Patents

Literature

90 results about "Suspension Dosage Form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A liquid dosage form that contains solid particles dispersed in a liquid vehicle. Note: A liquid is pourable; it flows and conforms to its container at room temperature. It displays Newtonian or pseudoplastic flow behavior.

Sustained-release drug delivery compositions and methods

InactiveUS20100092562A1Improve stabilityReduce molecular weightPowder deliveryOrganic active ingredientsImmediate releaseDecongestant

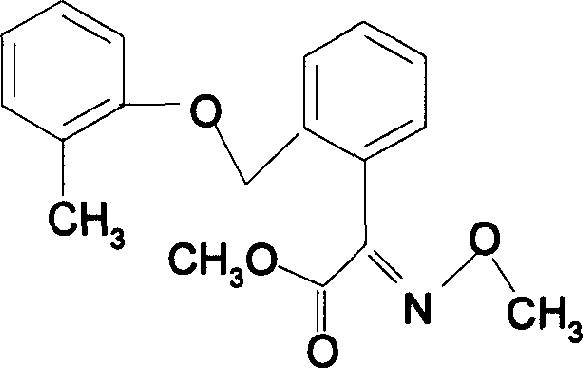

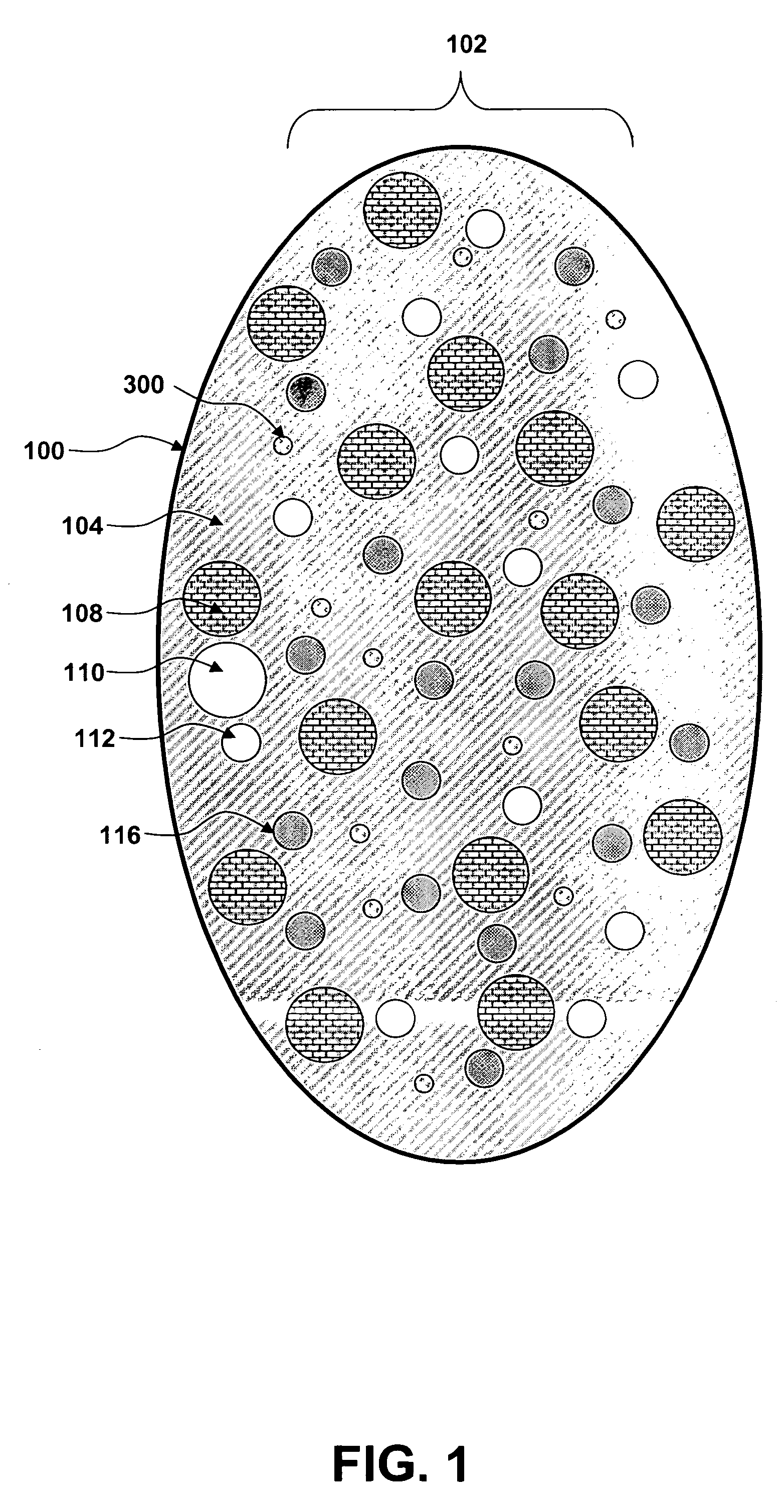

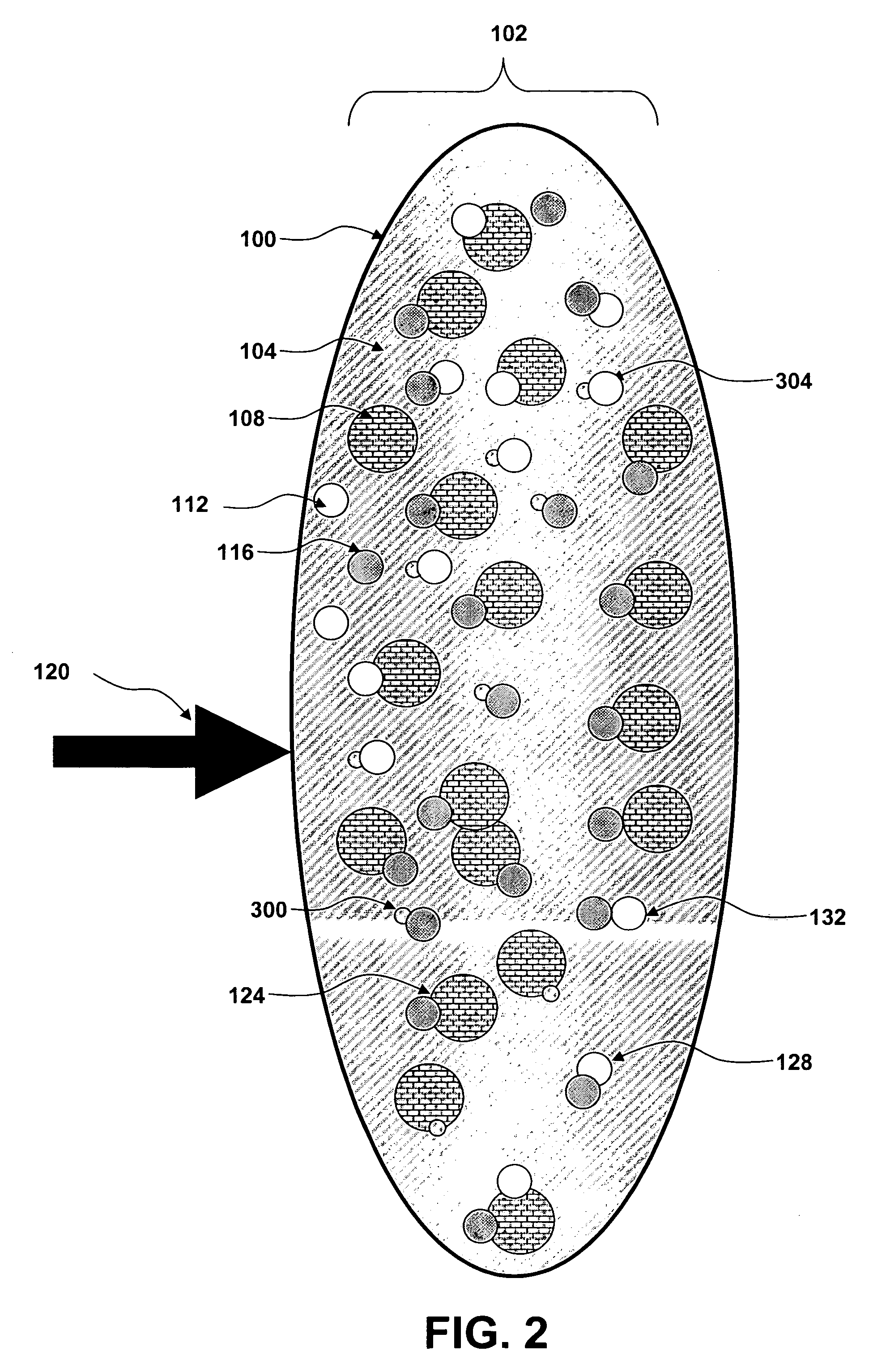

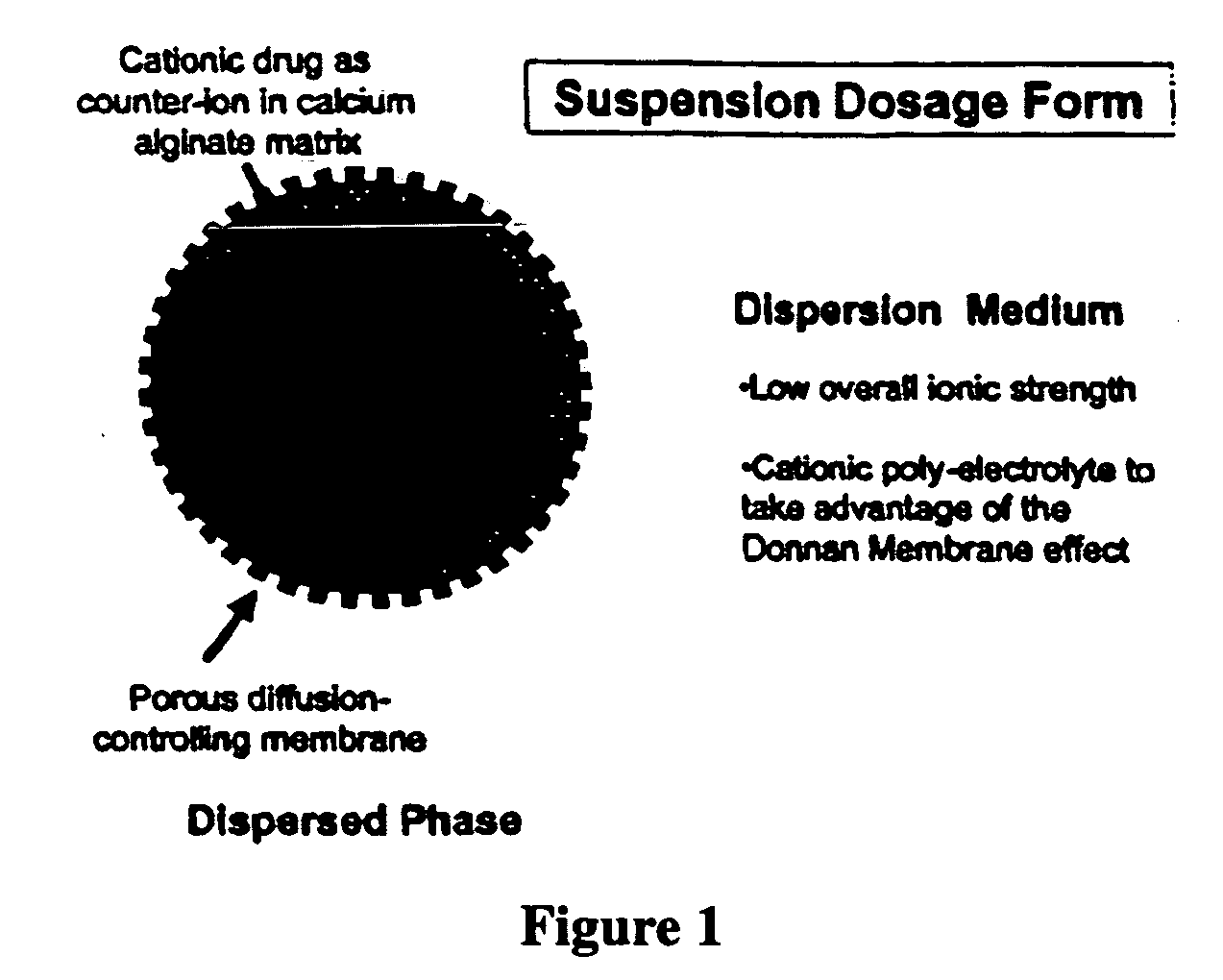

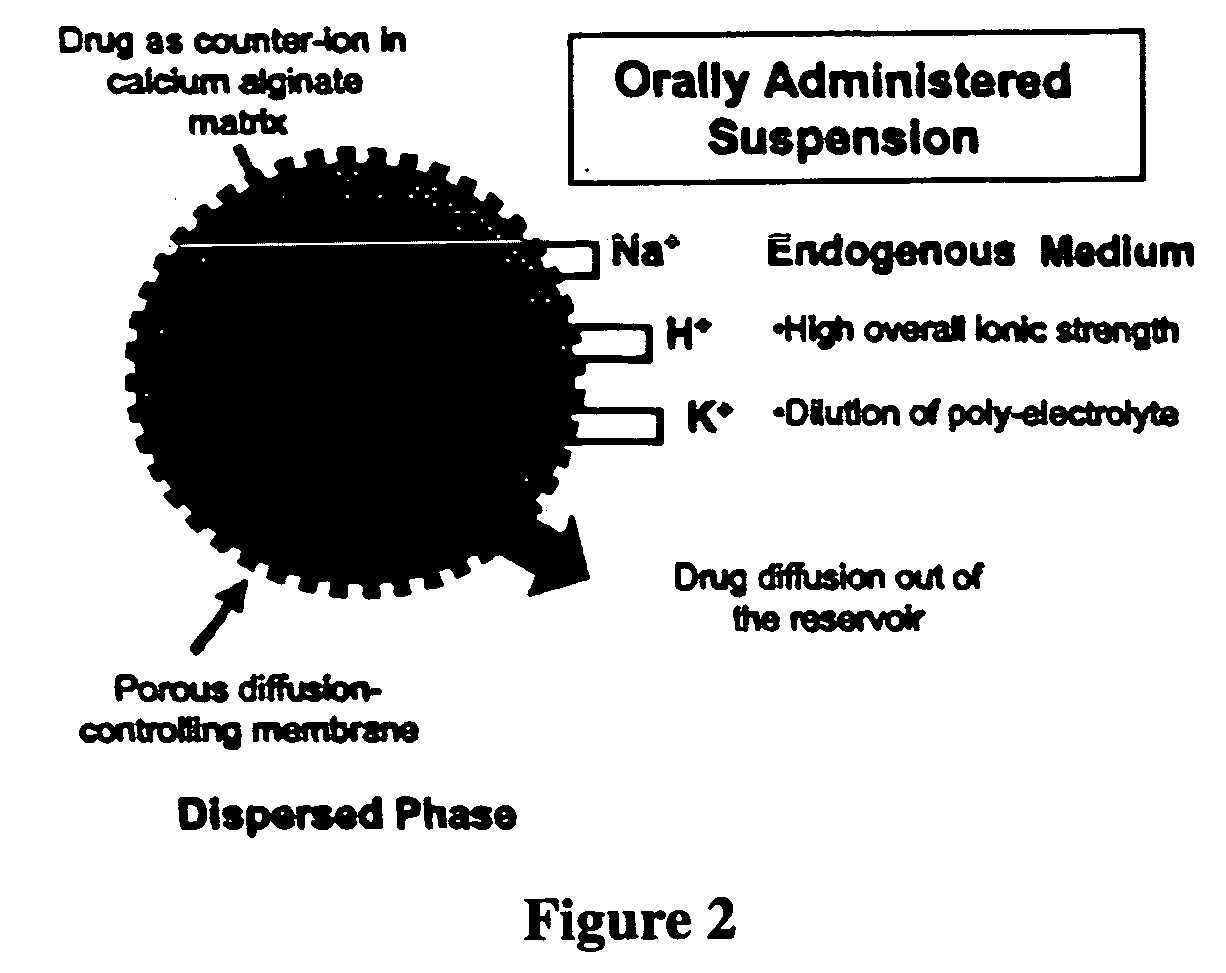

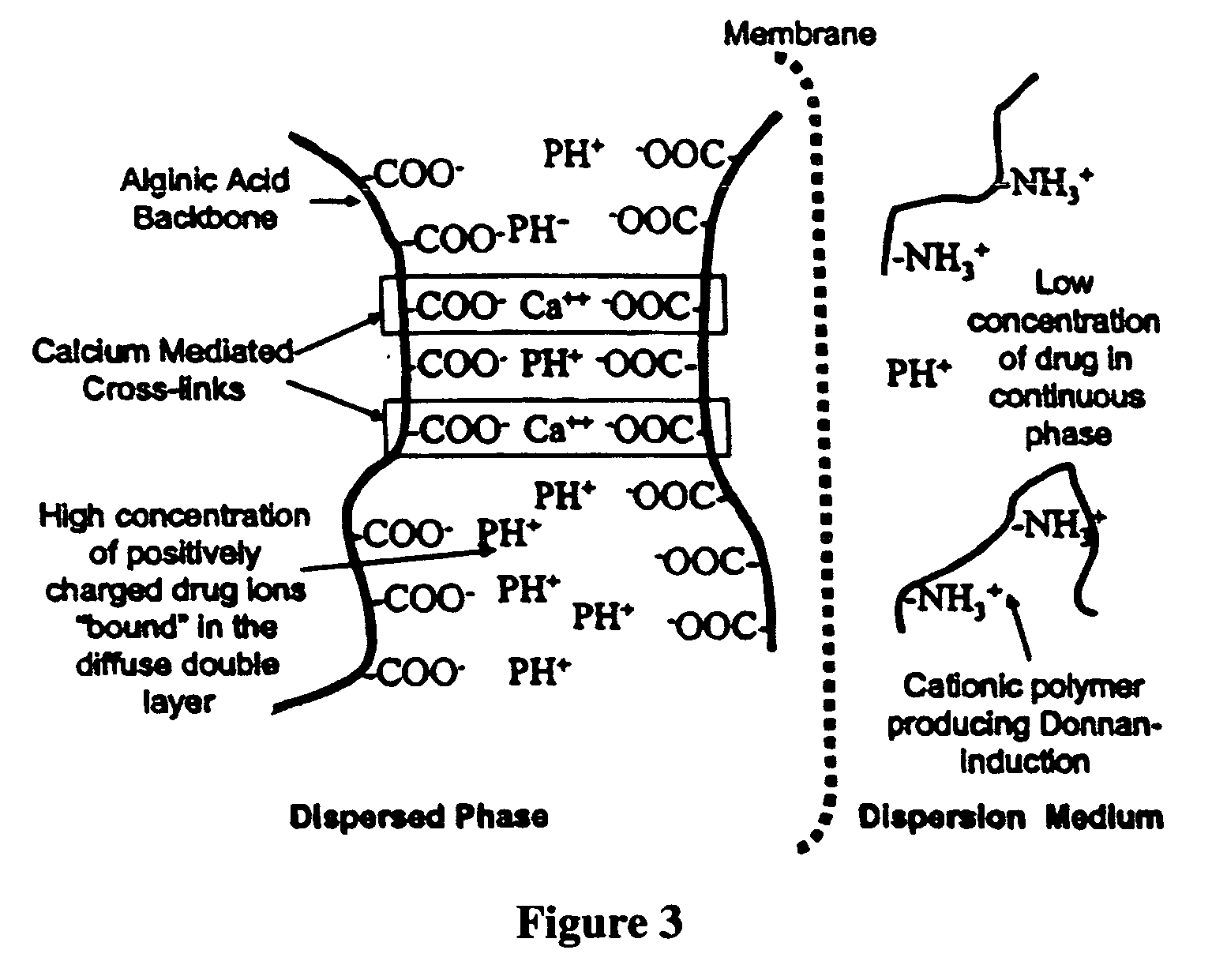

The present invention relates to liquid sustained release suspension dosage forms. In particular, the invention encompasses sustained release compositions comprising a dispersed phase, which contains an ion-exchange matrix drug complex, a diffusion controlling membrane coating and a dispersion medium comprising an excipient capable of impeding water activity such that drug dissolution is inhibited prior to administration. Further, the invention provides for compositions wherein several active ingredients associate in a single bead in the dispersed phase, such that the abuse potential of such active ingredients is reduced. The invention also encompasses sustained release formulations of combination drugs comprising an extended release phase and an immediate release phase. The formulations of the invention may be used to treat a variety of conditions and symptoms, including those that require administration of several drugs, such as cold and allergy symptoms. In one of the embodiments, the sustained release composition combines an antihistamine, an antitussive and a decongestant. The invention further provides for methods of making and using such formulations.

