A granule virus dry suspending agent and a preparing method thereof

A granular virus and dry suspension technology, which is applied in botany equipment and methods, insecticides, biocides, etc., can solve the problems of virus inactivation, unsuitability for industrial application, high energy consumption and high cost, and improve the formulation performance, not easy to cause phytotoxicity, and save the cost of adjuvants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

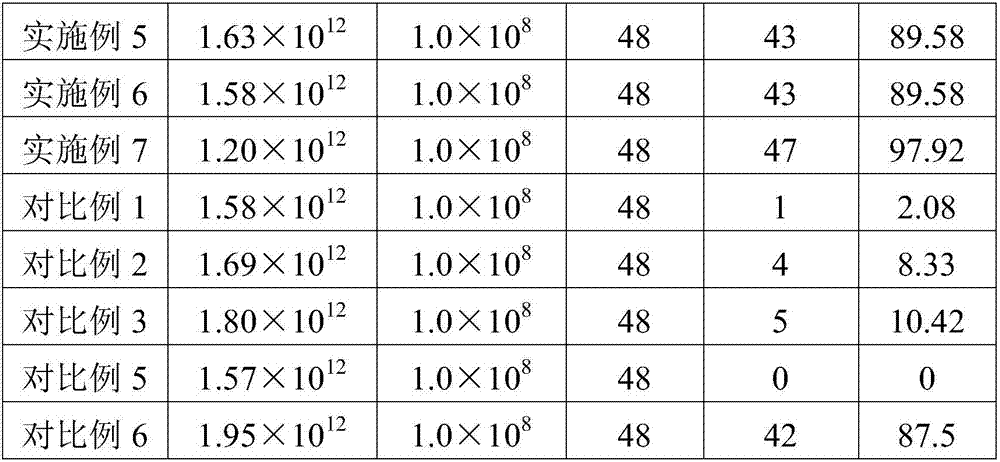

Examples

Embodiment 1

[0038] The dry suspension of Plutella xylostella granule virus in this embodiment is prepared by spray drying the Plutella xylostella granule virus water suspension, wherein the Plutella xylostella granule water suspension is made of the following components in percentage by weight: virus content 3.0×10 12 OB Plutella xylostella granule virus stock solution 20%, sodium lignosulfonate 7%, fatty alcohol polyoxyethylene ether 2%, ammonium sulfate 15%, trehalose 15%, nano-titanium dioxide 15%, white carbon black 26%.

[0039] The preparation method of the present embodiment Plutella xylostella granule virus dry suspension, the specific operation steps are:

[0040] 1) Take 2.0kg of diamondback moth granule virus stock solution, 0.7kg of sodium lignosulfonate, 0.2kg of fatty alcohol polyoxyethylene ether, 1.5kg of ammonium sulfate, 1.5kg of trehalose, 1.5kg of nano-titanium dioxide and 2.6kg of white carbon black, Mix evenly in a stirring tank, grind and homogenize through a sand ...

Embodiment 2

[0044] The dry suspension of Plutella xylostella granule virus in this embodiment is prepared by spray drying the Plutella xylostella granule virus water suspension, wherein the Plutella xylostella granule water suspension is made of the following components in percentage by weight: virus content 2.8×10 12 OB Plutella xylostella granulosa virus stock solution 22%, polycarboxylate D1001 6%, sodium lauryl sulfate K12 3%, calcium chloride 14%, modified starch 8%, sucrose 4%, nano-zinc oxide 14% , Kaolin 29%.

[0045] The preparation method of the present embodiment Plutella xylostella granule virus dry suspension, the specific operation steps are:

[0046] 1) Take Plutella xylostella granulosa virus stock solution 2.2kg, polycarboxylate D1001 0.6kg, sodium lauryl sulfate K120.3kg, calcium chloride 1.4kg, modified starch 0.8kg, sucrose 0.4kg, zinc oxide 1.4kg , kaolin 2.9kg, mix homogeneously in stirring tank, grind through sand mill, homogenize to the average particle diameter ...

Embodiment 3

[0050] The dry suspension of Plutella xylostella granule virus in this embodiment is prepared by spray drying the Plutella xylostella granule virus water suspension, wherein the Plutella xylostella granule water suspension is made of the following components in percentage by weight: virus content 2.6×10 12 OB / g Plutella xylostella granulosa virus stock solution 24%, polycarboxylate TERSPERSE2700 5%, sulfonate TERWET1004 4%, ammonium sulfate 7%, urea 6%, maltodextrin 14%, fluorescent whitening agent 12 %, bentonite 28%.

[0051] The preparation method of the present embodiment Plutella xylostella granule virus dry suspension, the specific operation steps are:

[0052] 1) Take Plutella xylostella granulosa virus stock solution 2.4kg, polycarboxylate TERSPERSE2700 0.5kg, sulfonate TERWET1004 0.4kg, ammonium sulfate 0.7kg, urea 0.6kg, maltodextrin 1.4kg, fluorescent whitening agent 1.2kg , bentonite 2.8kg, mix homogeneously in mixing tank, grind through sand mill, homogenize to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com