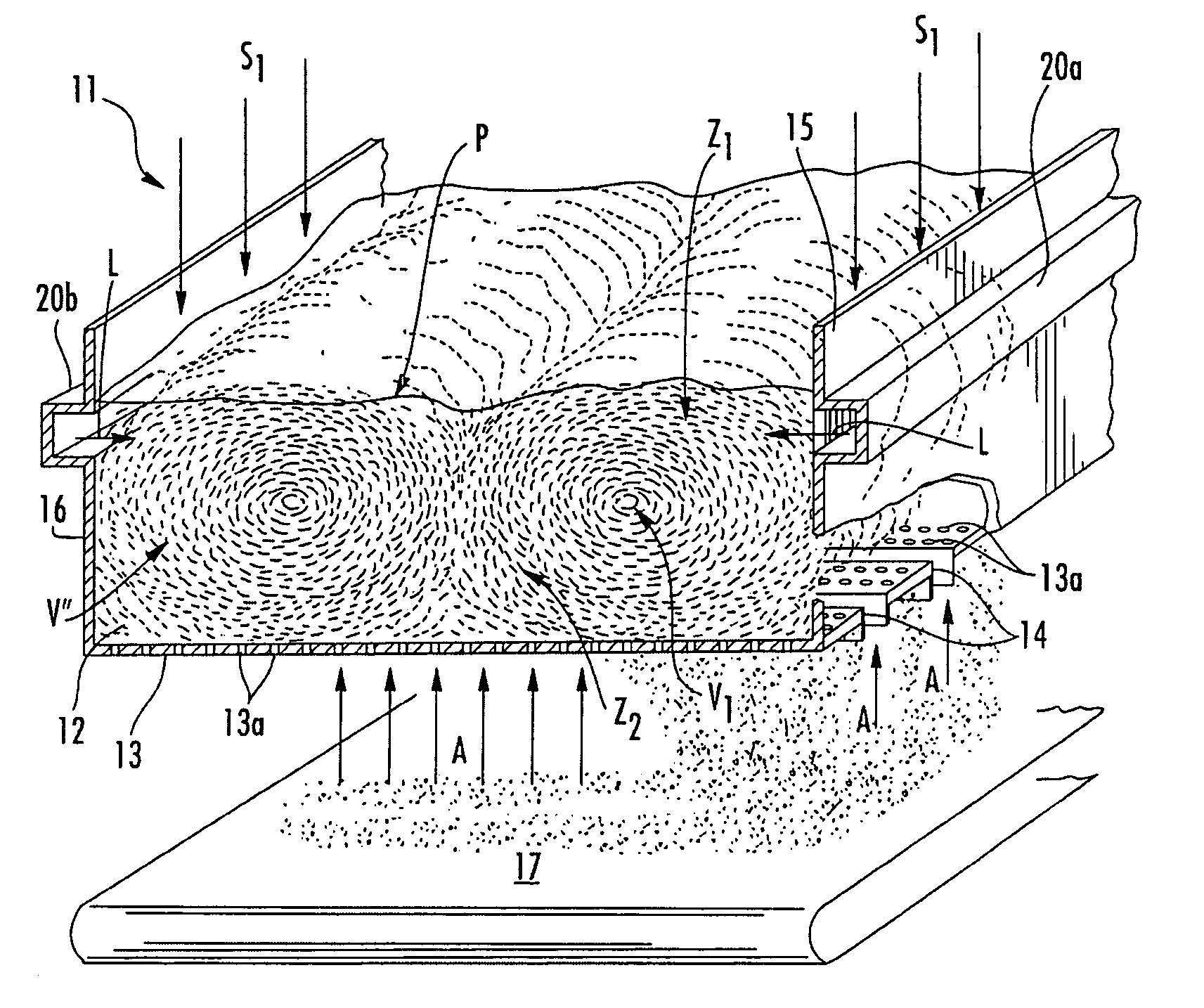

In order to produce granules granulometrically polidispersed in a very little range, a fluid bed granulation process of the type comprising the steps of preparing a fluid bed of seeds (S1) of the substance to be granulated, having a free surface (P) substantially horizontal; and feeding a continuous flow (L) of a fluid comprising a growth liquid, provides in the fluid bed for a continuous vortex (V) with a substantially horizontal axis, in which an upper zone (Z1) of seeds wetting and evaporation of possible solvent contained in the flow (L) and a lower zone (Z2) of solidification / consolidation of the growth liquid are identified.

Owner:CASALE SA

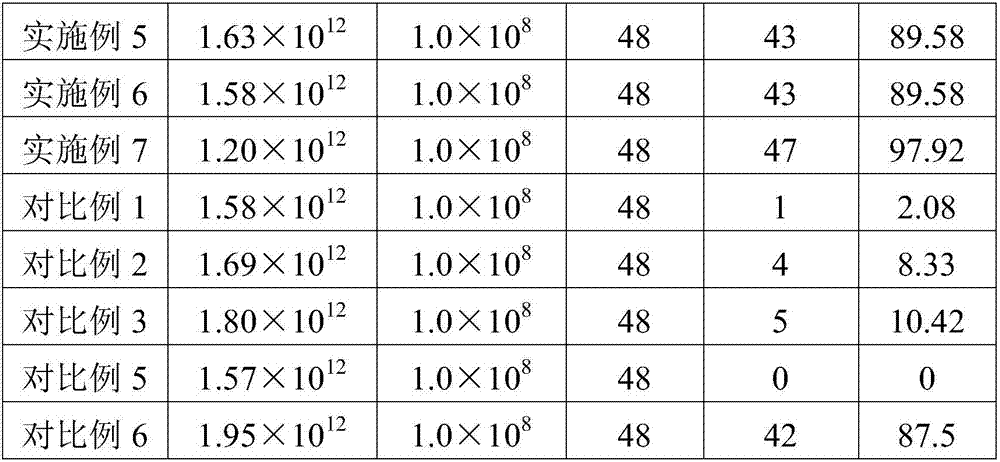

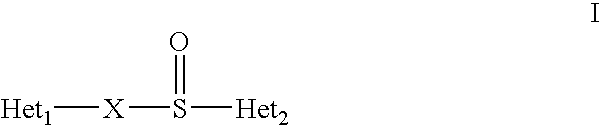

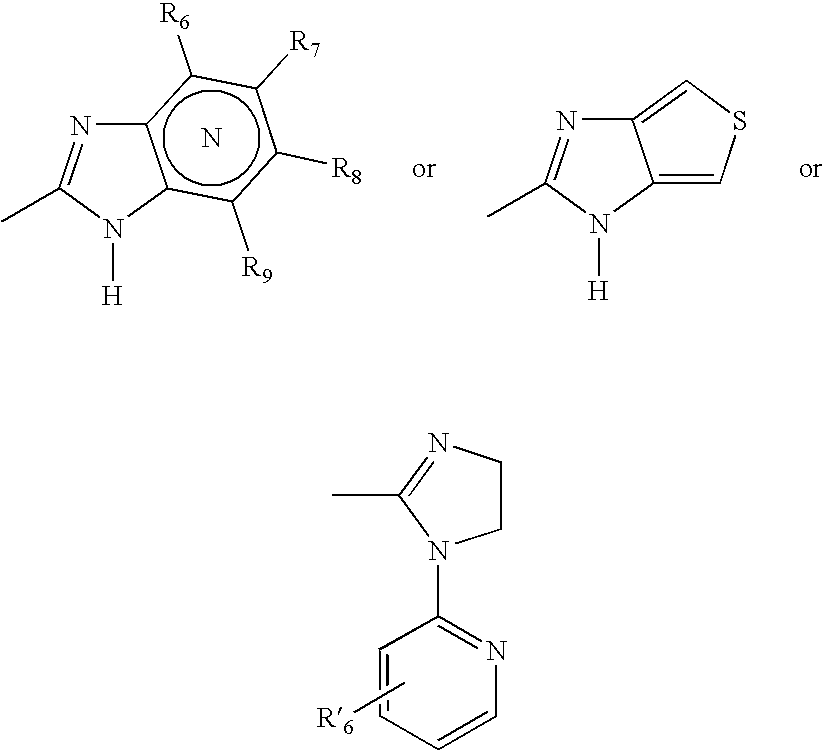

A granule virus dry suspending agent and a preparing method thereof

ActiveCN106857680AAvoid harmImprove the environmentBiocideDead animal preservationSuspending AgentsBiopesticide

The invention relates to the technical field of biopesticides, and particularly relates to a granule virus dry suspending agent and a preparing method thereof. The dry suspending agent is mainly prepared by subjecting a granule virus aqueous suspending agent to pressurized spray drying and fluid-bed granulation, wherein a hot-wind inlet temperature of spray drying is 130-150 DEG C, an outlet temperature is 70-90 DEG C, and the temperature of a fluid bed is 50-70 DGE C. The granule virus aqueous suspending agent comprises a spray drying protective agent. Through setting temperature parameters of spray drying, and combining the spray drying protective agent added into the granule virus aqueous suspending agent, preparation of the dry suspending agent by adopting a spray drying wet-method granulation process is achieved, defects of dry-method granulation are overcome, the prepared dry suspending agent has high pest killing activity, good suspension, dispersing and disintegration properties, the suspending rate of the dry suspending agent is greater than 85%, dispersibility of the dry suspending agent is greater than 85%, the dry suspending agent has loose granules and is easy to disintegrate, and killing toxicity for corresponding pests can be 90% or above.

Owner:HENAN JIYUAN BAIYUN IND +1

Microparticles containing a H+,K+-ATP-ase inhibitor

InactiveUS20080175917A1Reduce brittlenessHigh mechanical strengthBiocidePowder deliveryMicroparticleOrganic chemistry

Owner:GLAD HAKAN +1

Fluid bed granulation apparatus

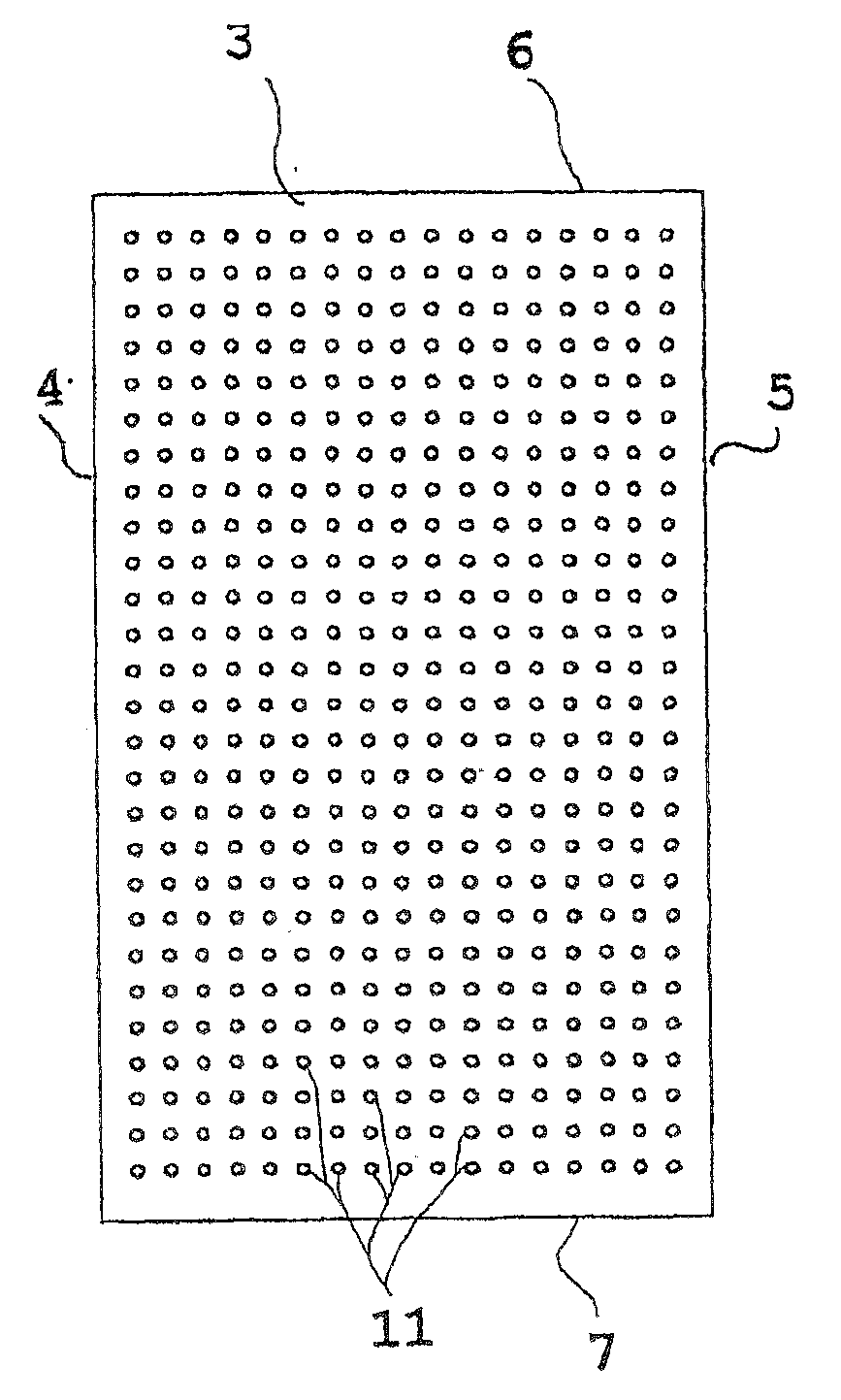

InactiveUS7182282B2The process is simple and effectiveLiquid fertiliser distributionFertiliser distributersEngineeringDistributor