Owner:UPM PHARMA

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

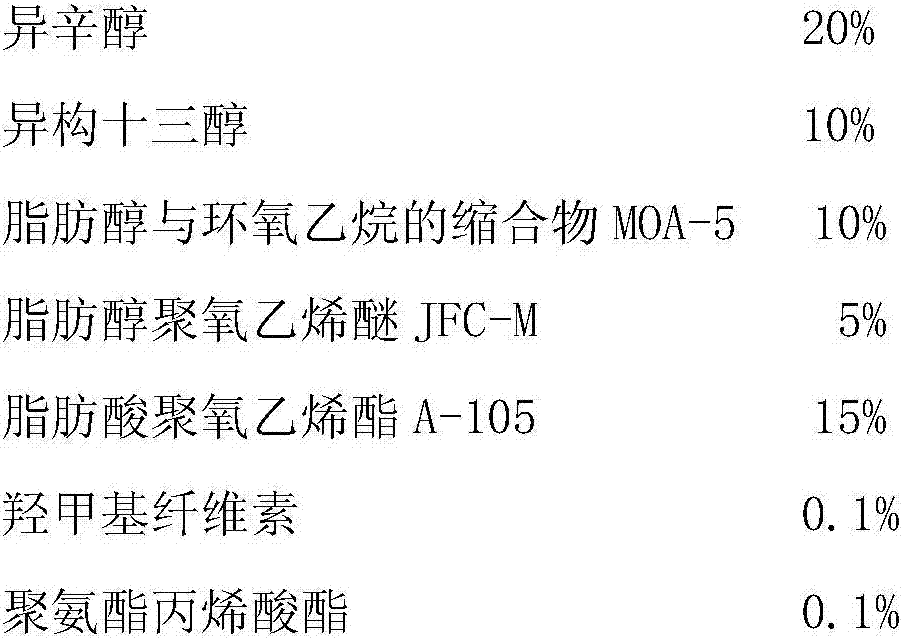

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

Aqueous sustained-release drug delivery system for highly water-soluble electrolytic drugs

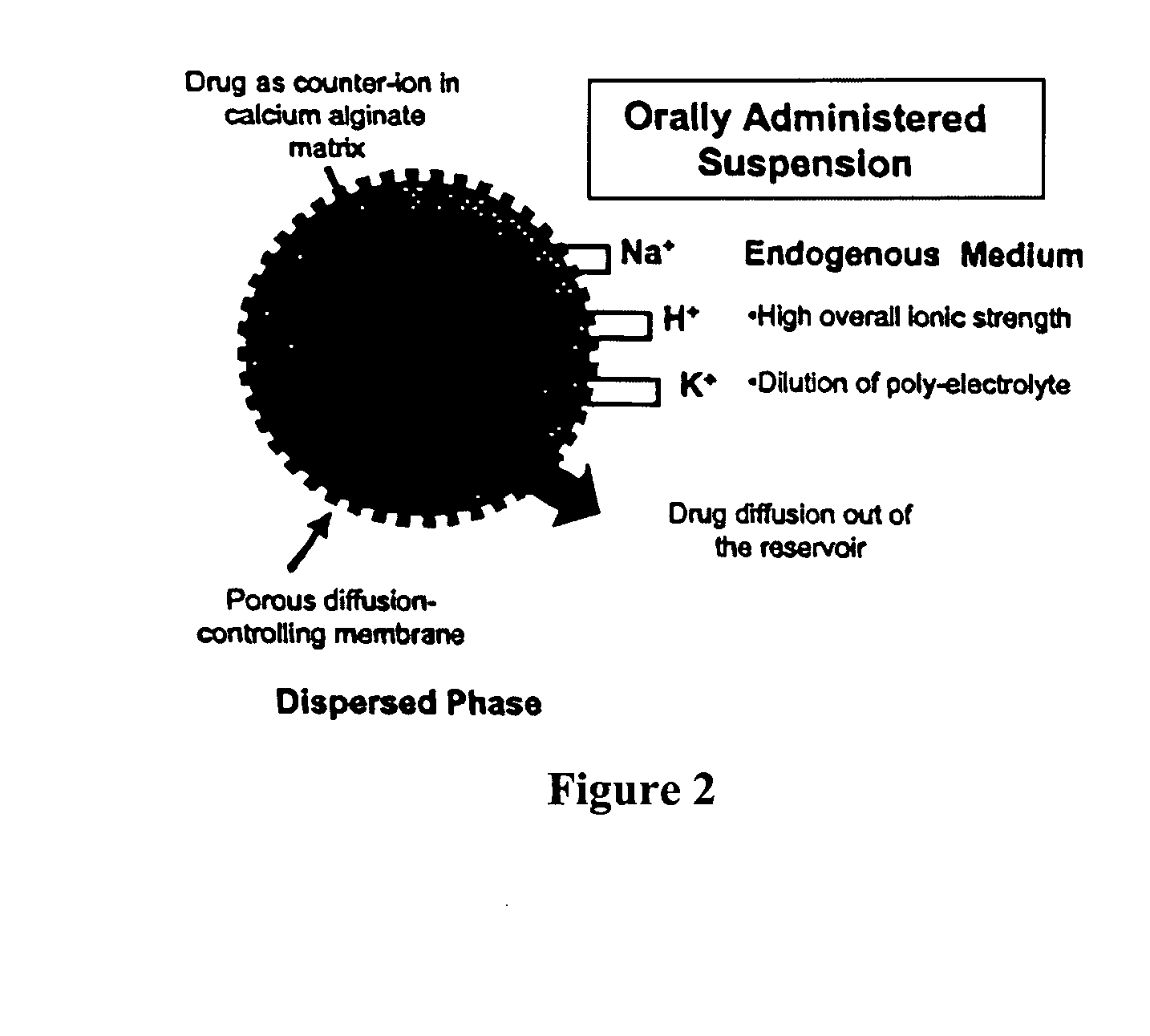

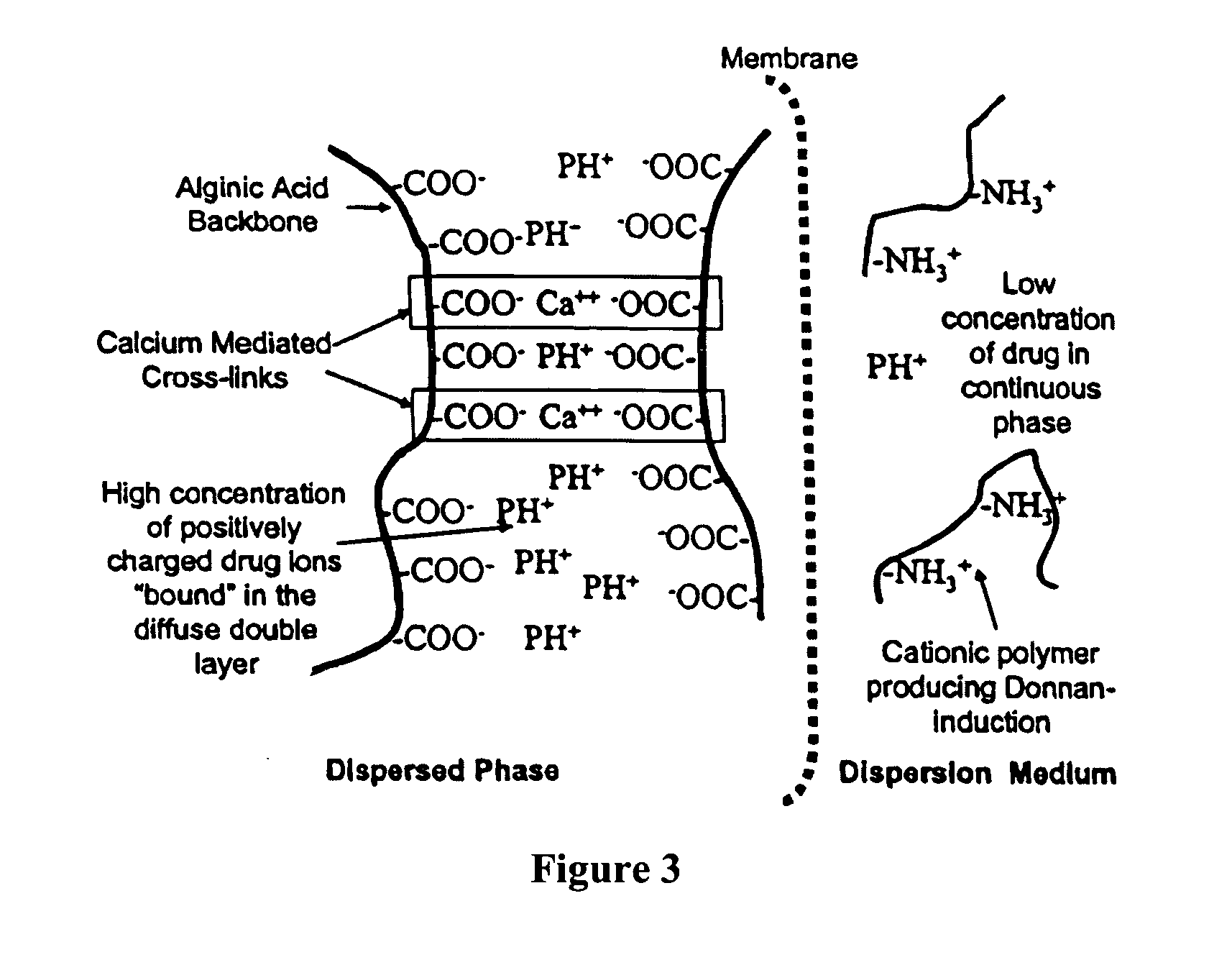

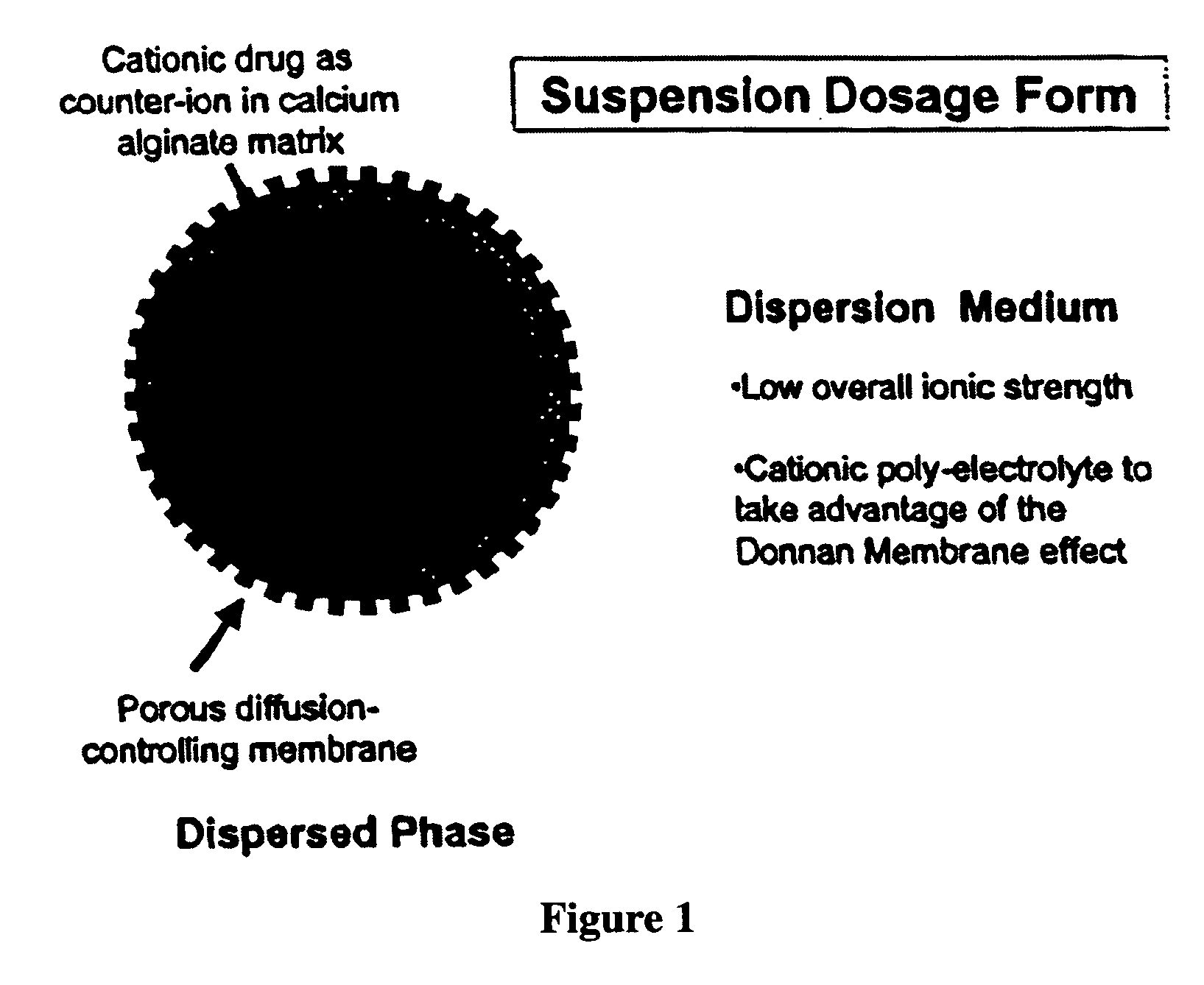

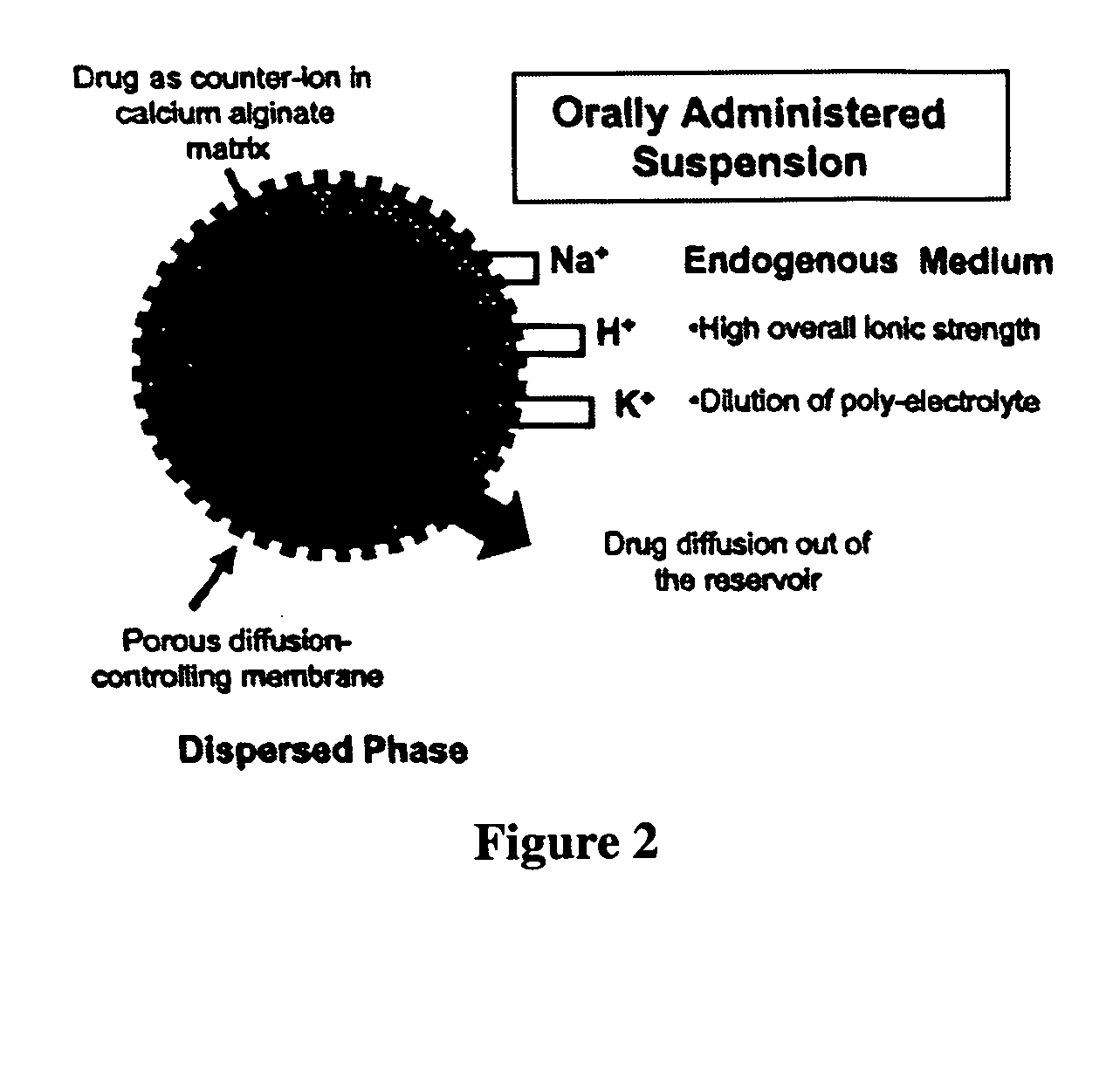

InactiveUS20050013792A1Change in permeabilityPowder deliveryNervous disorderPolyelectrolyteSustained release drug

