Pesticide-carrying microspherical suspending agent prepared by employing self-assembled lignin base material and method

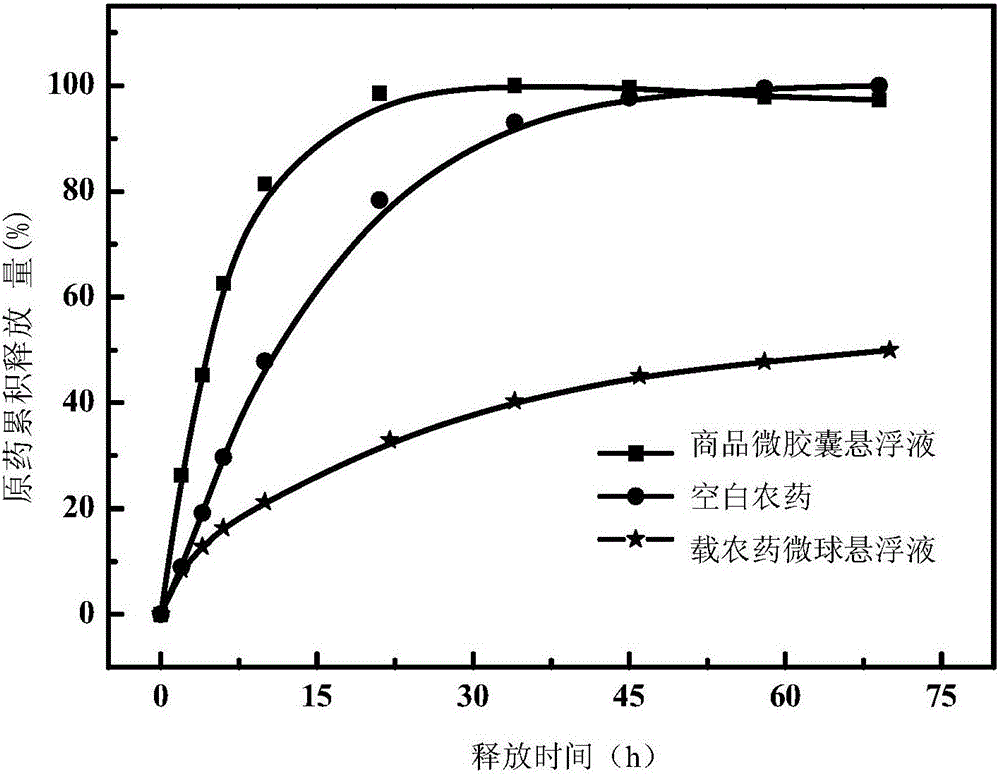

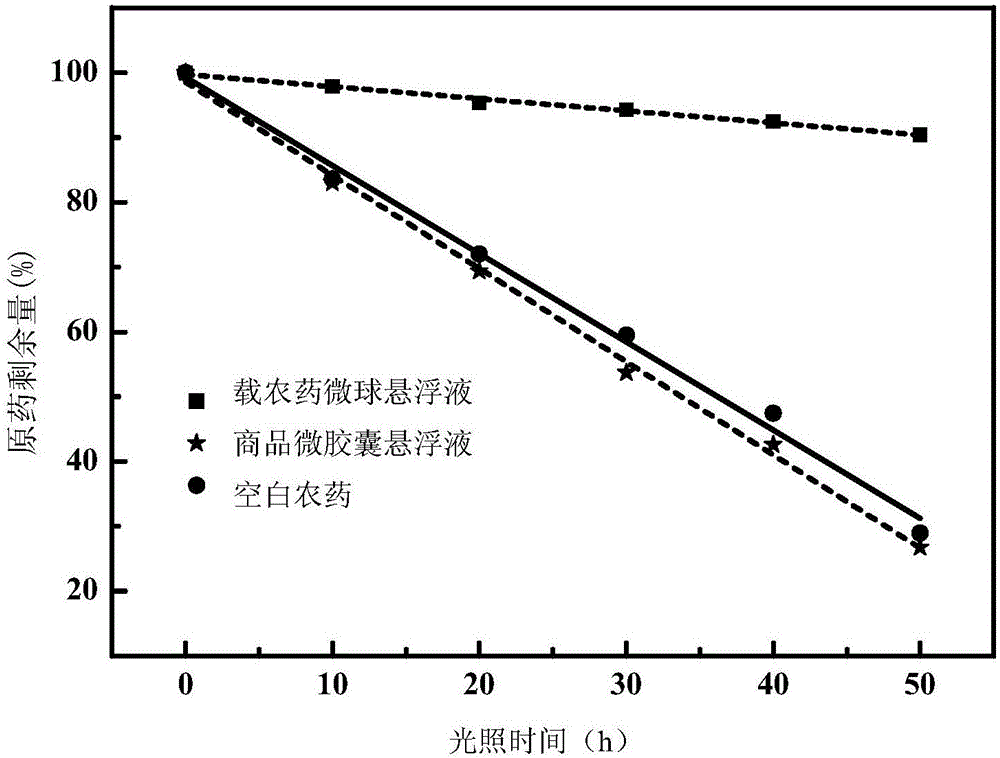

A lignin-based, pesticide microsphere technology, applied in the fields of botanical equipment and methods, chemicals for biological control, applications, etc., can solve the problems of easy photolysis and easy degradation of pesticides, and achieve simple equipment and green solvent. Non-toxic and pollution-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

