Phosphate biological ceramic microsphere, preparation method and apparatus thereof

A technology of bioceramics and ceramic microspheres, applied in dental preparations, pharmaceutical formulations, medical science, etc., can solve problems such as poor shape and large particle size distribution range of microspheres, and achieve low power, simple equipment, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Take HA powder and β-TCP powder by mass ratio HA: β-TCP=15: 85, mix evenly;

[0026] (2) taking account for HA and β-TCP mixed powder mass percent is 14% (NaPO 3 ) 6 and Mg(H 2 PO 4 ) 2 Prepare binder solution, wherein (NaPO 3 ) 6 and Mg(H 2 PO 4 ) 2 The mass ratio of is 3: 7; Get the gelatin solution that accounts for 1.5% gelatin of HA and β-TCP mixed powder quality;

[0027] (3) Mix the binder solution prepared in the previous step and the gelatin solution evenly, add the powder in (1) in the mixed solution, and stir to obtain a ceramic slurry;

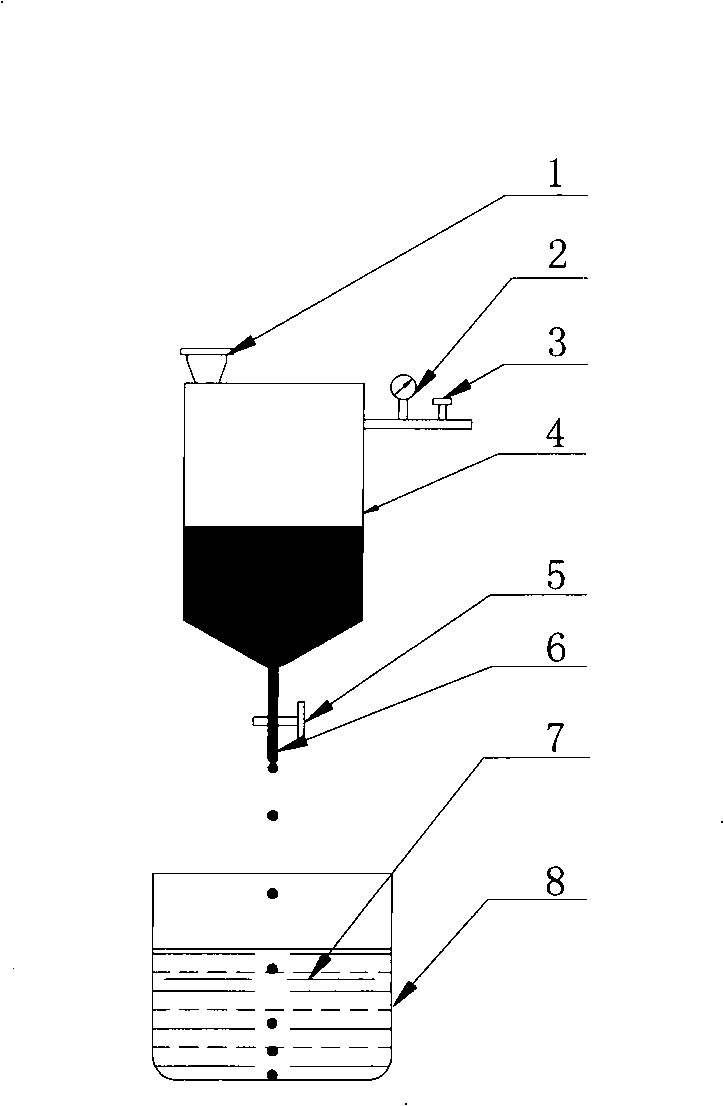

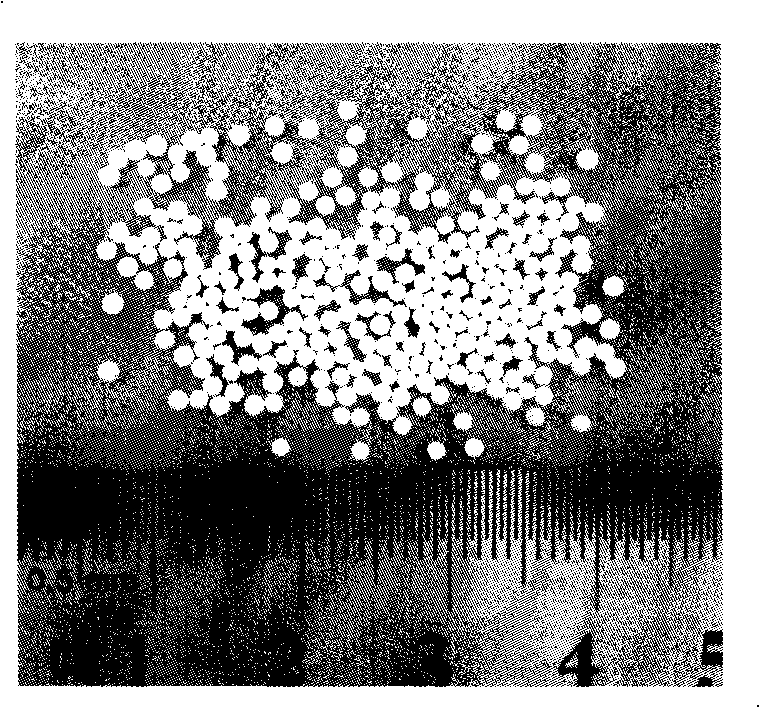

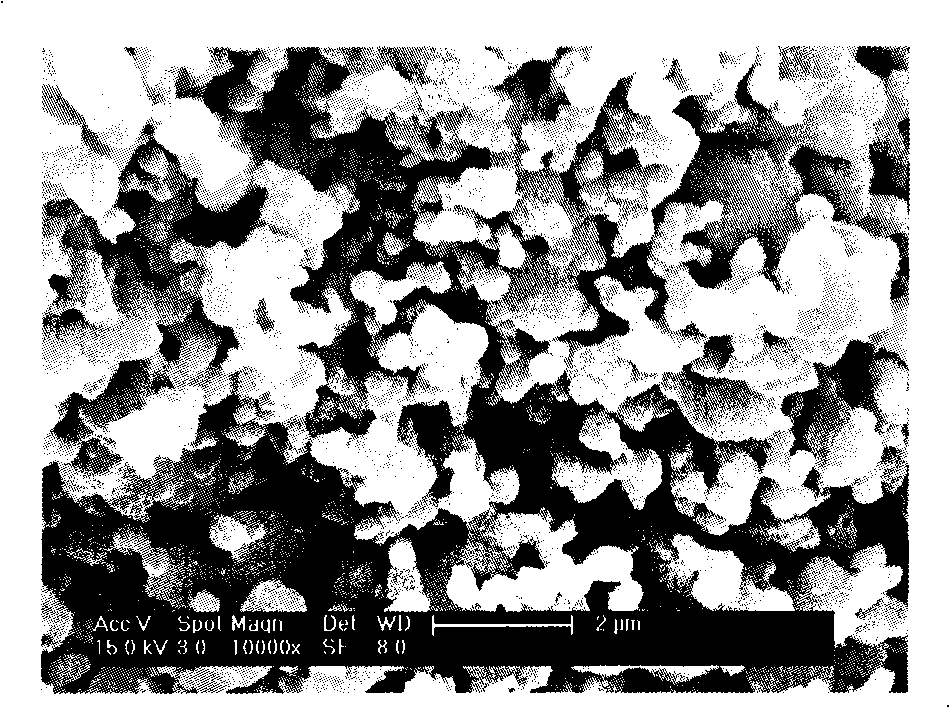

[0028] (4) if figure 1 As shown, the prepared ceramic slurry is put into the storage tank 4 from the feeding port 1, and the pressure in the storage tank 4 is controlled by the pressure gauge 2 and the pressure control valve 3 to be 0.08 ~ 0.5MPa, so as to ensure that the slurry flows from the pipe The catheter 6 with a diameter of φ0.5-3mm flows out evenly at a rate of 10-60 drops / min. The flow rate can be co...

Embodiment 2

[0031] (1) Take HA powder and β-TCP powder by mass ratio HA: β-TCP=5: 5, mix evenly;

[0032] (2) take account for HA and β-TCP mixed powder mass percentage and be 6% (NaPO 3 ) 6 and Mg(H 2 PO 4 ) 2 Prepare binder solution, wherein (NaPO 3 ) 6 and Mg(H 2 PO 4 ) 2 The mass ratio of is 5: 5; Get the gelatin solution that accounts for 4.5% gelatin mixed powder quality of HA and β-TCP;