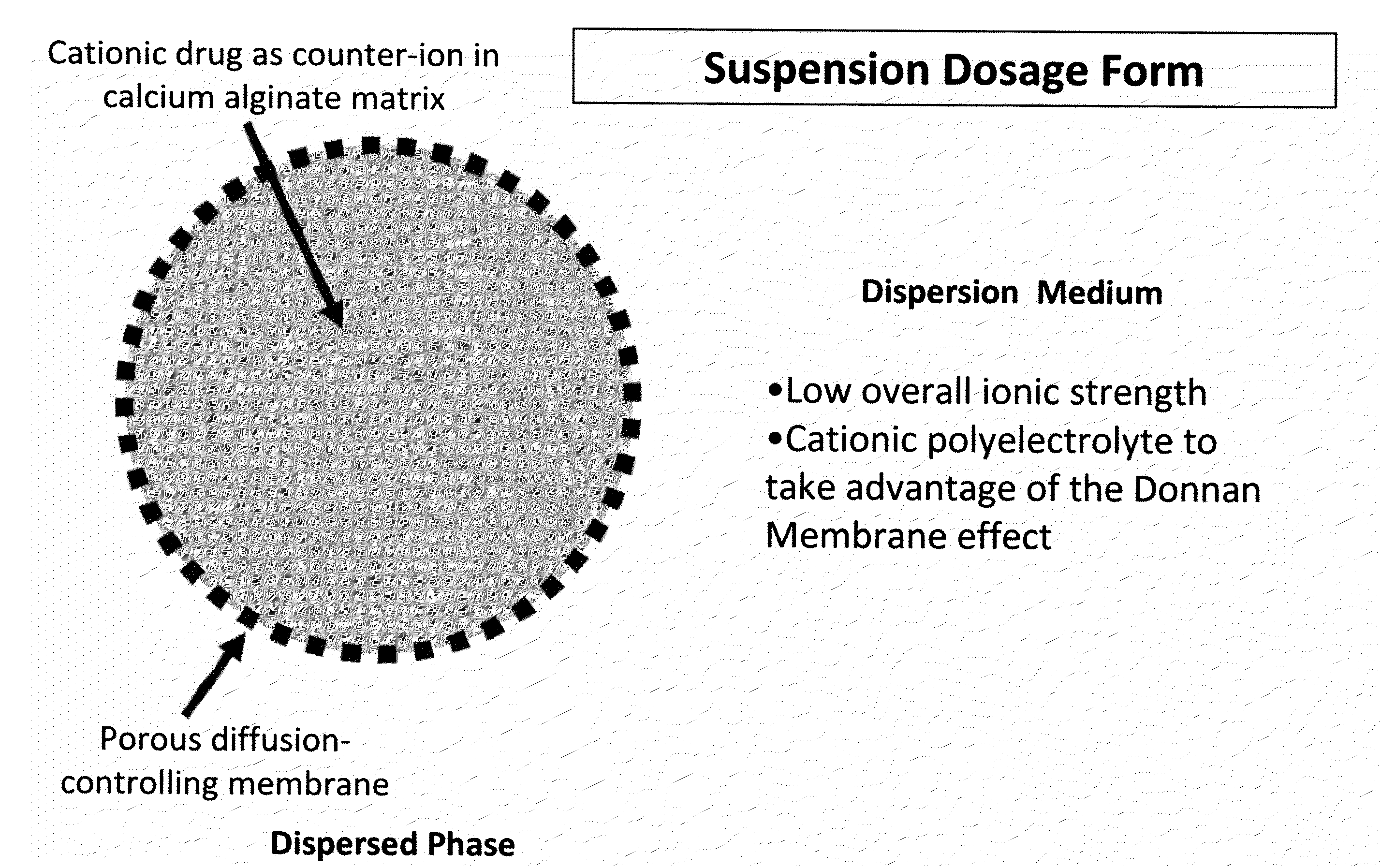

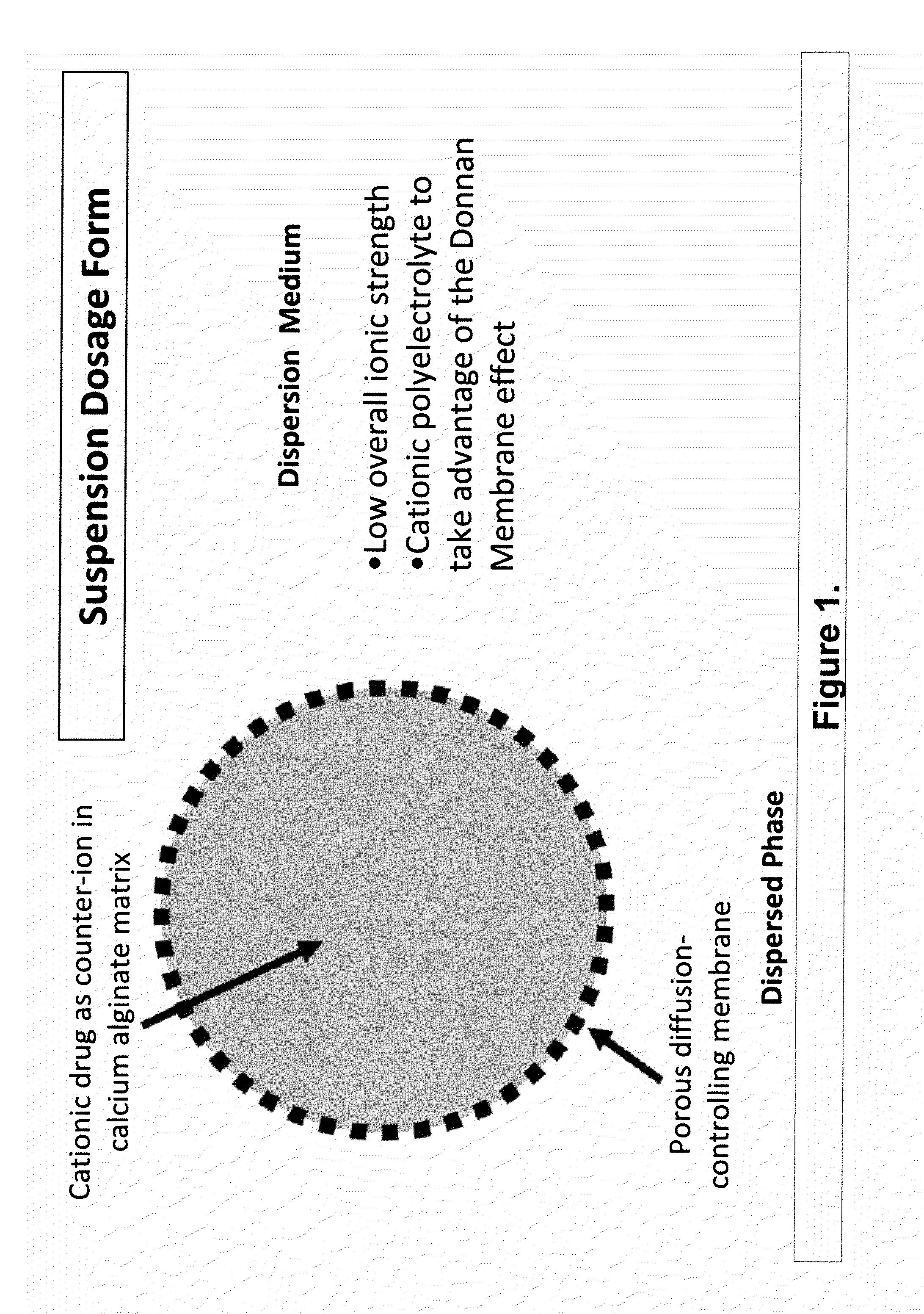

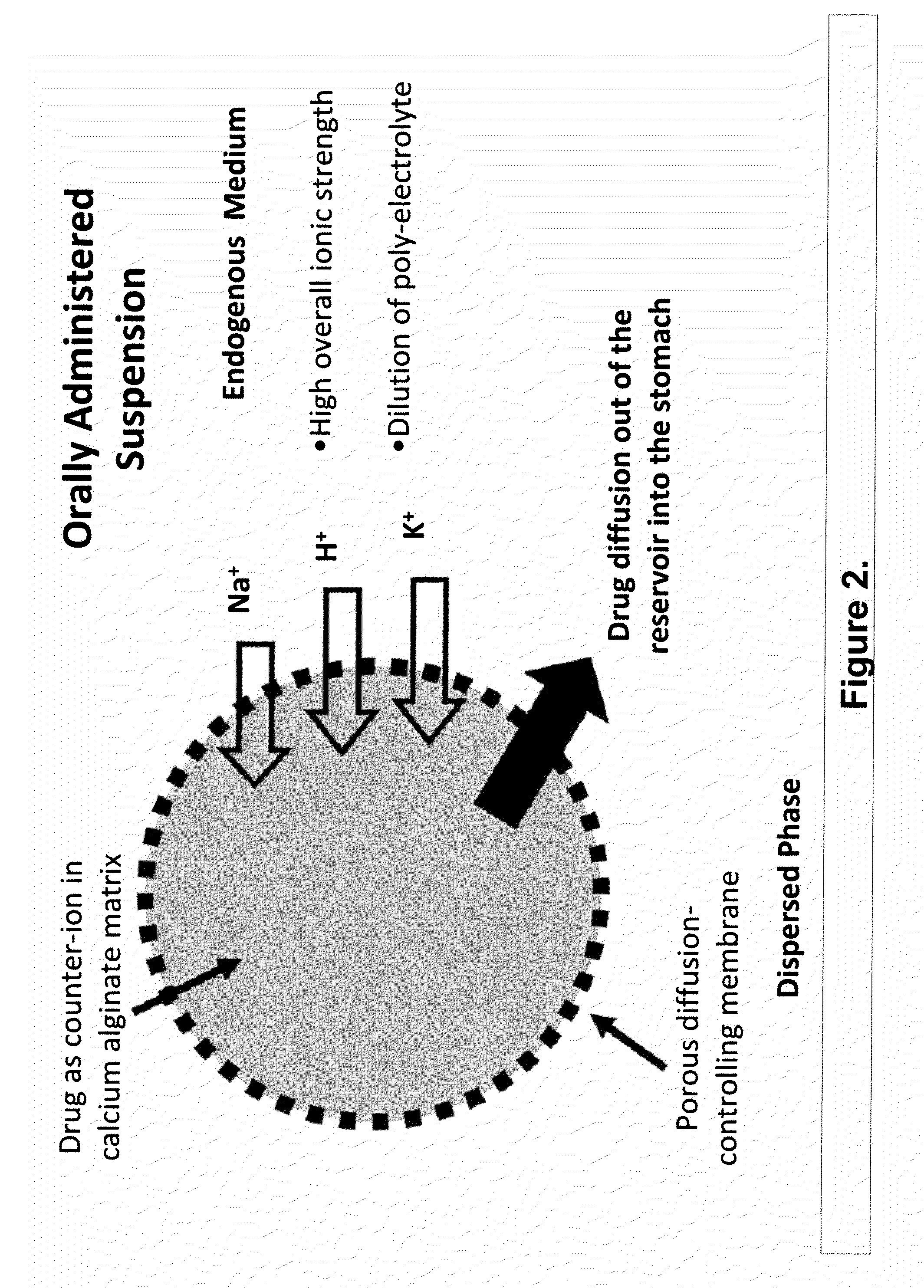

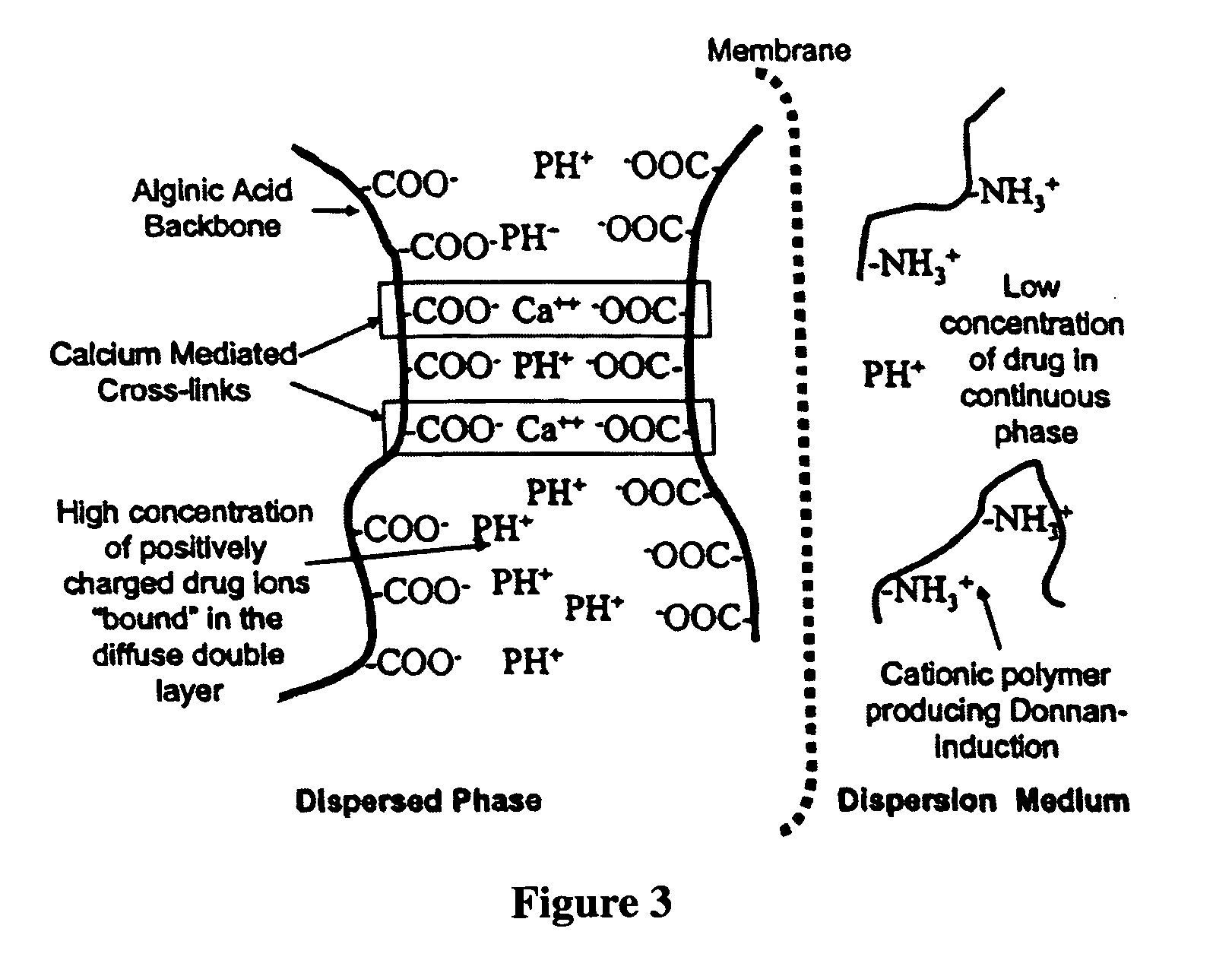

The present invention relates to liquid sustained release suspension dosage forms comprising ionized forms of water-soluble drugs. In particular, the invention encompasses a liquid form controlled release drug composition comprising a dispersed phase comprising an ion-exchange matrix drug complex comprising a pharmaceutically acceptable ion-exchange matrix and a water-soluble electrolytic drug associated with the ion-exchange matrix, wherein the surface charge of the ion-exchange matrix is opposite that of the electrolytic drug and a dispersion medium substantially free of diffusible counterions, further comprising a polyelectrolyte having the same charge as the electrolytic drug. The invention also provides methods for preparing such compositions and methods of treatment.

Owner:MARYLAND UNIV OF BALTIMORE +1

Aqueous sustained-release drug delivery system for highly water-soluble electrolytic drugs

InactiveUS20060134148A1Reduce molecular weightQuick releasePowder deliveryPharmaceutical non-active ingredientsElectrolysisIon exchange

Owner:HOLLENBECK R GARY

Electrically conductive composite material

InactiveUS20090117269A1Efficient transportImprove conductivityForce measurement by measuring frquency variationsSemiconductor/solid-state device manufacturingFiberElastomer