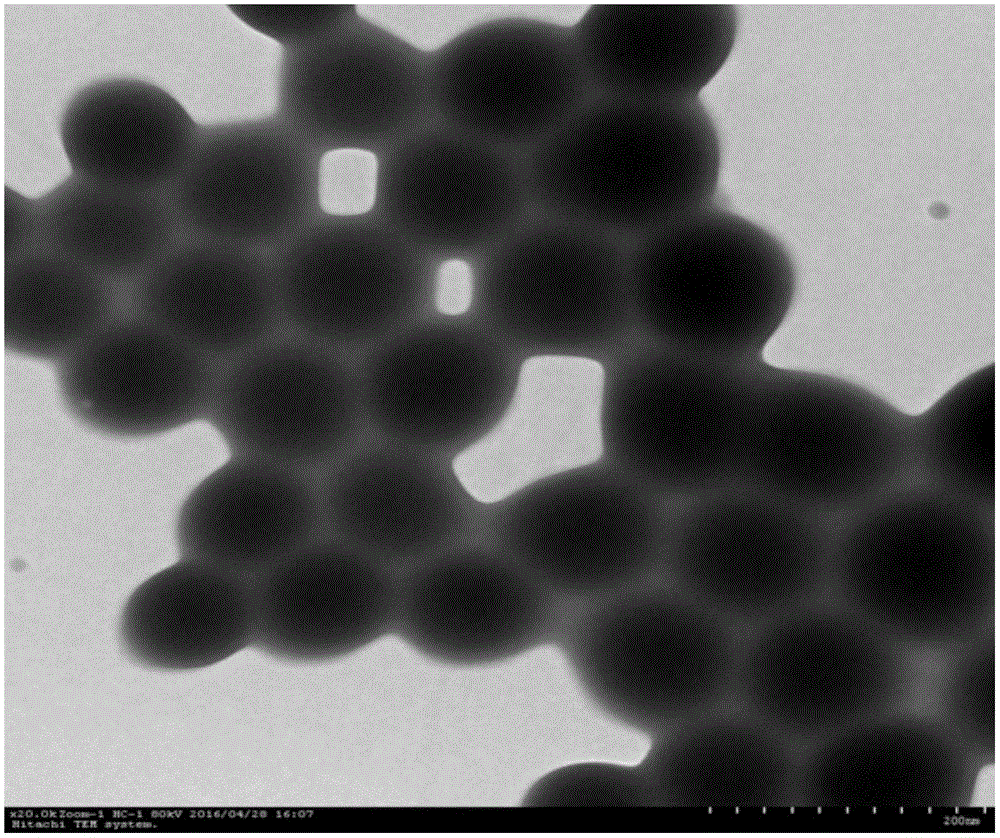

Embodiment 1

[0046] (1) Dissolve 318g of sodium lignosulfonate in 212g of water, and stir at room temperature for 72 hours at a speed of 800rmp to make a 60wt% aqueous solution of sodium lignosulfonate; 112.75g of cetyltrimethyl bromide Ammonium is dissolved in the alcohol-water mixed solvent that 67.65g ethanol and 45.1g water form, at normal temperature with the rotating speed of 700rmp stirring 72 hours, the cetyltrimethylammonium bromide mixed solution of making 50wt%; Lignin Sodium sulfonate aqueous solution and cetyltrimethylammonium bromide mixed solution are mixed in the ratio of 2.82:1 with the mass ratio of solute, that is, the mass ratio of sodium lignosulfonate and cetyltrimethylammonium bromide to form Anion and cation composite solution; under the condition of stirring (rotating speed is 500rpm), 2000g of water is evenly added dropwise in the composite solution within 30 minutes; after standing for 24 hours, the precipitate is washed with water, and the washed precipitate is w...

Embodiment 2

[0062](1) 220g sodium lignosulfonate was dissolved in 147g water, stirred at room temperature with a rotating speed of 750rmp for 68 hours to make 60wt% sodium lignosulfonate aqueous solution; 78g octadecyltrimethylammonium chloride Be dissolved in the alcohol-water mixed solvent that 46.8g ethanol and 31.2g water form, stir 68 hours with the rotating speed of 750rmp at normal temperature, make the cetyltrimethylammonium bromide mixed solution of 50wt%; The mixed solution of sodium lignosulfonate solution and cetyltrimethylammonium bromide is mixed at the ratio of solute mass ratio, that is, the mass ratio of sodium lignosulfonate to cetyltrimethylammonium bromide, which is 2.8:1, to form yin and yang Ion composite concentrated solution; under the condition of stirring (rotating speed is 800rpm), 1500g of water is evenly added dropwise into the composite solution within 30 minutes; after standing for 24 hours, the precipitate is washed with water, and the washed precipitate Fr...

Embodiment 3

[0066] (1) Dissolve 100g sodium lignosulfonate in 66.7g water, stir at room temperature for 50 hours with a rotating speed of 500rmp to make a 60wt% sodium lignosulfonate aqueous solution; dissolve 36g dodecyldimethylbenzyl Ammonium chloride was dissolved in an alcohol-water mixed solvent composed of 21.6g isobutanol and 14.4g water, and stirred at a speed of 750rmp for 48 hours at room temperature to form a 50wt% cetyltrimethylammonium bromide mixed solution; Sodium lignosulfonate aqueous solution and cetyltrimethylammonium bromide mixed solution with solute mass ratio, that is, the mass ratio of sodium lignosulfonate and cetyltrimethylammonium bromide is the ratio of 2.8:1 Mix to form an anion and cation composite concentrated solution; under the condition of stirring at a rotating speed of 500rmp, 1000g of water is evenly added dropwise into the composite concentrated solution within 30 minutes; Washing, the precipitate after washing is freeze-dried at -48°C to obtain the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com