Owner:CASALE SA

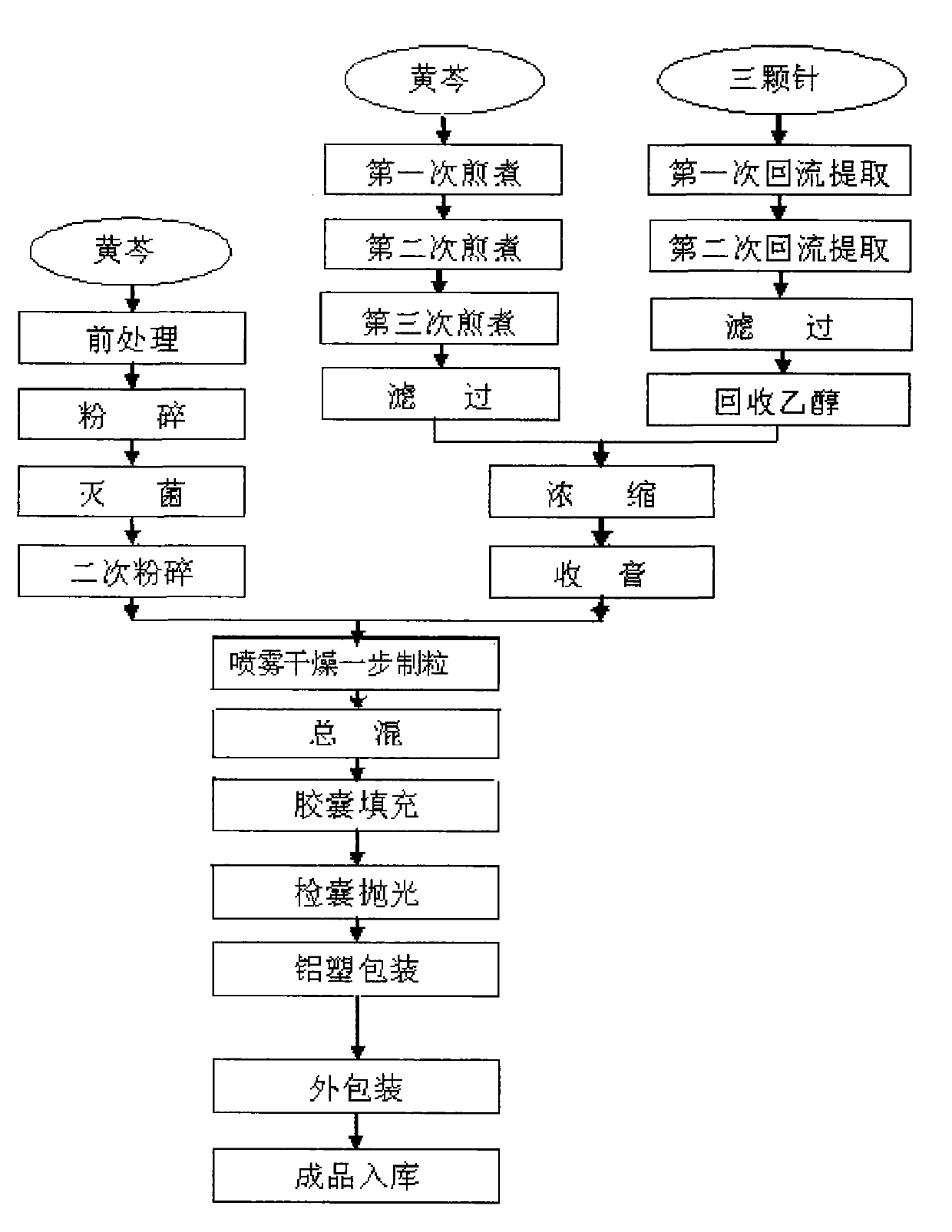

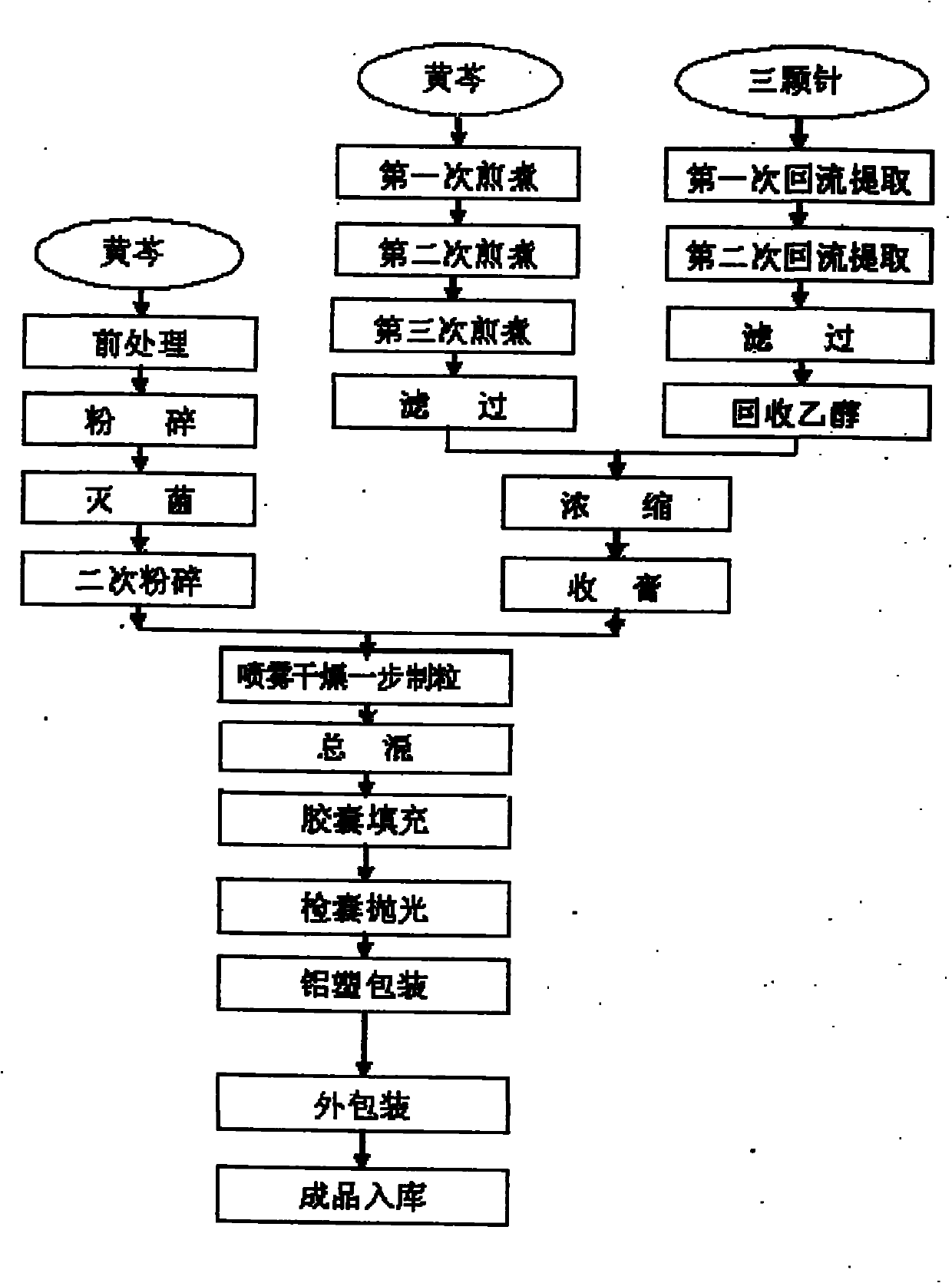

Inflammation diminishing capsules prepared from baical skullcap root and golden thread and preparation method thereof

InactiveCN101766687AUniform load variationGood content uniformityAntibacterial agentsAntipyreticMedicineBaical Skullcap Root

The invention discloses inflammation diminishing capsules prepared from baical skullcap root and golden thread and a preparation method thereof. The method is characterized in that a granulating process adopts spray drying one-step granulating technology, liquor is used as adhesive, the medicinal powder is blown to be stuck with the liquor together and directly prepared into dry grains with even size, and the dry grains are filled into capsules. The process of one-step granulating technology comprises the following steps: weighing a proper amount of baical skullcap root powder serving as an auxiliary material and feeding the baical skullcap root powder into a fluidized bed granulating chamber of a spray drying granulator, and blowing hot air into the fluidized bed granulating chamber to preheat the baical skullcap root powder; starting an air blower to make the air enter the granulating chamber through a filter device and a heat exchanger from an air inlet, make a negative pressure formed in the granulating chamber, and make the medicinal powder float up and down for preheating and drying; spraying a proportional quantity of medicinal extract concentrated solution to the granulating chamber through a spray nozzle to form fog drops, and agglomerating the fog drops and the baical skullcap root powder to form porous grains; blowing the hot air to dry the grains while spraying, and vibrating a powder catching bag at regular intervals; and repeating the operation till the specified amount of medicinal extract concentrated solution is completely sprayed. The method is suitable for the preparation and production of the inflammation diminishing capsules prepared from the baical skullcap root and the golden thread.