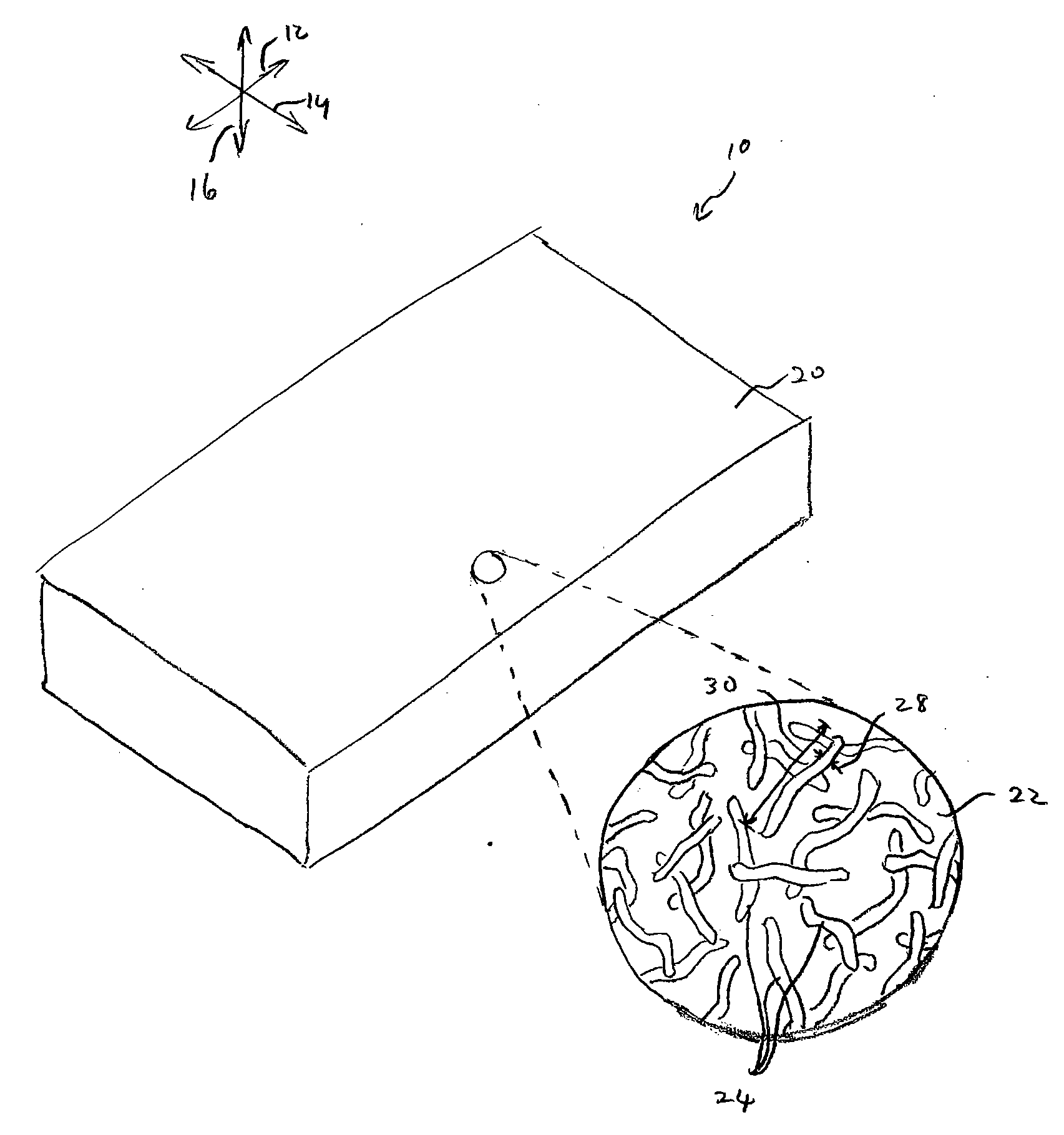

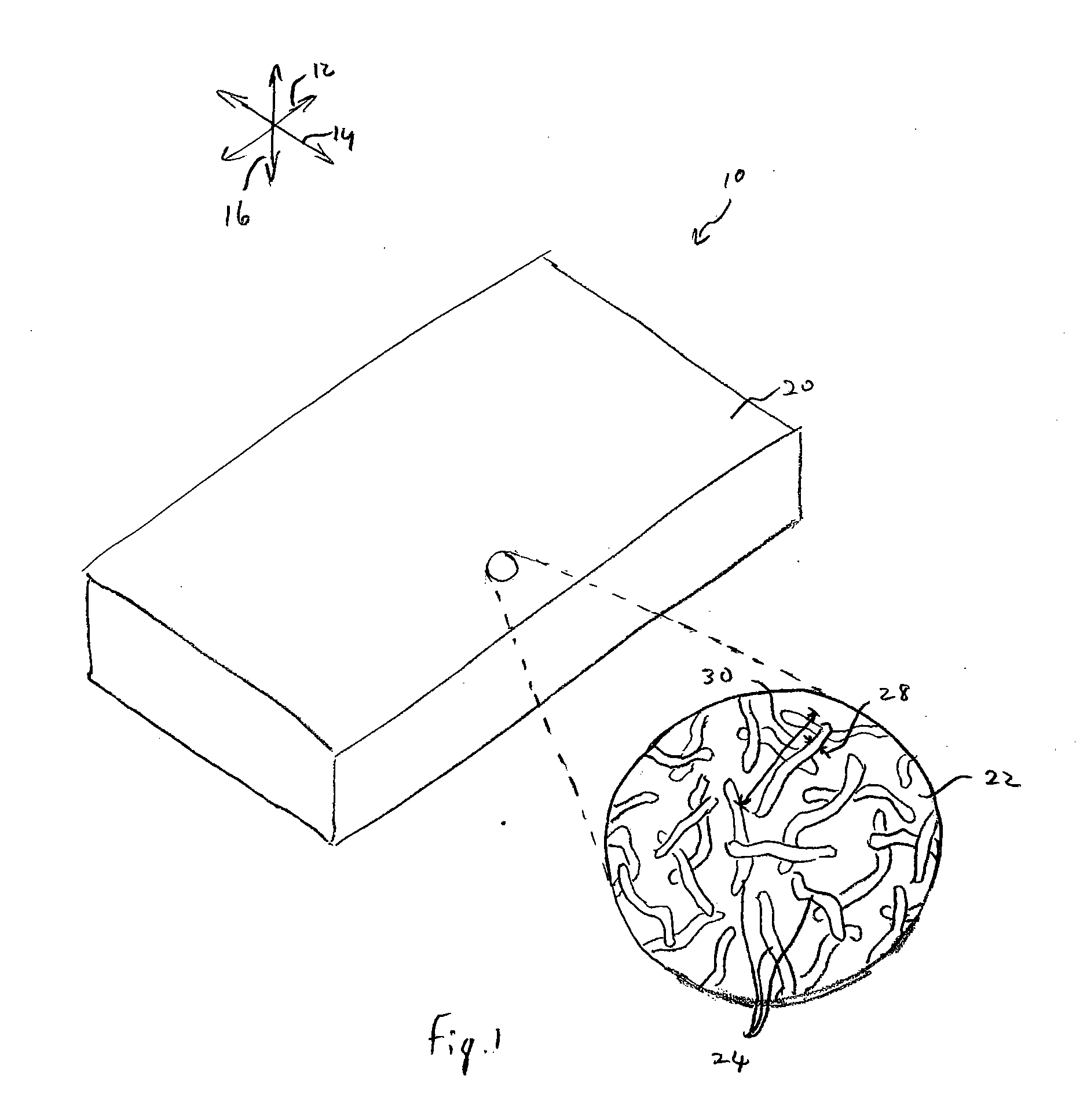

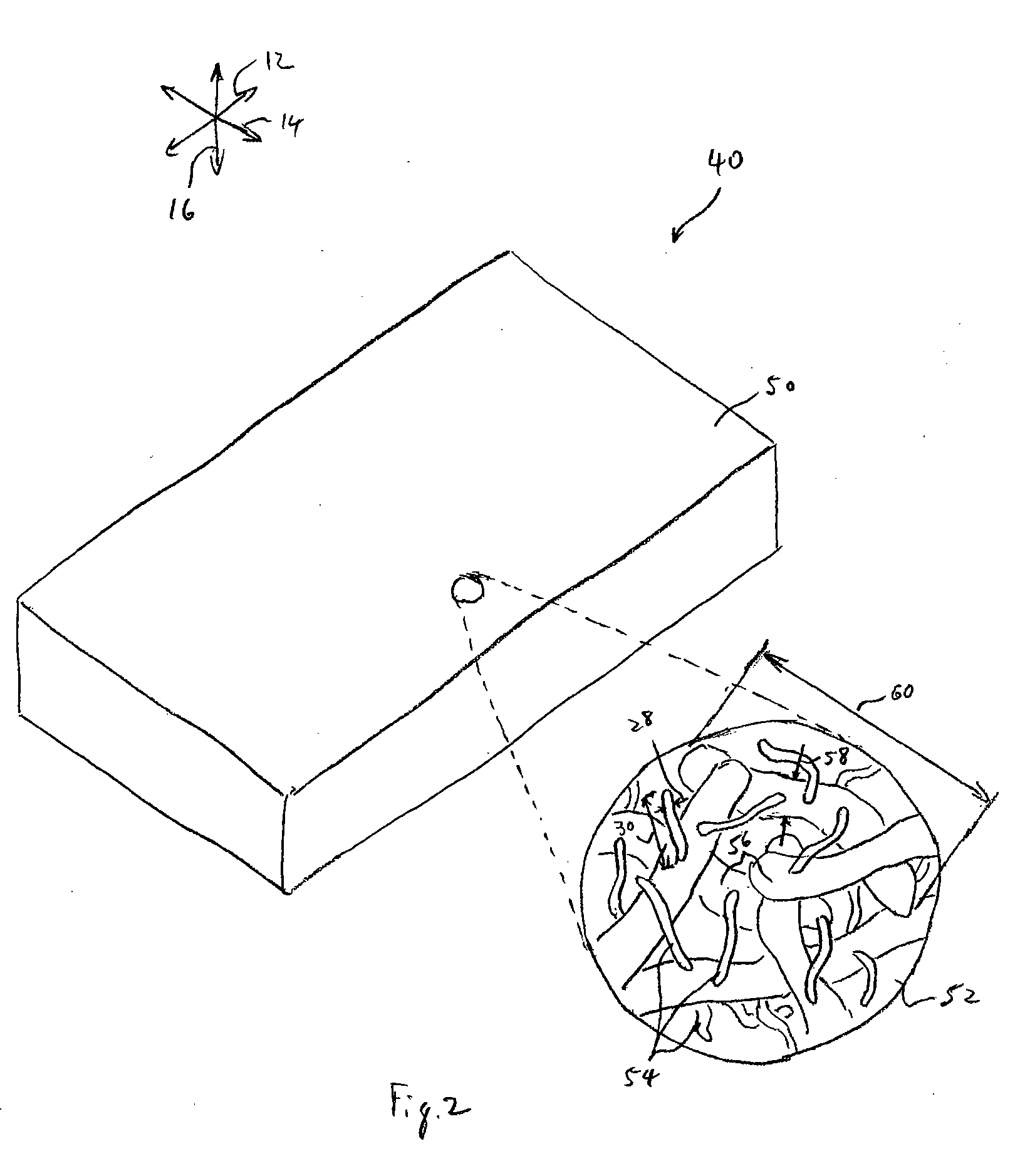

An electrically conductive composite material includes metallic nanostrands distributed throughout a matrix constructed of a polymer, ceramic, or elastomer. The nanostrands may have an average diameter under four microns and an average aspect ratio over ten-to-one. Larger fibers may also be included to enhance electrical conductivity or other properties. The nanostrands and / or fibers may be magnetically oriented to enhance electrical conductivity along one direction. A pressure sensor may be formed by utilizing an elastomer for the matrix. Electrical conductivity through the composite material varies in proportion to deflection of the elastomer. A composite material may be applied to a surface as an electrically conductive paint. Composite materials may be made by cutting a blank of the nanostrands to the desired shape, inserting the matrix, and curing the matrix. Alternatively, a suspension agent may first be used to dispose powdered nanostrands in the desired shape.

Owner:CONDUCTIVE COMPOSITES CO IP LLC

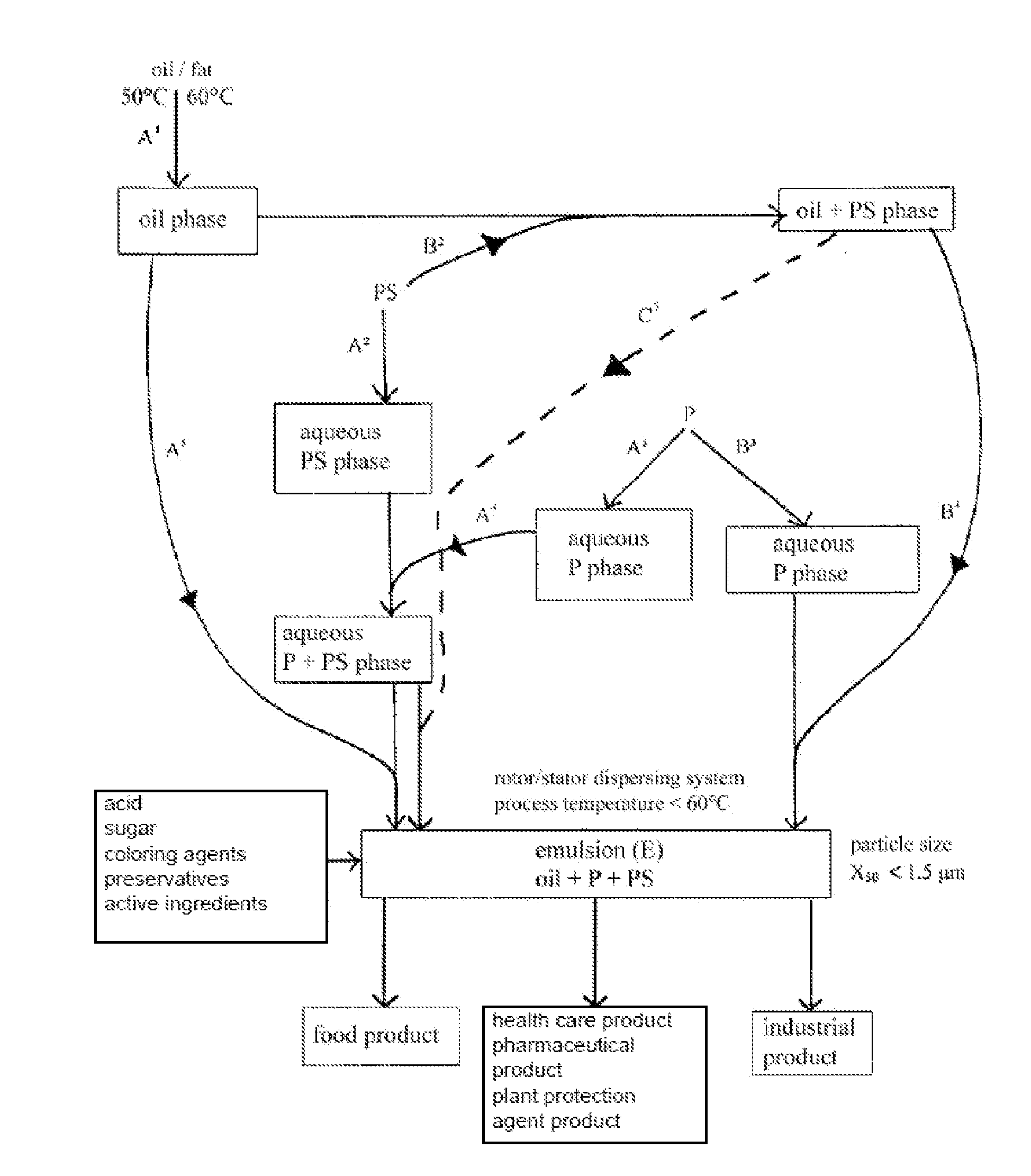

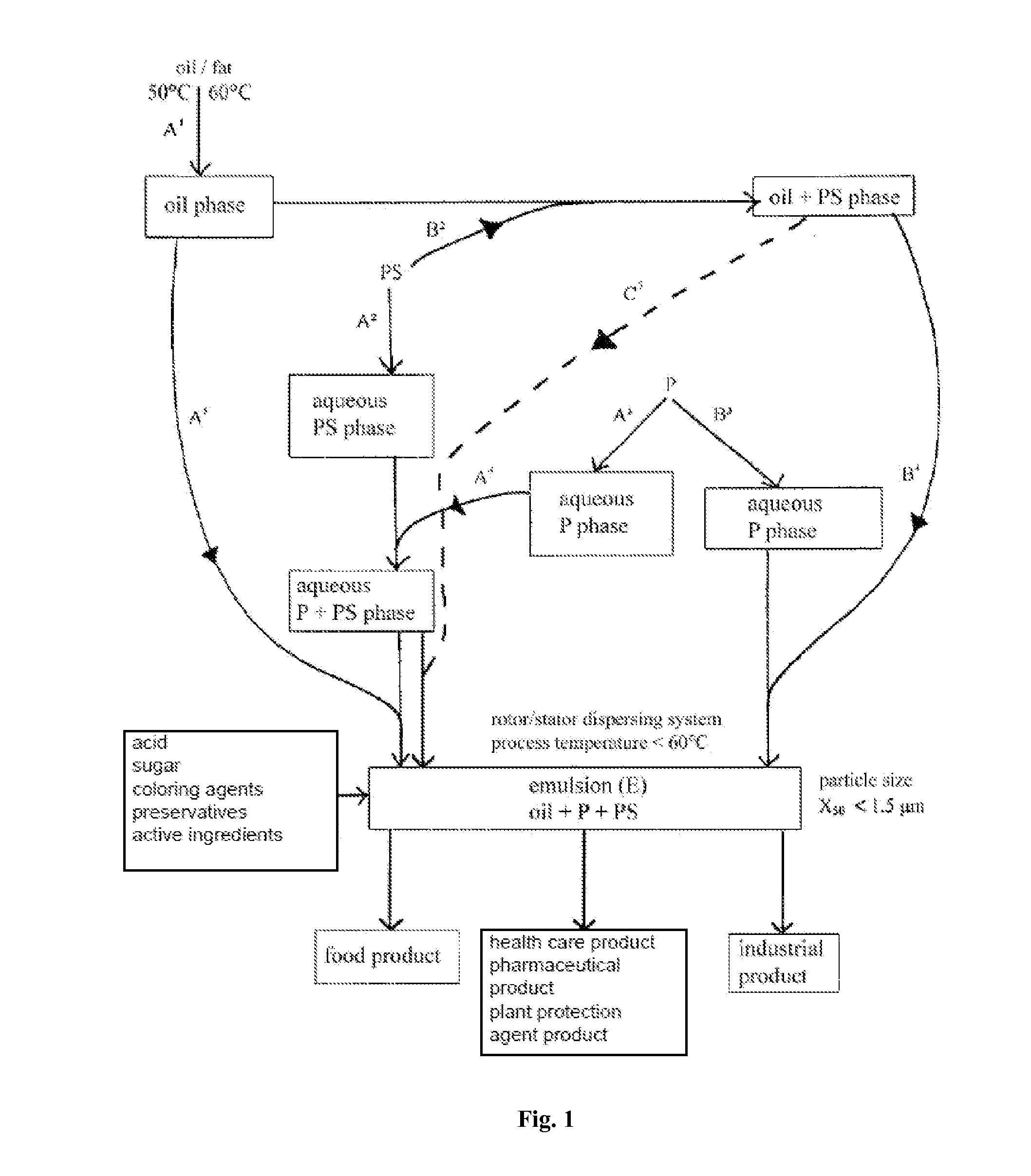

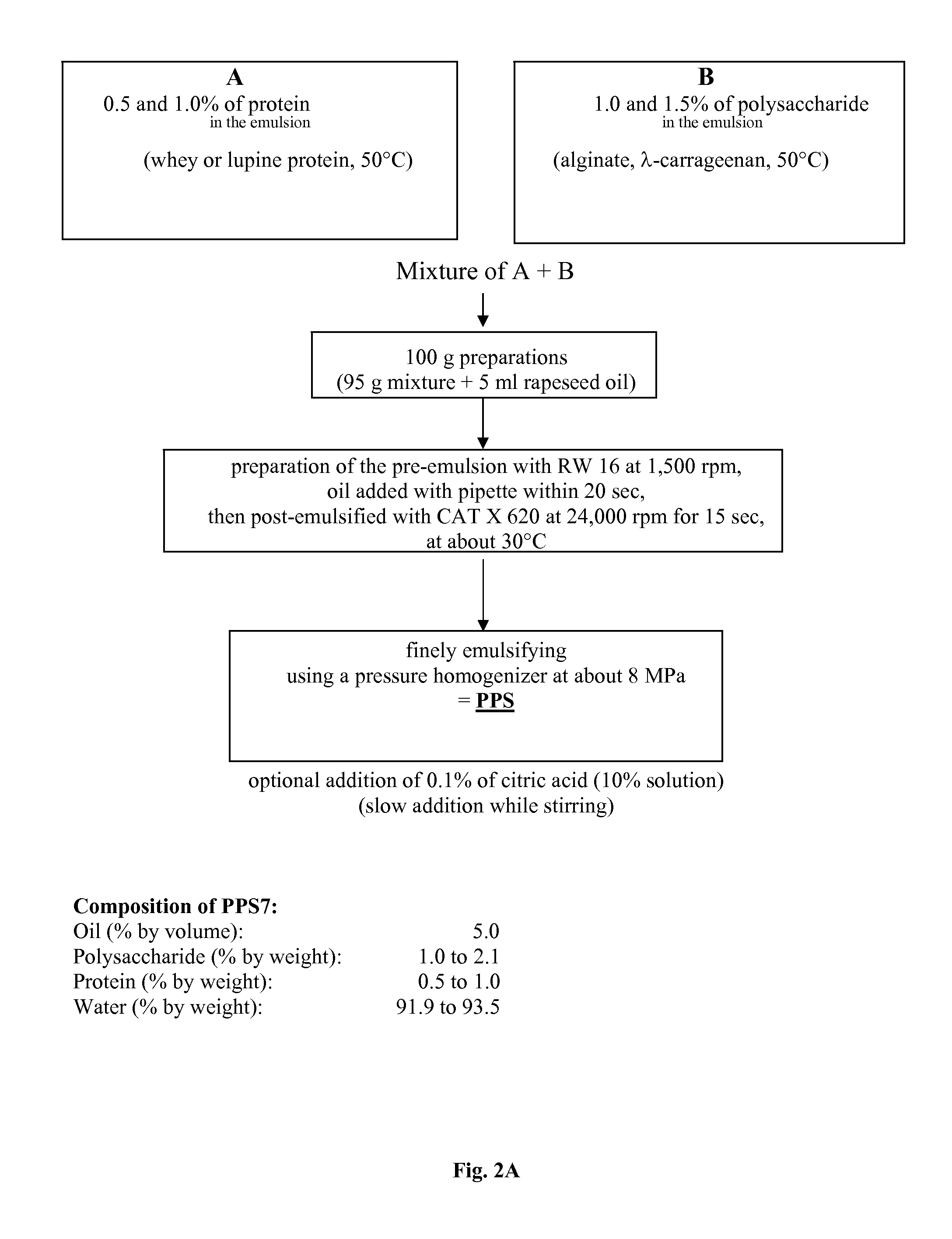

Concentrated, creamy to solid and dry compositions of an oil-in-water emulsion, method for the production thereof and use thereof for producing improved foods in terms of sensory aspects and nutrition physiology

InactiveUS20120135125A1Improve featuresEdible oils/fats ingredientsCosmetic preparationsFood additiveNutrition physiology

The invention relates to an oil-in-water emulsion, substantially comprising protein, polysaccharide and oil or fat having unique stabilizing properties, which is suited for use as a thickener, suspending agent, coating material and as an additive to food in the production of a plurality of products. Furthermore, foods are provided which have improved properties in terms of sensory aspects and nutrition physiology compared to conventionally produced products, and a method for the production thereof is provided. In addition, the emulsion and products produced according to the invention can be dried and subsequently rehydrated in order to obtain compositions that have substantially the same properties as the non-dried compositions.