[0033] (3) Mix the two solutions prepared in (2) evenly, add the powder in (1) into the mixed solution, and stir evenly to obtain a ceramic slurry;

[0034] (4) Add the prepared ceramic slurry into the storage tank 4 from the feeding port 1, and control the pressure in the storage tank 4 through the pressure gauge 2 and the pressure control valve 3 to be 0.08~0.5MPa, so as to ensure that the slurry flows from the pipe The catheter 6 with a diameter of φ0.5-3mm flows out evenly at a rate of 10-60 drops / min. The flow rate can be controlled by the flow control valve 5, and the droplets drop...

Embodiment 3

[0037] (1) Take HA powder and β-TCP powder by mass ratio HA: β-TCP=3: 7, mix evenly;

[0038] (2) Take 10% (NaPO 3 ) 6 and Mg(H 2 PO 4 ) 2 Prepare binder solution, wherein (NaPO3 ) 6 and Mg(H 2 PO 4 ) 2 The mass ratio of is 6: 4; Get the gelatin solution that accounts for 3% gelatin of HA / β-TCP mixed powder quality;

[0039] (3) Mix the two solutions prepared in (2) evenly, add the powder in (1) into the mixed solution, and stir evenly to obtain a ceramic slurry;

[0040] (4) Add the prepared ceramic slurry into the storage tank 4 from the feed port 1, and control the pressure in the storage tank 4 through the pressure gauge 2 and the pressure control valve 3 to be 0.08-0.5MPa, so as to ensure that the slurry flows from the pipe diameter The catheter 6 with a diameter of φ0.5-3mm flows out evenly at a rate of 10-60 drops / min. The flow rate can be controlled by the flow control valve 5, and the droplets drop into the condensate 7 in the heat preservation container 8 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com