Owner:JIANGXI BAISHEN PHARMA

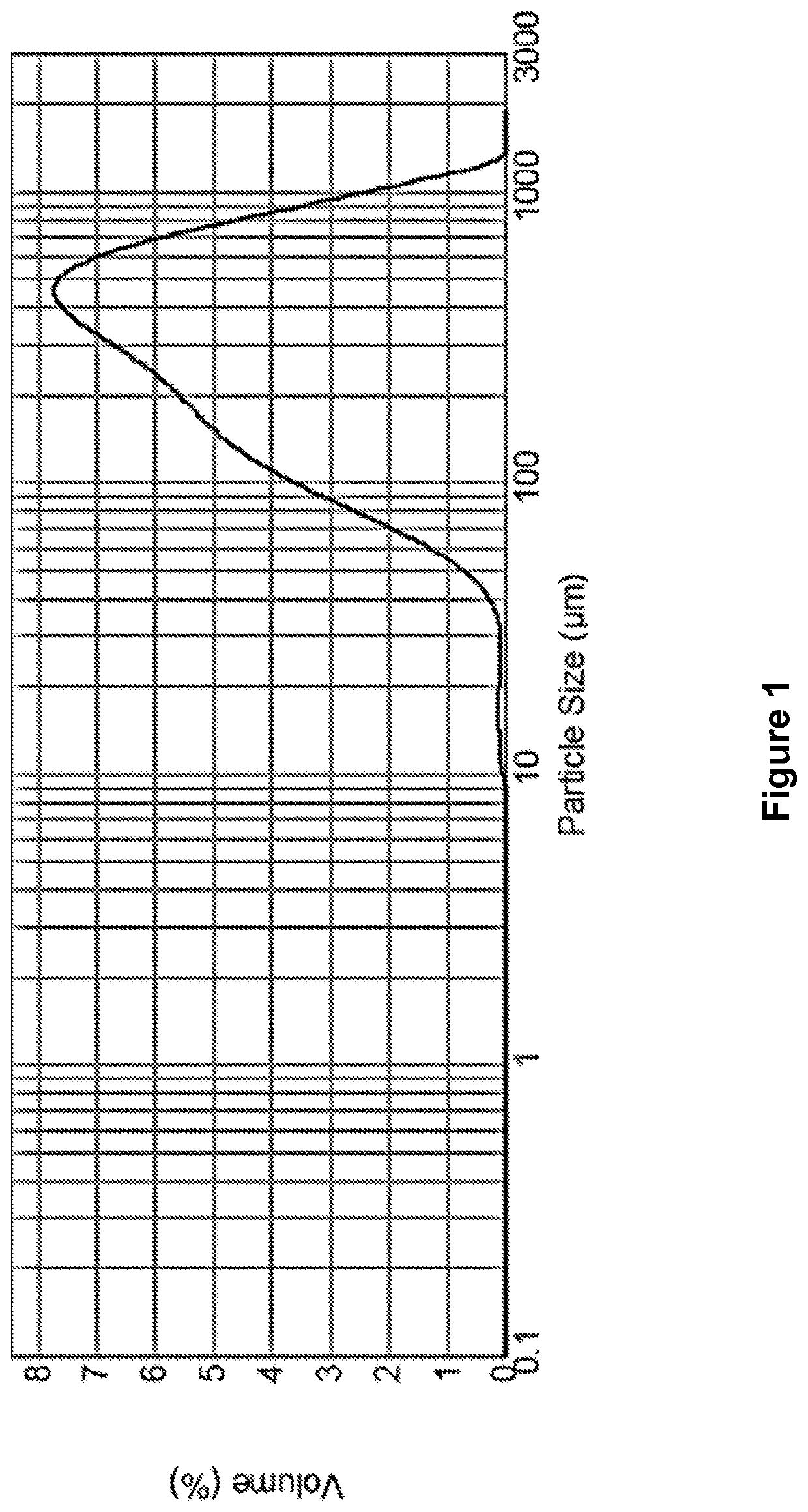

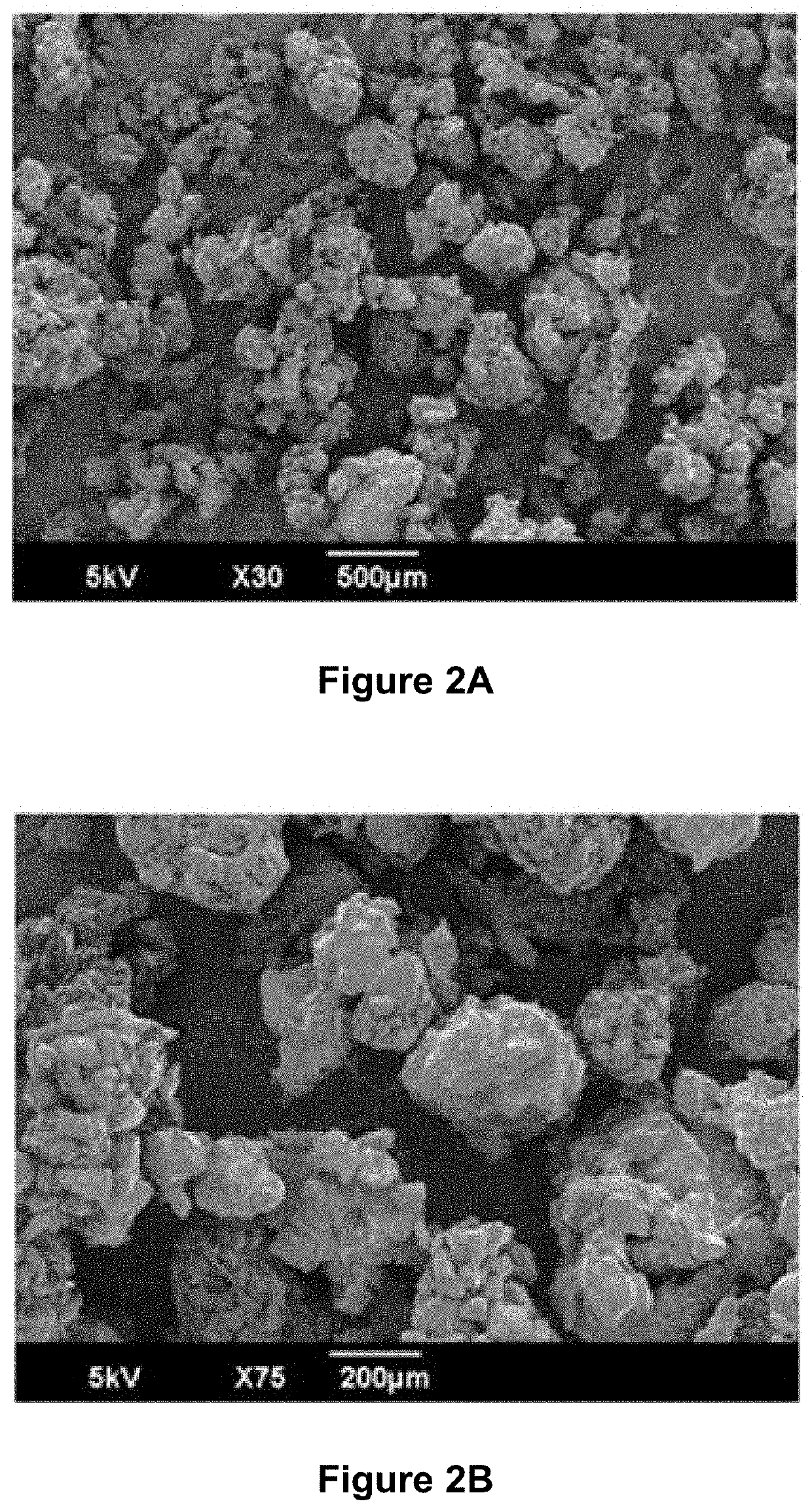

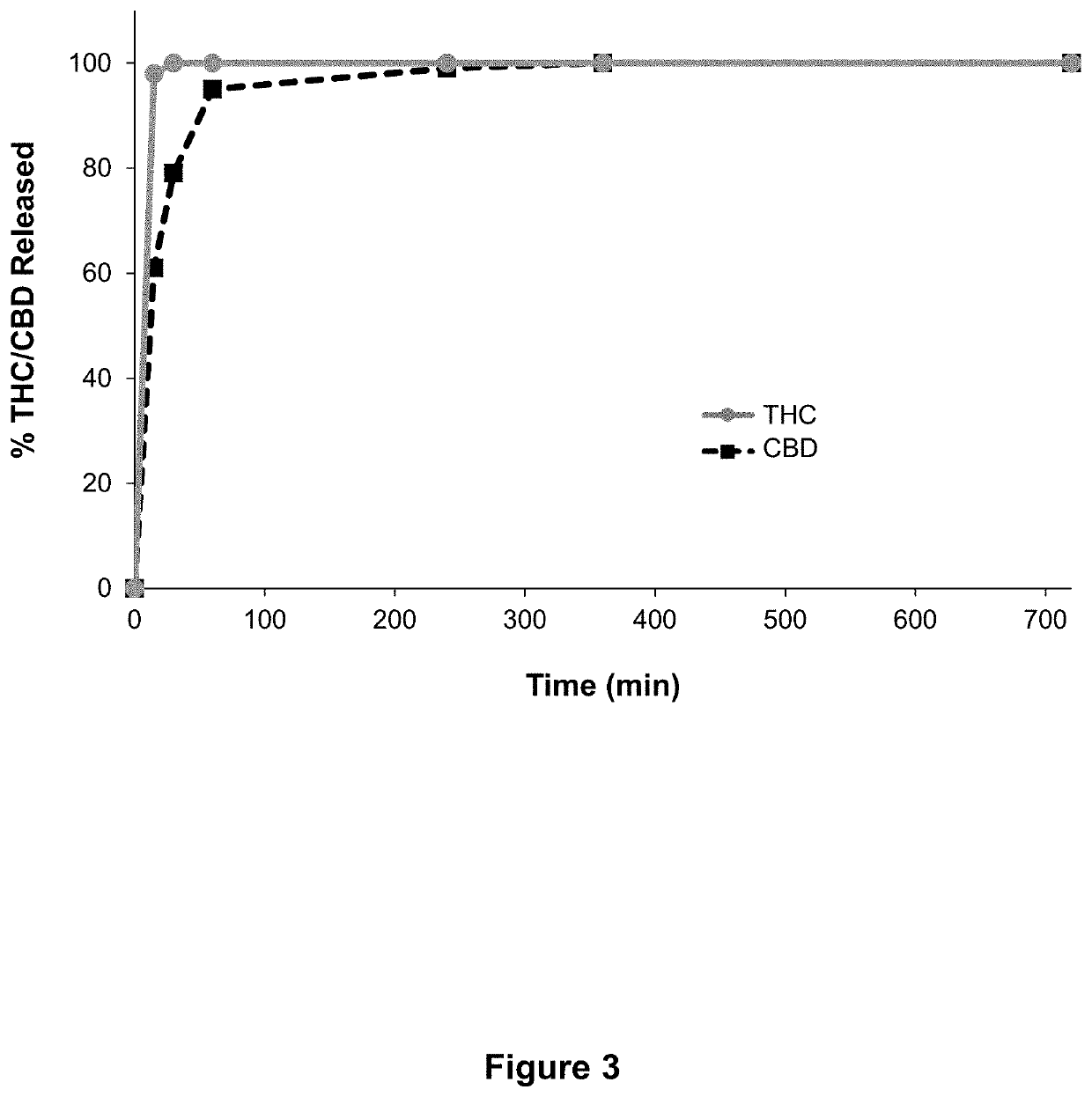

Immediate release formulations of cannabinoids

ActiveUS20200061022A1Uniform loadAccurate dosePowder deliveryHydroxy compound active ingredientsSpray GranulationImmediate release

Owner:GLATT GMBH

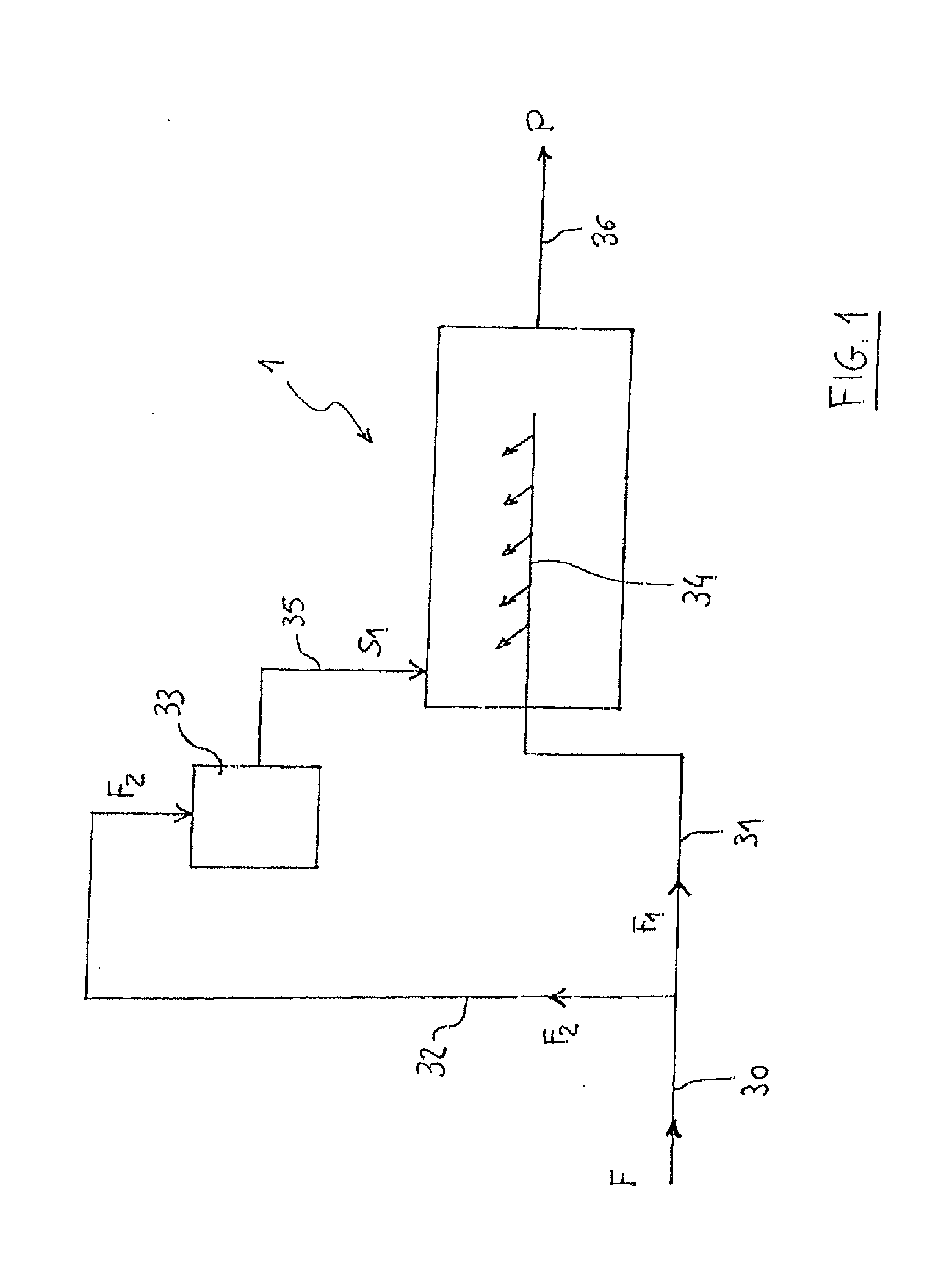

Fluid Bed Granulation Process and Apparatus

InactiveUS20100285214A1Reduce waste generationOptimize layoutLiquid surface applicatorsGranulation by powder suspensionEngineeringParticulate material