Owner:OPTISENS

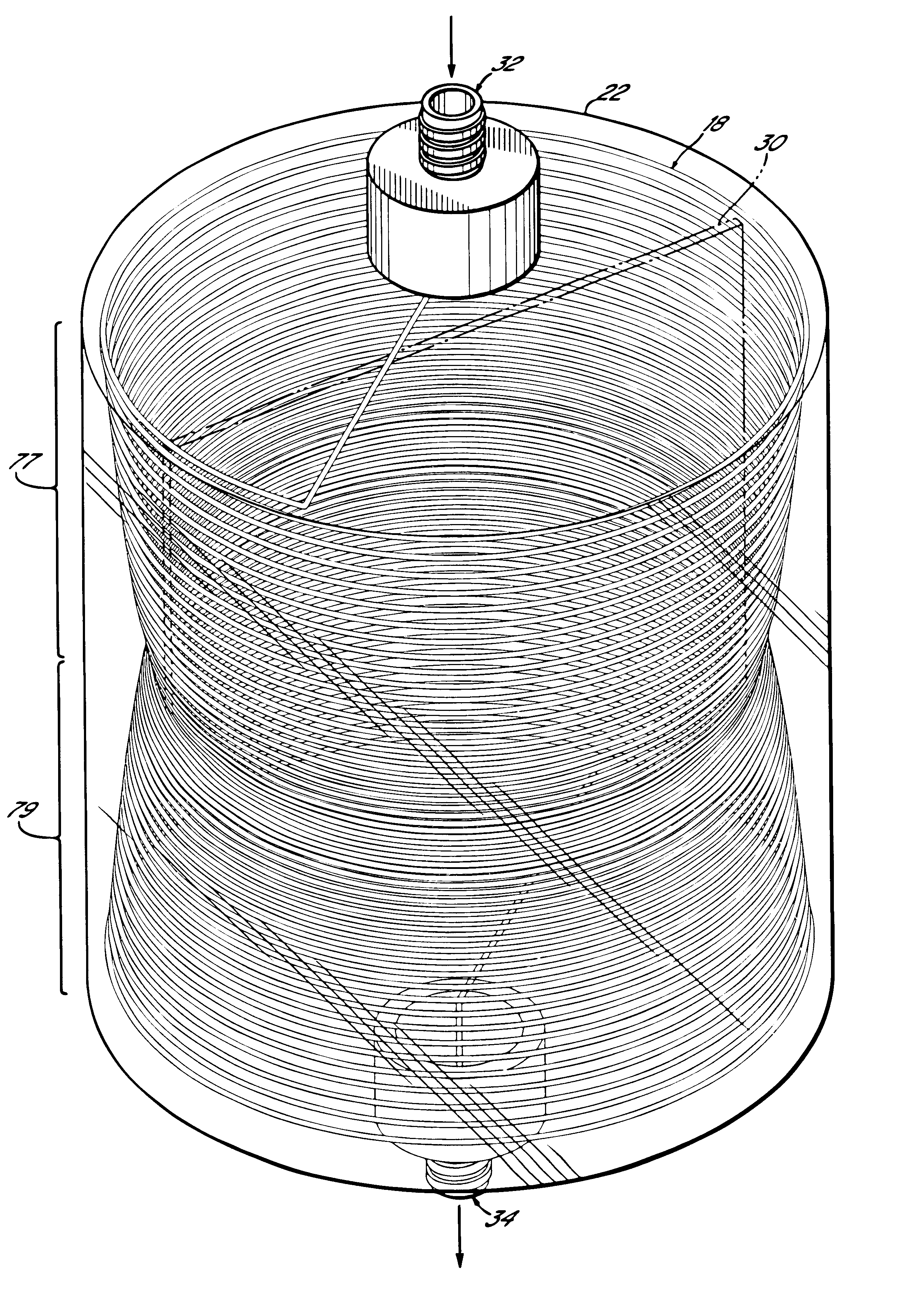

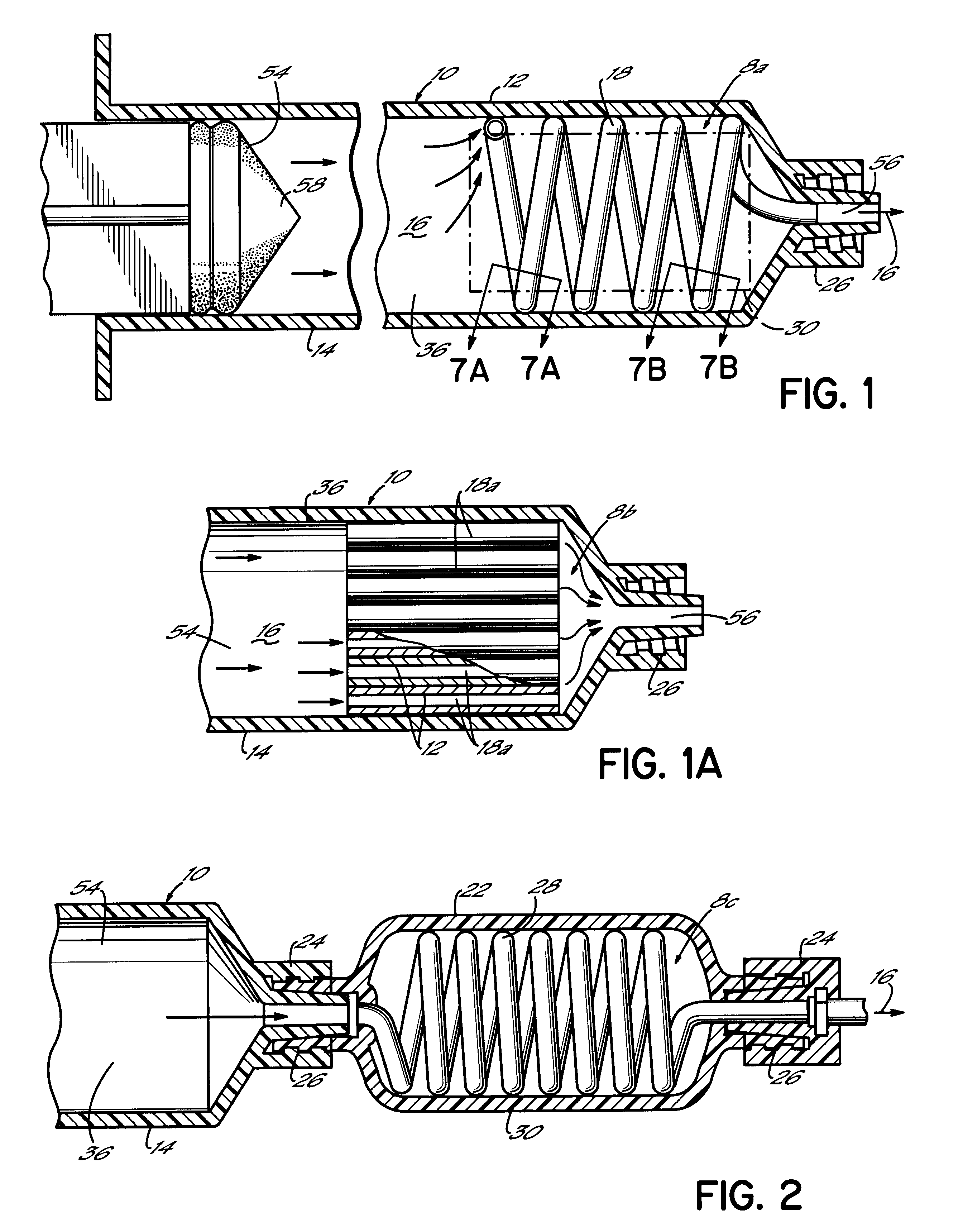

Suspension device and method

InactiveUS6871087B1Well mixedAltered radius of curvatureMedical devicesPressure infusionEngineeringSuspending Agents

A device and method for providing a suspended agent such as a contrast agent without mechanical resuspension. A volume of agent is divided into sub-volumes in a network of tubes, cells, sponges, grooves, etc. A propellant fluid flows through the network to release the suspended agent. The network may be internal to a container for the propellant fluid. Alternatively, the network may be adjacent an exit port of a container for the propellant fluid, or may be in-line between a propellant fluid container and a patient. The invention reduces sedimentation of agents into one or a few aggregates and eliminates a mechanical mixing step. The invention thus provides a uniformly suspended agent, improving patient health and safety and increasing cost and time savings.

Owner:MALLINCKRODT INC

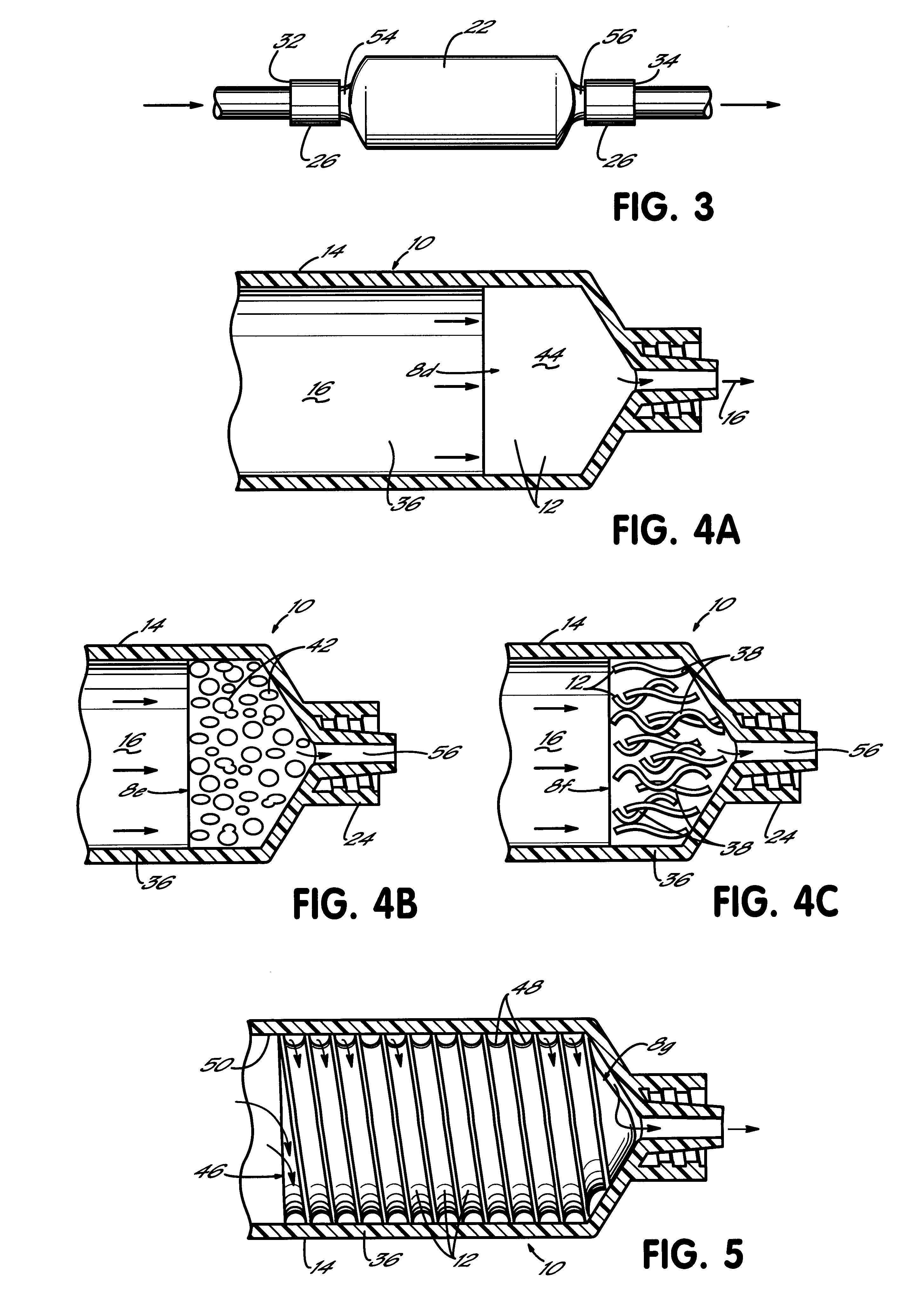

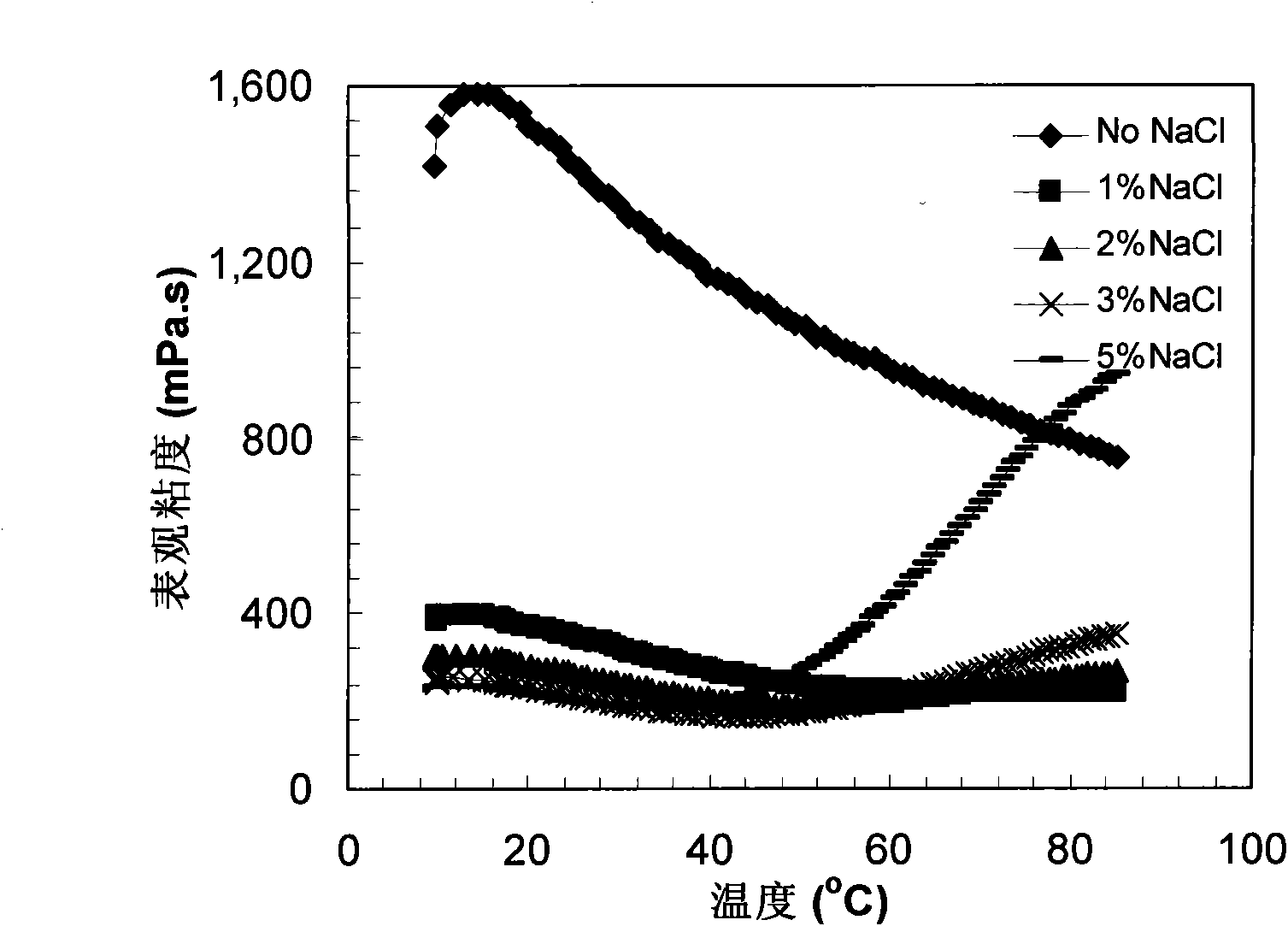

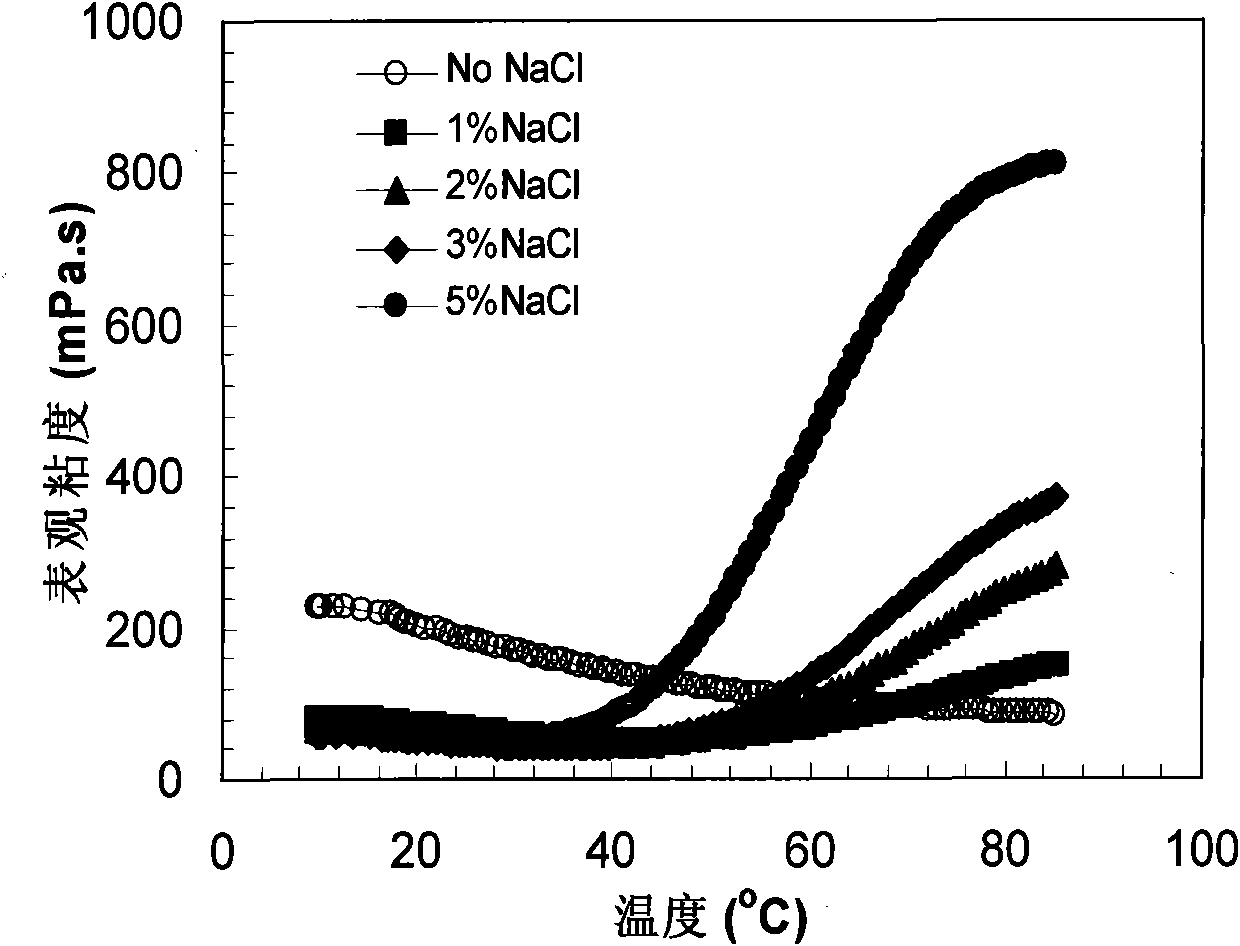

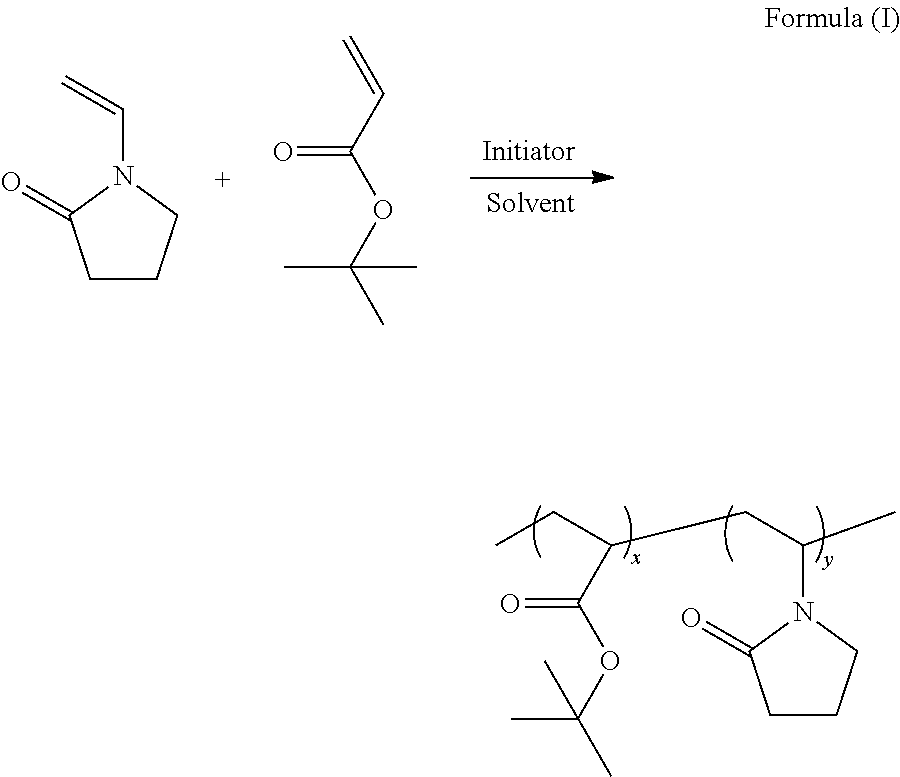

Novel anionic thermal tackifying water-soluble polymer

InactiveCN102070754AResponse temperature can be adjustedLow costCosmetic preparationsToilet preparationsSolubilityPolymer science

