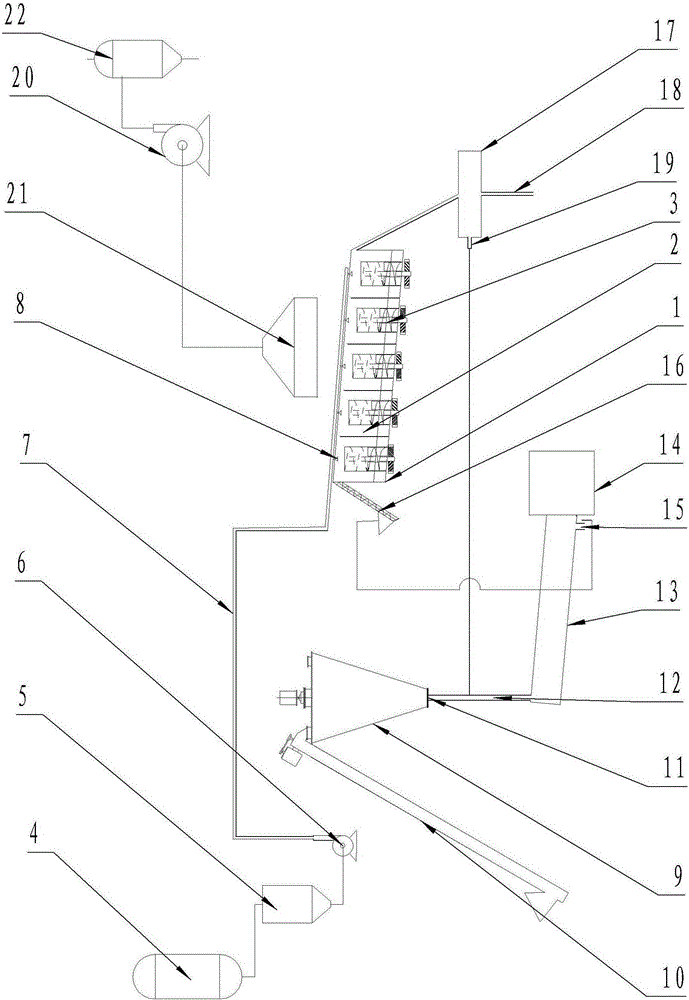

A kind of spiral fluidized bed granulation method and its equipment

A fluidized bed granulation and fluidized bed technology, applied in the direction of powder suspension granulation, etc., can solve the problems of dust pollution, granulation quality influence, separation difficulty, etc., and achieve the effect of reducing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

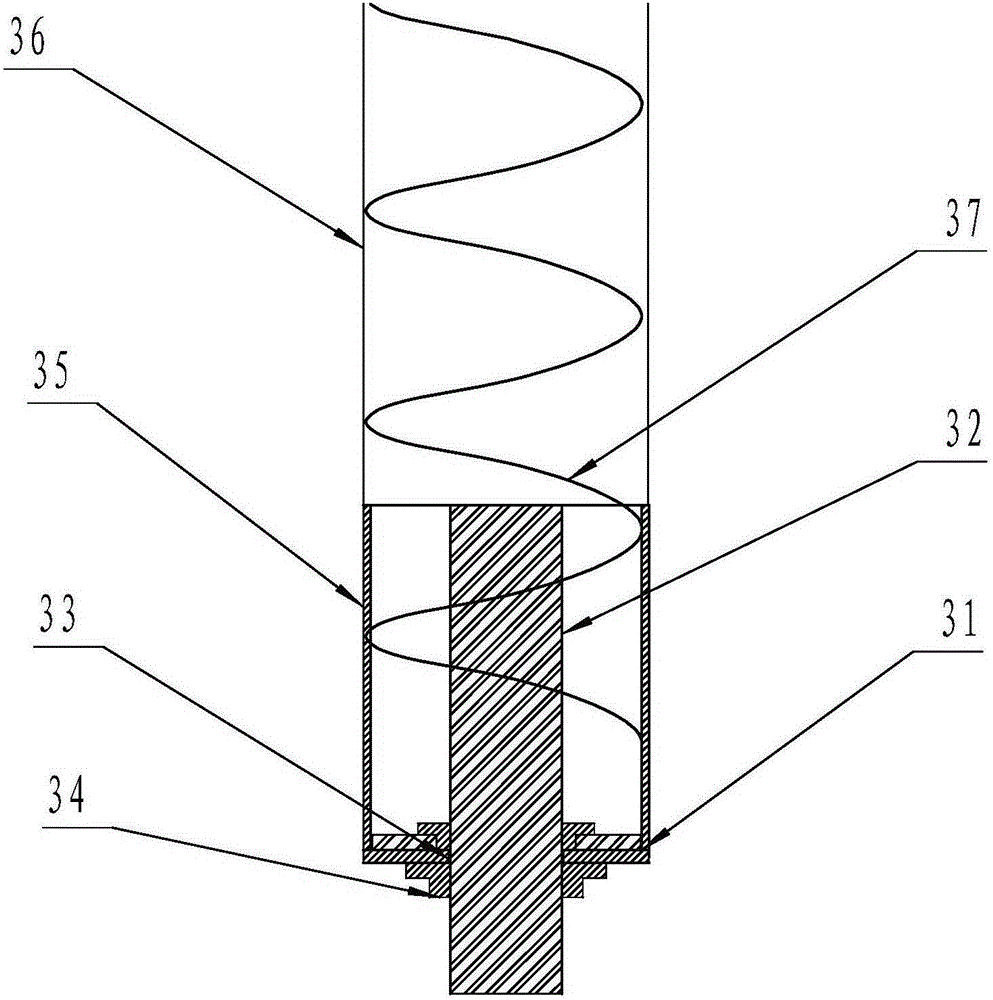

Method used

Image

Examples

Embodiment 1

[0019] A kind of spiral fluidized bed granulation method, it is characterized in that: comprise the following steps: A, the step that granulation binder is melted: After fully mixing the mixture of 80% urea and the ammonium chloride of weight 20%, add A total of 6% of water is put into the melting kettle 4 and heated until it is completely melted, and the temperature of the molten liquid is 100°C for standby; B, the steps of mixing, heating and transporting materials to the spiral fluidized bed group: in the material mixer 9, press The weight ratio is 30% monoammonium phosphate, 20% potassium sulfate, 10% potassium chloride, 20% potassium dihydrogen phosphate, 10% potassium nitrate and 10% trace elements. Mix the above materials evenly, and the materials should not have crystals. Water and materials enter the rotary drum heater 13 after they are mixed, use the hot blast stove 14 to generate heat through mass transfer and heat transfer, and heat the materials to 95°C. If urea is...

Embodiment 2

[0021] Embodiment 2, a kind of spiral fluidized bed granulation method is characterized in that: comprise the following steps: A, the step that granulation binder is melted: the ammonium chloride that weight is 85% urea and weight 15% After the mixture is fully mixed, add 10% of the total amount of water and put it into the melting kettle 4 to heat until it is completely melted, and the temperature of the molten liquid is 110°C for standby; B, the steps of mixing, heating and transporting materials to the spiral fluidized bed group: In the mixer 9, add 30% diammonium phosphate, 30% potassium sulfate, 15% potassium dihydrogen phosphate, 10% dipotassium hydrogen phosphate, 10% potassium nitrate and 5% trace elements by weight in proportion, and mix the above materials , the material can not contain crystal water, after the material is mixed, it enters the rotary drum heater 13, uses the hot blast stove 14 to generate heat through mass transfer heat transfer, and heats the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com