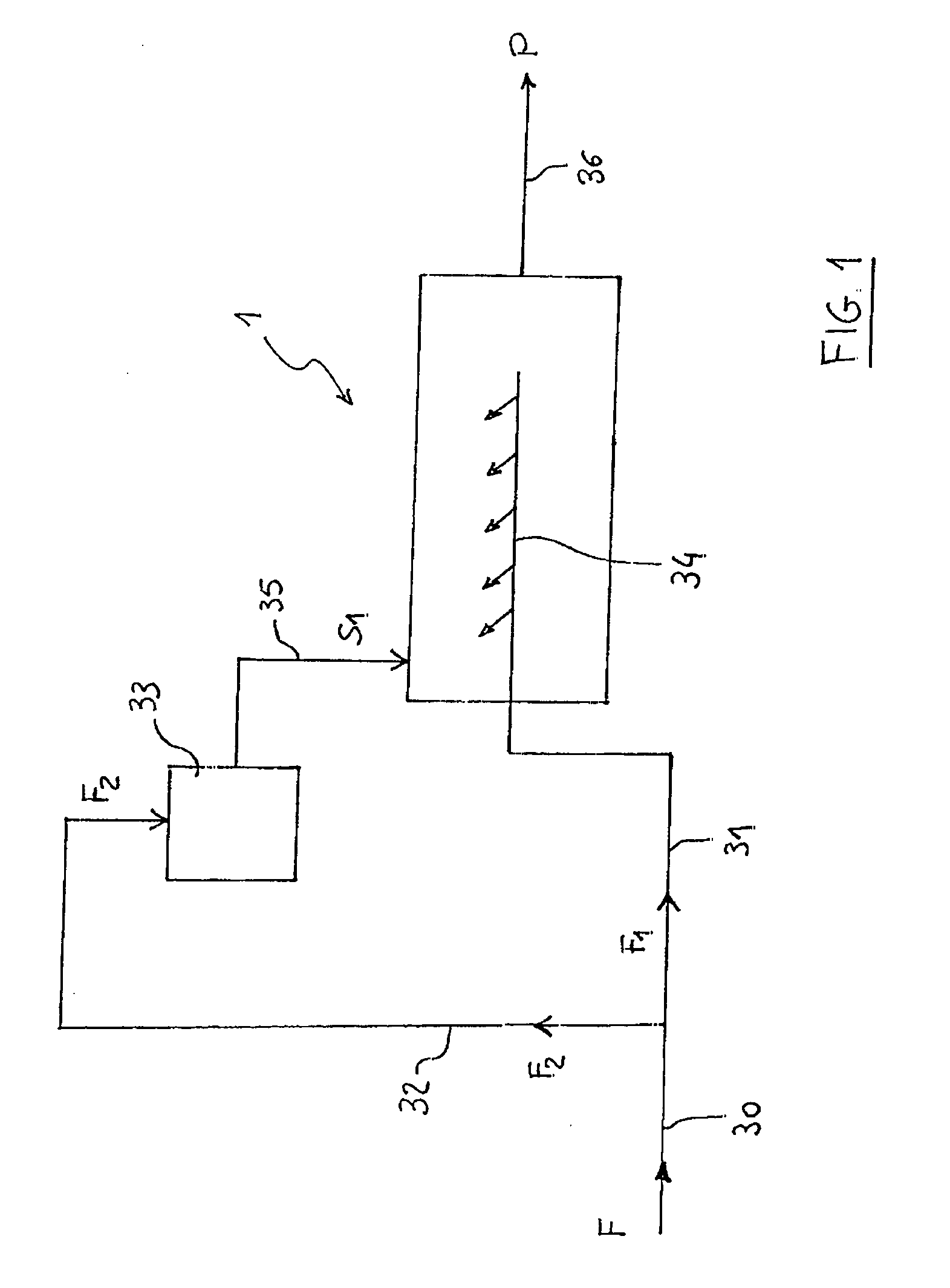

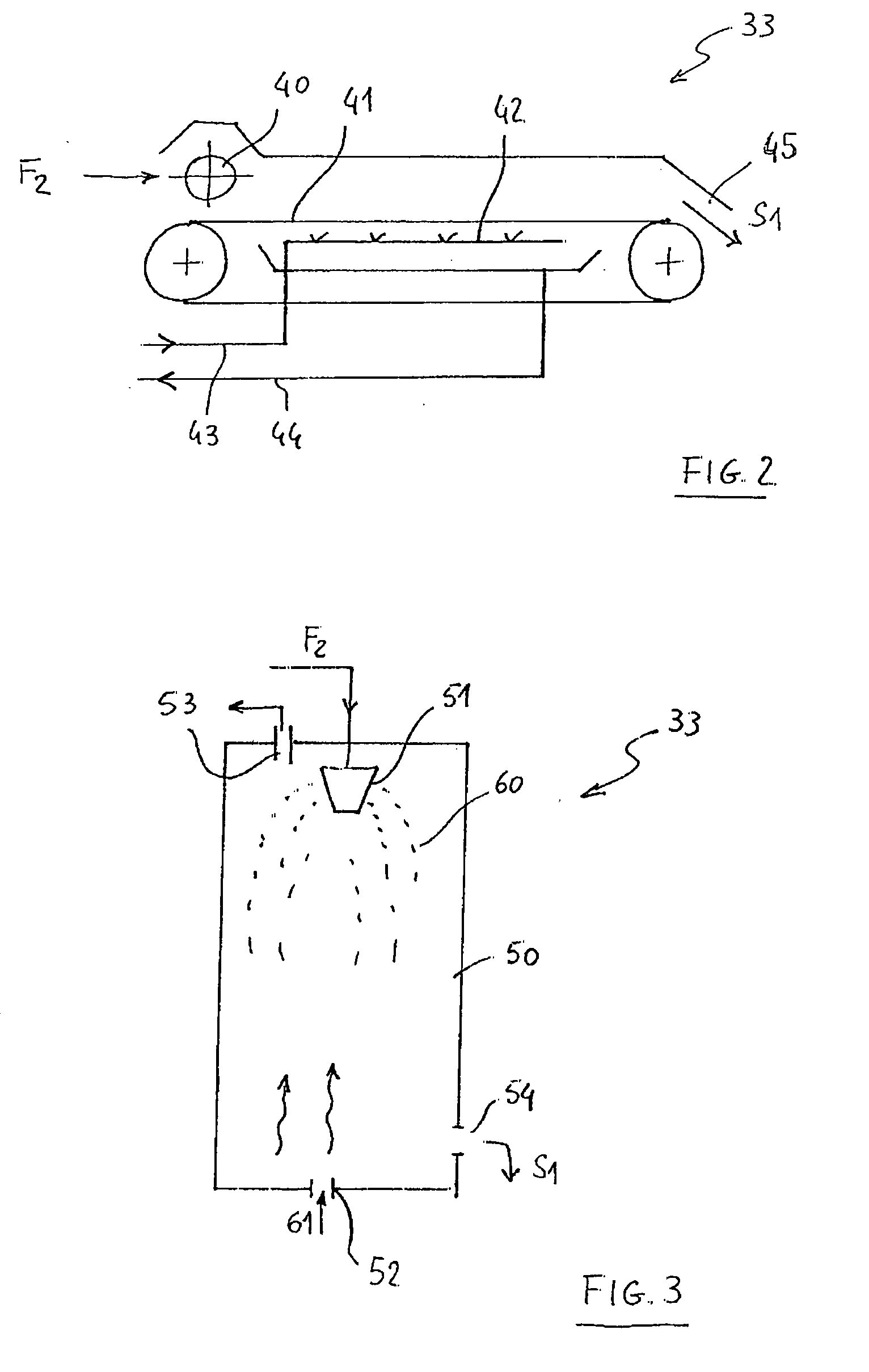

A fluid bed granulation process and apparatus, wherein a suitable fluid bed of a particulate material is maintained in a granulator (1) fed by an input flow (F) comprising a growth liquid (L) and by a flow (S1) of seeds adapted to promote the granulation, and wherein a part (F2) of said input flow (F) is taken upstream the feeding of the fluid bed, and used in a seeds generator (33), to produce the seeds for the fluid bed.

Owner:UREA CASALE SA

Fluid bed classification elements

InactiveUS9839891B2Gas current separationGranulation by powder suspensionLarge particleSmall particle

A classifying fluid bed granulation unit includes a perforated bed floor; a fluid bed section; a solid feed inlet or internal crushing device; a fluidization air inlet; a liquid solution or melt feed inlet and nozzles; an air outlet; and a product outlet; wherein the fluid bed section comprises at least one particle classification element comprising one or more vertically inclined channels having top and bottom end feed openings, and wherein the one or more vertically inclined channels have upper and lower side slots. In operation of the above fluid bed granulation unit, each channel of the element is separating particles into large particle and small particle fractions and transporting the large particle fraction upwards and the small particle fraction downwards in each channel, and the large particle and small particle fractions are transported out of the upper and lower side slots, respectively.