The invention relates to novel anionic thermal tackifying water-soluble polymer. According to requirements of actual application, a thermal tackifying temperature range is adjusted and controlled by varying a molecular structure. In the invention, a macromonomer radical copolymerization method is adopted; and the method can be used for preparing thermal tackifying polymer with higher solid content and high molecular weight and is easy for industrial production. The novel anionic thermal tackifying water-soluble polymer has the advantages of high water solubility, high thermal tackifying performance, wide tackifying temperature range, adjustable tackifying temperature, relatively low cost and the like, so the polymer has potential application value in water treatment, medicament release control, fluid resistance reduction, personal care products, papermaking, paints, food tackifiers, lubricants, dispersing agents and the like, particularly in the aspects of improvement on oil-gas recovery ratio, oil-gas drilling, production increase and the like.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Antiperspirant material and compositions containing it

InactiveUS6245324B1Reduced tendency to separateCosmetic preparationsToilet preparationsParticulatesEther

A particulate antiperspirant active material which has been surface treated with an alkanolamine is described. After surface treatment, the surface treatment agent is in intimate contact with the surface or outer layer of the substrate material, that is, the antiperspirant material may be either deposited on the surface or at least a fraction of the agent may be absorbed within the outer layer of the substrate. The resultant particulate material shows a reduced tendency to separate from a liquid carrier phase containing a polyglycol ether and a suspending agent.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Concave convex rod suspension agent

InactiveCN1912015AHigh suspension rateImprove adhesionBiocideInorganic pigment treatmentAnti freezingAgricultural engineering

The invention discloses an concave-convex bar suspending agent, and the key points of its technical solution: uniformly blending sodium modified concave-convex bar clay, sodium silicate, sodium dodecyl sulfate and polyacrylamide, then inputting the uniform mixture into a grinding machine to grinding into powder with grain size <=0.044 mm, and finally packaging into finished products. And it has characters of simple producing process, low cost, high suspending ratio, good diffusing stability, and excellent performances in the aspects of anti-freezing function, rheological property, film forming characteristic and adhesive property. And it is applied to make various pesticide suspending agents.

Owner:蒋文兰

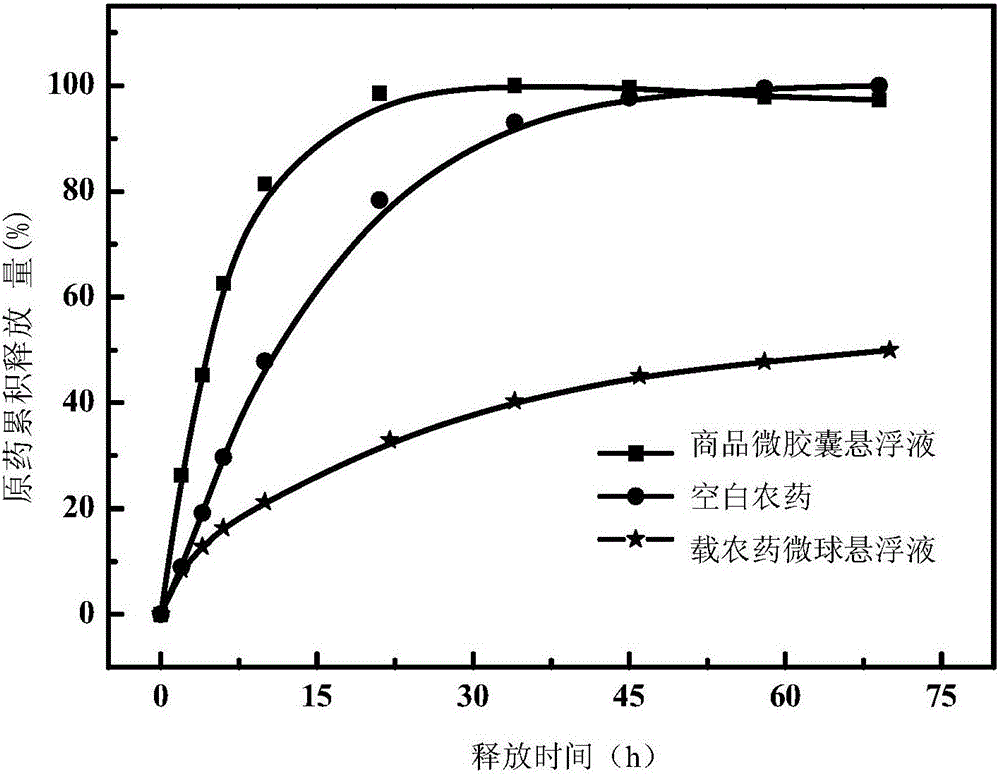

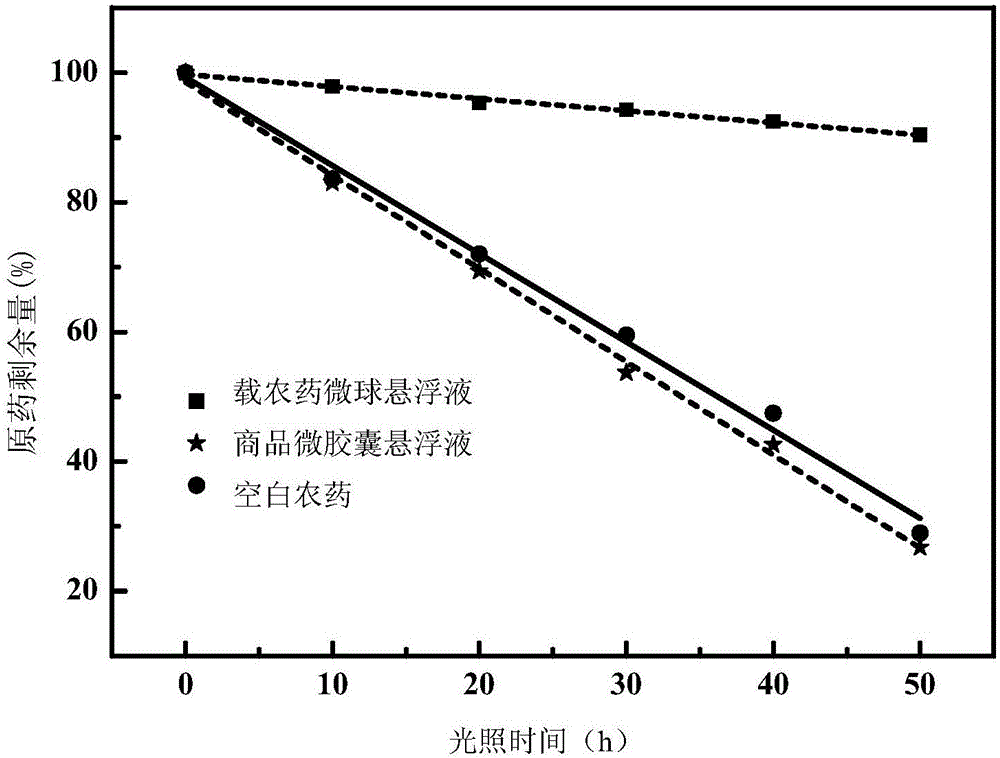

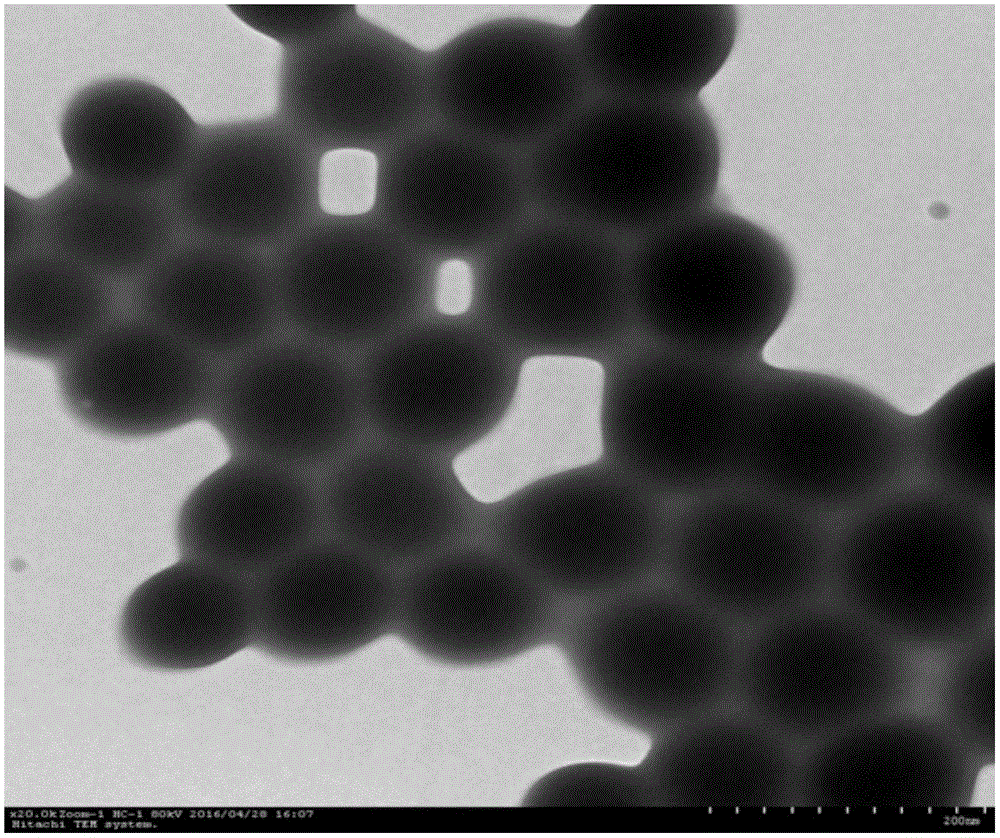

Pesticide-carrying microspherical suspending agent prepared by employing self-assembled lignin base material and method

InactiveCN106818728AReduce pollutionRealize high-value utilizationBiocideFungicidesOrganic solventMicrosphere

The invention belongs to the technical field of pesticide-carrying microsphere preparation and discloses a pesticide-carrying microspherical suspending agent prepared by employing a self-assembled lignin base material and a method. The method comprises the following steps of: (1) dissolving the self-assembled lignin base material and a pesticide raw material in an organic solvent, and ultrasonically dispersing the mixture to obtain an organic phase; and (2) under a stirring condition, uniformly adding water into the organic phase, then ultrasonically dispersing the mixture to obtain the pesticide-carrying microspherical suspending agent, wherein the mass ratio of the self-assembled lignin base material and the pesticide raw material is (1-10) to (1-10); the mass ratio of the self-assembled lignin base material and the organic solvent is (0.1-10) to (20-150); and the mass ratio of the self-assembled lignin base material and the water is (0.1-10) to (20-240). The preparation process provided by the invention is simple, and the carrier of the pesticide-carrying microspheres is green and degradable; the pesticide-carrying microspheres can slowly release the pesticide, and can effectively prevent photolysis of the raw pesticide.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing flow coating capable of overcoming sulfur seepage defect

InactiveCN105170894AReduce infiltrationPlay a protective effectFoundry mouldsFoundry coresPolyvinyl alcoholSlurry

The invention relates to a method for producing a flow coating, in particular to a method for preparing a flow coating capable of overcoming the sulfur seepage defect. The method comprises the following steps that a suspending agent is pretreated; polyving akohol is pretreated; a proper amount of water and a proper amount of treated suspending agent slurry are added into a dispersing kettle, stirring is started, and then a defoaming agent, a surface active agent, a thickening agent, a binding agent and the like are added; finally, the pretreated polyving akohol solution is added, and stirring is conducted for 10-20 minutes; the stirring speed is regulated to be kept being 500 r / min, and refractory aggregates are sequentially added into the dispersing kettle; the rotating speed is regulated to be 1200r / min after adding of the aggregates is completed, and dispersing is conducted for 20 minutes; and the baume degree is adjusted by means of water and controlled to be 80-90 degrees, and then the flow coating is obtained. The method is unique, the sulfur seepage preventing effect is remarkable, the anti-heat-crack effect is good, environmental friendliness is achieved, pollution is avoided, the viscosity is low, and the flow coating is nontoxic.

Owner:GANSU KOCEL CHEM

Water-based paint containing nano-zinc oxide and with enhanced high heat retaining property for evanescent mold casting and preparation method thereof

InactiveCN105057569AGood suspensionImprove thixotropyFoundry mouldsFoundry coresWater basedPyrophyllite

The invention relates to the technical field of evanescent mold casting, in particular to water-based paint containing nano-zinc oxide and with enhanced high heat retaining property for evanescent mold casting and a preparation method thereof. Pyrophyllite powder and quartz sand with different grain sizes are used as refractory aggregates of the water-based paint, so that the air permeability of a coating is good, and the coating is even and smooth. Mixed slurry of nano-zinc oxide, aluminum-magnesium silicate and sodium carboxymethylcellulose is used as a suspending agent which enables the water-based paint to be good in suspension property and thixotropy, and the heat retaining property of the coating is further improved. The air permeability of a coating surface can be improved after microcrystalline cellulose disperses in the coating. The paint coating prepared through the method is firm, insulated, compact, permeable and easy to clean; the liquid metal is not polluted and the surface quality of a casting is improved effectively.

Owner:MINGGUANG CITY LIUXIANG PUMP IND

High-temperature demolding protection lubricant for producing copper alloy finished piece by hot extrusion method

ActiveCN102250674ANo internal defectsFlat surfaceLubricant compositionVegetable oilSuspending Agents

The invention relates to a high-temperature demolding protection lubricant for producing a copper alloy finished piece by a hot extrusion method, belonging to the technical field of lubricants. The high-temperature demolding protection lubricant is prepared from the following raw materials: 50-75% of vegetable oil, 10-25% of lithium-based grease, 5-20% of lithium carbonate, 5-20% of graphite powder, 0.5-5% of ammonium salt, 1-10% of alkyl sulfonate and 0.5-5% of suspending agent. The high-temperature demolding protection lubricant provided by the invention has the following advantages: 1) a pressure gauge copper joint produced by using the hot extrusion method and using the lubricant provided by the invention has the characteristics of no internal defects, smooth surface and no material adhesion and carbon deposition phenomena; 2) the wear of a mold cavity is reduced, and the service life of the mold cavity is prolonged by more than one time; 3) no adhesion phenomenon is generated, the normal demolding of a hot-extrusion finished piece is guaranteed, and the production efficiency is increased by more than 30%; 4) no obvious oil smoke, dust or toxic and harmful gases are generated in the processing site, thereby the environmental pollution is eliminated; and 5) the raw materials are conveniently available and are relatively low in price, and the production cost is lowered by more than 20%.

Owner:杭州丰源铜业有限公司

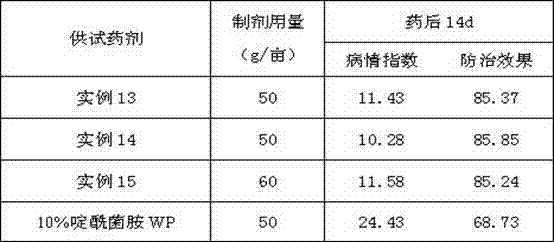

Phenoxy microbial ester water dispersible granules and water suspension agent

The present invention relates to a phenoxy bacterioester water dispersing granules preparation and a phenoxy bacterioester water suspension agent, the former is a granules preparation obtained by mixing phenoxy bacterioester with adjuvant and pilling material together, and can be quickly disintegrated in water, dispersed and formed into high suspended and stable dispersion system, and the latter is a high-dispersity and stable liquid preparation using water as medium and obtained by mixing phenoxy bacterioester together with adjuvant and water. As compared with wettable powder preparation said two preparations are large in density, small in volume, have good dispersity and high suspension rate, and can raise control effect.

Owner:ANHUI HUAXING CHEM IND CO LTD

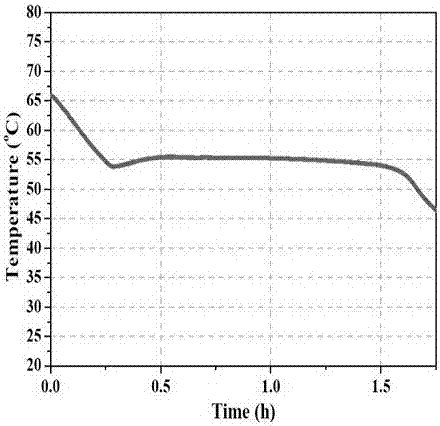

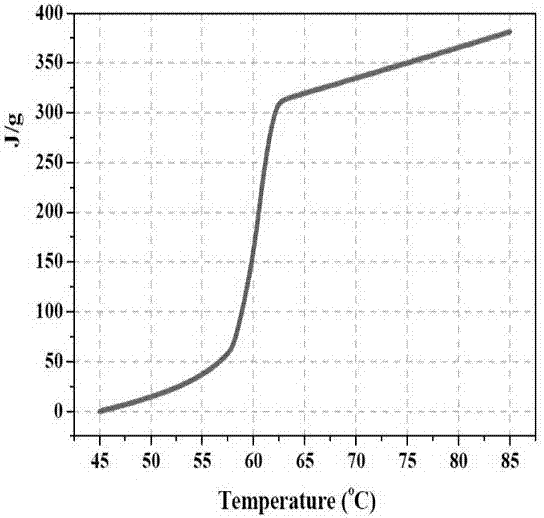

Composite phase change energy storage material and preparation method thereof

InactiveCN107446553APrevent subsidenceHigh thermal conductivityHeat-exchange elementsHigh energyHeat conducting

The invention discloses a composite phase change energy storage material and a preparation method thereof. The composite phase change energy storage material comprises the following components in percentage by mass: 86-95.5% of a main body material, 2.5-9% of a suspending agent, 1-2% of a nucleating agent and 1-5% of a heat-conducting enhancer. By selecting the proper material and aid proportion, the phase separation and supercooling degree degrees of the material are effectively reduced, and the material is applicable to various heat exchangers. Particularly, the heat-conducting enhancer is added into the system, so that the heat-conducting property of the material is improved by 3-4 times, the heat-conducting property of the system is realized, the stability of the system is realized, and the composite phase change energy storage material has the advantages of rich raw materials, low price, high energy storage density, low in corrosive property and the like.

