Composite phase change energy storage material and preparation method thereof

A technology of energy storage materials and composite phase change, applied in the field of energy storage materials, can solve problems such as unstable heat transfer, and achieve the effects of increasing overall stability, eliminating crystal deposition, and prolonging heat release time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

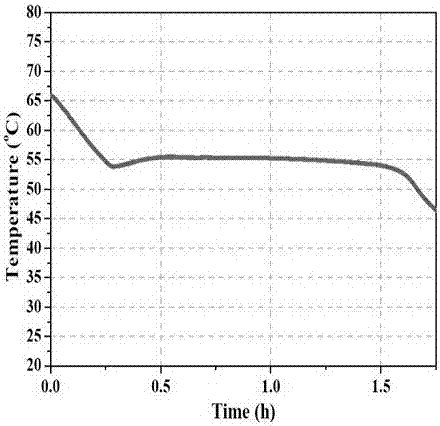

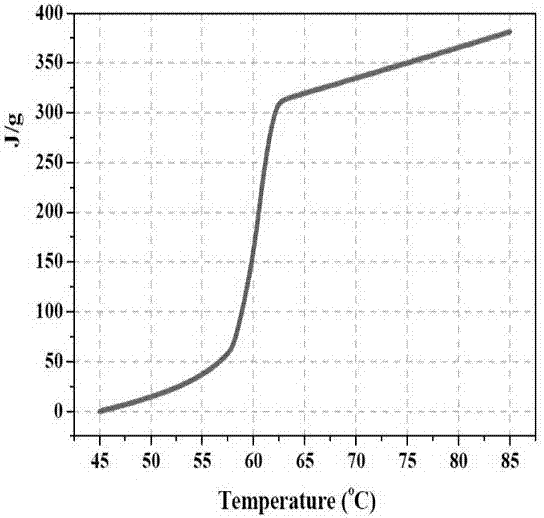

[0026] Weigh 100kg of sodium acetate trihydrate and 1.5kg of zinc acetate, heat and melt until the solution maintains a temperature of 65°C, then stir in the reaction vessel at a rate of 2500rpm, and add 1.11kg with a density of 1.4-1.5g / cm 3 The pre-mixture of foamed copper powder, 1.11kg carboxymethyl cellulose and 0.33kg of hydrophilic fumed silica was added in about half an hour, continued to stir for 1 hour, placed in a heat exchanger, left to cool, and obtained Mixed homogeneous phase change energy storage materials. The measured enthalpy value of a composite phase change energy storage material is 312kJ / kg, and the thermal conductivity is 0.7W / m·K.

Embodiment 2

[0028] Weigh 100kg of sodium acetate trihydrate and 1.67kg of zinc acetate, heat and melt until the solution maintains a temperature of 65°C, then stir in the reaction vessel at a rate of 2000rpm, and add 2.22kg with a density of 14-1.5g / cm 3 The pre-mixture of foamed copper powder, 1.11kg carboxymethyl cellulose and 0.55kg of hydrophilic fumed silica was added in about half an hour, continued to stir for 1 hour, placed in a heat exchanger, left to cool, and obtained Mixed homogeneous phase change energy storage materials. The measured enthalpy value of a composite phase change energy storage material is 292kJ / kg, and the thermal conductivity is 0.9W / m·K.

Embodiment 3

[0030] Weigh 100kg of sodium acetate trihydrate and 2.22kg of zinc acetate, heat and melt until the solution maintains a temperature of 65°C, and then stir in the reaction vessel at a rate of 3000rpm, while adding 3.33kg with a density of 1.4-1.5g / cm 3 The pre-mixture of foamed copper powder, 0.85kg carboxymethyl cellulose and 0.33kg of hydrophilic fumed silica was added in about half an hour, continued to stir for 1 hour, placed in a heat exchanger, and left to cool to obtain Mixed homogeneous phase change energy storage materials. The measured enthalpy value of a composite phase change energy storage material is 286kJ / kg, and the thermal conductivity is 1.2W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com