Owner:BEXO AS

Fluid Bed Granulation of Urea and Related Apparatus

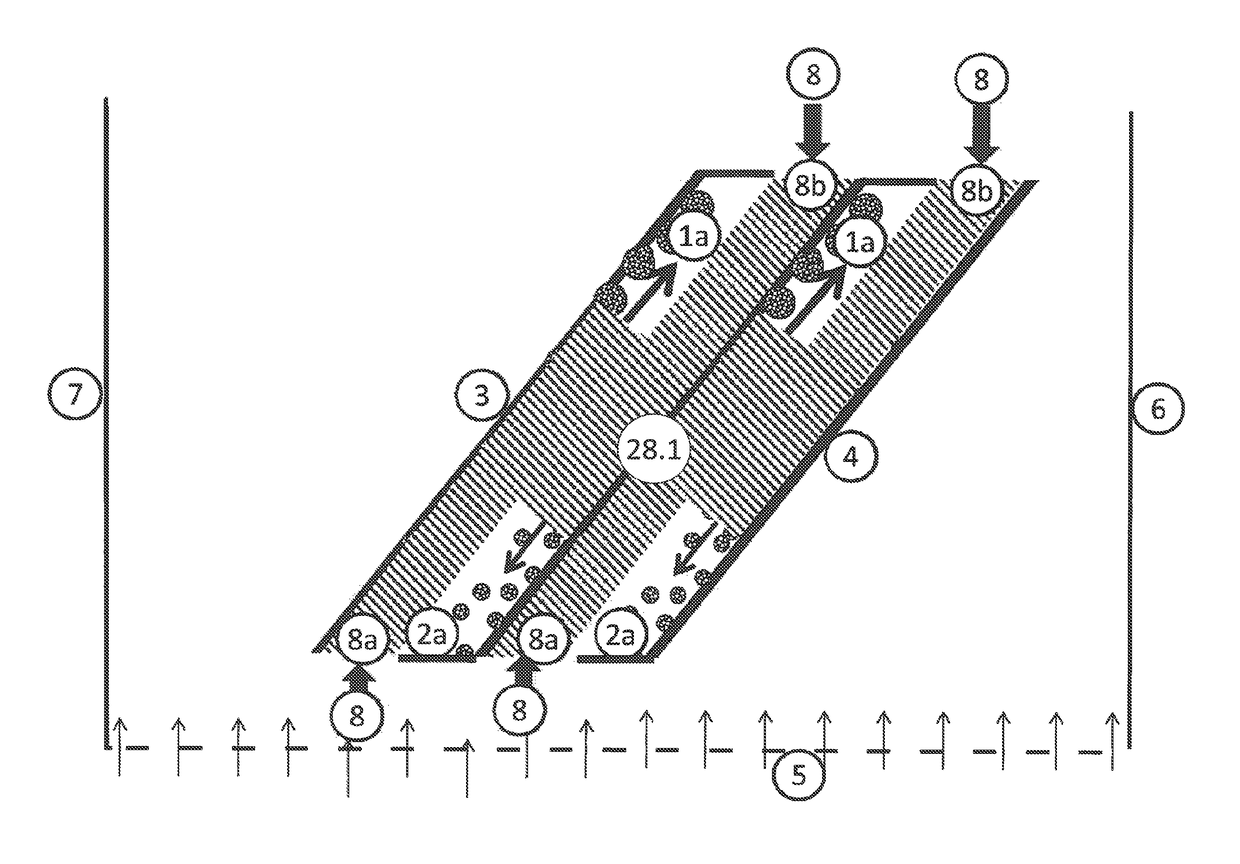

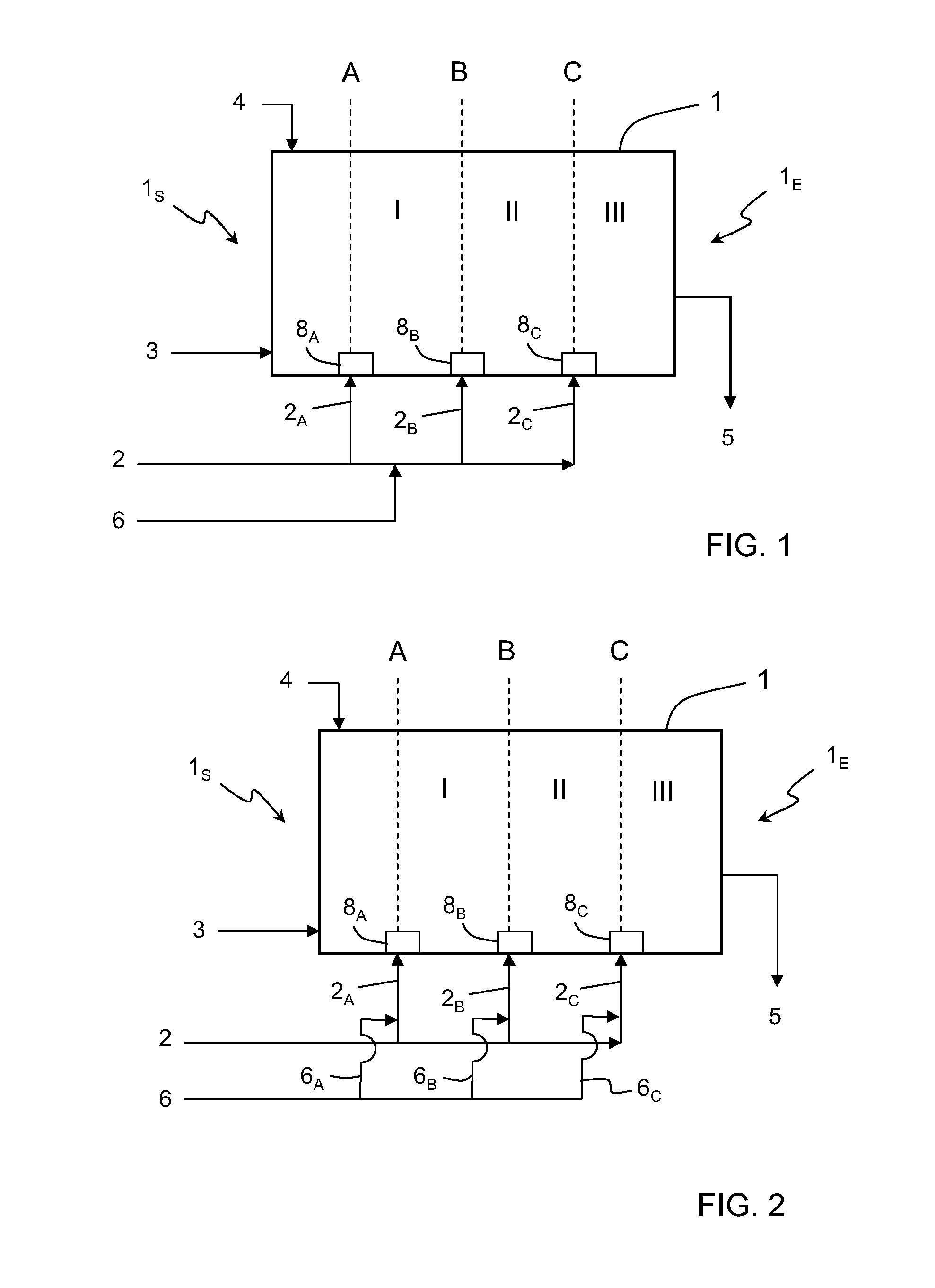

ActiveUS20130316078A1Easy to controlReduce in quantityUrea derivatives preparationLiquid surface applicatorsLongitudinal growthFluid Bed Granulation

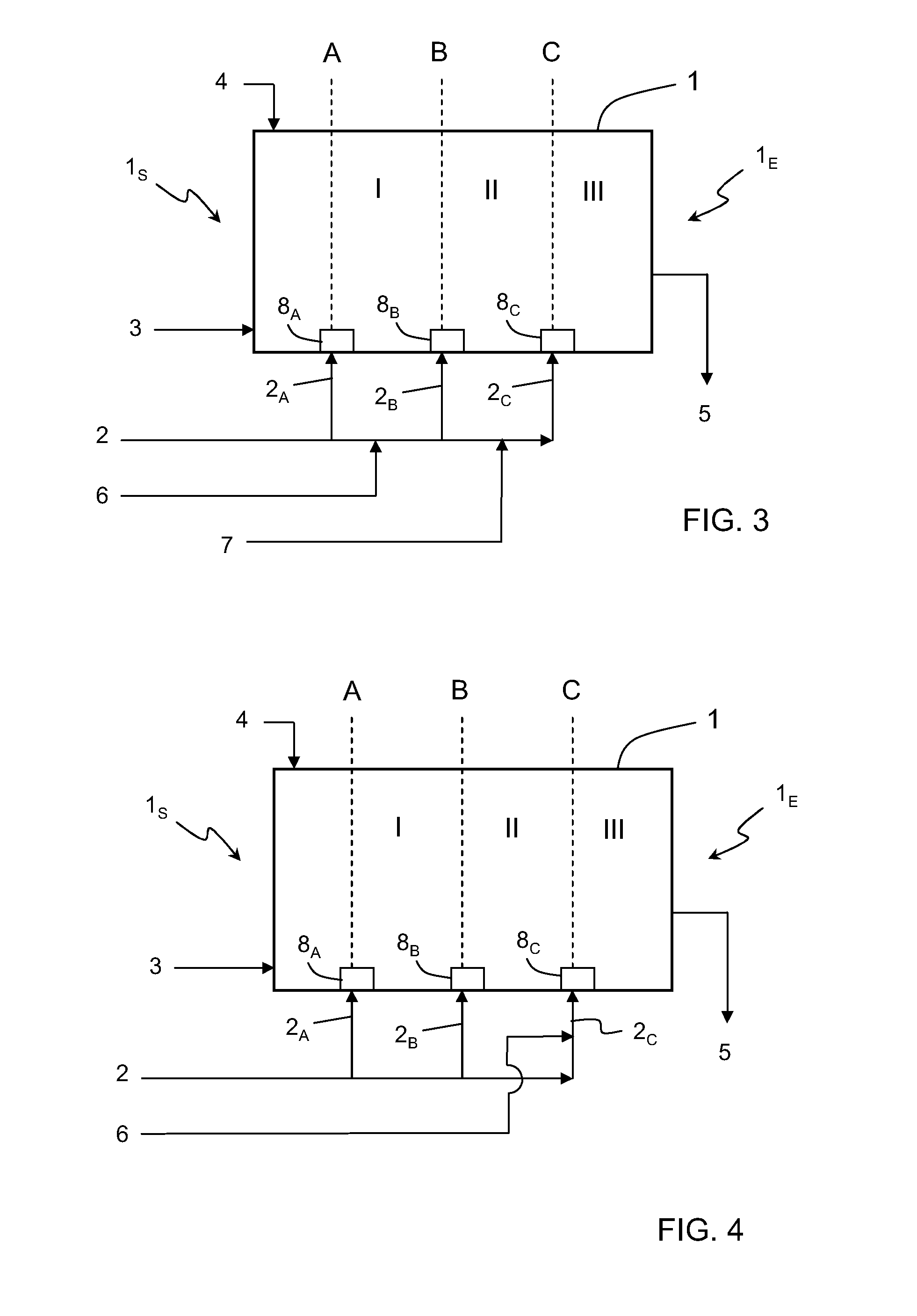

A process for preparation of a granular urea product by granulating a urea solution in a fluidized bed, where the granulation process takes place along a substantially longitudinal growth path, from a granulation starting end (1s) to a product discharge end (1E) of said fluidized bed, and said urea solution enters the fluidized bed by means of several urea inputs (2A, 2B, 2C) taken from a main urea feed (2), where an additive (6) is mixed with said urea solution said additive has a non-uniform concentration in said urea inputs, so that at least two of said urea inputs have a different concentration of additive.

Owner:CASALE SA

Fluid bed granulation process and apparatus

The present invention provides a fluid bed granulation process of an appropriate substance, comprising the cooling in a second fluid bed of the granules obtained. The same flow of fluidification air is used to form and support both fluid beds.

Owner:UREA CASALE SA

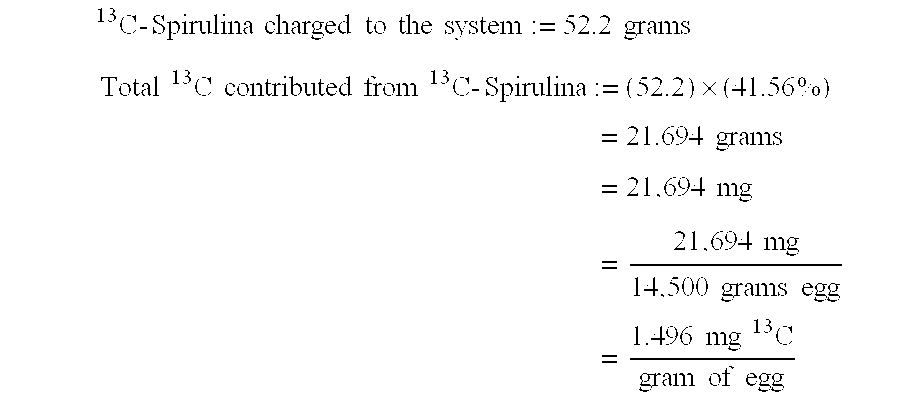

Fluid bed meal containing a marker and methods of making

A standardized, edible food containing a label for use in the measurement of gastric emptying by the quantification of marker excreted in the breath of the patient and methods of making the same using fluid bed granulation processing.

Owner:ADVANCED BREATH DIAGNOSTICS

Fluid bed granulation process and apparatus

ActiveUS20060151646A1Reduce air consumptionGas current separationGranulation by powder suspensionBiomedical engineeringFluid Bed Granulation

Fluid bed granulation process of an appropriate substance, comprising the cooling in a second fluid bed of the granules obtained. The same flow of fluidification air is used to form and support both fluid beds.