Owner:北京华厚能源科技有限公司

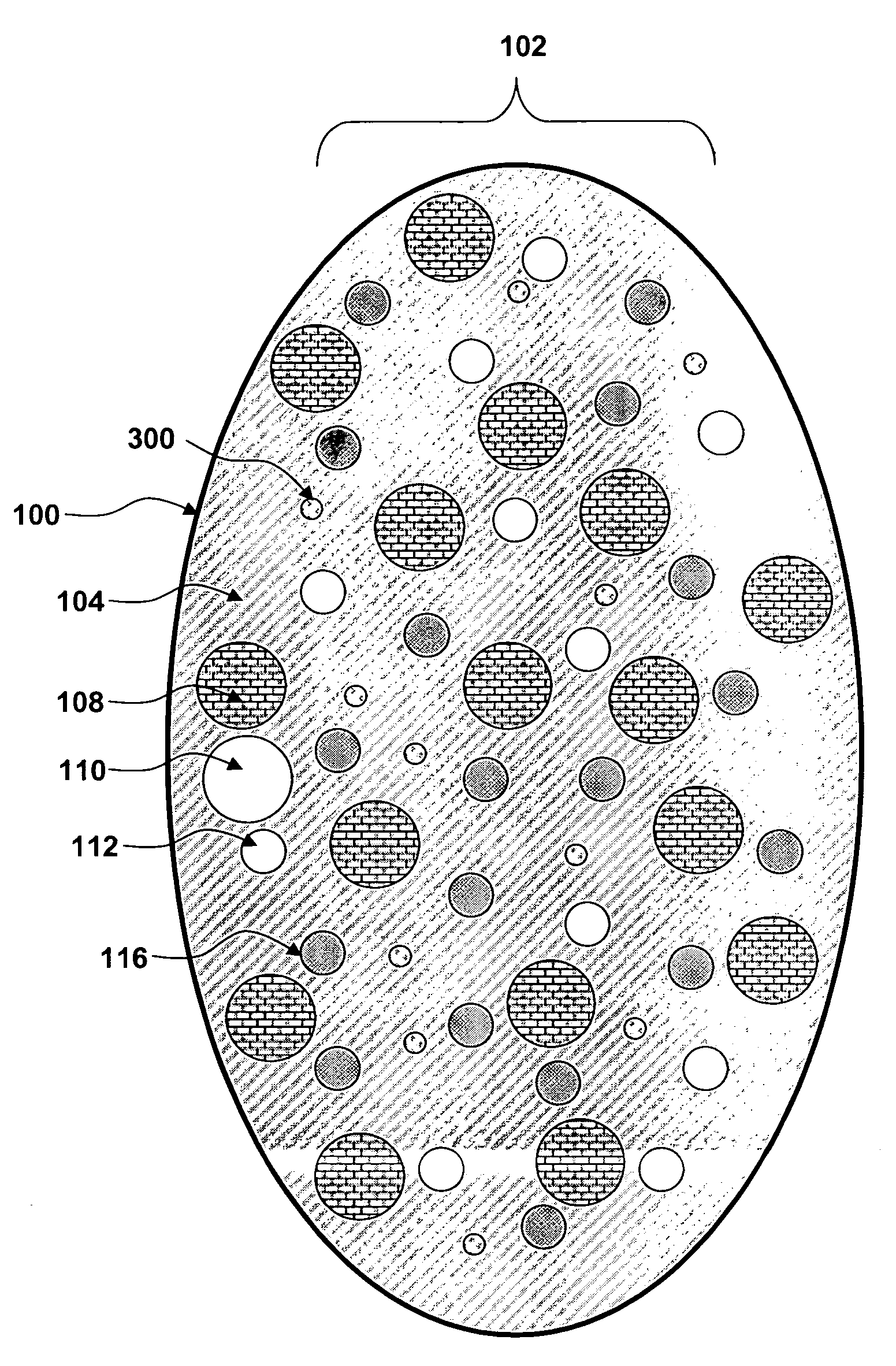

Energy absorbing composition and impact and sound absorbing applications thereof

A substantially non-elastic incompressible composition, which substantially does not quickly self-level under standard operating conditions, includes: a suspending agent which reacts substantially as a solid when subjected to forces below a critical force, and which becomes substantially flowable when subjected to forces above said critical force; ceramic microparticulates dispersed within the suspending agent; flexible-walled microparticulates dispersed within the suspending agent; and celled macroparticulates dispersed within the suspending agent. The composition provides an incident energy absorbing property. The incident energy may include sound energy, and the microparticulates and macroparticulates may convert some of the sound energy into heat, or may diffract the sound energy.

Owner:SEREFLEX GROUP

Cementing fluid and methods for producing the same

The presently disclosed and / or claimed inventive concept(s) relates generally to a cementing fluid for use in high temperature wellbore application. More particularly, the presently disclosed and / or claimed inventive concept(s) relates to a cementing fluid comprising an aqueous fluid, a hydraulically-active cementitous material, and a suspending agent, wherein the suspending agent is a high molecular weight hydrophobic copolymer or a cross-linked hydrophobic copolymer particulate. Additionally, the presently disclosed and / or claimed inventive concept(s) relates generally to the methods of making the cementing fluid containing the suspending agent.

Owner:HERCULES INC

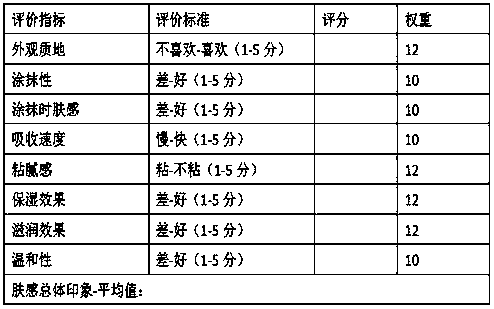

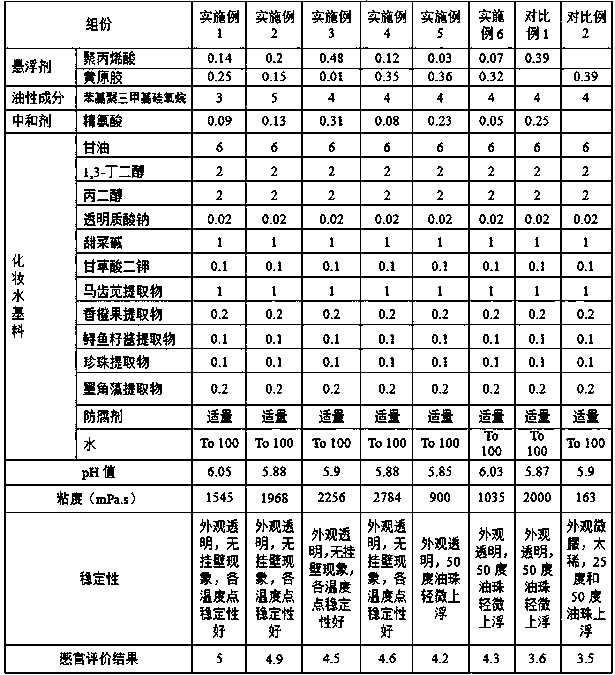

Suspension oil droplet toning lotion and preparation method thereof

ActiveCN107595761AUniform and stable suspensionReduce stimulationCosmetic preparationsToilet preparationsMedicineOil water

Owner:HUAANTANG BIOTECH GRP CO LTD

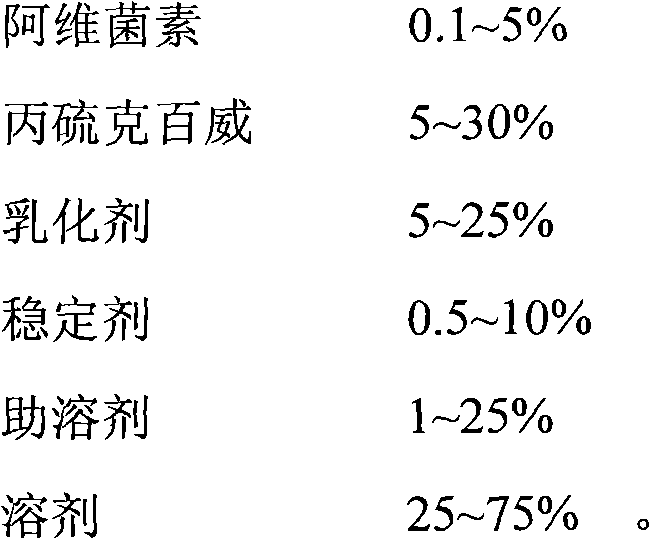

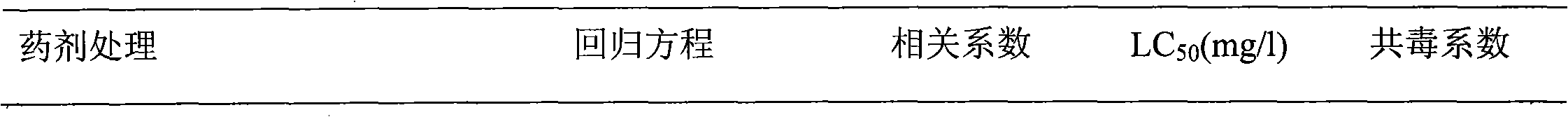

Avermectin and Carbosulfan Insecticide Composition

InactiveCN102265878AExpand insecticidal spectrumMany pest action sitesBiocideAnimal repellantsCecidomyiidaeAbamectin

The invention discloses an abamectin-benfuracarb pesticide composition. The abamectin-benfuracarb pesticide composition is a water emulsion comprising abamectin, benfuracarb, one or more cosolvents, a solvent, one or more emulsifiers and one or more stabilizing agents. The abamectin-benfuracarb pesticide composition has not only a water emulsion dosage form, but also a missible oil dosage form, amicron emulsion dosage form, a powder form, a wettable powder dosage form and a microcapsule suspension dosage form. The abamectin-benfuracarb pesticide composition has obvious synergistic effects onthrip, aphid, wireworm, potato flea beetle, beet flea beetle, eriophyesoleivorus and the like living on vegetables, expands a control spectrum, and has excellent control effects on thrip, aphid, cabbage caterpillar, wireworm, whitefly, scale insect, carposinaniponensiswalsingham, oriental fruit moth, red spider, apple skin worm, apple cecidomyiidae and the like living on vegetables, fruit trees and cotton. In addition, the abamectin-benfuracarb pesticide composition improves pesticide effects, reduces use cost and delays drug resistance generated by pests.

Owner:GAUNGXI TIANYUAN BIOCHEM

Aqueous sustained-release drug delivery system for highly water-soluble electrolytic drugs

InactiveUS20060018972A1Lower drug concentrationReduce molecular weightPowder deliveryPharmaceutical non-active ingredientsElectrolysisIon exchange

The present invention relates to liquid sustained release suspension dosage forms comprising ionized forms of water-soluble drugs. In particular, the invention encompasses a liquid form controlled release drug composition comprising a dispersed phase comprising an ion-exchange matrix drug complex comprising a pharmaceutically acceptable ion-exchange matrix and a water-soluble electrolytic drug associated with the ion-exchange matrix, wherein the surface charge of the ion-exchange matrix is opposite that of the electrolytic drug wherein the dispersed phase further comprises a non-electrolytic, soluble component having low molecular weight and a diffusion controlling membrane and a dispersion medium substantially free of diffusible counterions, further comprising an excipient capable of associating with water and impeding water activity such that drug dissolution is inhibited prior to administration. The invention also provides methods for preparing such compositions and methods of treatment.

Owner:UPM PHARMA

Suspension type waterborne grinding fluid preparation method

ActiveCN106281044AWon't scratchMany originsOther chemical processesPolishing compositions with abrasivesMontmorilloniteColloid

The invention provides a suspension type waterborne grinding fluid preparation method. The preparation method comprises the step one of preparing sub-nanometer montmorillonite suspension liquid; the step two of evenly mixing a dispersing agent, a chelating agent, a lubricating agent, an antirust agent and water according to a proportion to obtain a mixture; the step three of evenly mixing the suspension fluid and the mixture according a proportion to obtain suspension type waterborne grinding liquid. According to the preparation method, the sub-nanometer montmorillonite is utilized as a suspension agent, the colloid dispersion and the lamella adsorption property of particles of the montmorillonite are utilized, and the suspension dispersion montmorillonite colloid has a suspension and adsorption effect on abrasive micro powder when the abrasive micro powder is used. Due to the stability of the montmorillonite colloid, the grinding fluid also has a good suspension effect even if the grinding fluid is diluted by 20 times or more. Thus, the effects that the abrasive micro powder is good in suspension, low in viscosity and high in machining precision are achieved, the grinding fluid has the advantages of being low in cost, strong in dilution capacity and easy to clean, and the raw materials of the grinding fluid are easy to obtain.

Owner:XIAN BOER NEW MATERIAL CO LTD

Special synergist for low-capacity or ultra-low-capacity pesticide spraying and a preparation method and application thereof

The invention discloses a special synergist for low-capacity pesticide spraying and a preparation method thereof. The special synergist for low-capacity pesticide spraying comprises, by mass, 1-50% high-grade alcohols, 1-60% of surfactant, 0.1-10% of film-forming agent, 0.1-10% of thickening agent, 1-20% of condensation nucleus substances and the balance oil-phase carrier. The preparation method of the synergist comprises the following step that the high-grade alcohols, the surfactant, the thickening agent and the condensation nucleus substances are mixed and introduced into an oil phase understirring, the materials are ground by a grinding machine to be prepared into a stable oil suspending agent, then the film forming agent is added, the materials are fully stirred and filtered to remove residues, and the finished product is obtained. An application method of the synergist includes the steps that the special synergist for low-capacity or ultra-low-capacity pesticide spraying is selected, after the synergist and a prevention chemical are mixed evenly according to the density of 50 g per mu, water is added to 0.5-1 kg, after the materials are evenly mixed, and the mixture is poured into a low-capacity or ultra-low-capacity pesticide spraying mechanical box for pesticide spraying. Liquid pesticide evaporation can be remarkably inhibited, liquid pesticide flying and bouncing arereduced, and the liquid pesticide utilization rate is increased.

Owner:安徽尚禾沃达生物科技有限公司

Profile control system and preparation method thereof

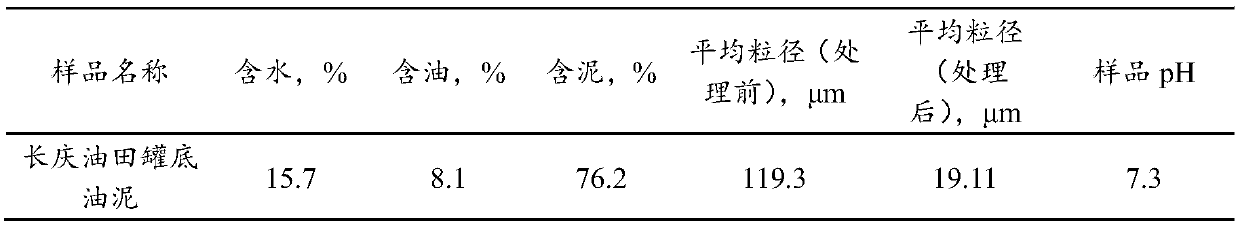

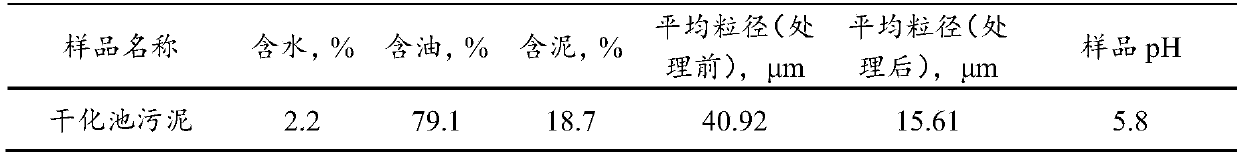

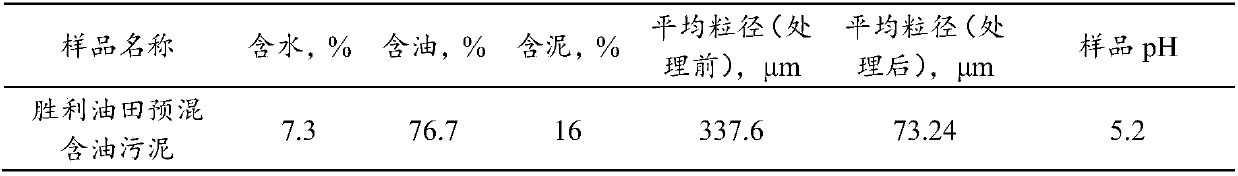

The invention provides a profile control system and a preparation method thereof, and relates to the technical field of a profile control system for an oil field. The profile control system comprises, by weight, 0.1-0.5 part of a suspending agent, 0.1-0.9 part of a crosslinking agent, 0.2-2 parts of an emulsifying dispersing agent, 20-60 parts of oil-containing sludge and 40-55 parts of water, wherein the suspending agent is an amphiphilic hydrophobically associated polymer, the amphiphilic hydrophobically associated polymer has amphiphilic characteristics and is compounded with the emulsifying dispersing agent to achieve a synergistic effect on one hand, so that the emulsifying dispersing performance of the profile control system is enhanced, on the other hand, the characteristics of temperature resistance and saline tolerance and spatial mesh structure of the amphiphilic hydrophobically associated polymer are used, and therefore the suspending performance of the profile control system is excellent. The above characteristics allow the profile control system to form stable gel under the situation of high oil-containing sludge content, and better sealing performance is achieved.

Owner:YANGTZE UNIVERSITY +1

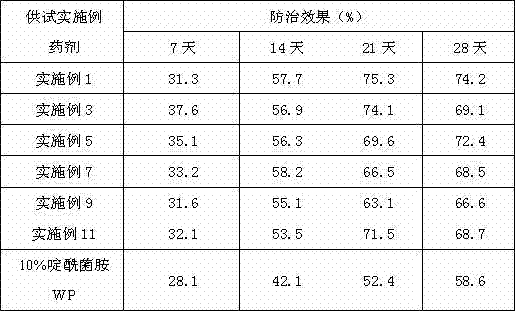

Ultra-low-volume liquid agent containing boscalid

The invention discloses an ultra-low-volume liquid agent containing boscalid and a preparation method of the liquid agent, aiming at solving the problem boscalid in market is made into suspension, missible oil and the like, and is mainly made into the suspension, but no ultra-low-volume liquid agent containing boscalid is available. The ultra-low-volume liquid agent comprises boscalid, an additive and a solvent. The liquid agent takes boscalid as an active component, and through mutual cooperation with the additive, the solvent and a second active solvent, the ultra-low-volume liquid agent with boscalid is prepared. The ultra-low-volume liquid agent disclosed by the invention has a high synergistic interaction effect, can effectively delay happening of disease resistance, is high in fast-acting property, long in lasting period and high in working effect, can effectively improve the utilization rate of pesticide, and is applicable to prevention of powdery mildew, botrytis, various rot diseases, brown rot, root rot and the like. Besides, the invention further provides a preparation method of the ultra-low-volume liquid agent. The method is simple in process and convenient to process.

Owner:GAUNGXI TIANYUAN BIOCHEM

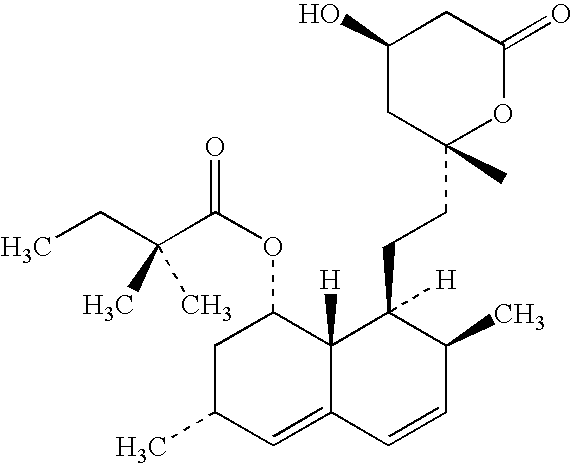

Liquid oral compositions

A suspension which is suitable for oral administration, comprising simvastatin, at least one suspending agent, and at least one preservative, wherein at least 90 wt % of the particles of simvastatin are less than 100 μm in diameter. The present invention also includes uses of the suspension and methods of making the suspension.

