Profile control system and preparation method thereof

A system and suspending agent technology, applied in the field of profile control system and its preparation, can solve the problems of low utilization rate of oily sludge, poor plugging performance, etc., achieve resource recycling and harmless treatment, and improve plugging performance , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing the above-mentioned profile control system. In parts by weight, oily sludge, emulsifying dispersant and water are mixed, stirred and pretreated to obtain a pretreatment system with a particle size of less than 42 μm, and the pH of the pretreatment system After adjusting to 6-8, mix with suspending agent to obtain thickened oily sludge, mix thickened oily sludge with cross-linking agent and gelatinize at a temperature of 55-65°C.

[0036] Wherein, a suspending agent solution can be prepared first, and the mass concentration of the suspending agent solution is 1000-6000 mg / L. The oily sludge and emulsifying dispersant can be mixed with water separately first and then mixed to make the pretreatment system fully emulsified and dispersed. Wherein, the process of stirring can be carried out in a blender. The pH of the pretreatment system can also be adjusted to 7.

Embodiment 1

[0039] This embodiment provides a profile control system, the preparation method of which profile control system comprises:

[0040] (1) configuration solution mass concentration is the suspending agent of 6000mg / L, and this suspending agent is FPAM;

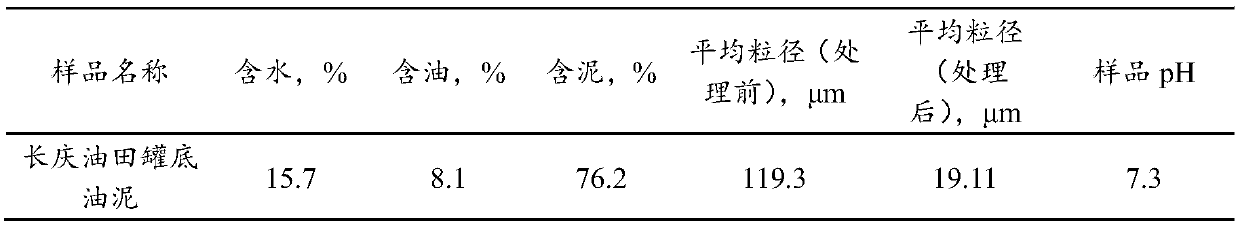

[0041] (2) 10g of glacial acetic acid, 6g of ethylenediamine and 15g of CrCl 3 ·6H 2 O was dissolved in 100g of water to form a chromium crosslinking agent; 0.4g of sodium secondary alkyl sulfonate and 0.2g of propylene glycol block polyether were dissolved in 25g of water to form an emulsified dispersant solution; 60g of Changqing oil field tank bottom Sludge is dissolved in 25g of water to obtain an aqueous solution of oily sludge;

[0042] (3) Add the emulsified dispersant solution and the oily sludge aqueous solution into the mixer for stirring pretreatment to obtain a pretreatment system with a particle size of less than 42 μm, wherein the particle settling time is more than 5 hours, and the oil-water separation time is m...

Embodiment 2

[0050] This embodiment provides a profile control system, the preparation method of which profile control system comprises:

[0051] (1) configuration solution mass concentration is the suspending agent of 6000mg / L, and this suspending agent is FPAM;

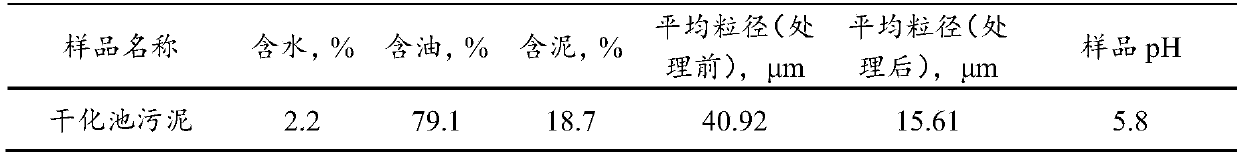

[0052] (2) 10g of glacial acetic acid, 6g of ethylenediamine and 15g of CrCl 3 ·6H 2 O was dissolved in 100g of water to form a chromium crosslinking agent; 0.4g of sodium secondary alkyl sulfonate and 0.2g of propylene glycol block polyether were dissolved in 25g of water to form an emulsified dispersant solution; 60g of Changqing oil field was dried Pool sludge is dissolved in 25g water to obtain an oily sludge aqueous solution;

[0053] (3) Add the emulsified dispersant solution and the oily sludge aqueous solution into the mixer for stirring pretreatment to obtain a pretreatment system with a particle size of less than 42 μm, wherein the particle settling time is more than 5 hours, and the oil-water separation time is more...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com