Owner:CASALE SA

Fluid Bed Granulation Process

InactiveUS20140283739A1Strict controlReduce formationLiquid surface applicatorsLiquid spraying apparatusEngineeringContinuous flow

Owner:UREA CASALE SA

Fluid Bed Granulation Process

ActiveUS20080124256A1Bacterial antigen ingredientsGranulation by powder suspensionHorizontal axisEvaporation

In order to produce granules granulometrically polidispersed in a very little range, a fluid bed granulation process of the type comprising the steps of preparing a fluid bed of seeds (S1) of the substance to be granulated, having a free surface (P) substantially horizontal; and feeding a continuous flow (L) of a fluid comprising a growth liquid, provides in the fluid bed for a continuous vortex (V) with a substantially horizontal axis, in which an upper zone (Z1) of seeds wetting and evaporation of possible solvent contained in the flow (L) and a lower zone (Z2) of solidification / consolidation of the growth liquid are identified.

Owner:CASALE SA

Fluid bed granulation process and apparatus

ActiveUS20070000813A1Completely processedReduce energy consumptionDrying using combination processesLiquid surface applicatorsComing outEngineering

Fluid bed granulation process comprising the step of cooling the granules in a cooling fluid bed (F2). At least part of the fluidizing air coming out from said cooling fluid bed (F2) is fed into the granulation fluid bed (F1).

Owner:CASALE SA

Fluid Bed Granulation Process and Apparatus

InactiveUS20140248426A1Optimize layoutReduce wasteLiquid surface applicatorsGranulation by powder suspensionEngineeringHydrology

A fluid bed granulation process and apparatus, wherein a suitable fluid bed of a particulate material is maintained in a granulator (1) fed by an input flow (F) comprising a growth liquid (L) and by a flow (S1) of seeds adapted to promote the granulation, and wherein a part (F2) of said input flow (F) is taken upstream the feeding of the fluid bed, and used in a seeds generator (33), to produce the seeds for the fluid bed.

Owner:CASALE SA

Fluid bed granulation process and apparatus

ActiveUS20070020338A1Easy to carryReliable recoveryPretreated surfacesGranular deliveryEngineeringMechanical engineering

A process for obtaining finished granules of a predetermined substance in a granulation fluid bed (F1) of the so-called vertical growth type, the bed being formed and maintained by a respective flow of fluidification air, comprises a transfer phase by falling of the finished granules in a pressurized space below the granulation bed and a recovery phase of the finished granules from the pressurized space.

Owner:CASALE SA

Fluid Bed Granulation Process

InactiveUS20100095886A1Strict controlReduce formationLiquid surface applicatorsLiquid spraying apparatusContinuous flowEngineering

A fluid bed granulation process of a predetermined substance comprises the steps of: forming, through a fluidification. air flow of predetermined flow rate, a fluid bed of granules of said substance to be granulated fed to it in the form of seeds,—feeding said fluid bed with a continuous flow of a growth substance (or liquid).

Owner:UREA CASALE SA

Trospium chloride composition and preparation method thereof

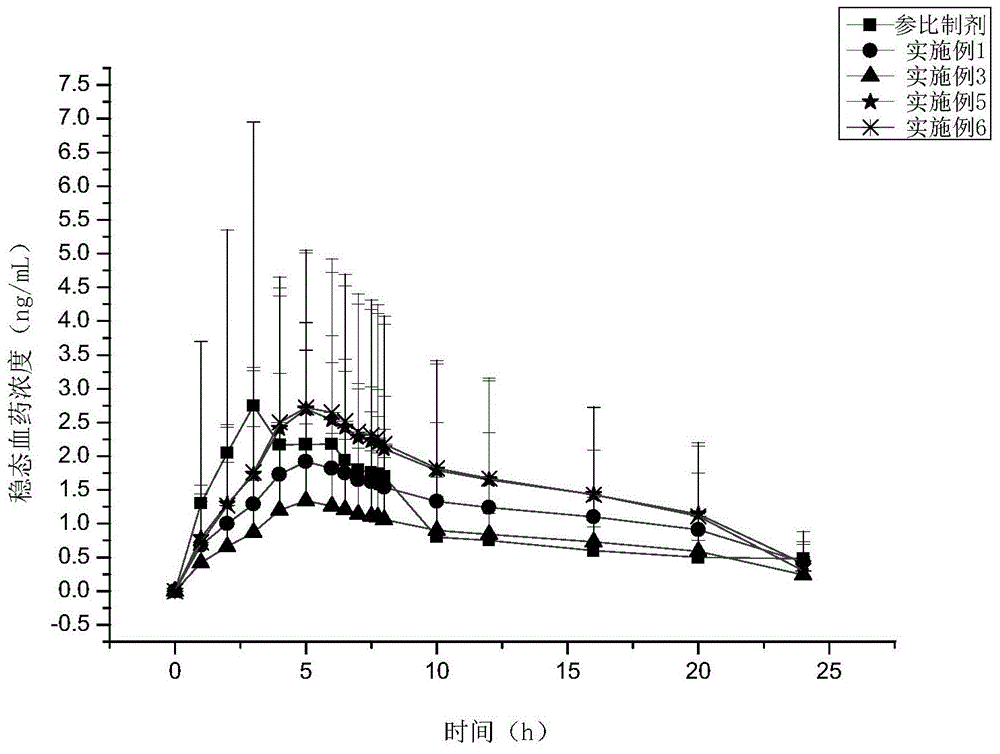

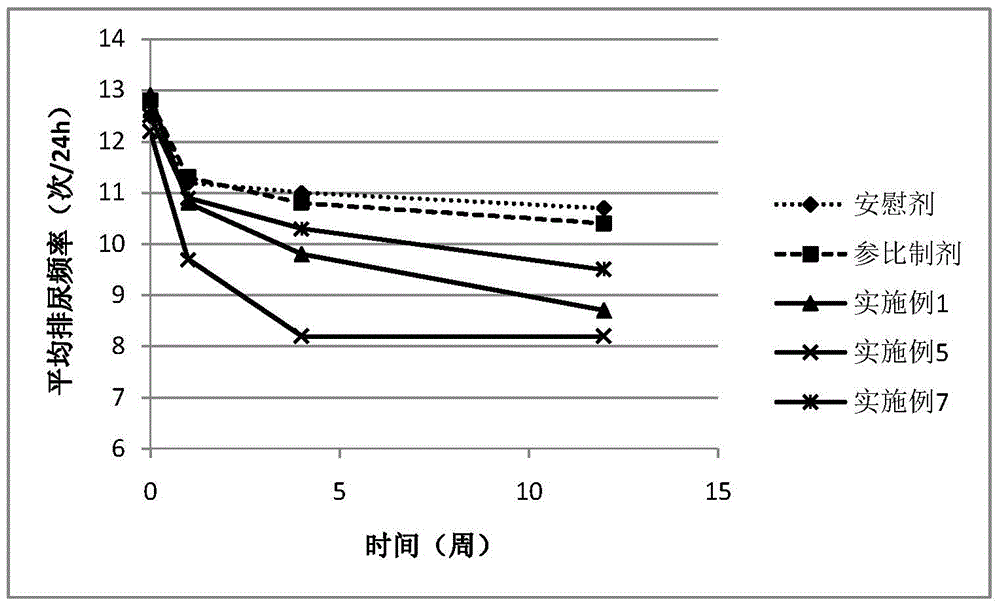

InactiveCN104887646AStable blood concentrationImprove medication safetyPharmaceutical non-active ingredientsUrinary disorderBlood concentrationMedicine

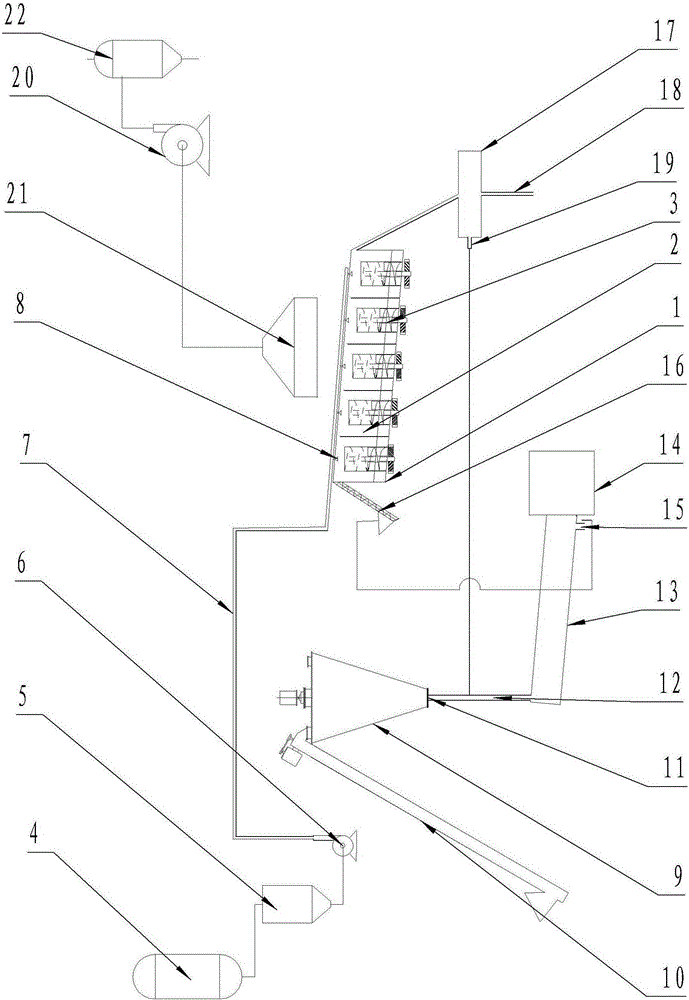

The invention discloses a trospium chloride composition and a preparation method thereof. The trospium chloride composition comprises, by weight, 2-10 parts of trospium chloride serving as an active ingredient, 80-200 parts of diluent, 1-20 parts of adhesion agent and 1-5 parts of antisticking agent. The trospium chloride composition has the advantages that by means of reasonable proportioning of the diluent and the adhesion agent, the composition can disperse in the stomach rapidly after being taken orally and floats partially to release medicine slowly, so that on one hand, stable blood concentration can be kept, adverse reaction incidence is decreased, and medication safety is improved; on the other hand, stopping time of the medicine in a gastrointestinal tract is prolonged, bioavailability is increased, therapeutic effects are improved and cost is saved. The preparation method of the trospium chloride composition has the advantages that a fluid-bed granulation technology is adopted to enable granulation to be completed at a step, so that time is saved, efficiency is improved and production cost is reduced greatly.