Owner:ROSEMONT PHARMA LTD

Carbon-nanofiber-enhanced light low-carbon-residue water-based paint for evaporative-pattern casting and manufacturing method thereof

InactiveCN105522103AImprove breathabilityImprove high temperature stabilityFoundry mouldsFoundry coresWater basedCarbon fibers

The invention relates to the technical field of evaporative-pattern casting, in particular to a nano-calcium-carbonate-enhanced low-carbon-residue water-based paint for evaporative-pattern casting and a manufacturing method thereof. According to the water-based paint, high-aluminum fine powder, magnesia and brown corundum powder which are different in particle sizes are mixed to serve as a refractory aggregate, so that the water-based paint has good air permeability and high-temperature stability; a mixed suspending agent prepared from nano calcium carbonate, sodium carboxymethylcellulose and other materials can be well mixed with inorganic powder and resin emulsion, so that the fluidity and coating property of the paint are improved effectively, and dimensional stability to heating is enhanced and improved; added nano ceria has oxygen storage capacity, and oxygen can be released in the casting process, so that the oxidative combustion efficiency of plastic is improved, and carbon residues are reduced. Moreover, a coating layer produced from the manufactured paint is stable in performance when heated, not prone to collapsing and breaking, compact and breathable and capable of being stripped off and removed easily; and the number of impurities on the surfaces of manufactured castings is smaller, and quality of the manufactured castings is better.

Owner:MINGGUANG CITY LIUXIANG PUMP IND

Stabilized suspension for production of fire-suppressing hydrogels

InactiveUS20180021612A1Extinguish and suppress and prevent fireFire extinguisherParticulatesLiquid medium

The present application provides a stabilized suspension for production of fire-suppressing hydrogels. Specifically, the present application provides a composition comprising: (i) at least one thickening agent; (ii) at least one liquid medium; and, (iii) at least one particulate suspending agent, wherein the composition consists of >75%, by weight, consumer-grade components and wherein the composition is a concentrate that forms a fire-suppressing hydrogel when mixed with water or an aqueous solution. Also provided is a hydrogel prepared from this composition methods of using the hydrogel to extinguish, suppress and / or prevent fires, including both class A and class B fires.

Owner:FIREREIN

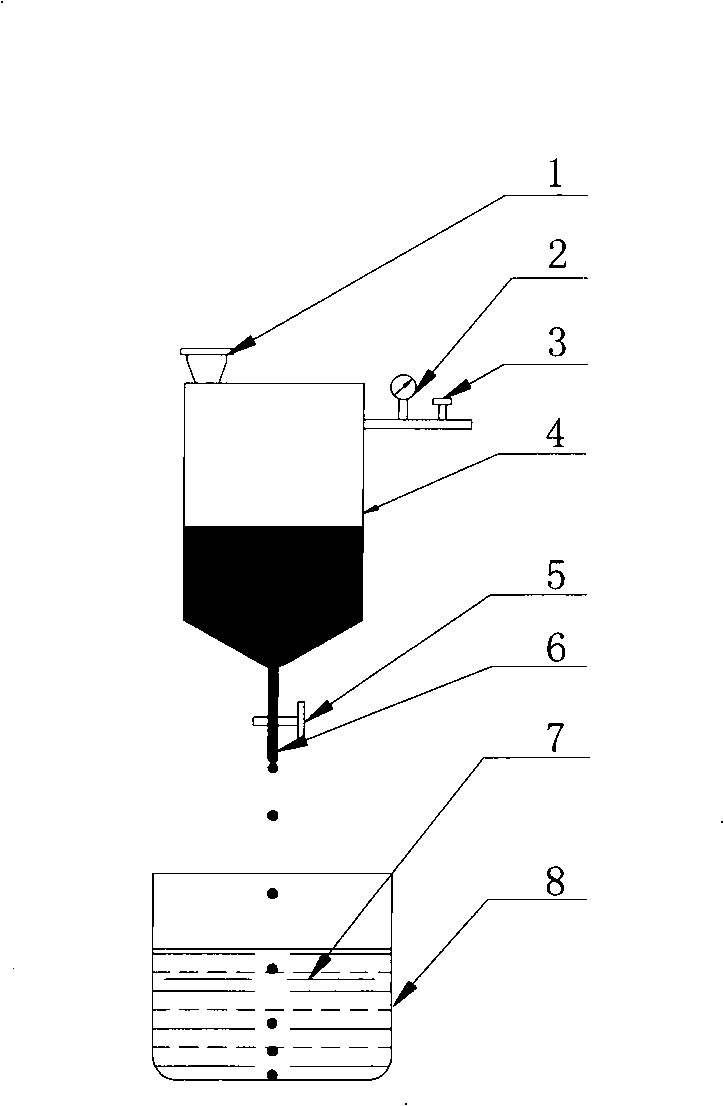

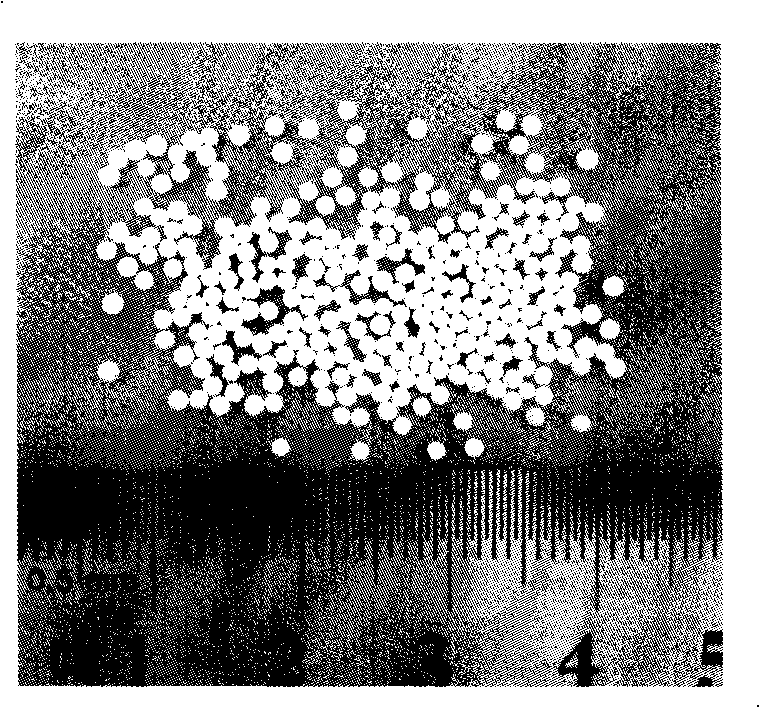

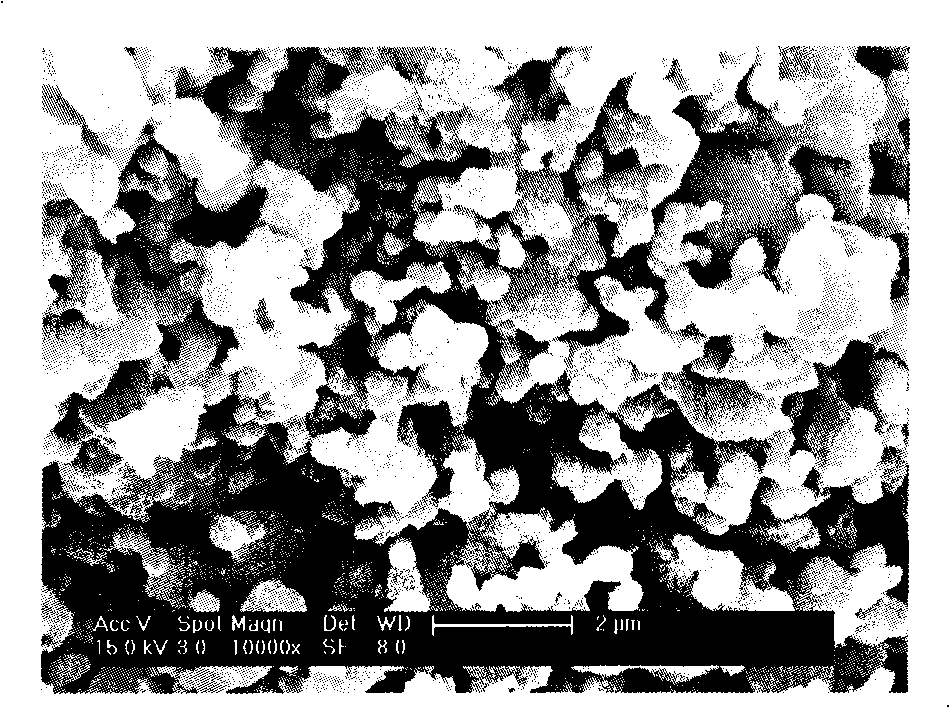

Phosphate biological ceramic microsphere, preparation method and apparatus thereof

InactiveCN101401953ALarge specific surface areaUniform particle size distributionImpression capsDentistry preparationsCross-linkPorosity

The invention relates to a phosphate bioceramic microsphere, a method and a device for preparing the same. The particle diameter of the phosphate bioceramic microsphere is between phi 0.8 and 4 millimeters; the interior of a particle body is micropores of which the aperture is less than 150 micrometers; the micropores are communicated with each other; the porosity of the micropores is between 65 and 90 percent; and the particle body consists of phosphates of calcium, magnesium and sodium. The method for preparing the phosphate bioceramic microsphere comprises the following steps: step one, weighing HA powder and beta-TCP powder, and mixing the powders evenly; step two, taking (NaPO3)6 and Mg(H2PO4)2 of which the mass is between 5 and 15 percent of the mixed powders of the HA and the beta-TCP to prepare a caking agent solution, and taking a suspending agent of which the mass is between 0.5 and 5 percent of the mixed powders of the HA and the beta-TCP to prepare a suspending agent solution; and step three, evenly mixing the caking agent solution prepared in the step two with the suspending agent solution, then adding the powders prepared in the step one into the obtained solution, and evenly mixing to obtain a ceramic slurry; step four, dripping the ceramic slurry prepared in the step three into a thermal insulation container for condensation to form spherical particles; and step five, cross-linking and sintering the spherical particles after the condensation to obtain the phosphate bioceramic microspheres.

Owner:SOUTHEAST UNIV

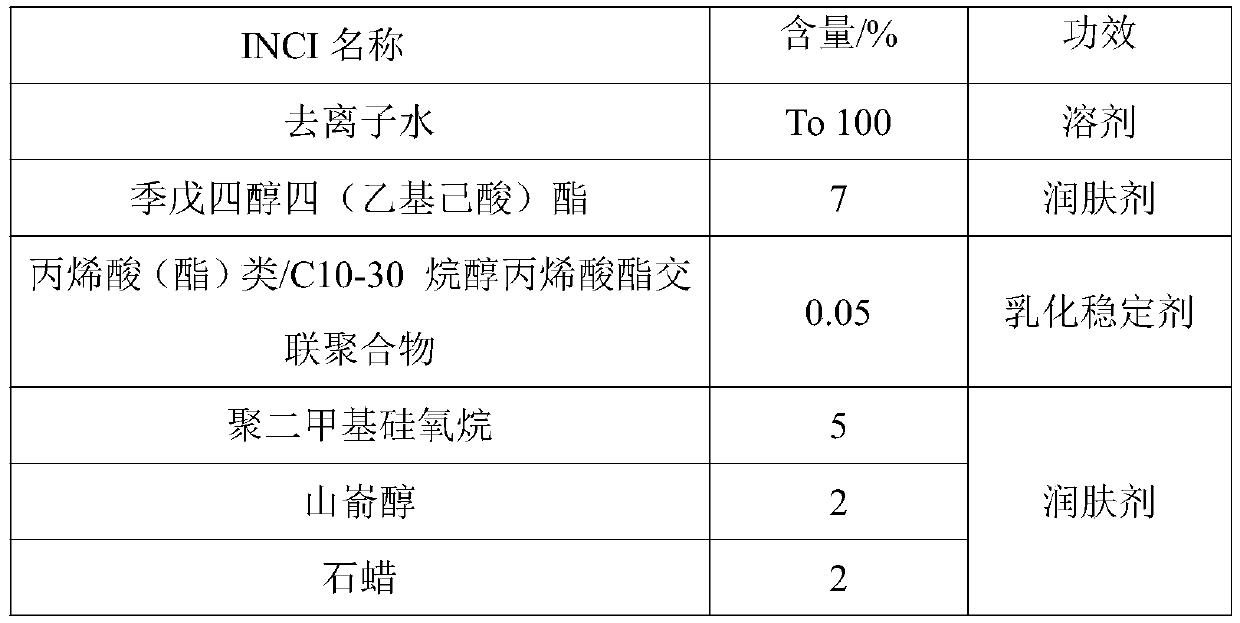

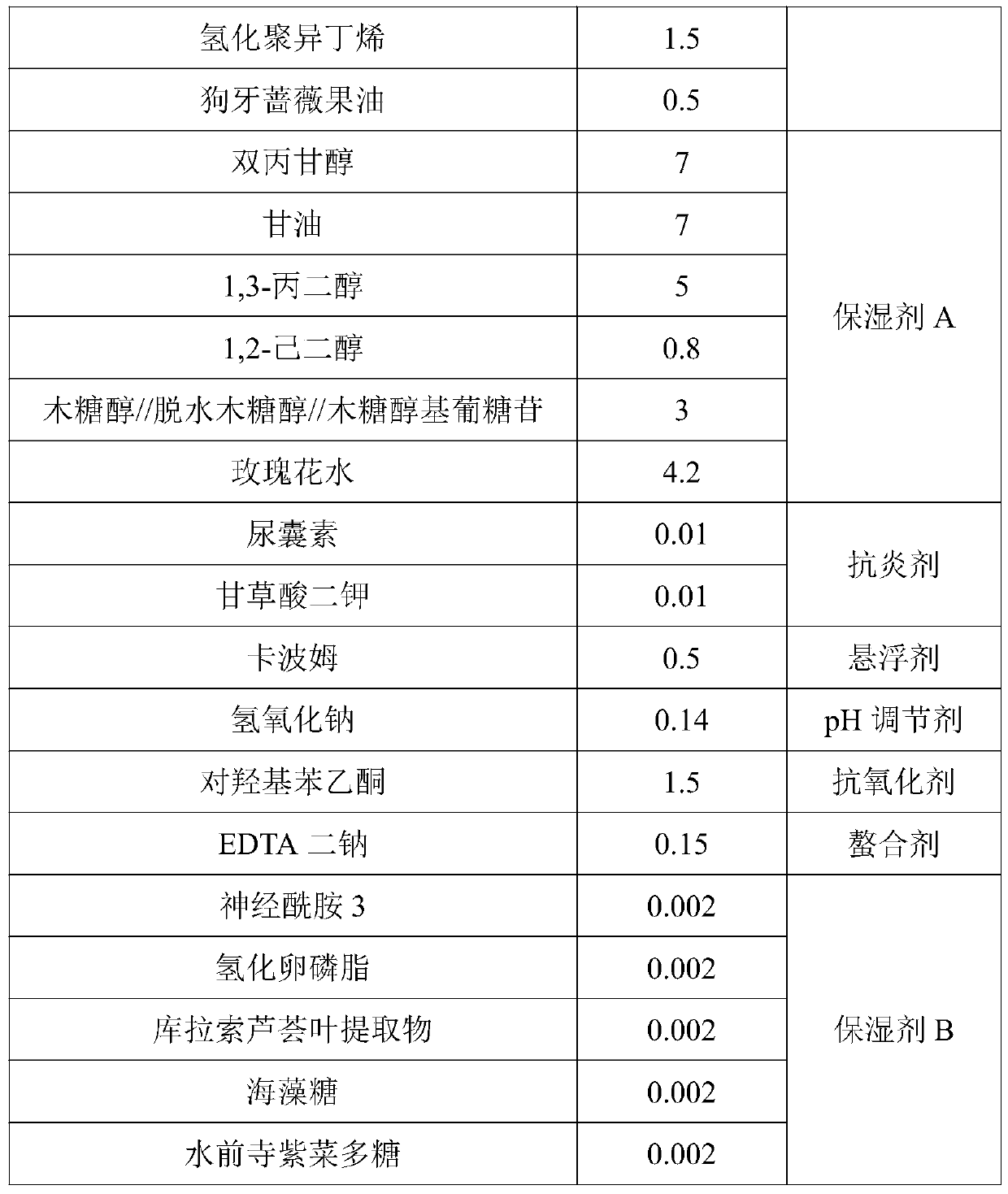

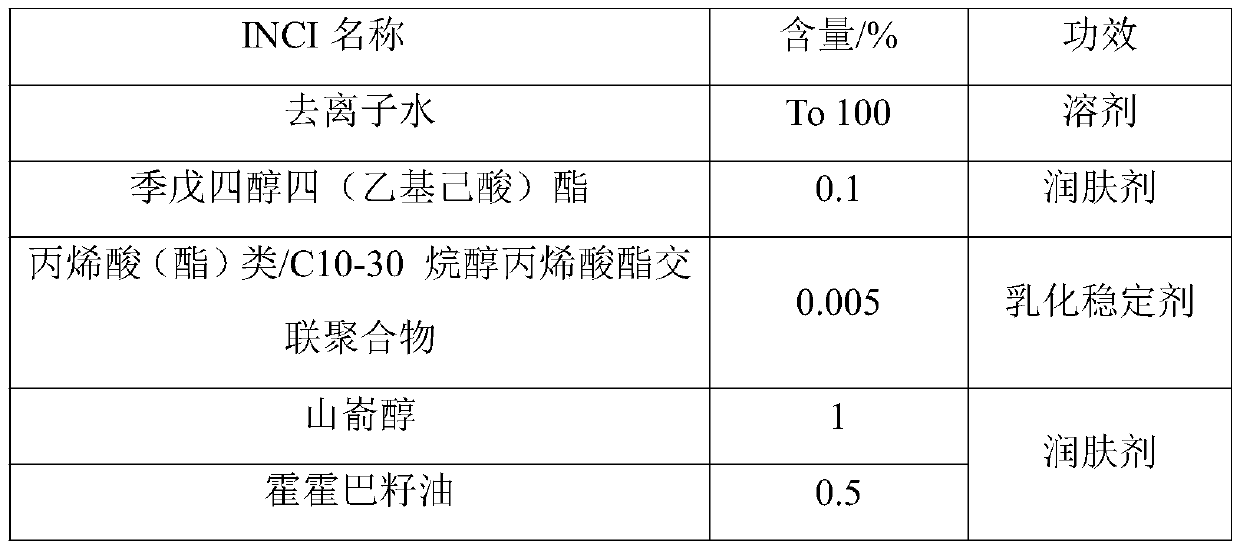

Micro condensate bead moisturizing skin care products and preparation method thereof

ActiveCN109846792AEvenly dispersedImprove stabilityCosmetic preparationsToilet preparationsCross-linkPentaerythritol

The invention relates to micro condensate bead moisturizing skin care products and a preparation method thereof, and aims to provide the micro condensate bead moisturizing skin care products which canenable efficacy components to release slowly, and are good in moisturizing effects, and before being used, the micro condensate bead moisturizing skin care products can be stably stored. The skin care products mainly consist of the following components of 0.1-7% of pentaerythrityl tetra-di-t-butyl hydroxyhydrocinnamate(ethyl caproic acid ), 0.005-0.05% of an acrylic acid (ester) / C10-30 alkanol acrylic ester cross-linking polymer, 0.4-11% of an emollient, 0.02-0.6% of an anti-inflammatory agent, 8-27% of a hydrating agent A, 0.01-0.15% of a chelating agent, 0.1-0.5% of a suspending agent, 0.01-0.14% of a pH adjusting agent, 0.01-4% of a hydrating agent B, 0.3-1.5% of an antioxidant and an appropriate amount of deionized water. The invention belongs to the technical field of skin care products.

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com