Fluid bed granulation process and apparatus

一种流化床、冷却流化床的技术,应用在造粒装置,流化床造粒领域,能够解决成本效益负面影响、消耗大能源等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

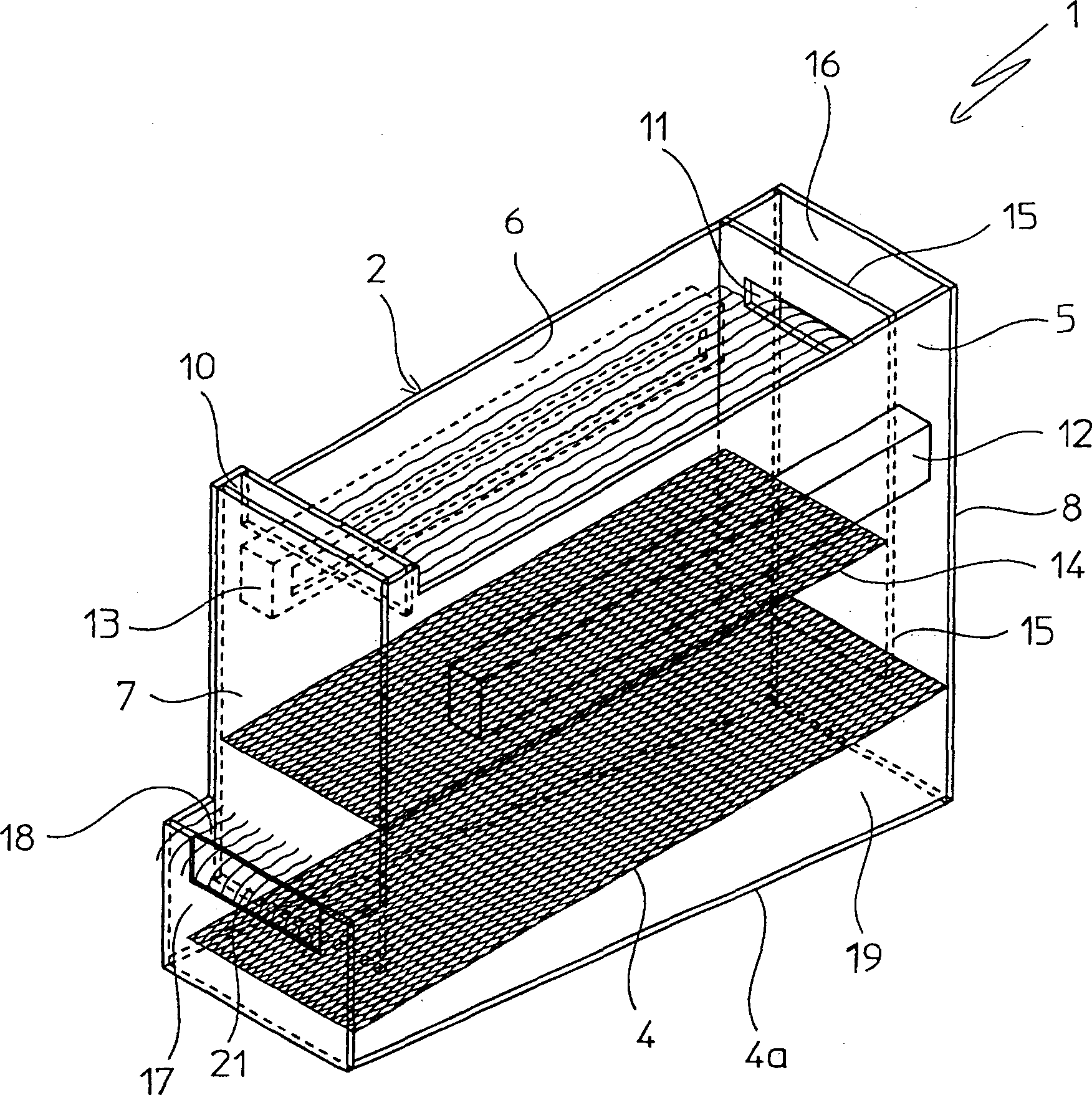

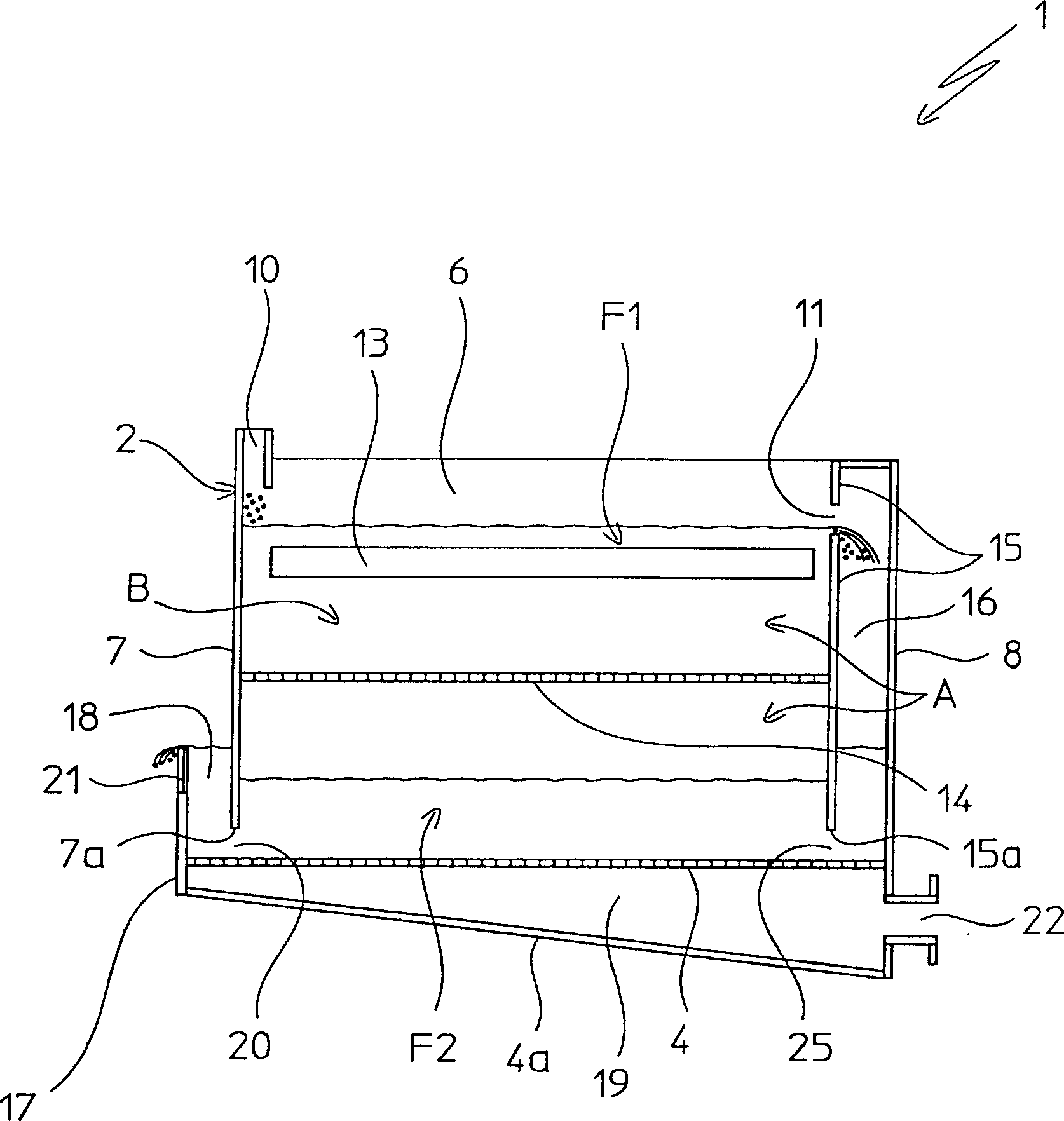

[0018] Referring to the accompanying drawings, the device for implementing the fluidized bed granulation method of the present invention is indicated by 1 as a whole.

[0019] The device consists of a self-supporting structure 2, substantially in the shape of a parallelepiped container, inside which delimits a space A in which are arranged two fluidized beds F1 and F2, which are described below will be more clear.

[0020] Said container structure 2 (hereinafter referred to simply as: container 2) has long side walls 5, 6, short front wall 7 (or top wall) and rear wall 8; The top is closed, and a double bottom plate is installed at the bottom of the container, and the upper bottom plate and the lower bottom plate are represented by 4 and 4a respectively.

[0021] According to a feature of the present invention, the top wall 7 of the container 2 has a bottom 7a separated from the bottom plate 4 of the double bottom plate, thereby defining a passage (or inlet and outlet) 20 so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com