Owner:STAIDSON (BEIJING) BIOPHARMACEUTICALS CO LTD +1

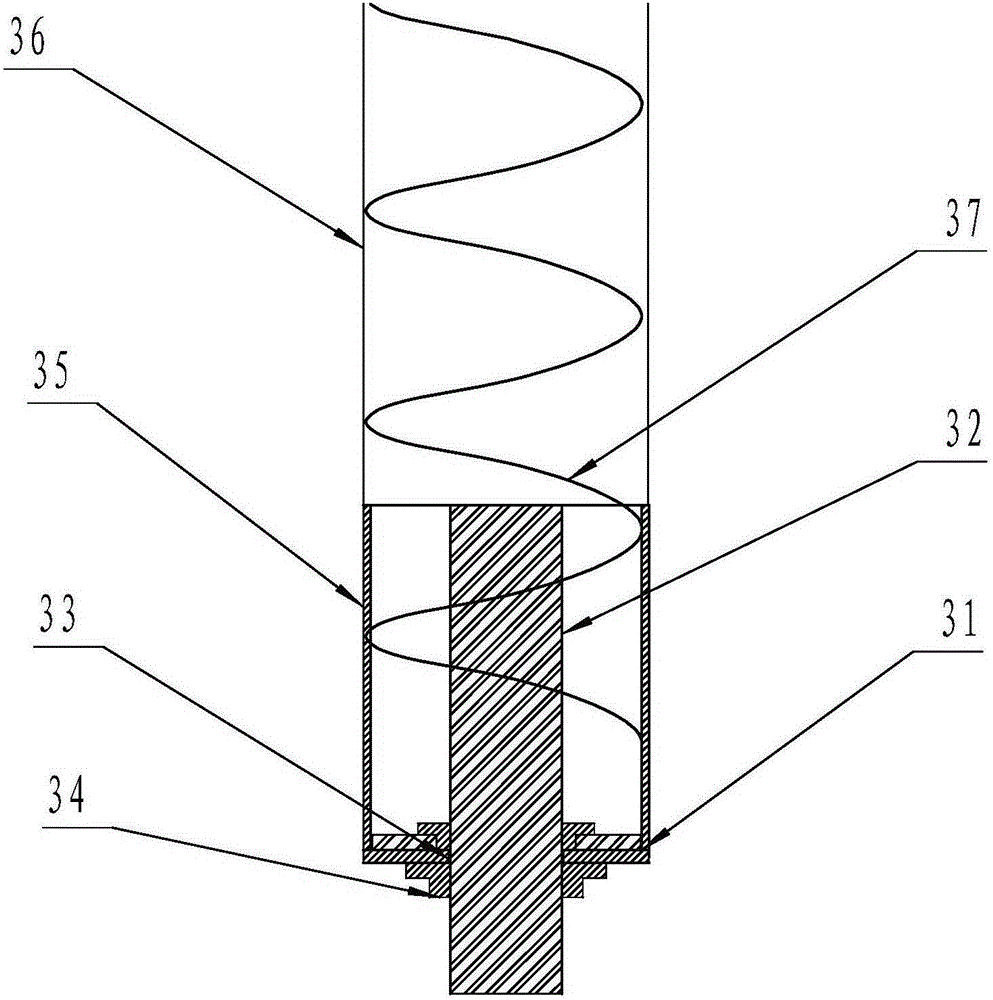

A kind of spiral fluidized bed granulation method and its equipment

ActiveCN104174331BReduce pollutionRealize fluidizationGranulation by powder suspensionAdhesiveProcess engineering

The invention discloses a spiral fluidized bed granulating method and equipment for realizing the spiral fluidized bed granulating method. The spiral fluidized bed granulating method comprises the following steps: A. melting granulating adhesive; B. mixing materials, heating and conveying to a spiral fluidized bed unit; C. granulating; D. screening granulated materials in the step C; and E. collecting dusts. The equipment for realizing the spiral fluidized bed granulating method comprises a granulating adhesive melting and conveying device, a material mixing, heating and conveying device, a granulating device, a screening device and a dust collecting device. The spiral fluidized bed granulating method and the equipment have the beneficial effects that a mechanical method is adopted to perform powdery material granulation, and the method and the equipment can be suitable for powdery material granulation, can overcome the defect that the traditional fluidized bed adopts wind powder as power and is not suitable for powdery material granulation, and can reduce dust pollution.

Owner:SHANDONG ZOETICLAND BIOLOGICAL TECH

Fluid Bed Granulation Process

ActiveUS20100140827A1Appropriate hardnessPigmenting treatmentEvaporationHorizontal axisBiomedical engineering

Fluid bed granulation process comprising the steps of: -forming a fluid bed of seeds (S1) of a chosen substance, -feeding said fluid bed with a continuous fluid flow (L) comprising a growth liquid, -inducing and maintaining a continuous vortex (V) in said fluid bed, the vortex (V) having a substantially horizontal axis, characterized in that said fluid flow (L) is fed into predetermined first zones (Z1) of said fluid bed, said first zones (Z1) being alternated to second zones (Z2) of said fluid bed in which said fluid flow (L) is not fed.

Owner:CASALE SA

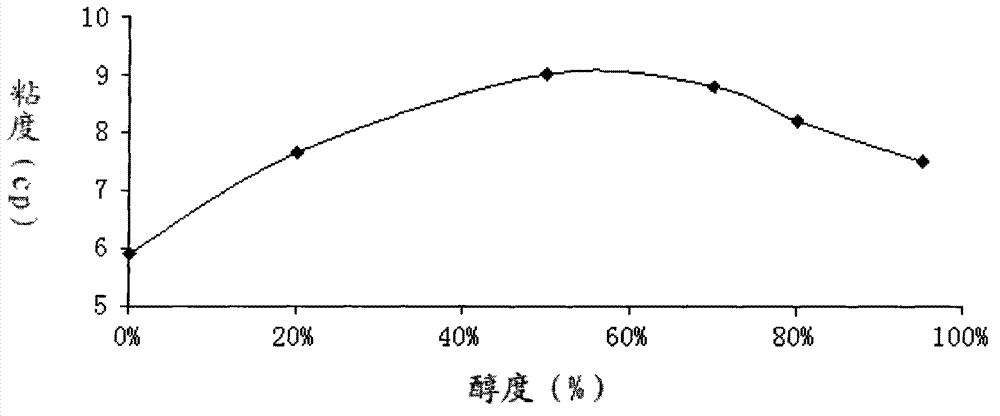

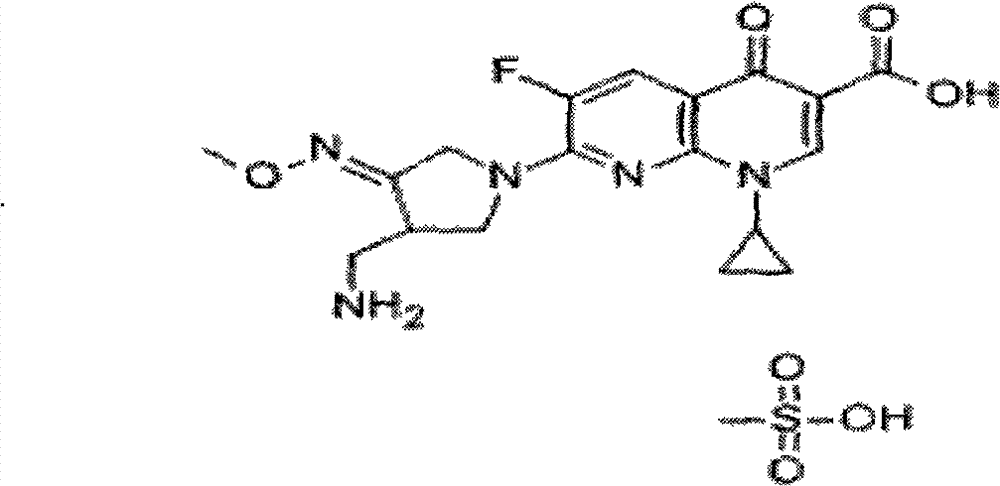

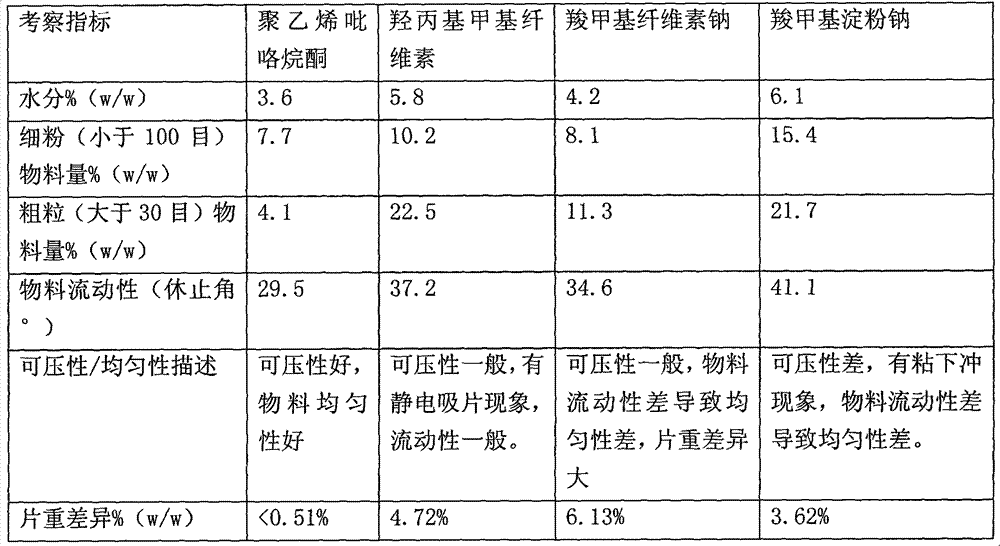

Preparation method of gemifloxacin mesylate medicinal composition

ActiveCN102949369ASolve the problem of high viscosityHigh drug loadingAntibacterial agentsOrganic active ingredientsMetallurgyGemifloxacin Mesylate

The invention provides a preparation method of gemifloxacin mesylate medicinal composition with large medicine loading capacity. The preparation method comprises a wet-method grain pre-manufacturing step and a fluidized bed grain manufacturing step. According to the preparation method of the gemifloxacin mesylate medicinal composition, disclosed by the invention, the wet-method grain pre-manufacturing step and the fluidized bed grain manufacturing step are combined, a suitable amount of disintegrating agents, and lubricant and the like are externally added after grains are dried and finished so that the gemifloxacin mesylate medicinal composition is pressed into tablets. The gemifloxacin mesylate tablets obtained by the preparation method disclosed by the invention avoids adverse factors of weight variation of pressed tablets influenced by grain unevenness generated because materials are adhered on the wall of a granulator during a wet-method grain manufacturing step or the fluidized bed grain manufacturing step, low grain yield after the materials are adhered on the wall of a granulator, and the like.

Owner:LIVZON PHARM GRP INC

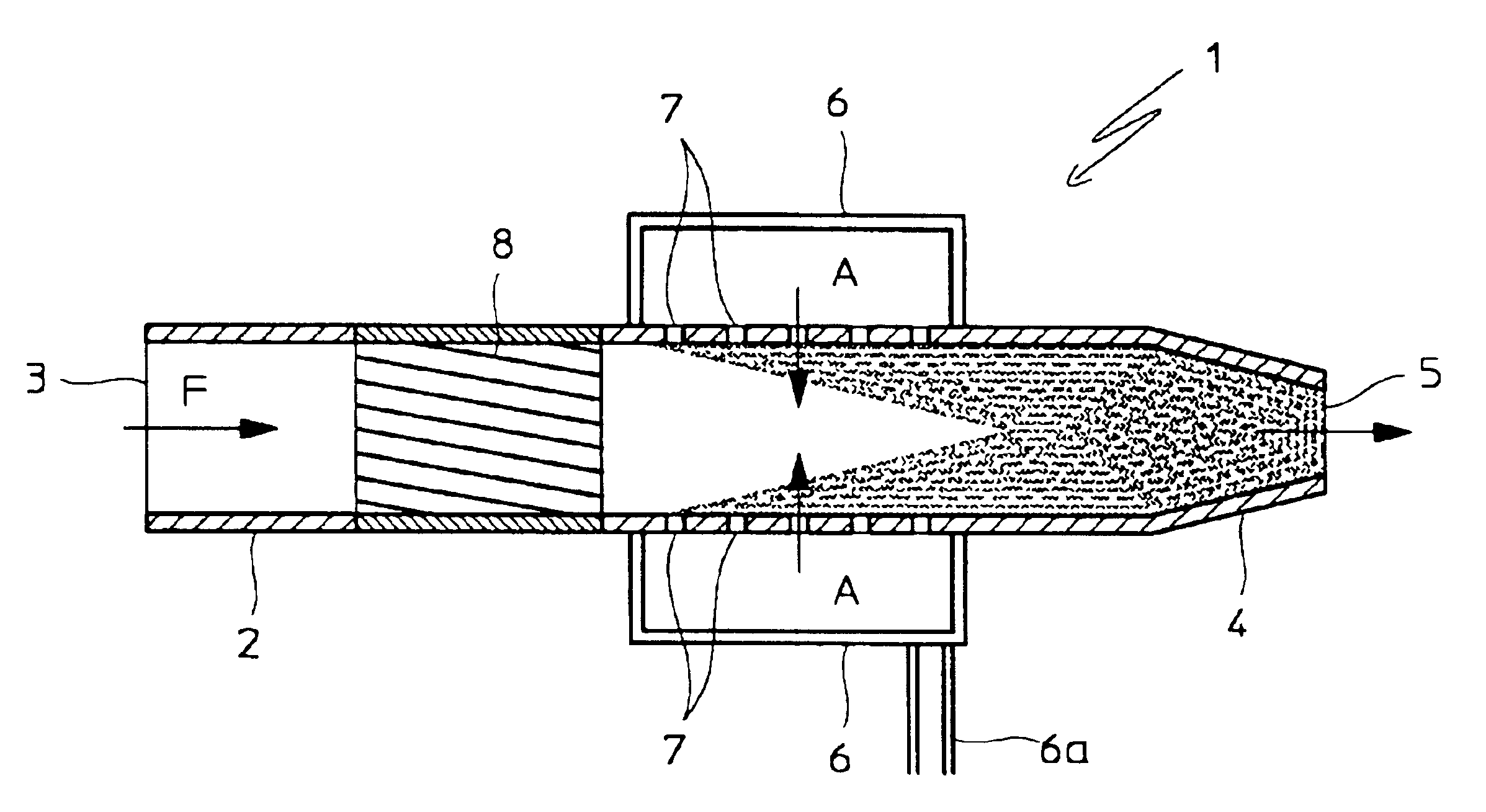

Fluid bed granulation apparatus

InactiveUS6957502B2Reduce in quantityReduce rateDrying machines with progressive movementsChemical/physical/physico-chemical nozzle-type rreactorsEmulsionEngineering

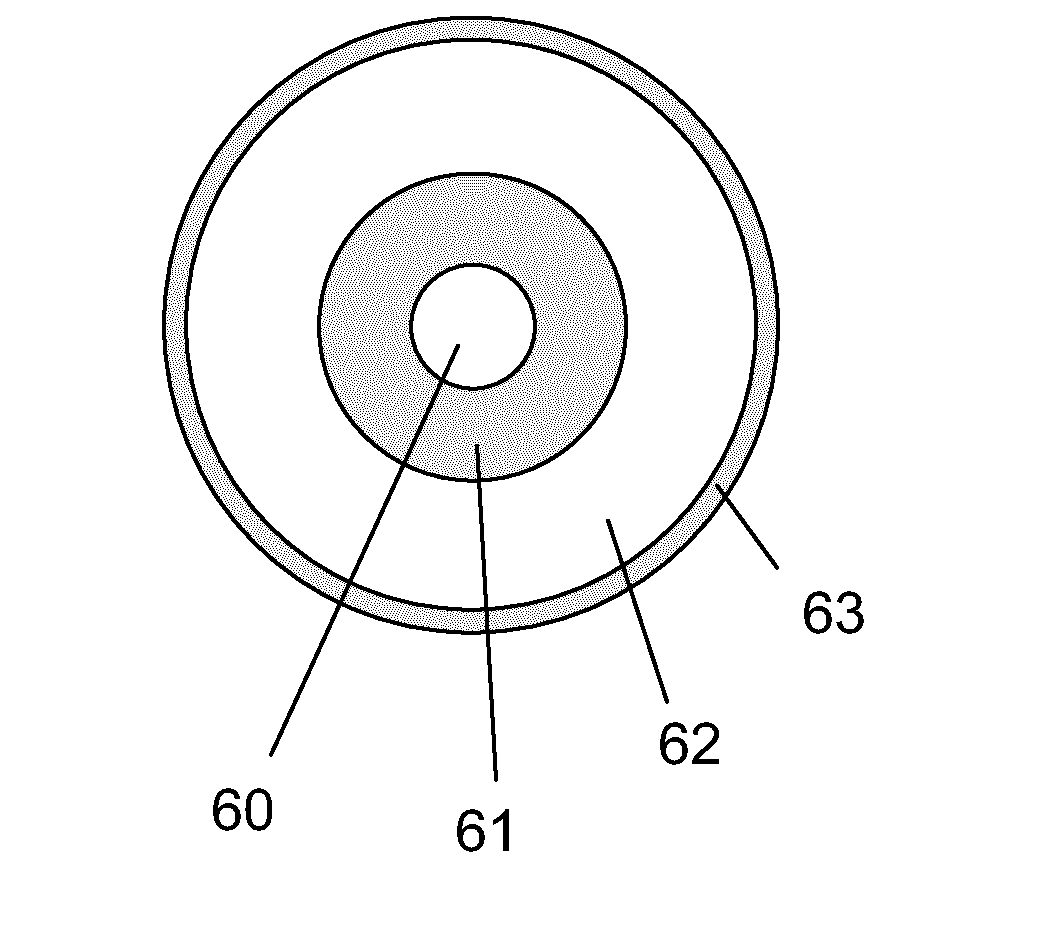

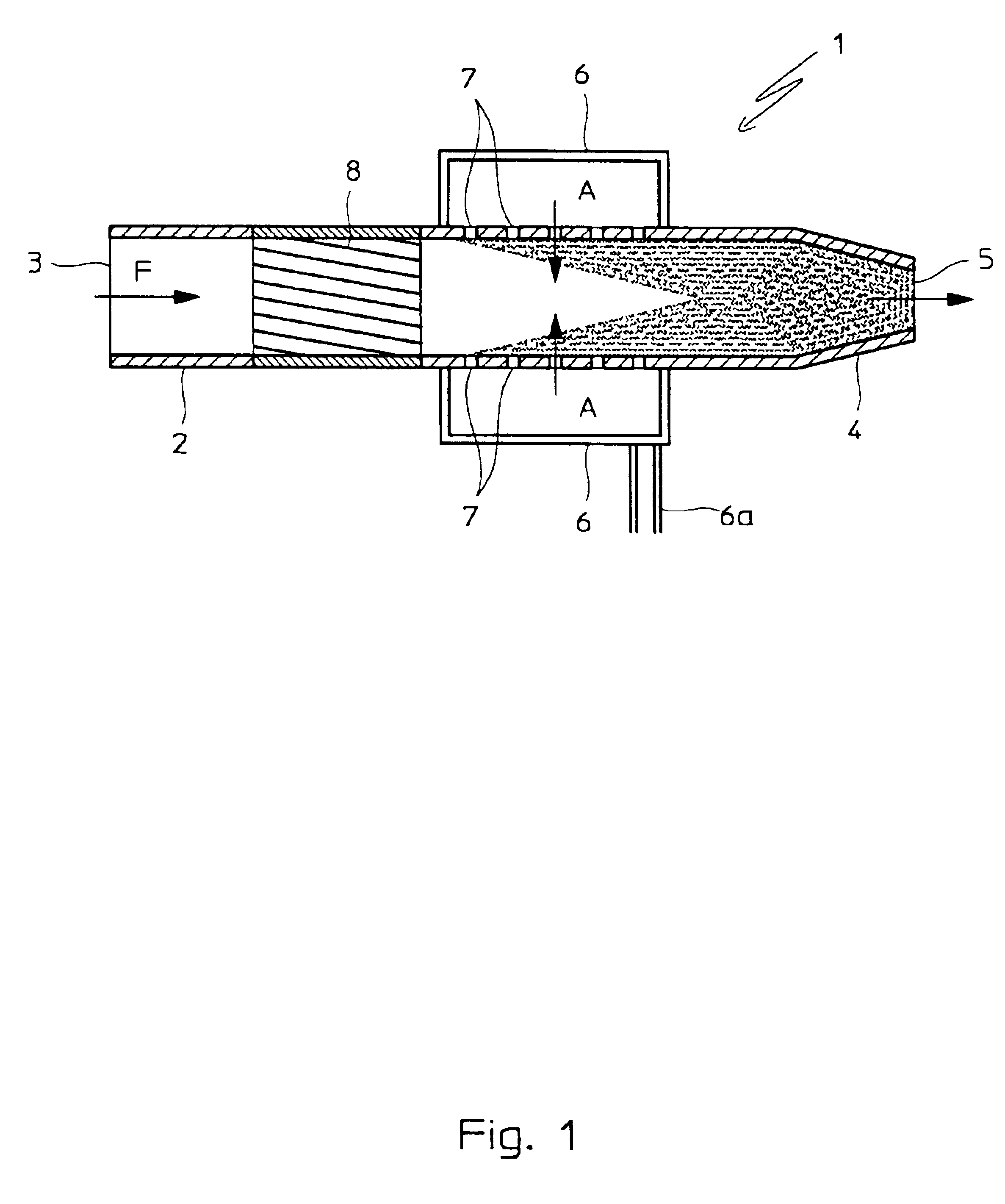

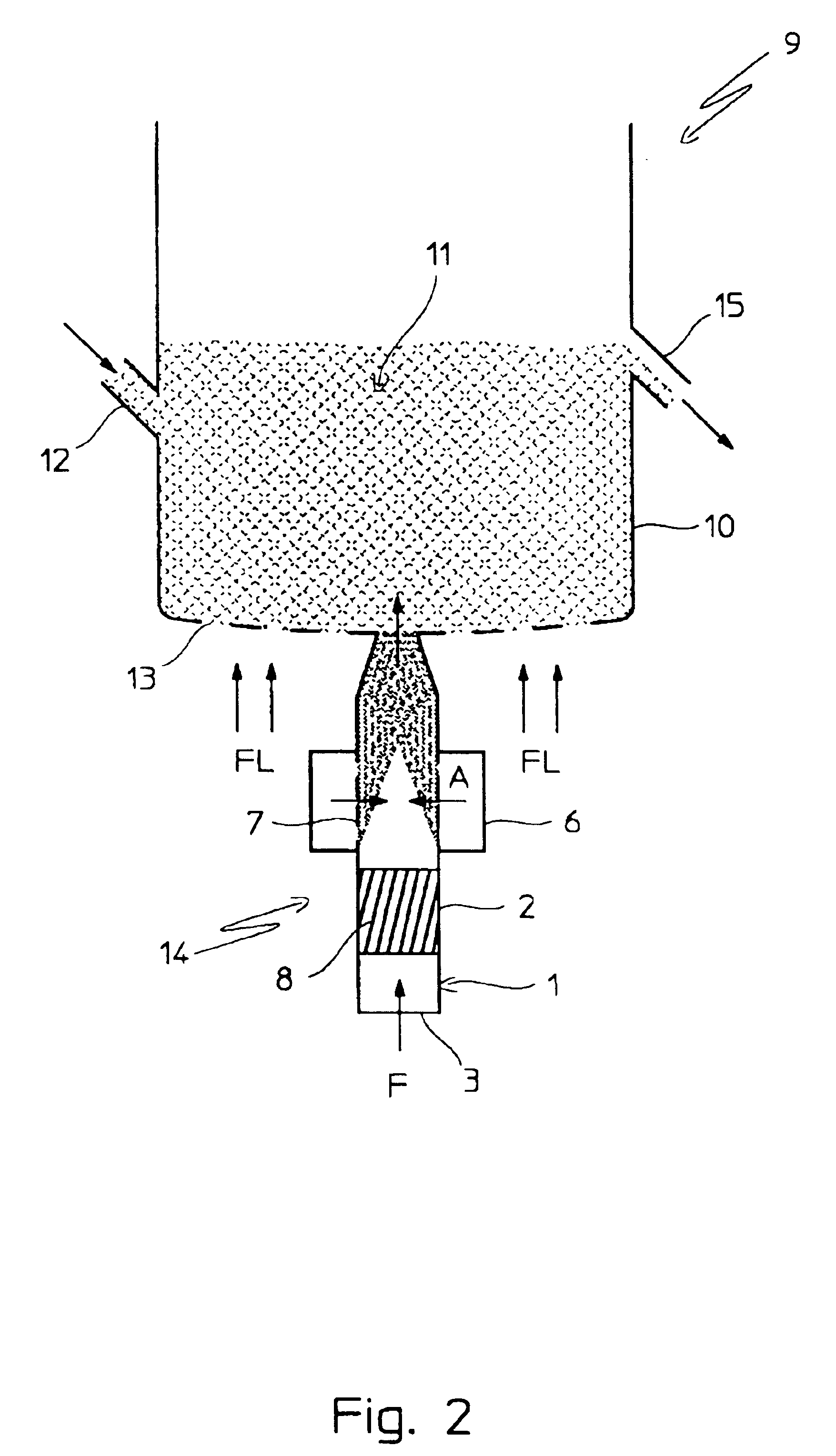

A nozzle for distributor devices of granule's growth liquid substance in fluid bed granulators, is distinguished by the fact that it comprises a duct (2) having, at one end, at least one inlet opening (3) for a flow (F) of a chosen granule's growth liquid substance, and, at the other end, a supply opening (5) for such substance, a gaseous flow distributor (6) externally associated to the duct (2) in predetermined spaced relationship from the supply opening (5) and in fluid communication with the inside of the duct (2), and emulsifying means (8) associated to the inlet opening (3) and the distributor (6) to obtain, inside the duct (2), an emulsion of the gaseous flow in the growth liquid substance.

Owner:CASALE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com